Page 1

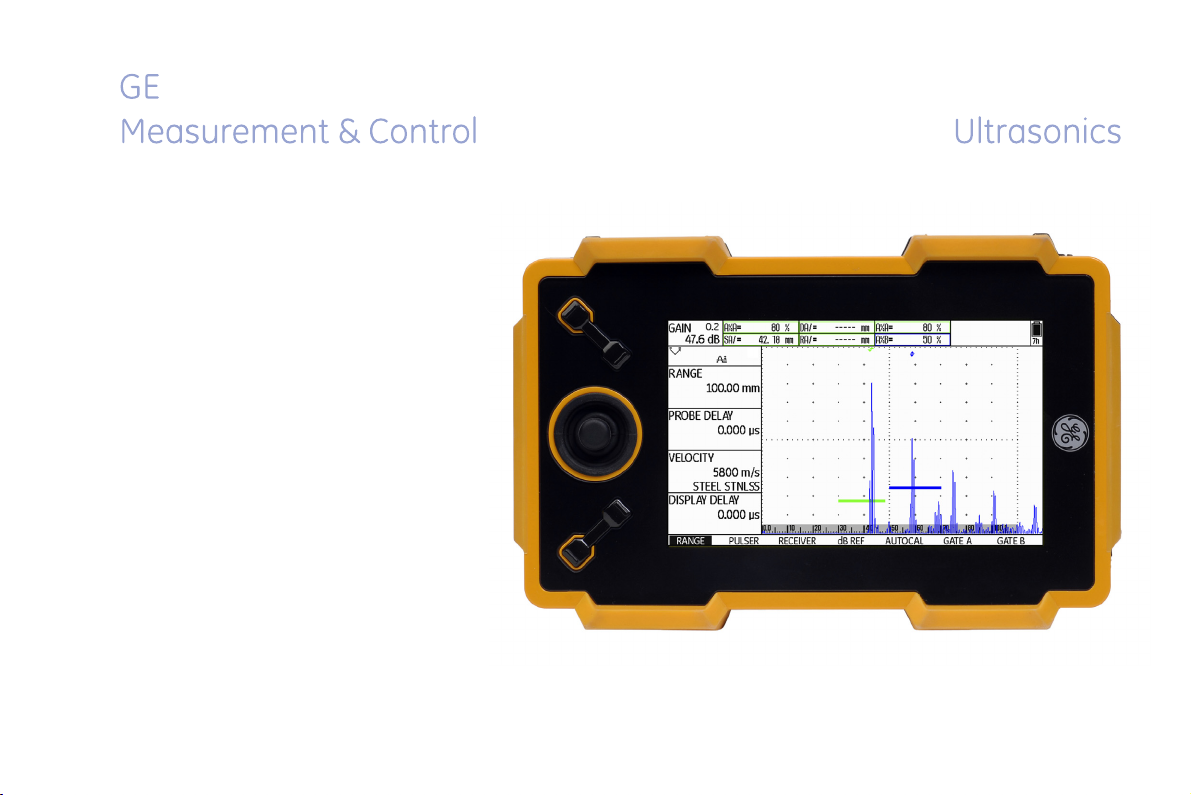

USM Go

USM Go+

Technical Reference and Operating Manual Id. No. 49 155

Page 2

This issue 6 (02/2013) applies to the following software versions:

USM Go: 2.08 (March 6, 2013)

USM Go+: 2.08 (May 28, 2013)

You will find the software version and the serial number of your instrument on the second operating level

(CONFIG2 - ABOUT)

© GE Sensing & Inspection Technologies GmbH | Technical content subject to change without notice.

Page 3

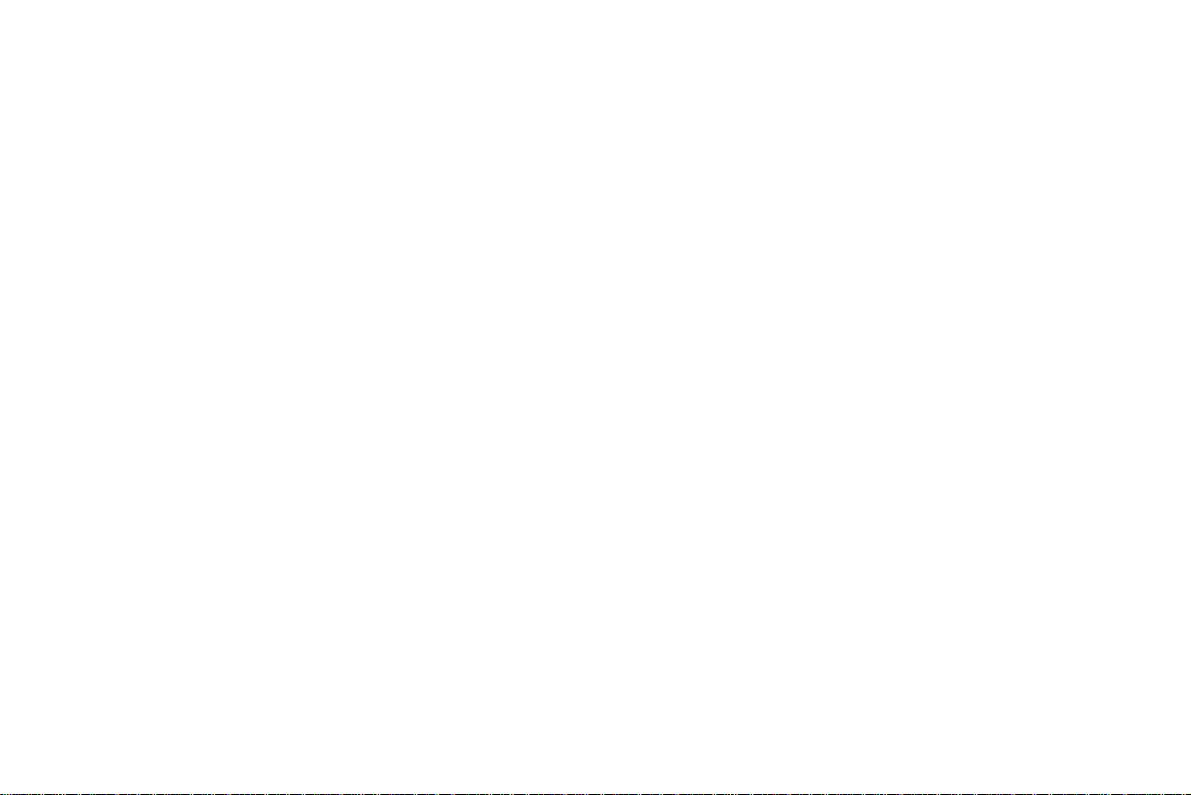

First operating level (Base)

To change between the first and the second operating level:

USM Go: Press the joystick for 2 seconds.

USM Go+: Press the center key of the keypad for 2 seconds.

USM Go Issue 6 (02/2013) 0-3

Page 4

First operating level (Options)

To change between the first and the second operating level:

USM Go: Press the joystick for 2 seconds.

USM Go+: Press the center key of the keypad for 2 seconds.

0-4 Issue 6 (02/2013) USM Go

Page 5

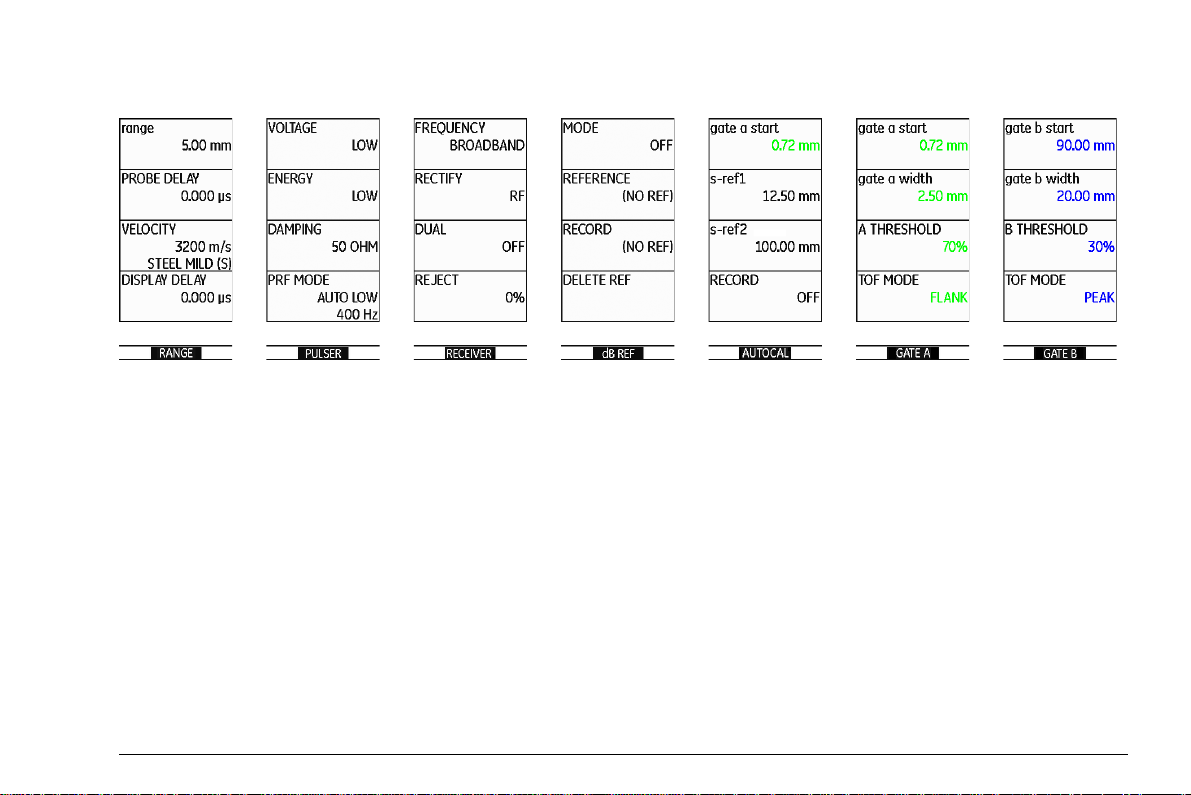

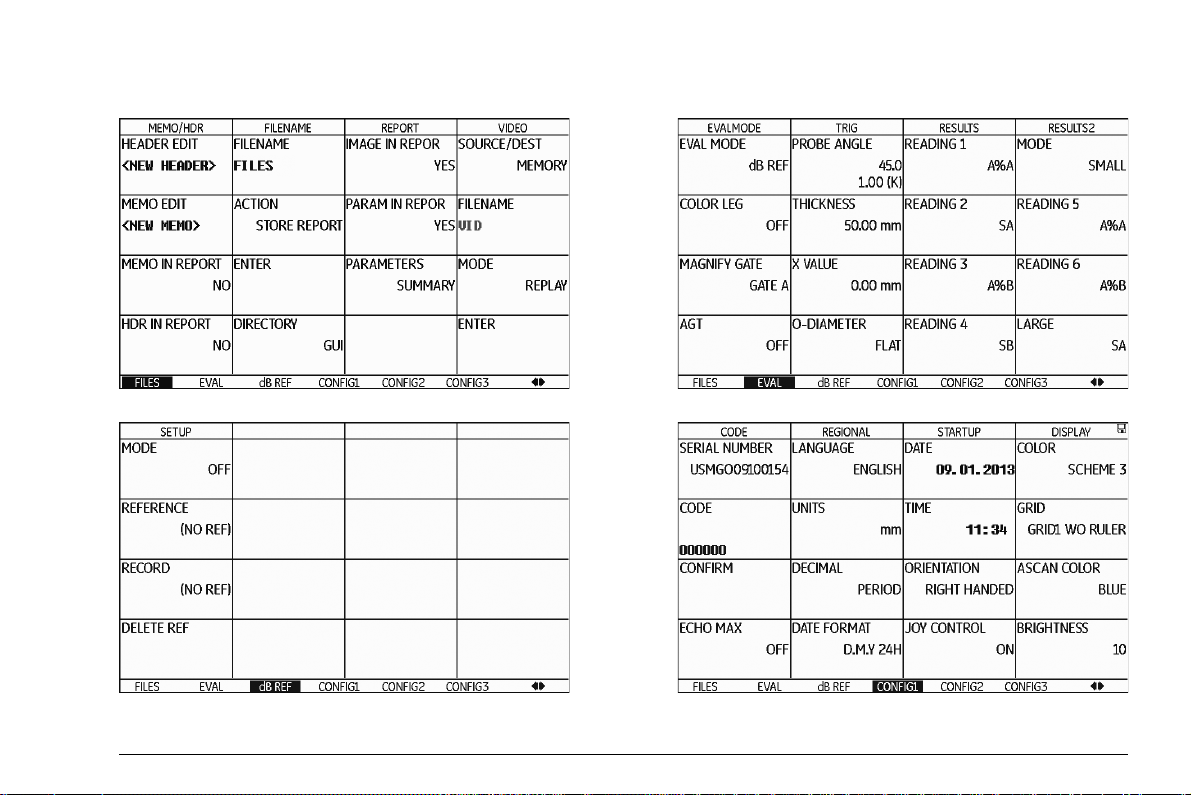

Second operating level

USM Go Issue 6 (02/2013) 0-5

Page 6

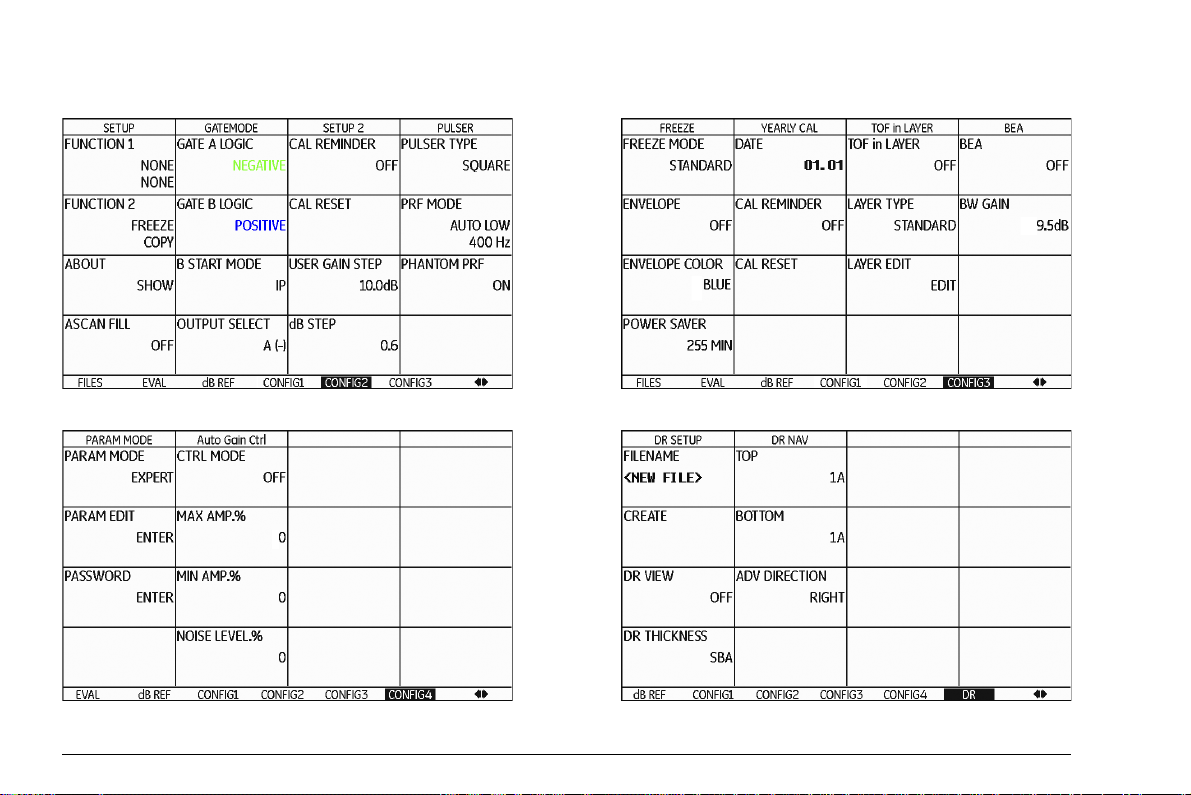

Second operating level (continued)

0-6 Issue 6 (02/2013) USM Go

Page 7

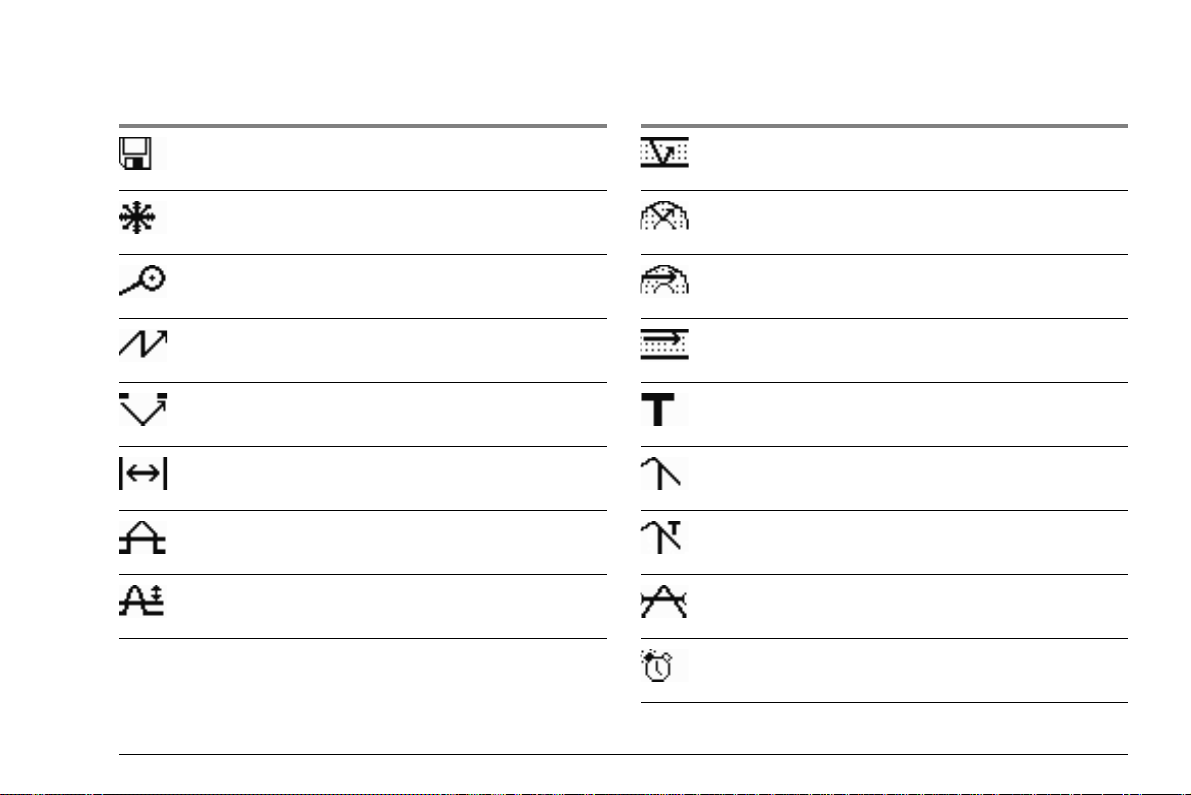

Status display icons

Icon Meaning Icon Meaning

SD memory card is inserted,

flashes when the SD card is accessed

Angle-beam probe 30° … 90°, flat surface,

Reflection from the backwall

Freeze active (Freeze),

Display is „frozen“.

Angle-beam probe 30°, curved surface,

Reflection from the inner surface of tube

Magnify gate is active Angle-beam probe 80°, curved surface,

Reflection from the outer surface of tube

Pulser-receiver separation is turned off Angle-beam probe 90°, surface wave

Pulser-receiver separation is turned on DAC mode = TCG is active

Pulser-receiver separation is turned on and set

DGS reference echo has been recorded

to through-transmission mode

Reject function is active DGS reference echo has been recorded,

transfer loss > 0

AGT is active dB REF is active

Calibration reminder

USM Go Issue 6 (02/2013) 0-7

Page 8

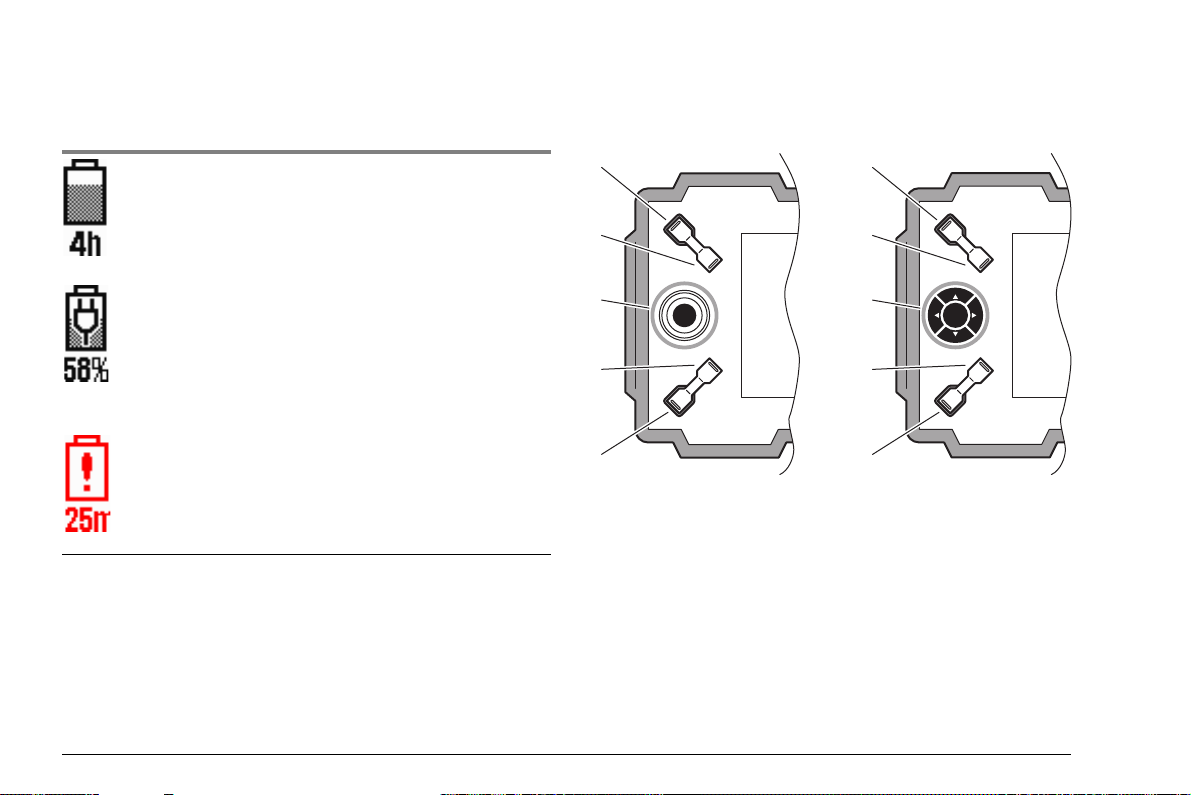

Power level indicators Keypad functions

3

4

2

2

3

4

5

5

USM Go USM Go+

Icon Meaning

Battery charge level,

remaining operating time

in hours (approximate value)

Charger/power adapter is connected,

percentage of battery charge level

(approximate value)

Warning: Low battery charge level,

remaining operating time

in minutes (approximate value)

1

1

1 Increasing the gain level in increments

2 Decreasing the gain level in increments

3 Navigation operating levels and function groups

4 Function key 1, individually assignable

5 Function key 2, individually assignable

0-8 Issue 6 (02/2013) USM Go

Page 9

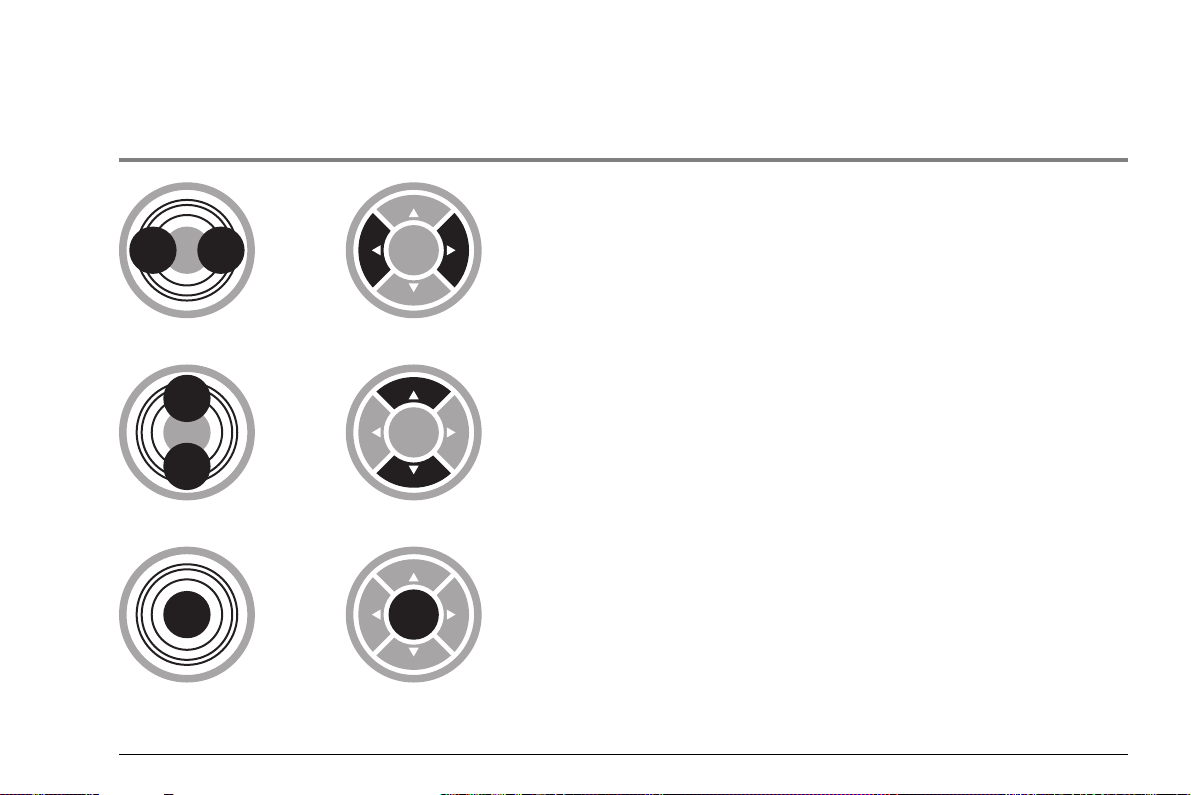

Navigation using joystick (USM Go) or keypad (USM Go+)

USM Go USM Go+ Function

Navigation between function groups,

adjusting values

Navigation within a function group,

adjusting values

Changing between operating levels (press for 2 seconds)

USM Go Issue 6 (02/2013) 0-9

Page 10

0-10 Issue 6 (02/2013) USM Go

Page 11

Contents

0 Übersichten

First operating level (Base). . . . . . . . . . . . 0-3

First operating level (Options). . . . . . . . . . 0-4

Second operating level . . . . . . . . . . . . . . . 0-5

Second operating level (continued) . . . . . 0-6

Status display icons . . . . . . . . . . . . . . . . . 0-7

Power level indicators. . . . . . . . . . . . . . . . 0-8

Keypad functions . . . . . . . . . . . . . . . . . . . 0-8

Navigation using joystick (USM Go)

or keypad (USM Go+). . . . . . . . . . . . . . . . 0-9

1 Introduction

1.1 Safety information . . . . . . . . . . . . . . . . . 1-2

Battery operation . . . . . . . . . . . . . . . . . . . 1-2

Software . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Defects/errors and exceptional stresses. . 1-3

1.2 Important information on

ultrasonic testing . . . . . . . . . . . . . . . . . . 1-3

Prerequisites for testing with

ultrasonic test equipment . . . . . . . . . . . . . 1-3

Operator training . . . . . . . . . . . . . . . . . . . . 1-4

Technical test requirements . . . . . . . . . . . 1-4

Limits of testing . . . . . . . . . . . . . . . . . . . . . 1-5

Ultrasonic wall thickness measurement . . 1-5

Effect of the test object material . . . . . . . . 1-5

Effect of temperature variations . . . . . . . . 1-6

Measurement of remaining wall thickness 1-6

Ultrasonic evaluation of flaws . . . . . . . . . . 1-6

Flaw boundary method . . . . . . . . . . . . . . . 1-6

Echo display comparison method . . . . . . . 1-7

1.3 The USM Go. . . . . . . . . . . . . . . . . . . . . . . 1-8

Instrument versions USM Go and USM Go+1-9

Options . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Special features of the USM Go . . . . . . . 1-11

1.4 The DMS Go. . . . . . . . . . . . . . . . . . . . . . 1-12

1.5 How to use this manual . . . . . . . . . . . . 1-12

USM Go Issue 6 (02/2013) 0-1

Page 12

Contents

1.6 Layout and presentation in

this manual . . . . . . . . . . . . . . . . . . . . . . 1-13

Attention and note symbols. . . . . . . . . . . 1-13

Listings . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Operating steps. . . . . . . . . . . . . . . . . . . . 1-13

2 Standard package and accessories

2.1 Standard package . . . . . . . . . . . . . . . . . . 2-2

2.2 Add-on functions . . . . . . . . . . . . . . . . . . 2-3

2.3 Preconfigured function packages. . . . . 2-4

2.4 Recommended accessories. . . . . . . . . . 2-5

3 Initial start-up

3.1 Instrument positioning . . . . . . . . . . . . . . 3-2

3.2 Power supply. . . . . . . . . . . . . . . . . . . . . . 3-2

Operation with charger/power adapter . . . 3-2

Operation using batteries . . . . . . . . . . . . . 3-4

Charging the batteries. . . . . . . . . . . . . . . . 3-8

3.3 Connecting a probe . . . . . . . . . . . . . . . . 3-9

3.4 Inserting the SD memory card. . . . . . . 3-10

3.5 Starting the USM Go . . . . . . . . . . . . . . . 3-11

Powering On . . . . . . . . . . . . . . . . . . . . . . 3-11

Powering Off . . . . . . . . . . . . . . . . . . . . . . 3-12

Factory default setting (Reset) . . . . . . . . 3-12

4 Principles of operation

4.1 Overview of operator's controls . . . . . . 4-2

4.2 Display screen. . . . . . . . . . . . . . . . . . . . . 4-3

A-scan representation . . . . . . . . . . . . . . . . 4-3

Functions on the display screen . . . . . . . . 4-4

Gain. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Measurement line . . . . . . . . . . . . . . . . . . . 4-5

Status display icons . . . . . . . . . . . . . . . . . 4-6

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

0-2 Issue 6 (02/2013) USM Go

Page 13

Contents

4.3 Navigation and function keys . . . . . . . . 4-7

Navigation. . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Function keys . . . . . . . . . . . . . . . . . . . . . . 4-7

Key combinations . . . . . . . . . . . . . . . . . . . 4-8

Power key . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.4 Operational concept . . . . . . . . . . . . . . . . 4-9

Operating levels . . . . . . . . . . . . . . . . . . . . 4-9

Selecting and setting functions . . . . . . . . . 4-9

Function HOME . . . . . . . . . . . . . . . . . . . 4-11

Activating functions. . . . . . . . . . . . . . . . . 4-12

4.5 Important default settings . . . . . . . . . . 4-13

Language setting . . . . . . . . . . . . . . . . . . 4-13

Units setting . . . . . . . . . . . . . . . . . . . . . . 4-14

Decimal separator. . . . . . . . . . . . . . . . . . 4-14

Date format, Date, and Time . . . . . . . . . 4-15

Selecting the instrument orientation . . . . 4-16

4.6 Default settings of the display. . . . . . . 4-16

Selecting the color scheme. . . . . . . . . . . 4-16

Selecting the A-scan color . . . . . . . . . . . 4-17

Selecting the grid . . . . . . . . . . . . . . . . . . 4-18

Setting the brightness . . . . . . . . . . . . . . . 4-18

4.7 Saving the settings. . . . . . . . . . . . . . . . 4-19

Recalling settings . . . . . . . . . . . . . . . . . . 4-21

Displaying dataset name. . . . . . . . . . . . . 4-22

5 Operation

5.1 Overview of the functions . . . . . . . . . . . 5-2

Function groups first operating level . . . . . 5-3

Function groups second operating level . . 5-4

5.2 Setting the gain. . . . . . . . . . . . . . . . . . . . 5-6

Setting the dB increment of gain. . . . . . . . 5-6

5.3 Assignment of function keys. . . . . . . . . 5-8

5.4 Setting the display range

(function group RANGE) . . . . . . . . . . . 5-10

RANGE . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

PROBE DELAY. . . . . . . . . . . . . . . . . . . . 5-11

VELOCITY . . . . . . . . . . . . . . . . . . . . . . . 5-12

DISPLAY DELAY . . . . . . . . . . . . . . . . . . 5-13

USM Go Issue 6 (02/2013) 0-3

Page 14

Contents

5.5 Setting the pulser

(function group PULSER). . . . . . . . . . . 5-14

VOLTAGE (pulser voltage) . . . . . . . . . . . 5-14

ENERGY. . . . . . . . . . . . . . . . . . . . . . . . . 5-15

WIDTH . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

DAMPING . . . . . . . . . . . . . . . . . . . . . . . . 5-17

PRF MODE (pulse repetition frequency) . .5-17

5.6 Setting the receiver

(function group RECEIVER). . . . . . . . . 5-19

FREQUENCY . . . . . . . . . . . . . . . . . . . . . 5-19

RECTIFY. . . . . . . . . . . . . . . . . . . . . . . . . 5-20

DUAL (pulser-receiver separation) . . . . . 5-20

REJECT . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

5.7 Setting the gates

(function groups

GATE A and GATE B) . . . . . . . . . . . . . . 5-22

Tasks of the gates. . . . . . . . . . . . . . . . . . 5-22

A-START/B-START

(starting point of the gate) . . . . . . . . . . . . 5-23

A-WIDTH/B-WIDTH

(width of the gates) . . . . . . . . . . . . . . . . . 5-23

A-THRESHOLD/B-THRESHOLD

(response and measurement

threshold of the gate) . . . . . . . . . . . . . . . 5-24

TOF MODE . . . . . . . . . . . . . . . . . . . . . . . 5-25

Starting point of gate B . . . . . . . . . . . . . . 5-27

Automatic gate height . . . . . . . . . . . . . . . 5-28

5.8 Calibrating the USM Go . . . . . . . . . . . . 5-29

Calibrating the display range. . . . . . . . . . 5-29

Choice of the measuring point . . . . . . . . 5-29

Calibration with straight-beam and

angle-beam probes . . . . . . . . . . . . . . . . . 5-30

Calibration using dual-element probes . . 5-34

5.9 Making measurements . . . . . . . . . . . . . 5-37

General notes . . . . . . . . . . . . . . . . . . . . . 5-37

5.10 dB-difference measurement

(function group dB REF) . . . . . . . . . . . 5-38

Recording a reference echo . . . . . . . . . . 5-39

Deleting a reference echo . . . . . . . . . . . . 5-39

Echo height comparison . . . . . . . . . . . . . 5-40

0-4 Issue 6 (02/2013) USM Go

Page 15

Contents

5.11 Rating of welds

(function group AWS D1.1) . . . . . . . . . 5-41

Rating of welds according to AWS D1.1. 5-42

5.12 Flaw position calculation with

angle-beam probes. . . . . . . . . . . . . . . . 5-45

PROBE ANGLE . . . . . . . . . . . . . . . . . . . 5-46

THICKNESS . . . . . . . . . . . . . . . . . . . . . . 5-47

X VALUE. . . . . . . . . . . . . . . . . . . . . . . . . 5-48

O-DIAMETER . . . . . . . . . . . . . . . . . . . . . 5-48

COLOR LEG. . . . . . . . . . . . . . . . . . . . . . 5-49

5.13 Defining the probe angle . . . . . . . . . . . 5-50

BLOCK . . . . . . . . . . . . . . . . . . . . . . . . . . 5-51

5.14 Enabling options (Upgrade). . . . . . . . . 5-52

5.15 Configuring the USM Go for

test tasks . . . . . . . . . . . . . . . . . . . . . . . . 5-53

TOF MODE. . . . . . . . . . . . . . . . . . . . . . . 5-53

Phantom echo detector. . . . . . . . . . . . . . 5-58

Configuring the measurement line . . . . . 5-59

Enlarged display of reading . . . . . . . . . . 5-62

LARGE (alarm signal). . . . . . . . . . . . . . . 5-64

MAGNIFY GATE (spanning the gate). . . 5-65

Activating the magnify gate function . . . . 5-66

Automatic A-scan freeze (Freeze) . . . . . 5-68

5.16 Setting the display . . . . . . . . . . . . . . . . 5-70

ASCAN FILL . . . . . . . . . . . . . . . . . . . . . . 5-71

Working with Echo Max . . . . . . . . . . . . . 5-72

5.17 General setup . . . . . . . . . . . . . . . . . . . . 5-73

EVAL MODE . . . . . . . . . . . . . . . . . . . . . . 5-73

Gate logic . . . . . . . . . . . . . . . . . . . . . . . . 5-74

Selecting the pulser type. . . . . . . . . . . . . 5-75

Locking the joystick. . . . . . . . . . . . . . . . . 5-76

Configuring the alarm output. . . . . . . . . . 5-77

Power saving mode . . . . . . . . . . . . . . . . 5-79

TOF in LAYER . . . . . . . . . . . . . . . . . . . . 5-80

Backwall echo attenuation (BEA) . . . . . . 5-82

Displaying the envelope curve

(ENVELOPE) . . . . . . . . . . . . . . . . . . . . . 5-83

Automatic gain control

(Auto Gain Control) . . . . . . . . . . . . . . . . . 5-84

USM Go Issue 6 (02/2013) 0-5

Page 16

Contents

Calibration reminder . . . . . . . . . . . . . . . . 5-86

Password protection . . . . . . . . . . . . . . . . 5-87

5.18 Distance-amplitude correction (DAC) . 5-91

Recording a DAC curve . . . . . . . . . . . . . 5-92

Setting up the DAC . . . . . . . . . . . . . . . . . 5-94

Turning the DAC evaluation off. . . . . . . . 5-95

Deleting the DAC curve . . . . . . . . . . . . . 5-96

Editing DAC points . . . . . . . . . . . . . . . . . 5-96

Adding DAC points . . . . . . . . . . . . . . . . . 5-97

Multiple DAC curves . . . . . . . . . . . . . . . . 5-97

AWS D1.1 in DAC/TCG . . . . . . . . . . . . . 5-99

Sensitivity correction . . . . . . . . . . . . . . . . 5-99

Echo evaluation using DAC/TCG . . . . . 5-100

5.19 Distance-amplitude curve according to

JIS Z3060-2002 (JISDAC) . . . . . . . . . . 5-102

Activating JISDAC

(DAC according to JIS) . . . . . . . . . . . . 5-102

Recording a DAC curve . . . . . . . . . . . . 5-102

Setting up JISDAC . . . . . . . . . . . . . . . . 5-105

Sensitivity correction . . . . . . . . . . . . . . . 5-106

Turning the JISDAC evaluation off . . . . 5-106

Deleting the DAC curve. . . . . . . . . . . . . 5-107

Echo evaluation using DAC . . . . . . . . . 5-107

5.20 Distance-amplitude curve

according to JB/T4730 and

GB 11345 (CNDAC) . . . . . . . . . . . . . . . 5-109

Evaluations according to CNDAC . . . . . 5-109

Standards and reference blocks . . . . . . 5-110

Activating the CNDAC. . . . . . . . . . . . . . 5-111

Recording a DAC curve . . . . . . . . . . . . 5-111

Setting up CNDAC . . . . . . . . . . . . . . . . 5-114

Sensitivity correction . . . . . . . . . . . . . . . 5-115

Adjusting reference lines. . . . . . . . . . . . 5-116

Turning the CNDAC evaluation off . . . . 5-116

Deleting the DAC curve. . . . . . . . . . . . . 5-117

Echo evaluation using DAC . . . . . . . . . 5-117

5.21 Evaluation according to the

DGS method . . . . . . . . . . . . . . . . . . . . 5-119

Using the DGS for measurements . . . . 5-119

Validity of the DGS method. . . . . . . . . . 5-121

0-6 Issue 6 (02/2013) USM Go

Page 17

Contents

Starting the echo height evaluation

according to DGS . . . . . . . . . . . . . . . . . 5-123

Basic settings for the

DGS measurement . . . . . . . . . . . . . . . . 5-123

Recording a reference echo and

turning the DGS curve on . . . . . . . . . . . 5-125

Locks, error messages . . . . . . . . . . . . . 5-127

Sound attenuation and

transfer correction. . . . . . . . . . . . . . . . . 5-128

Using multiple DGS curves. . . . . . . . . . 5-128

Turning the DGS evaluation off . . . . . . 5-129

Deleting a DGS reference echo . . . . . . 5-129

Probe data . . . . . . . . . . . . . . . . . . . . . . 5-130

trueDGS angle-beam probes . . . . . . . . 5-133

6 Documentation

6.1 Test reports. . . . . . . . . . . . . . . . . . . . . . . 6-2

Storing test reports . . . . . . . . . . . . . . . . . . 6-2

Displaying test reports . . . . . . . . . . . . . . . 6-4

Printing test reports. . . . . . . . . . . . . . . . . . 6-6

Deleting test reports . . . . . . . . . . . . . . . . . 6-7

Storing the A-scan and parameters

in the test report . . . . . . . . . . . . . . . . . . . . 6-9

6.2 Storing memos . . . . . . . . . . . . . . . . . . . 6-10

Creating a new memo file . . . . . . . . . . . . 6-10

Editing a memo file . . . . . . . . . . . . . . . . . 6-11

Attaching a memo file to test report . . . . 6-12

6.3 Storing a report header . . . . . . . . . . . . 6-13

Creating a new header file . . . . . . . . . . . 6-13

Editing a header file . . . . . . . . . . . . . . . . 6-14

Including a header file in the test report . 6-15

6.4 Viewing and storing parameters . . . . . 6-16

6.5 Videos . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Recording a video . . . . . . . . . . . . . . . . . . 6-17

Viewing a video. . . . . . . . . . . . . . . . . . . . 6-19

6.6 Documentation using UltraMATE . . . . 6-21

6.7 Data Recorder (option). . . . . . . . . . . . . 6-22

Creating a Data Recorder file . . . . . . . . . 6-23

Activating a Data Recorder file . . . . . . . . 6-25

Storing readings in the grid matrix . . . . . 6-26

USM Go Issue 6 (02/2013) 0-7

Page 18

Deleting readings . . . . . . . . . . . . . . . . . . 6-27

A-scan preview . . . . . . . . . . . . . . . . . . . . 6-28

Viewing Data Recorder files . . . . . . . . . . 6-28

Turning the grid matrix on/off . . . . . . . . . 6-29

Service interface (Mini RS232-C) . . . . . . . 8-3

8.2 Peripherals. . . . . . . . . . . . . . . . . . . . . . . . 8-4

9 Appendix

7 Maintenance and care

7.1 Instrument care. . . . . . . . . . . . . . . . . . . . 7-2

7.2 Battery care . . . . . . . . . . . . . . . . . . . . . . . 7-2

Battery care. . . . . . . . . . . . . . . . . . . . . . . . 7-2

Charging the batteries. . . . . . . . . . . . . . . . 7-3

7.3 Maintenance . . . . . . . . . . . . . . . . . . . . . . 7-3

7.4 Software updates . . . . . . . . . . . . . . . . . . 7-4

Download of update files. . . . . . . . . . . . . . 7-4

Installing an update. . . . . . . . . . . . . . . . . . 7-5

8 Interfaces and Peripherals

8.1 Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

USB interface . . . . . . . . . . . . . . . . . . . . . . 8-3

0-8 Issue 6 (02/2013) USM Go

9.1 Function directory. . . . . . . . . . . . . . . . . . 9-2

9.2 EU Declaration of Conformity . . . . . . . 9-11

9.3 Manufacturer/Service addresses. . . . . 9-11

9.4 Environmental protection regulations 9-13

WEEE directive (Waste Electrical and

Electronic Equipment) . . . . . . . . . . . . . . . 9-13

Disposal of batteries . . . . . . . . . . . . . . . . 9-14

9.5 Recycling directives . . . . . . . . . . . . . . . 9-16

Overview . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

Materials to be disposed of separately . . 9-19

Other materials and components . . . . . . 9-22

Recycling data of the USM Go . . . . . . . . 9-29

Page 19

10 Specifications

10.1 Specifications of

USM Go and USM Go+ . . . . . . . . . . . . . 10-2

Display screen . . . . . . . . . . . . . . . . . . . . 10-2

Display . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Connectors . . . . . . . . . . . . . . . . . . . . . . . 10-3

Memory. . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

Pulser . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

Receiver . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

Gates . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

Memory. . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

Environment . . . . . . . . . . . . . . . . . . . . . . 10-7

Protection . . . . . . . . . . . . . . . . . . . . . . . . 10-8

Options . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

10.2 Specifications according to

EN 12668 . . . . . . . . . . . . . . . . . . . . . . . 10-11

Contents

11 Index

USM Go Issue 6 (02/2013) 0-9

Page 20

0-10 Issue 6 (02/2013) USM Go

Page 21

Introduction 1

USM Go Issue 6 (02/2013) 1-1

Page 22

1 Introduction Safety information

ATTENTION

1.1 Safety information

The USM Go has been designed and tested according

to DIN

EN 61010-1: 2011-07, Safety requirements for

electrical equipment for measurement, control and lab

oratory use, and was technically in perfectly safe and

faultless condition when leaving the manufacturing

works.

In order to maintain this condition and to ensure a safe

operation, you should always read the following safety

information carefully before putting the instrument into

operation.

The USM Go is an instrument for materials testing. Any use for medical or any

other applications is not permitted!

The instrument may only be used in industrial environments.

The USM Go is waterproof according to IP67. It can be

operated either with the corresponding lithium-ion bat

teries or with the charger/power adapter. The charger/

power adapter meets the requirements of electrical

safety class II.

-

Battery operation

For the battery operation of the USM Go, we recommend the corresponding lithium-ion battery. You should

only use this battery for the battery operation.

You can charge the lithium-ion battery either within the

instrument itself or in an external charger. If a lithium-ion

battery is inserted, charging starts automatically as

soon as you connect the charger/power adapter to the

USM Go and to the mains power supply.

For power supply, please also see Chapter 3.2 Power

supply, page 3-2. For the use of batteries, please also

see Chapter 7.2 Battery care, page 7-2.

Software

According to the current state of the art, software is never completely free from errors. Before using any software-controlled test equipment, it is therefore necessary to make sure that the required functions operate

perfectly in the intended combination.

If you have any questions about the use of your test

equipment, please contact your nearest representative

of GE Sensing & Inspection Technologies.

1-2 Issue 6 (02/2013) USM Go

Page 23

Important information on ultrasonic testing 1 Introduction

Defects/errors and exceptional stresses

If you have reason to believe that a safe operation of

your USM Go is no longer possible, you have to discon

nect the instrument and secure it against unintentional

re-connection. Remove the lithium-ion battery.

A safe operation is no longer possible for example

● if the instrument shows visible damages,

● if the instrument no longer operates perfectly,

● after prolonged storage under adverse conditions

(e.g. exceptional temperatures or especially high air

humidity, or corrosive environmental conditions),

● after being subjected to heavy stresses during transportation.

1.2 Important information on ultrasonic testing

Please read the following information before using your

USM Go. It is important that you understand and ob

serve this information to avoid any operator errors that

might lead to false test results. Such false test results

could result in personal injuries or property damages.

Prerequisites for testing with ultrasonic test equipment

This operating manual contains essential information on

how to operate your test equipment. In addition, there

are a number of factors that affect the test results, but a

description of all these factors goes beyond the scope

of this operating manual. The three most important pre

requisites for a safe and reliable ultrasonic inspection

are:

● Operator training

● Knowledge of special technical test requirements and

limits

-

-

● Choice of appropriate test equipment

USM Go Issue 6 (02/2013) 1-3

Page 24

1 Introduction Important information on ultrasonic testing

Operator training

The operation of an ultrasonic test device requires proper training in ultrasonic test methods.

Proper training comprises for example adequate knowledge of:

● the theory of sound propagation,

● the effects of sound velocity in the test material,

● the behavior of the sound wave at interfaces between

different materials,

● the propagation of the sound beam,

● the influence of sound attenuation in the test object

and the influence of surface quality of the test object.

Lack of such knowledge could lead to false test results

with unforeseeable consequences. You can contact for

example NDT societies or organizations in your country

(DGZfP in Germany; ASNT in the USA), or also GE

Sensing & Inspection Technologies, for information on

the existing opportunities for training of ultrasonic in

spectors as well as on the qualifications and certificates

that can finally be obtained.

-

Technical test requirements

Every ultrasonic test is subject to specific technical test

requirements. The most important ones are:

● the definition of the scope of inspection

● the choice of the appropriate test method

● the consideration of material properties

● the determination of limits for recording and evalua-

tion.

It is the task of the those with overall responsibility for

testing to ensure that the inspector is fully informed

about these requirements. The best basis for such infor

mation is experience with identical test objects. It is also

essential that the relevant test specifications be clearly

and completely understood by the inspector.

GE Sensing & Inspection Technologies regularly holds

specialized training courses in the field of ultrasonic

testing. The scheduled dates for these courses will be

given to you on request.

-

1-4 Issue 6 (02/2013) USM Go

Page 25

Important information on ultrasonic testing 1 Introduction

Limits of testing

The information obtained from ultrasonic tests only refers to those parts of the test object which are covered

by the sound beam of the probe used.

Any conclusions from the tested parts to be applied to

the untested parts of the test object should be made with

extreme caution.

Such conclusions are generally only possible in cases

where extensive experience and proven methods of sta

tistical data acquisition are available.

The sound beam can be completely reflected from

boundary surfaces within the test object so that flaws

and reflection points lying deeper remain undetected. It

is therefore important to make sure that all areas to be

tested in the test object are covered by the sound beam.

Ultrasonic wall thickness measurement

All ultrasonic wall thickness measurements are based

on a time-of-flight measurement. Accurate measure

ment results require a constant sound velocity in the test

object. In test objects made of steel, even with varying

alloying constituents, this condition is mostly fulfilled.

The variation of sound velocity is so slight that it is only

-

of importance for high-precision measurements. In oth

er materials, e.g. nonferrous metals or plastics, the

sound velocity variations may be even larger and thus

affect the measuring accuracy.

Effect of the test object material

If the material of the test object is not homogeneous, the

sound waves may propagate at different velocities in dif

ferent parts of the test object. An average sound velocity

should then be taken into account for the range calibra

tion. This is achieved by using a reference block with a

sound velocity equal to the average sound velocity of

the test object.

If substantial sound velocity variations are expected,

then the instrument calibration should be adjusted to the

actual sound velocity values at shorter time intervals.

Failure to do so may lead to false thickness readings.

-

-

-

USM Go Issue 6 (02/2013) 1-5

Page 26

1 Introduction Important information on ultrasonic testing

Effect of temperature variations

The sound velocity within the test object also varies as

a function of the material's temperature. This can cause

appreciable errors in measurements if the instrument

has been calibrated on a cold reference block, whereas

the measurement is carried out on a warm test object.

Such measurement errors can be avoided either by ad

justing the temperature of the reference block used for

calibration or by taking the temperature effect into con

sideration on the basis of a correction factor obtained

from published tables.

Measurement of remaining wall thickness

The measurement of the remaining wall thickness on

plant components, e.g. pipes, tanks, and reaction ves

sels of all types which are corroded or eroded from the

inside, requires a perfectly suitable gauge and special

care in handling the probe.

The inspectors should always be informed about the

corresponding nominal wall thicknesses and the likely

amount of wall thickness losses.

-

Ultrasonic evaluation of flaws

In present-day test practice, there are basically two different methods of flaw evaluation:

If the diameter of the sound beam is smaller than the extent of the flaw, then the sound beam can be used to explore the boundaries of the flaw and thus determine its

area.

-

If, however, the diameter of the sound beam is larger

that the extent of the flaw, the maximum echo indication

from the flaw must be compared with the maximum

echo indication from an artificial flaw provided for com

parison purposes.

Flaw boundary method

The smaller the diameter of the probe's sound beam,

the more accurately the boundaries, i.e. the actual flaw

area, can be determined by the flaw boundary method.

If, however, the sound beam is relatively broad, the flaw

area determined can substantially differ from the actual

flaw area. Care should therefore be taken to select a

probe which will give a sufficiently narrow sound beam

at the position of the flaw.

-

1-6 Issue 6 (02/2013) USM Go

Page 27

Important information on ultrasonic testing 1 Introduction

Echo display comparison method

The echo from a small, natural flaw is usually smaller

than the echo from an artificial comparison flaw, e.g. cir

cular disc flaw of the same size. This is due, for instance, to the roughness of the surface of a natural flaw,

or to the fact that the sound beam does not impinge on

it at right angles.

If this fact is not taken into account when evaluating natural flaws, there is a risk of false evaluation.

In the case of very jagged or fissured flaws, e.g. shrink

holes in castings, it may be that the sound scattering oc

curring at the boundary surface of the flaw is so strong

that no echo at all is produced. In such cases, a different

evaluation method should be chosen, e.g. use of the

backwall echo attenuation in the evaluation.

The distance sensitivity of the flaw echo plays an important part when testing large components. Attention

should be paid here to choosing artificial comparison

flaws which are as far as possible governed by the same

"distance laws" as the natural flaws to be evaluated.

The ultrasonic wave is attenuated in any material. This

sound attenuation is very low, e.g. in parts made of finegrained steel, likewise in many small parts made of oth

-

er materials. However, if the sound wave travels larger

distances through the material, a high cumulative sound

attenuation can result, even with small attenuation coef

ficients. There is then a danger that echoes from natural

flaws appear too small. For this reason, an estimate

must always be made of the effects of attenuation on the

evaluation result and taken into account if applicable.

If the test object has a rough surface, part of the incident

sound energy will be scattered at its surface and is not

available for the test. The larger this initial scattering, the

smaller the flaw echoes appear, and the more errors oc

cur in the evaluation result.

It is therefore important to take the effect of the test object's surfaces on the height of the echo into account

(transfer correction).

-

-

-

USM Go Issue 6 (02/2013) 1-7

Page 28

1 Introduction The USM Go

1.3 The USM Go

The USM Go is a lightweight and compact ultrasonic

flaw detector which is especially suitable

● for locating and evaluating material flaws,

● for measuring wall thicknesses,

● for saving and documenting test results.

Due to its design, the USM Go can be used in almost all

flaw detection applications in a wide range of industries,

including aerospace, power generation, automotive, as

well as oil and gas. These include:

Weld inspection

● Trigonometric projections

● AWS

● DAC

● DGS

Inspection of forgings and castings

● Manual PRF adjustment

Rail inspection

● High PRF (up to 2000 Hz)

● Lightweight: 850 g (1.87 lb)

● Small and ergonomic

Inspection of composites

● RF display

● 2 gates A and B

● Gate B is triggered by the event in gate A

For even more demanding applications

● Narrow band-pass filters

● Low-noise digital amplifiers

● Optional square pulsers

● DAC (TCG) with 120 dB/µs slope

● Backwall echo attenuation (BEA)

● Phantom echo detector

● DGS

1-8 Issue 6 (02/2013) USM Go

Page 29

The USM Go 1 Introduction

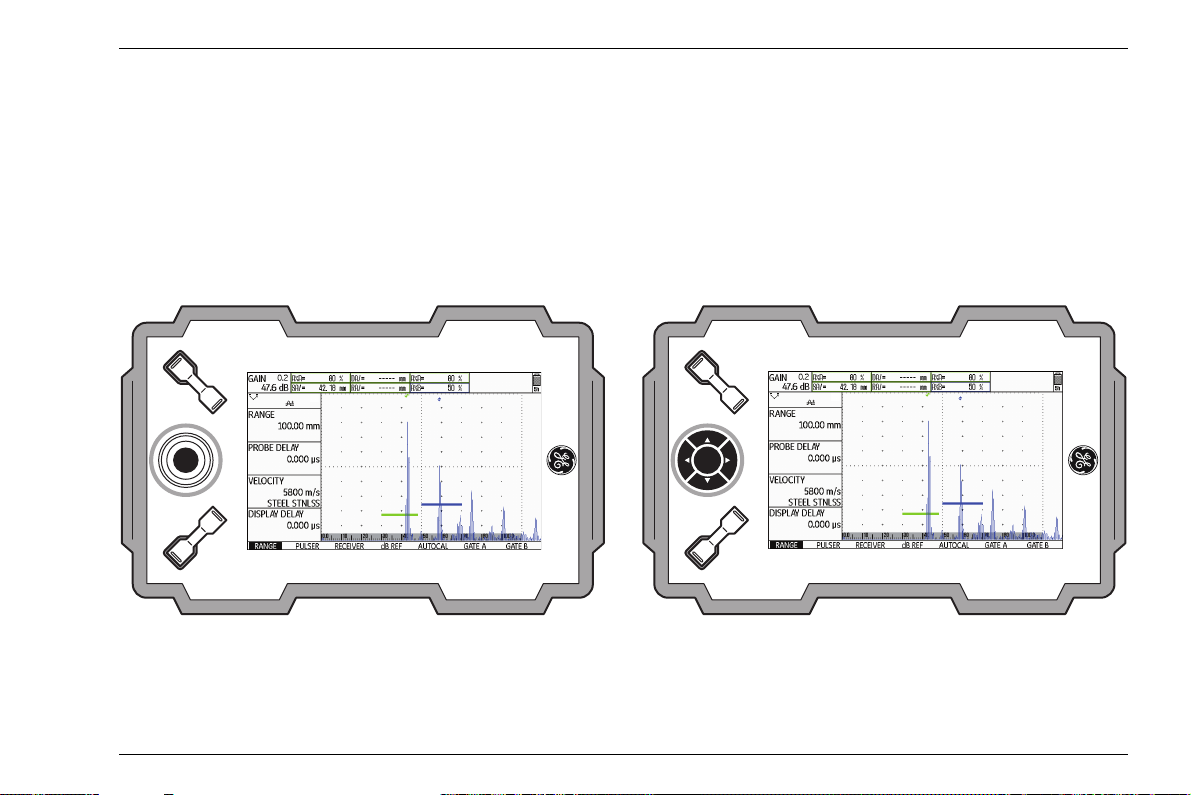

Instrument versions USM Go and USM Go+

A joystick is used in the USM Go for navigation, for

changing settings, and for selecting adjustment values.

USM Go

These functions are carried out by means of five keys in

the keypad of the USM

Go+. The arrow keys in the key-

pad correspond to the movement of the joystick in the

corresponding direction, and pressing the center key

corresponds to pressing the joystick.

USM Go+

USM Go Issue 6 (02/2013) 1-9

Page 30

1 Introduction The USM Go

Options

Various options extend the basic functions of the USM

Go and can be enabled by a code in each case.

USM Go Base

● Basic version, for universal ultrasonic

test jobs.

USM Go AWS

● Amplitude evaluation according to AWS D1.1 for the

weld inspection.

USM Go DAC

● DAC amplitude evaluation using up to 16 points according to EN 1712, EN 1713, EN 1714, ASME, and

ASME

III, in conformity with JIS Z3060

● DAC (TCG) 110 dB dynamic

● DAC (BEA) 120 dB/µs slope

USM Go DGS

● DGS amplitude evaluation according to EN 1712

USM Go with an on-board data logger

● Recording and documentation of measurement values in linear and grid file mode.

USM Go with square pulser

● Enables the fine adjustment of initial pulse parameters

● Voltage setting 120 … 300 V in increments of 10 V

● Pulse duration setting 30 … 500 ns in increments of

10

ns

● PRF

● 3G (gate C)

1-10 Issue 6 (02/2013) USM Go

Page 31

The USM Go 1 Introduction

Special features of the USM Go

● small, lightweight, rugged

● dust-tight and waterproof housing according to IP67

● long operating time (six hours) due to lithium-ion bat-

tery with internal and external charging possibility

● one-handed operation is possible

● keys for direct adjustment of gain

● two independent gates for accurate wall thickness

measurements from the material surface up to the

first echo or between two backwall echoes, including

a measurement on coated materials with a resolution

of 0.01 mm (up to 100 mm), referred to steel

● Magnify gate: spreading of the gate range over the

entire display range

● high-resolution color display (800 × 480 Pixel) for the

representation of digitized signals

● color display of gates and the corresponding readings

for easy distinction

● easily perceptible reflection geometry when using angle-beam probes due to changing A-scan or background color at every reflection point

● high memory capacity with 2 GB SD card. SD cards

with a memory capacity up to 16

GB can be used.

● increased calibration range: up to 9999 mm (steel),

depending on the frequency range

● semiautomatic two-point calibration

● pulse repetition frequency adjustable in 3 steps

(AUTO LOW, MED, HIGH) or MANUALLY in steps of

5

Hz.

● optional connection of phantom-echo detector

● choice of the frequency range for the connected

probe

● Signal display: full-wave rectification, positive or negative half rectification, and radio frequency

● display of seven user-selectable measured readings

at the top of the A-scan, one of which is displayed in

enlarged mode, or four user-selectable measured

readings displayed in enlarged mode

USM Go Issue 6 (02/2013) 1-11

Page 32

1 Introduction The DMS Go

1.4 The DMS Go

The USM Go uses the same operating principle as the

portable thickness gauge DMS Go.

You can extend your USM Go by a DMS Go quickly and

easily by means of a software upgrade. You will then

have two instruments available in one housing. When

you power the instrument on, you can choose the instru

ment that you want to use (see Chapter 3.5 Starting the

USM Go, page 3-11).

A separate operating manual is available for the DMS

Go. The functions of the DMS Go are therefore not de

scribed in the operating manual of the USM Go.

1.5 How to use this manual

This operating manual applies to all instrument versions

of the USM Go. Any differences in the functions or ad

justment values are marked in each case.

Before operating the instrument for the first time, it is absolutely necessary that you read the chapters 1, 3, and

4. They will inform you about the necessary prepara

tions of the instrument, give you a description of all keys

and displays, and explain the operating principle.

In doing this, you will avoid any errors or failures of the

instrument and be able to use the full range of instru

ment functions.

You will find the specifications of the instrument in

Chapter 10 Specifications.

-

-

-

1-12 Issue 6 (02/2013) USM Go

Page 33

Layout and presentation in this manual 1 Introduction

ATTENTION

Note

1.6 Layout and presentation in this manual

To make it easier for you to use this manual, all operating steps, listings, and special notes are always presented in the same way. This will help you find individual

pieces of information quickly.

Attention and note symbols

The ATTENTION symbol indicates peculiarities and special aspects in the operation

which could affect the accuracy of the re

sults.

Note contains e.g. references to other chapters or special recommendations for a function.

-

Listings

Listings are presented in the following form:

● Variant A

● Variant B

● ...

Operating steps

Operating steps appear as shown in the following example:

– Loosen the two screws at the bottom.

– Remove the cover.

–…

USM Go Issue 6 (02/2013) 1-13

Page 34

1-14 Issue 6 (02/2013) USM Go

Page 35

Standard package and accessories 2

USM Go Issue 6 (02/2013) 2-1

Page 36

2 Standard package and accessories Standard package

2.1 Standard package

Product code Description Order number

Ultrasonic flaw detector USM Go or USM Go+

TC-096 Transport case

LI-138 Lithium-ion battery, 7.4 V, 3.9 Ah, rechargeable

LiBC-139 AC power adapter/charger, 100V … 260V AC

SD memory card 2 GB

Display screen protector foils (10 pieces)

WS-342 Safety hand strap

Brief operating manual

Operating manual on CD

Manufacturer's certificate

2-2 Issue 6 (02/2013) USM Go

Page 37

Add-on functions 2 Standard package and accessories

2.2 Add-on functions

Product code Description Order number

DAC/TCG Echo evaluation method DAC, JISDAC, CNDAC, TCG

DGS Echo evaluation method DGS

AWS Echo evaluation method AWS D1.1

SWP Square-wave pulser

PPRF Phantom echo detector

3Gate Third gate C

DL Wall thickness data logger

USM Go Issue 6 (02/2013) 2-3

Page 38

2 Standard package and accessories Preconfigured function packages

2.3 Preconfigured function packages

Product code Description Order number

Basic Ultrasonic flaw detector USM Go or USM Go+

DAC Basic with DAC/TCG, AWS, SWP

DGS Basic with DGS, AWS, SWP

Advanced Basic with DAC, DGS, AWS, SWP, PPRF

2-4 Issue 6 (02/2013) USM Go

Page 39

Recommended accessories 2 Standard package and accessories

2.4 Recommended accessories

Product code Description Order number

LI-138 Lithium-ion battery, 7.4 V, 3.9 Ah, rechargeable

LiBC-139 AC power adapter/charger, 100V … 260V AC

CA-040 Battery adapter for external charging of battery

TC-096 Transport case

CH-097 Shoulder strap

WH-098 Shoulder bag for instrument and couplant

WS-342 Safety hand strap

EK-492 Ergonomic set (CH-097, WH-098, WS-342)

CBL-604 Probe cable: Lemo 00-90° - Microdot

CBL-819 Probe cable: Lemo 00-90° - Lemo 00

USM Go Issue 6 (02/2013) 2-5

Page 40

2 Standard package and accessories Recommended accessories

Product code Description Order number

CBL-820 Probe cable: Lemo 00-90° - Lemo 01

CBL-821 Probe cable: Lemo 00-90° - KBA 533

CBL-822 Probe cable: Lemo 00-90° - BNC

EN-499 Certificate EN 12668-1

2-6 Issue 6 (02/2013) USM Go

Page 41

Initial start-up 3

USM Go Issue 6 (02/2013) 3-1

Page 42

3 Initial start-up Instrument positioning

3.1 Instrument positioning

Fold out the prop-up stand on the rear side of the USM

Go and position the instrument on a flat base so that you

can easily read the display.

If the instrument has been brought from a cold room into

a warmer one, wait until it has adapted to the room tem

perature before you power it on (to avoid condensation).

If (in rare cases) condensation has developed inside the

instrument, the cover may mist up from the inside. In this

case, open the cover until the damp has dried up. You

should not power the instrument on until this has hap

pened.

-

3.2 Power supply

The USM Go can be operated either with an external

charger/power adapter or with the corresponding lithi

um-ion battery.

You can also connect the USM Go to the mains power

supply if the battery is in the instrument. A discharged

battery is charged in this case, during the instrument op

eration.

Operation with charger/power adapter

Connection to power supply

For the operation using a charger/power adapter, you

should only use the charger/power adapter included in

the standard package.

The charger/power adapter is automatically adjusted to

every AC voltage between 90

voltage).

V and 240 V (nominal

-

-

3-2 Issue 6 (02/2013) USM Go

Page 43

Power supply 3 Initial start-up

ATTENTION

1

2

Connecting the instrument

Connect the USM Go to the mains socket-outlet by

means of the corresponding charger/power adapter.

The socket-contact for connecting the charger/power

adapter is located on the side of the USM Go.

– Align the Lemo plug of the charger/power adapter

with the red mark on the socket (1).

– Push the plug into the socket until it locks into place

with a clearly audible click.

– When removing the Lemo plug, pull the metal sleeve

on the plug back first in order to open the lock.

In order to power the instrument off correctly,

press the power On/Off key (2) on the side of

the instrument. If the power supply is inter

-

rupted (removing the battery, disconnecting

the power plug), the operation does not end

correctly.

USM Go Issue 6 (02/2013) 3-3

Page 44

3 Initial start-up Power supply

21

Operation using batteries

You should only use the corresponding lithium-ion battery for the battery operation.

Inserting batteries

The battery compartment is located on the rear of the instrument. The cover is fastened with two attachment

screws.

– Turn the two attachment screws (1) of the battery

compartment counterclockwise by one quarter of a

turn each in order to loosen them.

– Lift the cover off upward. In the open battery compart-

ment, you will see several connector pins (2) on one

side.

3-4 Issue 6 (02/2013) USM Go

Page 45

Power supply 3 Initial start-up

1 2

– Place the battery in the battery compartment so that

the marking faces upwards and the contacts are

pushed against the connector pins (1).

– Insert the cover of the battery compartment with the

side opposite to the screws at first, and push the

lugs

(3) into the housing recesses.

– Press the cover firmly down on the side of the screws

and turn the two screws

(2) clockwise by one quarter

of a turn each in order to lock the cover.

3

USM Go Issue 6 (02/2013) 3-5

Page 46

3 Initial start-up Power supply

1 2

Checking the charge level of the lithium-ion battery

The lithium-ion battery is provided with a battery charge

level indicator. Five light-emitting diodes

(1) indicate the

level of battery charge. Check the battery charge level

before inserting it into the instrument.

The number of diodes that are lit up has the following

meaning:

● 5 LEDs: Battery charge level 100 … 80 %

● 4 LEDs: Battery charge level 80 … 60 %

● 3 LEDs: Battery charge level 60 … 40 %

● 2 LEDs: Battery charge level 40 … 20 %

● 1 LED: Battery charge level 20 … 10 %

● 1 LED is flashing: Battery charge level <10 %

– Press the key (2) next to the LEDs. The LEDs indi-

cate the battery charge level.

3-6 Issue 6 (02/2013) USM Go

Page 47

Power supply 3 Initial start-up

Note

Power level indicator

The USM Go is equipped with a power level indicator

that allows to estimate the remaining operating time of

the instrument. A battery icon with the corresponding

charge level is displayed in the top right corner on top of

the A-scan. The charge level is indicated in percent by

means of the battery icon.

Icon Meaning

Battery charge level,

remaining operating time

in hours (approximate value)

Charger/power adapter is connected,

percentage of battery charge level

(approximate value)

Warning: Low battery charge level,

remaining operating time

in minutes (approximate value)

The USM Go is automatically powered off if the operation is no longer ensured. All settings are retained during

battery exchange and are immediately available again

afterwards.

If the battery charge level is low, it is absolutely necessary that you finish your test job,

power off the instrument, and replace the

battery. You should carry a second battery

along with you if you cannot use mains pow

er supply to operate the instrument.

-

USM Go Issue 6 (02/2013) 3-7

Page 48

3 Initial start-up Power supply

Charging the batteries

You can charge the lithium-ion batteries either directly

within the instrument or in an external charger.

Internal charging

If a lithium-ion battery is inserted, charging starts automatically as soon as you connect the charger/power

adapter to the USM Go and to the mains power supply.

You can carry out ultrasonic tests and charge the batter

ies at the same time.

The charging time is approx. ten hours with simultaneous ultrasonic testing. If the instrument is not used for ultrasonic testing, the charging time is approx. eight

hours. This charging time applies to ambient tempera

tures of 25 … 30 °C.

-

Charging status

The LED on the charger/power adapter indicates the

status of charging.

off: Charger/power adapter is not con-

nected to the power supply

yellow steady light: Charger/power adapter is not con-

nected to the instrument or no batteries are inserted into the instru-

-

ment

flashing green light: Charging

green steady light: Charging is completed,

batteries are charged

External charging

You can charge lithium-ion batteries with an external

charger of the USM Go. Do not use any other chargers

for charging the lithium-ion batteries for the USM Go.

3-8 Issue 6 (02/2013) USM Go

Page 49

Connecting a probe 3 Initial start-up

ATTENTION

3.3 Connecting a probe

To prepare the USM Go for operation, you have to connect a probe to it. Any GEIT probe can be used for the

USM

Go, provided the appropriate cable is available

and the operating frequency is within an adequate

range.

If a probe is connected incorrectly, the consequence would be a mismatching which

may lead to considerable power losses or

even to echo waveform distortions.

The probe is connected to the sockets on the side of the

instrument casing.

Both connector sockets are equally suitable (connected

in parallel) for connecting probes equipped with only

one ultrasonic element (ultrasonic transducer) so that it

does not matter which one of the two sockets is used.

When connecting a dual-element (TR) probe (having

one transmitter or pulser element and one receiver ele

ment) or two probes (of which one is transmitting and

the other one receiving), attention should be paid to the

correct allocation of connecting cables (please see sym

bols on the instrument):

Icon Meaning

Pulser connection

Receiver connection

-

-

USM Go Issue 6 (02/2013) 3-9

Page 50

3 Initial start-up Inserting the SD memory card

2

3.4 Inserting the SD memory card

You can use any SD memory card in the USM Go. To

insert and to remove the memory card, you have to

open the watertight cover at the top of the instrument.

– Push the lock of the hinged cover (1) in the direction

of the arrow in order to open the cover.

– Insert the SD memory card into the card slot so that

the contacts (2) of the card face the instrument front

side.

– Press the card down into the card slot until it locks

into place.

– Close the cover and make sure that it is locked tightly.

If necessary, push the lock up to the limit stop in the

opposite direction of the arrow in order to close the

cover watertight again.

– To remove the SD card, open the cover and shortly

press down the card to unlock it.

1

3-10 Issue 6 (02/2013) USM Go

Page 51

Starting the USM Go 3 Initial start-up

1

3.5 Starting the USM Go

Powering On

To start the USM Go, shortly press the Power key (1) on

the side of the instrument casing.

The software is initialized. During this, the display will remain blank for about 3 seconds. If the license for the

DMS Go is also installed, the display will show the page

for selecting the required instrument. Select the re

quired instrument by means of the joystick (USM Go) or

the arrow keys of the keypad (USM

After that, the start display showing the name of the instrument and information on the software, serial number, and the installed options will appear.

The instrument carries out a self-check and then switches over to stand-by mode.

The settings of all function values and the default settings (language and units) are the same as before powering the instrument off.

Go+).

-

USM Go Issue 6 (02/2013) 3-11

Page 52

3 Initial start-up Starting the USM Go

Powering Off

To power the USM Go off, shortly press the Power

key

(1) on the side of the instrument casing.

The settings of all function values and the default settings (language and units) are retained after powering

off.

Factory default setting (Reset)

If you can no longer use the functions of your instrument

or if the instrument no longer reacts as expected, you

can reset it to the factory default settings. Any data

saved to the SD card will be retained, all other individual

settings, e.g. language and units, will be reset to the fac

tory default settings.

– Power the instrument off.

– Press the further end of the Gain key (1), the further

end of the Function key

multaneously, and hold all three keys pressed until

the start display or the page of the instrument selec

tion appears.

(2), and the Power key (3) si-

The instrument starts with the factory default settings

(for language selection,

page 4-13).

see Section Language setting,

1

-

-

2

3

3-12 Issue 6 (02/2013) USM Go

Page 53

Principles of operation 4

USM Go Issue 6 (02/2013) 4-1

Page 54

4 Principles of operation Overview of operator's controls

1

3

4

1

2

2

3

4

5

6 7

5

USM Go USM Go+

4.1 Overview of operator's controls

1 Increasing the gain level in increments

2 Decreasing the gain level in increments

3 Operating levels and function groups navigation

4 Function key 1, individually assignable

4-2 Issue 6 (02/2013) USM Go

5 Function key 2, individually assignable

6 Display for representation of A-scan and functions

7 Power key for powering on and off

Page 55

Display screen 4 Principles of operation

4.2 Display screen

A-scan representation

The USM Go has a high-resolution display screen for

the display of the A-scan.

A-scan display in the normal mode

A-scan display in the zoom mode

The gain and the adjusted dB step value are shown in

the top left corner of the display screen. The access to

all other instrument functions is disabled in the zoom

mode of the A-scan display.

Toggling the A-scan display mode

To toggle between the normal and the zoomed A-scan

display mode, shortly press the joystick (USM

the center key of the keypad (USM

Go+) once.

Go) or

USM Go Issue 6 (02/2013) 4-3

Page 56

4 Principles of operation Display screen

Functions on the display screen

Function groups

The names of the seven function groups are shown at

the bottom of the display screen. The currently selected

function group is highlighted.

First operating level (A-scan):

Second operating level (settings):

Functions

On the first operating level, the functions of the currently

selected function group are shown on the left of the dis

play screen, next to the A-scan.

The functions are hidden in the zoomed A-scan display

mode; no operation is possible in this case.

-

4-4 Issue 6 (02/2013) USM Go

Page 57

Display screen 4 Principles of operation

Note

Gain

The current gain value and the adjusted dB step value

are always displayed in the top left corner of the screen.

Measurement line

The measurement line on top of the A-scan shows seven different measurement readings. One reading can be

displayed in enlarged mode in a box on the far right. The

readings for the individual boxes are user selectable

(

see Section Configuring the measurement line,

page 5-59).

One or four measurement readings can be displayed in

enlarged mode. The number of the other boxes of the

measurement line is then reduced (

larged display of reading, page 5-62).

see Section En-

In addition to the measurement reading, the measuring

point (peak or flank) is displayed with a symbol in sound

path measurements:

^ = measuring point Peak

/ = measuring point Flank

Examples:

SA^ = sound path within gate A, at the measuring point

Peak

SA/ = sound path within gate A, at the measuring point

Flank

The measuring point for amplitude is marked

for the corresponding gate bar at the top

edge of the display by a triangle pointing up

wards in the color of the gate, the measuring

point for distance is marked by a triangle

pointing downwards.

-

USM Go Issue 6 (02/2013) 4-5

Page 58

4 Principles of operation Display screen

Status display icons

To the left of the A-scan, below the measurement line,

there is an area for various status displays. The status

display icons inform about active functions and certain

settings (

the beginning of the present operating manual).

see Section Status display icons, page 0-7 at

Alarms

You can display an alarm signal in the form of a virtual

LED in the far right box on top of the A-scan (

tion LARGE (alarm signal), page 5-64).

When an alarm is triggered, the color of the alarm signal

changes from green to red.

see Sec-

4-6 Issue 6 (02/2013) USM Go

Page 59

Navigation and function keys 4 Principles of operation

Note

4.3 Navigation and function keys

Navigation

A joystick is used in the USM Go for navigation, for

changing settings, and for selecting adjustment values.

These functions are carried out by means of five keys in

the keypad of the USM

pad correspond to the movement of the joystick in the

corresponding direction, and pressing the center key

corresponds to pressing the joystick.

The navigation is used

● for toggling between the operating levels,

● for selecting function groups,

● for selecting and setting functions,

● for selecting the zoom mode of A-scan display

Go+. The arrow keys in the key-

Function keys

Two key groups consisting of two function keys each are

arranged next to the display screen.

The two upper function keys are used for changing the

gain and turning the function AUTO

Key combinations, page 4-8).

The two lower function keys are used

● for changing values or settings,

● for selecting options,

● for triggering user-assigned functions (see Chapter

5.3 Assignment of function keys, page 5-8).

You can change many values either by

means of the navigation (small increments)

or by means of the lower function keys (large

increments).

80 on (see Section

USM Go Issue 6 (02/2013) 4-7

Page 60

4 Principles of operation Navigation and function keys

Key combinations

You can carry out some functions by means of key combinations. To achieve this, you have to press several

keys at the same time (

ator's controls, page 4-2).

Function Keys

HOME

Function key 1 + function key 2

see Section Overview of oper-

AUTO 80

UPDATE

RESET

Increase gain + decrease gain

Decrease gain + function key 2 + Power key

Increase gain + function key 2 + Power key

Power key

The key for powering the instrument on and off is located on the instrument side, next to the probe connectors.

4-8 Issue 6 (02/2013) USM Go

Page 61

Operational concept 4 Principles of operation

4.4 Operational concept

Operating levels

The USM Go is an easy-to-use instrument. It has two

operating levels between which you can toggle by

pressing the joystick (USM

(USM

Go+).

The first operating level shows the A-scan and is used

during normal operation.

It contains seven function groups for the settings during

normal operation.

The second operating level contains all functions for the

instrument configuration. This is where you will also find

functions for saving and printing, for data management

using the data logger, and for special applications, e.g.

software updates.

Go) or the center key

Selecting and setting functions

Shown below the A-scan are the seven function groups

which you can directly select using the navigation. The

name of the currently selected function group is high

lighted and the corresponding four functions are displayed on the left, next to the A-scan.

You can likewise directly select the individual functions

using the navigation.

If a function is selected, the name of the function group

is marked red. You can then change the value using the

navigation or the function keys.

-

USM Go Issue 6 (02/2013) 4-9

Page 62

4 Principles of operation Operational concept

Note

Coarse and fine adjustment of functions

You can choose between coarse and fine adjustment

for some functions.

The fine adjustment is made using the navigation. The

fastness of change is influenced by the movement of the

joystick during this (e.g. for the function VELOCITY).

You can lock the joystick in the USM Go. Any

changes to the adjustments using the joy

-

stick are then no longer possible (see Section Locking the joystick, page 5-76).

Use the lower function keys to make the coarse adjustment. The value will then change either in large increments (e.g. for the function RANGE) or you can choose

from a series of factory-saved values (e.g. for the func

-

tion VELOCITY)

During the fine adjustment, the name of the function is

displayed in lower-case letters (range), whereas it is

displayed in capital letters during the coarse adjustment

(RANGE).

As long as a function is selected, you can only change

the corresponding value but you cannot toggle between

the function groups. To toggle between the function

groups, you have to first select a function group again

using the navigation (the name is highlighted).

4-10 Issue 6 (02/2013) USM Go

Page 63

Operational concept 4 Principles of operation

Note

Function HOME

You can or must select the function HOME in various

cases (e.g. to confirm certain settings). To do this, press

the function keys at the same time (

view of operator's controls, page 4-2).

You can assign the function HOME to one of

the function keys (

of function keys, page 5-8).

Choosing the start value

You can use the function HOME for some functions to

quickly choose the start value of the adjustment range.

To do this, press the two lower function keys at the

same time after selecting the function. In this way, you

can e.g. set the value of the function DISPLAY DELAY

to 0.000 µs.

see Section Over-

see Section Assignment

This quick adjustment option is available for the following functions:

Function Function group

PROBE DELAY RANGE

DISPLAY DELAY RANGE

REJECT RECEIVER

USM Go Issue 6 (02/2013) 4-11

Page 64

4 Principles of operation Operational concept

Note

Activating functions

You have usually two options for choosing functions, for

triggering actions, or for changing settings on the sec

ond operating level:

● using the function keys directly after selecting a function,

● using the function keys or the navigation after activating a function.

The direct change of settings or functions is

disabled for some functions and, in any case,

you must activate the function first before

you can change any settings. This is the

case e.g. for the function DIRECTORY for

selecting a directory on the SD memory card.

-

Example

– Switch over to the second operating level.

– In the function group EVAL, select the function MAG-

NIFY GATE.

Option 1:

– Press the function keys to directly choose the gate for

the magnify gate function.

Option 2:

– Press the joystick (USM Go) or the center key of the

keypad (USM

Go+) briefly to activate the function

MAGNIFY GATE. The currently selected setting is

highlighted.

– After that, change the setting using either the naviga-

tion or the function keys.

– After changing the setting, press the joystick

(USM

Go) or the center key of the keypad

(USM

Go+) briefly again to deactivate the function.

You can then use the navigation again to switch over

to another function.

4-12 Issue 6 (02/2013) USM Go

Page 65

Important default settings 4 Principles of operation

4.5 Important default settings

Language setting

Use the function LANGUAGE (function group

CONFIG1 on the second operating level) to choose the

language for the displayed texts.

The following languages are available:

● Bulgarian ● Chinese ● German

● English ● Finnish ● French

● Italian ● Japanese ● Dutch

● Norwegian ● Polish ● Portuguese

● Romanian ● Russian ● Swedish

● Spanish ● Czech ● Hungarian

– Switch over to the second operating level.

– In the function group CONFIG1, select the function

LANGUAGE.

– Press the function keys to choose the required lan-

guage. The language changes immediately.

USM Go Issue 6 (02/2013) 4-13

Page 66

4 Principles of operation Important default settings

Units setting

You can use the function UNITS (function group

CONFIG1 on the second operating level) to select the

required units (mm, in, or µs). You can change the units

any time. All values are adjusted accordingly.

– Switch over to the second operating level.

– In the function group CONFIG1, select the function

UNITS.

Press the function keys to choose the required units.

Decimal separator

You can choose the decimal separator mark. All data

are displayed and saved using the selected decimal

separator.

– Switch over to the second operating level.

– In the function group CONFIG1, select the function

DECIMAL.

Press the function keys to choose the required setting.

4-14 Issue 6 (02/2013) USM Go

Page 67

Important default settings 4 Principles of operation

ATTENTION

Date format, Date, and Time

The date is saved together with the inspection results.

You can set the date format, the date, and the time us

ing the corresponding functions of the function group

CONFIG1 on the second operating level.

In view of a correct documentation, always

make sure that you are using the correct date

and the correct time. Remember to turn the

clock during the change from winter time to

summer time.

– Switch over to the second operating level.

– In the function group CONFIG1, select the function

DATE FORMAT.

– Press the function keys to change the date format.

The time format is changed together with the date for

mat.

– Select the function DATE.

– Press the joystick (USM Go) or the center key of the

keypad (USM

Go+) to change the setting. The first

value (day, month, or year) is highlighted.

– Use the navigation to change the highlighted value

and switch over to the next value.

– Change the other values in the same way.

-

– Finally, press the joystick (USM Go) or the center key

of the keypad (USM

Go+) to close the setting. The

new values apply immediately.

– Select the function TIME.

– Change the time in the same way as you did previ-

ously for the date.

– Finally, press the joystick (USM Go) or the center key

of the keypad (USM

Go+) to close the setting. The

new values apply immediately.

-

USM Go Issue 6 (02/2013) 4-15

Page 68

4 Principles of operation Default settings of the display

Selecting the instrument orientation

You can configure the instrument for right-handed or

left-handed operation (referred to the probe). The

screen display is then rotated through 180°, the func

tions of navigation and function keys are adjusted accordingly.

– Switch over to the second operating level.

– In the function group CONFIG1, select the function

ORIENTATION.

4.6 Default settings of the display

The USM Go is equipped with a high-resolution color

display. You can optimize the display according to your

own viewing habits and to the operating environment.

Selecting the color scheme

-

– Press the function keys to choose the required orien-

tation.

4-16 Issue 6 (02/2013) USM Go

Page 69

Default settings of the display 4 Principles of operation

Note

You can choose one of four color schemes using the

function COLOR (function group CONFIG1 on the sec

ond operating level). The color scheme determines the

color of all displays and of the background. You can set

the color of the A-scan separately (please see the sec

tion below).

All color schemes are suitable for indoor use.

For outdoor use, we recommend Scheme 3

and Scheme 4.

– Switch over to the second operating level.

– In the function group CONFIG1, select the function

COLOR.

– Press the function keys to select the required color

scheme.

Selecting the A-scan color

-

-

You can choose the color of the A-scan using the function

A-SCAN COLOR (function group CONFIG1 on the sec

ond operating level). The color options depend on the selected color scheme (see Section Selecting the color

scheme, page 4-16).

– Switch over to the second operating level.

– In the function group CONFIG1, select the function

A-SCAN COLOR.

-

– Press the function keys to choose the required color

for the A-scan.

USM Go Issue 6 (02/2013) 4-17

Page 70

4 Principles of operation Default settings of the display

Note

Selecting the grid

Using the function GRID (function group CONFIG1 on

the second operating level), you can choose a grid for

the A-scan. Two grids, each with and without a ruler at

the bottom edge of the display, are available as options.

– Switch over to the second operating level.

– In the function group CONFIG1, select the function

GRID.

– Press the function keys to choose the required grid

for the A-scan.

Setting the brightness

To set the brightness of the display, use the function

BRIGHTNESS (function group CONFIG1 on the second

operating level). You can choose a value from 1 to 10.

A high brightness value increases the power

consumption, due to which the operating

time is reduced in battery operation.

4-18 Issue 6 (02/2013) USM Go

Page 71

Saving the settings 4 Principles of operation

Note

– Switch over to the second operating level.

– In the function group CONFIG1, select the function

BRIGHTNESS.

– Press the function keys to select the required value.

You can extend the operating time by means

of the power saver function (

Power saving mode, page 5-79).

see Section

4.7 Saving the settings

You can save the current instrument settings to a file on

the SD memory card. The files for the USM

filename extension UGO.

Go have the

USM Go Issue 6 (02/2013) 4-19

Page 72

4 Principles of operation Saving the settings

ATTENTION

– Switch over to the function ACTION and press the

The filename can be up to 14 characters long

for saving data sets. However, only the first 7

characters are shown in the display on top of

the A-scan (

see Section Displaying dataset

name, page 4-22).

Please note this limitation when saving data

sets in order to avoid any confusions be

tween filenames starting with the same character.

function keys to select the function STORE DATA

SET.

– Switch over to the function FILENAME and briefly

press the joystick (USM

keypad (USM

Go+).

Go) or the center key of the

– Use the navigation to choose the option

<NEW

FILE> and briefly press the joystick (USM Go)

or the center key of the keypad (USM

Go+).

– Use the navigation to choose the first character of the

filename.

-

– Use the navigation to switch over to the next item,

and choose the next character.

– Switch over to the second operating level.

– Press the joystick (USM Go) or the center key of the

– In the function group FILES, select the function

DIRECTORY and briefly press the joystick (USM Go)

or the center key of the keypad (USM

Go+). The di-

keypad (USM

try.

Go+) briefly to close the filename en-

rectory of the SD memory card appears.

– Press the function keys to select a directory on the

SD card.

– Press the joystick (USM Go) or the center key of the

keypad (USM

Go+) briefly to choose the selected di-

rectory.

4-20 Issue 6 (02/2013) USM Go

Page 73

Saving the settings 4 Principles of operation

Note

Note

– Switch over to the function ENTER and briefly press

the joystick (USM

(USM

Go+).

Go) or the center key of the keypad

The current instrument settings are saved to the selected directory on the SD memory card under the name entered here.

You can create and delete directories by inserting the SD memory card into the SD card

reader of your PC or by connecting the

USM

Go to a PC via a USB cable (see Sec-

tion USB interface, page 8-3).

Recalling settings

You can recall and use instrument settings saved to the

SD memory card.

You can only recall datasets having the filename extension UGO. Other files on the SD

memory card are not displayed as options.

– Switch over to the second operating level.

– In the function group FILES, select the function

DIRECTORY and briefly press the joystick (USM Go)

or the center key of the keypad (USM

rectory of the SD memory card appears.

– Press the function keys to select a directory on the

SD card.

– Press the joystick (USM Go) or the center key of the

keypad (USM

Go+) briefly to choose the selected di-

rectory.

Go+). The di-

USM Go Issue 6 (02/2013) 4-21

Page 74

4 Principles of operation Saving the settings

Note

– Switch over to the function ACTION and press the

function keys to select the function RECALL DATA

SET.

– Switch over to the function FILENAME and briefly

press the joystick (USM

keypad (USM

Go+).

Go) or the center key of the

– Use the navigation to select the name of the required

dataset.

– Press the joystick (USM Go) or the center key of the

keypad (USM