Page 1

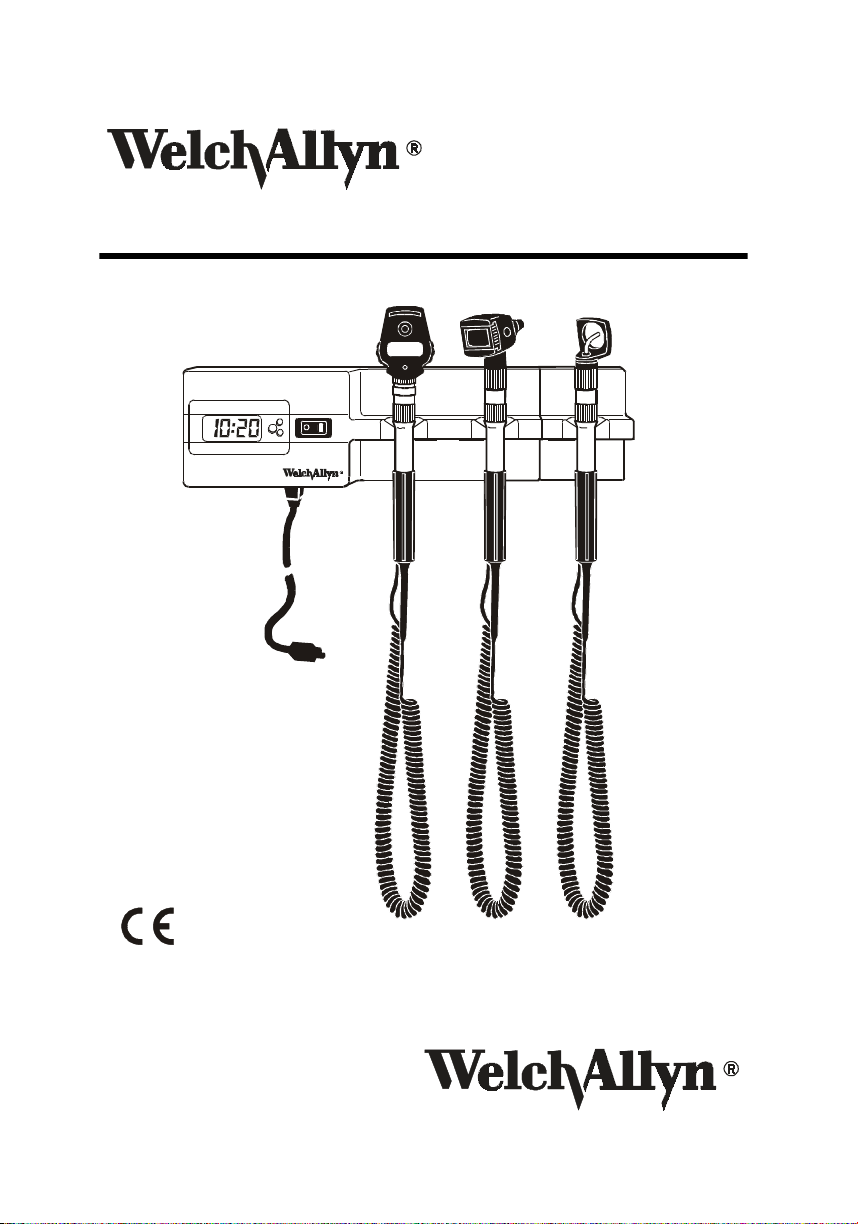

767 Diagnostic System

3.5v 767 Wall Transformer

Patent Pending

Listed to:

UL 544

CSA C22.2 No. 125

Page 2

Thank you for purchasing the Welch Allyn 3.5v 767 Wall Transformer. This manual

is meant to provide product specifications and instructions for usage and

maintenance. The instructions for use should be followed to ensure accurate and

reliable service.

The 3.5v 767 Wall Transformer carries a lifetime warranty against all

manufacturing defects.

against breakage during normal usage.

The coiled cords carry a special 10 year warranty

Page 3

Table of Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Avertissements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Mounting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Clock Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Mounting the Third Handle Module . . . . . . . . . . . . . . . . . . 7

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cleaning and Repai . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Page 4

Warnings

USE HOSPITAL-GRADE POWER INLET CORD ONLY.

REPLACE CLOCK BATTERY AS INSTRUCTED WITH Maxell 43 OR EQUIVALENT

BATTERY.

GREEN PILOT LIGHT INDICATES THAT THE POWER MAINS IS CONNECTED TO

APPLIANCE.

USE THIRD HANDLE MODULE (MODEL #76730) WITH WELCH ALLYN 3.5v 767 WALL

TRANSFORMER ONLY.

SERVICE TO BE PERFORMED BY AUTHORIZED WELCH ALLYN REPAIR DEPARTMENT

ONLY.

FUSE REPLACEMENT — TYPE T250, 250v SLOW BLOW 0.20 AMPERE (SHOULD B

REPLACED ONLY BY AUTHORIZED WELCH ALLYN REPA IR DEPARTMENT).

CAUTION: DISCONNECT THE SYSTEM FROM THE MAINS SUPPLY BEFORE

CONNECTING THE THIRD HANDLE (MODEL #76730).

THIS PRODUCT IS DESIGNED FOR INTERMITTANT USE, TYPICAL ON-TIME SHOULD

NOT EXCEED 2 MINUTES.

Avertissements

N’UTILISER QUE LE CORDON D’ALIMENTATION DE QUALITE HOPITAUX.

REMPLACER LA BATTERIE DE L’HORLOGE SELON LES INSTRUCTIONS PAR UNE

BATTERIE MAXELL 43 OU EQUIVALENT.

LE VOYANT VERT INDIQUE QUE L’INSTRUMENT EST BRANCHE SUR L’ALIMENTATION

SECTEUR.

N’UTILISER LE MODULE DE LA TROISIEME POIGNEE (MODELE NO. 6730) QU’AVEC LE

TRANSFORMATEUR MURAL WELCH ALLYN 767 DE 3,5V.

ATTENTION : NE CONFIER LES REPARATIONS QU’AU DEPARTEMENT DE REPARATION

AGREE WELCH ALLYN.

REMPLACEMENT DU FUSIBLE — TYPE T250, 250V, A ACTION RETARDEE 0,20

AMPERES (NE LE FAIRE REMPLACER QUE PAR LE DEPARTEMENT DE REPARATION

AGREE WELCH ALLYN).

ATTENTION : DEBRANCHER LE SYSTEME DE L’ALIMENTATION SECTEUR AVANT DE

RACCORDER LA TROISIEME POIGNEE (MODELE NO. 76730).

CE PRODUIT EST CONCU POUR ÊTRE UTILISÉ DE MANIÈRE INTERMITTENTE; NE PAS

L’UTILISER AU DELÀ DE 2 MÌNUTES.

1

Page 5

Mounting Instructions

Flat Side

Fasten mounting plate to the wall with enclosed screws, making sure that the screw hole

flanges face away from the wall and the smooth surface of the mounting plate is flush with

the wall. Depending on the mounting surface, alternative screws may be needed. With the

flat side of the plate on the mounting surface, level the plate as shown. Note that the plate

should be mounted so that the widest portion of the plate is horizontal (as shown). When

mounting screws are tightened, there will be a gap between the screw head and surface

of the plate.

Screw Hole

Flanges

BACKPLATE

TO

POWER

Mount the unit by fitting the round holes in the backplate over screw heads on the wall

mounting plate, then push downward on the unit to secure it to the wall. This slides the

tapered slots in the backplate over the shoulders in the mounting plate.

60 Hz AC and unit is ready for use.

Plug into 108-125v,

2

Page 6

Operation

ON/OFF

OPTIONAL

CLOCK

CLOCK

FAC EP LAT E

POWER

CORD

(3m)

SWITCH/

PILOT LIGH

Handles

Rheostat

Handle cradle

On-off switch/pilot light

Third Handle M odule

Power cor

Clock

3.5v

INSTRUMENT

HEAD

RHEOSTAT

THIRD

HANDLE

MODULE

HANDLE

CRADLE

HANDLES

Handles will accept any 3.5v Welch Allyn instrument

head.

Located on each handle. Turn clockwise to increase light

output, turn counterclockwise to decrease light output.

Instrument lights automatically when handle is lifted

TM

from the cradle engaging the OptiSense

Optical

Sensor. When handle is returned to the cradle the

TM

OptiSense

Optical Sensor is disengaged

automatically turning the instrument off.

Indicates the transformer is on (power mains is applied).

Option on this model. Refer to page 5 for operating

instructions.

Option on this model. Refer to page 7 for mounting and

operating instructions.

Can be plugged into any

108-125v, 60 Hz

outlet.

3

Page 7

Operating Instructions

Handles will accept any Welch Allyn 3.5v instrument head.

After plugging power cord into any 108-125v, 60 Hz outlet, turn power switch to on position,

illuminating the pilot light.

With power switch in on position,

instruments will automatically light when

handles are lifted from the handle cradle and

the OptiSense

Adjust rheostat on handle until desired light

output is obtained. Turning rheostat

clockwise increases light output,

counterclockwise decreases light output.

Note: Rheostat does not turn instrument

completely off. Returning handle to cradle will

disengage the OptiSense™ Optical Sensor

and turn the instrument completely off.

A built-in, automatic voltage regulator

provides maximum illumination and lamp life.

Instruments will automatically turn off when

the handle is placed back in the cradle. The

Welch Allyn 767 Wall Transformer can be

turned off by simply turning the power switch

to the OFF position. Pilot light alone draws

current when instruments are not in use.

When unit is not in use for more than a few

hours, turn power switch to OFF position to

ensure longer operating life. Unit can remain

plugged in permanently. The clock is powered by a battery and will keep time when power

switch is turned off.

TM

Optical Sensor is engaged.

RHEOSTAT

4

Page 8

Clock Option

CLOCK

MODULE

REMOVAL

TAB

Start/Stop button

START/STOP

BUTTON

Use this button to start and stop seconds count. Press

TIMER

BUTTON

CLOCK

BUTTON

ON-OFF SWITCH/

PILOT LIGHT

once to start the seconds. Press again to stop seconds.

Clock button

Use this button to return from seconds mode to hour/

minute by pressing once.

Timer button

Clock module removal tab

Use this button to change to seconds mode (timer).

Pull forward to remove clock module and gain access

for changing battery.

The clock, powered by a batt ery, operates separately from the main power supply. For this

reason the time will be displayed when the main unit is turned off or unplugged from the

wall power socket.

Engage Seconds Mode:

Press Timer Button to engage. Press Start/Stop button to begin seconds mode. Press the

Clock button to return the Hour/Minute display.

5

Page 9

Change Time:

The following steps should be followed when resetting the time:

1. Remove clock module by prying the clock faceplate from unit housing.

2. With clock in clock mode, press Start/Stop button for 5 seconds until time on clock

begins to flash.

3. Using Hour Set and Minute Set buttons on back of clock module, set time to correct

values.

4. Press Start/Stop button again to return clock to regular operation.

5. Replace clock module into unit by lining up edges and pressing into main housing.

Change Clock Battery:

1. Remove clock module by prying the clock faceplate from unit housing.

2. Remove battery by pushing battery out of retaining sleeve. For best results, use a pen

or pencil to pry against the faceplate housing wall.

3. Insert new battery. Welch Allyn recommends Maxell 43 or equivalent.

6

Page 10

Mounting the Third Handle Module

A Phillips screwdriver is needed to connect the Third Handle Module.

Mounting the Third Handle Module

1. Disconnect main unit power supply.

2. Remove main unit from the wall by lifting up and out (instructions found on page 2 of

this manual).

3. Attach stabilization bar to back of Third Handle Module (as shown using two enclosed

star washers and screws).

Step 3: Step 5:

BACK OF THIRD

HANDLE MODULE

STABILIZATION

BAR

4. Line up the metal stabilization bar with the groove on the back of the main unit. Also,

line up the connecting blades with the blade openings on the side of the main unit

housing.

5. Slide Third Handle Module into the main unit until firmly in place.

Step 6:

:

STAR

WASHERS

STABILIZATION

BAR

THIRD HANDLE MODULE

CONNECTION

BLADES

BACK G ROOVE

MAIN UNIT

6. Secure Third Handle Module in place (as shown using two enclosed star washers and

screws).

7. Place unit on the wall following the instructions foun d on page2 of this manual and

reconnect main unit power supply.

8. Place instrument on third handle and lift from cradle. This will test for correct

attachment.

7

Page 11

Maintenance

Like any other p iece of electric al equipm ent , peri odic electrical inspections should be

performed by qualified personnel. Welch Allyn recommends inspections every six months,

more often if used under adverse conditions.

Dielectric Breakdown:

Isolation between power pins and backplate (dead accessible metal) should withstand

1500VAC for one second without exceeding 12.5 mA of trip current.

Cleaning and Repair

not

Do

sterilize. May be cleaned by wiping with a dry cloth. Avoid using abrasive cleaning

materials on clock faceplate.

CLOCK

FAC E PL AT E

REPAIR

:

For all repairs, send unit to: Technical Service Department, Welch Allyn, Inc., 4341 State

Street Road, Skaneateles Falls, New York 13153, or in the U.S.A. call 1-800-535-6663. Fax:

315-685-4653 (Technical Services). In Canada call: 1-800-561-8797. Fax: 905-890-0008.

8

Page 12

Specifications

Model No.

Power Cord:

Input

Output: Model Nos. 76720, 76710 — 3.00-3.90v, .700-1.05A at 120 VAC

Supplied with two coiled cords, two handles, and power cord.

Leakage current is less than 10 microamps from any e xposed metal part.

Fuse: Replace with fuse specified on page 1 only.

Weight

instrument heads.)

Dimensions

76720

3.5v 767 Wall Transformer

(two-handle model with clock, instrument heads not included).

76710

3.5v 767 Wall Transformer

76730

: 108-125v., 60Hz. (0.5A @ 120V)

: Weight with mounting plate is 4.5 pounds (2.04kg). (NOTE: This is weight without

: H=4" (10.16cm) D=4" (10.16cm) W=12" (30.48cm)

Listed to UL544

Certified to CSA 22.2 No.125

Certified

(two-handle model without clock, instrument heads not included),

3.5v 767 Wall Transformer

Third Handle Module (instrument heads not included).

The CE mark on this product indicates it has been tested to and conforms

with the provisions noted within the 93/42/EEC Medical Device Directive.

Authorized European Representative Address:

European Regulatory Manager

Welch Allyn, Ltd.,

Kells Road, Navan,

County Meath,

Republic of Ireland

Tel. 353 46 28122

Fax 353 46 28536

9

Page 13

Welch Allyn, Inc.

4341 State Street Road

PO Box 220

Skaneateles Falls, NY 13153-0220

U.S.A.

Telephone: 800-535-6663 or

315-685-4100

Fax: 315-685-3361

Part No. 767036-2 Rev. D Printed in U.S.A.

Loading...

Loading...