Weed Eater TWISTER SB180 Owner’s Manual

(_) Trademark

Operator's Manual

Manual del Operador

Manuel de L'utilisateur

TWISTER SB180

IMPORTANT MANUAL - Do not throw away

MANUAL IMPORTANTE - No Io descarte

MANUEL IMPORTANT - A Conserver

WARNING: Read the operator's manual and follow all

warnings and safety instructions. Failure to do so can

result in serious injury. Always wear eye protection.

SB30

ADVERTENClA: Lea el manual del operador y siga todas

las advertencias e instrucciones de seguridad. El no

hacerlo puede resultar en lesiones graves.

AVERTISSEMENT: Lire le manuel de I'utilisateur et bien

respecter tousles avertissements et toutes les instructions

de s6curit6. Tout d6faut de le faire pourrait entraTner des

blessures graves.

Electrolux Home Products, Augusta, GA 30907

WCI Outdoor Products, Inc. 530088756 6/28/00

_ WARNING:

Safety Rules and Precautions can result in

serious injury.

KNOW YOUR UNIT

• Read your Operator's Manual carefully

until you completely understand and can

follow all warnings and safety instructions

before operating the unit.

• Restrict your unit to users who understand

and will follow all warnings and safety in-

structions in this manual.

PLAN AHEAD

• Always wear eye protection when operat-

ing, servicing, or performing maintenance

on your unit. Wearing eye protection will

help to prevent rocks or debris from being

blown or ricocheting into eyes and face

which can result in blindness and/or seri-

ous injury. Eye protection should meet the

requirements of ANSI Z87.1

• Always wear foot protection. Do not go

barefoot or wear sandals.

working with unit in dusty environments.

i Always wear respirator or face maskwhen

Secure hair above shoulder length. Se-

cure or remove jewelry, loose clothing, or

clothing with loosely hanging straps, ties,

tassels, etc. They can be caught inmoving

parts.

• Do not operate the unit when you are tired,

ill,upset, or if you are under the influence of

alcohol, drugs, or medication.

• Keep children, bystanders, and animals

away from work area a minimum of 30 feet

(10 m) when starting or operating unit. Do

not point the blower nozzle in the direction

of people or pets.

• Inspect the area before starting the unit.

Remove all debris and hard objects such

as rocks, glass, wire, etc. that can rico-

chet, be thrown, or otherwise cause injury

or damage during operation.

HANDLE FUEL WITH CAUTION, IT

IS HIGHLY FLAMMABLE

• Eliminate all sources of sparks or flame

(including smoking, open flames, or work

that can cause sparks) in the areas where

fuel is mixed, poured, or stored.

• Mix and pour fuel in an outdoor area; store

fuel in acool, dry, well ventilated place; and

use an approved, marked container for all

fuel purposes.

• Do not smoke while handling fuel or while

operating the unit.

• Make sure the unit is properly assembled

and in good operating condition.

• Do not fill fuel tank while engine is hot or

running.

• Avoid spilling fuel or oil. Wipe up fuel spills

before starting engine.

• Move at least 10 feet (3 meters) away from

fuel and fueling site before starting engine.

Failure to follow all

• Always store gasoline in a container ap-

proved for flammable liquids.

OPERATE YOUR UNIT SAFELY

WARNING: Stop the engine before

opening the vacuum inlet door. The engine

must be stopped and the impeller blades no

longer turning to avoid serious injury from the

rotating blades.

• Inspect unit before each use for worn,

loose, missing, or damaged parts. Do not

use until unit is in proper working order.

• Keep outside surfaces free of oil and fuel.

• Never start or run engine inside a closed

room or building. Breathing exhaust fumes

can kill.

• To avoid static electricity shock, do not

wear rubber gloves or any other insulated

gloves while operating the unit.

• Do not set unit on any surface except a

clean, hard area while engine is running.

Debris such as gravel, sand, dust, grass,

etc. could be picked up by the air intake

and thrown out through discharge open-

ing, damaging unit, property, or causing

serious injury to bystanders or operator.

• Avoid dangerous environments. Do not

use in unventilated areas or where explo-

sive vapors or carbon monoxide build up

could be present.

• Do not overreach or use from unstable

surfaces such as ladders, trees, steep

slopes, rooftops, etc. Keep firm footing

and balance at all times.

• Never place objects inside the blower

tubes; always direct the blowing debris

away from people, animals, glass, and

solid objects such as trees, automobiles,

walls, etc. The force of air can cause

rocks, dirt, or sticks to be thrown or to rico-

chet which can hurt people or animals,

break glass, or cause other damage.

• Never run unit without the proper equip-

ment attached. When using your unit as a

blower, always install blower tubes. When

using your unit as avacuum, always install

vacuum tubes and vacuum bag assembly.

Make sure vacuum bag assembly is com-

pletely zipped.

• Check air intake opening, blower tubes,

vacuum tubes, and elbow tube frequently,

always with the engine stopped and the

spark plug disconnected. Keep vents and

discharge tubes free of debris which can

accumulate and restrict proper air flow.

• Never place any object in the air intake

opening as this could restrict proper air

flow and cause damage to the unit.

• Never use for spreading chemicals, fertil-

izers, or other substances which may con-

tain toxic materials.

• To avoid spreading fire, do not use near

leaf or brush fires, fireplaces, barbecue

pits, ashtrays, etc.

• Use only for jobs explained in this manual.

2

MAINTAIN YOUR UNIT PROPERLY

• Have all maintenance other than the rec-

ommended procedures described in the

Operator's Manual performed by your

Service Dealer.

• Disconnect spark plug before performing

maintenance except for carburetor adjust-

ments,

• Use only recommended WEED EATER

replacement parts; use of any other parts

may void your warranty and cause dam-

age to your unit.

• Empty the fuel tank before storing the unit.

Use up fuel left in carburetor by starting the

engine and letting it run until it stops.

• Do not use any accessory or attachment

other than those recommended by the

manufacturer for use with your unit.

• Do not store the unit or fuel in a closed area

where fuel vapors can reach sparks or an

open flame from water heaters, electric

motors or switches, furnaces, etc.

• Store in a dry area out of reach of children.

SPECIAL NOTICE: For users on U.S.

Forest Land and in some states, including

California(Public Resources Codes 4442

and 4443), Idaho, Maine, Minnesota, New

Jersey, Oregon, and Washington: Certain in-

ternal combustion engines operated on for-

est, brush, and/or grass covered land in the

above areas are required to be equipped

with a spark arrestor, maintained in effective

working order, or the engine must be con-

structed, equipped, and maintained for the

prevention of fire. Check with your state or

local authorities for regulations pertaining to

these requirements. Failure to follow these

requirements is a violation of the law. This

unit is not factory equipped with a spark ar-

restor; however, a spark arrestor is available

as an optional part. If a spark arrestor is re-

quired in your area, contact your Authorized

Service Dealer for the correct kit. The spark

arrestor, blower tubes, and nozzles must be

assembled to the unit to be infull compliance

with the regulations.

SPECIAL NOTICE: Exposure to vibra-

tions through prolonged use of gasoline

powered hand tools could cause blood ves-

sel or nerve damage in the fingers, hands,

and joints of people prone to circulation dis-

orders or abnormal swelling. Prolonged use

in cold weather has been linked to blood ves-

sel damage in otherwise healthy people. If

symptoms occur such as numbness, pain,

loss of strength, change in skin color or tex-

ture, or loss of feeling in the fingers, hands, or

joints, discontinue the use of this tool and

seek medical attention. An antivibration sys-

tem does not guarantee the avoidance of

these problems. Users who operate power

tools on a continual and regular basis must

monitor closely their physical condition and

the condition of this tool.

PREPARATION

i_ WARNING: If you receive your unit

assembled, check each step to insure your

unit is properly assembled. Follow all safety

information in the manual and on the unit.

• No tools are required for assembly.

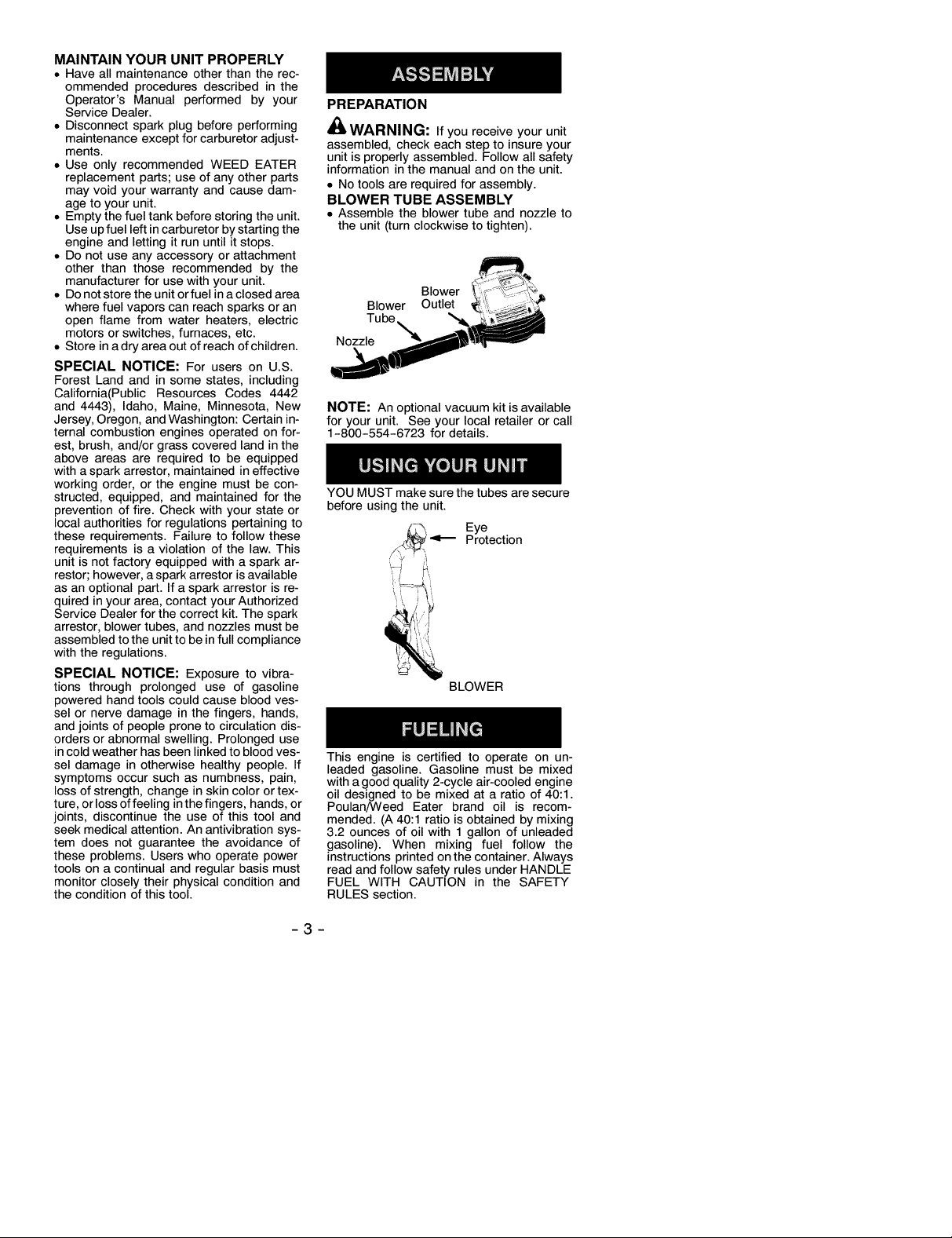

BLOWER TUBE ASSEMBLY

• Assemble the blower tube and nozzle to

the unit (turn clockwise to tighten).

Blower Outlet

Tube

Nozzle

NOTE: An optional vacuum kit is available

for your unit. See your local retailer or call

1-800-554-6723 for details.

YOU MUST make sure the tubes are secure

before using the unit.

This engine is certified to operate on un-

leaded gasoline. Gasoline must be mixed

with a good quality 2-cycle air-cooled engine

oil designed to be mixed at a ratio of 40:1.

Poulan/Weed Eater brand oil is recom-

mended. (A 40:1 ratio is obtained by mixing

3.2 ounces of oil with 1 gallon of unleaded

asoline). When mixing fuel follow the

nstructions printed on the container. Always

read and follow safety rules under HANDLE

FUEL WITH CAUTION in the SAFETY

RULES section.

Blower

, _ Protection

:_. Eye

BLOWER

3

TO STOP THE ENGINE:

• The ON/STOP switch is used to stop the en-

gine. The switch stays in the ON position.

To stop engine, press and hold the switch

• the STOP position until the engine

comes to a complete stop.

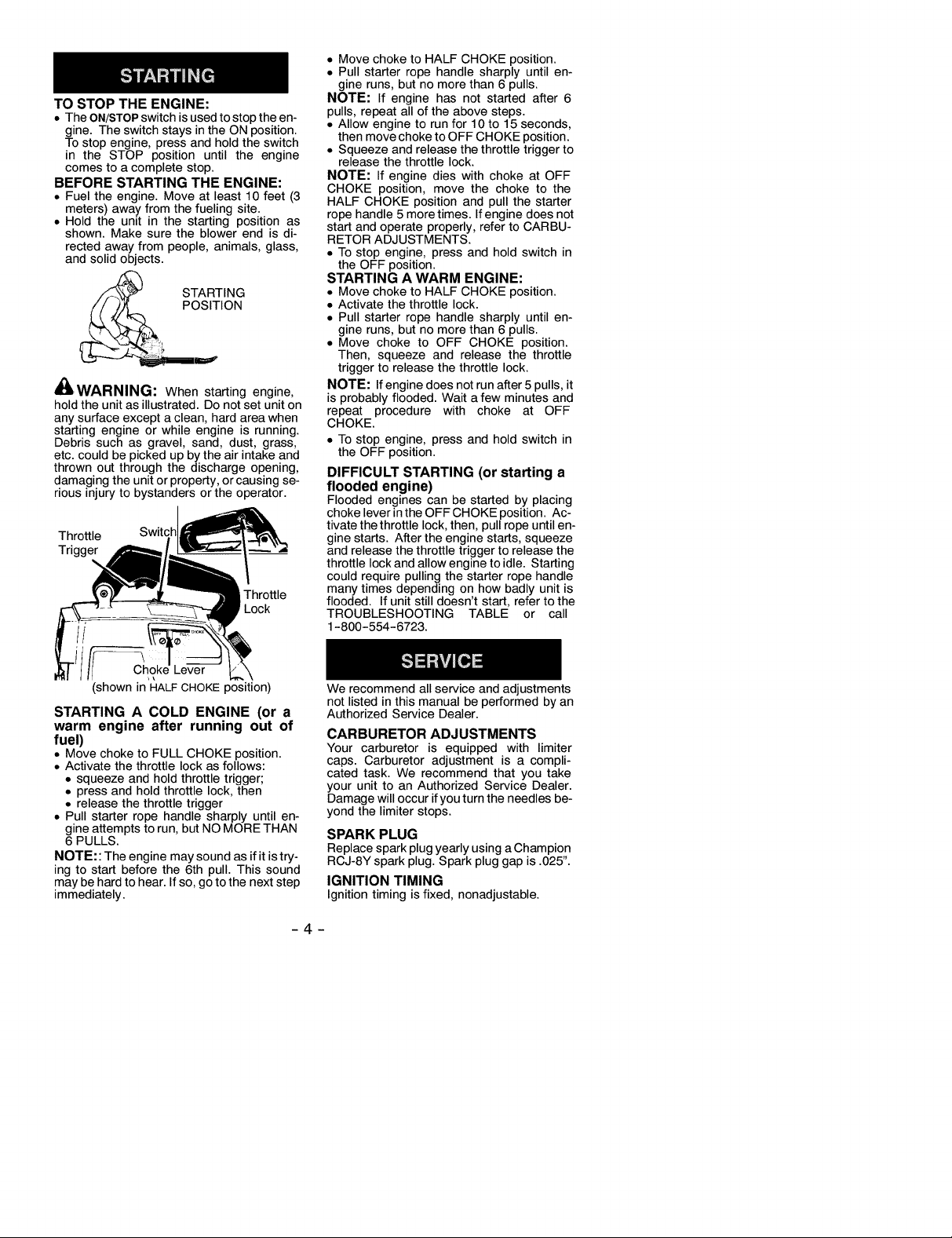

BEFORE STARTING THE ENGINE:

• Fuel the engine. Move at least 10 feet (3

meters) away from the fueling site.

• Hold the unit in the starting position as

shown. Make sure the blower end is di-

rected away from people, animals, glass,

and solid objects.

/_ STARTING

TION

I_WARNINL_: When starting engine,

hold the unit as illustrated. Do not set unit on

any surface except a clean, hard area when

starting engine or while engine is running.

Debris such as gravel, sand, dust, grass,

etc. could be picked up by the air intake and

thrown out through the discharge opening,

damaging the unit or property, or causing se-

rious injury to bystanders or the operator.

Throttle

Trigger

%

Switct-

Throttle

Lock

• Move choke to HALF CHOKE position.

• Pull starter rope handle sharply until en-

gine runs, but no more than 6 pulls.

NOTE: If engine has not started after 6

pulls, repeat all of the above steps.

• Allow engine to run for 10 to 15 seconds,

then move choke to OFF CHOKE position.

• Squeeze and release the throttle trigger to

release the throttle lock.

NOTE: If engine dies with choke at OFF

CHOKE position, move the choke to the

HALF CHOKE position and pull the starter

rope handle 5 more times. If engine does not

start and operate properly, refer to CARBU-

RETOR ADJUSTMENTS.

• To stop engine, press and hold switch in

the OFF position.

STARTING A WARM ENGINE:

• Move choke to HALF CHOKE position.

• Activate the throttle lock.

• Pull starter rope handle sharply until en-

gine runs, but no more than 6 pulls.

• Move choke to OFF CHOKE position.

Then, squeeze and release the throttle

trigger to release the throttle lock.

NOTE: Ifengine does not run after 5 pulls, it

is probably flooded. Wait a few minutes and

repeat procedure with choke at OFF

CHOKE.

• To stop engine, press and hold switch in

the OFF position.

DIFFICULT STARTING (or starting a

flooded engine)

Flooded engines can be started by placing

choke lever in the OFF CHOKE position. Ac-

tivate the throttle lock, then, pull rope until en-

gine starts. After the engine starts, squeeze

and release the throttle trigger to release the

throttle lock and allow engine to idle. Starting

could require pulling the starter rope handle

many times depending on how badly unit is

flooded. If unit still doesn't start, refer to the

TROUBLESHOOTING TABLE or call

1-800-554-6723.

(shown in HALF CHOKE position)

STARTING A COLD ENGINE (or a

warm engine after running out of

fuel)

• Move choke to FULL CHOKE position.

• Activate the throttle lock as follows:

• squeeze and hold throttle trigger;

• press and hold throttle lock, then

• release the throttle trigger

• Pull starter rope handle sharply until en-

gine attempts to run, but NO MORE THAN

6 PULLS.

NOTE:: The engine may sound as if it is try-

ing to start before the 6th pull. This sound

may be hard to hear. If so, go to the next step

immediately.

We recommend all service and adjustments

not listed in this manual be performed by an

Authorized Service Dealer.

CARBURETOR ADJUSTMENTS

Your carburetor is equipped with limiter

caps. Carburetor adjustment is a compli-

cated task. We recommend that you take

your unit to an Authorized Service Dealer.

Damage will occur ifyou turn the needles be-

yond the limiter stops.

SPARK PLUG

Replace spark plug yearly using a Champion

RCJ-8Y spark plug. Spark plug gap is .025".

IGNITION TIMING

Ignition timing isfixed, nonadjustable.

4