Page 1

GE

Inspection Technologies

DynaPOCKET

Pocket-Size Hardness Tester

standardized to ASTM A 956

Page 2

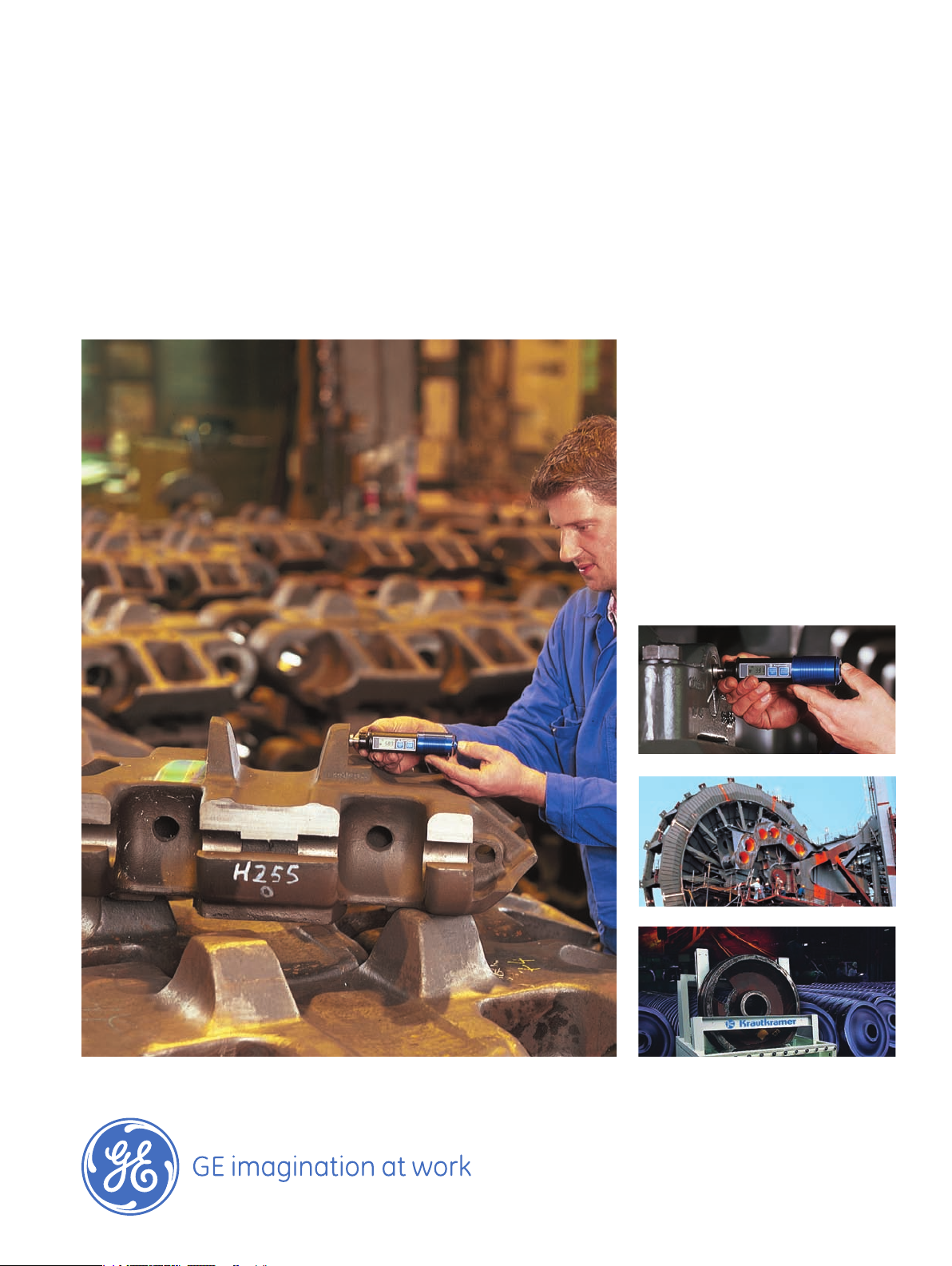

Mobile hardness testing - faster, easier.

With no trouble at all.

Are you facing the task of having

to determine the hardness of large,

non-transportable components?

Do you still work with a Poldi Hammer?

Do you need an economic and easy

method for on-site hardness testing?

In this case, we would recommend

to you our small, compact, rebound

hardness tester DynaPOCKET which

has no trouble at all in solving such

test tasks. This is possible because

the instrument’s size is yet smaller,

it’s yet faster in operation, and yet

easier to use.

With compact setup.

The DynaPOCKET integrates the

impact device and display or

evaluation unit into one instru

-

ment. This means: small dimen

sions, low weight, no cables. As

a result, you’ll have an extremely

compact hardness tester at your

disposal which really fits into any

pocket, and goes with you every

-

where without any problem.

No matter which test location,

which test position, and which

test direction you wish to work

in, the DynaPOCKET is the right

instrument.

With easy operation.

Needless to say, we have ensured

easy and straightforward opera

tion: All functions can be activated

in the DynaPOCKET with just two

keys.

The DynaPOCKET makes hardness

testing fast and easy as never

before: switching on, measuring,

and reading - in a matter of

seconds! The hardness value is

immediately digitally displayed

on the large and easy-to-read

LCD display.

Page 3

Naturally including innovative technology.

The “dynamic” method.

The DynaPOCKET operates according to the rebound method in which

an impact body is impelled against

the test surface by spring force.

Impact and rebound velocities are

each measured in non-contact

mode; the hardness value is calcu

lated on the basis of these two

readings. The harder the material,

the higher the rebound velocity and

the displayed hardness value. The

rebound method offers measure

ment with high precision and

reproducibility, and consequently

an especially high test reliability.

The patented technology.

Now, that’s what we call easy

testing: when using the DynaPOCKET,

you’ll measure immediately, every

where, in any direction – and all this

with constant accuracy. This is

ensured by our patented signal

processing which spares you the

trouble of having to input additional

correction factors for the impact

direction, no matter if you’re

measuring in horizontal or over

-

head positions.

The ease of use.

We even make the calibration of

the DynaPOCKET easy for you:

Standard conversion tables for

nine material groups are stored in

the instrument from which you

can choose the one that suits your

application. You’ll easily recognize

the material groups by the alphanu

merical abbreviations displayed by

the instrument (e.g. St for low-alloy/

unalloyed steel and cast steel, GCI

for gray cast iron, Cu for wrought

copper alloys, etc.).

The measurement itself is child’s

play, and the measured hardness

value is directly displayed. Of course

you can decide for yourself whether

you wish to see the single reading

or the arithmetical mean or aver

-

age value of a complete measure

-

ment set.

It goes without saying that the

DynaPOCKET makes various

hardness scales available for you

to choose from. A conversion is

possible to the following scales:

• HL Leeb

• HS Shore

• HB Brinell

• HRB Rockwell B

• HRC Rockwell C

• HV Vickers

• N/mm² Tensile strength

The DynaPOCKET is also able to

make conversions according to the

standard specifications DIN 50150

and ASTM E 140, provided the

material group in question is lowalloy/unalloyed steel and cast steel.

The instrument-specific conversion

tables apply to the other materials.

You can directly read the measured

hardness value on the large LCD display.

At the same time, the selected hardness

scale (in this case HL) and the option

Average x_ is displayed. The battery icon

informs you about the current battery

charge condition.

In the setup or configuration mode,

you can select different settings,

in this case e.g. the required hardness

scale (SCAL), or a material group (MAt).

Other setting options: Single/Average,

conversion according to DIN 50150,

ASTM E 140, or instrument-specific

conversion.

Page 4

www.ge.com/inspectiontechnologies

© 2006 General Electric Company. All Rights Reserved. We reserve the right to technical modifications without prior notice. GEIT-20029EN (04/06)

This is where the small DynaPOCKET comes out real big.

Mobile on site.

The DynaPOCKET is an instrument

for on-site hardness testing. Thanks

to its compact size, it enables tests

in almost any position, especially

in places where the access is

difficult due to the test object’s

geometry. Heavy, non-transport

able components are also a case

for the DynaPOCKET, the same as

permanently installed system

parts or machines.

Application examples.

Rebound hardness testing using

the DynaPOCKET is mainly suitable

for solid workpieces made of steel

or cast materials. The following are

typical applications:

• large, coarse-grain components

with surfaces as rolled

• forgings with inhomogeneous

surface structures

• workpieces made of cast

materials of all types

• material sorting in material

stores

• hardness testing of large series

products during the production.

Test method

Rebound hardness testing according

to ASTM standard specification A 956;

dynamic measuring method; ratio of

rebound (Rp) and impact (Ip) veloci

ties with output of hardness in Leeb’s

hardness value HL = 1000 Rp/Ip

Setup

Miniaturized processor-controlled

rebound hardness tester; impact

device and integrated electronics

Integrated impact device

Dyna D (tungsten carbide spherical

test tip); impact energy approx.

12 N/mm², diameter of spherical test

tip 3 mm / 0.1“

Materials tested

Forged, rolled and cast materials

Stored material groups

Low-alloy/unalloyed steel and cast

steel; tool steel; corrosion-resistant

steel; gray cast iron; nodular graph

ite iron; aluminum cast alloys; brass;

bronze; wrought copper alloys

Measuring range

Depending on the material group,

e.g for low-alloy steel: 150-1000 HL;

75-1000 HV; 75-700 HB; 35-100 HRB;

20-70 HRC; 30-100 HS; 250-2200 N/

mm²; 9 fixed material groups stored in

the instrument

Display

LCD, 4-digit display of the hardness

value and status symbols

Conversion scales and resolution

HL (1.0); HV (1.0); HB (1.0); HS (0.1);

HRC (0.1); HRB (0.1); N/mm² (5.0)

Conversion

According to DIN 50150, ASTM E 140,

instrument-specific conversion (Dyna)

Statistics

Display of average value

Automatic instrument switchoff

After 3 min. of non-use in the average

mode

Keypad

Membrane keypad with 2 keys

Specifications and Accessories

Power supply

Battery operation (2 x AAA cells, NiCd,

NiMH or AlMn)

Operating time

>4000 measurements depending on

battery type

Battery charge indication

LowBatt indicator, instrument switchoff

with low voltage

Permissible temperatures

Operation: -10°C to +50°C (14°F to 122°F)

Storage: -20°C to +70°C (-4°F to +158°F)

Lower temperatures according to

individual tests

Weight

approx. 200 g / 0.4 lb.

Dimensions

38 x 170 mm / 1.5" x 6.7"

(diameter x length)

Test attachments

For better positioning with curved

surfaces; for spherical, hollow spheri

cal, cylindrical and hollow cylindrical

surfaces (Dyna 41 and Dyna 42)

Other accessories

Transport case, cleaning brush,

hardness reference block MIC D62,

hardness reference block MPAcertified, grinding set for surface

treatment, exchange impact bodies.

Loading...

Loading...