Page 1

AutoSigma 3000

Technical Reference and Operation Manual

Ident No. 071-002-022

47DH01

105 952

Page 2

This Issue 04, 06/2007 applies to the software version 1.0

Subject to change without notice. Rev. 02.

Page 3

Content

1 Introduction . . . . . . . . . . . . . . . . . . . 1 - 1

1.1 Important notes . . . . . . . . . . . . . . . . . . . 1 - 2

1.2 How to use this manual . . . . . . . . . . . . . 1 - 4

Operation steps . . . . . . . . . . . . . . . . . . . . 1 - 4

Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

Button Operation (Keypad) . . . . . . . . . . . 1 - 5

2 Standard package and accessories . . 2 - 1

2.1 Standard package . . . . . . . . . . . . . . . . . 2 - 2

2.2 Recommended accessories . . . . . . . . . 2 - 3

3 Preparation for operation . . . . . . . . 3 - 1

3.1 Battery installation . . . . . . . . . . . . . . . . 3 - 2

Power requirements . . . . . . . . . . . . . . . . . 3 - 2

3.2 Probe connection . . . . . . . . . . . . . . . . . . 3 - 3

3.3 Probe identifi cation . . . . . . . . . . . . . . . . 3 - 4

3.4 Entering probe code data . . . . . . . . . . . 3 - 5

3.5 General parameter setting . . . . . . . . . . 3 - 6

3.6 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 7

Normal switch on . . . . . . . . . . . . . . . . . . . 3 - 7

Reset switch on . . . . . . . . . . . . . . . . . . . . 3 - 7

3.7 Basic measurement knowledge . . . . . . 3 - 9

4 Basic functions . . . . . . . . . . . . . . . . . 4 - 1

4.1 Measurement method . . . . . . . . . . . . . . 4 - 2

4.2 Display . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

4.3 Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

Key operation on standard model . . . . . . 4 - 3

Additional key operations on DL option . . 4 - 4

AutoSigma 3000 Issue 04, 06/2007 0 - 3

Page 4

Content

5 Operation . . . . . . . . . . . . . . . . . . . . . 5 - 1

5.1 Switching on . . . . . . . . . . . . . . . . . . . . . . 5 - 2

Example . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 2

5.2 Switching off . . . . . . . . . . . . . . . . . . . . . 5 - 3

5.3 Changing working parameters . . . . . . . 5 - 3

5.4 Entering reference block values . . . . . 5 - 4

User reference blocks . . . . . . . . . . . . . . . 5 - 5

Considerations . . . . . . . . . . . . . . . . . . . . . 5 - 5

5.5 Probe setting (SET PROBE) . . . . . . . . . 5 - 6

5.6 Taking a conductivity measurement . . 5 - 8

5.7 Data logging (internal) . . . . . . . . . . . . . . 5 - 9

Clearing the entire memory . . . . . . . . . . . 5 - 9

Setting the number of data fi les . . . . . . . 5 - 10

Data logging . . . . . . . . . . . . . . . . . . . . . . 5 - 10

Logging in a reading (general) . . . . . . . . 5 - 11

Selecting a fi le for logging . . . . . . . . . . . 5 - 12

Clearing a fi le . . . . . . . . . . . . . . . . . . . . . 5 - 13

Accessing a fi le location containing

stored data . . . . . . . . . . . . . . . . . . . . . . . 5 - 13

5.8 Customising the operating mode . . . . 5 - 14

Storing a customised mode . . . . . . . . . . 5 - 15

Recalling a customised mode . . . . . . . . 5 - 15

Setting the operating mode to User or

Supervisor . . . . . . . . . . . . . . . . . . . . . . . 5 - 15

6 External data handling devices . . . . 6 - 1

6.1 Connection . . . . . . . . . . . . . . . . . . . . . . . 6 - 2

6.2 Sending serial data to an external

device . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 3

Sending a single fi le . . . . . . . . . . . . . . . . . 6 - 3

Sending the entire memory . . . . . . . . . . . 6 - 4

Report format of transferred data . . . . . . . 6 - 5

Example of a report . . . . . . . . . . . . . . . . . 6 - 5

7 Specifi cations . . . . . . . . . . . . . . . . . . 7 - 1

Issue 04, 06/2007 AutoSigma 3000

0 - 4

Page 5

8 Maintenance and care . . . . . . . . . . . 8 - 1

8.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 2

8.2 Care of Batteries . . . . . . . . . . . . . . . . . . 8 - 2

9 Appendix . . . . . . . . . . . . . . . . . . . . . . 9 - 1

9.1 EC Declaration of Conformity . . . . . . . . 9 - 2

9.2 Manufacturer / Service address . . . . . . 9 - 2

Great Britain . . . . . . . . . . . . . . . . . . . . . . . 9 - 3

USA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 3

Germany . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 3

10 Index . . . . . . . . . . . . . . . . . . . . . . . . 10 - 1

Content

AutoSigma 3000 Issue 04, 06/2007 0 - 5

Page 6

0 - 6 Issue 04, 06/2007 AutoSigma 3000

Page 7

Introduction 1

AutoSigma 3000 Issue 04, 06/2007 1 - 1

Page 8

Introduction

Important notes

1.1 Important notes

GE Inspection Technologies Operating manuals provide functional information about a particular instrument or group of instruments. However, proper setup and use of this equipment and the performance of

electromagnetic tests requires familiarity with factors

which are beyond the scope of Operating manuals.

These factors include the following:

• Selection of appropriate cables, probes, fi xtures,

mechanical handling equipment and other accessories.

• Selection of proper test frequency, test mode and

other test parameters.

• Preparation of the test surface.

• Characteristics of the test material for example: conductivity, hardness, permeability, geometry, magnetic properties, heat treatment etc.

• Environmental factors such as temperature humidity, dust and electrical interference.

• Any individual factors that will depend on the particular test object or test being performed.

It is therefore imperative that operators are properly

trained in both general procedure for electromagnetic

training testing and in the set up and execution of the

particular test to be performed. It is the responsibility

of the instrument user to ensure that test operators are

trained to a suffi ciently high standard, suitable equipment is used in the correct manner and that any test

variables which may affect specifi c tests are taken into

account. Similarly, compliance with standards such as

ASTM, ASNT, API, ASME, BS etc., as well as the observance of any test procedure specifi ed by any government, manufacturer or other regulating authority is

the responsibility of the user.

Periodic calibration, cleaning and maintenance may

be necessary to ensure proper operation of the equipment.

Environmental conditions and regularity of use should

be considered when determining the frequency of

such checks, then this should be observed.

Incidents such as physical shock, immersion in liquid

and exposure to damaging environments such as excessive heat, moisture, dirt or dust can adversely affect equipment performance. The equipment must be

Issue 04, 06/2007 AutoSigma 3000

1 - 2

Page 9

Important notes

Introduction

examined for damage and recalibrated after any such

incident. Do not use any product which you know or

suspect to be faulty.

Reference samples used for calibration should, ideally,

have the same material properties as the object to be

tested, or a known relationship to it, established by a

laboratory test.

Equipment calibration should be checked frequently

during testing to assure valid test measurements.

As a matter of good practice and wherever possible,

suspected defects in critical areas should be cross

checked using appropriate alternative indication techniques.

Any question about the use, operation, specifi cations

or special considerations relative to the particular

GE Inspection Technologies product you are using

should be addressed to your local sales representative,

the distributor or GE Inspection Technologies direct.

Eddy current based instrumentation works by measuring minute electromagnetic fi elds. Interfering signals,

even at a level satisfying CE mark requirements, may

be able to mask or distort this information. The user is

responsible for ensuring that no such effect is occurring.

GE Inspection Technologies pursues a policy of continued development of its products. The company reserves the right to change specifi cations without prior

notice.

AutoSigma 3000 Issue 04, 06/2007 1 - 3

Page 10

Introduction

How to use this manual

1.2 How to use this manual

In order to simplify this operating manual, the operational steps, information listings etc, always have the

same format. This will enable you to quickly fi nd information.

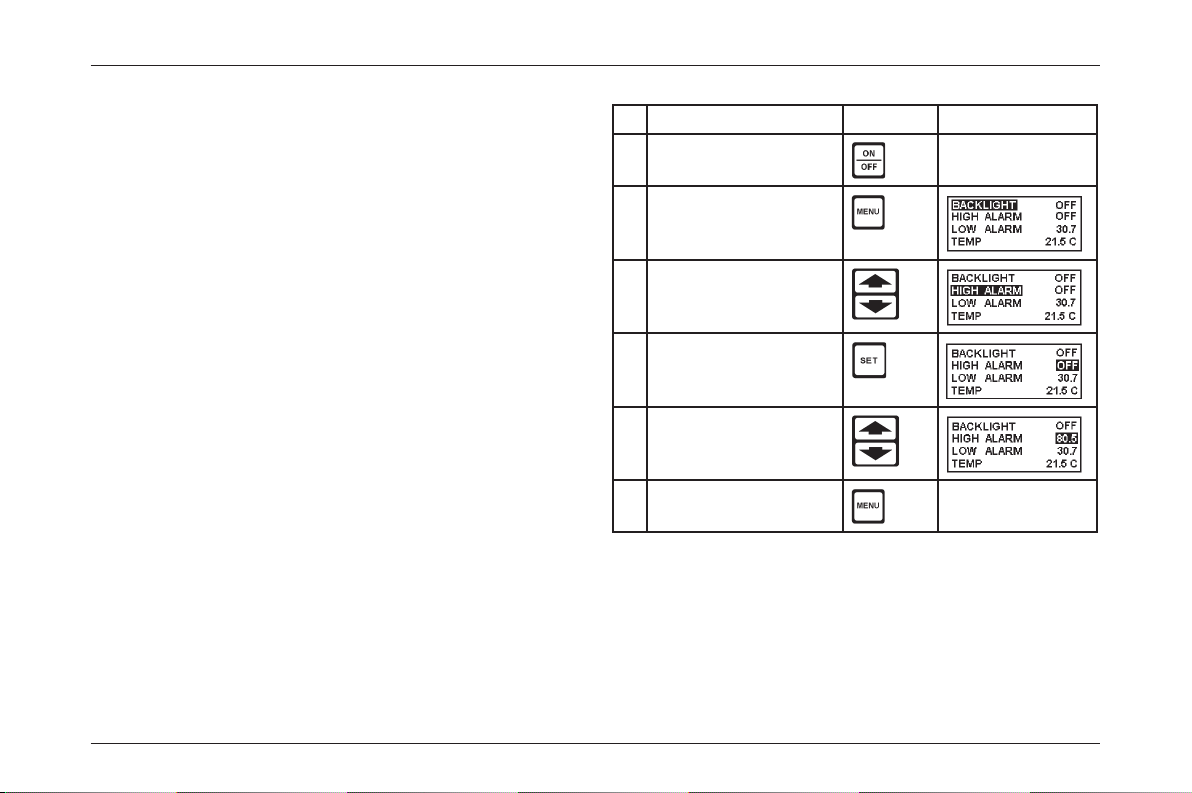

Operation steps

Operation steps are laid out in tables as shown in the

following example: To set the high alarm to trip at 80.5.

Step Key Display

1

From “Off” select measurement mode.

2

Enter parameter menu.

3

Step through the menu

to the “HIGH ALARM”

parameter.

4

Move across to the setting fi eld.

5

Increment/decrement to

required level.

6

Return to normal measurement mode.

Normal measurement display

Issue 04, 06/2007 AutoSigma 3000

1 - 4

Page 11

How to use this manual

Introduction

This action table indicates in step form:

– Switch on with a press of ON/OFF button.

– Press the MENU button.

– Press INCREMENT/DECREMENT button repeat-

edly until the required parameter is accessed.

– Press the SET button to move to the value setting

fi e l d .

The INCREMENT or DECREMENT buttons are then

used to set the required value.

– Press the MENU button to return the instrument to

its Measurement Mode ready to take readings.

Display fi gures in this manual may show XXXX, YYYY

or ZZZZ as numerical values etc. these indicate that

any valid number or menu item may be displayed.

Lists

Lists are arranged as follows with bulleted indents.

• 101.6 % IACS. Highest reading

• 101.2 % IACS. Mean reading

• 99.8 % IACS. Lowest reading

Notes

H

Note:

Under this heading you will fi nd special recommendations concerning measurement techniques, or references to important information in other chapters of the

manual.

Button Operation (Keypad)

• Press: Button contact then immediate release.

• Long Press: Button contact for a period of three

seconds or more then release.

AutoSigma 3000 Issue 04, 06/2007 1 - 5

Page 12

1 - 6 Issue 04, 06/2007 AutoSigma 3000

Page 13

Standard package and accessories 2

AutoSigma 3000 Issue 04, 06/2007 2 - 1

Page 14

Standard package and accessories

2.1 Standard package

Product code Description Order number

AutoSigma 3000 DL 47I001DL

Probe 12.7 mm (60/500 KHz) 47P001

Cable (Probe) 47A001

Probe fi nger support 47A005

Curve measurement adapter 47A006

Hard plastic packall case 47A008

Calibration Certifi cate –

Standard package

Issue 04, 06/2007 AutoSigma 3000

2 - 2

Page 15

Recommended accessories

2.2 Recommended accessories

Product code Description Order number

Soft Case with Shoulder Strap 47A009

Probe 8 mm (500 KHz) 47P002

Cable (Printer) 33A145

Cable (Data Logger) 47A003

Computer Interface Cable (PC) 33A146

Computer Interface Instructions –

Operator Reference Block Plate and 44A016

set of fi ve Operator Reference Blocks

See Data Sheet for details

Standard package and accessories

AutoSigma 3000 Issue 04, 06/2007 2 - 3

Page 16

2 - 4 Issue 04, 06/2007 AutoSigma 3000

Page 17

Preparation for operation 3

AutoSigma 3000 Issue 04, 06/2007 3 - 1

Page 18

Preparation for operation

Battery installation

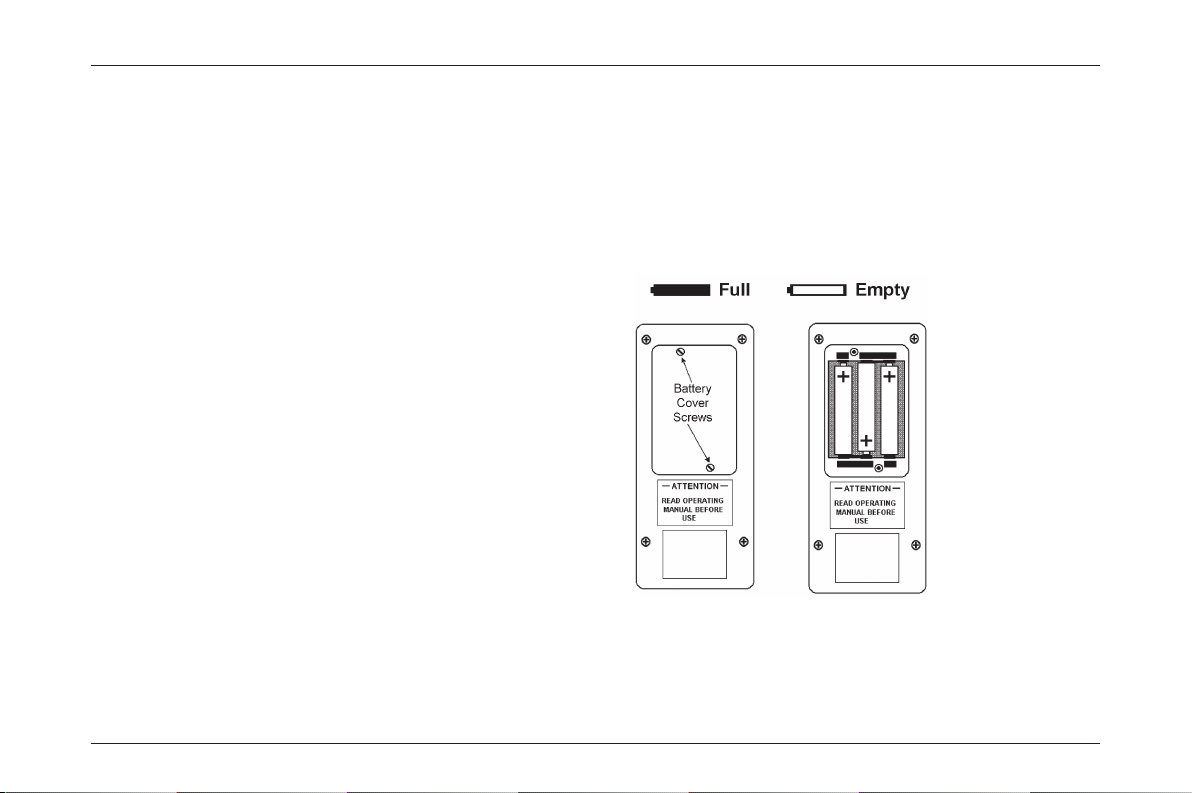

3.1 Battery installation

Power requirements

The AutoSigma 3000 can only be operated by battery,

using three AA size cells, Alkaline (preferred), Dry

Cell, or Ni-Cad .

H

Note:

If Ni-Cad batteries are used the battery level indication will not be correct, and they should be removed

for charging when the level indicator shows about

25 %. The AutoSigma 3000 has no provision for in situ

charging.

– Undo Battery Cover Screws and lift off the cover

(the screws are captive in the lid).

– Insert three AA alkaline cells as shown.

Alternative cells may be used if alkaline batteries are

not available, but unit operating time may be reduced

and battery level indication inaccurate.

If the batteries are installed incorrectly with the polarity

reversed, no damage to the AutoSigma 3000 will occur, but the instrument will not function.

– After the batteries have been installed, replace the

battery cover and refi t the screws. The Icon on the

display shows the battery charge.

Issue 04, 06/2007 AutoSigma 3000

3 - 2

Page 19

Probe connection

H

Note:

When the battery empty state is displayed, the batteries should be replaced at once.

The AutoSigma 3000 automatically turns off when

the batteries become too weak for reliable operation.

When using the equipment in remote locations it is advisable to carry spare batteries. Discharged or faulty

batteries are classifi ed as Special Waste and must be

disposed of accordingly.

Preparation for operation

3.2 Probe connection

The connecting cable for the probe is a 5 way LEMO

to 5 way LEMO and may be used either way round.

– Align the red dots of the LEMO plug and the socket

of the cable and plug together, they are polarised

and will therefore not engage unless correctly mated.

– Similarly attach the cable to the instrument.

The connectors are self locking and will not become

detached without being released by pulling the serrated section of the plug.

H

Note:

Before a probe can be used to take accurate measurements, its Code Number (if not already contained in

the probe fi le) must be entered into the instruments

operational memory – see section 3.3. Instruments

supplied from the factory with a probe will already

have the code number entered. 12.7 mm diameter

probes have a 4 digit code and 8 mm diameter probes

a 2 digit code.

AutoSigma 3000 Issue 04, 06/2007 3 - 3

Page 20

Preparation for operation

Probe identifi cation

If an instrument reset is carried out the Probe data will

be returned to “5555” or “55” thus requiring the probe

code number/s to be re-entered.

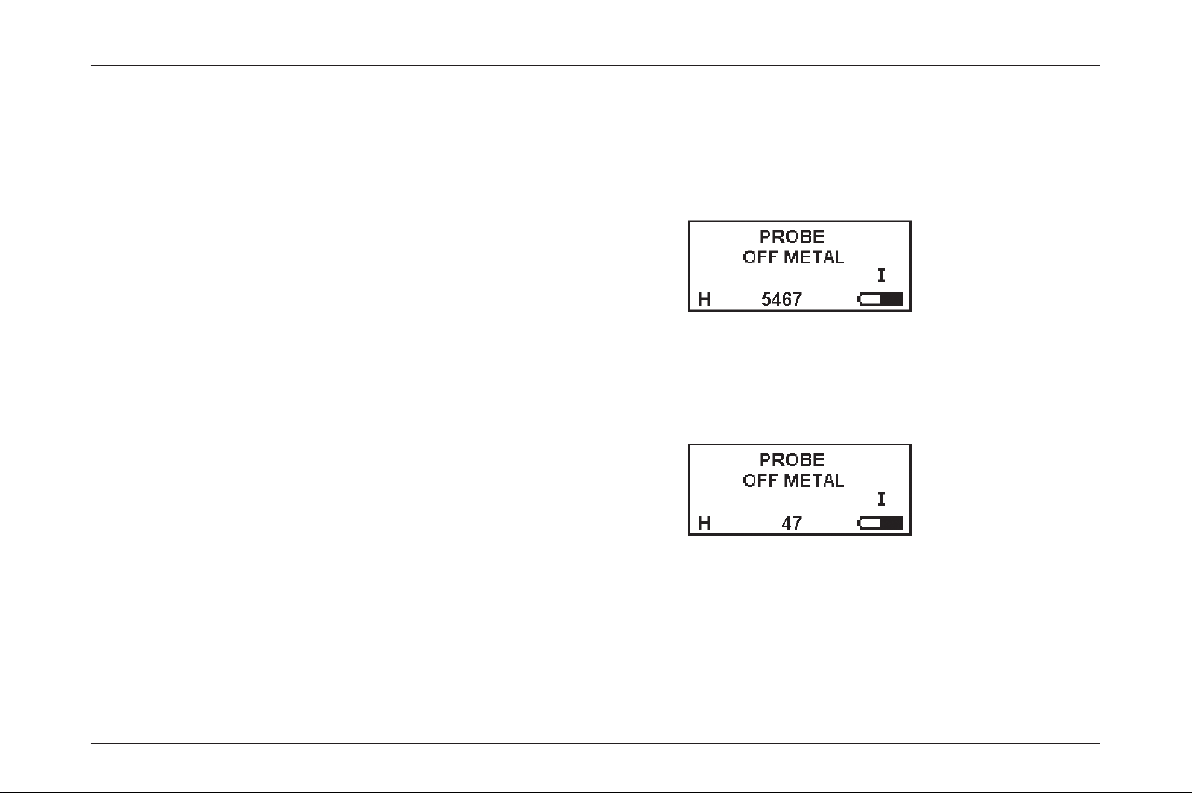

3.3 Probe identifi cation

12.7 mm Probe: Dual Frequency 60 and 500 kHz

(L/H) has a four-digit code (see below).

Probe code shown here on the display.

8 mm Probe: Single Frequency 500 kHz (H) only, has

a two-digit code.

Probe code shown here on the display.

Issue 04, 06/2007 AutoSigma 3000

3 - 4

Page 21

Entering probe code data

H

Note:

The H or L indication at the left bottom of the display indicates which operational frequency has been

selected for measurement, either frequency for the

12.7 mm probe. 500 kHz (H) only may be used for the

8 mm probe.

3.4 Entering probe code data

E.g. 12.7 mm H/L probe, code number is 6547. The

code is stored in the format below, there are code slots

for three large and three small diameter probes, and

their selection is sequential.

6 5 4 7

and is equivalent to data stores

D1 D2 D3 D4

Preparation for operation

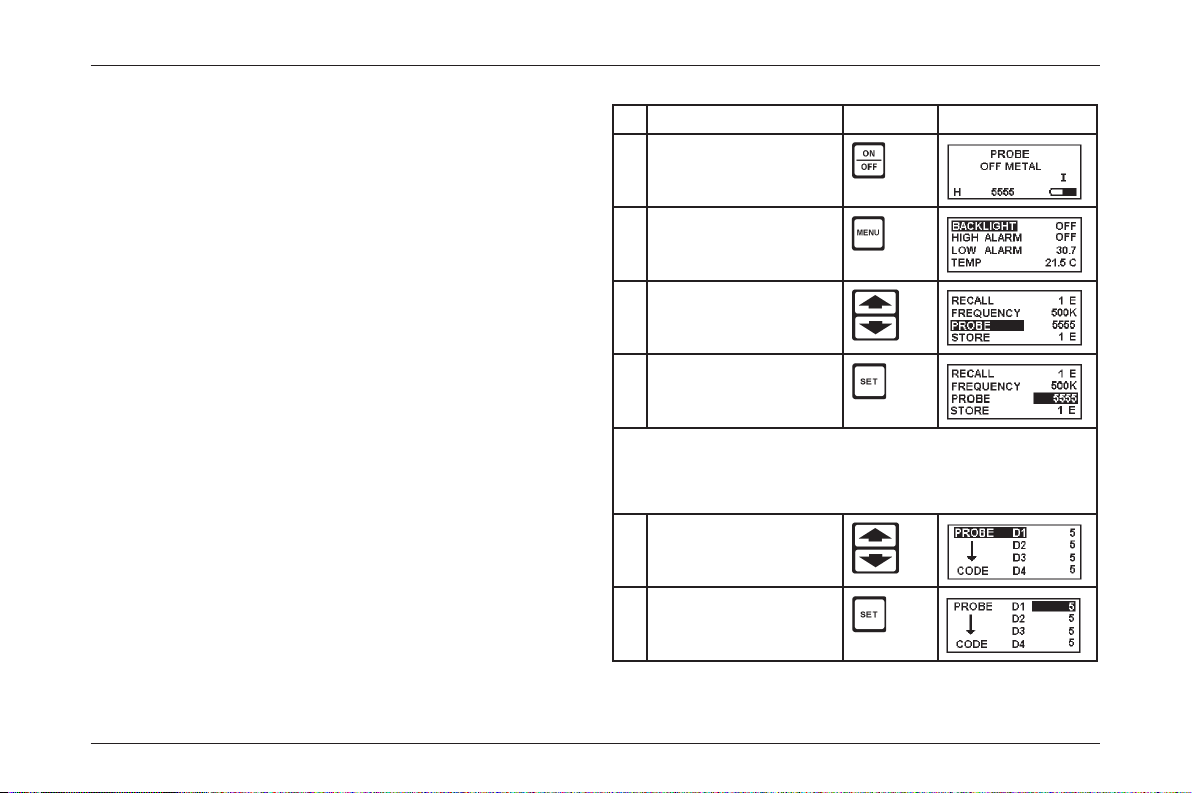

Step Key Display

1

From “Off” select measurement mode.

2

Open parameter menu.

3

Step through the menu

to the PROBE parameter.

4

Move to the setting fi eld.

If the probe code displayed has only two digits present, then

after step 4 select the slot required by inc/dec to one of the

three available four digit slots. Return to the parameter fi eld by

pressing SET and continue to PROBE D1 as normal step 5.

5

Step through the menu

to the PROBE D1 parameter.

6

Move across to the setting fi eld.

AutoSigma 3000 Issue 04, 06/2007 3 - 5

Page 22

Preparation for operation

General parameter setting

Step Key Display

7

Increment D1 value to 6.

8

Move back to parameter

fi e l d .

9

Enter the values for D2, D3 and D4

using the same method.

10

Store these settings

in the internal memory

(Single beep will occur

when complete).

11

Return to normal measurement mode (ready

for set probe routine).

long

press

3.5 General parameter setting

E.g. changing language to German (D) from Off condition.

H

Note:

This sequence is used to set any of the adjustable

menu parameters as listed in section 3.6.

Issue 04, 06/2007 AutoSigma 3000

3 - 6

Page 23

Start-up

Preparation for operation

Step Key Display

1

From “Off” select Measurement mode.

2

Open the parameter

menu.

3

Step through the menu

to the LANGUAGE parameter.

4

Move across to the setting fi eld.

5

Increment/Decrement to

the required language:

German.

6

Return to normal measurement mode.

Normal measurement display

3.6 Start-up

Normal switch on

Press ON/OFF button to bring the instrument into operation in the measurement mode with the parameter

values as they were when it was last switched off.

Reset switch on

Returns the instrument to it’s default settings, not active in User mode.

Step Key Display

1

From “Off” initialise sequence for access.

2

Press for start-up. Release SET button when

beep is heard.

3

Confi rm reset.

Normal measurement display

AutoSigma 3000 Issue 04, 06/2007 3 - 7

Page 24

Preparation for operation

Start-up

The instrument will revert to the default parameter values as below.

• Backlight Off

• High Alarm Off

• Low Alarm Off

• Temperature Units Celsius

• Recall 1

• Frequency 60 kHz

• Probes, 3 each 5555 / 55

• Store 1

• Units % IACS

• Contrast 7

• STD 1 60.50

• STD 2 8.870

• Audio Alarm Off

• Power Down 15 minutes

• Language English (GB)

• Baud Rate 1200

• D1, D2, D3, D4 5, 5, 5, 5

The following list shows the settings available for each

parameter.

Parameter Available States

Backlight On/Off

High Alarm 1.0 – 110 % IACS / Off

Low Alarm Off / 1.0 – 110 % IACS

Temperature Units Celsius / Fahrenheit

Recall 1 – 10

Frequency 60 / 500 kHz

Probe Codes 3 large and 3 small

Store 1 – 10

Units % IACS or MS/m

Contrast 3 – 10

STD 1 30 – 65 % IACS

STD 2 6 – 50 % IACS.

Audio Alarm On/Off

Power Down 15 / 10 / 5 / 1 minutes

Language English (GB) /German (D) /

French (F) etc.

Baud Rate 9600 / 4800 / 2400 / 1200

Issue 04, 06/2007 AutoSigma 3000

3 - 8

Page 25

Basic measurement knowledge

Preparation for operation

3.7 Basic measurement knowledge

Conductivity of metals is commonly measured in two

sets of units. In the SI system the unit of conductivity

is the MegaSiemens/meter (reciprocal ohm-meter).

Conductivities of metals at ambient temperature are

typically in the range of 1 to 60 MegaSiemens/meter.

For convenience metal conductivities are often expressed as a percentage of the conductivity of a standard sample of copper – the International Annealed

Copper Standard (IACS). 100 % IACS corresponds

to 58 MegaSiemens/meter. Note that since this “pure”

copper standard was established in 1913 pure copper

now often has a conductivity greater than 100 % IACS.

The AutoSigma 3000 measures the conductivity of

non-magnetic metals and alloys in the range 0.8 to

110.0 % IACS. It uses the Eddy Current technique for

measuring the conductivity of materials in % IACS, or

MegaSiemens/meter (set from the instruments menu

selections).

It is important to understand that eddy current measurement is essentially a “skin” effect. The eddy current fi eld intensity is greatest at the surface and decreases exponentially with depth. The depth at which

the fi eld strength reduces to 1/e (37 %) of its surface

value is referred to as the “standard depth of penetration”. This depends primarily on the operating frequency and the conductivity of the metal.

It is generally considered that materials of thickness

greater than three standard depths of penetration can

be measured without any correction factors being required.

For example at 60 kHz this fi gure (the “effective depth

of penetration”) is around 0.05" (1.25 mm) in Aluminium Alloys (conductivity approximately 35 % IACS) and

0.32" (8 mm) in Titanium alloy (conductivity approxi-

mately 1 % IACS). At 500 kHz the corresponding values are 0.02" (0.5 mm) and 0.11" (2.8 mm).

Care must also be taken when measuring non-homogeneous materials, for example materials which have

been surface heat-treated, clad or plated, or where the

surface is rough or corroded. Measurements at different frequencies will give different results due to the

AutoSigma 3000 Issue 04, 06/2007 3 - 9

Page 26

Preparation for operation

Basic measurement knowledge

different distribution of energy within layers of different conductivity. Care must be taken to always measure such materials at the same frequency (usually

60 kHz).

The conductivity of a material changes considerably

with temperature, but is normally specifi ed at 20 °C.

The AutoSigma 3000 indicates the materials 20 °C

conductivity value by applying a standard correction

algorithm, valid for the most common aluminium alloys. For the best accuracy, the instrument, material to

be tested, probe, and calibration standards should be

at the same temperature, close to 20 °C.

Other key factors are coating thickness/lift-off and material curvature.

Measurements can be made through layers of paint

or other non-conductive coatings up to a thickness of

0.020" (0.5 mm) with the 12.7 mm probe and 0.010"

(0.25 mm) with the 8 mm probe.

Use on curved surfaces requires some caution, with

concave surfaces the effect is primarily lift-off and the

instrument will compensate up to the point where the

spacing of the centre of the probe from the material

becomes excessive. With convex surfaces the indicated conductivity will decrease as the radius decreases.

Correction tables are required for radii below approximately 3" (75 mm).

To ensure proper operation the calibration standards,

instruments and probes should be checked and recalibrated on a regular basis (e.g. check on standards before each use and factory re-calibration every year).

Issue 04, 06/2007 AutoSigma 3000

3 - 10

Page 27

Basic functions 4

AutoSigma 3000 Issue 04, 06/2007 4 - 1

Page 28

Basic functions

Measurement method

4.1 Measurement method

The instrument uses a probe which is excited by an

AC signal (60 kHz “L” or 500 kHz “H”) from the main

unit. This AC signal uses the material to be measured

as a coupling medium to a detector coil also in the

probe. From the phase and amplitude of the detected

signal the instrument calculates the conductivity of the

coupling medium.

Only conductivity of non-magnetic metallic materials can be measured using this system. Conductivity

changes considerably with temperature so the probe is

fi tted with a thermistor. It’s temperature is monitored in

order to display a mathematically adjusted conductivity

reading relative to 20 °C. The instrument will indicate

the necessity for a Probe Reset after a temperature

change of +/–3 °C. The set routine should be carried

out just before a measurement if absolute accuracy is

required.

A certain amount of surface unevenness and nonmetallic

coatings up to 0.020" (0.5 mm) are allowed for in the

measurement system (0.010" (0.25 mm) only with the

8 mm probe). When the probe has exceeded this “liftoff” distance, PROBE OFF METAL will be displayed.

4.2 Display

The display is a back lit LCD, the back light can be set

ON or OFF. When in Measurement Mode the display

will indicate the numerical value of the material being

measured in % IACS (I) or MegaSiemens/meter (S)

depending on the units selected. PROBE OFF METAL

is displayed if the probe is in air and not in close proximity to a measurable material.

Other display modes can be selected which are used

for setting up operational parameters, or logging fi les

(see chapter 5). In these Modes the display will highlight the parameter being set and its current status. In

the measurement mode Alarm States are indicated

by icons at the bottom of the display. The frequency,

probe code selected, measurement units and state of

charge of the battery are also shown at the bottom of

the display.

Issue 04, 06/2007 AutoSigma 3000

4 - 2

Page 29

Keypad

Basic functions

4.3 Keypad

The AutoSigma 3000 has a membrane keypad, consisting of eight legend pads. The large central pad with

the up and down arrows has two switches, one under

each arrow. The upper arrow is the INCREMENT control and the lower arrow is the DECREMENT control,

they operate on the parameter fi eld or value selected.

The other pads only have one switch each. The basic

function of the other keys are as follows:

Key operation on standard model

ON/OFF This button switches the instrument on

and off; a short press is used to switch on

and a long press switches the instrument

off.

MENU This button is used to select set-up pa-

rameters and return the instrument to its

measurement mode.

SET This button toggles the display between

the menu parameter and its value fi eld,

and is also used in conjunction with the

ON button to reset the instrument to its

default settings.

SEND This button, on the basic version, is used

to enter the probe data into the internal

memory.

AutoSigma 3000 Issue 04, 06/2007 4 - 3

Page 30

Basic functions

Keypad

Additional key operations on DL option

H

Note:

If these keys are pressed on the older Basic Model

without the DL option the screen will indicate Data

Logger is not fi tted.

MEM This button selects the Memory Menu

(Files must have been allocated, and the

fi le selection be on a particular fi le not

ALL FILES).

FILE This button selects the FILE menu (With

ALL FILES cleared it will access the number of fi les set up).

C Depending on which menu is currently

selected, a long press of this button will

clear a single FILE, all FILES or a single

MEMORY location.

When the instrument is in the correct mode, a press

on this button will log the current valid reading into the

active memory location within the active fi le. The active location is automatically incremented, but if the

location is full then an error message is displayed indicating that the location or fi le is FULL. It is also used to

enter the probe code into the internal memory.

H

Note:

For correct button sequences see chapter 5 “Operation”.

Issue 04, 06/2007 AutoSigma 3000

4 - 4

Page 31

Operation 5

AutoSigma 3000 Issue 04, 06/2007 5 - 1

Page 32

Operation

Switching on

5.1 Switching on

– Press ON/OFF.

The instrument switches on in the normal Measurement mode and will operate according to previously

set parameters. A SET PROBE routine should be carried out before use (see section 5.5) The display will

show the conductivity of the material on which the

probe is placed or PROBE OFF METAL if the probe

is in air. The display also shows information such as

the operating frequency, measurement units, probe

code number, battery state and alarms (see below).

Also the word SET will appear on the bottom line if the

probe temperature has drifted +/–3 °C since the last

set routine was carried out. If the SET icon appears

then the set probe routine should be carried out to restore high accuracy measurement.

Example

Taking a reading of 60.5 % IACS (I) at a frequency of

500 kHz (H) with a probe whose code number is 5467.

At the bottom right a battery level of 50 % is indicated

and to its left the presence of the

upper alarm level has been exceeded.

Normal measurement display:

Display showing excessive temperature change. Set

probe routine must be carried out:

icon indicates the

Issue 04, 06/2007 AutoSigma 3000

5 - 2

Page 33

Switching off

Operation

5.2 Switching off

– Long press ON/OFF.

The instrument will beep twice if settings have been

changed and power down.

5.3 Changing working parameters

Follow the sequence in section 3.5.

H

Note:

The settings of some parameters are dependent on

others and if a confl ict is encountered error messages

will appear on the screen and/ or the instrument will

beep. Some are as follows:

With an 8 mm (two digit) probe code in place, you cannot select a frequency of 60 kHz (only useable with

12.7 mm probe). If it is attempted the instrument will

beep and not carry out the change. It is then necessary to move to the PROBE parameter and recall

the correct four digit code number appropriate to the

12.7 mm probe to be used.

When the set probe routine is being carried out, if the

wrong probe code is in place i.e. two digit number is

present (8 mm probe) when trying to set a 12.7 mm

probe which should have a four digit code number or

vice-versa. The display will show an error (see Figure below), and will prompt a press of the SET button

AutoSigma 3000 Issue 04, 06/2007 5 - 3

Page 34

Operation

Changing working parameters

which will move the display to the PROBE fi eld ready

to select the code number for the probe being set.

When the code number has been incremented to the

correct one, a press on the MENU button will take the

instrument back to the normal measurement display

which has the code indicated on the bottom line and

will show ERROR (see Figure below).

– To re-commence the set probe routine, once the

correct probe code has been entered, press SET.

5.4 Entering reference block

values

Before the AutoSigma 3000 DL can be set, the reference block values need to be entered. It is recommended that the STD blocks supplied with the unit are

used as these will provide the most effective and accurate setting. As an alternative user reference blocks

may be used, these will limit the instruments range

and can reduce accuracy.

Ensure that the instrument is set to the correct units

for the block values to be entered. If not change the

UNITS parameter value fi eld before moving to the STD

parameters and entering the block values. From the

normal measurement mode proceed as follows, e.g.

setting STD 1 (60.1) and STD 2 (8.91).

Issue 04, 06/2007 AutoSigma 3000

5 - 4

Page 35

Entering reference block values

Operation

Step Key Display

1

Open the parameter

menu.

2

Step through the menu

to the STD 1 parameter.

3

Move across to the setting fi eld.

4

Decrement to required

level.

5

Return to parameter

fi e l d .

6

Step to the STD 2 parameter.

7

Move across to the setting fi eld.

Step Key Display

8

Increment to required

level.

9

Return to normal measurement mode.

Normal measurement display

User reference blocks

Can be used to set the AutoSigma 3000 DL, provided

that

• STD 1 is within the range 30 to 63 % IACS,

• STD 2 is within the range 6 to 50 % IACS and

• STD 1 is at least 10 % IACS above STD 2.

The values are entered in the unit in the same way as

the STD blocks.

Considerations

If user reference blocks are used, accuracy can be

compromised and range limited.

AutoSigma 3000 Issue 04, 06/2007 5 - 5

Page 36

Operation

Entering reference block values

The absolute accuracy of the instrument will be dependent on the accuracy of the user reference blocks and

will no longer be to the accuracy stated in the “Specifi cations” chapter of these instructions. It is not recommended that measurements are made outside the

range of the two sample values; as the accuracy will

be totally dependent on the absolute accuracy of the

user reference blocks.

For the relative reading accuracy to be the same as

for GE Inspection Technologies STD blocks, the two

user reference block values must be accurate and lie

either side of the measurement range. e.g. If the measurement range is to be between 40 and 45 % IACS

then STD 1 should ideally be 50 % IACS or more and

STD 2 should be 35 % IACS or less.

It is possible to set the AutoSigma 3000 DL by using

one user reference block and one STD block, provided

that the above rules are complied with, the absolute

accuracy will again be dependent on the accuracy of

the user reference block.

5.5 Probe setting (SET PROBE)

Before the probe setting on the reference blocks can

take place, the value of the blocks must be entered in

the STD 1 and STD 2 menu slots in the units selected

(i.e. IACS or MS/m) The probe code must also be appropriate to the probe in use. Proceed following section 5.4 to set the reference block values. Then with

the instrument on and in the Measurement mode:

Issue 04, 06/2007 AutoSigma 3000

5 - 6

Page 37

Probe Setting (SET PROBE)

Operation

Step Key Display

1

From Measurement

mode initiate probe setting.

2

Hold probe in the air to

set liftoff. Press SET and

wait for sounder to beep.

3

Move probe onto the

STD 1 block. Press SET

and wait for sounder to

beep.

4

Move probe onto the

STD 2 block. Press SET

and wait for sounder

to beep, then remove

probe.

H

Notes:

Instrument will

return to the Measurement mode automatically, ready

to take readings.

If the calibration process has been interrupted during

the procedure the system will time out (indicated by

fi ve short beeps) after approximately 6 seconds and

return to the measurement mode with the setting factors unaltered.

If the blocks are used in the wrong sequence or the

probe has not contacted the STD’s correctly, the

display will indicate VALUE OUT OF RANGE SEQUENCE WILL RESTART the procedure will then

restart at step 1 as in the table above. This setting

procedure can be aborted at any time by pressing the

MENU button.

Because the air temperature can be different from the

STD sample temperature, it is recommended that the

probe is placed on the STD, for approximately 10 seconds prior to the set procedure and held on each block

for 5 seconds before SET is pressed (steps 3 and 4

above). By allowing the probe temperature to settle to

that of the STD blocks optimum setting is ensured.

AutoSigma 3000 Issue 04, 06/2007 5 - 7

Page 38

Operation

Taking a conductivity measurement

5.6 Taking a conductivity

measurement

Ensure the instrument is on and in Measurement

mode see section 5.1. Carry out set probe routine as in

sections 5.4 and 5.5.

With the probe in air the display should be as below.

With (H) if 500 kHz is selected or (L) if 60 Hz is selected. The battery indication should show some content,

and if the icon shows empty new batteries should be

fi t t e d .

The instrument is now ready to take a measurement.

The probe should be at the same temperature as the

material to be measured, if there is a difference the

probe and STD blocks should be allowed to stabilise

on the surface of the material to be measured. The set

probe routine should then be carried out at the temperature the measurements are to be taken at.

Place the probe on the surface of the material to be

measured, making sure it is as fl at as possible on the

surface and not overhanging the edge, the display will

then indicate the conductivity in the units selected.

If the material’s ambient temperature drifts beyond

+/–3 °C the display will indicate that a probe set routine is advisable. (SET will appear on the bottom line

of the display).

If measurements are to be carried out on round bars

or curved surfaces the correct probe and guide should

be used for ease of use and accuracy of results.

Issue 04, 06/2007 AutoSigma 3000

5 - 8

Page 39

Data logging (internal)

Operation

Thin sections may be measured using the high frequency 500 kHz range. Surface unevenness and

non-metallic coatings of up to 0.020" (0.5 mm) are

compensated for in the measurement system of the

12.7 mm probe, and 0.010" (0.25 mm) with the 8 mm

probe. If, however, the probe is too far from the surface

PROBE OFF METAL will be displayed.

H

Note:

Correction tables for curved surface measurement

etc., are given in application note AN 9603 (available

from GE Inspection Technologies).

5.7 Data logging (internal)

Clearing the entire memory

With the instrument in the Measurement mode:

Step Key Display

1

Open the fi le menu.

2

If XX is 0, memory is

already cleared. If not

press arrow keys repeatedly until the adjoining is

displayed.

3

Clear the fi les with a

long press on the C key.

4

Return to Measurement

mode.

If the number of data fi les require setting follow section 5.7 from the point where the number of fi les is displayed as 0.

AutoSigma 3000 Issue 04, 06/2007 5 - 9

Page 40

Operation

Data logging (internal)

Setting the number of data fi les

H

Note:

This can only be performed when the entire memory

is clear.

With the instrument in the Measurement mode:

Step Key Display

1

Open the fi le menu.

2

Select the number of

fi les required (e.g. 20).

3

Return to Measurement

mode.

H

Note:

The number of available fi les is 1 to 50. Incrementing or decrementing past these points will result in

the number reverting to the other end of the available

range. The number of storage locations in the fi les will

depend on the number of fi les selected – see the following fi le capacity table.

Data logging

Storage fi le capacity table

No of fi les Locations No of fi les Locations

01 500 26 19

02 250 27 18

03 166 28 17

04 125 29 17

05 100 30 16

06 83 31 16

07 71 32 15

08 62 33 15

09 55 34 14

10 50 35 14

11 4 5 36 13

12 41 37 13

13 38 38 13

Issue 04, 06/2007 AutoSigma 3000

5 - 10

Page 41

Data logging (internal)

Operation

No of fi les Locations No of fi les Locations

14 3 5 39 12

15 33 40 12

16 31 41 12

17 29 42 11

18 27 43 11

19 26 44 11

20 25 45 11

21 23 46 10

22 22 47 10

23 21 48 10

24 20 49 10

25 20 50 10

Logging in a reading (general)

H

Note:

The number of fi les must have been set and there

must be space left in fi le locations for logging to be

successful, if not appropriate messages will appear on

the display.

– With a reading on the display (e.g. 99.8) that is to

be logged press SEND.

If no logging has taken place since the number of fi les

have been set, the reading will be logged into location 1 of fi le 1 (Unless a fi le location is deliberately

selected for the reading). If previous logging has taken

place the next location will automatically be selected

to receive the new log.

Whilst logging is taking place the display will indicate:

When complete the display will revert to reading 99.8

and the next location 2 will then be automatically selected for further logging.

AutoSigma 3000 Issue 04, 06/2007 5 - 11

Page 42

Operation

Data logging (internal)

Logging can then be repeated until fi le 1 is full. When

this occurs the display will respond with:

When this occurs another fi le must be selected for

logging to continue. If during logging a fi le location is

selected that already contains a stored value then the

display will indicate this as follows:

When this occurs another fi le or fi le location must be

selected for logging to continue, or the fi le location

cleared. Press MEM to display the contents then a

long press on C to clear the fi le.

Selecting a fi le for logging

With the instrument in the Measurement mode:

Step Key Display

1

Open the fi le menu.

2

Select the next fi le required (e.g. 2).

3

Return to Measurement

mode.

With the instrument returned to the Measurement

mode further logging or measuring can take place.

Further logged readings will automatically be placed in

the next available empty fi le location.

Issue 04, 06/2007 AutoSigma 3000

5 - 12

Page 43

Data logging (internal)

Operation

Clearing a fi le

With the instrument in the Measurement mode:

Step Key Display

1

Open the fi le menu.

2

Select the fi le to be

cleared. If it is not the

current fi le (i.e. the one

displayed), press arrow

keys repeatedly.

3

Clear the displayed fi le.

4

Return to Measurement

mode.

With the instrument returned to the Measurement

mode further logging or measuring can take place.

Further logged readings will automatically be placed in

location 1 of FILE YY.

Accessing a fi le location containing stored

data

With the instrument in the Measurement mode:

Step Key Display

1

Open the fi le menu.

2

Select the fi le to be accessed.

3

Return to Measurement

mode.

4

Display the content from

the current fi le position.

5

Select the required position (e.g. 14) and read

the content: 67.1.

6

Return to Measurement

mode.

Normal measurement display

Normal measurement display

AutoSigma 3000 Issue 04, 06/2007 5 - 13

Page 44

Operation

H

Note:

Whilst selecting locations steps 4 and 5 you may move

to another fi le simply by pressing the FILE button and

incrementing to the required fi le. Press FILE again to

revert to location selection.

– Alternatively if you wish to clear this location contin-

ue from step 4.

– Long press C will clear the location and the display

will show:

Customising the operating mode

5.8 Customising the operating

mode

The operating mode of the AutoSigma 3000 DL can

be customised to suit a particular measurement procedure. Menu items can be selected and given a value

or a mode, a complete menu can then be stored, this

customised menu can then be recalled when required.

The AutoSigma 3000 DL may be set to User mode

where the menu cannot be selected or changed, or

Supervisor mode where the menu is fully functional.

This is achieved by sending instructions from a PC to

the AutoSigma 3000 DL.

H

Note:

This indicates that fi le XX location FF is empty and

can now accept a logged reading.

– To log to this location, press FILE again to revert to

location selection.

Issue 04, 06/2007 AutoSigma 3000

5 - 14

When in User mode the reset switch on facility is not

available.

Page 45

Customising the operating mode

Operation

Storing a customised mode

– In order to store a customised operating mode, se-

lect MENU then select STORE with the arrow keys.

– In the SET mode, select the required store location

(1 to 10) with the arrow keys and apply a long press

to SEND.

Two beeps will confi rm that the MENU SETTINGS

have been stored.

Recalling a customised mode

– To recall a customised operating mode select

RECALL from the menu with the arrow keys.

– In the SET mode select the required location (1 to

10) with the arrow keys and apply a long press to

SEND.

Two beeps will confi rm that the MENU SETTINGS

have been recalled.

Setting the operating mode to User or

Supervisor

The AutoSigma 3000 DL normally works in the Supervisor mode where the menu is fully functional, it is

supplied set to this mode, the instrument may also be

set to User mode where the menu cannot be selected

or changed.

To change between the User or Supervisor mode the

unit should be on and in the read mode and connected

to a suitable PC, via cable part no 33A146 (PC serial

cable).

H

Note:

To access the AutoSigma 3000 DL using a PC running

windows go into “Terminal” program (usually in accessories group) choose “Settings”; “Communications” in

the comms box select the COM port connected to the

AutoSigma 3000 DL (COM1 or COM2) then set baud

rate 1200; data bits 8; stop bits 1; parity none; fl ow

control; Xon/Xoff; Leave “parity check” and “carrier detect” unselected.

AutoSigma 3000 Issue 04, 06/2007 5 - 15

Page 46

Operation

Hit OK. On pressing return on the keyboard the screen

should respond with >.

– To select User type USER (slowly; 0.5 sec between

characters) and press return; the unit will now be in

the User mode and can be disconnected from the

PC.

In User mode the menu cannot be selected and the

settings present when the AutoSigma 3000 DL is converted will be retained.

– To select Supervisor, with the PC connected; type

SUPER (slowly) and return; the unit will now be in

Supervisor mode, the unit may now be disconnected from the PC.

Customising the operating mode

Issue 04, 06/2007 AutoSigma 3000

5 - 16

Page 47

External data handling devices 6

AutoSigma 3000 Issue 04, 06/2007 6 - 1

Page 48

External data handling devices

Connection

6.1 Connection

The 7 way Lemo Data Output socket is provided for

connection to Data Handling Devices, Printers and

PCs.

The communication link protocol depends on the cable

connected using an ASCII Data transfer. A Mitutoyo

data cable is automatically sensed so an external Data

Logger can request a reading.

If printers or PCs etc that use serial RS-232 format are

to be connected, converter leads are required. Product

codes: 47A004 (PC), 47A002 (Printer)

Signal identifi cation of connections to the 7 Pin LEMO

Data Output socket.

Pin 1 0 V

Pin 2 +5 VA

Pin 3 TXDATA1

Pin 4 ~CTSREQ

Pin 5 RXCLOCK

Pin 6 0 V

Pin 7 ~MITSEL

Issue 04, 06/2007 AutoSigma 3000

6 - 2

Page 49

Sending serial data to an external device

External data handling devices

6.2 Sending serial data to an

external device

Connect the external equipment to the instrument via

the correct interface cable and switch it on.

The AutoSigma 3000 DL will recognise the connection

and change the use of the SEND button from internal

data logging to external serial data transfer.

Individual fi les or the entire memory can be transmitted, but only fi les containing stored data will be transferred i.e. fi le active or fi le full.

A long press on the SEND button is used to initiate

data out transfer with the File menu set to a single fi le

or ALL FILES.

H

Note:

For correct handling of transmitted data PCs and printers should be set to Xon / Xoff protocol.

Sending a single fi le

With the instrument in the Measurement mode:

Step Key Display

1

Open the fi le menu.

2

If fi le to be transferred is

not current (i.e. the displayed one), select the

fi le required (e.g. 2).

3

Transfer the fi le with

a long press; after the

press the display will indicate the transfer.

When transmission is complete the display will revert

to the fi le selection.

H

Note:

To terminate a data transfer when in progress press

SEND. Display will respond for a short period with

AutoSigma 3000 Issue 04, 06/2007 6 - 3

Page 50

External data handling devices

then revert to the fi le selection.

Sending the entire memory

With the instrument in the Measurement mode:

Sending serial data to an external device

After transmission the display will return to ALL FILES.

H

Note:

To terminate a data transfer when in progress press

SEND. Display will respond for a short period with

Step Key Display

1

Open the fi le menu.

2

Press the arrow keys

repeatedly to select all

the fi les.

3

Transfer the fi les with

a long press; after the

press the display will indicate the transfer.

Issue 04, 06/2007 AutoSigma 3000

6 - 4

then revert to fi le selection ALL FILES.

H

Note:

During data transfers all instrument operations are

suspended.

Page 51

Sending serial data to an external device

External data handling devices

Report format of transferred data

Data transmitted to a serial printer is formatted as the

example shown below, and is suitable for any IBM

compatible serial printer.

Sections of the formatted report

Instrument Banner Instrument name.

File Header Various Fields including the fi le

number for the data to follow.

Readings A list of the measurement values

and their locations.

Statistics Various statistics

then repeated for each fi le transferred.

END OF REPORT message.

Example of a report

AutoSigma 3000 Issue 04, 06/2007 6 - 5

Page 52

6 - 6 Issue 04, 06/2007 AutoSigma 3000

Page 53

Specifi cations 7

AutoSigma 3000 Issue 04, 06/2007 7 - 1

Page 54

Specifi cations

Conductivity Range 0.8 % IACS to 110 % IACS (0.45 to 64 MegaSiemens/m)

Operating Frequencies 60 and 500 kHz Sinewave

Resolution 10 to 110 % IACS, readings 10.0 to 110.0 (1 dec. place)

0.8 to < 10 % IACS, readings 0.80 to 9.99 (2 dec. places)

Accuracy [+/–0.5 % IACS at 100 % IACS reducing to +/–0.1 % IACS at 10 % IACS

+/–0.1 % IACS below 10 % IACS] at 20 °C

[+/–0.8 % IACS at 100 % IACS reducing to +/– 0.2 % IACS at 10 % IACS

+/–0.2 % IACS below 10 % IACS] over range 0 °C to 40 °C with probe in contact

with metal

Probes 12.7 mm diameter, for 60 kHz, and 500 kHz. 8 mm probe operates at 500 kHz only.

Probes are interchangeable with simple customer re-setting procedure.

The probe fi eld is sharply defi ned and enables accurate measurements to be made

even with the probe in line with the extreme edge of the metal.

Special probe guides are available for measuring curved surfaces. The data for

three probes of each size can be stored in the probe data fi eld allowing for alternative probe usage.

Issue 04, 06/2007 AutoSigma 3000

7 - 2

Page 55

Specifi cations

Lift-Off 12.7 mm probe compensated to 0.020" (0.5 mm), 0.010" (0.25 mm) on 8 mm probe.

At 20 °C display changes to PROBE OFF METAL when the compensated probe LiftOff distance has been exceeded.

Conductivity Standards Attached to case top, removable for value verifi cation, and temperature sinking to

material to be measured.

Display Graphics LCD 122 × 32 pixels with electroluminescent backlight

Backlight has on and off modes.

Alarm Triggered at upper and lower selected values, indicated by LCD display icons

Calibration Automatically set when set probe sequence is carried out with the probe placed in

turn on the calibration blocks. The probe thermistor detects when a change in temperature of more than 3 °C has occurred since the last calibration and signals the

necessity for re-calibration by illuminating SET at the bottom of the display.

Temperature Measurement By probe thermistor (accurate to 0.5 °C), range 0 °C to +50 °C (32 °F to 122 °F)

The display shows the temperature at which the last measurement was taken.

Automatic Tempera t u r e Conductivity measurements are corrected to the 20 °C value when measured at

Compensation other temperatures.

AutoSigma 3000 Issue 04, 06/2007 7 - 3

Page 56

Specifi cations

Data Logger Memory Up to 500 readings, up to 50 fi les (DL model)

Serial Port RS-232 serial LEAD available for serial printer or PC etc.

Compatible with KB DMEDL software

Shoulder Bag To protect unit for mobile applications

Packall Case Small light rigid case. 9" × 12.25" × 4.25" (229 × 311 × 108 mm, H × W × D). To hold

unit, probe, probe cable, and operating manual, with further space for extra accessories

Power Source 3 × 1.5 V AA size alkaline batteries, approx. 100 hrs life without backlight

Auto Switch Off If the instrument is not used for “n” minutes, or if the battery falls to an unusable low

level, the instrument switches off automatically (“n” is user selectable).

Case High impact polycarbonate, splash proof

6.5" × 3.0" × 1.6" (165 × 76 × 41 mm, H × W × D)

Weight 14.5 oz (0.4 kg) including batteries

Environmental Range 0 to 95 % relative humidity, 0 °C to +50 °C for reliable operation

Issue 04, 06/2007 AutoSigma 3000

7 - 4

Page 57

Maintenance and care 8

AutoSigma 3000 Issue 04, 06/2007 8 - 1

Page 58

Maintenance and care

Cleaning

8.1 Cleaning

Use a soft cloth moistened with a soap or mild detergent to clean the case, buttons and display window.

A

Attention:

Do not use abrasive cleaning agents of any kind as

these will erase the legend graphics and scratch the

display window.

Do not use solvent cleaners of any kind, as they may

cause irreparable damage to case and contents.

8.2 Care of Batteries

H

Note:

On removal of the batteries the instruments will retain

its settings and stored data (DL model). Memory storage does not rely on battery power (make sure the

instrument is switched off before removal of the batteries).

When the batteries no longer have enough power to

drive the instrument, remove and dispose of them correctly. Do not leave discharged batteries in the battery

holders.

If the instrument is to be stored for some time without

being used, remove batteries before storing.

Issue 04, 06/2007 AutoSigma 3000

8 - 2

Page 59

Appendix 9

AutoSigma 3000 Issue 04, 06/2007 9 - 1

Page 60

Appendix

EC Declaration of Conformity

9.1 EC Declaration of Conformity

We declare that the AutoSigma 3000 DL Conductivity

Meter conforms to the following European directive:

• 89/336 (Electromagnetic compatibility)

The conformity of the above-mentioned product with

the regulations of the directive 89/336 is proven by the

observance of the standard specifi cations

• EN 50081-1 Emissions

• EN 50082-1 Immunity

9.2 Manufacturer / Service address

The AutoSigma 3000 DL is manufactured by:

GE Inspection Technologies Ltd

129-135 Camp Road

St Albans, Hertfordshire, AL1 5HL

GREAT BRITAIN

Phone +44 1727 795500

Fax +44 1727 795400

The AutoSigma 3000 DL is manufactured according

to state-of-the-art methods using high-quality components. Thorough in-process inspections or intermediate tests and a quality management system certifi ed to

DIN EN ISO 9001 ensure an optimum quality of conformance of the instrument.

Should you nevertheless detect an error on your instrument, switch the instrument off. Inform your local

GE Inspection Technologies Service indicating the error and describing it.

Keep the shipping container for any repairs possibly

required which cannot be made on the spot.

Issue 04, 06/2007 AutoSigma 3000

9 - 2

Page 61

Manufacturer / Service address

Appendix

If there is anything special that you would like to know

about the use, handling, operation and specifi cations

of the instruments, please contact your nearest

GE Inspection Technologies representative or directly:

Great Britain

GE Inspection Technologies Ltd

129-135 Camp Road

St Albans, Hertfordshire, AL1 5HL

GREAT BRITAIN

Phone +44 1727 795500

Fax +44 1727 795400

USA

GE Inspection Technologies, LP

50 Industrial Park Road

Lewistown, PA 17044

USA

Phone +1 717 - 242 03 27

Fax +1 717 - 242 26 06

Germany

GE Inspection Technologies GmbH

Robert-Bosch-Straße 3

50354 Hürth

GERMANY

Phone +49 (0) 22 33 - 601 111

Fax +49 (0) 22 33 - 601 402

AutoSigma 3000 Issue 04, 06/2007 9 - 3

Page 62

9 - 4 Issue 04, 06/2007 AutoSigma 3000

Page 63

Index 10

AutoSigma 3000 Issue 04, 06/2007 10 - 1

Page 64

Index

A

Accessories 2 - 3

Accuracy 7 - 2

Alarm 4 - 2, 7 - 3

Alkaline 3 - 2

Auto switch off 7 - 4

B

Bag shoulder 7 - 4

Basic measurement 3 - 9

Batteries 3 - 2, 4 - 2

Alkaline 3 - 2

Care of 8 - 2

Installation 3 - 2

Ni-Cad 3 - 2

C

Calibration 5 - 4, 7 - 3

Calibration standards 3 - 10

Case 7 - 4

Case packall 7 - 4

Cleaning 8 - 2

Compensation 7 - 3

Conductivity 3 - 9, 4 - 2, 5 - 8, 7 - 2

Conductivity standards 7 - 3

D

Data logger 4 - 4, 7 - 4

Data logging 5 - 9, 5 - 10

Data transfer 6 - 3

Report format 6 - 5

Issue 04, 06/2007 AutoSigma 3000

10 - 2

Page 65

Index

Default

Parameter values 3 - 8

Display 4 - 2, 5 - 2, 7 - 3, 8 - 2

E

Environment 7 - 4

Error messages 4 - 2, 5 - 2

External data handling

Sending entire memory 6 - 4

Sending single fi le 6 - 3

F

File header 6 - 5

I

IACS 3 - 8, 4 - 2, 5 - 5

Instrument banner 6 - 5

K

Keypad 4 - 3

L

Language changing 3 - 6

Lift-Off 7 - 3

M

Maintenance 8 - 2

Measurement 4 - 2, 5 - 2, 5 - 8, 6 - 3

Memory 5 - 9, 6 - 4, 7 - 4

Accessing fi le location 5 - 13

Clearing a fi le 5 - 13

Files 5 - 10

Logging in a reading 5 - 11

Selecting a fi le 5 - 12

Setting number of data fi les 5 - 10

AutoSigma 3000 Issue 04, 06/2007 10 - 3

Page 66

Index

N

Ni-Cad 3 - 2

O

Operating frequencies 7 - 2

Operation 3 - 2, 5 - 2

Customising operation mode 5 - 14

Keys 4 - 3

Recalling customised mode 5 - 15

Reference block values 5 - 4

Setting operating mode 5 - 15

Storing customised mode 5 - 15

Switching off 5 - 3

Switching on 5 - 2

User/Supervisor 5 - 15

Working parameters 5 - 3

P

Parameter setting 3 - 6

PC 5 - 15, 6 - 2

Power requirements 3 - 2

Power source 7 - 4

Printers 6 - 2

Probe 4 - 2, 5 - 2, 7 - 2

Connection 3 - 3

Entering probe code data 3 - 3

Identifi cation 3 - 4

Setting 5 - 6, 5 - 8

Probe code 3 - 3

R

Readings 6 - 5

Reference block 5 - 4

Reset 3 - 7

Issue 04, 06/2007 AutoSigma 3000

10 - 4

Page 67

Index

Resolution 7 - 2

RS-232 6 - 2

S

Serial port 7 - 4

Specifi cations 7 - 2

Start-up 3 - 7

Statistics 6 - 5

Supervisor mode 5 - 15

Support 9 - 2

T

Temperature 3 - 9, 4 - 2, 5 - 8

Temperature compensation 7 - 3

Temperature measurement 7 - 3

U

User mode 5 - 16

User reference blocks 5 - 5

W

Weight 7 - 4

AutoSigma 3000 Issue 04, 06/2007 10 - 5

Page 68

10 - 6 Issue 04, 06/2007 AutoSigma 3000

Loading...

Loading...