Page 1

Quick Installation Guide

MW500

1 SAFETY INSTRUCTIONS

This quick ins tallation guide co ntains the basic info rmation necessa ry to commission th e MW500. It has

been writte n to be used by qualifi ed personnel w ith suitable tr aining or techni cal qualifica tion for operati ng

this type of equ ipment. The personnel sh all follow all the safety inst ructions described in th is manual

defined by the loc al regulations. F ailure to comply wi th the safety instr uctions may resul t in death, serious

injury, and/or equipment damage.

2 SAFETY WAR NINGS IN THE MANUAL

NOTE!

It is not the intenti on of this guide to present a ll the possibilitie s for the application of th e

MW500, as well as W EG cannot take any liabili ty for the use of the MW500 wh ich is not

based on this guide.

For further information about installation, full parameter list and recommendations, visit the

website www.weg.net.

DANGER!

The procedur es recommended in this war ning have the purpose of protec ting the user

against death, serious injuries and/or considerable material damage.

ATTENTION!

The procedur es recomme nded in this wa rning have the p urpose of avoi ding materia l damage.

NOTE!

The information mentioned in this warning is important for the proper understanding and

good operation of the product.

High voltage s are present.

Components sensitive to electrostatic discharge.

Do not touch them.

Mandatory connection to the protective ground (PE).

Connection of the shield to the ground.

High temperature warning.

3 PRELIMINARY RECOMMENDATIONS

DANGER!

Always disconnect the general power supply before changing any electric component

associated to the inverter. Many components may remain loaded with high voltages and/ or

moving (fans), even a fter the AC power sup ply is disconne cted or turned off. Wai t for at least

ten minutes in ord er to guarantee the full di scharge of the capacito rs. Always connect the

grounding point of the inverter to the protection grounding.

NOTE!

Frequency Inve rter may interfere w ith other electronic e quipment. Follow the pr ecautions

recommended in manual available in www.weg.net.

Do not perf orm any withs tand voltag e test!

If necessary, contact the manufacturer.

ATTENTION!

The electronic boards have components sensitive to electrostatic discharges. Do not touch

the components or connectors directly. If necessary, first touch the grounding point of the

inverter, which m ust be connec ted to the protecti on ground or us e a proper groun ding strap.

Do not touch the fra me of the inverter directl y. The inverter may be very hot d uring and

after the operation.

ATTENTION!

When the inver ter is stored for a l ong period, i t becomes ne cessary to p erform the c apacitor

reforming. Ref er to the procedure re commended in www.weg.net.

4 ABOUT THE MW5 00

The MW500 is a hig h-performanc e, decentralized inve rter with IP66 degr ee of protection dust an wa ter.

The MW500 allo ws speed and torque control of th ree-phase induction moto rs. This product features

vector (V VW ) and scalar (V/f ) control - both progr ammable accord ing to your applicat ion.

5 NOMENCLATURE

Table 1: Nomenclatu re of the MW500 inverte rs

Product and

Series

Identifi cation of the M odel

Brake

Degree of

Protection

Conducted

Emission

Level

Disconnecting

Switch

Connection

Box

Hardware

Version

Special

Software

Version

Frame

Rated

Current

N° of

Phases

Rated

Voltage

Eg.: MW500 B 06P5 T 4 DB 66 C2 DS A56 --- ---

Available options

MW500

See Table 2 A56 = motor

connection box size

56 x 56 mm

Blank =

standard

DB = with dynamic b raking Sx = special

software

A70 = motor

connection box size

70 x 70 mm

Blank = standard

plug-in module

H00 = without

plug-in

66 = IP66/Nema4X (de gree of protection)

DS = with disconnecting switch

Blank = without disconnecting switch

Blank = It does not me et the standards le ves for

conducted emission

C2 = with internal RFI fi lter

Table 2: Availabl e options for each fi eld of the nomencla ture according to the r ated current and vol tage of the inverte r

Frame

Rated Output

Current

N° of Phases Rated Voltage

Available Options for the Remaining Identification

Codes of the In verters

Brake

Degree of

Protection

Conducted

Emission

Level

Disconnecting

Switch

Connection

Box

A

04P3 = 4.3 A

S = singlephase

power supply

2 = 200...240 V

DB 66 Blank or C2 Blank or DS

A56 or

A70

06P0 = 6.0 A

02P6 = 2.6 A

T = threephase

power supply

4 = 380...480 V

04P3 = 4.3 A

B

06P5 = 6.5 A

S = singlephase

power supply

2 = 200...240 V

10P0 = 10.0 A

6 RECEIVIN G AND STORAGE

The MW500 is sup plied packed in a card board box. There is an id entification labe l affixed to the outsid e

of the package, id entical to the one af fixed to the side of the inv erter.

Verify whether:

The MW500 identification label corresponds to the purchased model.

Any damage occurred during transportation.

Report any damage immediately to the carrier.

If the MW500 is not in stalled soon, stor e it in a clean and dr y location (tempe rature between -25 ºC a nd

60 ºC (-13 ºF and 140 ºF)), with a cover to p revent dust accumu lation inside it.

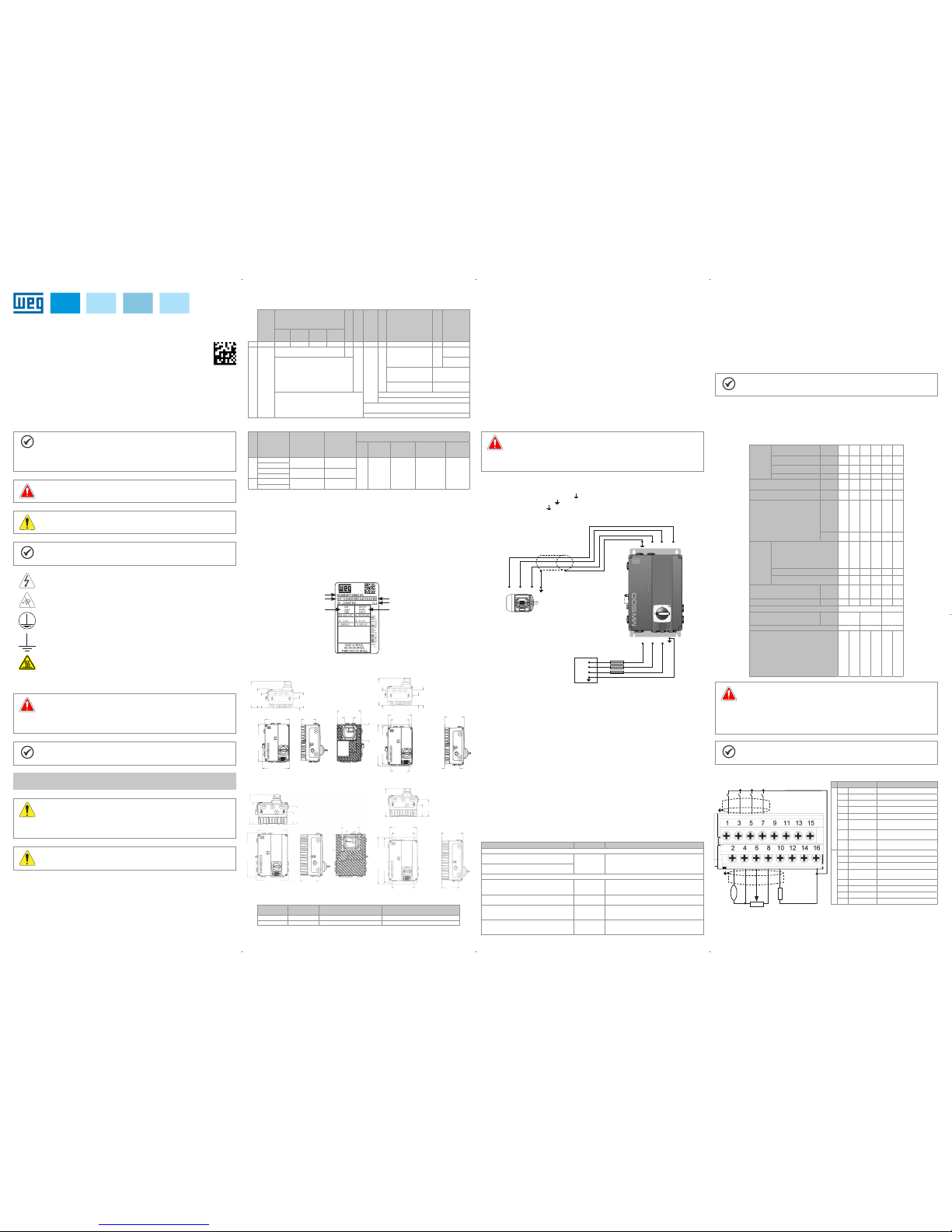

7 IDENTIFICATION LABEL

Rated input data

(voltage, curren t and

frequency)

Serial number

Manufacturing date

Rated output data

(voltage, current and

frequency)

WEG part number

MW500 model

Figure 1: Description of the MW500 ide ntification lab el

8 DIMENSIONS

177.6 (6.99)

161.5 (6.36)

240 (9.45)

153.7 (6.05)

171.8 (6.76)

125 (4.92 )

101.8

(4.01)

95 (3.74)

62

(2.44)

97 (3.82)

56 (2.2) x 56 (2.2)

96.6 (3.8)

174.4 (6,87)

97.6 (3.84)

99.6 (3.92)

64.4

(2.54)

151.8 (5. 98)

120 (4.72)

127.6 (5.02)

99.6 (3.92)

120 (4.72)

250 (9.84)

265 (10.43 )

(a) Inverter w ithout moun ting suppor t - frame A

(b) Inverter w ith mounti ng support - f rame A

206 (8.1)

189 (7.4 6)

269 (10. 61)

102 (4.03)

188 (7.3 9)

141 (5.55)

113 (4. 45)

114 (4.5)

56 x 56 (2.20 x 2.20)

113 (4. 45)

78 (3.07)

116 (4.57)

81

(3.19)

300 (11.8 1)

315 (12.4)

116 (4.57)

144 (5. 67)

180 (7.0 9)

150 (5.9 1)

150 (5.9 1)

191 ( 7.51 )

(c) Inverter w ithout moun ting suppor t - frame B

(d) Inverter w ith mounti ng support - f rame B

Frame Weight Kg (lb)

Recommended Torque

External Screws N.m (lbf.in)

Mounting Bolt Recommended Torque

N.m (lbf.in)

A 3.7 (8.1 6) 0.5 (4.34) 2 (17. 7)

B 5.3 (11.6 8) 0.5 (4.34) 2 (17.7)

Figure 2: (a) to (d) Inverter dimensio ns for mechanica l installation

9 INSTALLATION AND CONNECTION

Environmental Conditions Avoid:

Direct exposure to sunlight.

Inflammable, corrosive liquids or gases.

Metallic particles or oi l mist.

Environmental conditions permitted for the operation of the inverter:

Ambient temperature sur rounding the inver ter: from 0 ºC (32 °F) u ntil:

40 ºC (104 °F) - Nema4x /IP66 (mounted on the w all).

5 0 ºC (122 °F) - Nema4x/IP66 (m ounted integrated o n the motor.

For temperatures surround ing the inverte r higher than the sp ecifications a bove, it is necess ary to apply

a derating on the c urrent of 2 % for each Cel sius degree ( or 1.11 % each °F), limited to an in crease of

10 ºC (50 °F).

Air relative humidity: 5 % to 90 % n on-condensin g.

Maximum altitude: up to 1000 m (3.3 00 ft) - standard c onditions (no dera ting required of cur rent).

From 1000 m to 4000 m (3.300 ft to 13.200 ft) c urrent derating o f 1 % each 100 m (or 0.3 % each 100 ft)

above 1000 m (3.300 f t) altitude.

From 2000 m to 4000 m (6.600 ft to 13.200 f t) maximum vo ltage reduc tion (480 V for 380…48 0 V models)

of 1.1 % for each 100 m (330 ft) above 200 0 m (6.600 ft) altitu de.

Pollution degree: 2 (accordi ng to EN50178 and UL508C), with non -conductive po llution. Conde nsation

must not originate conduction through the accumulated residues.

10 ELECTRICAL INSTALLATION

DANGER!

The following information is merely a guide for proper installation. Comply with the

applicable local regulations for electrical installations.

Make sure the power supply is disconnected before starting the installation.

The MW500 must n ot be used as an emergency s top device. Provide other dev ices

for that purpose.

10.1 POWER CONNECTIONS

Descriptio n of the power terminal s:

Terminal X1 (L1/L, L2 /N and L3 (R, S , T, )): AC powe r supply.

Terminal X2 ( U/T1, V/T2, W/T3 , ): connection for the motor.

Terminal X3 (D C-, BR, DC+, ): DC bus and brake connection. DC- is the negative pole of the voltage

of the DC bus, BR is the c onnection of the b rake resistor and D C+ is the positive po le of the voltage of the

DC bus.

Shield

WEG industrial motor

U/T1

U/T1

V/T2

V/T2

W/T3

W/T3

R/L1 S/L2 T/L3

R/L1

S/L2

T/L3

Fuses

Input power supply

Figure 3: Power and grounding connection

10.2 INSTALLATIONS ACCORDING TO EUROPEAN DIRECTIVE OF ELECTROMAGNETIC

COMPATIBILITY

Inverters wi th option C2 or C3 (MW 500...C2...) feature internal RFI fi lter in order to red uce the

electromagnetic interference. Those inverters, when properly installed, meet the requirements of the

directive of electromagnetic compatibility.

These inverters were developed for professional applications only. Therefore, the emission limits of

harmonic cur rents by the standa rds EN 61000-3-2 and EN 61000 -3-2/A 14.

10.2 .1 Conformal Installation

1. Inverter with opt ional internal RFI fil ter MW500...C2... (with grounding switch of t he capacitors of the

internal RFI f ilter in the positio n ON).

2. Shielde d output cables (mo tor cables) with the s hield connected a t both ends, motor and inv erters, by

means of low impedance for high frequency connection. Maximum motor cable length and conducted

and radiated em ission levels acc ording to Table 5. If a lower cond ucted emission lev el and/or a longer

motor cable is de sired, then an ex ternal RFI f ilter must be us ed at the inver ter input. For mor e informatio n

(RFI filter commercial reference, motor cable length and emission levels) refer to the Table 5.

3. Shielded control cables, keeping the separations distance from other cables according to Table 3.2 the

user's manual.

4. Gro unding of the inv erter acco rding to instru ctions of Item 3. 2.4 Grounding Co nnections t he user's manua l.

5. Grounde d power supply.

10.2.2 Emission and Immunity Levels

Table 3: Emission and immunity levels

EMC Phenomenon Basic Standard Level

Emission:

Mains terminal d isturbance volt age Frequency

range: 150 kHz to 30 MHz)

IEC/EN 61800-3 It depe nds on the inverter m odel on the length o f the

cabo motor cable. R efer to Table 5

Electromagnetic radiation disturbance Frequency

Range: 30 MHz to 1000 MHz)

Immunity:

Fast transient-Burst IEC 61000-4-4 2 kV / 5 kHz (coup ling capacitor) in put cables

1 kV / 5 kHz control cabl es and remote HMI cab les

2 kV / 5 kHz (coupling ca pacitor) motor cabl es

Conducted Radio-Frequency Common Mode IEC 61000-4-6 0.15 to 80 MHz; 10 V; 80 % AM (1 kHz)

Motor, control and remote HMI cables

Surges

IEC 61000-4-5

1.2/50 μs, 8/20 μs

1 kV line-to-line coupling

2 kV line-to-ground coupling

Radio-Frequency Electromagnetic

Field IEC 61000-4-3

80 to 1000 MHz

10 V/m

80 % AM (1 kHz)

Definiti on of Standar d IEC/EM 61800 -3: "Adjusta ble Speed El ectrical Powe r Drives Syst ems"

Environments:

First Environment: environments that include domestic installations, as well as establishments directly

connected without intermediate transformer to a low-voltage power supply network which supplies

buildings used for domestic purposes.

Second Environment: includes all establishments other than those directly connected to a low-voltage

power supply network that supplies buildings used for domestic purposes.

Categories:

Category C1: inverters with a rate d voltage below 1000 V a nd intended for use in t he First Environm ent.

Category C2: inverters wit h a rated voltage below 100 0 V intended for use in th e First Environmen t, not

provided with a plug connector or movable installations. They must be installed and commissioned by a

professional.

NOTE!

A professional is a person or organization familiar with the installation and/or commissioning

of inverters, i ncluding their EM C aspects.

Categor y C3: inverte rs with a rated vo ltage below 100 0 V and intended f or use in the Sec ond Environm ent

only (not desig ned for use in the Firs t Environment.

The MW500 is sui table for application in a c ircuit able to supply not mo re than 30.000 symetric Ar ms

maximum of 20 0 V / 480 V, when protected by fus es classified as i ndicated below:

Table 4: List of mode ls of MW500 series, m ain electrica l specificatio ns

Inverter

Number of Input Phases

Power Supply R ated Voltage

Frame Size

Corrente Nominal de Saída

Maximum Motor

Recommended Fuse

Circuit Breaker

Power Wire Siz e

Grounding Wire Size

Dynamic

Braking

I²t [A²s]

UL [A]

Recommended WEG aR Fuse

Maximum Current

Recommend Resistor

Braking rms Current

Power Wire Siz e for DC

and BR Terminals

[Vrms]

[Arms]

[HP/kW ]

[A]

WEG

mm²

(AWG)

mm²

(AWG)

[A]

[Ω]

[A]

mm²

(AWG)

MW500A04P3S2DB66

1

200...

240

A

4,3 1/0.75 373 25 FNH00-25K-A 13,5 MPW18-3-U016

1.5

(16)

2.5

(14)

6 127 4.5

2.5

(14)

MW500A06P0S2DB66 6,0 1.5/ 1.1 420 20 FNH00-20K-A 25 MPW40-3-U025

2.5

(14)

2.5

(14)

8 100 5.7

2.5

(14)

MW500A02P6T4DB66

3

380...

480

2,6 1. 5/1.1 450 20 FNH00-20K-A 4,0 MPW18-3-U004

1.5

(16)

2.5

(14)

6 127 4.5

2.5

(14)

MW500A04P3T4DB66 4,3 2/1.5 450 20 FNH00-20K-A 6,3 MPW18-3-D063

1.5

(16)

2.5

(14)

6 127 4.5

2.5

(14)

MW500B 06P5T4DB 66...

3

380...

480

B

6,5 3 /2.2 450 - - 10 MPW25-10

1.5

(16)

2.5

(14)

8 100 5.7

2.5

(14)

MW500B10 P0T4DB66... 10 5/3.7 1000 - - 16 MPW25-16

2.5

(14)

2.5

(14)

16 47 11,5

2.5

(14)

DANGER!

The inverter m ust be connected to a p rotection groundi ng (PE).

Use grounding w iring with a gauge a t least equal to that i ndicated in Table 4.

The maximu m tightening torque of t he grounding conn ections is of 1.7 N.m (15 lbf.in).

Connect the gr ounding poi nts of the inver ter to a specifi c grounding ro d, or specif ic grounding

point or to the gen eral grounding po int (resistance ≤ 10 Ω).

Do not share the gr ounding wir ing with other e quipment tha t operate with hi gh currents (e.g.

high power motor s, soldering mach ines, etc.).

NOTE!

The wire gauge s listed in Table 4 are g uiding valu es. Installa tion conditi ons and the ma ximum

permitted voltage drop must be considered for the proper wiring sizing.

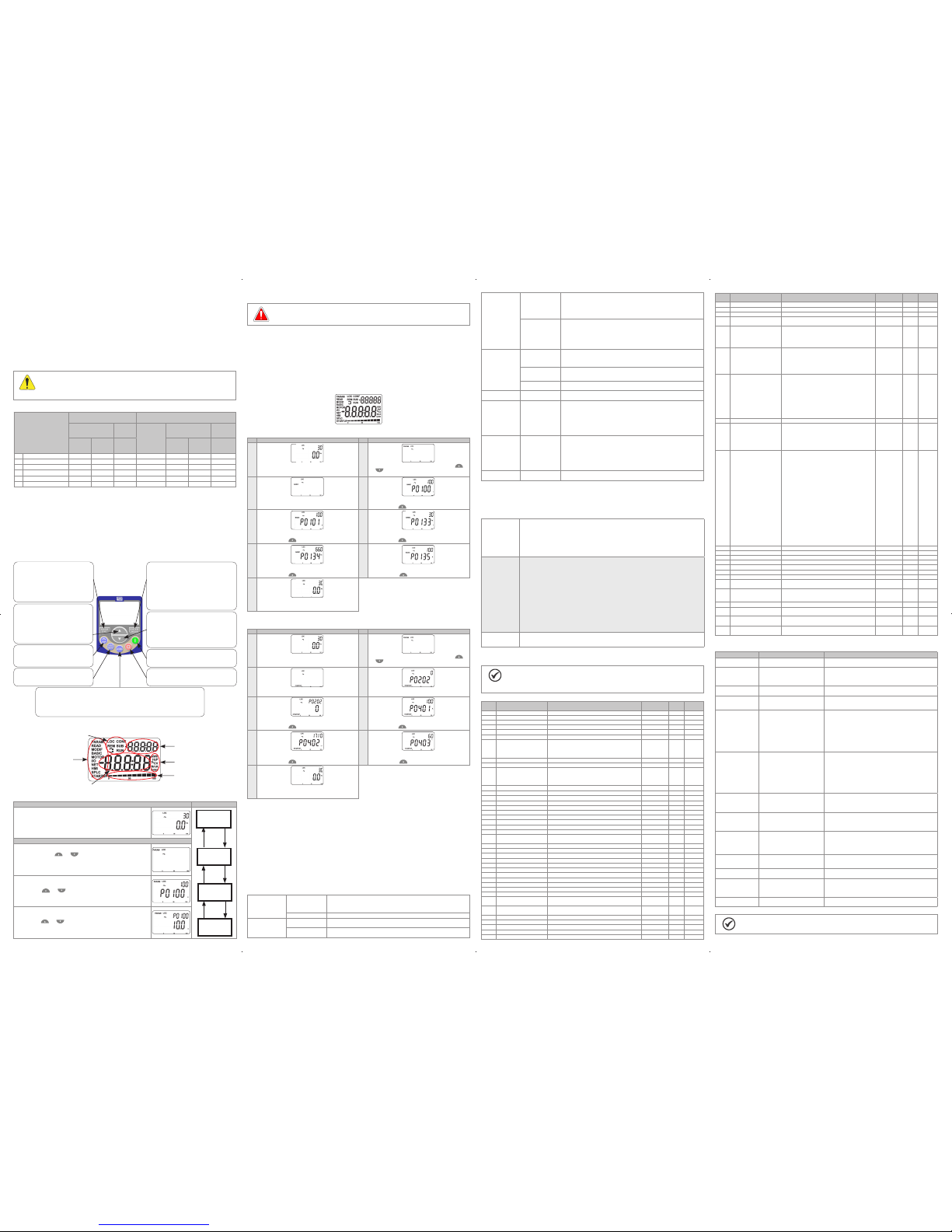

10.3 CONTROL CONNECTIONS

Connector Description

(**)

Upper terminal

1 DI1 Digital input 1

3 DI2 Digit al input 2

(*)

5 DI3 Digital input 3

7 D4 Digital input 4

9 + 24 V Power supply + 24 Vdc

11 DO1-RL-NO

Digital output 1

(Relay NO contact 1)

13 DO1-RL-C

Digital output 1

(Relay common point 1)

15 DO1-RL-NC

Digital output 1

(Relay NC contact 1)

Lower terminal

2 AO1 Analog out put 1

4 GND Reference 0 V

6 AI1 Analog input 1

8 + 10 V

Reference + 10 Vdc for

potentiometer

10 D O2-TR Digital output 2 (trans istor)

12 RS485 - A RS-485 (terminal A)

14 RS485 - B RS-485 (terminal B)

16 GND Reference 0 V

(*) Digital input 2 (DI2) can also be used as input in freq uency (FI).

For further deta ils refer to the progra mming manual of the M W500.

(**) For further information, refer to the detailed specification in Table 6.

AI1

AO1

GND

+10 V

DO2-T R

GND

+24 V

DO1-RL-NO

DO1-RL-C

DO1-RL-NC

DI1

DI2

DI3

DI4

≥5 kΩ

rpm

>300 Ω

RS-485 - A

RS-485 - B

Figure 4: Signals of the connector of t he CFW500-IOS plu g-in module

English

13309800

Page 2

For the corr ect connec tion of the con trol, use:

1. Gauge of the c ables: 0.5 mm² (20 AWG) to 1.5 mm² (14 AWG).

2. Maximu m torque: 0.5 N.m (4.50 lbf.in).

3. Wiring of the plu g-in module connec tor with shielded cab les separated from the ot her wiring (power,

command in 110 V / 220 Vac, etc.).

10.3 .1 RFI Filter

Built-in RFI filte r option is available to reduc e the conducted disturba nce from the inverter to the ma in

power supply in t he high frequency band (>150 kHz). It is neces sary to meet the maximum le vels of

conducted and radiated emissions of electromagnetic compatibility standards, such as EN 61800-3 and

EN 55011. For further detail s, refer to item 10.2 INSTALL ATIONS ACCORDING TO E UROPEAN DIR ECTIVE

OF ELECTROMAGNETIC COMPATIBILITY.

ATTENTION!

When inverte rs with intern al RFI filter is u sed in IT netwo rks (neutral c onductor not gr ounded

or grounded th rough a high ohm ic value resis tor), remove groun ding screw XE1, since th ose

kinds of netwo rk cause damage to th e filter capacitor s of the inverter.

Table 5: Conducte d and radiated emis sion levels, and add itional informa tion

Inverter Model

Without Ex ternal RFI Fi lter for

Decentralized Installation

With Exter nal RFI Filte r

Conducted Emission

- Maximum Motor

Cable Length

Radiated

Emission

External RFI

Filter Part

Number

(manufacturer:

XXX)

Conducted Emission -

Maximum

Motor Cable Le ngth

Radiated

Emission

- Category

Category C3Category

C2

Category

Category C2Category

C1

Without

Metallic

Cabinet

1 MW5 00A04P3 S2...C2... 10 m 5 m 30 m C2 - - - 2 MW5 00A06P 0S2...C2... 10 m 5 m 30 m C2 - - - 3 M W500A02 P6T4...C2... 10 m 5 m 30 m C3 - - - 4 M W500A04 P3T4...C2... 10 m 5 m 30 m C3 - - - 5 MW 500B06 P5T4...C2... 6 m - 6 m C3 - - - 6 M W500B10P 0T4...C2... 6 m - 6 m C3 - - - -

10.4 ACCESSORIES

The accesso ries are hardware r esources that ca n be added in the appli cation with the MW50 0.

The accesso ries are incorpor ated to the inverters in a n easy and quick way by us ing the "Plug and Play"

concept. Whe n an accessory is conn ected to the inverter, the cont rol circuitry identi fies the model and

informs the cod e of the accessory con nected in parameter P00 27. The accessor y must be installed or

modified with t he inverter de -energized. T hey may be ordere d separately a nd are sent in thei r own

package containing the components and manuals with detailed instructions for their installation, operation

and setting.

11 USE OF THE H MIR TO OPERATE THE INVE RTER

Press this key to accele rate the motor up to the spe ed set in P0122 within the tim e determined by the

acceleration ra mp. The motor speed is ke pt while the key is pres sed. When the key is rel eased, the

motor decelerates within the time determined by the deceleration ramp, until it stops.

This function is ac tive when all the con ditions below are m et:

1. Turn/Stop = Stop.

2. Enable General = Ac tive.

3. P0225 = 1 in LOC and/or P0228 = 1 in REM.

Press this key to commute b etween LOCAL

and REMOTE mode.

Active when:

P0220 = 2 or 3

Press this key to define t he motor rotation

direction.

Active when:

P0223 = 2 or 3 in LOC and/or

P0226 = 2 or 3 in REM

- When in the monitori ng mode: press this

key to increase the spe ed.

- When in the setting mo de, level 1: press this

key to go to the previous grou p.

- When in the setting m ode, level 2: press

this key to go to the next para meter.

- When in the setting m ode, level 3: press

this key to increase the c ontent of the

parameter.

- When in the setting m ode, level 1: press

this key to return to the moni toring mode.

- When in the setting m ode, level 2:

press this key to return to leve l 1 of the

setting mode.

- When in the setting m ode, level 3: press

this key to cancel the new v alue (new value

is not saved) and retur n to level 2 of the

setting mode.

When in the monitori ng mode: press this key to en ter

the setting mode.

- When in the setting m ode, level 1: press this key

to select the desire d parameter group - it sho ws the

parameter group selected.

- When in the setting m ode, level 2: press this key

to show the parameter - it s hows the content of the

parameter in order to c hange the content.

- When in the setting m ode, level 3: press this key to

save the new content of the p arameter - it returns to

level 2 of the setting mo de.

When in the monitor ing mode: press this key to

decrease the speed.

- When in the setting m ode, level 1: press this key to

go to the next group.

- When in the setting m ode, level 2: press this key to

go to the previous para meter.

- When in the setting m ode, level 3: press this key to

decrease the conte nt of the parameter

Press this key to accele rate the motor within th e time

determined by the acceleration ramp.

Active when:

P0224 = 0 in LOC or P0227 = 0 in REM

Press this key to decel erate the motor within t he time

determined by the deceleration ramp.

Active when:

P0224 = 0 in LOC or P0227 = 0 in REM

11.1 INDICATIONS OF DISPLAY

Main display

Menu (to select the

parameter group s) only one parameter

group is shown at

a time

Measurement unit

(it refers to the valu e

of the main indicat ion)

Secondary indication

Bar graph

Inverter status

11.2 OPERATING MODES OF THE HMI

Monitoring Mode

It is the initial sta tus of the HMIR after the poweri ng up and of the initializati on

screen, with default values

The field Menu is n ot active in this mode

The main display, sec ondary display and ba r graph indicate the value s of three

parameters prede fined by P0205, P0206 a nd P0207

From the monitorin g mode, when you p ress the key ENTER/MENU, you commu te

to the setting mode

Monitoring

Setting

level 2

Setting

level 3

Setting

level 1

Enter

Menu

Enter

Menu

Enter

Menu

Back

Esc

Back

Esc

Back

Esc

Setting Mode

Level 1:

This is the first le vel of the setting mode. It is p ossible to choose the par ameter

group using the keys and

The main display, secondary display, bar graph and measurement units are not

shown in this level

Press the key ENTER/MENU to go to level 2 of the s etting mode - p arameter se lection

Press the key BACK/ ESC to return to the moni toring mode.

Level 2:

O número do parâme tro é exibido no display princi pal e o seu conteúdo no

display secundário

Use the keys and to find the desired parame ter

Press the key ENTER/MENU to go to level 3 of the se tting mode - modifi cation

of the parameter conte nt

Press the key BACK/ ESC to return to level 1 of th e setting mode.

Level 3:

The content of the pa rameter is shown on th e main display an d the number of the

parameter is shown on the secondary display

Use the keys and to configure the new value for the selected parameter

Press the key ENTER/MENU to confirm th e modification (sa ve the new value) or

BACK/ESC to cance l the modific ation (not save the ne w value). In both case s, the

HMIR returns to level 2 of th e setting mode

12 START-UP PREPARATION

DANGER!

Always disconnect the main power supply before making any connection.

1. Check if the power, grounding and control connections are correct and firm.

2. Remove all m aterials left fro m the inside of the inve rter.

3. Check if the motor connections and motor current and voltage match the inverter.

4. Mechanically u ncouple the motor from the lo ad. If the motor cannot be uncoup led, be sure that its

turning in any di rection (clockw ise or counterclo ckwise) will not ca use damages to the mac hine or risk

of accidents.

5. Close the co vers of the inverter.

6. Measure th e power supply and ve rify if it is withi n the allowed range.

7. Apply powe r to the input: close the i nput disconnec ting switch.

8. Check the re sult of the first tim e power-up:

The HMI display indicates:

12.1 BASIC APPLICATION

Seq Display Indication/Action Seq Display Indication/Action

1

2

Monitoring mode

Press the key ENTER/MENU to enter the 1

st

level of

the programming mode

The PARAM group is selected, p ress the keys or

until selecting the BASIC group

3 4

When the BASIC group is s elected press the key

ENTER/MENU

Basic Applic ation routine is st arted. If necess ary, modify

the content of "P0100 - Acce leration Time"

Press the key for the next parameter

5 6

If necessar y, modify the content of "P0101 -

Deceleration Time"

Press the key for the next parameter

If necessar y, modify the content of "P0133 - Minim um

Speed"

Press the key for the next parameter

7 8

If necessar y, modify the conten t of "P0134 - Maximum

Speed"

Press the key for the next parameter

If necessar y, modify the conte nt of "P0135 - Maximum

Output Current"

Press the key for the next parameter

9

To end the Start-up rout ine, press the key BAC K/ESC

To return to the monitorin g mode, press the key

BACK/ ESC again

12.2 V/F CON TROL TYPE (P0 202 = 0)

Seq Display Indication/Action Seq Display Indication/Action

1

2

Monitoring mode

Press the key ENTER/MENU to enter 1

st

level of

programming mode

The PARAM group is selected, p ress the keys or

until selecting the STARTUP group

3 4

When the STARTUP group is sele cted press the key

ENTER/MENU

If necessar y, press ENTER/MENU to modify the

content of "P0202 - Cont rol Type" for P0202 = 0 (V/f)

5 6

When the desire d value is reached, press ENTER/

MENU to save the modification

Press the key for the next parameter

If necessar y, modify the content of "P0401 - Motor

Rated Current”

Press the key for the next parameter

7 8

If necessar y, modify the content of "P0402 - Moto r

Rated Speed"

Press the key for the next parameter

If necessar y, modify the content of "P0403 - Moto r

Rated Frequency

Press the key for the next parameter

9

To end the Start-up rout ine, press the Key B ACK/ESC

To return to the monitorin g mode, press the key

BACK/ESC again

13 TECHNICAL SPECIFICATIONS

POWER DATA

Power Supply:

Tolerance: -15 % to +10 %.

Frequency: 50 /60 Hz (48 Hz to 62 Hz).

Phase imbal ance: ≤ 3 % of the rated phas e-to-phase input vo ltage.

Overvolt age according to Cate gory III (EM 61010/UL 508C).

Transient voltage according to Category III.

Maximum of 10 co nnections per ho ur (1 every 6 minutes).

Typical effi ciency: ≥ 97 %.

14 ELECTRONICS/GENERAL DATA

Table 6: Electronics/general data

Control Method Types o f control:

- V/f (Scalar))

- VVW: voltage vector control.

PWM SVM (Space Vector Modulation)

Output frequency 0 to 500 Hz, resol ution of 0.015 Hz

Performance V/f control S peed regulatio n: 1 % of the rated speed (wit h slip compensat ion)

Speed variati on range: 1:20

Vector control (VVW) Speed regulatio n: 1 % of the rated speedl

Speed variati on range: 1:30

Inputs

(*)

Analog Knob addit ional input for sp eed reference var iation

1 insulated inpu t. Levels: (0 to 10) V or (0 to 20) mA or (4 to 20) mA

Linearity e rror ≤ 0.25 %

Impedance: 100 kΩ fo r voltage input, 50 0 Ω for current input

Programmable functions

Maximum volt age permitted in t he input: 30 Vdc

Digital 4 insulated inputs

Programmable functions:

- active high (PNP): ma ximum low level of 15 Vdc / mi nimum high leve l of 20 Vdc

- active low (NPN): max imum low level of 5 Vdc / mini mum high level of 9 Vdc

Maximum input voltage of 30 Vdc

Input current: 4.5 mA

Maximum input current: 5.5 mA

Outputs

(*)

Relay 1 relay with NC/NO contact

Maximum voltage: 240 Vac

Maximum current: 0.5 A

Programmable functions

Transistor 1 insulated digital output open sink (uses as reference the 24 Vdc power supply)

Maximum current 150 mA

(**)

(maximum capacity of the 24 Vdc) power supply

Programmable functions

Power supply 24 Vdc power supply. Maximum capacity: 150 mA

10 Vdc power supply. Maximum capacity: 2 mA

Communication Interface RS-485 Insulated RS-485

Modbus-RTU protocol with maximum communication of 38.4 kbps

Safety Protection Overcurrent/phase-phase short circuit in the output

Overcurrent/phase-ground short circuit in the output

Under/overvoltage

Overtemperature in the heatsink

Overload in the motor

Overload in the power module (IGBTs)

External alarm/fault

Setting error

Human-machine

interface (keypad)

Remote keypad

(HMIR)

9 keys: Start/Sto p, up arrow, down arrow, Direction of Rotati on, Jog, Local/

Remote,

BACK/ESC and ENT ER/MENU

LCD display

View/edition of all parameters

Indication accuracy:

- current: 5 % of the rated cu rrent

- speed resoluti on: 0.1 Hz

Enclosure Degree of protection IP66

UL type 4X

(*) The numbe r and/or type of analog/digita l inputs/outputs may vary, depend ing on the Plug-in module (acce ssory) used. For the table abov e, it was

considered the standard plug-in module. For further information, refer to the programming manual and the guide supplied with the optional item.

(**) The maxim um capacity of 150 mA must be consi dered by adding the load of the 24 V power s upply and transistor outpu t, that is, the sum of the

consumption of both mus t not exceed 150 mA.

15 CONSIDERED STANDARDS

Table 7: Considered standards

Safety

standards

EN 61800-5-1 - safety ele ctrical, therma l and energy requi rements

EN 50178 - electronic equi pment for use in power i nstallations

EN 60204-1 - safety of mach inery. Electric al equipment of mac hines. Part 1: gener alrequirement s

Note: For the machine to comply with this standard, the manufacturer of the machine is responsible

for installing an e mergency stop dev ice and equipme nt to disconnect the i nput power suppl y

EN 60146 (IEC 146) - semiconduc tor converters

EN 61800-2 - adjustabl e speed elect rical power dri ve systems - part 2: g eneral requi rements - rating

specifications for low voltage adjustable frequency AC power drive systems

Electromagnetic

compatibility (EMC)

standards

EN 61800-3 - adjusta ble speed electrical pow er drive systems - part 3: EMC prod uct standard

including specific test methods

EN 55011 - limits and methods o f measurement of radio di sturbance character istics of industrial,

scientific and medical (ISM) radio-frequency equipment

CISPR 11 - industrial, sci entific and medical (ISM ) radio-frequency equip ment - electromagnetic

disturbance ch aracteristics - l imits and methods of m easurement

EN 61000-4-2 - electromagnetic compatibility (EMC) - part 4: testing and measurement techniques

- section 2: electrostatic discharge immunity test

EN 61000-4-3 - electromagnetic compatibility (EMC) - part 4: testing and measurement techniques

- section 3: radiated, radio-frequency, electromagnetic field immunity test

EN 61000-4-4 - electromagnetic compatibility (EMC) - part 4: testing and measurement techniques

- section 4: electrical fast transient/burst immunity test

EN 61000-4-5 - electromagnetic compatibility (EMC) - part 4: testing and measurement techniques

- section 5: surge immunity test

EN 61000-4-6 - electromagnetic compatibility (EMC) - part 4: testing and measurement techniques

- section 6: immuni ty to conducted dis turbances, indu ced by radio-freq uency fields

Mechanical

construction

standards

EN 60529 - degrees o f protection provid ed by enclosures (I P code)

UL 50 - enclosure s for electrical e quipment

16 MAIN PAREMETERS

NOTE!

ro = read only para meter.

V/f = parameter avai lable in V/f mode.

cfg = configur ation parameter, value c an only be change d with the motor stoppe d.

Param. Description Adjustable Range

Factory

Setting

Propr. Groups

P0000 Access to Parameters 0 to 9999 0

P0001 Speed Reference 0 to 65535 ro READ

P0002 Motor Speed 0 to 65535 ro READ

P0003 Motor Current 0.0 to 200.0 A ro READ

P0004 DC Link Vol tage (Ud) 0 to 2000 V ro READ

P0005 Motor Frequency 0.0 to 500.0 Hz ro READ

P0006 Inverter Status 0 = Ready

1 = Run

2 = Undervoltage

3 = Fault

4 = Self-Tuning

5 = Configuration

6 = DC-Braking

7 = Sleep Mode

ro READ

P0007 Motor Voltage 0 to 2000 V ro READ

P0011 Power Factor -1.00 to 1.00 A ro READ

P0012 DI8 to DI1 Status Bit 0 = DI1

Bit 1 = DI2

Bit 2 = DI3

Bit 3 = DI4

Bit 4 = DI5

Bit 5 = DI6

Bit 6 = DI7

Bit 7 = DI8

ro READ, I/O

P0022 FI Hz Val ue 1 to 20000 Hz ro R EAD, I/O

P0023 Mai n SW Version 0.00 to 6 55.35 ro READ

P0030 Heatsink Temperature -20 to 150 ºC ro READ

P0037 Motor Overload Ixt 0 to 100 % ro READ

P0047 CONFIG Status 0 to 999 ro READ

P0048 Present Ala rm 0 to 999 ro READ

P0049 Present Fault 0 to 999 ro READ

P0050 La st Fault 0 to 999 ro READ

P0100 Acceleration Time 0.1 to 999.0 s 10,0 s BASIC

P0101 Deceleration Time 0.1 to 999.0 s 10,0 s BASIC

P0120 Speed Ref. Ba ckup 0 = Inactive

1 = Active

3 = Backup by P0121 1

P0121 S peed Reference v ia HMI 0.0 to 500.0 Hz 3.0 Hz

P0124 Multispe ed Ref. 1 -500.0 to 500.0 Hz 3.0 Hz

P0125 Multispe ed Ref. 2 -500.0 to 500.0 Hz 10.0 (5.0) Hz

P0126 Multisp eed Ref. 3 -500.0 to 500.0 Hz 20.0 (10.0) Hz

P0127 Multispe ed Ref. 4 -500.0 to 500.0 Hz 30.0 (20.0) Hz

P0128 Multisp eed Ref. 5 -500.0 to 500.0 Hz 40.0 (30.0) Hz

P0129 Multisp eed Ref. 6 -500.0 to 500.0 Hz 50.0 (40.0) Hz

P0130 Multispe ed Ref. 7 - 500.0 to 500.0 Hz 60.0 (50.0) Hz

P0131 Multispee d Ref. 8 - 500.0 to 500.0 Hz 66.0 (55.0) Hz

P0133 Minimum Speed 0.0 to 500.0 Hz 3.0 Hz BASIC

P0134 Maximu m Speed 0.0 to 500.0 Hz 66.0 (55.0) Hz BASIC

P0135 Max. Output Current 0.0 to 200.0 A 1.5 x I

nom

BASIC,

MOTOR

P0136 Manual Torque Boost 0.0 to 30.0 % According to

inverter model

V/f BASIC,

MOTOR

P0137 Autom. Torque Boost 0.0 to 30.0 % 0.0 % V/f MOTO R

P0138 Slip Compensation -10.0 to 10.0 % 0.0 % V/f MOTOR

P0139 Output Current Filter 0 to 9999 ms 50 ms

P0142 Max. Output Voltage 0.0 to 100.0 % 100.0 % cfg, V/f

P0143 Interm. Output Voltage 0.0 to 100.0 % 66.7 % cfg, V/f

Param. Description Adjustable Range

Factory

Setting

Propr. Groups

P0145 Field Weakening Frequency 0.0 to 50 0.0 Hz 60.0 (50.0) Hz cfg, V/f

P0146 Interm ediate Frequency 0.0 to 500.0 Hz 40.0 (33.3) Hz cf g, V/f

P0156 Overl. Cur r. 100 % Speed 0.0 to 200.00 A 1.1 x Inom MOTOR

P0202 Control Type 0 = V/f

1 a 4 = Not Used

5 = VVW 0 cfg STA RTUP

P0204 Load/Save Parameters 0 and 1 = Not Used

2 = Reset P0045

3 and 4 = Not Used

5 = Load WEG 60 Hz

6 = Load WEG 50 Hz

7 = Load User 1

8 = Load User 2

9 = Save User 1

10 = Save User 2

0 cfg

P0220 LOC/REM Selection Source 0 = Always LO C.

1 = Always REM.

2 = HMI Key (LOC)

3 = HMI Key (REM)

4 = DIx

5 = Serial/USB (LOC)

6 = Serial/USB (REM )

7 and 8 = Not Used

9 = CO/DN/DP (LOC)

10 = CO/DN/DP (REM)

11 = SoftPLC

4 cfg I/O

P0221 LOC Reference Sel. 0 = Keypad

1 = AI1

2 = AI2

3 = AI3

4 = FI

5 = AI1 + AI2 > 0

6 = AI1 + AI2

7 = E.P.

8 = Multispeed

9 = Serial/USB

10 = Not Used

11 = CO/DN/DP

12 = SoftPLC

13 = Not Used

14 = AI1 > 0

15 = AI2 > 0

16 = AI3 > 0

17 = FI > 0

18 = Knob

18 cfg I/O

P0222 REM R eference Sel. See options in P0221 9 cfg I/O

P0223 LOC FWD/REV Selection 0 = Always F WD

1 = Always REV

2 = HMI Key (FWD)

3 = HMI Key (REV)

4 = DIx

5 = Serial/USB (F WD)

6 = Se rial/ USB (REV )

7 and 8 = Not Used

9 = CO/DN/DP (H)

10 = CO/DN/DP (AH)

11 = Not Used

12 = SoftPLC

4 cfg I/O

P0263 DI1 Function 0 = Not Used

1 = Run/Stop

2 = General Enable

3 = Quick Stop

4 = FWD Run

5 = REV Run

6 = Start

7 = Stop

8 = Clockwise Rotat ion Dir

9 = LOC/REM

10 = JOG

11 = Increase E.P.

12 = Decrease E.P.

13 = Multispeed

14 = 2nd Ramp

15 to 17 = Not Used

18 = Sem Alarme Ext.

19 = Sem Falha Ext.

20 = Reset

21 = SoftPLC

22 = Manual/Auto PID

23 = Not Used

24 = Disable Flying Sta rt

25 = Not Used

26 = Program. Off

27 = Load User 1

28 = Load User 2

29 = PTC

30 and 31 = Not Used

32 = 2nd Ramp Multispeed

33 = 2nd Ramp E.P. Ac.

34 = 2nd Ramp E.P. De.

35 = 2nd Ramp FWD Run

36 = 2nd Ramp REV Run

37 = Start / Inc. E.P.

38 = Dec. E.P. / Stop

39 = Function 1 Application

40 = Function 2 Application

41 = Function 3 Application

42 = Function 4 Application

43 = Function 5 Application

44 = Function 6 Application

45 = Function 7 Application

46 = Function 8 Application

1 cfg I/O

P0264 DI2 Function See options in P0263 8 cfg I/O

P0265 DI3 Function See options in P0263 20 cfg I/O

P0266 DI4 Function See options in P0263 9 cfg I/O

P0267 DI5 Function See options in P0263 0 cfg I/O

P0268 DI6 Function See options in P0263 0 cfg I/O

P0269 DI7 Function See options in P0263 0 cfg I/O

P0270 DI8 Function See options in P0263 0 cfg I/O

P0295 VFD R ated Curr. 0.0 to 200.0 A According to

inverter model

ro READ

P0296 Power Supply Rated Voltage 0 = 200 / 240 V

1 = 380 / 480 V

2 = 500 / 600 V

According to

inverter model

ro, cfg READ

P0297 Switching Frequency 1500 to 15000 kH z 4000 kHz

P0401 Motor Rate d Current 0.0 to 200.0 A 1.0 x I

nom

cfg MOTOR,

STARTU P

P0402 Motor R ated Speed 0 to 30000 rpm 1710 (1425) rpm cfg MOTOR,

STARTU P

P0403 Motor Ra ted Frequency 0 to 500 Hz 60 (50) Hz cfg MOTOR,

STARTU P

17 FAULTS AND ALARMS

Falha / Alarme Descrição Causas Prováveis

A0046

Motor Overload

Motor overload alarm Overload on the m otor shaft

A0050

Power Module

Overtemperature

Overtemperature alarm from the

power module temperature sensor

(NTC)

High ambient te mperature ar ound the inver ter (>50 °C (> 122 °F))

and high output current

Blocked or defec tive fan

Heatsink is too dir ty, preventing the ai r flow

A0090

External Alarm

External ala rm via DIx (option "No

External Ala rm" in P026x)

Wiring on DI1 to DI8 inp uts are open or have po or contact

A0700

Communication Fault

with Remote HMI

No communication with remote HMI,

but there is no spee d command or

reference for this s ource

Check if the communication interface with the HMI is properly

configured in parameter P0312

HMI cable disconnected

F0021

Undervoltage on the

DC Link

Undervoltage fault on the

intermediate circuit

Wrong voltage supply; check if the data on the inverter label

complies with the power supply and parameter P0296

Supply voltage to o low, producing vo ltage on the DC li nk below

the minimum value ( in P0004):

Ud < 200 Vdc in 200 / 240 Vac (P0296 = 0)

Ud < 360 Vdc in 380 / 480 Vac (P029 6 = 1)

Ud < 500 Vdc in 500 / 600 Vac (P0 296 = 2)

Phase fault in the i nput

Fault in the pre-c harge circuit

F0022

Overvoltage on the DC

Link

Overvoltage fault on the intermediate

circuit

Wrong voltage supply; check if the data on the inverter label

complies with the power supply and parameter P0296

Supply voltage i s too high, producing volta ge on the DC link

above the maximu m value (in P0004):

Ud > 410 Vdc in 200 / 240 Vac (P0296 = 0)

Ud > 810 Vdc in 380 / 480 Vac (P0296 = 1)

Ud > 1000 Vdc in 500 / 600 Vac (P02 96 = 2)

Load inertia is to o high or deceler ation ramp is too fast

P0151 or P0153 setting is too high

F0031

Communication Fault

with Plug-in Module

Main control cann ot set a

communication link with the plug-in

module

Plug-in module is damaged

Plug-in module is not properly connected

Problem in the ide ntificati on of the plug-i n module; refe r to P0027

for further information

F0051

IGBTs Overtemperature

Overtemperature fault measured

on the temperature s ensor of the

power pack

High ambient te mperature arou nd the inverte r (>50 °C (>122 °F))

and high output current

Blocked or defec tive fan

Heatsink is too dir ty, preventing the ai r flow

F0070

Overcurrent/Short

Circuit

Overcurrent or short circuit on the

output, DC link or bra king resistor

Short circuit between two motor phases

Short circuit of the rheostatic braking resistor connecting cables

IGBTs module in short circuit or damaged

Start with too sh ort accelerat ion ramp

Start with motor spinning without the Flying Start function

F0072

Motor Overload

Motor Overload Faul t (60 s in

1.5xInom)

P0156, P0157 and P0158 setting is too low in re lation to the

motor operating current

Overload on the m otor shaft

F0080

CPU Fault (Watchdog)

Fault related to the supervision

algorithm

Electric noise

Inverter firmware fault

F0084

Auto-diagnosis Fault

Fault related to the auto matic

identification a lgorithm of the inve rter

hardware and plug-in module

Poor contact in the connection between the main control and

the power pack

Hardware not compatible with the firmware version

Defect on the inter nal circuits of the i nverter

F0091

External Fault

External faul t via DIx (“No Exte rnal

Fault” in P026x)

Wiring on DI1 to DI8 inp uts are open or have po or contact

NOTE!

For further information, refer www.weg.net.

Document: 10003693218 / 00

Loading...

Loading...