Page 1

DynaPOCKET

Technical Reference and Operating Manual

Ident-No. 28 674

Page 2

Content

This Issue 03, 04/2005 applies to the software version V 01.01.01

The software version is indicated in the display (ref. chapter 3.3).

Subject to change without notice.

0-2 Issue 03, 04/2005 Krautkramer DynaPOCKET

Page 3

Content

1 Introduction ...................................... 1 -1

1.1 Safety information .................................. 1 -2

Batteries ................................................... 1 -2

Software ................................................... 1 -2

1.2 About this manual .................................. 1 -3

Important information ................................ 1 -3

1.3 Layout and presentation in this manual 1 -4

Attention and note symbols ...................... 1 -4

Listings ..................................................... 1 -4

Operating steps ........................................ 1 -4

1.4 Prerequisites for hardness testing ......... 1 -5

Operator training ....................................... 1 -5

Technical test requirements ...................... 1 -6

Choice of the appropriate test equipment .. 1 -6

1.5 Krautkramer DynaPOCKET ..................... 1 -7

1.6 Important information about hardness

testing using the DynaPOCKET ............. 1 -9

Test material ............................................. 1 -9

The rebound method ................................. 1 -9

Conversion of hardness values ............... 1 -10

2 Scope of supply and accessories .. 2 -1

2.1 Scope of supply ...................................... 2 -3

2.2 Recommended accessories ................... 2 -5

2.3 Spare parts requirements ....................... 2 -6

3 Operation .......................................... 3 -1

3.1 Preparation .............................................. 3 -2

Inserting batteries ..................................... 3 -2

3.2 Fundamental principles of operation .... 3 -3

Display and keys ...................................... 3 -3

How to handle the impact device .............. 3 -5

3.3 Hardness measurement .......................... 3 -6

Switch-on .................................................. 3 -6

Switch-off ................................................. 3 -6

Carrying out a measurement ..................... 3 -6

Closing a measurement set ...................... 3 -7

Deleting measured values ......................... 3 -7

Krautkramer DynaPOCKET Issue 03, 04/2005 0-3

Page 4

Content

3.4 Selecting instrument settings ................ 3 -8

Setup mode .............................................. 3 -8

Measurement mode and

display of measured values ...................... 3 -8

Material group ........................................... 3 -9

Hardness scale ....................................... 3 -10

Conversion .............................................. 3 -11

4 Maintenance and care ...................... 4 -1

4.1 Care ......................................................... 4 -2

Caring for the instrument ........................... 4 -2

Caring for rechargeable batteries ............... 4 -2

Charging the batteries ............................... 4 -2

How to handle alkaline batteries ................ 4 -3

4.2 Maintenance ............................................ 4 -3

Impact device ........................................... 4 -3

5 Function check and

troubleshooting ................................ 5 -1

5.1 Checking the function ............................. 5 -2

5.2 Troubleshooting ...................................... 5 -2

Error codes ............................................... 5 -3

6 Technical data .................................. 6 -1

Housing .................................................... 6 -2

Display and keypad .................................. 6 -2

Power supply and operating time ............... 6 -3

Ambient conditions ................................... 6 -3

Evaluation ................................................. 6 -4

0-4 Issue 03, 04/2005 Krautkramer DynaPOCKET

Page 5

Content

7 The rebound hardness testing

method .............................................. 7 -1

7.1 The hardness testing method ................ 7 -2

7.2 Conversion of hardness values .............. 7 -3

Material groups ......................................... 7 -4

Application ranges of the conversion tables . 7 -5

7.3 The treatment of test material ................ 7 -6

Surface quality .......................................... 7 -6

Curved surfaces........................................ 7 -6

Measurements on small objects ............... 7 -6

Minimum wall thicknesses ........................ 7 -6

7.4 Information about the

statistical evaluation ............................... 7 -8

8 Annex ................................................ 8 -1

8.1 EU declaration of conformity ................. 8 -2

8.2 Manufacturer/Service addresses ............ 8 -2

9 Index .................................................. 9 -1

Krautkramer DynaPOCKET Issue 03, 04/2005 0-5

Page 6

0-6 Issue 03, 04/2005 Krautkramer DynaPOCKET

Page 7

Introduction 1

Krautkramer DynaPOCKET Issue 03, 04/2005 1-1

Page 8

Introduction Safety information

1.1 Safety information

The DynaPOCKET is designed and tested according to

DIN EN 61 010 Part 1, March 1994, “Safety requirements for electric measuring, control and laboratory

equipment“, and was technically in perfectly safe and

faultless condition when leaving the manufacturing

works.

In order to maintain this condition and to ensure a safe

operation, it is absolutely necessary that you read the

following safety information before putting the instrument into operation.

A Attention:

The DynaPOCKET is an instrument for materials

testing. Any use for medical applications or other

purposes is not permitted!

The instrument may only be used in industrial

environments.

Batteries

The DynaPOCKET can be operated with AAA-sized

AlMn cells or rechargeable NiCads and NiMH batteries.

NiCads or NiMH batteries can not be charged within

the instrument. They must be charged with a specifically approved external battery charger.

For information on how to properly handle the batteries,

please refer to chapter 4

Maintenance and care

.

Software

According to the present state of the art, software is

never completely free from errors.

Before using any software-controlled test equipment,

you should ensure that the required functions operate

perfectly as intended.

If you have any questions about the use of your test

equipment, please contact your local GE Inspection

Technologies representative.

1-2 Issue 03, 04/2005 Krautkramer DynaPOCKET

Page 9

About this manual Introduction

1.2 About this manual

In the following section you will learn how to use this

manual. Please read through these instructions carefully carefully to operate all functions of the

DynaPOCKET quickly and reliably.

This will enable you to take full advantage of the

instrument’s capabilities. Also, you will avoid any incorrect test results due to malfunctions or operating errors. Such incorrect test results may cause personal

injuries or material damages.

Important information

Even if you should be familiar with hardness testing

methods, please review the information in the chapters

1.4, 1.5 and 7.

In chapter 1.4, you will find important limitations and

prerequisites for hardness testing in general (training,

knowledge of the specific technical test requirements

and limits, choice of the appropriate test equipment).

In chapter 1.5, you will find complete information about

hardness testing using the DynaPOCKET that must

always be followed to ensure correct measurement

results.

Chapter 7 describes the rebound hardness testing

method.

Krautkramer DynaPOCKET Issue 03, 04/2005 1-3

Page 10

Introduction Layout and presentation in this manual

1.3 Layout and presentation in

this manual

To make it easier for you to use this manual, all operating steps, notes, etc. are always presented in the same

way. This will help you find individual pieces of information quickly.

Attention and note symbols

A Attention:

The Attention symbol indicates peculiarities and

special aspects in the operation which could affect the

accuracy of the results.

H Note:

Note contains e.g. references to other chapters or

special recommendations for a function.

Listings

Listings are presented in the following form:

❚ Variant A

❚ Variant B

❚ ...

Operating steps

Operating steps appear as shown in the following

example:

– Position the DynaPOCKET vertically to the

surface to be tested.

– Use your thumb to press the release button.

1-4 Issue 03, 04/2005 Krautkramer DynaPOCKET

Page 11

IntroductionPrerequisites for hardness testing

1.4 Prerequisites for hardness

testing

This operating manual contains all essential information on how to operate the DynaPOCKET. In addition,

there are a number of factors which affect the results.

A description of these factors would go beyond the

scope of an operating manual. The following list therefore contains only the three most important conditions:

❚ operator training

❚ knowledge of special technical test requirements

and limits

❚ choice of the appropriate test equipment

A Attention:

Lack of knowledge of the above-mentioned subjects

may lead to incorrect test results and thus have unforeseeable consequences.

Operator training

The reliable and safe operation of a hardness testing

device requires a proper training in the field of materials testing.

A proper training comprises for example adequate

knowledge of:

❚ hardness testing on metallic materials,

❚ effects due to material properties, especially due to

the microstructure, on hardness testing and on the

corresponding choice of the appropriate hardness

tester,

❚ limits relating to the use of conversion of different

hardness values such as Vickers, Rockwell and

Brinell,

❚ effects of surface finish on the hardness value,

❚ effects of the test load on the determined hardness

value.

Krautkramer DynaPOCKET Issue 03, 04/2005 1-5

Page 12

Introduction Prerequisites for hardness testing

Technical test requirements

Every hardness test is subject to specific technical

test requirements. The most important ones are :

❚ definition of the scope of test

❚ choice of the appropriate test method

❚ consideration of material properties

❚ determination of limits for evaluation

Choice of the appropriate test equipment

It is the task of those with overall responsibility for

testing to ensure that the inspector is fully informed

about the technical test requirements. Moreover, a

clear and thorough interpretation of the corresponding

test specifications is absolutely necessary.

Information about test methods and test specifications

may be obtained, for example, from various institutions,

industrial enterprises and authorities.

1-6 Issue 03, 04/2005 Krautkramer DynaPOCKET

Page 13

IntroductionKrautkramer DynaPOCKET

1.5 Krautkramer DynaPOCKET

The Krautkramer DynaPOCKET is a handy and easyto-use rebound hardness tester enabling the user to

carry out tests quickly and effortlessly.

You can use the DynaPOCKET to carry out measurements anywhere and in any direction; the direction

does not have to be set in advance.

The DynaPOCKET is mainly suitable

❚ for measuring the hardness of low-alloy or unalloyed

steels,

❚ for measuring the hardness of high-alloy steels,

❚ for measuring the hardness of nonferrous metals.

The DynaPOCKET operates according to the rebound

method (according to ASTM standard A 956). In this

method, an impact body is impelled against the test

surface by spring force.

Impact and rebound speeds are measured in non-contact mode and the hardness value is calculated on the

basis of these two measurements. The hardness value

is immediately displayed. Apart from this, a high reproducibility of the test results is ensured.

The DynaPOCKET has only two operating keys to

carry out all functions.

The large display indicates the current single value or

the statistical average of a measurement set, depending on the selected mode.

Krautkramer DynaPOCKET Issue 03, 04/2005 1-7

Page 14

Introduction Krautkramer DynaPOCKET

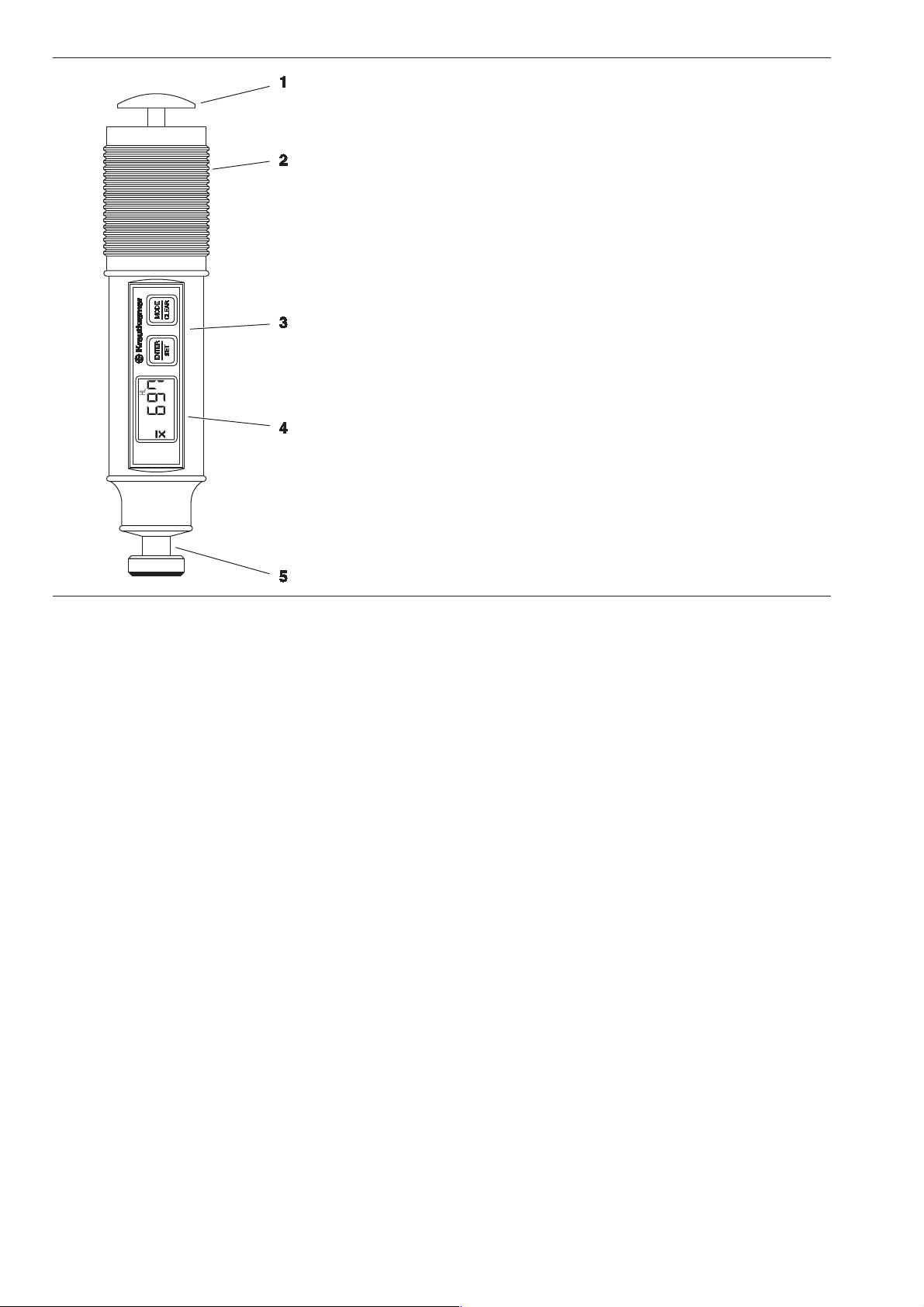

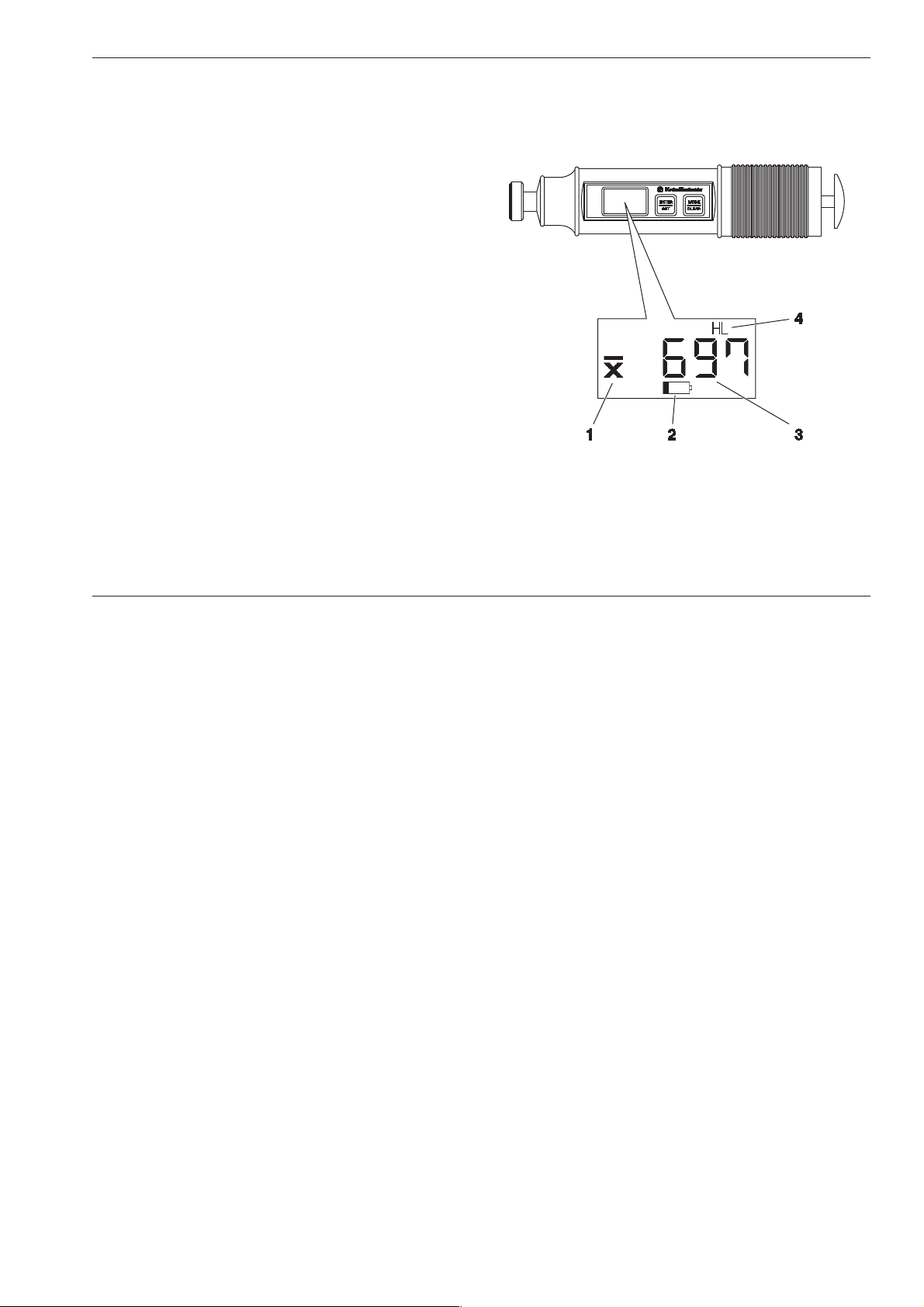

1 Release button

2 Loading tube

3 Operating keys

4 Display

5 Impact device with test attachment

1-8 Issue 03, 04/2005 Krautkramer DynaPOCKET

Page 15

Important information about hardness testing using the DynaPOCKET Introduction

1.6 Important information about

hardness testing using the

DynaPOCKET

The following section contains a summary of the most

important technical test requirements that you always

have to observe in order to obtain reliable and reproducible measurement results.

Test material

Surfaces must be free from any impurities (oil, dust,

rust, etc.). Rough surfaces lead to a greater variation

of the single values. If necessary, prepare rough surfaces, using our grinding set MIC 1060 (ref. chapter 2).

Test objects having a mass of at least 5 kgs can be

tested without any additional supports; objects weighing less require a support to which they have to be

tightly coupled. Please use large, inflexible and rigid

metal supports for this purpose.

The test objects should have a minimum wall thickness of 20 mm. We recommend the use of the UCI

hardness tester MIC 10 for test objects having thinner

wall thicknesses.

A Attention:

A yielding or springiness of the test objects may lead

to measuring errors! Please also refer to chapter 7.3.

The rebound method

The rebound method is a dynamic method with a very

high reproducibility of the measurements. The rebound

method does not replace the classical Brinell hardness

testing or other standardized methods, but rather

complements them.

The remaining energy of an impact body is measured

after rebounding from the material surface. Please observe that the loss of energy is also effected by the

material’s mechanical properties, i.e. mainly on its

modulus of elasticity or Young’s modulus.

The direct comparison with results obtained from standardized hardness measurements on specific materials

is therefore important for the evaluation of the measuring accuracy of the rebound method.

Krautkramer DynaPOCKET Issue 03, 04/2005 1-9

Page 16

Introduction Important information about hardness testing using the DynaPOCKET

A Attention:

It is absolutely necessary that you set your

DynaPOCKET to the appropriate material group

before testing (ref. chapter 3.4).

The material group for low-alloy or unalloyed steel is

defined as default setting in the instrument.

Please also read chapter 7 on the rebound method.

A Attention:

You should not carry out hardness measurements

twice at the same test position, otherwise faulty measurements are possible due to the surface hardening.

The distance between the test positions should be at

least 3 mm.

Conversion of hardness values

The conversion of the HL value determined according

to the rebound method into standard hardness scales

is carried out on the basis of defined conversion tables

depending on the material group.

The conversion into tensile strength values is made

according to DIN 50150 on the basis of the HB values.

You should carry out conversions only

❚ if the specified test method cannot be applied (for

example because there is no suitable instrument

available),

❚ if it’s not possible to section the part to perform the

specified test method.

Please observe the limitations regarding the conversion into DIN 50150.

A Attention:

Any illegal or unacceptable conversions may lead

to grave errors in the interpretation of measurement results.

1-10 Issue 03, 04/2005 Krautkramer DynaPOCKET

Page 17

Scope of supply and accessories 2

Krautkramer DynaPOCKET Issue 03, 04/2005 2-1

Page 18

Scope of supply and accessories Scope of supply

This chapter informs you about the scope of supply in

our standard package and the accessories available for

the DynaPOCKET.

It describes

❚ accessories included in the scope of supply of our

standard package

❚ recommended accessories

❚ spare parts requirements

2-2 Issue 03, 04/2005 Krautkramer DynaPOCKET

Page 19

Scope of supply Scope of supply and accessories

2.1 Scope of supply

Product name Description Order no.

DynaPOCKET Plus DynaPOCKET Plus – Portable hardness tester 35 158

according to the rebound method with an integrated

impact device D and digital display of the

measured value in HV, HB, HRB, HRC, HS, HL or

N/mm², including hardness reference block

consisting of:

Basic instrument DynaPOCKET 35 159

Hardness reference block MIC D 62 34 394

Operating manual German/English 28 674

Quick Reference Guide German/English 28 675

Transport case 09 554

Cleaning brush 34 420

2 AlMn batteries (type AAA) 100 612

Test attachment dia. 13.5 mm 34 656

Krautkramer DynaPOCKET Issue 03, 04/2005 2-3

Page 20

Scope of supply and accessories Scope of supply

Product name Description Order no.

DynaPOCKET DynaPOCKET – Portable hardness tester 35 114

according to the rebound method with an integrated

impact device D and digital display of the

measured value in HV, HB, HRB, HRC, HS, HL or

N/mm²

consisting of:

Basic instrument DynaPOCKET 35 159

Operating manual German/English 28 674

Quick Reference Guide German/English 28 675

Transport case 09 554

Cleaning brush 34 420

2 AlMn batteries (type AAA) 100 612

Test attachment dia. 13.5 mm 34 656

2-4 Issue 03, 04/2005 Krautkramer DynaPOCKET

Page 21

Recommended accessories Scope of supply and accessories

2.2 Recommended accessories

Product name Description Order no.

MIC 300 Technical book on hardness testing (German only) 28 837

MIC 1060 Grinding set for surface treatment 34 380

Dyna 41 1 set (5 pieces) of test attachments 34 536

for cylindrical surfaces

Dyna 42 1 set (5 pieces) test attachments 34 539

for spherical surfaces

Krautkramer DynaPOCKET Issue 03, 04/2005 2-5

Page 22

Scope of supply and accessories Spare parts requirements

2.3 Spare parts requirements

Product name Description Order no.

2 AlMn batteries (type AAA) 100 612

MIC D 62 Hardness reference block 620 HV100 34 393

MIC D 62-MPA Hardness reference block 620 HV100, 34 573

certified by the material testing institute MPA

Cleaning brush for impact device D 34 420

Standard test attachment for impact device D 34 312

Test attachment for impact device D, dia. 13.5 mm 34 656

Impact body D, new 34 443

Impact body D, exchange replacement by 34 572

GE Inspection Technologies Service

2-6 Issue 03, 04/2005 Krautkramer DynaPOCKET

Page 23

Operation 3

Krautkramer DynaPOCKET Issue 03, 04/2005 3-1

Page 24

Operation Preparation

3.1 Preparation

Inserting batteries

You can operate the DynaPOCKET with AAA-sized

AlMn batteries or rechargeable NiCd or NiMH batteries.

You need 2 pieces of each. AlMn batteries are recommended for the longest operating time.

– Open the cover of the battery compartment.

– Insert the batteries while observing the correct

polarity as shown in the battery compartment.

– Replace the lid and snap the cover back in place.

The lock must perceptibly snap in.

H Notes:

Remove the batteries from the instrument if you’re not

going to use it for a longer period of time!

Used or defective batteries are special waste and must

be disposed of according to the legal requirements!

The following icon indicates the battery voltage is getting too low:

In this case, exchange the batteries immediately. The

DynaPOCKET automatically switches off if the battery

voltage is too weak to ensure reliable operation. It may

happen that the instrument cannot be switched on

again without battery exchange.

H Note:

If you remove the batteries from the instrument for

more than about 3 minutes, the last settings are lost

(e.g. measurement mode and hardness scale).

You will find more information about batteries in

chapter 5.1.

3-2 Issue 03, 04/2005 Krautkramer DynaPOCKET

Page 25

Fundamental principles of operation Operation

3.2 Fundamental principles of

operation

Display and keys

The display consists of the following areas:

1 Average

If you have selected the measurement set mode,

the icon for average value is displayed.

2 Battery

The battery voltage icon flashes to indicate that the

batteries require replacement.

3 Measured value

The measured hardness value (or the statistical

average with measurement sets) is shown in large

digits in the middle of the display. This area also

applies to other text displays when selecting default

settings, and for error codes.

4 Hardness scale

The selected hardness scale is displayed in the

area above or below the measured value.

Krautkramer DynaPOCKET Issue 03, 04/2005 3-3

Page 26

Operation Fundamental principles of operation

The DynaPOCKET has two keys which you can use

to carry out all functions. Each activates several different functions, depending on the current mode of the

instrument.

Key ENTER/SET

Mode Function

Instrument off Switch-on

Single measurement None

Measurement set Start new measurement set

Setting Set selected parameter

Key MODE/CLEAR

Mode Function

Instrument off Switch-on

Single measurement None

Measurement set Display and delete last value

Setting Apply setting and

select the next parameter

3-4 Issue 03, 04/2005 Krautkramer DynaPOCKET

Page 27

OperationFundamental principles of operation

How to handle the impact device

Ensure the use of the propriate test attachment for

your application.

– Press either key to switch the instrument on.

– Place the DynaPOCKET with the test attachment on

a flat surface.

– Load the impact device by pressing the blue cylinder

down to the end stop and then moving it slowly back

to the initial position.

– Place the DynaPOCKET vertically on the test

surface.

– Use your thumb to press the release button.

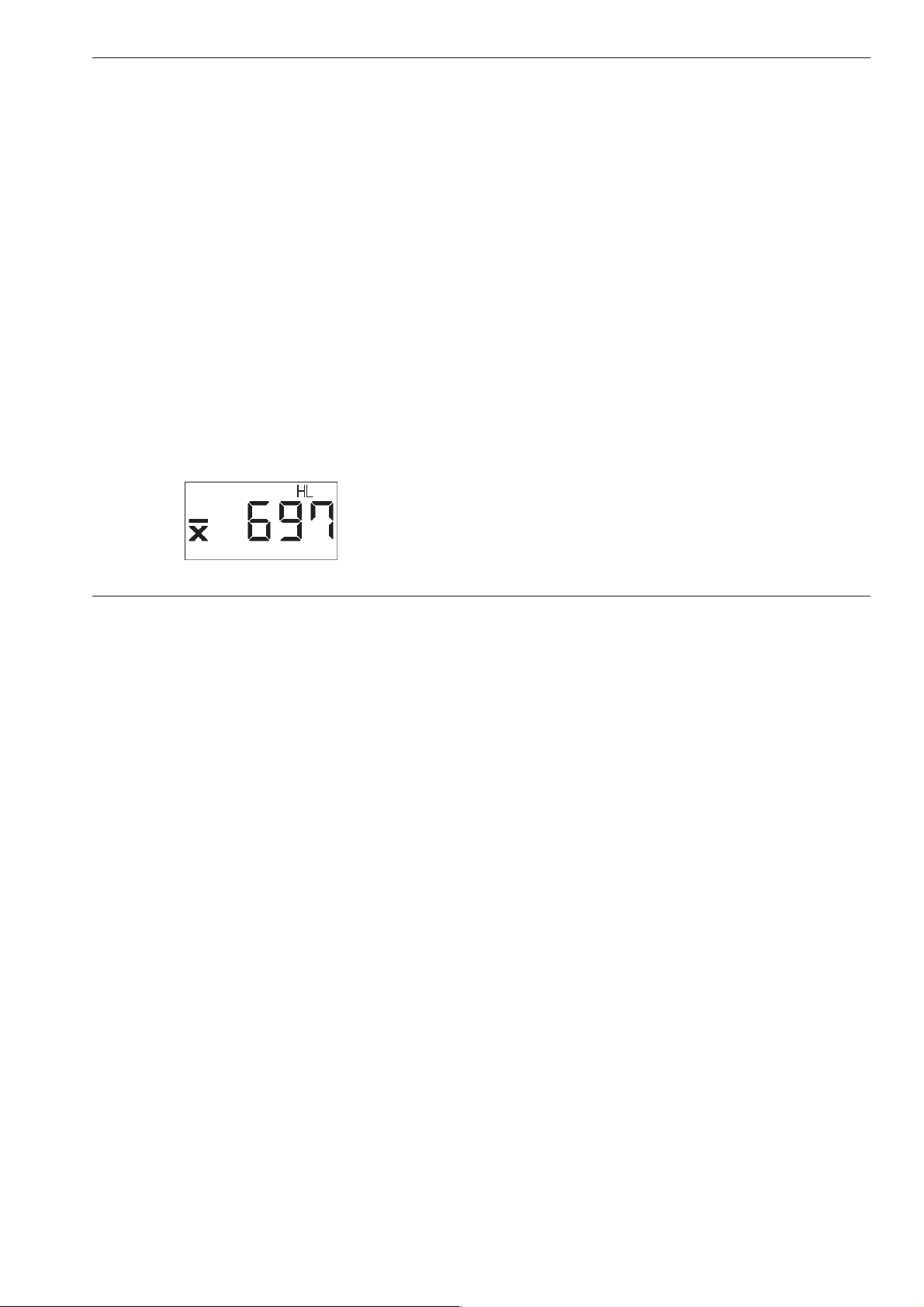

The measured value (or the statistical average) is

digitally displayed:

A Attention:

Do not load the impact device at the actual test location but (due to surface hardening) at another location

(e.g. table or another part of the test object). After that,

place it at a new test position for another measurement.

Do not perform two measurements at the same test

location, otherwise measuring errors may occur due to

surface hardening effects. Maintain a minimum spacing

of 3 mm.

The loading tube should not be pushed in (loading tube

must be at the farthest stop) when releasing for measurement.

Test attachments Dyna 41 and Dyna 42

The test attachments Dyna 41 and Dyna 42, which you

use for a better positioning on curved surfaces, have a

special geometry for use on cylindrical surfaces or

spherical surfaces (ref. chapter 2).

Krautkramer DynaPOCKET Issue 03, 04/2005 3-5

Page 28

Operation Hardness measurement

3.3 Hardness measurement

If you intend to measure on low-alloy or unalloyed

steels, no adjustment to the instrument setting is required because the DynaPOCKET is set to this material group as default setting.

When measuring on high-alloy steels as well as on

other materials, such as nonferrous metals, you have

to select the required material group before carrying

out the measurement.

Switch-on

– Briefly press either key to switch the DynaPOCKET

on.

Immediately after activating, the instrument carries out

a self-test and displays the installed software version

(e.g. 100 for software version 1.00) on the display. After that, the DynaPOCKET is ready for measurement.

Switch-off

The DynaPOCKET is automatically switched off if not

used for approx. 1 minute (single value) resp. for

approx. 3 minutes (measurement set).

This limits unnecessary battery drain to extend the

operating time.

H Note:

When switching off, the displayed reading (or the complete set with measurement sets) is deleted, the selected settings are retained.

If you remove the batteries from the instrument,

the individual settings are lost after about 3 minutes

(e.g. measurement mode and hardness scale).

Carrying out a measurement

– Check that the test attachment is suitable and that

the required settings (e.g. hardness scale) are

selected.

– Position the DynaPOCKET and carry out the mea-

surement. The measured values are digitally displayed.

3-6 Issue 03, 04/2005 Krautkramer DynaPOCKET

Page 29

OperationHardness measurement

Closing a measurement set

If you use measurement sets, you can close a measurement set at any time and start a new set. The previous measured values stored for the calculation and

their displayed arithmetic mean are deleted.

– Press the ENTER/SET key. The actual average

value flashes.

– Press the ENTER/SET key a second time to close

the current measurement set and to delete the

stored values. The display indicates 0 as a current

reading.

Deleting measured values

If you are using measurement sets, you can delete the

most recent reading at any time to remove an erraneous

measurement from the statistical average.

– Press the MODE/CLEAR key for about 2 seconds.

The last value measured flashes.

– Press the MODE/CLEAR key a second time to

delete the value. The measured value is deleted and

the average is automatically recalculated.

– You can repeat the procedure to sequence through

the readings deleting each until all measured values

are deleted.

H Note:

As long as the display is flashing, you can abort the

deletion.

– Briefly press the ENTER/SET key to cancel the

process of deleting.

Krautkramer DynaPOCKET Issue 03, 04/2005 3-7

Page 30

Operation Selecting instrument settings

3.4 Selecting instrument settings

Setup mode

You can set various parameters for your work with the

DynaPOCKET. To do this, change over to the setup

mode first.

– If necessary, press one of the two keys to switch

the instrument on.

– Press the two keys simultaneously to select the

setup mode.

The first setup parameter is displayed:

– Press the MODE/CLEAR key to activate the next

parameter. After the last parameter, the instrument

exits the setup mode and returns to the measurement display.

Measurement mode and display of

measured values

You can choose between single measurements and

measurement sets. In the case of single measurements,

the current individual value is displayed. Selecting measurement sets, the arithmetic mean calculated on the

basis of consecutive readings is displayed.

Setting options:

Measurement set with average display

Single measurement

– Activate setup mode and select the parameter S/A

with the MODE/CLEAR key.

– Press the ENTER/SET key in order to change the

current setting.

– Press the MODE/CLEAR key to confirm the se-

lected setting. Press the key again to exit the setup

mode and return to the measurement mode.

3-8 Issue 03, 04/2005 Krautkramer DynaPOCKET

Page 31

Selecting instrument settings Operation

Material group

If you intend to carry out measurements on high-alloy

steels or on other materials, such as nonferrous metals, you must set the DynaPOCKET to the required

material.

Choose the appropriate material from the 9 material

groups stored in the DynaPOCKET.

Setting options:

St Low-alloy/unalloyed steel and cast steel

ASt Tool steel

SSt Corrosion-resistant steel

GCI Gray cast iron

NCI Nodular graphite cast iron

AL Aluminum cast alloys

brS Brass

brZ Bronze

– Press the two keys simultaneously to select the

setup mode.

– Select the parameter MAt with the MODE/CLEAR

key.

– Press the ENTER/SET key to change the current

setting.

– Use the MODE/CLEAR key to confirm the selected

setting, and press the key again, if necessary, to go

to the measurement mode.

Cu Wrought copper alloys

Krautkramer DynaPOCKET Issue 03, 04/2005 3-9

Page 32

Operation Selecting instrument settings

Hardness scale

In the default setting, the measurement result is displayed as HL value (Leeb’s hardness according to the

rebound hardness testing method). You can select another hardness scale if required.

Setting options:

HS Shore

HB Brinell

HRB Rockwell B

HRC Rockwell C

HL Leeb

HV Vickers

N/mm2 Tensile strength

– Press the two keys simultaneously to select the

setup mode.

– Press the ENTER/SET key to change the current

setting.

– Use the MODE/CLEAR key to confirm the selected

setting, and press the key again, if necessary, to go

to the measurement mode.

The selected new hardness scale is shown in the display in the area above or below the measured value.

– Select the parameter SCAL with the MODE/CLEAR

key.

3-10 Issue 03, 04/2005 Krautkramer DynaPOCKET

Page 33

Conversion

The DynaPOCKET provides verious conversion options. The conversions according to DIN 50150 and

ASTM E140 only apply to the material group St (steel

and cast steel) (please refer to overview of conversion

ranges in chapter 7.2).

Setting options:

dynA DynaPOCKET-specific

din DIN 50150

E140 ASTM E140

– Press the two keys simultaneously to select the

setup mode.

– Select the parameter Con with the MODE/CLEAR

key.

– Press the ENTER/SET key to change the current

setting.

OperationSelecting instrument settings

– Use the MODE/CLEAR key to confirm the selected

setting, and press the key again, if necessary, to go

to the measurement mode.

Krautkramer DynaPOCKET Issue 03, 04/2005 3-11

Page 34

3-12 Issue 03, 04/2005 Krautkramer DynaPOCKET

Page 35

Maintenance and care 4

Krautkramer DynaPOCKET Issue 03, 04/2005 4-1

Page 36

Maintenance and care Care

4.1 Care

Caring for the instrument

Prevent dust and dirt from collecting in the guide tube

of the impact device.

Clean the instrument and the accessory parts only by

means of a dry cloth.

A Attention:

Don’t use water for cleaning! The DynaPOCKET is

neither watertight nor humidity-proof.

Don’t use solvents! The paint coating and the plastic

parts may become brittle or be damaged.

Caring for rechargeable batteries

The capacity and service life of batteries mainly depend on proper handling. You should therefore

observe the following tipswhen using rechargeable

batteries:

❚ before the initial start-up,

❚ after a storage period of 3 months or longer,

❚ after frequent partial discharge.

Charging the batteries

NiMH batteries or NiCads can be charged using only a

specifically approved external battery charger. Read

the operating manual of the battery charger and pay

special attention to the safety precautions recommended there.

4-2 Issue 03, 04/2005 Krautkramer DynaPOCKET

Page 37

Maintenance Maintenance and care

How to handle alkaline batteries

As improper handling or misuse of batteries may cause

damages to the instrument, please observe the following recommendations:

❚ Only use leak-proof batteries!

❚ Remove the batteries from the instrument if you’re

not planning to use it for extended periods of time!

A Attention:

Never attempt to charge AlMn batteries (explosion

hazard)!

H Note:

Used or defective batteries are special waste and must

be disposed of according to the legal requirements!

To protect the environment, please use storage batteries whenever possible!

4.2 Maintenance

The instrument requires basically no maintenance

work.

A Attention:

Any repair work may only be carried out by authorized

GE Inspection Technologies Service personnel.

Impact device

The impact device must be cleaned after approx. 1,000

measurements or in the case of incorrect measured

values.

– Unscrew the test attachment and remove the impact

body from the guide tube.

– Clean the test attachment, impact body and test tip

using a dry cloth.

– Clean the inside of the guide tube using the cleaning

brush.

A Attention:

Never use oil to clean the impact device!

Krautkramer DynaPOCKET Issue 03, 04/2005 4-3

Page 38

4-4 Issue 03, 04/2005 Krautkramer DynaPOCKET

Page 39

Function check and troubleshooting 5

Krautkramer DynaPOCKET Issue 03, 04/2005 5-1

Page 40

Function check and troubleshooting Checking the function

5.1 Checking the function

Please check the functioning of the impact device and

hardness tester by measuring the HL hardness value

on the hardness reference block before using the instrument for the first time, and afterwards from time to

time (always after 1,000 impacts at the latest).

– Take the hardness reference block from the case

and place it on a solid base support.

– Carry out 3 to 5 measurements on the hardness

reference block. Ensure that the spacing between

the measurement locations is a minimum of 3 mm.

– Read the average and compare it with the reference

value of the hardness reference block.

In the case of larger deviations, the tungsten-carbide

ball functioning as a spherical test tip must be replaced.

5.2 Troubleshooting

When turned on, the DynaPOCKET carries out

an automatic system self-test. In addition, the

DynaPOCKET’s self-monitoring function is active

during the operation.

If system errors or operating errors should occur, they

are displayed by a corresponding error code (e.g. E 0.1).

5-2 Issue 03, 04/2005 Krautkramer DynaPOCKET

Page 41

Error codes Function check and troubleshooting

Error codes

Code Cause Action

E 0.0 Internal error in the EPROM/RAM Remove the batteries and re-insert

them after approx. 1 minute.

Switch the instrument on; if the error

occurs again, contact your nearest

GE Inspection Technologies Service.

E 0.1 Battery voltage is too low Exchange the batteries.

E 0.2 Error with self-test Switch the instrument on again; if the

error occurs again, contact your nearest

GE Inspection Technologies Service.

E 1.0 Evaluation error, impossible to carry out Carry out the measurement once again.

a correct evaluation of the measurement. If necessary, clean the impact device.

E 1.1 Evaluation of the measurement is not yet Please carry out the measurement again.

complete.

Krautkramer DynaPOCKET Issue 03, 04/2005 5-3

Page 42

5-4 Issue 03, 04/2005 Krautkramer DynaPOCKET

Page 43

Technical data 6

Krautkramer DynaPOCKET Issue 03, 04/2005 6-1

Page 44

Technical data

Housing

Setup Miniaturized processor-controlled rebound hardness tester.

Impact device with integrated electronics.

Battery compartment 2 AAA cells, lid with snap-in lock

Dimensions (dia. × L) approx. 38 × 170 mm / 1.5 x 6.7 in

Weight approx. 200 g / 0.4 lb.

Impact energy approx. 12 Nmm

Impact device Dyna D (for all materials enabling testing)

Switch-on press of a key

Switch-off automatic switch-off after approx. 1 min (single measurement mode) /

3 min (measurement set with average display)

Display and keypad

Display LCD, display of the hardness value via 4 seven-segments, status indicators

Keypad Membrane keypad with 2 click keys

6-2 Issue 03, 04/2005 Krautkramer DynaPOCKET

Page 45

Power supply and operating time

Batteries 2 × size AAA cells. AlMn or rechargeable with NiCad or NiMH,

(external charging only).

Operating time > 4,000 measurements

Battery charge indicator Low-Batt indicator, hardware switch-off with undervoltage.

Ambient conditions

Operation –10 °C to +50 °C / 14 °F to 122 °F

Storage –20 °C to +70 °C / -4 °F to 150 °F

Rel. humidity of air 10 to 80 % (no condensation allowed, moisture condenstation excluded)

Vibration resistance 5 g (5 to 150 Hz, half-sine)°F

Shock resistance 11 g (11 ms, sine)

Technical data

Krautkramer DynaPOCKET Issue 03, 04/2005 6-3

Page 46

Technical data

Evaluation

Measured quantity Characteristic of the induced coil voltage,

determination of the hardness value according to HL = V1/V2 × 1000

Data buffer Battery-backed RAM memory. With loss of battery voltage the data and set

values are lost after 3 minutes.

Measurement uncertainty + 4 HL of the average (5 measurements) from reference value of the hardness

reference plate (0.5 % at 800 HL)

Note: The given tolerances apply for measurements at room temperature.

Statistics Average

Conversion according to DIN, ASTM, Dyna

Conversion scales HL (1.0)

and resolution HV (1.0)

HB (1.0)

HS (0.1)

HRC (0.1)

HRB (0.1)

N/mm² (5.0)

Material groups please see page 7-4

Conversion ranges please see page 7-5

6-4 Issue 03, 04/2005 Krautkramer DynaPOCKET

Page 47

The rebound hardness testing method 7

Krautkramer DynaPOCKET Issue 03, 04/2005 7-1

Page 48

The rebound hardness testing method The hardness testing method

7.1 The hardness testing method

In the following section, you will find some helpful information about the hardness testing method of the

DynaPOCKET.

The DynaPOCKET is an integrated instrument, consisting of impact body, impact device and display unit.

The impact body has a tungsten-carbide ball as a

spherical test tip, and a permanent magnet for generating a voltage pulse. The impact device has a spring

drive for loading and impelling the impact body, and an

induction coil for detecting the magnet in the impact

body. In rebound hardness testing, the speed variation

due to the impact body’s collision with the workpiece

surface is measured.

To carry out the measruement, the impact energy is

set via the spring. The impact body located in the tube

of the impact device is impelled against the test surface by means of the release button.

In this process, the impact body’s magnet induces a

voltage signal in the coil, with the amplitude of this

signal being proportional to the impact phase speed

(Ip). The impact causes a plastic deformation of the

material, and a permanent spherical indentation is cre-

ated in the surface. This plastic deformation brings

about a loss of energy of the impact body, and consequently leads to a lower speed after the rebound phase

(Rp).

The hardness value is calculated from the ratio of

these two speeds and displayed as follows:

HL = 1000 Ip/Ap

please also refer to VDI reports no. 308 (1978).

The speed ratio is determined exactly at the time of the

impact/rebound using the special signal processing. The

speed ratio is therefore unaffected by the impact direction. As opposed to this, other rebound hardness testers

require that the impact direction be predefined in fixed

steps (effects of gravitation on the speed ratio) – which

is a considerable handicap with frequently changing test

positions.

H Note:

With DynaPOCKET, it is not necessary to specify the

impact direction.

7-2 Issue 03, 04/2005 Krautkramer DynaPOCKET

Page 49

Conversion of hardness values The rebound hardness testing method

7.2 Conversion of hardness

values

Please observe the following with regard to the conversion of hardness values (ref. DIN 50 150 or ASTM

E 140):

Hardness values which are measured according to

different methods cannot be converted into one another via generally applicable relations.

The reason for this lies, firstly, in the fact that the penetration behaviour of a material is determined by its

stress-deformation behaviour. Secondly, the shape and

the material of the indenter, the size of indentation, and

consequently the zone measured differ according to

the hardness testing method.

You should therefore know that the conversion of hardness values both into one another and into tensile

strength values can be inaccurate or unacceptable,

depending on the material, its treatment and surface

finish.

Indicate hardness values according to the scale determined experimentally with the hardness testing method

used (e.g. rebound method in HL).

Only carry out conversions:

❚ if the specified test method cannot be applied, e.g.

because there is no suitable instrument available,

❚ if it’s impossible to take the required samples for the

specified test method.

Special aspects related to the conversion in the

DynaPOCKET

In the default setting, the conversion of hardness values

into other scales, which you can select on the instrument, is carried out according to the instrument-specific

conversion tables; however, you can also carry out a

conversion according to DIN 50 150 or ASTM E 140. All

limitations mentioned in these standards regarding the

conversion apply.

Moreover, please keep in mind that the conversions

according to DIN 50 150 and ASTM E 140 (for Rockwell

scales) only apply to the material group 1 (low-alloy/

unalloyed steel). The instrument-specific conversion is

used for other material groups after selecting DIN 50

150 or ASTM E 140.

DynaPOCKET provides 9 material groups from which

you have to choose the one corresponding to your test

material.

Krautkramer DynaPOCKET Issue 03, 04/2005 7-3

Page 50

The rebound hardness testing method Conversion of hardness values

Please take into account with the steel material groups

that the hardness values situated in the lower hardness ranges (up to approx. 500 HL) are less materialdependent than those in the upper ranges. Please

check the calibration of your instrument, in particular

if the hardness values in question are situated above

500 HL.

You will find the conversion options available for the

individual material groups stored in the DynaPOCKET

in the overview given on the next page. Due to the

higher material dependence, converted hardness values show considerably larger differences in the upper

hardness ranges.

Material groups

Code designation Material group

St Low-alloy/unalloyed steel and cast steel

ASt Tool steel

SSt Corrosion-resistant steel

GCI Gray cast iron

NCI Nodular graphite cast iron

AL Aluminum cast alloys

brS Brass

brZ Bronze

Cu Wrought copper alloys

7-4 Issue 03, 04/2005 Krautkramer DynaPOCKET

Page 51

The rebound hardness testing methodConversion of hardness values

Application ranges of the conversion tables

Conversion Material HV HB HRB HRC HS N/mm²

mode group

DIN St 80 – 1000 80 – 650 40 – 106 19 – 70 30 – 100 275 – 2200

ASTM St 90 – 1000 90 – 560 52 – 102 19 – 70 30 – 100 300 – 2200

Dyna St 75 – 1000 75 – 700 35 – 100 20 – 70 30 – 100 250 – 2200

ASt 75 – 1000 20 – 70

SSt 75 – 1000 75 – 700 35 – 100 20 – 70

GCI 90 – 350

NCI 120 – 400

AL 20 – 180 10 – 85

brS 40 – 180 10 – 95

brZ 45 – 320

Cu 45 – 320

Measuring range for the default scale HL: 150 – 1000

Krautkramer DynaPOCKET Issue 03, 04/2005 7-5

Page 52

The rebound hardness testing method The treatment of test material

7.3 The treatment of test material

In order to obtain reliable and reproducible measurement results, you have to observe a few notes on the

quality and treatment of the test material. Therefore,

please read the following information.

Surface quality

The surface must be clean, free of oil, grease and

dust. The peak-to-valley height or surface roughness

should not exceed 10 micrometers.

You should therefore grind off rougher surfaces, for

example using the battery-driven grinder MIC 1060

(ref. chapter 2).

Curved surfaces

In the case of surfaces showing a radius of curvature

< 30 mm (convex or concave), a correspondingly

shaped test attachment must be used for a firm and

secure positioning of the impact device.

Measurements on small objects

Due to the impact effect of the impact device, vibrations liable to cause a corruption of the measurement

results may occur with smaller or more lightweight test

objects.

❚ Objects having a mass less than 2 kgs must always

be fixed to the support using couplant so that no

vibrations can occur.

❚ Test objects having a mass between 2 kgs and

5 kgs must be placed on a large metal support

(e.g. a table) so that they are not moved or do not

start to vibrate by to the impact. If necessary,

couple the test objects using our couplant ZG.

Minimum wall thicknesses

Similar problems occur with test objects having small

wall thicknesses. Walls, e.g. on tubes, can start to

vibrate due to the impact of the impact device in a

similar way as the membrane of a drum. This generally

results in indicating too low hardness values.

7-6 Issue 03, 04/2005 Krautkramer DynaPOCKET

Page 53

For this reason, we recommend minimum test object

wall thicknesses of 20 mm for rebound hardness testing.

For measurements below 20 mm wall thickness, the

use of the UCI hardness tester MIC 10 is recommended. You should compare the measured hardness

values to those of a stationary hardness tester.

The rebound hardness testing methodThe treatment of test material

Krautkramer DynaPOCKET Issue 03, 04/2005 7-7

Page 54

The rebound hardness testing method Information about the statistical evaluation

7.4 Information about the

statistical evaluation

With a corresponding setting, the DynaPOCKET displays the statistical average ( x¯ ).

Every measurement is subject to a measurement uncertainty. In this connection, the measuring errors consist of the following single errors:

❚ the basic measurement inaccuracy of the method of

measurement used,

❚ the handling of the probes,

❚ the preparation of the material to be measured

(surface or heat treatment),

❚ the homogeneity of the material to be measured,

❚ external influences (contamination, humidity, tem-

perature).

The statistiscal evaluation is intended to help you to

better assess your measurements and to make more

reliable decisions on the quality of the material under

test.

The average of a measurement set is the more accurate, the more single measurements you carry out. At

the same time, however, many single measurements

mean that more “outliers” are included. For this reason,

the difference between minimum value and maximum

value is no reliable yardstick for the evaluation of a

measurement set containing more than around 12 measuring points.

The average ( x¯ ) is arithmetically calculated:

(x1 + x2 + x3 + ... + xn)

x¯ =

with

x¯ = Average

x = Single measurement

n = Number of measurements

n

7-8 Issue 03, 04/2005 Krautkramer DynaPOCKET

Page 55

Annex 8

Krautkramer DynaPOCKET Issue 01, 12/99 8-1

Page 56

Annex EU declaration of conformity

8.1 EU declaration of conformity

The DynaPOCKET meets the requirements of the following EU directives:

❚ 89/336/EEC (Electromagnetic compatibility)

The conformity with the requirements of the

EU directive 89/336/EEC is proved by the compliance

with the following standard specifications

❚ EN 55011, 12/1998, Class A, Group 2

❚ EN 50082-2, 02/1996

8.2 Manufacturer/

Service addresses

The Krautkramer DynaPOCKET is manufactured by:

GE Inspection Technologies GmbH

Robert-Bosch-Straße 3

D – 50354 Hürth

Phone +49 (0) 22 33 - 601 111

Fax +49 (0) 22 33 - 601 402

The Krautkramer DynaPOCKET is manufactured according to state-of-the-art methods using high-quality

components. Thorough in-process inspections or intermediate tests and a quality management system certified to DIN EN ISO 9001 ensure an optimum quality of

conformance of the instrument. Should you nevertheless detect an error on your instrument or on the software, inform your local GE Inspection Technologies

Service indicating the error and describing it.

If there is anything special that you would like to know

about the use, handling, operation and specifications

of the system, please contact your nearest GE Inspection Technologies representative or directly:

8-2 Issue 03, 04/2005 Krautkramer DynaPOCKET

Page 57

Manufacturer/Service addresses Annex

GE Inspection Technologies GmbH

Service-Center

Robert-Bosch-Straße 3

D – 50354 Hürth

or:

Postfach 1363

D – 50330 Hürth

Phone +49 (0) 22 33 - 601 111

Fax +49 (0) 22 33 - 601 402

France

GE Inspection Technologies Scs

SAC Sans Souci

68, Chemin des Ormeaux

F – 69760 Limonest

Phone +33 47 - 217 92 20

Fax +33 4 7 - 847 56 98

Great Britain

GE Inspection Technologies

892 Charter Avenue

Canley

GB – Coventry CV4 8AF

Phone +44 845 - 130 - 3925

Fax +44 845 - 130 - 5775

USA

GE Inspection Technologies, LP

50 Industrial Park Road

USA – Lewistown, PA 17044

Phone +1 717 - 242 03 27

Fax +1 717 - 242 26 06

Krautkramer DynaPOCKET Issue 03, 04/2005 8-3

Page 58

8-4 Issue 01, 12/99 Krautkramer DynaPOCKET

Page 59

Index 9

Krautkramer DynaPOCKET Issue 03, 04/2005 9-1

Page 60

Index

A

Accessories . . . . . . . . . . . . . . . . . . . . . . 2 -5

Addresses . . . . . . . . . . . . . . . . . . . . . . . 8 -2

Ambient conditions . . . . . . . . . . . . . . . . 6 -3

Attachment . . . . . . . . . . . . . . . . . . . . . . 3 -5

B

Batteries . . . . . . . . . . . . . . . 1 -2, 2 -3, 4 -2

C

Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 -2

Charging handle . . . . . . . . . . . . . . . . . . . 1 -8

Check . . . . . . . . . . . . . . . . . . . . . . . . . . 5 -2

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . 4 -3

Cleaning of impact device . . . . . . . . . . . 4 -3

Control elements . . . . . . . . . . . . . . . . . . 1 -8

Conversion . . . . . . . . 1 -10, 3 -11, 6 -4, 7 -3

Conversion table . . . . . . . . . . . . . . . . . . 7 -5

Curved surfaces . . . . . . . . . . . . . . . . . . . 3 -5

D

Declaration of conformity . . . . . . . . . . . . 8 -2

Deleting measured values . . . . . . . . . . . 3 -7

Display . . . . . . . . . . . . . . . . . 1 -8, 3 -3, 6 -2

DynaPOCKET . . . . . . . . . . . . . . . . . . . . 1 -7

E

Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 -2

Error codes . . . . . . . . . . . . . . . . . . . . . . 5 -3

EU declaration of conformity . . . . . . . . . 8 -2

Evaluation . . . . . . . . . . . . . . . . . . . . . . . 6 -4

F

Function check . . . . . . . . . . . . . . . . . . . 5 -2

Functional description . . . . . . . . . . . . . . 7 -2

9-2 Issue 03, 04/2005 Krautkramer DynaPOCKET

Page 61

Index

G

Grinding set . . . . . . . . . . . . . . . . . . . . . . 2 -5

H

Hardness measurement . . . . . . . . . . . . . 3 -6

Hardness reference block . . . . . . . . . . . 2 -3

Hardness scale . . . . . . . . . . . . . 1 -10, 3 -10

Hardness testing . . . . . . . . . . . . . . . . . . 1 -5

Hardness testing method . . . . . . . . . . . . 7 -2

I

Impact device . . . . . . . . . . . . . . . 1 -8, 3 -5

Impact device cleaning . . . . . . . . . . . . . 4 -3

Inserting batteries . . . . . . . . . . . . . . . . . 3 -2

Instrument settings . . . . . . . . . . . . . . . . 3 -8

K

Keypad. . . . . . . . . . . . . . . . . . . . . . . . . . 6 -2

Keys . . . . . . . . . . . . . . . . . . . . . . 1 -8, 3 -4

M

Maintenance . . . . . . . . . . . . . . . . . . . . . 4 -3

Material . . . . . . . . . . . . . . . . . . . . . . . . . 1 -9

Material group . . . . . . . . . . . . . . . . . . . . 3 -9

Material groups . . . . . . . . . . . . . . . . . . . 7 -3

Mean . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -8

Measurement mode . . . . . . . . . . . . . . . . 3 -8

Measurement set . . . . . . . . . . . . . . . . . . 3 -7

Method . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -6

O

Operating keys . . . . . . . . . . . . . . . . . . . . 1 -8

Operating time . . . . . . . . . . . . . . . . . . . . 6 -3

Operation . . . . . . . . . . . . . . . . . . . . . . . . 3 -3

Operator training . . . . . . . . . . . . . . . . . . 1 -5

Order numbers . . . . . . . . . . . . . . . 2 -3, 2 -4

P

Position . . . . . . . . . . . . . . . . . . . 1 -10, 3 -5

Power supply . . . . . . . . . . . . . . . . . . . . . 6 -3

Preparation . . . . . . . . . . . . . . . . . . . . . . 3 -2

Krautkramer DynaPOCKET Issue 03, 04/2005 9-3

Page 62

Index

R

Rebound method . . . . . . . . . . . . . . . . . . 1 -7

Release button . . . . . . . . . . . . . . . . . . . . 1 -8

Requirements . . . . . . . . . . . . . . . . . . . . . 1 -6

Results . . . . . . . . . . . . . . . . . . . . . . . . . 1 -5

S

Safety information . . . . . . . . . . . . . . . . . 1 -2

Scale . . . . . . . . . . . . . . . . . . . . . 1 -10, 3 -10

Scope of supply . . . . . . . . . . . . . . . . . . . 2 -3

Service addresses . . . . . . . . . . . . . . . . . 8 -2

Setting options . . . . . . . . . . . . . . . . . . . . 3 -8

Settings . . . . . . . . . . . . . . . . . . . . . . . . . 3 -8

Single measurement . . . . . . . . . . . . . . . 3 -8

Software . . . . . . . . . . . . . . . . . . . . . . . . 1 -2

Spare parts . . . . . . . . . . . . . . . . . . . . . . 2 -6

Surface . . . . . . . . . . . . . . . . . . . . . . . . 1 -10

Surface, curved . . . . . . . . . . . . . . . . . . . 3 -5

Surfaces . . . . . . . . . . . . . . . . . . . . . . . . 7 -6

Switch-off . . . . . . . . . . . . . . . . . . . . . . . . 3 -6

Switch-on . . . . . . . . . . . . . . . . . . . . . . . . 3 -6

Symbols . . . . . . . . . . . . . . . . . . . . . . . . 1 -4

System errors . . . . . . . . . . . . . . . . . . . . 5 -2

T

Technical data . . . . . . . . . . . . . . . . . . . . 6 -2

Test attachment . . . . . . . . . . 1 -8, 2 -3, 3 -5

Test material . . . . . . . . . . . . . . . . 1 -9, 7 -6

Test method . . . . . . . . . . . . . . . . . . . . . . 1 -6

Test position . . . . . . . . . . . . . . . . 1 -10, 3 -5

Test results . . . . . . . . . . . . . . . . . . . . . . 1 -5

Testing method. . . . . . . . . . . . . . . . . . . . 7 -2

Training . . . . . . . . . . . . . . . . . . . . . . . . . 1 -5

Troubleshooting . . . . . . . . . . . . . . . . . . . 5 -2

W

Wall thickness . . . . . . . . . . . . . . . 1 -9, 7 -6

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . 7 -6

9-4 Issue 03, 04/2005 Krautkramer DynaPOCKET

Loading...

Loading...