Welch Allyn Euro-Med Rose Coated Electrosurgical Instrumentation User Manual

Directions for Use & Sterilization

Euro-Med

®

Rose Coated

Electrosurgical

Instrumentation

Part Number # 883421 • Rev. A

Skaneateles Falls, NY 13153 USA

Phone: (315) 685-4560

Toll Free: (800) 535-6663

Fax: (315) 685-3361

Skaneateles Falls, NY 13153 USA

Phone: (315) 685-4560

Toll Free: (800) 535-6663

Fax: (315) 685-3361

NOTICE

To insure proper handling, read the following care and

maintenance instructions before using the Euro-Med

®

Rose Coated Electrosurgical Instrumentation.

ELECTROSURGICAL SPECULA PRODUCT #

Pederson

Medium • 114mm x 22mm 88350

Large • 121mm x 26mm 88352

Graves

Medium • 113mm x 33mm 88346

Large • 125mm x 35mm 88348

Prima Series

®

Medium • 113mm x 33mm 88338

Large • 125mm x 35mm 88340

ELECTROSURGICAL RETRACTORS

Cer-View

™

Lateral Wall Retractors

57mm x 22mm 88342

Working Length: 110mm

70mm x 22mm 88344

Working Length: 110mm

ELECTROSURGICAL INSTRUMENTATION

Campion Forceps 88354

Tissue Forceps 88358

Two-Prong Hook

Length: 260mm 88360

Single Tooth Tenaculum

Length: 240mm 88362

Ring Forceps

Length: 220mm 88356

ENDOCERVICAL SPECULA

Regular

Length: 240mm • Tip size: 6mm 88364

Medium

Length: 240mm • Tip size: 5mm 88366

Complete Product Listing

NOTE • Measurements listed below are Length x Width

Euro-Med

®

Rose Coated Electrosurgical Instrumentation

COLD SOAK STERILIZATION GUIDELINES

1

Thorough cleaning is essential prior to soaking. Failure to properly clean the instrument

prior to soaking may result in protein deposits. These deposits will give the appearance

of corrosion when hardened, and will impair sterilization.

2

Plastic soaking trays are recommended to avoid scratching of the instruments.

Plastic also has better material compatibility with metal instruments when sterilizing.

3

Use only a cold soak solution that has FDA clearance and EPA registration.

Solutions which contain 2% Glutaraldehyde are recommended.

4

Follow the solution manufacturer’s instructions to determine soaking time and

temperature for disinfecting or sterilizing the instrument.

5

Rinse the instruments in sterile water following cold soaking to adequately remove

any solution residue. Cold soak solutions may cause irritation to skin or tissue.

A minimum of two separate rinses with gentle agitation is recommended. A longer

rinse time also reduces the amount of solution residue.

ETO STERILIZATION GUIDELINES

Rose coated electrosurgery instruments are sterilizable using gas following the equipment

manufacturer’s recommendations and AAMI guideline ANSI/AAMI ST-41-1992 for

Good Hospital Practice: Ethylene Oxide Sterilization & Sterility Assurance.

SPECIAL NOTE ON ELECTROSURGICAL HOOKS

Since the coating used to insulate the instruments would significantly dull the

electrosurgical hooks, making them ineffective for their intended use, the tips are not

coated. As long as the exposed hook tip is completely embedded in tissue, no arcing

of the electrical current will occur.

PREPARATION AND PRECAUTIONS

1

Thoroughly examine the integrity of the Rose coating on all instrumentation before

performing every electrosurgical procedure. If any flaws such as cracks,

tears, or chips are seen, DO NOT USE THE INSTRUMENT. Electrode contact with

uncoated sections of instruments used in electrosurgery may result in an electrical shock.

Note: Coating wear at pivot points is considered normal in everyday use. Care must be taken during

the procedure to avoid contact with these areas.

2

NEVER scrub coated instruments with abrasive cleaners or stiff brushes. Use of

these cleaning methods may result in damage to the coating. Only use a soft

material or brush during cleaning procedures.

3

Doctors may use Rose coated electrosurgery instruments for other gynecology procedures.

4

DO NOT use ultrasonic cleaning methods.

5

DO NOT use a glass bead sterilizer.6DO NOT soak in bleach solution.

7

DO NOT use Rose coated electrosurgery instruments for laser procedures.

CLEANING AND STAIN REMOVAL

1

LUGOL’S SOLUTION PERMANENTLY STAINS the Rose coated instruments

unless the instruments are immediately cleaned and treated with StainEnder

™

or a similar solution

after use.

2

Wash the instruments immediately after use with hot soapy water. Rinse with hot water.

To minimize the potential of contamination of the StainEnder solution, use disinfectant

prior to inserting them in the cleaning solution.

3

Completely immerse the instrument in undiluted StainEnder. Allow the instrument to

soak until all stains are removed. Lugol’s not immediately removed from the instrument

may either require additional soaking time or result in permanent staining. Any permanent

Lugol’s stains will appear as a whitish residue after autoclaving.

4

StainEnder is not a disinfectant. The solution may become contaminated if the

instruments are not disinfected prior to immersion. If this is suspected, or if the solution

no longer removes stains, discard the solution following standard bio-hazard disposal

instructions.

AUTOCLAVE STERILIZATION GUIDELINES

All Rose coated electrosurgery instruments are autoclavable.

AAMI guideline SSSA 1988 for

Good Hospital Practice: Steam Sterilization & Sterility

Assurance

is recommended. It is recommended that a maximum temperature cycle

of 275°F be utilized, following the AAMI guidelines.

STERRAD STERILIZATION GUIDELINES

The Sterrad sterilization process is approved for these devices. Accomplish Sterrad

sterilization for electrosurgical coated intruments per the manufacturer’s recommended

procedure.

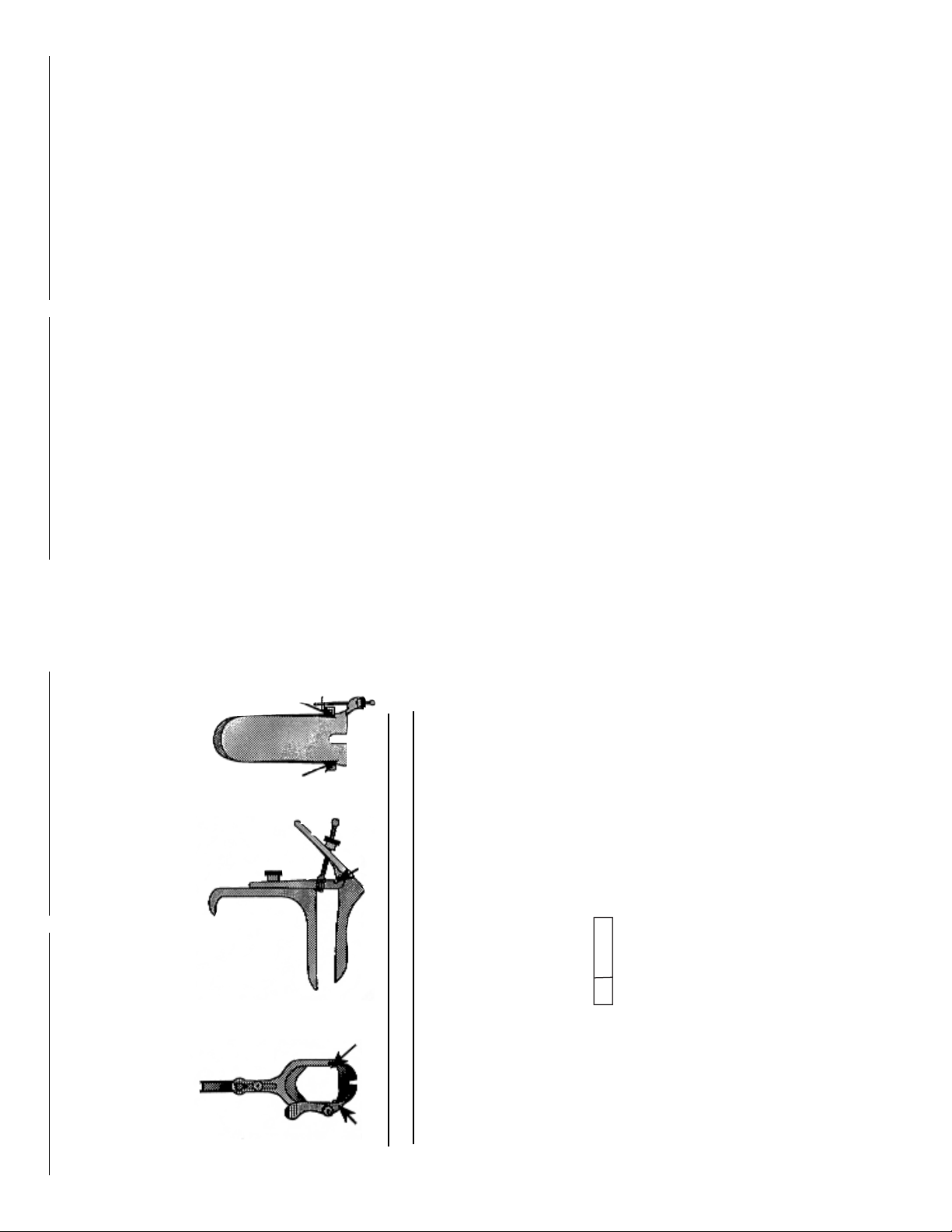

NOTICE

Over time and use, the coating at the hinge points will wear off due to friction at the contact areas. This will not

affect the safety or efficacy of the instrument. Exposure of base metal in these areas is expected and is not a

cause for rejection or return of the instrument. Operators should notice these points and avoid contact with them

during electrosurgical procedures.

TOP VIEW

SIDE VIEW

BACK VIEW

HINGE

POINT

HINGE

POINT

HINGE

POINT

HINGE

POINT

HINGE

POINT

1

2

STERILE EO

Contact Welch Allyn, Inc. at 1-800-535-6663 for information on instrument repair.

Loading...

Loading...