Page 1

DMS Go+

Technical Reference and Operating Manual

Page 2

This edition 4 (05/2014) applies to the software version 3.20 (April 2, 2014)

You will find the software version and the serial number of your instrument at CONFIG - ABOUT.

© GE Sensing & Inspection Technologies GmbH | Technical content subject to change without notice.

Page 3

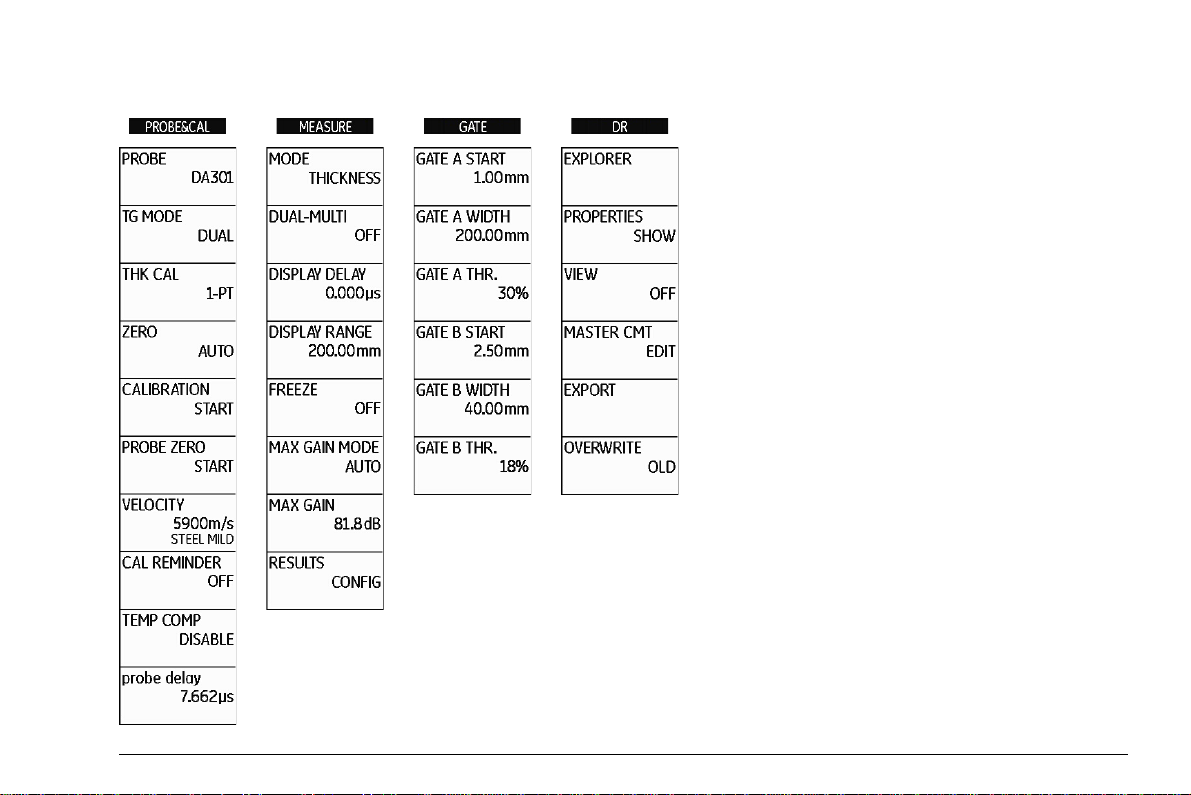

Function groups and functions

DMS Go+ Edition 4 (05/2014) 0-3

Page 4

Function groups and functions (cont'd)

0-4 Edition 4 (05/2014) DMS Go+

Page 5

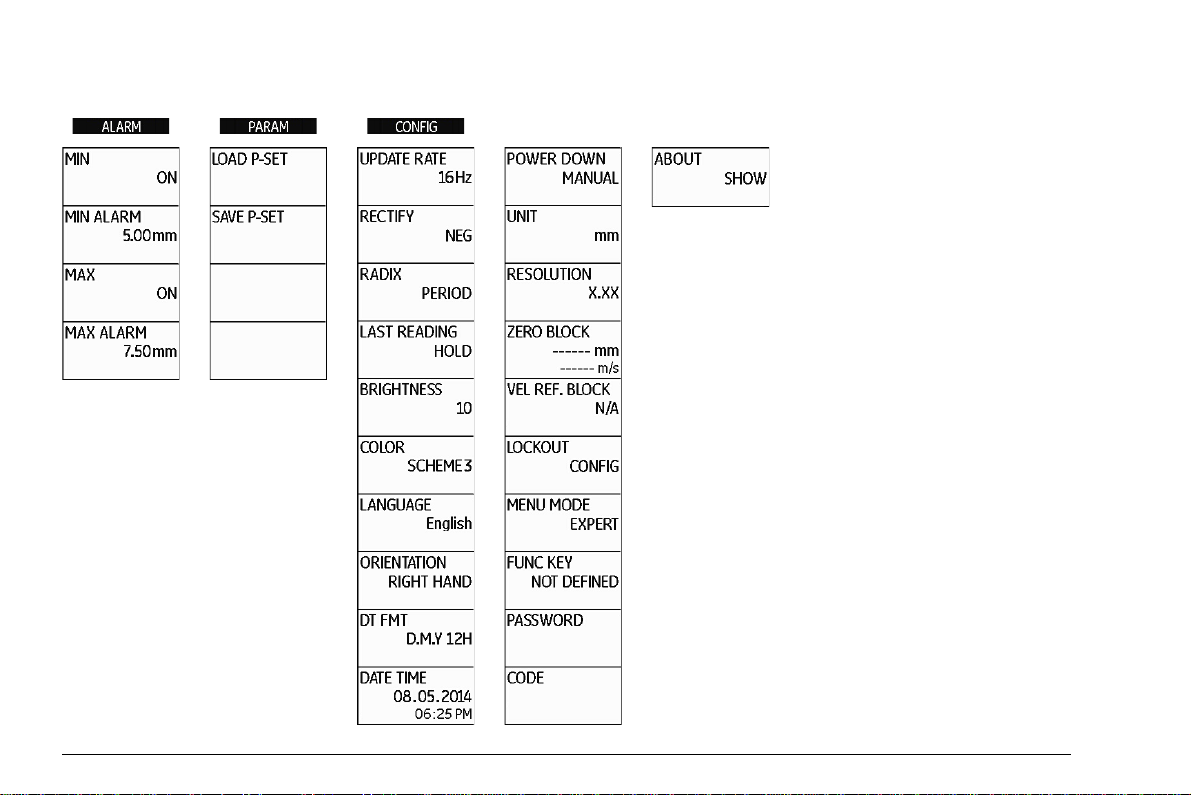

Status display icons Power level indicators

Icon Meaning

SD memory card is inserted,

flashes when the SD card is accessed

Display memory active (Function FREEZE),

display is „frozen“.

Measurement mode S-IP, DUAL

Measurement mode S-PEAK, S-FLANK

Measurement mode DUAL-MULTI

Alarm threshold exceeded or fallen below

Reminder for calibration

Icon Meaning

Battery charge level,

remaining operating time

in hours (approximate value)

Charger/power adapter is connected,

percentage of battery charge level

(approximate value)

Warning: Low battery charge level,

remaining operating time

in minutes (approximate value)

DMS Go+ Edition 4 (05/2014) 0-5

Page 6

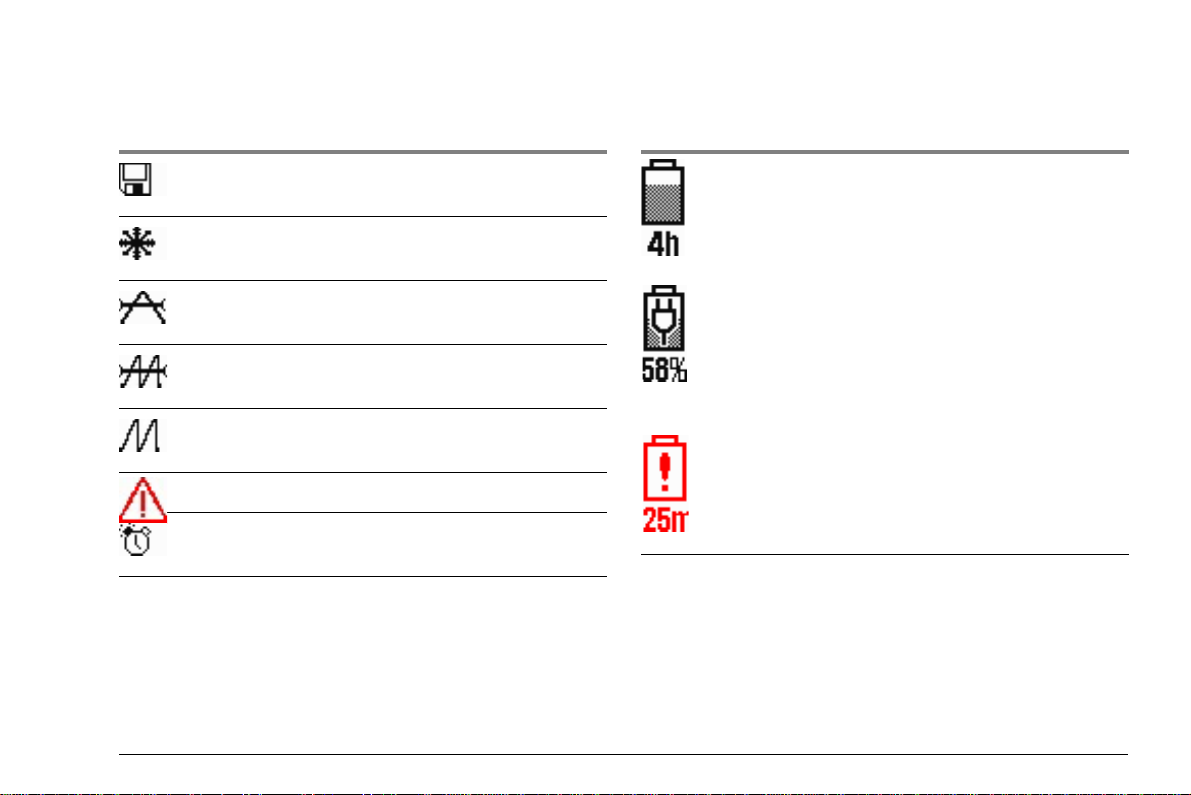

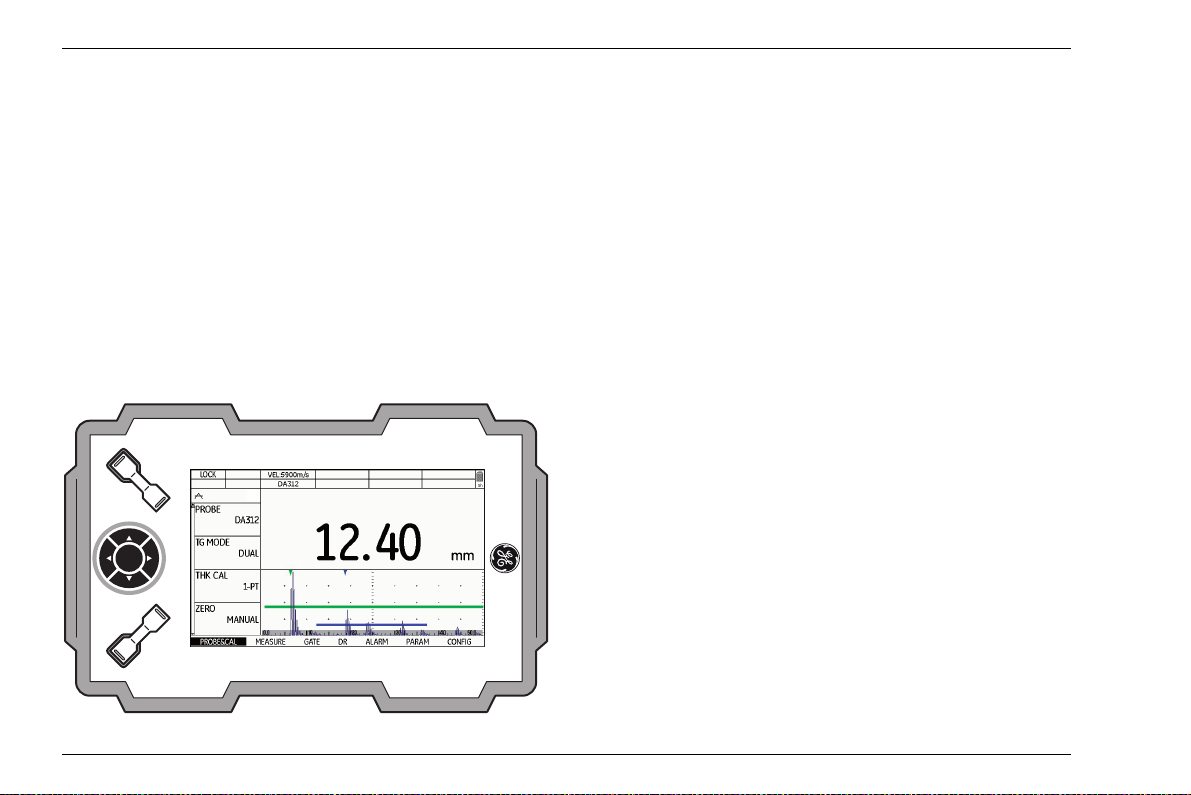

Basic key functions

1

2

3

4

5

1 Function key 1, functions are context-dependent

2 Function key 2, functions are context-dependent; keys 1 and 2 simultaneously: Save screen shot

3 Keypad, navigation between function groups and functions, changing settings

4 Function key 3, functions are context-dependent

5 Function key 4, function individually assignable (CONFIG – FUNC KEY),

0-6 Edition 4 (05/2014) DMS Go+

Page 7

Navigation

Keys Function

Navigation between function groups,

adjusting values

Navigation between functions

within a function group

Changing the display orientation (landscape - portrait)

DMS Go+ Edition 4 (05/2014) 0-7

Page 8

0-8 Edition 4 (05/2014) DMS Go+

Page 9

Contents

0 Overview

Function groups and functions . . . . . . . . . 0-3

Function groups and functions (cont'd). . . 0-4

Status display icons . . . . . . . . . . . . . . . . . 0-5

Power level indicators. . . . . . . . . . . . . . . . 0-5

Basic key functions . . . . . . . . . . . . . . . . . . 0-6

Navigation. . . . . . . . . . . . . . . . . . . . . . . . . 0-7

1 Introduction

1.1 Safety information . . . . . . . . . . . . . . . . . 1-2

Battery operation . . . . . . . . . . . . . . . . . . . 1-2

Software . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Defects/errors and exceptional stresses. . 1-3

1.2 Important information on

wall thickness measurement . . . . . . . . . 1-4

Prerequisites for the use of ultrasonic

thickness gauges . . . . . . . . . . . . . . . . . . . 1-4

Limits of ultrasonic testing . . . . . . . . . . . . 1-5

Ultrasonic wall thickness measurement . . 1-5

Effect of the test object material . . . . . . . . 1-6

Effect of temperature variations . . . . . . . . 1-6

Measurement of remaining wall thickness 1-6

Choice of the probe. . . . . . . . . . . . . . . . . . 1-7

Use of couplants . . . . . . . . . . . . . . . . . . . . 1-7

Doubling of measured value . . . . . . . . . . . 1-7

1.3 Important information on wall thickness

measurement using the DMS Go+ . . . . 1-8

Probe zero offset. . . . . . . . . . . . . . . . . . . . 1-8

Measuring accuracy . . . . . . . . . . . . . . . . . 1-8

Probes. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.4 The DMS Go+ . . . . . . . . . . . . . . . . . . . . 1-12

Overview of functions . . . . . . . . . . . . . . . 1-12

Options . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

1.5 Wall thickness measurement

using the DMS Go+. . . . . . . . . . . . . . . . 1-15

Principle of ultrasonic measurement. . . . 1-15

Dual mode (measurement mode DUAL). 1-16

Single-element mode (measurement

modes S-IP, S-PEAK, S-FLANK) . . . . . . 1-17

Multi-echo mode

(measurement mode DUAL-MULTI). . . . 1-17

DMS Go+ Edition 4 (05/2014) 0-1

Page 10

Contents

TopCOAT method

(measurement mode TOP-COAT) . . . . . 1-18

Auto-V (measurement mode AUTO-V). . 1-19

B-scan. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Display orientation . . . . . . . . . . . . . . . . . 1-21

1.6 The USM Go+ . . . . . . . . . . . . . . . . . . . . 1-22

1.7 How to use this manual . . . . . . . . . . . . 1-22

Overview . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

1.8 Layout and presentation in

this manual . . . . . . . . . . . . . . . . . . . . . . 1-24

Attention and note symbols. . . . . . . . . . . 1-24

Listings . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Operating steps. . . . . . . . . . . . . . . . . . . . 1-24

2 Standard package and accessories

2.1 Standard package . . . . . . . . . . . . . . . . . . 2-2

2.2 Add-on functions . . . . . . . . . . . . . . . . . . 2-3

2.3 Preconfigured function packages. . . . . 2-4

2.5 Recommended probe cables . . . . . . . . 2-10

2.6 Recommended accessories. . . . . . . . . 2-12

3 Initial start-up

3.1 Instrument positioning . . . . . . . . . . . . . . 3-2

3.2 Power supply. . . . . . . . . . . . . . . . . . . . . . 3-2

Operation with charger/power adapter . . . 3-2

Operation using batteries . . . . . . . . . . . . . 3-4

Charging the batteries. . . . . . . . . . . . . . . . 3-8

3.3 Connecting a probe . . . . . . . . . . . . . . . . 3-9

Dual-type connectors . . . . . . . . . . . . . . . . 3-9

Single-type connectors . . . . . . . . . . . . . . . 3-9

3.4 Inserting the SD memory card . . . . . . . 3-10

3.5 Starting the DMS Go+ . . . . . . . . . . . . . . 3-11

Powering On . . . . . . . . . . . . . . . . . . . . . . 3-11

Powering Off . . . . . . . . . . . . . . . . . . . . . . 3-12

Factory default setting (Reset) . . . . . . . . 3-12

2.4 Recommended probes . . . . . . . . . . . . . . 2-5

0-2 Edition 4 (05/2014) DMS Go+

Page 11

Contents

4 Principles of operation

4.1 Overview of operator's controls . . . . . . 4-2

4.2 Display screen . . . . . . . . . . . . . . . . . . . . 4-3

Display modes . . . . . . . . . . . . . . . . . . . . . 4-3

Functions on the display screen . . . . . . . . 4-5

Icons and information . . . . . . . . . . . . . . . . 4-5

Display of reading . . . . . . . . . . . . . . . . . . . 4-6

4.3 Navigation and function keys . . . . . . . . 4-7

Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Function keys . . . . . . . . . . . . . . . . . . . . . . 4-7

Power key . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Key combinations . . . . . . . . . . . . . . . . . . . 4-8

4.4 Operational concept . . . . . . . . . . . . . . . . 4-9

Changing the display views . . . . . . . . . . . 4-9

Selecting and setting functions. . . . . . . . 4-10

5 Operation

5.1 Default settings . . . . . . . . . . . . . . . . . . . . 5-2

Language setting . . . . . . . . . . . . . . . . . . . 5-2

Units setting . . . . . . . . . . . . . . . . . . . . . . . 5-3

Resolution setting . . . . . . . . . . . . . . . . . . . 5-3

Radix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Last reading . . . . . . . . . . . . . . . . . . . . . . . 5-4

Date format, Date, and Time. . . . . . . . . . . 5-5

Selecting the instrument orientation . . . . . 5-6

Display orientation . . . . . . . . . . . . . . . . . . 5-6

Assignment of function key 4 . . . . . . . . . . 5-7

Function lockout . . . . . . . . . . . . . . . . . . . . 5-8

Password protection . . . . . . . . . . . . . . . . 5-10

Power saving mode . . . . . . . . . . . . . . . . 5-12

Configuring data boxes . . . . . . . . . . . . . . 5-13

5.2 Default settings of the display. . . . . . . 5-15

Setting the brightness . . . . . . . . . . . . . . . 5-15

Selecting the color scheme. . . . . . . . . . . 5-16

DMS Go+ Edition 4 (05/2014) 0-3

Page 12

Contents

5.3 Operating modes and views . . . . . . . . 5-17

Changing the operating mode or view . . 5-17

5.4 Saving the settings . . . . . . . . . . . . . . . . 5-18

Loading settings . . . . . . . . . . . . . . . . . . . 5-19

Deleting settings . . . . . . . . . . . . . . . . . . . 5-19

5.5 Preparing for measurements . . . . . . . . 5-20

Choosing the probe type. . . . . . . . . . . . . 5-21

Choosing the measurement mode . . . . . 5-22

5.6 Carrying out the calibration. . . . . . . . . 5-24

Calibrations . . . . . . . . . . . . . . . . . . . . . . . 5-24

Probe zero offset. . . . . . . . . . . . . . . . . . . 5-25

Calibration to zero and to sound velocity 5-27

Setting the sound velocity . . . . . . . . . . . . 5-31

5.7 Carrying out measurements . . . . . . . . 5-32

5.8 A-scan configuration . . . . . . . . . . . . . . 5-33

Setting the display range . . . . . . . . . . . . 5-33

Setting the gain . . . . . . . . . . . . . . . . . . . . 5-34

Selecting the display update rate . . . . . . 5-35

Selecting the rectification mode . . . . . . . 5-36

Setting the probe delay . . . . . . . . . . . . . . 5-36

5.9 Setting the gates . . . . . . . . . . . . . . . . . . 5-37

Task of the gates. . . . . . . . . . . . . . . . . . . 5-37

Gate start . . . . . . . . . . . . . . . . . . . . . . . . 5-37

Gate width . . . . . . . . . . . . . . . . . . . . . . . . 5-38

Gate threshold. . . . . . . . . . . . . . . . . . . . . 5-38

5.10 Configuring alarm functions . . . . . . . . 5-39

Minimum value alarm . . . . . . . . . . . . . . . 5-39

Maximum value alarm . . . . . . . . . . . . . . . 5-39

5.11 MIN/MAX mode . . . . . . . . . . . . . . . . . . . 5-40

Switching the MIN/MAX mode on . . . . . .5-41

Clearing a sequence of measurements . 5-41

5.12 Thickness profiles with the B-scan . . . 5-42

Switching the B-scan display on . . . . . . . 5-43

Setting the display time . . . . . . . . . . . . . . 5-43

Setting the waiting time . . . . . . . . . . . . . . 5-44

Minimum value line . . . . . . . . . . . . . . . . . 5-44

Recording a B-scan. . . . . . . . . . . . . . . . . 5-45

0-4 Edition 4 (05/2014) DMS Go+

Page 13

Contents

5.13 Differential value display . . . . . . . . . . . 5-46

Switching the differential value

display on . . . . . . . . . . . . . . . . . . . . . . . . 5-46

5.14 A-scan view . . . . . . . . . . . . . . . . . . . . . . 5-47

5.15 Other functions . . . . . . . . . . . . . . . . . . . 5-48

Saving calibration block data . . . . . . . . . 5-48

Calibration reminder . . . . . . . . . . . . . . . . 5-50

Temperature compensation . . . . . . . . . . 5-51

Display freeze (FREEZE) . . . . . . . . . . . . 5-52

Gate magnifier (ZOOM) . . . . . . . . . . . . . 5-53

5.16 Enabling options (Upgrade). . . . . . . . . 5-54

6 Data Recorder

6.1 Overview of functions . . . . . . . . . . . . . . 6-2

6.2 File types . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

File type LINEAR . . . . . . . . . . . . . . . . . . . 6-4

File type CUSTOM LINEAR . . . . . . . . . . . 6-5

File type CUSTOM POINT . . . . . . . . . . . . 6-5

File type GRID . . . . . . . . . . . . . . . . . . . . . 6-6

File type CUSTOM GRID . . . . . . . . . . . . . 6-6

File type BOILER . . . . . . . . . . . . . . . . . . . 6-7

6.3 Master comment list . . . . . . . . . . . . . . . . 6-8

Creating a master comment list . . . . . . . . 6-8

Changing master comments . . . . . . . . . . . 6-9

6.4 Working with files . . . . . . . . . . . . . . . . . 6-11

Creating a new file . . . . . . . . . . . . . . . . . 6-11

Deleting files . . . . . . . . . . . . . . . . . . . . . . 6-13

6.5 Saving measurement results. . . . . . . . 6-14

Loading a file. . . . . . . . . . . . . . . . . . . . . . 6-14

Saving readings . . . . . . . . . . . . . . . . . . . 6-15

Special measuring point functions . . . . . 6-16

Selecting individual measuring points. . . 6-16

Clearing a reading. . . . . . . . . . . . . . . . . . 6-17

Overwriting readings . . . . . . . . . . . . . . . . 6-17

Saving readings with A-scans . . . . . . . . . 6-18

Adding comments . . . . . . . . . . . . . . . . . . 6-20

Editing a file comment list . . . . . . . . . . . . 6-22

DMS Go+ Edition 4 (05/2014) 0-5

Page 14

Contents

6.6 Editing files . . . . . . . . . . . . . . . . . . . . . . 6-24

Expanding the file capacity . . . . . . . . . . . 6-24

Deleting parts of a file . . . . . . . . . . . . . . . 6-26

Editing header data. . . . . . . . . . . . . . . . . 6-27

Adding a Microgrid . . . . . . . . . . . . . . . . . 6-29

Automatic advance . . . . . . . . . . . . . . . . . 6-33

6.7 Evaluations . . . . . . . . . . . . . . . . . . . . . . 6-36

Viewing statistical evaluations . . . . . . . . 6-36

Changing the view (Spread – List) . . . . . 6-38

Viewing stored reading attachments. . . . 6-39

6.8 Documenting measurements. . . . . . . . 6-40

Data export . . . . . . . . . . . . . . . . . . . . . . . 6-40

Screen shots . . . . . . . . . . . . . . . . . . . . . . 6-41

7 Special functions of the DMS Go+ TC

7.1 Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.2 Measurement mode Auto-V . . . . . . . . . . 7-6

Applications. . . . . . . . . . . . . . . . . . . . . . . . 7-6

Choosing the probe. . . . . . . . . . . . . . . . . . 7-6

Activating Auto-V. . . . . . . . . . . . . . . . . . . . 7-6

Zeroing for Auto-V. . . . . . . . . . . . . . . . . . . 7-7

Checking reference block data . . . . . . . . . 7-7

7.3 Measurement mode TopCOAT. . . . . . . . 7-9

Applications. . . . . . . . . . . . . . . . . . . . . . . . 7-9

Choosing the probe. . . . . . . . . . . . . . . . . . 7-9

Activating TopCOAT . . . . . . . . . . . . . . . . . 7-9

Zeroing for TopCOAT . . . . . . . . . . . . . . . 7-10

Checking reference block data . . . . . . . . 7-10

Sound velocity in the test object.. . . . . . . 7-11

Calibration to the sound velocity . . . . . . . 7-12

Sound velocity in the coating . . . . . . . . . 7-13

8 Maintenance and care

8.1 Instrument care . . . . . . . . . . . . . . . . . . . . 8-2

8.2 Battery care . . . . . . . . . . . . . . . . . . . . . . . 8-2

Battery care. . . . . . . . . . . . . . . . . . . . . . . . 8-2

Charging the batteries. . . . . . . . . . . . . . . . 8-3

8.3 Maintenance . . . . . . . . . . . . . . . . . . . . . . 8-3

0-6 Edition 4 (05/2014) DMS Go+

Page 15

Contents

8.4 Software updates . . . . . . . . . . . . . . . . . . 8-4

Download of update files . . . . . . . . . . . . . 8-4

Installing an update. . . . . . . . . . . . . . . . . . 8-5

9 Interfaces and Peripherals

9.1 Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

USB interface . . . . . . . . . . . . . . . . . . . . . . 9-3

Service interface (Mini RS232-C) . . . . . . . 9-3

9.2 Peripherals . . . . . . . . . . . . . . . . . . . . . . . 9-4

10 Appendix

10.1 Application notes . . . . . . . . . . . . . . . . . 10-2

General notes . . . . . . . . . . . . . . . . . . . . . 10-2

10.2 Sound velocities . . . . . . . . . . . . . . . . . . 10-4

10.3 Data Recorder file types. . . . . . . . . . . . 10-7

File type LINEAR . . . . . . . . . . . . . . . . . . 10-7

File type GRID . . . . . . . . . . . . . . . . . . . . 10-9

File type CUSTOM LINEAR . . . . . . . . . 10-11

File type CUSTOM GRID . . . . . . . . . . . 10-13

File type CUSTOM POINT . . . . . . . . . . 10-15

File type BOILER . . . . . . . . . . . . . . . . . 10-17

10.4 Flag symbols . . . . . . . . . . . . . . . . . . . . 10-19

10.5 Function directory . . . . . . . . . . . . . . . 10-20

10.6 EU Declaration of Conformity . . . . . . 10-25

10.7 Manufacturer/Service addresses. . . . 10-25

10.8 Environmental protection

regulations. . . . . . . . . . . . . . . . . . . . . . 10-27

WEEE directive (Waste Electrical

and Electronic Equipment) . . . . . . . . . . 10-27

Disposal of batteries . . . . . . . . . . . . . . . 10-28

10.9 Recycling directives . . . . . . . . . . . . . . 10-30

Overview . . . . . . . . . . . . . . . . . . . . . . . . 10-30

Materials to be disposed of separately . 10-33

Other materials and components . . . . . 10-36

Recycling data of the DMS Go+ . . . . . . 10-43

DMS Go+ Edition 4 (05/2014) 0-7

Page 16

11 Specifications

11.1 Specifications of the DMS Go+ . . . . . . 11-2

Display screen . . . . . . . . . . . . . . . . . . . . 11-2

Display . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

Connectors . . . . . . . . . . . . . . . . . . . . . . . 11-4

Pulser . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

Receiver . . . . . . . . . . . . . . . . . . . . . . . . . 11-5

Memory . . . . . . . . . . . . . . . . . . . . . . . . . . 11-5

Environment . . . . . . . . . . . . . . . . . . . . . . 11-6

Protection . . . . . . . . . . . . . . . . . . . . . . . . 11-7

Options . . . . . . . . . . . . . . . . . . . . . . . . . . 11-8

11.2 Specifications according to

EN 12668 . . . . . . . . . . . . . . . . . . . . . . . . 11-9

12 Index

0-8 Edition 4 (05/2014) DMS Go+

Page 17

Introduction 1

DMS Go+ Edition 4 (05/2014) 1-1

Page 18

1 Introduction Safety information

ATTENTION

1.1 Safety information

The DMS Go+ has been designed and tested according

to DIN

EN 61010-1: 2011-07, Safety requirements for

electrical equipment for measurement, control and lab

oratory use, and was technically in perfectly safe and

faultless condition when leaving the manufacturing

works.

In order to maintain this condition and to ensure a safe

operation, you should always read the following safety

information carefully before putting the instrument into

operation.

The DMS Go+ is an instrument for materials testing. Any use for medical or any

other applications is not permitted!

The instrument may only be used in industrial environments.

The DMS Go+ is waterproof according to IP67. It can be

operated either with the corresponding lithium-ion bat

teries or with the charger/power adapter. The charger/

power adapter meets the requirements of electrical

safety class II.

-

Battery operation

For the battery operation of the DMS Go+, we recommend the corresponding lithium-ion battery. You should

only use this battery for the battery operation.

You can charge the lithium-ion battery either within the

instrument itself or in an external charger. If a lithium-ion

battery is inserted, charging starts automatically as

soon as you connect the charger/power adapter to the

DMS Go+ and to the mains power supply.

For power supply, please also see Chapter 3.2 Power

supply, page 3-2. For the use of batteries, please also

see Chapter 8.2 Battery care, page 8-2.

Software

According to the current state of the art, software is never completely free from errors. Before using any software-controlled test equipment, it is therefore necessary to make sure that the required functions operate

perfectly in the intended combination.

If you have any questions about the use of your test

equipment, please contact your nearest representative

of GE.

1-2 Edition 4 (05/2014) DMS Go+

Page 19

Safety information 1 Introduction

Defects/errors and exceptional stresses

If you have reason to believe that a safe operation of

your DMS Go+ is no longer possible, you have to dis

connect the instrument and secure it against unintentional reconnection. Remove the lithium-ion battery.

A safe operation is no longer possible for example

● if the instrument shows visible damages,

● if the instrument no longer operates perfectly,

● after prolonged storage under adverse conditions

(e.g. exceptional temperatures or especially high air

humidity, or corrosive environmental conditions),

● after being subjected to heavy stresses during transportation.

-

DMS Go+ Edition 4 (05/2014) 1-3

Page 20

1 Introduction Important information on wall thickness measurement

ATTENTION

1.2 Important information on wall thickness measurement

Please read the following information before

using your thickness gauge. It is very import

ant that you understand and observe this information to avoid any errors when using the

instrument that might lead to false measure

ment results. Decisions made on the basis of

false measurement results may lead to prop

erty damages and personal injuries.

Prerequisites for the use of ultrasonic thickness gauges

This operating manual contains essential information on

how to operate your thickness gauge. In addition, there

are a number of factors that affect the measurement re

sults. A description of all these factors would go beyond

the scope of an operating manual. Therefore, only the

most important prerequisites for a safe and reliable ul

trasonic thickness measurement are mentioned here:

-

● Training of the instrument operator (operator)

● Knowledge of special technical measurement re-

quirements and limits

● Choice of the appropriate measuring device

The operation of an ultrasonic measuring device requires proper training in ultrasonic thickness measure-

ment. Proper training comprises for example adequate

knowledge of the following:

● Theory of the propagation of sound waves in materi-

-

als

-

● Effects of the sound velocity of test material

● Behavior of sound waves at interfaces between dif-

ferent materials

● Propagation of the sound beam within the material

● Effect of the surface quality of test material.

-

1-4 Edition 4 (05/2014) DMS Go+

Page 21

Important information on wall thickness measurement 1 Introduction

Lack of such knowledge could lead to false measurement results with unforeseeable consequences. Information about the existing training opportunities for ultrasonic inspectors and about the qualifications and certificates that can finally be obtained is available at the

national NDT societies or at GE.

GE holds specialized training courses in the field of ultrasonic testing at regular intervals. The scheduled

dates for these courses will be given to you on request.

Limits of ultrasonic testing

The information obtained from ultrasonic tests only refers to those parts of the test object which are covered

by the sound beam of the probe used. Should any con

clusions from the tested parts be applied to the untested

parts of the test object, they should therefore be made

with extreme caution. Such conclusions are generally

only possible in cases where extensive experience of

the components to be tested and proven methods of

statistical data acquisition are available.

Boundary surfaces within the test object can completely

reflect the sound beam, resulting in reflection points

which lie beyond this, for example the component's

backwall, remaining undetected. It is therefore import

ant to make sure that all areas to be tested in the test

object are covered by the sound beam.

Ultrasonic wall thickness measurement

All ultrasonic wall thickness measurements are based

on a time-of-flight measurement of the sound pulse in

the test object. Accurate measurement results therefore

require a constant sound velocity in the test object. This

requirement is generally met in test objects made of

steel, even with different alloying constituents. The vari

ation of sound velocity is so slight that it is only of impor-

tance for high-precision measurements. In other materials, for example nonferrous metals or plastics, the

sound velocity is nevertheless subject to larger varia

tions. These may affect the measuring accuracy.

-

-

-

DMS Go+ Edition 4 (05/2014) 1-5

Page 22

1 Introduction Important information on wall thickness measurement

Effect of the test object material

If the material is not homogeneous, the sound waves

may propagate at different velocities in different parts of

the test object. In this case, an average sound velocity

should therefore be taken into account for the instru

ment calibration.

However, the best results are obtained when the instrument is calibrated using a reference block made of the

same material as the test object. This calibration block

should have plane-parallel surfaces and a thickness

corresponding to the maximum thickness of the test ob

ject. The operator

should additionally keep in mind that the sound velocity

is liable to vary substantially due to heat treatments.

This fact must be taken into account when assessing

the accuracy of the wall thickness measured by the in

strument.

If substantial sound velocity variations are expected,

then the instrument calibration should be adjusted to the

actual sound velocity values at shorter time intervals.

Failure to do so may lead to false thickness readings.

-

Effect of temperature variations

The sound velocity within the test object also varies

along with material's temperature. This can cause ap

preciable errors in measurements if the instrument has

been calibrated on a cold reference block, whereas the

thickness measurement is carried out on a warm test

object. Such measurement errors can be avoided either

by adjusting the temperature of the reference block

used for calibration or by taking the temperature effect

on the sound velocity into consideration on the basis of

a correction factor obtained from published tables.

-

Measurement of remaining wall thickness

The measurement of the remaining wall thickness on

plant components, e.g. pipes, tanks, or reaction vessels

of all types which are corroded or eroded from the in

side, requires a perfectly suitable gauge and special

care in handling the probe.

The operator should always be informed about the corresponding nominal wall thicknesses as well as about

the likely amount of wall thickness losses.

-

-

1-6 Edition 4 (05/2014) DMS Go+

Page 23

Important information on wall thickness measurement 1 Introduction

Choice of the probe

The probe used for the measurement must be in good

condition, i.e. its coupling face or delay line should not

show any considerable wear. The measuring range (ap

plication range) specified for the corresponding probe in

the data sheets must cover the complete thickness

range to be inspected. The temperature of the test ob

ject must be within the permissible temperature range of

the selected probe.

Use of couplants

The operator must be familiar with the use of the ultrasonic couplant to the effect that the couplant is applied

equally during every measurement so that variations in

the couplant layer thickness and errors in the subse

quent measurement results are avoided. The instrument calibration and the actual wall thickness measurement should be carried out under identical coupling conditions. During this process, the quantities of couplant

used should be as small as possible and a constant

pressure should be applied to the probe.

-

In the case of curved coupling faces, for example on

tubes, the dual-element probe used for the measure

ment should be coupled in such a way that its acoustic

separation layer forms an angle of 90° with reference to

-

the tube's longitudinal axis.

Doubling of measured value

-

A dangerous measuring error in ultrasonic thickness

measurement can occur if the thickness is measured

below the application range (operating range) specified

for the probe used. In this case, the first backwall echo

is too small for an evaluation, whereas the second back

wall echo has an adequately high amplitude and is

therefore evaluated by the instrument. This results in a

wall thickness reading which is twice as large as the ac

tual wall thickness. In order to avoid such measuring errors, the operator must carry out an additional check

measurement using another probe at the limit of the ap

plication range.

-

-

-

-

DMS Go+ Edition 4 (05/2014) 1-7

Page 24

1 Introduction Important information on wall thickness measurement using the DMS Go+

ATTENTION

1.3 Important information on wall thickness measurement using the DMS Go+

Please always read the following information

about the special features in wall thickness

measurement using the DMS Go+. It is abso

lutely necessary that you observe this information in order to always obtain correct

measurement results.

Probe zero offset

High differences in temperature

If the differences in temperature between the storage

and inspection site are high, it is necessary that you wait

approx. 2 minutes before you use the instrument after

connecting the probe.

at temperatures below –10 °C. You should therefore

carry out a 2-point calibration and repeat it in the case

of major temperature jumps.

Couplant residues

In order to ensure a correct probe zero offset, make sure

that you always remove the couplant residues before

carrying out a new measurement after decoupling the

probe.

-

Measuring accuracy

Keep in mind that the measuring accuracy is not identical with the display accuracy.

The measuring accuracy depends on the following factors:

● Temperature

● Probe delay line

● Constancy of sound velocity

● Uniformity of surface quality

Temperatures below –10 °C

The probe zero offset does not always function correctly

1-8 Edition 4 (05/2014) DMS Go+

Page 25

Important information on wall thickness measurement using the DMS Go+ 1 Introduction

Probes

Please note that only probes specified in chapter 2 of

this manual are accepted for the DMS Go+.

V-path correction

The following probes have only one transducer element

and therefore require no V-path correction:

● K 1 SC ● K-PEN ● G5 KB

● G 2 N ● CLF 5 ● CLF 4

● CA 215 ● CA 214 ● CA 211

● CA 211 A ● A DFRP ● A2 DFR

● A2 DFR ● A2 10 M ● 5 M 5 DFR

All probes equipped with a transmitter and a receiver element require a V-path correction due to the inclined position of their transducer elements (with wall thicknesses < 60 mm in steel).

The V-path correction is stored in the DMS Go+ for the

following probes:

● Alpha2 D ● CA 211A ● DA 301

● DA 303 ● DA 312 ● DA 312 B1

● DA 501 EN ● DA 503 EN ● DA 507

● DA 512 ● D 590 ● FH 2 E

● HT 400 A ● KBA 525 ● KBA 560

● OSS 10 ● TC 560 ● D 790

DMS Go+ Edition 4 (05/2014) 1-9

Page 26

1 Introduction Important information on wall thickness measurement using the DMS Go+

The following probes have been corrected individually

during the manufacturing process; the V-path correction

is stored in the probe. For some of these probes

(marked with *), this was additionally done for the oper

ating mode DUAL-MULTI.

● DA 401 ● DA 403 ● DA 408

● DA 411 ● DA 412* ● DA 451*

● DA 453 ● DA 458 ● DA 461*

● DA 462* ● DA 455 ● DA 465

● DA 467 ● DA 469 ● FH 2 ED REM

Zeroing

The correct zeroing is important for the measuring accuracy of probes equipped with a transmitter and a receiver element. A difference is made between two methods:

1 Zeroing before coupling the probe

(OFF-BLOCK zeroing)

2 Zeroing during probe coupling

(ON-BLOCK zeroing)

Zeroing before coupling the probe (OFF-BLOCK

zeroing)

After powering the DMS Go+ on, the length of the delay

line below the transmitter element is determined at reg

ular intervals whenever the probe is not coupled for the

wall thickness measurement. In this regard, it is import

ant that the coupling face of the probe is free from couplant to a large extent in order to avoid any faulty measurements.

This method is of advantage in cases where rough or

curved surfaces may result in a critical coupling. When

determining wall thicknesses in plastics, only probes

with zeroing before coupling should be chosen:

● DA 401 ● DA 403 ● DA 408

● DA 411 ● DA 412 ● D 790

● FH 2 E ● KBA 525 ● KBA 560

● HT 400 A ● TC 560

-

-

1-10 Edition 4 (05/2014) DMS Go+

Page 27

Important information on wall thickness measurement using the DMS Go+ 1 Introduction

Zeroing during probe coupling (ON-BLOCK zeroing)

After coupling the probe (but before each individual wall

thickness measurement), the length of the delay line be

low the transmitter element is determined at first. The

actual wall thickness measurement is not carried out till

after that.

This method is of advantage whenever a high stability

and reproducibility of the measured values are required.

For example, if the temperature of the part to be tested

differs largely from that of the probe, the delay lines are

cooled down during coupling and thus reduced, or they

are heated up and thus extended. Each zero drift is thus

compensated for immediately before every wall thick

-

ness measurement in the case of these probes:

● DA 301 ● DA 303 ● DA 305

● DA 312 ● DA 312 B... ● DA 315

● DA 317 ● DA 319 ● DA 451*

● DA 453* ● DA 461* ● DA 462*

● DA 465* ● DA 467* ● DA 469*

In the case of probes marked with *, the zero is determined as an arithmetic mean of the two probe delay

lines. For example, probes showing beveled wear can

thus comply with their original measured-value toler

ance better.

-

DMS Go+ Edition 4 (05/2014) 1-11

Page 28

1 Introduction The DMS Go+

1.4 The DMS Go+

Overview of functions

The DMS Go+ is a portable thickness gauge with an integrated data recorder You can use this instrument for

measuring the wall thickness on a large variety of com

ponents, for example on tubes, pressure vessels, and

other equipment parts whose wall thickness is subject to

a gradual reduction.

This makes the DMS Go+ especially suitable for measurement tasks for the documented corrosion test.

Special features of the DMS Go+

● high measuring stability and reliability thanks to the

zero crossing method

● automatic gain control for an improved reproducibility

during corrosion tests

● dust-tight and waterproof housing according to IP67

-

● low weight (845 g incl. batteries)

● long operating time (8 hours) due to lithium-ion bat-

tery with internal and external charging possibility

● one-handed operation is possible

● high-resolution color screen (800 x 480 pixels) for the

display of measured values and A-scan

● enlarged display of measured values which are easy

to read even from a greater distance

● color-coded display of gates for easy differentiation

1-12 Edition 4 (05/2014) DMS Go+

Page 29

The DMS Go+ 1 Introduction

● high memory capacity with 2GB SD card. SD cards

with a memory capacity up to 16

GB can be used.

● measuring range 0.25 … 14000 mm (steel), depending on the probe, material, and surface

● digital resolution 0.01 mm or 0.1 mm (selectable)

over the entire measuring range

● units selectable between inch and mm

● integrated data recorder for 100,000 measurements

per file. Several files can be saved to the SD card.

● up to 16 user-definable comments for every file format with up to 16 alphanumeric characters per measuring point

● automatic probe detection with dialog probes, optimized setup and power of the instrument, especially

higher measuring accuracy thanks to the individual Vpath correction data stored in the corresponding

probe used

● MicroGrid function for testing the direct surroundings

of the measuring point

● single-element operating mode with measurement at

echo flank or echo peak

● MIN operating mode with increased pulse repetition

frequency for detecting the smallest reading in a se

ries of measurements

● Dual-Multi operating mode for measuring through

coatings

● adjustable minimum and maximum limits with alarm

signaling through color change of the reading

● locking function to prevent unintentional changes to

the adjustment values

-

DMS Go+ Edition 4 (05/2014) 1-13

Page 30

Options

Various options extend the basic functions of the DMS

Go+ and can be enabled by a code in each case.

DMS Go+ Base

● Basic version, for universal

ultrasonic wall thickness measurement

DMS Go+ TC

● TopCOAT technology for the simultaneous measurement of coating thickness and metal thickness

● Auto-V function for the wall thickness measurement

of components with unknown sound velocity, without

calibration block during the measurement

DMS Go+ DR

● Extended data recorder

DMS Go+ Advanced

● TopCOAT technology for the simultaneous measurement of coating thickness and metal thickness

● Auto-V function for the wall thickness measurement

of components with unknown sound velocity, without

calibration block during the measurement

● Extended data recorder

1-14 Edition 4 (05/2014) DMS Go+

Page 31

Wall thickness measurement using the DMS Go+ 1 Introduction

1.5 Wall thickness measurement using the DMS Go+

Principle of ultrasonic measurement

At first, the DMS Go+ generates an electric initial pulse

which is guided to the transmitter element of the probe.

Once there, it is converted into a mechanical ultrasonic

pulse. By means of a couplant, the ultrasonic pulse is

transmitted from the probe to the material to be tested

which it passes through at a velocity typical of the mate

rial (sound velocity of the material) until it encounters a

change in the material. Part of the pulse energy is re

flected from there and sent back to the probe (echo). If

the signal reaches the backwall of the test object before

that, the reflected pulse is called backwall echo.

A probe can have one (single-element probe) or several

transducer elements (dual-element probe).

Dual-element probes are especially suitable in the case

of:

-

-

● flaws reaching close to the sound entry surface, i.e.

especially in the case of

● deep-level corrosion and erosion.

DMS Go+ Edition 4 (05/2014) 1-15

Page 32

1 Introduction Wall thickness measurement using the DMS Go+

dual-element probe

backwall

test object

transmitter element

transmitted pulse reflected pulse

receiver element

Dual mode (measurement mode DUAL)

In the dual mode, the tasks of transmitting (T) and receiving (R) are solved by two transducer elements arranged in such a way that they are mechanically separated from each other. An initial pulse is triggered on the

transmitter side and transmitted to the test object. The

echoes are received on the receiver side and reconvert

ed into (very weak) electric pulses.

The DMS Go+ measures the time between transmitting

and receiving the sound pulse (time of flight). The DMS

Go+ determines the material thickness on the basis of

the measured time and the material's sound velocity.

The operating principle of a dual-element probe is

shown in the following figure.

-

1-16 Edition 4 (05/2014) DMS Go+

Page 33

Wall thickness measurement using the DMS Go+ 1 Introduction

probe

2nd backwall echo

boundary surface

between

coating and

1st backwall echo

coating

test object

Single-element mode (measurement modes S-IP, S-PEAK, S-FLANK)

A single-element probe is used for transmitting and receiving the echoes in the single-element mode. For the

wall thickness measurement, the DMS Go+ determines

the time of flight between the entry echo and the first

echo exceeding the gate A. The entry echo (interface

echo) is generated at the transition of the initial pulse

from the probe to the test object.

Multi-echo mode (measurement mode DUAL-MULTI)

The multi-echo mode is recommended, for example, for

the wall thickness measurement of coated test objects.

In this mode, two (or several) backwall echoes are used

for determining the wall thickness. The multi-echo mode

is possible using dual-element probes.

As before, an initial pulse is transmitted by a transducer

element to the test material. In the multi-echo mode,

however, part of the sound pulse energy is reflected

from the boundary surface between the coating (paint

coating) and the test material.

The rest of the energy of the first pulse transmitted passes further through the test material and returns as a

backwall echo.

The time of flight between the two successive backwall

echoes is used, together with the material's sound ve

locity, for determining the material thickness. The

echoes from the coating are ignored in this process.

The operating principle of the multi-echo mode is shown

in the following figure.

DMS Go+ Edition 4 (05/2014) 1-17

Page 34

1 Introduction Wall thickness measurement using the DMS Go+

probe

test object

coating

TopCOAT method (measurement mode TOP-COAT)

The patented TopCOAT method optimizes the corrosion measurement through paint coatings. In this process, the test object and paint coating are measured at

one go, and the two values are displayed on the screen.

Measurements using this method are even possible on

heavily corroded backwalls.

A special probe equipped with two pairs of transmitter/

receiver elements is used for the TopCOAT method.

The first pair of transmitter/receiver elements determines the coating thickness by means of a longitudinal

sound wave propagating beneath the surface of the test

object. At the same time, the second pair determines the

total wall thickness and reduces this value by the coat

ing thickness. The two values are displayed simultaneously on the DMS Go+ screen.

Measurements according to the TopCOAT method are

only possible using the DMS Go+ TC.

The following figure shows the operating principle of the

TopCOAT method using a special probe.

-

1-18 Edition 4 (05/2014) DMS Go+

Page 35

Wall thickness measurement using the DMS Go+ 1 Introduction

probe

test object

Auto-V (measurement mode AUTO-V)

The function Auto-V enables to measure the wall thickness of uncoated test objects without knowing the material's sound velocity. In this function, the sound velocity is determined simultaneously with the wall thickness

measurement. Uncoated materials can thus be mea

sured without an additional calibration and without the

use of reference blocks.

The function Auto-V also uses the probe described with

two pairs of transmitter/receiver elements. One pair of

transmitter/receiver elements calculates the material's

sound velocity by means of a longitudinal sound wave

propagating beneath the surface of the test object and

by means of the known sound path (distance between

transmitter and receiver). At the same time, the second

pair determines the time of flight of the sound pulse in

the test object and uses this value and the material'

sound velocity determined by the first pair to calculate

the wall thickness.

In this way, variations in the sound velocity due to temperature variations or local inhomogeneities within the

material are also included in the wall thickness calcula

tion.

-

The function Auto-V is only available in the version DMS

Go+ TC.

-

DMS Go+ Edition 4 (05/2014) 1-19

Page 36

1 Introduction Wall thickness measurement using the DMS Go+

B-scan

The B-scan is a special, path-dependent representation

of the test object's wall thickness. This representation is

ideal for the display of corroded sections. The probe is

guided over the section to be tested of the component

for this representation.

The cross section of the test object shown in the display

of DMS Go+ gives the operator a quick overview of the

thickness distribution on the component. In this regard,

the minimum wall thicknesses become especially well

visible. The following display shows a typical

B-scan in the display of DMS Go+.

1-20 Edition 4 (05/2014) DMS Go+

Page 37

Wall thickness measurement using the DMS Go+ 1 Introduction

Display orientation

You can change the screen display of DMS Go+ from

landscape to portrait mode (

see Section Display orien-

tation, page 5-6).

In addition, you can toggle between right-hand and lefthand operation (

see Section Selecting the instrument

orientation, page 5-6).

Display orientation in landscape mode

Display orientation in portrait mode

DMS Go+ Edition 4 (05/2014) 1-21

Page 38

1 Introduction The USM Go+

1.6 The USM Go+

The DMS Go+ uses the same operating principle as the

portable flaw detector USM Go+.

Your DMS Go+ can use all functions of the flaw detector

USM Go+ by means of a simple software upgrade. You

will then have two instruments available in one housing.

When you power the instrument on, you can choose the

instrument that you want to use (

ing the DMS Go+, page 3-11).

A separate operating manual is available for the USM

Go+. The functions of the USM Go+ are therefore not

described in the operating manual of the DMS Go+.

see Chapter 3.5 Start-

1.7 How to use this manual

This operating manual applies to all instrument versions

of the DMS Go+. Any differences in the functions or ad

justment values are marked in each case.

Before operating the instrument for the first time, it is absolutely necessary that you read the chapters 1, 3,

and

4. They will inform you about the necessary preparations of the instrument, give you a description of all

keys and displays, and explain the operating principle.

In doing this, you will avoid any errors or failures of the

instrument and be able to use the full range of instru

ment functions.

You will find the specifications of the instrument in

Chapter 11 Specifications.

-

-

1-22 Edition 4 (05/2014) DMS Go+

Page 39

How to use this manual 1 Introduction

Overview

The operation of the DMS Go+ is easy and quick to

learn. To be able to use the instrument quickly, you

should make yourself familiar with its preparation for

use and its basic functions. Please read the following

chapter carefully for this purpose:

Chapter 3 Initial start-up

This is where you'll find all the preparatory measures required for using the instrument.

Chapter 4 Principles of operation

gives you an overview of the operating principle of the

instrument and of the basic operating steps.

Chapter 5 Operation

shows you the settings that you can define and the operating steps needed for the measurement. It shows the

further options and functions presented by the DMS

Go+.

Chapter 6 Data Recorder

This chapter describes the functions and options for using the data recorder, as well as the documentation of

the measurement results.

Chapter 7 Special functions of the DMS Go+ TC

This chapter describes the options Auto-V and

TopCOAT.

Chapter 10 Appendix

You can find additional information about special measurements, the data recorder files types, a function reference, and tables with typical sound velocities in the

Annex.

DMS Go+ Edition 4 (05/2014) 1-23

Page 40

1 Introduction Layout and presentation in this manual

ATTENTION

Note

1.8 Layout and presentation in this manual

To make it easier for you to use this manual, all operating steps, listings, and special notes are always presented in the same way. This will help you find individual

pieces of information quickly.

Attention and note symbols

The ATTENTION symbol indicates peculiarities and special aspects in the operation

which could affect the accuracy of the re

sults.

Note contains e.g. references to other chapters or special recommendations for a function.

-

Listings

Listings are presented in the following form:

● Variant A

● Variant B

● ...

Operating steps

Operating steps appear as shown in the following example:

– Loosen the two screws at the bottom.

– Remove the cover.

–…

1-24 Edition 4 (05/2014) DMS Go+

Page 41

Standard package and accessories 2

DMS Go+ Edition 4 (05/2014) 2-1

Page 42

2 Standard package and accessories Standard package

2.1 Standard package

Product code Description Order number

Thickness gauge DMS Go+

TC-096 Transport case 109 709

LI-138 Lithium-ion battery, 7.4 V, 3.9 Ah, rechargeable 109 707

LiBC-139 AC power adapter/charger, 100V … 260V AC 109 708

SD memory card 8 GB

Display screen protector foils (10 pieces)

WS-342 Safety hand strap 109 753

Quick Start Guide

Operating manual on CD

Manufacturer's certificate

2-2 Edition 4 (05/2014) DMS Go+

Page 43

Add-on functions 2 Standard package and accessories

2.2 Add-on functions

Product code Description Order number

TC TopCOAT and Auto-V

DR Extended Data Recorder

DMS Go+ Edition 4 (05/2014) 2-3

Page 44

2 Standard package and accessories Preconfigured function packages

2.3 Preconfigured function packages

Product code Description Order number

Base Thickness gauge DMS Go+ or DMS Go+

TC Base with TopCOAT and Auto-V

DR Base with Extended Data Recorder

Advanced Base with TopCOAT, Auto-V, and Extended Data Recorder

2-4 Edition 4 (05/2014) DMS Go+

Page 45

Recommended probes 2 Standard package and accessories

2.4 Recommended probes

Product code Description Order number

Probes for corrosion measurements

(one-sided zeroing during coupling):

DA 301 5 MHz, measuring range 1.2 … approx. 200 mm 56 904

DA 303 2 MHz, measuring range 5 … approx. 300 mm 56 905

DA 0.8 G 800 kHz, measuring range 7 … approx. 60 mm 66 501

DA 312 10 MHz, measuring range 0.6 … approx. 50 mm 56 906

DMS Go+ Edition 4 (05/2014) 2-5

Page 46

2 Standard package and accessories Recommended probes

Product code Description Order number

Dialog probes for corrosion measurements

(one-sided zeroing before coupling):

DA 401 5 MHz, measuring range 1.2 … approx. 200 mm 58 637

DA 403 2 MHz, measuring range 5 … approx. 300 mm 58 639

DA 408 800 kHz, measuring range 7 … approx. 60 mm 58 644

DA 411 as DA 401, connectors at the top 58 857

DA 412 10 MHz, measuring range 0.6 … approx. 50 mm 58 638

2-6 Edition 4 (05/2014) DMS Go+

Page 47

Recommended probes 2 Standard package and accessories

Product code Description Order number

Probes for high-temperature measurements

DA 315 2 MHz, measuring range 5 … 150 mm, up to +200 °C 57 167

DA 317 5 MHz, measuring range 2 … 80 mm, up to +200 °C 57 168

DA 319 10 MHz, measuring range 1 … 15 mm, up to +200 °C 57 169

DA 305 High-temperature probe, 5 MHz

56 911

measuring range approx. 4 … 60 mm, up to +600 °C

HT 400 A High-temperature probe,

113-224-760

measuring range 0.5 … approx. 300 mm, up to +540 °C

DMS Go+ Edition 4 (05/2014) 2-7

Page 48

2 Standard package and accessories Recommended probes

Product code Description Order number

Probes for special test tasks:

DA 312 B16 10 MHz, measuring range 0.6 … approx. 12 mm, dia. 3 mm 66 934

KBA 525 10 MHz, measuring range 0.6 … approx. 20 mm, dia. 5 mm 113-516-002

FH2ED-REM Dialog probe, 8 MHz,

113-552-009

measuring range 0.75 … approx. 50 mm, remote control key

TC-560 5 MHz, measuring range 2 … approx. 200 mm

113-544-214

for TopCOAT operating mode (only DMS Go+ TC)

2-8 Edition 4 (05/2014) DMS Go+

Page 49

Recommended probes 2 Standard package and accessories

Product code Description Order number

Probes for precision measurements in

single-element mode (DMS Go+ and DMS Go+ TC):

CLF 4 Delay probe, 15 MHz, measuring range 0.25 … approx. 25 mm 113-527-665

CLF 5 Contact probe, 10 MHz, measuring range 1 … approx. 50 mm 113-526-005

CA 211 A Contact probe, 5 MHz, measuring range 2 … approx. 380 mm 113-544-000

CA 214 5 MHz, only in connection with N 12,5 K delay line 65 121

N 12,5 K Delay line for CA 214 66 382

G5KB Contact probe, 5 MHz, measuring range 2 … approx. 635 mm 58 504

G2N Contact probe, 2 MHz, measuring range 3 … approx. 635 mm 58 501

K1SC Contact probe, 1 MHz, measuring range 5 … approx. 635 mm 59 074

DMS Go+ Edition 4 (05/2014) 2-9

Page 50

2 Standard package and accessories Recommended probe cables

2.5 Recommended probe cables

Product code Description Order number

DA 231 1.5 m (for DA 401, DA 403, DA 408) 53 616

DA 233 1.5 m (for DA 315, DA 317, DA 319, DA 411) 54 999

DA 235 1.5 m (for DA 305, DA 412) 54 374

KBA 531 A 1.5 m (for TC-560), with cable gland,

with special stainless steel jacket

KBA 535 1.5 m (for HT 400 and HT 400A), with cable gland,

with special stainless steel jacket

KBA 536 1.5 m (for HT 400 and HT 400A), with cable gland, 118-140-100

HT-B Bell-housing grip, plug-on type for HT 400 and HT 400A 118-080-342

ET-104 Extension tube, plug-on type for HT 400 and HT 400A 118-100-104

CL 331 1.5 m (for CLF 4, CA 211 A) 58 160

2-10 Edition 4 (05/2014) DMS Go+

118-140-058

118-140-099

Page 51

Recommended probe cables 2 Standard package and accessories

Product code Description Order number

MPKLL 2 2 m (for CA 214, G5KB, G2N) 58 791

MPKL 2 2 m (for K1SC) 50 486

DMS Go+ Edition 4 (05/2014) 2-11

Page 52

2 Standard package and accessories Recommended accessories

2.6 Recommended accessories

Product code Description Order number

ZGM Hihg-temperature coupling paste, 200 … 600 °C, 100g tube 56 567

LI-138 Lithium-ion battery, 7.4 V, 3.9 Ah, rechargeable 109 707

LiBC-139 AC power adapter/charger, 100 V … 260 V AC 109 708

CA-040 Battery adapter for external charging of battery 109 713

TC-096 Transport case 109 709

CH-097 Shoulder strap 109 710

WH-098 Shoulder bag for instrument and couplant 109 711

WS-342 Safety hand strap 109 753

EK-492 Ergonomic set (CH-097, WH-098, WS-342) 109 754

2-12 Edition 4 (05/2014) DMS Go+

Page 53

Recommended accessories 2 Standard package and accessories

Product code Description Order number

UL MATE L Basic data transfer program UltraMATE L 022-104-560

UL MATE Evaluation and documentation program UltraMATE 022-103-660

DMS Go+ Edition 4 (05/2014) 2-13

Page 54

2 Standard package and accessories Recommended accessories

2-14 Edition 4 (05/2014) DMS Go+

Page 55

Initial start-up 3

DMS Go+ Edition 4 (05/2014) 3-1

Page 56

3 Initial start-up Instrument positioning

Note

3.1 Instrument positioning

Fold out the prop-up stand on the rear side of the

DMS

Go+ and position the instrument on a flat base so

that you can easily read the display.

If the instrument has been brought from a cold room into

a warmer one, wait until it has adapted to the room tem

perature before you power it on (to avoid condensation).

If (in rare cases) condensation has developed inside the

instrument, the cover may mist up from the inside. In this

case, open the top cover until the damp has dried up.

You should not power the instrument on until this has

happened.

Don't leave the cover and the lid of the battery compartment open for any longer than is

needed for exchanging the memory card or

the battery. Otherwise, moisture may pene

trate into the instrument.

3.2 Power supply

The DMS Go+ can be operated either with an external

charger/power adapter or with the corresponding lithi

um-ion battery.

You can also connect the DMS Go+ to the mains power

supply if the battery is in the instrument. A discharged

battery is charged in this case, during the instrument op

eration.

Operation with charger/power adapter

Connection to power supply

For the operation using a charger/power adapter, you

should only use the charger/power adapter included in

the standard package.

The charger/power adapter is automatically adjusted to

every AC voltage between 90

voltage).

V and 240 V (nominal

-

-

3-2 Edition 4 (05/2014) DMS Go+

Page 57

Power supply 3 Initial start-up

ATTENTION

1

2

Connecting the instrument

Connect the DMS Go+ to the mains socket-outlet by

means of the corresponding charger/power adapter.

The socket-contact for connecting the charger/power

adapter is located on the side of the DMS Go+.

– Align the Lemo plug of the charger/power adapter

with the red mark on the socket (1).

– Push the plug into the socket until it locks into place

with a clearly audible click.

– When removing the Lemo plug, pull the metal sleeve

on the plug back first in order to open the lock.

In order to power the instrument off correctly,

press the power On/Off key (2) on the side of

the instrument. If the power supply is inter

rupted (removing the battery, disconnecting

the power plug), the operation does not end

correctly.

DMS Go+ Edition 4 (05/2014) 3-3

Page 58

3 Initial start-up Power supply

21

Operation using batteries

You should only use the corresponding lithium-ion battery for the battery operation.

Inserting batteries

The battery compartment is located on the rear of the instrument. The cover is fastened with two attachment

screws.

– Turn the two attachment screws (1) of the battery

compartment counterclockwise by one quarter of a

turn each in order to loosen them.

– Lift the cover off upward. In the open battery compart-

ment, you will see several connector pins (2) on one

side.

3-4 Edition 4 (05/2014) DMS Go+

Page 59

Power supply 3 Initial start-up

1 2

– Place the battery in the battery compartment so that

the marking faces upwards and the contacts are

pushed against the connector pins (1).

– Insert the cover of the battery compartment with the

side opposite to the screws at first, and push the

lugs

(3) into the housing recesses.

– Press the cover firmly down on the side of the screws

and turn the two screws

(2) clockwise by one quarter

of a turn each in order to lock the cover.

3

DMS Go+ Edition 4 (05/2014) 3-5

Page 60

3 Initial start-up Power supply

1 2

Checking the charge level of the lithium-ion battery

The lithium-ion battery is provided with a battery charge

level indicator. Five light-emitting diodes

(1) indicate the

level of battery charge. Check the battery charge level

before inserting it into the instrument.

The number of diodes that are lit up has the following

meaning:

● 5 LEDs: Battery charge level 100 … 80 %

● 4 LEDs: Battery charge level 80 … 60 %

● 3 LEDs: Battery charge level 60 … 40 %

● 2 LEDs: Battery charge level 40 … 20 %

● 1 LED: Battery charge level 20 … 10 %

● 1 LED is flashing: Battery charge level <10 %

– Press the key (2) next to the LEDs. The LEDs indi-

cate the battery charge level.

3-6 Edition 4 (05/2014) DMS Go+

Page 61

Power supply 3 Initial start-up

Note

Power level indicator

The DMS Go+ is equipped with a power level indicator

that allows to estimate the remaining operating time of

the instrument. A battery icon with the corresponding

charge level is displayed in the top right corner on top of

the A-scan. The battery icon indicates the remaining op

erating time or the battery charge level.

Icon Meaning

Battery charge level,

remaining operating time

in hours (approximate value)

Charger/power adapter is connected,

percentage of battery charge level

(approximate value)

Warning: Low battery charge level,

remaining operating time

in minutes (approximate value)

The DMS Go+ is automatically powered off if the operation is no longer ensured. All settings are retained during

battery exchange and are immediately available again

afterwards.

If the battery charge level is low, it is abso-

lutely necessary that you finish your test job,

power off the instrument, and replace the

battery. You should carry a second battery

along with you if you cannot use mains pow

er supply to operate the instrument.

-

DMS Go+ Edition 4 (05/2014) 3-7

Page 62

3 Initial start-up Power supply

Charging the batteries

You can charge the lithium-ion batteries either directly

within the instrument or in an external charger.

Internal charging

If a lithium-ion battery is inserted, charging starts automatically as soon as you connect the charger/power

adapter to the DMS Go+ and to the mains power supply.

You can carry out ultrasonic tests and charge the batter

ies at the same time.

The charging time is approx. ten hours with simultaneous ultrasonic testing. If the instrument is not used for ultrasonic testing, the charging time is approx. eight

hours. This charging time applies to ambient tempera

tures of 25 … 30 °C.

-

Charging status

The LED on the charger/power adapter indicates the

status of charging.

off: Charger/power adapter is not con-

nected to the power supply

yellow steady light: Charger/power adapter is not con-

nected to the instrument or no batteries are inserted into the instru-

-

ment

flashing green light: Charging

green steady light: Charging is completed,

batteries are charged

External charging

You can charge lithium-ion batteries with an external

charger of the DMS Go+. Do not use any other chargers

for charging the lithium-ion batteries for the DMS Go+.

3-8 Edition 4 (05/2014) DMS Go+

Page 63

Connecting a probe 3 Initial start-up

Note

ATTENTION

3.3 Connecting a probe

You can connect all probes recommended in chapter 2

of this manual. In addition to the probe, you need a suit

able probe cable for the connection between the probe

and the instrument. The probe connectors are located

on the side of the instrument.

Probes with zeroing before coupling should

not be coupled when the instrument is pow

ered on. The DMS Go+ tries to detect a zero

point as long as the probe is coupled.

Dual-type connectors

Most probe cables have a dual-type connector for both

connection sockets on the instrument. To prevent a

wrong connection, these connectors and the connection

sockets on the probe and on the instrument are provid

ed with lugs.

– Connect the probe cable with the probe.

– Connect the probe cable with the probe connections

on the side of the instrument.

Single-type connectors

-

Both connector sockets are equally suitable (connected

in parallel) for connecting single-element probes so that

it does not matter which one of the two sockets is used.

When connecting a dual-element (TR) probe (having

one transmitter or pulser element and one receiver ele

ment) or two probes (of which one is transmitting and

the other one receiving), attention should be paid to the

correct allocation of connecting cables (please see sym

bols on the instrument):

Icon Meaning

-

If a probe is connected incorrectly, the consequence would be a mismatching which

may lead to considerable power losses or

even to echo waveform distortions.

Transmitter connection

Receiver connection

-

-

DMS Go+ Edition 4 (05/2014) 3-9

Page 64

3 Initial start-up Inserting the SD memory card

2

3.4 Inserting the SD memory card

You can use any standard SD memory card in the DMS

Go+. To insert and to remove the memory card, you

have to open the watertight cover at the top of the instru

ment.

– Push the lock of the hinged cover (1) in the direction

of the arrow in order to open the cover.

– Insert the SD memory card into the card slot so that

the contacts (2) of the card face the instrument front

side.

– Press the card down into the card slot until it locks

into place.

– Close the cover and make sure that it is locked tightly.

If necessary, push the lock up to the limit stop in the

opposite direction of the arrow in order to close the

cover watertight again.

– To remove the SD card, open the cover and shortly

press down the card to unlock it.

1

-

3-10 Edition 4 (05/2014) DMS Go+

Page 65

Starting the DMS Go+ 3 Initial start-up

1

3.5 Starting the DMS Go+

Powering On

To start the DMS Go+, shortly press the Power key (1)

on the side of the instrument casing.

The software is initialized. During this, the display will remain blank for about 3 seconds. If the license for the

USM Go is also installed, the display will show the page

for selecting the required instrument. Choose the re

quired instrument using the arrow keys on the keypad.

After that, the start display showing the name of the instrument and information on the software, serial number, and the installed options will appear.

The instrument carries out a self-check and then switches over to stand-by mode.

-

The settings of all function values and the default settings (language and units) are the same as before powering the instrument off.

DMS Go+ Edition 4 (05/2014) 3-11

Page 66

3 Initial start-up Starting the DMS Go+

Powering Off

To power the DMS Go+ off, shortly press the Power key

on the side of the instrument casing.

The settings of all function values and the default settings (language and units) are retained after powering

off.

Factory default setting (Reset)

If you can no longer use the functions of your instrument

or if the instrument no longer reacts as expected, you

can reset it to the factory default settings. Any data

saved to the SD card will be retained, all other individual

settings, e.g. language and units, will be reset to the fac

tory default settings.

– Power the instrument off.

– Press the further ends of the two Function keys (1

and 2), and the Power key

hold all three keys pressed until the start display or

the page of the instrument selection appears.

(3) simultaneously, and

The instrument starts with the factory default settings

(for language selection,

page 5-2).

1

-

2

see Section Language setting,

3

3-12 Edition 4 (05/2014) DMS Go+

Page 67

Principles of operation 4

DMS Go+ Edition 4 (05/2014) 4-1

Page 68

4 Principles of operation Overview of operator's controls

1

3

4

2

5

6 7

4.1 Overview of operator's controls

1 Function key 1, functions are context-dependent

2 Function key 2, functions are context-dependent;

keys 1 and 2 simultaneously: Save screen shot

3 Keypad, navigation between function groups and

functions, changing settings

4 Function key 3, functions are context-dependent

4-2 Edition 4 (05/2014) DMS Go+

5 Function key 4, function is individually assignable

(CONFIG – FUNC KEY),

6 Display for representation of readings,

A-scan, B-scan, functions, and data

7 Power key for powering on and off

Page 69

Display screen 4 Principles of operation

Note

4.2 Display screen

Display modes

The DMS Go+ has a high-resolution display screen for

the representation of the A-scan or the B-scan, for the

display of readings, important setup parameters and

icons, as well as for the representation of different

menus.

Normal display mode reading and A-scan

For toggling between the different display

modes and operating modes,

Operating modes and views, page 5-17.

Display mode reading and B-scan

see Section

DMS Go+ Edition 4 (05/2014) 4-3

Page 70

4 Principles of operation Display screen

Display mode Data Recorder

If a data recorder file is loaded, you will see the name

and the structure of the data recorder file above the cur

rent reading.

The functions to the left on the display screen are used

for navigating within the data recorder file.

Landscape and Portrait mode

You can change the screen display of DMS Go+ from

landscape to portrait mode.

4-4 Edition 4 (05/2014) DMS Go+

Page 71

Display screen 4 Principles of operation

Functions on the display screen

Function groups

The names of the seven function groups are shown at

the bottom of the display screen. The currently selected

function group is highlighted.

Functions

The functions of the currently selected function group

are shown on the left side of the display screen.

Icons and information

Keypad functions

You can see the current functions of the four function

keys in the top left corner of the display screen. The

functions are context-dependent and change during the

operation.

Data boxes

The current sound velocity of the material and the name

of the selected probe are displayed at the top center.

Six other data boxes are user-assignable for different

data and information.

DMS Go+ Edition 4 (05/2014) 4-5

Page 72

4 Principles of operation Display screen

Status display icons

The status displays in the top left corner of the display

screen, above the functions, inform about certain active

functions, operating modes, or operating status (

see

Section Status display icons, page 0-5).

Display of reading

The current reading is always displayed in enlarged

mode above the A-scan or B-scan.

If an alarm threshold is exceeded, the displayed reading

is red.

4-6 Edition 4 (05/2014) DMS Go+

Page 73

Navigation and function keys 4 Principles of operation

Note

4.3 Navigation and function keys

Keypad

The five keys of the keypad next to the display screen

are used

● for navigation between and within the function

groups,

● for changing settings, and

● for selecting adjustment values.

If a key is pressed for a longer time, the adjustment values change in larger increments.

The center key of the keypad is normally used for toggling between the display modes Landscape and Portrait.

In special contexts, the keys have further functions

which are described together with the corresponding ac

tion in this manual.

Function keys

Apart from the keypad, two groups of keys, including

two function keys each, are arranged next to the display

screen (

page 4-2).

The functions of three function keys are context-dependent and change automatically during the operation.

The current functions are displayed in the top left corner

of the display screen (

page 4-5).

The function of the function key number 4 is user-assignable (see Section Assignment of function key 4,

page 5-7).

see Section Overview of operator's controls,

see Section Keypad functions,

Power key

The key for powering the instrument on and off is located on the instrument side, next to the probe connectors.

-

DMS Go+ Edition 4 (05/2014) 4-7

Page 74

4 Principles of operation Navigation and function keys

Key combinations

You can carry out some functions by means of key combinations. To achieve this, you have to press several

function keys at the same time (

of operator's controls, page 4-2).

Function Keys

Screen shot Function key 1 + function key 2

Update Function key 2 + function key 4 + Power key

Reset Function key 1 + function key 4 + Power key

see Section Overview

4-8 Edition 4 (05/2014) DMS Go+

Page 75

Operational concept 4 Principles of operation

4.4 Operational concept

Changing the display views

The display view changes automatically after selecting

the corresponding instrument function or the operating

mode (function MODE).

Normal view reading and A-scan

Every time the DMS Go+ is powered on, the normal

view with the large display of reading and the functions

groups and functions can be seen.

View Data Recorder

If a data recorder file has been loaded, additional information about the file is automatically displayed above

the reading together with the file structure including the

saved readings.

A description of how to handle data recorder files is given in Chapter 6 Data Recorder.

DMS Go+ Edition 4 (05/2014) 4-9

Page 76

4 Principles of operation Operational concept

Selecting and setting functions

Shown below the A-scan are the seven function groups

which you can directly select using the keys of the key

pad. The name of the currently selected function group

is highlighted and the corresponding functions are dis

played in a list at the left screen edge.

A vertical scroll bar at the utmost screen edge shows the

current position in the list for function groups containing

more than four functions.

-

–Press the left or right arrow keys in order to choose

a function group.

– Press the down arrow key in order to select the first

function of the function group chosen previously.

– Press the left or right arrow keys in order to change

the setting.

– Press the function key 1 (function HOME) in order to

exit the function.

Coarse and fine adjustment of functions

You can choose between coarse and fine adjustment

for some functions.

Use the lower function keys to make the coarse adjustment. The value will then change either in large increments (e.g. for the function DISPLAY RANGE) or you

can choose from a series of factory-saved values (e.g.

for the function VELOCITY)

The fine adjustment is made by means of the left and

right arrow keys of the keypad. The fastness of change

is influenced by the duration of the key depression

during this (e.g. for the function VELOCITY).

4-10 Edition 4 (05/2014) DMS Go+

Page 77

Operational concept 4 Principles of operation

During the coarse adjustment, the name of the function is

displayed in capital letters (DISPLAY RANGE), whereas

it is displayed in lower-case letters during the fine adjust

ment (display range).