Page 1

Mentor

Visual iQ VideoProbe

User’s Manual

08/2019

MVIQAMANUAL Rev.L

1

Page 2

2

08/2019

Page 3

Table of Contents

Introduction ............................................................................................................................................ 4

Standard Equipment ............................................................................................................................. 5

Optional Features .................................................................................................................................. 5

Safety Information.................................................................................................................................6

Informations sur la sécurité ................................................................................................................ 8

Start Up ...............................................................................................................................................10

Component Identication ..................................................................................................................10

Touchscreen and Keys – Dual Control Systems ............................................................................11

Unpacking, Assembling, and Powering the Visual iQ ....................................................................12

About the Battery ................................................................................................................................ 14

Supplying Power to the Visual iQ ......................................................................................................15

Changing Probes and Optical Tips ...................................................................................................16

Setting Up the Visual iQ Operating System ....................................................................................17

Working with Proles ..........................................................................................................................18

System Setup ........................................................................................................................................ 19

Loading a Logo .....................................................................................................................................19

Setting Date and Time ........................................................................................................................19

Loading and Selecting the Operating Language ...........................................................................20

Other System Settings ....................................................................................................................... 20

Steering Sensitivity Settings .............................................................................................................20

Screen & Display Setup ......................................................................................................................21

Connectivity Setup ..............................................................................................................................22

Image & Video Setup ...........................................................................................................................24

Measurement & Annotation Setup ..................................................................................................25

Capturing and Adjusting Images ......................................................................................................26

Steering the Probe ...............................................................................................................................26

Guiding the Insertion Tube Into the Inspection Area ....................................................................26

Working with a Split Screen ...............................................................................................................35

Working with Video .............................................................................................................................38

Recording Live Video ...........................................................................................................................38

Working with a Recalled Video ..........................................................................................................38

Using External Video ...........................................................................................................................39

Measuring Features and Indications ...............................................................................................39

3D Measurement Types and Special Capabilities ..........................................................................41

Measurement Plane (3D Phase and 3D Stereo) .............................................................................43

Placing a Measurement Plane (3D Phase and 3D Stereo) ............................................................44

Measurement Plane Warnings (Edge View Angle) ........................................................................45

3D Phase Measurements (3DPM) ......................................................................................................46

3D Stereo Measurements ...................................................................................................................49

Stereo Measurements ........................................................................................................................ 53

Comparison Measurements............................................................................................................... 59

Troubleshooting Measurements ...................................................................................................... 60

Managing Files ..................................................................................................................................... 61

Working with Removable Storage Devices ..................................................................................... 61

MDI ............................................................................................................................................... 63

Stopping and Resuming an Inspection ............................................................................................ 67

Generating an MDI Report ................................................................................................................. 68

Customizing an MDI Report ............................................................................................................... 69

Maintenance and Troubleshooting .................................................................................................. 70

Inspecting and Cleaning the System ............................................................................................... 70

Troubleshooting Guide ....................................................................................................................... 72

Appendix A. Technical Specications ............................................................................................... 75

Appendix B. Optical Tip Table ............................................................................................................ 78

Appendix C. Chemical Compatibility ............................................................................................... 79

Appendix D. Warranty ........................................................................................................................ 79

Appendix E. Verifying Measurement Tips ........................................................................................ 80

Appendix F. Environmental Compliance ........................................................................................ 82

Appendix G. Regulatory Compliance ................................................................................................ 83

Appendix H. Creating a Personalized Logo File .............................................................................. 87

Appendix I. Open Source Software Availability ............................................................................. 89

Appendix J. Restoring Factory Settings ........................................................................................... 89

Appendix K. Updating Mentor Visual iQ Software ........................................................................ 90

Appendix L. LongSteer™ Specications........................................................................................... 91

Appendix M. InspectionWorks Connect (IWC) Optional Collaboration Capability ................... 92

Appendix N. InspectionWorks Insight .............................................................................................. 97

Appendix O. Controlling the iQ with a Keyboard............................................................................97

Appendix P. Controlling the iQ with an iPad.................................................................................... 98

Appendix P. VideoProbe 3D Measurement Handbook ................................................................... 99

Appendix Q: EIRP ............................................................................................................................... 111

Index .............................................................................................................................................. 115

08/2019

3

Page 4

Introduction

About this Manual

This manual and the related equipment is intended for visual inspection technicians with a basic understanding of inspection principles and practices, and who are familiar with

basic computer operations, but who may not have experience with a video borescope system. The manual contains safety, compliance, and basic operating and maintenance

instructions for the Visual iQ VideoProbe™ system. To ensure operator safety, please read and understand this manual prior to using the system.

Technical Support

For additional assistance, go to www.ge-mcs.com for a complete listing of contact information. Technical Support contact information follows:

Global Phone: 1-866-243-2638

Email: RemoteService@GE.com

System Overview

The rugged and dependable Mentor Visual iQ® system is an advanced exible video borescope used for remote visual inspection.

Working through access passages, the Visual iQ system delivers high-resolution images of internal details of turbine engines, airframes, automotive engines, piping, vessels, windturbine gear boxes, underwater structures, etc.

With TrueSight™, Mentor Visual iQ delivers HD visuals, a high-intensity light source, and superior visual processing, for clearer, sharper videos and still images right on your device.

The probe’s beroptic bundle illuminates the inspection area with light generated by an advanced Light Engine in the probe. At the end of the probe, a miniature camera assembly

converts the image into an electronic image, and sends it back through the probe. The system displays the image on the handset. No focusing is required, because the Visual iQ

system contains a xed-focus optical system with a large depth of eld.

Measurement capabilities (standard with the Visual iQ Analyze conguration) allow your system to analyze and measure indications and features. Real3D™ provides a fully surfaced

point cloud of the target surface to view, manipulate and optimize measurement cursor locations.

The Visual iQ system is compatible with USB thumb drives, USB keyboards, USB portable drives, and most other USB-based storage devices.

With our QuickChange™ interchangeable probes, you can quickly recongure the system for maximum productivity. This feature is available with either the Visual iQ Touch or

Analyze conguration.

Available in three versions (identied as the Inspect, Touch, and Analyze congurations) to meet diverse inspection needs across industries. Refer to the guide on the following

page to determine the right one for your application.

4

08/2019

Page 5

Standard Equipment

Visual iQ AC Adapter/Battery Charger Safety and Essential Use Hard Copy

2-hour Li-Ion Battery Optical Tip Storage Case Quickstart Card

Visual iQ Storage Case USB Thumbdrive Containing Documentation, including User's Manual

Optional Features

Display Port Video Cable Keyboard (wired or wireless) Software: Inspection Manager (Re-measurement PC Application)

Insertion Tube Gripper Optical Tips Upgrade either Visual iQ Touch or Analyze congurations with

Insertion Tube Rigidizer Measuring Optical Tips the purchase of 3D Phase or 3D Stereo measurement, STEREO

Handset Holder Mini-Magic Arm Clamp Kit measurement, or Probability of Detection capabilities. Features

Headset (wired or wireless) Magic Arm Kit included in the Probability of Detection upgrade includes HDR (High-

Cables External Monitor Dynamic Range), ANR (Adaptive Noise Reduction), Distortion

Belt Clip Large Visual iQ Case Correction, and Preset Image Transformation Settings.

InspectionWorks Connect, internet-based video collaboration

capability.

Insight is a Cloud-based data storage option.

iView is a feature that allows users to control system with a iPad®

.

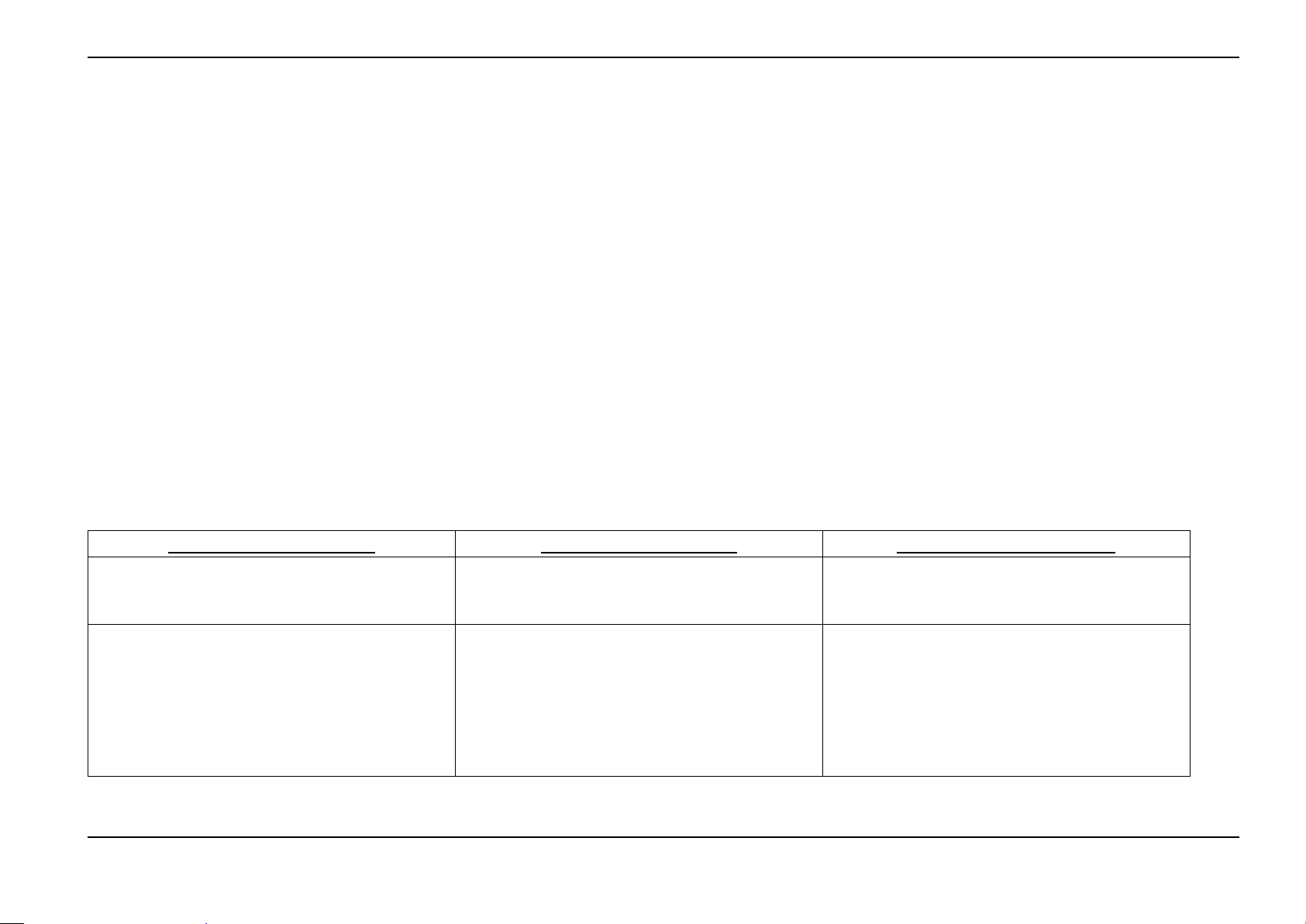

Mentor Visual iQ – Available in Three Congurations

Mentor Visual iQ Inspect* Mentor Visual iQ Touch* Mentor Visual iQ Analyze**

Excellent image quality and connectivity in a value-priced

package. Upgradable to Touch or Analyze congurations.

n

Value priced option

n

Choose from 7 probe length and diameter

congurations

*Purchase 3D Phase measurement, 3D Stereo measurement, Stereo measurement, or Probability of Detection upgrades

**Purchase Stereo measurement as an option

08/2019

Adds the versatility of interchangeable probes and

productivity enhancements. Upgradable to Analyze

conguration.

All the features of Mentor Visual iQ Inspect, plus…

n

Interchangeable probes

n

Touchscreen interface

n

Menu-Directed-Inspection software

n

16GB internal memory

Sets the industry standard with powerful measurement and

analysis software combined with extreme image quality

and greater probability of detection.

All the features of Mentor Visual iQ Touch, plus…

n 3D Phase Measurement

n

3D Stereo Measurement

n

Probability of Detection upgrade, which includes High-

Dynamic Range, Adaptive Noise Reduction, Distortion

Correction, and Preset Image Transformations

5

Page 6

Safety Information

Note: Before using or servicing the system, read and understand the following safety information.

Symbols and Terms

The following symbols appear on the product: , . See accompanying documentation.

General Warnings

The following warning statements apply to use of the system in general. Warning statements that apply specically to particular procedures appear in the corresponding

sections of the manual.

Do not allow the conductive insertion tube, system or its working tools to come in direct contact with any voltage or current source. Prevent all contact with live electrical

conductors or terminals. Damage to the equipment and/or electrical shock to the operator may result.

Do not use this system in explosive environments.

USE PROPERLY. Using any piece of this equipment in a manner not specied by the manufacturer may impair the product’s ability to protect the user from harm.

General Cautions

The following caution statements apply to use of the Visual iQ device in general. Caution statements that apply specically to particular procedures appear in the corresponding

sections of the manual.

Before using the camera system, install an optical tip or the head guard, which prevents damage to the tip-attachment mechanism. Keep the head guard on whenever no

optical tip is in place.

Handle the Probe Carefully: Keep the insertion tube away from sharp objects that might penetrate its outer sheath. Keep the whole insertion tube as straight as possible during

operation; loops or bends anywhere in the tube decrease its ability to steer the probe tip. Avoid bending the insertion tube sharply.

Note: Always use the Home function to straighten the bending neck before withdrawing insertion tube from an inspection area or putting probe away. Never pull, twist, or

straighten the bending neck by hand; internal damage may result. At the rst sign of damage, return the probe for repair.

Certain substances may damage the probe. For a list of substances that are safe for the probe, see “Chemical Compatibility” in the Appendix.

6

08/2019

Page 7

Battery Warnings

Only use the battery and power supply specied for use with the system. Before use, thoroughly review the instructions in this manual for the battery and battery charger to

fully understand the information contained in them, and observe the instructions during use.

WARNING

• Do not place the battery in re or exceed the battery operating temperature.

• Do not pierce the battery with nails, strike the battery with a hammer, step on the battery, or otherwise subject it to strong impacts or shocks.

• Do not expose the battery to water or salt water, or allow the battery to get wet (IP65 – Disassembled, IP67 – Assembled).

• Do not disassemble or modify the battery.

• The instrument contains a Lithium Ion battery and magnesium in its case. Should the instrument be involved in a re, use an extinguisher approved for use on electrical and

ammable metal res. Water must not be used.

Battery Communication Error: Exists when the Visual iQ shows this message on the display. If the problem persists, please contact your nearest customer support

center.

Using the battery outside its recommended operating range will result in degradation of the performance and service life. When storing the battery, be sure to remove it from

the handset.

Recommended ambient temperature range for Li-ion battery operation:

Discharge (when using the instrument): -20°C to 46°C

Recharging: 0°C to 40°C

Storage: -25°C to +60°C

08/2019

7

Page 8

Informations sur la sécurité

Remarque: avant l’utilisation ou l’entretien du système, vous devez lire et comprendre les informations de sécurité qui suivent.

Symboles et termes employés

Les symboles suivants sont apposés sur le produit: , . Voir la documentation jointe.

Avertissements généraux

Les avertissements suivants s’appliquent à l’utilisation du système en général. Les avertissements qui s’appliquent spéci quement à des procédures particulières sont indiqués

dans les sections correspondantes de ce manuel.

Le système Visual iQ et les outils de travail qui l’accompagnent ne doivent jamais entrer en contact direct avec une source de tension ou de courant. Évitez tout contact

avec des conducteurs ou des bornes électriques sous tension. L’équipement risquerait d’être endommagé, ou l’opérateur de subir un choc électrique.

N’utilisez pas ce système dans un environnement à risque d’explosion.

UTILISER CORRECTEMENT. Si un élément de cet équipement est utilisé d’une manière non indiquée par le fabricant, l’utilisateur peut ne plus être protégé des risques de

blessure.

Mentions générales « Attention »

Les mentions « Attention » qui suivent s’appliquent à l’utilisation de l’appareil Visual iQ en général. Les mentions « Attention » qui s’appliquent spéci quement à des procédures

particulières sont indiquées dans les sections correspondantes du manuel.

MANIPULER LA SONDE AVEC PRÉCAUTION. Maintenez la gaine de la sonde à l’écart d’objets pointus ou tranchants qui risqueraient de traverser son fourreau. Maintenez toute

la gaine aussi droite que possible pendant l’utilisation : en cas de boucle ou de courbure, il est plus dif cile de piloter le bout de la sonde. Évitez de trop courber la gaine.

Remarque : utilisez toujours le bouton de rangement pour redresser le béquillage avant de rétracter la gaine de la zone d’inspection ou de ranger la sonde. Ne manipulez

jamais le béquillage à la main pour le tirer, le courber ou le redresser : vous risqueriez de l’endommager à l’intérieur. Envoyez la sonde en réparation au premier signe

d’endommagement.

Certaines substances risquent d’endommager la sonde. Pour consulterla liste des substances sans danger pour la sonde, voir Compatibilité Chimique en annexe.

L’appareil comporte une batterie lithium ion et du magnésium à l’intérieur de son boîtier. En cas d’incendie de l’appareil, servez-vous d’un extincteur agréé pour une utilisation

sur les incendies électriques et les métaux inammables. En aucun cas, n’utilisez de l’eau.

8

08/2019

Page 9

Avertissements liés à la batterie

Utilisez uniquement la batterie et l’alimentation spéci ées pour être utilisées avec le système Visual iQ. Avant utilisation, lisez attentivement les instructions contenues dans ce

manuel relatives à la batterie et au chargeur de batterie pour bien les comprendre, et respectez ces instructions pendant l’utilisation de l’appareil.

AVERTISSEMENT

• Ne jetez pas la batterie au feu et ne dépassez pas sa temperature de fonctionnement.

• Ne percez pas la batterie avec des clous, ne la frappez pas avec un marteau, ne marchez pas dessus et ne la soumettez pas à des impacts ou des chocs violents.

• N’exposez pas la batterie à l’eau douce ou salée, et évitez de la mouiller.

• Ne désassemblez pas la batterie et ne la modi ez pas.

Erreur de communication de la batterie. Veuillez contacter le Service clientèle au numéro +1 315 554 2000.

L’utilisation de la batterie en dehors de la plage de fonctionnement recommandée entraînerait une dégradation de ses performances et de sa longévité. Lorsque vous stockez la

batterie, veillez à la retirer de sa base.

Plage de température recommandée pour le fonctionnement de la batterie Lithium-Ion.

Décharge (à l’utilisation de l’appareil) : -20°C à +46°C Recharge , 0°C à +40°C Stockage, -25°C à +60°C

08/2019

9

Page 10

Start Up

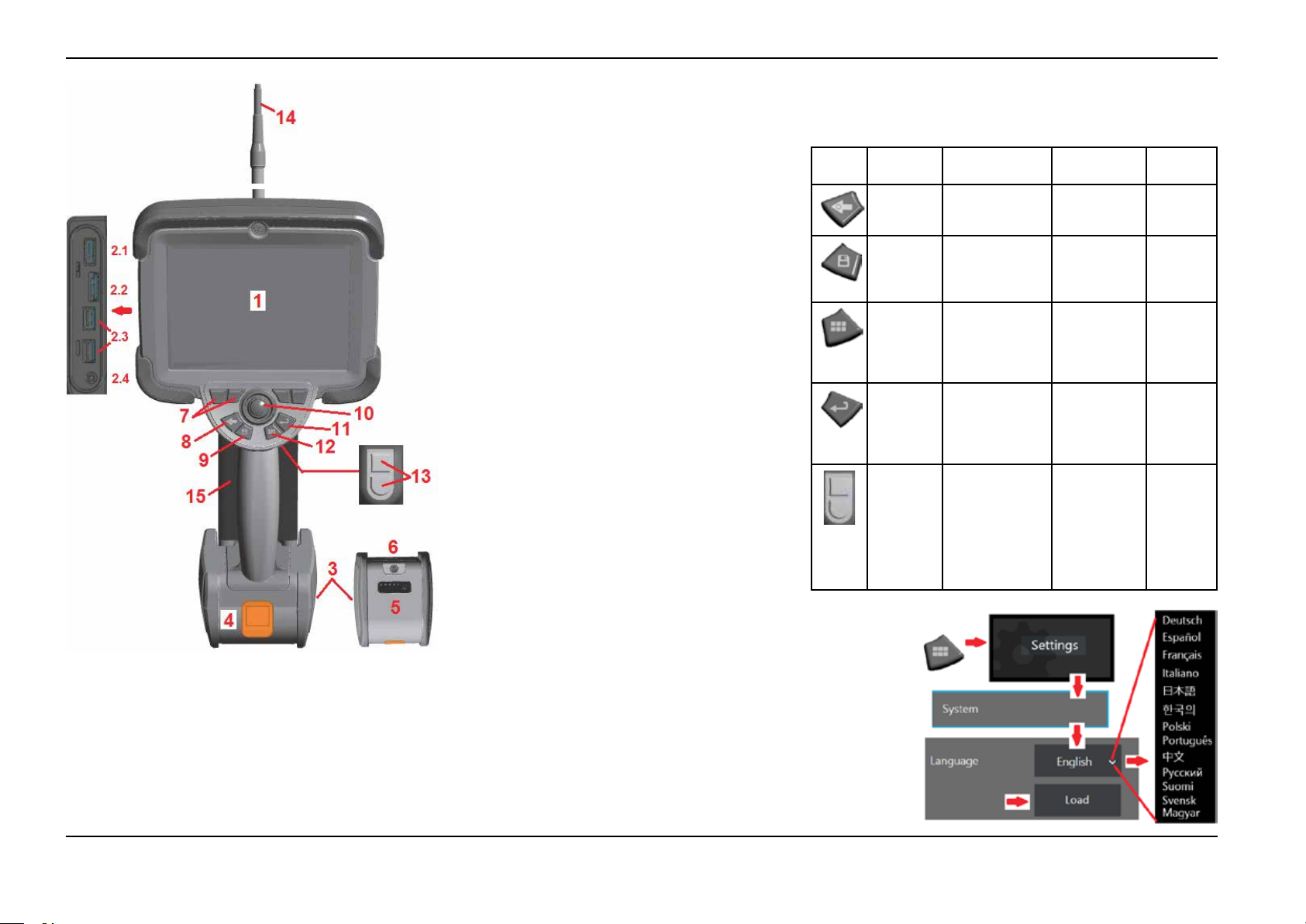

Component Identication

1 – LCD Touchscreen

Hard

Key

2 – DisplayPort Output (2.1), USB 3.0 Client

Micro B Port (2.2), Two USB 3.0 Host

Type A Ports (2.3), 3.5 mm Headset/

Microphone Jack (2.4).

3 – Two-hour Lithium Ion Battery

4 – Battery Release Button

5 – Battery Charge Indicator

6 – AC Adaptor Input

7 – Function (or Soft) Keys (four total)

8 – Back Button: short press moves back

one screen, long press moves to live screen.

This also serves as the POWER ON button.

9 – Save Button: short press launches a

Quick Save, long press opens or closes the

Save Options Menu. Double press to record

a Screenshot.

10 – Joystick Controls Articulation and Menu

Navigation (push the joystick left/right/

up/down to navigate menus and sub-menus).

11 – Enter Button: short press toggles between frozen and live

frames and selects Done / Accept, a long press performs a 3DPM

Capture.

Name Short

Back

button (and

Power On)

Save

button

Menu

button

Enter

button

Trigger

buttons

(upper

and lower)

Press

Moves back one

screen

Quick save

(assigns default

name and

location)

Opens or closes

Global Menu

Toggles between

live and frozen

images. Also

conrm selection

(Done/Accept).

Upper is same as

Enter button

Lower toggles

articulation mode

between steerand-stay and

steering modes

Long

Press

Moves to live

image

Save with

options

available

Toggles

between rst

and second

rows of soft

buttons

Performs

3DPM capture

Upper is same

as Enter

button

Lower returns

articulation

system to

neutral position

Double

Press

Record a

Screenshot

Note: Follow the selection sequence shown here to select the Operating Language.

12 – Menu Button: short press opens or closes the Global Menu, long press toggles between rst and second level soft button rows.

13 – Trigger Button 1 (Upper): provides the same function as the Enter Button. Trigger Button 2 (Lower): short press toggles

articulation mode between steer-and-stay and steering modes. When in steer-and-stay mode, a Lock icon appears. Long press

returns the articulation system to the neutral (home) position.

14 – Insertion Tube/Camera assembly

15 – Interchangeable VideoProbe (Note: Includes Insertion Tube/Camera assembly)

10

08/2019

Page 11

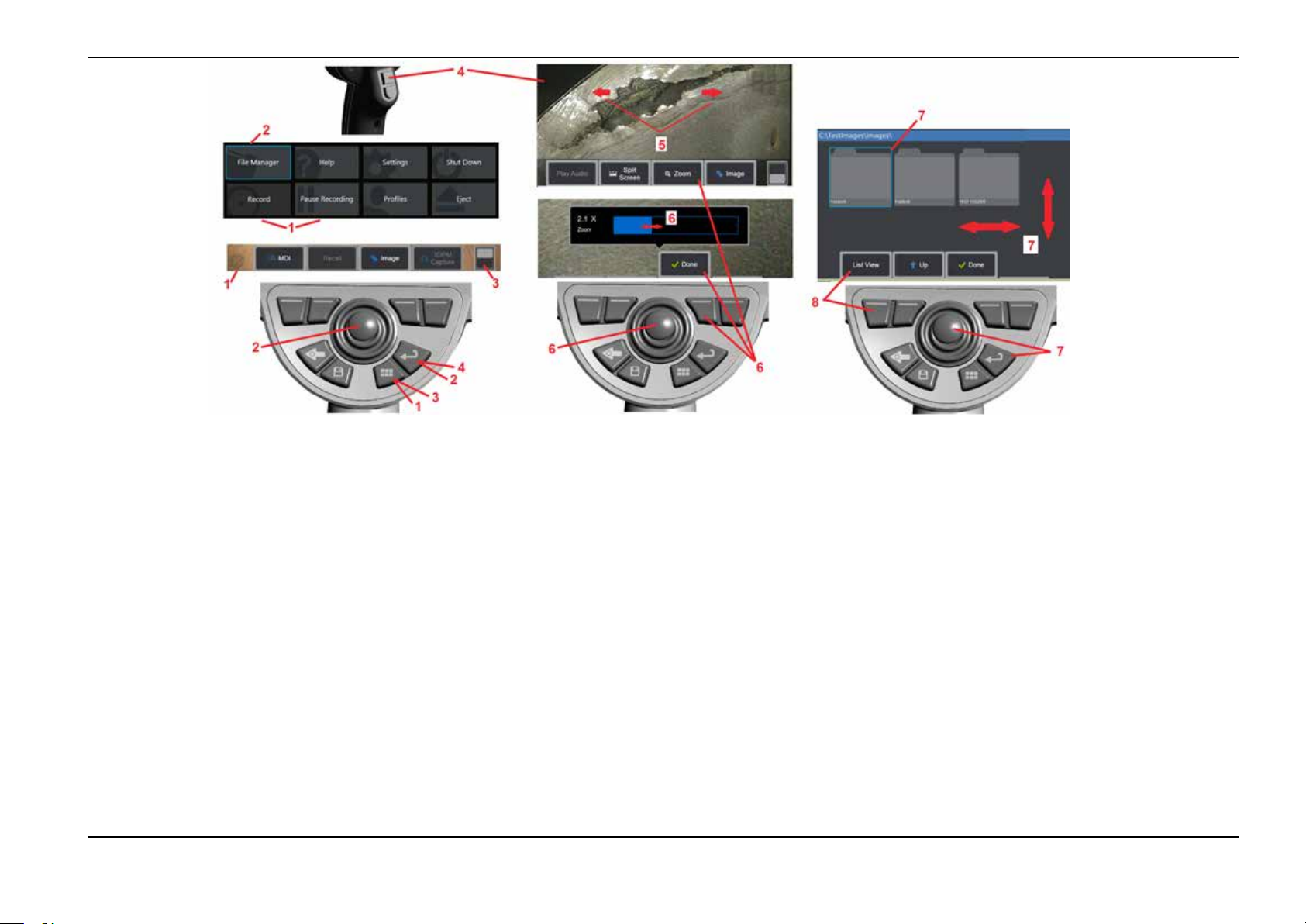

Touchscreen and Keys – Dual Control Systems

Most functions can be accomplished using the touchscreen or with a combination of

key presses and joystick movements. The following examples illustrate various control

techniques that can be used on most Visual iQ display screens.

1 – Touch the lower left corner of the display screen (typically contains the GE Logo) or

short-press the Menu key to open the Global Menu.

2 – The selected item in any menu or list is identied by this blue outline. Tap the display

screen to select another item or to launch the selected item. Alternatively, use the joystick

to select another item by moving the blue cursor, then short-press the Enter key to

launch. Note that a short press of the Enter key accepts or launches most selected

choices or actions.

3 – Tap the display to toggle between the upper and lower softkey bar (double-tap to

hide or show the softkey and status bars). Alternatively, long-press the Menu key to

switch between the upper and lower softkey bars.

4 – Tap anywhere on a displayed Live Image to freeze and unfreeze it. Alternatively, short-

press either the Enter key or the Upper Trigger key to freeze and unfreeze a live display.

Note that the Upper Trigger key performs the identical functions as the Enter key.

5 – Position two ngers on the display screen and move them apart to zoom in on a

feature of the display (perform the opposite action to zoom out). Once zoomed (in a

frozen image), you can drag with your nger to change the displayed view.

6 – Select the Zoom function using either soft keys or the touch screen (all displayed

soft-key bar items can be selected either with the corresponding soft key or by tapping

the touch screen). Use the joystick to change the zoom magnication bar (this and other

blue bars can also be adjusted by dragging them using the touch screen), then select

Done. Once zoomed, you can use the joystick to move the displayed view.

7 – When the File Manager screen appears, the selected le or folder is identied by this

blue outline. Tap the display screen to select another item or to launch the selected le

or open the selected folder. Note that you can also display additional items (or directly

access additional stored images) by simply swiping the display screen in any of the

directions shown. Alternatively, use the joystick to select another item by moving the

blue cursor, then short-press the Enter key to launch the le or open the folder.

8 – Select any feature in the Soft Key Bar by either touching that feature on the display

screen (in this case, touching the box containing the words List View) or pressing the

corresponding soft key.

Note: Connecting a Bluetooth or USB-wired keyboard allows for remote control of iQ

functions and probe articulation. See Appendix O for a list of function key and key-

press combinations equivalent to iQ button and joystick operations.

08/2019

11

Page 12

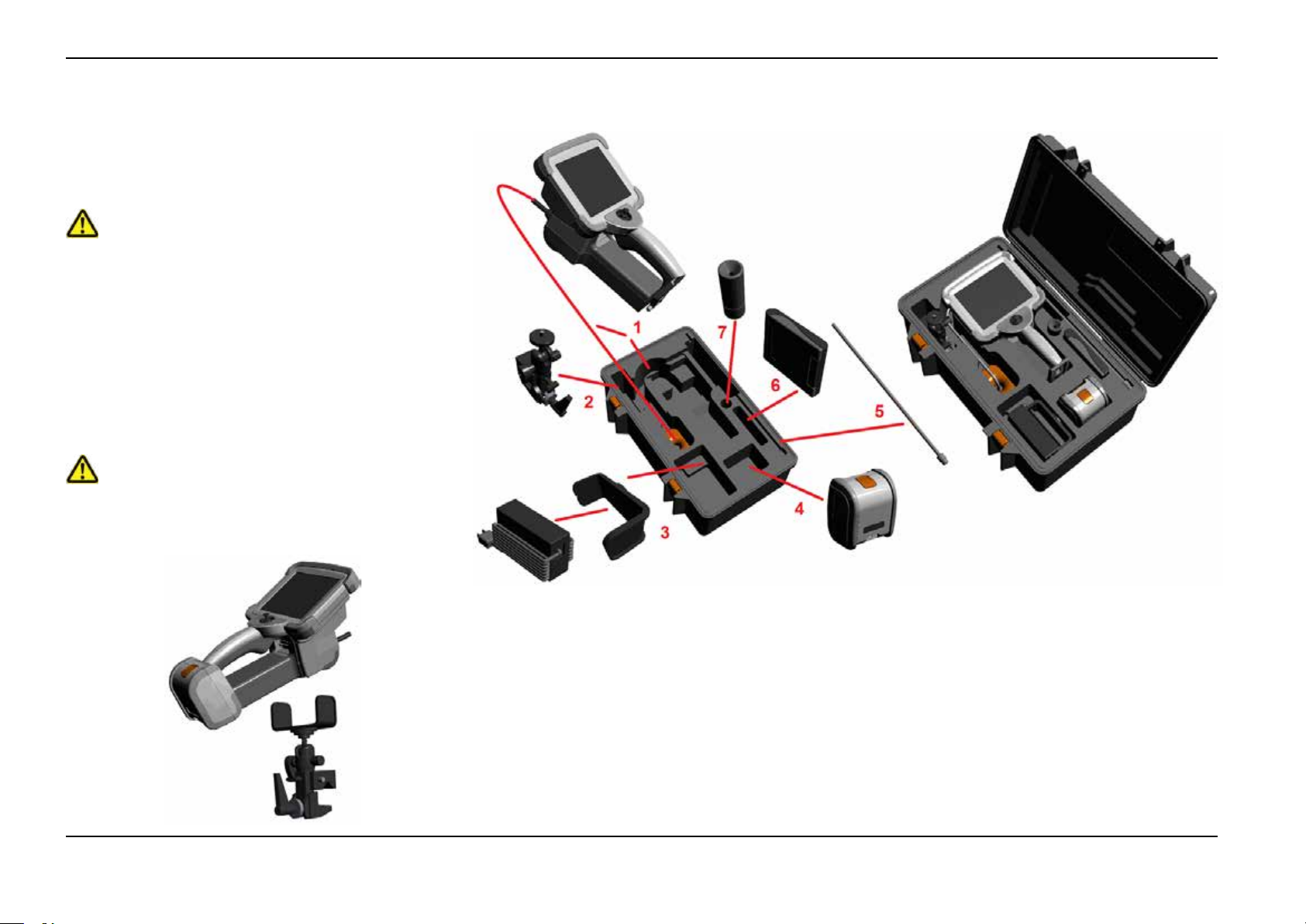

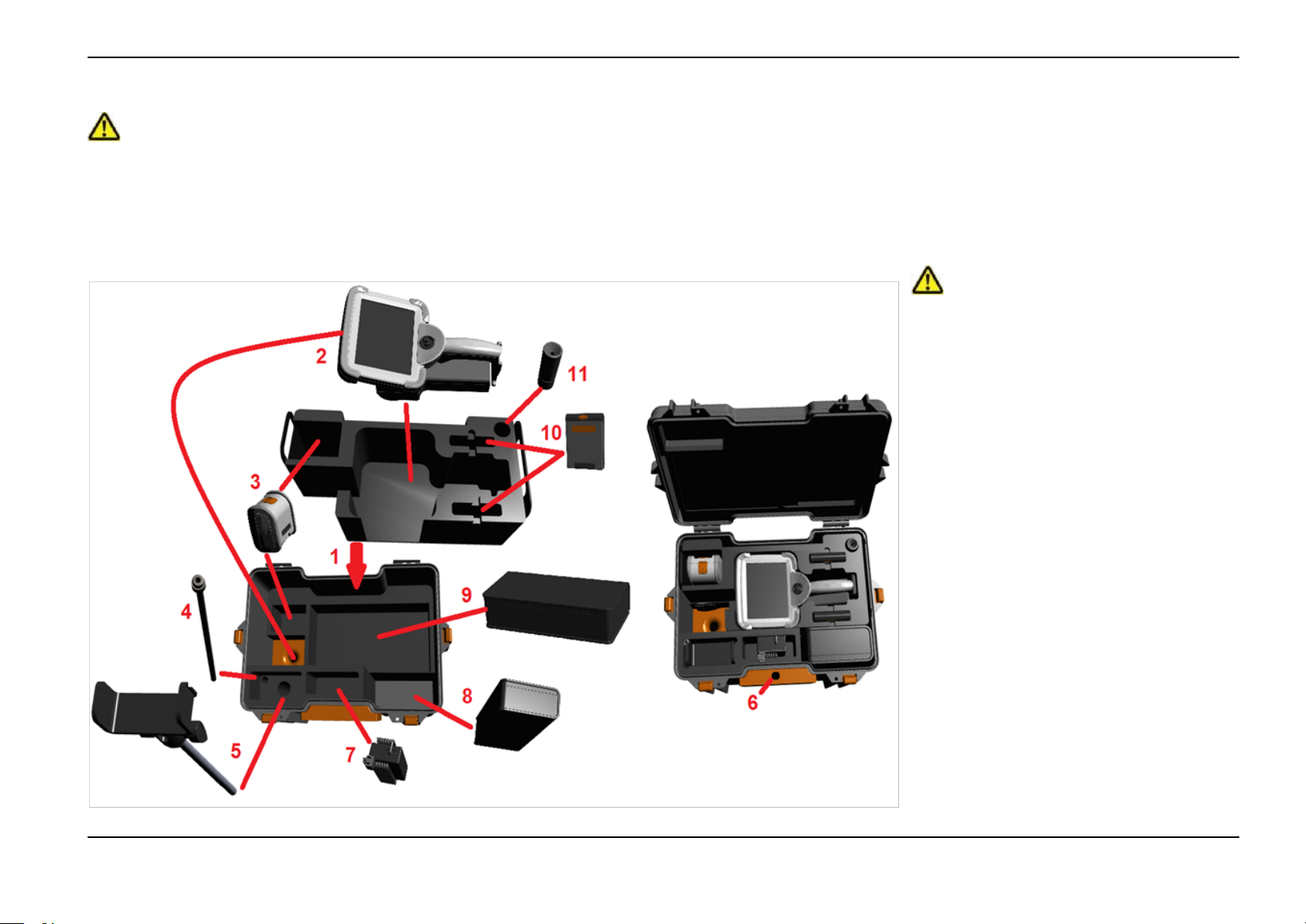

Unpacking, Assembling, and Powering the Visual iQ

Unpacking and Putting Away

the System (Small Case)

Caution: If you do not pack the system carefully, as

described here, damage might occur.

1 – The insertion tube (shown in red for clarity) is held in the

case’s internal storage reel, which is accessed through the

orange funnel shown here. Install the insertion tube before

installing the probe-and-handset assembly and remove it

after removing the probe-and-handset assembly. Be sure

to straighten any loops or twists in the insertion tube before

feeding it into the funnel. Note that the insertion tube’s rubber

Torsional Strain Relief base should be routed through the case’s

curved passage shown here.

Caution: Before using the camera system, install an

optical tip or the head guard, which prevents damage to

the tip-attachment mechanism. Keep the head guard on

whenever no optical tip is in place.

12

2 – Install clamp in the orientation shown here (clamp and mounting bracket assembly appears at left)

3 – Power supply / Battery Charger and Mounting Bracket are oriented and installed in this slot

4 – Battery must be removed prior to installing the iQ in the case.

5 – Rigidizer

6 – A case holding tips (or cleaning kit) ts in this slot.

7 – Gripper may be used alone, or with Rigidizer, to aid in orienting camera.

08/2019

Page 13

Unpacking and Putting Away the System (Large Case)

Caution: If you do not pack the system carefully, as described here, damage might occur.

1 – Remove tray to access additional storage space.

2 – The insertion tube (shown in red for clarity) is held in the case’s internal storage reel, which is accessed through the orange funnel shown here. Install the insertion tube before

installing the probe-and-handset assembly and remove it after removing the probe-and-handset assembly. Be sure to straighten any loops or twists in the insertion tube before

feeding it into the funnel.

Caution: Before storing the insertion

tube, rst remove the optical tip and install the

head guard, which prevents damage to the tip

attachment mechanism. Keep the head guard on

whenever no optical tip is in place.

3 – Storage locations for two batteries. Battery must

be removed prior to installing the iQ in the case.

4 – Rigidizer

5 – Mounting bracket and post

6 – Mounting bracket post ts in this hole

08/2019

7 – Power supply / Battery Charger installed in this

slot

8 – Extra Pod in case

9 – Extra VideoProbe in case

10 – Two cases holding tips and a cleaning kit t

in these slots.

11 – Gripper may be used alone, or with Rigidizer,

to aid in orienting camera.

13

Page 14

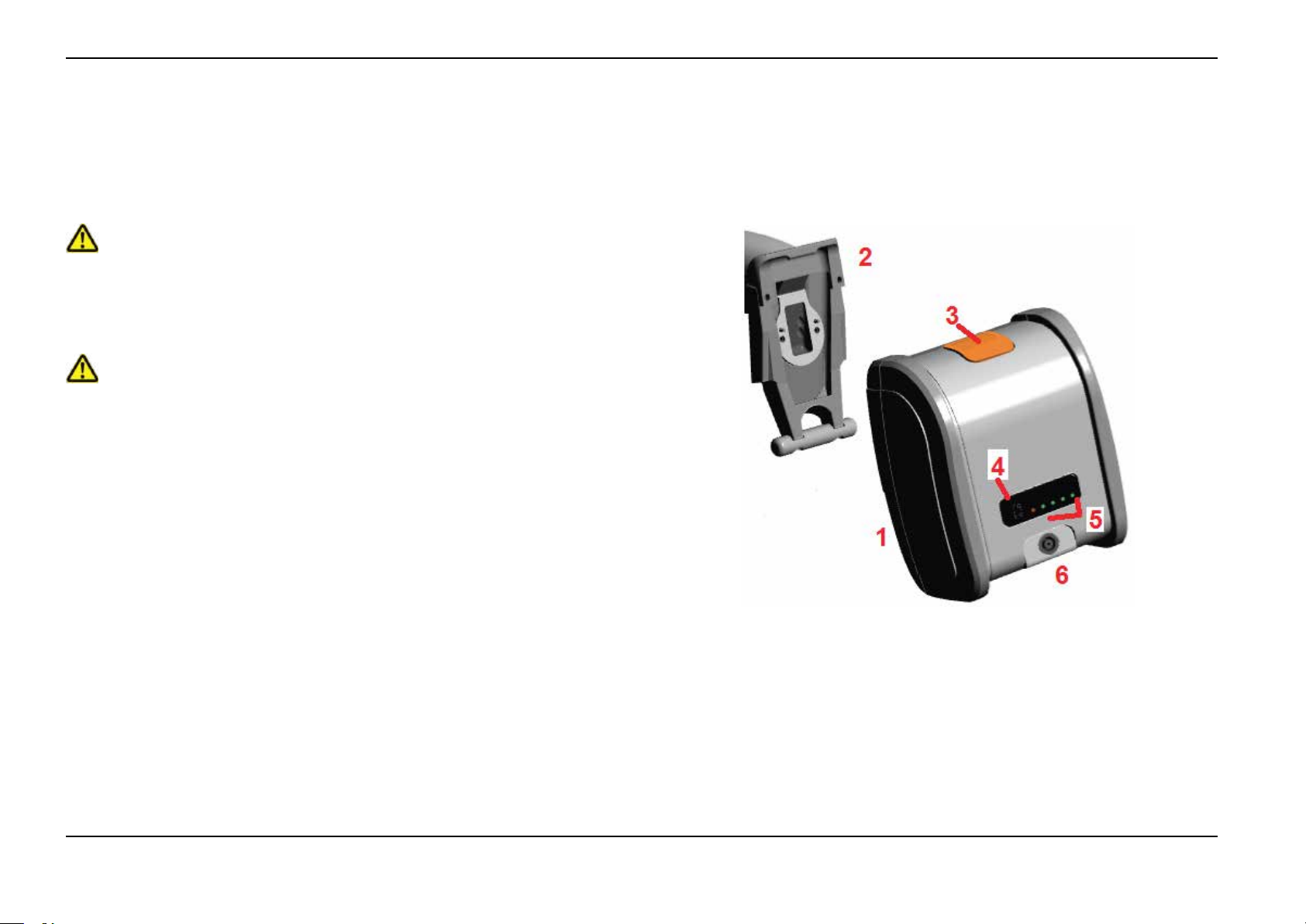

About the Battery

The Visual iQ is powered by a 10.8 V (nominal), 73 Wh, 6.8 Ah Lithium Ion battery.

Installing the Battery

Insert the battery into the handset. The battery is installed properly when the latching

mechanism is engaged.

Caution—Do not force the battery (1) into the handset (2), as damage may occur.

The battery is keyed and may only be installed in the proper orientation.

Removing the Battery

Press battery release button (3) to release the battery.

Caution—Do not remove the battery while the system is operating.

Battery Charge Level

Check the battery charge by pressing the battery symbol (4) on the front of the battery.

Each light (5) represents approximately 20% of the battery charge capacity.

Charging the Battery

Connect the DC output of the battery charger into the Visual iQ battery (6) and then

plug the included AC to DC power adaptor into a suitable AC power source. The LED

battery lights will illuminate according to the amount of charge attained. The system

may operate while charging.

Note: The battery may be charged while connected to an operating Visual iQ or while

disconnected from the iQ.

Note: When the battery is fully charged, the LED battery lights will turn off.

Note: Battery run time approximately equals battery charge time; therefore, a two hour

battery will take approximately two hours to charge. Charging time will be longer if the

battery is connected to an operating Visual iQ system while charging.

Note: All batteries are shipped with a partial charge. Batteries should be fully charged

prior to use.

14

08/2019

Page 15

Supplying Power to the Visual iQ

The Visual iQ is powered by a 10.8 V (nominal), 73 Wh, 6.8 Ah Lithium Ion battery.

The battery is charged by connecting the power adaptor to the battery, then connecting

the supplied AC-to-DC power adaptor to a suitable (100-240 VAC, 50-60 Hz, <1.5 A rms)

AC power source. The power adaptor delivers to the battery 18 Volts at 3.34 Amps.

Note: When powering a system with an AC power source, connect the power plug to a

properly grounded source for reliable touchscreen operation.

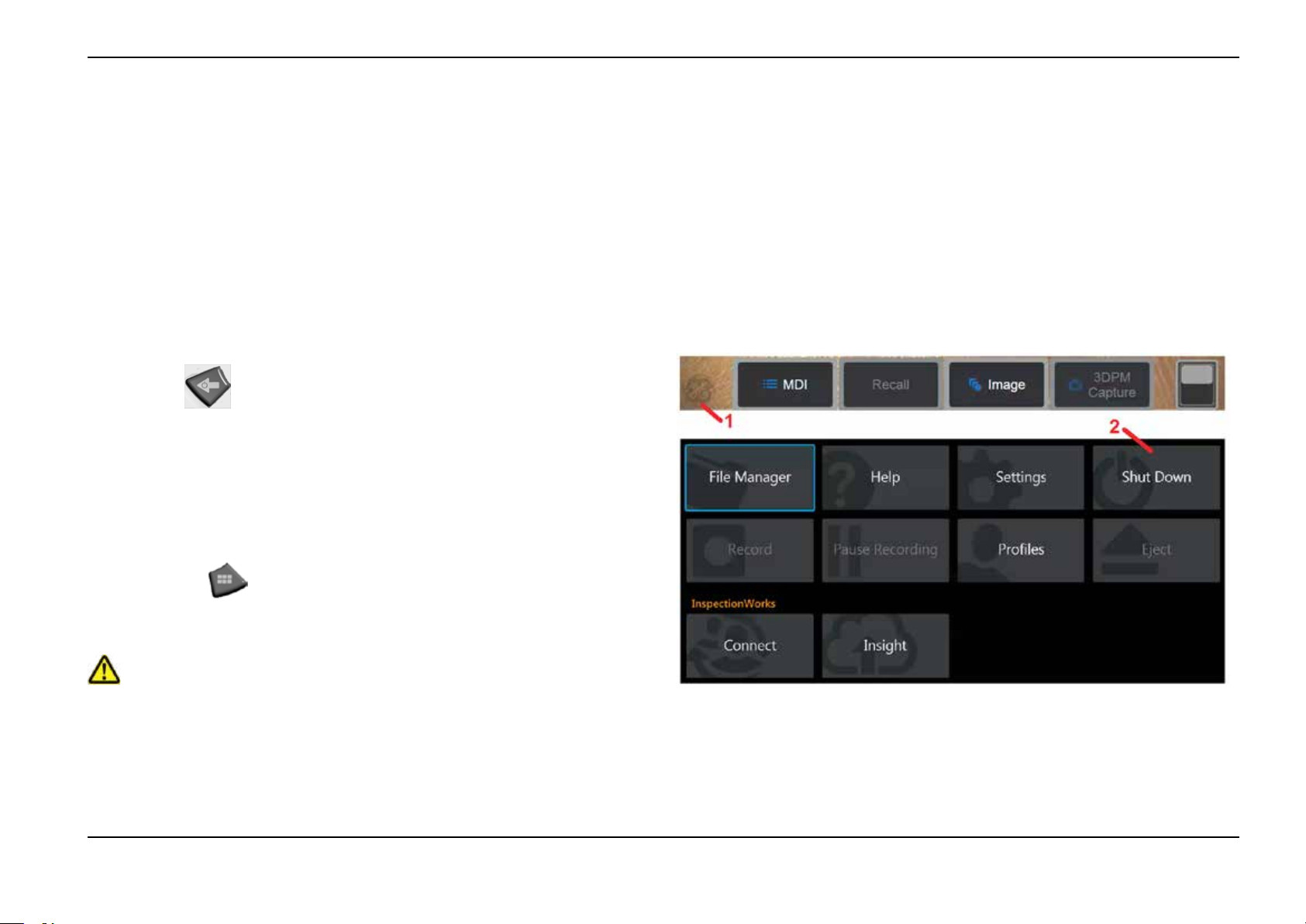

Powering the Visual iQ On and O

System Power On

Press and hold until the unit turns on. The buttons and Liquid Crystal Display (LCD)

will light and begin the power-up sequence. After approximately 35 seconds, the system

screen will display live video and on-screen controls. The system is now ready for use.

Note: All batteries are shipped with a partial charge. Batteries should be fully charged

prior to use.

System Power O

Touch the lower left corner of the display screen (which typically contains the on-screen

GE Logo (

provides access to several features including Shut Down (2). Select Shut Down to power

off the Visual iQ.

battery after powering off as described above.

08/2019

1) or the hard key at any time to open or close the Global Menu, which

Caution—Do not power off the Visual iQ by removing its battery. Only remove

15

Page 16

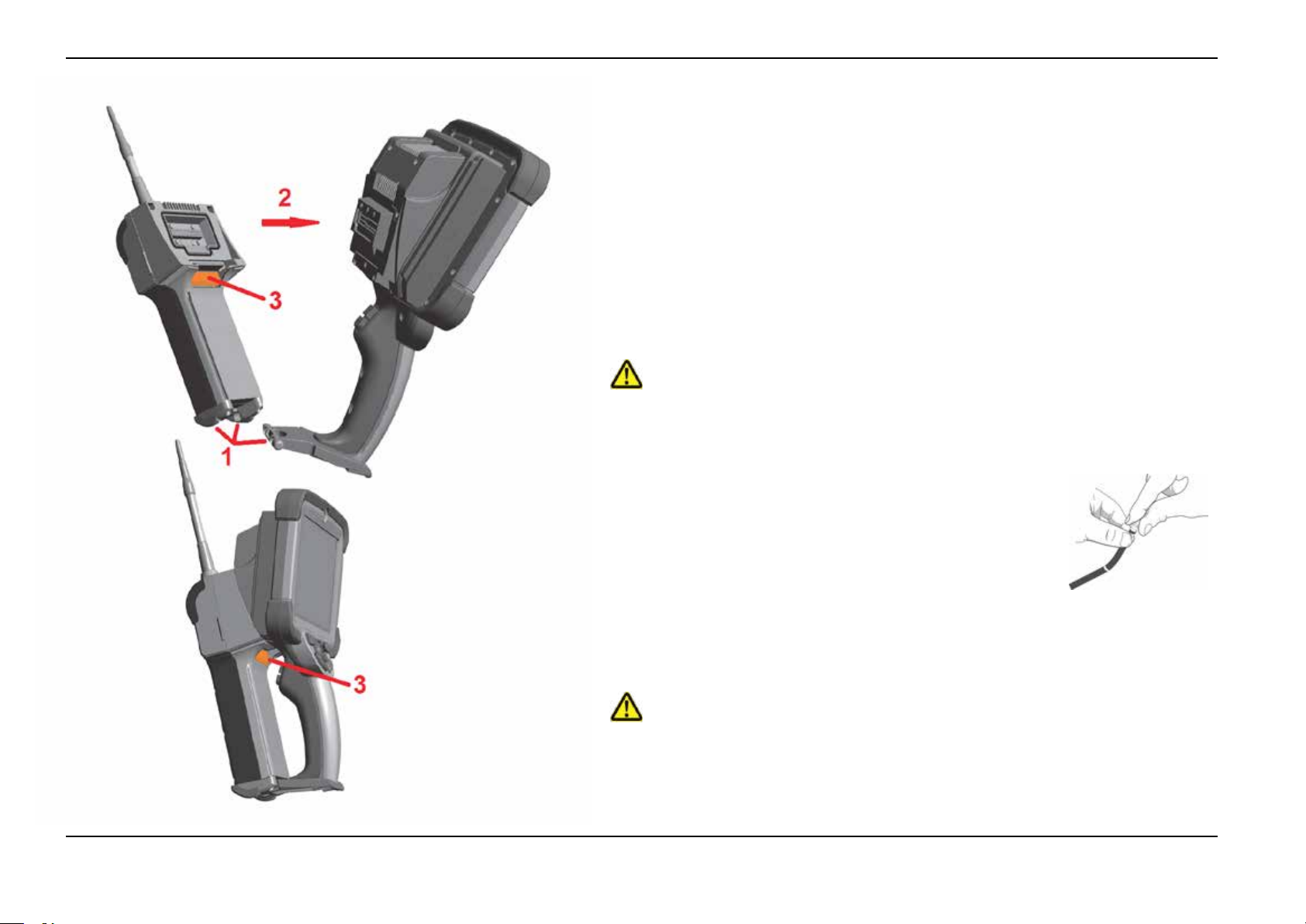

Changing Probes and Optical Tips

Attaching and Removing the Probe

To attach the probe to the handset:

1 – Insert the pin at the base of the handset into the mating groove at the bottom of the probe.

2 – Rotate the probe towards the back of the handset, applying enough pressure for the latching

mechanism to “click.”

To remove the probe from the handset:

3 – Press this latching-mechanic's release button to separate the probe and handset.

Changing the Optical Tip

Optical tips are threaded onto the probe with a double set of threads to prevent them from

falling into the inspection area. Each optical tip provides a unique depth of eld, eld of view,

and direction of view. For a list of available tips, see Appendix B – Optical Tip Table.

Caution—Use only nger pressure to remove or attach tips. Using force (including pliers

or other tools) might damage the bending neck. Take care not to cross the threads. To reduce

cross-threading risk: When installing a tip by hand (6.1mm & 8.4mm) or with an installation tool

(4mm), rotate the tip counter clockwise to level the threads before rotating clockwise to thread the

tip on the camera. Reverse the leveling process when removing tips.

To Remove an Optical Tip: Support the bending neck and head of

the probe with one hand, and with the other gently turn the optical

tip counterclockwise (be sure to use a tip tool when removing 4.0 mm

tips), Turn until the tip spins freely, indicating that it has cleared the

rst set of threads. Gently pull the tip away from probe and continue

turning counterclockwise, engaging the second set of threads. Turn

until you can remove it.

To Attach an Optical Tip: Verify that the optical tip and camera head threads are clean, then

grasp the head of the probe with one hand, and with the other gently turn the tip clockwise.

Turn until it spins freely, indicating that it has cleared the rst set of threads. Gently push the

tip in, then turn clockwise again, engaging the second set of threads. Turn until nger tight.

16

Caution—Do not over-tighten tips. Pull on the tip gently to verify that it is securely attached.

If the second set of threads does not engage, turn the tip slightly in a counterclockwise direction

to allow the threads to levelize.

Note: Measurement tips must be tightened rmly to ensure accuracy.

08/2019

Page 17

Setting Up the Visual iQ

Operating System

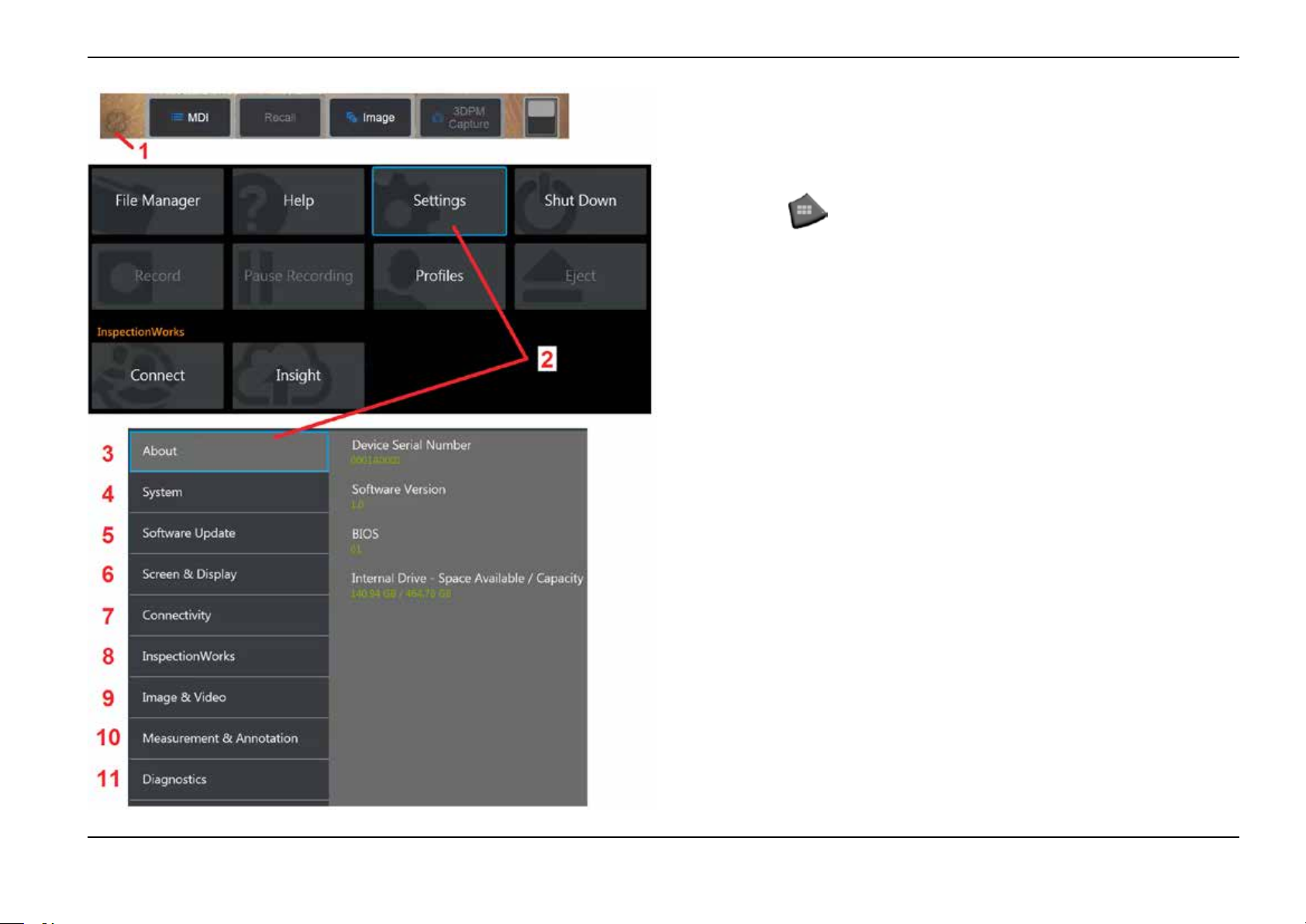

1 – Select the lower left corner of the display (which typically contains the on-screen

GE Logo) or the

provides access to several features including the Settings Menu.

hard key at any time to open or close the Global Menu, which

2 – Tap to open the Settings Menu.

3 – Lists the device’s serial number and software version.

4 – Access to set a Password, Restore Defaults, adjust Date, Time, and operating

Language, and alter various other system settings. Click here to learn more about

the System Menu.

5 – Control automatic software update capability and manually update through web

connection or connected USB drive.

6 – Allows the user to turn various on-screen indicators on and off as well as adjust

display brightness. Click here to learn more about Display Setup.

7 – Allows the user to turn Wi-Fi and Bluetooth connections on and off as well as work

with networks and identify folders for le sharing. Click here to learn more about

Connectivity Settings.

8 – Settings related to optional internet service that enables video collaboration between

inspectors and remotely located experts.

9 – Allows the user to specify the default directories into which image les and videos

are stored. Also used to select image le type, video format, and sound-related settings.

Controls MDI Annotation and imports Distortion Correction Tables. Click here to learn

more about Image and Video Settings.

08/2019

10 – Allows the user to set their preferred measurement units (inches vs. mm), manage

and verify measurement tips, select the desired annotation style, and import and export

preset annotations.

11 – Generates a Troubleshooting Log to be emailed to and evaluated by GE Technical

Support. If log generation is required, GE Technical Support will guide the user through

the process.

17

Page 18

Working with Proles

A Prole denes several parameter settings. As long as more than one prole is available,

(the Visual iQ is delivered with only a Default Prole), the operator is asked to select a

Prole every time the system is powered on. Follow these instructions to create a new

prole or select an existing one.

1 – To create a New Prole, touch the lower left corner of the display (or press the

hard key) to open the Global Menu, then select Proles.

2 – In this case, the Default Prole is active and it is the only one dened. Select New

to create a new prole.

3 – The Virtual Keyboard opens. Enter a Name for the new prole.

4 – After entering a name and clicking Done, the new prole is added to the list of available

proles. This prole includes the settings in place, at the time of its creation, for each of

the parameters listed below. Anytime the prole is reactivated, the system will apply the

settings associated with the activated prole. The parameters affected include:

18

System Settings Including:

Watermark Logo ON/OFF

Time Format

Date Format

Language

Power Management

USB Slave Mode

Steering Sensitivity

Screen & Display Settings – All Parameters

Connectivity Settings Including:

Wi-Fi on/off

Bluetooth on/off

Image & Video Settings – All parameters

except Distortion Correction Table

Measurement & Annotation Including:

Presets

Zoom Window

3DPM Mask

3DPM Save Format

Stereo Index

Stereo Index Minimum

Units

5 – Each time the Visual iQ is powered on, you’ll be asked to select from the list of

available proles. Selecting the Default Prole returns the settings for all prole-controlled

parameters to those specied by the default prole.

08/2019

Page 19

System Setup

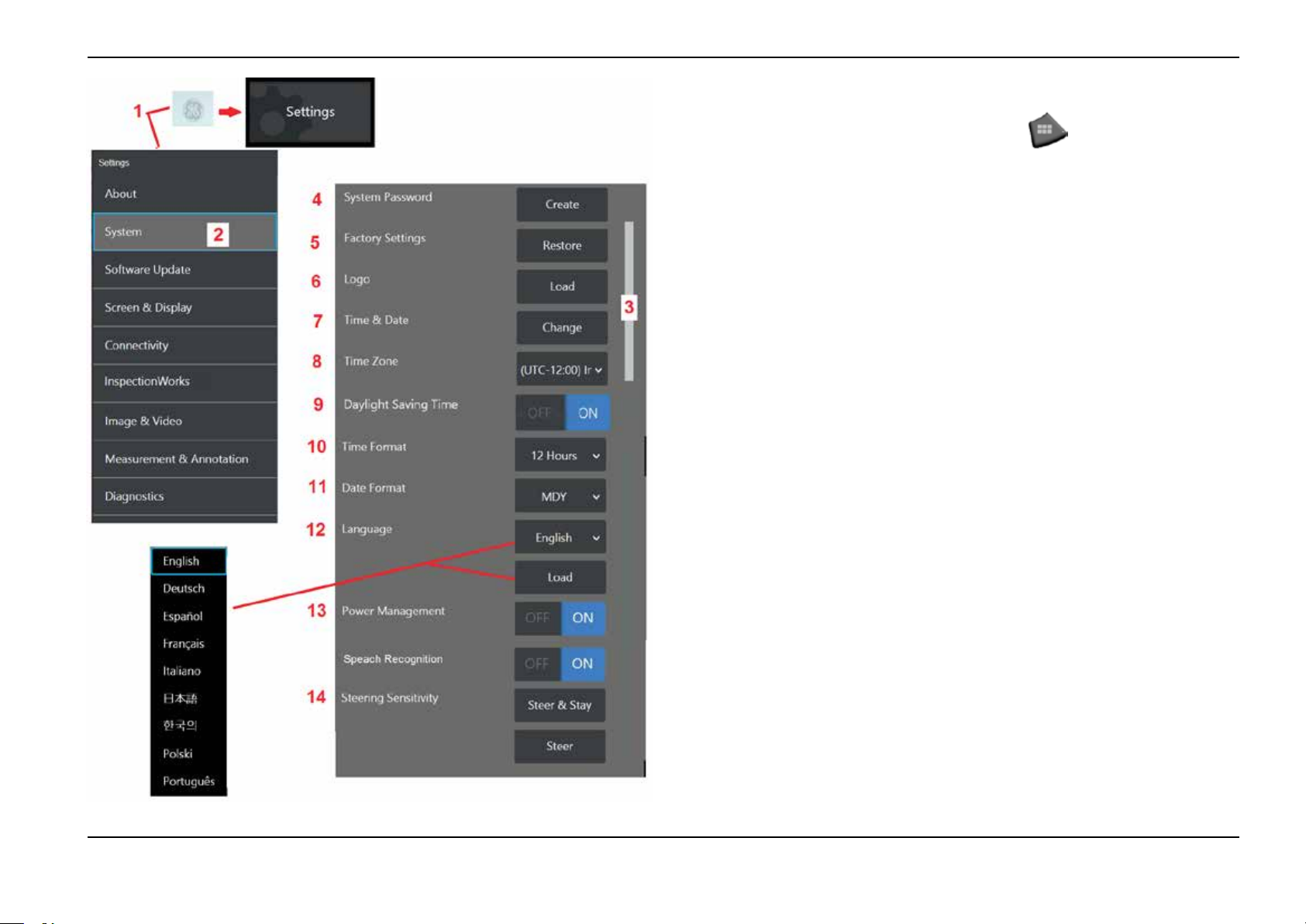

1 – Tap the on-screen GE Logo (or press the hard key) to open the

Global Menu, then open the Settings Menu.

2 – Select to alter the system-specic settings shown here.

3 – Drag your nger up or down the screen. This bar will move to show the current

position among the list of system-specic settings.

4 – Tap to open the virtual keyboard and create or change a System Password. Once

created, accessing the iQ’s operating screens requires rst entering the password. This

password is for the entire system and is not associated with the active prole.

Note: Entering a password requires the Default Prole be active.

5 – Select and follow the on-screen prompts to restore the active Prole to the Factory

Default Settings.

Loading a Logo

A logo can be loaded onto the display screen provided it is PNG le type (with dimensions

smaller than 140 x 140).

6 – Select Load, then navigate the instrument or an external drive to select any PNG le

type as the on-screen logo. Click here for more information on creating and loading

a personalized logo le.

08/2019

Setting Date and Time

7 – Adjust Time and Date settings.

8 – Select the Time Zone in which you are operating.

9 – Indicate whether or not the instrument should automatically adjust for time changes

due to Daylight Savings.

19

Page 20

10 – Specify 12 or 24 hour Time Format.

Steering Sensitivity Settings

11 – Specify DMY, YMD, or MDY as the Date Format.

Loading and Selecting the Operating Language

12 – Choose from the operating Languages currently available for use. Selecting Load

allows you to upload a new version of any of the existing translations available in the iQ.

Once selected, the File Manager screen allows you to navigate to the modied translation

le.

Other System Settings

13 – Setting Power Management to ON conserves battery power by putting the Visual iQ

into sleep mode after 10 minutes of inactivity. When in sleep mode, in which only the hard

keys remain lit, touching any key or the joystick returns the iQ to a fully powered state.

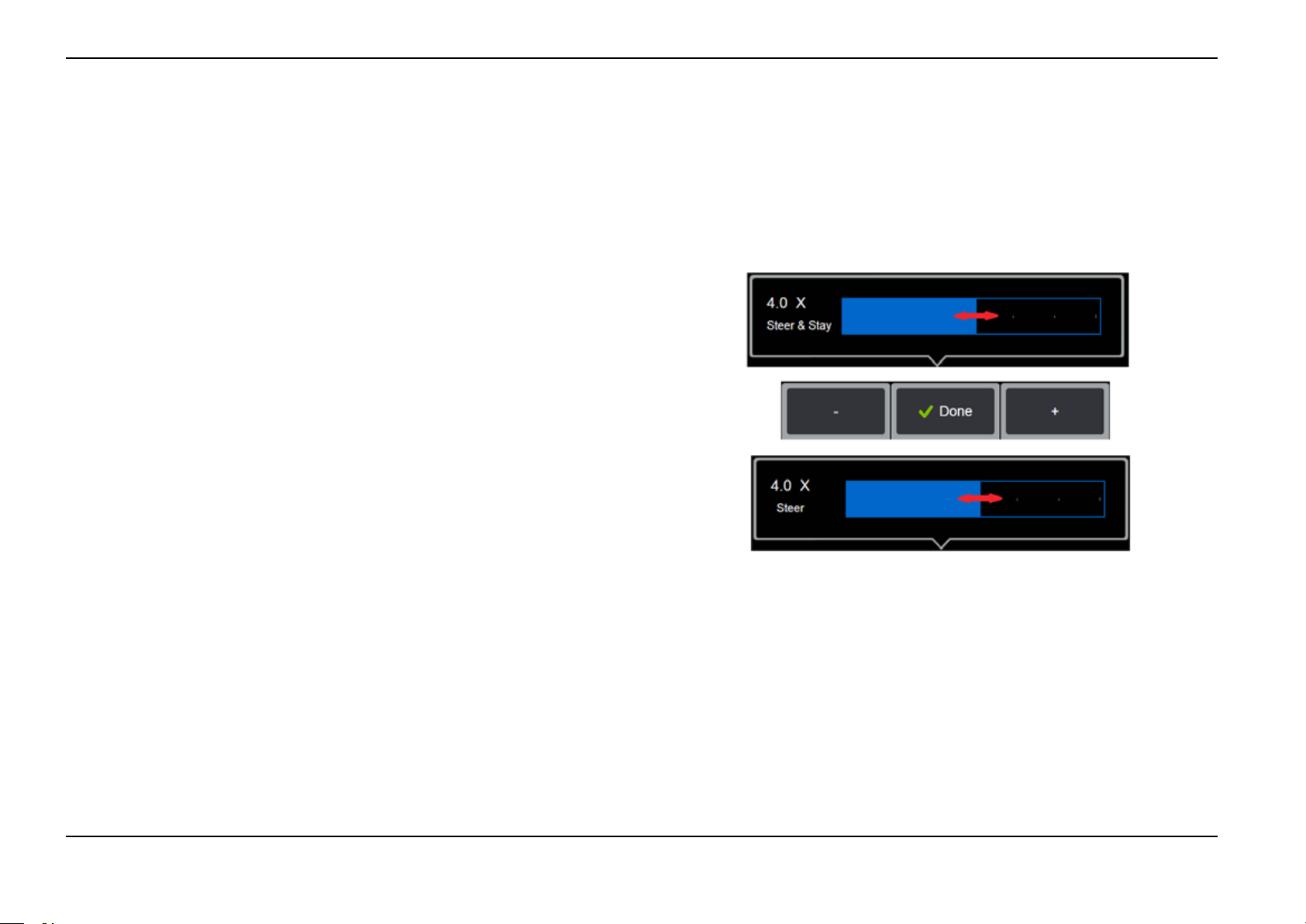

14 – The user can select from two probe steering modes: Steer or Steer and Stay™.

In either mode, the bending neck articulates to follow the joystick motion. The modes

differ in how they behave after the bending neck is positioned (click here to learn about

the dierences between these modes). Select either button shown here then drag the

setting bar to set the sensitivity of either Steer or Steer and Stay mode. The higher the

setting, the more the bending neck will articulate with a change in joystick position. For

instance, increasing the setting from 2.0 to 4.0 means that a similar joystick movement

will produce a greater amount of bending neck articulation.

20

08/2019

Page 21

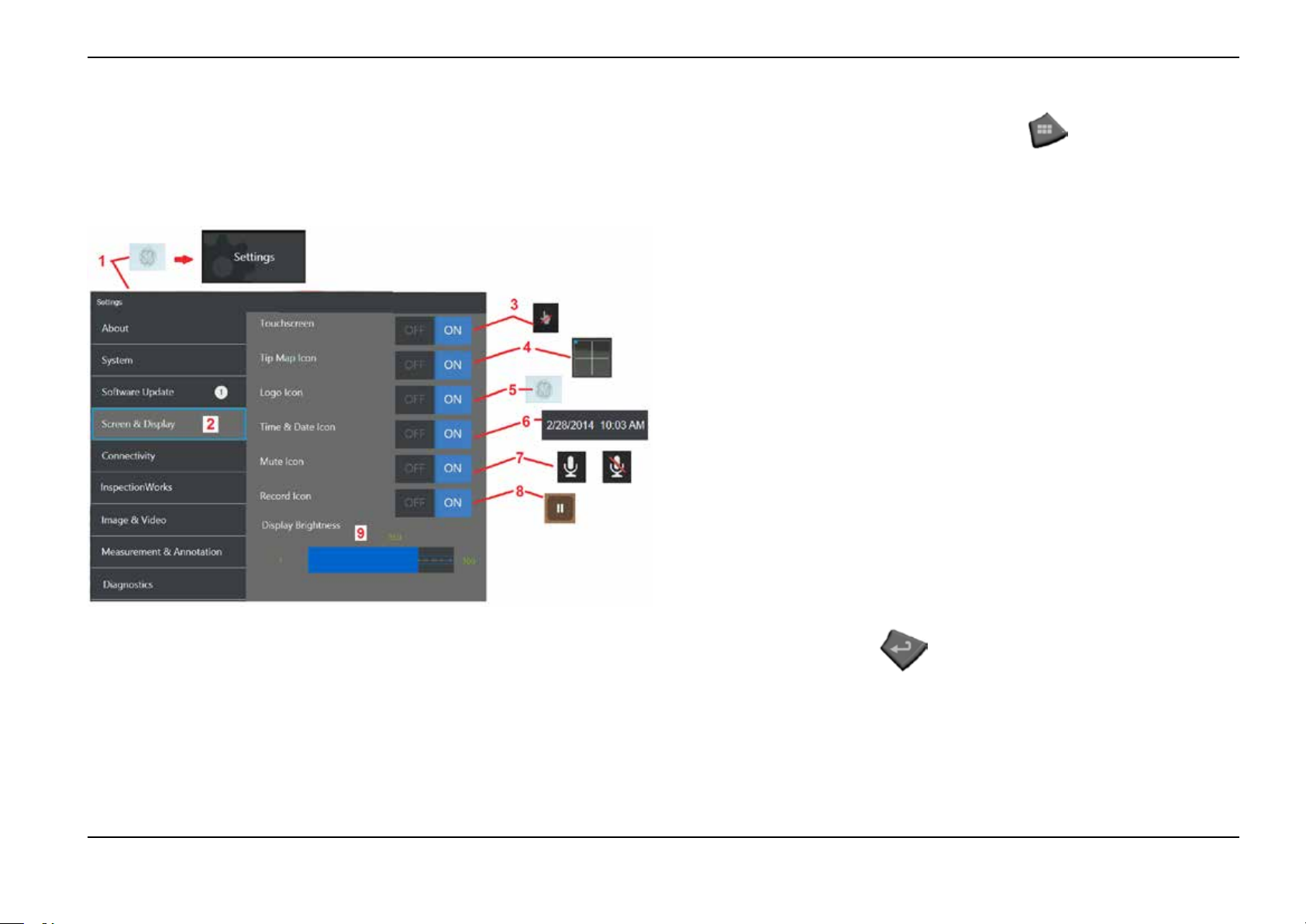

Screen & Display Setup

1 – Tap the on-screen GE Logo (or press the hard key) to open the

Global Menu, then open the Settings Menu.

2 – Select to alter the display-screen appearance and operation.

3 – Turn the display screen’s touch-sensitive control ON or OFF. Once turned OFF, the icon

shown here appears at the top of the display screen. Once disabled, use a combination

of joystick and hard key press to re-enable the touchscreen.

4 – The Tip Map (shown here) graphically represents the extent to which the optical

tip is articulated by positioning a bright dot at some distance from the crosshairs. The

closer the dot appears to the center of the crosshairs, the straighter the tip’s position.

5 – The customizable watermark shown here appears in the bottom left corner of the

display screen. Tapping this location opens the Global Menu. Turning this icon OFF

causes it to disappear while tapping in its former location still opens the menu.

6 – Turn the displayed date and time, which appears on the status bar at the display’s

upper right corner, ON or OFF.

7 – Select to turn the Sound Recording and/or Sound Recording Muted icons (shown

here) ON or OFF. These icons appear in the display’s bottom right corner when recording

video with an audio stream. Note that when these icons are visible (turned ON), selecting

the onscreen icon mutes or unmutes the sound recording.

08/2019

8 – Display or hide touch-screen pause and play controls during video recording.

9 – Control the display’s brightness by using your nger to drag this bar right or left (or

select with the joystick, press

and then position with the joystick).

21

Page 22

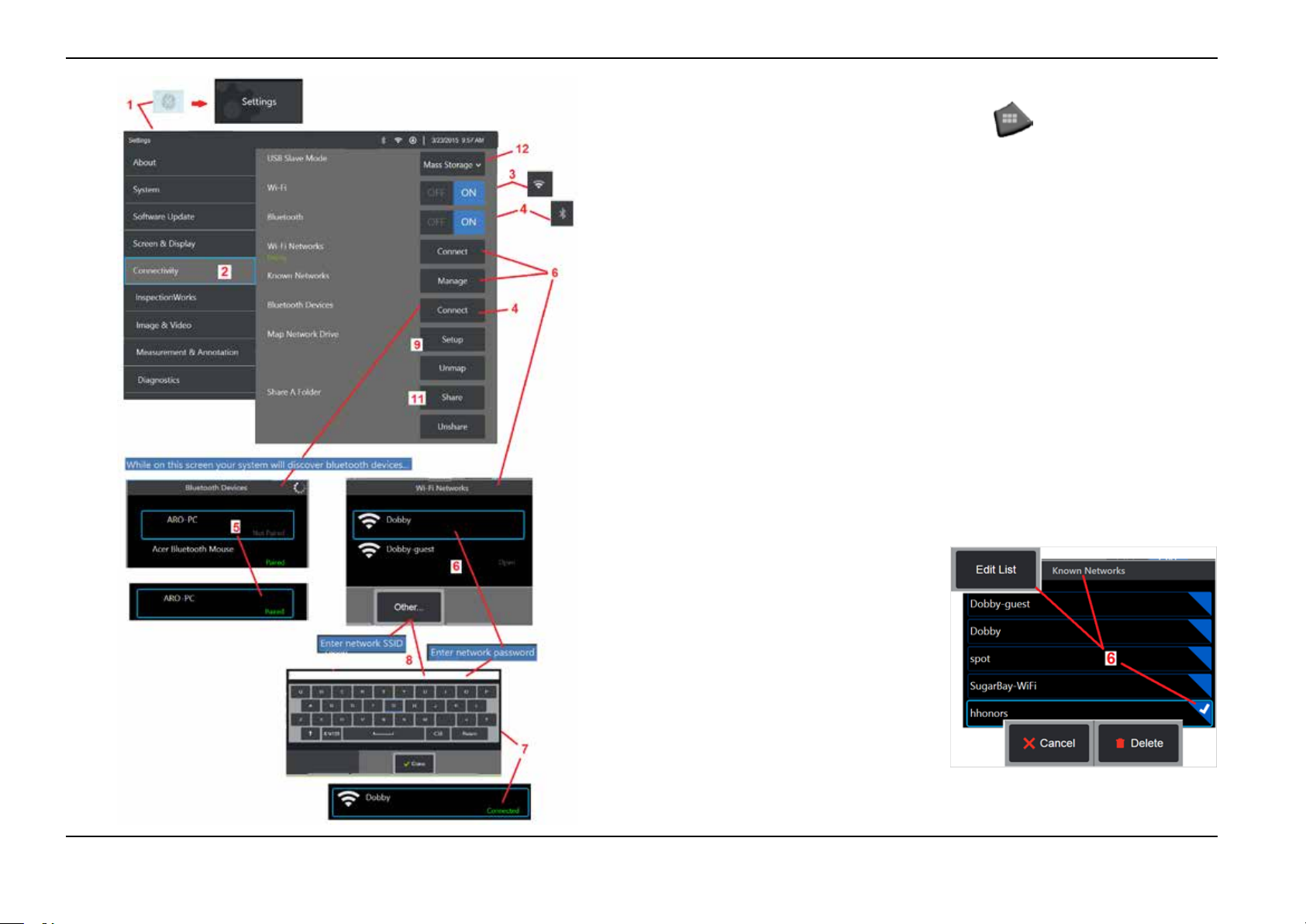

Connectivity Setup

1 – Tap the on-screen GE Logo (or press the hard key) to open the

Global Menu, then open the Settings Menu.

2 – Select to work with settings that control the connection of the Visual iQ to WiFi networks

and Bluetooth devices.

3 – Turn the WiFi connection ON or OFF. Once turned ON, the icon shown here appears at

the top of the display screen.

Making Bluetooth Connections

4 – Turn the Bluetooth connection ON or OFF. Once turned ON, the icon shown here appears

at the top of the display screen. The icon is gray if Bluetooth is ON or white if Bluetooth is ON

and paired with a device. Then, select Connect to display a list of available Bluetooth Devices

to which the iQ can connect.

5 – Available Bluetooth Devices that appear on this list can be paired with by simply tapping

the on-screen listing. Note that pairing a keyboard may require inputting a PIN. When the

device status switches from Not Paired to Paired, it is in Bluetooth communication with the

Visual iQ. Note: Connecting a Bluetooth or USB-wired keyboard allows for remote control

of iQ functions and probe articulation. See Appendix O for a list of function key and key-

press combinations equivalent to iQ button and joystick operations.

Working with WiFi

6 – Select Connect to display a list of available

WiFi networks to which the iQ can connect. Tap

the screen to select an already known network

from this list. (Select Manage Known Networks at

any time to review the list of already-recognized

networks and/or Edit the list by removing networks

to which you no longer wish to automatically

connect). Once Edit List is selected, tap the blue

corner of any network to delete it from the list.

22

7 – If prompted by the onscreen instructions,

use the Virtual Keyboard to enter the network’s

password.

8 – Selecting Add Network allows you to enter the

SSID and security information for a hidden network not shown above.

08/2019

Page 23

Mapping the Network Drive and Sharing Folders

9 – If you choose to give the Visual iQ’s File Manager access to a folder on a network-

connected computer, click on Setup (see above) to open the network-mapping process

shown here. Next, select Done to conrm that the network connected PC has at least

one folder identied for sharing.

10 – Enter the drive letter you wish to assign (in the Visual iQ’s File Manager) to the

shared folder, then input the complete path to the folder on the network-connected

PC. Following is an example of a complete path to insert in the Folder line: \\Device

Name\TestShare Folder. When the folder path and username/password (assuming it

is a password protected network) have been entered, click Done.

11 – To share one of the Visual iQ’s folders with a network-connected computer, click

on Setup (see above) to open the le-selecting process. The path in the blue bar shown

here identies the folder that will be shared. Next, select Done to display the Warning

statement listing the folder that will be shared, and select Done again to conrm that

the identied folder is the one you wish to share with a network-connected PC.

12 – Set the USB Slave Mode to Mass Storage or Disable. When set to Mass Storage,

a connected computer can work directly with les stored on the Visual iQ’s hard drive

for le management purposes. In this state, the iQ will not perform inspection functions.

When le management functions are complete, change setting to Disable to return

inspection functionality.

08/2019

23

Page 24

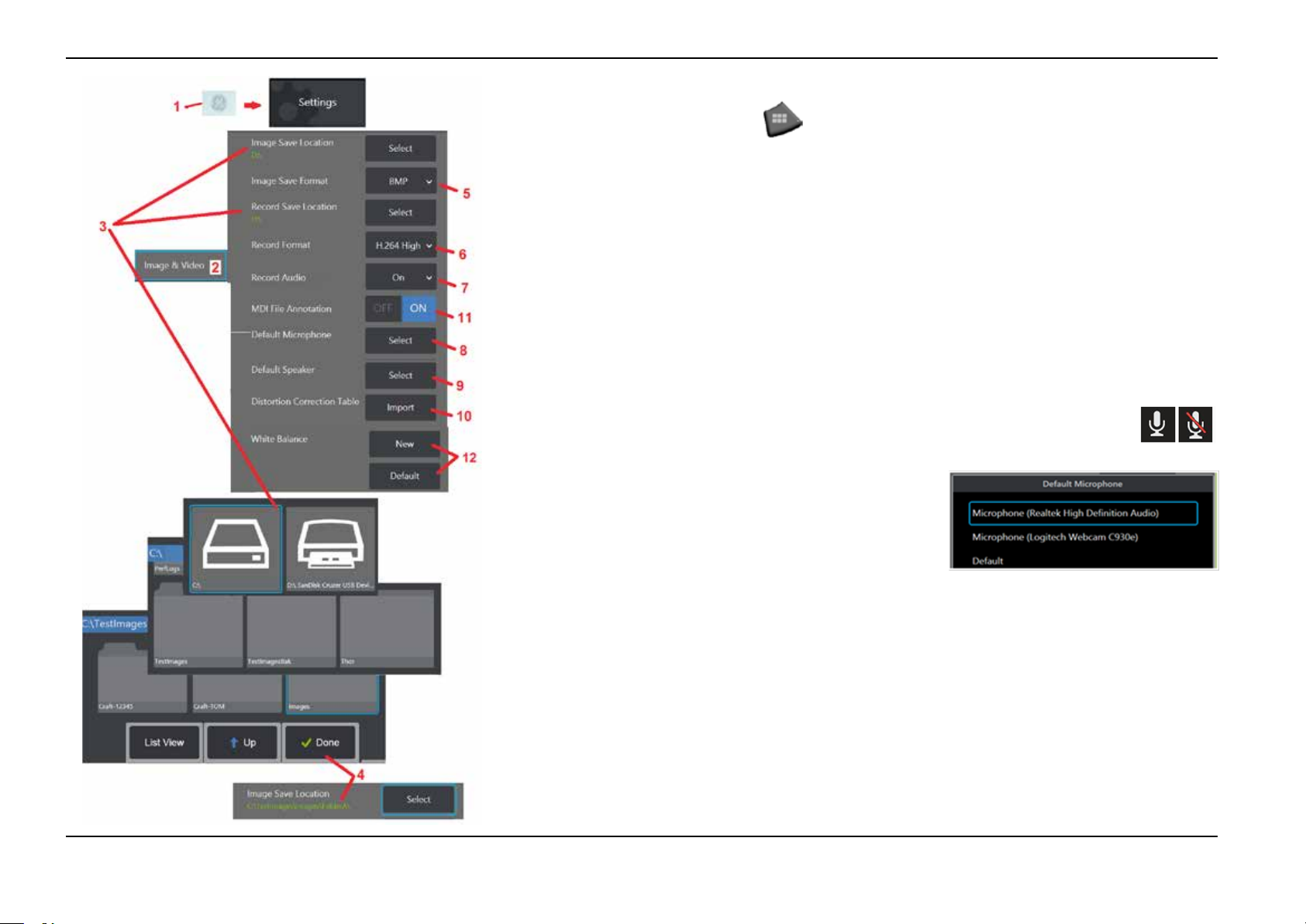

Image & Video Setup

1 – Tap the on-screen GE Logo (or press ) to open the Global Menu, then open the Settings Menu.

2 – Select to change Image and Video related settings and defaults.

3 – Follow the procedure shown here to change either the Image Save Location or Video Save Location. These

represent the two locations where quick-save images or videos are automatically stored. In the example shown

here, these locations are both initially set to the D: drive. Press the Select soft key and then choose the desired

directory path. When the desired storage location is opened, select the Done soft key to complete the process.

Note: The DVD drive may not serve as either the default or alternative saving location. Files must rst be

saved in a directory located in the instrument’s memory or on a connected USB storage device. Files can

later be copied and pasted to optical media in an attached DVD drive.

4 – Using the process outlined above, the default Image Save Location is changed to C:\TestImages\Images\

FolderA\. This is the location where quick-saved images are stored (Click to learn more about Saving Images).

5 – Choose either BMP or JPEG as the default image le type.

6 – Set the video recording format to either H.264 High or H.264 Low. (Click for Working with Video).

7 – Determines if the microphone icon (at right) appears in the display’s bottom right corner during

video recording. When displayed, tap the icon to mute or unmute the recording of sound along

with video. Click here to learn more about muting or turning sound

ON when recording live video.

8 – When set to Default, the system will normally recognize the

connected Microphone. Alternatively, choose a microphone from

those available (choices are only those devices already connected

to the Visual iQ or paired via Bluetooth).

9 – When set to Default, the system will normally recognize the

connected Speaker. Alternatively, choose a speaker from those available (choices are only those devices that

are already connected to the Visual iQ or paired via Bluetooth).

10 – Should a not-yet-dened tip conguration require an alternative Distortion Correction Table, Contact GE

Technical Support. A table supplied by GE Technical Support will include instructions on how to Import the le.

11 – When set to OFF, the menu-directed inspection stage name is not saved in the image but will still appear

during the MDI process.

24

Executing a White Balance

A white balance corrects the color so that white appears white despite any slight hues that may exist under the

lighting conditions present when performed.

12 – Select New and follow the prompts or select Default to restore factory color settings.

08/2019

Page 25

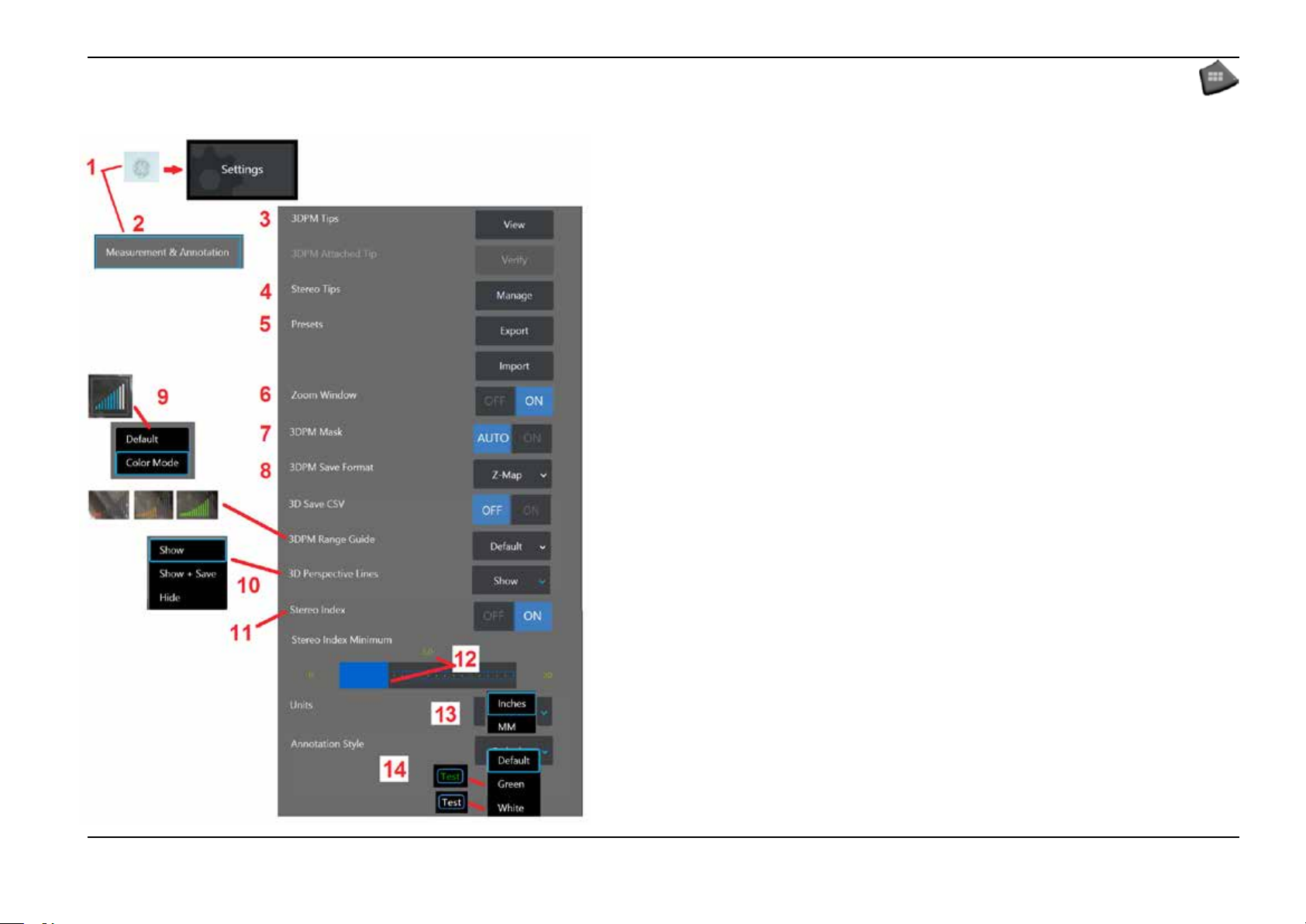

Measurement & Annotation Setup

1 – Tap the lower-left corner of the display (typically contains a GE Logo) or (or press the

hard key) at any time to open the Global Menu, which provides access to the Settings Menu.

2 – Select to alter the Measurement and Annotation-specic settings shown here.

3 – View the list of 3DPM Tips already calibrated for use with the attached probe.

4 – Select to view a list of Stereo Tips already-calibrated for use with the attached probe. The

Add Tip and Edit List options are not intended for general use. Deleting a tip through the Edit

List option will permanently remove that tip’s calibration data requiring the probe and tip to be

returned to an authorized GE Inspection Technologies service center for re-calibration.

5 – Save Preset Annotation (notes) to an external storage device or Import preset notes to the

instrument from an external device.

6 – Displays or removes the Zoom Window (used for detailed cursor placement during

measurement).

7 – Select AUTO to show the 3DPM red/yellow un-measurable pixel mask only when a cursor is

placed on a red/yellow pixel. Select ON to always show the pixel mask when measuring.

8 – Select Z-Map for most usage. P-Map images contain additional data and may be requested

by GE Technical Support to aid in troubleshooting.

9 – Determine the type of Range Guide to display during 3DPM measurement. As the tip-to-target

distance decreases, the 3DPM Range Guide displays an increasing number of illuminated bars.

In Default mode, the illuminated bars are all blue. In Color Mode, the bar color transitions from

red, when few bars are illuminated, to green, when most of the bars are illuminated. Click here

to learn more about making 3DPM measurements and the Range Guide.

10 – Displays four dotted lines in the full-image point cloud view. These lines represent eld of view,

providing the user with a better sense of probe orientation relative to the viewed surface. When

using a measurement plane in conjunction with a Point-to-Line, Area, or Depth measurement

type, an Edge View Angle is also included in both full-image and measurement-image point

cloud views. These lines may be Hidden, Shown in the point cloud view during measurement or

Shown and Saved along with the saved measurement image.

11 – Controls the display of the Stereo Index, which appears during Stereo Measurement. Click

here for more about Stereo Index.

12 – Sets a threshold value for the Stereo Index below which the index ashes during Stereo

Measurement. This may be used to warn the user of low-index measurements where the

accuracy may be reduced.

13 – Specify the unit of measurement as Inches or Millimeters.

14 – Annotation may be added to any frozen or recalled image. Select the Annotation Style to

change the color of the letters displayed. Text colors available include black (Default), Green,

and White.

08/2019

25

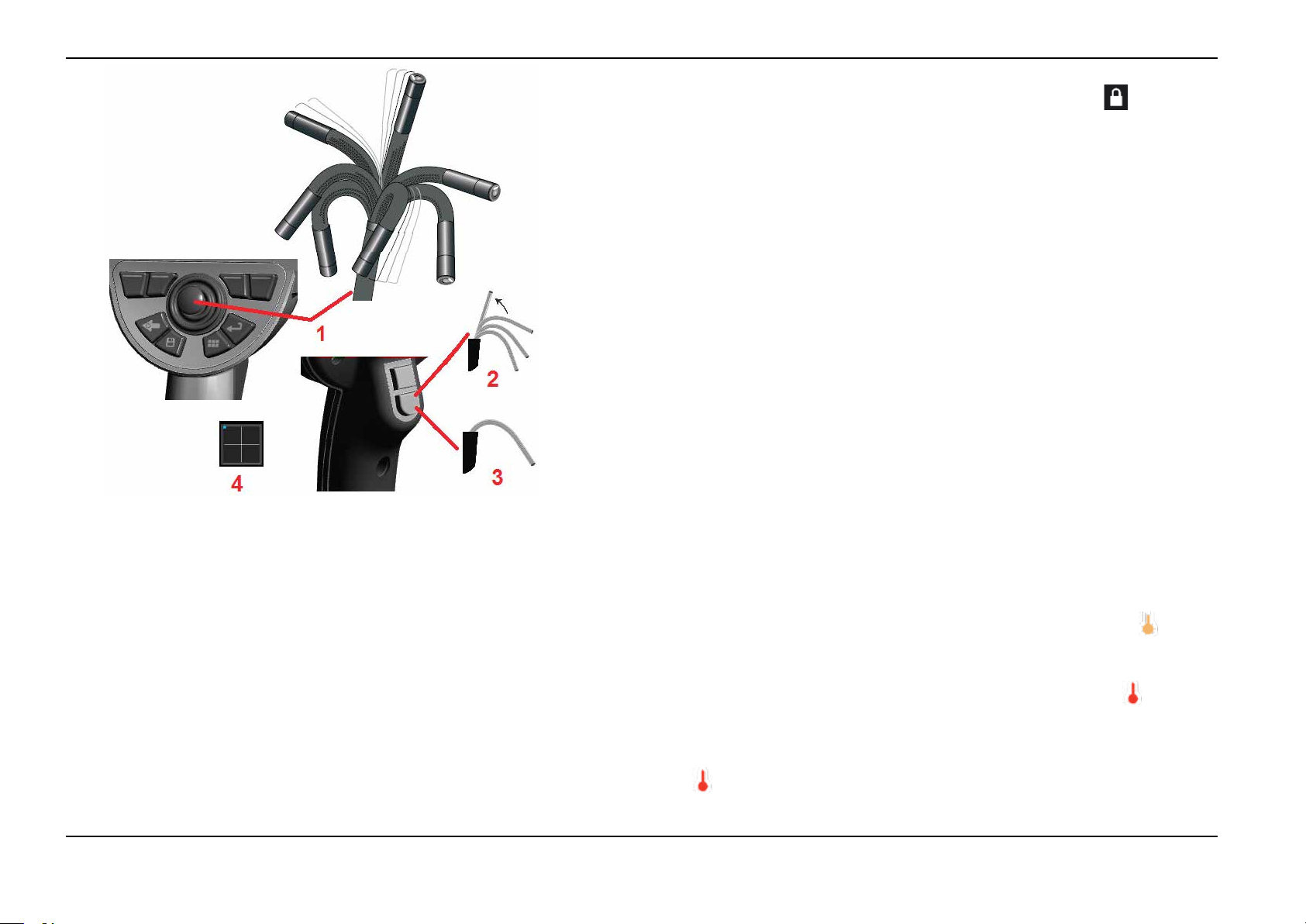

Page 26

the joystick while in Steer-and-Stay mode, the bending neck articulates. When you stop

Capturing and Adjusting Images

Steering the Probe

When you are viewing a live image, you can aim the probe’s camera by controlling its

bending neck.

1 – Steering the Bending Neck: While viewing a live image, move the joystick toward

the feature you want to see. The bending neck articulates so that the probe tip moves

in that same direction.

2 – Straightening the Bending Neck: Long press this button to HOME or straighten the

bending neck for safe withdrawal and storage of the insertion tube.

3 – Setting the Steering Mode: Short press this button to choose between Steer or

Steer and Stay mode. In either mode, the bending neck articulates to follow the joystick

motion. They differ in how they behave after the joystick is released (click here to learn

how to setup the sensitivity of either mode). Steer mode allows the bending neck to

drift towards a straight position when the joystick is released. Steer and Stay mode holds

the bending neck in its articulated position when the joystick is released. If you move

moving the joystick, the bending neck stays in the new position. This

when in Steer and Stay mode.

Note: Connecting a Bluetooth or USB-wired keyboard allows for remote control of iQ

functions and probe articulation. See Appendix O for a list of function key and key-press

combinations equivalent to iQ button and joystick operations.

icon appears

4 – Tip Map. This on-screen icon indicates the relative positions of the steering motors.

When the illuminated dot appears in the center of the crosshairs, the motors are centered.

The bending neck position generally follows the motor positions but is affected by the

shape of the insertion tube and other mechanical effects. The further the dot appears

from the center of the icon, the more the bending neck is articulated. Depending on the

rotation of the insertion tube and camera, the viewing area may or may not align with

the direction indicated on the Tip Map.

Guiding the Insertion Tube Into the Inspection Area

With the desired optical tip installed, guide the insertion tube into the inspection area.

Use your hands to push the tube until it reaches an area you want to inspect. Twist the

insertion tube gently to bring the desired scene into view. Accessories are available to

make it easier to maneuver the tube:

• Rigidizers: Rigid or semi-exible guide tubes (available in different lengths) keep the

tube supported as you insert it or allows the tube to span a recess.

• Grippers: Cylindrical handles that slide over the insertion tube to make it easier to control.

Grippers are threaded to connect to rigidizers and to access port couplers.

Temperature Sensor Warnings

When excessive temperature is detected, the applicable icon displays in the status bar, and

one of the warning messages listed below appears across the top of the display screen:

• Probe tip temperature has entered the WARNING Zone—this message displays in an

orange banner when tip temperature exceeds approximately 95°C and

in the status bar.

• Probe tip temperature has entered the CRITICAL Zone—this message displays in a

red banner when tip temperature exceeds approximately 100°C and

the status bar.

• System is overheated, system shut down initiated—this message displays in a red

banner when internal temperatures exceed limits. Shutdown automatically initiates

and

When either the CRITICAL Zone or System Overheat warning appears, take immediate

action to lower the temperature to which the indicated component is exposed.

appears in the status bar.

appears in

appears

26

08/2019

Page 27

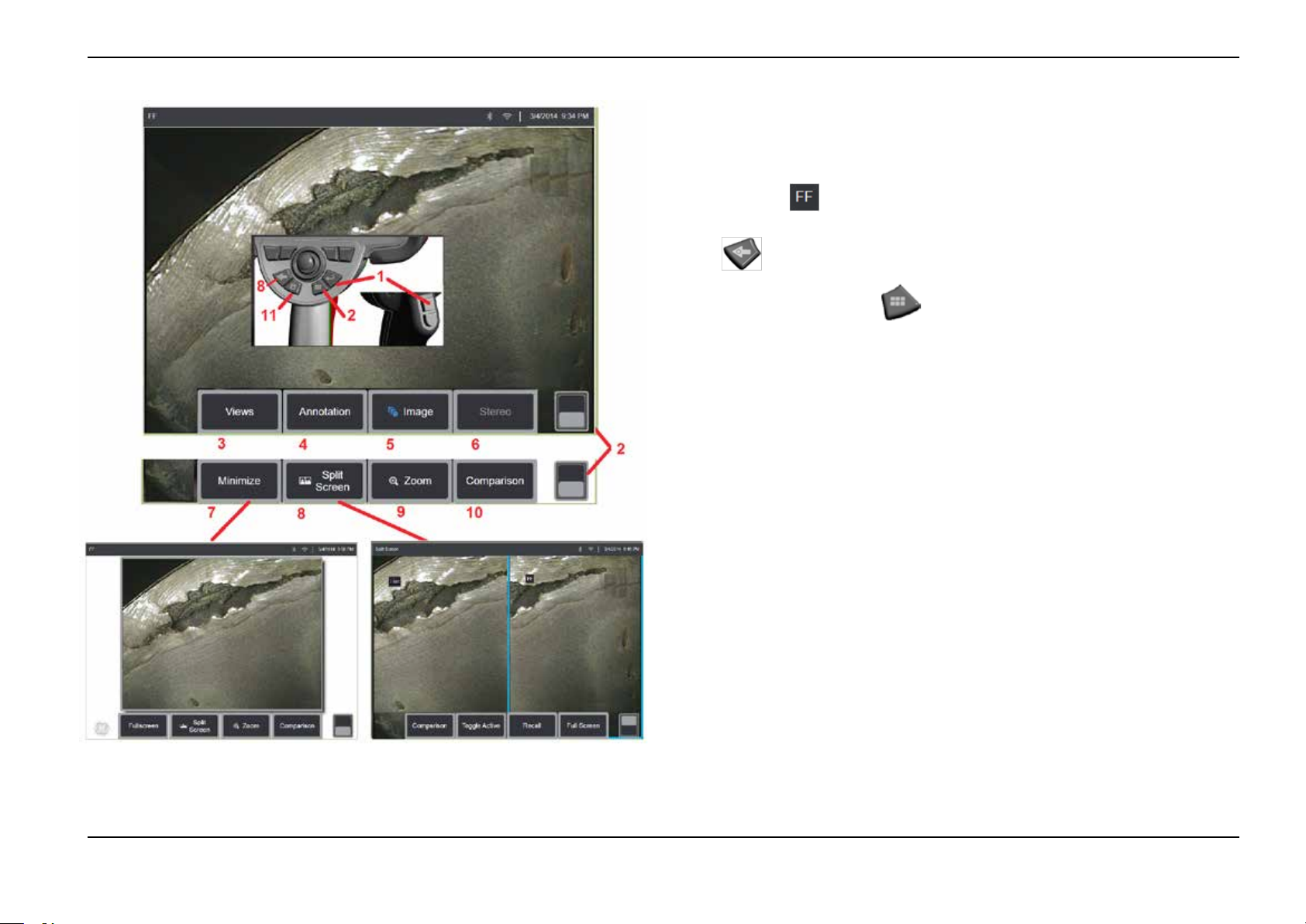

Freezing the Image

Freeze an image to temporarily capture it for review or adjustment. Moving the joystick

in a frozen view does not articulate the probe tip.

1 – Briey press either of these keys or tap anywhere on a live on-screen image to freeze

the display. The

key menu opens, allowing for adjustment of the frozen image. Reverse this process (or

press

) to unfreeze the display.

icon appears in the upper left corner of the display and the soft

2 – Tap (or press and hold the key) to toggle between the upper and lower soft

key menus. Double tapping in this location hides or displays the soft keys and status bar.

3 – Select any one of up to four Views available when a 2D image is frozen or six Views

when a 3DPM image is recalled (click here to learn more about each view).

4 – Add notes or arrows to the frozen image (Click here to learn more about annotating

images).

5 – Select and adjust four image transformation settings including Brightness, Distortion

Correction, Invert, and Inverse+. (Click here to learn about image settings).

6 – When a stereo tip is calibrated to the system, Stereo appears in white text. Press to

perform stereo measurement. If no stereo tips are calibrated, Stereo appears in gray

and may not be selected. (Click here to learn more about Stereo Measurements).

7 – Minimize the image to view unobscured by soft keys and status bar.

8 – Opens a Split Screen showing both frozen and live images. Press Full Screen to

return to single screen view. (Click here to learn about working with Split Screens).

9 – Zoom in or enlarge a portion of the frozen image (Click here to learn about the

Zoom feature).

Note: If you zoom in on a frozen image and then move the joystick or drag the image

with your nger, the image pans as the system electronically reviews the entire image.

08/2019

10 – Measure features of the frozen image (Click here to learn about Comparison

measurements).

11 – Press or press-and-hold to Save the frozen image (Click here to learn about the

Save feature). Double press this key to save a Screenshot of the display screen.

27

Page 28

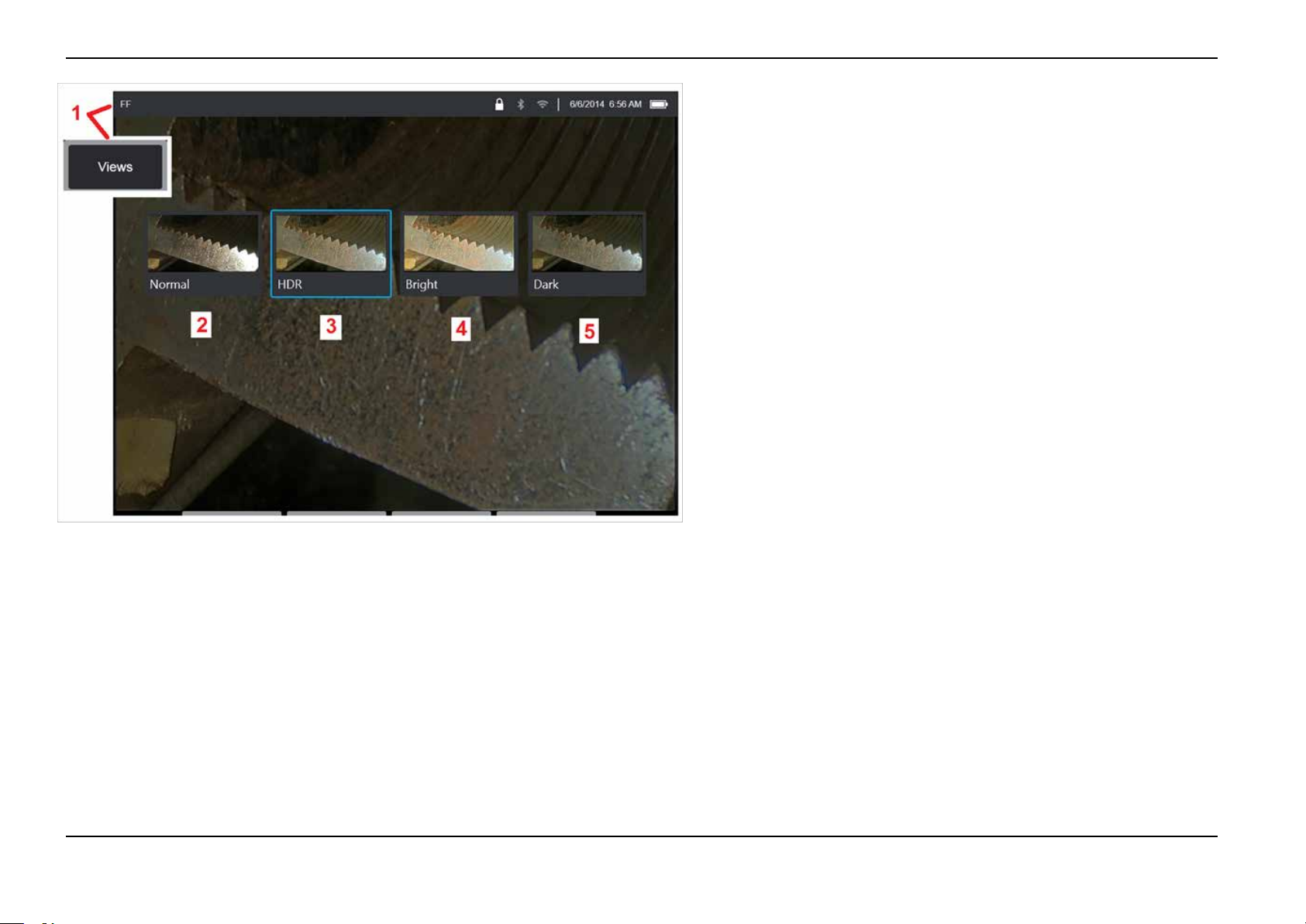

Selecting a View

When a 2D image is frozen (or a 3DPM image is recalled), the user can select

from various Views as described below.

1 – Anytime an image is frozen, select to choose from all available View options.

2 – Displays a normal dynamic range image created by applying Adaptive

Noise Reduction (ANR) processing to live video frames prior to the freeze request.

3 – HDR is a high dynamic range image generated by combining normal

brightness ANR images captured before the freeze request with images of

different brightness levels captured after the freeze request. This reduces the

glare (number of saturated pixels) and increases brightness in dark areas.

4 – Displays a view similar to HDR but gives up some detail in bright areas to

further brighten dark areas.

5 – Displays a view similar to HDR but gives up brightness in dark areas to show

more detail in bright areas.

Note: To optimize the quality of all captured images, hold the probe tip still

at the time of capture. Increasing the live image brightness prior to image

capture will improve the quality of the "HDR" and "Bright" images in darker

areas.

Note: Point Cloud and Depth Prole views are only available when working

with 3DPM and 3DST images. Click here to learn more about working with

these views.

28

Note: Once an image is saved with any one of these View options active, only

that option and Normal are available when the saved image is recalled.

08/2019

Page 29

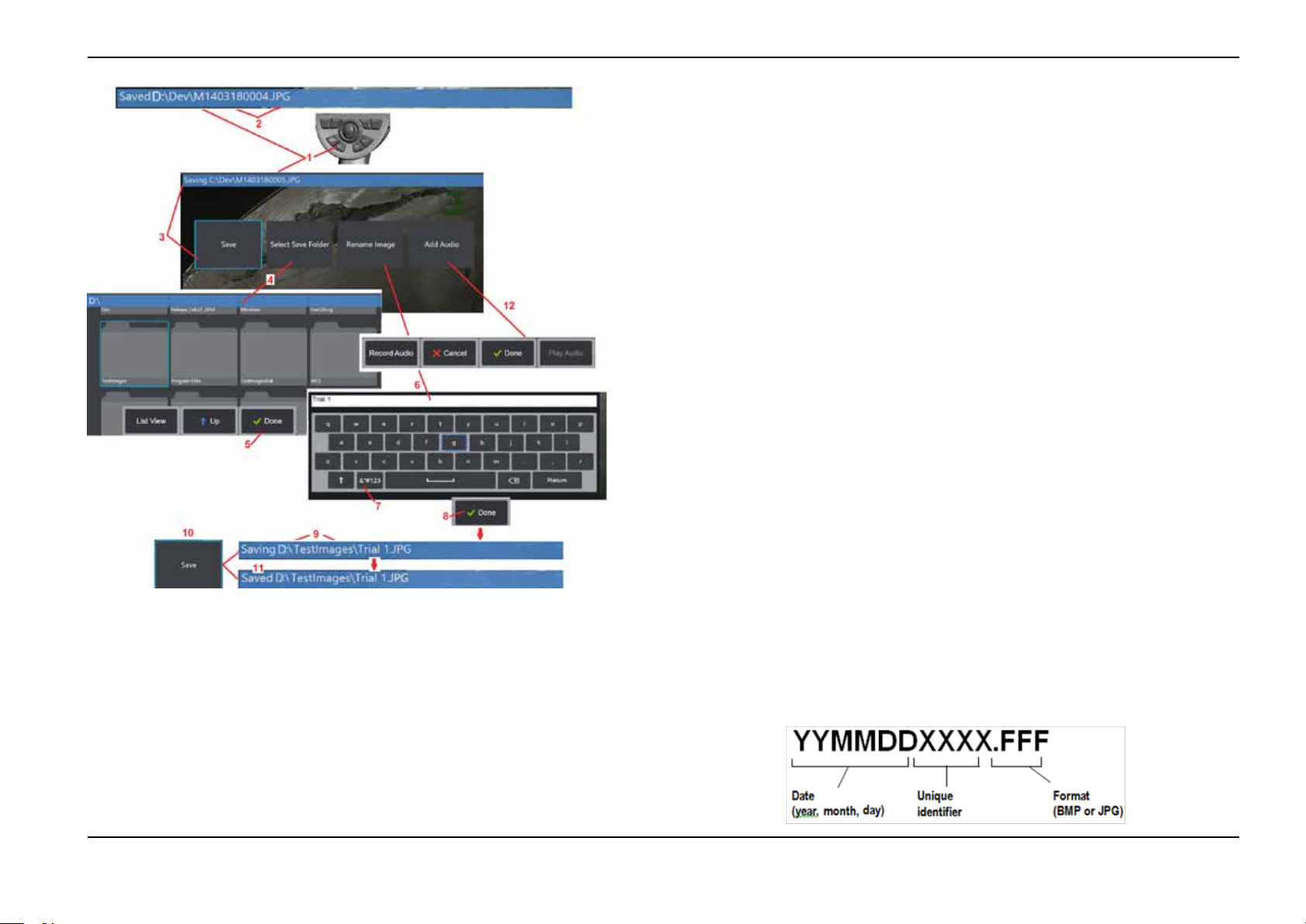

Note: Screenshots are BMP image les of the display screen, do not contain RVI data

of any type, are stored in an automatically created subfolder titled “Screenshots,” and

are assigned the auto-generated image le name but identied with the addition of the

letters “ss.”

Note: The DVD drive may not serve as either the default or alternative saving location.

Files must rst be saved in a directory located in the instrument’s memory or on a

connected USB storage device. Files can later be copied and pasted to optical media in

an attached DVD drive.

2 – At all times, the intended saving location (in this case the Dev directory located on the

D drive) is listed here. After a le is stored, the status bar at the top of the screen indicates

“Saved.” The le name (described below) and format are also listed.

Note: Each time les are pasted to the DVD drive, the optical media is auto-ejected to

avoid loss of data.

3 – While in the process of assigning an alternative name or destination for the image le,

the status bar at the top of the screen indicates “Saving.”

4 – Choose an alternative directory into which the le will be stored.

Note: Tap and open the target folder

5 – Tap to complete the target directory selection.

6 – Select to Rename the le prior to saving. The virtual keyboard opens.

7 – Select to choose from numeric characters or symbols.

Saving Image Files

Image les can be stored in the Visual iQ or a detachable device. The Quick-Save

feature stores a le with a default name and le type in a default directory (Click

here to learn more about setting default le names, types, and directories).

Alternatively, use the Save Options Menu.

1 – Perform a short press of this hard key to Quick Save the displayed image in the

default directory. A long press of this key opens the Save Options Menu. Double

pressing this key saves a Screenshot of the display screen.

08/2019

8 – Tap after typing the desired name.

9 – The status bar now indicates the new target directory (in this case, TestImages) and the

new le name (Trial 1).

10 – Tap to complete the saving process.

11 – The status bar now indicates that the le has been “Saved.”

12 – Add audio comments to the le before completing the saving process (Click here to

learn more about recording audio comments).

29

Page 30

Working with a Recalled Image

Image and video les can be stored in the Visual iQ or a detachable device. The Recall feature

allows these stored les to be displayed, measured, and annotated. Follow these steps to

locate and Recall a stored le:

1 – Recall a stored image or video by tapping the on-screen GE Logo (or press the hard

key) to open the Global Menu, then select File Manager.

Note: Selecting the Recall soft key (when enabled) automatically opens the last saved image

(provided one has been saved since the iQ was last powered ON). Moving the joystick (or

dragging the display with your nger) left or right recalls other images stored in the same

folder as the originally recalled image.

2 – Controls the File Manager’s appearance (both Thumbnail and List Views are shown here).

3 – Select to navigate to the next higher directory within the File Manager.

4 – Select to Copy, Rename, and otherwise Edit stored les (Click here to learn more about

the le Edit feature).

5 – Choose which le types to display.

6 – Tap to switch between the Soft Key Bar’s top and bottom row. Double tapping in this

location hides or displays the soft keys and status bar.

7 – Determine the order in which folders or les are listed (by date or alphabetical order).

8 – Tap screen to select the folder to open.

9 – Tap screen to select the le to Recall.

10 – Once an image is recalled, various actions can be taken (see soft key menus below). Click

on any of the following to learn more about the function:

30

-Select the displayed View

- Annotate by adding text or arrows

-Measure image features

-Play recorded audio

- Open a Split Screen to display

any two images (live, frozen, or

recalled)

- Use Zoom to magnify

- Adjust the Image

11 – Press to open an onscreen

list of the displayed file’s Detailed

properties.

08/2019

Page 31

Zoom to Magnify

The Zoom feature magnies the view of live, frozen, and recalled images. Because the

zooming process is digital, pixilation increases as the image is magnied.

Note: The Visual iQ oers two equivalent zooming methods.

1 – Select this soft key to launch the Zoom control bar.

2 – Position one nger on either side of a feature, then slide ngers apart to increase

magnication (Zooms IN). Moving ngers towards each other decreases magnication

(Zooms OUT).

3 – Touch and slide this bar left or right (or move it with the Joystick) to decrease

or increase the amount of image magnication. Repeat this process to return to a

unmagnied image (Zoom value of 1X).

4 – Select when the image magnication process is complete.

5 – When the image is zoomed, the icon appears in the display’s status bar along

with a value representing the amount of image magnication (2.1 times is shown here).

Note: Whenever a frozen or recalled image is magnied with the Zoom feature, simply

drag your nger across the display screen or use the Joystick to view o-screen

portions of the magnied image.

08/2019

31

Page 32

Image Transformation Settings

These settings, accessed by selecting the Image Menu, alter the appearance of live

images. (Some of these settings also affect frozen or recalled images.) At any time, the

values assigned to these eight transformation settings can be saved as a user-named

Preset. When recalled, all transformation settings will revert to these “preset” values.

(Click here to learn about working with Preset Image Transformation Settings)

1 – Double tap this switch to hide or display the Soft Key Bar.

2 – Tap to switch between the Soft Key Bar’s top and bottom row.

3 – Tap on-screen Image button or press the corresponding key to display the Image

Menu.

4 – Tap the on-screen Brightness icon to adjust the displayed image. The adjustment

bar shown will then appear – drag it to the left or right. You can adjust the brightness of

live, frozen, and recalled images as well as recorded video. The brightness level selected

when an image is saved will be maintained when the image is recalled.

Note: When viewing live images, adjusting the brightness means controlling exposure

time and camera gain. When viewing still images or recorded video, adjusting the

brightness means controlling digital gain.

5 – Tap on-screen Invert icon to turn ON or OFF. When turned ON, appears at

the top of the display. This feature horizontally ips any image.

32

Note: This feature allows you to “correct” images when using a side-view optical tip,

since the prism contained in these tips would otherwise show an inverted image.

08/2019

Page 33

6 – Tap to turn Adaptive Noise Reduction (ANR) ON or OFF. ANR works to reduce the

amount of noise (which appears as a grainy image) visible when the probe is positioned

in a dark area. The ANR setting (ON or OFF) applies only to live video. ANR is automatically

applied to reduce noise in all frozen and saved images, even when the ANR setting is set

to OFF. When turned ON, appears at the top of the display.

Note: Keep the probe still when capturing an image. Noise increases with probe

movement.

9 – Tap to turn the Single View feature ON or OFF. Single View is useful while positioning

a stereo optical tip. This feature makes it easier to navigate the camera by temporarily

eliminating the second image.

10 – Tap the on-screen Long Exposure icon to brighten live images by increasing

the camera’s maximum exposure time. Exposure settings can vary from 1X to 600X.

Note: The longer the exposure, the greater the risk of blurring the image. Keep the

probe tip as still as possible when capturing an image with a long exposure.

7 – Tap to turn Inverse+ either ON or OFF. When turned ON, appears at the top

of the display. The Inverse+ function enhances image contrast – often making subtle

details more visible in low light or poor contrast images. Turning Inverse+ ON reverses

the image’s dark and light areas, much the same as a photographic negative.

8 – Tap to turn Distortion Correction either ON or OFF. The Distortion Correction function

corrects the wide-angle edge distortion that occurs when using optical tips with various

angle elds of view

Note: When saving a corrected image, the face of the image will be labeled 120 Deg.

Note: When viewing a corrected image, the selected tip eld of view (FOV) angle is

overlaid in the lower right corner.

11 – Tap to turn the illumination LED ON or OFF

12 – Tap the on-screen Color Saturation button to adjust the amount of color in the

image. While the adjustment can only be made while viewing live video, the adjusted

color is preserved in subsequently frozen and saved images. This may be useful when

assessing for heat-related conditions indicated by subtle color changes.

13 – Tap on-screen DONE button or press the corresponding key to close the Image

Menu and return to the Soft Key Bar. Any changes to image transformation settings

will remain until manually modied or otherwise altered by recalling a stored Preset .

Pressing

Note: Any changes made to image transformation settings are lost during power

down.

while viewing live video turns off all transforms.

14 – Tap on-screen Preset button or press the corresponding key to create and

name a Preset containing the values currently assigned to each of the eight Image

Transformation settings. Recalling the Preset later allows you to automatically change all

Image Transformation settings to the stored values. (Click here to learn about Working

with Preset Image Transformation Settings).

15 – Tap on-screen Reset Transforms to restore the factory default values for each

of these eight settings.

08/2019

33

Page 34

Working with Preset Image Transformation

Settings

Values assigned to the image transformation settings can be saved as a user-named

Preset. When recalled, all transformation settings will revert to the values assigned when

the Preset was created. Each user-named Preset appears as a soft key in the Image

Menu. To load a Preset, simply select its soft key or press the corresponding button.

1 – Tap the on-screen Image button or press the corresponding key to display

the Image Menu, which contains the eight image transformation settings.

Adjust settings as needed.

2 – To save the image transformation settings in a user-named Preset, select Save to

Preset. The Preset List will open.

3 – Tap to select any one of the ve Presets. The virtual keyboard will open, allowing

you to name the Preset.

4 – After entering a name for the Preset, select Done.

5 – The user-named Presets appear as soft keys in the Image Menu. Select any of these

to load the settings stored in the corresponding Preset.

6 – Tap here to toggle between the upper and lower Soft Key Bars.

34

Note: Presets are stored only for the prole that is logged in at the time they are created.

08/2019

Page 35

Working with a Split Screen

A split screen displays two images side-by-side in any combination of live, frozen, or

recalled. Since half-screen still images are cropped, dragging a nger across the display

or moving the joystick allows you to pan side-to-side within the image.

1 – Press at any time to launch the Split Screen feature. One half of the screen will initially

show a live image, the other shows a frozen version of the image that appeared when

Split Screen was selected.

Note: To exit Split Screen mode, press

until a full-screen reappears.

2 – Each displayed image will be identied as either Live, Frozen (FF), or Recalled.

3 – Select which image is active by touching either side of the split screen, or by selecting

this soft key, or moving the joystick left or right. Only one image is active at a time, as

indicated by the blue outline around the active image.

4 – Change the magnication of the active image by zooming IN or OUT (Click here to

learn more about the Zoom feature).

5 – Select to Recall a stored image into whichever side of the display is currently active

(Click here to work with Recalled images).

6 – Temporarily displays the active image as a full screen. This action DOES NOT cause

the display to exit Split Screen mode.

7 – Measurement mode available for still images. This soft key is labeled with the most

advanced measurement mode (3DPM, Stereo, or Comparison) available for the active

still image. It allows measurement to be entered with the active image. Exiting from

measurement will return to the current Split Screen view. (Click here to learn more

about Comparison measurement mode).

08/2019

35

Page 36

Annotating with Text and Arrows

Annotating an image means adding text or arrows to point out areas of interest: cracks,

indications, etc. You can annotate live, frozen, and recalled images.

1 – Select to launch the Annotation feature.

2 – Tap to switch between the Soft Key Bar’s top and bottom row. Double tapping in

this location hides or displays the soft keys and status bar.

3 – Adding annotation begins by selecting Text or Arrow.

4 – Selecting Text opens the Virtual Keyboard. Enter the desired note. Note: Adjusting

the color of annotation may make it more visible against a specic image. Click here

to learn how to change the color of annotation text.

5 – Select to add the entered note to a list of up to 100 Preset notes, which can be

repeatedly used without typing.

6 – Select Done when nished typing the note, which will appear on the image

surrounded by a blue box indicating it is selected. While in this selected state, the note

can be moved (by dragging with your nger or using the joystick), Edited, or Deleted.

Select Done again to de-select the note.

7 – A selected Arrow (added in the same way as a note) appears with a ball at one end.

Move the arrow around the display by dragging with your nger (near the arrowhead)

or using the joystick. The arrow may also

be rotated by moving the ball with your

nger or with the Rotate soft key.

36