Page 1

Smart Relay

SRW 01 (Ethernet)

Motors | Automation | Energy | Transmission & Distribution | Coatings

User's Manual

Page 2

Page 3

User’s Manual

Series: SRW 01

Language: English

Document Nº: 10002415831 / 01

Models: 0.25...840 A

Software Version: 2.0X

Publication Date: 11/2017

Page 4

Summary of Reviews

The information below describes the revisions made to this manual.

Version Review Description

V1.0X R00 First edition

V2.0X R01 General review

Page 5

Contents

QUICK REFERENCE OF THE PARAMETERS .......................................... 0-1

1 SAFETY INSTRUCTIONS ....................................................................... 1-1

1.1 SAFETY WARNINGS IN THE MANUAL ............................................................... 1-1

1.2 PRELIMINARY RECOMMENDATIONS ...............................................................1-1

2 GENERAL INFORMATION ...................................................................... 2-1

2.1 ABOUT THE MANUAL..........................................................................................2-1

2.2 TERMS AND DEFINITIONS USED IN THE MANUAL ......................................... 2-1

2.3 ABOUT THE SRW 01 ............................................................................................ 2-3

2.4 SRW 01 IDENTIFICATION LABEL ....................................................................... 2-6

2.5 HOW TO SPECIFY THE SRW 01 MODEL ........................................................... 2-6

2.6 RECEIVING AND STORAGE ................................................................................ 2-6

2.7 POWER FACTOR .................................................................................................. 2-7

3 INSTALLATION AND CONNECTION ...................................................... 3-1

3.1 MECHANICAL INSTALLATION ............................................................................ 3-1

3.1.1 Environmental Conditions ..........................................................................3-1

3.1.2 Mounting ...................................................................................................... 3-1

3.2 ELECTRICAL INSTALLATION .............................................................................. 3-3

3.3 RELAY POWER SUPPLY ...................................................................................... 3-4

3.4 POWER CABLES .................................................................................................. 3-4

3.5 CURRENT MEASUREMENT UNIT (UMC) CONNECTION ................................. 3-5

3.6 CONNECTION OF THE CURRENT/VOLTAGE MEASUREMENT UNIT (UMCT) 3-6

3.7 EXTERNAL CURRENT TRANSFORMER (CT) USE ............................................ 3-7

3.8 USB CONNECTION .............................................................................................. 3-7

3.9 CONNECTION OF THE CONTROL UNIT (UC) DIGITAL INPUTS ...................... 3-8

3.9.1 Identification of the Digital Inputs Types (UC) .......................................... 3-8

3.9.2 Connection of an External Power Supply for the Digital Inputs

(24 Vdc) ..................................................................................................................3-8

3.10 CONNECTION OF THE CONTROL UNIT (UC) DIGITAL OUTPUTS ................ 3-9

3.11 EXPANSION DIGITAL UNIT (EDU) CONNECTION ...........................................3-9

3.12 CONNECTION OF THE EXPANSION DIGITAL UNIT (EDU) DIGITAL

INPUTS ......................................................................................................................3-10

3.13 CONNECTION OF THE EXPANSION DIGITAL UNIT (EDU) DIGITAL

OUTPUTS .................................................................................................................. 3-11

3.14 CONNECTION OF THE EARTH LEAKAGE SENSOR (ELS) ...........................3-11

3.15 SHORT CIRCUIT RANGES (UL) .......................................................................3-12

4 HUMAN-MACHINE INTERFACE (HMI) .................................................. 4-1

4.1 KEYS .....................................................................................................................4-2

4.2 HMI LOCAL MESSAGES .....................................................................................4-2

4.3 PARAMETERIZATION ..........................................................................................4-2

4.4 PARAMETER STRUCTURE ................................................................................. 4-3

4.5 PASSWORD FOR PARAMETERIZATION ............................................................ 4-3

4.6 COPY FUNCTION ................................................................................................. 4-4

4.6.1 Procedure to Be Used to Copy Parameter Sets and/or User Programs

from the SRW 01-A (Source) to the SRW 01-B (Destination) ...........................4-5

Page 6

Contents

5 PARAMETERIZATION ............................................................................. 5-1

5.1 LOCAL/REMOTO..................................................................................................5-2

5.2 LOCAL/REMOTE COMMAND .............................................................................5-2

5.3 DIGITAL INPUTS AND OUTPUTS ........................................................................ 5-6

5.4 OPERATION MODES .......................................................................................... 5-10

5.4.1 SRW 01 Check Back .................................................................................5-10

5.4.2 Transparent Mode .....................................................................................5-12

5.4.2.1 Connection Diagram – Transparent Mode ....................................5-13

5.4.3 Overload Relay ..........................................................................................5-13

5.4.3.1 Connection Diagram – Overload Relay .........................................5-14

5.4.4 Direct Starter .............................................................................................5-14

5.4.4.1 Connection Diagram – Direct Starter ............................................5-15

5.4.4.2 Operation Diagram – Direct Starter ............................................... 5-16

5.4.5 Reversing Starter ......................................................................................5-16

5.4.5.1 Connection Diagram – Reversing Starter .....................................5-17

5.4.5.2 Operation Diagram – Reversing Starter ........................................ 5-18

5.4.6 Star-Delta Starter ...................................................................................... 5-19

5.4.6.1 Connection Diagram – Star-Delta Starter .....................................5-20

5.4.6.2 Operation Diagram – Star-Delta Starter ........................................5-21

5.4.7 Dahlander Starter ...................................................................................... 5-21

5.4.7.1 Connection Diagram – Dahlander Starter ..................................... 5-22

5.4.7.2 Operation Diagram – Dahlander Starter ........................................5-23

5.4.8 Pole Changing Starter ..............................................................................5-23

5.4.8.1 Connection Diagram – Pole Changing Starter ..............................5-24

5.4.8.2 Operation Diagram – Pole Changing Starter ...............................5-25

5.4.9 PLC Mode ..................................................................................................5-25

5.4.9.1 Connection Diagram – PLC ............................................................5-26

5.5 MOTOR CONFIGURATION ................................................................................ 5-26

5.6 COMMUNICATION ............................................................................................. 5-29

5.6.1 Ethernet .....................................................................................................5-30

5.7 PROTECTION CONFIGURATION PARAMETERS ............................................5-31

5.7.1 Hysteresis ..................................................................................................5-32

5.7.2 External Fault .............................................................................................5-33

5.7.3 Current Imbalance between Phases .......................................................5-35

5.7.4 Earth Fault ..................................................................................................5-36

5.7.5 Phase Loss (Current) ................................................................................5-37

5.7.6 Overcurrent ................................................................................................ 5-37

5.7.7 Undercurrent ..............................................................................................5-38

5.7.8 Frequency Out of Range ........................................................................... 5-39

5.7.9 Earth Leakage ...........................................................................................5-40

5.7.9.1 Earth Leakage Protection Operation ............................................. 5-40

5.7.9.2 Inhibition of the Earth Leakage Protection at Starting ................5-41

5.7.9.3 Trip Inhibition Function in Case of Short Circuit ..........................5-42

5.7.9.4 Verification of the Earth Leakage Current Measuring ................. 5-43

5.7.10 PTC Thermal Protection .........................................................................5-43

5.7.11 Overload ................................................................................................... 5-44

5.7.12 Service Factor .........................................................................................5-48

5.7.13 Cooling Time ............................................................................................5-48

5.7.14 Overload Parameterization ....................................................................5-49

5.7.14.1 Tripping Class Programming Suggestion ...................................5-49

Page 7

Contents

5.7.15 Tripping Class Programming Example .................................................. 5-50

5.7.15.1 Reduction of the Time from Cold to Warm Starting ................... 5-51

5.7.16 Phase Sequence ......................................................................................5-51

5.7.17 Voltage Unbalance .................................................................................. 5-51

5.7.18 Phase Loss (Voltage) ............................................................................... 5-52

5.7.19 Overvoltage ..............................................................................................5-53

5.7.20 Undervoltage ...........................................................................................5-54

5.7.21 Underpower ............................................................................................. 5-54

5.7.22 Overpower ...............................................................................................5-55

5.7.23 Power Under Factor ................................................................................ 5-56

5.7.24 Power Over Factor .................................................................................. 5-57

5.7.25 Reset Button ............................................................................................ 5-58

5.7.25.1 Reset ...............................................................................................5-58

5.7.25.2 Trip Test .......................................................................................... 5-58

5.7.26 Reset to the Factory Settings ................................................................5-59

5.7.27 Auto-Reset ............................................................................................... 5-60

5.7.28 Ladder Program Execution ....................................................................5-60

5.7.29 User Parameters .....................................................................................5-61

6 MONITORING ......................................................................................... 6-1

6.1 MONITORING PARAMETERS ............................................................................. 6-1

7 DIAGNOSIS ............................................................................................. 7-1

7.1 DIAGNOSIS VIA LEDS ..........................................................................................7-1

7.2 DIAGNOSIS VIA HMI ............................................................................................ 7-2

7.3 HISTÓRICO DE DESARMES ................................................................................7-3

8 TECHNICAL CHARACTERISTICS ......................................................... 8-1

8.1 MECHANICAL DATA ............................................................................................8-3

Page 8

Contents

Page 9

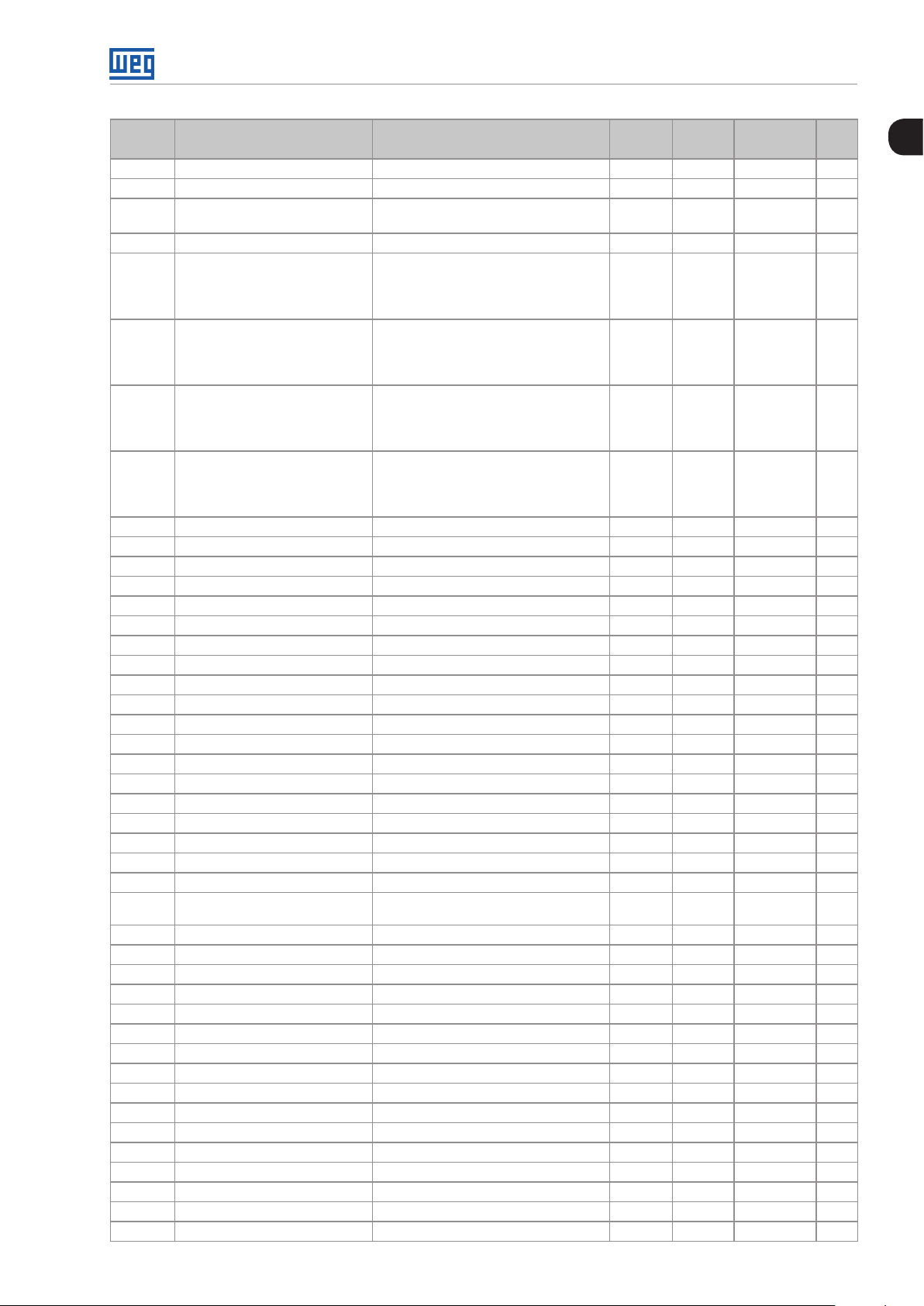

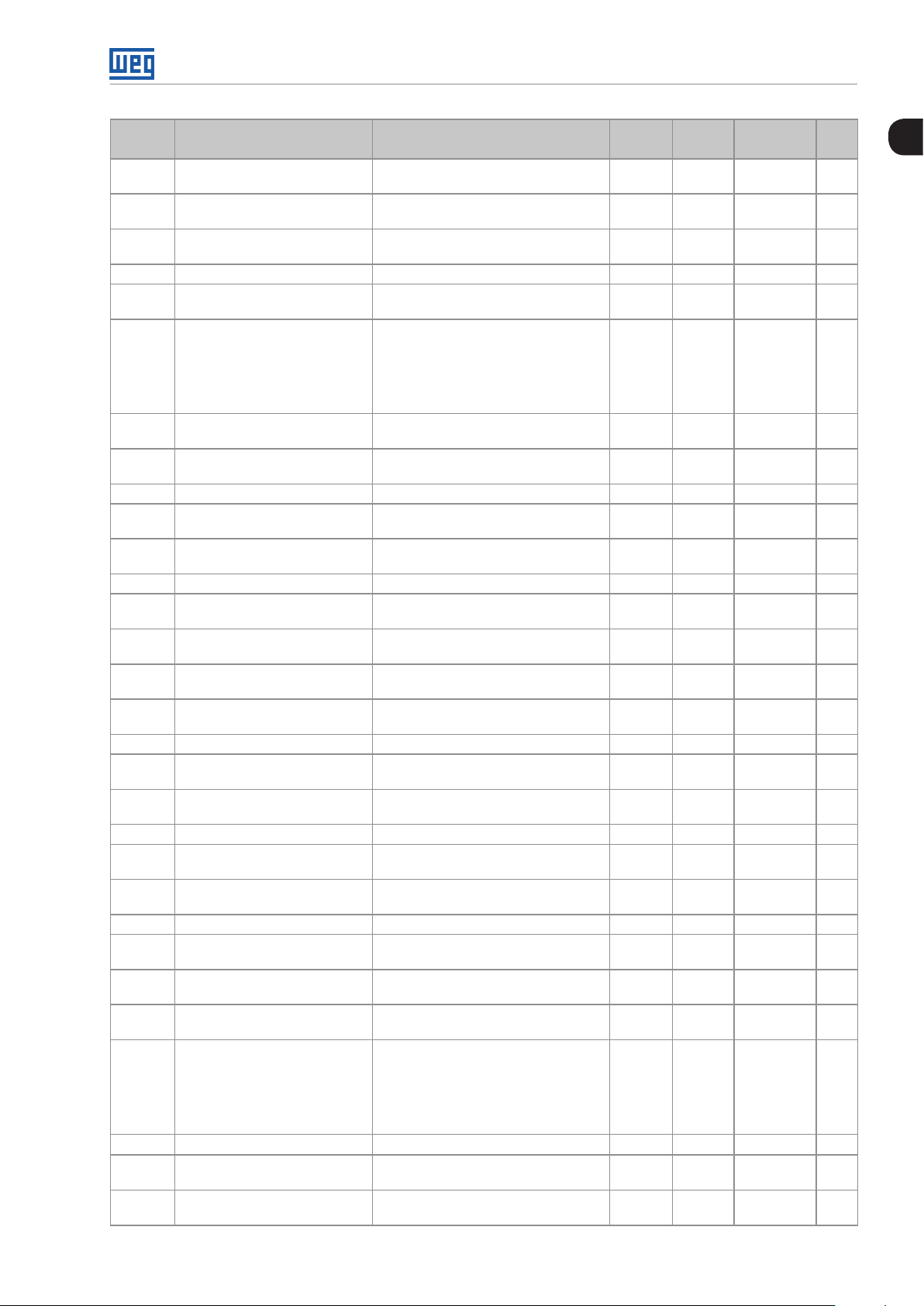

Quick Reference of Parameters

QUICK REFERENCE OF THE PARAMETERS

Parameter Description Adjustable Range

P000 Access to the Parameters 0 to 9999 0 rw 4-4

P001 Scan Cycle Time 0.0 to 6553.5 ms - RO 5-60

P002 IN % Current 0 to 999 % - RO 6-3

P003 True RMS Current 0.0 to 6553.5 A - RO 6-3

P004 Average Voltage True RMS 0 to 1000 V - RO 6-3

P005 Line Frequency 0.0 to 99.9 Hz - RO 6-4

P006 Relay Status (binary) bit0 = Error

P007 Relay Status 2 (binary) bit0 = HMI 0 key

P008 Power Factor 0.00 to 1.00 - RO 6-5

P009 Motor Reactive Power 0.0 to 6553.5 kVAr - RO 6-5

P010 Motor Active Power 0.0 to 6553.5 kW - RO 6-5

P011 Motor Apparent Power 0.0 to 6553.5 kVA - RO 6-5

P012 Digital Inputs I11 to I16 Status

(decimal)

P013 Digital Outputs O1 to O4 Status

(binary)

P014 Last Error 0 to 200 - RO 6-6

P015 Second Error 0 to 200 - RO 6-6

P016 Current Error 0 to 200 - RO 6-6

P020 PTC Value (ohms) 0 to 10000 Ω - RO 6-6

P023 Firmware Version (UC) 0.00 to 655.35 - RO 6-7

P024 Type of Protection (UC) 0 = PTC

P026 Firmware Version (UMC/UMCT) 0.00 to 655.35 - RO 6-7

P027 Firmware Version (EDU) 0.00 to 655.35 - RO 6-7

P029 Value of Addressing Switches 0000h to 00FFh - RO 6-7

P030 L1 Phase True RMS Current 0.0 to 6553.5 A - RO 6-7

P031 L2 Phase True RMS Current 0.0 to 6553.5 A - RO 6-8

P032 L3 Phase True RMS Current 0.0 to 6553.5 A - RO 6-8

P033 Line Voltage L1-L2 0 to 1000 V - RO 6-8

P034 Line Voltage L2-L3 0 to 1000 V - RO 6-8

P035 Line Voltage L3-L1 0 to 1000 V - RO 6-8

P036 Earth Leakage Percentage Current 0 to 3334 % - RO 6-8

P037 Earth Leakage True RMS Current 0.000 to 10.000 A - RO 6-9

P042 Powered Relay Time 0 to 65530 h - RO 6-9

P043 Motor Running Time 0 to 65530 h - RO 6-9

P044 Meter kWh 0.0 to 999.9 kWh - RO 6-9

P045 Meter MWh 0 to 65535 MWh - RO 6-9

P046 Meter kVArh 0.0 to 999.9 kVArh - RO 6-10

P047 Meter MVArh 0 to 65535 MVArh - RO 6-10

P050 Motor Thermal Protection 0 to 100 % - RO 6-10

P051 Current Imbalance Level 0 to 100 % - RO 6-10

P052 Earth Fault Level 0 to 200 % - RO 6-11

P053 Voltage Unbalance Level 0 to 100 % - RO 6-11

P060 Number of Starts 0 to 65535 - RO 6-11

bit1 = Trip

bit2 = Alarm/Fault

bit3 = Motor On

bit4 = Remote Mode

bit1 = HMI I key

bit2 = Speed Direction/Speed

bit3 = Motor Transition

bit4 = Cooling Time

0 to 63 - RO 5-8

bit0 = O1

bit1 = O2

bit2 = O3

bit3 = O4

1 = ELS

2 = PTC/ELS

Factory

Setting

- RO 6-4

- RO 6-4

- RO 6-6

- RO 6-7

User

Setting

Proprieties Page

0

SRW 01 | 0-1

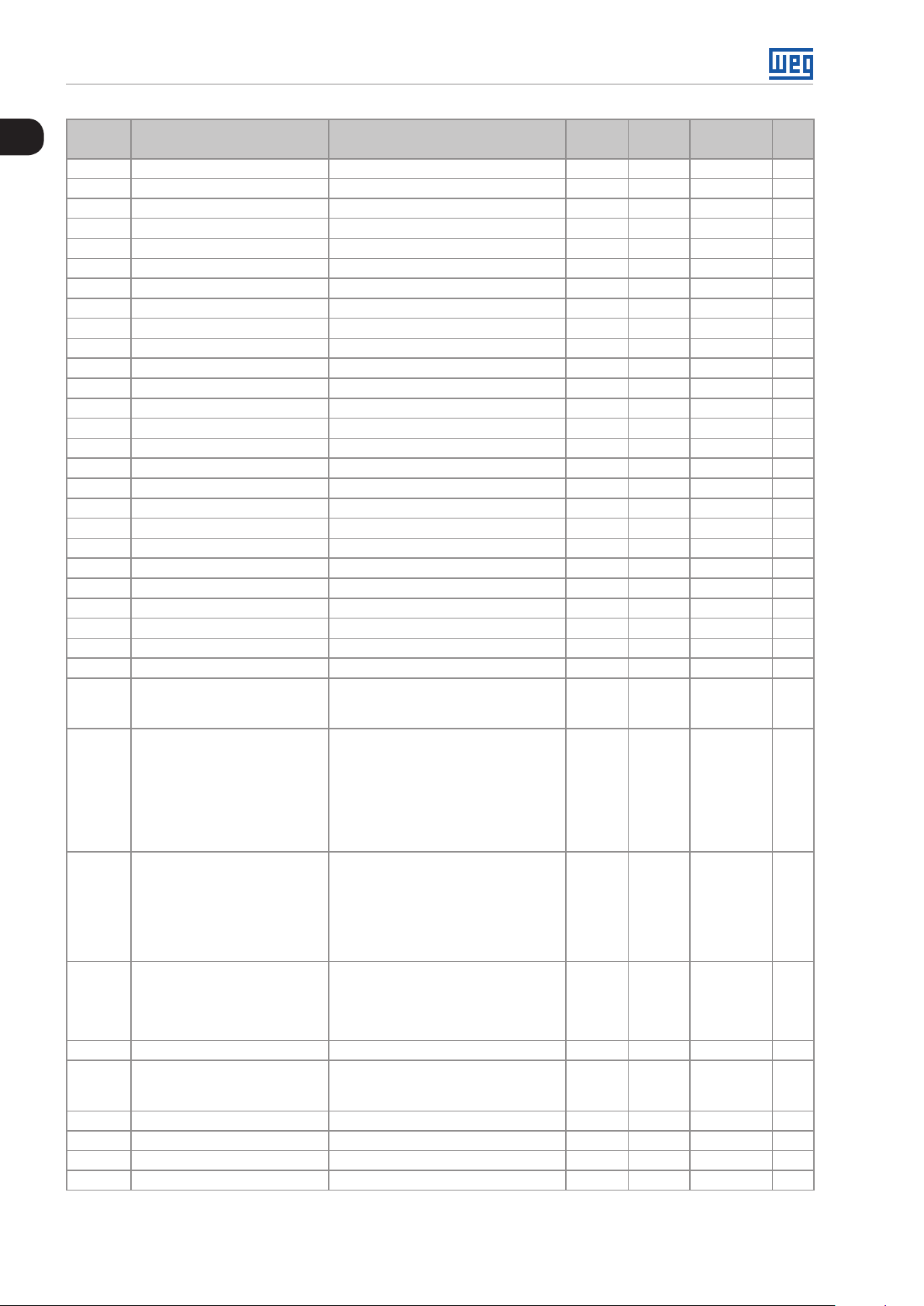

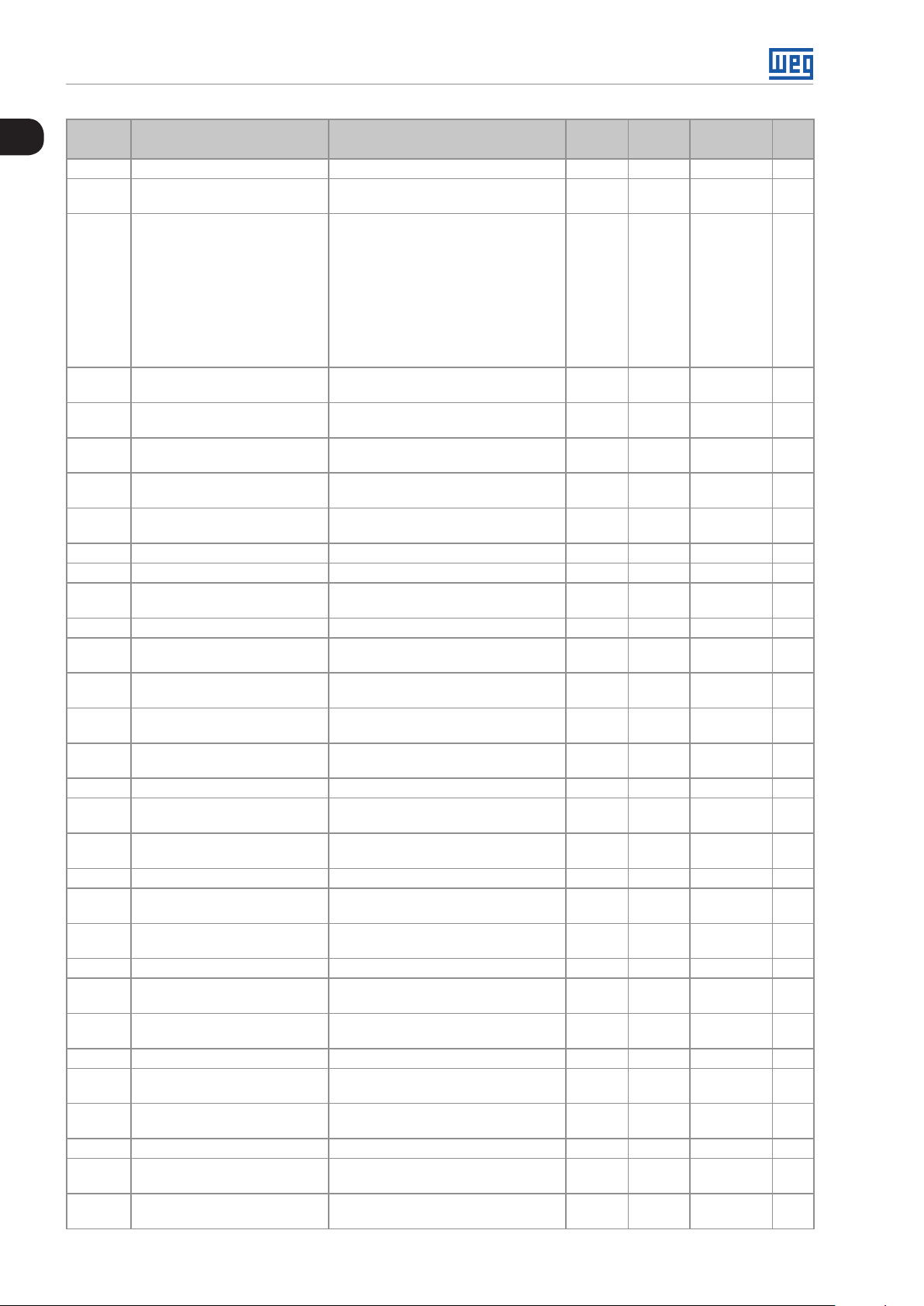

Page 10

Quick Reference of Parameters

0

Parameter Description Adjustable Range

P061 Number of Overload Trips 0 to 65535 - RO 6-11

P062 Number of Current Imbalance Trips 0 to 65535 - RO 6-11

P063 Number of Earth Fault Trips 0 to 65535 - RO 6-11

P064 Number of Phase Loss (Current)

Trips

P065 Number of Overcurrent Trips 0 to 65535 - RO 6-12

P066 Number of Undercurrent Trips 0 to 65535 - RO 6-12

P067 Number of Frequency Out of Range

Trips

P068 Number of PTC Trips 0 to 65535 - RO 6-12

P069 Number of Earth Leakage Trips 0 to 65535 - RO 6-12

P070 Number of External Fault Trips 0 to 65535 - RO 6-13

P071 Trip Status 1 (binary) bit0 = PTC

P072 Trip Status 2 (binary) bit0 = Phase Loss (Current)

P073 Trip Status 3 (binary) bit0 = Earth Leakage

P075 Alarm Status 1 (binary) bit0 = PTC

P076 Alarm Status 2 (binary) bit0 = Phase Loss (Current)

P077 Alarm Status 3 (binary) bit0 = Earth Leakage

P078 General Trip Status 2 0 to 65535 - RO 6-14

P079 General Alarm Status 2 0 to 65535 - RO 6-15

P080 General Trip Status 0 to 65535 - RO 6-15

P081 General Alarm Status 0 to 65535 - RO 6-15

P082 Total Number of Trips 0 to 65535 - RO 6-15

P084 Communication Protocol 0 = None

P085 Type of Digital Inputs UC 0 = Invalid

P086 Digital Inputs I5 to I10 Status

(decimal)

P087 Digital Outputs O5 to O8 Status

(binary)

P100 Number of Voltage Unbalance 0 to 65535 - RO 6-16

P101 Number of Phase Loss (Voltage) 0 to 65535 - RO 6-16

P102 Number of Overvoltage Trips 0 to 65535 - RO 6-17

P103 Number of Undervoltage Trips 0 to 65535 - RO 6-17

0 to 65535 - RO 6-12

0 to 65535 - RO 6-12

bit1 = Out of Frequency

bit2 = Undercurrent

bit3 = Overcurrent

bit1 = Current Imbalance

bit2 = Earth Fault

bit3 = Overload

bit1 = External Fault

bit2 = Trip Test

bit3 = Phase Sequence

bit1 = Out of Frequency

bit2 = Undercurrent

bit3 = Overcurrent

bit1 = Current Imbalance

bit2 = Earth Fault

bit3 = Overload

bit1 = External Fault

bit2 = No Function

bit3 = No Function

1 = Modbus-RTU

2 = DeviceNet

3 = Profibus DP

4 = Modbus-TCP

5 = Ethernet/IP

6 = ProfiNet IO

1 = Invalid

2 = 24 Vdc

3 = 110 Vac

0 to 63 - RO 5-9

bit0 = O5

bit1 = O6

bit2 = O7

bit3 = O8

Factory

Setting

- RO 6-13

- RO 6-13

- RO 6-13

- RO 6-14

- RO 6-14

- RO 6-14

- RO 6-15

- RO 3-8

- RO 5-9

User

Setting

Proprieties Page

0-2 | SRW 01

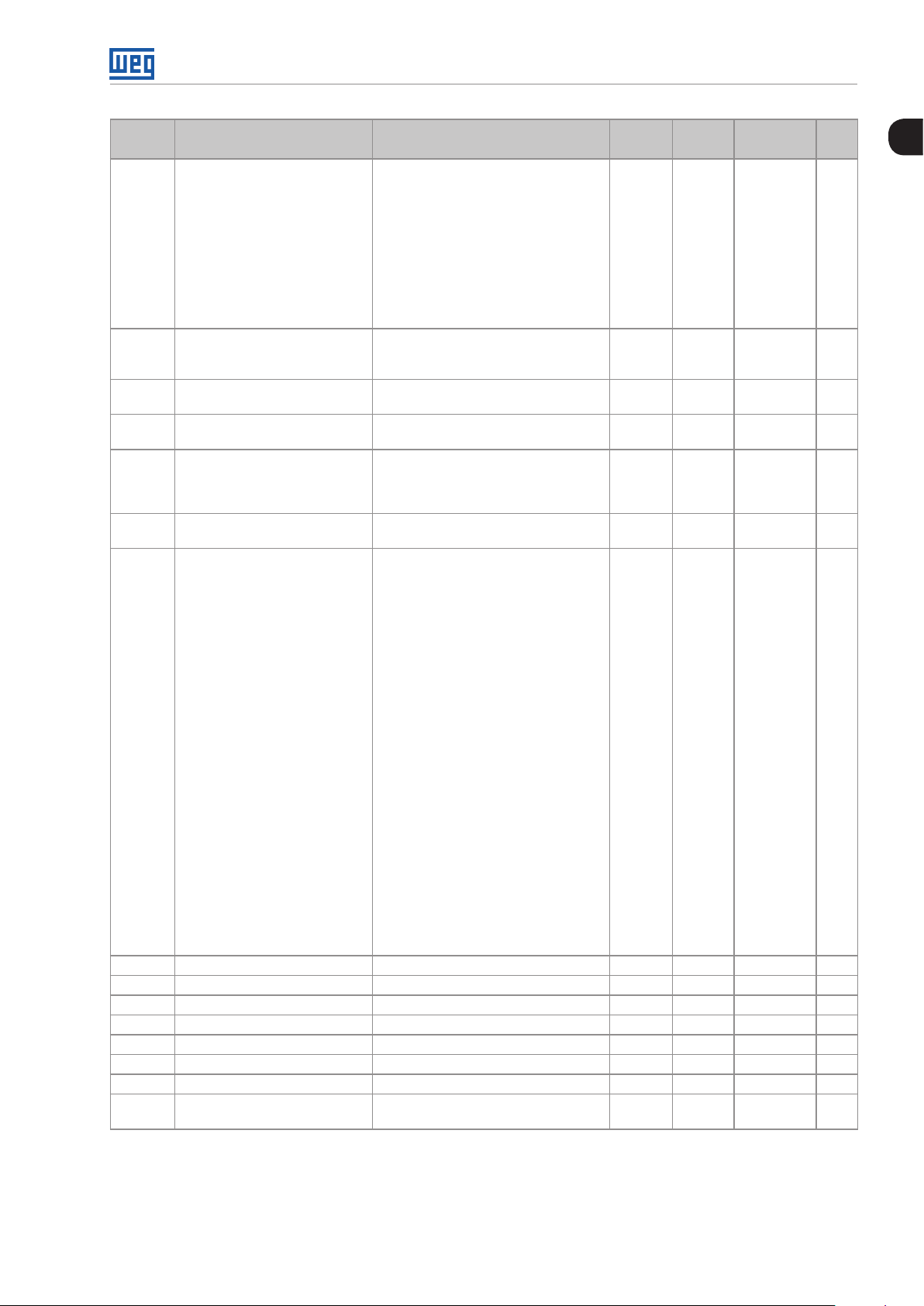

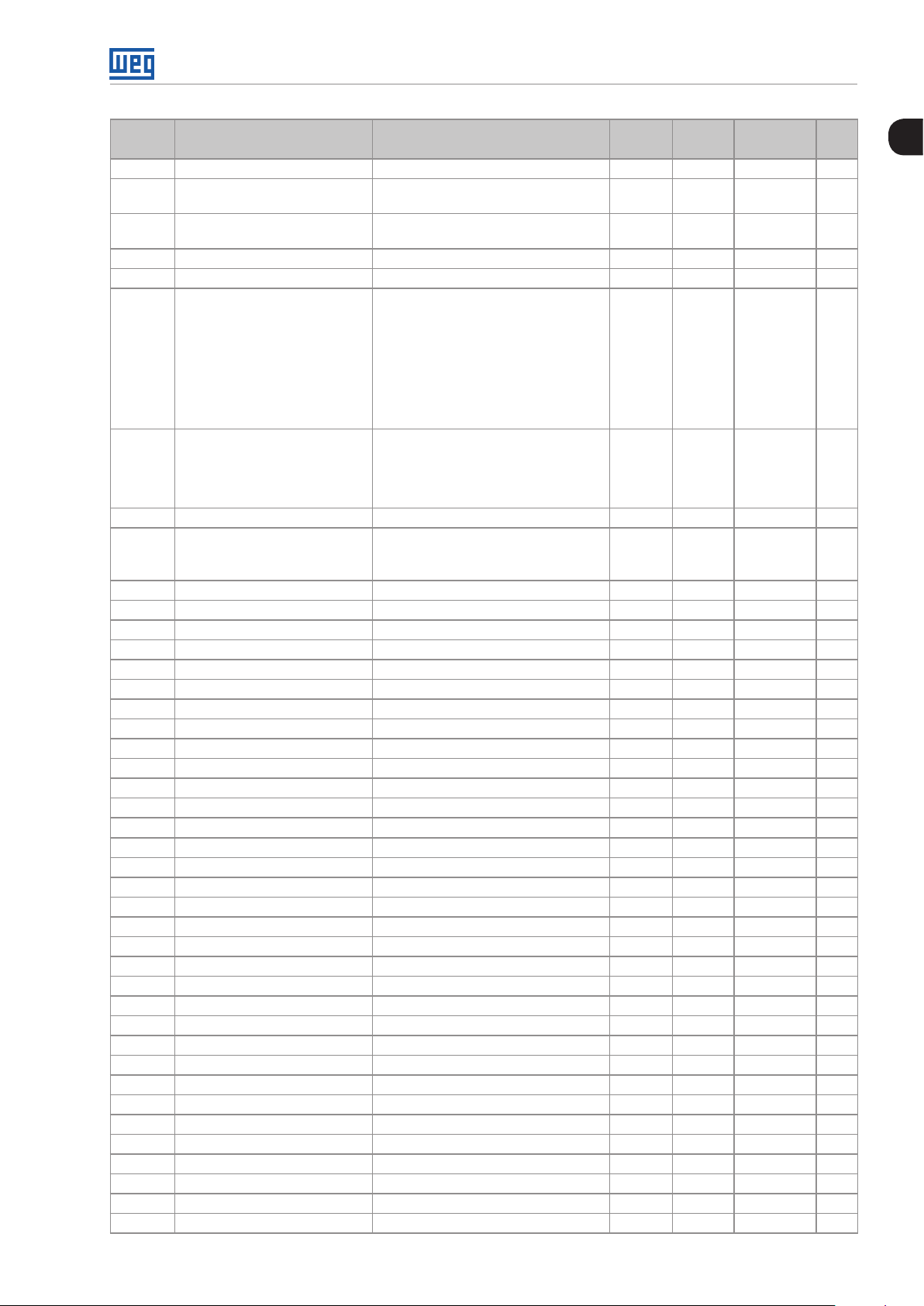

Page 11

Quick Reference of Parameters

Parameter Description Adjustable Range

P104 Number of Underpower 0 to 65535 - RO 6-17

P105 Number of Overpower Trips 0 to 65535 - RO 6-17

P106 Number of Power Under Factor

Trips

P107 Number of Power Over Factor Trips 0 to 65535 - RO 6-18

P110 Trip Status 4 (binary) bit0 - Voltage Unbalance

P111 Trip Status 5 (binary) bit0 - Underpower

P115 Alarm Status 4 (binary) bit0 - Voltage Unbalance

P116 Alarm Status 5 (binary) bit0 - Underpower

P118 Parameter Defined by User 1 1 to 1109 5 Sys, rw 7-3

P119 Parameter Defined by User 2 1 to 1109 20 Sys, rw 7-3

P120 Last Error Code 0 to 200 - RO 7-4

P121 Phase L1 Current Last Error 0.0 to 6553.5 A - RO 7-4

P122 Phase L2 Current Last Error 0.0 to 6553.5 A - RO 7-4

P123 Phase L3 Current Last Error 0.0 to 6553.5 A - RO 7-5

P124 Thermal Protection Last Error 0 to 100 % - RO 7-5

P125 Earth Leakage Current Last Error 0.000 to 10.000 A - RO 7-5

P126 Logical Status Last Error 0 to 65535 - RO 7-6

P127 Voltage L1-L2 Last Error 0 to 1000 V - RO 7-6

P128 Voltage L2-L3 Last Error 0 to 1000 V - RO 7-6

P129 Voltage L3-L1 Last Error 0 to 1000 V - RO 7-7

P130 Defined by User 1 Last Error 0 to 65535 - RO 7-7

P131 Defined by User 2 Last Error 0 to 65535 - RO 7-7

P135 Second Error Code 0 to 200 - RO 7-4

P136 Phase L1 Current Second Error 0.0 to 6553.5 A - RO 7-4

P137 Phase L2 Current Second Error 0.0 to 6553.5 A - RO 7-4

P138 Phase L3 Current Second Error 0.0 to 6553.5 A - RO 7-5

P139 Thermal Protection Second Error 0 to 100 % - RO 7-5

P140 Earth Leakage Current Second

Error

P141 Logical Status Second Error 0 to 65535 - RO 7-6

P142 Voltage L1-L2 Second Error 0 to 1000 V - RO 7-6

P143 Voltage L2-L3 Second Error 0 to 1000 V - RO 7-6

P144 Voltage L3-L1 Second Error 0 to 1000 V - RO 7-7

P145 Defined by User 1 Second Error 0 to 65535 - RO 7-7

P146 Defined by User 2 Second Error 0 to 65535 - RO 7-7

P150 Third Error Code 0 to 200 - RO 7-4

P151 Phase L1 Current Third Error 0.0 to 6553.5 A - RO 7-4

P152 Phase L2 Current Third Error 0.0 to 6553.5 A - RO 7-4

P153 Phase L3 Current Third Error 0.0 to 6553.5 A - RO 7-5

P154 Thermal Protection Third Error 0 to 100 % - RO 7-5

P155 Earth Leakage Current Third Error 0.000 to 10.000 A - RO 7-5

P156 Logical Status Third Error 0 to 65535 - RO 7-6

P157 Voltage L1-L2 Third Error 0 to 1000 V - RO 7-6

P158 Voltage L2-L3 Third Error 0 to 1000 V - RO 7-6

P159 Voltage L3-L1 Third Error 0 to 1000 V - RO 7-7

0 to 65535 - RO 6-17

bit1 - Phase Loss (Voltage)

bit2 - Overvoltage

bit3 - Undervoltage

bit1 - Overpower

bit2 - Power Under Factor

bit3 - Power Over Factor

bit1 - Phase Loss (Voltage)

bit2 - Overvoltage

bit3 - Undervoltage

bit1 - Overpower

bit2 - Power Under Factor

bit3 - Power Over Factor

0.000 to 10.000 A - RO 7-5

Factory

Setting

- RO 6-18

- RO 6-18

- RO 6-18

- RO 6-19

User

Setting

Proprieties Page

0

SRW 01 | 0-3

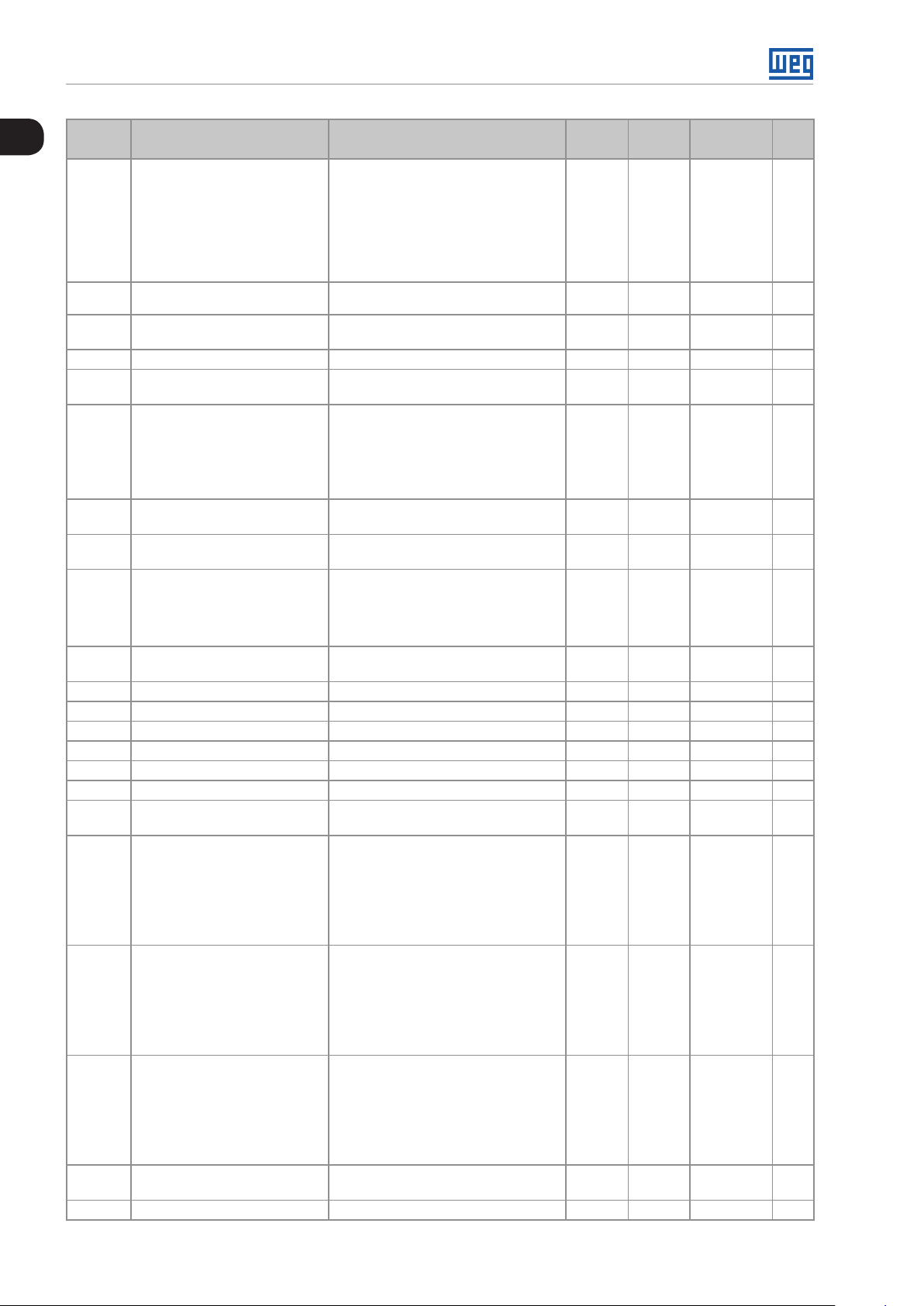

Page 12

Quick Reference of Parameters

0

Parameter Description Adjustable Range

P160 Defined by User 1 Third Error 0 to 65535 - RO 7-7

P161 Defined by User 2 Third Error 0 to 65535 - RO 7-7

P165 Fourth Error Code 0 to 200 - RO 7-4

P166 Phase L1 Current Fourth Error 0.0 to 6553.5 A - RO 7-4

P167 Phase L2 Current Fourth Error 0.0 to 6553.5 A - RO 7-4

P168 Phase L3 Current Fourth Error 0.0 to 6553.5 A - RO 7-5

P169 Thermal Protection Fourth Error 0 to 100 % - RO 7-5

P170 Earth Leakage Current Fourth Error 0.000 to 10.000 A - RO 7-5

P171 Logical Status Fourth Error 0 to 65535 - RO 7-6

P172 Voltage L1-L2 Fourth Error 0 to 1000 V - RO 7-6

P173 Voltage L2-L3 Fourth Error 0 to 1000 V - RO 7-6

P174 Voltage L3-L1 Fourth Error 0 to 1000 V - RO 7-7

P175 Defined by User 1 Fourth Error 0 to 65535 - RO 7-7

P176 Defined by User 2 Fourth Error 0 to 65535 - RO 7-7

P180 Fifth Error Code 0 to 200 - RO 7-4

P181 Phase L1 Current Fifth Error 0.0 to 6553.5 A - RO 7-4

P182 Phase L2 Current Fifth Error 0.0 to 6553.5 A - RO 7-4

P183 Phase L3 Current Fifth Error 0.0 to 6553.5 A - RO 7-5

P184 Thermal Protection Fifth Error 0 to 100 % - RO 7-5

P185 Earth Leakage Current Fifth Error 0.000 to 10.000 A - RO 7-5

P186 Logical Status Fifth Error 0 to 65535 - RO 7-6

P187 Voltage L1-L2 Fifth Error 0 to 1000 V - RO 7-6

P188 Voltage L2-L3 Fifth Error 0 to 1000 V - RO 7-6

P189 Voltage L3-L1 Fifth Error 0 to 1000 V - RO 7-7

P190 Defined by User 1 Fifth Error 0 to 65535 - RO 7-7

P191 Defined by User 2 Fifth Error 0 to 65535 - RO 7-7

P200 Password Status 0 = Inactive

1 = Active

2 = Change Password

P202 Operation Mode 0 = Transparent

1 = Overload Relay

2 = Direct Starter

3 = Reversing Starter

4 = Star/Delta

5 = Dahlander

6 = Pole Changing

7 = PLC

P204 Counter Reset / Factory Settings 0 = No Function

1 = Reset of the Motor Running Time

2 = It resets the Protection counters and

the Number of Starts counter

3 = Resets Power Meters

4 = Reset Trip History

5 = Reset to the Factory Settings

P205 Reading Parameter Selection 1 = P002 (% IN Current)

2 = P003 (True RMS Current)

3 = P005 (Line Frequency)

4 = P006 (Relay Status (binary))

5 = User defined

P206 User Selection 1 to 1109 3 Sys, rw 4-3

P208 Check Back Type 0 = Motor Current

1 = Digital Input Ix

2 = Simulation

P209 Execution Time 0.1 to 99.0 s 0.5 s Sys, CFG 5-11

P210 Star/Delta Time 1 to 999 s 25 s Sys, CFG 5-19

P211 Check Back Time 0.1 to 99.0 s 0.5 s Sys, CFG 5-12

P212 Motor Transition Time 0.01 to 99.00 s 0.05 s Sys, CFG 5-17

Factory

Setting

1 Sys, rw 4-4

1 Sys, CFG 5-10

0 Sys, rw 5-60

2 Sys, rw 4-3

0 Sys, CFG 5-11

User

Setting

Proprieties Page

0-4 | SRW 01

Page 13

Quick Reference of Parameters

Parameter Description Adjustable Range

P220 Local/Remote Selection 0 = Always Local

P229 Local Command Selection 0 = Ix

P230 Two or Three-wire Command (Ix) 0 = Two wires (Switch)

P231 Stop Logic with Three-wire

Command (Ix)

P232 Remote Command Selection 0 = Ix

P233 Retentive or Impulsive Control

(Fieldbus)

P277 Digital Output O1 Function 0 = Internal Use

P278 Digital Output O2 Function See Options in P277 0 Sys, CFG 5-6

P279 Digital Output O3 Function See Options in P277 1 Sys, CFG 5-6

P280 Digital Output O4 Function See Options in P277 1 Sys, CFG 5-6

P281 Digital Output O5 Function See Options in P277 1 Sys, CFG 5-6

P282 Digital Output O6 Function See Options in P277 1 Sys, CFG 5-6

P283 Digital Output O7 Function See Options in P277 1 Sys, CFG 5-6

P284 Digital Output O8 Function See Options in P277 1 Sys, CFG 5-7

P294 Expansion Digital Unit (EDU) 0 = EDU Not Used

1 = Always Remote

2 = HMI key (LOC)

3 = HMI key (REM)

4 = Digital Input I13

5 = Digital Input I14

6 = Fieldbus (LOC)

7 = Fieldbus (REM)

8 = USB/Ladder

9 = Digital Input I15

10 = Digital Input I16

1 = HMI

2 = USB/Ladder

1 = Three wires (Pushbutton)

0 = Digital Input I11 (NC)

1 = Digital Input I11 (NO)

1 = HMI

2 = USB/Ladder

3 = Fieldbus

0 = Retentive (Switch)

1 = Impulsive (Pushbutton)

1 = Ladder

2 = Fieldbus

3 = Alarm/Fault Signal (NO)

4 = Trip/Error Signal (NO)

5 = Trip/Error Signal (NC)

6 = Check Back Signal (NO)

7 = Trip Signal PTC (NO)

8 = Trip Signal Out of Frequency (NO)

9 = Trip Signal Undercurrent (NO)

10 = Trip Signal Overcurrent (NO)

11 = Trip Signal Phase Loss (current) (NO)

12 = Trip Signal Current Imbalance (NO)

13 = Trip Signal Earth Fault (NO)

14 = Trip Signal Overload (NO)

15 = Trip Signal Earth Leakage (NO)

16 = Trip Signal External Fault (NO)

17 = Trip Signal Trip Test (NO)

18 = Trip Signal Phase Sequence (NO)

19 = Trip Signal Voltage Unbalance (NO)

20 = Trip Signal Phase Loss (voltage) (NO)

21 = Trip Signal Overvoltage (NO)

22 = Trip Signal Undervoltage (NO)

23 = Trip Signal Underpower (NO)

24 = Trip Signal Overpower (NO)

25 = Trip Signal Power Under Factor (NO)

26 = Trip Signal Power Over Factor (NO)

1 = EDU Used

Factory

Setting

2 Sys, rw 5-2

0 Sys, rw 5-2

1 Sys, CFG 5-5

0 Sys, CFG 5-5

3 Sys, rw 5-3

1 Sys, CFG 5-3

0 Sys, CFG 5-6

0 Sys, CFG 3-10

User

Setting

Proprieties Page

0

SRW 01 | 0-5

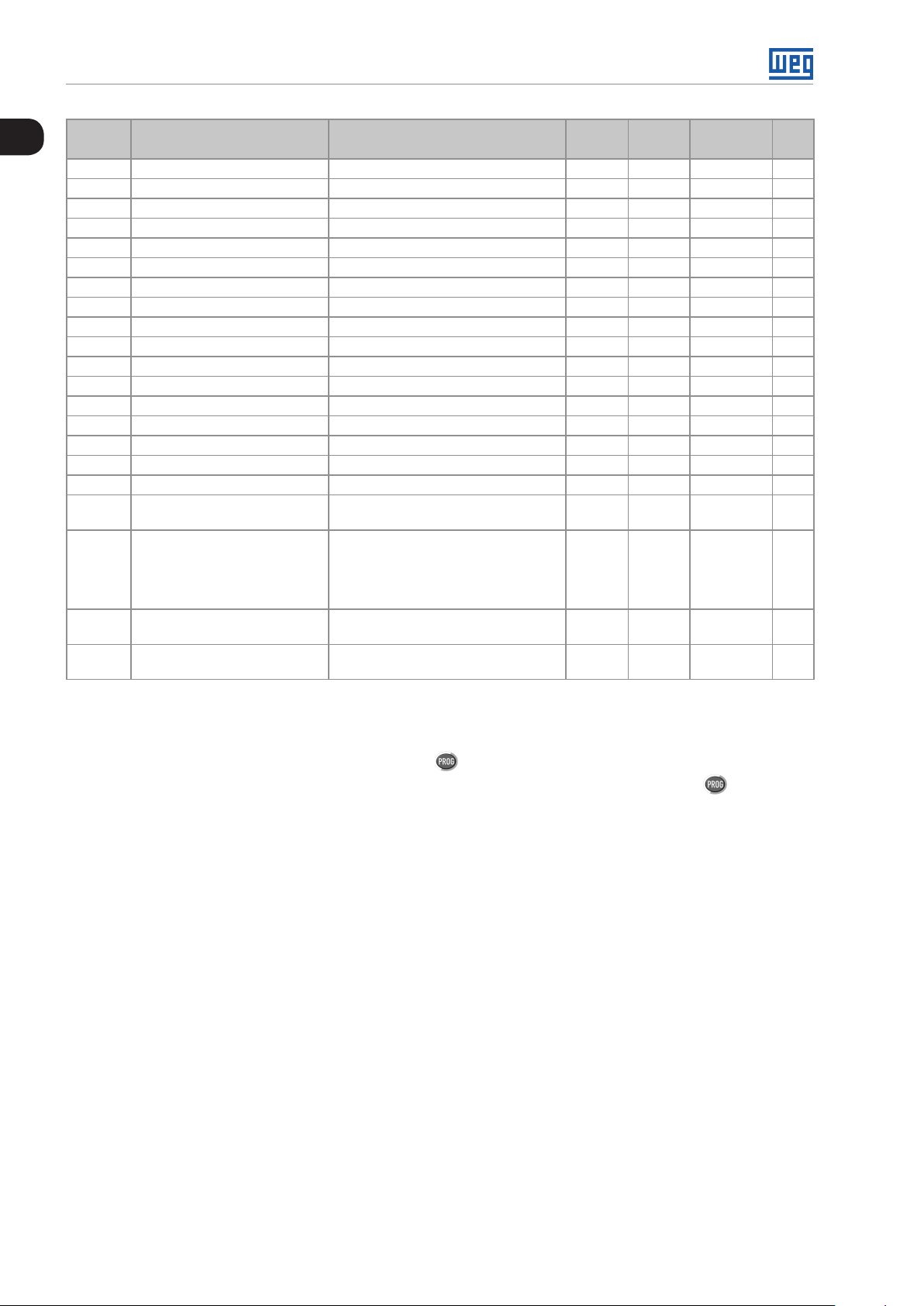

Page 14

Quick Reference of Parameters

0

Parameter Description Adjustable Range

P295 Currente and/or Voltage

Measurement Unit (UMC/UMCT)

P296 Number of Turns Through the UMC/

UMCT

P297 Motor Type 0 = Three-Phase

P298 External CT Primary Current 1 a 5000 A 1 A Sys, CFG 5-27

P299 External CT Secondary Current 0 = 1 A

P310 Configuration of the Serial Interface

Bytes

P311 Action for HMI Communication Error 0 = Only Fault Indication

P312 Action for EDU Communication

Error

P313 Action in Case of Communication

Error

P315 Action in the Local/Remote

Transition

P400 Motor Nominal Voltage 0 to 1000 V 380 V Sys, CFG 5-28

P401 Motor Nominal Current 1 0.0 to 5000.0 A 0.5 A Sys, CFG 5-28

P402 Motor Nominal Current 2 0.0 to 5000.0 A 0.5 A Sys, CFG 5-29

P404 Motor Rated Power 0.1 to 6553.5 kW 75.0 kW Sys, CFG 5-29

P406 Service Factor 1.00 to 1.50 1.15 Sys, CFG 5-48

P407 Line Frequency 0 to 99 Hz 60 Hz Sys, CFG 5-39

P408 Motor Phase Sequence 0 = 1-2-3

P500 Parameter Upload/Download 0 = No Function

P501 User Program Upload/Download 0 = No Function

P601 Reset Selection 0 = Without Local Reset

P602 Function Test/Reset Button 0 = Disabled

P605 Hysteresis 0 to 15 % 5 % Sys, rw 5-33

0 = UMC0/UMCT0 (0.25 – 2.5 A)

1 = UMC1/UMCT1 (0.5 – 5 A)

2 = UMC2/UMCT2 (1.25 – 12.5 A)

3 = UMC3/UMCT3 (2.5 – 25 A)

4 = UMC4/UMCT4 (12.5 – 125 A)

5 = UMC5/UMCT5 (42 – 420 A)

6 = UMC6/UMCT6 (84 – 840 A)

7 = UMC1/UMCT1 + External CT

1 to 10 1 Sys, CFG 5-27

1 = Single-Phase

1 = 5 A

0 = 8 data bits, no parity, 1 stop bit

1 = 8 data bits, even parity, 1 stop bit

2 = 8 data bits, odd parity, 1 stop bit

3 = 8 data bits, no parity, 2 stop bit

4 = 8 data bits, even parity, 2 stop bit

5 = 8 data bits, odd parity, 2 stop bit

1 = The Motor is Turned Off

0 = Only Fault Indication

1 = The Motor is Turned Off

0 = Only Fault Indication

1 = The Motor is Turned Off

2 = The Motor is Turned Off and the

Commands are Reset

3 = It Changes to Local

0 = Keep Motor Status

1 = The Motor is Turned Off

1 = 3-2-1

1 = Save Bank 1

2 = Save Bank 2

3 = Save Bank 3

4 = Load Bank 1

5 = Load Bank 2

6 = Load Bank 3

1 = Save Applicative 1

2 = Save Applicative 2

3 = Save Applicative 3

4 = Load Applicative 1

5 = Load Applicative 2

6 = Load Applicative 3

1 = Front Button

2 = Reset key (HMI)

3 = Digital Input I13

4 = Digital Input I14

5 = Digital Input I15

6 = Digital Input I16

1 = Enabled

Factory

Setting

1 Sys, CFG 5-26

0 Sys, CFG 5-27

0 Sys, CFG 5-27

3 Sys, CFG 5-30

0 Sys, rw 5-4

0 Sys, rw 3-10

0 Sys, rw 5-30

0 Sys, CFG 5-3

0 Sys, CFG 5-29

0 Sys, rw 4-5

0 Sys, rw 4-6

1 Sys, rw 5-58

1 Sys, rw 5-59

User

Setting

Proprieties Page

0-6 | SRW 01

Page 15

Quick Reference of Parameters

Parameter Description Adjustable Range

P606 External Fault Protection 0 = Disabled

P607 Auto-reset External Fault 0 = Disabled

P608 External Fault Timing 0 = Disabled

P609 External Fault Time 1 to 99 s 1 s Sys, rw 5-34

P610 External Fault Monitoring of

Protection

P611 External Fault Signal 0 = Digital Input I11

P612 External Fault Signal Logic 0 = Digital Input NC

P613 External Fault Protection Action 0 = Alarm

P614 Current Imbalance 5 to 100 % 40 % Sys, rw 5-36

P615 Current Imbalance Time 0 = Disabled

P616 Current Imbalance Protection Action 0 = Alarm

P617 Earth Fault 40 to 100 % 50 % Sys, rw 5-36

P618 Earth Fault Time 0 = Disabled

P619 Earth Fault Protection Action 0 = Alarm

P620 Phase Loss (Current) Time 0 = Disabled

P621 Phase Loss (Current) Protection

Action

P622 Overcurrent 50 to 1000 % 400 % Sys, rw 5-38

P623 Overcurrent Time 0 = Disabled

P624 Overcurrent Protection Action 0 = Alarm

P625 Undercurrent 5 to 100 % 20 % Sys, rw 5-38

P626 Undercurrent Time 0 = Disabled

P627 Undercurrent Protection Action 0 = Alarm

P628 Frequency Out of Range 5 to 20 % 5 % Sys, rw 5-39

P629 Frequency Out of Range Time 0 = Disabled

P630 Frequency Out of Range Protection

Action

P631 Earth Leakage Protection 0 = Disabled

P632 Earth Leakage Current Level

Selection

P633 Earth Leakage Time 0.1 to 99.0 s 0.5 s Sys, rw 5-41

P634 Earth Leakage Protection Action 0 = Alarm

P635 Earth Leakage Start Up Inhibit 0 = Disabled

1 = Enabled

1 = Enabled

1 = Enabled

0 = Always

1 = Only When the Motor is Running

1 = Digital Input I12

2 = Digital Input I13

3 = Digital Input I14

4 = Digital Input I15

5 = Digital Input I16

1 = Digital Input NO

1 = Switch Off (Trip)

1 to 99 s = Enabled

1 = Switch Off (Trip)

1 to 99 s = Enabled

1 = Switch Off (Trip)

1 to 99 s = Enabled

0 = Alarm

1 = Switch Off (Trip)

1 to 99 s = Enabled

1 = Switch Off (Trip)

1 to 99 s = Enabled

1 = Switch Off (Trip)

1 to 99 s = Enabled

0 = Alarm

1 = Switch Off (Trip)

1 = Enabled

0 = 0.3 A

1 = 0.5 A

2 = 1 A

3 = 2 A

4 = 3 A

5 = 5 A

1 = Switch Off (Trip)

1 = Enabled

Factory

Setting

0 Sys, rw 5-33

0 Sys, rw 5-34

0 Sys, rw 5-34

0 Sys, rw 5-34

3 Sys, rw 5-35

1 Sys, rw 5-35

1 Sys, rw 5-35

3 s Sys, rw 5-36

1 Sys, rw 5-36

3 s Sys, rw 5-37

1 Sys, rw 5-37

3 s Sys, rw 5-37

1 Sys, rw 5-37

3 s Sys, rw 5-38

1 Sys, rw 5-38

0 s Sys, rw 5-39

1 Sys, rw 5-39

0 s Sys, rw 5-39

1 Sys, rw 5-40

0 Sys, rw 5-41

2 Sys, rw 5-41

1 Sys, rw 5-41

0 Sys, rw 5-41

User

Setting

Proprieties Page

0

SRW 01 | 0-7

Page 16

Quick Reference of Parameters

0

Parameter Description Adjustable Range

P636 Earth Leakage Start up Time Inhibit 1 to 600 s 5 s Sys, rw 5-42

P637 Earth Leakage Short circuit Trip

Inhibit

P640 Relay Tripping Class 0 = Disabled

P641 Overload Protection Action 0 = Alarm

P642 Cooling Time 0 = Disabled

P643 Auto-reset 0 = Disabled

P644 PTC Protection 0 = Disabled

P645 PTC Protection Action 0 = Alarm

P646 Overload Protection Pre-Alarm 0 to 99 % 80 % Sys, rw 5-45

P647 Overload Pre-alarm Auto-Reset 0 to 99 % 75 % Sys, rw 5-45

P648 Phase Sequence 0 = Disabled

P649 Voltage Unbalance 1 to 30 % 5 % Sys, rw 5-52

P650 Voltage Unbalance Time 0 = Disabled

P651 Voltage Unbalance Protection

Action

P652 Phase Loss Time (Voltage) 0 = Disabled

P653 Phase Loss Protection Action

(Voltage)

P654 Overvoltage 1 to 30 % 15 % Sys, rw 5-53

P655 Overvoltage Time 0 = Desabilitado

P656 Overvoltage Protection Action 0 = Alarm

P657 Undervoltage 1 to 30 % 15 % Sys, rw 5-54

P658 Undervoltage Time 0 = Disabled

P659 Undervoltage Protection Action 0 = Alarm

P660 Underpower 1 to 100 % 30 % Sys, rw 5-55

P661 Underpower Time 0 = Disabled

P662 Underpower Protection Action 0 = Alarm

P663 Overpower 1 to 100 % 30 % Sys, rw 5-55

P664 Overpower Time 0 = Disabled

P665 Overpower Protection Action 0 = Alarm

P666 Power Under Factor 0.00 to 1.00 0.60 Sys, rw 5-56

P667 Power Under Factor Time 0 = Disabled

P668 Power Under Factor Protection

Action

0 = Disabled

1 = Enabled

1 = Class 5

2 = Class 10

3 = Class 15

4 = Class 20

5 = Class 25

6 = Class 30

7 = Class 35

8 = Class 40

9 = Class 45

1 = Switch Off (Trip)

1 to 3600 s =Enabled

1 = Enabled

1 = Enabled

1 = Switch Off (Trip)

1 = Enabled

1 to 99 s = Enabled

0 = Alarm

1 = Switch Off (Trip)

1 to 99 s = Enabled

0 = Alarm

1 = Switch Off (Trip)

1 to 99 s = Habilitado

1 = Switch Off (Trip)

1 to 99 s = Enabled

1 = Switch Off (Trip)

1 to 99 s = Enabled

1 = Switch Off (Trip)

1 to 99 s = Enabled

1 = Switch Off (Trip)

1 to 99 s = Enabled

0 = Alarm

1 = Switch Off (Trip)

Factory

Setting

0 Sys, rw 5-42

2 Sys, rw 5-44

1 Sys, rw 5-44

0 s Sys, rw 5-48

0 Sys, rw 5-60

0 Sys, rw 5-43

1 Sys, rw 5-44

0 Sys, rw 5-51

3 s Sys, rw 5-52

1 Sys, rw 5-52

3 s Sys, rw 5-52

1 Sys, rw 5-53

3 s Sys, rw 5-53

1 Sys, rw 5-53

3 s Sys, rw 5-54

1 Sys, rw 5-54

0 s Sys, rw 5-55

1 Sys, rw 5-55

0 s Sys, rw 5-55

1 Sys, rw 5-56

0 s Sys, rw 5-56

1 Sys, rw 5-57

User

Setting

Proprieties Page

0-8 | SRW 01

Page 17

Quick Reference of Parameters

Parameter Description Adjustable Range

P669 Power Over Factor 0.00 to 1.00 0.89 Sys, rw 5-57

P670 Power Over Factor Time 0 = Disabled

P671 Power Over Factor Protection

Action

P680 Status Word 0000h to FFFFh - RO 5-30

P682 Control Word 0000h to FFFFh 0000h rw 5-30

P751 Ethernet Communication Status 0 = Setup

P753 Ethernet Baud Rate 0 = Auto

P756 Modbus TCP Timeout 0.0 to 65.5 s 0.0 s Sys, rw 5-30

P760 IP Address Config 0 = Parameters

P761 IP Address Config (1) 0 to 255 192 Sys, rw 5-30

P762 IP Address Config (2) 0 to 255 168 Sys, rw 5-30

P763 IP Address Config (3) 0 to 255 0 Sys, rw 5-30

P764 IP Address Config (4) 0 to 255 10 Sys, rw 5-30

P765 CIDR Subnet 0 to 31 24 Sys, rw 5-30

P766 Default Gateway Configuration (1) 0 to 255 0 Sys, rw 5-30

P767 Default Gateway Configuration (2) 0 to 255 0 Sys, rw 5-30

P768 Default Gateway Configuration (3) 0 to 255 0 Sys, rw 5-30

P769 Default Gateway Configuration (4) 0 to 255 0 Sys, rw 5-30

P799 UMC/UMCT Gain Adjustment 0.900 to 1.100 1.000 Sys, rw 5-27

P800 Read Word #1 0 to 65535 680 Sys, rw 5-30

P801 Read Word #2 0 to 65535 0 Sys, rw 5-30

P802 Read Word #3 0 to 65535 0 Sys, rw 5-30

P803 Read Word #4 0 to 65535 0 Sys, rw 5-30

P804 Read Word #5 0 to 65535 0 Sys, rw 5-30

P805 Read Word #6 0 to 65535 0 Sys, rw 5-30

P806 Read Word #7 0 to 65535 0 Sys, rw 5-30

P807 Read Word #8 0 to 65535 0 Sys, rw 5-30

P808 Read Word #9 0 to 65535 0 Sys, rw 5-30

P809 Read Word #10 0 to 65535 0 Sys, rw 5-30

P810 Read Word #11 0 to 65535 0 Sys, rw 5-30

P811 Read Word #12 0 to 65535 0 Sys, rw 5-30

P812 Read Word #13 0 to 65535 0 Sys, rw 5-30

P813 Read Word #14 0 to 65535 0 Sys, rw 5-30

P814 Read Word #15 0 to 65535 0 Sys, rw 5-30

P815 Read Word #16 0 to 65535 0 Sys, rw 5-30

P816 Read Word #17 0 to 65535 0 Sys, rw 5-30

P817 Read Word #18 0 to 65535 0 Sys, rw 5-30

P818 Read Word #19 0 to 65535 0 Sys, rw 5-30

P819 Read Word #20 0 to 65535 0 Sys, rw 5-30

P850 Write Word #1 0 to 65535 682 Sys, rw 5-31

P851 Write Word #2 0 to 65535 0 Sys, rw 5-31

P852 Write Word #3 0 to 65535 0 Sys, rw 5-31

1 to 99 s = Enabled

0 = Alarm

1 = Switch Off (Trip)

1 = Init

2 = Wait Comm

3 = Idle

4 = Data Active

5 = Error

6 = Reserved

7 = Exception

8 = Access Error

1 = 10Mbit/s, half duplex

2 = 10Mbit/s, full duplex

3 = 100Mbit/s, half duplex

4 = 100Mbit/s, full duplex

1 = DHCP

2 = DCP

Factory

Setting

0 s Sys, rw 5-57

1 Sys, rw 5-57

- RO 5-30

0 Sys, rw 5-30

1 Sys, rw 5-30

User

Setting

Proprieties Page

0

SRW 01 | 0-9

Page 18

Quick Reference of Parameters

0

Parameter Description Adjustable Range

P853 Write Word #4 0 to 65535 0 Sys, rw 5-31

P854 Write Word #5 0 to 65535 0 Sys, rw 5-31

P855 Write Word #6 0 to 65535 0 Sys, rw 5-31

P856 Write Word #7 0 to 65535 0 Sys, rw 5-31

P857 Write Word #8 0 to 65535 0 Sys, rw 5-31

P858 Write Word #9 0 to 65535 0 Sys, rw 5-31

P859 Write Word #10 0 to 65535 0 Sys, rw 5-31

P860 Write Word #11 0 to 65535 0 Sys, rw 5-31

P861 Write Word #12 0 to 65535 0 Sys, rw 5-31

P862 Write Word #13 0 to 65535 0 Sys, rw 5-31

P863 Write Word #14 0 to 65535 0 Sys, rw 5-31

P864 Write Word #15 0 to 65535 0 Sys, rw 5-31

P865 Write Word #16 0 to 65535 0 Sys, rw 5-31

P866 Write Word #17 0 to 65535 0 Sys, rw 5-31

P867 Write Word #18 0 to 65535 0 Sys, rw 5-31

P868 Write Word #19 0 to 65535 0 Sys, rw 5-31

P869 Write Word #20 0 to 65535 0 Sys, rw 5-31

P899 Update Ethernet Configuration 0 = Normal Operation

P1000 User Program Status 0 = No Program

P1001 User Program Disabling 0 = Executes User Program

P1010 to

P1109

User Parameters 0 to 65535 0 Us, rw 5-61

1 = Update Configuration

1 = Install. Program

2 = Incompat. Program

3 = Program Stopped

4 = Program Running

1 = Stops User Program

Factory

Setting

0 Sys, CFG 5-31

- RO 5-61

0 Sys, rw 5-61

User

Setting

Proprieties Page

RO = read-only parameter.

rw = reading/writing parameter.

CFG = configuration parameter, it can only be changed with a stopped motor.

Sys = system parameter. Its value is updated when the key is pressed.

Us = User parameter. Its value is instantaneously updated by the HMI, even before pressing the key.

0-10 | SRW 01

Page 19

Safety Instructions

1 SAFETY INSTRUCTIONS

This manual contains the necessary information for the correct use of the SRW 01 smart relay.

It has been developed to be used by personnel with adequate training or technical qualification to operate this

type of equipment.

1.1 SAFETY WARNINGS IN THE MANUAL

The following safety warnings are used in this manual:

DANGER!

The nonobservance of the procedures recommended in this warning can lead to death, serious injuries

and considerable material damage.

ATTENTION!

The nonobservance of the procedures recommended in this warning can lead to material damage.

NOTE!

The text intents to supply important information for the correct understanding and good operation of

the product.

1.2 PRELIMINARY RECOMMENDATIONS

DANGER!

Only qualified personnel familiar with the SRW 01 smart relay and associated equipment should plan

or implement the installation, start-up, operation and maintenance of this equipment These personnel

must follow all the safety instructions included in this Manual and/or defined by local regulations.

Failure to comply with these instructions may result in life threatening and/or equipment damage.

1

NOTE!

For the purpose of this manual, qualified personnel are those trained to be able to:

1. Install, power-up, and operate the SRW 01 according to this manual and to the effective legal safety

procedures.

2. Use protection equipment according to the established standards.

3. Provide first aid services.

DANGER!

Always disconnect the main power supply before touching any electrical device associated with the

relay.

ATTENTION!

Control, sensor and communication cables must be installed observing the minimun distance of 25 cm

away from power cables, and preferably installed in grounded metal conduits.

ATTENTION!

For digital inputs, it is recomended the use of shielded cables when the cable length exceeds 200 m

or if they are subject to electromagnetic interference.

If any further information is necessay to install the cable, refer to the cable manufacturer for the proper

installation.

SRW 01 | 1-1

Page 20

Safety Instructions

NOTE!

The incorrect selection of the Current Measurement Unit (UMC) or Current/Voltage Measurement Unit

(UMCT), by means of parameter P295 and/or lack of the setting of the motor rated current (P401 and/

or P402), may result in the incorrect communication of the value of measured current, making bit 3 of

parameter P006 – Relay Status (binary) indicate that the motor in ON, not allowing the modification of

parameters whose modification is only allowed when the motor is not energized.

In the attempt of modifying those parameters, the message “stop” will flash for three seconds on the

1

HMI and the modification will not be accepted.

In those cases, disconnect the cable that interconnects the Control Unit (UC) and the Current

Measurement Unit (UMC) or Current/Voltage Measurement Unit (UMCT). The Control Unit (UC) will

signal by means of the status led and message “E0085” on the HMI that there is no communication

with the UMC/UMCT and the current informed will be zero (0).

Set parameter P295 according to the Current Measurement Unit (UMC) or Current/Voltage Measurement

Unit (UMCT) obtained and set the motor rated current (P401 and/or P402) according to data on the

motor nameplate. After setting those parameters, reconnect the connecting cable between the UC

and the UMC/UMCT and run an error reset using the front button, and then set the other parameters

of the system.

ATTENTION!

The digital inputs and outputs functions of the Control Unit are automatically configured according to

the selection of the operating mode through parameter P202. The factory default operating mode is

the overload relay mode (P202 = 1); digital outputs O1 and O2 are used to signal Trip NO (normally

open) and Trip NC (normally closed), respectively.

ATTENTION!

The electronic boards contain components sensitive to electrostatic discharges. Do not touch

components and connectors directly.

NOTE!

Read this manual completely before installing or operating the relay.

1-2 | SRW 01

Page 21

General Information

2 GENERAL INFORMATION

2.1 ABOUT THE MANUAL

This manual presents the instructions for the installation and commissioning of the Smart Relay WEG, SRW 01,

as well as its main characteristics.

In order to get information on other functions, accessories and operation conditions, refer to the following manuals:

Ladder programming manual – WLP.

Ethernet communication manual.

These manuals are they are available for download on the website: www.weg.net.

2.2 TERMS AND DEFINITIONS USED IN THE MANUAL

Amp, A: ampere is the electric current level unit of measurement.

V: volt is the voltage unit of measurement.

PC: Personal computer

PE: protective earth.

UMCT: Current/Voltage Measurement Unit.

W: watt, basic unit of real power. It is obtained by the direct product of voltage (V) by the current (I).

kW: kilowatts = 1000 (103) W.

VA: volt ampere, unit of measurement of apparent power.

kVA: kilovolt-ampere = 1000 (103) VA.

VAr: reactive volt-ampere, unit of measurement of reactive power.

kVAr: kiloVolt-ampere-reactive = 1000 (103) VA.

2

kWh: kilowatt-hour, it represents the consumed power in a time period. And the product of the load real power

(kW) by the number of hours (h) it was on.

MWh: megawatt-hour = 1,000,000 (106) W or 1000 (103) kW.

PTC: resistor whose resistance value in ohms increases proportionally to the temperature increase; used as a

temperature sensor in electric motors.

HMI: human-machine interface; It is a device that allows the motor control, as well as viewing and editing the relay

parameters. It presents keys for the motor command, navigation keys and a display.

Flash Memory: non-volatile memory that can be electronically written and erased.

Ram Memory: random access memory (volatile).

USB: universal serial bus; is a serial bus standard that allows devices to be connected using the plug and play

concept.

°C: celsius or centigrade degrees.

º F: fahrenheit.

SRW 01 | 2-1

Page 22

General Information

AC: alternating current.

DC: direct current.

CV: cheval vapeur = 736 Watts (unit of power, used to indicate the mechanical power of electric motors).

hp: horse power = 746 Watts (unit of power, used to indicate the mechanical power of electric motors).

SF: service factor.

Hz: hertz.

mA: milliamp = 0.001 ampere.

min: minute.

2

ms: millisecond = 0.001 second.

rms: “root mean square”; effective value.

rpm: revolutions per minute; speed unit.

s: second.

V: volts.

Ω: ohms.

NO: normally open contact.

NC: normally closed contact.

Check Back: verification of running motor.

Trip: switching off of the motor by the action of a protection.

UC: control unit.

UMC: current measurement unit.

MC: communication module.

mm: millimeter.

in: inch.

m: meter.

ELS: earth leakage sensor.

RCD: according to IEC 60755, mechanical switching device (or device association developed to cause contacts

to open when a residual current reaches a certain value under specific conditions (Residual Current Device).

FLA: set current at full load (Full Load Amps).

EDU: Expansion Digital Unit.

2-2 | SRW 01

Page 23

General Information

2.3 ABOUT THE SRW 01

The SRW 01 is a low voltage electric motor management system that presents cutting edge technology and has

network communication capabilities. For being modular, its functionalities can be extended, making it a versatile

product, and prepared for several applications.

The SRW 01 has a modular design that allows the expansion of the relay functionalities. The Control Unit (UC)

can be mounted together with the Current Measurement Unit (UMC), forming a single unit, or separated (up to 2

meters [6.56 ft]) from it.

By using the Expansion Digital Unit (EDU), it is possible to increase the number of digital inputs and outputs in the

Control Unit (SRW01-UC), in a total of 12 digital inputs and 8 outputs.

It is possible to use a Current/Voltage Measurement Unit (UMCT) in place of a Current Measurement Unit (UMC).

Besides measuring the motor currents (like the UMC), it is possible to monitor the voltages up to 690 V, phase

sequence, power factor (cos ϕ) and all motor powers.

In order to exchange information via Ethernet communication network, the SRW 01 features two RJ45 ports with

integral switch, which enables the execution of different network topologies of the fieldbus technique.

The SRW 01 has an USB port that makes the parameterization, monitoring and programming of the relay easier

by using a PC with the WLP software. Because of the thermal memory, the relay is able to keep the motor thermal

image even when it is not energized.

2

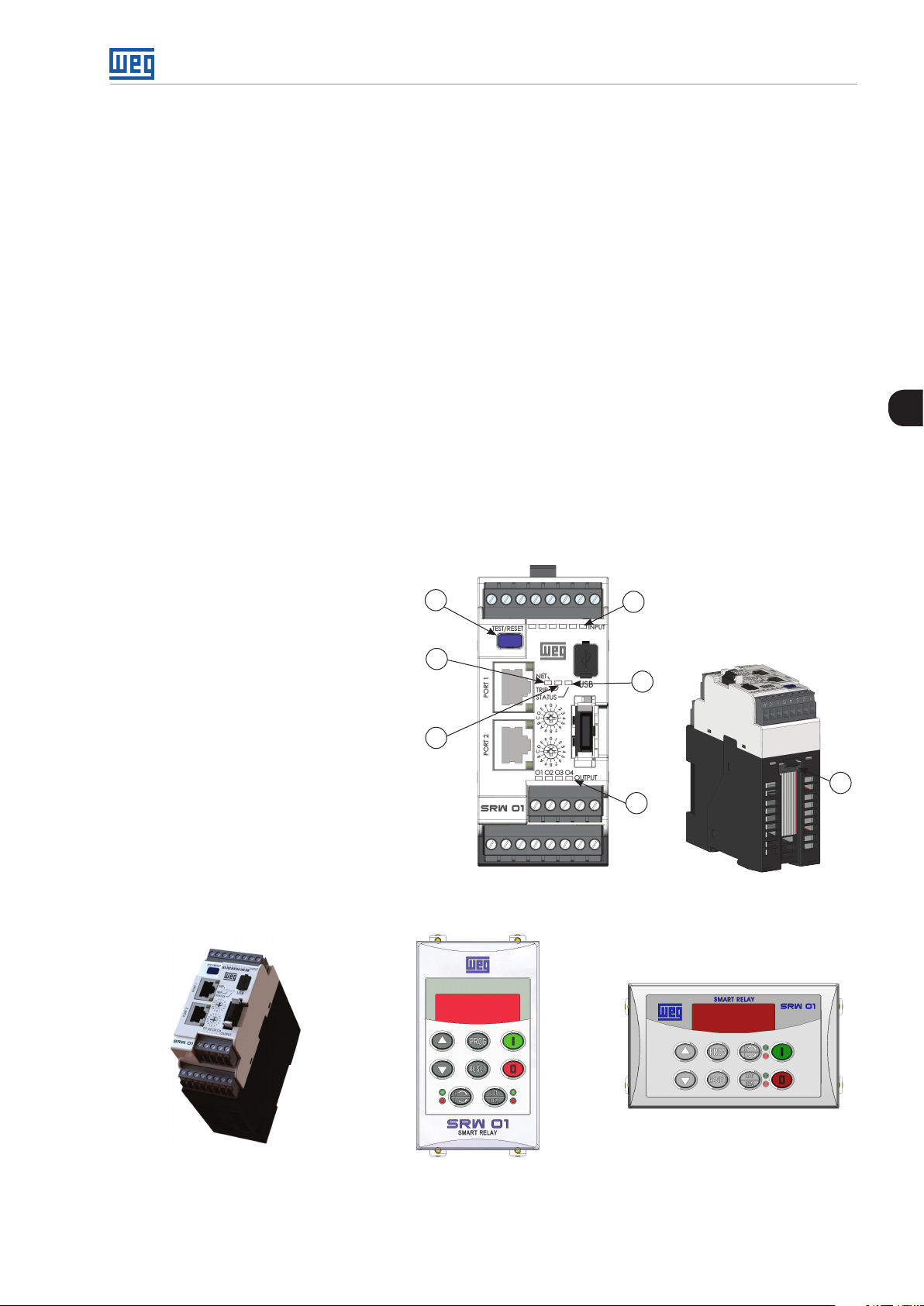

1 - Digital input indication Led’s

2 - Digital output indication Led’s

3 - Network Led (Net) – indication according to the Table

7.1 on page 7-1

4 - Trip Led

Green – normal operation without Trip

Flashing Green – protection alarm

Flashing red – protection Trip

5 - Status Led

Green – normal operation without fault or alarm

Flashing Green – system alarm

Flashing red – system error

6 - Reset Button

7 - Current Measurement Unit (UMC) connector or

Current/ Voltage Measurement Unit (UMCT)

Figure 2.1: SRW 01 control unit identification

6

I11 I12 I13 I14 I15 I16

3

4

1

5

7

2

(a) Control Unit - SRW 01 - UC (b) HMI (vertical) (c) HMI2 (horizontal)

SRW 01 | 2-3

Page 24

General Information

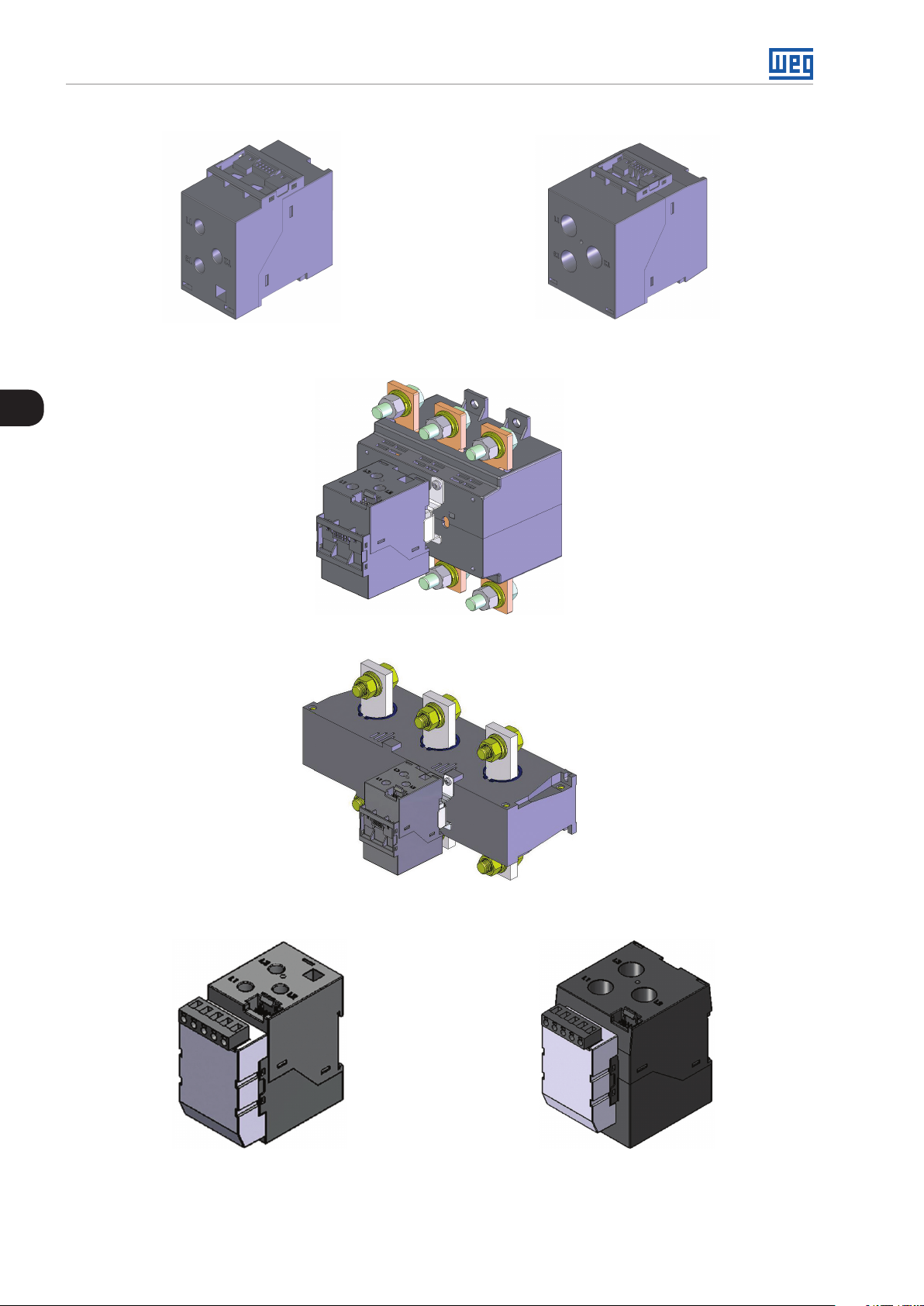

(d) Current Measurement Units - SRW 01 -

UMC1 (5 A), 2 (12.5 A) and 3 (25 A)

(e) Current Measurement Unit -

SRW 01 - UMC4 (125 A)

2

(f) Current Measurement Unit - SRW 01 - UMC5 (420 A)

(g) Current Measurement Unit (with busbar accessory) - SRW 01 - UMC6 (840 A)

(h) Current/Voltage Measurement Unit -

SRW 01-UMCT 1 (5 A), 2 (12.5 A) and 3 (25 A)/690 V

2-4 | SRW 01

(i) Current/Voltage Measurement Unit -

SRW 01-UMCT 4 (125 A)/690 V

Page 25

General Information

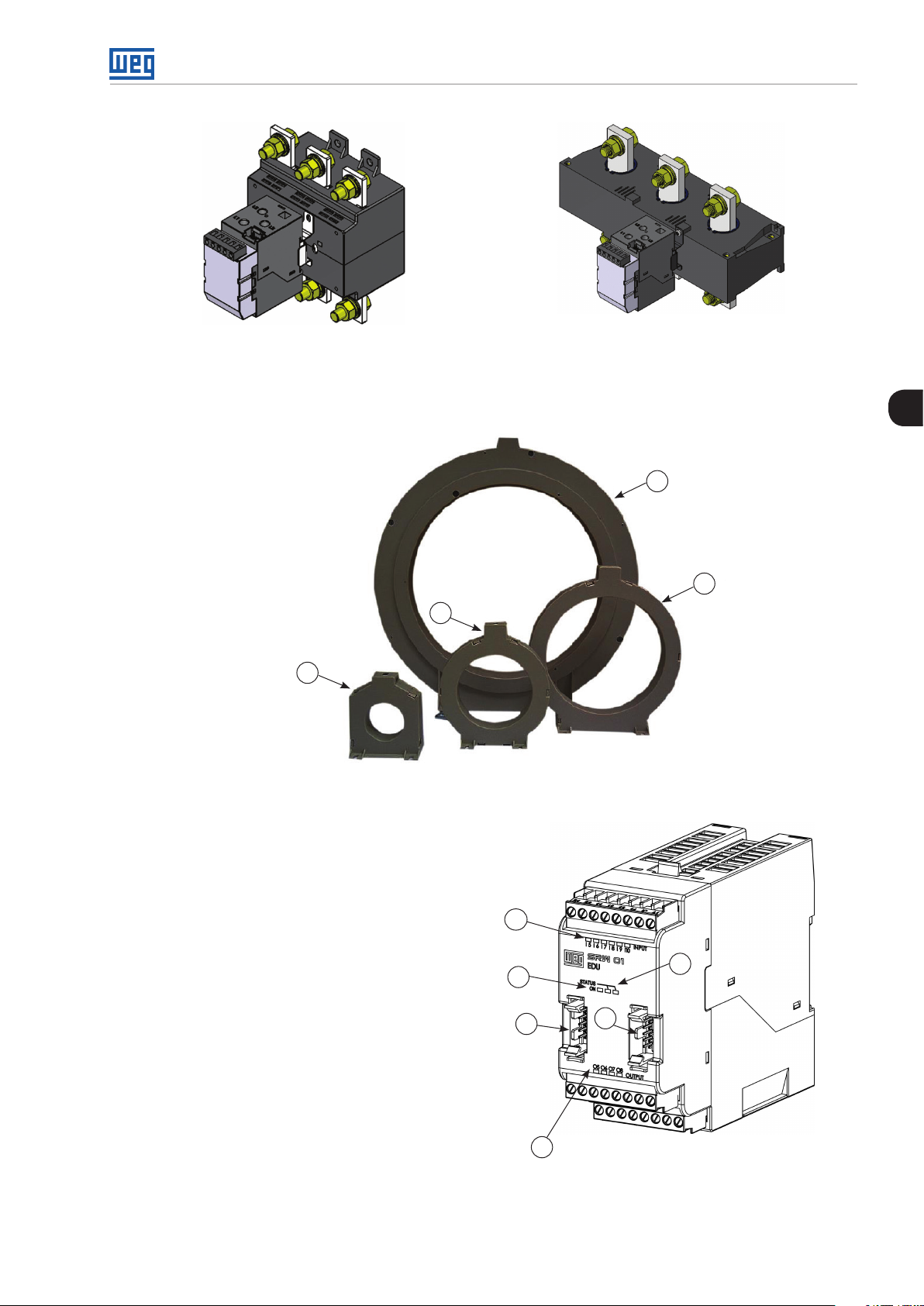

(j) Current/Voltage Measurement Unit – SRW 01-UMCT 5

(420 A/690 V)

1 - SRW01-EL1

2 - SRW01-EL2

3 - SRW01-EL3

4 - SRW01-EL4

2

1

(m) Earth Leakage sensors - SRW01-ELS

(l) Current/Voltage Measurement Unit – SRW 01-UMCT 6

(840 A/690 V) – with busbar accessory

2

4

3

1 - Digital input indication Led’s

2 - Digital output indication Led’s

3 - On Led

Green - Energized device

Off - Deenergized device

4 - Status Led

Green - Normal operation

Flashing green - Communication to the Control Unit (UC)

has been reestablished

Flashing red - No communication with the Control Unit (UC)

5 - Connector for the Control Unit (UC)

6 - Connector for the HMI

(n) Expansion Digital Unit – SRW 01-EDU

Figure 2.2: (a) to (n) SRW 01 components

1

3

5

2

6

4

SRW 01 | 2-5

Page 26

General Information

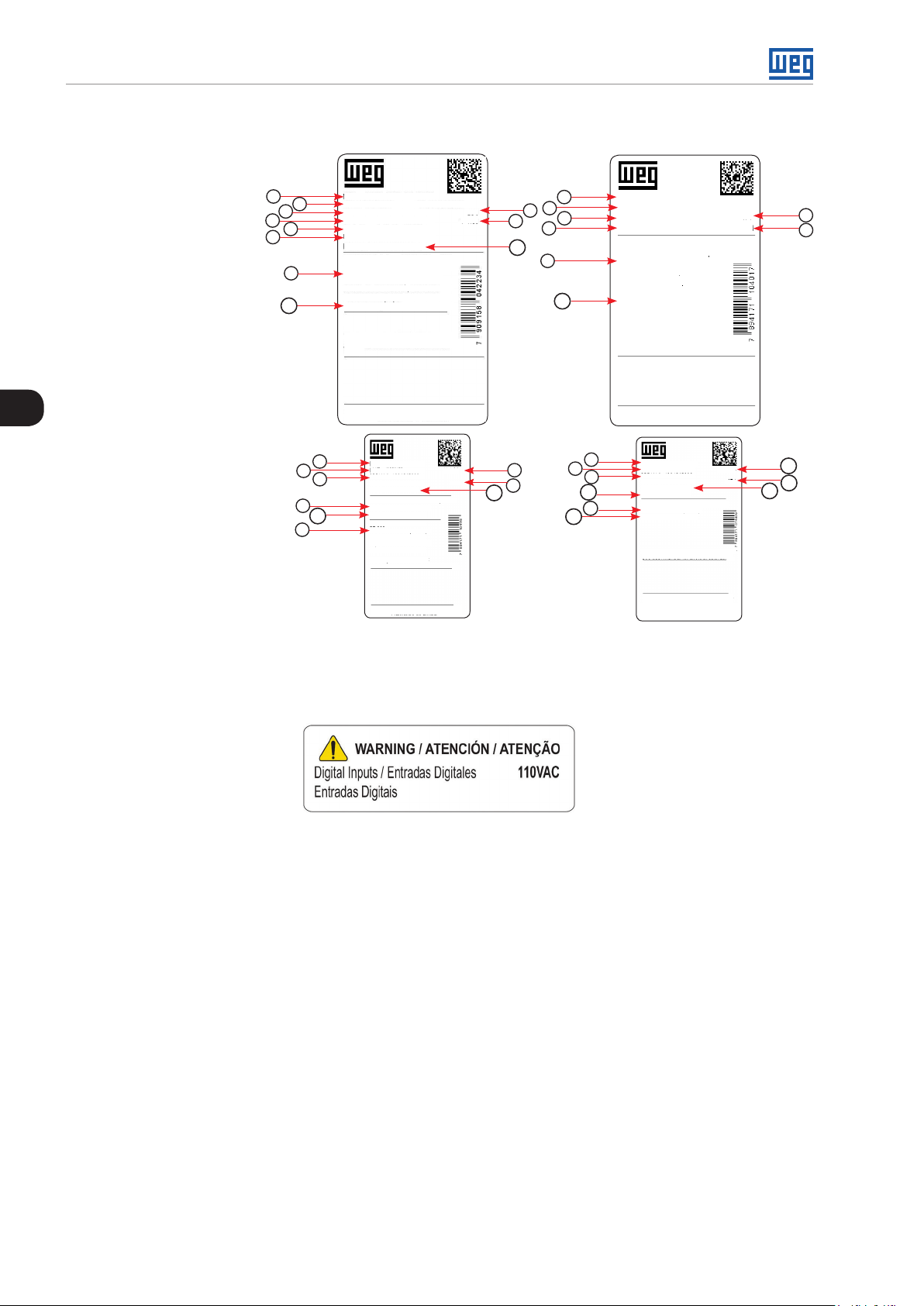

2.4 SRW 01 IDENTIFICATION LABEL

1 - Product model

2 - WEG part number

3 - Serial number

4 - Manufacturing date

5 - Maximum ambient temperature

6 - Firmware version

7 - UC supply voltage (voltage and

frequency)

8 - Digital input voltage

9 - Connection to the input terminals

T1 and T2

1

3

7

8

9

5

11

10 -UMC/UMCT current range

11 - Protection degree

12 - UMCT voltage range

13 - Connection to the input

terminals E1 and E2

2

2

MOD.: SRW01-UCE1TE1E47

MAT.: 12105800 OP.: 1234567890

SERIAL#: 1234567890

Us.: 110-240V 50/60Hz-DC

Digital Inputs I11-I16: 24VDC

Inputs Terminals T1-T2: PTC

Inputs Terminals E1-E2: ELS

IEC 60947-4-1 Ui 300V/Uimp 4kv

IEC 60947-5-1 Ui 300V/Uimp 4kv

MAX. TA: 55°C (131°F)

AC15 Ie/Ue 1.5A/120V, 0.75A/240V

DC13 Ie/Ue 0.22A/125V, 0.1A/250V

Fuse max.: 6A gl/gG

Protection degree: IP20

Tripping current at 125% of FLA

Aux. Cont. 3A/30VDC/250VAC resistive

C300

MADE IN BRAZIL HECHO EN BRASIL

FABRICADO NO BRASIL

V 1.00

1

2

20 J

4

6

3

8

13

5

11

MOD.: SRW01-EDU2

MAT.: 10675557 OP.: 12345678

SERIAL#: 1234567890

Digital Inputs I5-I10: 110V50/60Hz

IE C 6 09 47 -4- 1 Ui 300V/Uimp 4kv

IE C 6 09 47 -5- 1 Ui 300V/Uimp 4kv

MAX. TA: 55°C (131°F)

AC15 Ie/Ue 1.5A/120V, 0.75A/240V

DC13 Ie/Ue 0.22A/125V, 0.1A/250V

Fuse max.: 6A gl/gG

Protection degree: IP20

Aux. Cont. 3A/30VDC/250VAC resistive

C300

Use only with: SRW01-UC V3.00 or later

MADE IN BRAZIL HECHO EN BRASIL

FABRICADO NO BRASIL

47 I

V 1.00

4

6

11

1

2

3

12

5

MOD.: SRW01-UMCT1

MAT.: 12345678

SERIAL#: 1234567890

OP.: 12345678

le.: 0,5-5A 50/60 Hz

Ue.: 690V 50/60Hz

IEC 6 0947 -4-1 Ui 690V / Uimp 6K V

MAX. TA: 55°C (131°F)

Protection degree: IP20

Use only with SRW01-UC V4.00 or later

See user manual for short circuit ratings

MADE IN BRAZIL HECHO EN BRASIL

FABRICADO NO BRASIL

V 1.234

47 l

4

10

6

1

2

3

5

11

5

MOD.: SRW01-UMC1

MAT.: 10558179

SERIAL#: 1234567890

OP.: 12345678

le.: 0,5-5A 50/60 Hz

IEC 6 0947 -4-1 Ui 690V / Uimp 6K V

MAX. TA: 55°C (131°F)

Protection degree: IP20

UL 508

MAX. TA: 40°C (104°F)

Voltage 600 VAC

Trip current at 125% of FLA

75°C CU wire only

Use only with SRW01-UC

See user manual for short circuit ratings

MADE IN BRAZIL HECHO EN BRASIL

FABRICADO NO BRASIL

V 1.00

47 l

6

4

10

Figure 2.3: Identification labels at the UC, UMC, EDU and UMCT laterals

There is a warning label at the top of the Control Unit (UC) and of the Expansion Digital Unit (EDU), which informs

the voltage of the digital inputs for the acquired model.

Figure 2.4: Warning labels at the UC and EDU tops

2.5 HOW TO SPECIFY THE SRW 01 MODEL

In order to specify the SRW 01 model, refer to the catalog available for download on the website: www.weg.net.

2.6 RECEIVING AND STORAGE

The SRW 01 is supplied packed in a cardboard box. There is a label outside the box describing the product main

characteristics: model, WEG part number, serial number, manufacturing date and firmware version.

In order to open the package:

1. Put the package on a table.

2. Open the package.

3. Take out the product.

2-6 | SRW 01

Page 27

General Information

Verify if:

The identification label matches the bought model.

Damage occurred during transportation. If any problem is detected, contact the carrier immediately.

If the SRW 01 is not going to be installed soon, keep it in the closed package and store it in a clean and dry

place with temperature between - 25 °C and + 80 °C (- 13 °F and + 176 °F).

2.7 POWER FACTOR

The power factor (also called cos ϕ or cosine phi) indicates what percentage of total power supplied (kVA) is

effectively used as real power (kW). It can be defined as the relation between the apparent power (S) and the real

power (P), or also as the cosine of the displacement between the voltage and current signals.

The apparent power (S), measured in kVA, is the total power generated and transmitted to the load. The real

power (P), measured in kW, is the one that effectively performs the work, and the reactive power (Q), measured in

kVAr, is only used to create and maintain the electromagnetic fields within the motor.

Thus, while the real power is always consumed in the execution of the work, the reactive power, besides not

producing work, circulates between the loads and the power supply, taking a “space” in the electric system that

could be used to supply more real power.

The power factor is a dimensionless number between 0.00 and 1.00 and shows the efficiency level of the use of

electric systems. Therefore, when we say the power factor is 0.80, it means that 80 % of the apparent power (S)

is transformed into real power (P).

The measurement of the power factor, taking into account that the voltage is sine-shaped and the load linear (if

there are no harmonics), is obtained by observing the phase displacement between voltage and current in one of

the phases that supply the motor in the fundamental frequency. For inductive loads, as in case of asynchroous

motors (induction motors), the current signal will always be delayed in relation to the voltage signal.

According to trigonometry, the sinusoidal function can be mapped in a circumference, seeing that a full cycle of

the sinusoid is represented by 360º. As the voltage and current signals have the same period, the displacement

between signals is easily obtained.

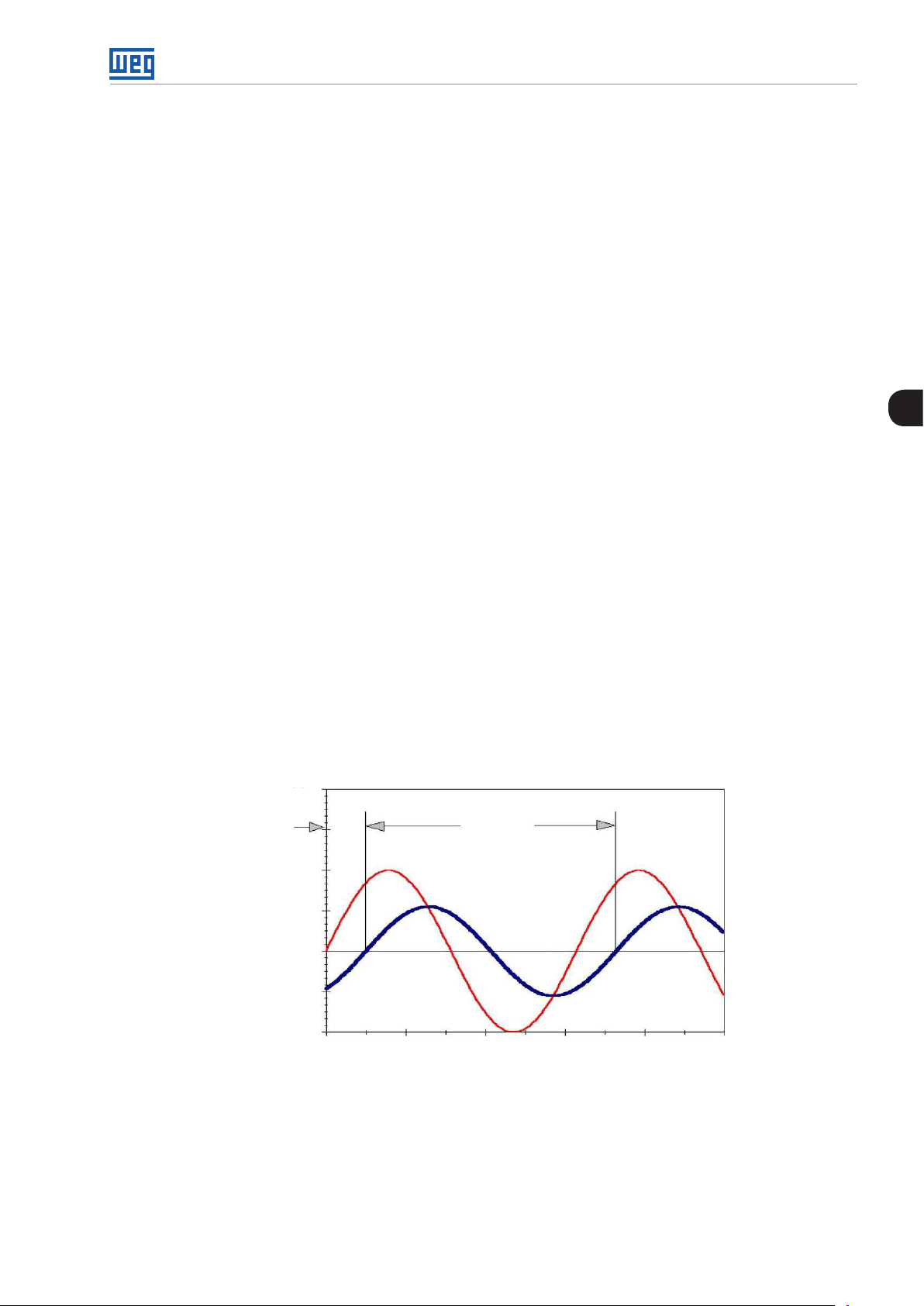

Voltage [V]

Current [A]

ϕ

360º

2

Time [s]

Figure 2.5: Displacement between voltage and current signals

After obtaining the displacement (ϕ) between the voltage and current signals, the power factor is calculated by

means of equation 01.

Power Factor = cos (ϕ)

Equation 01: Calculation of the power factor

SRW 01 | 2-7

Page 28

General Information

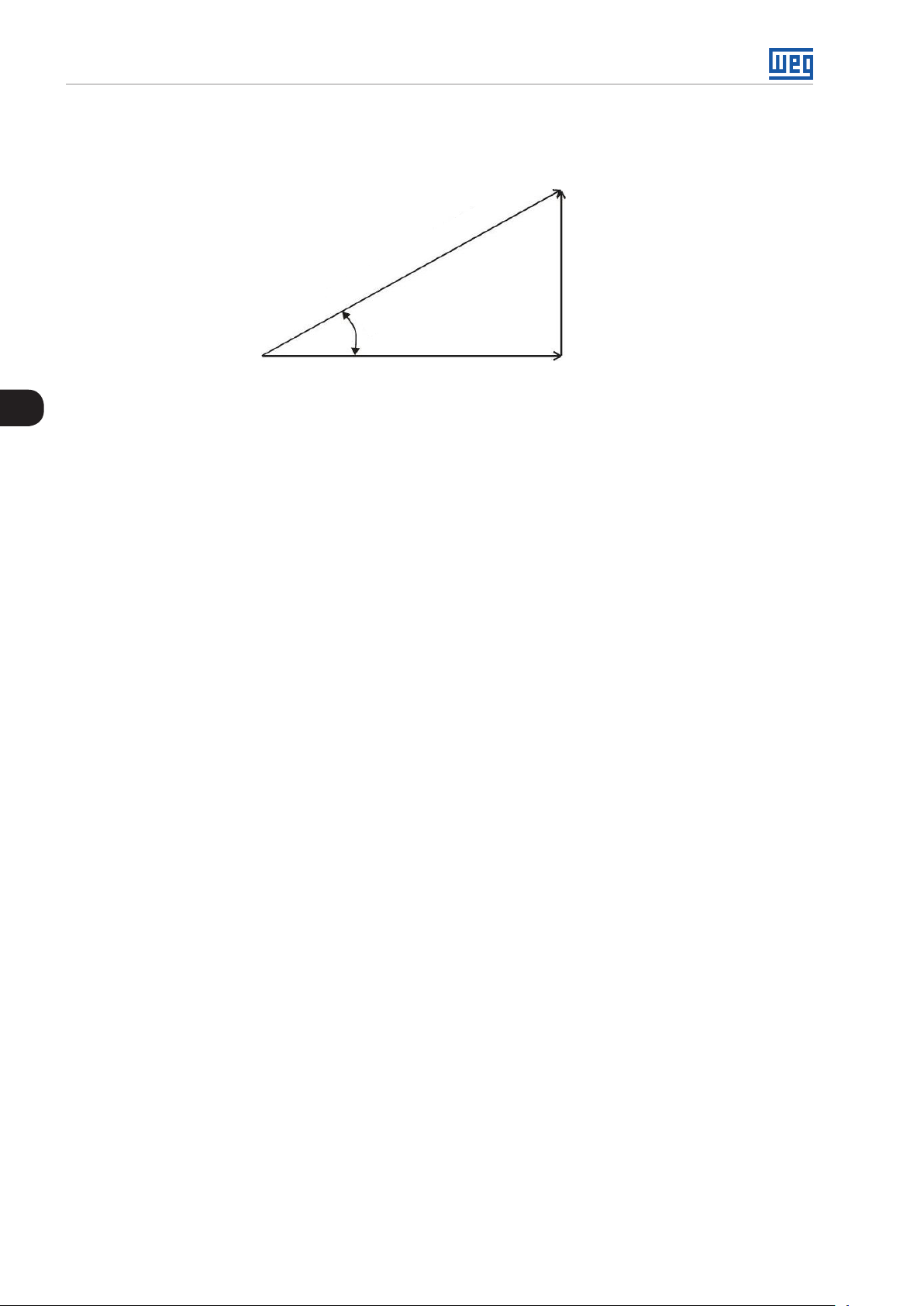

From the power factor value, in the case of sine-shaped waves, the real (P), reactive (Q) and apparent (S) powers

can be represented by vectors that form a right triangle, also known as power triangle, as shown in Figure 2.6 on

page 2-8 from which the power relations can be obtained.

Reactive

power

Apparent power (kVA)

ϕ

(kVAr)

Real power (kW)

Figure 2.6: Power triangle

2

2-8 | SRW 01

Page 29

Installation and Connection

3 INSTALLATION AND CONNECTION

This chapter describes the procedures for the electrical and mechanical installation of the SRW 01. The orientations

and suggestions shall be followed in order to guarantee personnel and equipment safety, as well as the proper

operation of the relay.

3.1 MECHANICAL INSTALLATION

3.1.1 Environmental Conditions

Avoid:

Exposure to direct sunlight, rain, high humidity, or sea-air.

Explosive or corrosive gases or liquids.

Excessive Vibration.

Dust, metallic particles or oil mist in the air.

Closeness to strong magnetic fields or high-current cables.

Allowed environmental conditions for operation:

3

Temperature: According IEC: 0 °C to 55 °C (32 °F to 131 °F).

According UL: 0 °C to 40 °C (32 °F to 104 °F).

Humidity: 5 % to 90 % non-condensing.

Pollution degree: 2 (according to UL508) with non-conductive pollution. Condensation shall not originate

conduction through the accumulated residues.

Maximum altitude: 2000 m (6.600 ft) above sea level - nominal conditions. For applications at higher altitudes,

contact WEG.

NOTE!

In order to prevent overheating, the ventilation openings must not be blocked. It is recommended to

provide a side clearance of at least 10 mm (± 0.39 in), and a top and bottom clearance of at least 30

mm (±1.18 in) so as to allow a good air circulation and better cooling.

3.1.2 Mounting

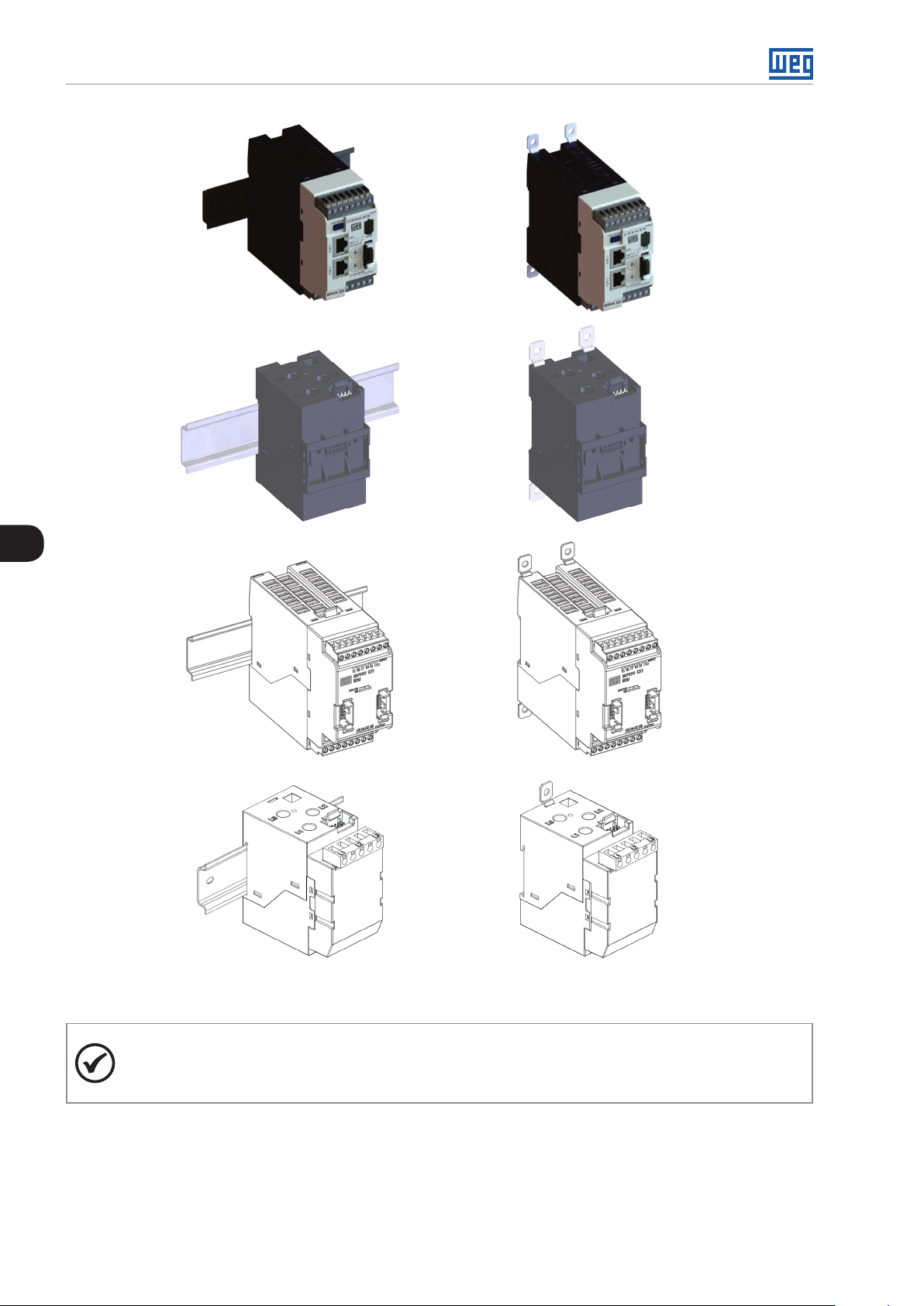

The Control Unit (UC), Current Measurement Unit (UMC1, 2, 3 and 4), the Expansion Digital Unit (EDU) and

Current/Voltage Measurement Unit (UMCT1, 2, 3 and 4) can be installed in any position.

They can be mounted on a 35 mm (1.38 in) DIN rail or through the fixing adapter (PLMP) with M4 screws.

SRW 01 | 3-1

Page 30

Installation and Connection

3

(a) 35 mm (1.38 in) DIN rail mounting (b) Secured with screws

Figure 3.1: (a) and (b) UC, UMC, EDU and UMCT mounting

NOTE!

The Control Unit (UC) can be mounted together with the Current Measurement Unit (UMC), making a

single unit, or separately (up to 2 meters). The Current/Voltage Measurement Unit (UMCT) only allows

the mounting separate from the Control Unit (UC).

3-2 | SRW 01

Page 31

3.2 ELECTRICAL INSTALLATION

DANGER!

The following information serves as guidance for a correct installation. The applicable electrical

installation regulations must also be followed.

DANGER!

Make sure the AC power supply is disconnected before beginning the connections.

I11 I12 I13 I14 I15 I16

XC1

USB

Connector

Connector

for the

HMI and

expansions

Installation and Connection

I11 I12 I13 I14 I15 I16 IC A1

T1 T2 E1 E2 PE

XC1

XC2

3

XC6

Figure 3.2: Control unit connections

XC1 terminal strip:

Digital inputs – I11, I12, I13, I14, I15 and I16.

24 Vdc output for the 24 Vdc digital inputs - IC.

Power supply terminal A1.

XC2 terminal strip:

Inputs T1 and T2 - PTC.

Inputs E1 and E2 - earth leakage sensor (ELS).

Conection to the protective earth - PE.

NOTE!

It is recommended the use of properly grounded shielded cables for the circuits of the PTC and earth

leakage sensor (ELS). The connection of the cable shield to the protection earth must be as short as

possible.

XC2

XC6

A2 C1 O1 O2 C3 O3 C4 O4

ATTENTION!

Terminal strip XC2 pin PE must obligatorily be connected to a protective earth.

SRW 01 | 3-3

Page 32

Installation and Connection

XC6 terminal strip:

Power supply terminal A2.

Digital outputs – O1, O2, O3 and O4. The outputs O1 and O2 share the common terminal C1.

ATTENTION!

The incorrect application or installation of the SRW 01 may result in damage to its components, faults

or reduction of the useful life of the product due to wiring or application errors, as well as the incorrect

setting of the operation mode, rated current of the motor, incorrect selection of the Current Measuring

Unit (UMC) or Current/Voltage, Measuring Unit (UMCT), incorrect or improper supply source for the

digital inputs, application of voltage on the terminals T1, T2, E1 and E2.

3.3 RELAY POWER SUPPLY

NOTE!

The power supply must be compatible with the SRW 01 nominal voltage.

The SRW 01 is fed through the terminals A1 and A2 from the terminal strips XC1 and XC6, respectively.

Supply voltage:

3

110 to 240 Vac and Vdc.

24 Vac and Vdc.

NOTE!

Check the nameplate on the product to know which model of the control unit was acquired:

110 to 240 Vac/Vdc or 24 Vac/Vdc supply voltage.

3.4 POWER CABLES

The SRW 01 performs the protection of three-phase and single-phase loads.

The power cable wiring diagram is illustrated in the Figure 3.3 on page 3-4.

(a) Three-phase (b) Single-phase

Figure 3.3: (a) and (b) Three-phase and single-phase of the Current Measurement Unit (UMC) and Current/Voltage Measurement Unit

3-4 | SRW 01

(UMCT)

Page 33

Installation and Connection

ATTENTION!

It is essential that all motor supply conductors that cross the windows of the Current/Voltage

Measurement Unit (UMCT) have the direction indicated in Figure 3.3 on page 3-4, seeing that the

input terminals (power supply line) are identified as L1, L2 and L3 and the output terminals (motor) are

identified as T1, T2 and T3.

When using the Current/Voltage Measurement Unit (UMCT), it is possible to monitor the voltage of the power

supply line (power), even with the motor Off. Connect the terminals of the power supply L1, L2 and L3 (or L1 and

L2, for single-phase loads) – after passing by the protection circuit (circuit breakers or fuses) – to the connection

terminals L1, L2 and L3 (or L1 and L2, for single-phase loads) of the Current/Voltage Measurement Unit (UMCT).

Observe the correct connection between the terminals ( L1 → L1, L2 → L2 and L3 → L3).

ATTENTION!

If the connection T2 - L3 is used with a single-phase motor, then the SRW 01 earth fault protection

will actuate.

3.5 CURRENT MEASUREMENT UNIT (UMC) CONNECTION

The SRW 01 has 6 current measurement units:

UMC1 (0.5 – 5 A)

UMC2 (1.25 – 12.5 A)

UMC3 (2.5 – 25 A)

UMC4 (12.5 – 125 A)

UMC5 (42 – 420 A)

UMC6 (84 – 840 A)

(*)

(*) For the 0.25 -2.5 A range the UMC1 (5 A) with 2 turns in the primary must be used, according to the Figure

3.4 on page 3-5.

3

Figure 3.4: 0.25 to 2.5 A current range connection - two turns in the UMC1

The Current Measurement Unit (UMC) or Current/Voltage Measurement Unit (UMCT) is connected to the Control

Unit (UC) by means of a ribbon-cable with a maximum length of two meters (check the cable models in the catalog

available for download on the website www.weg.net).

The Current Measurement Unit (UMC) measures the current of the 3 motor phases. The RMS current value of

each phase is transmitted digitally to the Control Unit (UC).

The Control Unit (UC) signalizes through the status led and the “E0085” HMI message, if the Current Measurement Unit

(UMC) or Current/Voltage Measurement Unit (UMCT) is not communicating with the UC.

SRW 01 | 3-5

Page 34

Installation and Connection

NOTE!

The Control Unit (UC) reports value 0 (zero) for the reading of currents if the measured current is

below 15 % of the rated current (P401 and/or P402). For measurements above 15 %, the bit 3 of the

parameter P006 - Relay Status (binary) will present the value 1, indicating that the motor is running.

NOTE!

The Control Unit (UC) shows 0 (zero) for voltage, power factor (cos ϕ), energy consumption and

powers, if the Current Measurement Unit (UMC) is used.

ATTENTION!

For applications with frequency inverters or similar equipments, the Current Measurement Unit (UMC)

should be installed between the line and the inverter. Its installation at the frequency inverter output is

not allowed if the fundamental output frequency is different from 50/60 Hz.

3.6 CONNECTION OF THE CURRENT/VOLTAGE MEASUREMENT UNIT (UMCT)

It is possible to use a Current/Voltage Measurement Unit (UMCT) instead of a Current Measurement Unit (UMCT).

Besides measuring the motor currents (like the UMC), it is possible to monitor the line voltages up to 690 V, phase

sequence, power factor (cos ϕ) and all motor powers.

The SRW 01 has 6 current/voltage measurement units:

3

UMCT1 (0.5 – 5 A / 690 V)

(*)

UMCT2 (1.25 – 12.5 A / 690 V)

UMCT3 (2.5 – 25 A / 690 V)

UMCT4 (12.5 – 125 A / 690 V)

UMCT5 (42 -420 A / 690 V)

UMCT6 (84 – 840 A / 690 V)

(*) For the 0.25 -2.5 A range the UMCT1 (5 A) with 2 turns in the primary must be used, according to the Figure

3.4 on page 3-5.

NOTE!

The True RMS L3-L1 voltage value is calculated from the True RMS voltage measurements of phases

L1-L2 and L2-L3.

NOTE!

The Control Unit (UC) shows 0 (zero) for the voltage readings if the measured voltage in below 35 V.

ATTENTION!

The incorrect selection of the Current Measuring Unit (UMC) or Current/Voltage Measurement Unit

(UMCT) using parameter P295 may result in the incorrect communication of the measured current

value sent to the Control Unit (UC) and possible motor damages.

3-6 | SRW 01

Page 35

Installation and Connection

3.7 EXTERNAL CURRENT TRANSFORMER (CT) USE

For applications with higher currents or that are out of the UMC/UMCT model range presented above, it is

possible to use external current transformers (CTs), supplied by the user.

The CTs must have the same specification, being installed separately, one for each motor phase, and have a

suitable ratio for the current range. Additionally, the CT must be specified to be able to supply the VA (burden)

according to the secondary current and cables length. They must be classified as protective CTs in order to

withstand high currents during short intervals without saturating. Normally, they must withstand surges of 20 times

the rated current and present an accuracy ≤ ± 2 %.

The SRW 01 accepts CT secondary currents of 1 or 5 A. The Current Measurement Unit UMC1 or Current/

Voltage Measurement Unit UMCT1 (0.5 - 5 A) must be used in this type of application. If necessary, it is possible

to increase the number of primary turns by passing the CT secondary cables several times through the UMC/

UMCT window, according to the Figure 3.4 on page 3-5. The Figure 3.5 on page 3-7 presents a typical wiring

diagram using external CTs.

I12

L1

TC1

L2

TC2

L3

TC3

L2 L3

L1

T2 T3

T1

SRW01 - UMC1

I11

SRW01 - CB

A2 C1

I13

O1

I15 I16

I14

O2

C3

SRW01 - UC

A1

IC

O3 C4 O4

3

U

V

W

M

3 ~

Figure 3.5: Typical wiring diagram using external CTs

ATTENTION!

The incorrect selection of a current transformer and/or parameterization error at the Control Unit (UC)

will result in an incorrect current calculation, which could cause incorrect indication and possible motor

damages.

ATTENTION!

Change the external current transformer (CT) only with the system powered off.

A CT secondary should never be open circuited while the CT primary circuit is energized.

NOTE!

Some parameters can be changed during the operation. However, there are others that can only be

changed with a stopped motor, according to the quick parameter reference.

3.8 USB CONNECTION

The USB interface is used for monitoring, parameterization and programming of the relay through a PC with the

WLP software.

Basic procedure for data transfer between PC and SRW 01:

1. Install the WLP software in the PC.

2. Connect the PC to the SRW 01 through the USB cable.

3. Switch on the SRW 01 and start the WLP software.

SRW 01 | 3-7

Page 36

Installation and Connection

4. Close the WLP software after finishing the data transfer between the PC and the SRW 01.

5. Disconnect the USB cable.

NOTE!

In order to get more information about the WLP software use, refer to the WLP manual, available for

download on the website: www.weg.net.

3.9 CONNECTION OF THE CONTROL UNIT (UC) DIGITAL INPUTS

The Control Unit has 6 optically isolated digital inputs.

The digital inputs can be activated by applying 24 Vdc, available on the IC pin of XC1 connector, through an

internal isolated power supply, as shown in Figure 3.6 on page 3-8 or through an external power supply of 24

Vdc, as shown in Figure 3.7 on page 3-9.

3

XC1

I12 I13

I11

Figure 3.6: 24 Vdc digital inputs activation

I14

I15 I16 IC

3.9.1 Identification of the Digital Inputs Types (UC)

The SRW 01 indicates the type of digital inputs of Control Unit, which is showed at the parameter P085.

P085 – Type of Digital Inputs (UC)

A1

Range: 0 = Invalid

1 = Invalid

Factory

Setting:

-

2 = 24 Vdc

3 = 110 Vac

Proprieties: RO

Description:

It indicates whether the digital inputs are 24 Vdc or 110 Vac.

3.9.2 Connection of an External Power Supply for the Digital Inputs (24 Vdc)

The 24 Vdc digital inputs can be activated by an external power supply. By using this external power supply the

SRW 01 makes available only 5 digital inputs, because the power supply reference must be connected to the

digital input I16, according to the Figure 3.7 on page 3-9.

3-8 | SRW 01

Page 37

Installation and Connection

24Vdc Power

Supply

+

-

XC1

I11 I12 I13 I14 I15 I16 IC A1

Figure 3.7: External 24 Vdc power supply connection

3.10 CONNECTION OF THE CONTROL UNIT (UC) DIGITAL OUTPUTS

The Control Unit (UC) presents 4 digital outputs, via relays, with the following internal wiring:

Digital outputs O1 and O2 share the common terminal C1.

Digital output O3 with common C3.

Digital output O4 with common C4.

A2 C1 O1 O2 C3 O3 C4 O4

Figure 3.8: Digital output internal wiring diagram

NOTE!

When driving inductive loads (contactors, relays, solenoids, etc.), overvoltage suppressors must be

connected in parallel with the coils of those devices. The connection must be done directly to the coil

terminals. RC filters must be used for AC power supply, and freewheel diodes in case of DC power

supply.

3.11 EXPANSION DIGITAL UNIT (EDU) CONNECTION

The Expansion Digital Unit (SRW01-EDU) offers the option of increasing the number of digital inputs and outputs at

the Control Unit (SRW01-UC). It has 6 digital inputs and 4 digital outputs. It is possible to use only one Expansion

Digital Unit (EDU) with each Control Unit, totalizing 12 inputs and 8 outputs. The Expansion Digital Unit (EDU)

digital inputs and outputs can be used to transfer any information to the system, to signalize the status of an

external device, to indicate Error/Trip, alarm or fault in the system etc.

3

The verification of the presence (connection) of the Expansion Digital Unit (EDU) is only performed if parameter P294

is set to “1”, indicating the use of the EDU. If the Expansion Digital Unit (EDU) is present and the communication

between both has been established, the Expansion Digital Unit (EDU) signalizes it through the status led in solid

green.

If the Expansion Digital Unit is connected without the proper setting of parameter P294 or if the communication

with the Expansion Digital Unit (EDU) is not established, the Expansion Digital Unit (EDU) signalizes error through

its status led in solid red. Refer to the Chapter 7 DIAGNOSIS on page 7-1 n this manual to obtain details on the

Expansion Digital Unit (EDU) signalization leds.

SRW 01 | 3-9

Page 38

Installation and Connection

P294 – Expansion Digital Unit (EDU)

Adjustable

Range:

0 = EDU Not Used

1 = EDU Used

Factory

Setting:

0

Proprieties: Sys, CFG

Description:

It enable the use of Expansion Digital Unit (EDU).

Once the communication between the Control Unit (UC) and the Expansion Digital Unit (EDU) has been established,

if an interruption in the communication between the devices occurs, the action programmed by the user in the

parameter P312 will take place.

P312 – Action for EDU Communication Error

Adjustable

Range:

Proprieties: Sys, rw

Description: