Page 1

GE Inspection Technologies

Mobile hardness tester

with the double assignment.

Ultrasonics Ultrasonics

GE Inspection Technologies

Krautkramer MIC 20

When to choose which method?

The UCI method is recommended for testing fine-grained materials having almost

any shapes and sizes. It is especially used

whenever material properties have to be

determined within close tolerances. The

small UCI probes equipped with a Vickers

diamond are also a good choice for hardness testing on welded components, most

of all for the critical heat-affected zone.

Rebound hardness testing is mainly carried

out on large components having rough sur

surface structure, as well as on cast mate

rials of all kinds.

The MIC 20 consequently places the

complete range of applications at your

disposal. For example UCI testing:

• on ready-assembled machines

• in the heat-affected zone of a weld (e.g.

pipeline)

• on coatings (e.g. printing industry)

• on hardened surfaces (e.g. tooth flanks

-

or tooth gullet)

faces, on forgings having an inhomogeneous

Specifications and Accessories

Test methods

UCI method: hardness testing with an indenter

according to Vickers, evaluation of the test

indentation under load.

Rebound method according to the ASTM standard

specification A956: dynamic test method with a

ratio of rebound (Rp) and impact (Ip) speed with

hardness output in Leeb HL = 1000 Rp/Ip

UCI probes

To be selected according to application:

Handheld probes:

10 N (1 kgf) standard MIC 201-A

short MIC 201-AS

extended MIC 201-AL

50 N (5 kgf) standard MIC 205-A

short MIC 205-AS

extended MIC 205-AL

98 N (10 kgf) standard MIC 2010-A

Motor probes:

8.6 N (0.9 kgf) MIC 211

3 N (0.3 kgf) MIC 2103-A

1 N (0.1 kgf) MIC 2101-A

Rebound impact devices

To be selected according to application:

Ø 3 mm spherical tungsten carbide

metal tip Dyna D

Ø 5 mm spherical tungsten carbide

metal tip Dyna G

Diamond test tip Dyna E

Measuring ranges/conversions (UCI)

20-1740 HV / 76-618 HB / 41-105 HRB /

20.3-68.0 HRC / 255-2180 N/mm² (only with

98 N/10 kgf handheld probe)

Measuring ranges/conversions (rebound)

Depending on material group and impact device:

150-1000 HL / 75-1000 HV / 75-700 HB / 30100 HS / 35-100 HRB / 19-70 HRC /

250-2200 N/mm²

Display

Color display or color TFT display, 1/4 VGA,

5.7”, 115.2 mm x 76.8 mm / 4.5” x 3.0”

Diaolog languages

German, English (among others)

Conversion

Automatically according to DIN 50150,

ASTM E 140

Evaluation

Representation of test data as a curve, histogram,

or in tabular form; calculation of statistical data,

e.g.: average, standard deviation, range

Automatic instrument shutdown

After a user-selectable period of time with automatic saving of test data and instrument settings

Keyboard

Sealed membrane keypad with integrated touch

screen

For example rebound hardness testing:

-

• on motor units or machine parts made

of steel and cast aluminum alloys

• on solid, coarse-grained components

having a surface as rolled

• on large series parts during the produc

tion

• for material differentiation in material

depots

• on wrought copper alloys.

Operating time

With NiMH battery pack MIC 20-BAT approx.

4 hours in continuous operations

Battery charge indicator

Low-Batt indicator, instrument shutdown with

low voltage

Operating system

WinCE

Interfaces

RS 232 bidirectional, Ethernet 10 Mbit

Temperature ranges

Operation: 0 °C to 50 °C/-32 °F to 122 °F

Storage: -20 °C to 70 °C/-4 °F to 158 °F

Weight

Approx. 1.4 kg / 3.1 lbs (incl. MIC 20-BAT)

Size

78 mm x 215 mm x 180 mm /

3.1" x 8.5" x 7.1" (H x W x D)

Accessories

Transport case, large selection of guides and supports (UCI method), test attachments (rebound

method), hardness reference plates and blocks including certificate, NiMH battery, battery-powered

grinding set for surface treatment, printer cable,

application software, data transmission cable

More details on our extensive range of probes and

accessories on request.

Combined Hardness Tester

according to the UCI and Rebound Methods

-

We reserve the right to technical modifications without prior notice.

GEInspectionTechnologies.com

©2004 General Electric Company. All rights reserved.

GEIT-20026US (09/04)

Page 2

GE Inspection Technologies

Ultrasonics

One instrument two test methods

a thousand and one applications.

Static plus dynamic.

For the first time the Krautkramer MIC 20

combines the quasi-static UCI and the

dynamic rebound hardness testing methods: the MIC 20 now places "hardness

testing in a twin pack" at your disposal

with these two different physical methods

- and covers their complete application

range.

This makes the MIC 20 a universal instru

ment: you can use it to test fine-grained

materials having different masses and

shapes or heat treated surfaces (UCI

method), as well as large, coarse-grained

components, forgings, and cast materials

(rebound method).

The two methods.

The UCI method (Ultrasonic Contact

Impedance) determines the hardness of

a material on the basis of the size of the

test indentation left behind in the material by a Vickers diamond after applying

the test load.

In the case of the rebound method, an

impact body is impelled by spring force

against the test surface. The impact and

rebound velocities are each measured in

a non-contact mode; the hardness value

is calculated from these two values.

The MIC 20 automatically sets to the

corresponding method as soon as you

connect a UCI probe or a rebound impact

device.

The double benefits.

The two methods enable you to easily

measure the hardness of your test object

in a matter of seconds: place probe or impact device on the test object, and read

the measured value on the display. In this

way you can measure anywhere and in

any direction. We have used a patented

signal processing to also put this advantage into practice for the rebound hardness method.

In addition, the following applies to the

two test methods: easy and fast calibra

tion capability, presentation of the results

according to the usual hardness scales,

extremely easy handling in mobile use in

daily testing situations.

-

Hardness testing

can be easy.

The many years of experience that we

have…

of mobile hardness testing have left their

mark on this combined instrument. Possibility to use proven Krautkramer technology: the complete range of UCI handheld

and motor probes with different test loads

and oscillation rod lengths can be used

just like all rebound impact devices from

our product range. This ensures optimum

adaptation to the test task and material.

For you this also means: you can simply

extend the range of applications of your

MIC 20 that you have bought for a specific subsequent application: all you need

are the corresponding probes or impact

devices which you then connect - and

there you have another hardness tester.

Field-oriented ease of operation…

is characteristic of the MIC 20. You can

directly see the indicated measured value

according to the selected hardness scale

on the large color LCD or the color TFT

display. The graphic user interface shown

on the display is adapted to the known

Windows standard and is intuitively presented. You don't need any mouse for

the operation, merely a pen to touch the

touch screen and to set the functions. As

an alternative, you also have conventional

pushbuttons at your disposal for most

settings.

You will soon be able to cope with the

operating concept: three main menus

ensure easy access to the essential

functions - so there's no chance of getting

lost in a menu maze!

The MIC 20 makes for example the cali

bration easy for you. The setting parameters are then simply filed and recalled

by pressing a button or by a "click" in the

corresponding application case.

-

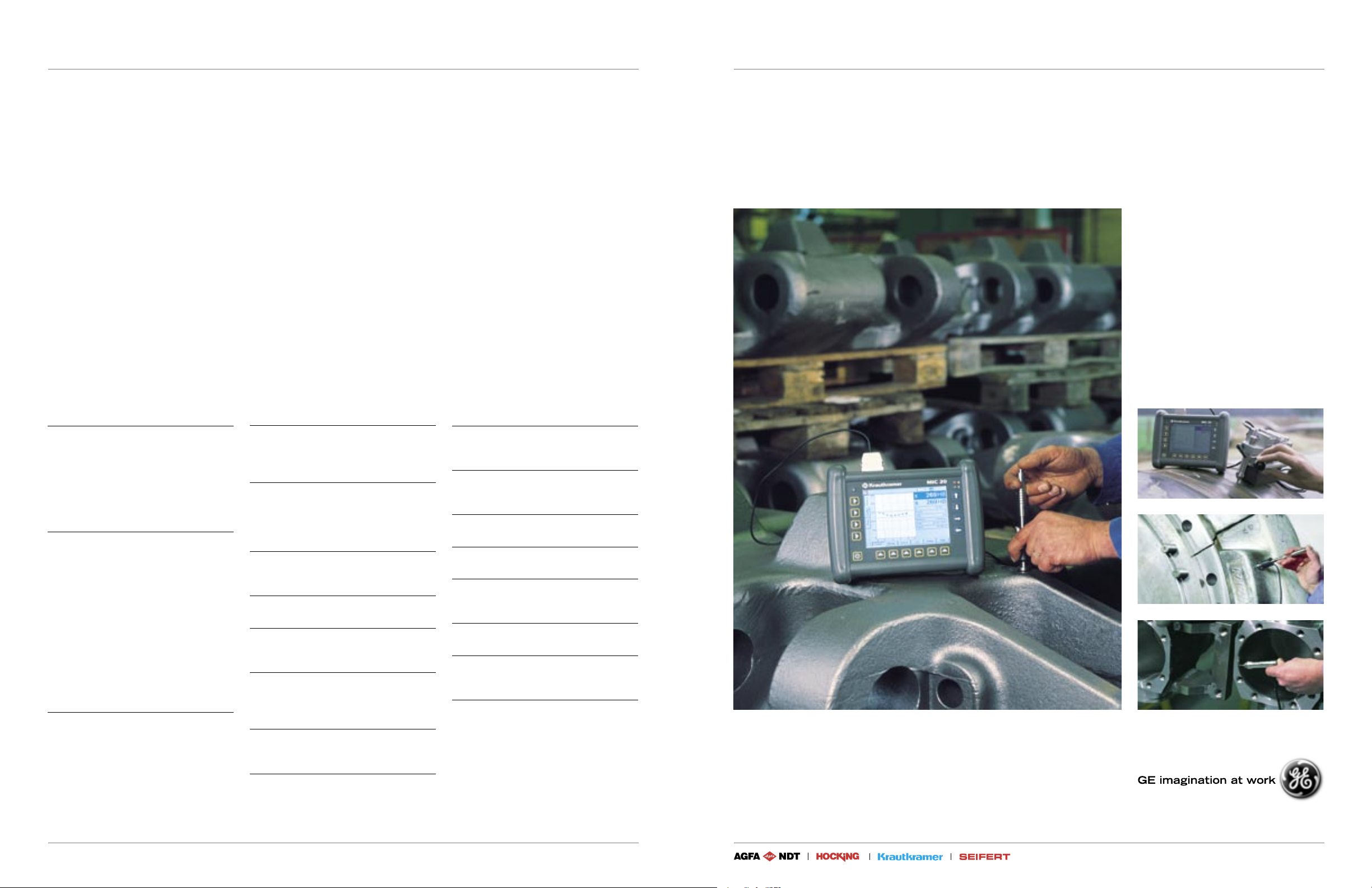

"Hardness testing as a twin pack":

The MIC 20 with a selection of rebound impact devices

and UCI probes, as well as with the quick support

including motorprobe.

A straightforward data memory enables

convenient and structured saving and

management of test results. The MIC 20

also presents the necessary functions for

your analysis: you can have your series

of measurements displayed as a curve,

histogram, or as a table with statistical

data. You can print the data either di

rectly on a printer or transfer them to the

PC by means of the application software

UltraDAT. You can use e.g. the Windows

standard applications for further processing, evaluation, and statistics.

-

The user-friendly display of the MIC 20: you will see all

information at a glance. To store your data, just create

different directories as required: the input of alphanu

merical data is no problem either.

-

The on-site use…

with the mobile and flexible MIC 20 will

certainly be something that you will like:

besides a mains connection, the instrument is operated by means of our rechargeable battery pack allowing internal

charging in the instrument. The display

is switched off after a certain period of

time and can be reactivated by touching

the touch screen. A complete shutdown

can also be triggered automatically after a

preset period of time - which ensures an

energy-saving operation.

Loading...

Loading...