Page 1

GE

Inspection Technologies

dynamic 41 digital detectors

GE’s superior image quality X-ray detectors for

2D radiographic inspection and 3D CT

dynamic 41|100 and 41|200

Key features & benets

• 16” X-ray detectors with 100 µm / 200 µm pixelsize

(16 or 4 MPixels) designed and optimized for longterm

reliability at industrial high-energy use

• High-resolution images for easy detection of subtle

indications (up to 50 µm /100 µm feature detection

with minifocus X-ray tubes)

• Next generation photodiode design for up to 10x

improvedeciencyandsensitivitycomparedto

state of the art 200 µm pixel DXR detectors allows

2x resolution increase without cycle time impact

(41|100) or 2-3x cycle time increase without

image quality impact (41|200)

• Detection of 2x smaller defects without increase of

geometricmagnicationallowsimagingoflarge

objects at higher resolution (41|100)

Page 2

GE’s dynamic 41 detectors -

Powering the next generation of X-ray inspection and CT

The dynamic 41|100 and 200 detectors are the rst in GE’s next generation industrial X-ray at panel detector

platform. The 41|100 detector combines superior image quality with improved detection speed at 410 x 410 mm²

detection area and 100 μm pixel size. It achieves 100 micron results at 200 micron eciency and contrast-to-noise-

ratio, while the new 41|200 detector increases industrial inspection speed by factor 2-3, allowing high throughput

fully automated CT on the production oor.

Based on proprietary GE Healthcare X-ray detector technology, GE Inspection Technologies exclusively oers its

rst 100 μm, 16M pixel detector designed and optimized exclusively for rough and high-energy industrial X-ray ap-

plications to its radiography and CT customers. GE’s proprietary Endurance

tion and brightness compared to conventional GadOx or other powder based scintillators.

TM

CsI scintillator oers superior resolu-

100 µm imaging: See more to know more

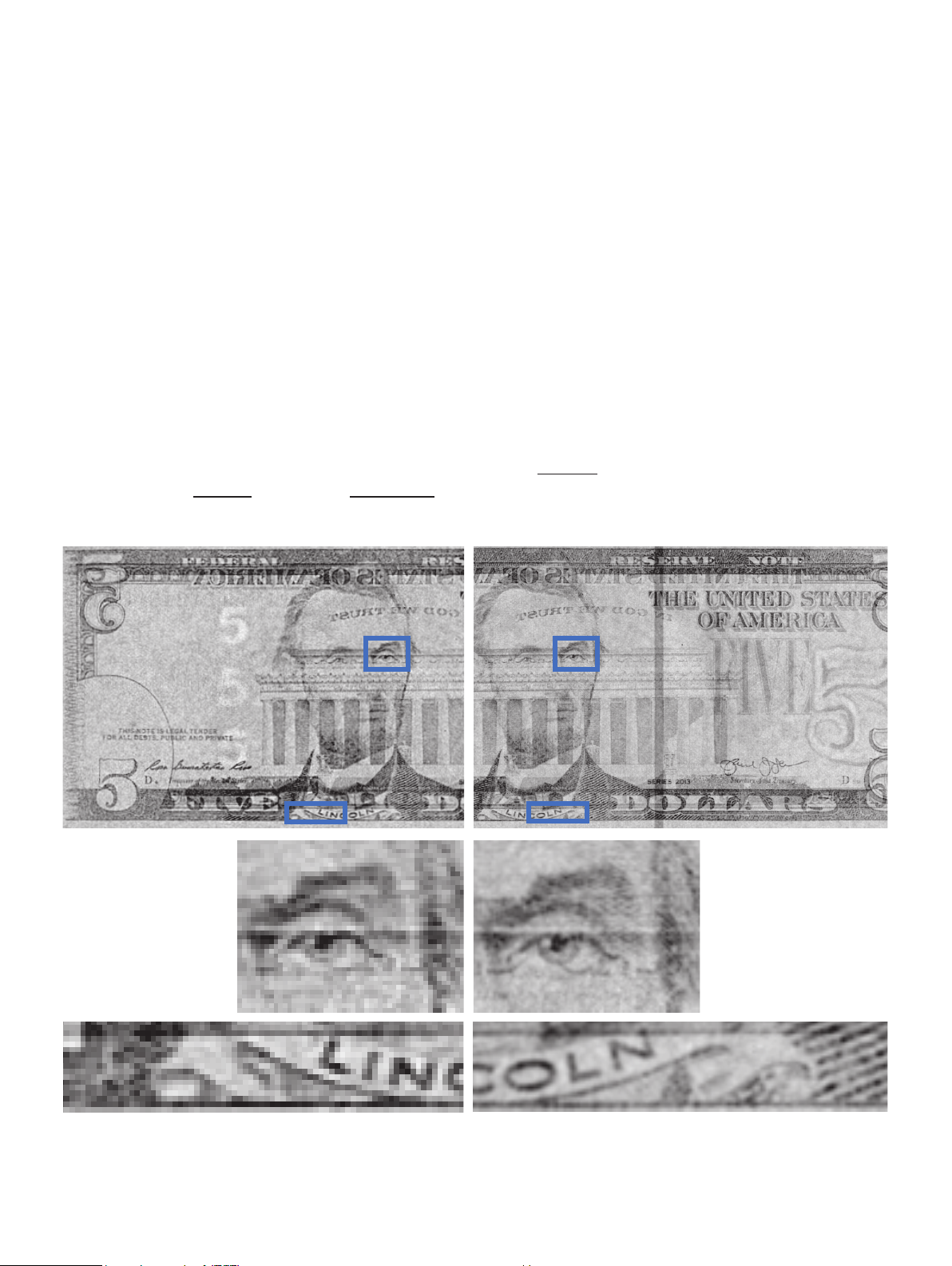

The 5 US dollar bill comparison clearly visualizes the quality gain: at identical kV parameters, the new dynamic 41|100

detector provides doubled resolution at comparable signal-to-noise-ratio and dynamic range.

Conventional DXR250 200 µm pixel detector dynamic 41|100 detector

State of the art DXR at panel detector with

200 μm pixel size

Superior GE dynamic 41|100 detector providing 100 µm

pixel size for superior image quality and doubled

resolution to detect two times smaller defects

Page 3

Key Applications - Increasing industrial

inspection quality and productivity

The dynamic 41 detectors demonstrate their excellent performance especially

at industrial CT for failure analysis and 3D metrology as well as at 2D radiographic inspection of parts such as

•Aerospaceandautomotivecastings

•Additivemanufacturedandcompositeparts

Doubled productivity at same quality level

Due to its equivalent or even higher sensitivity compared to state of the art 200 μm pixelsize detectors, the new

dynamic 41|100 detector allows a 2x resolution increase without cycle time impact or comparable result quality at signi-

cant reduced acquisition time (dynamic 41|100 & 200). The comparison below shows pores in a scanned aluminum casting.

State of the art detector

DXR250 (200 µm pixel)

Baseline scan time

Doubled resolution

Without the need to change the system geometry parameters, the new

dynamic 41|100 detector allows imaging of larger objects at the

same resolution due to less required geometric

magnication. Alternatively, users are

able to detect 2x smaller

defects without

increasing

the geometric

magnication.

X-ray source

Advanced dynamic 41 series

Same quality level at half

baseline scan time with

41|100 and 41|200

Small sample

ROI 1

Same scan time as baseline

but doubled resolution with

41|10 0

ROI 2

Large sample

200 µm

100 µm

Focus-Object-Distance (FOD)

Focus-Detector-Distance (FDD)

Scan resolution of ROI 1 is equivalent to ROI 2, but ROI 2 is 8 times larger due to smaller pixel allowing

scanning larger parts with smaller magnication.

Page 4

Detector characterization parameter

The dynamic 41|100 and 41|200 detector characterization according to ASTM E2597-14 for AL, TI and Inconel is displayed below*:

*) Valid for specic detector gain settings

Aluminum Al-6061 Titanum Ti-6Al4V Inconel 718

Specic Material

Thickness Range

SRB (basic spatial

resolution)

12

9

6

3

0

Specic Material

Thickness Range

CS (contrast

sensitivity)

SRB (basic spatial

resolution)

12

9

6

3

0

Specific Material

Thickness Range

CS (contrast

sensitivity)

SRB (basic spatial

resolution)

12

9

6

3

0

CS (contrast

sensitivity)

Eciency =

dSNRn@1mGy Image Lag

41|200 41|100 41|200 41|10 0 41|200 41|10 0

Eciency =

dSNRn@1mGy Image Lag

Efficiency =

dSNRn@1mGy Image Lag

Exclusiveness

GE Inspection Technologies is the unique CT manufacturer not assembling core components mostly acquired by

dierent suppliers, but combining GE proprietary core components like X-ray tubes, generators, software and

also digital detectors to harmonized high performing systems. Hence, the new dynamic 41 detector series is

exclusively available for following systems:

• phoenix v|tome|x m

• phoenix v|tome|x c

• phoenix v|tome|x L

• Seifert x|cube

TechnicalSpecications

Detector dynamic 41|100 dynamic 41|200

Pixel Size 100 μm; 200 μm with 2 x 2

binning

Active Area (approx.) 405 x 405 mm (16” x 16”)

Pixel Matrix 4096 x 4096 (16 MP),

usable: 4048 x 4048

Max. Frame Rate Full FOV: 3 fps;

20 x 20 cm ROI: 5 fps

Dynamic Range 10 000 : 1

Lifetime Extension Design optimized for industrial high energy CT applications

Low Ghosting To take images in quick succession

High Sensitivity Shorter exposures for same brightness

ASTM E2597/DICONDE Compliant

200 μm, 400 μm with 2 x 2

binning

2048 x 2048 (4 MP),

usable: 2024 x 2024

Full FOV: 12 fps;

20 x 20 cm ROI: 30 fps

dynamic 41|100 & 41|200 Your Advantages

• Large area detector with superior image and

result quality

• GE’s proprietary dynamic 41 detector family is

exclusively available for GE Inspection Techno-

logies system customers

• Reduce inspection times due to increased

detector sensitivity, faster frame rates, larger

imaging area and adaptive imaging modes

• 100 μm resolution captured with the eciency

and CNR of a state of the art 200 μm detector

Premium CT results in less time

•

Awarded by

Frost & Sullivan as

Global Industrial CT

Systems Company of

the Year 2016

© 2019 Baker Hughes a General Electric Company. Baker Hughes reserves the right to make changes in specications and features shown herein, or discontinue the product described at any time without notice

or obligation. Contact your BHGE representative for the most current information. The Baker Hughes logo is a trade mark of Baker Hughes, a GE company. The GE Monogram is a trademark of the General Electric

Company. Other company or product names mentioned in this document may be trademarks of their respective companies, which are not aliated with Baker Hughes / GE.

Contact: GE Sensing & Inspection Technologies GmbH, phoenix|x-ray, Niels-Bohr-Str. 7, 31515 Wunstorf, Germany, T +49 (0)5031 172 0, phoenix-info@ge.com

www.gemeasurement.com/x-ray

phoenix-info@ge.com

GEIT-31354EN (04/19)

Loading...

Loading...