Page 1

PocketMIKE

Operating Manual

©2004 GE Inspection Technologies, LP

50 Industrial Park Road

Lewistown, PA 17044

Phone: +1 (717) 242-0327

Fax: +1 (717) 242-2606

www.GEInspectionTechnologies.com

021-002-279

GE Inspection Technologies Systems GmbH

Robert-Bosch-Straße 3

D – 50354 Hürth

Phone: +49 (0) 2233 601111

Fax.: +49 (0) 2233 601402

Page 2

Page 3

PocketMIKE

Operating Manual version 2.0

Page 4

Page 5

Important Notice

The following information must be read and understood by any user of

a GE Inspection Technologies ultrasonic thickness gauge. Failure to

follow these instructions can lead to errors in thickness measurements

or other test results. Decisions based on erroneous results can, in turn,

lead to property damage, personal injury or death.

General Warnings

Proper use of ultrasonic test equipment requires three essential elements:

◆ Selection of the correct test equipment.

◆ Knowledge of the specific “test application requirements.”

◆ Training on the part of the instrument operator.

This operating manual provides instruction in the basic set up and

operation of the GE Inspection Technologies thickness gauge.

There are, however, additional factors which affect the use of ultrasonic

test equipment. Specific information regarding these additional factors

is beyond the scope of this manual. The operator should refer to textbooks on the subject of ultrasonic testing for more detailed information.

Operator Training

Operators must receive adequate training before using ultrasonic test

equipment. Operators must be trained in general ultrasonic testing

procedures and in the set up and performance required by a particular

test. Operators must understand:

◆ Soundwave propagation theory.

◆ Effects of the sound velocity of the test material.

◆ Behavior of the sound wave where two different materials

are in contact.

◆ Areas covered by the sound beam.

PocketMIKE Operating Manual Page i

Page 6

More specific information about operator training, qualification,

certification, and test specifications is available from various technical

societies, industry groups, and government agencies.

Testing Limitations

In ultrasonic testing, information is obtained only from within the limits

of the sound beam. Operators must exercise great caution in making

inferences about the test material outside the limits of the sound beam.

For example, when testing large materials it may be impossible or

impractical to inspect the entire test piece. When a less-than-complete

inspection is to be performed, the operator must be shown the specific

areas to inspect. Inferences about the condition of areas not inspected,

based on data from the evaluated areas, should only be attempted by

personnel fully qualified and trained in applicable standards of statistical evaluation. In particular, materials subject to erosion or corrosion, in

which conditions can vary significantly in any given area, should only

be evaluated by fully trained and experienced operators.

Sound beams reflect from the first interior surface encountered. Because of part geometry and overlapped flaws or overlapped surfaces,

thickness gauges may measure the distance to an internal flaw rather

than to the back wall of the material. Operators must take steps to

ensure that the entire thickness of the test material is being examined.

Ultrasonic Thickness Measurement

Critical Operating Procedures

The following operating procedures must be observed by all users of

ultrasonic thickness gauges in order to minimize errors in test results.

1. Calibration of Sound Velocity

The principle of operation of an ultrasonic thickness gauge is that the

instrument measures the time of flight of an ultrasonic pulse through

the test piece and multiplies this time by the sound velocity of the

material. Thickness measuring error is minimized by ensuring that the

sound velocity to which the instrument is calibrated is the sound

Page ii PocketMIKE Operating Manual

Page 7

velocity of the material being tested. Actual sound velocities in materials often vary significantly from the values found in published tables.

In all cases, best results are obtained if the instrument is calibrated on a

velocity reference block made from the same material as the test piece;

this block should be flat and smooth and as thick as the maximum

thickness of the test piece.

Operators should also be aware that the sound velocity may not be

constant in the material being tested; heat treating, for example, can

cause significant changes in sound velocity. This must be considered

when evaluating the accuracy of the thickness provided by this instrument. Instruments should always be calibrated before testing, and the

calibration should be checked after testing, to minimize testing errors.

2. Probe Zero Procedure

Probe zeroing is the process of measuring the time of flight of sound

through the transducer. The transducer time of flight is then automatically removed from each measurement so that only the test piece time

of flight is used to calculate and display the thickness value. The probe

zeroing process is performed automatically while the probe is coupled.

3. Effects of Temperature on Calibration

Temperature variations change the sound velocity of materials and

transducer delay lines and, therefore, calibrations. All calibrations

should be performed on-site, and with test blocks at the same

temperature as the test piece, to minimize errors due to temperature

variations.

4. Transducer Selection

The transducer used in testing must be in good condition without

noticeable wear of the front surface. Badly worn transducers will have a

reduced effective measuring range. The specified range of the transducer must include the complete range of thicknesses to be tested. The

temperature of the material to be tested must be within the transducer’s

temperature range.

PocketMIKE Operating Manual Page iii

Page 8

5. Use of Couplants

Operators must be familiar with the use of ultrasonic couplants. Testing

skills must be developed so that couplant is used and applied in a

consistent manner to minimize variations in couplant layer thickness

and errors in test results. Calibration and actual testing should be

performed under similar coupling conditions, using a minimum amount

of couplant and applying consistent pressure on the transducer.

6. Doubling

Ultrasonic thickness gauges will, under certain conditions, display

readings which are twice (or, in some cases, three times) the actual

material thickness being measured. This effect, commonly known as

“doubling,” can occur below the minimum specified range of the

transducer. If the transducer being used is worn, doubling is possible at

a thickness greater than the minimum of the specified range.

When using a new transducer, any reading which is less than twice the

minimum specified range of the transducer may be a “doubled” reading, and the thickness of the material being tested should be verified by

the use of other methods. If the transducer shows any sign of wear,

doubling may occur at a thickness greater than twice the minimum of

the specified range. This thickness should be determined by calibrating

the PocketMIKE on reference blocks that represent the complete range

of possible thicknesses that may be encountered in testing. This is

particularly important when the test piece is being ultrasonically

measured for the first time or in any case where the history of thickness

of the test specimen is unknown.

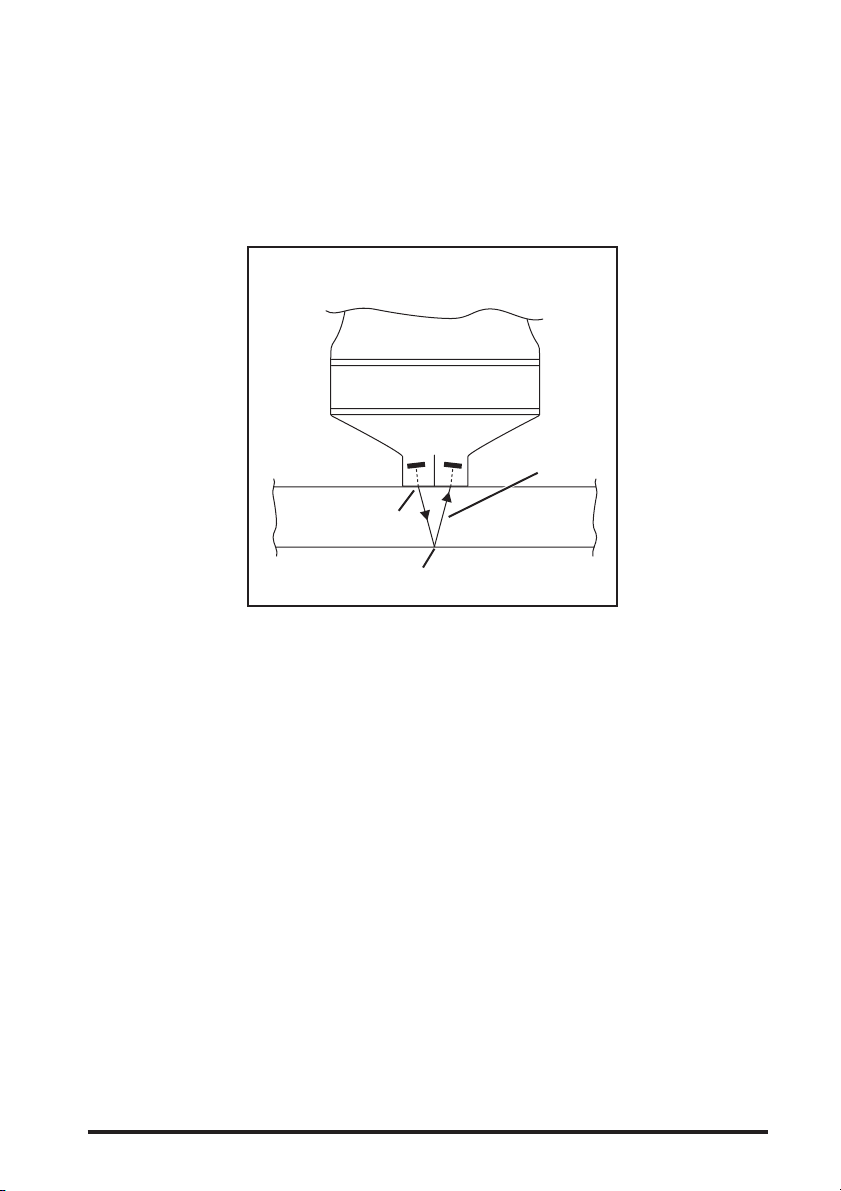

Physics of Ultrasound

These instruments operate on the ultrasonic pulse-echo principle,

similar to sonar. A short ultrasonic pulse is transmitted into the part by a

probe (transducer). The pulse travels through the material under test

until it encounters an interface, that is a material with substantially

different physical characteristics, such as air or liquid, at the back

surface of the part. At the interface, the pulse is reflected back to the

probe.

Page iv PocketMIKE Operating Manual

Page 9

The time needed for the pulse to make this round trip is divided by two

and multiplied by the sound velocity of the material under test. The

result is the thickness of the material.

The figure below illustrates the pulse-echo principle of ultrasonic

thickness measurement.

Dual

Probe

Acoustic

Zero

Backwall Echo

Dual Element Thickness Measurement

V-Path of

Pulse

PocketMIKE Operating Manual Page v

Page 10

Page vi PocketMIKE Operating Manual

Page 11

Contents

Chapter 1: Getting Started ................................................................... 1

1.1 Installing the Battery ...................................................................................... 1

1.2 Powering On the Instrument ......................................................................... 2

Chapter 2: Quick Help for Interpreting the Keypad and

Display Screen ..................................................................................... 3

2.1 Keypad Operations ......................................................................................... 4

2.2 Display Indicators ........................................................................................... 5

2.3 Types of Display Screens ................................................................................ 6

Chapter 3: Setting Up the Instrument ................................................. 9

3.1 Adjusting the Display’s Brightness (Backlight) .......................................... 10

3.2 Thickness Calibration ................................................................................... 11

3.3 Velocity Calibration ...................................................................................... 12

3.4 Setting the Measurement Units and Resolution ......................................... 13

3.5 Reversing the Display’s Orientation ........................................................... 13

3.6 Replacing the Probe ...................................................................................... 14

3.7 Disabling Instrument Adjustment Controls ............................................... 15

3.8 Rotating the Display ..................................................................................... 15

Chapter 4: Measuring Thickness ...................................................... 17

Chapter 5: Specifications and Declaration ....................................... 19

5.1 Specifications ................................................................................................. 19

5.2 EC Declaration of Conformity ..................................................................... 20

Chapter 6: Application Considerations ............................................. 21

6.1 Material Consistency in Test Specimen ...................................................... 21

6.2 Flaws in the Specimen Being Tested ............................................................ 22

6.3 Condition of the Test Specimen’s Surface................................................... 22

6.4 Test Specimens with Curved Surfaces ........................................................ 22

Chapter 7: Troubleshooting Guide ................................................... 25

Chapter 8: Warranty and Repair ....................................................... 27

8.1 Warranty ........................................................................................................ 27

8.2 Service ............................................................................................................ 29

Chapter 9: Appendix .......................................................................... 31

Index ................................................................................................... 33

PocketMIKE Operating Manual Page vii

Page 12

Page viii PocketMIKE Operating Manual

Page 13

Getting Started

To begin using your PocketMIKE, you need only install a battery in

the instrument and power it on.

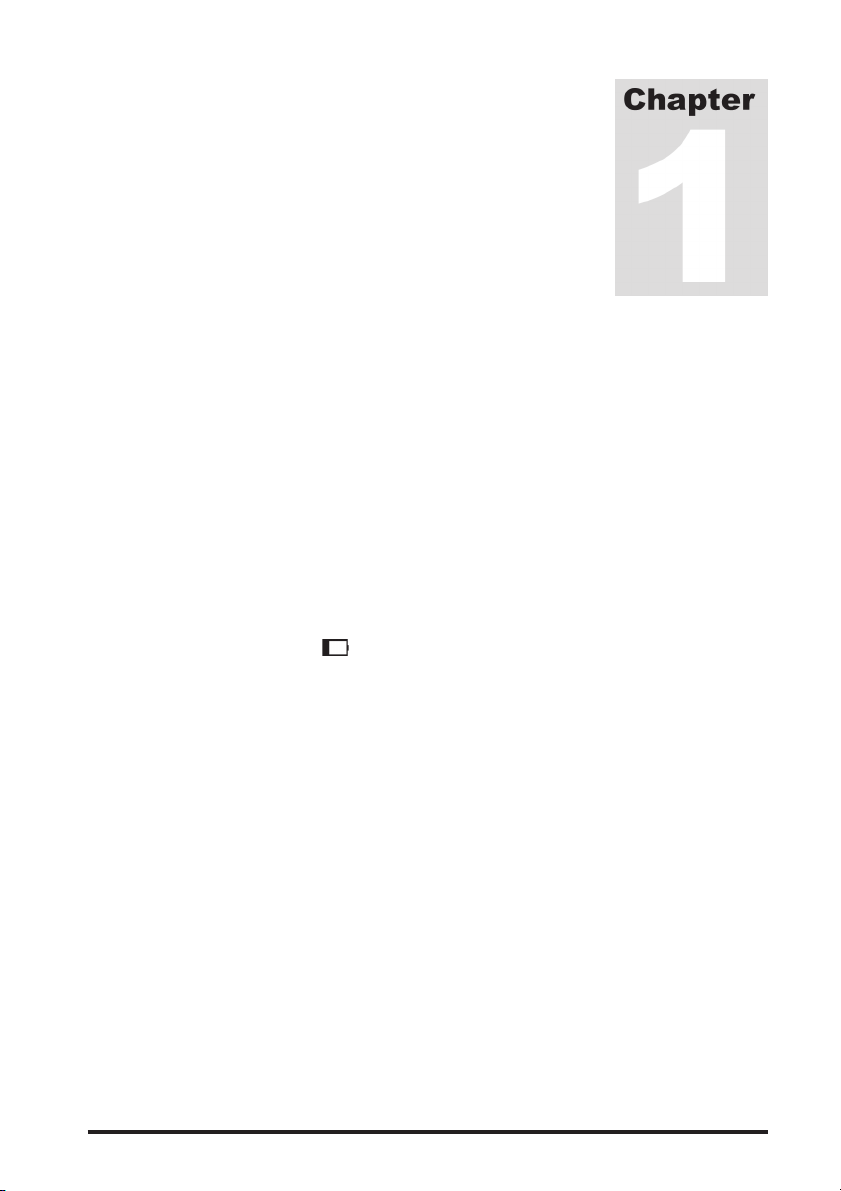

1.1 Installing the Battery

◆ The instrument is powered by one “AA” size Alkaline

battery.

◆ An alkaline battery will provide approximately 80 hours of

service life.

◆ Replace the battery as soon as possible after the low battery

indicator (

To install the battery, refer to Figure 1-1 and follow these steps:

) appears on the instrument’s display.

Step 1—Unscrew the probe locking ring and remove the probe from its

sealed position.

Step 2—Insert one “AA” battery in the instrument. Make sure the

battery poles are oriented as shown in Figure 1-1. The instrument will

not function if the battery is inserted incorrectly.

Step 3—Reinstall and finger tighten the probe locking ring until the

ring is seated against the instrument body.

PocketMIKE Operating Manual Page 1

Page 14

Figure 1-1—Battery Replacement

NOTE: Avoid using tools which may over-tighten the probe locking

ring.

NOTE: When the low battery indicator ( ) lights, replace the battery

as soon as possible. When the battery is too weak for reliable operation,

the instrument automatically powers off. Instrument settings are saved

and restored when batteries are replaced and the instrument is again powered on.

1.2 Powering On the Instrument

To power on the instrument, simply press . Pressing and holding

this key for more than three seconds, when the instrument is on, will

cause it to power off. If the instrument is uncoupled and no keys are

pressed for three minutes, the instrument will automatically power off.

Page 2 PocketMIKE Operating Manual

Page 15

Quick Help for

Interpreting the Keypad

and Display Screen

PocketMIKE controls and settings are displayed in the instrument’s

screen and adjusted using various combinations of key presses. This

chapter identifies the display screen’s features, the keypad functions,

and the general display structure. Topics covered include:

◆ Keypad Operations (section 2.1)

◆ Display Indicators (section 2.2)

◆ On-Screen Menu Structure (section 2.3)

FIGURE 2-1—PocketMIKE

PocketMIKE Operating Manual Page 3

Page 16

2.1 Keypad Operations

The following is a brief summary of each key’s function. For more

complete information, refer to the referenced manual section.

Powers the instrument on and off (section 1.2)

Launches and ends the thickness calibration

process (section 3.2)

Reverses display orientation (section 3.5)

Changes on-screen values when in thickness and

velocity calibration modes (sections 3.2 and 3.3)

Changes setting when in Backlight Adjustment

mode (section 3.1)

Reverses display orientation (section 3.5)

Changes on-screen values when in thickness and

velocity calibration modes (sections 3.2 and 3.3)

Changes setting when in Backlight Adjustment

mode (section 3.1)

and Simultaneous pressing of these keys selects

measurement units and resolution (section 3.4)

Simultaneous pressing and HOLDING these keys

activates and deactivates SAFE mode in which most

instrument controls are disabled (section 3.7)

Launches and ends the Velocity Calibration process

and activates Backlight Adjustment mode

(sections 3.3 and 3.1)

Page 4 PocketMIKE Operating Manual

Page 17

2.2 Display Indicators

The PocketMIKE display (Figure 2-2) includes indicators (icons)

around its perimeter and text or numerical values in its center. Indicators and other display contents vary in response to instrument settings,

key presses, and measurement status. The following is a summary of

display indicators. For more complete information, refer to the

referenced manual section.

FIGURE 2-2—Each of these screen

indicators are displayed only under

certain conditions.

Indicates instrument is in Thickness Measurement

mode when display is not inverted (chapter 4).

Thickness Calibration mode is in process

(section 3.2).

Velocity Calibration mode is in process

(section 3.3).

Indicates instrument is in Backlight Adjustment

mode (section 3.1).

Indicates a low battery condition (section 1.1).

Displayed when probe is coupled (chapter 4).

Unit of measurement set to inches (Imperial Units)

(section 3.4).

Unit of measurement set to millimeters (Metric

Units) (section 3.4).

PocketMIKE Operating Manual Page 5

Page 18

SAFE Control lockout is activated, instrument controls are locked

out (section 3.7).

donE Displayed when lockout mode has been disabled (section 3.7).

HOT Instrument’s internal temperature has exceeded defined

limits (chapter 4)

FAIL (Diagnostic Message displayed after power-up)

Instrument memory is corrupted. Return for service.

CAL Calibration mode for sound velocity is active. Thickness

may be calibrated.

2.3 Types of Display Screens

The PocketMike offers three general display screen modes, similar to

the three shown below:

◆ Thickness Measurement Display (Figure 2-3)

◆ Calibration Mode (Figure 2-4)

◆ Backlight Adjustment Mode (Figure 2-5)

FIGURE 2-3—In thickness measurement

mode,

upper edge. Other on-screen indicators

are shown here. See Chapter 4 for more

details related to Thickness Measurement

mode and related display indicators.

Page 6 PocketMIKE Operating Manual

appears along the display’s

Page 19

FIGURE 2-4—While the calibration process is underway,

appears (and flashes) along the display’s edge. The calibration

display varies depending on whether velocity or thickness

calibration mode is indicated. See sections 3.2 and 3.3 for more

details related to instrument calibration.

FIGURE 2-5—Pressing twice (when operating in Thickness

Measurement mode) launches the Backlight Adjustment mode.

Pressing

or sets backlight to On, OFF, or Auto (section 3.1).

PocketMIKE Operating Manual Page 7

Page 20

Page 8 PocketMIKE Operating Manual

Page 21

Setting Up the

Instrument

Instrument settings can be configured to match your test conditions.

This chapter explains how to configure the instrument to measure

thickness. Topics covered include:

◆ Adjusting Display Brightness or Backlighting (section 3.1)

◆ Thickness Calibration (section 3.2)

◆ Velocity Calibration (section 3.3)

◆ Setting the Measurement Units and Resolution

(section 3.4)

◆ Reversing the Instrument’s Display Orientation (section 3.5)

◆ Replacing a Probe (section 3.6)

◆ Disabling All Adjustment Controls (section 3.7)

◆ Rotating the Display (section 3.8)

NOTE: Prior to setting up an instrument, a battery must be installed and

the instrument must be powered on. Refer to Chapter 1 for information

on installing a battery and turning the instrument on.

NOTE: Before using this instrument, read the “Important Notices” at

the beginning of this manual, and Chapter 6 — Application Consider-

ations, for important information on test conditions that affect measurement results.

PocketMIKE Operating Manual Page 9

Page 22

3.1 Adjusting the Display’s Brightness

(Backlight)

The instrument’s backlight feature illuminates the display to improve

visibility when operating in low light conditions. Note that using the

backlight feature reduces battery life.

Press

When this mode is active,

When Auto mode is selected, the backlight automatically illuminates

each time a key is pressed or when the probe is coupled. The backlight

remains illuminated for approximately 4 seconds after which it automatically extinguishes. It will re-illuminate with the next key press or

coupling.

one or two times to activate the Backlight Adjustment mode.

appears in the display’s corner. Press

or to select between the following backlight modes:

◆ On

◆ OFF

◆ Auto

Page 10 PocketMIKE Operating Manual

Page 23

3.2 Thickness Calibration

NOTE: Worn, cracked, or otherwise damaged probe tips will affect the

accuracy of thickness measurements. Refer to section 3.6 for information on probe replacement.

The instrument offers two calibration modes, thickness and velocity

(section 3.3). To launch thickness calibration mode, press

the instrument’s display shows the

throughout the calibration process,

indication. Note that

appears (and flashes) along

the display’s upper edge. Figure 3-1 illustrates the displayed parameters and key presses required to navigate through the thickness

calibration process. Note that calibration should be performed with the

instrument set to its highest resolution.

NOTE: Calibration standards of known thickness should be of the same

material, sound velocity, and curvature of the material being tested. Best

results are achieved with a standard that is slightly thicker than the thickest expected test piece.

anytime

Uncouple when reading is stable then

press

nominal value.

FIGURE 3-1—Thickness Calibration Procedure

PocketMIKE Operating Manual Page 11

or to adjust reading to

Page 24

3.3 Velocity Calibration

The user can directly specify the acoustic velocity of the material

being tested. To launch velocity calibration mode, press

the instrument’s display shows

currently set acoustic velocity (in units of inches-per-microsecond or

meters-per-second depending on units-of-measurement settings).

. The instrument displays the

anytime

Note that throughout the velocity calibration process,

(and flashes) along the display’s upper edge. Figure 3-2 illustrates the

displayed parameters and key presses required to navigate through the

velocity calibration process.

NOTE: A thickness standard is not required to perform a velocity calibration. However, following a velocity calibration the instrument’s accuracy should be checked using a sample of known thickness and with a

sound velocity that matches the user-inputted value. A table of approximate sound velocities for various materials can be found in Chapter 9.

appears

FIGURE 3-2—Velocity Calibration Procedure

Page 12 PocketMIKE Operating Manual

Page 25

3.4 Setting the Measurement Units

and Resolution

Measured thickness can be displayed in either metric or imperial units

and to one of two levels of resolution. Available measurement units

and resolution include:

— 0.00 inches — 0.0 mm

— 0.000 inches — 0.00 mm

Notice that the active units of measurement are indicated by

, which appear along the bottom of the display. To select the unit

and resolution of measurement. Press

anytime

also determine the units in which acoustic velocity is displayed.

NOTE: Selecting a resolution setting of 0.0 mm or 0.00 inch may

increase battery life.

is displayed. The unit of measurement selected will

and simultaneously

3.5 Reversing the Display’s

Orientation

The displayed thickness and units of measurement ( or ) can

be reversed (displayed upside down) to allow for easy display-screen

reading with the instrument in either the probe up or probe down

orientation. To reverse the display, simply press

instrument’s display shows

return the display to its original orientation. Note that the orientation

of other on-screen indicators do not change. A press of the key

return the display to its normal orientation and enter velocity calibration mode.

. A second press of either key will

or anytime the

or

will

PocketMIKE Operating Manual Page 13

Page 26

3.6 Replacing the Probe

Worn, cracked, or otherwise damaged probe (transducer) contact

surfaces can affect measurement accuracy. The probe and locking ring

are replaced as an assembly. Refer to Figure 3-3 for the probe replacement procedure. Always recalibrate the instrument after the probe is

replaced or removed.

FIGURE 3-3—Probe Replacement

Page 14 PocketMIKE Operating Manual

Page 27

3.7 Disabling Instrument Adjustment

Controls

The control lockout feature disables all instrument controls (except

Power Off and Display Reversal). To activate the lockout, simultaneously press and hold

the word “SAFE” appears on the display screen. When lockout mode

is activated, the instrument calibration, units of measurement, and

backlight setting can not be adjusted. This mode is disabled by repeating the simultaneous key press and is indicated when “donE” appears

on the display. Note that powering the instrument off and back on does

not disable the lockout mode.

and for longer than three seconds until

3.8 Rotating the Display

The plastic display housing on the top of the PocketMike can be

rotated through 180 degree of motion. To rotate the display housing

grasp the PocketMike in one hand while gently turning the display

housing. Do not attempt to turn the display housing past its limits or

damage could result.

PocketMIKE Operating Manual Page 15

Page 28

Page 16 PocketMIKE Operating Manual

Page 29

Measuring Thickness

The PocketMIKE measures thickness in units of inches or mm. Read

the following notices and instructions before measuring thickness.

NOTE: The instrument is designed to measure materials with surface

temperatures of up to 100°C. However, the instrument’s internal electronics should not be allowed to reach temperatures above 60°C for extended periods of time. When internal instrument temperature reaches

60°C, the instrument displays the word “Hot.” This warning will remain

until the instrument’s internal temperature drops below 55°C. When internal temperature reaches 85°C, the HOT warning is momentarily displayed, than the instrument is automatically powered off.

NOTE: Before using this instrument, read the “Important Notices” at

the beginning of this manual, and Chapter 6 — Application Considerations, for important information on test conditions that affect measurement results.

NOTE: ALWAYS calibrate the PocketMIKE before measuring thickness. Refer to sections 3.2 and 3.3 for instructions.

When

ness. Follow these steps to measure thickness:

Step 1—Remove dirt, loose material, and couplant residue from the

surface of the test piece.

Step 2—Be sure that the instrument has been calibrated to match the

sound velocity of material being tested.

PocketMIKE Operating Manual Page 17

is displayed, the instrument is ready to measure thick-

Page 30

Step 3—Place a drop of couplant on the material surface at the measurement point.

Step 4—Position the transducer in steady contact with the surface of

the material at the measurement point. When coupling is achieved,

will be displayed.

Material thickness is displayed in the user-specified measurement unit

(inches or millimeters) and resolution as described in section 3.4.

When the probe is uncoupled,

will no longer appear along the

edge of the display but the instrument will continue to display the last

measured thickness. Refer to Figure 4-1 to interpret display indicators.

FIGURE 4-1—Thickness Measurement Mode

NOTE: Only couplants approved by GE Inspection Technologies should

be used. Other couplants, e.g. oil, may affect the instrument's functionality or cause damages!

Page 18 PocketMIKE Operating Manual

Page 31

Specifications and

EC Declaration of

Conformity

5.1 Specifications

Operating Principal Pulse-Echo

Probe 5 MHz, 0.475 inch (12 mm) Diameter

Probe Zero Automatic, ON-Block

Instrument Calibration Known Thickness

Known Velocity

Units of Measure mm or inch

Backlight Auto/OFF/On

Approximate Measuring Range 0.040" (1mm) to 9.999" (250 mm),

Material and Application Dependent

Display Resolution 0.001 inch for < 10.000 inches

0.01 inch for ≥ 10.00 inches

0.01 mm for < 100.00 mm

0.1 mm for ≥ 100.00 mm

Reading Stability +/- .001 inches

Operating Temperature -10°C to +50°C (10°F to +120°F)

Storage Temperature -20°C to +60°C (-4°F to +140°F)

Probe Surface Temperature -10°C to +100°C (10°F to +212°F)

Maximum coupling time 3 sec at 100°C

(212°F). One minute cool down.

Power Source Qty 1, 1.5 VDC, AA Alkaline Battery

PocketMIKE Operating Manual Page 19

Page 32

Battery Life Up to 80 hours, with the backlight

off, at 22°C (72°F), and with the probe

coupled 25% of the time

Instrument Weight 5.2 ounces (150 grams) with battery

Instrument Dimensions 4.00 in (105 mm) x 1.38 in

(39 mm) nominal diameter

Environmental IP67

5.2 EC Declaration of Conformity

GE Inspection Technologies Systems GmbH

Robert-Bosch-Strasse 3

D – 50354 Hürth

We herewith declare in sole responsibility that the product which this

declaration refers to, meets the requirements of the following directives:

89/336/EEC (incl. amendments) EEC directive on the electromagnetic

compatibility

The conformity with the requirements of the directive 89/336/EEC is

proved by meeting the standard specifications:

IEC 61000-6-2:2001 (Immunity to interference for industrial environment)

IEC/CISPR11:1998 + A1:1999 + A2:2002 Class A, Group 2

(Emitted interference for ISM equipment)

Note:

Class-A instruments are instruments suitable for use in all other areas

except for the living area and except for areas which are directly connected

to a low-voltage supply network (also) feeding residential buildings.

Class-A instruments are provided for the operation in an industrial environment.

The Group 2 comprises all ISM equipment (industrial, scientific, and

medical radiofrequency equipment) in which RF energy is intentionally

generated and/or used as electromagnetic radiation for the purpose of

material treatment, as well as EDM and arc-welding devices.

Page 20 PocketMIKE Operating Manual

Page 33

Application

Considerations

Measuring thickness under certain conditions requires special considerations. In this chapter you will find a summary of special considerations related to the following variables in testing applications:

◆ Material Consistency in Test Specimen (section 6.1)

◆ Flaws in the Specimen Being Tested (section 6.2)

◆ Condition of the Test Specimen’s Surface (section 6.3)

◆ Test Specimens with Curved Surfaces (section 6.4)

6.1 Material Consistency in Test

Specimen

Maximum measurement accuracy will be obtained if the work piece and

the calibration piece are the same temperature, shape, material, and size.

NOTE: At velocities greater than 6240 m/s the instrument will automatically adjust its gain to improve measurement consistency.

NOTICE

Since sound velocity varies from test piece to work piece, accuracy of

measurement depends on consistency of sound velocity. Sound velocity

also varies with internal stress, so that heat treatment of the material

will also effect accuracy. The following table expresses accuracy

variations for some common materials. Actual accuracy may be different.

Aluminum +/– 2% Cast Iron +/– 8%

Steel +/– 0.5% Nylon +/– 10%

NOTE: These specifications are intended only as a general guide.

PocketMIKE Operating Manual Page 21

Page 34

6.2 Flaws in the Specimen Being

Tested

If, during testing, the PocketMIKE suddenly reads a value which is

much thinner than the apparent thickness of the part, it may be reading

the distance to a flaw in the test piece, rather than the distance to the

backwall. If the cause is unclear, further examination of the part with

an ultrasonic flaw detection instrument or other suitable GE Inspcetion

Technologies method is recommended.

6.3 Condition of the Test Specimen’s

Surface

A regular pattern on the surface under test, such as machine grooves,

may cause a false thickness reading when using a dual element probe.

Higher frequency probes are especially sensitive to this condition. The

problem can usually be corrected by rotating the probe so that the

crosstalk barrier is at a right angle to the grooves.

It is possible for the surface of a test piece to be too rough to permit a

good reading. Excess couplant could be trapped between the probe and

surface under test, causing a false reading. A very rough surface may

prevent coupling altogether (no coupling indicator). This problem can

be corrected by grinding the surface until it is smooth enough to

permit good coupling.

6.4 Test Specimens with Curved

Surfaces

When measuring on curved surfaces, such as tubes or pipes, be sure to

keep the probe centered on the part and as stable as possible. As a rule,

smaller diameter probes improve coupling and minimize “rocking” on

curved parts. In some cases, special probes with contoured faces to

match surface curvature may be needed. Practice may be helpful to

develop the proper technique.

Page 22 PocketMIKE Operating Manual

Page 35

When using a flat dual probe, position the crosstalk barrier at a right

angle to the long axis of the part, as shown in Figure 6-1.

PROBE

CROSSTALK

BARRIER

LONG AXIS

OF TUBE

CONTACT

FÄCE

FIGURE 6-1—Crosstalk Barrier Orientation

PocketMIKE Operating Manual Page 23

Page 36

Page 24 PocketMIKE Operating Manual

Page 37

Troubleshooting

Guide

Should your instrument malfunction, refer to the guidelines that

correspond to the problem you’re experiencing:

PocketMIKE Operating Manual Page 25

Page 38

Page 26 PocketMIKE Operating Manual

Page 39

Warranty and Repair

8.1 Warranty

There are no warranties, expressed or implied by either distributor or

the manufacturer on new equipment except the manufacturer’s warranty against defects in material and workmanship set forth below:

GE Inspection Technologies warrants new instruments manufactured

by GE Inspection Technologies and delivered to the original retail

purchaser F.O.B. GE Inspection Technologies’s factory, to be free from

defects in material and workmanship under normal use and service, for

a period of two years from delivery of the instrument or unless otherwise stated by GE Inspection Technologies.

GE Inspection Technologies warrants new transducers manufactured

by GE Inspection Technologies and delivered to the original retail

purchaser F.O.B. GE Inspection Technologies’s factory, to be free from

defects in material and workmanship under normal use and service, for

ninety (90) days from the date of purchase.

These warranties are subject to the following limitations to which the

Buyer expressly agrees:

A. GE Inspection Technologies’s obligation under this warranty is

limited solely to repairing or replacing, at our option, and which,

upon examination by GE Inspection Technologies shall be found

to its reasonable satisfaction to have been thus defective. THIS

REMEDY IS EXPRESSLY SUBSTITUTED FOR ANY AND

ALL OTHER REMEDIES POSSIBLE UNDER THE UNIFORM

COMMERCIAL CODE, STATE, COMMON OR STATUTORY

LAW OR OTHERWISE.

PocketMIKE Operating Manual Page 27

Page 40

B. The provisions of this warranty SHALL NOT APPLY:

◆ To any instrument or transducer, which has been subject to

misuse, negligence or accident or which has been repaired

or altered outside GE Inspection Technologies’s factory in

any way so as to, in GE Inspection Technologies’s sole but

reasonable judgment affect its performance and reliability.

◆ To any instrument or transducer, which has been subjected

to an environment, chemistry or temperature that is not

compatible with the materials of construction.

◆ To any parts of an instrument or transducer, which, under

normal usage, would not or are not expected to last the

warranty period, i.e. “wear” items (i.e. batteries and

cables).

◆ To any instrument or transducer, which have not been

subject to proper care and maintenance.

◆ GE Inspection Technologies shall not be liable for any

damages, whether direct or indirect, economic, commercial,

incidental, or consequential, and whether arising from GE

Inspection Technologies’s negligence, breach of contract,

product liability, warranty or any other reason.

◆ To any instruments or transducer not manufactured by GE

Inspection Technologies. For equipment furnished, but not

manufactured by GE Inspection Technologies, GE Inspection Technologies assigns to the Buyer any warranty and/or

claim it may have against the manufacturer or supplier of

the equipment.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY OTHER

WARRANTIES, EXPRESSED OR IMPLIED INCLUDING ANY

IMPLIED OR EXPRESSED WARRANTY OF MERCHANTABILITY, SUITABILITY OR FITNESS FOR A PARTICULAR PURPOSE

and GE Inspection Technologies neither assumes nor authorizes

another to assume any liability in connection with such equipment,

except as provided above.

Page 28 PocketMIKE Operating Manual

Page 41

8.2 Service

GE Inspection Technologies offers a complete Service Department for

repair and recertification of our products. You do not need a preauthorization number to send your GE Inspection Technologies unit

in for repair. Simply, provide the following information:

◆ Company Name

◆ Contact Name

◆ Phone Number

◆ Company Address

◆ Model Number

◆ Serial Number

◆ Accessories

◆ Description of problem or work required

◆ Any additional comments

and send it with your unit to:

GE Inspection Technologies, LLC

50 Industrial Park Road

Lewistown, PA 17044

U.S.A.

Phone: +1 (717) 242-0327

Fax.: +1 (717) 242-2606

or:

GE Inspection Technologies Systems GmbH

Robert-Bosch-Straße 3

D – 50354 Hürth

Germany

Phone: +49 (0) 2233 601111

Fax.: +49 (0) 2233 601402

PocketMIKE Operating Manual Page 29

Page 42

When shipping your unit, please take care to protect it from transit

damage. Static sensitive parts must be packaged in anti-static bags,

foam, or tubes. All products should be sent back in their original carry

cases, or wrapped in bubble wrap or other available packaging material.

GE Inspection Technologies warrants all repairs for a full 90 days.

Page 30 PocketMIKE Operating Manual

Page 43

Appendix

)evaWlanidutignoL(slairetaMsuoiraVniseiticoleVdnuoSlacipyT

rePsehcnI

dnocesorciM

munimulA0052.0036nolyN0001.0052

ssarB0071.0034cilonehP0650.0041

muimdaC0011.0082munitalP0061.0014

norItsaC0081.0064salgixelP0011.0082

reppoC0081.0064enelyhteyloP0070.0081

niseRyxopE0011.0082enerytsyloP0390.0042

)nworC(ssalG0022.0065enahteruyloP0070.0081

)wodniW(ssalG0072.0086nialecroP0022.0065

dloG0031.0033)lytuB(rebbuR0370.0091

lenocnI0022.0065).cluV(rebbuR0090.0032

daeL0580.0022revliS0041.0063

muisengaM0032.0085leetS0032.0085

esenagnaM0081.0064niT0031.0033

munedbyloM0052.0036muinatiT0042.0016

lenoM0012.0035netsgnuT0012.0035

enerpoeN0360.0061cniZ0061.0014

lekciN0022.00652yolacriZ0091.0074

Typical values for the sound velocity of many common materials.

Because processing, exact material composition, and temperature

affect velocity, these values may not precisely match the velocity

in the material being tested.

NOTE: This information is provided for the convenience of the user. GE

Inspection Technologies assumes no responsibility for inaccuracies. Actual

velocities depend on exact composition, temperature, and processing of each

material.

rePsreteM

dnoceS

rePsehcnI

dnocesorciM

dnoceS

rePsreteM

PocketMIKE Operating Manual Page 31

Page 44

Page 32 PocketMIKE Operating Manual

Page 45

Index

A

Auto .......................................................................................................... 10

B

Backlight .................................................................................................. 10

Backlight Adjustment ............................................................................. 10

Batteries .................................................................................................... 1

Battery indicator ....................................................................................... 2

Brightness ............................................................................................... 10

C

CAL ............................................................................................................. 6

Calibration ............................................................................................... 11

Curved Surfaces ..................................................................................... 22

D

Display ....................................................................................................... 5

donE ........................................................................................................... 6

E

EC Declaration of Conformity ............................................................... 20

F

FAIL ............................................................................................................ 6

Features ................................................................................................... 19

Flaws in the Specimen ........................................................................... 22

PocketMIKE Operating Manual Page 33

Page 46

H

HOT warning ........................................................................................... 17

K

Keypad ....................................................................................................... 4

L

Lockout .................................................................................................... 15

M

Material Consistency .............................................................................. 21

P

Powering On the Instrument ................................................................... 2

Probe transducer .................................................................................... 14

R

Repair ....................................................................................................... 29

Resolution ............................................................................................... 13

Reverse the display ................................................................................ 13

S

SAFE ........................................................................................................ 15

Service ..................................................................................................... 29

Specifications ......................................................................................... 19

Surface ..................................................................................................... 22

T

Temperature ............................................................................................ 17

Thickness ................................................................................................ 17

Thickness calibration ............................................................................. 11

Troubleshooting ..................................................................................... 25

Page 34 PocketMIKE Operating Manual

Page 47

U

Units of measurement ............................................................................ 13

V

Velocity calibration ................................................................................. 12

W

Warranty .................................................................................................. 27

PocketMIKE Operating Manual Page 35

Loading...

Loading...