Page 1

GE

Sensing & Inspection Technologies

Ultrasonic Transducers

For Flaw Detection and Sizing

gg

Page 2

www.gesensinginspection.com

imagination at work

TÜV

Rheinland

Product Safety

©2008 GE. All rights reserved.

GEIT-20117EN (04/08)

e

i

n

h

l

R

a

n

V

d

Ü

T

o

.

f

c

n

N

I

o

,

r

CUS

a

t

c

h

i

r

A

e

m

Page 3

1

Table of Contents

Transducer Selection Criteria and Performance 2

General Information—Contact Inspection and Immersion Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Transducer Selection Criteria—European Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Transducer Selection Criteria—North American Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Contact Transducers 5

Straight Beam Contact Transducers, Protective Face . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

European

North American

Straight Beam Contact Transducers, Wear Resistant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

European

North American

Straight Beam Contact Transducers, Delay Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

European

North American

Straight Beam Contact Transducers, Dual Element (TR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

European

North American

Angle Beam Transducers—Large Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

European

North American

Angle Beam Transducers—Small Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

European

North American

Angle Beam Transducers—Dual Element (TR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Immersion Transducers 31

European . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

North American . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Transducers for Specific Applications 35

Special Application Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Phased Array Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Transducer Accessories 37

Cables and Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Couplants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Calibration Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Transducer Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Transducer Certification 41

Tables and Formulas 43

Page 4

2

Transducer Selection Criteria and Performance

General Information

The ultrasonic transducers in this catalog are divided into two

general categories, Contact and Immersion.

Transducers for the Contact

Inspection Method

Straight Beam—Single Element

• Parts with regular geometry and

relatively smooth contact surface

• Flat or curved contact surface

• Flaw or backwall parallel to surface or

detectable with beam normal to surface

• Preferred for penetration of thick

sections

• Delay line types improve near surface

resolution

• Requires couplant layer, typically a gel, oil, or paste

• Typically used for manual inspection

Straight Beam—Dual Element (TR)

• Transmit and receive elements

separated by crosstalk barrier

• Flaw or backwall parallel to surface or

detectable with beam normal to surface

• Best for thin sections, near surface

resolution

• Requires couplant layer, typically a gel,

oil, or paste

• Typically used for manual inspection

Angle Beam

• Element mounted on integral or

replaceable wedge

• Uses refraction to transmit shear or

longitudinal wave at a

predetermined angle

• Most standard transducers generate

shear waves by mode conversion

• Preferred for parts with inclined

flaws, such as welds

• Available in both single and dual element types

• Requires couplant layer, typically a gel, oil, or paste

• Sometimes used in mechanized or automated testing

Transducers for the Immersion Method

Immersion Transducers

• Acoustically matched for best

efficiency in water

• Suitable for parts with irregular

geometries

• Commonly used in mechanized or

automated testing

• Best method for consistent coupling and reproducible results

• Large parts can be tested using probe holders, bubblers, or

water jets

• Transducers can be focused to improve

results

Focused Immersion Transducers

• Spherical focus forms a point or spot

• Cylindrical focus forms a line

Advantages of Focusing

Spherical (Spot,

Point) Focus

Cylindrical (Line)

Focus

Increase sensitivity to small flaws

Improve near surface resolution

Correct for contoured surfaces

Improve signal-to-noise ratio

Page 5

3

Transducer Selection Criteria—European Standards

For transducers manufactured to European standards, technical and performance information is provided throughout this catalog

based on the definitions below. A comprehensive data sheet is supplied with most flaw detection transducers at no charge.

Description Explanation

Element size D or a x b

Diameter D or length x width a x b of the transducer element. The size of the element strongly affects the shape of the

transmitted sound field. Slight deviations, (e.g., imperfect shape or positions with reduced radiation due to poor bonding)

cause considerable evaluation errors, even when calibrated to a reference flaw.

Nominal frequency f

The mean frequency of all probes of the same type. The frequency has a great influence on the evaluation of reflectors.

Even the shape of the sound field and the reflection behaviour of angled reflectors are strongly dependent on the

frequency. With increasing frequency, the echo height from non-vertically positioned reflectors to the sound beam

decreases. This is why each probe is checked by our Quality Control to see if its frequency coincides with the nominal

frequency, according to the identification label, within very narrow tolerances. This is entered into the probe data sheet.

Bandwidth B

The range of frequencies in the echo pulse whose amplitude, at the most, is 6 dB less than the maximum amplitude.

fo- f

u

B = ------------ X 100%

f

fo= upper, fu= lower frequency limit for a 6 dB drop in amplitude.

With B = 100%, a 4 MHz, probe for example, has an foof 6 MHz and an fuof 2 MHz. Large bandwidths mean shorter echo

pulses, which mean high resolution and a good penetration power, because the lower frequencies of the pulse become less

attenuated than the nominal frequency. At high attenuation, the frequency of reflected signals decreases, compared to the

nominal frequency, as the distance increases. This must be taken into account with flaw evaluation. The bandwidth of each

probe is therefore checked and must, within narrow tolerances, coincide with the mean value of all probes.

Focal distance F

Near field length N

The distance of a small reflector from the probe producing the highest possible echo. Probes are focused in order to detect

small reflectors and produce a high echo amplitude. Focusing is only possible within the near field of the probe.

The near field length N is the focal distance of the unfocused probe which constitutes the sound pressure maximum at the

largest distance from the probe. N is determined by D, c and f.

D

2

eff

D

2

eff

. f

For D >> λ is: N = --------- = -------------

4 λ 4 c

λ = wave length c = sound velocity D

eff

= effective element diameter

Focal point and near field length are the distances with the best sound concentration and reflector recognition. Therefore,

when a probe is selected for a critical test, the flaw expectancy range must be in the focal area or near field length. The

data in the tables refers to steel with the exception of immersion testing in water.

Focal diameter FD

6

Diameter of the sound field in the focal distance or near field length with a 6 dB drop of the echo indication.

F . c 1 F

For D >> λ is: FD 6= ------ = ---- k . D

eff

with k = -----

f - D

eff

4 N

Pulse shape

The presentation of signals, as they are at the instrument input coming from plane reflectors.

Spectrum

Display of all the frequencies in the echo pulse. The frequency amplitudes are shown over the frequency.

Beam angle ß

The angle between the main beam and the normal axis of the test surface.

Page 6

4

Transducer Selection Criteria—North American Standards

For transducers manufactured to North American standards, GE Inspection Technologies offers three

performance ranges: Alpha, Benchmark, and Gamma Series. Waveform and frequency certification,

per ASTM E-1065, are supplied with all flaw detection transducers at no charge.

Alpha Series Features

• Recommended for applications where resolution is the primary consideration.

• Suitable for applications such as thickness measurement and near-surface flaw detection.

• Very short pulse—mechanically damped to the limit of current technology.

• Gain is usually lower than that of the Gamma and Benchmark Series.

• Broadband—typical 6 dB bandwidths range from 50% to 100%.

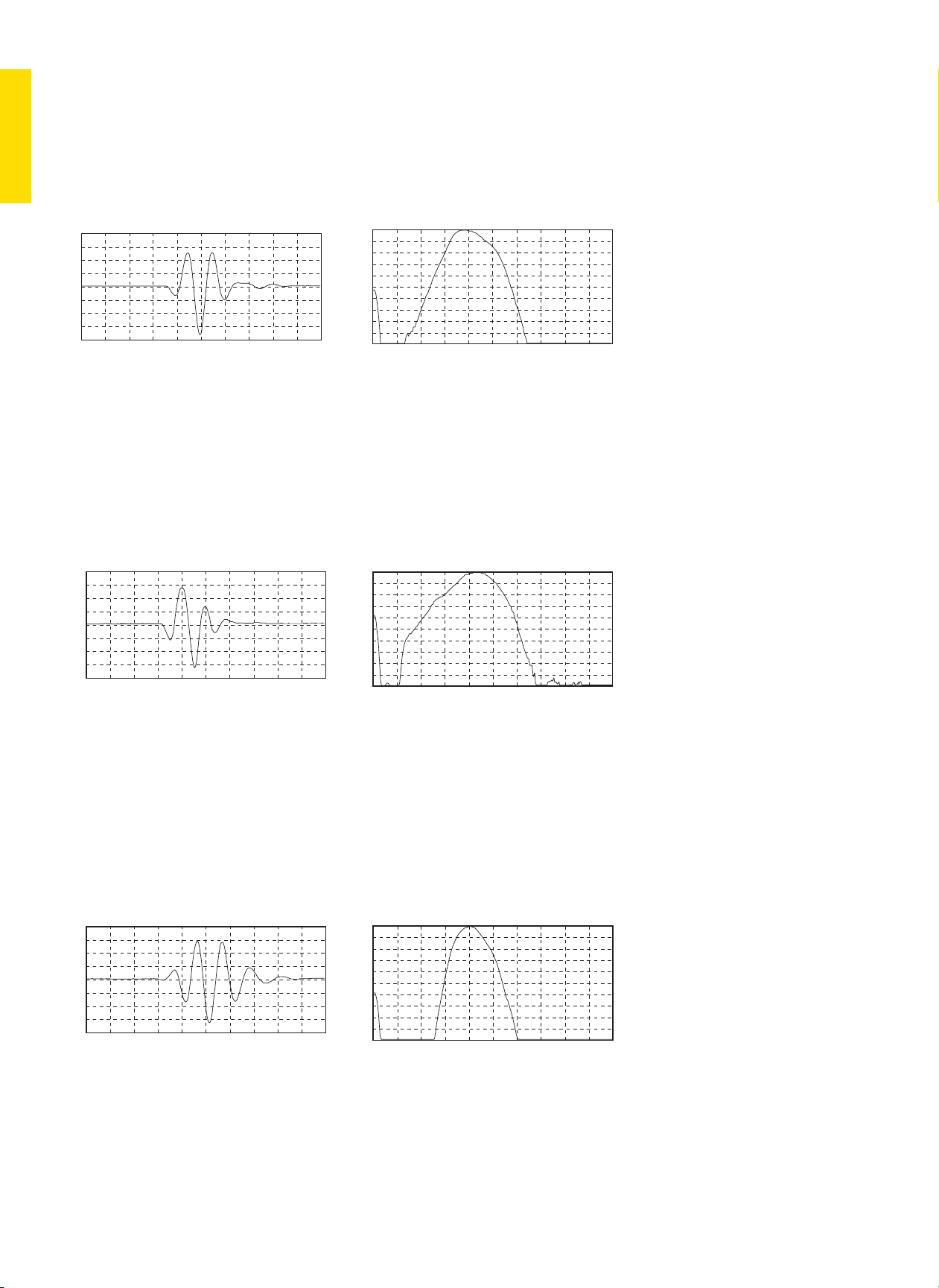

• Typical Alpha waveforms (right) exhibit one to two full ring cycles, depending on frequency, size and

other parameters.

Benchmark Series Features

• Proprietary BENCHMARK COMPOSITE®(piezocomposite) active elements.

• Penetration in attenuative materials is far superior to conventional transducers.

• High signal to noise on coarse grain metals, fiber reinforced composites, et al.

• Short pulse—resolution usually superior to Gamma Series.

• Gain is usually higher than that of the Gamma and Alpha Series.

• Very broadband—typical 6 dB bandwidths range from 60% to 120%.

• Low acoustic impedance element improves performance of angle beam, delay line, and immersion

probes—excellent match to plastic and water.

Gamma Series Features

• General purpose transducers, recommended for the majority of applications.

• Medium pulse, medium damping—best combination of gain and resolution.

• Matching electrical network ensures maximum gain and optimum waveform for general use.

• Medium bandwidth—typical 6 dB bandwidths range from 30% to 50%.

• Typical Gamma waveform exhibits three to four full ring cycles, depending on frequency, size and

other parameters.

100.0m Volts/div

200.0ns/div

100.0m Volts/div

200.0ns/div

2 dB/div

1.25MHz/div

Real Time

Real Time

Real Time

Spectrum

Spectrum

Spectrum

1.25MHz/div

100.0m Volts/div

2 dB/div

200.0ns/div

2 dB/div

1.25MHz/div

Page 7

5

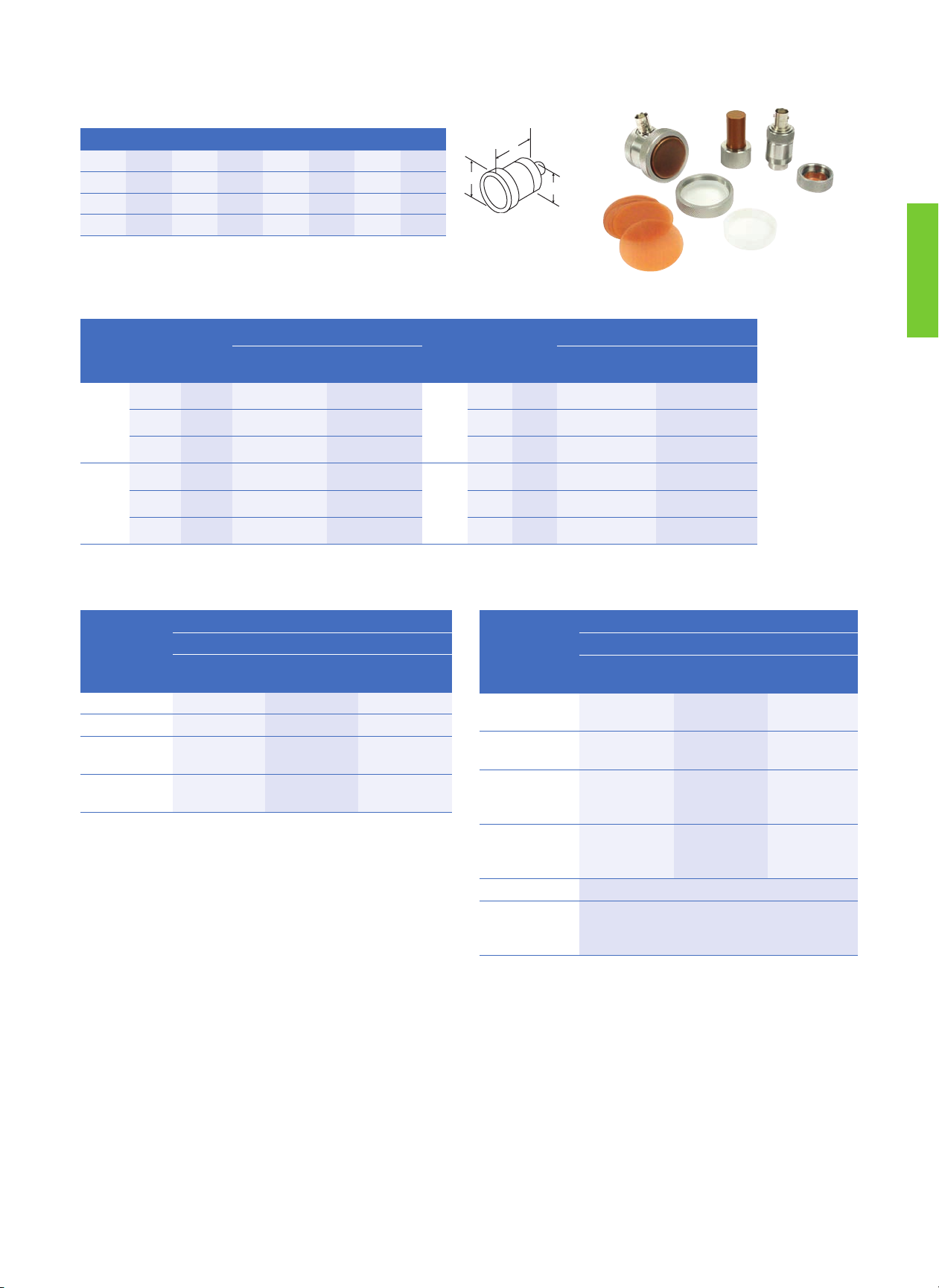

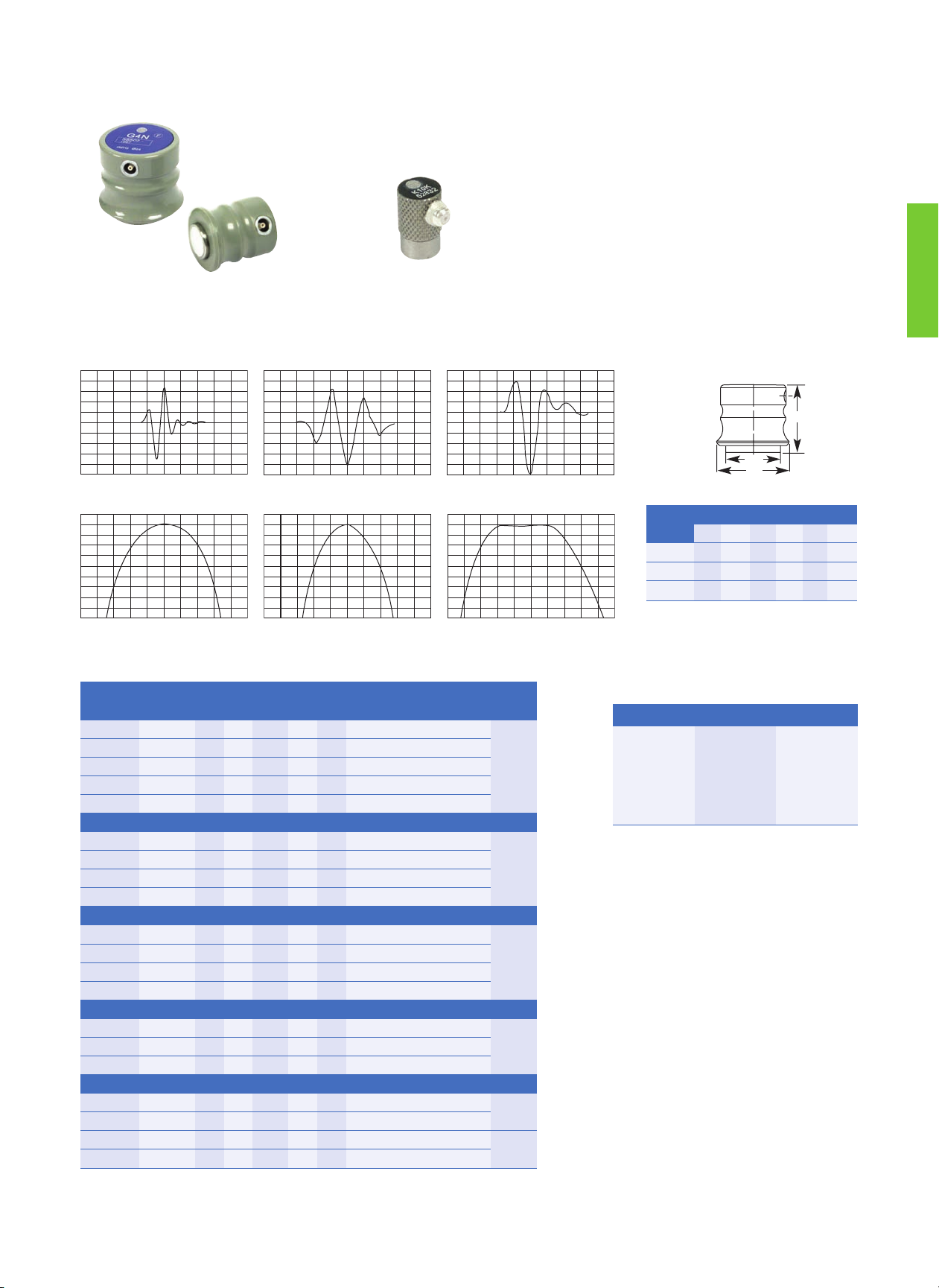

Straight Beam Contact Transducers, Protective Face

Applications

• General purpose, larger parts with simple geometry

• Forgings, billets

• Plates, bars, square profiles

• Containers, machine components, shells

• Inspection at high temperature with delay line

Features and Benefits

• European models have replaceable membrane:

– Improves coupling on uneven or curved surface

– Extends transducer life.

– Suitable for DGS flaw sizing method

– High temperature delay lines also available

– Lemo 1 (B..S) or Lemo 00 (MB..S) connector, side mount standard, top mount optional

• North American models can be used with three types of protective face:

– Membrane improves coupling on uneven or curved surface.

– Wear cap extends transducer life indefinitely when replaced periodically.

– High temperature delay line enables testing on surfaces up to 400°F (200°C).

– BNC connector, side or top mount

Contact Transducers

Page 8

6

Custom configurations are available by special order.

Description Type Remark

Protective

membrane

(1 set = 10 pcs)

ES45 (53756)

ES24 (53769)

for B..S;

for MB..S;

Delay line or delay

wedges

Special order e.g., for testing at high

temperatures.

Cables PKLL2 (50326)

MPKL2 (50486)

for B..S

for MB..S

Type

Order

Code

D

mm inf(MHz)Nmm in

Notes Sketch

B 1 S 57744 24 0.94 1 23 0.9

Type 2

B 1 S-EN 500035 24 0.94 1 23 0.9 DIN EN 12668-2 compliant

B 1 S-O 57755 24 0.94 1 23 0.9 Top connector

B 2 S 57745 24 0.94 2 45 1.8

B 2 S-EN 500036 24 0.94 2 45 1.8 DIN EN 12668-2 compliant

B 2 S-O 57756 24 0.94 2 45 1.8 Top connector

B 2 S-O-EN 500267 24 0.94 2 45 1.8

DIN EN 12668-2 compliant,

top connector

B 4 S 57746 24 0.94 4 88 3.5

B 4 S-EN 500037 24 0.94 4 88 3.5 DIN EN 12668-2 compliant

B 4 S-O 57757 24 0.94 4 88 3.5 Top connector

B 4 S-O-EN 500268 24 0.94 4 88 3.5

DIN EN 12668-2 compliant,

top connector

B 5 S 57747 24 0.94 5 110 4.3

MB 2 S 57748 10 0.39 2 8 0.3

Type 3

MB 2 S-EN 500038 10 0.39 2 8 0.3 DIN EN 12668-2 compliant

MB 2 S-O 57975 10 0.39 2 8 0.3 Top connector

MB 4 S 57749 10 0.39 4 16 0.6

MB 4 S-EN 500039 10 0.39 4 16 0.6 DIN EN 12668-2 compliant

MB 4 S-O 57976 10 0.39 4 16 0.6 Top connector

MB 5 S 57750 10 0.39 5 20 0.8

MB 5 S-O 57977 10 0.39 5 20 0.8 Top connector

Accessories

For explanations to the table data, refer to Selection Criteria on pages 2 through 4.

Protective Face Transducers—European Standards

Types B..S and MB..S

Typical waveform and frequency spectrum

50mV/Div

0,5μS/Div 0 - 4MHz

2dB/Div

B2S

pulse shape

spectrum

C

A

B

B..S

MB..S

Case

Type

A B C

mm in mm in mm in

Type 2 30 1.18 59 2.32 45 1.69

Type 3 20 0.79 43 1.77 25 0.98

Page 9

7

Protective Face Transducers—North American Standards

Protective Face Combination Transducers—Type PFCR (Side Mount BNC), PFCS (Top Mount BNC)

Note: Protective face option kits sold separately. Custom configurations are available by special order.

Protective Face Option Kits—PFCR/PFCS

Element Ø A B C

mm in mm in mm in mm in

13 0.50 19.1 0.75 30.5 1.20 23.9 0.94

19 0.75 25.4 1.00 30.5 1.20 30.2 1.19

25 1.00 31.8 1.25 30.5 1.20 36.6 1.44

Freq.

(MHz)

Element Ø

mm in

Order Code

Freq.

(MHz)

Element Ø

mm in

Order Code

Gamma Series

PFCR

Gamma Series

PFCS

Gamma Series

PFCR

Gamma Series

PFCS

1.0

13 0.50 241-240 241-260

3.50

13 0.50 243-240 243-260

19 0.75 251-240 251-260 19 0.75 253-240 253-260

25 1.00 261-240 261-260 25 1.00 263-240 263-260

2.25

13 0.50 242-240 242-260

5.0

13 0.50 244-240 244-260

19 0.75 252-240 252-260 19 0.75 254-240 254-260

25 1.00 262-240 262-260 25 1.00 264-240 264-260

Order Code

Transducer Element Ø

.5 in

(13 mm)

.75 in (19 mm) 1.00 in

(25 mm)

Spare Membranes

pkg. of 12 pcs.

118-220-020 118-220-021 118-220-022

Spare Wear Caps

pkg. of 12 pcs.

118-240-123 118-240-122 118-240-121

Hi-Temp. Delay

Line* 1.0 in

(25.4 mm) length

118-440-027 118-440-031 118-440-035

Hi-Temp. Delay

Line* 1.5 in

(38.1 mm) length

118-440-029 118-440-033 118-440-037

BNC Cable 118-140-016

Membrane, Wear

Cap and Delay

Line Couplant

118-300-740

Kit Styles

Order Code

Transducer Element Ø

.5 in

(13 mm)

.75 in

(19 mm)

1.00 in

(25 mm)

PM 118-450-120 118-450-140 118-450-160

PWC 118-450-220 118-450-240 118-450-260

PHTD - 1.0 in

(25.4 mm) Delay

118-450-320 118-450-340 118-450-360

PHTD - 1.5 in

(38.1 mm) Delay

118-450-420 118-450-440 118-450-460

* High Temp (PHTD) delay line: maximum temperature 400°F (200°C), maximum

contact time 10 seconds; cool to ambient before reuse.

B

A

C

Style PM Kit includes a knurled ring, gland nut, wrench,

12 membranes, and a 2 oz. bottle of couplant (transducer not

included).

Style PWC Kit includes a knurled ring, three wear caps, and a

2 oz. bottle of couplant (transducer not included). This option may

not be usable if near surface resolution is critical.

Style PHTD Kit includes a knurled ring, high temperature delay

line, and a 2 oz. bottle of couplant (transducer not included).

Page 10

8

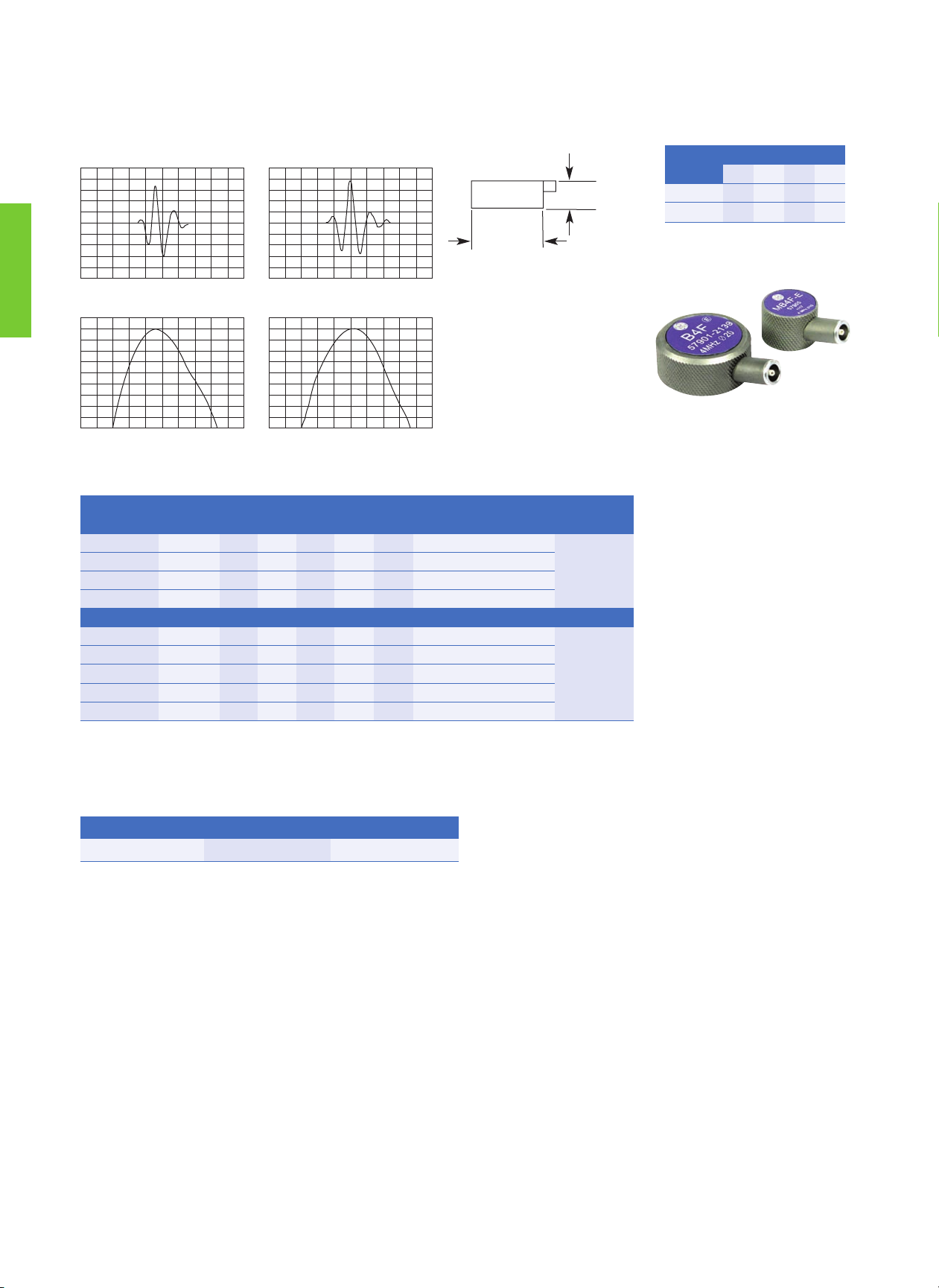

Applications

• General purpose, metal parts with simple geometry

• Manual inspection of plate, large forgings, billets, castings

• Smaller models for pipe and tube, tanks, bars, small forgings

• Lamination, delamination

• Bond testing

• Thick sections or difficult to penetrate materials

Features and Benefits

• Permanent, abrasion—resistant wear plate

• Best match to metals

• Higher gain reserve than protective face models

• Fingertip models for access to tight spaces

• Comfortable grip

• European models have side mounted Lemo 00 connectors, side mounted Microdot on K..K and G..K types.

• North American models have BNC connectors (side or top mount), side mounted Microdot on F type.

Straight Beam Contact Transducers, Wear Resistant

Page 11

9

Type

Order

CodeDmm inf(MHz)Nmm in

Notes Sketch

K 1 G 58506 24

0.94

1 23

0.9

Type 5

K 2 G 58507 24

0.94

2 45

1.8

K 2 G-EN 500071 24

0.94

2 45

1.8

DIN EN 12668-2 compliant

K 4 G 58508 24

0.94

4 88

3.5

K 4 G-EN 500072 24

0.94

4 88

3.5

DIN EN 12668-2 compliant

K 1 N 67620 10

0.39

1 4

0.2

Type 6

K 2 N 58509 10

0.39

2 8

0.3

K 4 N 58510 10

0.39

4 16

0.6

K 5 N 58511 10

0.39

5 20

0.8

K 5 K 52831 5

0.20

5 5

0.2

Type 7

K 5 K-EN 500061 5

0.20

5 5

0.2

DIN EN 12668-2 compliant

K 10 K 52832 5

0.20

10 10

0.4

K 10 K-EN 500062 5

0.20

10 10

0.4

DIN EN 12668-2 compliant

G 1 N 58500 24

0.94

1 23

0.9

Type 5G 2 N 58501 24

0.94

2 45

1.8

G 4 N 58502 24

0.94

4 88

3.5

G 2 KB 58503 10

0.39

2 8

0.3

Type 6

G 5 KB 58504 10

0.39

5 20

0.8

G 5 K 53057 5

0.20

5 5

0.2

Type 7

G 10 K 53052 5

0.20

10 10

0.4

Custom configurations are available by special order.

Description Type Remark

Probe Cable MPKL2

(50486)

MPKM2

(52999)

for K..G, K..N,

G..N, and

G..KB

for K..K and

G..K

Accessories

For explanations to the table data, refer to Selection Criteria on pages 2 through 4.

K..G, G..N K..N, G..KB

K..K, G..K

Wear Resistant Transducers—European Standards

Typical waveform and frequency spectrum

Types K..G, K..N, K..K, G..N, G..KB and G..K

3V/Div 0,2V/Div

0,1μS/Div0,5μS/Div

0 - 4MHz 0 - 10MHz

2dB/Div 2dB/Div

K2G-F K5K

A

C

B

0, 5V/Div

G2N-F

0, 25μS/Div

2dB/Div

0 - 4MHz

Case

Type

A B C

mm in mm in mm in

Type 5 30 1.18 37 1.46 40 1.57

Type 6 15 0.59 31 1.22 26 1.02

Type 7 10 0.39 17 0.67

Page 12

10

Wear Resistant Transducers—European Standards

For explanations to the table data, refer to Selection Criteria on pages 2 through 4.

Custom configurations are available by special order.

Description Type Remark

Cable MPKL2 (50486) for B..F and MB..F

Types B..F and MB..F

Typical waveform and frequency spectrum

B

A

1,0V/Div 2,0V/Div

0,2μS/Div

0,5μS/Div

0 - 4MHz 0 - 8MHz

2dB/Div 2dB/Div

B2F MB4F

Type

Order

CodeDmm inf(MHz)Nmm in

Notes Sketch

B 1 F 57899 20

0.79

1 16

0.6

Type 8

B 2 F 57900 20

0.79

2 31

1.2

B 4 F 57901 20

0.79

4 62

2.4

B 5 F 57902 20

0.79

5 76

3.0

MB 2 F 57904 10

0.39

2 8

0.3

Type 9

M B 4 F 57905 10

0.39

4 16

0.6

M B 4 F-EN 500073 10

0.39

4 16

0.6

DIN EN 12668-2 compliant

MB 5 F 57906 10

0.39

5 19

0.8

MB 10 F 57903 10

0.39

10 32

1.4

Case

Type

A B

mm in mm in

Type 8 31 1.22 16 0.63

Type 9 19 0.75 16 0.63

Accessories

Page 13

11

Fingertip Contact Transducers—Type F

Element Ø A B

mm in mm in mm in

6

0.25

12.7

0.50

16.8

0.66

10

0.375

16.0

0.63

16.8

0.66

13

0.50

19.1

0.75

16.8

0.66

Freq.

(MHz)

Element Ø

mm in

Order Code

Freq.

(MHz)

Element Ø

mm in

Order Code

Benchmark

Series

Alpha

Series

Gamma

Series

Accessories

Benchmark

Series

Alpha

Series

Gamma

Series

Accessories

2.25

6

.250

822-000 122-000 222-000

Cables

BNC

118-140-012

LEMO-1

118-140-022

5.0

6

.250

824-000 124-000 224-000

Cables

BNC

118-140-012

LEMO-1

118-140-022

10

.375

832-000 132-000 232-000 10

.375

834-000 134-000 234-000

13

.500

842-000 142-000 242-000 13

.500

844-000 144-000 244-000

3.5

6

.250

123-000 223-000

10.0

6

.250

126-000 226-000

10

.375

133-000 233-000 10

.375

136-000 236-000

13

.500

143-000 243-000 13

.500

146-000 246-000

A

B

Custom configurations are available by special order.

Type F

Standard Contact Transducers—Type RHP-CR (Side Mount BNC), RHP-CS (Top Mount BNC)

Freq.

(MHz)

Element Ø

mm in

Order Code

Freq.

(MHz)

Element Ø

mm in

Order Code

Alpha Series Gamma Series Accessories Alpha Series Gamma Series Accessories

.5

19 0.75

250-043-CR

250-123-CS

Cables

BNC

118-140-016

LEMO-1

118-140-018

3.5

13 0.50

243-043-CR

243-123-CS

Cables

BNC

118-140-016

LEMO-1

118-140-018

25 1.00

260-043-CR

260-123-CS

19 0.75

253-043-CR

253-123-CS

1.0

13 0.50

241-043-CR

241-123-CS

25 1.00

263-043-CR

263-123-CS

19 0.75

251-043-CR

251-123-CS

5.0

13 0.50

144-043-CR

144-123-CS

244-043-CR

244-123-CS

25 1.00

261-043-CR

261-123-CS

19 0.75

154-043-CR

154-123-CS

254-043-CR

254-123-CS

2.25

13 0.50

142-043-CR

142-123-CS

242-043-CR

242-123-CS

25 1.00

164-043-CR

164-123-CS

264-043-CR

264-123-CS

19 0.75

152-043-CR

152-123-CS

252-043-CR

252-123-CS

10.0 13 0.50

246-043-CR

246-123-CS

25 1.00

162-043-CR

162-123-CS

262-043-CR

262-123-CS

Custom configurations are available by special order.

Wear Resistant Transducers—North American Standards

A

B

Element Ø A B

mm in mm in mm in

13 0.50 29.2 1.15 38.1 1.50

25 0.75 35.6 1.40 38.1 1.50

19 1.00 41.9 1.65 38.1 1.50

Type RHP

Page 14

12

Straight Beam Contact Transducers, Delay Line

Applications

• Thickness measurement

• Near surface flaw detection

• Inspection of thin sections

• Curved parts, tubing, pipe

• Composites and plastics

• Turbine blades

Features and Benefits

• Excellent near surface resolution.

• Replaceable delay line—long life and versatility.

• Higher frequencies improve resolution and small flaw detectability.

• All models have side mounted Microdot connector.

Page 15

13

Description Type Remark

Cable

Delay Line

(exchangeable)

MPKM2 (52999)

CLFV1 (54258)

CLFV3 (54262)

.37 in (9.5 mm) for G.MN

.49 in (12.5 mm) for G.MN

0, 25μS/Div

2dB/Div

0 - 20MHz

21

ø 7.6

13

Delay Line Transducers—European Standards

Typical waveform and frequency spectrum

2, 5V/Div

G10MN

Type

Order

CodeDmm inf(MHz)

N

mm in

Sketch

G 5 MN 53046 5 0.20 5 5 0.2

Type 14G 10 MN 53047 5 0.20 10 10 0.4

G 15 MN 53058 5 0.20 15 15 0.6

Custom configurations are available by special order.

Type G..MN

Accessories

Page 16

14

Delay Line Transducers—North American Standards

Removable Delay Line—Type DFR

*H-007 fits .125 in (3 mm) and .25 in (6 mm) units only with exception of Mini DFR.

Custom configurations are available by special order.

Element Ø A B C

mm in mm in mm in mm in

3 or 6 0.125 or 0.25 13 0.51 21.3 0.84 7.6 0.30

13 0.50 22.4 0.88 35.1 1.38 15.2 0.60

Mini-DFR

3 0.125 10.41 0.41 19.6 0.77 4.8 0.19

Freq.

(MHz)

Element

Ø

mm in

Order Codes

Alpha

Series

Delay Line

10-PK .38 in

(9.5 mm) Lg

Delay Line

10-PK .5 in

(12.7 mm) Lg

Accessories

2.25

6 .250 122-660 118-440-050 118-440-051

Cables

BNC

118-140-012

LEMO-1

118-140-022

Delay Line

Couplant

118-300-740

Spring Loaded

VEE Block

118-480-007

13 .500 140-500 118-440-052

3.5 6 .250 123-660 118-440-050 118-440-051

5.0

6 .250 124-660 118-440-050 118-440-051

13 .500 144-660 118-440-052

10.0

6 .250 126-660 118-440-050 118-440-051

13 .500 140-602 118-440-052

15.0 6 .250 127-660 118-440-050 118-440-051

22.0 3 .125 118-660 118-440-050 118-440-051

Mini-

DFR

20.0

3 .125 518-650 118-440-502

C

B

A

K-PEN Replaceable Delay Line Pencil Probe

• Focused, high resolution pencil probe

• Interchangeable delay lines, two tip diameters

• Extremely small contact area

• Tightly curved surfaces, such as turbine blades

• Wall thickness measurement from the bottom of an external pit

• Straight, right angle and 45° handles

• Straight model has removable handle

Freq.

(MHz)

Order Code

Straight K-PEN 45° K-PEN

Right Angle

K-PEN

.065 in (1.7 mm)

Tip Delay 10-PK

.090 in (2.3 mm)

Tip Delay 10-PK

BNC Cable

7.5 389-042-200 389-042-880 389-042-870

387-003-109 387-003-110 118-140-012

20.0 389-030-290 389-041-270 389-040-660

Types DFR and K-PEN

4.93

0.30

0.42

1.10

0.30

0.78

0.42

4.25

0.30

0.78

3.75

Page 17

15

Applications

• Remaining wall thickness, corrosion, erosion

• Near surface flaw detection

• Small parts—screws, bolts, pins

• Cladding and weld overlay

• Bond testing

• Railroad wheels

• Core flaws in shafts, bars, billets

• Coarse grain materials

Features and Benefits

• Excellent near surface resolution

• Improved coupling on curved and rough surfaces

• Reduce noise caused by scattering

• Can be contoured for curved parts

• European models have side mounted Lemo 00 connectors, side mounted Microdot SEB..KF types

• North American models have fixed BNC cable (ADP) or side mounted MMD (FDU)

Straight-Beam Contact Transducers, Dual Element (TR)

Page 18

16

Type

Order

Code

a x b

mm inf(MHz)Fmm in

Notes Sketch

SEB 1 57466 21 /2 ø 0.83 1 20 0.8

Type 15

SEB 1-EN 500176 21 /2 ø 0.83 1 20 0.8 DIN EN 12668-2 compliant

SEB 2 57467 7 x 18 .28 x .71 2 15 0.6

SEB 2-EN 500063 7 x 18 .28 x .71 2 15 0.6 DIN EN 12668-2 compliant

SEB 2-0° 57468 7 x 18 .28 x .71 2 30 1.2 Elements at 0° included angle

SEB 2-EN-0° 500065 7 x 18 .28 x .71 2 30 1.2

Elements at 0° included angle

DIN EN 12668-2 compliant

SEB 4 57469 6 x 20 .24 x .79 4 12 0.5

SEB 4-EN 500064 6 x 20 .24 x .79 4 12 0.5 DIN EN 12668-2 compliant

SEB 4-0° 57470 6 x 20 .24 x .79 4 25 1.0 Elements at 0° included angle

SEB 4-EN-0° 500066 6 x 20 .24 x .79 4 25 1.0

Elements at 0° included angle

DIN EN 12668-2 compliant

MSEB 2 57461 11 /2 ø 0.43 2 8 0.3

Type 16

MSEB 2-EN 500067 11 /2 ø 0.43 2 8 0.3 DIN EN 12668-2 compliant

MSEB 4 57462 3.5 x 10 .14 x .39 4 10 0.4

MSEB 4-EN 500068 3.5 x 10 .14 x .39 4 10 0.4 DIN EN 12668-2 compliant

MSEB 4-0° 57463 3.5 x 10 .14 x .39 4 18 0.7 Elements at 0° included angle

MSEB 5 57464 9 /2 ø 0.35 5 10 0.4 Typical bandwidth 100%

SEB 2 KF5 56464 8 /2 ø 0.31 2 6 0.24

Type 17

SEB 4 KF8 56465 8 /2 ø 0.31 4 6 0.24

SEB 4 KF8-EN 500069 8 /2 ø 0.31 4 6 0.24 DIN EN 12668-2 compliant

SEB 5 KF3 56466 8 /2 ø 0.31 5 3 0.12

SEB10 KF3 56867 5 /2 ø 0.20 10 3 0.12

Type 18

SEB10 KF3-EN 500070 5 /2 ø 0.20 10 3 0.12 DIN EN 12668-2 compliant

Custom configurations are available by special order.

Description Type Remark

Cable SEKG2 (53887)

SEKM2 (53001)

for SEB.., MSEB..,

for SEB..KF

Accessories

For explanations to the table data, refer to Selection Criteria on pages 2 through 4.

SEB MSEB SEB...KF

Dual Element (TR) Contact Transducers—European Standards

2dB/Div2dB/Div

10mV/Div0, 2V/Div

MSEB4

SEB4KFB

0, 2μs/Div

0-8MHz

0, 2μs/Div

0-8MHz

Typical waveform and frequency spectrum

Case

Type

A B C D

mm in mm in mm in mm in

Type 15 30 1.18 65 2.56 28.5 1.12 10 0.39

Type 16 20 0.79 45 1.77 16.5 0.65 5 0.20

Type 17 14 0.55 17 0.67 13 0.51 6.4 0.25

Type 18 14 0.55 17 0.67 7.5 0.30 6.4 0.25

Types SEB and MSEB

A

C

B

Types 15 and 16 Types 17 and 18

D

C

B

D

A

Page 19

17

Dual Element (TR) Contact Transducers—North American Standards

Dual Element Transducers—Types ADP and FDU

FDUADP

Element Ø A B

mm in mm in mm in

6 .25 9.7 0.38 12.7 0.50

10 .375 12.7 0.50 12.7 0.50

Element Ø A B C

mm in mm in mm in mm in

6 0.25 12.7 .50 16.3 .64 9.1 .36

10 0.375 16.0 .63 16.3 .64 11.9 .47

13 0.50 19.1 .75 17.3 .68 15.2 .60

Freq.

(MHz)

Element Ø Order Code

Freq.

(MHz)

Element Ø Order Code

mm in ADP Dual

FDU Dual

†

mm in ADP Dual

FDU Dual

†

2.25

6 .250 222-700 222-680

5.0

6 .250 224-700 224-680

10 .375 232-700 232-680 10 .375 234-700 234-680

13 .500 242-700 13 .500 244-700

3.5

6 .250 223-700 223-680 7.5 8 .300 135-700

10 .375 233-700 233-680

10.0

6 .250 389-002-771

13 .500 243-700 13 .500 389-021-830

† Standard MMD to BNC dual cable (118-140-014) sold separately. Custom configurations are available by special order.

B

A

B

A

C

Types ADP and FDU

ADP

FDU

Page 20

18

Applications

• General weld inspection, larger objects, thicker sections

• Pipes, tanks, pressure vessels

• Axles, forgings, castings

• Bridges and other structures

• Railroad wheels and rail

Features and Benefits

• European models have integral wedge

– Maximum precision and repeatability for DGS flaw sizing method

– Durable, ergonomically designed die cast housing

– Replacement soles (sold separately) for extended service life

– Lemo 1 connector on WB and WK types, side mount standard, top mount optional

– Lemo 00 connector on SWB and SWK types, side mount

• North American models have interchangeable wedges (sold separately)

– Maximum versatility and service life

– Custom wedge angles and curvatures can be special ordered

– AWS models available for AWS Structural Welding Code D1.1

– High temperature wedges available for testing to 200°C (400°F)

– BNC connector, top mount

Angle Beam Transducers—Large Sizes

Page 21

19

Type

Order

Code

a x b

mm in

f

(MHz)ß(Steel)Nmm in

Notes Sketch

WB 45-1

WB 45-1-EN

WB 45-O1

56993

500207

57217

20 x 22

20 x 22

20 x 22

.79 x .87

.79 x .87

.79 x .87

1

1

1

45

45

45

45

45

45

1.8

1.8

1.8

DIN EN 12668-2 compliant

Top connector

Type 21

WB 60-1

WB 60-1-EN

WB 60-O1

56994

500208

57218

20 x 22

20 x 22

20 x 22

.79 x .87

.79 x .87

.79 x .87

1

1

1

60

60

60

45

45

45

1.8

1.8

1.8

DIN EN 12668-2 compliant

Top connector

WB 70-1

WB 70-1-EN

WB 70-O1

56995

500209

57219

20 x 22

20 x 22

20 x 22

.79 x .87

.79 x .87

.79 x .87

1

1

1

70

70

70

45

45

45

1.8

1.8

1.8

DIN EN 12668-2 compliant

Top connector

WB 35-2

WB 35-2-EN

WB 35-O2

WB 35-O2EN

56998

500054

57222

500058

20 x 22

20 x 22

20 x 22

20 x 22

.79 x .87

.79 x .87

.79 x .87

.79 x .87

2

2

2

2

38

38

38

38

90

90

90

90

3.5

3.5

3.5

3.5

DIN EN 12668-2 compliant

Top connector

DIN EN 12668-2 compliant

WB 45-2

WB 45-2-EN

WB 45-O2

WB 45-O2EN

56999

500055

57223

500059

20 x 22

20 x 22

20 x 22

20 x 22

.79 x .87

.79 x .87

.79 x .87

.79 x .87

2

2

2

2

45

45

45

45

90

90

90

90

3.5

3.5

3.5

3.5

DIN EN 12668-2 compliant

Top connector

DIN EN 12668-2 compliant

WB 60-2

WB 60-2-EN

WB 60-O2

WB 60-O2EN

57000

500056

57224

500060

20 x 22

20 x 22

20 x 22

20 x 22

.79 x .87

.79 x .87

.79 x .87

.79 x .87

2

2

2

2

60

60

60

60

90

90

90

90

3.5

3.5

3.5

3.5

DIN EN 12668-2 compliant

Top connector

DIN EN 12668-2 compliant

WB 70-2

WB 70-2-EN

WB 70-O2

WB 70-O2EN

57001

500057

57225

500280

20 x 22

20 x 22

20 x 22

20 x 22

.79 x .87

.79 x .87

.79 x .87

.79 x .87

2

2

2

2

70

70

70

70

90

90

90

90

3.5

3.5

3.5

3.5

DIN EN 12668-2 compliant

Top connector

DIN EN 12668-2 compliant

WB 80-2

WB 80-2-EN

WB 80-O2

57002

500278

57226

20 x 22

20 x 22

20 x 22

.79 x .87

.79 x .87

.79 x .87

2

2

2

77

77

77

90

90

90

3.5

3.5

3.5

DIN EN 12668-2 compliant

Top connector

WB 90-2

WB 90-2-EN

WB 90-O2

57003

500266

57227

20 x 22

20 x 22

20 x 22

.79 x .87

.79 x .87

.79 x .87

2

2

2

90

90

90

90

90

90

3.5

3.5

3.5

DIN EN 12668-2 compliant

Top connector

Large Angle Beam Transducers—European Standards

WB45-2 WK60-2

0.1V/Div

1.0μs/Div

5dB/Div

0-4 MHz

0.1V/Div

1.0μs/Div

5dB/Div

0-4 MHz

C

D

B

A

Typical waveform and frequency spectrum

Types WB/WK and SWB/SWK

WB-O

Case

Type

A B C D

mm in mm in mm in mm in

Type 20 21.5 0.85 37 1.46 31 1.22 3 0.12

Type 21 29 1.14 53.5 2.11 45 1.77 5 0.20

Types WB/WK and SWB/SWK

WB, WK

SWB, SWK

Page 22

20

Large Angle Beam Transducers—European Standards

Description Type Remark

Cable PKLL2 (50326)

MPKL2 (50486)

for WB.., WK..

for SWB.., SWK..

Spare sole

(1 set = 10 pcs)

WP(E) (57276)

SWP (58514)

for WB.., WK..

for SWB.., SWK

Type

Order

Code

a x b

mm in

f

(MHz)ß(Steel)Nmm in

Notes Sketch

WB 35-4

WB 35-O4

57004

57228

20 x 22

20 x 22

.79 x .87

.79 x .87 44

38

38

180

180

7.1

7.1 Top connector

Type 21

WB 45-4

WB 45-4-EN

WB 45-O4

57005

500200

57229

20 x 22

20 x 22

20 x 22

.79 x .87

.79 x .87

.79 x .87

4

4

4

45

45

45

180

180

180

7.1

7.1

7.1

DIN EN 12668-2 compliant

Top connector

WB 60-4

WB 60-4-EN

WB 60-O4

57006

500201

57230

20 x 22

20 x 22

20 x 22

.79 x .87

.79 x .87

.79 x .87

4

4

4

60

60

60

180

180

180

7.1

7.1

7.1

DIN EN 12668-2 compliant

Top connector

WB 70-4

WB 70-4-EN

WB 70-O4

57007

500202

57231

20 x 22

20 x 22

20 x 22

.79 x .87

.79 x .87

.79 x .87

4

4

4

70

70

70

180

180

180

7.1

7.1

7.1

DIN EN 12668-2 compliant

Top connector

WB 80-4

WB 80-O4

57008

57232

20 x 22

20 x 22

.79 x .87

.79 x .87

4

4

77

77

180

180

7.1

7.1 Top connector

SWB 45-2

SWB 60-2

SWB 70-2

58414

58415

58416

14 x 14

14 x 14

14 x 14

.55 x .55

.55 x .55

.55 x .55

2

2

2

45

60

70

39

39

39

1.5

1.5

1.5

Type 20

SWB 45-5

SWB 60-5

SWB 70-5

58420

58421

58422

14 x 14

14 x 14

14 x 14

.55 x .55

.55 x .55

.55 x .55

5

5

5

45

60

70

98

98

98

3.9

3.9

3.9

WK 45-1

WK 60-1

WK 70-1

67889

67890

67891

20 x 22

20 x 22

20 x 22

.79 x .87

.79 x .87

.79 x .87

1

1

1

45

60

70

45

45

45

1.8

1.8

1.8

Piezocomposite

element

Type 21

WK 45-2

WK 60-2

WK 70-2

57011

57012

57013

20 x 22

20 x 22

20 x 22

.79 x .87

.79 x .87

.79 x .87

2

2

2

45

60

70

90

90

90

3.5

3.5

3.5

SWK 45-2

SWK 60-2

SWK 70-2

58843

58844

58845

14 x 14

14 x 14

14 x 14

.55 x .55

.55 x .55

.55 x .55

2

2

2

45

60

70

39

39

39

1.5

1.5

1.5

Piezocomposite

element

Type 20

Custom configurations are available by special order.

Accessories

For explanations to the table data, refer to Selection Criteria on pages 2 through 4.

Page 23

21

Large Angle Beam Transducers—North American Standards

Angle Beam Transducers—Types SWS and AWS

Element Size A B C D

mm in mm in mm in mm in mm in

13 Ø .50 Ø 18.3 .72 25.4 1.00 19.1 .75 20.6 .81

13 x 25 .50 x 1.0 18.5 .725 38.4 1.51 19.1 .75 33.3 1.31

19 x 25 .75 x 1.0 25.4 1.00 38.1 1.5 19.1 .75 33.3 1.31

25 Ø 1.0 31.0 1.22 41.9 1.65 19.1 .75 35.1 1.38

16 x 16 .63 x .63 18.5 .73 31.8 1.25 19.1 .75 25.4 1.00

16 x 19 .63 x .75 18.5 .73 31.8 1.25 19.1 .75 25.4 1.00

19 x 19 .75 x .75 21.6 .85 31.8 1.25 19.1 .75 25.4 1.00

Freq.

(MHz)

Element Ø

mm in

Order Codes

Freq.

(MHz)

Element Ø

mm in

Order Codes

Gamma

Series

Benchmark

Series

Standard

Wedge

(W = 118-340)

Hi-Temp

Wedge*

(W = 118-340)

Accessories

Gamma

Series

Benchmark

Series

Standard

Wedge

(W = 118-340)

Hi-Temp

Wedge*

(W = 118-340)

Accessories

0.50 25 1.0 260-600

W-021 45°

W-022 60°

W-023 70°

W-025 90°

W-081 45°

W-082 60°

W-083 70°

Cables

BNC

118-140-016

LEMO-1

118-140-018

Wedge

Couplant

118-300-740

2.25

AWS

Series

16 x16.63 x

.63

292-603 892-603

W-104 45°

W-105 60°

W-106 70°

Cables

BNC

118-140-016

LEMO-1

118-140-018

Wedge

Couplant

118-300-740

16 x19.63 x

.75

292-601 892-601

W-104 45°

W-105 60°

W-106 70°

1.0

13 0.5 241-600 841-600

W-009 45°

W-010 60°

W-011 70°

W-013 90°

W-076 45°

W-077 60°

W-078 70°

19 x19.75 x

.75

292-604 892-604

W-104 45°

W-105 60°

W-106 70°

13 x 250.5 x

1

291-600 891-600

W-015 45°

W-016 60°

W-017 70°

W-019 90°

W-070 45°

W-086 60°

W-071 70°

3.5

13 0.5 243-600 843-600

W-009 45°

W-010 60°

W-011 70°

W-013 90°

W-076 45°

W-077 60°

W-078 70°

19 x25.75 x

1

291-605 891-605

W-051 45°

W-052 60°

W-053 70°

W-054 90°

13 x250.5 x

1

293-600 893-600

W-015 45°

W-016 60°

W-017 70°

W-019 90°

W-070 45°

W-086 60°

W-071 70°

25 1.0 261-600 861-600

W-021 45°

W-022 60°

W-023 70°

W-025 90°

W-081 45°

W-082 60°

W-083 70°

19 x25.75 x

1

293-605 893-605

W-051 45°

W-052 60°

W-053 70°

W-054 90°

2.25

13 0.5 242-600 842-600

W-009 45°

W-010 60°

W-011 70°

W-013 90°

W-076 45°

W-077 60°

W-078 70°

25 1.0 263-600 863-600

W-021 45°

W-022 60°

W-023 70°

W-025 90°

W-081 45°

W-082 60°

W-083 70°

13 x250.5 x

1

292-600 892-600

W-015 45°

W-016 60°

W-017 70°

W-019 90°

W-070 45°

W-086 60°

W-071 70°

5.0

13 .5 244-600 844-600

W-009 45°

W-010 60°

W-011 70°

W-013 90°

W-076 45°

W-077 60°

W-078 70°

19 x25.75 x

1

292-605 892-605

W-051 45°

W-052 60°

W-053 70°

W-054 90°

13 x25.5 x

1

294-600 894-600

W-015 45°

W-016 60°

W-017 70°

W-019 90°

W-070 45°

W-086 60°

W-071 70°

25 1.0 262-600 862-600

W-021 45°

W-022 60°

W-023 70°

W-025 90°

W-081 45°

W-082 60°

W-083 70°

19 x25.75 x

1

294-605 894-605

W-051 45°

W-052 60°

W-053 70°

W-054 90°

25 1.0 264-600 864-600

W-021 45°

W-022 60°

W-023 70°

W-025 90°

W-081 45°

W-082 60°

W-083 70°

D

C

B

A

* Duty Cycle: at 400°F (200°C), maximum contact time is 10 seconds; cool to ambient before reuse. Note: Standard wedge angles are specified for carbon steel. Custom

configurations are available by special order.

Types SWS and AWS

Page 24

22

Applications

• General weld inspection, smaller objects, thinner sections

• Tubes, pipes, pressure vessels, containers

• Pumps, valve housings

• Turbine blades, shafts

• Wheel rims

Features and Benefits

• European models have integral wedge

– Maximum precision and repeatability for DGS flaw sizing method

– Durable, ergonomically-designed die cast housing

– Replacement soles (sold separately) for extended service life

– Lemo 00 connector on MWB and MWK types, side mount standard, top mount optional

• North American models have interchangeable wedges (sold separately)

– Maximum versatility and service life

– Custom wedge angles and curvatures can be special ordered

– Both quick change and screw mounted styles available

– Microdot connector on MSW-QC and MSWS types, MMD on SMSWS

Angle Beam Transducers—Small Sizes

Page 25

23

Small Angle Beam Transducers—European Standards

Typical wavefarm and frequency spectrum

0, 2μs/Div

0, 2V/Div 0.5V/Div

5dB/Div2dB/Div

0-8 MHz

MWB45-4 MWK45-4

24

14

22

2

Type

Order

Code

a x b

mm inf(MHz)ß(Steel)Nmm in

Notes Sketch

MWB 35-2

MWB 35-2EN

MWB 35-O2

MWB 35-O2EN

56920

500040

57204

500044

8 x 9

8 x 9

8 x 9

8 x 9

.31 x .35

.31 x .35

.31 x .35

.31 x .35

2

2

2

2

38

38

38

38

15

15

15

15

0.6

0.6

0.6

0.6

DIN EN 12668-2 compliant

Top connector

DIN EN 12668-2 compliant

Type 23

MWB 45-2

MWB 45-2EN

MWB 45-O2

MWB 45-O2EN

56921

500041

57205

500045

8 x 9

8 x 9

8 x 9

8 x 9

.31 x .35

.31 x .35

.31 x .35

.31 x .35

2

2

2

2

45

45

45

45

15

15

15

15

0.6

0.6

0.6

0.6

DIN EN 12668-2 compliant

Top connector

DIN EN 12668-2 compliant

MWB 60-2

MWB 60-2EN

MWB 60-O2

MWB 60-O2EN

56922

500042

57206

500046

8 x 9

8 x 9

8 x 9

8 x 9

.31 x .35

.31 x .35

.31 x .35

.31 x .35

2

2

2

2

60

60

60

60

15

15

15

15

0.6

0.6

0.6

0.6

DIN EN 12668-2 compliant

Top connector

DIN EN 12668-2 compliant

MWB 70-2

MWB 70-2EN

MWB 70-O2

MWB 70-O2EN

56923

500043

57207

500234

8 x 9

8 x 9

8 x 9

8 x 9

.31 x .35

.31 x .35

.31 x .35

.31 x .35

2

2

2

2

70

70

70

70

15

15

15

15

0.6

0.6

0.6

0.6

DIN EN 12668-2 compliant

Top connector

DIN EN 12668-2 compliant

MWB 80-2

MWB 80-O2

MWB 90-2

56924

57208

56925

8 x 9

8 x 9

8 x 9

.31 x .35

.31 x .35

.31 x .35

2

2

2

77

77

90

15

15

15

0.6

0.6

0.6

Top connector

Surface wave

MWB-O MWB, MWK

Type MWB/MWK

Type 23

0, 2μs/Div

0-8 MHz

Page 26

24

Description Type Remark

Cable MPKL2 (50486) for MWB.., MWK..

Spare sole (1 set = 10 pcs) MWP(E) (57277) for MWB.., MWK..

Type

Order

Code

a x b

mm in

f

(MHz)ß(Steel)Nmm in

Notes Sketch

MWB 35-4

MWB 35-4EN

MWB 35-O4

MWB 35-O4EN

56926

500047

57210

500235

8 x 9

8 x 9

8 x 9

8 x 9

.31 x .35

.31 x .35

.31 x .35

.31 x .35

4

4

4

4

38

38

38

38

30

30

30

30

1.2

1.2

1.2

1.2

DIN EN 12668-2 compliant

Top connector

DIN EN 12668-2 compliant

Type 23

MWB 45-4

MWB 45-4EN

MWB 45-O4

MWB 45-O4EN

56927

500048

57211

500236

8 x 9

8 x 9

8 x 9

8 x 9

.31 x .35

.31 x .35

.31 x .35

.31 x .35

4

4

4

4

45

45

45

45

30

30

30

30

1.2

1.2

1.2

1.2

DIN EN 12668-2 compliant

Top connector

DIN EN 12668-2 compliant

MWB 60-4

MWB 60-4EN

MWB 60-O4

MWB 60-O4EN

56928

500049

57212

500237

8 x 9

8 x 9

8 x 9

8 x 9

.31 x .35

.31 x .35

.31 x .35

.31 x .35

4

4

4

4

60

60

60

60

30

30

30

30

1.2

1.2

1.2

1.2

DIN EN 12668-2 compliant

Top connector

DIN EN 12668-2 compliant

MWB 70-4

MWB 70-4EN

MWB 70-O4

MWB 70-O4EN

56929

500050

57213

500238

8 x 9

8 x 9

8 x 9

8 x 9

.31 x .35

.31 x .35

.31 x .35

.31 x .35

4

4

4

4

70

70

70

70

30

30

30

30

1.2

1.2

1.2

1.2

DIN EN 12668-2 compliant

Top connector

DIN EN 12668-2 compliant

MWB 80-4

MWB 80-O4

MWB 90-4

56930

57214

56931

8 x 9

8 x 9

8 x 9

.31 x .35

.31 x .35

.31 x .35

4

4

4

7

77

90

30

30

30

1.2

1.2

1.2

Top connector

Surface wave

MWK 45-2

MWK 60-2

MWK 70-2

67488

67489

67490

8 x 9

8 x 9

8 x 9

.31 x .35

.31 x .35

.31 x .35

2

2

2

45

60

70

15

15

15

0.6

0.6

0.6

Piezocomposite

element

Type 23

MWK 45-4

MWK 60-4

MWK 70-4

58938

58939

58940

8 x 9

8 x 9

8 x 9

.31 x .35

.31 x .35

.31 x .35

4

4

4

45

60

70

30

30

30

1.2

1.2

1.2

Custom configurations are available by special order.

Accessories

For explanations to the table data, refer to Selection Criteria on pages 2 through 4.

Small Angle Beam Transducers—European Standards

Page 27

25

Small Angle Beam Transducers—North American Standards

Miniature Angle Beam Transducers–Type MSW-QC (Quick Change)

Replaceable Wedge 10 mm (.375 in)

Wedge

Angle

A B C D E Thread

mm in mm in mm in mm in mm in in

45° 14.0 .55 22.6 .89 11.9 .47 14.7 0.58 14.0 0.55 1/2 - 28

60° 14.0 .55 26.4 1.04 14.0 .55 14.7 0.58 14.0 0.55 1/2 - 28

70° 14.0 .55 30.2 1.19 14.7 .58 14.7 0.58 14.0 0.55 1/2 - 28

90° 14.0 .55 29.2 1.15 15.5 .61 14.7 0.58 14.0 0.55 1/2 - 28

Replaceable Wedge 6 mm (.25 in)

Wedge

Angle

A B C D E Thread

mm in mm in mm in mm in mm in in

45° 11.4 .45 19.1 .75 9.4 .37 14.1 0.56 10.7 0.42 3/8 - 32

60° 11.4 .45 21.3 .84 11.2 .44 14.1 0.56 10.7 0.42 3/8 - 32

70° 11.4 .45 25.4 1.00 12.7 .50 14.1 0.56 10.7 0.42 3/8 - 32

90° 11.4 .45 24.1 .95 12.7 .50 14.1 0.56 10.7 0.42 3/8 - 32

Note: Standard wedge angles are specified for carbon steel. Custom configurations are available by special order.

Replaceable Wedge 13 mm (.50 in)

Wedge

Angle

A B C D E Thread

mm in mm in mm in mm in mm in in

45° 17.8 .70 26.7 1.05 14.0 .55 16.5 0.65 17.8 0.70 5/8 - 24

60° 17.8 .70 31.5 1.24 16.3 .64 16.5 0.65 17.8 0.70 5/8 - 24

70° 17.8 .70 35.8 1.41 17.3 .68 16.5 0.65 17.8 0.70 5/8 - 24

90° 17.8 .70 35.3 1.39 18.5 .73 16.5 0.65 17.8 0.70 5/8 - 24

Type MSW-QC

A

B

C

D

E

Freq.

(MHz)

Element Ø

mm in

Order Codes

Freq.

(MHz)

Element Ø

mm in

Order Code

Gamma

Series

Benchmark

Series

Alpha

Series

Standard

Wedge

(W = 118-340)

Accessories

Gamma

Series

Benchmark

Series

Alpha

Series

Standard

Wedge

(W = 118-340)

Accessories

1.0 13 .500 241-590 241-591

W-210 30°

W-211 45°

W-212 60°

W-213 70°

W-214 90°

Cables

BNC

118-140-012

LEMO-1

118-140-022

Wedge

Couplant

118-300-740

5.0

6 .250 224-590 224-591 124-591

W-200 30°

W-201 45°

W-202 60°

W-203 70°

W-204 90°

Cables

BNC

118-140-012

LEMO-1

118-140-022

Wedge

Couplant

118-300-740

1.5

10 .375 231-590 231-596

W-220 30°

W-221 45°

W-222 60°

W-223 70°

W-224 90°

10 .375 234-590 234-591 134-591

W-220 30°

W-221 45°

W-222 60°

W-223 70°

W-224 90°

13 .500 241-595 241-596

W-210 30°

W-211 45°

W-212 60°

W-213 70°

W-214 90°

13 .500 244-590 244-591 144-591

W-210 30°

W-211 45°

W-212 60°

W-213 70°

W-214 90°

2.25

6 .250 222-590 222-591 122-591

W-200 30°

W-201 45°

W-202 60°

W-203 70°

W-204 90°

7.5

6 .250 225-591 125-591

W-200 30°

W-201 45°

W-202 60°

W-203 70°

W-204 90°

10 .375 232-590 232-591 132-591

W-220 30°

W-221 45°

W-222 60°

W-223 70°

W-224 90°

10 .375 235-591 135-591

W-220 30°

W-221 45°

W-222 60°

W-223 70°

W-224 90°

13 .500 242-590 242-591 142-591

W-210 30°

W-211 45°

W-212 60°

W-213 70°

W-214 90°

13 .500 245-591 145-591

W-210 30°

W-211 45°

W-212 60°

W-213 70°

W-214 90°

3.5

6 .250 223-590 223-591 123-591

W-200 30°

W-201 45°

W-202 60°

W-203 70°

W-204 90°

10

6 .250 226-590

W-200 30°

W-201 45°

W-202 60°

W-203 70°

W-204 90°

10 .375 233-590 233-591 133-591

W-220 30°

W-221 45°

W-222 60°

W-223 70°

W-224 90°

10 .375 236-590

W-220 30°

W-221 45°

W-222 60°

W-223 70°

W-224 90°

13 .500 243-590 243-591 143-591

W-210 30°

W-211 45°

W-212 60°

W-213 70°

W-214 90°

13 .500 246-590

W-210 30°

W-211 45°

W-212 60°

W-213 70°

W-214 90°

Page 28

26

Miniature Angle Beam Transducers–Type MSWS (Captive Screw Mount)

Note: Standard wedge angles are specified for carbon steel. Custom configurations are available by special order.

Replaceable Wedge .50 in (13 mm)

Wedge

Angle

A B C D E F

mm in mm in mm in mm in mm in mm in

45° 18.5 .73 24.4 .96 10.7 .42 14.2 .56 18.5 .73 12.7 .50

60° 18.5 .73 27.4 1.08 12.7 .50 14.2 .56 18.5 .73 12.7 .50

70° 18.5 .73 29.5 1.16 13.7 .54 14.2 .56 18.5 .73 12.7 .50

90° 18.5 .73 39.6 1.56 14.7 .58 14.2 .56 18.5 .73 12.7 .50

Freq.

(MHz)

Element Ø

mm in

Order Codes

Freq.

(MHz)

Element Ø

mm in

Order Codes

Gamma

Series

Standard

Wedge

(W = 118-340)

Accessories

Gamma

Series

Standard

Wedge

(W = 118-340)

Accessories

1.0 13 .500 241-580

W-040 45°

W-042 60°

W-044 70°

W-046 80°

W-048 90°

Cables

BNC

118-140-012

LEMO-1

118-140-022

Wedge

Couplant

118-300-740

5.0

6 .250 224-580

W-028 45°

W-030 60°

W-032 70°

W-034 80°

W-036 90°

Cables

BNC

118-140-012

LEMO-1

118-140-022

Wedge

Couplant

118-300-740

2.25

6 .250 222-580

W-028 45°

W-030 60°

W-032 70°

W-034 80°

W-036 90°

13 .500 244-580

W-040 45°

W-042 60°

W-044 70°

W-046 80°

W-048 90°

13 .500 242-580

W-040 45°

W-042 60°

W-044 70°

W-046 80°

W-048 90°

10.0

6 .250 226-580

W-028 45°

W-030 60°

W-032 70°

W-034 80°

W-036 90°

3.5

6 .250 223-580

W-028 45°

W-030 60°

W-032 70°

W-034 80°

W-036 90°

13 .500 246-580

W-040 45°

W-042 60°

W-044 70°

W-046 80°

W-048 90°

13 .500 243-580

W-040 45°

W-042 60°

W-044 70°

W-046 80°

W-048 90°

A

B

D

E

F

C

Replaceable Wedge .25 in (6 mm)

Wedge

Angle

A B C D E F

mm in mm in mm in mm in mm in mm in

45° 11.9 .47 15.2 .60 7.6 .30 7.9 .31 12.2 .48 8.6 .34

60° 11.9 .47 16.5 .65 8.9 .35 7.9 .31 12.2 .48 8.6 .34

70° 11.9 .47 17.8 .70 9.7 .38 7.9 .31 12.2 .48 8.6 .34

90° 11.9 .47 22.9 .90 9.7 .38 7.9 .31 12.2 .48 8.6 .34

Type MSWS

Small Angle Beam Transducers—North American Standards

Page 29

27

Subminiature Angle Beam Type SMSWS (Screw Mount)

Note: Standard wedge angles are specified for carbon steel. Custom configurations

are available by special order.

Angle

A B C D E F

mm in mm in mm in mm in mm in mm in

45° 7.9 .31 6.4 .25 5.3 .21 4.8 .19 5.8 .23 7.1 .28

60° 7.9 .31 10.7 .42 5.3 .21 4.8 .19 5.8 .23 7.1 .28

70° 7.9 .31 10.7 .42 5.3 .21 4.8 .19 5.8 .23 7.1 .28

90° 7.9 .31 18.3 .72 8.6 .34 4.8 .19 5.8 .23 7.1 .28

Freq.

(MHz)

Element Ø

mm in

Order Codes

Gamma

Series

Standard

Wedge

(W = 118-340)

Accessories

2.25 3 .125 212-585

W-120 45°

W-121 60°

W-122 70°

W-123 90°

Cable

BNC

118-140-047

Wedge

Couplant

118-300-740

5.0 3 .125 214-585

W-120 45°

W-121 60°

W-122 70°

W-123 90°

10.0 3 .125 216-585

W-120 45°

W-121 60°

W-122 70°

W-123 90°

A

B

C

D

E

F

Small Angle Beam Transducers—North American Standards

Page 30

28

Applications

• VS shear wave type

– Detection of small, near surface flaws

– Thin-walled tubes and containers

– Rings

• VRY and VSY longitudinal wave types

– Coarse grain weld inspection

– Attenuative materials

– Austenitic welds

– "Creeping wave" applications with 70° models

Features and Benefits

• Excellent near surface resolution

• Reduce noise caused by scattering

• Durable, ergonomically-designed die cast housing

• Types VS and VSY have side mounted Microdot connectors

• Type VRY has Lemo 00 connectors

Angle Beam Transducers, Dual Element (TR)

Page 31

29

For explanations to the table data, refer to Selection Criteria on pages 2 through 4.

Accessories Description Type Remark

Cable SEKM2 (53001) for VS

SEKL2 (50710) for VRY

SEKN2 (53775) for VSY

Custom configurations are available by special order.

D

C

B

A

Type

Order

Code

a x b

mm in

f

(MHz)ß(Steel)Fmm in

Notes Sketch

VS 45

VS 45-EN

57660

500194

3.5 x 10

3.5 x 10

.14 x .39

.14 x .39

4

4

45

45

10

10

0.4

0.4 DIN EN 12668-2 compliant

Type 30

VS 60

VS 60-EN

57661

500195

3.5 x 10

3.5 x 10

.14 x .39

.14 x .39

4

4

60

60

10

10

0.4

0.4 DIN EN 12668-2 compliant

VS 70

VS 70-EN

57662

500196

3.5 x 10

3.5 x 10

.14 x .39

.14 x .39

4

4

70

70

10

10

0.4

0.4 DIN EN 12668-2 compliant

VRY 45 57663 10 x 22 .39 x .87 1.8 45 40 1.6

VRY and VSY angles are

longitudinal (compression)

wave suitable for testing

coarse grain materials.

Type 31VRY 60 57664 10 x 22 .39 x .87 1.8 60 35 1.4

VRY 70 57665 10 x 22 .39 x .87 1.8 70 35 1.4

VSY 45-2

VSY 60-2

VSY 70-2

67154

67155

67156

5 x 10

5 x 10

5 x 10

.20 x .39

.20 x .40

.20 x .41

2

2

2

45

60

70

16

16

16

0.6

0.6

0.6

70° models suitable for

creeping wave excitation in

mild steel.

Type 32

VSY 45-4

VSY 60-4

VSY 70-4

54577

54578

54579

5 x 10

5 x 10

5 x 10

.20 x .42

.20 x .43

.20 x .44

4

4

4

45

60

70

20

20

20

0.8

0.8

0.8

VRY 45

VSY 45

2ømV/Div

0, 5μs/Div

2dB/Div

0-4 MHz

2ømV/Div

0, 2μs/Div

2dB/Div

0-8 MHz

Typical waveform and frequency spectrum

Types VS, VRY and VSY

Case

Type

A

B

C

D

mm in mm in mm in mm in

Type 30 14 0.55 24 0.94 22 0.87 2 0.08

Type 31 29 1.14 53.5 2.1 45 1.77 5 0.20

Type 32 15 0.59 30 1.8 27 1.06

Angle Beam Transducers, Dual Element (TR)

Page 32

30

Page 33

31

Immersion Transducers

Applications

• Parts with irregular or complex geometry, such as gears and valves

• Automated or mechanized scanning

• Applications requiring very high near surface resolution or detection of very small flaws

• Scanning pipes, tubes and tanks

• Plates, billets and bars

• Disks, axles and shafts

Features and Benefits

• Acoustically matched for best efficiency in water

• Can be focused to a point (spherical) or to a line (cylindrical) for improved resolution, sensitivity and

signal-to-noise ratio (refer to Selection Criteria on pages 2 through 4)

• European models have fixed cable with LEMO-1 connector.

• North American models have waterproof UHF connector, except IPS type, which has non-waterproof Microdot.

Notes:

N = Near field length in water

Min = Minimum recommended focal length in water

Max = Maximum recommended focal length in water

Distances in steel are approximately 1/4 the distances given for water. Longer or shorter focal lengths may be available by special order.

Minimum and Maximum Standard Focal Lengths (Longer or

Shorter Focal Lengths May Be Available By Special Order)

Element Diameter: mm (in)

Frequency

(MHz)

mm

25.4

(in)

(1.0)mm20.0

(in)

(0.79)mm19.1

(in)

(0.75)mm12.7

(in)

(0.5)mm10.0

(in)

(0.39)mm9.5

(in)

(0.375)mm6.4

(in)

(0.25)mm5.0

(in)

(0.2)

1.0

N 109 (4.3) 67 (2.7) 61 (2.4) 28 (1.1)

Min 50 (2) 40 (1.5) 40 (1.5) 25 (1)

Max 75 (3) 50 (2) 50 (2) 25 (1)

2.0

N 135 (5.3) 34 (1.3)

Min 40 (1.5) 20 (0.8)

Max 100 (4) 25 (1)

2.25

N 245 (9.6) 138 (5.4) 61 (2.4) 34 (1.4) 16 (0.6)

Min 50 (2) 40 (1.5) 25 (1) 20 (0.8) 13 (0.5)

Max 150 (6) 100 (4) 50 (2) 25 (1) 13 (0.5)

3.5

N 381 (15) 215 (8.4) 94 (3.7) 53 (2.1) 24 (0.9)

Min 50 (2) 40 (1.5) 25 (1) 20 (0.8) 13 (0.5)

Max 200 (8) 150 (6) 60 (2.5) 40 (1.5) 17 (0.7)

4.0

N 270 (10.7) 67 (2.6)

Min 40 (1.5) 20 (0.8)

Max 200 (8) 50 (2)

5.0

N 544 (21.4) 337 (13.4) 307 (12.0) 137 (5.4) 84 (3.3) 76 (3.0) 35 (1.3) 21 (0.9)

Min 50 (2) 40 (1.5) 40 (1.5) 25 (1) 20 (0.8) 20 (0.8) 13 (0.5) 10 (0.4)

Max 200 (8) 200 (8) 200 (8) 100 (4) 60 (2.4) 50 (2) 25 (1.0) 15 (0.6)

10.0

N 615 (24.1) 272 (10.7) 152 (6.0) 69 (2.7) 42 (1.7)

Min 40 (1.5) 25 (1) 20 (0.8) 13 (0.5) 10 (0.4)

Max 200 (8) 150 (6) 100 (4) 50 (2) 30 (1.2)

15.0

N 406 (16) 228 (9.0) 104 (4.0)

Min 25 (1) 20 (0.8) 13 (0.5)

Max 150 (6) 150 (6) 60 (2.5)

Page 34

32

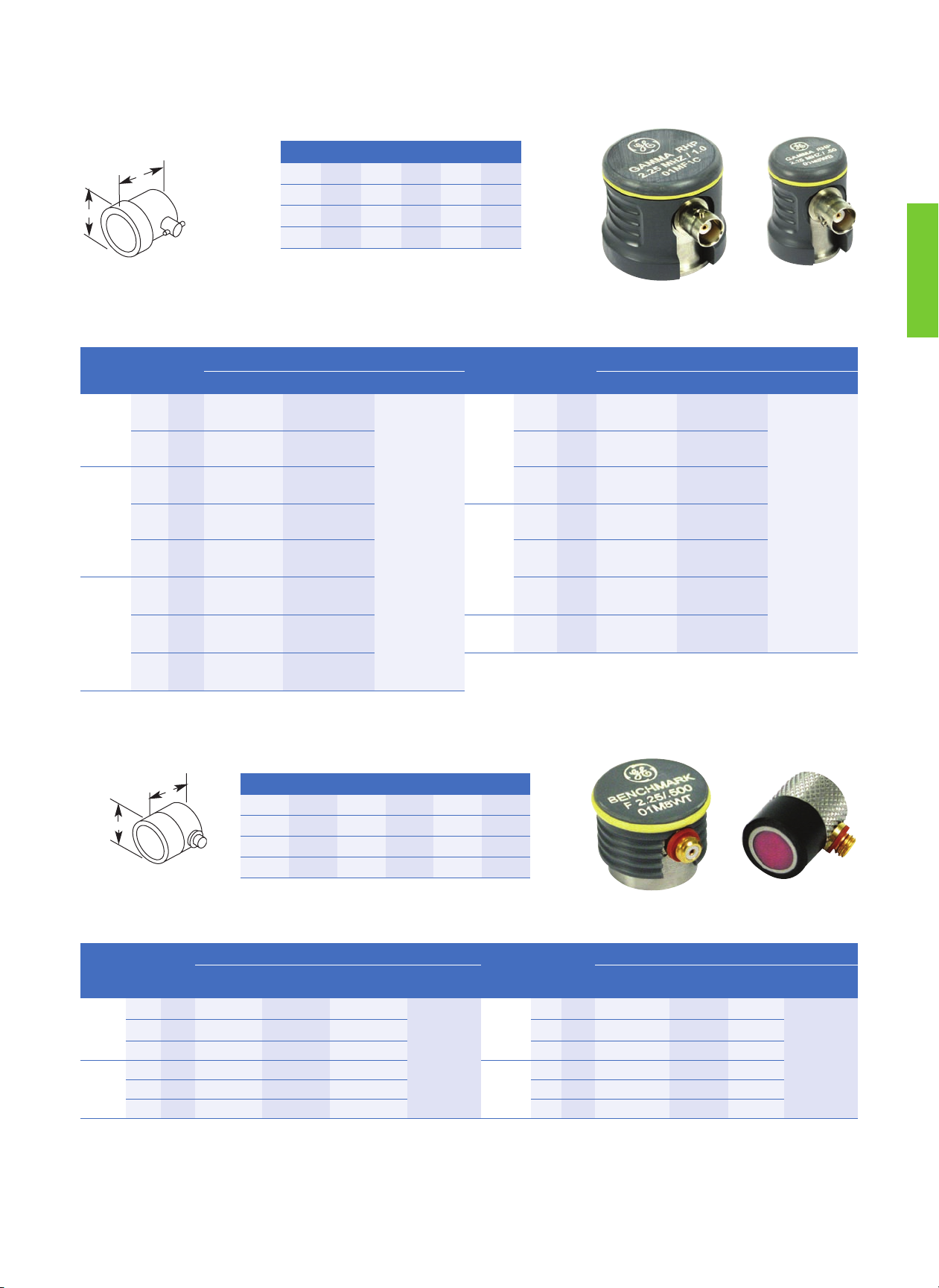

Immersion Transducers—European Standards

Z..N, H..N and L..N Z..K, H..K and L..K Z..M, H..M and L..M

Case

Type

A B C

mm in mm in m feet

Type 33 24 0.94 60 2.36 2.5 8.2

Type 34 13 0.51 60 2.36 2.5 8.2

Type 35 9.5 0.37 25 0.98 1.5 3.9

Z4N Z4K

1,0V/Div0,4V/Div

2dB/Div 2dB/Div

0, 5μS/Div0, 2μS/Div

0 - 8MHz

Typical waveform and frequency spectrum

0 - 8MHz

1, 0V/Div

H5K

0, 1μs/Div

2dB/Div

C

B

A

0-10 MHz

Types Z, H and L

Type

Order

CodeDmm inf(MHz)Nmm in

Notes Sketch

Z 1 N

Z 2 N

Z 4 N

Z 5 N

53317

53318

53319

54705

20

20

20

20

0.79

0.79

0.79

0.79

1

2

4

5

64

127

254

318

2.5

5.0

10.0

12.5

High sensitivity (gain

reserve) for testing small to

mid-size objects.

Type 33

Z 2 K

Z 4 K

Z 5 K

Z 10 K

53341

53342

53732

54704

10

10

10

10

0.39

0.39

0.39

0.39

2

4

5

10

32

64

80

160

1.3

2.5

3.1

6.3

Type 34

Z 5 M

Z 10 M

Z 15 M

55468

53367

55576

5

5

5

0.20

0.20

0.20

5

10

15

20

40

60

0.8

1.6

2.4

Type 35

H 1 N

H 2 N

53042

530432020

0.79

0.7912

64

127

2.5

5.0

Shock wave transducers

especially suitable for

thickness measurement or

other applications requiring

high resolution.

Type 33

H 2 K

H 5 K

H 10 K

53300

53032

55818

10

10

10

0.39

0.39

0.39

2

5

10

32

80

160

1.3

3.1

6.3

Type 34

H 5 M

H 10 M

53258

5304155

0.20

0.20510

20400.8

1.6

Type 35

L 1 N

L 2 N

53133

531342020

0.79

0.7912

63

127

2.5

5.0

Broadband for applications

requiring high resolution.

Type 33

L 2 K

L 5 K

53137

531391010

0.39

0.3925

32801.3

3.1

Type 34

L 5 M 53143 5 0.20 5 20 0.8 Type 35

Also available with spherical (point) and cylindrical (line) focusing. Specify focal length. For available focal lengths,

refer to the table at beginning of the Immersion Transducers section.

Custom configurations are available by special order.

For explanations to the table data, refer to Selection Criteria on pages 2 through 4.

Page 35

33

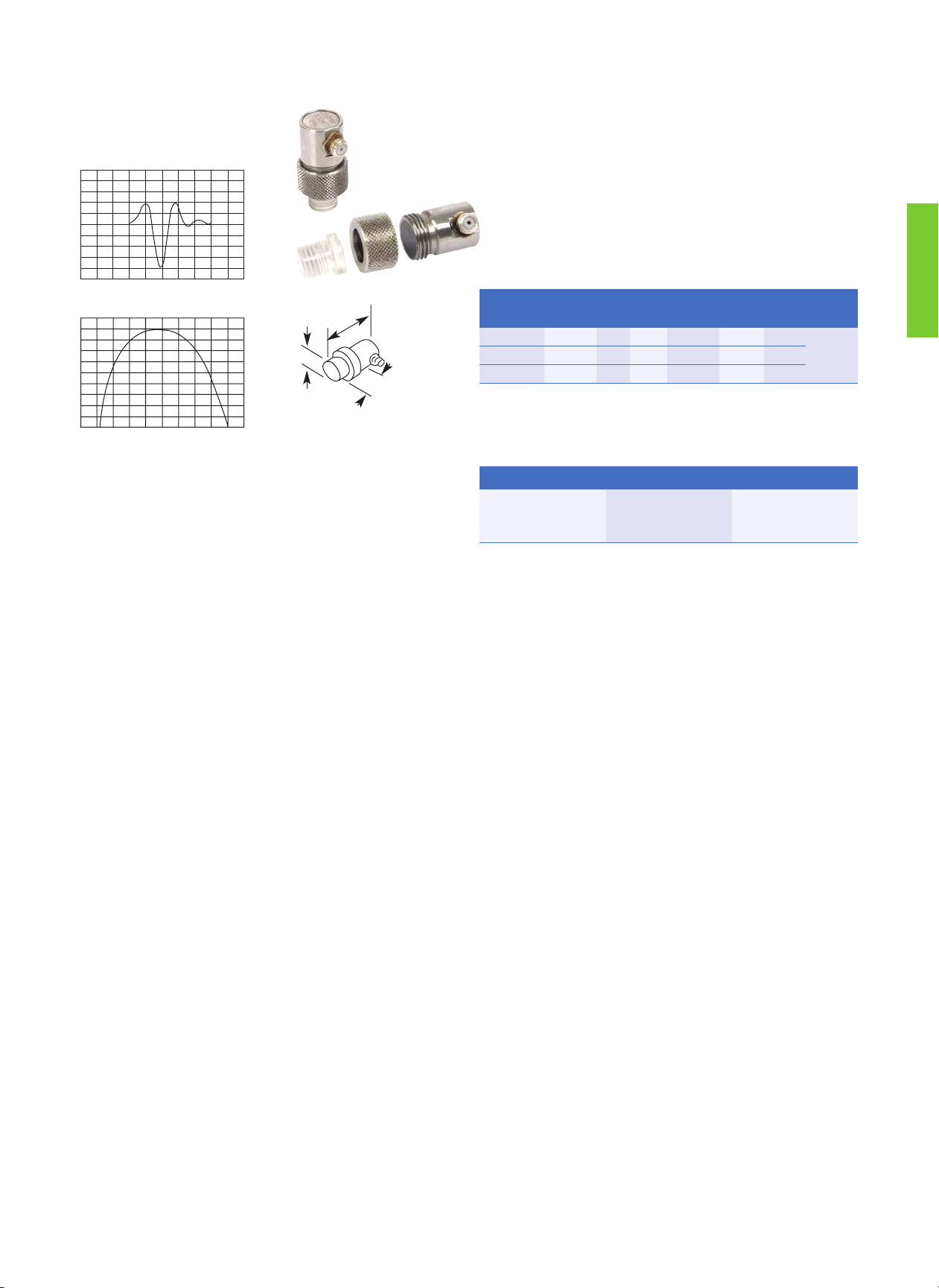

Immersion Transducers—North American Standards

Immersion Transducers—Types ISS and IS

* Focus: S = Spherical, C = Cylindrical, N = Non-focus. Focal length must be specified. For available focal lengths, refer to the table at the beginning of the Immersion

Transducers section. Custom configurations are available by special order.

Freq.

(MHz)

Element Ø

mm in

Order Code

Freq.

(MHz)

Element Ø

mm in

Order Code

*Focus

Alpha

Series

Gamma

Series

Benchmark

Series

*Focus

Alpha

Series

Gamma

Series

Benchmark

Series

1.0

19 .750

S

C

N

251-360

251-370

251-380

5.0

6 .250

S

C

N

124-280

124-290

124-300

224-280

224-290

224-300

824-300

25 1.00

S

C

N

261-360

261-370

261-380

861-360

861-370

861-380

10 .375

S

C

N

134-280

134-290

134-300

234-280

234-290

234-300

834-280

834-290

834-300

2.25

6 .250

S

C

N 122-300

222-280

222-290

222-300 822-300

13 .500

S

C

N

144-280

144-290

144-300

244-280

244-290

244-300

844-280

844-290

844-300

10 .375

S

C

N

132-280

132-290

132-300

232-280

232-290

232-300 832-300

19 .750

S

C

N

154-360

154-370

154-380

254-360

254-370

254-380

854-360

854-370

854-380

13 .500

S

C

N

142-280

142-290

142-300

242-280

242-290

242-300

842-280

842-290

842-300

25 1.00

S

C

N

164-360

164-370

164-380

264-360

264-370

264-380

864-360

864-370

864-380

19 .750

S

C

N

152-360

152-370

152-380

252-360

252-370

252-380

852-360

852-370

852-380

10.0

6 .250

S

C

N

126-280

126-290

126-300

226-280

226-290

226-300

25 1.00

S

C

N

162-360

162-370

162-380

262-360

262-370

262-380

862-360

862-370

862-380

10 .375

S

C

N

136-280

136-290

136-300

236-280

236-290

236-300

3.5

13 .500

S

C

N

143-280

143-290

143-300

243-280

243-290

243-300

843-280

843-290

843-300

13 .500

S

C

N

146-280

146-290

146-300

246-280

246-290

246-300

19 .750

S

C

N

153-360

153-370

153-380

253-360

253-370

253-380

853-360

853-370

853-380

19 .750

S

C

N

156-360

156-370

156-380

256-360

256-370

256-380

25 1.00

S

C

N

163-360

163-370

163-380

263-360

263-370

263-380

863-360

863-370

863-380

15.0

6 .250

S

C

N

127-280

127-290

127-300

Note: Waterproof cables are in the Accessories Section.

6 .250 1.5 in S

127-302

(TTC-100)

10 .375

S

C

N

137-280

137-290

137-300

13 .500

S

C

N

147-280

147-290

147-300

Element Ø

A

B

mm in mm in mm in

6 .25 16 0.63 39.4 1.55

10 .375 16 0.63 39.4 1.55

13 .50 16 0.63 39.4 1.55

19 .75 25.4 1.00 45.0 1.77

25 1.0 31.8 1.25 46.2 1.82

B

IS

ISS

A

Types ISS and IS

Page 36

34

Immersion Transducers—North American Standards

Immersion Transducers—Type IPS

Immersion Transducers—Type IR

Freq.

(MHz)

Element Ø

mm in

Order Code

Freq.

(MHz)

Element Ø

mm in

Order Code

*Focus

Alpha

Series

Gamma

Series

Accessories *Focus

Alpha

Series

Gamma

Series

Accessories

2.25 6 0.25 N 122-340 222-340

Cable

BNC

118-140-012

Non-

waterproof

10.0 6 0.25

S

C

N

126-320

126-330

126-340

226-320

226-330

226-340

Cable

BNC

118-140-012

Non-

waterproof

5.0 6 0.25

S

C

N

124-320

124-330

124-340

224-320

224-330

224-340

15.0 6 0.25

S

C

N

127-320

127-330

127-340

Freq.

(MHz)

Element Ø

mm in

Order Code

Freq.

(MHz)

Element Ø

mm in

Order Code

*Focus

Alpha

Series

Gamma

Series

*Focus

Alpha

Series

Gamma

Series

2.25

6 0.25 N 122-420 222-420

5.0

6 0.25SC

N

124-400

124-410

124-420

224-400

224-410

224-420

10 0.375SC

N

132-400

132-410

132-420

232-400

232-410

232-420

10 0.375S C

N

134-400

134-410

134-420

234-400

234-410

234-420

13 0.50

S

C

N

142-400

142-410

142-420