Page 1

Krautkramer MIC 20

Technical Reference and Operating Manual

Ident No. 28 702

Page 2

This Issue 02, 04/2005 applies to the software version V 01.00

The version number of the software is displayed in the menu bar line on the screen

or in the menu Config – Info (ref. chapter 4.7).

Subject to change without notice.

0-2 Issue 02, 04/2005 Krautkramer MIC 20

Page 3

Contents

1 Introduction ....................................... 1-1

1.1 Safety information ................................... 1-2

Power supply ............................................. 1-2

Software .................................................... 1-3

1.2 About this manual ................................... 1-3

Important information ................................. 1-3

1.3 Layout and presentation in this manual . 1-4

Attention and note symbols ....................... 1-4

Listings ...................................................... 1-4

Operating steps ......................................... 1-4

1.4 Prerequisites for hardness testing .......... 1-5

Operator training ........................................ 1-5

Technical test requirements ....................... 1-6

Choice of the appropriate test equipment ... 1-6

1.5 Important information about hardness

testing using the Krautkramer MIC 20 .... 1-7

Test material .............................................. 1-7

Test method ............................................... 1-7

Conversion of hardness values .................. 1-9

1.6 The Krautkramer MIC 20 ......................... 1-10

Special features of the MIC 20.................. 1-11

Large variety of application possibilities ....1-12

2 Standard package and accessories 2-1

2.1 Standard package .................................... 2-3

2.2 Required accessories .............................. 2-5

2.3 Recommended accessories

(general) .................................................... 2-7

2.4 Recommended accessories

(UCI method) ............................................ 2-8

2.5 Recommended accessories

(rebound method) ...................................2-11

2.6 Spare parts requirements

(UCI method) ...........................................2-12

2.7 Spare parts requirements

(rebound method) ...................................2-13

Krautkramer MIC 20 Issue 02, 04/2005 0-1

Page 4

ContentsContents

3 Initial start-up ..................................... 3-1

3.1 Power supply ........................................... 3-2

Operation using the power supply unit ........ 3-2

Operation using the battery pack

MIC 20-BAT ............................................... 3-3

3.2 Connecting a probe or

an impact device ...................................... 3-4

Connecting a UCI probe ............................. 3-5

Connecting an impact device ..................... 3-6

Disconnecting the connecting cable ........... 3-7

Exchanging the test attachment ................ 3-8

3.3 Turning on/off .......................................... 3-8

Turning on .................................................. 3-8

Turning off .................................................. 3-8

Emergency-stop ......................................... 3-9

Cold start ................................................... 3-9

4 Operation ........................................... 4-1

4.1 Fundamental principles of operation ..... 4-2

Operator’s controls and displays ................ 4-3

Display screen ........................................... 4-3

User interface ............................................ 4-4

Virtual keyboard......................................... 4-5

Operation using the keypad or

touch screen .............................................. 4-6

Installing the instrument ............................. 4-6

4.2 Probe and impact device ......................... 4-7

Guiding the probe ....................................... 4-7

Operating the impact device ...................... 4-8

4.3 Hardness testing .....................................4-10

Starting and closing a test series .............. 4-10

Viewing and evaluating test results ...........4-11

Conversion into other hardness scales ...... 4-14

4.4 Calibration ...............................................4-15

Carrying out the calibration ....................... 4-16

Saving calibration data ..............................4-18

0-2 Issue 02, 04/2005 Krautkramer MIC 20

Page 5

Contents

Deleting calibration data ............................4-19

Restoring the standard calibration ............. 4-20

4.5 Saving the test data ................................4-21

Saving files ............................................... 4-22

Deleting files or directories ........................4-22

Opening and closing directories ................4-23

Creating new directories ............................4-23

Opening files .............................................4-24

Editing saved files .................................... 4-24

File management using instrument keys ...4-25

4.6 Printing test reports ................................ 4-25

Prerequisites for printing ...........................4-26

Selecting and printing a test series ........... 4-27

4.7 Instrument configuration ........................4-30

Evaluation parameters ..............................4-30

System settings........................................ 4-35

System information ...................................4-39

4.8 Saving and loading

instrument parameters ...........................4-41

Saving instrument parameters .................. 4-41

Loading and deleting

instrument parameters ..............................4-41

4.9 Functional tests ......................................4-42

Functional test for UCI method .................4-42

Functional test for rebound method ........... 4-43

4.10 Calibrating the touch screen ..................4-44

4.11 Troubleshooting ......................................4-45

Error messages ........................................ 4-45

Errors ........................................................ 4-45

5 Care and maintenance ...................... 5-1

5.1 Care .......................................................... 5-2

Care of instrument ..................................... 5-2

Care of batteries ........................................ 5-2

Charging the batteries ................................ 5-3

Krautkramer MIC 20 Issue 02, 04/2005 0-3

Page 6

Contents

5.2 Maintenance ............................................. 5-4

Cleaning the probe ..................................... 5-4

Cleaning the impact device ........................ 5-4

6 Interfaces and data transfer.............. 6-1

6.1 Interfaces .................................................. 6-2

Serial interface RS232 ............................... 6-3

Ethernet interface ...................................... 6-3

6.2 Data transfer to a printer .......................... 6-4

Requirements for printing ........................... 6-4

6.3 Data transfer to a computer ..................... 6-5

7 Hardness testing method ................. 7-1

7.1 The UCI method ....................................... 7-2

The treatment of test material .................... 7-3

7.2 The rebound method ............................... 7-5

The treatment of test material .................... 7-6

7.3 Conversion of hardness values ............... 7-8

7.4 Information on the

statistical evaluation ............................... 7-12

Statistical average .................................... 7-12

Relative range of spread ...........................7-13

Relative standard deviation ....................... 7-13

Calculation of process capability ...............7-13

8 Specifications .................................... 8-1

Basic instrument ........................................ 8-2

Connections and interfaces ........................ 8-2

Power supply and operating time ................ 8-3

Ambient conditions .................................... 8-3

Evaluation .................................................. 8-4

9 Annex ................................................. 9-1

9.1 EC Declaration of Conformity ................. 9-2

9.2 Manufacturer/Service addresses ............. 9-2

10 Index ................................................. 10-1

0-4 Issue 02, 04/2005 Krautkramer MIC 20

Page 7

Introduction 1

Krautkramer MIC 20 Issue 02, 04/2005 1-1

Page 8

IntroductionIntroduction Safety information

1.1 Safety information

The Krautkramer MIC 20 is designed and tested according to DIN EN 61 010 Part 1, March 1994, “Safety

requirements for electric measuring, control, and laboratory devices”, and was technically in a perfectly safe

and faultless condition when leaving the manufacturing

works.

In order to maintain this condition and to ensure a safe

operation, it is absolutely necessary that you read the

following safety information before putting the instrument into operation.

A Attention:

The Krautkramer MIC 20 is an instrument meant for

materials testing. Any use in medical or other applications is not allowed!

The instrument may only be used in industrial environments.

Power supply

Battery pack and power supply unit

The Krautkramer MIC 20 can be operated using the

battery pack MIC 20-BAT, or a power supply unit. You

can charge the battery pack MIC 20-BAT in the instrument itself while the instrument is supplied with power

via the power supply unit and turned off. As soon as

you turn the instrument on, the power supply to the

battery compartment is interrupted.

NiCd or NiMH single cells

The operation using NiCd or NiMH single cells is likewise possible but is not recommended because of the

clearly reduced operating time.

A Attention:

You cannot charge NiCd or NiMH single cells in the

instrument itself but only by means of an external battery charger approved for this purpose.

If you are only using the power supply unit for a longer

period of time, you should remove the batteries from

the instrument.

1-2 Issue 02, 04/2005 Krautkramer MIC 20

Page 9

IntroductionIntroductionSafety information

H Note:

Alkaline cells are not suitable due to their high internal

impedance.

Software

According to the current state of the art, software is

never completely free from errors or defects.

For this reason, before using any software-controlled

test equipment, it should be ensured that the required

functions operate perfectly in the intended combination.

If you have any questions regarding the use of the instrument, please contact your nearest GE Inspection

Technologies representative.

1.2 About this manual

This manual describes the operation of the hardness

tester Krautkramer MIC 20.

Please read carefully through this manual in order to be

able to operate all functions of your instrument quickly

and reliably. You’ll be able to use the complete range of

instrument functions and, at the same time, to avoid

faults and operating errors which may lead to incorrect

test results.

Important information

Even if you might be familiar with hardness testing

methods, please always observe the information in

chapters 1.4 and 1.5. In chapter 1.4, you will find important limitations and prerequisites for hardness testing in

general (training, knowledge of the specific technical

test requirements and limits of testing, choice of the

appropriate test device).

In chapter 1.5, you will find concrete information about

hardness testing using the MIC 20 that you always have

to follow in order to ensure correct test results.

Krautkramer MIC 20 Issue 02, 04/2005 1-3

Page 10

IntroductionIntroduction Layout and presentation in this manual

1.3 Layout and presentation in

this manual

To make it easier for you to use the manual, the operating steps, notes, etc. are always presented in the same

way. This will help you find individual pieces of information quickly.

Attention and note symbols

A Attention:

You will find the Attention symbol in the case of any

peculiarities or special aspects in the operation which

could affect the correctness of the results.

H Note:

At Note, you will find e.g. references to other chapters

or special recommendations for a function.

Listings

Listings are presented in the following form:

❚ Variant A

❚ Variant B

❚ ...

Operating steps

Operating steps appear as shown in the following example:

– Place the handheld probe vertically to the surface to

be tested.

– Hold the probe tight with one hand so that the foot

stays perpendicular to the surface during the measurement.

1-4 Issue 02, 04/2005 Krautkramer MIC 20

Page 11

IntroductionIntroductionPrerequisites for hardness testing

1.4 Prerequisites for hardness

testing

In this operating manual you will find all essential information on how to operate the Krautkramer MIC 20. In

addition, there are a number of factors which affect the

test results. As a description of these factors would go

beyond the scope of an operating manual, only the

three most important conditions are therefore described

here:

❚ operator training

❚ knowledge of special technical test requirements and

limits

❚ choice of the appropriate test equipment

A Attention:

Lack of knowledge of the above-mentioned subjects

may lead to incorrect test results with unforeseeable

consequences.

GE Inspection Technologies organizes training courses

in the field of hardness testing. You will receive information on the scheduled dates on request.

Operator training

The reliable and safe operation of a hardness testing

device requires a proper training in materials testing.

A proper training comprises for example adequate

knowledge of:

❚ hardness testing on metallic materials

❚ effects due to material properties, especially due to

the microstructure, on hardness testing and on the

corresponding choice of the appropriate hardness

tester

❚ problems relating to the comparability of different

hardness values, such as Vickers, Rockwell, and

Brinell

❚ effects due to surface finish on the hardness value

❚ effects of the test load on the determined hardness

value

Krautkramer MIC 20 Issue 02, 04/2005 1-5

Page 12

IntroductionIntroduction Prerequisites for hardness testing

Technical test requirements

Every hardness test is subject to specific technical test

requirements. The most important ones are:

❚ definition of the scope of testing

❚ choice of the appropriate test method

❚ consideration of material properties

❚ determination of limits for evaluation

Choice of the appropriate test equipment

It is the task of those responsible for the test to fully

inform the operator about the technical test requirements. Moreover, a clear and thorough interpretation of

the corresponding test specifications is absolutely necessary.

Information about test methods and test specifications

may be obtained, for example, from various institutions,

industrial companies, and authorities.

1-6 Issue 02, 04/2005 Krautkramer MIC 20

Page 13

IntroductionIntroductionImportant information about hardness testing using the Krautkramer MIC 20

1.5 Important information about

hardness testing using the

Krautkramer MIC 20

Please find in the following a summary of the most

important technical test requirements that you always

have to observe in order to obtain reliable and reproducible test results.

A Attention:

Do not carry out the hardness test twice at the same

test position, otherwise measuring errors may occur

due to the hardness increase of the surface. The distance between the test positions should be at least

3 mm.

Krautkramer MIC 20 Issue 02, 04/2005 1-7

Test material

The surfaces must be free from any impurities (oil,

dust, etc.) and rust. The peak-to-valley height should

not exceed approx. 30 % of the penetration depth.

Rough surfaces lead to a higher variation range of the

single readings. If necessary, polish rougher surfaces,

for example using our grinding set MIC 1060 (ref. chapter 2).

Test method

The MIC 20 supports both quasi-static hardness testing

according to the UCI method and dynamic hardness

testing according to the rebound method.

All Krautkramer UCI probes and the rebound impact

devices D, G, and E are supported in these processes.

The UCI method

The UCI method is a comparative method (contribution

of the Young’s modulus to the measurement) with a

very high reproducibility of measurements. The UCI

method does not replace the classical Vickers hardness testing method but constitutes a fast and reliable

addition to it.

Page 14

IntroductionIntroduction Important information about hardness testing

The direct comparison with the results of the standardized Vickers measurement according to the material

samples is therefore indispensable for the assessment

of the measuring accuracy of the UCI method. This

means:

The test forces (probes) must match the surface quality

of the material:

❚ Smooth, homogeneous surfaces require low test

forces.

❚ Rougher, coarse-grained surfaces require as high

test forces as possible.

A Attention:

It is absolutely necessary that you calibrate your

MIC 20 to the material to be tested.

The calibration is required only once for this since you

can save calibrations and recall them again as required

without any problem (ref. chapter 4.4).

The calibration for low-alloy or unalloyed steel is already

predefined in the instrument. You should check them

from time to time (ref. chapter 4.9 Functional tests).

Please also read the notes on the UCI method in chapter 7.

The Rebound method

The rebound method is a dynamic method with a very

high reproducibility of measurements. The rebound

method does not replace the classical Brinell hardness

testing method or other standardized methods but constitutes a fast and reliable addition to them.

The still existing energy of an impact body after the

rebound from the material surface is measured. It

should be kept in mind in this regard that the loss of

energy suffered in this process also depends on the

mechanical properties of the material, i.e. mainly on its

Young’s modulus or modulus of elasticity.

The direct comparison with the results of the standardized Vickers measurement according to the material

samples is therefore indispensable for the assessment

of the measuring accuracy of the method. This means:

1-8 Issue 02, 04/2005 Krautkramer MIC 20

Page 15

IntroductionIntroductionImportant information about hardness testing

A Attention:

It is absolutely necessary that you set your MIC 20 to

the suitable material group before carrying out the test

and that you additionally calibrate it if necessary.

The calibration is necessary only once in this process

since you can save the calibrations and recall them

again as required without any problem (ref. chapter 4.4).

The material group for low-alloy or unalloyed steel is

predefined in the instrument as a default setting.

You should check this from time to time (ref. chapter

4.9 Functional tests).

Test objects having a mass of at least 5 kg can be

tested without any additional supports; more leightweight objects require a support to which they have to

be rigidly coupled. You should use large metal supports

that do not give way for this purpose.

The test objects should have a minimum wall thickness

of 20 mm. We recommend the UCI method, or the use

of a suitable UCI probe in combination with the MIC 20

for test objects having smaller wall thicknesses.

A Attention:

Should the test objects give way or spring, the result

may be measuring errors!

Please read also chapter 7 on the rebound method.

Conversion of hardness values

The conversion of hardness values into other hardness

scales is only possibly with restrictions.

Hardness values determined according to different

methods cannot be converted into each other by

means of generally applicable relations. The restrictions

regarding the conversion, stated in the DIN 50 150,

ASTM E140 specifications, must therefore always be

taken into account!

The indentation behavior of the material is determined

by its stress-strain behavior. Shape and material of the

indenter, the size of indentation, and consequently the

measured area vary, depending on the test method

used.

The conversion of hardness values both into one another and into tensile strength values can be inaccurate

Krautkramer MIC 20 Issue 02, 04/2005 1-9

Page 16

Introduction Important information about hardness testing

or unacceptable depending on the material, treatment

condition, and surface quality.

A Attention:

Any illegal or unacceptable conversions may lead

to serious errors in the interpretation of test results.

1.6 The Krautkramer MIC 20

The Krautkramer MIC 20 is a mobile and easy-to-use

hardness tester which can be equally used for tests

according to the UCI method and for tests according to

the rebound method.

After connecting the probe, the instrument is automatically set to the corresponding test method; tests can be

carried out quickly and without any problem.

The fact that both methods are supported leads to a

large variety of application possibilities with only one

single instrument. Additional probes extend the range of

applications if required.

The operation of the Krautkramer MIC 20 (calibration,

setup, evaluation, data memory) is carried out by

means of the graphic user interface presented on the

display and adapted to the known Windows standard.

The mouse is replaced by the touch screen for this

purpose.

As an alternative, conventional buttons are available for

most operating functions.

1-10 Issue 02, 04/2005 Krautkramer MIC 20

Page 17

IntroductionThe Krautkramer MIC 20

Special features of the MIC 20

❚ Measurements on castings and forgings, hardened

surfaces and welds

❚ Automatic adaptation of the test method and of the

test parameters to the connected probe

❚ Color LCD 5.7" for displays and operating functions

(TFT or CSTN)

❚ Support of all Krautkramer UCI probes

❚ Support of the Krautkramer rebound

impact devices D, G, and E

❚ Non-directional measurement (patented signal

processing with the rebound method)

❚ Storage of measurement data and clear representa-

tion of measurement series as a diagram and histogram

❚ Simple and fast calibration, saving and recalling of

calibration data at the press of a button

❚ Output of measurement data directly to a printer or

transfer to a computer

Krautkramer MIC 20 Issue 02, 04/2005 1-11

Page 18

Introduction The Krautkramer MIC 20

❚ Operation using the battery pack or power supply

unit

Large variety of application possibilities

You can use the Krautkramer MIC 20 to measure anywhere and in any direction; the direction must not be

set beforehand.

The MIC 20 is mainly suitable

❚ for measuring hardness of low-alloy or unalloyed

steels,

❚ for measuring hardness of high-alloy steels,

❚ for measuring hardness of nonferrous metals.

The MIC 20 is available in two versions:

❚ Basic version MIC 20 with color CSTN screen

❚ MIC 20 TFT with color TFT display screen

1-12 Issue 02, 04/2005 Krautkramer MIC 20

Page 19

Standard package and accessories 2

Krautkramer MIC 20 Issue 02, 04/2005 2-1

Page 20

Standard package and accessories Standard package

This chapter informs you about the standard package

and the accessories available for the Krautkramer

MIC 20.

It describes

❚ component parts of the product

❚ required and recommended accessories

❚ spare parts requirements

2-2 Issue 02, 04/2005 Krautkramer MIC 20

Page 21

2.1 Standard package

Product code Description Order no.

MIC 20 Portable Hardness Tester according to the quasi-static 35 468

Standard package and accessoriesStandard package

UCI principle and the dynamic Rebound principle.

Display of the hardness values in HV, HB, HRC,

HRB, N/mm

in HL and HS.

including:

Instrument MIC 20 35 493

Mains adapter 101 075

Transport case 101 554

Operating manual German 28 701

or

Operating manual English 28 702

2

and additional for the Rebound principle

Krautkramer MIC 20 Issue 02, 04/2005 2-3

Page 22

Standard package and accessories Standard package

Product code Description Order no.

MIC 20 TFT Portable Hardness Tester according to the quasi-static 35 479

UCI principle and the dynamic Rebound principle.

Display of the hardness values in HV, HB, HRC, HRB,

2

N/mm

and additional for the Rebound principle

in HL and HS.

including:

Instrument MIC 20 TFT 35 492

Mains adapter 101 075

Transport case 101 554

Operating manual German 28 701

or

Operating manual English 28 702

2-4 Issue 02, 04/2005 Krautkramer MIC 20

Page 23

2.2 Required accessories

Product code Description Order no.

MIC 201-A Handheld probe 10 N 34 104

MIC 205-A Handheld probe 50 N 34 105

MIC 2010-A Handheld probe 98 N 34 106

MIC 201-AL Extended handheld probe 10 N 34 392

MIC 205-AL Extended handheld probe 50 N 34 282

MIC 201-AS Short handheld probe 10 N 34 711

MIC 205-AS Short handheld probe 50 N 34 712

Standard package and accessoriesRequired accessories

Handheld Probes (UCI method)

(each probe complete with cable)

Krautkramer MIC 20 Issue 02, 04/2005 2-5

Page 24

Standard package and accessories Required accessories

Product code Description Order no.

Motorized Probes (UCI method)

(each probe complete with cable)

MIC 211-A Motor probe 8.6 N 34 381

MIC 2103-A Motor probe 3 N 34 382

MIC 2101-A Motor probe 1 N 35 577

Impact Devices (rebound method)

(each without connecting cable for impact device)

Dyna D Impact device with 3 mm tungsten-carbide 34 248

Dyna G Impact device with 5 mm tungsten-carbide 34 549

Dyna E Impact device with diamond-tipped body 34 588

Dyna 50 Connecting cable for impact device 34 329

2-6 Issue 02, 04/2005 Krautkramer MIC 20

Page 25

Recommended accessories (general)

2.3 Recommended accessories (general)

Product code Description Order no.

MIC 20-BAT NiMH accumulator pack, 4.5 Ah, internal charging 35 452

MIC 1060 Battery grinding set 34 380

MIC 300 Technical book on hardness testing (only in German) 28 837

Printer cable (serial/parallel) for connection to 101 761

Hewlett Packard Printers of the hpdeskjet 9xx series

UDAT UltraDAT data management program for transfer and 35 549

documentation of hardness measurement data

Data transfer cable from the instrument to a PC 101 785

ZG-F Couplant 54 558

Standard package and accessories

Krautkramer MIC 20 Issue 02, 04/2005 2-7

Page 26

Standard package and accessories

2.4 Recommended accessories (UCI method)

Product code Description Order no.

Guiding devices and test supports

MIC 270 Surface attachment for MIC 201-A, MIC 205-A, 32 084

MIC 2010-A

MIC 271 Prism adapter for MIC 201-A, MIC 205-A 32 993

MIC 220 Test specimen holder for MIC 2101-A, MIC 2103-A 30 766

and MIC 211-A

MIC 221 Universal test support with instrument holder 33 541

MIC 227 Test support for determination of hardness progression 35 264

MIC 222-A Precision test support 35 546

MIC 2221 Magnetic foot for support MIC 222-A 33 909

MIC 2220 Support block for flat, thin parts 33 651

Recommended accessories (UCI method)

MIC 225 Camshaft test stand 34 869

2-8 Issue 02, 04/2005 Krautkramer MIC 20

Page 27

Recommended accessories (UCI method)

Product code Description Order no.

MIC 100 Probe attachment set 29 929

MIC 100-1 Prism attachment 29 920

MIC 120 Magnetic probe shoe for curved surfaces 31 854

MIC 223 Quick test support with magnetic foot 34 020

MIC 25C Hardness Reference Plate 25 HRC 33 905

MIC 45C Hardness Reference Plate 45 HRC 33 906

MIC 65C Hardness Reference Plate 65 HRC 33 907

MIC 1V100 Hardness Reference Plate 150 HV10 34 279

MIC 2V010 Hardness Reference Plate 240 HV1 33 896

Standard package and accessories

Guiding devices for motor probes

Hardness reference plates with MPA certificate

MIC 2V050 Hardness Reference Plate 240 HV5 33 899

Krautkramer MIC 20 Issue 02, 04/2005 2-9

Page 28

Standard package and accessories

Product code Description Order no.

MIC 2V100 Hardness Reference Plate 240 HV10 33 902

MIC 5V010 Hardness Reference Plate 540 HV1 33 897

MIC 5V050 Hardness Reference Plate 540 HV5 33 900

MIC 5V100 Hardness Reference Plate 540 HV10 33 903

MIC 8V010 Hardness Reference Plate 840 HV1 33 898

MIC 8V050 Hardness Reference Plate 840 HV5 33 901

MIC 8V100 Hardness Reference Plate 840 HV10 33 904

Recommended accessories (UCI method)

2-10 Issue 02, 04/2005 Krautkramer MIC 20

Page 29

Recommended accessories (rebound method)

Standard package and accessories

2.5 Recommended accessories (rebound method)

Product code Description Order no.

Hardness reference blocks (rebound method)

MIC D62 Hardness reference block 620 HV100 34 393

MIC D62MPA Hardness reference block 620 HV100, 34 573

certified by MPA, Germany

MIC G38 Hardness reference block 380 HV100 34 631

MIC G38MPA Hardness reference block 380 HV100, 34 657

certified by MPA, Germany

Test attachments for Dyna D and E (rebound method)

Dyna 41 Set (5 pcs.) of test attachments for cylindrical and 34 536

hollow-cylindrical surfaces

Dyna 42 Set (5 pcs.) of test attachments for spherical and 34 539

hollow-spherical surfaces

Krautkramer MIC 20 Issue 02, 04/2005 2-11

Page 30

Standard package and accessories

2.6 Spare parts requirements (UCI method)

Product code Description Order no.

MIC 1050 Probe cable for handheld probes 34 071

MIC 1051 Probe cable for motor probes 34 378

MIC 1052 Probe cable for shortened handheld probes for 34 713

MIC 201-AS and MIC 205-AS

Ball headed probe grip 33 854

Spare parts requirements (UCI method)

2-12 Issue 02, 04/2005 Krautkramer MIC 20

Page 31

Spare parts requirements (rebound method)

Standard package and accessories

2.7 Spare parts requirements (rebound method)

Product code Description Order no.

Impact body D, new 34 443

Impact body G, new 34 596

Impact body E, new 34 593

Impact body D, replacement in exchange by 34 572

Krautkramer Service Department

Impact body G, replacement in exchange by 35 265

Krautkramer Service Department

Dyna 50 Connecting cable for impact device 34 329

Cleaning brush for Dyna D or Dyna E 34 420

Cleaning brush for Dyna G 34 618

Standard test attachment for impact device D or E 34 312

Test attachment for impact devices D or E, 34 656

Ø = 13.5 mm

Krautkramer MIC 20 Issue 02, 04/2005 2-13

Page 32

Standard package and accessories

Product code Description Order no.

Spare parts requirements (Rebound method)

Standard test attachment for impact device G 34 569

Test attachment for impact device G, 34 634

diameter = 50 mm

Replacement grinder for battery grinding set MIC 1060 18 115

2-14 Issue 02, 04/2005 Krautkramer MIC 20

Page 33

Initial start-up 3

Krautkramer MIC 20 Issue 02, 04/2005 3-1

Page 34

Initial start-up Power supply

3.1 Power supply

You can operate the Krautkramer MIC 20 either with the

battery pack MIC 20-BAT or with the power supply unit.

The operation with the power supply unit is possible

even if the battery pack MIC 20-BAT is in the instrument. The power supply to the battery compartment is

then automatically interrupted.

Operation using the power supply unit

The Krautkramer MIC 20 is supplied either with a desktop power supply unit or with a plug-in power supply

unit. The power supply unit is automatically set to any

a.c. voltage between 100 and 240 V (nominal voltage).

Operation using the desktop power supply unit

The desktop power supply unit is provided with a cable

equipped with a Euro plug connector and inlet connector for non-heating appliances.

Plug the cable’s inlet connector for non-heating appliances in the socket for non-heating appliances of the

power supply unit.

Operation using the plug-in power supply unit

The plug-in power supply unit is delivered with two different socket-outlet adapters – for Euro and U.S. standard. If the adapter plug on your power supply unit does

not correspond to your socket-outlet standard, you can

exchange it.

Just pull off the attached adapter, and replace it with

the required one.

H Note:

You should exchange the socket-outlet adapter only

once; the plug-in power supply unit is not meant for

frequent exchanges.

3-2 Issue 02, 04/2005 Krautkramer MIC 20

Page 35

Initial start-upPower supply

Connecting

Use the corresponding power supply unit to connect the

Krautkramer MIC 20 to a suitable mains socket-outlet.

The socket-contact for the power supply unit cable is

located at the back of the instrument.

Operation using the battery pack

MIC 20-BAT

You can operate the Krautkramer MIC 20 with the NiMH

battery pack MIC 20-BAT (ref. chapter 2).

The operation is likewise possible with 6 NiCd or NiMH

single C-cells each, however, it is not recommended

because of the clearly reduced operating time.

Inserting batteries

The battery compartment is located in the instrument

bottom.

– Move the fastener towards the lid center in order to

open the lid, and remove the lid.

– Insert the plug of the battery pack into the socket-

contact in the battery compartment until it snaps into

place. When inserting the battery pack, make sure

that no squeezing or kinking of the cables is possible.

– If you use single cells, insert the individual cells into

the battery compartment one by one. Follow the instructions regarding alignment and polarity in the

battery compartment.

– Place the lid back on, move the fastener back and

close the battery compartment so that the fastener

locks home perceptibly.

Krautkramer MIC 20 Issue 02, 04/2005 3-3

Page 36

Initial start-up Power supply

H Notes:

Remove the batteries from the instrument if you’re not

going to use it for a longer period of time!

Used or defective batteries are special waste and have

to be disposed of as provided by the law!

When using the battery pack MIC 20-BAT (unless NiMH

or NiCd single cells are used), the current status of the

battery is indicated on the display of the MIC 20 by an

icon:

An alarm is output with low voltage. In such a case,

exchange the batteries at once. The Krautkramer

MIC 20 is automatically turned off if the voltage gets

too low in order to ensure a reliable mode of functioning.

You will find more details on the care and charging of

batteries in chapter 5.

3.2 Connecting a probe or an

impact device

You can connect probes for the quasi-static hardness

testing according to the UCI method as well as impact

devices for the dynamic hardness testing according to

the rebound method to the MIC 20.

Probes and impact devices are connected to the

MIC 20 via corresponding connecting cables. The connecting cables are equipped with a round plug for the

connection to the probe or to the impact device, and

with a square plug for the connection to the instrument.

H Note:

You should only change the probe or the impact device

when the MIC 20 is switched off.

3-4 Issue 02, 04/2005 Krautkramer MIC 20

Page 37

Connecting a UCI probe

– Align the round plug of the cable correctly with the

socket of the probe by means of the markings, and

push it carefully into the socket until it locks into

place.

– Plug the square plug of the connecting cable in the

socket at the back of the instrument.

– Check that both plugs fit tightly.

– Attach the probe handle to the probe if necessary.

– Screw on the conical test attachment for short-time

measurements using the UCI handheld probes

MIC 201-A, MIC 205-A, or MIC 2010-A. Use the cylindrical test attachment for measurements with defined dwell times.

– Switch the MIC 20 on. An icon in the top left corner

of the screen shows that a probe has been correctly

connected:

Initial start-upConnecting a probe or an impact device

Conical probe attachment for

short-time measurements

Cylindrical probe attachment for

measurements with a defined

dwell time

Krautkramer MIC 20 Issue 02, 04/2005 3-5

Page 38

Initial start-up Connecting a probe or an impact device

H Note:

If you want to carry out measurements with defined

dwell times, please use the support

MIC 222-A (support with precise probe guidance).

This will help you to avoid measuring inaccuracies to a

large degree.

In addition, other accessories are available to make the

measurements easier for you to carry out (ref.

chapter 2).

Connecting an impact device

The following impact devices are available for use in

combination with the MIC 20:

❚ Dyna D

Standard impact device for all materials that can be

tested

❚ Dyna G

Impact device for solid test objects, e.g. castings or

forgings

❚ Dyna E

Impact device for the hardness range over 650 HV

A Attention:

The impact device Dyna G must only be used up to a

hardness to be tested of max. 650 HB, otherwise the

impact body may be destroyed.

H Note:

A larger test attachment (diameter 50 mm) is available

for the impact device Dyna G for a more stable measurement on large, flat workpieces.

3-6 Issue 02, 04/2005 Krautkramer MIC 20

Page 39

Connecting a probe or an impact device

Initial start-up

For measurements on test objects having curved surfaces, you have special test attachments at your disposal in order to achieve a better positioning with the

impact devices Dyna D and Dyna E (ref. chapter 2).

– Align the round plug of the cable correctly with the

socket of the probe by means of the markings, and

push it carefully into the socket until it locks into

place.

– Plug the square plug of the connecting cable in the

socket at the back of the instrument.

– Check that both plugs fit tightly.

– Screw on the suitable test attachment for measure-

ments on curved surfaces if necessary.

– Switch the MIC 20 on. An icon in the top left corner

of the screen shows that a probe has been correctly

connected:

Disconnecting the connecting cable

The round plug is provided with a bayonet lock, the

square plug has two locking clips.

– Carefully pull the outer ring of the round plug on the

probe or on the impact device in order to release the

lock, and pull off the plug.

– Press the two lateral clips of the square plug on the

instrument in order to release the lock, and pull off

the plug.

Krautkramer MIC 20 Issue 02, 04/2005 3-7

Page 40

Initial start-up

Connecting a probe or an impact device

Exchanging the test attachment

You can use special test attachments for testing on

small parts and on uneven surfaces in order to achieve

a better positioning of the probe or of the impact device.

– Slowly unscrew the currently used test attachment

counter-clockwise by hand.

– Place the required test attachment on carefully.

Make sure that the threads are not damaged by tilting.

– Carefully screw on the test attachment clockwise

and by only using manual force all the way to the

limit stop.

3.3 Turning on/off

Turning on

– Briefly press the button o to turn the instrument on.

The operating system will start, and some information,

e.g. about the software, is briefly displayed on the

screen. When the instrument is ready, you will see the

graphic user interface.

Turning off

– Briefly press the button o to turn the instrument off.

A Attention:

You should always use the button

erly turn the instrument off. In the case of an interruption of the power supply (battery removal, unplugging of

power plug), the instrument is not turned off properly,

and data may be lost.

o in order to prop-

3-8 Issue 02, 04/2005 Krautkramer MIC 20

Page 41

Turning on/off

Emergency-stop

If the instrument no longer shows any reaction, you can

turn it off without saving the current data. Afterwards,

you can turn it back on as usual.

Initial start-up

– To turn off, keep the button

the screen is blanked, and the instrument is turned

off.

o pressed down until

Cold start

If the instrument no longer reacts and cannot be started

properly, you can reset the settings with a cold start.

A Attention:

In a cold start, the files LastMeasure.mes and last.set

are deleted so that the last measurement series and

the saved calibration data may be lost.

– To switch on the instrument, briefly press

the button

– As soon as the start screen (blue background) ap-

pears, press the button

Krautkramer MIC 20 Issue 02, 04/2005 3-9

o.

.

Page 42

3-10 Issue 02, 04/2005 Krautkramer MIC 20

Page 43

Operation 4

Krautkramer MIC 20 Issue 02, 04/2005 4-1

Page 44

Operation Fundamental principles of operation

4.1 Fundamental principles of operation

4-2 Issue 02, 04/2005 Krautkramer MIC 20

Page 45

OperationFundamental principles of operation

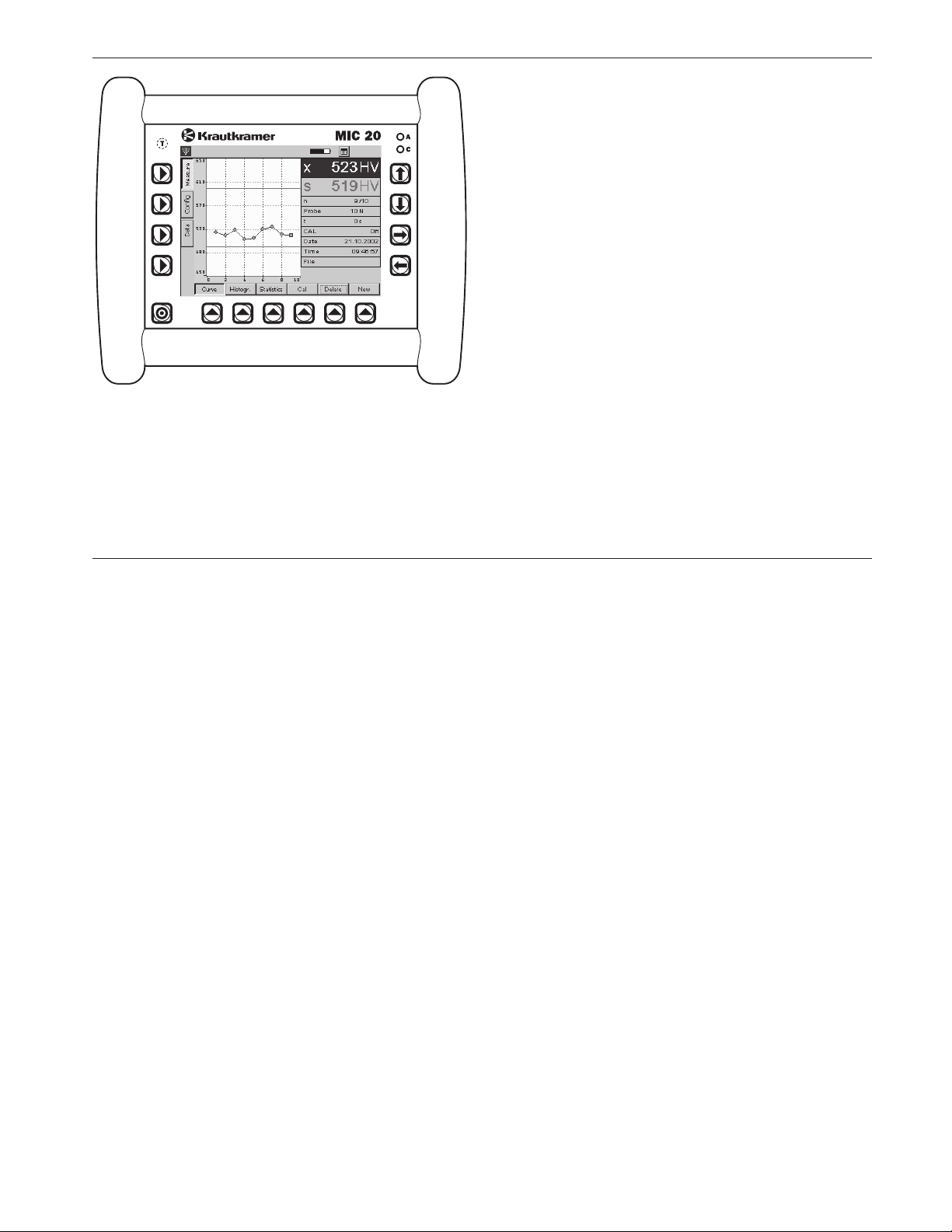

Operator’s controls and displays

1 Temperature sensor (no operating function)

2 Select keys to select the main menus

3 Touch-sensitive screen (touch screen), for direct

operation of the graphic interface

4 Key to turn on and off

5 Red LED,

is lit in the case of alarms and if the preset threshold

values for hardness measurements are exceeded

6 Green LED,

is lit with an active charging process,

flashes quickly with a finished charging process,

flashes slowly if the battery voltage or the temperature are out of tolerances

7 Arrow keys for navigation in the menus, and for acti-

vation of functions

8 Select keys for submenus and functions

Display screen

The Krautkramer MIC 20 is equipped with a touch

screen enabling a direct operation of the menus appearing on the screen.

The graphic user interface is adapted to the known

Windows standards. The operation by means of a

mouse (selecting and clicking) is in this case replaced

with direct touch on the screen. A mouse pointer is

therefore not necessary.

To select or to mark an element of the user interface,

just touch the corresponding point of the screen briefly

with your finger or with the pen provided for the instrument.

The pen is located in the holder at the instrument bottom.

A Attention:

Do not touch the touch screen with any hard or sharpedged objects (e.g. ball-point pen or screw driver). The

touch-sensitive surface may be severely damaged by

them.

Krautkramer MIC 20 Issue 02, 04/2005 4-3

Page 46

Operation Fundamental principles of operation

Do not apply any high pressure to the screen, the touch

screen needs only slight pressure to react.

User interface

The 3 main menus Data, Config, and Measure are dis-

played on the screen. The 3 main menus have different

user interfaces.

The buttons as well as the option and other boxes

shown on the user interface can be operated by directly

touching the touch screen, or by pressing the corresponding key next to the screen.

H Note:

The contents of the menu differ in some details, depending on the fact whether a probe or an impact device is connected to the MIC 20.

Main menu Measure Main menu Config

4-4 Issue 02, 04/2005 Krautkramer MIC 20

Main menu Data

Page 47

Virtual keyboard

A virtual keyboard is available for text and value inputs

and is automatically displayed if the corresponding

input fields are activated.

The virtual keyboard can also be turned on and off by

hand.

– Touch the button with the keyboard icon on it, next to

the battery icon. The virtual keyboard is displayed.

– Touch the broad bar above the displayed keys, keep

the pen pressed down, and move the keyboard with

the pen pressed down.

– Touch the button with the keyboard icon on it once

again. The virtual keyboard is turned off again.

OperationFundamental principles of operation

Krautkramer MIC 20 Issue 02, 04/2005 4-5

Page 48

Operation Fundamental principles of operation

Operation using the keypad or touch

screen

You can use either the keys arranged around the screen

to operate all menus and functions or, as an alternative,

directly the touch screen.

At the beginning, use both alternatives in order to test

the advantages of either one in practice.

In general, this manual only describes the direct operation by means of the touch screen. If the operation alternative using the keyboard presents a special advantage, it is additionally mentioned at that point.

The keys and menus or functions are arranged in such

a way that a clear assignment can always be seen.

Consequently, you’ll always have the following two alternatives:

– Touch the button of a function.

or

– Press the key next to (or below) the function.

Installing the instrument

The instrument has a prop-up lever stand at its bottom

enabling you to install the instrument at varying angles.

You should always ensure that you have a good view of

the screen in order to work as ergonomically as possible and to avoid overstraining yourself unnecessarily.

– Fold out the lever stand, and let it lock into the re-

quired position.

– Install the instrument in such a way that you have a

good and non-dazzling view of it.

4-6 Issue 02, 04/2005 Krautkramer MIC 20

Page 49

Probe and impact device

Operation

4.2 Probe and impact device

Guiding the probe

A Attention:

Make sure that the probe is connected before switching

the MIC 20 on so that the instrument is automatically

set to the UCI method.

Reliable measurement results can only be obtained if

you know how to handle the probe correctly and safely.

Please always observe the following rules:

❚ Avoid any rough placing of the probe on the test sur-

face in order not to damage the diamond.

❚ Do not move the probe under load on the test material.

❚ Pay attention to guiding the probe smoothly and

steadily using your both hands.

❚ Do not carry out measurements twice at the same

test position. The distance between the test positions

should be at least 3 mm.

H Note:

After placing the probe on the test surface, the measurement must be carried out within 3 seconds. Otherwise an error message will be given and you have to

start the process again.

– Select the main menu Measure.

– If necessary, remove the rubber protection cap from

the probe.

– Screw on the conical test attachment for short-time

measurements.

– Hold the probe with your both hands in order to have

the best possible control during guidance and during

impressing in the material surface.

– Place the probe vertically on the surface to be

tested. An icon at the top edge on the screen shows

the contact of the probe with the test material:

Krautkramer MIC 20 Issue 02, 04/2005 4-7

Page 50

Operation

Probe and impact device

– Hold the probe with one hand tightly enough so that it

doesn’t tilt and press it evenly and steadily against

the surface with the other hand.

– Increase the pressure steadily until the probe’s spe-

cific load is attained and you hear an acoustic signal.

The measured hardness value is displayed on the

screen.

– Lift off the probe and place it again at another posi-

tion in order to carry out other measurements.

H Note:

If you have pressed the probe down up to the limit stop

without any measured value being determined (no

acoustic signal), check the following possible causes:

❚ The load was applied too fast. Try again by increas-

ing the pressure more slowly.

❚ The instrument has not been calibrated correctly

beforehand.

❚ The hardness of the surface tested is beyond the

probe’s range of measurement.

Operating the impact device

A Attention:

Make sure that the impact device is connected before

switching the MIC 20 on so that the instrument is automatically set to the rebound method.

The impact device Dyna G must only be used up to a

hardness to be tested of max. 650 HB, otherwise the

impact device may be destroyed.

Reliable measurement results are only obtained if you

know how to handle the impact device correctly and

safely.

You should always observe the following rules:

❚ Always use an impact device suitable for the appli-

cation and equipped with the appropriate test attachment.

❚ Do not carry out measurements twice at the same

test position. The distance between the test positions

should be at least 3 mm.

4-8 Issue 02, 04/2005 Krautkramer MIC 20

Page 51

Probe and impact device

Operation

❚ Never load the impact device at the actual test posi-

tion (surface hardening) but somewhere else (e.g. at

a table or another position of the test object).

❚ Keep the following in mind when using the test at-

tachments Dyna 41 and Dyna 42 so that the impact

device is correctly loaded: do not tension the impact

device by pushing the load tube through „in the air”

but by e.g. pressing one finger against it or by placing the impact device on the test surface. After that,

put the impact device at the actual test position.

– Select the main menu Measure.

– Tension the impact device by pushing the load tube

all the way through to the limit stop and by moving it

slowly back to the initial position.

– Place the impact device vertically on the test sur-

face and press it slightly against it with one hand so

that it doesn’t tilt.

– Use the index finger of the other hand to press the

release button. An acoustic signal is heard if the

measurement was successful.

– Lift off the impact device. The measured hardness

value is displayed on the screen.

Release button

Load tube

Test attachment

Krautkramer MIC 20 Issue 02, 04/2005 4-9

Page 52

Operation

Hardness testing

4.3 Hardness testing

A Attention:

In order to obtain correct measurement results, it is

absolutely necessary to calibrate the MIC 20 to the test

object’s material before starting any measurements.

You have to repeat the calibration process for every

new material. You must likewise repeat the calibration

whenever you change the test method.

The calibration is described in detail in the following

chapter 4.4. As you have to carry out measurements

for the calibration, please read the present chapter first

in order to learn how to edit measurement series and

view measurement results.

H Note:

When the MIC 20 is switched off, the instrument settings (including calibration) of the last measurement are

saved and will again be available unchanged when the

instrument is switched on the next time. Check the

current settings prior to every measurement series.

Starting and closing a test series

If you use test series, you can end a test series any

time, and start a new one. The statistical evaluations

always refer to the currently active test series.

– Select the main menu Measure.

– Select one of the functions Curve, Histogr. or Sta-

tistics at the bottom edge of the display.

– Touch the button New in order to start a new test

series.

– Touch the button Delete in order to delete a test se-

ries that has possibly already been recorded. The

readings are deleted, and a new test series is

started.

You can now start measuring.

The processes of saving and editing test results are

described later in this manual (ref. chapter 4.5).

4-10 Issue 02, 04/2005 Krautkramer MIC 20

Page 53

Hardness testing

Operation

Viewing and evaluating test results

Various information is shown to you in the main menu

Measure, depending on the selected view, e.g. the current hardness value, the list of previous measured values, or the statistical distribution of measured values.

Details depend on the current method of measurement.

You can choose between three display view modes for

measurements:

You have a choice between three display modes for the

measurements:

❚ Curve

❚ Histogram

❚ Statistics

H Note:

The different display modes have no effect on the process of measurement.

The current reading (s), the current statistical average

(x), and the number of measurements (n) can be seen

in all four display modes.

– Select the main menu Measure.

– Select one of the functions at the bottom edge of the

display in order to see the corresponding display

mode.

Curve function

The measured hardness values are displayed as a

curve in a diagram. The shape of the curve helps you

with the evaluation of the test results.

Krautkramer MIC 20 Issue 02, 04/2005 4-11

Page 54

Operation

Hardness testing

The horizontal green lines show the tolerance limit settings. Readings within the tolerance range are displayed

in green, readings outside in red.

In addition to the diagram, other information is displayed for every measured value:

Probe Test load of the probe or

type of the impact device

t Dwell time (only with UCI method)

CAL Calibration number (Off = standard material)

Mat. Selected material group

(only with rebound method)

Date Date of measurement

Time Hour of time of measurement

File File name when editing an already saved

measurement series

You can delete individual test results.

– Touch the required reading to select it.

– Touch the button Delete. The selected reading is

immediately deleted.

H Note:

You can also select the reading by means of the arrow

keys to the right of the screen display.

4-12 Issue 02, 04/2005 Krautkramer MIC 20

Page 55

Hardness testing

Operation

Histogr. function

The histogram shows the statistical distribution of the

readings of the current test series.

Besides the graphics, additional statistical single values are displayed (ref. chapter 7.4):

S Standard deviation (absolute and percentage)

R Range of spread (absolute and percentage)

cp Process capability index

cpk Critical process capability index

Statistics function

The Statistics function shows the test results of a test

series in tabular form.

Krautkramer MIC 20 Issue 02, 04/2005 4-13

Page 56

Operation

Hardness testing

Besides the table, additional statistical single values

are displayed (ref. chapter 7.4):

S Standard deviation (absolute and percentage)

R Range of spread (absolute and percentage)

Min Minimum value

Max Maximum value

Test results situated within the set tolerance limits are

shown in blue characters, test results outside the tolerance are shown in red characters.

You can delete individual test results.

– Touch the required reading in order to select it.

– Touch the button Delete. The selected reading is

immediately deleted.

H Note:

You can also select the reading by means of the arrow

keys to the right of the screen.

Conversion into other hardness scales

You can directly convert the test results obtained into

other hardness scales.

A Attention:

Any illegal or unacceptable conversions may lead

to serious errors in the interpretation of test results.

You should always pay attention to the information

given in chapter 7.3 of this manual regarding the conversion of test results.

4-14 Issue 02, 04/2005 Krautkramer MIC 20

Page 57

Hardness testing

Operation

H Note:

The list of hardness scale options is not automatically

adapted to the test method or the impact device used.

If your choice is not accepted by the instrument, the

selected conversion is not possible. A corresponding

note is displayed on the screen.

– Touch the abbreviation of the current hardness scale

(e.g. HV) at the item Average (x) in the right-hand

screen section. An options menu is displayed.

– Touch the abbreviation of the required hardness

scale (e.g. HB). All values of the current

measurement series are displayed in the new scale.

4.4 Calibration

A Attention:

In order to obtain correct measurement results, it is

absolutely necessary to calibrate the MIC 20 to the test

object’s material before starting any measurements.

You have to repeat the calibration for every new material. When changing the test method, you have to likewise repeat the calibration procedure.

H Note:

If you want to measure on low-alloy or unalloyed steels,

there’s no need to set the instrument because this material group is the default setting of the MIC 20.

When switching the MIC 20 off, the instrument settings

(including calibration) of the last measurement are

saved and will be available again unchanged when the

instrument is switched on the next time. Check the

current settings prior to every measurement series.

Krautkramer MIC 20 Issue 02, 04/2005 4-15

Page 58

Operation

Calibration

Carrying out the calibration

The calibration procedure is basically identical for the

UCI method and for the rebound method.

You only have to start by selecting one of the material

groups stored in the instrument as an additional action

with the rebound method.

You need a reference block made of the same material

with known hardness for the calibration. During the calibration, you determine the calibration number that you

need in other measurements on this material.

The calibration number is an auxiliary value that simplifies the subsequent change of the calibration setting.

The calibration number has no physical reference whatsoever and consequently no name either.

As you can save the calibration in the MIC 20, you only

have to carry out the calibration once for a certain material.

Only with calibration for rebound method:

If you want to carry out measurements on high-alloy

steels or on other materials, e.g. nonferrous metals,

you have to set the MIC 20 to the required material. To

do this, you start by choosing the suitable material

from the 9 existing ones. For precision measurements,

you have to carry out a calibration afterwards for the

adjustment.

– Touch the button Cal. The calibration menu is dis-

played.

– Touch the list box Material group. The list of the

stored material groups appears.

4-16 Issue 02, 04/2005 Krautkramer MIC 20

Page 59

Calibration

Operation

– Touch the material group corresponding to the test

object. The list is closed again.

– Finally, touch the button OK to close the menu.

Notes on the material groups:

The MIC 20 makes 9 material groups available. However, not all material groups are suitable for the different

impact devices. Please observe the assignment in the

table below:

Material group Impact device

ST - steel and cast steel D E G

AST - tool steel D E

SST - stainless steel D

GCI - gray cast iron D G

NCI - nodular cast iron D G

AL - aluminum cast alloys D

BRZ - bronze D

CU - wrought copper alloys D

Calibration for UCI and rebound method:

– Carry out a series of measurements consisting of

about 5 single measurements on your reference

block.

– Touch the button Cal. The calibration menu is dis-

played.

The current statistical average of your measurements

is displayed at the item Real value. However, this value

does not correspond to the known, real hardness value

because you have not yet calibrated the instrument.

You will now have to adapt the displayed value to the

known hardness value of your reference block.

– Double-touch the item Target value in order to mark

the value displayed there.

BRS - brass D

Krautkramer MIC 20 Issue 02, 04/2005 4-17

Page 60

Operation

Calibration

– Touch the button Select at the bottom edge of the

screen. The virtual keyboard is displayed, and you

can input the required target value.

– Key in the value by touching the corresponding char-

acters on the keyboard.

– Finally, touch the displayed Return (ENTER) key. The

keyboard disappears again.

According to the input hardness value, the MIC 20

will automatically determine the calibration number

which is immediately displayed at the item Cal.

Number.

Having calibrated the MIC 20, you can carry out

hardness tests as described above.

– Touch the button OK in order to close the calibration

menu. You will see the normal display screen again.

An icon at the top edge of the screen shows that a

calibration is active (calibration number non-0):

A Attention:

The calibration is active when the calibration menu is

closed, however, it is not automatically saved. If you

want to use a calibration again some time later, you

have to save it under a new name (please see the following section).

Saving calibration data

If you want to use a calibration several times (e.g. after

switching the instrument off and on again, or after exchanging the probe), you have to save it. To do this,

you have to enter a name for the calibration.

H Notes:

You cannot edit or overwrite saved calibrations. In order

to save any changes, you have to enter a new name.

Calibrations for the UCI method are independent of the

probe, and consequently they apply to all UCI probes.

Calibrations for the rebound method are dependent of the

4-18 Issue 02, 04/2005 Krautkramer MIC 20

Page 61

Calibration

Operation

type of the impact device, and the letter of the impact

device is therefore added to their name (D, G, or E).

– Touch the button Cal. The calibration menu is dis-

played and you will see the current calibration.

– Double-touch the item Name in order to mark the

name displayed there.

– Touch the button Select at the bottom edge of the

screen. The virtual keyboard is displayed, and you

can key in the required name for the calibration.

– Finally, touch the button OK in order to close the

menu. The current calibration is now saved under the

input name, and you can always restore it at a later

date.

Deleting calibration data

You can always delete calibrations that are no longer

needed.

– Touch the button Cal. The calibration menu is dis-

played.

– Touch the item List containing the saved calibration

data. The list appears.

– Touch the name of the required calibration.

– Touch the button Delete at the bottom edge of the

screen. The current calibration is deleted after confirming the safety prompt. The following calibration in

the list is now active.

– Finally touch the button OK in order to close the

menu.

Krautkramer MIC 20 Issue 02, 04/2005 4-19

Page 62

Operation

Calibration

Restoring the standard calibration

If you want to reset the calibration to the standard or

default setting again after calibrating to a special material, just choose the option STANDARD from the list of

calibration data. This setting is factory-programmed and

cannot be deleted.

– Touch the button Cal. The calibration menu is dis-

played.

– Touch the item List containing the saved calibration

data. The list appears.

– Touch the option STANDARD. The default setting is

restored.

– Finally, touch the button OK in order to close the

menu.

The icon for the active calibration is no longer shown at

the top edge of the screen.

H Note:

You can always restore all other saved calibration data

as well in exactly the same way by making your choice

from the list.

4-20 Issue 02, 04/2005 Krautkramer MIC 20

Page 63

Saving the test data

Operation

4.5 Saving the test data

A Attention:

Before starting a new test series, you can save the

current test series to a file in the memory of the

Krautkramer MIC 20. You can restore and view the

data saved in this way any time later on.

You can interrupt and save test series any time by

starting a new test series.

Depending on the configuration of the instrument, you

are automatically prompted to save as soon as the last

value that was set for a test series has been recorded.

– Select one of the functions Curve, Histogram or

Statistics at the bottom edge of the display.

– Touch the button New in order to start a new test

series. Three new buttons are displayed at the bottom edge of the display.

– If necessary, touch the button Edit if you want to

make some further changes to the current test series (record other readings, delete reading or conversions). You will again see the display mode that was

last selected.

– Touch the button Delete in order to delete the current

test series.

– Touch the button Save in order to save the current

test series. The window for selecting the directory

and file name appears.

You can now select a directory and assign a file name

as you’re used to do in common Windows applications.

H Note:

The selection of the directory and the assignment of

the file name are not necessary if you activate Auto

save to (please see chapter 4.7).

Krautkramer MIC 20 Issue 02, 04/2005 4-21

Page 64

Operation

Saving the test data

Saving files

– Touch the name of a directory in order to select the

directory.

– Touch the text box at the bottom edge of the display.

The virtual keyboard is displayed, and you can key

in the required file name.

– Enter a name by touching the corresponding charac-

ters on the keyboard.

– Finally, touch the displayed ENTER key. The key-

board disappears again.

– Touch the button Save. The test series is saved to

the currently selected directory using the specified

name.

Deleting files or directories

A Attention:

When a directory is deleted, all files stored there are

likewise deleted. You cannot cancel the deletion.

– Touch the name of a directory or a file in order to

select the directory or file.

– Touch the button Delete. A safety prompt appears.

– Touch the button Yes in order to confirm the deletion

process. The selected directory or the selected file is

deleted.

4-22 Issue 02, 04/2005 Krautkramer MIC 20

Page 65

Saving the test data

Operation

Opening and closing directories

– Double-touch a directory. The directory is opened.

or

– Briefly touch a directory in order to select it, and then

touch the button Open.

– Double-touch an open directory. The directory is

closed.

or

– Briefly touch an open directory in order to select it,

and then touch the button Close.

Creating new directories

– Touch the name of a directory in order to select the

directory.

– Touch the text box at the bottom edge of the display.

The virtual keyboard is displayed, and you can key

in a name of a directory.

– Enter a name by touching the corresponding charac-

ters on the keyboard.

– Finally, touch the displayed ENTER key. The key-

board will again disappear.

– Touch the button NewDir. The new directory is cre-

ated in the currently selected directory using the

specified name.

Krautkramer MIC 20 Issue 02, 04/2005 4-23

Page 66

Operation

Saving the test data

Opening files

You can open saved files, and view the readings of a

test series stored there.

– Touch the name of a file in order to select the file.

– Touch the button Open. The file is opened.

After opening the file, the main menu Measure will automatically appear. You can change between the different

display modes, as well as view the saved data.

If you start a new test series, the open file is closed

without editing it.

You can also edit the open file. If the edited data should

be saved, you have to save the file afterwards using a

new name.

Editing saved files

If you want to edit an already saved file, you have to

save this file afterwards using a new name.

– Open the required file.

– If necessary, edit the required data in the main menu

Measure (e.g. deleting of single readings).

– Go to the main menu Data.

You can now enter a new file name as described above,

and save the edited file.

H Note:

You cannot add any other readings to a saved file. The

file LastMeasure.mes, where the current readings that

have not yet been saved are automatically filed when

the MIC 20 is switched off, is an exception. You can

continue with the measurement series after opening

this file the next time the instrument is switched on.

4-24 Issue 02, 04/2005 Krautkramer MIC 20

Page 67

Saving the test data

Operation

File management using instrument keys

All main functions of file management, known to you

from the Windows Explorer, are available to you in the

main menu Data. Analogously to the operation using

the mouse, the operation by means of the touch screen

is the most convenient way with the Krautkramer

MIC 20.

The operation using the keys arranged around the display screen, however, only makes a limited functionality available.

You can always navigate in the file structure, as well as

select files and directories using the arrow keys to the

right of the display screen.

The keys below the display screen enable you to operate the buttons appearing above each one of them, and

carry out the corresponding functions (e.g. Delete,

Open, or Close).

The access to the text box for keying in file or directory

names, however, is not possible by means of the instrument keys. A character can only be keyed in via

the virtual keyboard.

4.6 Printing test reports

You can print out the results of a test series in the form

of a test report. To do this, you have to save the test

results to a file beforehand.

You have a choice between two types of reports:

❚ Compact

❚ Complete

The compact-type report contains the following data:

❚ Date and name of the file

❚ Information about the instrument and the probe or

impact device

❚ Name of the operator

❚ Remarks on the test series

❚ All statistical evaluations referring to the test series

❚ Data regarding the tolerance threshold settings

Krautkramer MIC 20 Issue 02, 04/2005 4-25

Page 68

Operation

Printing test reports

H Note:

The compact-type report contains no single readings.

The complete-type report contains, in addition to the

data of the compact-type report, the following:

❚ graphic display of the hardness values in a diagram

(analogously to the display mode Curve)

❚ list of hardness values in tabular form (analogously

to the display mode Statistics)

For both report types you can addionally select the

options Color and Draft. The option Draft will accelerate

the printing process with a slight loss of quality.

Prerequisites for printing

The following requirements must be met for the printout

of test reports.

A PCL-compatible laser or ink-jet printer must be connected to the serial interface of the instrument. To connect the printer, you need a serial printer cable, or a

serial-parallel converter (order no. 101 761).

H Note:

Information about the configuration of your model of

printer you find in the documentation of the printer

used.

Serial printer

– Connect the printer with the serial interface (9-pin

Sub-D-socket).

– Set the data transmission parameters on your printer

as follows:

1 start bit

1 stop bit

8 data bits

no parity check

software handshake on

– Ensure that the baud rate set in the printer agrees

with that selected in the MIC 20 (ref. following section).

4-26 Issue 02, 04/2005 Krautkramer MIC 20

Page 69

Printing test reports

Operation

Parallel printer

– Connect the printer by the serial-parallel-cable with

the serial interface (9-pin Sub-D-socket).

– Ensure that the baud rate setting of the serial-parallel

converter agrees with that selected in the MIC 20

(ref. following section). The recommended baud rate

is 4800.

Selecting and printing a test series

After connecting and configuring a compatible printer,

you can select the required measured value file

(*.mes), and print out the test report.

H Note:

Due to the baud rate of 4800, the printout is recommended in the draft mode.

– Go to the main menu Data.

– Touch the required measured value file in order to

select it.

– Touch the button Print. A dialog box appears.

– Touch the list boxes one after another, and select the

printer, the interface, and the mode of the report.

– Touch the button OK. The printing process starts

immediately.

Krautkramer MIC 20 Issue 02, 04/2005 4-27

Page 70

Operation

Specimen test report complete

Printing test reports

4-28 Issue 02, 04/2005 Krautkramer MIC 20

Page 71

Specimen test report compact

OperationPrinting test reports