Page 1

Service and

Repair Instructions

ACCUVAC Rescue

Aspirator

WM 10600

Page 2

Contents

Introduction

1.

Overview

2.

Safety instructions

2.1

Special symbols on the appliance

3.

Description

3.1

Purpose

3.2

Function

4.

Operation

5.

Operating and Display Elements

5.1

Operation

5.2

Service

6.

Maintenance

6.1

Disposal

7.

Function checks

7.1

Intervals

7.2

Performing the function check

8.

Troubleshooting

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . .

. . . . . . . . . .

. . . . . . . . .

10

12

3

4

5

5

6

6

6

7

8

8

8

9

9

9

9

9.

Repairs: Information and Instructions

9.1

General

9.2

Opening the device

9.3

Closing the device

9.4

Replacing release catch

9.5

Replacing membrane keyboard

9.6

Changing the power pack

9.7

Initializing the power pack

9.8

Changing fuse F1 or F2

9.9

Checking connector between circuit

board and power pack

9.10

9.11

9.12

9.13

9.14

10.

Spare Parts

10.1

11.

Tools and Test Equipment

12.

Technical Changes

13.

Technical Data

13.1

14.

Repair and Test Report

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

Fitting new circuit board WM 10680

Fitting new pump

Changing fuse in vehicle plug

Changing the muffler

Electrical circuit diagram

. . . . . . . . . . . . . . . . . . . . . . . . .

Spare parts list

Safe distances

. . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . .

. . . . . . . . . . .

. . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . .

. .

. . . . . . .

. . . . . . . . . .

15

15

15

16

16

17

19

20

21

21

22

24

25

25

26

27

27

29

29

30

31

32

© Copyright Weinmann GmbH & Co. KG.

The content and presentation are copyright protected and may only be used by authorised Weinmann Service Partners in the

course of their service operations. The content must not be reproduced or passed on to third parties. The complete documents

must be returned on termination of the cooperation with Weinmann.

2

Page 3

Introduction

For decades Weinmann has been developing,

manufacturing and marketing appliances for emer

gency medical treatment,

inhalation

In 1986 Weinmann launched the first

aspirator on the market.

The improved

provides users with an appliance that is an

indispens

situations. The

to clear the airways, as when preparing for intuba

tion, for example, but also for removing

material.

In stable positioning of injured patients the

ACCUVAC Rescue

flating vacuum mattresses and inflatable splints.

Using the

user more time to look after the patient and perform

other measures.

The purpose of these Service and Repair Instruc

tions is to make sure you as an

familiar with the

functionality and technology and how to repair it.

Combined with training you have already re

therapy.

ACCUVAC Rescue

able aid in many emergency health care

ACCUVAC Rescue

ACCUVAC Rescue

ACCUVAC Rescue

oxygen therapy and

ACCUVAC

aspirator

is used not only

vomited

aspirator can be used for de

aspirator gives the

expert specialist

aspirator: its

are

-

-

ceived

from Weinmann, this makes you a member

-

-

-

of the “authorized expert personnel”

which means you can give your customers proper

instruction, remedy faults independently,

the final checks specified in the Operating Instruc

tions,

and carry out any repairs in accordance with

these Service and Repair Instructions.

In the event of a warranty claim the

aspirator is to be sent to Weinmann

So that we can process warranty claims or requests for generous treatment of complaints,

please send the purchase receipt (invoice) with the

appliance.

Repairs may only be carried out by Weinmann or

by expert personnel.

You are responsible for any repairs you make and for

the relevant warranty!

Only original Weinmann spare parts must be used

for repairs.

Please remember:

Your customer trusts you and relies on your quality,

just as you rely on Weinmann.

category,

perform

-

ACCUVAC Rescue

.

Note:

For the following information, please consult the

ACCUVAC Rescue Operating Instructions:

• Safety information

• Assembly with wall bracket,

Fitting accessories

• Operation

• Hygienic preparation

• Warranty

Introduction

3

Page 4

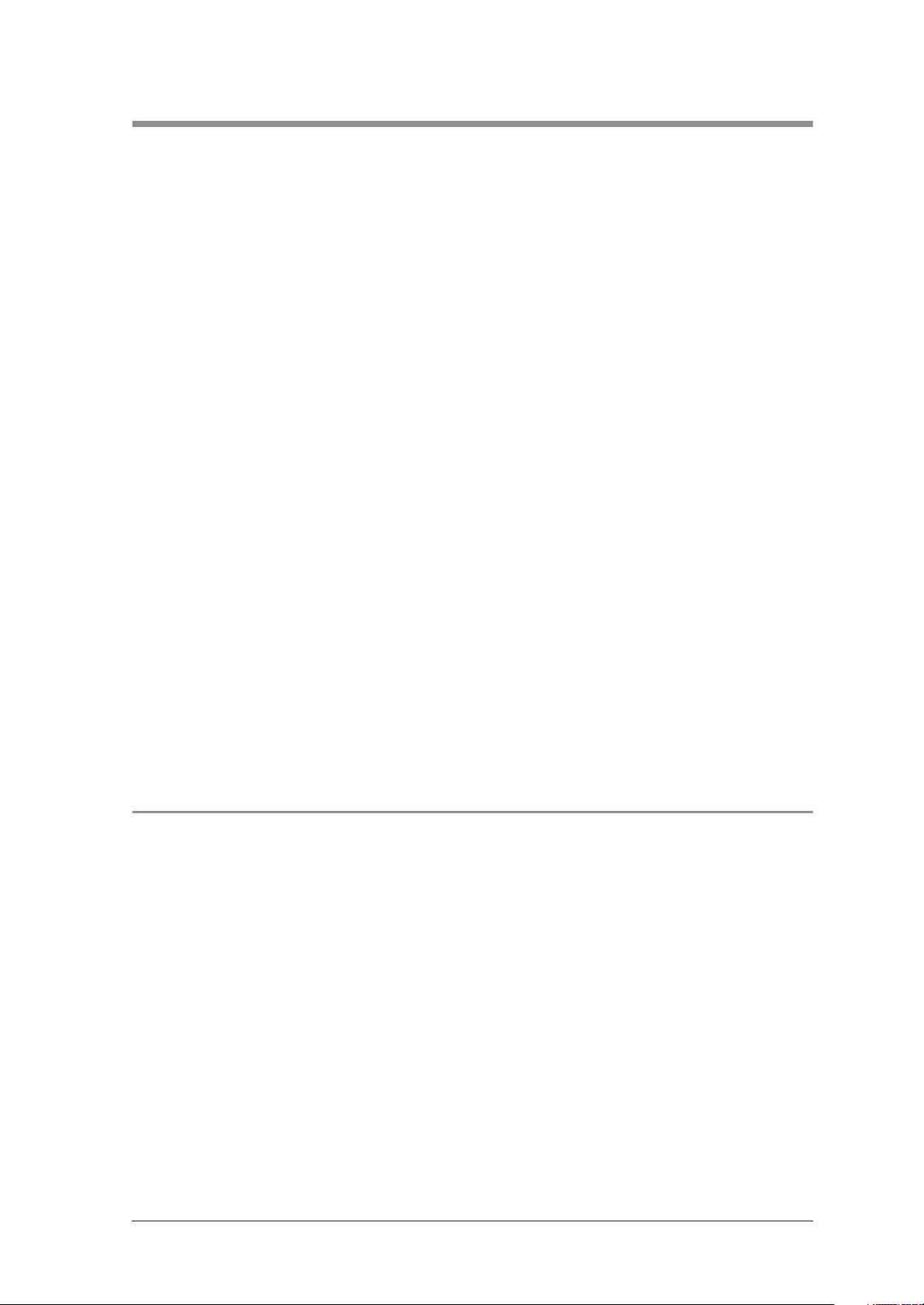

1. Overview

13,8 V

Wall bracket

WM 15208

fingertip

18 Vent tab

19 Filter cover

20 Bacteria filter

21 Locking tab

23 Secretion cover

24 Ball (overfill guard)

22 Bracing clip

25 Sealing ring

26 Nozzle with

27 Aspiration tube

Re-usable collection canister

14 Fuse F1 15 Fuse F2

ACCUVAC Rescue - interior

28 Collection canister

29 Support

10 Connection cable

17 Plug X3 16 Power pack

Accessories

30 Disposable bag container WM 15268

Accessory bag

nozzle and fingertip

31 Aspiration tube with

33 Disposable bag

32 Intermediate tube

WM 10655

34 Vacuum tube

36 Collection

35 T-piece

canister

Mains/charger unit

WM 2645

WM 15172

37 Holder set

ACCUVAC Rescue from front with

disposable collection canister

4 Overview

tion canister

6 Re-usable collec-

5 Release catch

4 Membrane keyboard

3 Capacity indicator

2 Vacuum control

switch

1 On/Off

7 Motor unit

8 Tube holder plate

ACCUVAC Rescue from rear without collection canister

5 Release catch

12 Muffler

13 Suction port

(hidden)

11 Power socket

9 Loops for

(hidden)

accessory bag

10 Connection cable

Page 5

2. Safety instructions

2.1 Special symbols on the appliance

The symbol on the filter cover 19 draws attention to

the built-in bacteria filter 20. This must be changed

or sterilized after use to prevent the risk of infection

(see “5. Cleaning and disinfecting” in the operation manual).

The warning symbol in the capacity indicator 3

draws attention to the risk of complete discharging,

which could damage the power pack 16. If the

10% LED lights up, it is time to recharge the

ACCUVAC Rescue immediately (see “4.4 Charging the ACCUVAC Rescue” in the operation

manual).

Safety instructions 5

Page 6

3. Description

3.1 Purpose

ACCUVAC Rescue is a mobile and portable electrically powered aspirator (suction pump).

It is used for:

• aspirating accumulations of blood, secretions

and food from the oral cavity, the nose and

throat region and the bronchial system;

• deflating vacuum mattresses and inflatable

splints.

ACCUVAC Rescue:

• can when used by a skilled operator eliminate

obstruction of the respiratory tract and hence

the risk of respiratory failure;

• cuts energy consumption by reducing power

output on reaching the necessary vacuum;

3.2 Function

An electrically powered diaphragm pump generates the vacuum necessary for aspiration.

Use the vacuum control 2 to preselect the desired

vacuum between –0.05 bar and –0.8 bar. The

membrane keyboard 4 is illuminated so that you

can see the operating status even after dark.

• can optionally be powered

– by a rechargeable internal power pack;

– or by an external DC source supplying

12.0 - 13.8 V;

• is also suitable for use in wards.

The ACCUVAC Rescue must not be used:

• in medical rooms where potential

equalization is necessary

(e.g. heart surgery);

• in explosion-risk areas.

Note

Once the preselected vacuum is reached, the pump

switches to standby. If the vacuum changes, the pump

starts up again to restore the vacuum to the preselected level.

The aspirated material passes through the aspiration tube 27 into the collection canister.

Re-usable collection canister

The re-usable collection canister 6 is fixed to the

side of the motor unit and directly connected to the

suction port 13 of the motor unit 7. There is thus no

need for an intermediate tube.

A replaceable hydrophobic bacteria filter 20 in the

secretion cover 23 prevents bacteria and droplets

of moisture from finding their way into the motor

unit 7 and passing into the environment via the

muffler 12.

The bacteria filter is designed for multiple re-use

and sterilisation.

6 Description

Page 7

Important: Do not immerse the bacteria filter in dis-

infectant liquid, as this adversely affects its hydrophobic properties.

An overfill system prevents secretions from entering

the motor unit. The ball 24 floats on the surface of

the secretion until it blocks the exit.

Power supply

Power can be drawn from:

• the built-in power pack 16.

• a 12-volt vehicle electrical system, using the

connecting cable.

• the mains and charger unit available as an

accessory.

The capacity indicator 3 shows the charge status

of the power pack in percent.

Charging of the power pack starts automatically

as soon as the appliance is switched off and connected to an external power supply (see ”13.

Technical Data“ on page 30).

4. Operation

ACCUVAC Rescue may only be used by trained staff

instructed in aspiration techniques. Incorrect use can

cause serious bodily harm.

Operation is described in the operating

instructions.

Operation 7

Page 8

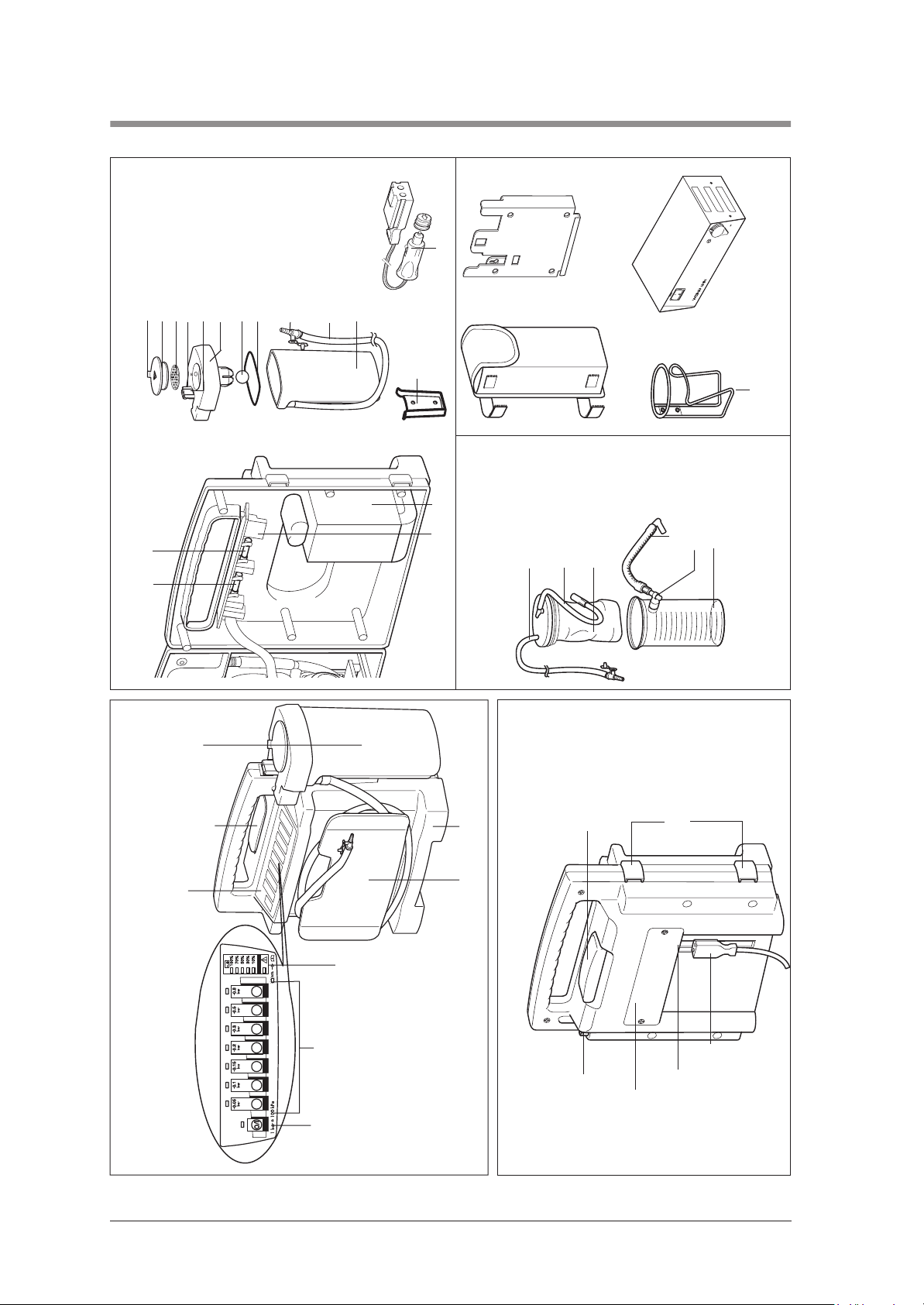

5. Operating and Display Elements

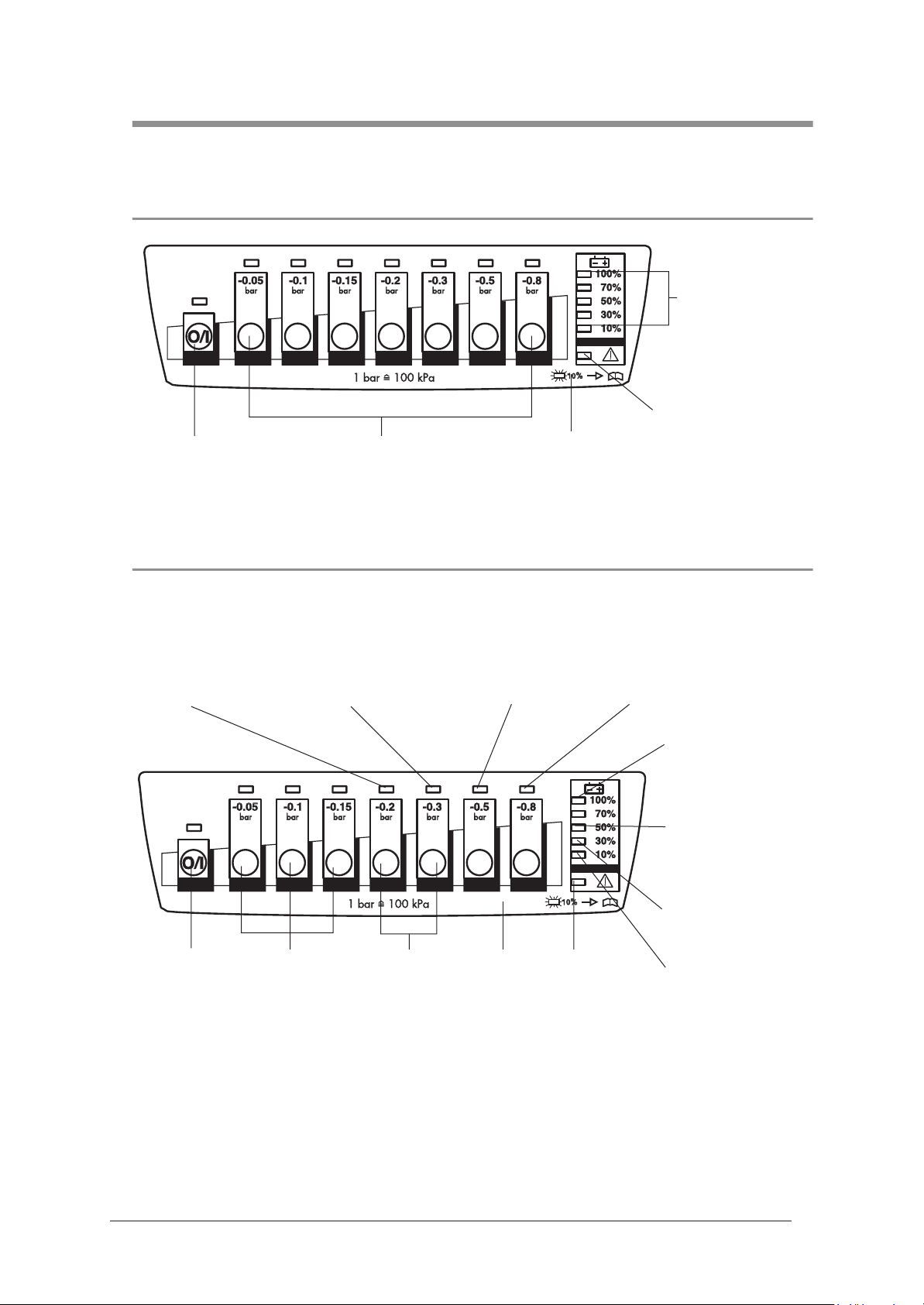

5.1 Operation

Main switch Keys for desired

suction level

Membrane

keyboard

Capacity

indicator

Adequate external

voltage available

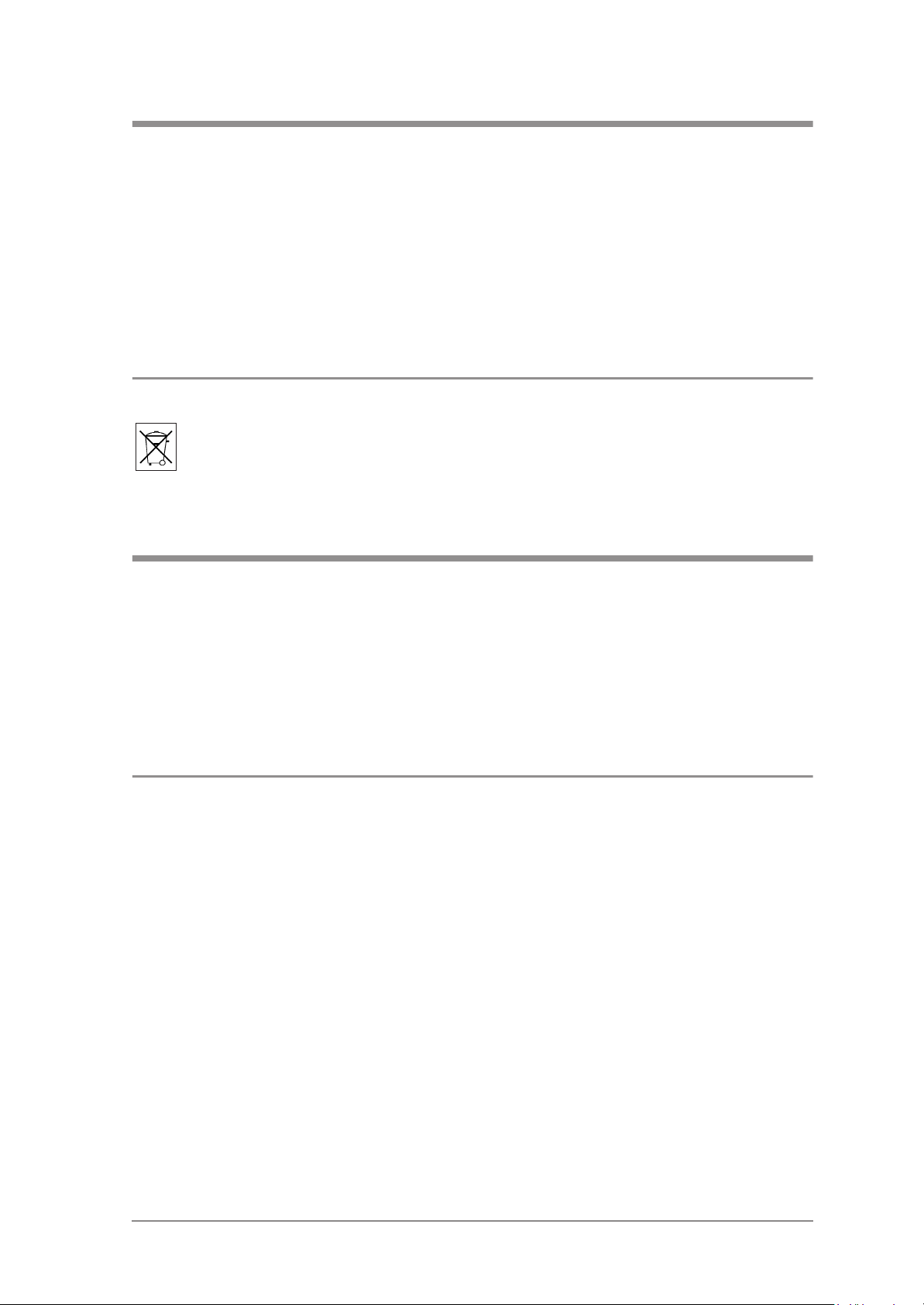

5.2 Service

Bring up service display by pressing keys –0.2 and –0.3 simultaneously.

Charging was

terminated due to

power pack

overvoltage.

Main switch Press

simultaneously

Charging was

terminated due to

incorrect temperature

of power pack.

to initialize

power pack.

Press

simultaneously

for service

display.

Charging was

terminated due to

maximum charging

time being exceeded.

Membrane

keyboard

Adequate

external voltage

available.

Power pack was

discharged down to

discharging limit

voltage.

Charging was

terminated.

A new power pack

was installed. Its

capacity is unknown.

The last charging

operation was

successfully completed.

Initialize power pack

(if LED flashing).

8 Operating and Display Elements

Page 9

6. Maintenance

The ACCUVAC Rescue needs no maintenance,

but please be sure to observe the intervals specified for regular final checks (see ”7.1 Intervals“ on

page 9).

To maintain battery operation and service life we

recommend performing calibration every 8 weeks

according to item 7.1.2 of the description and

6.1 Disposal

Do not dispose of the unit with domestic waste. For proper waste disposal of the equipment, please

contact an approved and certified waste disposal site for electronic goods. Ask your Environmental

Officer or town council for the address.

7. Function checks

operating instructions. This process involves the

necessary specific battery discharging and

recharging.

We recommend that you have any servicing, such

as inspections and repair work, carried out by the

manufacturer – Weinmann – or by expert

personnel.

If the final check reveals defects or deviations from

the specified values, the ACCUVAC Rescue must

not be used again until the faults have been rectified.

7.1 Intervals

To ensure that a properly functioning

ACCUVAC Rescue is always available, it is essential to observe the following intervals.

Before every use

• Perform a function check (see ”7.2 Performing

the function check“ on page 10).

After every use

• Clean, disinfect and/or sterilize the unit and

its parts (see operating instructions “5.

Cleaning and disinfecting”);

• Perform a function check (see ”7.2 Performing

the function check“ on page 10).

Every 6 weeks

• Check the power pack charge level by switching on the ACCUVAC Rescue and reading the

We recommend that you always keep a stock of

the following:

• Aspiration tube 27, WM 10662

• Nozzle with fingertip 26, WM 10666

• Filter 20, WM 10675

capacity indicator. If the capacity is 50% or

less, you should recharge the power pack (see

operating instructions “4.4 Charging the

ACCUVAC Rescue”).

At least every 6 months

• Perform a function check (see ”7.2 Performing

the function check“ on page 10).

• Make a visual inspection of the muffler for

clogging. If it is clogged, fit a new muffler (see

”9.13 Changing the muffler“ on page 25).

After all repairs

• Clean, disinfect and/or sterilize the unit and

its parts (see operating instructions “5. Cleaning and disinfecting”);

• Perform a function check (see ”7.2 Performing

the function check“ on page 10).

Maintenance 9

Page 10

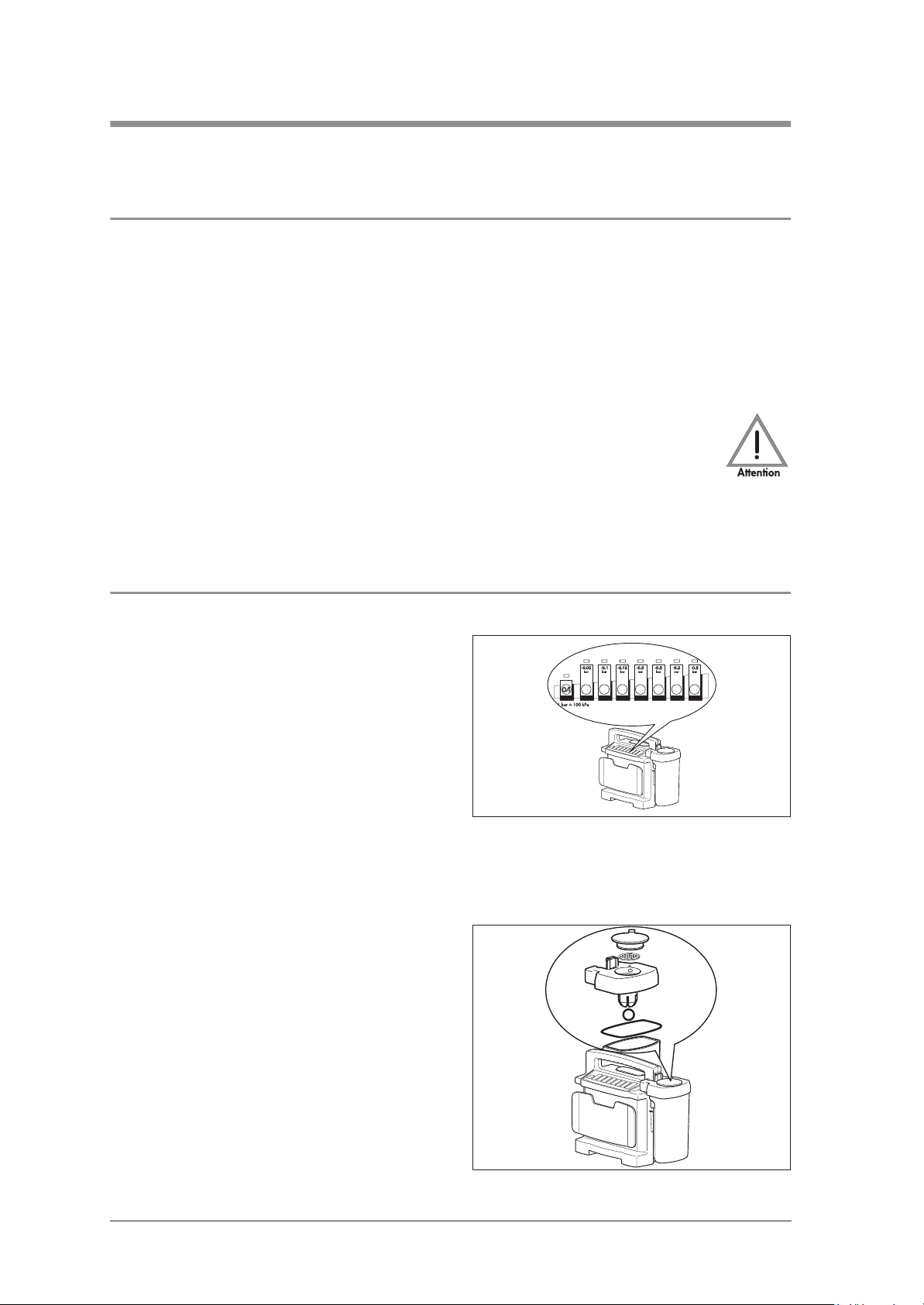

7.2 Performing the function check

1. Assemble ACCUVAC Rescue ready for use.

2. Check that all tubes, the collection canister 28,

secretion cover 23 and filter cover 19 are in

perfect condition. Any damaged and/or worn

parts must be replaced.

4. Switch on the ACCUVAC Rescue.

All LEDs light up for one second after switching

on. After that, only those LEDs that indicate the

operating status stay on. Check the charge

level of the power pack by reading the

capacity indicator 3. If necessary, recharge

the power pack (see operating instructions

“4.4 Charging the ACCUVAC Rescue”).

5. Battery test

A battery test should always be performed

when there are doubts about the performance

of the rechargeable battery, however at the

latest two years after the battery was last

changed.

Procedure:

Charge the ACCUVAC Rescue for 8 hours using the WM 2645 mains charger or for 14

hours using the WM 10750 plug-in power

supply unit. Set a short interval timer to 20 minutes and start the ACCUVAC. After an operating time of 20 minutes the red LED should not

be lit up and the ACCUVAC should be in operation.

If the red LED lights up after 20 minutes, or the

ACCUVAC is no longer working, the battery

is spent and must be replaced. In this case

please replace the battery as described in

section 9.6.

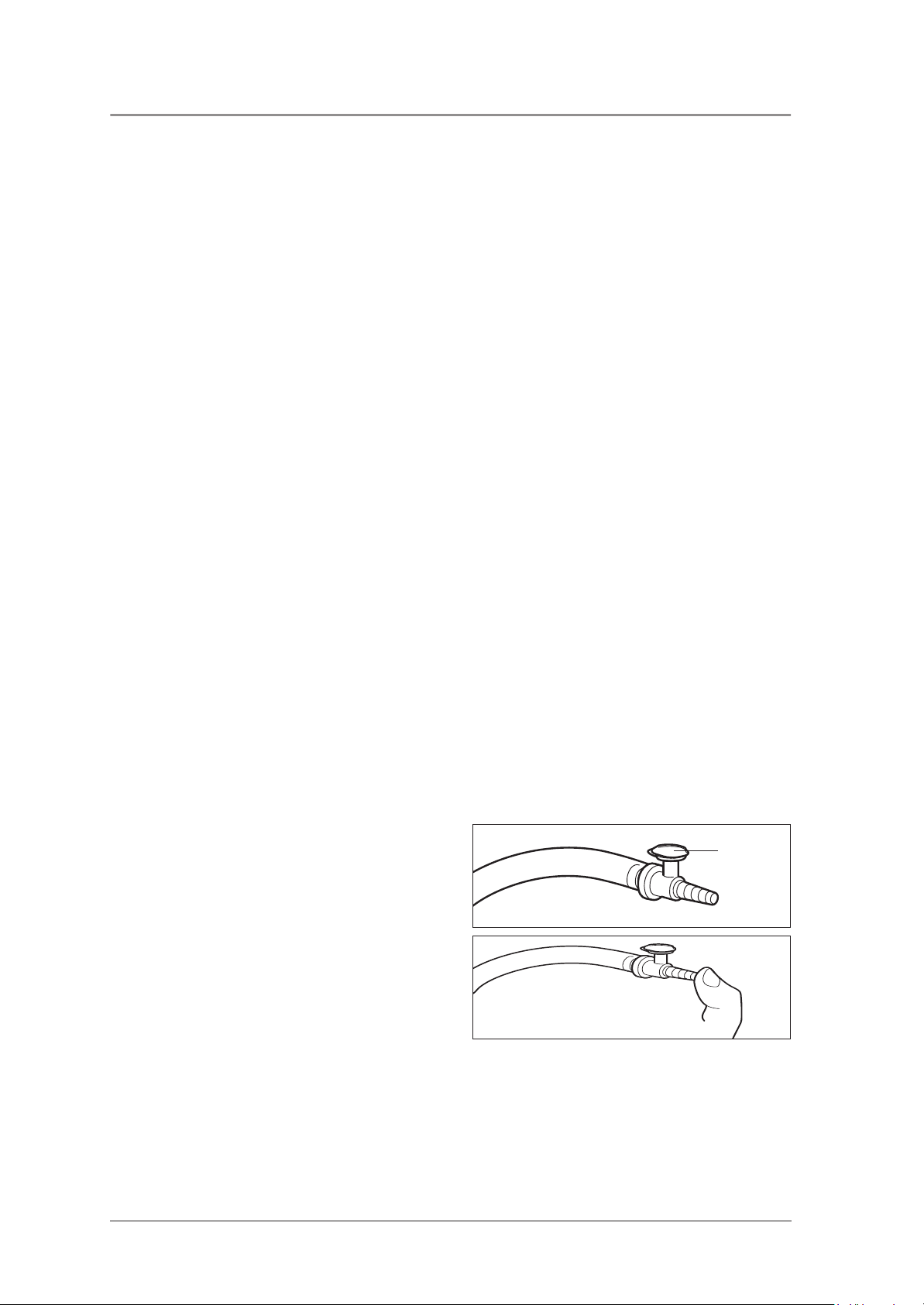

6. Insert the stopper in the fingertip.

3. Check that all tubes are securely connected

and that the secretion cover 23 is firmly in

place.

stopper

7. Use your thumb to hold the nozzle

8. Switch on the aspirator and preselect the maximum vacuum of –0.8 bar. The

ACCUVAC Rescue must reach this vacuum in

not more than 20 seconds. You can tell that

this is the case because the pump stops.

If it takes more than 20 seconds before the

pump stops, the suction capacity is reduced.

Check for possible faults (see ”8. Troubleshooting“ on page 12).

10 Function checks

26 closed.

Page 11

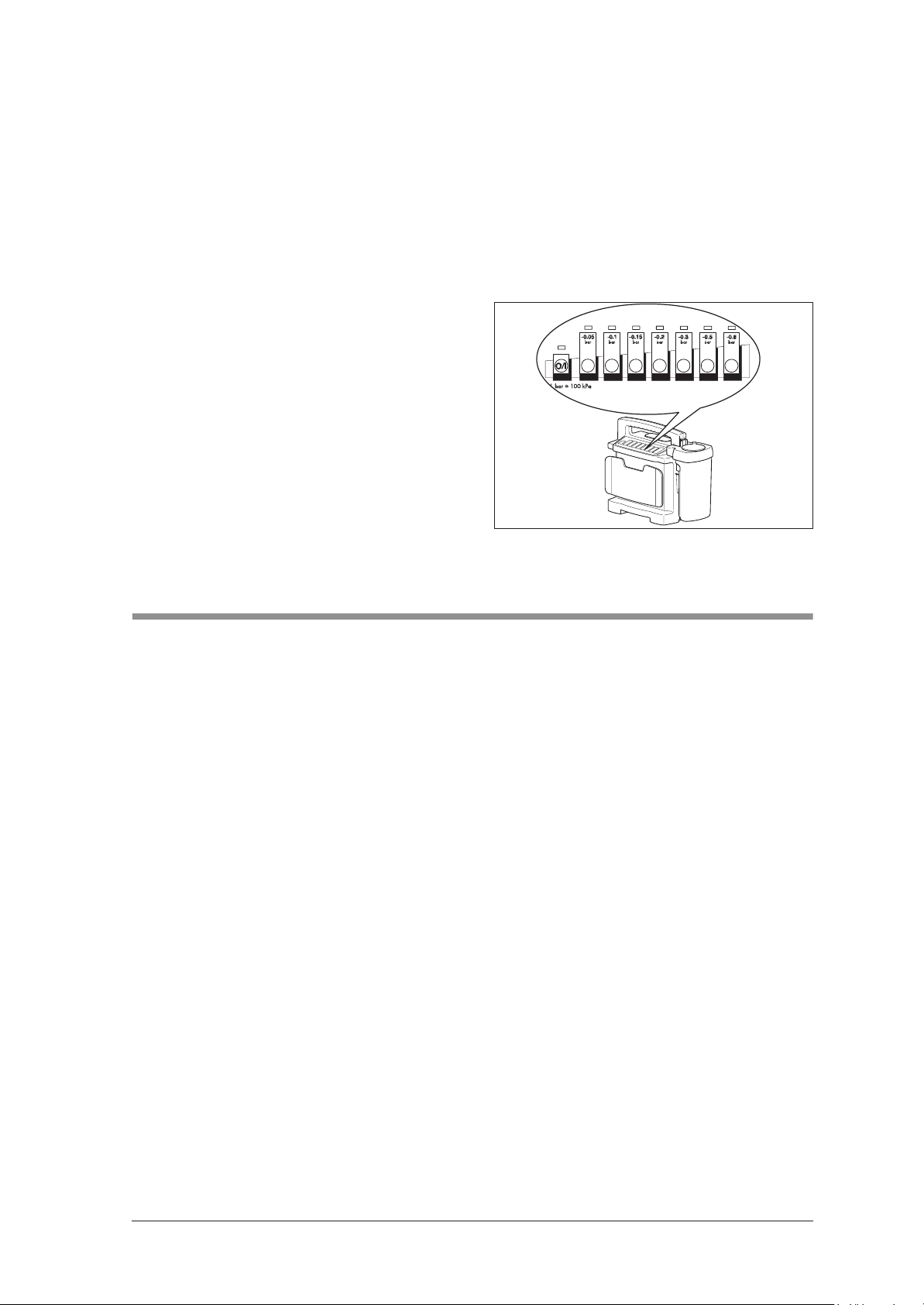

9. Open the suction opening of the nozzle 26.

The aspirator must start running again.

10. Preselect a vacuum of –0.3 bar.

11. Close the end of the nozzle 26 again.

12. As soon as the pump stops, select a vacuum of

–0.2 bar without opening the fingertip.

The vacuum must not fall to –0.2 bar within 10

seconds.

You can tell that the vacuum is falling off by the

fact that the LED above the –0.2 bar button

starts flashing and the pump starts up. This

means there is a leak. In this case check all

tube connections and the re-usable collection

canister 6.

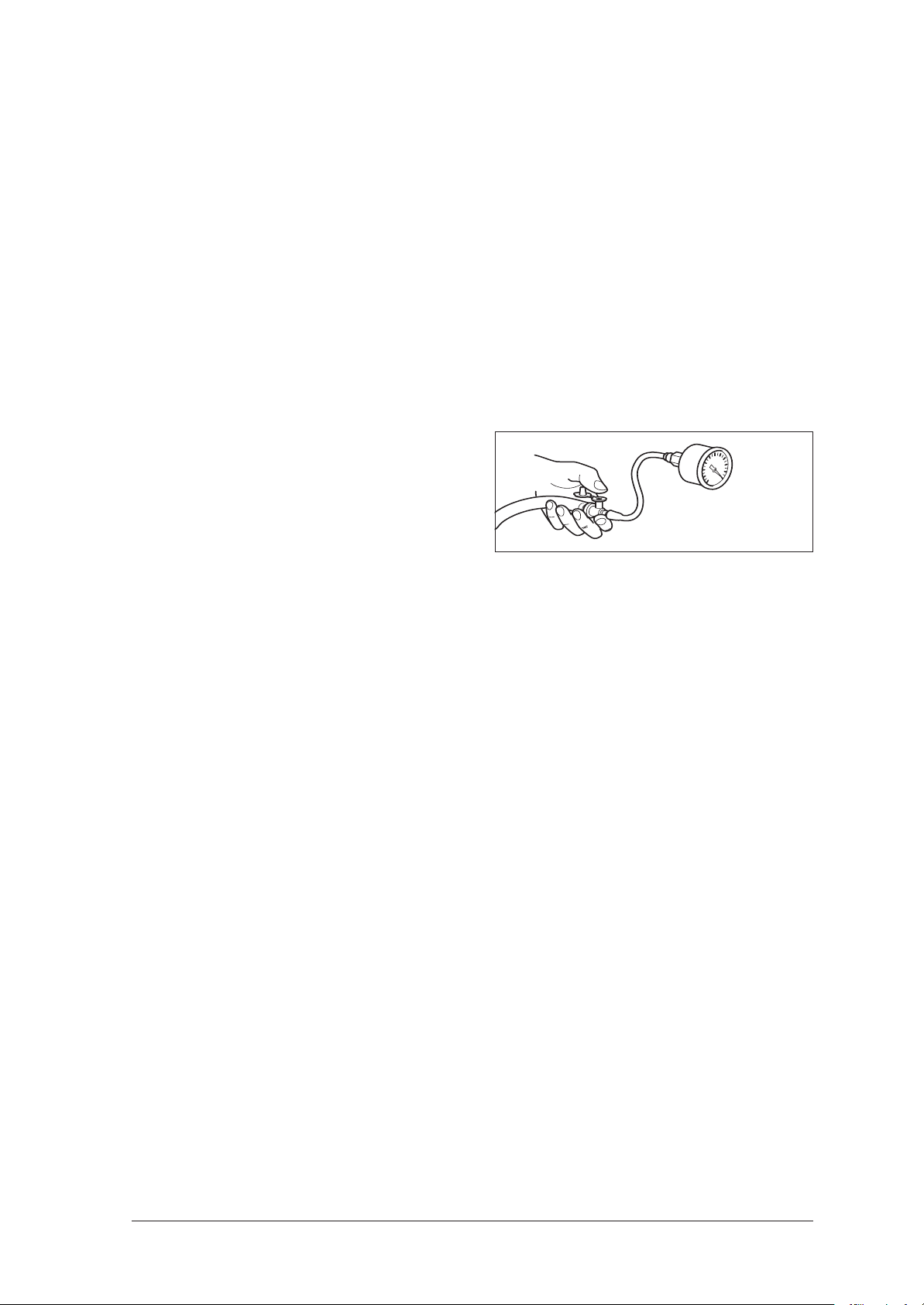

13. Connect the test pressure gage 0 to –1 bar to

the fingertip.

14. Check the accuracy of all suction levels with

the test pressure gage. Start at –0.05 bar. The

tolerance of the individual suction levels must

not exceed +/– 0.04 bar (5% of end value on

scale).

15. Remove the test pressure gage from the fingertip.

-0,4

-0,6

-0,2

-0,8

bar

0

O

2

-1,0

16. Switch off the ACCUVAC Rescue.

Function checks 11

Page 12

8. Troubleshooting

Clear blockage in tube system.

Disconnect external power supply and power

pack from circuit board for at least 2 minutes.

First check the connection between the circuit

board and the front membrane. Otherwise fit

new front membrane.

… fit new circuit board (9.10, page 22)

… fit new pump (9.11, page 24)

Disconnect external power supply and power

pack from circuit board for at least 2 minutes.

Fit new fuse (9.8, page 21)

Perform several charge/discharge cycles. If

unsuccessful, fit new power pack (9.6,

page 19)

Correct polarity and if necessary replace fuse

F1 (9.8, page 21)

Make sure connection snaps in

Detach tube from pressure sensor. Switch

appliance off and on again. Pump must now

run.

Vacuum in system

Controller hanging. Perform reset.

Fault Cause Localize fault Remedy

If display test functions on switching on and the

appropriate set value LED flashes when the

relevant set value key is pressed, the front

membrane is in order. If not, the cause of the

fault may be either the front membrane or the

circuit board.

Connect circuit board to functioning pump and

switch on. If pump does not run, …

Connect pump to functioning circuit board and

Front membrane faulty

Circuit board defective

switch on. If pump does not run, …

Pump defective

If Rescue does not charge up, fuse F1 is

Controller hanging Perform reset

Fuse F1 or F2 in appliance defective

probably defective.

Fuse in vehicle plug defective Fit new fuse (9.12, page 25)

Power pack fully discharged

If an external power supply with incorrect

polarity is connected, a protective diode

ensures that fuse F1 blows to protect the

electronic system.

Incorrect polarity of vehicle power socket

Snap-in connection between circuit board and

power pack not properly engaged

12 Troubleshooting

Appliance does not start. O/I indicator and

capacity indicator show ready for operation

Appliance does not start. O/I indicator does

not show ready for operation

Page 13

Check that all tubes are securely connected and

that filter cover and secretion cover are firmly

installed

Disconnect secretion container from pump unit.

Switch on pump and run at a setting of 0.8 bar.

Hold thumb over suction port. The maximum

vacuum is reached within 5 sec. and the pump

stops. If the pump starts up again within 10 to

… charge power pack (9.6, page 19)

20 sec., the leak is in the pump unit.*

Connect charger WM 2645. If the pump now

runs much more “powerfully” than with the

power pack, you must …

… fit new pump (9.11, page 24)

Connect pump to functioning circuit board and

switch on. If pump does not run …

External power supply must be between 12.0

and 13.8 V.

Allow appliance to cool below +40° C

Check service display (2.1, page 5). If the x-

LED lights up, the external power supply is in

order.

Check service display (2.1, page 5). If the 0.3

bar LED lights up, the power pack temperature

Warm appliance to above +5° C

is not in the operating range 5°C to 45°C

Check service display (2.1, page 5). If the 0.3

bar LED lights up, the power pack temperature

Fit new fuse (9.8, page 21)

is not in the operating range 5°C to 45°C

Check service display (2.1, page 5). If the 0.2

bar LED lights up (power pack overvoltage),

fuse F2 may have blown.

Make sure connection snaps in (9.9, page 21)

Check service display (2.1, page 5). if the 0.2

bar LED lights up (power pack overvoltage), the

connector to the power pack may be loose.

Fault Cause Localize fault Remedy

Leak in suction side of appliance

Power pack not sufficiently charged

Filter clogged Fit new filter (operating instructions 5.3)

Fault in pump

Appliance does not reach maximum vacuum of

–0.8 bar in 20 seconds, but capacity indicator

shows ready for operation

Muffler clogged Fit new muffler (9.13, page 25)

Pump keeps on starting up Leak on suction side of appliance. see above*

External power supply too weak.

Temperature of power pack too high.

No charging possible above +40° C

Temperature of power pack too low.

No charging possible below +5° C

Not charging

Fuse F1 or F2 defective

Fuse in vehicle plug defective Fit new fuse (9.12, page 25)

Snap-in connection between power pack and

circuit board not properly engaged

Troubleshooting 13

Page 14

Initialize (see ”9.7 Initializing the power pack“

on page 20)

Check service display. If the 50% LED lights up,

the software has detected an “unknown” power

pack. This happens when changing the power

pack, fitting a new fuse F2, and sometimes if

power pack is fully discharged, i.e. whenever

the power pack is disconnected from the circuit

board. The software sets the capacity counter to

0% (red LED is on during pumping and

charging) if it detects a power pack voltage of

<10 V during pump operation.

Check vehicle electrical system

… initialize (see ”9.7 Initializing the power

pack“ on page 20)

Check service display (2.1, page 5). If the 30%

LED lights up, the power pack was fully charged

during the last charging operation. Tip: it may

be that the capacity counter is on 99%, with the

result that the 100% LED does not light up.

Switch on pump for approx. 30 sec. and then

charge again. After a few minutes the 100%

LED should light up. If not, the capacity counter

is completely out of adjustment. In that case you

must …

Perform several charge/discharge cycles

(operating instructions 4.4, page 17). If

Charge appliance, switch on and set to 0.8

bar. If the pump power falls off after a few

minutes, the power pack is damaged.

Check service display (2.1, page 5). If the 0.2

unsuccessful, fit new power pack (9.6,

page 19).

bar LED lights up (power pack overvoltage), the

internal resistance of the power pack may be

very high due to age.

Capacity counter cleared.

Charging and aspiration continue to work

Fault Cause Localize fault Remedy

Green 10% LED flashing.

14 Troubleshooting

properly despite this message

Charger does not meet specifications Use mains/charger unit WM 2645

Vehicle electrical system is not supplying 12.0 –

13.8 V

Capacity counter out of adjustment

100% LED does not light up on completion of

charging

Power pack damaged by being fully

discharged

Power pack at end of service life

Page 15

9. Repairs: Information and Instructions

9.1 General

An ESD workplace is essential for making repairs to

the ACCUVAC Rescue.

No work should be performed on the appliance

without a thorough knowledge of the Operating Instructions and the Service and Repair Instructions,

which must always be complied with.

ACCUVAC Rescue is only intended for the purpose described (see ”3.1 Purpose“ on page 6).

9.2 Opening the device

Tools and equipment required:

• Phillips screwdriver size 2.

1. Switch off the ACCUVAC Rescue.

2. Disconnect the aspirator from the external

power supply.

3. Remove the collection canister 28 and any

accessories.

When replacing components or individual parts,

be sure to use only original Weinmann parts.

A function check (see ”7.2 Performing the function

check“ on page 10) must be performed after every

repair.

When ordering the rear part of the case, please

state the appliance type, appliance number and

year of manufacture.

4. Unscrew the holder 29 for the collection

canister.

5. Open the case by unscrewing the 6 crosshead screws 46. When opening the case, be

careful not to damage the silicone sealing

cord.

6. Carefully pull the front and rear case elements

apart.

46

Repairs: Information and Instructions 15

Page 16

9.3 Closing the device

Tools and equipment required:

• Phillips screwdriver size 2

1. Carefully put the front and rear case elements

together again.

2. Screw the case together again, making sure

that the silicone sealing cord is correctly

inserted and is not jammed or otherwise

damaged.

3. Perform a function check (see ”7.2 Performing

the function check“ on page 10).

9.4 Replacing release catch

Tools and equipment required:

46

• Phillips screwdriver size 2;

• Screwdriver, size 1;

• Flat or pointed pliers.

1. Open the device (see ”9.2 Opening the device“ on page 15).

2. Place the ACCUVAC Rescue on its front.

3. Push out retaining pins 63 from release catch

62 and remove them.

4. Remove the old or defective release catch 62.

To do so, use a flat / blunt object to press

down snap lock 65, which is located below

release catch 62.

5. Take the new release catch 62 and insert it in

the rear wall of the case.

6. Take O-ring 64 and locate it in the rear wall of

the case between the loops of the release

catch and the rear wall attachment point.

7. Take the retaining pins 63 and insert them in

the bushing from outside to inside until you

hear them click into place.

62

63

64

8. Close the device (see ”9.3 Closing the device“ on page 16).

9. Perform a function check (see ”7.2 Performing

the function check“ on page 10).

16 Repairs: Information and Instructions

Page 17

9.5 Replacing membrane keyboard

X4

Tools and equipment required:

• Phillips screwdriver size 1;

• 7mm open-end wrench.

1. Open the device (see ”9.2 Opening the device“ on page 15).

2. Carefully detach electrical power pack connector X3 from the circuit board.

3. Unscrew power pack holder (4 cross-head

screws 40).

4. Remove power pack.

40X3

5. Carefully detach electrical connectors X1 and

X2 of internal wiring harness from circuit

board.

6. Carefully detach electrical connector X4 to

motor from circuit board.

7. Carefully detach pressure measurement tube 47

from pressure sensor on circuit board.

8. Carefully open up cable grip of ribbon cable

connector X5. Then carefully remove ribbon

cable (do not touch the ribbon cable contacts

with your fingers, as this can cause oxidation.)

9. Unscrew 4 retaining screws 46 from the circuit

board. Remove the circuit board.

10. Detach the front keyboard 4 from inside

through the front of the case, by pressing the

membrane keyboard out upwards and carefully pulling it off.

X2 X147

X4

X5

46

11. Clean the old adhesive area until no adhesive

residues are left.

12. Take the new membrane keyboard and remove the protective layer from the adhesive

surface. Run the ribbon cable through the

opening in the case front.

Take care when inserting the ribbon cable

through the opening in the housing; it must be

properly routed without any kinks.

13. Stick the new membrane keyboard in the correct position on the case.

Repairs: Information and Instructions 17

Page 18

14. Pull the protective film off the new membrane

40

keyboard.

15. Insert the circuit board again and screw it up

firmly.

16. Carefully restore electrical connections X1, X4

and X5.

X4

X5

X1

46

17. Carefully attach electrical connector X2.

18. Fit tube 47 onto the board again.

19. Insert the power pack again and screw it firmly

in place.

20. Make the electrical connection X3 to the power pack.

21. Close the device (see ”9.3 Closing the device“ on page 16).

22. Perform initialization (see ”9.7 Initializing the

power pack“ on page 20).

23. Perform a function check (see ”7.2 Performing

the function check“ on page 10).

X247

X3

18 Repairs: Information and Instructions

Page 19

9.6 Changing the power pack

The ACCUVAC Rescue is fitted with a high-grade nickel-cadmium power pack.

Tools and equipment required:

• Phillips screwdriver size 2.

1. Open the device (see ”9.2 Opening the device“ on page 15).

2. Carefully disconnect the power pack connector X3 from the circuit board.

3. Unscrew the power pack holder (4 cross-head

screws).

4. Remove the faulty power pack 16.

Help protect the environment!

Don’t throw the old power pack in the garbage can – take it to a local collection point

for environment-friendly disposal.

5. Wait half a minute before fitting the new

power pack. This will allow the capacitors on

the circuit board to discharge.

6. Fit the new power pack with its holder.

7. Carefully push power pack connector X3 onto

the circuit board until it snaps into place.

8. Close the device (see ”9.3 Closing the device“ on page 16).

9. Perform initialization (see ”9.7 Initializing the

power pack“ on page 20).

Note:

The green 10% LED of the capacity indicator 3

continues to flash until the electronic control

system is synchronized with the power pack.

Although the ACCUVAC Rescue will function

when the power pack is charged, the indicator

will not show the charge status of the power pack

unless the system is initialized.

10. Perform a function check (see ”7.2 Performing

the function check“ on page 10).

X3

Repairs: Information and Instructions 19

Page 20

9.7 Initializing the power pack

Initialization matches the capacity indicator 3 to

the energy content of the power pack.

The power pack must be initialized:

• every time a new power pack is fitted;

• every time fuse F2 is changed;

• if the 10 % LED is flashing.

Perform initialization as follows:

1. Charge the ACCUVAC Rescue for about 5

minutes.

2. Disconnect the ACCUVAC Rescue from the external power supply.

3. Press the O/I button to switch on the

ACCUVAC Rescue.

4. Press the following three buttons simultaneously:

-0.05 bar, -0.1 bar, -0.15 bar.

The power pack is now being initialized. All

the LEDs in the capacity indicator strip are

flashing.

5. Press the -0.8 bar button.

The pump now runs at the highest speed and

the power pack discharges until it is completely empty without suffering any damage. Once

the power pack is discharged, the pump stops

automatically. With an empty power pack the

initialization process takes about 5 minutes,

with a full power pack up to 45 minutes.

6. Now connect the ACCUVAC Rescue to an external power supply in order to recharge it.

The charging process takes about 2 hours.

If the pump ran for a long time when discharging because of substantial residual

capacity in the power pack, this may have

heated up the power pack. In this case

charging will not start until the power pack has

cooled down below 40 °C. Depending on

residual capacity this may take up to

45 minutes.

20 Repairs: Information and Instructions

Page 21

9.8 Changing fuse F1 or F2

Important

Never touch the circuit board, as this can damage the

electronic system.

Tools and equipment required:

• Phillips screwdriver size 2.

1. Open the device (see ”9.2 Opening the device“ on page 15).

2. Remove the faulty fuse 14/15. The fuses are

identified on the circuit board.

3. Insert a new fuse. Always use approved fuses

(see ”13. Technical Data“ on page 30).

4. Close the device (see ”9.3 Closing the device“ on page 16).

5. Perform initialization if you have removed fuse

15 (F2) from its holder (see ”9.7 Initializing the

power pack“ on page 20).

6. Perform a function check (see ”7.2 Performing

the function check“ on page 10).

14 15

9.9 Checking connector between circuit board and power pack

Tools and equipment required:

• Phillips screwdriver size 2.

1. Open the device (see ”9.2 Opening the device“ on page 15).

2. Check connector X3.

3. Close the device (see ”9.3 Closing the device“ on page 16).

4. Perform initialization (see ”9.7 Initializing the

power pack“ on page 20).

5. Perform a function check (see ”7.2 Performing

the function check“ on page 10).

X3

Repairs: Information and Instructions 21

Page 22

9.10 Fitting new circuit board WM 10680

40

Important!

For this operation it is essential to use an ESD workplace because of the risk of damage to the circuit

board by static electricity.

Tools and equipment required:

• Phillips screwdriver size 2.

1. Open the device (see ”9.2 Opening the device“ on page 15).

2. Carefully detach electrical power pack connector X3 from the circuit board.

X4

X2 X1

X3

3. Unscrew power pack holder (4 cross-head

screws 40).

4. Remove power pack.

5. Carefully detach electrical connectors X1 and

X2 of internal wiring harness from circuit

board.

6. Carefully detach electrical connector X4 to

motor from circuit board.

7. Carefully detach pressure measurement tube 47

from pressure sensor on circuit board.

X3

X4 X2 X147

22 Repairs: Information and Instructions

Page 23

8. Carefully open up cable grip of ribbon cable

connector X5. Then carefully remove ribbon

cable (do not touch the ribbon cable contacts

with your fingers, as this can cause oxidation.)

9. Unscrew 4 retaining screws 46 from the circuit

board.

10. Insert the new circuit board in reverse order.

Then route connecting cable so it cannot come

into contact with the pump.

• Attention!

Do not connect electrical power pack

connector X3 yet.

• Wait half a minute to allow the capacitors on the

circuit board to discharge.

11. Carefully connect electrical power pack

connector X3.

12. Close the device (see ”9.3 Closing the device“ on page 16).

X3

X4

46

X5

13. Perform initialization (see ”9.7 Initializing the

power pack“ on page 20).

The green 10% LED of the capacity indicator continues flashing until the electronic control system

has been synchronized with the power pack.

Although the fully charged ACCUVAC Rescue can

be used, the power pack charge status is not displayed.

14. Perform a function check (see ”7.2 Performing

the function check“ on page 10).

Repairs: Information and Instructions 23

Page 24

9.11 Fitting new pump

56

The pump is only available as a complete replacement unit.

Tools and equipment required:

• Phillips screwdriver size 2.

1. Open the device (see ”9.2 Opening the device“ on page 15).

2. Carefully detach electrical power pack connector X3 from the circuit board.

3. Open the cable clamp and use a diagonal

cutter to cut through the cable binder. Then remove the motor cable.

4. Remove the O-ring.

X3

5. Unscrew 4 screws 40 from support.

6. Detach silicone fabric tube 57 from inlet port of

pump.

7. Unwind the rolled-up silicone fabric tube 56

from the motor.

8. Detach tube 56 from faulty vacuum pump,

attach it to outlet of new pump 42 and wind it

round motor.

9. Finish fitting the new vacuum pump in reverse

order. To prevent damage, pressure measurement tube 47 must be routed between the inlet

and outlet tubes of the pump.

10. Close the device (see ”9.3 Closing the device“ on page 16).

11. Perform a function check (see ”7.2 Performing

the function check“ on page 10).

47

42

57

40

24 Repairs: Information and Instructions

Page 25

9.12 Changing fuse in vehicle plug

Tools and equipment required:

• Phillips screwdriver size 2.

1. Use a screwdriver to open the vehicle plug.

Note: The central contact of the plug is the plus

pole. The plus lead of the cable has either a

square cross-section or colored markings.

The outer contact of the plug is the minus pole.

The minus lead of the cable is round and

black.

2. Change the faulty fuse 58. Use only approved

fuses (see ”13. Technical Data“ on page 30).

3. Screw the vehicle plug together again.

4. Perform a function check (see ”7.2 Performing

the function check“ on page 10).

9.13 Changing the muffler

Tools and equipment required:

• Phillips screwdriver size 2.

1. Use a screwdriver to unscrew the cover plate

(2 cross-head screws 41).

58

2. Remove the old muffler 12.

3. Insert a new muffler 12.

41

12

Repairs: Information and Instructions 25

Page 26

4. Refit the cover plate 59.

Note that there is a projecting lug on the back

of the cover plate. Be sure to fit the cover plate

so that this lug locates the muffler in position.

5. Perform a function check (see ”7.2 Performing

the function check“ on page 10).

9.14 Electrical circuit diagram

X1

+

red

59

projecting lug

X1

-

black

X2

Power pack, NiCad

Charging/operating contacts

WM 10647

Vacuum pump

WM 10694

Membrane keypad,

Rescue

red

black

X2

X3

X4

X5

Printed circuit board

Accuvac Rescue

WM 10680

26 Repairs: Information and Instructions

Page 27

10. Spare Parts

10.1 Spare parts list

Note:

The item numbers in the following table are identical with the numbers used in these Service and Repair

Instructions and the Operating Instructions.

Item No. Spare Part Order No.

4 Membrane keyboard ACCUVAC Rescue WM 10645

6

19

20

22

23

24

25

26

27

28

8 Tube holder plate, red WM 10623

12 Muffler WM 10665

14 Fuse, external power supply (F1) WM 2692

15 Fuse, power pack (F2) WM 2692

16 NiCad power pack WM 10647

29

30

36

33

31

35

34

Re-usable canister, complete

consisting of:

– Filter cover

– Bacteria filter

– Bracing clip

– Secretion cover

– Ball

– Sealing ring

– Nozzle with fingertip

– Aspiration tube

– Collection canister 900 ml

Holder set for re-usable canister

consisting of:

– Holder

– Fixing elements

Set, disposable bag container, complete

consisting of:

– disposable bag container, complete

– Collection canister

– Disposable bag

– Aspiration tube with nozzle and fingertip

– T-piece

– Vacuum tube

WM 10630

WM 10632

WM 10675

WM 10641

WM 10636

WM 10643

WM 10635

WM 10666

WM 10662

WM 10631

WM 15271

WM 10640

WM 53053

WM 15268

WM 10730

WM 10731

WM 10732

WM 10733

WM 10738

WM 10740

37 Holder set

WM 15172

consisting of:

– Holder

– Fixing elements

38 Front case element, Rescue, assembled, reconditioned* WM 10606

39 Rear case element, Rescue, assembled, reconditioned* WM 10607

40 Oval head screw KB 40x14 WM 23158

41 Countersunk screw KB 40x12 WM 58360

42 Vacuum pump, complete (new)* WM 10694

WM 10735

WM 51091

Spare Parts 27

Page 28

Item No. Spare Part Order No.

43 Vacuum pump, complete (exchange unit)* WM 10605

44 PCB Rescue WM 10680

45 PCB Rescue, exchange unit WM 10604

46 Oval head screw M3x14 WM 53032

47 Pressure measurement tube

WM 10661

consisting of:

– Tube, silicone fabric 3x3; 220 mm long

– Tube nozzle

48 Washer DIN 125 WM 50235

49 Spring washer DIN 127 WM 50350

50 Internal wiring harness, Rescue WM 10686

51 Oval head screw for clip, KB 35x8 WM 58350

52 Washer 4.3 DIN 125 WM 50240

53 Tube, silicone 7x2.5; 690 mm long WM 10668

54

Tube system, internal

WM 10761

WM 10658

WM 10660

consisting of:

55

56

57

58 Fuse, vehicle plug WM 10673

59 Cover plate, red WM 10625

– T reducer 8-4-8

– Tube, silicone fabric 8x3.5; 210 mm long

– Tube, silicone fabric 8x3.5; 70 mm long

WM 10663

WM 10669

WM 10664

60 Round cord 930 mm long WM 10612

61 Cable tie WM 4668

5

Set release catch, red

consisting of:

62

63

64

65

– Release catch, red *

– Retaining pin

– O-ring 2.9 x 1.78

– Snap lock

Tube, silicone fabric 6x3.5; 50 mm long

Tube, silicone fabric 6x3.5; 200 mm long

Operating instructions WM 16136

* When ordering, please state type, appliance no. and year of manufacture

WM 15396

WM 10624

WM 10697

WM 1145/80

WM 10627

WM 10766

WM 10765

28 Spare Parts

Page 29

11. Tools and Test Equipment

Following is a list of tools and test equipment mentioned in these Service and Repair Instructions.

See the relevant chapter for details of the tools and

test equipment needed in each case.

Special tools can be obtained from the

manufacturer, Weinmann.

• Cross-head screwdriver, size 1

• Cross-head screwdriver, size 2

• Pliers

• Vacuum test pressure gage set WM 15294

12. Technical Changes

Technical change From Device No. Date

Reinforced release catch 2117 09.11.98

Software update Version 3.0 4500 22.08.00

New holder for release catch 6730 16.07.01

Case reinforced, use of washers discontinued 8105 20.11.01

Printed circuit board with radio suppression 9145 07.06.02

Vacuum pump without side walls 10048 22.10.02

Appliance plate with e1 mark 13445 28.06.04

Tools and Test Equipment 29

Page 30

13. Technical Data

ACCUV

AC Rescue

Product category according

to 93/42/EEC

Dimensions

WxHxD in mm

Weight approx. 5.1 kg

Canister volume 900 ml

Suction capacity at 12 V

with free flow

Max. vacuum at 12 V 0.8 bar (80 kPa)

Aspiration tube

Hydrophobic bacteria filter

Motor output 50 W

Rated voltage 12 V

Maximum current

consumption

Temperature range

Operation

Charging

Storage

Electromagnetic

compatibility:

Radio interference

suppression

Radio interference resistance

Classification according to EN 60601-1:

Protection against electric shock: class II; with charger: class I

Degree of protection against electric shock: BF

Degree of protection against water: IPX 1 (drip water)

Classification according to

EN ISO 10079-1

II b

370x280x140

> 20 l/min

diam. 10 mm,

length 1300 mm

size rating 1 µm,

water breakthrough

pressure 0.3 bar

3.5 A

–18 °C to +40 °C

+ 5 °C to +40 °C

–40 °C to +70 °C

EN60601-1-2

EN 55011

IEC 1000-4 Parts 2–5 & 11

high vacuum/high flow

ACCUVAC Rescue

Norms complied with

Vehicle plug fuse

Internal fuse F1

external power supply

Internal fuse F2

power pack

Power pack type Nickel cadmium 2.8 Ah

Charging voltage 12.0 to 13.8 V

Operating time after

charging for 2 hours

Operating mode S2 60 min

Service life of power pack

Collection canister APEC

Secretion cover Silicone

Ball PVDF

Filter cover Silicone

Filter holder APEC

EN 60601-1, EN ISO 100791, EN 1789

8 A, DIN 72581,

identification color white

4 A slow-acting,

low breaking capacity

G fuse links 5x20 mm,

conforms to IEC 127

4 A slow-acting,

low breaking capacity

G fuse links 5x20 mm,

conforms to IEC 127

45 min at maximum suction

400 charge/discharge cycles in

approx. 3 years

Materials

From serial no. 13445/2004

(Subject to technical change without notice)

30 Technical Data

Page 31

13.1 Safe distances

The ACCUVAC Rescue is intended for operation in an electromagnetic environment in which high-frequency

interference variables are controlled. The customer or user of the ACCUVAC Rescue can help avoid electromagnetic interference by maintaining the minimum safe distance between portable and mobile high-frequency telecommunication devices (transmitters) and the ACCUVAC Rescue depending on the rated output of the

transmitter as given below.

Recommended safe distances between portable or mobile HF telecommunication

devices (e.g. mobile phones) and the ACCUVAC Rescue

Rated output of

HF device

in W

150 kHz - 80 MHz

d=(3,5/V1) x √√√√P

0.01 0.12 0.12 0.23

0.1 0.37 0.37 0.74

1 1.17 1.17 2.33

10 3.69 3.69 7.38

100 11.67 11.67 23.33

Safe distance depending on transmission frequency

in m

80 MHz - 800 MHz

d=(3,5/V1) x √√√√P

800 MHz – 2,5 GHz

d=(3,5/V1) x √√√√P

Technical Data 31

Page 32

14. Repair and Test Report

Device master data

Keep a record of all tests or repairs performed (please copy attached form for use).

Service performed in

accordance with ACCUVAC-

Service and Repair Instructions

Company

Date Signature

___________ ________________

Company

Date Signature

___________ ________________

Company

Date Signature

___________ ________________

maintenance / repair / comments

Maintenance and repair work carried out in accordance with service document

Company

Date Signature

___________ ________________

32 Repair and Test Report

22525 Hamburg

WM 10600 ACCUVAC Rescue

Manufacturers: Weinmann GmbH + Co.

Device mode: ACCUVAC

WM 10700 ACCUVAC Rescue

Device no.: _______________________

Production date: ___________________

Page 33

Page 34

Page 35

Page 36

WM 16293b - 07/06 · Printed on 100% recycled paper

For decades Weinmann has been

developing, producing and marketing

medical devices for markets around

the world. In cooperation with our

partners we design economic health

systems for diagnosis and therapy in

Sleep Medicine, Home Mechanical

Ventilation, Oxygen Medicine

and Emergency Medicine.

Weinmann

Geräte für Medizin GmbH + Co. KG

P.O. Box 540268 · D-22502 Hamburg

Phone +49/40/5 47 02-0

Fax +49/40/5 47 02-461

E-mail int.sales@weinmann.de

Internet www.weinmann.de

Loading...

Loading...