Page 1

CL 5

Operating Manual

Ident-Nr. 021-002-296

Issue 01

Page 2

Issue 01, 04/2005 applies to software version XX.04.XX

Page 3

CL 5 Issue 01, 04/05 0-1

Contents

1 General Information........................... 1-1

1.1 Supplying Power to the CL 5................. 1-2

1.2 Powering On and Off the Instrument .... 1-4

1.3 Key Features of the CL 5........................ 1-4

CL 5 Precision Thickness

Measurement Base Instrument .............. 1-5

Instrument Options .................................. 1-6

1.4 Whats in this Manual ............................ 1-6

2 Understanding the Keypad,

Menu System, and Displays ............. 2-1

2.1 Keypad Features .................................... 2-2

2.2 Interpreting Display Screens ................. 2-2

2.3 Working with the Configuration

Display .................................................2-10

3 Setting Up the CL 5 ........................... 3-1

3.1 Connecting a Probe and Loading a

Setup File ............................................. 3-3

3.2 Configuring the Instrument ................... 3-6

3.2.1 Setting Instrument Gain ................ 3-8

3.2.2 Setting Update Rate ..................... 3-8

3.2.3 Setting Nominal Thickness ........... 3-8

3.3 Instrument Calibration........................... 3-9

3.4 Setting the Maximum and Minimum

Alarms .................................................. 3-9

3.5 Creating and Erasing Custom Setup

Files .....................................................3-11

3.6 Locking and Unlocking Instrument

Settings ...............................................3-14

4 Measuring Thickness ........................ 4-1

4.1 Selecting the Displayed View ................ 4-2

4.2 Normal Measurement Mode

(No A-Scan) .......................................... 4-3

4.3 Min Scan and Max Scan Measurement

Mode..................................................... 4-6

Page 4

0-2 Issue 01, 04/05 CL 5

Contents

4.4 Differential/Rate-of-Reduction

Measurement Mode ............................. 4-8

4.5 Thickness + A-Scan Measurement

Mode (Optional) ..................................4-10

4.6 Velocity Measurement Mode

(Optional) ............................................. 4-8

5 Using the Optional Data Recorder ... 5-1

5.1 Creating a New Data Recorder File ....... 5-2

5.2 Recalling and Erasing Stored Data

Recorder Files ...................................... 5-4

5.3 Recording Thickness and Velocity

Measurements in Data Recorder

Files ...................................................... 5-5

5.3.1 Recording A-Scans in Data

Recorder Files .............................. 5-6

5.3.2 Navigating Through Data

Recorder Files .............................. 5-6

5.4 Printing a Report.................................... 5-6

6 I/O Features........................................ 6-1

6.1 Transmitting Data to an External

Device ..................................................... 6-2

6.2 Setting Communication Speed

(Baud Rate) and Connecting to a PC... 6-4

6.3 Remote Commands ............................... 6-4

7 Specifications

7.1 Instrument Specifications ..................... 7-2

7.2 A-Scan Option Features ......................... 7-5

7.3 Velocity Measurement Option

Features................................................ 7-5

7.4 Data Recorder Option Features ............. 7-6

7.5 CL 5 Probe/Transducer

Specifications....................................... 7-6

Page 5

CL 5 Issue 01, 04/05 0-3

Contents

8 Maintenance

Care of the Instrument .................................... 8-2

9 Appendix............................................ 9-1

9.1 Resetting the Operating Software ......... 9-2

9.2 Upgrading the Operating Software ....... 9-2

9.3 EMC Documentation .............................. 9-3

9.4 Manufacturer/Service Addresses .......... 9-5

10 Index ................................................. 10-1

Page 6

0-4 Issue 01, 04/05 CL 5

Important Notice

Important Notice

The following information must be read and understood

by any user of a GE Inspection Technologies ultrasonic

thickness gauge. Failure to follow these instructions

can lead to errors in thickness measurements or other

test results. Decisions based on erroneous results can,

in turn, lead to property damage, personal injury or

death.

General Warnings

Proper use of ultrasonic test equipment requires three

essential elements:

Selection of the correct test equipment.

Knowledge of the specific test application

requirements.

Training on the part of the instrument operator.

This operating manual provides instruction in the basic

set up and operation of the thickness gauge. There are,

however, additional factors which affect the use of

ultrasonic test equipment. Specific information

regarding these additional factors is beyond the scope

of this manual. The operator should refer to textbooks

on the subject of ultrasonic testing for more detailed

information.

Operator Training

Operators must receive adequate training before using

ultrasonic test equipment. Operators must be trained in

general ultrasonic testing procedures and in the set up

and performance required by a particular test.

Operators must understand:

Soundwave propagation theory.

Effects of the velocity of sound of the test material.

Behavior of the sound wave where two different

materials are in contact.

Areas covered by the sound beam.

More specific information about operator training, qualification, certification, and test specifications is available from various technical societies, industry groups,

and government agencies.

Page 7

CL 5 Issue 01, 04/05 0-5

Important Notice

Testing Limitations

In ultrasonic testing, information is obtained only from

within the limits of the sound beam. Operators must

exercise great caution in making inferences about the

test material outside the limits of the sound beam. For

example, when testing large materials it may be

impossible or impractical to inspect the entire test

piece.

When a less-than-complete inspection is to be

performed, the operator must be shown the specific

areas to inspect. Inferences about the condition of

areas not inspected, based on data from the evaluated

areas, should only be attempted by personnel fully

trained in applicable statistical and probability

techniques. In particular, materials subject to erosion

or corrosion, in which conditions can vary significantly

in any given area, should only be evaluated by fully

trained and experienced operators.

Sound beams reflect from the first interior surface

encountered. Because of part geometry and overlapped flaws or overlapped surfaces, thickness gauges

may measure the distance to an internal flaw rather

than to the back wall of the material. Operators must

take steps to ensure that the entire thickness of the

test material is being examined.

Ultrasonic Thickness Measurement Critical

Operating Procedures

The following operating procedures must be observed

by all users of ultrasonic thickness gauges in order to

minimize errors in test results.

1. Calibration of Sound Velocity

The principle of operation of an ultrasonic thickness

gauge is that the instrument measures the time of flight

of an ultrasonic pulse through the test piece and

multiplies this time by the velocity of sound in the

material. Thickness measuring error is minimized by

ensuring that the sound velocity to which the instrument is calibrated is the sound velocity of the material

being tested. Actual sound velocities in materials often

vary significantly from the values found in published

tables. In all cases, best results are obtained if the

instrument is calibrated on a velocity reference block

made from the same material as the test piece; this

block should be flat and smooth and as thick as the

maximum thickness of the test piece.

Page 8

0-6 Issue 01, 04/05 CL 5

Important Notice

Operators should also be aware that the sound velocity

may not be constant in the material being tested; heat

treating, for example, can cause significant changes in

sound velocity. This must be considered when evaluating the accuracy of the thickness provided by this

instrument. Instruments should always be calibrated

before testing, and the calibration should be checked

after testing, to minimize testing errors.

2. Probe Zero Procedure

When performing a one-point calibration with a contact

probe, the probe zero procedure must be performed as

described in this manual. The probe zero block should

be clean, in good condition, and without noticeable

wear. Failure to properly perform the probe zero

procedure will cause inaccurate thickness readings.

3. Effects of Temperature on Calibration

Temperature variations change the sound velocity of

materials and transducer delay lines and, therefore,

calibrations. All calibrations should be performed onsite, and with test blocks at the same temperature as

the test piece, to minimize errors due to temperature

variations.

4. Transducer Selection

The transducer used in testing must be in good

condition without noticeable wear of the front surface.

Badly worn transducers will have a reduced effective

measuring range. The specified range of the transducer

must include the complete range of thicknesses to be

tested. The temperature of the material to be tested

must be within the transducers temperature range.

5. Use of Couplants

Operators must be familiar with the use of ultrasonic

couplants. Testing skills must be developed so that

couplant is used and applied in a consistent manner to

minimize variations in couplant layer thickness and

errors in test results. Calibration and actual testing

should be performed under similar coupling conditions,

using a minimum amount of couplant and applying

consistent pressure on the transducer.

6. Doubling

Ultrasonic thickness gauges will, under certain

conditions, display readings which are twice (or, in

some cases, three times) the actual material thickness

Page 9

CL 5 Issue 01, 04/05 0-7

Important Notice

being measured. This effect, commonly known as

doubling, can occur below the minimum specified

range of the transducer. If the transducer being used is

worn, doubling is possible at a thickness greater than

the minimum of the specified range.

When using a new transducer, any reading which is

less than twice the minimum specified range of the

transducer may be a doubled reading, and the

thickness of the material being tested should be

verified by the use of other methods. If the transducer

shows any sign of wear, doubling may occur at a

second echo or other echo signal combinations may

produce a readable signal. The instrument reading and

apparent thickness are up to about twice the actual

value, resulting in a thickness greater than twice the

minimum of the specified range. This thickness should

be determined by calibrating the instrument/transducer

combination on reference blocks that represent the

complete range of possible thicknesses that may be

encountered in testing. This is particularly important

when the test piece is being ultrasonically measured for

the first time or in any case where the history of thickness of the test specimen is unknown.

Safety Information

Attention:

The CL 5 is an instrument for materials testing. Any

use for medical applications or other purposes is not

allowed.

The CL 5 may only be used in industrial environments.

The CL 5 can be operated with batteries or while

plugged into an electrical outlet using the AC charger.

The power supply unit has the electrical safety class II.

Batteries:

For the battery operation of the CL 5, we recommend

the use of a lithium-polt battery pack provided.

Operation using alkaline batteries, NiMH or NiCAD

cells is possible. You should only use the products

recommended by us for the battery operation. Do not

attempt to use any lithium batteries that are not

provided with the instrument. Do not attempt to charge

the provided batteries on an outside charger.

Page 10

0-8 Issue 01, 04/05 CL 5

Important Notice

Software:

According to the current state of the art, software is

never completely free from errors. Before using any

software-controlled test equipment, please make sure

that the required functions operate perfectly in the

intended combination.

Defects/errors and exceptional stresses

If you have reason to believe that a safe operation of

your CL 5 is no longer possible, you have to disconnect

the instrument and secure it against unintentional

reconnection. Remove the batteries if necessary.

A safe operation is no longer possible e.g.:

The instrument shows visible damages

The instrument no longer operates perfectly

After prolonged storage under adverse conditions like

exceptional temperatures and/or especially high air

humidity, or corrosive environmental conditions.

Being subjected to heavy stresses during

transportation

Service

Every effort has been made to provide you with a

reliable product. However, should service become

necessary, GE Inspection Technologies, has established a number of Factory Trained Service Centers.

For the location of the nearest facility refer to section

9.4 of this manual.

Page 11

CL 5 Issue 01, 04/05 1-1

General Information 1

Page 12

1-2 Issue 01, 04/05 CL 5

General Information Supplying Power to the CL 5

The CL 5 is an ultrasonic precision thickness

measurement device. Its available with optional live

A-Scan display, acoustic velocity measurement

capability, and a data recorder in which as many

10,000 thickness measurements per file can be stored.

This chapter of your manual introduces the key

features of the CL 5 and the contents of this operating

manual. The next chapter explains the keypad

functions and display-menu contents. Closely

reviewing the material in these two chapters will help

you make better use of the more detailed information

found throughout the rest of this manual.

In this chapter, youll learn

How to install batteries or connect the AC power

adapter to the instrument (Section 1.1)

How to Power on and off the instrument

(Section 1.2)

The features of the instrument and base instrument

package contents (Section 1.3)

The general content of each chapter in this manual

(Section 1.4)

1.1 Supplying Power to the

CL 5

The instrument is powered by a Lithium (Li) battery

pack.

It will also accept three AA size Alkaline, NiCAD,

or NiMH (nickel metal hydride) battery types.

The Lithium battery, which is recommended, will

provide up to approximately 25 hours of service life.

This pack (and only this pack) may be recharged in

the instrument using the charger provided with your

instrument.

When other types of rechargeable batteries are

used, they must be removed from the instrument for

charging.

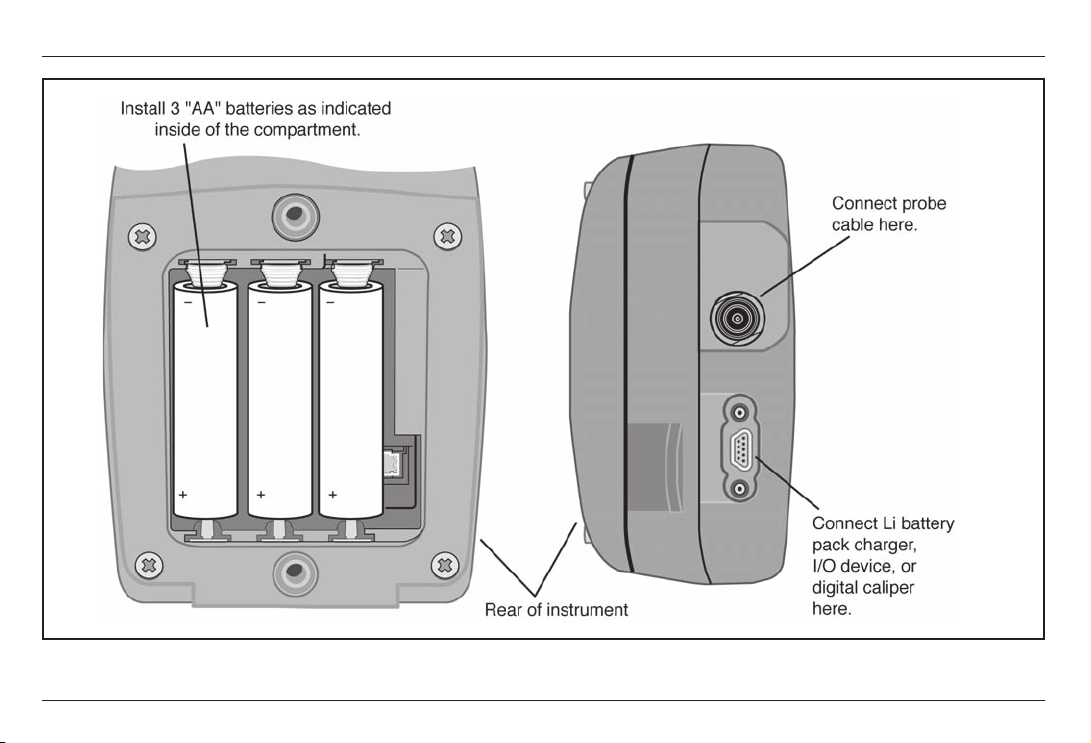

To install batteries, remove the battery-compartment

cover as shown in Figure 1-1. After inserting the Li

pack or three AA batteries according to the polarity

indicated in the battery compartment, replace the

compartment cover. Instructions on specifying battery

type are found in Section 3.2.

Page 13

CL 5 Issue 01, 04/05 1-3

Supplying Power to the CL 5

General Information

FIGURE 1-1Insert batteries as shown here. Notice the location of the External Power Connector to which the

instruments Li battery packs charger be connected.

Page 14

1-4 Issue 01, 04/05 CL 5

. Note:

When the battery indicator is in the last quarter as

indicated by the display-screen symbol

, replace

the batteries as soon as possible. The CL 5

automatically shuts off when batteries are too weak for

reliable operation. However, settings are saved and

restored when the instrument is turned on again. When

testing in remote locations, always carry spare

batteries.

. Note:

The instrument can be operated while the Li battery

packs charger is connected. This charger is connected

to the instrument though the connector shown in

Figure 1-1. When the charger is powering the

instrument,

appears on the display screen. The

charger may only be connected when the GE

Inspection Technologies Li battery pack is installed in

the instrument.

1.2 Powering On and Off the

Instrument

After a power source has been provided, power on the

instrument by pressing and holding

until the

instrument turns on. Press and hold when the

instrument is on to turn if off.

1.3 Key Features of the CL 5

Large Hollow/filled thickness digits

Alarm Bar Graph

Standard and Custom parameter setups

Supports delay and contact probes

Alphanumeric naming of data locations

Lockout feature with password access

Lightweight .75 lbs (.34 Kg)

Large LCD Display with Backlight and Adjustable

Contrast

General Information Powering On and Off the Instrument

Page 15

CL 5 Issue 01, 04/05 1-5

Approximately 25 hours life with the Li battery

pack or 3 AA alkaline batteries

Easy-to-use, single-level menu system

Multiple display-screen languages

User-selectable measurement resolution to 0.0001

inch (0.001 mm)

Normal (thickness), Min-Scan, Max-Scan, and

Differential/Rate of Reduction Measurement Modes

are Standard

Optional A-Scan provides A-Scan plus Thickness

Optional Data Recorder stores up to 10,000 thick-

ness measurements with A-Scan images attached

in as many as 120 data recorder files

Optional Velocity Measurement Mode includes an

electronically connected digital caliper for exact

measurement and automatic input of nominal

thickness

Field upgrades available via the GE Inspection

Technologies web site

Compatible with UltraMATE

©

and UltraMATE LITE

©

software programs

CL 5 Precision Thickness Measurement

Base Instrument

Contents of the CL 5 Base Instrument

CL 5 Instrument

Lithium Battery Pack

Lithium Battery Pack Recharger

Plastic Carrying Case

Wire Stand

Two-Point Check Block (uncertified)

Couplant Sample

Firmware Upgrade CD-ROM (requires Serial PC

cable)

Operating Manual

Operating Instruction Card

Certificate of Conformity

Key Features of the CL 5 General Information

Page 16

1-6 Issue 01, 04/05 CL 5

Instrument Options

A-Scan Upgrade Option

Data Recorder Upgrade Option

Velocity Measurement Option

1.4 Whats in this Manual

The CL 5 Operating Manual is divided into ten

chapters. All chapters except 4 and 5 apply to all

instruments. The last two sections of Chapter 4 apply

only to instruments equipped with the A-Scan or

Velocity measurement options. Chapter 5 applies only

to instruments equipped with the Data Recorder option.

Note that any CL 5 can be retrofitted to incorporate

these options. Following is a summary of Chapters 1

through 10:

Chapter 1General Introduction

Supplying Power to the instrument

Powering on and off the instrument

Overview of instrument features

Explanation of the operating manual contents

Chapter 2Understanding the Keypad, Menu

System, and Displays

Operations performed by each key

Navigating the display screens

Overview of menu functions

Explanation of display features (base model, data

recorder, and A-Scan equipped instruments)

Definition of icons

Chapter 3Setting Up the CL 5

Install a probe and configure the instrument by

loading a setup file

Set up the instrument display appearance (for base

model and A-Scan equipped instruments) and make

other configuration settings

General Information Whats in the Manual

Page 17

CL 5 Issue 01, 04/05 1-7

Whats in this Manual

General Information

Adjust the instrument gain setting

Specify the nominal material thickness

Calibrate and zero the instrument/probe combination

Set maximum and minimum alarm values

Create and erase custom setup files

Lock and unlock instrument controls

Chapter 4Measuring Thickness

Specify and use the Normal measurement mode (No

A-Scan)

Operate in Min-Scan and Max-Scan Measurement

mode

Operate in Differential/Rate of Reduction

measurement mode

Select and interpret the A-Scan plus Thickness

measurement mode (Optional)

Magnify the displayed A-Scan using the Zoom

control

Freeze the thickness reading and A-Scan

Connect the digital caliper and measure acoustic

velocity (Optional)

Chapter 5Using the Optional Data Recorder

Create, recall, and delete data recorder files

Store A-Scan and thickness readings in data

recorder files

Navigate data recorder file locations

Attach notes to the data recorder file

Print reports

Chapter 6I/O Technical Details

Configure the instrument to communicate with PCs

and printers

Thickness value format

Remote control codes

Page 18

1-8 Issue 01, 04/05 CL 5

Chapter 7Specifications

Chapter 8Maintenance

Chapter 9Appendix

Reset the operating software

Upgrade the operating software

EMC documentation

How to obtain service

Chapter 10Index

Whats in this Manual General Information

Page 19

CL 5 Issue 01, 04/05 2-1

Understanding the Keypad,

Menu System, and Displays

2

Page 20

2-2 Issue 01, 04/05 CL 5

Understanding the Keypad, Menu System, and Displays Keypad Features

The CL 5s display, keypad, and functional commands

are easy to interpret and use. In this chapter youll find

a brief explanation of all display and keypad features.

Youll also find references to manual sections where

more detailed information is available.

Note that the CL 5s display screen contents vary

depending on the optional features installed and the

operational settings selected. Display screens shown

in this chapter represent those found in all instrument

configurations including:

Base Model

A-Scan Option Installed

Data Recorder Option Installed

A-Scan and Data Recorder Options Installed

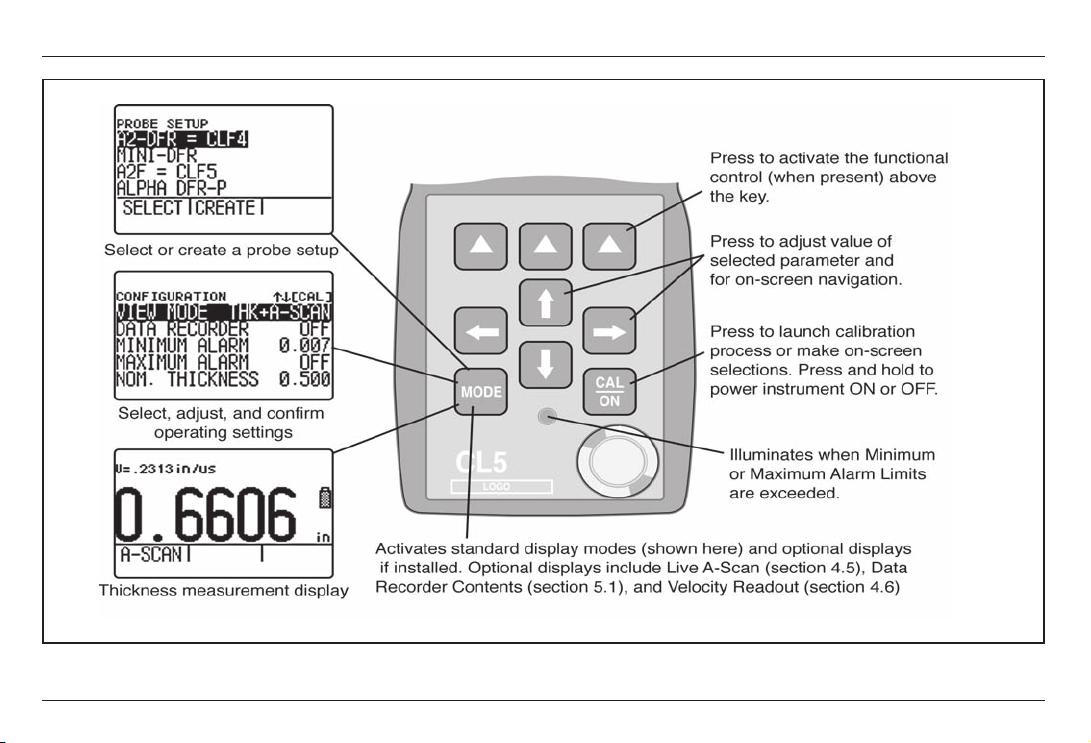

2.1 Keypad Features

The instruments keypad includes dedicated keys

(

and ), arrow keys ( , , , ), and three

virtual function keys ( ). Key functions are described

in Figure 2-1.

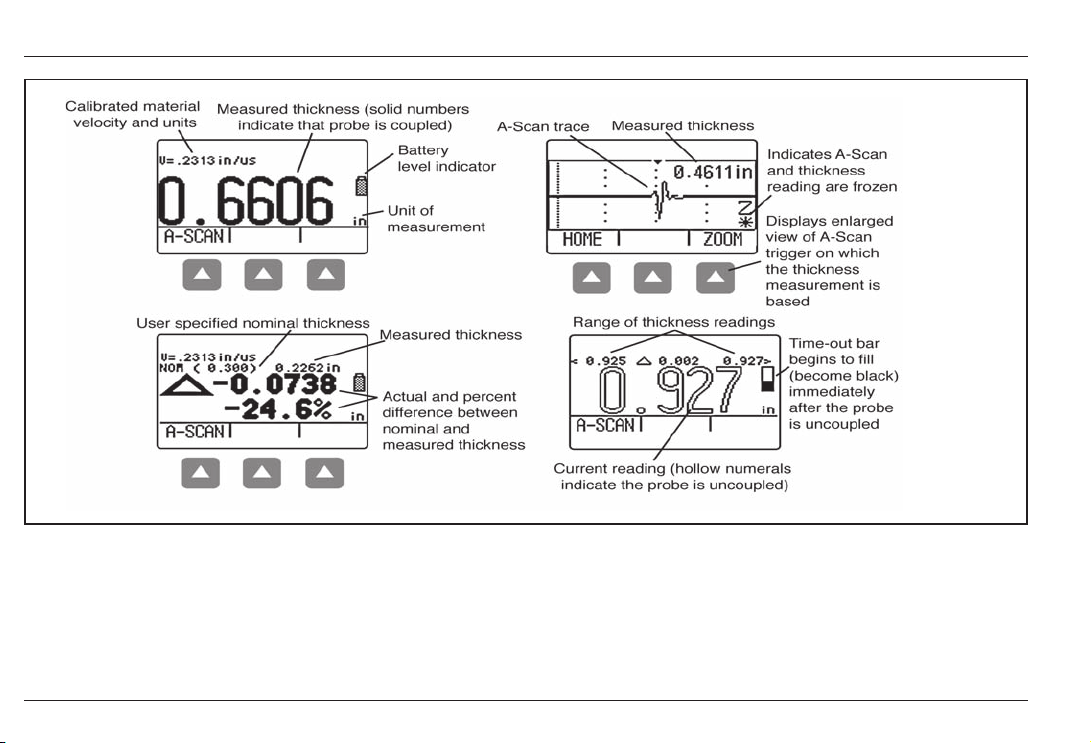

2.2 Interpreting Display Screens

This section of your manual describes the layout of the

CL 5s primary display modes including the:

Measurement Display Mode Indicates measured

thickness, contains status icons, displays data

recorder location and file name (when this option is

installed and activated), and the live A-Scan display

(when this option is installed and activated). Figure

2-2 shows four representative display screens.

Page 21

CL 5 Issue 01, 04/05 2-3

Interpreting Display Screens

Understanding the Keypad, Menu System, and Displays

FIGURE 2-1Key Functions

Page 22

2-4 Issue 01, 04/05 CL 5

Interpreting Display Screens

Understanding the Keypad, Menu System, and Displays

FIGURE 2-2MEASUREMENT DISPLAY MODE The displays appearance varies based on installed instrument

options as well as instrument display settings. NORMAL view mode is available in all instruments regardless of the

installed options. Additional measurement view modes are available when the A-Scan or Data Recorder options are

installed. Depending on the view selected, the display may contain the current thickness value, a live A-Scan,

minimum thickness value, maximum thickness value, and differential value in the unit of measurement or as a

percentage when compared to a nominal value.

Page 23

CL 5 Issue 01, 04/05 2-5

Understanding the Keypad, Menu System, and Displays Interpreting Display Screens

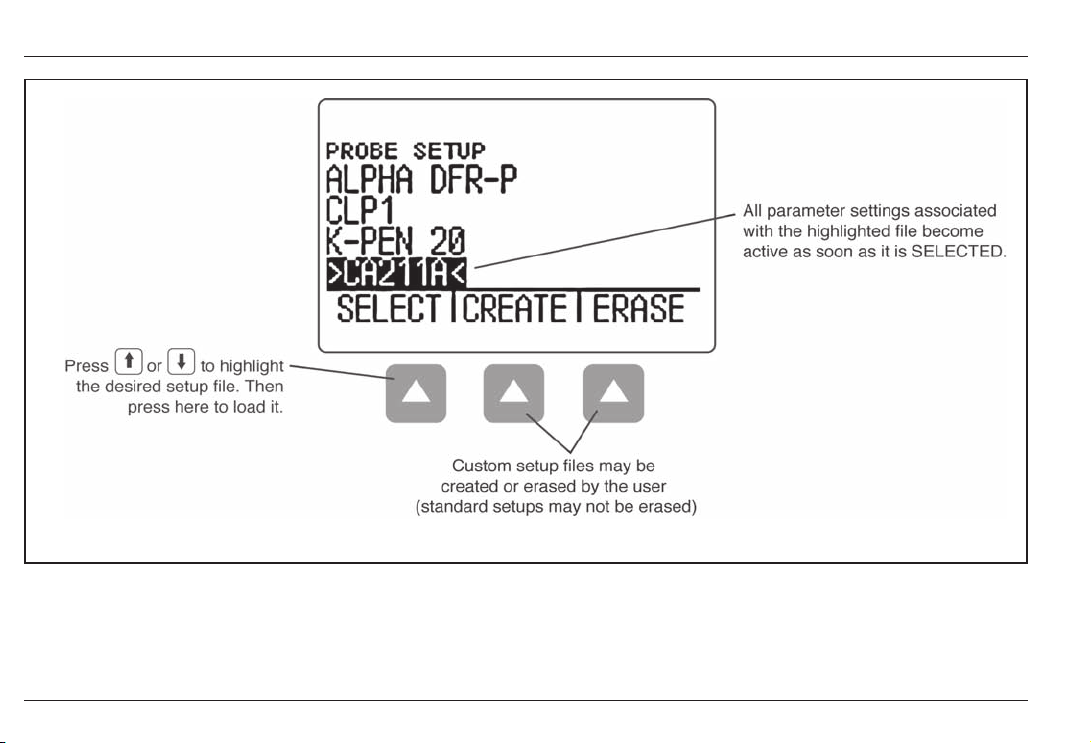

Probe Setup Display Mode Allows the user to

select a standard preloaded instrument setup (each

matched to a specific probe model) or a custom

user-defined setup. Custom Setups are created

using this display screen. They can be downloaded

to a PC using the UltraMATE© software package

and then downloaded into any CL 5 instrument. The

contents of a Custom Setup file vary depending on

the instruments configuration. See Section 3.5 for

information on custom setups. (Figure 2-3).

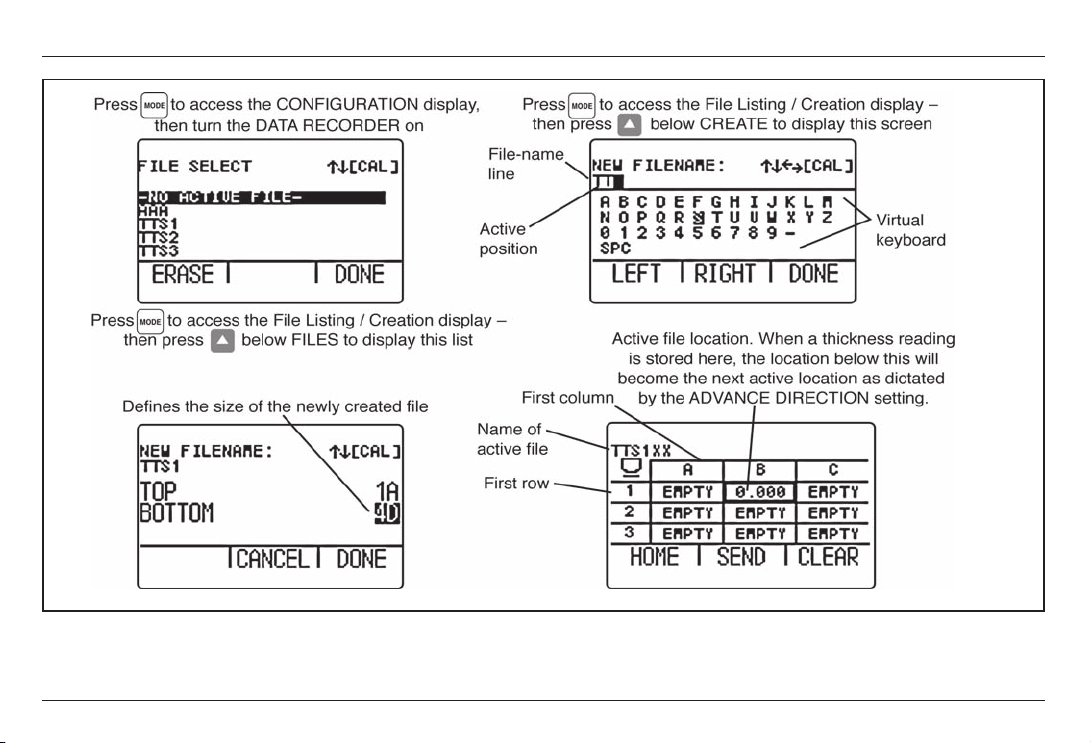

File Display Mode Allows the user to create and

store thickness readings in data recorder files. This

feature is only available when the data recorder

option is installed and activated. Accompanying

A-Scans can be stored with thickness readings by

holding

below the SEND Function for three

seconds. (Figure 2-4)

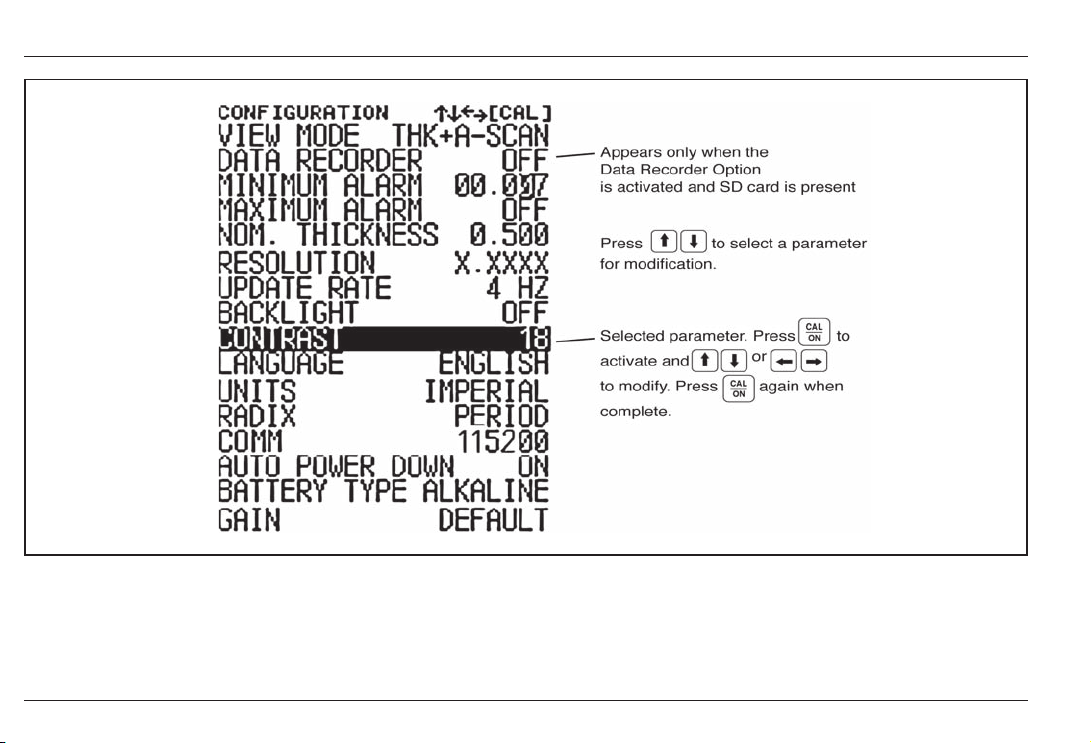

Configuration Display Mode Instrument controls

are accessed through this screen. The controls

listed on the configuration display screen vary

depending on the installed options. (Figure 2-5)

Page 24

2-6 Issue 01, 04/05 CL 5

Interpreting Display Screens

Understanding the Keypad, Menu System, and Displays

FIGURE 2-3PROBE SETUP DISPLAY MODE Allows selection of a preloaded or Custom Setup file, which

automatically recalls all parameter settings. Note that Custom Setups can be downloaded from an UltraMate©

equipped PC to any instrument, or created using this display (see Section 3.5 for information on Custom Setup files).

Page 25

CL 5 Issue 01, 04/05 2-7

Understanding the Keypad, Menu System, and Displays Interpreting Display Screens

FIGURE 2-4FILE DISPLAY MODE When installed and activated, the data recorder option allows users to create

data recorder files, store thickness readings (and accompanying A-Scans), and navigate through file contents as

shown here. See Chapter 5 to work with Data Recorder files.

Page 26

2-8 Issue 01, 04/05 CL 5

Interpreting Display Screens

Understanding the Keypad, Menu System, and Displays

FIGURE 2-5CONFIGURATION DISPLAY MODE The contents of the Configuration display depend on the

instruments installed-option configuration. All settings listed on the Configuration display are described in Section

2.3.

Page 27

CL 5 Issue 01, 04/05 2-9

2.3 Working with the

Configuration Display

The Configuration display is accessed by pressing .

With this screen displayed, you can adjust most CL 5

controls.

VIEW MODE In base-model units this parameter

offers 4 settings. In A-Scan equipped instruments this

parameter allows the measurement and live A-Scan to

be displayed. See Section 4.1 to select the view to be

displayed.

DATA RECORDER When the optional data recorder

is installed, setting this parameter to ON activates the

file recording capability and the data recorder file

display.

MINIMUM ALARM Enables and sets the minimum

alarm value. (Section 3.4)

MAXIMUM ALARM Enables and sets the maximum

alarm value. (Section 3.4)

NOMINAL THICKNESS Set the nominal thickness

value that is then used to calculate and the differential

and rate of reduction measurement values when

selected by the VIEW MODE parameter.

(Section 3.2.3)

RESOLUTION Controls the format (number of

decimal places) of the thickness measurement

displayed, printed in a report, and stored in a Data

Recorder file. (Section 3.2)

UPDATE RATE Rate at which the measurement

reading is updated. (Section 3.2.2)

BACKLIGHT Turns the displays backlight feature to

ON, OFF, or AUTO (AUTO switches backlighting on

whenever a key is pressed or the probe is coupled)

CONTRAST Sets the displays contrast level (select

then press

or to change contrast)

LANGUAGE Sets the instrument displays language

(Section 3.2)

UNITS Sets the unit of measurement to inches or

millimeters (Section 3.2)

Understanding the Keypad, Menu System, and Displays Working with the Configuration Display Module

Page 28

2-10 Issue 01, 04/05 CL 5

Working with the Configuration Display Module

Understanding the Keypad, Menu System, and Displays

RADIX Selects a period (.) or comma (,) to be used

as a decimal point (Section 3.2)

COMM Specifies the baud rate of the attached

printer or PC

AUTO POWER DOWN Selects the battery-life saving

ON, which powers down the instrument if no key

presses or measurement occur for four minutes, or the

OFF setting, which will only power down the instrument

when

is pressed.

BATTERY TYPE Select the installed battery type to

ensure accurate remaining battery-life indication.

Choose from Alkaline, NiMHD, or NiCAD. (See

Section 1.1 to install batteries)

GAIN Selects the default or reduced level of gain

corresponding to the active setup file (Section 3.2.1)

Page 29

CL 5 Issue 01, 04/05 3-1

Setting Up the CL 5 3

Page 30

3-2 Issue 01, 04/05 CL 5

Setting Up the CL 5 Connecting a Probe and Loading a Setup File

Prior to measuring thickness, the instrument must be

properly setup. This chapter explains the steps that

must be taken prior to measurement, to ensure that the

display appearance, ultrasonic settings, and

measurement mode match the desired configuration.

The steps described in this chapter apply to all

instruments, regardless of whether or not they

incorporate the A-Scan or Data Recorder options.

Most fundamental instrument parameters are

automatically set to a default value based on the Setup

file selected by the user. The instrument is supplied

with standard Setup files, named to match the probe for

which they are intended. Loading these standard setup

files (or a Custom Setup file like the ones described in

Section 3.5) is the first step to setting up the

instrument.

In preparation for measuring thickness, this chapter

explains how to

Install a probe and configure the instrument by

loading a Setup file (Section 3.1)

Set up the instrument display appearance

(Section 3.2)

Set the instruments Gain and Update Rate

(Section 3.2)

Calibrate the instrument/probe combination

(Section 3.3)

Set maximum and minimum alarm values

(Section 3.4)

Create and Erase Custom Setup Files (Section 3.5)

Lock and unlock instrument controls (Section 3.6)

Page 31

CL 5 Issue 01, 04/05 3-3

Connecting a Probe and Loading a Setup File

Setting Up the CL 5

3.1 Connecting a Probe and

Loading a Setup File

Prior to measuring thickness, you must connect a

probe to the instrument and select a setup file thats

compatible with the probe (Figure 3-1). The CL 5

supports delay line and contact probe types (see

Chapter 7 for specifications).

Once a probe is connected, press to activate the

Probe Setup display. The Probe Setup display, which is

shown in Figure 3-2, allows the user to select a

standard or Custom Setup file (see Section 3.5 to

create or erase Custom Setup files).

FIGURE 3-1Connecting a Probe Cable

Page 32

3-4 Issue 01, 04/05 CL 5

The following instrument settings are automatically

adjusted when the Setup file is activated:

Custom Setup Filename

Source Setup Filename

View Mode

Gain

Measured Value display resolution

Measurement Mode

Nominal Thickness when Differential, %RR, or

Velocity modes are selected

Minimum Alarm Setting

Maximum Alarm Setting

Zero Offset for contact probes only

Velocity

. Note:

While Custom Setups can be created in any

instrument, the parameter settings, which may be

modified and then saved in a Custom Setup, depend

on the instruments configuration. In a base model

instrument, only the setup name, material velocity

value (determined via calibration), alarm thickness

values, and UT settings related to the probe setup can

be modified and stored in a custom setup.

Setting Up the CL 5 Configuring the Instruments Display

Page 33

CL 5 Issue 01, 04/05 3-5

Configuring the Instruments Display

Setting Up the CL 5

FIGURE 3-2Selecting a Setup File

Page 34

3-6 Issue 01, 04/05 CL 5

3.2 Configuring the Instrument

Prior to using the CL 5 to measure thickness, some or

all of the following parameters must be specified using

the Configuration display shown in Figure 3-3.

Language Set the displayed language to English,

German, French, Spanish, Italian, etc.

Units Set the unit of measurement to inches or

millimeters

Resolution Sets the number of decimal places to

which thickness measurements are displayed

Update Rate Update the displayed measurement

at a rate of 4 or 8 Hz

Radix Select a period (.) or comma (,) to be used

as a decimal point

Battery Type Select from Alkaline, NiCAD, or NiMH

Auto Power Down Select ON to automatically turn

the instrument off five minutes after the last key

press (no data will be lost) or OFF to allow the

instrument to remain on until manually powered off.

Contrast Adjusts the display contrast

Backlight Adjusts the display lighting (a setting of

ON increases battery usage, a setting of AUTO

causes backlighting to illuminate and remain on for

Five Seconds after each key press.)

Each of these parameters is set the same way:

Step 1: Press

multiple times to access the display

(shown in Figure 3-3).

Step 2: Press

or to select each parameter you

would like to modify.

Step 3: When the desired parameter is highlighted,

press

to activate it.

Setting Up the CL 5 Configuring the Instruments Display

Page 35

CL 5 Issue 01, 04/05 3-7

Configuring the Instruments Display

Setting Up the CL 5

FIGURE 3-3Changing Parameter Settings

Page 36

3-8 Issue 01, 04/05 CL 5

Step 4: Press or to adjust the parameters value.

Step 5: Press

when the parameter is set to the

desired value.

Step 6: Continue selecting other parameters for

modification as outlined in Steps 2 through 5. When

complete with all modifications, press to return to

the measurement display.

3.2.1 Setting Instrument Gain

Instrument gain level is set to either a DEFAULT value

or to a noise-reducing LOW setting. To select the

instrument gain setting:

Step 1: Press

Step 2: Select the GAIN control

Step 3: Press

to activate the control, then or

to adjust the setting.

Step 4: Press when the adjustment is complete.

3.2.2 Setting Update Rate

Measurements are updated at a rate of 4 or 8 Hz, as

selected by the user. To select the measurement

update rate:

Step 1: Press

Step 2: Select the UPDATE RATE control

Step 3: Press to activate the control, then or

to adjust the setting.

Step 4: Press

when the adjustment is complete.

3.2.3 Specifying Nominal Thickness

When the VIEW parameter is set to DIFF/RR%, the

displayed thickness includes two differential values (in

the instruments units and as a percentage) that

represent the variation from user-specified nominal

thickness (Section 4.4). Nominal thickness is also

Setting Up the CL 5 Instrument Calibration

Page 37

CL 5 Issue 01, 04/05 3-9

Instrument Calibration

Setting Up the CL 5

used to calculate material velocity when the velocity

measurement option is installed. In VELOCITY view

mode, nominal thickness can be manually input or

directly measured using a connected digital micrometer

(Section 4.6). To manually input or modify the nominal

thickness:

Step 1: Press

Step 2: Select the NOM THICKNESS control

Step 3: Press

to activate the control, then or

to adjust the selected place value and or to

select another value.

Step 4: Press

when the adjustment is complete.

3.3 Instrument Calibration

Before measuring thickness with the CL 5, the

instrument and connected probe must be calibrated.

Its important that the setup file corresponding to the

attached probe be selected prior to launching the

calibration process.

Calibration requires the use of one or more standards

of known thickness. When a contact probe is installed,

either a one or two point calibration can be specified.

Note that contact probe types require zeroing and the

zeroing process is automatically accomplished as part

of calibration. To calibrate the instrument, follow the

instructions in Figure 3-4 and on your instruments

display screen.

. Note:

Proper calibration affects the accurate operation of the

instrument. The instrument should be calibrated if there

is a change in the type or temperature of the material

being tested, if the attached probe is changed, after

performing any parameter adjustment, or at intervals

specified in your test procedures.

3.4 Setting the Maximum and

Minimum Alarms

The CL 5 is equipped with a red LED (at the bottom

center of the instruments key pad) that illuminates

whenever the user-inputted minimum or maximum

Page 38

3-10 Issue 01, 04/05 CL 5

Setting Up the CL 5 Setting the Maximum and Minimum Thickness Alarms

FIGURE 3-4Instrument Calibration Procedure

Page 39

CL 5 Issue 01, 04/05 3-11

Creating and Erasing Custom Setup Files

Setting Up the CL 5

alarm is violated. Note that the inputted alarm value

will correspond to a thickness except when the

VELOCITY measurement option is installed and

activated. In this case the alarm settings will represent

velocity values. To input a minimum or maximum

alarm:

Step 1: Press to access the Configuration display

(shown in Figure 3-3).

Step 2: Press or to select

MINIMUM ALARM or MAXIMUM ALARM

Step 3: When the desired parameter is highlighted,

press

to activate it.

Step 4: Press or to change the selected position

in the alarm thickness and

or to adjust the value

of the selected position. To switch the alarm setting to

OFF from any other value, simultaneously press

and .

Step 5: Press

when the alarm thickness is set to

the desired value.

3.5 Creating and Erasing Custom

Setup Files

After loading a Standard Setup and performing the

necessary adjustments to optimize performance for a

given application, the instrument settings can be

stored and named as a Custom Setup file. The

instrument is capable of storing up to 5 Custom Setup

files, which can be erased at any time

(Figure 3-5).

Custom Setups can be created from any CL 5 keypad.

Custom Setups created using a base-model instrument

include the following settings:

User-assigned Custom Setup file name

VELOCITY

Page 40

3-12 Issue 01, 04/05 CL 5

Setting Up the CL 5 Locking and Unlocking Instrument Controls

FIGURE 3-5Follow this procedure to create or erase a Custom Setup file. Custom Setup file names may contain up

to 16 characters.

Page 41

CL 5 Issue 01, 04/05 3-13

Locking and Unlocking Instrument Controls

Setting Up the CL 5

MINIMUM ALARM

MAXIMUM ALARM

Custom Setups created using instruments equipped

with an optional A-Scan display store the same

parameters as a base-model unit as well as settings

that affect measurement. A full listing of parameter

settings stored in Custom Setup files is found in

Table 3-1.

Tab le 3-1

CUSTOM SETUP FILE CONTENTS

Custom Setup File Name Nominal Thicknesswhen differential, %RR, or Velocity

mode is selected

Source Setup File Name Minimum Alarm Thickness

Gain Maximum Alarm Thickness

Resolution of Displayed Values Zero Offset

View Mode Velocity

Measurement Mode

Whenever a Standard or Custom Setup file is recalled,

all of the instrument settings revert to those settings

stored in the file. Note that thickness measurements

are part of Data Recorder files (see Chapter 5) and are

not stored in Setup files.

. Note:

UltraMATE can be used to transfer Custom Setup files

to a PC where they are stored. The stored Setup file

can then be downloaded to any CL 5.

Page 42

3-14 Issue 01, 04/05 CL 5

3.6 Locking and Unlocking

Instrument Controls

Any instrument function can be made nonoperational

(locked) using the lockout display. Note that this

display is only accessible from the measurement

screen. Follow the instructions in Figure 3-6 to access

this display and lockout (or enable) some or all

function keys.

Setting Up the CL 5 Locking and Unlocking Instrument Controls

Page 43

CL 5 Issue 01, 04/05 3-15

FIGURE 3-6Procedure for locking and unlocking function keys

Locking and Unlocking Instrument Controls Setting Up the CL 5

Page 44

3-16 Issue 01, 04/05 CL 5

Setting Up the CL 5 Locking and Unlocking Instrument Controls

THIS PAGE LEFT INTENTIONALLY BLANK.

Page 45

CL 5 Issue 01, 04/05 4-1

Measuring Thickness 4

Page 46

4-2 Issue 01, 04/05 CL 5

Measuring Thickness Selecting the Displayed View

After setting up the instrument, as described in

Chapter 3, additional adjustments can be made to

select the type of measurement made and the way in

which it is displayed. In this chapter, youll also find

information related to configuring and working with the

optional A-Scan display including how to:

Select the measured value to view (Section 4.1)

Work with Normal measurement mode (Section 4.2)

Use the Min Scan and Max Scan measurement

modes (Section 4.3)

Interpret the Differential/Rate-of-Reduction

measurement mode (Section 4.4)

Work with the optional Thickness + A-Scan

measurement mode (Section 4.5)

Use the optional Velocity measurement mode

(Section 4.6)

. Note:

Load a Setup file corresponding to the connected probe

prior to making the adjustments described in this

chapter. Loading a Setup file after these adjustments

are made will force certain settings back to the default

value stored in the file.

. Note:

After making some or all of the adjustments described

in this chapter, the modified instrument setup can be

stored by creating a Custom Setup file. Your instrument

will store up to 5 Custom Setup files, which are

created (and erased) via the setup display. See

Section 3.5 for step-by-step instructions to create a

Custom Setup file.

4.1 Selecting the Displayed View

The measurement displayed by the instrument is

modified by

Step 1: Press multiple times to access the

configuration menu

Page 47

CL 5 Issue 01, 04/05 4-3

Step 2: Press or to select the VIEW MODE

parameter

Step 3: Press

to activate this parameter

Step 4: Scroll through the available modes by pressing

or . Press to select the displayed mode

(described below).

Base model instruments offer four display modes. In

addition, two more display modes are available

depending on the installed options. Display modes

include:

NORMAL (Thickness Only) The thickness value

appears as large digits in the center of the display. No

live A-Scan is displayed but an A-Scan snapshot of

the triggering echo can be accessed (Section 4.2).

MIN SCAN (Minimum Thickness Scan) Allows the

user to continuously evaluate material thickness

(provided the probe remains coupled or is uncoupled

only briefly) then, when the evaluation period is

complete, the minimum material thickness is

displayed. During the evaluation period, thickness is

displayed along with the minimum and maximum

observed thickness values (and the calculated

difference between the two). The display also includes

a time-out bar, which begins to fill as soon as the

probe is uncoupled. Recoupling the probe before the

time-out period expires allows the user to continue with

the same evaluation period. When the evaluation period

is complete (after the probe is uncoupled and the timeout bar fills), the minimum thickness observed during

the evaluation period is displayed. Its corresponding AScan can also be displayed by pressing

. At this

point the screen is frozen. Recouple the probe to

reactivate the display screen (Section 4.3).

MAX SCAN (Maximum Thickness Scan) Allows the

user to continuously evaluate material thickness

(provided the probe remains coupled or is uncoupled

only briefly) then, when the evaluation period is

complete, the maximum material thickness is

displayed. During the evaluation period, thickness is

displayed along with the minimum and maximum

observed thickness values (and the calculated

difference between the two). The display also includes

a time-out bar, which begins to fill as soon as the

probe is uncoupled. Recoupling the probe before the

time-out period expires allows the user to continue with

Measuring Thickness

Selecting the Displayed View

Page 48

4-4 Issue 01, 04/05 CL 5

the same evaluation period. When the evaluation period

is complete (after the probe is uncoupled and the timeout bar fills), the maximum thickness observed during

the evaluation period is displayed. Its corresponding AScan can also be displayed by pressing

. At this

point the screen is frozen. Recouple the probe to

reactivate the display screen (Section 4.3).

. Note:

During the placement of a very sensitive probe on the

part surface, excess couplant may cause erroneous

results. To eliminate the effect of excessive couplant,

couple the probe firmly to the part, then press

under

the ASCAN function, then press

under HOME.

This restarts the scanning session while the probe is

properly in contact with the part.

DIFF / RR% (Differential / Rate-of-Reduction) The

currently measured and user-inputted nominal

thickness appear along the top of the display while the

difference between these two values (measured minus

nominal values expressed in percentage and

dimensional terms) appears in the middle of the

display. Note that the displayed differences can have

positive or negative values (Section 4.4).

THK + A-SCAN (Thickness and A-Scan) An A-Scan

appears in the center portion of the display and the

thickness value is shown in the displays upper righthand corner (Section 4.5).

VELOCITY (Material Velocity) The material velocity

value appears as large digits in the center of the

display. This velocity calculation requires an accurate

NOMINAL THICKNESS value which can be inputted by

the user or by using the connected digital caliper. Note

that no live A-Scan is displayed but an A-Scan

snapshot of the triggering echo can be accessed

(Section 4.6).

4.2 Normal Measurement Mode

(No Live A-Scan)

When NORMAL view mode is active, the display only

contains a thickness reading (see Section 4.1 to select

view mode). While no live A-Scan is available, an AScan Snapshot can be accessed at any time by

pressing

directly below A-SCAN on the function bar

(Figure 4-1).

Measuring Thickness Normal Measurement Mode

Page 49

CL 5 Issue 01, 04/05 4-5

FIGURE 4-1NORMAL view mode displays only the thickness reading. Selecting the A-SCAN function bar option

allows you to view a Snapshot of the A-Scan echo that is represented by the thickness reading. This A-Scan is frozen.

No live A-Scan echo is available in this view mode.

Measuring Thickness

Normal Measurement Mode

Page 50

4-6 Issue 01, 04/05 CL 5

4.3 Min Scan and Max Scan

Measurement Modes

These modes allow the user to continuously evaluate

material thickness then, when the evaluation period is

complete, display the extreme (minimum or maximum)

material thickness observed. During the evaluation

period, thickness is displayed along with the minimum

and maximum observed thickness values (Figure 4-2).

See Section 4.1 to select view mode.

FIGURE 4-2MIN SCAN and MAX SCAN views allow the user to observe thickness measurements over an area, and

display the maximum and minimum thickness encountered during the evaluation period. The time-out feature

(represented by the bar shown here) allows the user to momentarily uncouple during the evaluation period, and then

recouple to continue the same period. In these modes the instrument will continue to collect and compare thickness

readings for as long as the probe remains coupled.

Measuring Thickness Min Scan and Max Scan Measurement Modes

Page 51

CL 5 Issue 01, 04/05 4-7

4.4 Differential / Rate-ofReduction Measurement

Mode

This view mode displays the currently measured and

user-inputted nominal thickness, along with the

difference between these two values (measured minus

nominal) expressed in percentage and dimensional

terms. Note that the displayed differences can have

positive or negative values (Figure 4-3). See Section

4.1 to select view mode and 3.2.3 to specify

nominal thickness.

Measuring Thickness

Differential/Rate-of-Reduction Measurement Mode

FIGURE 4-3The DIFF / RR% view compares the live measurement with a user-inputted nominal material thickness.

This comparison is then expressed as a differential measurement and a percentage of the nominal thickness.

Page 52

4-8 Issue 01, 04/05 CL 5

4.5 Thickness + A-Scan

Measurement Mode (Optional)

This optional view mode displays both a live A-Scan

reading and corresponding thickness value. Selecting

FIND moves the triggering echo to the center of the

display while FREEZE captures the live A-Scan. After

the display is frozen, select ZOOM to magnify the

triggering echo (Figure 4-4). See Section 4.1 to select

view mode.

FIGURE 4-4THK + A-SCAN view mode displays, freezes, and magnifies a live A-Scan.

Measuring Thickness Thickness + A-Scan Measurement Mode

Page 53

CL 5 Issue 01, 04/05 4-9

4.6 Velocity Measurement Mode

(Optional)

This optional view mode displays measured material

velocity (see Section 4.1 to select view mode). The

material velocity calculation depends on the value

inputted for the test materials nominal thickness. This

nominal thickness value can be manually inputted

(Section 3.2.3) or by using the digital caliper supplied

with all instruments that incorporate the Velocity option.

(Figures 4-5 and 4-6). Note that when operating in

VELOCITY view mode, material velocity values may

be entered for MINIMUM and MAXIMUM ALARMs

(Section 3.4).

FIGURE 4-5VELOCITY view mode allows measurement of acoustic velocity based on a user inputted (or manually

measured) mechanical thickness.

Measuring Thickness

Velocity Measurement Mode

Page 54

4-10 Issue 01, 04/05 CL 5

Measuring Thickness Velocity Measurement Mode

FIGURE 4-6Direct input of nominal thickness in VELOCITY mode.

Page 55

CL 5 Issue 01, 04/05 5-1

Using the Optional Data Recorder 5

Page 56

5-2 Issue 01, 04/05 CL 5

Using the Optional Data Recorder Creating a New Data Recorder File

. Note:

The instructions here apply only to instruments

equipped with a Data Recorder.

When installed and activated, the data recorder option

allows users to create Data Recorder files, store

thickness readings (and accompanying A-Scans when

desired), and navigate through file contents. In this

chapter youll learn how to

Create Data Recorder files (Section 5.1)

Recall and erase Data Recorder files (Section 5.2)

Store thickness readings in Data Recorder files

(Section 5.3)

Store A-Scans in Data Recorder files (Section 5.3.1)

Navigate Data Recorder file locations to store or

delete readings (Section 5.3.2)

Print reports (Section 5.4)

5.1 Creating a New Data Recorder

File

To create a new Data Recorder file, you need only

specify a file name. In most cases, however, youll

wish to enter additional information. Parameters that

can be adjusted during the file-naming process include:

The first (TOP) and last (BOTTOM) positions in the

Data Recorder file (Figure 5-2 describes how these

define the number of locations in the new file)

The ADVANCE DIRECTION (described in

Figure 5-2)

NOTES related to the data file

Follow Steps 1 through 5 in Figure 5-1 to create a new

Data Recorder file.

. Note:

Once created, the file name and size parameters can

NOT be edited. Only the ADVANCE DIRECTION

parameter and NOTES contents can be modified. To

accomplish this, first select the file then activate and

modify the parameter.

Page 57

CL 5 Issue 01, 04/05 5-3

Creating a New Data Recorder File

Using the Optional Data Recorder

FIGURE 5-1Creating a New Data Recorder File

Page 58

5-4 Issue 01, 04/05 CL 5

5.2 Recalling and Erasing Stored

Data Recorder Files

Stored files can be recalled or erased at any time.

Once recalled, thickness measurements can be stored

in empty file locations, existing measurements can be

deleted and the advance direction can be changed. To

recall a Data Recorder file:

Step 1: Press

to access the CONFIGURATION

display, then set DATA RECORDER to ON.

Step 2: Press

again to launch the File Display

mode

Step 3: Activate the file selection function by pressing

below FILES. A file list will appear on the display.

Using the Optional Data Recorder Recalling and Erasing Stored Data Recorder Files

FIGURE 5-2Defining the Size and Advance Direction of a Data Recorder File

Page 59

CL 5 Issue 01, 04/05 5-5

Step 4: Press or to select the stored file you

wish to recall, and then press

.

To erase a Data Recorder file:

Step 1: Press

to launch the File Display mode

Step 2: If required, press

below FILES to obtain a

list of stored files.

Step 3: Press or to select the stored file you

wish to erase, and then press and hold below

ERASE.

. Note:

Once erased, the Data Recorder file and any stored

thickness measurements can not be retrieved.

5.3 Recording Thickness and

Velocity Measurements in

Data Recorder Files

The Data Recorder must be enabled (turned ON) via

the CONFIGURATION display. Once the Data Recorder

is turned on, the contents of the active Data Recorder

file are displayed in the File Navigation Grid shown in

Figure 5-2.

To store a thickness reading in the selected file

position, press

below SEND. Remember that the

units of the thickness value, and the number of

decimal places to which the thickness is recorded, are

determined by the UNITS and RESOLUTION settings

as described in Section 3.2.

. Note:

Pressing and holding below SEND for three

seconds will cause the thickness and displayed AScan to be stored in the selected position as described

in Section 5.3.1.

Recording Thickness Measurements in Data Recorder Files Using the Optional Data Recorder

Page 60

5-6 Issue 01, 04/05 CL 5

. Note:

Pressing

below SEND with the instrument

connected to a PC that has the applicable software

installed and running will result in the thickness reading

being sent out the I/O port as described in Section 6.1.

5.3.1 Recording A-Scans in Data

Recorder Files

An A-Scan can be stored in that active position of the

Data Recorder by pressing and holding (for three

seconds)

below SEND.

5.3.2 Navigating Through Data Recorder

Files

When the Data Recorder is turned on, the contents of

the active Data Recorder file are displayed in the

File Navigation Grid shown in Figure 5-2. Once the

navigation grid is activated,

, , , and can be

used to select any file position. Note that a heavier grid

box appears around the selected file position. Once a

file position is selected:

The current thickness reading can be sent to an

EMPTY file position

A measurement value can be stored by pressing

below SEND

An already stored value can be deleted by pressing

below CLEAR

5.4 Printing a Report

. Note:

The following procedure explains how to print the

contents of a stored Data Recorder file.

Once the instrument is configured for the connected

PC (see Section 6.2), you can proceed with the report

printing process. A printed report will include:

Printing a Report Using the Optional Data Recorder

Page 61

CL 5 Issue 01, 04/05 5-7

A file header listing Data Recorder file name

A description of the files structure including number

of rows, columns, and a listing of NOTES

All thickness measurements stored in the Data

Recorder file, along with an indication if the file has

an A-Scan attached or resulted from a Minimum or

Maximum thickness scanning session.

Attached A-Scans are NOT printed as part of the

report

Step 1: Press to access the Data Recorder file

display as shown in Figure 5-2.

Step 2: Follow the regular procedure to select the file

to be printed.

Step 3: Press

below PRINT to launch the report

printing process. All features listed above will be

included in the printed report.

Using the Optional Data Recorder Printing a Report

Page 62

5-8 Issue 01, 04/05 CL 5

Printing a Report

Using the Optional Data Recorder

THIS PAGE LEFT INTENTIONALLY BLANK.

Page 63

CL 5 Issue 01, 04/05 6-1

I/O Features 6

Page 64

6-2 Issue 01, 04/05 CL 5

I/O Features Transmitting Thickness Data Through an External Device

. Note:

The instructions in this chapter apply to all

instruments.

The instrument can communicate with external devices

in several ways. All of these communication methods

rely on the instruments I/O port. The following cables

are available for connection to this RS-232 port (see

Figure 3-1 for location):

USB PC Cable

Serial PC Cable

Digital CaliperVelocity Option

Li Battery Packs Charging cable

The instrument determines if the cable is connected to

a device provided the device is not off line or busy.

Individual thickness readings and A-Scans can be

transmitted to an attached device. With the use of

remote codes, a PC can control the instrument.

In this chapter you will find:

The byte structure used when thickness readings

are transmitted through the I/O port (Section 6.1)

Remote commands (Section 6.2)

6.1 Transmitting Data to an

External Device

When below SEND is pressed to transmit a

thickness or velocity value through the I/O port, data

will be transmitted at 8 data bits, 1 stop bit, no parity,

and at the user-specified baud rate. The transmitted

data will be in a 13-byte message format, structured as

shown in Table 6-1. Note that data can be transmitted

(and SEND appears) only when the PC cable is

connected to a device that can receive data.

Page 65

CL 5 Issue 01, 04/05 6-3

Transmitting Thickness Data Through an External Device

I/O Features

Table 6-1

Format of Transmitted Thickness Measurements

Byte 1 "+" or "-" for displayed differential thickness values

"?" for displayed high resolution metric velocity values

" " (space) for all other di splayed values

Byte 2,3,4,5,6 Display value (4 digits and decimal point)

.0000

0.000

00.00

000.0

0000.

Byte 7 " " (space)

Byte 8,9,10,11 "IN " for displayed inch thickness values

"MM " for displayed metric thickness values

Byte 12 Carriage Return (ASCII 13)

Page 66

6-4 Issue 01, 04/05 CL 5

6.2 Setting Communication

Speed (Baud Rate) and

Connecting to a PC

Using the proper cable, the instruments I/O port can

be connected to a PC. Before connecting to a PC do

the following:

Step 1: Press

to display the CONFIGURATION

menu

Step 2: Select the COMM (communication) control

Step 3: Press

to activate the control, then or

to adjust the selected baud rate to match that of the

connected device. Data transfer will not occur if the

selected baud rate does not match the device.

Step 4: Press

when the desired value is selected.

6.3 Remote Commands

The CL 5 can receive coded instructions from a

personal computer or terminal connected to the RS-232

I/O Features Setting Communication Speed and Type

I/O port. Queries, key presses and adjusting

instrument settings can be done remotely by using a

user written program or a commercially available serial

communications program such as Windows

HyperTerminal. After starting and configuring the

program, commands are inputted using the computer

keyboard.

Two types of command structures are possible:

To request the status or value of a function the

following sequence is used:

<ESC><COMMAND><RETURN>

To execute a keypad operation or adjust a setting

the following sequence is used:

<ESC><COMMAND><SPACE><VALUE><RETURN>

Examples:

<ESC><8J><RETURN>

The CL 5 will now return the version of

instrument operating software.

Page 67

CL 5 Issue 01, 04/05 6-5

Setting Communication Speed and Type

I/O Features

<ESC><7K><SPACE><11><RETURN>

The CL 5 now displays the Setup Screen

listing all stored default and custom probe

setups.

Remote Control Codes:

The following is a partial listing of remote commands.

Additional remote commands are available upon

request.

Strings inside [ ] are values / parameters

Codes supporting queries are indicated with *

Page 68

6-6 Issue 01, 04/05 CL 5

I/O Features

Setting Communication Speed and Type

edoCyreuQretemaraPegnaRnoituloseRnoitcnuF

*DI).qerton(seY ."5LC"snruterTNEMURTSNI:noitacifitnedI

*PD).qerton(seY fotsilanruterlliwTNEMURTSNI:steSretemaraPfoyrotceriD

elifehtsatamrofemasehtni)sputesmotsuc(stesretemarap

:erutcurtsyrotcerid

XXXXXXXXXXXXXXXX1000

XXXXXXXXXXXXXXXX2000

XXXXXXXXXXXXXXXX3000

XXXXXXXXXXXXXXXX4000

*RD).qerton(seY htiwselifredroceratadfotsilanruterlliwTNEMURTSNI:yrotceriD

42sis'Xybdetacidnidleifemanelif(noitamrofniepytelif

:)sretcarahc

).delbanesinoitporedroceRataDnehwdetroppusylno(

DIRGXXXXXXXXXXXXXXXX1000

NIILCXXXXXXXXXXXXXXXX2000

)n(XFONrebmunelif

tsilridno

ot1

forebmuN

selif

1 ebdluohs)n(.)n(ybdetacidnielifehttimsnartlliwTNEMURTSNI

.tsilyrotceridehtnodeyalpsidsarebmunelifeht

).delbanesinoitporedroceRataDnehwdetroppusylno(

UF sihT.edomeviecerelifotnioglliwTNEMURTSNI:daolpUeliF

.stesretemaraprofdesuebtondluohs

).delbanesinoitporedroceRataDnehwdetroppusylno(

]n[UPretemaraP

rebmuntes

11ot1

no7ot1(

)P5LC

1 tesretemarapotnioglliwTNEMURTSNI:daolpUteSretemaraP

ottesretemaraphcihwsetacidni]n[retemarapehT.edomeviecer

.dedaolpuenoehthtiwecalper

)deunitnoC(

Page 69

CL 5 Issue 01, 04/05 6-7

edoCyreuQretemaraPegnaRnoituloseRnoitcnuF

]n[DPONretemaraP

rebmuntes

11ot0

no7ot0(

)P5LC

tesretemarapotnioglliwTNEMURTSNI:daolnwoDteSretemaraP

setacidni]n[.tesretemarapdetseuqerehtgnidnesedomdaolnwod

.detseuqersitahtrebmuntesretemarapeht

.sretemaraptnemurtsnievitcayltneserpehtsdnes0

MA noelbaliavayromemnruterlliwTNEMURTSNI:yromeMelbaliavA

.setybnidracDS

]rts[PAONputeS

emaN

.deificepsemangnirtsretemarapehtybdetacidniputesehtsdaoL

]n[FASEYrebmunelif

tsilridno

rebmunot1

seliffo

1.elifredroceratadevitcaehtyreuQ/teS:eliFevitcA

]n[K7ONsserpyek

edoc

1.etucexeotsserpyektahwdetacidnieulav=]n[:sserPyeK

0YEK_ON_EDOCKenifed#

11F_EDOCKenifed#

22F_EDOCKenifed#

33F_EDOCKenifed#

4WORRA_PU_EDOCKenifed#

5WORRA_NWOD_EDOCKenifed#

6WORRA_TFEL_EDOCKenifed#

7WORRA_THGIR_EDOCKenifed#

8EDOM_EDOCKenifed#

9FFO_NO_EDOCKenifed#

H7ON .edomweivtnemerusaemGTottnemurtsnisteS:EMOH

)deunitnoC(

Setting Communication Speed and Type

I/O Features

Page 70

6-8 Issue 01, 04/05 CL 5

I/O Features Setting Communication Speed and Type

edoCyreuQretemaraPegnaRnoituloseRnoitcnuF

R7ON riehtotsretemarapgniwollofehtsteseR.teserretemaraptfoS

:stluafed

ssenkcihT:edoMweiV

DOIREP:xidaR

FFO:thgilkcaB

hsilgnE:egaugnaL

)detcetedsiyrettabiLsselnu(enilaklA:seirettaB

otuA:nwoDrewoP

HCNI:stinU

XXX.X:noituloseR

)sretemaraptuokcollla(FFO:stuOkcoL

000.0:ssenkcihTlanimoN

)FFO(000.0:smralAxaM/niM

)detceffa-ton(etarduaB

J8)qerton(SEY rebmunnoisrevmetsySgnitarepOrofyreuQ

K8)qerton(SEY rebmuNlaireStnemurtsnIrofyreuQ

M8 .gnirtsnoisiveredoctooBrofyreuQ

N8 .gnirtsnoisiverngisedAGPFrofyreuQ

T8)qerton(SEY .erutarepmettnemurtsnilanretnirofyreuQ

Y8ONDCL

yromeM

pmuD

niyromemyalpsidDCLehtfopamtibehtgniniatnocatadpmudlliW

.stamroflarevesfoeno

rofetybyromemoedivehtspmudsihT.pmudyranibehtsisihT

.etyb

)deunitnoC(

Page 71

CL 5 Issue 01, 04/05 6-9

Setting Communication Speed and Type

I/O Features

edoCyreuQretemaraPegnaRnoituloseRnoitcnuF

C9ONenon edomnoitarugifnoc/noitarbilacyrotcafotnitnemurtsnisecalP

D9ONenon daolnwoD.edomnoitarugifnoc/noitarbilacyrotcafnielihwylnoevitcA

ehT.tnemurtsniehtmorfatadnoitarbilacevitcayltneserpeht

ecapsnoitarbilacehtfosetyb652gnidnesybdnopserlliwtnemurtsni

.enohcaeretfaRCahtiwtamrofrebmunlamicedni

U9ONenon daolpU.edomnoitarugifnoc/noitarbilacyrotcafnielihwylnoevitcA

ottcepxelliwtnemurtsniehT.tnemurtsniehtotecapsnoitarbilaceht

ehT.hcaeretfaRCahtiwecapsnoitarugifnocfosetyb652eviecer

.dessecorpsietybhcaeretfaRCahtiwdnopserlliwtnemurtsni

P9ONresluP

elbasid

selbasiD.edomnoitarugifnoc/noitarbilacyrotcafnielihwylnoevitcA

.snoitarblacniagrofreslup

elbane-0

elbasid-1

A9ONenon MORPEEotnikcabecapsnoitarbilacdetadpumargorP

SMSEY :sutatselpuoc,yticolev,ssenkcihttnemurtsnitneserpehtrofyreuQ

)sdleifdetimiledammoc(:tamroFtuptuO

sutatselpuoc,yticoleV,ssenkcihT

.noitulosermm100.nirebmunelohwaebsyawlalliwssenkcihT

.s/m1.0nieblliwyticoleV

delpuocnurof"U",delpuocrof"C"eblliwgalfelpuoC

)deunitnoC(

Page 72

6-10 Issue 01, 04/05 CL 5

I/O Features Setting Communication Speed and Type

edoCyreuQretemaraPegnaRnoituloseRnoitcnuF

W8ONgnimaertS

edoMataD

1

2

3

4

5

edomanitnemurtsniehttuplliw)0(fforo)x(noedomsihtgninruT

retfaTRAUehtrevodneseblliwFOTdnaeulavssenkcihtehterehw

duabwolstanwodtnemurtsniehtwolsyamsihT.noitisiuqcahcae

.edompaC-niMnigninnurnehwrosetar

)sdleifdetimiledammoc(:tamroFtuptuO

SUTATSELPUOC,YTICOLEV,SSENKCIHT

.noitulosermm100.nirebmunelohwaebsyawlalliwssenkcihT

noitulosers/m1nideyalpsidyticoleV

delpuocnurof"U",delpuocrof"C"eblliwgalfelpuoC

SUTATSELPUOC,SUTATSMRALA,SSENKCIHT

:sadeyalpsidsimralA

mralaon:Ñ)nofi(mralanimnahtsselsissenkciht:<

)nofi(mralaxamnahtretaergsissenkciht:>

SUTATSELPUOC,FOT

sdnoces-onanninoituloserthgilffoemiT

SUTATSELPUOC,%RR,ECNEREFFID,SSENKCIHT

ssenkcihtlanimonmorfdetaluclacsiecnereffiD

ssenkcihtlanimonmorfecnereffidegatnecrepehtsi%RR

SUTATSELPUOC,KCIHTXAM,KCIHTNIM,SSENKCIHT

noitulosermm100.ni,seulavssenkcihtehterassenkcihtxamdnaniM

ngis-ehtsadeyalpsideblliwxaMdnaniM.noisseserutpacehtrof

sahxamronimwenondnadetratssinoisseserutpacwenanehw

.derutpacneeb

RTONssenkcihT

yalpsiD

noituloseR

xxxx.x-0

xxx.x-1

xx.x-2

x.x-3

noituloseryalpsidssenkcihtsteS

RPONtuokcoL

drowssaP

teseR

otsretemaraptuokcolllastesdna5LCotdrowssaptuokcolehtsteseR

.dekcolnu

Page 73

CL 5 Issue 01, 04/05 7-1

Specifications 7

Page 74

7-2 Issue 01, 04/05 CL 5

Specifications Instrument Specifications

This chapter lists the features and specifications of your CL 5 including:

• Instrument Specifications (Section 7.1)

• Features of the Optional A-Scan (Section 7.2)

• Features of the Velocity Measurement Option (Section 7.3)

• Features of the Optional Data Recorder (Section 7.4)

• Probe Specifications (Section 7.5)

7.1 Instrument Specifications

Operating Principle: Ultrasonic, pulse echo measurement method

Measuring Range: 0.006 to 20.00 inch depending on probe and material

0.16 to 500 mm

Measuring Resolution: inch 0.001 default (selectable 0 .0001, 0.001, 0.01 inch)

mm 0.01 default (selectable 0.001, 0.01, 0.1 mm)

Material Velocity Range: 0.03937 to 0.78736 in/µs

1000 to 19999 m/s

Material Velocity Resolution: 0.00001 in/µs

0.1 m/s

Page 75

CL 5 Issue 01, 04/05 7-3

Instrument Specifications Specifications

Units: Inch or millimeter

Calibration: Enter velocity or thickness

Contact: One point or Two point calibration

Delay: One point

Pulser:

Excitation Pulse: Spike Pulser

Voltage: 100 V into 50 ohm load, using 20 MHz Scope

Receiver

Bandwidth: 1.0 to 10 MHz @ -3 dB

Gain: Automatic Gain Control

Display Type: High Resolution: Graphical LCD 64 x 128 Pixels,

2.25 ´ 2.56 (40 ´ 57 mm) with backlight and adjustable contrast.

Update Rate: 4 Hz or 8 Hz (User Selectable)

Thickness Value Display: 5 digit 0.75 (19 mm) high NORMAL MODE

5 digit 0.25 (6 mm) high with display of A-SCAN)

Page 76

7-4 Issue 01, 04/05 CL 5

Display of Last Reading: Solid filled or hollow digits indicate coupled or uncoupled condition.

Setups: 6 Standard Setups for Contact and Delay probes

5 Custom Setups with up to 16 character alphanumeric name

Alarm Settings: Minimum and Maximum Alarms

Range of 0.005-20 in. (0.1-508 mm)

Red LED illuminates and < or > displayed when alarms are enabled and

violated.

Power Requirements: Standard Li Battery Pack with on-board charger.

Batteries 3 each, AA size Alkaline, NiCad or NiMH

Battery Life/Operating Time: Approximately 24 hours

Instrument Shut-0ff: Selectable ALWAYS ON or AUTO OFF after 3 minutes of inactivity

Language: Selectable English, German, French, Spanish, and Italian

Baud Rate: Selectable 115200, 57600, 9600, 1200

Specifications Instrument Specifications

Page 77

CL 5 Issue 01, 04/05 7-5

I/O Connectors

Transducer: 00 Lemo (coax)

RS-232, Battery Charger: MicroD9 (Female),

Charger 100240 V, 5060 Hz

Temperature

Operating: +10°F to +140°F (-10°C to +60°C)

Storage: -10°F to +160°F (-20°C to +70°C)

Weight: 0.92 lbs. (420 g) including batteries

Size: 7.1 H x 3.7 W x 1.8 D (180 mm x 94 mm x 46 mm)

Instrument specifications subject to change without prior notice.

7.2 A-Scan Option Parameter Adjustments

Display View Thickness + A-Scan

Instrument specifications subject to change without prior notice.

7.3 Velocity Measurement Option Features

Display View VELOCITY Measurement

A-Scan Option Parameter Adjustments Specifications

Page 78

7-6 Issue 01, 04/05 CL 5

7.4 Data Recorder Option Features

Capacity: 120 files each containing 10,000 readings with or without A-Scan

attachments (May vary based on size of SD card used.)

File Structures Grid created from instrument keypad and Custom Linear created with

UltraMATE

File Naming: Up to 24 character alphanumeric name

Optional Software: UltraMATE and UltraMATE Lite

Instrument specifications subject to change without prior notice.

7.5 CL 5 Probe/Transducer Specifications

Model Probe Nominal Contact Measuring

Type Freq. Diameter Range

A-2 DFR & CLF4 Standard Delay Line 15 MHz 0.30 in. 0.007 to 1.0 in.

7.6 mm 0.18 to 25.4 mm Steel

Specifications Data Recorder Option Features

Page 79

CL 5 Issue 01, 04/05 7-7

Model Probe Nominal Contact Measuring

Type Freq. Diameter Range

Alpha 2F & CLF5 Fingertip Contact 10 MHz 0.38 in. 0.060 to 10.0 in.

9.5 mm 1.52 to 254 mm

Steel

Alpha DFR-P Plastics, Delay Line 22 MHz 0.30 in. 0.005 to 0.15 in.

7.6 mm 0.13 to 3.8 mm

Plastic

Mini-DFR Thin Range Delay Line 20 MHz 0.19 in. 0.005 to 0.200 in.

4.8 mm 0.13 to 5.1 mm

Steel

CL1P1 Pencil Probe 15 MHz 0.065 or 0.090 in. 0.008 to 0.175 in.

1.7 or 2.3 mm 0.20 to 4.4 mm

Steel

CA211A Standard Contact 5 MHz 0.75 in. 0.060 to 20.0 in.

19.1 mm 1.52 to 508 mm

Steel

Note: Other Probe Models Available upon request

Cl 5 Probe/Transducer Specifications Specifications

Page 80

7-8 Issue 01, 04/05 CL 5

Specifications CL 5 Probe/Transducer Specifications

THIS PAGE WAS INTENTIONALLY LEFT BLANK.

Page 81

CL 5 Issue 01, 04/05 8-1

Maintenance 8

Page 82

8-2 Issue 01, 04/05 CL 5

Maintenance Care of the Instrument

Care of the Instrument

Clean the instrument housing and display using a soft

cloth lightly dampened with water or a mild windowcleaning product. Never use harsh solvents as they

could cause the plastic to become brittle or damaged.

Care of Delay Line Probes

Replace delays showing signs of excessive wear or

those embedded with metal turnings. Delays in good

condition should periodically have the couplant

between the probe face and delay refreshed as follows:

Remove the delay by unthreading the knurled ring

Wipe clean the mating surfaces of the delay and

transducer face

Apply a fresh drop of lightweight oil (recommend

XD-740 couplant) and replace the delay line

Proper Cable Handling

Avoid twisting or knotting of the cable

Grasp the cable only by the connectors when

connecting or disconnecting from the instrument

Batteries

Periodically inspect the batteries for signs of leakage

or corrosion. If either occurs, remove and replace ALL

the batteries. Take care to properly dispose of the

defective batteries.

Page 83

CL 5 Issue 01, 04/05 9-1

Appendix 9

Page 84

9-2 Issue 01, 04/05 CL 5

Appendix Resetting the Operating Software