Page 1

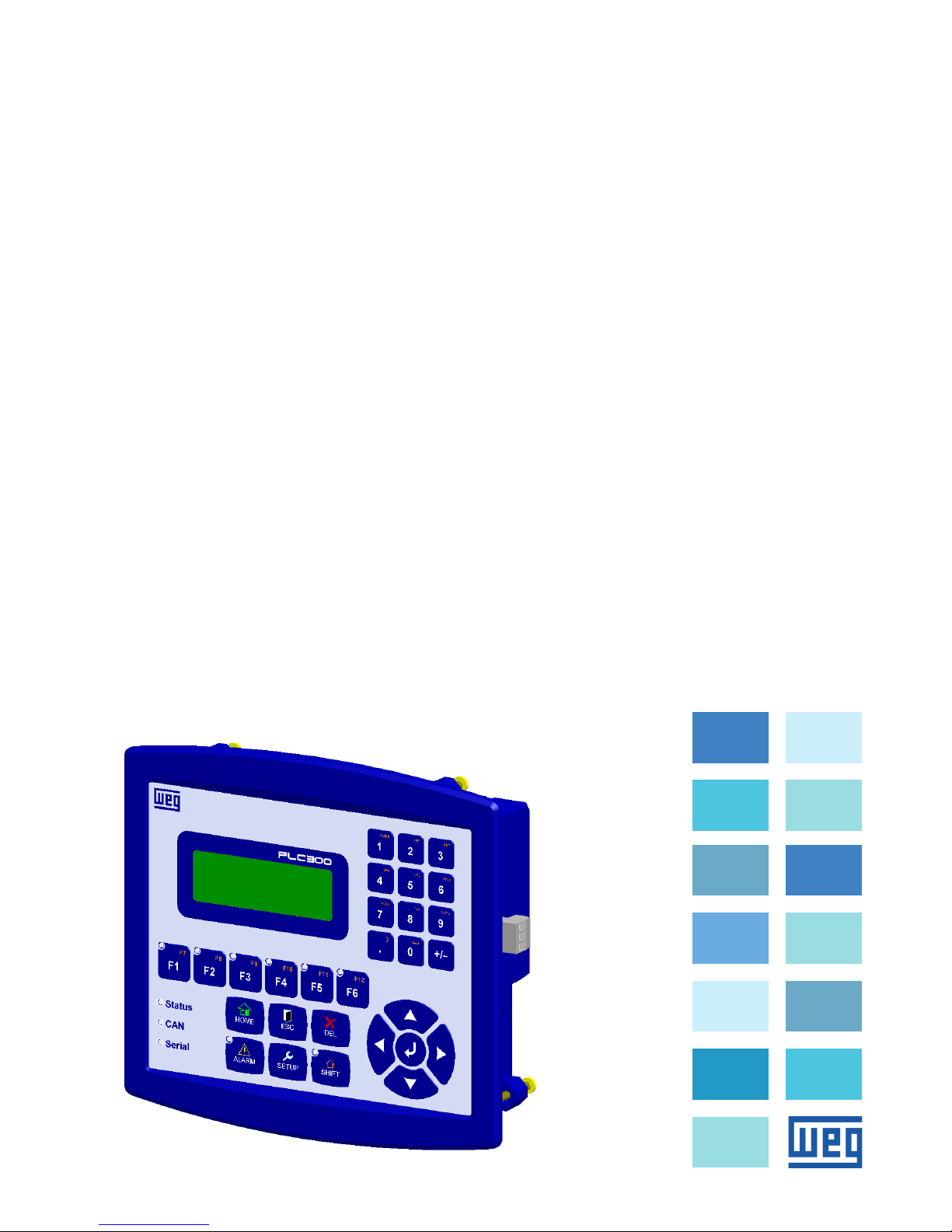

Programmable Logic Controller

PLC300

User’s Manual

Motors | Automation | Energy | Transmission & Distribution | Coatings

Page 2

Page 3

User’s Manual

Series: PLC300

Language: English

Document Number: 10004642446 / 00

Models: with and without HMI

Publishing Date: 04/2017

Page 4

Page 5

Index

1 SAFETY INSTRUCTIONS ....................................................................... 1-1

1.1 SAFETY WARNINGS IN THIS MANUAL ...................................................... 1-1

1.2 SAFETY WARNINGS IN THE PRODUCT .................................................... 1-1

1.3 PRELIMINARY RECOMMENDATIONS ....................................................... 1-2

2 INTRODUCTION TO PLC300 ................................................................ 2-1

3 CONNECTORS ........................................................................................3-1

3.1 CONNECTORS PINOUTS ............................................................................3-2

4 CONNECTIONS ......................................................................................4 -1

4.1 SUPPLY .......................................................................................................... 4-1

4.2 CAN NETWORK ............................................................................................ 4 -1

4.3 DIGITAL INPUTS .......................................................................................... 4 -1

4.4 DIGITAL OUTPUTS ....................................................................................... 4-2

4.5 ANALOG INPUT ............................................................................................ 4-3

4.6 ANALOG OUTPUT ........................................................................................4-4

4.7 ENCODER INPUT .........................................................................................4-5

4.8 RS-232 INTERFACE ..................................................................................... 4-7

4.9 RS-485 INTERFACE .....................................................................................4-8

4.10 ETHERNET INTERFACE ............................................................................. 4-9

5 DESCRIPTION OF THE KEYS ..............................................................5-1

6 EXPANSIONS ..........................................................................................6-1

7 CONFIGURATION OF THE PLC300 ......................................................7-1

7.1 SET CLOCK .................................................................................................. 7-1

7.2 LANGUAGE SELECTION .............................................................................. 7-2

7.3 LCD CONTRAST ........................................................................................... 7-2

7.4 KEYBOARD BEEP ......................................................................................... 7-2

7.5 ANALOG INPUT ............................................................................................ 7-2

7.6 IOA CARD (AOS) ........................................................................................ 7-3

7.7 ENCODER SUPPLY ...................................................................................... 7-3

7.8 RS-232 SETUP .............................................................................................. 7-3

7.9 RS-485 SETUP .............................................................................................. 7- 4

7.10 CAN SETUP ................................................................................................ 7-5

7.11 LAN SETUP ................................................................................................. 7- 5

7.12 MB TCP SETUP ........................................................................................... 7-6

7.13 SD CARD – BACKUP HMI VERSION ......................................................... 7-7

7.14 USER PROGRAM ...................................................................................... 7-10

7.15 SETUP MENU PASSWORD ...................................................................... 7-10

7.16 WATCHDOG ................................................................................................7-11

8 I/O STATUS..............................................................................................8 -1

9 DESCRIPTION OF THE PLC300 OPERATION .....................................9-1

9.1 SCREEN MANAGEMENT ............................................................................. 9-1

9.1.1 Levels of Access .................................................................................. 9 -1

9.1.2 Function Keys: F1...F12.......................................................................9-2

Page 6

Index

9.1.3 Composition of a Screen ...................................................................9-3

9.1.4 Text Component: Writing of Static Text ...........................................9-3

9.1.5 Numeric Input Component: Data Numeric Input ............................9-3

9.1.6 Numeric Output Component: Data Numeric Output ......................9-5

9.1.7 Message Component: Output with Texts for a Variable ................ 9-5

9.1.8 Bar Graph Component: Bar Graph ................................................... 9-6

9.1.9 Text Output .......................................................................................... 9-7

9.1.10 Text Input ........................................................................................... 9-7

9.2 AUTOMATIC SOFTWARE RECOVERY - ASR ............................................ 9-7

10 ALARMS ..............................................................................................10-1

10.1 INTERNAL ALARMS ................................................................................. 10 -1

10.2 USER ALARMS ......................................................................................... 10-2

10.3 ALARM SCREENS .................................................................................... 10-2

11 OPERATION OF THE LEDS ................................................................ 11-1

12 BATTERY REPLACEMENT ................................................................12-1

13 DESCRIPTION OF THE MODELS .....................................................13 -1

14 SELF-TEST ..........................................................................................14 -1

15 TECHNICAL SPECIFICATIONS .........................................................15 -1

15.1 STANDARDS MET ..................................................................................... 15-3

16 DIMENSIONS ......................................................................................16 -1

16.1 MECHANICAL MOUNTING ...................................................................... 16-3

Page 7

Safety Instructions

PLC300 | 1-1

1 SAFETY INSTRUCTIONS

This manual contains the information for the correct use of the programmable controller

PLC300.

It was developed to be used by people with proper technical training or qualification to

operate this kind of equipment.

1.1 SAFETY WARNINGS IN THIS MANUAL

In this manual, the following safety warnings are used:

DANGER!

The procedures recommended in this warning have the purpose of protecting

the user against death, serious injuries and considerable material damages.

ATTENTION!

The procedures recommended in this warning have the purpose of avoiding

material damages.

NOTE!

The information mentioned in this warning is important for the proper

understanding and good operation of the product.

1.2 SAFETY WARNINGS IN THE PRODUCT

The following symbols are attached to the product, serving as safety notices:

High voltages are present.

Components sensitive to electrostatic discharge.

Do not touch them.

Mandatory connection to the protective earth (PE).

Page 8

Safety Instructions

1-2 | PLC300

1.3 PRELIMINARY RECOMMENDATIONS

DANGER!

Only qualified personnel, familiar with PLC300 and related equipment must

plan or perform the installation, commissioning, operation and maintenance

of this equipment.

The personnel must follow the safety instructions described in this manual

and/or defined by local standards.

The noncompliance with the safety instructions may result in death risk

and/or equipment damage.

NOTE!

For the purposes of this manual, qualified personnel are those trained in

order to be able to:

1. Install, ground, power up and operate the PLC300 in accordance with

this manual and the safety legal procedures in force.

2. Use the protective equipment in accordance with the standards.

3. Give first aid.

DANGER!

Always disconnect the general power supply before touching any electrical

device associated to the PLC.

ATTENTION!

The electronic cards have component parts sensitive to electrostatic

discharge. Do not touch directly the component parts or connectors.

NOTE!

Fully read this manual before installing or operating this equipment.

Page 9

Introduction to PLC300

PLC300 | 2-1

2 INTRODUCTION TO PLC300

PLC300 is a PLC with integrated HMI, developed to meet the need of interface with the

user on panels and machines and at the same time a complete expandable PLC, fast

and with several communication ports, enabling the product to be master of CANopen

networks (CAN network) and/or Modbus RTU (RS-485 network) as well as Modbus TCP

(Ethernet network).

Some important characteristics:

High processing speed:

The PLC300 uses a 32 bit ARM Cortex-M3 processor, running at 120 MHz, which provides

a high processing speed.

HMI - Human-Machine Interface:

The PLC300 has an integrated HMI with LCD display with backlight of 4 lines and 20

characters each, in addition to the keyboard with function keys programmed by the user,

all with LEDs, <ALARM> key, <HOME> key, etc., and alpha-numeric keyboard.

Version without HMI:

It is possible to assemble the PLC on a DIN rail, in a version without HMI (keyboard and

display). In this case, the back part of the product becomes the front and features a small

display of 2 lines and 16 characters with a button to check the I/O status.

Programming:

In addition to the ladder programming, the WPS allows the assembly of the screens,

graphically, configuration of the alarms, assignment of the function keys, configuration of

the equipment, besides the firmware, which can be updated directly via PC.

The programming can be done via USB, Ethernet or Serial RS232 and RS485.

Hot Download:

Allows hot loading of the resource, that is, it is possible to change the ladder program,

screens, alarms and logs with the current program running, and after the conclusion of

the download, the new program is executed automatically. For further information, refer

to the WPS manual.

Large memory capacity:

The PLC300 features a static RAM memory with battery and capacity of 1 MByte to store

screens, alarms, program and other user’s data. The memory allocation can be configured

by the user via the WPS.

Bootloader:

The bootloader is an auxiliary program that executes the main firmware of the PLC300,

which, in turn, executes all the functionalities.

It is through the bootloader that new firmware can be saved to the PLC300 via USB or Serial.

Page 10

Introduction to PLC300

2-2 | PLC300

If during the update/saving of the firmware, the process is interrupted for some reason,

the message “Bootloader V6.xy” will be displayed on the screen and the red LEDs of the

Status, CAN and Serial will keep flashing. If that happens, just download the updated

firmware via WPS.

SD memory card (Secure Digital):

The PLC300 allows saving data and program, logging events, recipes in a SD memory card.

The memory card must be SD type with FAT32 formatting with capacity up to 32G. The

faster the card (class of the card), the shorter the recording time. This is important in case

of regular variable log recordings, for instance. It is recommended the use of class 10 cards.

Automatic Software Recovery - ASR:

It automatically recovers the PLC300 software, including configurations and retentive

markers.

See Section 9.2 AUTOMATIC SOFTWARE RECOVERY - ASR on page 9-7 of this manual.

RTC – Real Time Clock:

Real time clock that allows recording events such as alarms and logs, besides specific

blocks such as alarms or interruptions.

Digital, PWM and analog outputs:

8 digital, galvanically insulated, protected, 500 mA (each), 24 Vdc, PNP outputs.

The 10 bit analog output has independent terminals for current or voltage.

Fast output up to 300 kHz with capacity of 100 mA in 24 Vdc can be programmed in PWM.

It can be used as standard digital output.

Digital and analog inputs:

Ten isolated, digital inputs are available, at 24-Vdc level, able to produce interruption.

Two of them are fast and can be used to count pulses of up to 100 kHz, or as encoder

input in quadrature.

A 12-bit, differential, analog input is also available.

Encoder input:

Quadrature encoder input, with additional signals and detection of split cable with optional

alarm.

Maximum frequency: 100 kHz.

Page 11

Introduction to PLC300

PLC300 | 2-3

Watchdog:

The PLC300 has a user-configurable watchdog with minimum time of 300 ms.

In case of watchdog, the state of the outputs can be configured, as well as an output for

exclusive use of the watchdog.

Expansion modules:

Up to 2 I/O expansion modules can be connected to the PLC300. The following modules

are compatible:

IOA-01: 1 analog input of 14 bits in voltage and current; 2 digital inputs; 2 analog outputs

of 14 bits in voltage and current; 2 open collector digital outputs.

IOB-01: 2 analog inputs insulated in voltage and current; 2 digital inputs; 2 analog outputs

insulated in voltage and current (same output programming of the standard CFW-11); 2

open collector digital outputs.

IOC- 01: 8 digital inputs; opto-coupled; 24 Vdc; high/low level actuation; 4 digital outputs;

relay NO contacts; capacity of 240 Vac/1 A.

IOC-02: 8 digital inputs; opto-coupled; 24 Vdc; high/low level actuation; 8 digital outputs,

open collector; 24 V/0.1 A.

IOC-03: 8 digital inputs; optocoupled; 24 Vdc; configurable, high/low level actuation;

7 PNP, protected outputs; 24 Vdc; 500 mA.

IOE-01: 5 inputs of single or triple PTC thermistors with reinforced insulation compared

to the 0 V of the PLC300.

IOE-02: 5 inputs of PT100 thermistors with reinforced insulation compared to the

0 V of the PLC300.

IOE-03: 5 thermistor inputs type KTY84 with reinforced insulation in relation to the

0 V of PLC300.

Communication interfaces:

The PLC300 has the following communication interfaces:

RS-485 insulated with Master/Slave Modbus RTU protocol.

CAN insulated with Master/Slave CANopen protocol.

RS-232 with Modbus RTU protocol for monitoring and remote programming, via modem

on telephone line, and ASCII protocol for bar code readers.

USB to communicate with the computer.

Ethernet 10/100 with Modbus TCP protocol.

Page 12

Introduction to PLC300

2-4 | PLC300

Power Supply:

The PLC300 needs external supply of 24 Vdc +/-15 % with capacity of at least 500 mA.

Internally, there is an insulated DC/DC converter that provides the voltages necessary for

the product. Being insulated, it allows the user to use the same source to supply other

devices, such as the digital inputs and outputs.

Keys with functionalities at power on:

If some keys are pressed when switching on the PLC300, the following functions are

executed:

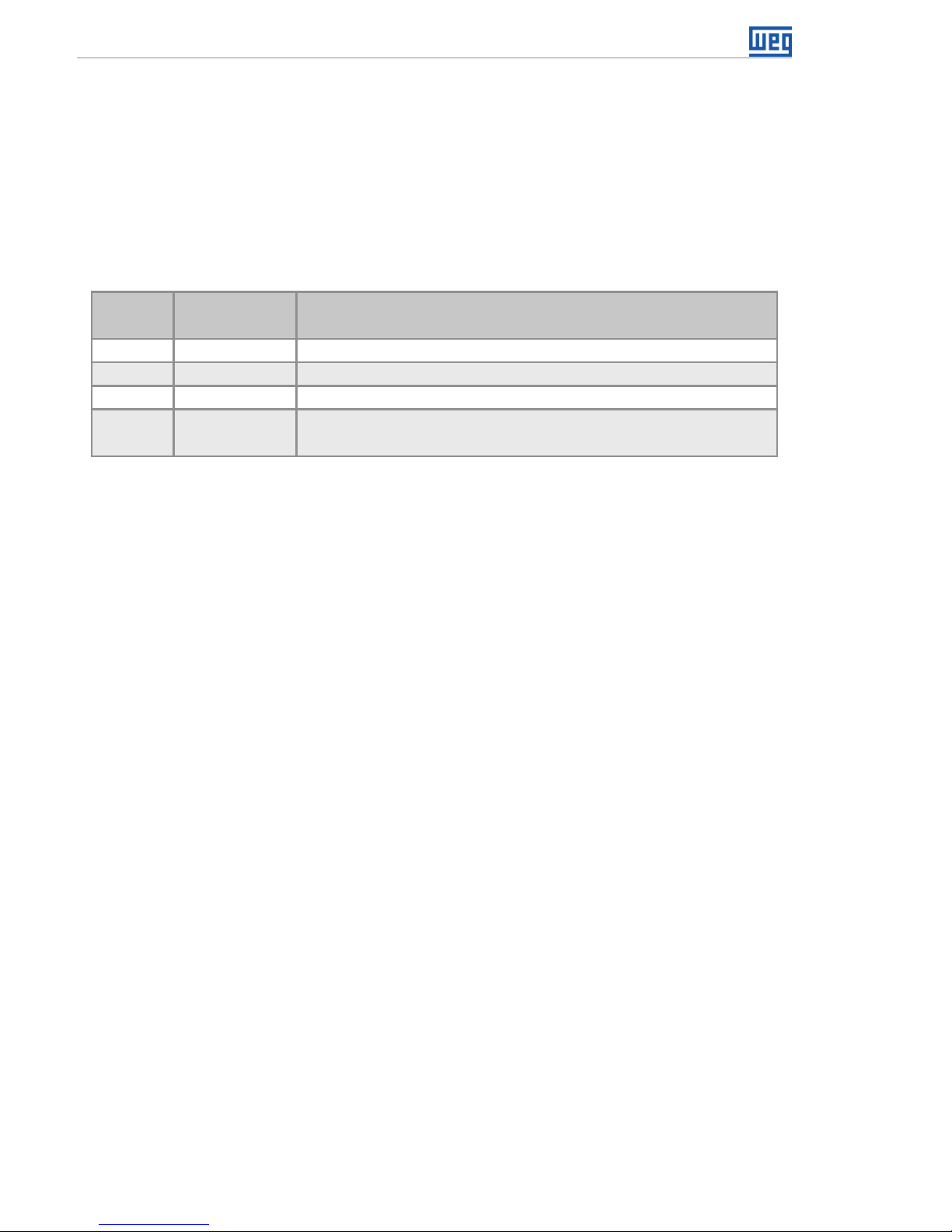

Key

Pressed Time

at Power on (t)

Functionality

SETUP t > 5 seconds. Loads factory default.

ALARM t > 5 seconds. Stops user program.

DEL t > 5 seconds. Cleans memory (deletes application, screens, …).

F6 -- Performs self-diagnosis, further details in Chapter 14 SELF-TEST

on page 14-1.

Important Note:

From the V1.50, in order to upload the factory default, stop the user’s program or clean the memory by mean

of the power on, it is necessary to type the SETUP current password for the function to be executed.

Type the current SETUP password and then press <ENTER>. In case the password is incorrect or if you

press <ESC>, the action will not be executed.

Note that when you upload the factory default or clean the memory, the SETUP password goes back to the

factory default value: '0000'.

NOTE: to clean the memory (deletes application, screens, etc.) on versions without HMI (BP and BS), turn on

the PLC300 holding the button and release it after the message “Release the Key” appears. Press the button

again for two seconds and release.

Page 13

Connectors

PLC300 | 3-1

3 CONNECTORS

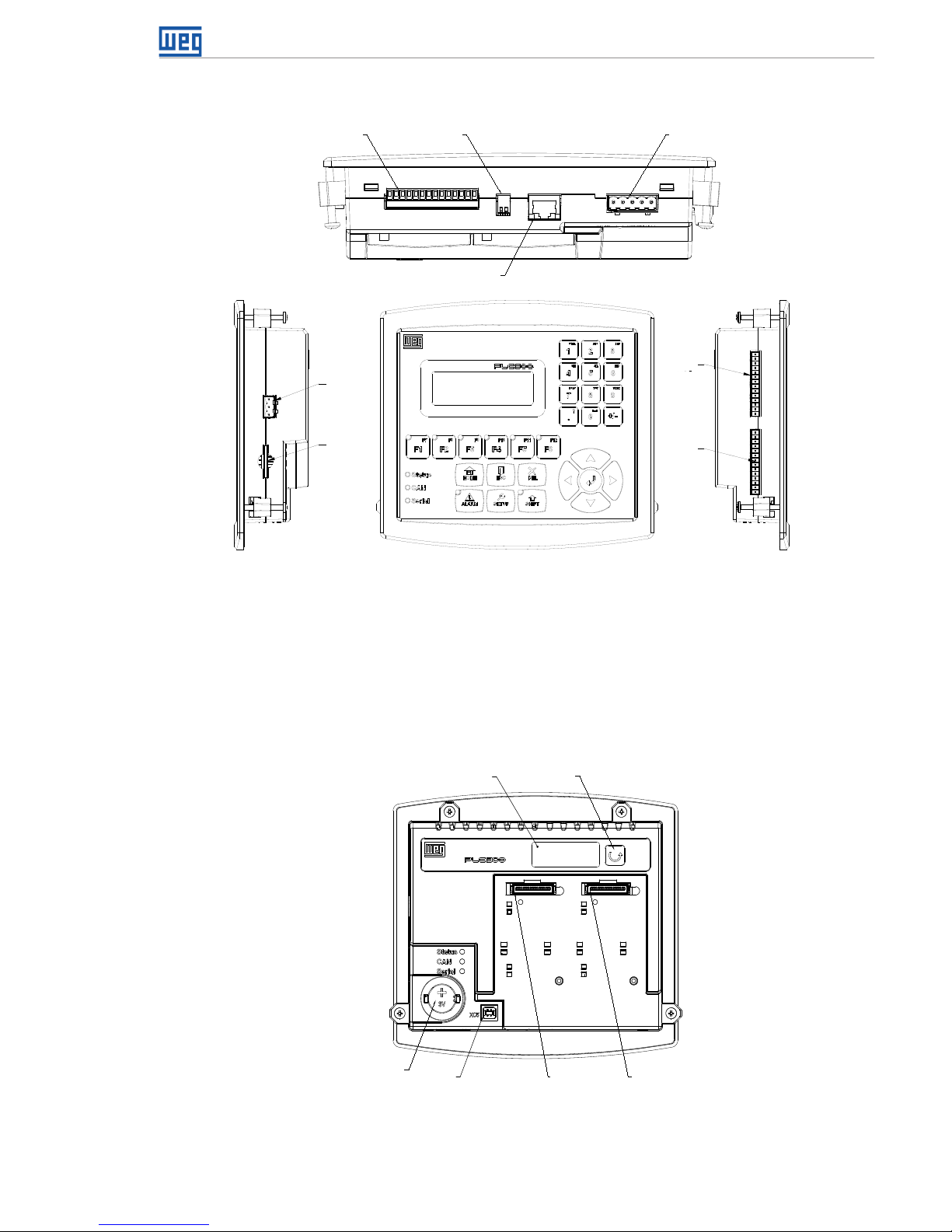

a)

XC3 S1 XC6

XC4

XC1

XC8

XC7

XC2

XC1 – digital and analog inputs.

XC2 – digital, PWM and analog outputs.

XC3 – encoder RS-232 and RS-485 input.

XC4 – Ethernet.

XC5 – USB.

XC6 – CAN.

XC7 – SD card.

XC8 – Power input 24 Vdc.

S1 – Turn on/off RS-485 termination resistors.

b)

Battery

Back

display

Back

key

XC11

Slot1

XC12

Slot2

XC5

XC11 – expansion slot 1

XC12 – expansion slot 2

Figure 3.1 (a) and (b) - Position of the connectors

Page 14

Connectors

3-2 | PLC300

3.1 CONNECTORS PINOUTS

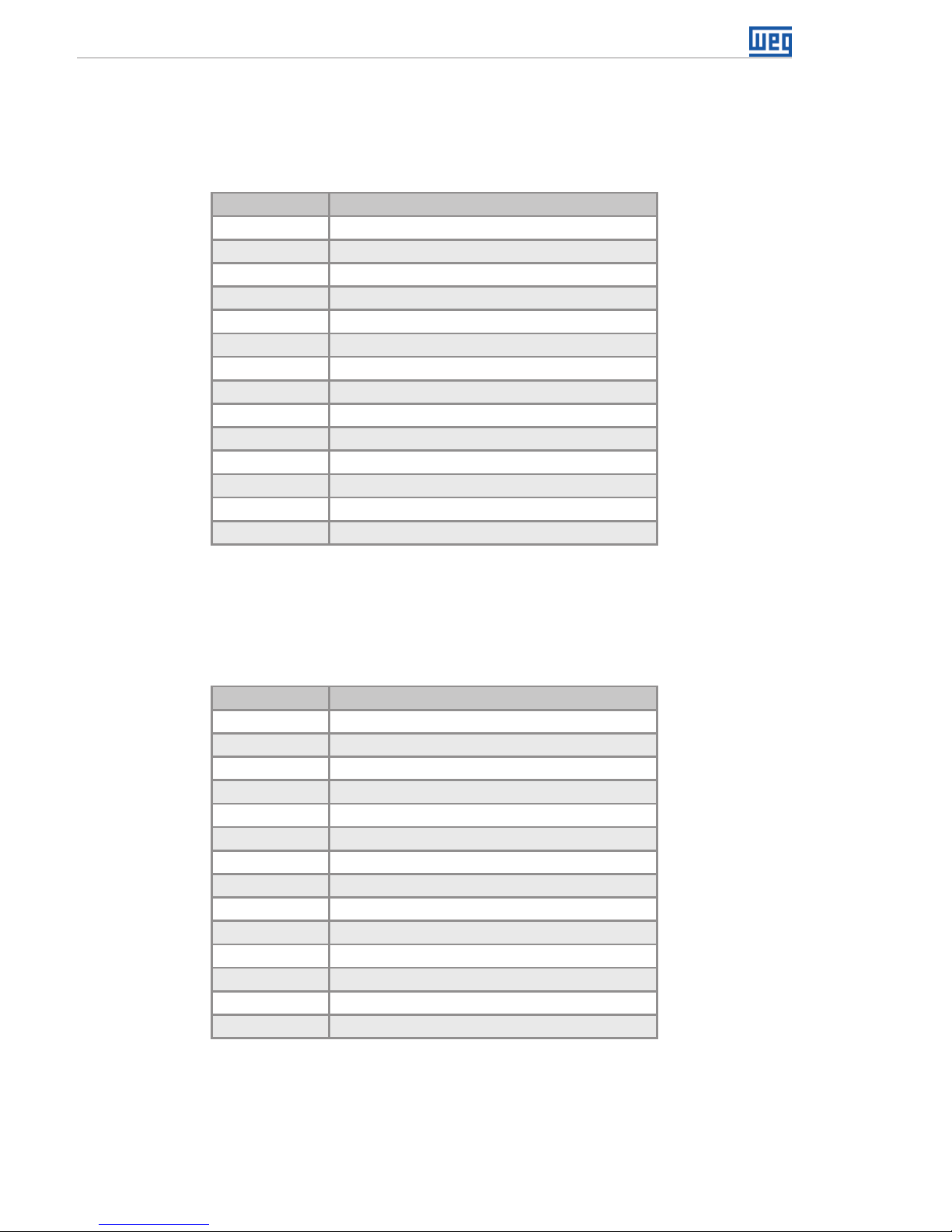

XC1 – Digital and Analog Inputs

Tab l e 3 .1: Function of the digital and analog input pins

Pin Function

1 DI1 - digital input 1.

2 DI2 - digital input 2.

3 DI3 - digital input 3.

4 DI4 - digital input 4.

5 DI5 - digital input 5.

6 DI6 - digital input 6.

7 DI7 - digital input 7.

8 DI8 - digital input 8.

9 DI9 - digital input 9 (fast)

(*)

.

10 DI10 - digital input 10 (fast)

(*)

.

11 Common of the inputs DI1...DI8.

12 Common of the inputs DI9...DI10.

13 (AI1+) analog input 1 (+).

14 (AI1-) analog input 1 (-).

(*) DI9 and DI10 can be used for reading encoder signals, A and B,

respectively.

XC2 – Digital, PWM and Analog Outputs

Table 3 . 2: Function of the digital, PMW and analog output pins

Pin Function

1 DO1 - digital output 1.

2 DO2 - digital output 2.

3 DO3 - digital output 3.

4 DO4 - digital output 4.

5 DO5 - digital output 5.

6 DO6 - digital output 6.

7 DO7 - digital output 7.

8 DO8 - digital output 8.

9 DO9 - fast output 9 (PWM).

10 GNDBB – 0 V digital outputs.

11 VBB – (20...30 Vdc) for the digital outputs.

12 AO1(V) – analog output 1 in voltage.

13 AO1(I) – analog output 1 in current.

14 AO1 – common.

Page 15

Connectors

PLC300 | 3-3

XC3 – Encoder input, RS-232 and RS-485

Table 3 . 3: Function of the pins of the encoder, RS-232 and RS-485 input

Pino Função

1 A - encoder A signal.

2

A - encoder A signal.

3 B - encoder B signal.

4

B

- encoder B signal.

5 Z - encoder Z signal.

6

Z - encoder Z signal.

7 +5/12 Vdc - encoder supply.

8 0 V – encoder supply.

9 RS-232 rate.

10 RS-232 RX.

11 RS-232 GND.

12 RS-485 signal A (-).

13 RS-485 signal B (+).

14 RS-485 GND (insulated).

XC6 – CAN

Table 3 . 4 : Function of the pins of the XC6 - CAN

Pin Function

1 V -

2 CANL

3 SHIELD

4 CANH

5 V + (11 to 30 Vdc)

XC8 – Power Supply

Table 3.5: Function of the pins of the XC8 - Power Supply

Pin Function

1 V+ (20 to 28 Vdc)

2 GND

3 Ground

XC4 – Ethernet

Ethernet standard connector.

Page 16

Connectors

3-4 | PLC300

Page 17

Connections

PLC300 | 4-1

4 CONNECTIONS

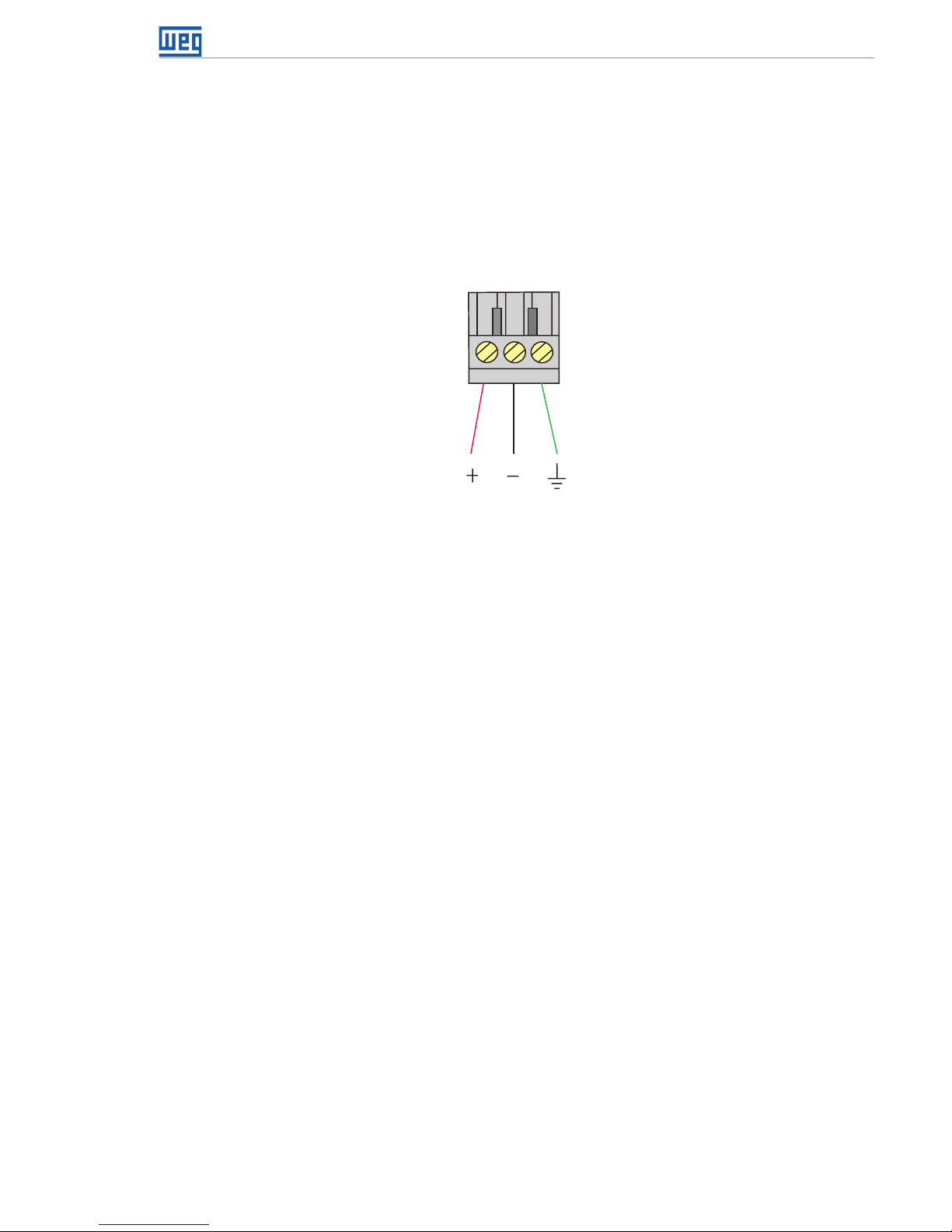

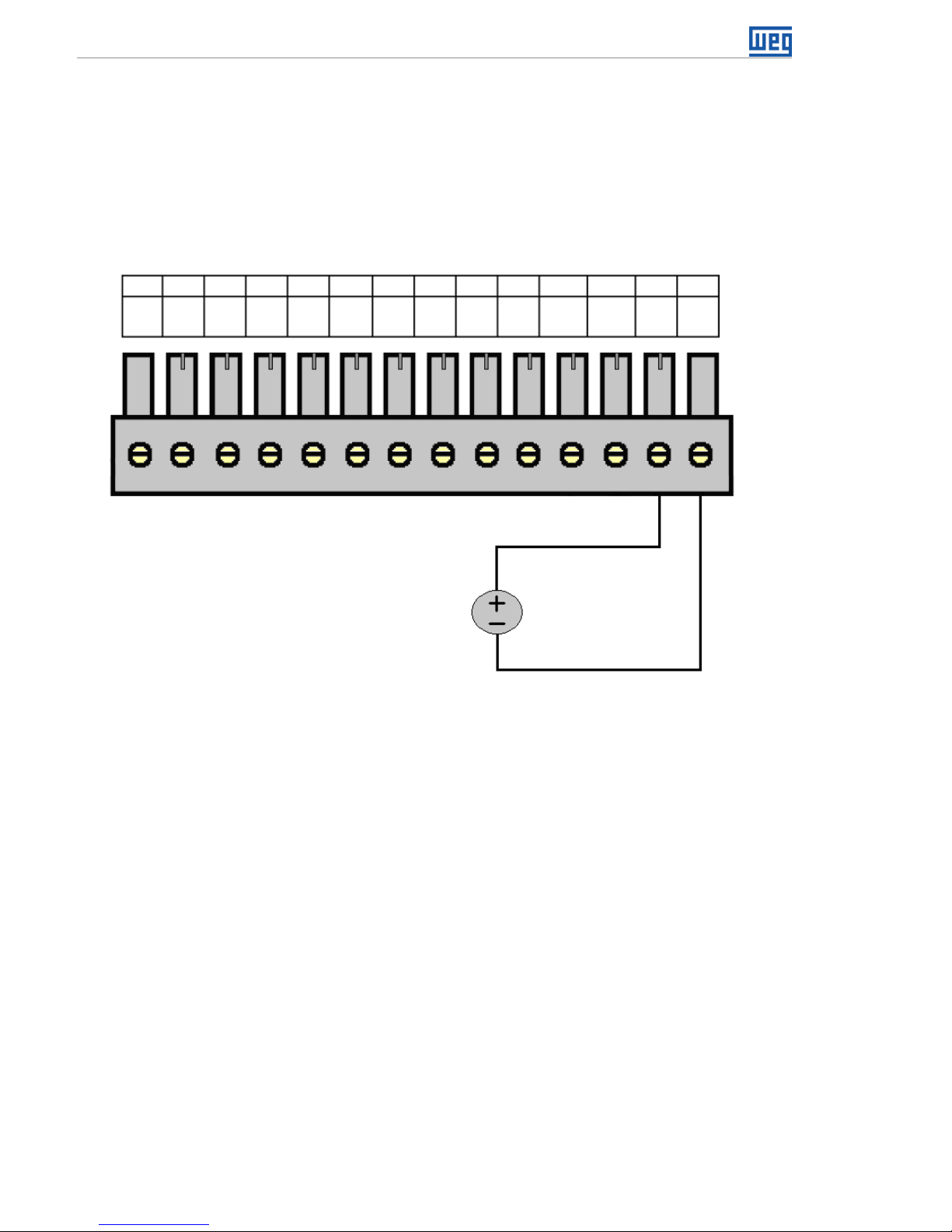

4.1 SUPPLY

The PLC300 must be powered by a power supply of 24 Vdc ± 15 % with capacity of at

least 500 mA.

The grounding connection is important.

1 2 3

Figure 4.1: XC8: Power connector of the PLC300

4.2 CAN NETWORK

See the CANopen manual.

4.3 DIGITAL INPUTS

The 10 insulated digital inputs must be excited by an external source of 24 Vdc. The inputs

are bidirectional, which means the input common can be connected to either the GND or

the VDC of the supply.

Two common pins are provided: one for DI1 to DI8 and another for DI9 to DI10.

Thus, you can connect one group in VDC and another in the GND, providing more flexibility

to the project by allowing both contacts NPN and PNP of any device to be connected to

the PLC300 inputs.

All the DIs can generate interruption in the user program and can be used as count task.

The DIs 9 and 10 are faster and can read a signal of up to 100 kHz, and they can also

operate as encoder input. The other DIs can count up to 4 kHz.

The drive levels for the DIs are from 10 to 30 Vdc for high level and less than 3 Vdc for

low level.

Page 18

Connections

4-2 | PLC300

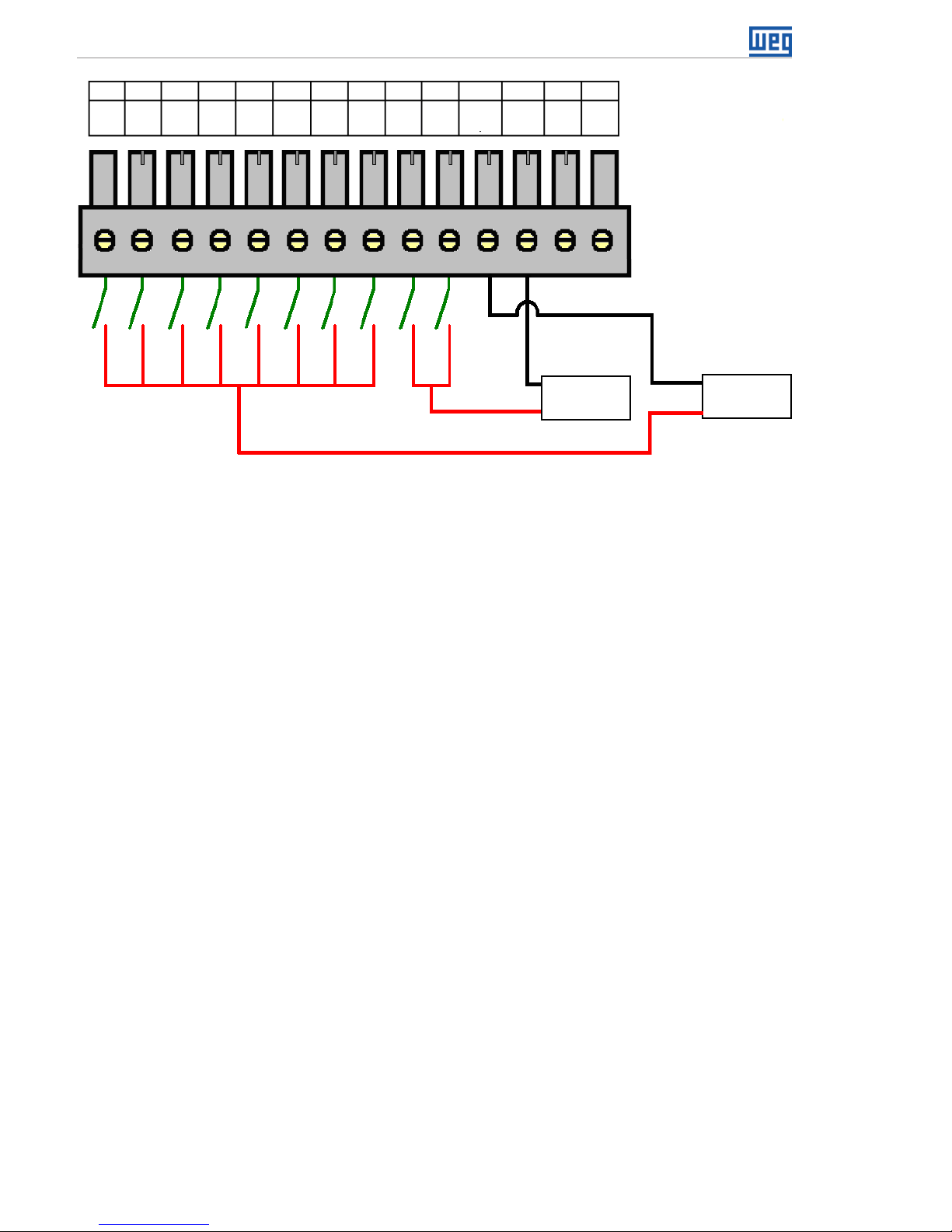

24 Vcc

XC1

24 Vcc

PNP

XC1

PNP or NPN

DI

1

1 74 102 85 11 12 13 143 96

DI

9

DI

5

DI

3

COM1COM2AI1

(+)

AI1

(-)

DI

7

DI

2

DI

10

DI

6

DI

4

DI

8

(-)

(-)

(+)

(+)

Figure 4.2: Example of connection of the digital inputs (XC1)

Notes about the example:

1. Inputs DI1 to DI8 are bidirectional, that is, they can operate as NPN or PNP. The fast

inputs DI9 and DI10 are PNP.

2. PNP is the type of input whose common is connected to the GND and the input is

excited by the VDC.

3. NPN is the type of input whose common is connected to the VDC and the input is

excited by the GND.

Encoder function DI9 and DI10:

Inputs DI9 and DI10 can also operate for the reading on an encoder in quadrature or to

count pulses.

In case of quadrature, connect signal A of the encoder to the input DI9, and signal B to

input DI10.

For pulse count, input DI9 will determine the count direction (incrementing or decrementing)

and input DI10 will receive the pulses.

Those configurations should be performed via WPS.

4.4 DIGITAL OUTPUTS

The PLC300 has eight insulated and protected digital outputs, besides a fast PWM output

that can generate pulses of up to 300 kHz with variable duty cycle from 0 to 100 %.

This output can also be used as a standard digital output, but it is not protected.

Page 19

Connections

PLC300 | 4-3

The circuit of the digital outputs must be externally powered by a supply of 24 Vdc,

connected to the pins VBB(+) and GNDBB(-)

(1)

.

The outputs DO1 to DO8 are of PNP

(2)

type and can provide a current of up to 500 mA each.

DO9 is a Push-Pull

(3)

output, PWM type, and can supply up to 100 mA.

(1) See description of XC2.

(2) PNP Output: activate load connected to GNDBB.

(3) Push-Pull Output: Bi-directional, i.e., activates the load connected to GNDBB or to VBB.

Supply

24 Vdc

XC2

L1 L2 L3

L4

DO

1

1 74 102 85

11 12

13

143 96

DO

9

DO

5

DO

3

VBB

COM

AO1

AO1

(I)

AO1

(V)

DO

7

DO

2

GND

BB

DO

6

DO

4

DO

8

(-)

(+)

Figure 4.3: Example of connection of the digital outputs (XC2)

Notes about the example:

1. The example shows two standard loads, L1 and L2, connected to the DO3 and DO5

outputs, which, when driven, apply VBB to the load (PNP outputs).

2. Loads L3 and L4 are connected to DO9, in push-pull format, i.e., when L3 is energized,

L4 is not, and vice-versa.

4.5 ANALOG INPUT

The analog input AI1 is differential, 12 bits, and can read signals from a voltage or current

source. If the signal source is far from the PLC, it is advisable to use a shielded cable.

Page 20

Connections

4-4 | PLC300

By means of the equipment setup, you can choose among the modes: voltage 0 to 10 V,

current 0 to 20 mA or current 4 to 20 mA.

When in current mode 4 to 20 mA, a broken wire alarm can be programmed. In this case,

if the input signal is below 2 mA, the alarm is generated, indicating the opening of the

current loop.

Below, a simple example of connection.

0 to 10 V

0 to 20 mA,

or

4 to 20 mA,

XC1

DI

1

1 74 102 85

11 12

13 143 96

DI

9

DI

5

DI

3

COM1COM2AI1

(+)

AI1

(-)

DI

7

DI

2

DI

10

DI

6

DI

4

DI

8

Figure 4.4: Example of connection of the analog input (XC1)

Note: AI1 operating mode must be chosen in the PLC setup: ‘Voltage 0 to 10 V’, ‘Current

0 to 20 mA’ or ‘Current 4 to 20 mA’.

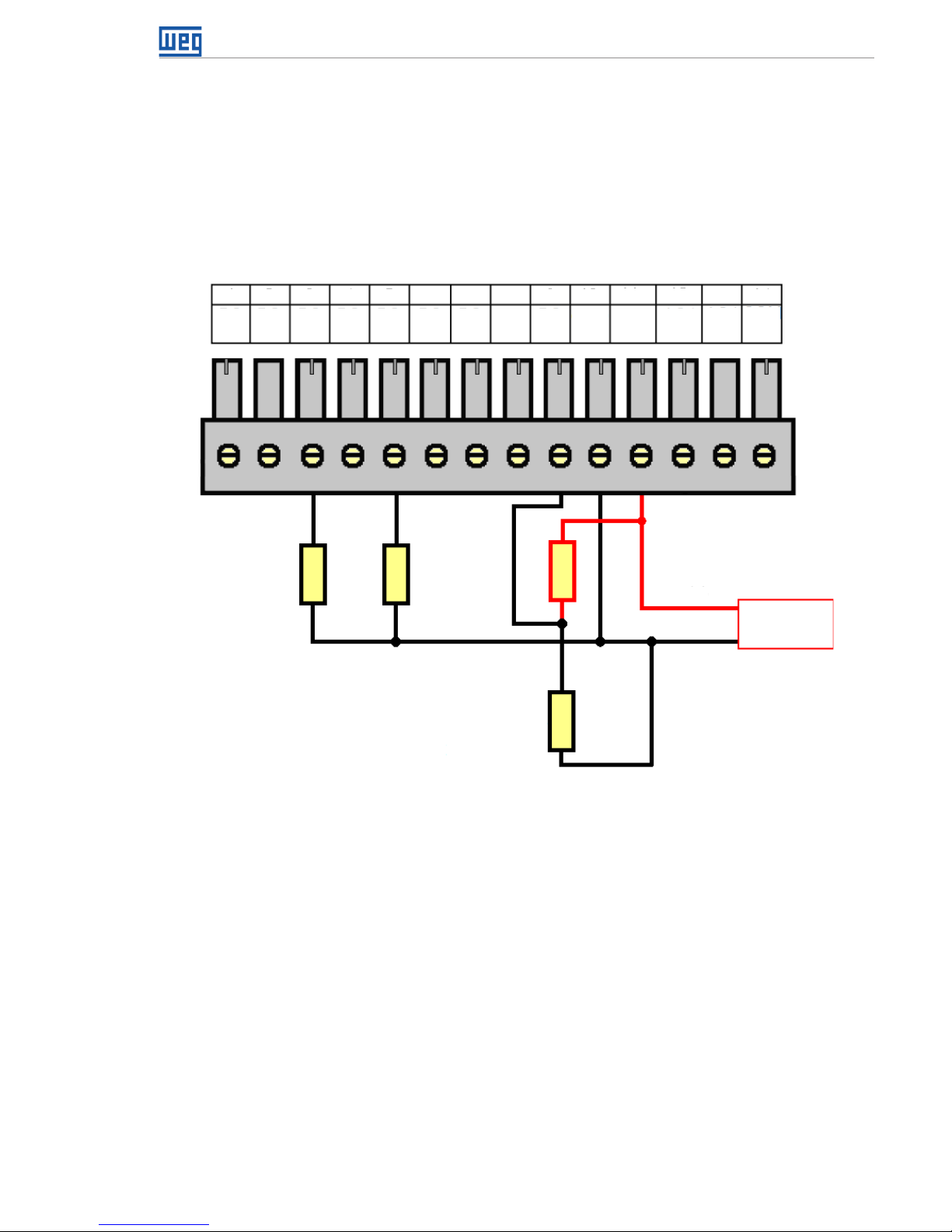

4.6 ANALOG OUTPUT

The analog output AO1, 10 bit resolution, has output in current and/or voltage, with

independent terminals, which means there is no need to configure the operating mode;

simply connect the load to the correct terminal, in voltage or current.

In voltage, the output varies between 0 and 10 V. In current, the output range is from 0 to

20 mA, for a resistive load lower or equal to 500 Ω.

The voltage and current outputs can be used simultaneously, but obviously with the same

value, since they are the same output, just in different ways.

Page 21

Connections

PLC300 | 4-5

XC2

L2

I

L1

+

V

-

DO

1

1 74 102 85 11 12 13 143 96

DO

9

DO

5

DO

3

VBB

COM

AO1

AO1

(I)

AO1

(V)

DO

7

DO

2

GND

BB

DO

6

DO

4

DO

8

Figure 4.5: Example of connection of the analog output (XC2)

4.7 ENCODER INPUT

The PLC300 features an insulated input for differential encoder, with its own supply of 5 or

12 V. The maximum frequency of the pulses is 100 kHz. Maximum length of the encoder

cable: 30 m. This input has a circuit that detects fault in the encoder signals, in case of

encoder with complementary signals. This fault can generate an alarm that must be

enabled on the WPS. A non-complementary encoder can also be used, but, in this case,

the fault circuit must remain disabled.

An internal insulated supply of 5 or 12 Vdc, with capacity of up to 300 mA, is available for

the encoder. The selection between 5 or 12 V must be done in the PLC setup. The default

value is 5 V.

The ladder offers a READENC block (encoder counter), that must be used to count.

A system marker indicates the encoder speed in hertz (Hz). The direction of rotation is also

informed by a system marker.

Page 22

Connections

4-6 | PLC300

(*)

5/12 V

A A B B Z Z 0 V

ENC

XC3

+V*

ENC

A

ENC

A

ENCBENCBENCZENCZENC

+V*

ENC

0 V

232TX232RX232

GND

485A485B485

GND

1 74 102 85 11 12 13 14

3

96

Figure 4.6: Encoder connection

24 V Encoder : You can connect a 24 V encoder, since externally powered and only signals

A, B, and Z are used.

The 0 V of the encoder must be connected to 0 V of XC3 (pin 8)

A, B and Z

signals are NOT tolerant to 24 V.

The signals A, B and Z can be used to fast counting and interrupts, also in 24 V.

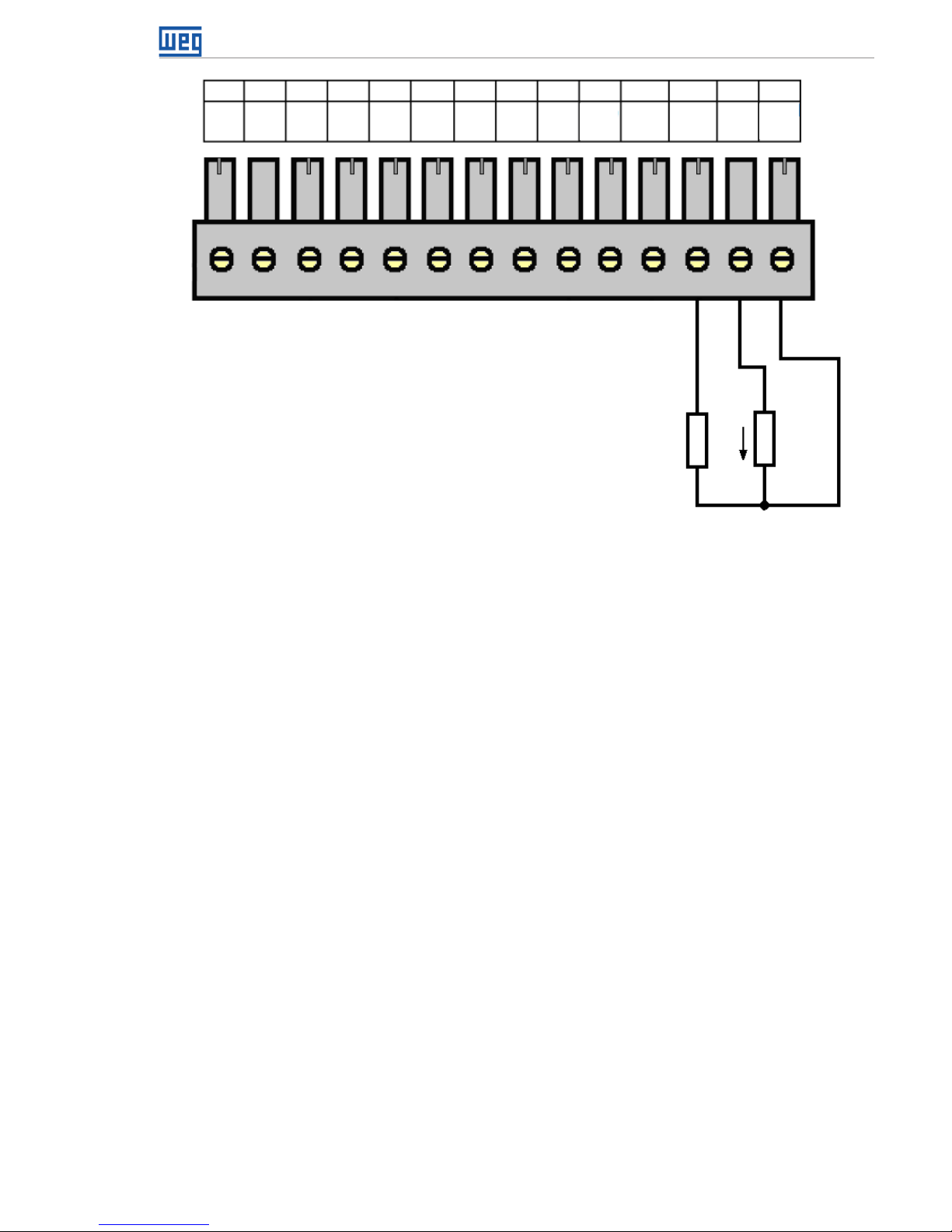

Encoder PNP: if an encoder with PNP outputs is used, resistors of 1 K ohm must be

connected from the used signals to the 0 V.

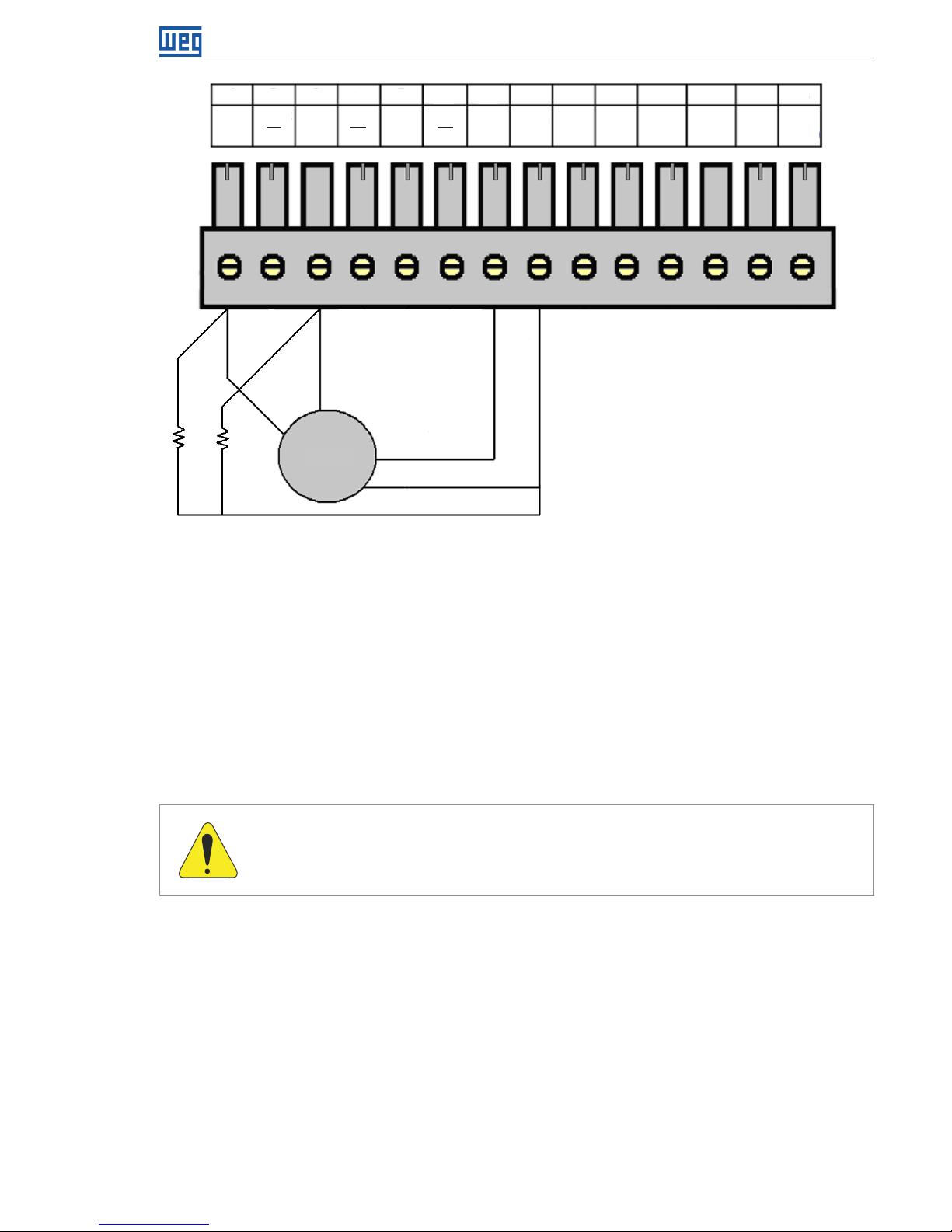

E.g.: PNP encoder with A and B signals.

Page 23

Connections

PLC300 | 4-7

A

1KR 1KR

B

0 V

(*)

5/12 V

ENC

XC3

+V*

ENC

A

ENC

A

ENCBENCBENCZENCZENC

+V*

ENC

0 V

232TX232RX232

GND

485A485

B

485

GND

1

7

4

10

2 85

11 12

13

14

3

9

6

Figure 4.7: PNP encoder connection with signals A and B

4.8 RS-232 INTERFACE

This non-insulated RS-232 serial interface is intended to point-to-point communication.

It was developed for remote connection, through a modem connected to the telephone

line. All the operations performed by the USB via WPS, can be done by this interface, i.e.,

programming, monitoring, setup, etc.

The configuration of this interface is done by the setup menu.

ATTENTION!

Do not connect the GND of the RS232 (pin 11) to the ground of the system.

Page 24

Connections

4-8 | PLC300

Modem

RS232

RX

TX

GND

XC3

ENC

A

ENC

A

ENCBENCBENCZENCZENC

+V*

ENC

0 V

232TX232RX232

GND

485A485

B

485

GND

1

7

4 102 85 11 12 13 14

3

9

6

Figure 4.8: Connecting the RS-232

Note: For further information, consult the manual for serial communication, available for

download on the website: www.weg.net.

4.9 RS-485 INTERFACE

Insulated, multipoint serial interface intended for network communication. It can operate

as master or slave with the Modbus RTU protocol.

The S1 key allows the connection of termination resistors.

The configuration of this interface is done by the setup menu.

Page 25

Connections

PLC300 | 4-9

Twisted pair

Bus RS-485

GND

A

B

XC3

ENC

A

ENC

A

ENCBENCBENCZENCZENC

+V*

ENC

0 V

232TX232RX232

GND

485A485

B

485

GND

1

7

4

10

2

8

5

11

12

13

14

3

9

6

Figure 4.9: Connecting the RS-485

Note: For further information, consult the manual for serial communication, available for

download on the website: www.weg.net.

4.10 ETHERNET INTERFACE

See the Modbus TCP communication manual, available for download on the website:

www.weg.net.

Page 26

Connections

4-10 | PLC300

Page 27

Description of the Keys

PLC300 | 5-1

5 DESCRIPTION OF THE KEYS

Alpha-numeric keyboard

The twelve keys in the upper right part enter numbers, letters and symbols.

The input of letters or symbols it is allowed from firmware version 2.10 up.

Function keys

There are six keys with LED indicators <F1>…<F6>, which implement up to twelve functions,

being <F7>…<F12> activated with the <SHIFT> key.

When a function key has some assignment on the current screen, the respective LED

turns on.

The function keys can be used for BIT functions:

Set bit.

Clear bit.

Toggle bit.

Momentary On.

The function keys can also access a certain screen programmed by the user.

<HOME> key

Goes to ‘HOME’ screen, or the user zero screen.

<ESC> key

Used to abandon or abort certain internal operations, such as setup, to leave internal

screens, to abandon editing, etc.

<DEL> key

Deletes the digit under the cursor when entering numerical data.

When in the alarm history, if pressed for t>3s, clears all the alarm history, after confirmation.

<ALARM> key

When an alarm is activated, the key LED flashes to indicate a new active alarm.

By pressing the <ALARM> key, the list of active alarms is shown and the LED stops flashing,

indicating the acknowledgement of the alarm.

If the alarm is normalized, it leaves the list of active alarms and goes to the alarm history,

which can be seen by pressing <SHIFT><ALARM>.

Page 28

Description of the Keys

5-2 | PLC300

<SETUP> key

Three functions can be accessed by means of this key: when pressed normally, it enters

the status of the I/Os (Status PLC300); when pressed for t>3s, it enters the PLC300 setup;

when pressed after the <SHIFT> key, it shows the opening screen of the product, where

you can see the firmware version.

<SH IF T> key

When pressed once, it enables the second function of the keys, the LED keeps on until

any key is pressed. If pressed twice in a row, it locks the second function of the keys, in

this case, the LED keeps flashing until the <SHIFT> key is pressed again, turning off the

second function.

Page 29

Expansions

PLC300 | 6-1

6 EXPANSIONS

Up to two expansions can be connected to the PLC300. These expansions are the I/O type

of the CFW11 (Frequency Inverter WEG 11). The detection of the expansions is automatic

and the status of the I/Os can be checked by pressing SETUP and browsing with the

arrows <> and <>.

Address of the I/Os of the expansions

The digital and analog inputs and outputs of the expansions have fixed physical address

ranges, according to the slot where the expansion is placed, i.e.:

Slot 1 – XC11

Digital inputs: start at DI101

Digital outputs: start at DO101

Analog inputs: start at AI101

Analog outputs: start at AO101

Slot 2 – XC12

Digital inputs: start at DI201

Digital outputs: start at DO201

Analog inputs: start at AI201

Analog outputs: start at AO201

The following modules are available:

IOA-01: 1 analog input of 14 bits in voltage and current; 2 digital inputs; 2 analog outputs

of 14 bits in voltage and current; 2 open collector digital outputs. The analog input can be

in voltage (0 to 10 V / -10 to 10 V) or in current (0 to 20 mA / 4 to 20 mA).

The value read in AI101, for example, will be between-32768 and 32767. Further information

can be found in the expansion installation guide.

IOB-01: 2 analog inputs insulated in voltage and current; 2 digital inputs; 2 analog outputs

insulated in voltage and current; 2 open collector digital outputs. One of the analog inputs

is 0 to 10 V and the other -10 to 10 V when configured for voltage. If configured for current,

they can be 0 to 20 mA or 4 to 20 mA. The value read in AI101, for example, will be -32768

and 32767 for the configuration -10 to 10 V or 0 to 32767 for the other configurations.

Further information can be found in the expansion installation guide.

IOC-01: 8 Digital inputs; opto-coupled; 24 Vdc; configurable, high/low level actuation; 4

digital outputs; NO-contacts relay; capacity 240 Vac/1 A.

IOC-02: 8 Digital inputs; opto-coupled; 24 Vdc; configurable, high/low level actuation; 8

digital outputs; open collector; 24 V/0.1 A.

IOC-03: 8 digital inputs; optocoupled; 24 Vdc; configurable, high/low level actuation; 7 PNP,

protected outputs; 24 Vdc; 500 mA.

IOE-01: 5 inputs of single or triple PTC thermistors, with reinforced insulation compared

to the 0 V of the PLC300.

Page 30

Expansions

6-2 | PLC300

IOE-02: 5 inputs of PT100 thermistors with reinforced insulation compared to the 0 V of

the PLC300.

IOE-03: 5 inputs of KTY84 thermistors with reinforced insulation compared to the 0 V of

the PLC300.

NOTE: For the expansion modules IOE-01, IOE-02 and IOE-03, the value read in AI101...105

or AI201...205 will be the temperature in °C multiplied by 10, that is, for a temperature of

32.1 °C, the value read will be 321.

For further information, refer to the expansion module installation guide.

Page 31

Configuration of the PLC300

PLC300 | 7-1

7 CONFIGURATION OF THE PLC300

Setup Function via HMI keyboard

In order to access the setup function via keyboard, press the <SETUP> key until an internal

screen appears and prompts to enter a password.

[ SE TU P ]

Ty pe 4 d i g Pa s s wo rd .

Pa sw d: __ __ (ES C ab t)

The initial password of the setup function is ‘0000’, and can be modified after entering

the setup.

The arrows <> and <> browse through the functions of the setup. <ENTER> selects

the function to be edited. <ESC> returns to the screen previous to the setup.

[ -- SE TU P PL C30 0- - ]

-- -- -- -- -- - - - -- -- -- -

>S et C lo ck

La ng ua ge S el e c t io n

7.1 SET CLOCK

When entering the screen of the adjustment of the clock, the current date and time are

shown. The cursor on the day of the month shows the item to be edited. The arrows <>

and <> browse between the fields.

By pressing <ENTER>, the cursor flashes indicating the editing of the field. To enter the

new value, you can use the numeric keyboard directly, or the arrows <> and <>.

The year can vary between 00 and 99, i.e., from 2000 to 2099.

The day of the week is calculated considering the date, and shown on the lower line.

The <DEL> key returns to the initial value, with no change.

Press <ENTER> to exit and save.

If you want to abort the editing, press <ESC>.

Press <ESC> to return to the main menu of the setup.

Cl oc k Ad ju st

-- -- -- -- -- - - - -- -- -- -

29 /0 9/ 09 14 :0 6: 55

Tu es da y

Page 32

Configuration of the PLC300

7-2 | PLC300

7.2 LANGUAGE SELECTION

It allows selecting the language of internal screens and messages between Portuguese

(PT) or English (EN).

The home screen shows the current language 'PT' or 'EN'; by pressing any arrow, the

language is switched.

To exit, press ESC to abort the selection or ENTER to accept it.

La ng ua ge S el e c t io n

-- -- -- -- -- - - - -- -- -- -

EN

7.3 LCD CONTRAST

The adjustment screen of the LCD contrast shows a bar graph indicating the level of

contrast of the display. The arrows <> and <> increase the contrast and the arrows

<> and <> decrease it.

Press ESC or ENTER to exit.

LC D Co nt ra st

-- -- -- -- -- - - - -- -- -- -

LC D: [ .. .. .. . . ]

7.4 KEYBOARD BEEP

Enables the beep of the keys.

The initial screen shows the current state, the standard is OFF. The arrows toggle between

on and off.

Press <ESC> or <ENTER> to exit.

Ke yb oa rd B ee p

-- -- -- -- -- - - - -- -- -- -

Of f

7.5 ANALOG INPUT

Selects one of the three operating modes of the AI1 analog input: ‘Voltage 0 to 10 V’,

‘Current 0 to 20 mA’ or ‘Current 4 to 20 mA’.

In the option 4 to 20 mA, the value that the ladder sees is a proportional, standardized

value, that is, 4 to 20 mA → 0 to 32767.

Page 33

Configuration of the PLC300

PLC300 | 7-3

The arrows select the mode that is activated only if <ENTER> is pressed.

<ESC> exits without changing the mode.

An al og I np ut

-- -- -- -- -- - - - -- -- -- -

Vo lt ag e 0 to 1 0V

7.6 IOA CARD (AOS)

Selects one of the four operating modes of the analog outputs (AOs) of the IOA accessories

installed, seeing that the AOs 101 and 102 are the AOs 1 and 2 of the IOA card installed in

the slot 1 of the PLC300, and the AOs 201 and 202 are the AOs 1 and 2 of the IOA card

installed in the slot 2.

IO A Ca rd ( AO S)

-- -- -- -- -- - - - -- -- -- >A O1 01 :0 t o 10 V

AO 10 2: 0 to 1 0V

The arrows <> and <> select the AO to be changed. By pressing <ENTER>, the cursor

flashes in the operating mode to be changed.

The arrows <> and <> browse through the possible operating modes:

0 to 20 mA, 4 to 20 mA, 0 to 10 V and -10 to +10 V.

<ENTER> accepts the changed value. <ESC> aborts.

<ESC> returns to the main menu of the setup.

7.7 ENCODER SUPPLY

Selects the power supply of the encoder between 5 or 12 V.

The arrows select the wanted voltage, which becomes valid only if <ENTER> is pressed.

<ESC> exits without changing the encoder voltage.

En co de r Su pp l y

-- -- -- -- -- - - - -- -- -- -

En co de r 12 V

7.8 RS-232 SETUP

It is possible to configure the baud rate, the parity and the number of stop bits of the RS232 serial interface.

Page 34

Configuration of the PLC300

7-4 | PLC300

RS 232 S e t up

-- -- -- -- -- - - - -- -- -- >B au d Ra te :9 6 0 0 bp s

Pa ri ty :N O

St op B it s: 1s b

The arrows <> and <> select the option to be changed. By pressing <ENTER>, the

cursor flashes in the operating mode to be changed.

The arrows <> and <> browse through the possible values:

Baud rate: 1200, 2400, 4800, 9600,19200, 38400 or 57600 b ps.

Parity: N O,O D D,E V EN .

Stop bits: 1 or 2sb.

<ENTER> accepts the changed value. <ESC> aborts.

<ESC> returns to the main menu of the setup.

7.9 RS-485 SETUP

It is possible to configure the baud rate, the parity and the number of stop bits, the mode

(master/slave/telegram1) and the address of the PLC300 in a Modbus RTU network by

means of the RS-485 serial interface.

RS 48 5 Se tu p

-- -- -- -- -- - - - -- -- -- >B au d Ra te :1 9 2 0 0b ps

Pa ri ty :N O

St op B it s: 1s b

Mo de :M as te r

Ad dr es s : 00 1

The arrows <> and <> select the option to be changed. By pressing <ENTER>, the

cursor flashes in the operating mode to be changed.

The arrows <> and <> browse through the possible values:

Baud rate: 1200, 2400, 4800, 9600, 19200, 38400 or 57600b ps.

Parity: N O,O D D,E V EN .

Stop bits: 1 or 2sb.

Mode: Master, Slave or Telegra m.

(1) There are two modes reserved for future aplications.

Page 35

Configuration of the PLC300

PLC300 | 7-5

Address: 1 to 24 7.

In the editing of the address, in addition to the upward and downward keys, the number can be

typed directly by the numeric keyboard. The <DEL> key returns to the initial value, with no change.

<ENTER> accepts the changed value. <ESC> aborts.

<ESC> returns to the main menu of the setup.

7.10 CAN SETUP

It is possible to configure the baud rate and the address of the PLC300 in a CANopen

network, through the CAN Interface.

The arrows <> and <> select the option to be changed. By pressing <ENTER>, the

cursor flashes in the operating mode to be changed.

CA N Se tu p

-- -- -- -- -- - - - -- -- -- -

>B au d Ra te :1 M b p s

Ad dr es s : 00 1

The arrows <> and <> browse through the possible values:

Baud rate: 20, 50, 100, 125, 250, 500 (Kbps), 1 Mbps

Address: 1 to 127

In the editing of the address, in addition to the upward and downward keys, the number

can be typed directly by the numeric keyboard. The <DEL> key returns to the initial value,

with no change.

<ENTER> accepts the changed value. <ESC> aborts.

<ESC> returns to the main menu of the setup.

7.11 LAN SETUP

It is possible to configure the IP address, subnet mask, default gateway, DHCP, speed and

duplex mode of the PLC300 in an Ethernet network.

LA N Se tu p

-- -- -- -- -- - - - -- -- -- -

>I P Ad dr es s:

19 2. 16 8. 00 0 . 0 10

Su bn et :

25 5. 25 5. 25 5 . 0 00

Ga te wa y:

00 0. 00 0. 00 0 . 0 00

DH CP :

Di sa bl ed

Sp ee d/ Du pl e x :

Au to

Page 36

Configuration of the PLC300

7-6 | PLC300

The arrows <> and <> select the option to be changed. By pressing <ENTER>, the

cursor flashes in the operating mode to be changed.

In the editing of the IP address, subnet mask and default gateway, the number can be

typed directly by the numeric keyboard. The <DEL> key deletes the last digit.

IP Address: 4 bytes of address that identify the PLC300 in the IP network;

Subnet: 4 bytes that identify the subnet to which the PLC300 belongs in the IP network;

Gateway: 4 address bytes that identify the default gateway to access other subnets in the

IP network;

The arrows <> and <> browse through the possible values:

DHCP: Disabled, Enabled.

Speed/Duplex: Auto, 10MBps Full Duplex, 10MBps Half Duplex, 100MBps

Full Duplex, 100MBps Half Duplex.

<ENTER> accepts the changed value. <ESC> aborts.

<ESC> returns to the main menu of the setup.

7.12 MB TCP SETUP

It is possible to configure the TCP port, Unit ID, IP authentication and timeout of the Gateway

Modbus TCP/RTU of the PLC300 in an Ethernet network by using the Modbus TCP protocol.

MB T CP C on fi gu r a t io n

-- -- -- -- -- - - - -- -- -- >T CP P or t:

00 50 2

Un it ID :

25 5

IP a ut he nt ic a t i on :

00 0. 00 0. 00 0 . 0 00

GW T im eo ut

01 00

The arrows <> and <> select the option to be changed. By pressing <ENTER>, the

cursor flashes in the operating mode to be changed.

The arrows <> and <> browse through the possible values:

TCP Port: 0 to 65535.

Unit ID: 1 to 255.

Gateway Timeout: 20 to 5000 ms.

Page 37

Configuration of the PLC300

PLC300 | 7-7

In the editing of the TCP port, in addition to the upward and downward keys, the number

can be typed directly by the numeric keyboard. The <DEL> key returns to the initial value,

with no change.

In the editing of the authentication of the IP address, the number can be typed directly by

the numeric keyboard. The <DEL> key deletes the last digit.

IP Authentication: 4 address bytes that identify the only remote IP address that can connect

to the PLC300. All the fields in zero disable the IP authentication and any remote address

can connect to PLC300.

<ENTER> accepts the changed value. <ESC> aborts.

<ESC> returns to the main menu of the setup.

7.13 SD CARD – BACKUP HMI VERSION

It allows to record (PLC300 -> SD card) or upload (SD card -> PLC300) a resource, setup

configurations and firmware in the SD card connected to the PLC300.

For protection of the user’s data, a protection password for the SD card can be programmed

in the WPS. In this case, a screen to enter a password of up to eight digits will be displayed.

In order to access the functions of backup and data restoration, the password must be

entered correctly.

SD C ar d - Ba ck up

-- -- -- -- -- - - - -- -- -- -

Un lo ck P as sw o r d :

The memory card must be of the SD type with FAT32 formatting. The faster the card (class

of the card), the shorter the recording time. This is important in case of regular variable

log recordings, for instance.

The arrows <> and <> select the option to be performed.

SD C ar d - Ba ck up

-- -- -- -- -- - - - -- -- -- -

>E qu ip .N um . :

Sa ve R es ou rc e

Lo ad R es ou rc e

Sa ve S et up

Lo ad S et up

Sa ve Fi r m wa re

Lo ad Fi r m wa re

Sa ve Fu l l B ac ku p

Lo ad Fu l l B ac ku p

The ‘Equip. Num.:’ or number of the equipment indicates the folder where the files of the

selected function will be recorded or from where they will be uploaded. It may vary from

0001 to 9999.

Page 38

Configuration of the PLC300

7-8 | PLC300

When selecting the functions of recording resource, setup, firmware or general, the files are

recorded in the following folders, respectively, according to the number of the equipment.

\PLC300\0001\Resource

\PLC300\0001\Setup

\PLC300\0001\Firmware

Important: The existing files in the destination folders will be overwritten when executing

the recording functions.

When selecting the functions of upload of resource, setup, firmware or general, the existing

files in the respective folders will be uploaded to the PLC300.

To select the wanted option, place the cursor (>) on the option and press <ENTER>; at this

point the character ‘?’ is shown at the end of the line and the block type cursor flashes,

waiting for confirmation or cancellation. Press <7> (PQRS) and <ENTER> to confirm. Any

other key is considered as NOT. <ESC> cancels the confirmation.

After its confirmation, the operation is performed and a screen is shown with the result,

error or success.

Possible error causes:

Invalid or nonexistent files.

Review of the files incompatible with the firmware version of the PLC300.

Folder with the equipment number different from that configured in the setup.

SD card without space for writing or with writing protection activated.

Version of the bootloader will not allow to upload the firmware through the SD card; check

if the marker %SW0016 (bootloader version) is equal to or above 200.

In case of firmware upload, after the confirmation and upload, the PLC is reinitialized.

The general backup is merely all the operations in sequence, that is, firmware, setup and

resource.

In case of upload of general backup, first the firmware is uploaded, and then the PLC is

reinitialized. Before starting the user’s program, the setup and the resource are uploaded,

displaying a screen with the result of the upload, success or fault.

SD CARD – BACKUP (BLIND VERSION, WITHOUT HMI)

In the versions without HMI (models BP and BS), the display and the back key are used

to perform upload/backup.

Long strokes on the back key are used to enter the backup menu and also to select

(confirm) the operation.

Page 39

Configuration of the PLC300

PLC300 | 7-9

A beep is emitted every time the key is pressed for a long period, indicating that the key

can already be released.

With the equipment in operation, press the key for some seconds, then a timed screen

will appear:

SD C ar d - Ba ck up

-- -- -- -- -- - - - -- -- -- -

If the memory card is not present or with an invalid format, an error message will be shown:

In va li d SD C ar d

or n ot P re se nt .

In order to protect the user’s data, a protection password for the SD card can be set on

the WPS. In the case of the PLC300 Blind (without HIM), the unlocking must be done by

means of the menu ‘Communication-> Online Commands’, on the WPS.

In case an attempt to access protected data occurs, the following screen is shown:

SD C ar d - Ba ck up

Bl oc ke d (W PS ) .

In case it is blocked or if it was unblocked by the WPS, the menu with the options

is presented:

>E qu ip .N um . : 0 00 1

Sa ve R es ou rc e

Lo ad R es ou rc e

Sa ve S et up

Lo ad S et up

Sa ve Fi r m wa re

Lo ad Fi r m wa re

Sa ve Fu l l B kp .

Lo ad Fu l l B kp .

Short strokes on the key will browse through the circular options, that is, when reaching

the last option, goes back to the first.

The key must be pressed for some seconds to select an option and then the selected

option is executed.

After executing some operation, a success or an error message is shown in case, for

instance, of success when recording the resource:

Re so ur ce :

Su cc es sfu l W r i t e

This message remains on the display for about two seconds and then returns to the SD card

menu.

Page 40

Configuration of the PLC300

7-10 | PLC300

The menu output is executed by timeout, i.e., in about 10 s without operation, the PLC300B

display will show the status of the I/Os again.

EDITING OF THE EQUIPMENT NUMBER (BLIND VERSION, WITHOUT HMI)

To edit the number of the equipment, press the key for some seconds, then the cursor

flashes on the number.

The number of the equipment always goes back to 0001 when it enters the editing mode

in the blind version (without HMI).

Short strokes on the key will increment the number; if the key remains pressed, the number

is increased rapidly.

To accept the entered value, simply release the key; in about five seconds the editing mode

is completed, maintaining the current value and returning to the backup menu.

7.14 USER PROGRAM

Allows to stop or execute the user program.

The current status of the program is also shown.

The <ENTER> key selects between ‘Stop’ or ‘Run’.

Us er P ro gr am

-- -- -- -- -- - - - -- -- -- St at us :R un n i n g

>S to p

In the option ‘Stop’ or ‘Execute’ ENTER or arrows, toggles the value, that is, if the program

is running the message ‘Stop’ changes to ‘Execute’ and the program is stopped.

<ESC> returns to the main menu of the setup.

7.15 SETUP MENU PASSWORD

Allows changing the password of the setup function.

The standard password is ‘0000’. The new password must be a number with four digits.

Ch an ge SE TU P Pa ss w d

-- -- -- -- -- - - - -- -- -- -

Ne w pa ss wo rd :

Type the new password and press <ENTER>.

The arrow <> or <DEL> keys serve as backspace.

Page 41

Configuration of the PLC300

PLC300 | 7-11

The new password must be confirmed on the next line.

Ch an ge SE TU P Pa ss w d

-- -- -- -- -- - - - -- -- -- Ne w pa ss wo rd : * * **

Re ty pe : ** **

If there is a typo and the confirmation fails, the new password is requested again, until it

is confirmed or <ESC> is pressed.

If there is a confirmation of the new password, the message is shown:

PASSWORD REDEFINED.

Indicating success in the operation. In this case, the screen to change the password is

abandoned, returning to the main menu of the setup.

<ESC> returns to the main menu of the setup without changing the password.

The arrow <> or <DEL> keys work as backspace.

7.16 WATCHDOG

It allows configuring the watchdog of the PLC300.

Wa tc hd og

-- -- -- -- -- - -- -- -- -- >T im e WD :0 05 0 0m s

Re se t PL C: No

WD O ut pu t: No n e

Ou tp ut St :T u rn o ff

The arrows <> and <> select the option to be changed. By pressing <ENTER>, the

cursor flashes in the operating mode to be changed.

The arrows <> and <> browse through the possible values:

WD Time: allows configuring the watchdog overflow time from 300 ms to 99999 ms.

Reset PLC: defines whether the occurrence of WD will reset the PLC and run the

application again, or it will go to a safe state, configured in the following options.

WD Output: allows choosing an output of exclusive use for the WD, which can be DO8

or DO9. The writing on it via Ladder will have no effect; it will remain in high level until the

occurrence of the watchdog.

Output St.: allows configuring whether the other outputs will keep the state or will turn

of in the occurrence of the WD.

Page 42

Configuration of the PLC300

7-12 | PLC300

<ENTER> accepts the changed value. <ESC> aborts.

<ESC> returns to the main menu of the setup.

Page 43

I/O Status

PLC300 | 8-1

8 I/O STATUS

By pressing the <SETUP> key rapidly, we enter the check screen of the I/O status. The

arrows <> and <> browse through the status screens. These screens depend on the

hardware, if there is expansion or not, and the function of the digital output DO9, for instance.

Internal digital Inputs and outputs

You can check on the first screen the level of the ten internal digital inputs: DI1 to DI10 and

of the internal digital outputs.

[- S TA TU S PL C30 0 - ]

10 .. 7. .4 .. 1

I1 0. .0 1: 0 01 0 0 0 10 11

00 9. .0 1: 10 00 11 00 0

In the example, the outputs 1, 2, 4 and 8, as well as the outputs 4, 5 and 9 are active.

If the digital output 9 is programmed as PWM output, instead of 0 or 1, the letter ‘P’ is shown.

[- S TA TU S PL C30 0 - ]

10 .. 7. .4 .. 1

I1 0. .0 1: 0 01 0 0 0 10 11

00 9. .0 1: P0 00 11 00 0

Internal analog input and output

By pressing the arrow <>, we go to the next status screen, which shows the internal

analog input and output:

[- S TA TU S PL C30 0 - ]

AI 1: 9 .1 V 18 .2 m A

Ao 1: 10 .0 V 20 . 0 m A

The example screen above shows the voltage at the analog input AI1, of 9.1 V, or, if you

are measuring current, 18.2 mA.

In the option 4 to 20 mA, for input AI1, the value that the ladder sees is a proportional,

standardized value, that is, 4 to 20 mA → 0 to 32767, but the status shows the real value

of the current.

The analog output AO1, is with 10 V or 20 mA, simultaneously, depending on the physical

output that is being used (see XC2).

Digital output DO9 in PWM

If he digital output DO9 is programmed as PWM, by pressing the key <>, we can see

the screen that shows this output data:

[- S TA TU S PL C30 0 - ]

DO 9 - PW M

FR EQ UE NC Y :1 0 . 1 2k Hz

DU TY C YC LE :8 4 . 9 0%

Page 44

I/O Status

8-2 | PLC300

Expansions

If there are expansions, we access the screens that show their status by pressing <>.

The expansion screens depend on the kind of I/O that each expansion contains.

For instance, an IOA-01, which has 1 analog input, 2 analog outputs, 2 digital inputs and

2 digital outputs:

[- S TA TU S PL C30 0 - ]

10 8. .. 4. .1

I1 08 .. 10 1: 0 0 0 0 00 11

O1 08 .. 10 1: 0 0 0 0 00 10

The example screen shows the digital inputs and outputs of the expansion IOA-01, in the

slot 1, where the inputs DI101 and DI102, as well as the output DO102, are active.

By pressing the arrow <>, again, we can see the analog inputs of this expansion:

[- S TA TU S PL C30 0 - ]

AI 10 1: -1 0. 0V - 1 9 . 0m A

AI 10 2: 8 .3V 16 .6 mA

←

AI102 only in the IOB card

By pressing the arrow <>, again, the analog inputs of this expansion are shown:

[- S TA TU S PL C30 0 - ]

AO 10 1: 8.3V 1 6 .6 mA

AO 10 2: 1 .0 V 2 .0 mA

IOE Card (thermistor reading):

The IOE cards have five inputs for reading PTC, PT-100 or KTY-84 thermistors.

In the user program (ladder), the thermal sensors are treated as analog inputs (AI101...

AI105 or AI201...AI205).

The status screens show the temperature in each sensor, between -20 °C and +200 °C.

If the monitored temperature is lower than -20 °C the thermal sensor is probably with a

broken wire, which is indicated by the symbol: “=/=(FP)”.

[- S TA TU S PL C30 0 - ]

S1 01 : 1 05oC

S1 02 : - 13oC

S1 03: = / =(FP )

By pressing the key <> again, the other two temperatures are shown:

[- S TA TU S PL C30 0 - ]

S1 04 : 58oC

S1 05 : 27oC

Page 45

I/O Status

PLC300 | 8-3

Status of the Ethernet Interface

You may check on the last screen, the MAC Address of the PLC300 and its current IP

address.

[- S TA TU S PL C30 0 - ]

MA C Ad dr es s

38 -31 - A C- 00 -0 0- 00

IP : 19 2. 16 8. 0 . 1

Date, time and Scan cycle

After the ethernet status, a screen shows the scan cycle of the user’s program, as well as

the date and time of the RTC.

[- S TA TU S PL C30 0 - ]

Sc an C yc le : 5.7 ms

06 /0 2/ 12 1 6: 1 8 : 06

Mo nd ay

BAC K DIS PLAY

The back display, which has two lines with 16 characters each, always shows the I/O status.

It serves mainly for the case of the PLC300 mounted without HMI (keyboard and front

display). If there is a front display, it helps check the status from the inside of the panel door.

The initial screen shows the status of the internal digital I/Os, that is, DI10 to DI01 and

DO09 to DO01.

By pressing the back key, we alternate the status screens. Those screens depend on

the hardware, for instance, whether there is expansion or not, and the DO9 digital output

function.

Internal digital inputs and outputs

The level of the ten internal digital inputs can be checked on the first screen: DI10 to DI1

and of the internal digital outputs.

I1 0- 1: 00 10 0 0 1 01 1

O0 9- 1: 1 00 01 1 0 0 0

In the example, the outputs 1, 2, 4 and 8, as well as the outputs 4, 5 and 9 are active.

If the digital output 9 is programmed as PWM rapid output, instead of 0 or 1, the letter

‘P’ is shown.

I1 0- 1: 00 10 0 0 1 01 1

O0 9- 1: P 00 01 1 0 0 0

Page 46

I/O Status

8-4 | PLC300

Internal analog input and output

By pressing the back key, we go to the next status screen, which shows the internal analog

input and output:

AI 1: 9 .1 V 18 .2 m A

AO 1: 10 .0 V 20 . 0 m A

The example screen above shows the voltage at the analog input AI1, of 9.1 V, or, if you

are measuring current, 18.2 mA.

In the option 4 to 20 mA, the value that the ladder sees is a proportional, standardized

value, that is, 4 to 20 mA → 0 to 32767, but the status shows the real value of the current.

The analog output AO1, is with 10 V or 20 mA, simultaneously, depending on the physical

output that is being used (see XC2).

Digital output DO9 in PWM

If the digital output DO9 is programmed as PWM, by pressing the back key, we can see

the screen that shows this output data:

FR EQ .: 1 0. 12 k H z

DU TY : 8 4. 90 %

Expansions

If there are expansions, we access the screens that show their status by pressing the

back key. The expansion screens depend on the type of I/O that each expansion contains.

For instance, an IOA-01, which has 1 analog input, 2 analog outputs, 2 digital inputs and

2 digital outputs:

I1 08 -0 1: 00 0 0 0 01 1

O1 08 -0 1: 00 0 0 0 01 0

Note that, due to the lack of space, the numbers are abbreviated. ‘I108-01’ means the

digital inputs of the slot 1, ranging from 108 to 101. Likewise, ‘O108-01’ indicates the digital

outputs of the slot 1, ranging from 108 to 101.

The example screen shows the digital inputs and outputs of the expansion IOA-01, in

the slot 1, where the inputs DI101 and DI102, as well as the output DO102, are active, by

pressing the rear key again, we can see the analog inputs and outputs of this expansion,

one per screen:

AI 10 1: -1 0. 0V

20 .0 mA

AO 10 1: -1 0. 0V

20 .0 mA

AO 10 2: 9. 0V

18 .0 mA

Page 47

I/O Status

PLC300 | 8-5

IOE Card (thermistor reading):

The IOE cards have five inputs for reading PTC, PT-100 or KTY-84 thermistors.

In the user program (ladder), the thermal sensors are treated as analog inputs (AI101...AI105

or AI201...AI205).

The status screens show the temperature in each sensor, between -20 °C and +200 °C.

If the monitored temperature is lower than -20 °C, the thermal sensor is probably with a

broken wire, which is indicated by the symbol: “=/=(FP)”.

S1 01 : 1 05oC

S1 02 : - 13oC

The two following temperatures will be shown by pressing the <> key.

S1 03: = / =( FP )

S1 04 : 58oC

By pressing the <> key again, the last temperature is shown.

S1 05 : 27oC

Status of the Ethernet Interface

You may check on the last two screens, the MAC Address of the PLC300 and its current

IP address.

MA C Ad dr es s:

3831 A C 0 0 0 0 00

IP A dd re ss :

19 2. 16 8. 0. 1

Date, time and Scan cycle

After the Ethernet status, we can see a screen that shows the user program scan cycle,

besides the RTC date and time:

Sc an : 99 9. 9 ms

06 /0 2/ 12 1 6: 1 8

Page 48

I/O Status

8-6 | PLC300

Page 49

Description of the PLC300 Operation

PLC300 | 9-1

9 DESCRIPTION OF THE PLC300 OPERATION

WPS Software (Weg Programming Suite)

The PLC300 programming is done by means of the WPS software. With this tool, you can

develop and monitor the ladder program.

The screens and the alarms are also programmed by the WPS, by means of the screen

editor.

The configuration of the equipment, described previously, can be executed by the WPS,

particularly useful when the version without HMI is being used.

Startup

When connected, the PLC300 displays an opening screen for about 2 s which shows the

firmware version of the equipment:

[ PL C30 0 ]

[ WE G ]

[- -- -- -- -- - - - -- -- -- ]

[ PT V4 .0 0 ]

After the opening, the PLC goes to the HOME screen, or zero screen of the user. In case

there are no uploaded screens, a default screen is shown:

De fa ul t HO ME .

User Program

When the PLC300 is energized, it is checked if there is a valid ladder program in the

memory; if any, the program is started immediately.

9.1 SCREEN MANAGEMENT

Up to 512 screens can be used by the user. These screens characterize the application,

by means of menus, data input and variable monitoring, etc. The screens interact with the

ladder program by means of markers (ladder variables), as well as with the user via keyboard.

The browsing between the screens is executed by the function keys, which must be properly

programmed to go to the wanted screen.

The <HOME> key always goes to the initial screen of the user (zero screen).

9.1.1 Levels of Access

Except for the zero screen (HOME), the other screens can be programmed with an access

password. Up to nine levels of access can be programmed to allow different kinds of

users with access to certain screens. The level of access zero means that the screen has

free access.

The higher the level of access, the greater the privilege. To access a level-five screen, it is

Page 50

Description of the PLC300 Operation

9-2 | PLC300

necessary to have a password of higher level or equal to the level 5.

In addition to the property of the level of access, you can set the ‘auto logoff’, which resets

the password entered to access level prior to the screen that has just left.

When trying to access a screen with level of access higher than zero, the following screen

is shown, waiting to enter the password.

[A CC ES S TO SC N: 0 02 ]

[A CC ES S LE VE L : 5]

[6 D IG IT P AS SW O R D ]

▓

The password must have six numerals. Arrows <> or <DEL> delete the typed character.

After typing the six numerals, press <ENTER> to access the screen. If you do not have the

level of access, press <ESC> to return to the previous screen.

In case of an invalid password, either by a typo or level of access lower than the required,

the following message appears flashing:

** IN VA LI D PA S S W OR D* *

returning to the password entry screen.

9.1.2 Function Keys: F1...F12

The function keys can be programmed to execute BIT or SCREEN functions. The

programming of each function key is independent for each screen, that is, the same

function key can have different actions for each screen. When the function key has a certain

assignment on the current screen, the LED corresponding to the key goes on.

The BIT actions are:

ON: turns on a certain Boolean variable (bit marker).

OFF: turns off a certain Boolean variable (bit marker).

Toggle: inverts the status of a certain Boolean variable (bit marker).

Momentary ON: turns on a certain Boolean variable (bit marker) only while the key is

pressed; when you release the key, the marker returns to zero.

In the SCREEN function, when the key is pressed, the programmed screen appears.

Page 51

Description of the PLC300 Operation

PLC300 | 9-3

9.1.3 Composition of a Screen

The screen can be composed by Text, Input, Output, Message and Bargraph elements.

Each element is placed in a certain position, forming a layout defined by the user.

Example of user’s screen:

F1 :G o to s cr ee n 5

Ra di us :1 .23cm

En co de r:3032 4p

Te mp .: [ . .. . . . .]

This screen shows the following components:

Tex t: “F1: Go to screen 5”, “R ad iu s:”, “cm”, “Enco der:”, “p” and “Te m p .:”

Input: “1.23”, numeric input which goes to a certain marker.

Output: “30324”, monitoring value of a certain variable.

Bar graph: “[▌▌▌▌▌.......]” bar graph proportional to a certain variable.

9.1.4 Text Component: Writing of Static Text

Fixed texts that compose the screen, such as help, units and information in general.

The properties of this component are: line (y), column (x), width and blink.

For further details, consult the WPS online help.

9.1.5 Numeric Input Component: Data Numeric Input

Allows the user to enter a number. The content goes to a marker defined by the user. The

input data can be Boolean, integer or floating point.

When it is not being edited, the input field shows the current value of the variable.

The input field is indicated by the line cursor, underlining the far right digit of the current

value of the variable.

When there is more than one input field on the same screen, the arrows <> and <>

are used to select the field that will be edited. The line cursor underlines the value that

will be edited.

To enter numbers, it is necessary to press <ENTER>, then the data filed can be incremented

or decremented using the arrows < > and <>, respectively. It is also possible to change

the digits using the arrows <> and <>. In case some number is typed, the field will be

erased and the new number entered.

Page 52

Description of the PLC300 Operation

9-4 | PLC300

Only numbers are allowed, including sign and decimal point. After typing the number, press

<ENTER> to update the value. The <DEL> key deletes the character under the cursor.

<ESC> exits without changing the value.

Properties of the input component: line (y), column (x), width, data type, maximum and

minimum and number of decimal digits.

The width must provide sign (in case of variable with sign) and the decimal point, if present.

In case of a integer variable with decimal places, the maximum and minimum values do

not consider the point. For instance: WORD with two decimal places: 0.00 to 655.35, but

the minimum and the maximum are: 0 and 65535.

Variable types: BOOL, SINT, USINT (BYTE), INT, UINT (WORD), DINT, UDINT (DWORD)

and REAL.

If the entered value is out of the maximum or minimum limits, the value is not accepted

and a warning screen appears:

[- -- -- -- -- - - - -- -- -- ]

[ VA LU E OU T ]

[ OF R AN GE . ]

[- -- -- -- -- - - - -- -- -- ]

The number of decimal places limits the display of places after the decimal point.

Examples:

Number of decimal places: 2

Variable type: REAL (floating point)

Typed number: 1.2258

Displayed value (after the <ENTER>): 1.23

Value stored in the marker: 1.2258

Number of decimal places: 3

Variable type: WORD (16-bit whole):

Typed number: 1.2258

Displayed value (after the <ENTER>): 1.225

Value stored in the marker: 1225

NOTE!

A maximum of 12 inputs can be placed in each screen.

Notes:

in the REAL variable, the typed value is completely stored, though only two decimal

places are shown, with rounding.

Page 53

Description of the PLC300 Operation

PLC300 | 9-5

in the WORD variable, the typed value is truncated (not rounded) and as this is a integer

number, the stored value is multiplied by 1000, which is the power 103, where 3 is the

number of decimal places.

9.1.6 Numeric Output Component: Data Numeric Output

It shows the value of a variable on the display. The allowed types are: BOOL, SINT, USINT

(BYTE), INT, UINT (WORD), DINT, UDINT (DWORD) and REAL.

The properties of the output component are: line (y), column (x), width, update period,

blink, data type, and number of decimal digits.

The width must foresee sign (in case of variable with sign) and the decimal point, if there is.

The blink property makes the displayed value blink.

The update period is the time in milliseconds (ms) to update the displayed value with the

content of the variable.

Example:

Number of decimal places: 2

Variable type: WORD (16-bit integer)

Value stored in the marker: 12258

Displayed value: 122.58

9.1.7 Message Component: Output with Texts for a Variable

Shows texts for certain values of a variable. The allowed types are: BOOL, SINT, USINT

(BYTE), INT, UINT (WORD), DINT and UDINT (DWORD). The properties of the output

component are: line (y), column (x), width, update period, data type and a table with the

values and texts.

The width must be sufficient to hold the texts that will be shown.

This component is particularly useful for variables that store status, for instance, a boolean

variable. It can be shown: ‘ON’ or ‘OFF’.

The values which do not appear on the table will be shown numerically.

The update period is the time in milliseconds (ms) to update the displayed value with the

content of the variable.

Page 54

Description of the PLC300 Operation

9-6 | PLC300

Example:

Variable type: BYTE (8 bit integer)

Table Count:

Tab l e 9.1: Example of text for values of the variable

Index Value Tex t

1 0 “Sunday”

2 1 “Monday”

3 2 “Tuesday”

4 3 “Wednesday”

5 4 “Thursday”

6 5 “Friday”

7 6 “Saturday”

In this example, the PLC300 will show the texts, which are the days of the week, for variable

values between 0 and 6; if the content of the variable is out of these values, the proper

number will be shown.

NOTE!

A maximum of 12 outputs (output + message) can be placed on each screen.

9.1.8 Bar Graph Component: Bar Graph

It shows a bar built with block type characters, proportional to the value of a variable.

The allowed types are: SINT, USINT (BYTE), INT, UINT(WORD), DINT, UDINT(DWORD)

and REAL.

Properties of the bar graph: line(y), column (x), width, data type, maximum and minimum.

The width must be sufficient for the bar plus two delimiting characters,

‘[‘ and ‘]’.

It corresponds to 0 %, that is, the minimum value:

Te mp .: [. .. . . . .. ]

It corresponds to 50 % of the value between the minimum and maximum.

Te mp .: [ . .. . ]

It corresponds to 100 %, that is, the maximum value:

Te mp .: [ ]

Note: “T e m p.:” is a Text component, it is not part of the bar graph.

Page 55

Description of the PLC300 Operation

PLC300 | 9-7

NOTE!

A maximum of 4 bargraphs can be placed on each screen.

9.1.9 Text Output

Shows text (string) on the ‘Ouput’ function of the screens of the PLC300 with HMI. This

option only accepts STRING.

The string is terminated with the NULL (0) character and is shown in one line of the display,

being then limited to 20 characters. The excess will be truncated.

9.1.10 Text Input

The Text Input component, from firmware version 2.10 up, allows the input of STRING

variables, and they can contain letters, numbers, signals, etc.

In order to insert letters, just use the <SHIFT> key after entering the field. If pressed twice,

the shift function will remain selected, enabling the entering of several letters. The arrows

<> and <> toggle from high to low case.

9.2 AUTOMATIC SOFTWARE RECOVERY - ASR

When energizing the PLC300, if it is detected that the Resource, CANopen Configuration

or Setup are invalid (battery fault, for instance), the corresponding files contained in the

flash memory will be loaded. Those files will be automatically created at the moment of

the download of the Resource and CANopen Configuration or in case there is a change

in the Setup by the HMI or WPS.

At the power-up, a backup of the retentive markers and recipe will be made so that, if

there is data loss in the memory, the configuration of the last power on will be recovered.

If the recovery of the software occurs, an alarm will be generated indicating that the

Resource was invalid, and it was recovered from the Flash memory; the system marker

that indicates the alarm can be used for some treatment in the Resource.