Page 1

GE Inspection Technologies

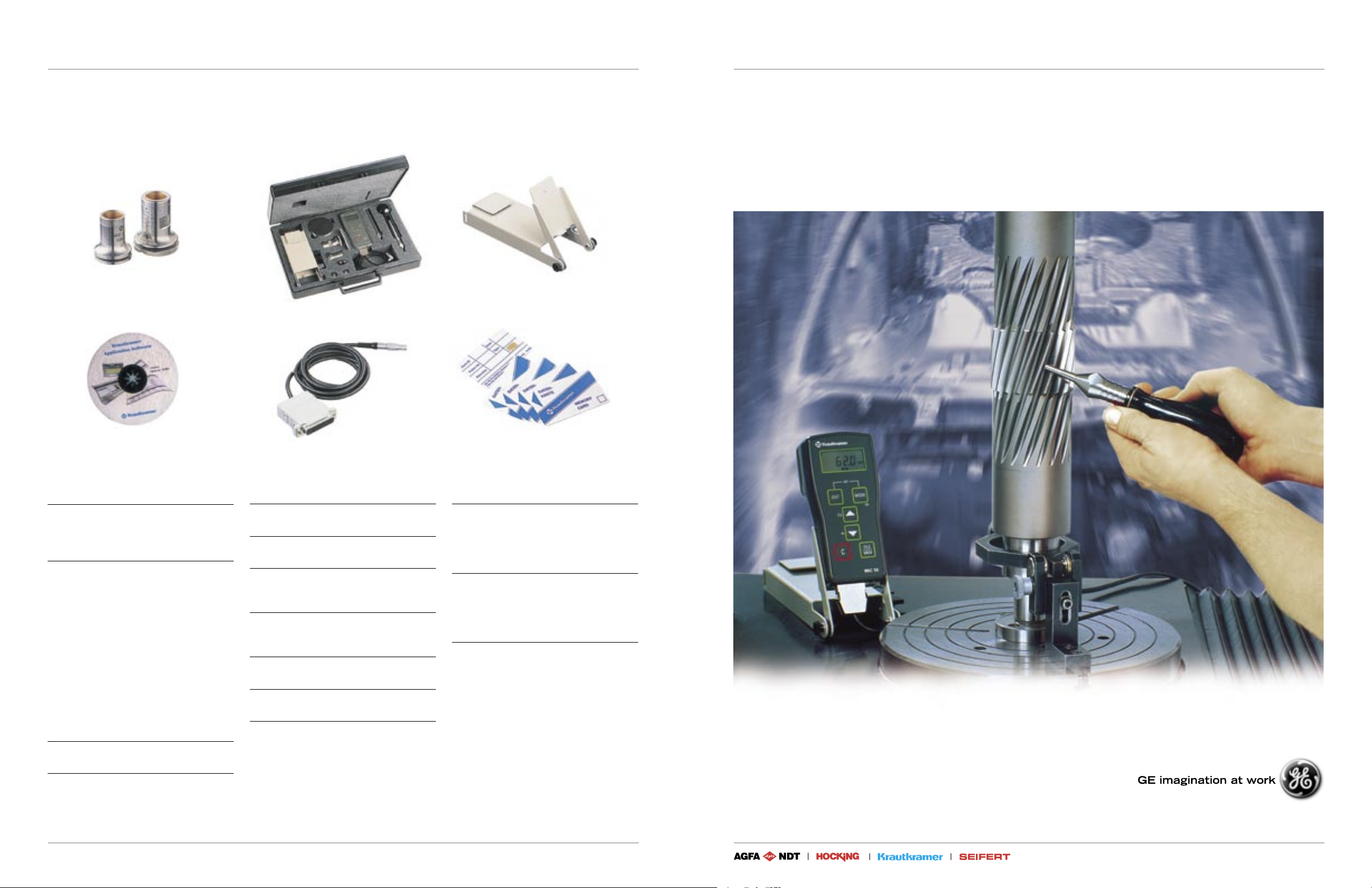

Accessories and specifications:

Ultrasonics Ultrasonics

GE Inspection Technologies

Krautkramer MIC 10

Quick hardness testing made easy.

Versatile in application and data storage.

Flat probe shoe attachment MIC 270

Prism shoe attachment MIC 271

Application Software

UltraHARD

Method of measurement:

Vickers penetration with indentation evaluation

by the UCI method under load

(diamond angle 136°)

UCI probes:

To be selected according to application:

Handheld probes:

10 N (1 kgf) standard MIC 201-A

short MIC 201-AS

extended MIC 201-AL

50 N (5 kgf) standard MIC 205-A

short MIC 205-AS

extended MIC 205-AL

98 N (10 kgf) standard MIC 2010-A

Motor probes:

8.6 N (0.9 kgf) MIC 211

3 N (0.3 kgf) MIC 2103-A

1 N (0.1 kgf) MIC 2101-A

Range:

20 - 1740 HV

Conversion:

HV, HB, HRC, HRB

N/mm² (only with the 10 kgf handheld probe)

according to DIN 50150, ASTM E 140

for MIC 10 and accessories

for printer and PC

Display:

4 digit LCD with switchable backlight

Weight:

approx. 300g

Dimensions:

160 x 70 x 45 mm,

6.3 x 2.8 x 1.8 inches (W x H x D)

Permissible ambient temperature:

In operation: -15°C to 55°C(5°F to 131°F)

In storage: -20°C to 60°C (-4°F to 140°F)

Power:

2 x 1.5V AA batteries

Operational duration:

approx. 15 hours without backlight

Interface (for version MIC 10 DL):

RS232C bidirectional

Carrying case

Serial data cable

GEInspectionTechnologies.com

Instrument carrier and prop-up stand

for the storage of measurement and

calibration data as well as report formats

Memory cards

Data Logger (for version MIC 10 DL):

Internal memory for up to 1800 measurments,

memory card for up to 590 measurements. Dependent on the number of measurements per

set. Warning given with memory overflow.

Statistics:

Display of the average value.

For version MIC 10 DL: printout with maximum,

minimum, average value, absolute and relative

range, absolute and relative standard deviation.

Probe accessories:

Handheld probe or motorized probe (is selected

according to application),

Guiding devices and test supports,

TGDL/PC-data cable (version MIC 10 DL)

Application software

Further information about our extensive probe and

accessory program will be given on request.

MIC 1040

We reserve the right to technical modifications without prior notice.

©2004 General Electric Company. All rights reserved.

GEIT-20027US (09/04)

Page 2

GE Inspection Technologies

Ultrasonics

Quick hardness testing

wherever you wish.

As with all other hardness testers from

our MICRODUR line, the MIC 10

operates according to the UCI method

(Ultrasonic Contact Impedance). This

method enables quick and easy measure-

ment: position probe and read off the

value. This operational ease is achieved

because the Vickers diamond indent in

the material’s surface is electronically

measured and instantly displayed as a

hardness value without using the

cumbersome optical evaluation of a mi-

croscope normally associated with Vickers

hardness testing.

The small, handy MIC 10 makes life easy

for you: a hardness tester that you can

take anywhere - on scaffolds for testing

large containers and pipes, or for testing

components at any location. The small

narrow probes even enable you to make

measurements on positions difficult to ac

-

cess, such as tooth flanks or roots of gears.

You can measure in any direction, e.g.

in the horizontal or overhead positions.

The instrument carrier and prop-up stand

permits two hand operation, for correct

probe positioning and guidance.

Easy operation, high performance

and unique data processing.

What this small instrument can do.

By pressing a key, you can display your

reading as a single value or as the active

arithmetical average value of a hardness

measurement set. Editing of erroneous

single values, without having to interrupt

the measurement set, is just as simple.

Adjustable alarm thresholds show you

critical measurement values both visually

and with audiable alarms. The calibration

parameters for measurements on low and

non-alloyed steel are preprogrammed into

the MIC10; however, the instrument can

be easily and quickly recalibrated to other

materials.

Instrument operation can be customized

for specific testing requirements:

unnecessary functions can be inhibited,

e.g. various hardness scales or the rec-

alibration capability. This reduces key

presses and simplifies operation.

Saving data - unlimited possibilities.

We have given a lot of thoughts to the

subject of saving data and have come up

with the MIC 10 DL in order to give you

special support with repetitive testing and

documentation.

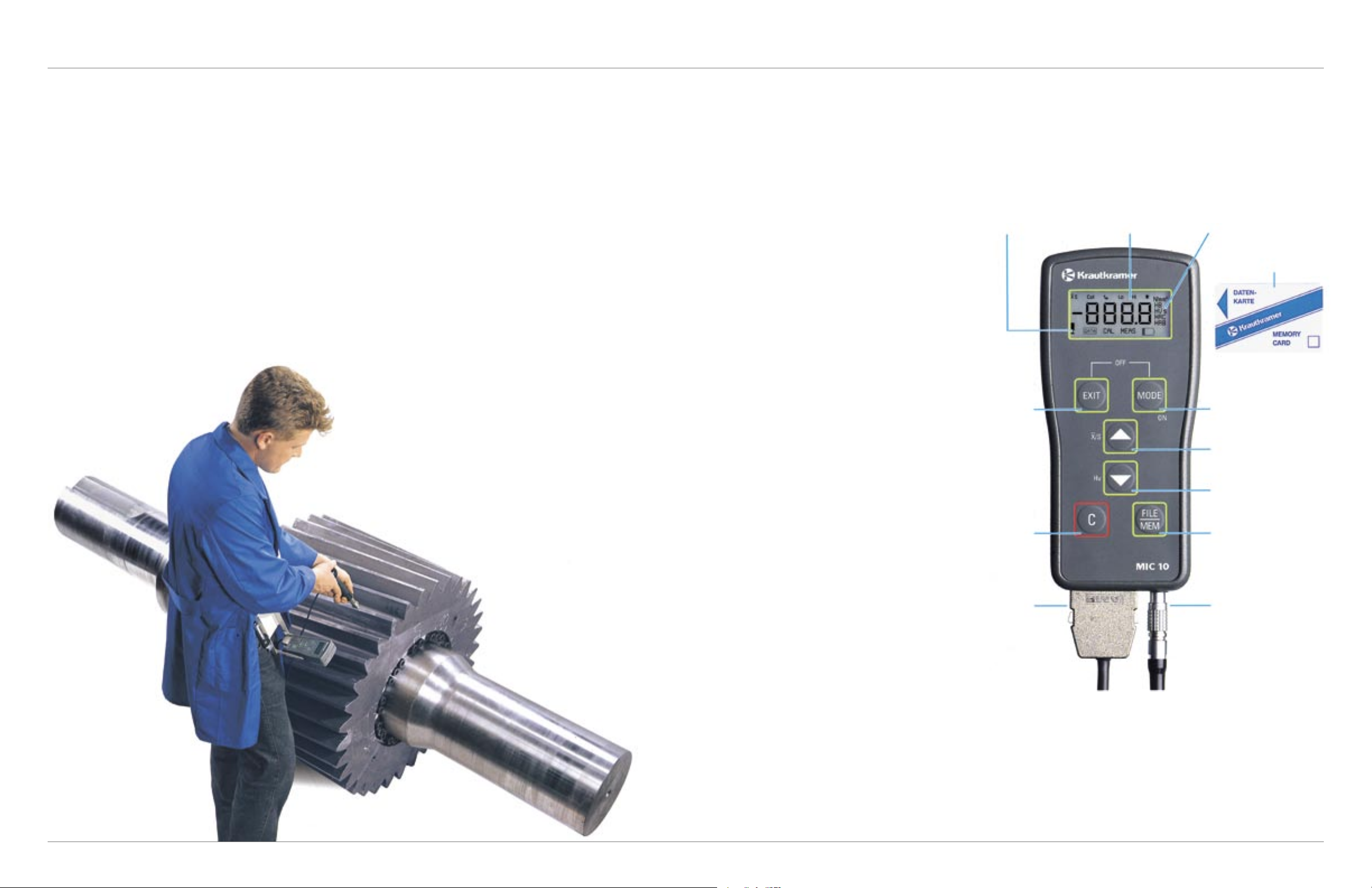

Display sector "Status":

Probe contact

Data Logger

Altered calibration

Measurement readiness

Termination of a

measurement set,

adjustment sequence

or a sequence for

data processing

Clear data/

function reset

Battery

Display sector "Set":

Averange and single value display

Calibration

Measurement time

Alarm threshold

Display backlight

Display sector

"Hardness Scales"

Memory card* for storage and

recall of measurement and

calibration values as well as

report formats

Switch on

Function select

Average or single value mode

Function adjustment

Hardness scale selection

Function adjustment

Active measurement check

Memory with data transfer

to a printer or PC*

Memory cards are available in addition to

the internal memory of the instrument,

these not only store measurement data

but also material dependent instrument

settings and report formats. You are able

to calibrate the instrument automatically

for specific material using the informa

-

tion stored on the memory card. Reports

can be created in an individual format

and printed via the RS 232C interface of

the MIC 10. Once again, the operation is

simple: switch on data logger or insert a

memory card and measure.

Probe connector

After measurement, the complete

measurement set is automatically stored

at the next available location and can

be recalled at any time, displayed and

printed.

RS232 C data output port*

*Only for Data Logger

version MIC 10 DL

Additionally, the user programs of the

UltraHARD series offer you a range of

possibilities for data transfer to a PC and

further data processing like evaluation,

statistics and documentation.

Loading...

Loading...