Waygate Technologies MIC 10 Operating Manual

GE |

|

Inspection Technologies |

Ultrasonics |

Krautkramer MIC 10

Operating Manual 084-028-547

g |

GEInspectionTechnologies.com |

©2005 General Electric Company. All rights reserved. We reserve the right to technical modifications without prior notice

Contents

1 Introduction . . . . . . . . . . . . . . . . . . 1- 1

1.1 Krautkrämer MIC 10 . . . . . . . . . . . . . . 1- 2

1.2 Information on these instructions. . . 1- 3

1.3 The layout and presentation of

these instructions . . . . . . . . . . . . . . . 1- 5

1.4 Conditions for hardness testing . . . 1- 6

Training of the operator . . . . . . . . . . . . 1- 6 Test requirements . . . . . . . . . . . . . . . . . 1- 7 Selection of a suitable test setup . . . . . 1- 7

1.5 Important notes on MIC 10. . . . . . . . . 1- 7

New display . . . . . . . . . . . . . . . . . . . . . . 1- 7 Test material . . . . . . . . . . . . . . . . . . . . . 1- 8 UCI method . . . . . . . . . . . . . . . . . . . . . . 1- 8

Conversion of hardness values . . . . . . 1- 9 Protection against moisture . . . . . . . . . 1- 9

2 Scope of delivery and accessories 2- 1

2.1 Scope of delivery . . . . . . . . . . . . . . . . 2- 3

2.2 Required accessories . . . . . . . . . . . . . 2- 4

2.3 Recommended accessories. . . . . . . . 2- 7

3 Preparations for operation . . . . . . 3- 1

3.1 Battery supply . . . . . . . . . . . . . . . . . . 3- 2

The use of batteries or accumulators . 3- 2

Krautkrämer MIC 10 |

Issue 08, 08/01 |

0-1 |

Contents

3.2 Connection of hand-held probes . . . 3- 3

4 Basics of operation . . . . . . . . . . . . . 4- 1

4.1 Display. . . . . . . . . . . . . . . . . . . . . . . . . 4- 2

4.2 Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . 4- 4

4.3 Operation concept . . . . . . . . . . . . . . . 4- 5

The MEASUREMENT level . . . . . . . . . 4- 5 Changing between levels . . . . . . . . . . . 4- 5 SET level . . . . . . . . . . . . . . . . . . . . . . . 4- 5 Changing the settings. . . . . . . . . . . . . . 4- 7 Resetting set functions . . . . . . . . . . . . . 4- 7 Function blocking . . . . . . . . . . . . . . . . . 4- 7

4.4 Handling the probe . . . . . . . . . . . . . . 4- 8

5 Operation . . . . . . . . . . . . . . . . . . . . . 5- 1

5.1 Hardness measurement. . . . . . . . . . . 5- 2

Turning on the instrument and

viewing the software version number. . 5- 2 Turning the instrument off . . . . . . . . . . 5- 3 Automatic instrument switch-off . . . . . . 5- 3 Setting the display backlight. . . . . . . . . 5- 4 Selecting the measurement reading

display. . . . . . . . . . . . . . . . . . . . . . . . . . 5- 4 Selecting the hardness scale . . . . . . . 5- 5 Setting the alarm threshold . . . . . . . . . 5- 6 Carrying out the measurement. . . . . . . 5- 9 Deleting the last measurement reading 5-10 Viewing the last average value . . . . . . 5-10 Viewing measurement set and

deleting any measurement value . . . . . 5-11 Measuring other material . . . . . . . . . . . 5-15 Measuring with defined measurement

times (dwell time) . . . . . . . . . . . . . . . . . 5-18

0-2 |

Issue 08, 08/01 |

Krautkrämer MIC 10 |

Contents

Contents

5.2 Data storage (only MIC 10 DL). . . . . . 5-20

Switching the Data Logger on. . . . . . . . 5-21 Storing the measurement in the Data Logger or on the Memory Card . . . . . . 5-22 Viewing a file and deleting single measurement readings . . . . . . . . . . . . . 5-23 Deleting a file . . . . . . . . . . . . . . . . . . . . 5-29 Deleting the whole memory . . . . . . . . . 5-30 Changing the number of the

Memory Card. . . . . . . . . . . . . . . . . . . . . 5-30 Using the Memory Card as a Parameter Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31 Parallel use of Memory Cards on the

MIC 10 and the DynaMIC . . . . . . . . . . . 5-33

6 Configuration . . . . . . . . . . . . . . . . . 6- 1

Basic procedure . . . . . . . . . . . . . . . . . . 6- 2 Selecting the language for the report printout (only for MIC 10 DL) . . . . . . . . 6- 3 Selecting the report format (only for

MIC 10 DL) . . . . . . . . . . . . . . . . . . . . . . 6- 4 Inhibiting hardness scales. . . . . . . . . . . 6- 4

DIN 50150 or ASTM E 140. . . . . . . . . . 6- 5 Inhibiting calibration. . . . . . . . . . . . . . . . 6- 5 Inhibiting the dwell time. . . . . . . . . . . . . 6- 6 Inhibiting alarm thresholds . . . . . . . . . . 6- 6 Adjusting the time period for the

display backlight . . . . . . . . . . . . . . . . . . 6- 7 Switching off the Data Logger

(only MIC 10 DL). . . . . . . . . . . . . . . . . . 6- 8 Switching the Memory Card off

(only MIC 10 DL). . . . . . . . . . . . . . . . . . 6- 8

7 Documentation (only MIC 10 DL) . 7- 1

7.1 Printing data . . . . . . . . . . . . . . . . . . . . 7- 2

Preparing the printer . . . . . . . . . . . . . . . 7- 2 Printing all files . . . . . . . . . . . . . . . . . . . 7- 3 Printing single files . . . . . . . . . . . . . . . . 7- 3 Selection of the report language. . . . . . 7- 4 Selection of report format . . . . . . . . . . . 7- 5 Complete printout of a measurement

set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7- 6 Short printout of a measurement set . . 7- 7

Krautkrämer MIC 10 |

Issue 08, 08/01 |

0-3 |

Contents

Contents

Printout of all measurement sets

as a list . . . . . . . . . . . . . . . . . . . . . . . . . 7- 8 Printout in DIN A4 format . . . . . . . . . . . 7- 8

7.2 Data transfer with the user program UltraDOC . . . . . . . . . . . . . . . . . . . . . . . 7- 9

8 Care and maintenance . . . . . . . . . . 8- 1

8.1 Care . . . . . . . . . . . . . . . . . . . . . . . . . . . 8- 2

Care of instrument . . . . . . . . . . . . . . . . 8- 2 Care of batteries . . . . . . . . . . . . . . . . . 8- 2 Battery charging . . . . . . . . . . . . . . . . . . 8- 2 Treatment of AlMn batteries. . . . . . . . . 8- 3

8.2 Maintenance . . . . . . . . . . . . . . . . . . . . 8- 4

9 Function check and

troubleshooting . . . . . . . . . . . . . . . . 9- 1

9.1 Check function . . . . . . . . . . . . . . . . . . 9- 2

Visual check of the Vickers diamond . 9- 2 Checking the measurement accuracy 9- 2

9.2 Troubleshooting . . . . . . . . . . . . . . . . . 9- 3

10 Specifications . . . . . . . . . . . . . . . . 10- 1

11 Interface and peripherals

(only MIC 10 DL) . . . . . . . . . . . . . . 11- 1

11.1 Interface RS 232 . . . . . . . . . . . . . . . . 11- 2

Pin layout . . . . . . . . . . . . . . . . . . . . . . 11- 2 Data format. . . . . . . . . . . . . . . . . . . . . 11- 3

11.2 Data transfer with a printer . . . . . . . 11- 3

11.3 Data transfer with a PC . . . . . . . . . . 11- 4

Remote operation of the MIC 10 DL . 11- 4 Code list for remote operation . . . . . . 11- 6

0-4 |

Issue 08, 08/01 |

Krautkrämer MIC 10 |

Contents

|

|

|

|

Contents |

12 Appendix . . . . . . . . . . . . . . . . . . . . . |

12- 1 |

14 |

Index . . . . . . . . . . . . . . . . . . . . . |

. . . 14- 1 |

12.1 The UCI method . . . . . . . . . . . . . . . . |

12- 2 |

15 |

Assembly Instructions, |

|

|

|

|

Spare Parts List . . . . . . . . . . . . |

. . . 15- 1 |

12.2 Conversion of hardness values. . . . 12- 3

Special factors of MIC 10 . . . . . . . . . . 12- 3

12.3 Preparation of the test material. . . . 12- 4

Surface finish. . . . . . . . . . . . . . . . . . . . 12- 4

Measuring small test pieces . . . . . . . . 12- 4

12.4 Notes on statistical evaluation . . . . 12- 6

Calculating the statistical data . . . . . . 12- 7

12.5 EC declaration of conformity . . . . . 12- 8

12.6 Service addresses. . . . . . . . . . . . . . . 12- 9

13 Changes . . . . . . . . . . . . . . . . . . . . . 13- 1

Krautkrämer MIC 10 |

Issue 08, 08/01 |

0-5 |

Contents

0-6 |

Issue 08, 08/01 |

Krautkrämer MIC 10 |

Introduction 1

Krautkrämer MIC 10 |

Issue 08, 08/01 |

1-1 |

Introduction

1.1 Krautkrämer MIC 10

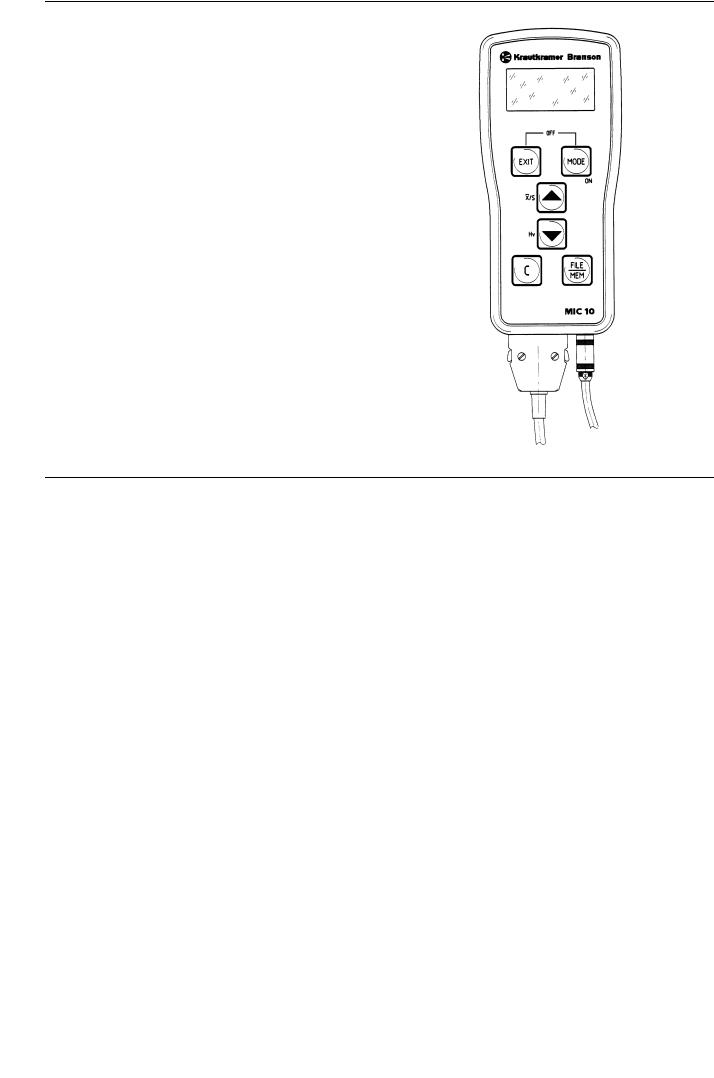

The hardness tester MIC 10 from Krautkrämer is handy, easy to operate and can carry out tests quickly without any difficulty.

It mainly is suitable

•for hardness measurement of low and non-alloyed steels,

•for hardness measurement of high-alloyed steels,

•for hardness measurement of nonferrous metals. The MIC 10 can be delivered in two versions:

•the basic version "B"

•the Data Logger version "DL"

As opposed to the B version, the DL version has additional functions for data storage:

You can store readings in the instrument in order to have them printed or, using special software, transfer them to a PC. With the auxiliary Memory Card you have access to almost unlimited storage possibilities and flexible data processing.

1-2 |

Issue 08, 08/01 |

Introduction

Krautkrämer MIC 10

Krautkrämer MIC 10

Krautkrämer MIC 10

Information on these instructions |

Introduction |

Compared to customary Vickers low-load hardness testers, the MICRODUR series from Krautkrämer does not evaluate with a microscope but uses the UCI method electronically. The measured hardness is instantly displayed digitally and high reproducibility of the test results is achieved. The indent in the surface of the material is microscopic.

We are constantly working on further instrument development. Therefore we hope that you appreciate our right to carry out technical changes.

Your nearest Krautkrämer Sales Center is ready to help you concerning service questions. In addition to this, you can contact our Customer Service or Service Center directly at our company. The addresses are shown on pages 12-8 - 12-9 under "Service addresses".

1.2Information on these instructions

In the following you will find information about how to use these instructions.

Please read these instructions carefully in order to operate the MIC 10 functions quickly and effectively.

In doing this you will be able to take full advantage of the function range of the instrument. At the same time, you will also avoid errors and wrong operation which in turn would cause incorrect test results and thus could lead to injury and damage.

Important information

Even if you have experience in hardness testing you must observe the information given in Chapters 1.4 and 1.5. Chapter 1.4 contains important limitations and conditions for hardness testing (training of the operator, knowledge of the special technical requirements and limitations, selection of the suitable test setup). In Chapter 1.5 you will find special information about hardness testing with the MIC 10. Please pay attention to this information in order to obtain precise measuring results.

Krautkrämer MIC 10 |

Issue 08, 08/01 |

1-3 |

Information on these instructions |

Introduction |

Introduction |

Information on these instructions |

Please always look up in Chapter 13 to see if there are any current changes. This chapter describes corrections which have been added at short notice and which are not yet included in the general manual. If there are no additional corrections, the chapter remains empty.

The operation of the MIC 10 is easy and quick to learn. In order to be able to use the instrument quickly you should become acquainted with preparation as well as the basic functions of the MIC 10. To do this, read the following chapters carefully:

Chapter 3 Preparations for operation

Here you will find all the steps necessary for application of the instrument.

Chapter 4 Basics of operation

This gives you an insight into MIC 10 operation as well as a few important steps which always reoccur during operation.

Chapter 5.1 Hardness measurement

All operation steps are shown which are required during the measurement procedure.

Chap. 5.2 Data storage (only for MIC 10 DL)

The MIC 10 base instrument does not have these function- s. You learn how to store data, to display, change and delete stored data. Using the special Memory Card you can reload stored instrument settings into the MIC 10.

Chapter 6 Configuration

This gives you information about additional possibilities concerning instrument adjustment.

Chapter 7 Documentation (only for the MIC 10 DL)

You can document the measurement readings via a printer or transfer them to a computer using special software and evaluate them there. Various possibilities are available for your printouts.

Chapter 10 Interfaces and peripherals

(only for MIC 10 DL)

In this chapter you learn about connecting the MIC 10 to a computer or printer. You can remote control the instrument via a computer.

Chapter 12 Appendix

The appendix supplies you with information about conversion of hardness values into other scales, the UCI method, the treatment of test materials as well as the statistical evaluation of the measurement results.

1-4 |

Issue 08, 08/01 |

Krautkrämer MIC 10 |

Introduction |

Information on these instructions |

The layout and presentation of these instructions |

Introduction |

1.3The layout and presentation of these instructions

In order to simplify the layout of these instructions, the operation steps, lists, notes etc. are always put in the same form. In this way, you will be able to quickly find individual information.

The individual functions are described in the operation steps so that you are immediately able to work with the function which you require.

Operation steps

The operation steps are shown in the following way:

–...

–...

–...

Listing

Listing is made as follows:

•...

•...

Note and attention symbols

You will find the following symbol when there are specialities to be observed concerning instrument operation:

0Note: ...

Information to reliable and error-free operation of the instrument is found under the following

symbol:

) Attention: ...

Krautkrämer MIC 10 |

Issue 08, 08/01 |

1-5 |

The layout and presentation of these instructions |

Introduction |

Introduction |

Conditions for hardness testing |

1.4 Conditions for hardness testing

You will find all the essential instructions for operation of the MIC 10. In addition to this there are a series of factors which affect the test results. Due to the fact that a description of these factors would extend beyond the scope of this manual, the three most important conditions are as follows:

•training of the operator

•knowledge of the special technical requirements and limits

•selection of the suitable test setup

Training of the operator

For reliable application of a hardness tester suitable training in the field of material testing is required.

Suitable training means, for example, suitable knowledge about:

•hardness testing on metallic materials.

•effects of material properties, especially the structure, on the hardness test and the selection of a suitable hardness testing setup connected with it.

•the problems of comparability of different hardnesses such Vickers, Rockwell and Brinell. Also refer to the information given in the Appendix.

•the effects of surface treatment on the hardness value.

•the effect of the test load, and the size of the indent connected with it, on the determined hardness value.

Please read also the instructions in chapter 1.5.

) Attention:

Insufficient knowledge of the above mentioned fields can cause wrong test results and could have unforseeable consequences.

1-6 |

Issue 08, 08/01 |

Krautkrämer MIC 10 |

Introduction |

Conditions for hardness testing |

Important notes on MIC 10 |

Introduction |

Test requirements

Every hardness test has certain requirements. The most important are:

•determination of the test scope

•selection of a suitable testing technique

•consideration of the material properties

•Determination of the evaluation limits

1.5 Important notes on MIC 10

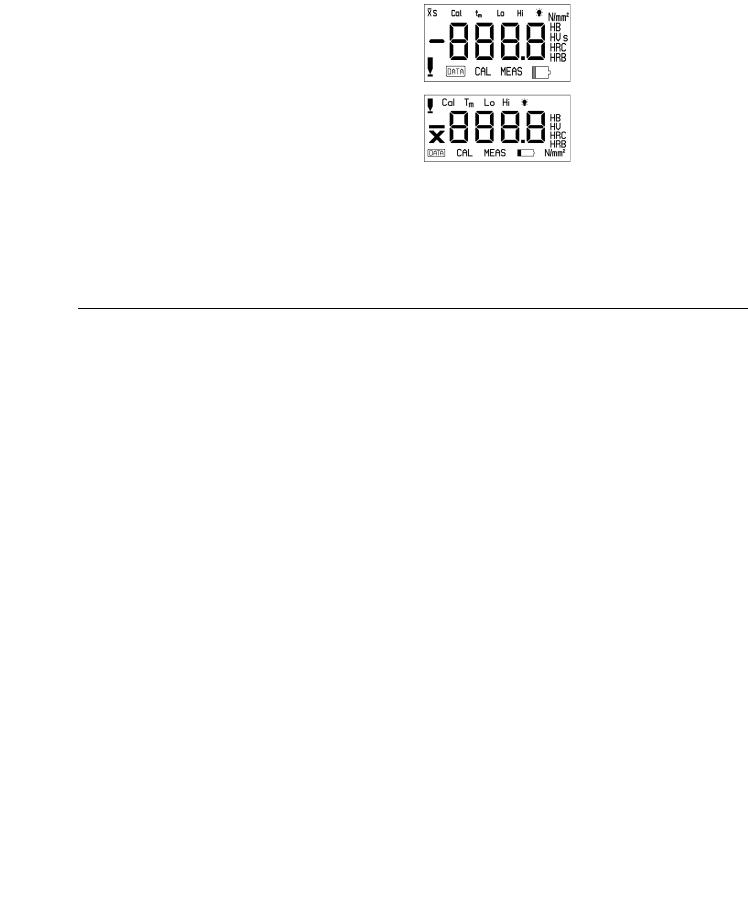

New display

The MIC 10 display has changed as from instrument serial number 1001. Please take into account when retrofitting new software to an instrument having a smaller serial number. This change does not affect the operation in any way.

Selection of a suitable test setup

It is the task of the person responsible for the test to inform the operator about the test requirements. In addition to this, a clear and complete interpretation of the corresponding test specifications is urgently required.

Information about the test method and test specifications are, amongst others, obtainable from different institutes, industrial companies and authorities.

Old Display

New Display

The average is now indicated with before the reading; the indication S for the single value is dropped (no indication=single value). The indication s (seconds) for the dwell time is likewise dropped. The indication for the probe contact and the hardness scale N/mm2 are located elsewhere on the display.

before the reading; the indication S for the single value is dropped (no indication=single value). The indication s (seconds) for the dwell time is likewise dropped. The indication for the probe contact and the hardness scale N/mm2 are located elsewhere on the display.

Krautkrämer MIC 10 |

Issue 08, 08/01 |

1-7 |

Important notes on MIC 10 |

Introduction |

Introduction |

Important notes on MIC 10 |

In the following you will find a summary of the most important technical test requirements that you always have to comply with to ensure correct measurements.

Test material

The test loads (probes) must match the surface quality of the material:

•smooth, homogeneous surfaces require low test loads

•rougher, coarse-grained surfaces require as high test loads as possible.

The surfaces must always be free of any impurities (oil, dust, etc.) and rust.

The surfaces roughness should not exceed approx. 30 % of the penetration depth.

Thin metal sheets must have a thickness corresponding to the tenfold indentation depth of the Vickers diamond.

For more details, please also read Chapter 12.3 and especially the tables on page 12-5.

UCI method

The UCi method is a comparative method (contribution of the Young’s modulus to the measurement) with a very high reproducibility of the measurements. The UCI method does not replace the classical testing according to Vickers, but it forms a quick and reliable complement to it.

The direct comparison with the results from the standardized Vickers measurement according to the material samples is therefore imperative for the evaluation of the measurement accuracy of the UCI method. This means:

) Attention:

It is absolutely necessary that you calibrate your MIC 10 to the material under test.

For this purpose, the calibration only has to be carried out once since you can easily store and recall or set a calibration.

The calibration for low-alloy or unalloyed steel is already preset in the instrument. Check it from time to time (refer to Chapter 9.1 Check function)

For more details on the UCI method, please also read Chapter 12.1.

1-8 |

Issue 08, 08/01 |

Krautkrämer MIC 10 |

Introduction |

Important notes on MIC 10 |

Important notes on MIC 10 |

Introduction |

Conversion of hardness values

The conversion of hardness values into other hardness scales is only possible with certain restrictions. You should only carry out conversions if

•the specified test method cannot be applied (e.g. because there is no suitable test instrument)

•it is not possible to take the required samples for the specified test method.

Please read also Chapter 12.2 for this.

) Attention:

Wrong calibration and unacceptable or illegal conversions can cause grave errors in the interpretation of measurement result.

Protection against moisture

) Attention:

Only use the MIC 10 DL (Data Logger version with board slot) in a dry environment and only clean it with a dry cloth.

Krautkrämer MIC 10 |

Issue 08, 08/01 |

1-9 |

Important notes on MIC 10 |

Introduction |

1-10 |

Issue 08, 08/01 |

Krautkrämer MIC 10 |

Scope of delivery and accessories 2

Krautkrämer MIC 10 |

Issue 07, 10/97 |

2-1 |

Scope of delivery and accessories

This chapter gives information about MIC 10 accessories (for versions B and DL).

It describes:

•accessories in the delivery package

•accessories required for operation

•recommended accessories for instrument and probes including hardness reference blocks

2-2 |

Issue 08, 08/01 |

Krautkrämer MIC 10 |

Scope of delivery and accessories

Scope of delivery |

Scope of delivery and accessories |

|

2.1 Scope of delivery |

|

|

Product name |

Description |

Order no. |

|

|

|

|

|

|

MIC 10 |

Portable Hardness Tester with digital display for |

|

|

hardness tests with Vickers diamond and measure- |

|

|

ment in HV, HB, HRB, HRC, N/mm2 |

34 101 |

|

or: |

|

MIC 10 DL |

as above; but with: |

|

|

interface for connection of a printer or computer |

|

|

as well as a Data Logger with card reader and |

|

|

Memory Card |

34 103 |

|

2 AlMn batteries (Mignon) |

06 563 |

|

Case |

14 823 |

|

Operating manual, English |

28 547 |

|

Brief operating instructions, English |

28 549 |

|

or: |

|

|

Operating manual, German |

28 546 |

|

Brief operating instructions,German |

28 548 |

|

|

|

Krautkrämer MIC 10 |

Issue 07, 10/97 |

2-3 |

Scope of delivery |

Scope of delivery and accessories |

Scope of delivery and accessories |

Required accessories |

|

Product name |

Description |

Order no. |

|

|

|

|

|

|

|

only for MIC 10 DL: |

|

MIC 1000 |

Memory Card (1 pc.) |

34 125 |

2.2 Required accessories

TZ 1-2 |

1 Set (2 pcs.) AlMn cells (Mignon), for single use only |

34 107 |

|

or: |

|

NiMH 1-2 |

1 Set (2 pcs.) of NiMH cells, rechargeable |

34 109 |

MIC 1050 |

Probe cable |

34 071 |

|

Only for MIC 10 DL: |

|

TGDL/PC |

Data cable |

13 647 |

|

Hand-held probes such as: |

|

MIC 201-A |

Hand-held probe |

34 104 |

|

consisting of: |

|

|

Probe 10 N (1 kgf) |

32 097 |

|

Special grip |

33 053 |

|

Probe attachment, cylindrical |

33 844 |

2-4 |

Issue 08, 08/01 |

Krautkrämer MIC 10 |

Scope of delivery and accessories |

Required accessories |

Required accessories |

Scope of delivery and accessories |

|

Product name |

Description |

Order no. |

|

|

|

|

|

|

MIC 1050 |

Probe connection cable |

34 071 |

|

Operating instructions (G/E) |

28 513 |

|

or: |

|

MIC 205-A |

Hand-held probe |

34 105 |

|

consisting of: |

|

|

Probe 50 N (5 kgf) |

31 991 |

|

with accessories (as MIC 201-A) |

|

|

or: |

|

MIC 2010-A |

Hand-held probe |

34 106 |

|

consisting of: |

|

|

Probe 98 N (10 kgf) |

33 766 |

|

Spherical headed grip |

33 854 |

|

Probe attachment, cylindrical |

33 846 |

MIC 1050 |

Probe connection cable |

34 071 |

|

Operating instructions (G/E) |

28 536 |

|

or: |

|

MIC 205-AL |

Hand-held probe with long oscillation rod |

34 282 |

|

consisting of: |

|

|

Probe 50 N |

34 155 |

|

Probe grip |

33 053 |

|

Screw cap, cylindrical |

34 184 |

|

|

|

Krautkrämer MIC 10 |

Issue 07, 10/97 |

2-5 |

Required accessories |

Scope of delivery and accessories |

Scope of delivery and accessories |

Required accessories |

|

Product name |

Description |

Order no. |

|

|

|

|

|

|

MIC 1050 |

Probe connection cable |

34 071 |

|

Operating instructions (G/E) |

28 591 |

|

or: |

|

MIC 201-AL |

Hand-held probe with long oscillation rod |

34 392 |

|

consisting of: |

|

|

Probe 10 N |

34 390 |

|

and accessories such as MIC 205-AL |

|

2-6 |

Issue 08, 08/01 |

Krautkrämer MIC 10 |

Scope of delivery and accessories |

Required accessories |

Recommended accessories |

Scope of delivery and accessories |

|

2.3 Recommended accessories |

|

|

Product name |

Description |

Order no. |

|

|

|

|

|

|

MIC 270 |

Surface attachment for hand-held probes |

32 084 |

MIC 271 |

Prism attachment for hand-held probes |

32 993 |

MIC 222 |

Test support for precise probe guiding |

33 652 |

MIC 2221 |

Magnetic foot for support stand of the MIC 222 |

33 909 |

MIC 2220 |

Support block for flat, thin parts |

33 651 |

MIC 300 |

Manual for hardness testing |

28 837 |

MIC 1040 |

Support and positioning device |

34 148 |

MIC 1090 |

Battery charger unit for NiMH and/or NiCd cells |

34 212 |

MIC 1060 |

Grinding set for surface finish |

34 380 |

|

only for MIC 10 DL: |

|

MIC 230 W |

Software for storage of the Data Logger, |

|

|

creation of a calibration table (Windows) |

33 930 |

|

including operating manual (German/English) |

28 535 |

Krautkrämer MIC 10 |

Issue 07, 10/97 |

2-7 |

Recommended accessories |

Scope of delivery and accessories |

Scope of delivery and accessories |

Recommended accessories |

|

Product name |

Description |

Order no. |

|

|

|

|

|

|

MIC 1000 |

Memory Card (1 pc.) |

34 125 |

MIC 1001 |

1 Set (5 pcs.) of Memory Cards |

34 126 |

|

Hardness reference blocks, such as: |

|

|

MIC 25C |

Hardness reference block 25 HRC |

33 905 |

|

MIC 45C |

Hardness reference block 45 HRC |

33 906 |

|

MIC 65C |

Hardness reference block 65 HRC |

33 907 |

|

MIC2V010 |

Hardness reference block 240 HV1 |

33 896 |

|

MIC5V010 |

Hardness reference block 540 HV1 |

33 897 |

|

MIC8V010 |

Hardness reference block 840 HV1 |

33 898 |

|

MIC2V050 |

Hardness reference block 240 HV5 |

33 899 |

|

MIC5V050 |

Hardness reference block 540 HV5 |

33 900 |

|

MIC8V050 |

Hardness reference block 840 |

HV5 |

33 901 |

MIC2V100 |

Hardness reference block 240 |

HV10 |

33 902 |

MIC5V100 |

Hardness reference block 540 |

HV10 |

33 903 |

MIC8V100 |

Hardness reference block 840 |

HV10 |

33 904 |

2-8 |

Issue 08, 08/01 |

Krautkrämer MIC 10 |

Scope of delivery and accessories |

Recommended accessories |

Preparations for operation |

3 |

Krautkrämer MIC 10 |

Issue 08, 08/01 |

3-1 |

Preparations for operation |

Battery supply |

In order to prepare the MIC 10 for operation you must carry out the following:

•check the battery supply

•connect the probe

3.1 Battery supply

The MIC 10 is driven by batteries or accumulators. For this you need two 1.5 V Mignon cells (DIN 40 766):

•dry cells (AlMn) or

•rechargeable (Nickel-Cadmium or Nickel-Metalhy- drid).

We recommend the use of Nickel-Metalhydrid batteries because the operation time is increased by 60%

The use of batteries or accumulators

You can insert batteries (AlMn) or accumulators (NiCd, NiMH).

–Loosen the screws on the battery compartment (e.g. with a coin).

–Open the battery compartment.

–Insert the batteries, observing the correct polarity (this is marked in the battery compartment).

–Screw the cover back onto the battery compartment.

battery compartment

3-2 |

Issue 08, 08/01 |

Krautkrämer MIC 10 |

Preparations for operation |

Battery supply |

Connection of hand-held probes |

Preparations for operation |

0Note:

If the instrument is not going to be used for a long period, remove the batteries from the compartment!

When the battery voltage is too low a symbol will appear on the MIC 10 display:

If this symbol appears, the batteries must be immediately changed. The MIC 10 automatically switches off if the batteries are too low in order to guarantee reliable measurement.

When measurements are made at remote locations a spare set of batteries should be present.

Further information with regard to batteries and accumulators can be found in Chapter 8.1.

0Note:

Used or defective batteries are special refuse and must be disposed of according to the governing laws!

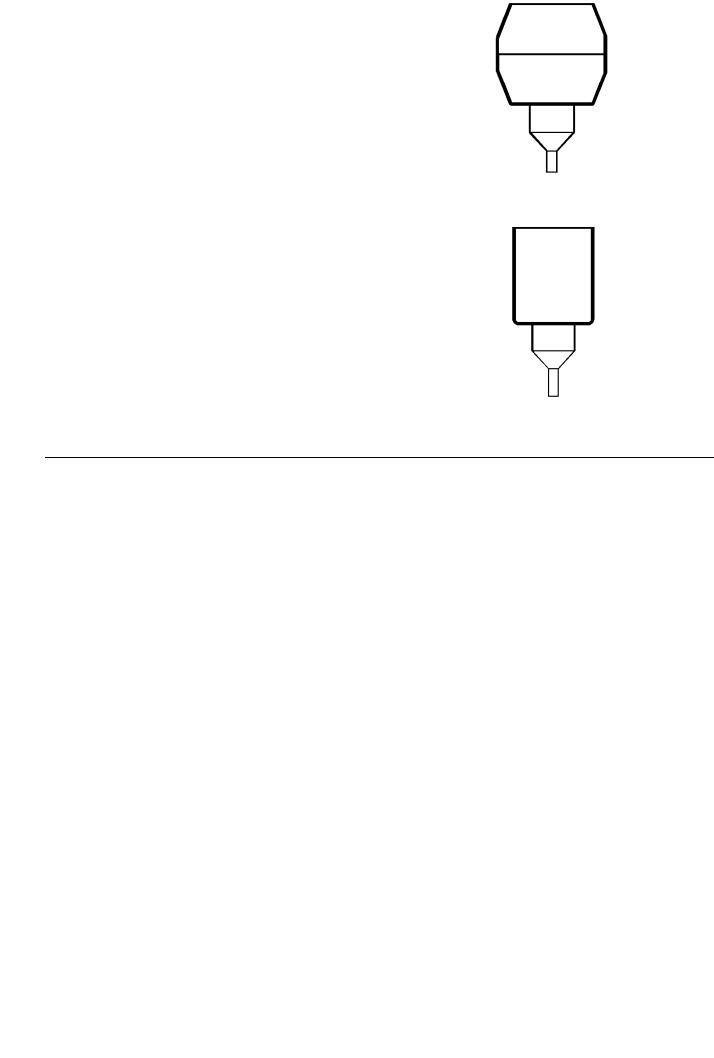

3.2 Connection of hand-held probes

In order to prepare the MIC 10 for operation, the probe must be connected. The probes available for the

MIC 10 are: MIC 201-A (1 kgf), MIC 205-A (5 kgf) and MIC 2010-A (10 kgf).

–Connect the probe to the probe cable. The red marking points at probe socket and cable connector must be on top of each other.

–Connect the probe cable to the MIC 10 socket.

–Place the probe grip onto the probe.

–Screw on the conical probe attachment for short measurements (refer to Chapter 2.2 Required accessories).

socket for probe connection

Krautkrämer MIC 10 |

Issue 08, 08/01 |

3-3 |

Connection of hand-held probes |

Preparations for operation |

Preparations for operation |

Connection of hand-held probes |

– Screw on the cylindrical probe attachment for meas- |

|

urements with defined measurement times (refer to |

|

Chapter 2.2 Required accessories). |

|

The MIC 10 is now ready for operation. |

|

0Note: |

|

If you wish to carry out measurements with defined |

|

measurement times, use a test support: |

|

• DH 191 test support for series measurements |

|

• MIC 222 test support for precise probe guiding |

|

By doing this you will avoid measurement inaccuracies. |

Conical probe attachment for short measurements |

There are also other accessories available which sim- |

|

plify measurement (refer to Chapter 2.3 Recom- |

|

mended accessories). |

|

Cylindrical probe attachment for measurements with defined time

3-4 Issue 08, 08/01 Krautkrämer MIC 10

Preparations for operation |

Connection of hand-held probes |

Basics of operation 4

Krautkrämer MIC 10 |

Issue 08, 08/01 |

4-1 |

Loading...

Loading...