Page 1

Operator’s Manual

Model HD160B

Heavy Duty Autoranging

Digital Multimeter

• Bedienungsanleitung

• Manual de Instrucciones

• Manuel d’Utilisation

¤

TM

Digital MultiMeter/MultiTester

Page 2

- 1 -

CONTENTS

Introduction ........................................ 2

Safety Information ..............................2

Instrument Familiarization...................3

Measurement Procedures ................... 6

Menu Functions ...............................12

Specifications ................................... 14

Maintenance and Repair ...................16

EXPLANATION OF SYMBOLS

Attention! Refer to Operating

Instructions

Ground connection

Alternating current

Direct current

Dangerous voltage may be

present at terminals

This instrument has double

insulation

WARRANTY

The HD160B Digital Multimeter is warranted against any defects of material or

workmanship within a period of one (1) year following the date of purchase of the multimeter

by the original purchaser or original user.

Any multimeter claimed to be defective during the warranty period should be returned with

proof of purchase to an authorized Wavetek Meterman Service Center or to the local Wavetek

Meterman dealer or distributor where your multimeter was purchased. See maintenance

section for details.

Any implied warranties arising out of the sale of a W

avetek Meterman multimeter, including

but not limited to implied warranties of merchantability and fitness for a particular purpose, are

limited in duration to the above stated one (1) year period. Wavetek Meterman shall not be

liable for loss of use of the multimeter or other incidental or consequential damages,

expenses, or economical loss or for any claim or claims for such damage, expenses or

economical loss.

Some states do not allow limitations on how long implied warranties last or the exclusion

or limitation of incidental or consequential damages, so the above limitations or exclusions

may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights which vary

from state to state.

Page 3

INTRODUCTION

The Wavetek digital multimeter HD160B is a Heavy Duty 4-digit, autoranging, ACcoupled true RMS measuring instrument that measures voltage, current,

resistance, continuity and diode junctions. It also has a Safety Tester™ to indicate

that a voltage is present, even if the meter’s battery is dead. Menu selection allows

Range Lock, Probe Hold, Relative Measurement, Auto Min Max Measurement and

backlight ON/OFF. The instrument is completely sealed.

WARNINGS AND PRECAUTIONS

■ This instrument is EN61010-1:1993 certified for Installation Category III,

1500VDC/1000VAC. It is recommended for use in distribution level and fixed

installations, as well as lesser installations, and not for primary supply lines,

overhead lines and cable systems. ■ All inputs are protected against continuous

overload conditions up to the limits of each function's stated input protection (see

specifications). Never exceed these limits nor the ratings marked on the

instrument itself. ■ For voltage measurements, the circuit under test must be

protected by a 20A fuse or circuit breaker. ■ Exercise extreme caution when:

measuring voltage >20V, current >10mA, AC power line with inductive loads, AC

power line during electrical storms. High voltages can be lethal and high voltage

transients may occur at any time. ■ Operator injury or damage to the multimeter

may occur during current measurements if the fuse blows in a circuit with open

circuit voltage >600V (500V in mA input). ■ Always inspect your DMM, test

leads and accessories for signs of damage or abnormality before every use. If an

abnormal condition exists (broken or damaged test leads, cracked case, display

not reading, etc.), do not use. ■ When testing for voltage or current, make sure

these ranges function correctly. Take a reading of a known voltage or current first.

n Never ground yourself when taking measurements. Do not touch exposed metal

pipes, outlets, fixtures, etc., which might be at ground potential. Keep your body

isolated from ground and never touch exposed wiring, connections, test probe

tips, or any live circuit conductors. Do not use the Flex-Strap to attach the meter

to your body. ■Always measure current in series with the load – NEVER connect

the multimeter ACROSS a voltage source. Check fuse first. ■ Never replace a fuse

with one of a different rating. ■ Do not operate instrument in an explosive

atmosphere (flammable gases, fumes, vapor, dust.) ■ Do not use this or any

piece of test equipment without proper training ■ CRT SERVICE SAFETY

REMINDER : A potential danger exists when measuring voltages in the horizontal

output and damper stages of CRT equipment. (High voltage transients greater than

- 2 -

Page 4

8,000 V). Refer to your CRT service manual for proper servicing instructions.

PREPARATION FOR USE – UNPACKING

Your shipping carton should include the multimeter, a holster with flex strap, one

test lead set (one black, one red), one 9V battery (installed), one spare fuse, a hex

wrench (held inside holster) and this manual. If any of the items are damaged or

missing, immediately return the complete package to the place of purchase for an

exchange.

PROTECTIVE HOLSTER

The holster/tilt stand provides additional protection of the meter from accidental

falls and provides greater ease of use. Both test lead probes can be attached to the

holster for storage. One probe can be attached for measurement, holding the

meter with probe in one hand and the second probe in the other hand.

OVERLOAD INDICATION

Input Overload (highest range in autoranging) is

indicated by “I.OL” and a continuous tone. Remove

test leads from the measurement setup as the input

is beyond the range of the meter.

Display Overload (input exceeds the selected range

while range is locked) is also indicated by “I.OL”. Select the next higher range

until a value is displayed, or return to autoranging. If overload still exists in the

highest range, remove test leads from the measurement setup as input is beyond

the range of the meter.

Note: In both instances, overload indication is normal in the OHMS and continuity

ranges (no sound) when the leads are not connected to anything or when the

measured value is higher than the selected resistance range.

- 3 -

Page 5

- 4 -

4 digit LCD with unit indicators

Low Battery

Function/Range

Selector

HD160B

010203040

RANGE

MENU

OFF

V

V

A

10A

mA

COM

CACAT IIIT III

MAX

40mA MAX

FUSED

MAX

20A/10sec

FUSED

V

A

SAFETY

TESTER

500V AC

MAX

480V

240V

120V

50V

24V

SELECT

CLEAR

HOLD REL MAX MIN

mV

AM

AC

k

1500V

1000V

Menu bar – see “Menu Functions”, page 12

40-Segment

Bargraph

Safety Tester and

LED display

Menu Buttons

(see page 12)

High input for

voltage

and resistance

COM Input – common or low input for all measurements

10A Input

mA Input

Page 6

Display Symbols

Dangerous voltage warning (also double beep tone). Indicates input voltages

higher than 30VAC or 60VDC.

Polarity indication

Low-battery voltage

Menu Functions - See page 11

Audible Feedback

The meter emits a single beep when a parameter is changed, a “valid” front panel

button is pushed, or Auto Min Max or Probe Hold values are updated. A double

beep indicates a dangerous input voltage (>30VAC or 60VDC).

The meter emits a continuous tone in the case of input overload, for continuity

measurement when resistance is <50Ω, and for current measurements, when the

10A input is used and the current exceeds 10A.

Analog Bargraph

The analog bargraph indicates which percentage of the range a displayed

measurement relates to. The zero segment is lit when the instrument is turned on.

If the input is less than 40% of range, each segment equals 1% of range. If the

input is above 40% of range, each segment equals 10% of range. Example: a

300mV input in the 1V range (30%) is represented by 30 segments

( ); a 600mV input (60%) will be represented by 6 segments

().

Exception: in the 40mA range, one segment represents one mA.

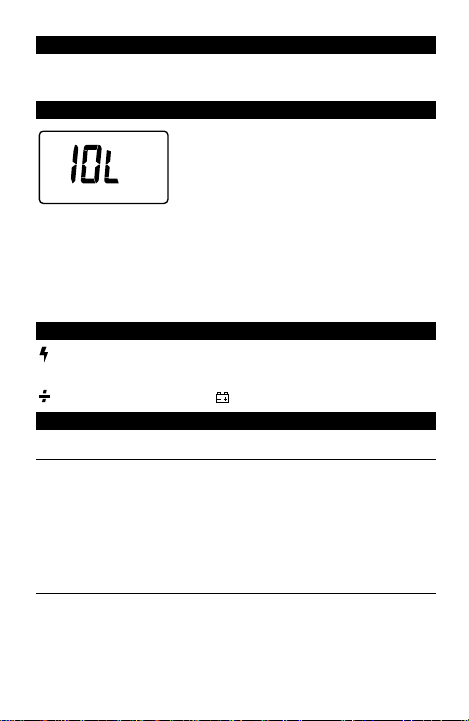

SAFETY TESTERTM(See Fig. 1)

The Safety Tester™ is designed to provide a quick sure look at a circuit for

voltages up to 480VDC or ACrms. It will indicate the five voltage levels even if

the meter has a dead battery or blown fuses. ¶ Position the Range Selector

Switch in the Safety Tester™ position. Â Connect the test leads to the COM and

VΩ inputs then across the circuit to be tested. ’ Note which, if any, LED(s) is(are)

lit for voltage level.

WARNING - The Safety Tester™ is designed as additional level of fail-safe

protection, but should not be trusted on a meter which has known operational

problems or has been damaged. It can not indicate the presence of voltage over

0

0102030

- 5 -

Page 7

- 6 -

and above all failures (i.e. a broken test lead or hidden internal circuit damage)

Meters with problems or damage should only be repaired or certified operational

at an authorized Wavetek Service Center.

All 4 lit

at 240V

120

3

red

LCD not powered in

Safety Tester mode

120

TM

HD160B

MENU

OFF

V

V

A

10A10A

mAmA

COMCOM

CACAT III

MAX

40mA MAX

FUSED

MAX

20A/10sec

FUSED

V

A

SAFETY

TESTER

500V AC

MAX

480V

240V

120V

50V

24V

SELECT

CLEAR

1500V

1000V

2

1

Fig. 1

MEASURING PROCEDURES

GENERAL: Turn instrument on by turning function/range switch away from OFF

and selecting the parameter you want to measure.

Ranging: This instrument is autoranging on all ranges. It automatically selects

the range that gives the best resolution for the measured value. A range can be

locked through menu selection (see Menu Functions, page 12). You can tell

which range you are in by the position of the decimal point and the measurement

unit displayed.

General Measurement Procedures: n When connecting or disconnecting test

Page 8

- 7 -

HD160B

010203040

MENU

OFF

V

V

A

10A10A

mAmA

COMCOM

CACAT IIIT III

MAX

40mA MAX

FUSED

MAX

20A/10sec

FUSED

V

A

SAFETY

TESTER

500V AC

MAX

480V

240V

120V

50V

24V

SELECT

CLEAR

V

1500V

1000V

red

2

1

3

4

V or

V

> 20V

leads to a circuit, always turn off power to device or circuit being tested and

discharge all capacitors. n Strictly observe the max input limits. n Do not change

functions while test leads are connected to circuit.

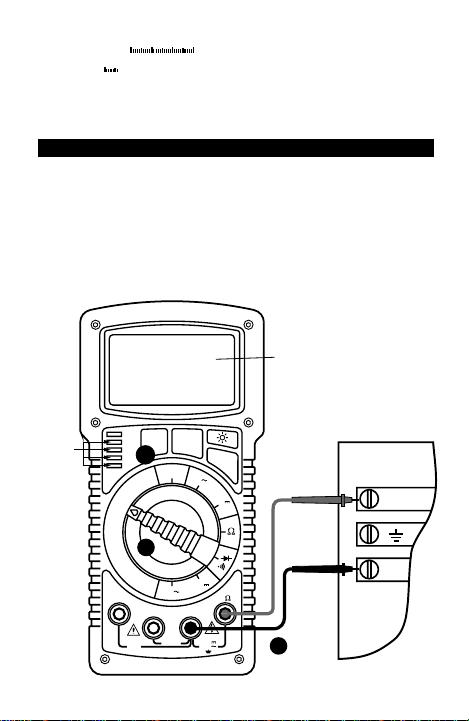

DC AND AC VOLTAGE MEASUREMENT (See Fig. 2)

❶ Connect test leads as shown in figure 1. ❷ Turn function selector switch to V

or V . ❸ Touch Probe tips across voltage source (in parallel with circuit). ❹

Voltage value will appear on Digital Display along with the voltage polarity (for DC).

True RMS AC Measurements: Model HD160B is an AC-coupled True-RMS

measuring meter. It measures the true RMS value of distorted AC voltage or

current signals. The Crest Factor handling capability is shown in

Fig. 2

Page 9

Table 1. The Crest Factor is the Peak Voltage divided by the RMS voltage.

Note: To accurately measure a DC voltage with an AC component, measure the

AC component first with selector switch set to V . Note the measurement and

range used. Switch to V , activate Range Lock (see Menu Functions, page 12)

and select a range equal to or higher then the V range used previously. Note the

measurement. The result is the measured AC Voltage on top of the measured DC

component. (Max input is 1500V for any combination).

DC AND AC CURRENT MEASUREMENT (See Fig. 3)

❶ Connect red test lead to the mA input for current measurements up to 40mA or

to the 10A input for current measurements to 10A. Connect black test lead to

COM input connector. ❷Set the Function Switch to A or A as required. ❸

Open circuit in which current is to be measured (voltage between this point and

ground must not exceed 600V on 10A input or 500V on mA input). Securely

connect test leads in series with the load. ❹ Turn on power to circuit being tested.

➎ Read current value on Digital Display.

Note: If, in the 10A range, the meter is exposed to current greater than 10A, it

should be turned off and allowed to cool for at least 10 minutes

Incorrect Input Warning: “FErr” is displayed when a test lead is connected to

current input, but the selector switch is not set to a current range.

- 8 -

Wave form, Crest Factor Additional correction from 1.5 to 5.0

Table 1

5.0

5%

4.0

3.0

4%

3%

2%

2.5

0%

1.0

Input RMS, Percentage of Full-Scale

100%806040200

Page 10

- 9 -

True RMS AC Measurements: Model HD160B is an AC-coupled True-RMS

measuring meter. It measures the true RMS value of distorted AC voltage or

current signals. The Crest Factor handling capability is shown in table 1. The

Crest Factor is the Peak Voltage divided by the RMS voltage.

HD160B

010203040

MENU

OFF

V

V

A

10A10A

mAmA

COMCOM

CACAT IIIT III

MAX

40mA MAX

FUSED

MAX

20A/10sec

FUSED

V

A

SAFETY

TESTER

500V AC

MAX

480V

240V

120V

50V

24V

SELECT

CLEAR

A

1500V

1000V

Discharge

capacitors

3b

3a

3c

3d

2

1

4

5

red

A or A

Fig. 3

Page 11

- 10 -

RESISTANCE MEASUREMENT (See Fig. 4)

❶ Turn off any power to the resistance to be measured and discharge any

capacitors. Any voltage present during a resistance measurement will cause

inaccurate readings.❷ Connect test leads as shown in figure 4. ❸ Set

Function/Range Switch to Ω position. ❹ Connect test leads to circuit being

measured. ➎ Read resistance value on Digital Display. Open circuits will be

displayed as “I.OL”.

Note: When measuring very low resistances, use Relative Measurement to

eliminate the test lead resistance (see Menu Functions, page 12).

HD160B

010203040

MENU

OFF

V

V

A

10A10A

mAmA

COMCOM

CACAT IIIT III

MAX

40mA MAX

FUSED

MAX

20A/10sec

FUSED

V

A

SAFETY

TESTER

500V AC

MAX

480V

240V

120V

50V

24V

SELECT

CLEAR

k

1500V

1000V

1

4

3

5

red

2

Fig. 4

Page 12

- 11 -

DIODE AND CONTINUITY TEST (See Fig. 5)

The diode test measures the voltage drop across a diode junction. ❶ Connect the

test leads as shown in figure 5. ❷ Set the Function/Range switch to . ❸

Apply probe tip of red lead to the anode and of black lead to the cathode of the

diode. ❹ The meter’s display indicates the forward voltage drop (approx. 0.6V for

silicon diode or 0.4V for germanium diode). An open diode is indicated by “I OL”.

➎ Reverse test lead connections to the diode to perform a reverse bias test. “I OL”

indicates a good diode. Notes: “I OL” for both reverse and forward bias tests

indicates an open diode. A low voltage reading for both bias tests indicates a

shorted diode. If the diode is shunted by a resistor of 1000 ohms or less, it must

be removed from the circuit before taking the measurement. Bipolar transistor

Hz

HD160B

010203040

MENU

OFFOFF

V

V

A

10A10A

mAmA

COMCOM

CACAT IIIT III

MAX

40mA MAX

FUSED

MAX

20A/10sec

FUSED

V

A

SAFETY

TESTER

500V AC

MAX

480V

240V

120V

50V

24V

SELECT

CLEAR

mV

1500V

1000V

DC

DC

Anode Cathode

2

3

550 - 900mV

good

Reverse Bias Test

good

bad

bad

<1V

Anode Cathode

1

red

red

4

5

Fig. 5

Page 13

- 12 -

junctions may be tested in the same manner described above as emitter-base and

base-collector junctions are diode junctions.

When measuring continuity (also for shorted diodes) the meter emits a

continuous tone when the resistance value falls below 50Ω.

MENU FUNCTIONS

Press the MENU key to engage the

menu (menu bar flashes) and

continue pressing to move the cursor

( ) to the desired function. Press

SELECT to activate the function (the

selection remains displayed, while the

non-selected items continue flashing

for a few seconds and then turn off).

Several functions can be selected

concurrently. To deactivate a function, press the MENU key to engage the menu

and continue pressing to move the cursor in front of the desired (active) function.

Then press CLEAR to deactivate. Press CLEAR twice to deactivate all active

functions. Turning the function/range selector also deactivates all menu functions.

Note: “Relative Mode” is the only menu function available with “Diode Junction

Test”. All menu functions are available for all other measurement functions.

Display Backlight Button: Model HD160B has Digi-Glo

TM

backlighting, one of the best backlights available in the industry. This

button turns the backlight on and off. To conserve battery life,

backlight will automatically turn off after approximately 60 seconds.

RANGE LOCK

Locks the currently displayed range. Each subsequent push of

the button moves to a higher range. From highest range the meter

returns to the lowest range. The meter functions in the 4000 count mode when

range is locked.

PROBE HOLD

TM

Probe Hold keeps the measurement on the display for later

viewing (even after test leads are removed from circuit). Select HOLD

before taking a measurement. The meter beeps to indicate that a stable

measurement has been recorded.

RANGE HOLD REL MAX MIN

MENU

SELECT

CLEAR

RANGE

HOLD

Page 14

- 13 -

RELATIVE MODE

Take a measurement first and then activate Relative Mode,

while the measurement is displayed. The measurement is stored as

reference value and the display is reset to zero. The reference value is now

deducted from subsequent measurements and only the difference is displayed.

AUTO MIN MAX

TM

Records the minimum and maximum values of both

positive and negative polarity input signals, while displaying the

current value. The meter beeps each time a new MIN or MAX value is recorded.

“Auto Min Max” is fully autoranging for best resolution and updates every time

the display changes by one or more counts. To view the recorded values, engage

the menu with the MENU key and move the cursor to MAX MIN. Continue

pressing the SELECT key to view max values (only MAX displayed in menu bar)

and min values (only MIN displayed in menu bar). To view recorded min/max

resistance values, short the test leads together. “Auto Power Down” is disabled

when MAX MIN is enabled.

AUTO-POWER DOWN

In order to save battery life, your multimeter powers down automatically after

approximately 30 Minutes of inactivity. You can turn it back on by simply

pressing the menu button, or by turning the function selector switch to OFF and

back to a measuring function. The instrument does not power down while in Auto

Min Max mode.

INCORRECT INPUT WARNING

The meter displays a function error code “FErr” when a test lead is placed in the

10A input jack and the Selector switch is not set to current. (If the DMM is

connected to a voltage source with leads set for current, very high current could

result). All current ranges are protected with fast acting fuses.

SAFETY TEST LEADS

The test leads included with your meter have shrouded banana plugs to eliminate

the possibility of shock if the plugs accidentally pull out of the meter while making

a measurement. The test leads also have insulated probe tips to avoid causing

shorts when making measurements in dense component areas. Replacement part

number for Safety test leads is TL245.

REL

MAX MIN

Page 15

- 14 -

General Specifications

Display: 4 digit LCD, 9999 counts, with

annunciators, menu features and 41

segment bargraph.

Polarity Indication: Automatic

Input overload indication: I.OL.

Low Battery Indication: ; less than 50

hours battery life remain, accuracy is no

longer guaranteed

Display Update Rate: 2/sec, nominal;

20/sec for bargraph.

Oper. Temp. 0°C to +50°C

@ 0 - 80%R.H.

Storage Temp: -40°C to 70°C @ 0 to 95%

RH, battery removed

Altitude: 2000 meters - indoor/outdoor use

Temperature coefficient: <0.1 x (spec. accu-

racy)/°C (-0° to 20°C and 30° to 50°C)

Fusing: 0.25A/500V; I.R. 10kA (6.35x32mm)

20A/600V; I.R.100kA (10x38mm)

Power: Standard 9-volt battery, NEDA

1604, JIS 006P, IEC 6F22

Auto Power-Down: Meter powers down

after approximately 30 minutes of

inactivity. Not in Min/Max function.

Battery Life (typical): 450 hours, alkaline.

Backlight usage consumes extra power

and will decrease battery life

significantly. Backlight auto-off after

approx. 60 seconds.

Dimensions, without holster (H x W x D): ,

200x102x59 mm (7.9” x 4;0” x 2;3”)

Weight (incl. battery): 642 g (22 oz)

Accessories: Test leads, spare 0.25A/500V

fuse and battery (installed), hex wrench

(inside holster), flex strap and

Operator’s Manual

* in instrument

Case material: Reinforced, high-impact,

fire retardant thermoplastic

Safety: Meets EN61010-1 Cat III -

1500VDC or 1000VAC.

Class 2. EN60529:IP67

EMC: Meets EN55011, EN61326-1

EMC: This product complies

with requirements of the

following European Community

Directives: 89/336/EEC (Electromagnetic

Compatibility) and 73/23/EEC (Low

Voltage) as amended by 93/68/EEC (CE

Marking).

However, electrical noise or intense

electromagnetic fields in the vicinity of the

equipment may disturb the measurement

circuit. Measuring instruments will also

respond to unwanted signals that may be

present within the measurement circuit.

Users should exercise care and take

appropriate precautions to avoid

misleading results when making measurements in the presence of electronic

interference.

Electrical Specifications

Accuracy at 23°C ± 5°C, <75% RH,

guaranteed for one year.

DC Volts

Ranges: 1, 10, 100, 1500V

Resolution: 0.1mV in 1V range:

Accuracy, 1V range: ±(0.25%rdg +6dgt)

Accuracy, 10V to 1500V ranges: ±(0.1%

rdg +2dgt)

Input Impedance: 10MΩ

CMRR: >120dB up to 1500Vdc

NMRR: >60dB at 50 or 60Hz

OL Protection: 1500VDC or 1000Vrms.

Transient protection: 6kV for 10µSec.

AC Volts.

Ranges: 10, 100, 1000V

Resolution: 1mV in 10V range

Accuracy, 10V range:

45Hz-10kHz: ±(1.5% rdg +5dgt)

SPECIFICATIONS

Page 16

Accuracy,100V range:

2-30V: 45Hz-10kHz: ±(1.5% rdg +3dgt)

2-30V: 10kHz-30kHz: ±(2.5% rdg +5dgt)

30-100V, 1000V: 45Hz-1kHz: ±(1.5% rdg

+3dgt)

Input Impedance: 10MΩ shunted by <100pF

Conversion type: True RMS, AC coupled

Crest factor: 1:1 through 5:1

OL Protection, <10Hz: 400VAC or 533V

peak; >10Hz: 1000Vrms or 1000V peak.

6kV transient protection.

DC Current

Ranges: 10, 40mA, 10A

Resolution: 1µA in 10mA range

Accuracy, 10, 40mA, 10A: ±(0.75% +5dgt)

Voltage burden, mA ranges: 20mV/mA;

A ranges: 30mV/A

OL Protection: 40mA input: F0.25A/500V

fuse; 10kA I.R. 10A input: F20A/600V

fuse;100kA I.R.; 20A max. for 10 sec.

AC Current (45Hz-1kHz)

Ranges: 10, 40mA, 10A

Resolution: 1µA in 10mA range

Accuracy, 10, 40mA, 10A: ±(1.75% +5dgt)

Voltage burden, mA ranges: 20mV/mA; A

ranges: 30mV/A

Conversion type: True RMS AC coupled

Crest factor 1:1 through 5:1

OL Protection: see DC current.

Resistance

Ranges: 1, 10, 100kΩ, 1, 10, 40MΩ

Resolution, 0.1Ω in 1kΩ range

Accuracy, 1kΩto 1MΩranges:

±(0.5%rdg +1dgt);

10MΩ range: ±(1.0%rdg +2dgt)

40MΩ range: ±(1.5%rdg +2dgt)

Max test current: 1.0mA in 1kΩ rg; 150µA

in 10kΩ rg; 15µA in 100kΩ rg; 1.5µA

in 1MΩ rg; 0.2µA in 10 and 40MΩ rgs.

Max open circuit voltage: 3.0V in 1kΩ

range; 1.3V in other ranges.

Response time: 1s in 1kΩ range; 3s in

other ranges

Overload protection, all ranges: 500VDC

or AC RMS

Diode/Continuity Test

Range: 1.0V, 2.25V

Resolution: 0.1mV in 1.0V range

Accuracy: ±(1.0%rdg +1dgt)

Short circuit current: 1.5mA

Max open circuit voltage: 3.0Vdc

Display response: <1s

Continuity threshold: 50Ω ±25

Overload prot.: 500VDC or RMS AC

Safety Tester

TM

Signal voltage levels: 24V, 50V, 120V,

240V and 480V

Maximum input: 600VAC for 60 sec

Optional Accessories

DL243C Standard Test Lead Set

DL248C Deluxe Test Lead Set

TL245 Standard Replacement Test Leads

TL35A Test Leads with Alligator Clips

CT231A 150A AC Current Clamp

CT232A 1000A AC Current Clamp

CT234A 400A AC Current Clamp

CT235 1000A AC/DC Clamp

CT236A 500A AC Clamp (mV output)

CT237 200A AC/DC Current Clamp

CT238 20A AC/DC Current Clamp

RF241 650MHz RF Probe

TC 253A Temperature Converter (900°C/1652°F)

VC221A Padded Vinyl Case. Fits meter & holster.

DC205B Deluxe Hard-Shell Carry Case

DC207B Large Deluxe Hard-Shell Carry Case

with extra space for accessories

HV231-10 High Voltage Probe

- 15 -

Page 17

MAINTENANCE & REPAIR

If there appears to be a malfunction during the operation of the meter, the

following steps should be performed in order to isolate the cause of the problem:

❶ Check the battery. ❷ Review the operating instructions for possible mistakes in

operating procedure. ❸ Inspect and test the Test Probes for a broken or

intermittent connection. ❹ Inspect and test the fuses. See Fuse Replacement.

Except for the replacement of the battery or fuse, or test probes, repair of the

multimeter should be performed only by a Factory Authorized Service Center or

by other qualified instrument service personnel.

The front panel and case can be cleaned with a mild solution of detergent and

water. Apply sparingly with a soft cloth and allow to dry completely before using.

Do not use aromatic hydrocarbons or chlorinated solvents for cleaning.

BATTERY / FUSE REPLACEMENT (See Fig. 6)

Preliminary: Disconnect test leads from circuit and meter. Turn off the meter,

remove the holster and place the meter face down on a clean padded surface.

Unscrew 6 securing screws with the hex wrench located inside the holster and

remove rear case cover. A flat blade screwdriver may be needed to separate the

case halves because of the tight fit of the case seal. Make sure no dirt, grease, or

other contaminates get into the meter. Do not touch any circuit parts other than the

battery and fuse holders.

Battery replacement: Lift

battery cover from rear case by

lifting on the side tab with your

thumb. Install a new 9 volt

alkaline battery type NEDA

1604, JIS 006P, or IEC 6F22.

Install the new battery

observing the correct polarity.

Warning: Failure to turn off the multimeter before installing the battery could

result in damage to the instrument and to the battery if the battery is connected

incorrectly to the multimeter.

Fuse replacement: Remove the fuse covers and carefully pry up one end of

suspect/blown fuse using a small flat blade screwdriver. Replace with only one of

the following:

10A input: F20A/600V fuse (10mm x 38mm), I.R. 100kA – Wavetek p/n

FP425, Little Fuse p/n KLK-20, or Bussmann p/n. KTK-20.

ONLY

LIFT HERE

Fig. 6

Battery

Cover

LIFT FLAT

Do not pry on

case edge or

shield spring

(not shown)

- 16 -

Page 18

40mA input: 0.25A/500V fuse (6.35mm x 32mm), I.R. 10kA –

Wavetek p/n FP375.

Warning: Use only an equivalent fuse to the one specified. Use of an incorrect

fuse could result in serious injury or even death.

Reassembly: Reassemble the instrument ensuring correct alignment of the

case halves, case seal and screws. Tighten screw snugly. Do not over-tighten as

this may strip the case threads.

REPAIR

Read the warranty located at the front of this manual before requesting warranty or non-warranty

repairs. For warranty repairs, any multimeter claimed to be defective can be returned to any

Wavetek Meterman authorized distributor or to a Wavetek Meterman Service Center for an overthe-counter exchange for the same or like product. Non-warranty repairs should be sent to a

Wavetek Meterman Service Center. Please call Wavetek Meterman or enquire at your point of

purchase for the nearest location and current repair rates. All multimeters returned for warranty

or non-warranty repair or for calibration should be accompanied by the following information or

items: company name, customer’s name, address, telephone number, proof of purchase

(warranty repairs), a brief description of the problem or the service requested, and the

appropriate service charge (for non-warranty repairs). Please include the test leads with the

meter. Service charges should be remitted in the form of a check, a money order, credit card

with expiration date, or a purchase order made payable to Wavetek Meterman or to the specific

service center. For minimum turn-around time on out-of-warranty repairs please phone in

advance for service charge rates. The multimeter should be shipped with transportation charges

prepaid to one of the following addresses or to a service center:

in U.S.A. in Canada in Europe

Wavetek Meterman Wavetek Meterman Wavetek Meterman

1420 75th Street SW 400 Britannia Rd. E.Unit #1 52 Hurricane Way

Everett, WA 98203 Mississauga, ON L4Z 1X9 Norwich, NR6 6JB, U.K.

Tel: 1-877-596-2680 Tel: (905) 890-7600 Tel: int + 44-1603-404824

Fax: 425-446-6390 Fax: (905) 890-6866 Fax: int + 44-1603-482409

The instrument will be returned with the transportation charges paid by Wavetek Meterman.

- 17 -

Page 19

- 18 -

Operator’s Manual

Model HD160B

Heavy Duty Multimeter

mit Auto-Bereichswahl

• Bedienungsanleitung

¤

TM

Digital MultiMeter/MultiTester

Page 20

- 19 -

INHALT

Einleitung ......................................... 20

Sicherheitsinformationen .................. 20

Vorstellung des Gerätes..................... 21

Meßprozeduren ................................ 24

Menü-Funktionen ............................. 29

Spezifikationen ................................. 32

Wartung und Reparatur ..................... 34

ERKLÂRUNG DER SYMBOLE

Achtung! Bitte Anleitung

lesen

Erdanschluß

Wechselstrom

Gleichstrom

Eine gefährliche Spannung

kann an den Eingängen

anliegen

Dieses Gerät ist doppelt

geisoliert

D GEWÄHRLEISTUNG

Die Digitale Multimeter Modelle HD160B ist ab Kaufdatum für ein (1) Jahr gegen Material-

und Herstellungsfehler gewährleistet. Siehe Kapitel "Unterhalt und Reparatur" für Einzelheiten.

Implizierte Schadeforderungen sind auch auf ein Jahr beschränkt. W

avetek Meterman ist nicht

ansprechbar für Gebrauchsverluß oder Folgeschäden, Ausgaben, Gewinnverluß, usw.

EINLEITUNG

Das Wavetek Modell HD160B ist ein “Heavy Duty” 4-stelliges AC-gekoppeltes,

echt-effektivwertmessendes Digitalmultimeter mit automatischer Bereichswahl.

Es mißt Spannung, Strom, Widerstand und Durchgang und führt Diodentest aus.

Es hat einen Sicherheitstester mit welchem eine anliegende Spannung

festgestellt werden kann, auch bei entladener Batterie. Eine Menüwahl umfaßt

Bereichssperre, Meßwertspeicher, Relativmessung, Auto Min Max. und

Anzeigen-Rückbeleuchtung. Das Gerät ist vollständig abgedichtet.

Page 21

WARNUNGEN UND VORSICHTSMAßNAHMEN

■ Dieses Gerät ist EN61010-1:1993 zertifiziert für Installationsklasse III,

1500VDC/1000VAC. Anwendung ist empfohlen auf Verteilerebene und festen

Anlagen sowie untergeordneten Systemen, jedoch nicht für Starkstromnetze und

Hochspannungsanlagen. ■ Überschreiten Sie nie die kontinuierlichen

Überlastgrenzen der verschiedenen Meßfunktionen (siehe Spezifikationen) oder

andere Grenzen welche auf dem Gerät markiert sind. ■ Für

Spannungsmessungen muß der Meßkreis mit einer 20A Sicherung oder einem

Trennschalter abgeschirmt sein. ■ Vorsicht beim Messen von Spannungen >20V

// Strömen >10mA // Netzstrom/-spannung bei induktiver Last oder bei Gewittern

// Strom, wenn die Sicherung durchbrennt in einem Schaltkreis mit

Leerlaufspannung >600V (>500V beim mA Eingang) // beim Messen an

Bildröhrgeräten (hohe Spannungsspitzen) ■ Unsersuchen Sie Gerät, Meßkabel,

Verbinder, usw. vor jeder Messung. Beschädigte Teile nicht verwenden ■

Meßspitzen und Stromkreis während der Messung nicht berühren • Sich selbst

isolieren ! Das Gerät nicht mit der Trageschlaufe am eigenen Körper befestigen. ■

Bei Strommessung, Multimeter immer in Serie mit Schaltkreis verbinden – Nie in

parallel mit Spannungsquelle. ■ Sicherung immer mit gleichwertiger ersetzen. ■

Gerät nicht in explosiver Umgebung verwenden.

GEBRAUCHSVORBEREITUNG - AUSPACKEN

Die Verpackung sollte enthalten: ein Multimeter, ein Schutzholster mit Schlaufe,

ein Meßkabelsatz (ein schwarz, ein rot), eine 9V Batterie (im Gerät), eine

Ersatzsicherung, ein Sechskantschlüssel (im Schutzholster befestigt) und diese

Anleitung. Wenn ein Teil fehlt oder beschädigt ist, bitte bei der Verkaufstelle

umtauschen.

SCHUTZ-HOLSTER

Das Schutzholster bietet eine zusätzliche Beschirmung des Gerätes vor Stürzen

und Stößen. Die Meßsonden können am Holster befestigt werden.

ÜBERLASTANZEIGE

- 20 -

Page 22

Eingangs-Überlast (höchster Bereich in

automatischer Bereichswahl): “I.OL” Anzeige und

Dauerton. Messung unterbrechen da der Meßwert

die Eingangsgrenze überschreitet.

Bereichs-Überlast (Der Eingang überschreitet

den betreffenden Bereich bei manueller Bereichswahl - RANGE LOCK): “I.OL”

Anzeige. Höheren Bereich wählen oder Messung unterbrechen.

Anmerkung: Überlastanzeige ist normal bei Widerstandsmessung wenn

Meßkabel/-spitzen frei stehen oder wenn der Meßwert den Bereich überschreitet.

In allen anderen Fällen ist die Ursache der Überlast sofort zu entfernen. Höheren

Bereich wählen oder Messung unterbrechen.

ANZEIGENSYMBOLE

Gefährliche Eingangsspannung - über 30VAC oder 60VDC (auch

doppelter Biep-Ton)

Polaritätsanzeige

Batterie entladen

MENÜFUNKTIONEN - Siehe Seite 29

AKUSTISCHE ANZEIGEN

Das Gerät gibt einen Einzelton ab bei Funktionswechsel, bei Aktivierung einer

“validen” Taste und wenn neue Auto Min Max- und Anzeigenspeicherwerte erfaßt

werden. Ein Doppelton zeigt eine gefährliche Eingangsspannung (über 30VAC

oder 60VDC) an.

Ein Dauerton wird abgegeben bei Eingangsüberlast und bei Durchgangsmessung,

wenn der Widerstand unter 50Ω liegt. Wenn beim RMS225 im 10A Bereich

gemessen wird, wird ein Dauerton abgegeben wenn der Eingangsstrom 10A

überschreitet.

BALKENANZEIGE

Die Balkenanzeige gibt an welchem Prozentwert des Meßbereiches der Meßwert

entspricht. Das erste Segment leuchtet beim Einschalten des Gerätes auf. Liegt der

Eingang unter 40% des Meßbereichs, dann entspricht jedes Segment 1% des

Meßbereichs. Liegt der Eingang über 40% des Meßbereichs, dann entspricht

jedes Segment 10% des Meßbereichs. Beispiel: Ein Eingang von 300 mV im 1V

Bereich (30%) wird durch 30 Segmente angezeigt ( ); ein Eingang

0102030

- 21 -

Page 23

- 22 -

4 Digit LCD mit Einheitsanzeigen

Batterie

entladen

Funktions-/

Bereich-Schalter

HD160B

010203040

RANGE

MENU

OFF

V

V

A

10A

mA

COM

CACAT IIIT III

MAX

40mA MAX

FUSED

MAX

20A/10sec

FUSED

V

A

SAFETY

TESTER

500V AC

MAX

480V

240V

120V

50V

24V

SELECT

CLEAR

HOLD REL MAX MIN

mV

AM

AC

k

1500V

1000V

Menübalken – siehe “Menüfunktionen”, Seite 29

40-Segment

Bargraf

Sicherheitstester

und LED Anzeige

Menutasten

(siehe Seite 29)

V-Ω Eingang.

Hoch für

Spannung und

Widerstand

COM Eingang – Referenzpunkt für alle Messungen

10A Eingang

mA Eingang

Page 24

Sicherheitstester (Siehe Fig. 1)

Der Sicherheitstester erlaubt fünf Spannungspegel bis 480V DC oder AC schnell

und sicher festzustellen – auch bei entladener Batterie. ❶ Wahlschalter auf

“Safety Tester” Position stellen. ❷ Meßkabel mit COM und VΩ Eingängen und

Schaltkreis verbinden. ❸ Spannungspegel (falls vorhanden) mit aufleuchtenden

LEDs feststellen.

WARNUNG - Verlassen Sie sich nicht auf den Sicherheitstester falls Sie bei Ihrem

- 23 -

von 600 mV (60%) durch 6 Segmente ( ).

Ausnahme: Im 40 mA Bereich steht jedes Segment für 1 mA.

0

4 LEDs

leuchten

bei 240V

120

3

rot

Keine Anzeige in der

Spannungstestfunktion

120

HD160B

MENU

OFF

V

V

A

10A10A

mAmA

COMCOM

CACAT III

MAX

40mA MAX

FUSED

MAX

20A/10sec

FUSED

V

A

SAFETY

TESTER

500V AC

MAX

480V

240V

120V

50V

24V

SELECT

CLEAR

1500V

1000V

2

1

Fig. 1

Page 25

Meßgerät irgendwelche Funktionsmängel feststellen – keine Spannungsanzeige

kann auch an einem Bruch im Meßkabel oder einem beschädigten Meßkreis

liegen. Ein defektes Gerät soll nur durch eine durch Wavetek anerkannte

Servicestelle repariert werden.

MEßPROZEDUREN

Einschalten: Gerät einschalten durch Funktions-/Bereichsschalter weg von OFF

nach der gewünschten Funktion zu drehen.

Bereichswahl: Das Gerät wählt automatisch den Bereich der die beste

Auflösung bietet. Ein Bereich kann durch Menüwahl festgehalten werden (siehe

Menüfunktionen, Seite 29). Der Dezimalpunkt und die angezeigte Einheit geben an

in welchem Bereich Sie sich befinden.

Allgemein: ■ Vor Verbinden und Trennen der Meßkabel mit dem Schaltkreis,

diesen abschalten und Kondensatoren entladen. ■ Maximale Grenzen nicht

überschreiten. ■ Keinen Funktionswechsel vornehmen während die Meßspitzen

mit dem Schaltkreis verbunden sind.

GLEICH- UND WECHSELSPANNUNGSMESSUNG (SIEHE FIG. 2)

❶ Meßkabel gemäß Fig.2 verbinden. ❷ Funktionsschalter auf V or V

stellen. ❸ Meßspitzen mit Meßkreis verbinden – parallel zur Spannungsquelle. ❹

Meßwert ablesen (automatische Polaritätsanzeige bei DC Messungen).

Echt-Effektivwertmessung: Modell HD160B ist ein AC-gekoppeltes EchtEffektivwert-messendes Gerät. Es mißt den echten Effektivwert auch von verzerrten

Spannungs- und Stromeingängen. Der Crest Faktor Bereich ist in Tabelle 1

aufgeführt. Der Crest Faktor ist die Spitzenspannung geteilt durch die Effektivwertspannung.

Anmerkung: Um eine Gleichspannung mit Wechselspannungskomponente

richtig zu messen, messen Sie zuerst die Wechselspannung mit dem

Funktionsschalter auf V . Notieren Sie den Bereich. Schalten Sie nach V ,

aktivieren Sie Range Lock (siehe Menüfunktionen, Seite 29), und wählen Sie

einen Bereich ebenso hoch oder höher als der vorhin gewählte V Bereich.

Notieren Sie die Ablesung. Das Resultat ist die gemessene Gleichspannung mit

der gemessenen Wechselspannungskomponente. (Max Eingang ist 1500V für

jede Kombination).

- 24 -

Page 26

- 25 -

HD160B

010203040

MENU

OFF

V

V

A

10A10A

mAmA

COMCOM

CACAT IIIT III

MAX

40mA MAX

FUSED

MAX

20A/10sec

FUSED

V

A

SAFETY

TESTER

500V AC

MAX

480V

240V

120V

50V

24V

SELECT

CLEAR

V

1500V

1000V

rot

2

1

3

4

V oder

V

> 20V

Fig. 2

Tabelle 1

Wellenform, Crest Factor Zusätzliche Korrektur von 1.5 bis 5.0

Effektiv-Wert Eingang, % vom Endbereich

5.0

4.0

3.0

2.5

1.0

5%

4%

3%

2%

0%

100%806040200

Page 27

HD160B

010203040

MENU

OFFOFF

V

V

A

10A

mA

COM

CACAT IIIT III

MAX

40mA MAX

FUSED

MAX

20A/10sec

FUSED

V

A

SAFETY

TESTER

500V AC

MAX

480V

240V

120V

50V

24V

SELECT

CLEAR

A

1500V

1000V

Kondensatoren

entladen

3b

3a

3c

3d

2

1

4

5

rot

A oder A

Fig. 3

GLEICH- UND WECHSELSTROMMESSUNG (SIEHE FIG. 3)

❶ Rotes Meßkabel mit dem 40mA Eingang verbinden für Messungen bis 40mA

oder mit dem 10A Eingang für Messungen bis 10A. Schwarzes Meßkabel mit

COM verbinden. ❷ Funktionsschalter auf A oder A stellen. ❸ Meßkreis

öffnen (an dieser Stelle darf das Potential gegenüber Erde 600V mit 10A Eingang

oder 500V mit mA Eingang nicht überschreiten). Meßspitzen sicher in Serie mit

dem Stromkreis verbinden. ❹ Meßkreis einschalten. ➎ Stromwert ablesen.

- 26 -

Page 28

- 27 -

Anmerkung: Wenn im 10A Bereich kurzzeitig ein Strom höher als 10A anliegt,

Gerät abschalten und mindestens 10 Minuten abkühlen lassen.

Eingangswarnung: “FErr” wird angezeigt wenn ein Meßkabel mit einem Stromeingang verbunden ist, der Wahlschalter jedoch nicht auf einem Strombereich

steht.

Echt-Effektivwertmessung: Modell HD160B ist ein AC-gekoppeltes EchtEffektivwertmessendes Gerät. Es mißt den echten Effektivwert auch von verzerrten

Spannungs- und Stromeingängen. Der Crest Faktor Bereich ist in Tabelle 1

aufgeführt. Der Crest Faktor ist die Spitzenspannung geteilt durch die Effektivwertspannung.

WIDERSTANDSMESSUNG (SIEHE FIG. 4)

HD160B

010203040

MENU

OFFOFF

V

V

A

10A10A

mAmA

COMCOM

CACAT IIIT III

MAX

40mA MAX

FUSED

MAX

20A/10sec

FUSED

V

A

SAFETY

TESTER

500V AC

MAX

480V

240V

120V

50V

24V

SELECT

CLEAR

k

1500V

1000V

1

4

3

5

rot

2

Fig. 4

Page 29

HD160B

010203040

MENU

OFF

V

V

A

10A10A

mAmA

COMCOM

CACAT IIIT III

MAX

40mA MAX

FUSED

MAX

20A/10sec

FUSED

V

A

SAFETY

TESTER

500V AC

MAX

480V

240V

120V

50V

24V

SELECT

CLEAR

mV

1500V

1000V

DC

DC

Anode Kathode

2

3

550 - 900mV

gut

Messung in Sperrrichting

gut

schlecht

schlecht

<1V

Anode Kathode

1

rot

rot

4

5

Fig. 5

- 28 -

❶ Jede Spannung vom Widerstand abschalten und Kondensatoren entladen. Eine

am Widerstand anliegende Spannung würde das Resultat verfälschen. ❷ Rotes

Meßkabel mit V•Ω Eingang und schwarzes mit COM verbinden. ❸ Funktionsschalter auf Ω-Position stellen. ❹ Meßspitzen mit Widerstand/ Schaltkreis

verbinden. ➎ Meßwert ablesen. Ein offener Schaltkreis wird mit Überlast

angezeigt.

Anmerkung: Bei niedrigen Widerstandswerten mit Relativmessung (siehe Seite

29) den Widerstand der Meßkabel kompensieren.

Dioden- und Transistortest (Fig. 5)

Page 30

- 29 -

Der Diodentest zeigt den Spannungsabfall über den Diodendurchgang. ❶ Rotes

Meßkabel mit V-Ω Eingang und schwarzes mit COM Eingang verbinden. ❷

Funktionsschalter auf stellen. ❸ Meßkabel mit Diode verbinden – rotes

mit Anode; schwarzes mit Kathode. ❹ Spannungsabfall in Durchlaßrichtung

ablesen (ung. 0.6V für eine Silikon-Diode und 0.4V für eine Germaniumdiode.

Eine offene Diode wird mit Überlast angezeigt. ➎ Verbindung umdrehen um in

Sperrrichtung zu messen. Überlast zeigt eine gute Diode an.

Anmerkung: Überlast in beiden Richtungen zeigt eine offene Diode an; eine

niedrige Ablesung eine kurzgeschlossene Diode. Transistorübergänge können wie

Dioden getestet werden.

Bei Durchgangsmessung (auch bei kurzgeschlossenen Dioden) wird ein

Dauerton abgegeben wenn der Widerstand unter 50Ω fällt.

MENÜFUNKTIONEN

Menü aktivieren durch die MENUTaste zu drücken (Menübalken

flickert). Taste weiter drücken bis

Cursor ( ) vor der gewünschten

Funktion steht. SELECT-Taste

drücken um die Funktion zu

aktivieren (die gewählte Funktion

bleibt angezeigt – andere

Funktionen flickern einige

Sekunden und verschwinden). Mehrere Funktionen können gleichzeitig gewählt

werden. Um eine Funktion zu desaktivieren, MENU-Tastedrücken um das Menü

zu aktivieren und weiter drücken um den Cursor vor die gewünschte aktive

Funktion zu bringen. CLEAR-Taste drücken um Funktion zu desaktivieren.

CLEAR-Tastezwei mal drücken um alle Funktionen zu desaktivieren. Drehen des

Funktionsschalters desaktiviert auch all Menüfunktionen.

Anmerkung: Beim Diodentest steht nur die Relativmessung im Menü zur

Verfügung. Für andere Meßfunktionen stehen alle Menüfunktionen zur Verfügung.

Rückbeleuchtungstaste: Modell HD160B hat Digi-Glo

TM

Rückbeleuchtung, eine der besten Anzeigenrückbeleuchtungen auf dem

Markt. Diese Taste schaltet die Rückbeleuchtung ein und aus. Um die

Batterie zu schonen, schaltet die Rückbeleuchtung nach 60 Sek. automatisch ab.

BEREICHSSPERRE

Sperrt den aktiven Bereich. Jeder weiterer Tastendruck wählt

RANGE HOLD REL MAX MIN

MENU

SELECT

CLEAR

RANGE

Page 31

- 30 -

einen höheren Bereich. Auf den höchsten Bereich folgt wieder der

niedrigste Bereich. Der Anzeigebereich ist 4000 Punkte.

ANZEIGESPERRE

Probe Hold

TM

erhält die Anzeige für spätere Ablesung (auch wenn die

Meßkabel vom Schaltkreis getrennt sind). HOLD vor der Messung

drücken. Ein Biepton befestigt die Erfassung eines stabilen Meßwertes.

RELATIVMESSUNG

Zuerst eine Messung vornehmen und dann, mit angezeigtem Meß-

wert die Relativmessung aktivieren. Der angezeigte Meßwert wird als

Referenzwert gespeichert und die Anzeige zurück auf Null gebracht. Der

gespeicherte Referenzwert wird von folgenden Messungen abgezogen und nur die

Differenz wird angezeigt.

AUTO MIN MAX

TM

Speichert minimale und maximale Werte von Eingängen

positiver und negativer Polarität mit gleichzeitiger Anzeige des

aktuellen Wertes. Ein Biepton befestigt jede Erfassung eines neuen MIN- oder

MAX-Wertes. “Auto Min Max” funktioniert mit automatischer Bereichswahl für

beste Auflösung. Um die gespeicherten Werte zu besichtigen, drücken Sie zuerst

die MENU-Taste um das Menü zu aktivieren, und dann weiter um den Cursor

vor MAX MIN zu bringen. Drücken Sie die SELECT-Taste weiter um max. Werte

anzuzeigen (nur MAX im Menübalken) oder um min. Werte anzuzeigen (nur MIN

im Menübalken) . Um gespeicherte min/max Widerstandswerte anzuzeigen

müssen die Meßspitzen miteinander verbunden (kurzgeschlossen) sein.

Automatische Abschaltung ist bei MIN MAX Messung inaktiv.

AUTOMATISCHE ABSCHALTUNG

Um die Batterie zu schonen, schaltet das Gerät automatisch nach ung. 30 Minuten

Inaktivität ab (nach 6 Minuten in der Ω Funktion, ohne Eingangswechsel). Sie

können es wieder einschalten durch die Menütaste zu drücken oder den

Funktionsschalter nach OFF und wieder zurück nach einer Meßfunktion zu drehen.

EINGANGSWARNUNG

“FErr” wird angezeigt wenn ein Meßkabel mit dem 10A Eingang verbunden ist, der

Wahlschalter jedoch nicht auf einer Stromfunktion steht. (Würde mit dem

Stromeingang Spannung gemessen werden, dann könnte ein sehr hoher Strom im

Gerät entstehen). Alle Strombereiche sind mit flinken Sicherungen geschützt.

Sicherheitsmeßkabel

Die Meßkabel haben versenkte Bananenstecker um elektrischen Schock zu

vermeiden. Die Meßspitzen sind zum Teil isoliert, um Kurzschlüsse in dichten

Schaltungen zu vermeiden. Diese Isolation kann entfernt werden.

Ersatzteilnummer ist TL245.

HOLD

REL

MAX MIN

Page 32

- 31 -

Allgemeine Spezifikationen

Anzeige: 4-stelliges LCD, 9999 Punkte, mit

Einheits- und Funktionsanzeigen,

Menübalken und 41-Segment Bargraf

Polaritätsanzeige: Automatisch

Überlastanzeige: “I.OL”

Entladene Batterieanzeige: . Es bleiben

noch etwa 50 Stunden. Genauigkeit nicht

länger garantiert

Anzeigeerneuerung: 2/Sek, nominal; 20/Sek

für Bargraf

Betriebstemperatur (0 bis 80% R.F.):

0°C bis +50°C,

Lagertemp: -40°C bis 70°C, 0 bis 95% R.F.,

Batterie entfernt

Höhenlage: 2000m - Anwendung innen und

außen

Temp.koeffizient: <0,1x spez. Genauigk./°C (-

0° bis 20°C und 30° bis 50°C)

Sicherungen: 0.25A/500V - 10kA (6.35x32mm);

20A/600V - 100kA (10x38mm)

Stromversorgung: Standard 9-Volt Batterie,

NEDA 1604, JIS 006P, IEC 6F22

Automatische Abschaltung: nach 60 Minuten

Inaktivität. Nicht bei Min/Max Funktion

Batterielebensdauer, Alkali (typ.): 450 St.;

Die Anzeigerückbeleuchtung ist leistungs-

intensiv und verkürzt die Batterielebens-

dauer beträchtlich. Automatische

Abschaltung nach etwa 60 Sekunden

Abmessungen - ohne Schutzholster: (HxBxT):

200 x 102 x 59 mm

Gewicht (mit Batterie): 642 Gramm

Zubehör: Meßkabel, Ersatzsicherung (0,25A/

500V) und Batterie (im Gerät), Sechskant-

schlüssel (im Holster), Schlaufe und

Anleitung

Gehäusematerial: Verstärktes, feuerwehrendes,

stoßbeständiges Thermoplastik

Sicherheit: Gemäß EN61010-1 Cat III -

1500VDC oder 1000VAC; Pollutionsgrad 2

EN60529:IP67

EMC: Gemäß EN55011, EN61326-1

EMC Dieses Produkt beantwortet an

die Bestimmungen der folgenden

EWG Richtlinien: 89/336/EEC

(Elektromagnetische Kompatibilität) und

73/23/EEC (Niedrige Spannung) geändert

durch 93/68/EEC (CE Marking).

Elektrisches Rauschen und starke magnetische Felder in der direkten Umgebung des

Meßgerätes können jedoch den Meßkreis

beeinflussen. Das Gerät kann auch durch

Störsignale im gemessenen Schaltkreis

beeinflußt werden. Der Anwender muß

Vorsichtsmaßnahmen treffen um

irreführende Meßergebnisse bei

Messungen in der Umgebung von starken

elektromagnetischen Feldern zu vermeiden.

Elektrische Spezifikationen

Genauigkeiten bei 23°C ± 5°C, <75% R.F., für

ein Jahr garantiert

Gleichspannung

Bereiche: 1, 10, 100, 1500V

Auflösung, 1V Bereich: 0,1mV

Genauigkeit, 1V Bereich: ±(0.25%vMW +6Dgt)

Genauigkeit, 10V bis 1500V Bereiche:

±(0.1%vMW +2Dgt)

Eingangsimpedanz: 10MΩ

CMRR bis 1500VDC: >120dB

NMMR (50-60Hz): >60dB

Überlastschutz, 1500VDC 1000VAC.

Transientenschutz: 6kV für 10 Sekunden.

Wechselspannung

Bereiche: 10, 100, 1000V

Auflösung, 10V Bereich: 1mV

Genauigkeit,

10V Bereich:

45Hz-10kHz: ±(1.5% vMW +5Dgt)

100V Bereich:

2-30V: 45Hz-10kHz: ±(1.5% vMW +3Dgt)

2-30V: 10kHz-30kHz: ±(2.5% vMW +5Dgt)

30-100V, 1000V: 45Hz-1kHz: ±(1.5% vMW

+3Dgt)

Eingangsimpedanz: 10MΩ // <100pF

AC Umsetzung: Echt-effektiv, AC gekoppelt

Crest Faktor: 1:1 bis 5:1

SPEZIFIKATIONEN

Page 33

Überlastschutz,

<10Hz: 400VAC oder 533V Spitze;

>10Hz: 1000Veff oder 1000V Spitze; 6kV

Transientenschutz.

Gleichstrom

Bereiche: 10, 40mA, 10A

Auflösung, 10mA Bereich: 1µA

Genauigkeit, 10, 40mA, 10A

±(0.75% vMW +5Dgt)

Spannungsabfall, mA Bereiche: 20mV/mA;

A Bereiche: 30mV/A

Überlastschutz: 40mA Eingang: F0.25A/500V

Sicherung; 10kA Trennvermögen

10A Eingang: F20A/600V Sicherung;100kA

Trennvermögen. 20A max für 10 Sekunden.

Wechselstrom (45Hz-1kHz)

Bereiche: 10, 40mA, 10A

Auflösung, 10mA Bereich: 1µA

Genauigkeit: 10, 40mA, 10A:

±(1.75% vMW +5Dgt)

Spannungsabfall, mA Bereiche: 20mV/mA;

A Bereiche: 30mV/A

AC Umsetzung: Echt-effektiv, AC gekoppelt

Crest Faktor 1:1 bis 5:1

Überlastschutz: siehe Gleichstrom.

Widerstand

Bereiche: 1, 10, 100kΩ, 1, 10, 40MΩ

Auflösung, 1KΩ Bereich: 0,1Ω

Genauigkeit, 1kΩ bis 1MΩ Bereiche:

±(0.5%vMW +1Dgt);

10MΩ Bereich: ±(1.0%vMW +2Ddgt)

40MΩ Bereich: ±(1.5%vMW +2Dgt)

Max Teststrom: 1.0mA im 1kΩBer.; 150µA im

10kΩ Ber.; 15µA im 100kΩ Ber.; 1.5µA im

1MΩ Ber; 0.2µA in 10 und 40MΩ

Bereichen.

Max Leerlaufspannung: 3.0V im 1kΩ Bereich;

1.3V in allen anderen Bereichen.

Ansprechzeit: 1s im 1kΩ Bereich; 3s in

anderen Bereichen

Überlastschutz, alle Bereiche: 500VDC oder

AC eff

Dioden-/Durchgangstest

Bereich: 1.0V, 2.25V

Auflösung, 1.0V Bereich: 0.1mV

Genauigkeit: ±(1.0%vMW +1Dgt)

Kurzschlußstrom: 1.5mA

Max. Leerlaufspannung: 3.0VDC

Ansprechzeit: <1 Sek.

Ansprechschwelle: 50Ω ±25Ω

Überlastschutz: 500VDC oder AC eff

Sicherheitstester

Signalpegel: 24V, 50V, 120V, 240V und 480V.

Max. Eingang: 600VAC für 60 Sek.

Options-Zubehör

DL243C Standard Meßkabelsatz

DL248C Deluxe Meßkabelsatz

TL245 Ersatzsicherheitsmeßkabel

TL35A Ein Meßkabelsatz, ein Paar

Krokodilkemmen

CT231A 150A AC Stromzange

CT232A 1000A AC Stromzange

CT234A 400A AC Stromzange

CT235 1000A AC/DC Stromzange

CT236A 500A AC Stromzange (mV Ausgang)

CT237 200A AC/DC Stromzange

CT238 20A AC/DC Stromzange

RF241 650MHz RF Meßkopf

TC 253A Temperatur/Spannungsumsetzer

(900°C/1652°F)

VC221A Gepolsterte Vinyl-Tragetasche (für Meter

und Holster)

DC205B Deluxe Tragekoffer

DC207B Deluxe Tragekoffer mit Raum für

Zubehör.

HV231-10 Hochspannungssonden

- 32 -

Page 34

WARTUNG & REPARATUR

Prüfen Sie zuerst folgende Fehlerquellen: Meßkabel (Brüche), Anschluß, Zustand

von Batterie und Sicherungen, richtiger Meßvorgang, Eingangs- und

Bereichsgrenzen, usw.

Mit Ausnahme des Batterie-, Sicherungs- und Meßkabelwechsels soll jede

Reparatur nur durch eine durch Wavetek Wandel Goltermann anerkannte

Servicestelle durchgeführt werden.

Das Gerät kann mit einer milden Seifenlösung gereinigt werden. Sparsam

auftragen und vor Gebrauch gut trocknen lassen.

BATTERIE/SICHERUNGSAUSTAUSCH (FIG. 6)

Allgemein: Meßkabel vom Schaltkreis und Multimeter entfernen. Gerät

abschalten, Shutzholster entfernen und Gerät mit Vorderseite nach oben auf eine

saubere, weiche Unterlage legen. Die 6 Schrauben mit dem Sechskantschlüssel

(im Holster) lösen und Geräterückseite abziehen. Benützen Sie eventuell einen

platten Schraubenzieher um die Gehäusehelften zu trennen - der eng anliegende

Dichtungsring hält die beiden Hälften zusammen. Stellen Sie sicher daß kein

Staub, Öl usw. in das Gerät kommt. Schaltkreis nicht berühren.

Batteriewechsel: Batterie

von der Geräteunterseite

entfernen durch mit dem

Daumen den seitlichen Lappen

anzuheben. Neue 9V Alkali

Batterie NEDA Typ 1604, JIS

006P oder IEC 6F22 unter

Beachtung der Polarität

installieren.

Warnung: Nicht-Abschalten des Gerätes zum Batteriewechsel kann Batterie und

Gerät zerstören.

Sicherungswechsel: Vorsichtig ein Ende der verdachten Sicherung mit einem

kleinen, platten Schraubenzieher aus dem Sicherungshalter frei machen und

Sicherung abziehen. Durchgebrannte Sicherung(en) mit gleichwertiger(n)

ersetzen:

10A Eingang: F20A/600V Sicherung (10mm x 38mm), Trennverm. 100kA.Wavetek Ref. FP425, Little Fuse Ref. KLK-20 oder Bussmann Ref. KTK-20.

40mA Eingang: 0.25A/500V Sicherung (6,35mm x 32mm), T.v. 10kA –

Nur hier anheben

Fig. 6

Batterie

Deckel

Flach anheben

Gehäusewand

nicht als Stütze

verwenden

- 33 -

Page 35

Wavetek FP375.

Warnungen: Verwendung einer falschen Sicherung kann zu ernstigen

Verletzungen führen.

Gerät wieder zusammensetzen: Guten Sitz der Gehäusehälften, des

Dichtungsringes und der Schrauben beachten. Schrauben nicht zu fest anziehen

um das Gewinde des Gehäuses nicht zu beschädigen.

REPARATUR

Lesen Sie die Gewährl ei stung bevor Sie eine Reparat ur unter oder außerhalb Gewährleistung

anfragen. Unter Gewährleistung bringen Sie bitte das def ekte Gerät zu ei ner aner kannten

Wavetek Meterman Verkaufsstelle oder Servicestelle füreinen direkten Umtausch. Außerhalb

Gewährlei st ung senden Sie das Gerät zu einer Wavetek Meterman anerkannten Servicestelle.

Bitte informieren Sie sich bei Wavetek Meterman oder ihrem Fachhändler nach der dichtst

beigelegen Adresse und nach aktuellen Reparaturgebühren. Bitte senden Sie folgende

Informationen und Dokumente mit: Firmenname, Kundenname, Adresse, Telefoonnummer,

Kaufnachweis (für Reparaturen unter Gewährl eistung), ei ne kurz e Beschr eibung der

gewünschten Handlung, und di e gefordert e Bezahl ung ( Eingr iffe außerhal b der

Gewährleistung). Bitte auch Testkabel beifügen. Bezahlungen in Form eines Checks,

Bezahlungsformulieren, Kredietkarte mit Verf alldatum, usw. bitte in Namen der Servicestelle

aufstellen. Bitte Multimeter (Frei) senden an:

in U.S.A. in Canada in Europe

Wavetek Meterman Wavetek Meterman Wavetek Meterman

1420 75th Street SW 400 Britannia Rd. E.Unit #1 52 Hurricane Way

Everett, WA 98203 Mississauga, ON L4Z 1X9 Norwich, NR6 6JB, U.K.

Tel: 1-877-596-2680 Tel: (905) 890-7600 Tel: int + 44-1603-404824

Fax: 425-446-6390 Fax: (905) 890-6866 Fax: int + 44-1603-482409

oder an die Ihnen mitgetei lte Adresse. Multimeter wird (Frei) zurück geschickt.

- 34 -

Page 36

- 35 -

Operator’s Manual

Model HD160B

Multímetro Digital

Robusto Con Selección Automatica

de Escala

• Manual de Instrucciones

¤

TM

Digital MultiMeter/MultiTester

Page 37

- 36 -

CONTENIDOS

Introducción ................................. 37

Información de seguridad ............ 37

Familiarización con el instrumento38

Procedimientos de medida ........... 39

Funciones de menú ...................... 46

Especificaciones .......................... 49

Mantenimiento y reparación ......... 51

EXPLANATION OF SYMBOLS

¡Atención! Consulte las

Instrucciones de Uso

Conexión a tierra

Corriente alterna

Corriente continua

Puede haber tensión

peligrosa en los terminales

Este instrumento tiene

doble aislamiento

GARANTIA

Esto instrumento está garantizado contra cualquier defecto de material o de

mano de obra durante un periodo de un (1) año contado a partir de la fecha de

adquisición. En la sección de “Mantenimiento y Reparación” se explican los

detalles relativos a reparaciones en garantía.

Cualquier otra garantía implícita está también limitada al periodo citado de un

(1) año. Wavetek Wandel Goltermann no se hará responsable de pérdidas de uso

del multímetro, ni de ningún otro daño accidental o consecuencial, gastos o

pérdidas económicas, en ninguna reclamación a que pudiera haber lugar por

dichos daños, gastos o pérdidas económicas.

Page 38

INTRODUCCIÓN

El multímetro digital HD160B está instrumento robusto de 4 dígitos, con

selección automática de escala y medida de verdadero valor eficaz con

acoplamiento en CA. Miden tensión, corriente, resistencia, continuidad y uniones

de diodo. Dispone de un comprobador de seguridad, denominado Safety Tester

TM

,

que indica la presencia de tensión aunque la pila del medidor esté agotada. El

menú de selección permite activar bloqueo de escala, retención de sonda,

medidas relativas, medidas automáticas mín/máx y iluminación de pantalla.

El instrumento está completamente sellado.

ADVERTENCIAS Y PRECAUCIONES

■ Este instrumento está homologado según EN61010-1:1993 para la Categoría

de Instalación III - 1500Vcc o 1000Vca. Su uso está recomendado en el nivel de

distribución y en instalaciones fijas, así como en instalaciones menores, pero no

en líneas principales de suministro, líneas aéreas ni sistemas de cable. ■ No

supere nunca los límites de entrada para las diferentes funciones (vea

Especificaciones), ni los límites marcados en el instrumento. ■ Para medidas de

tensión, el circuito sometido a prueba debe estar protegido con un fusible de 20 A

o un disyuntor. ■Tenga especial cuidado al: medir tensión >20 V // corriente >10

mA // tensión de red de CA con cargas inductivas // tensión de red de CA durante

tormentas eléctricas // corriente, si salta el fusible en un circuito con tensión de

circuito abierto >600 V (500 V en la entrada de mA) // trabajar con pantallas TRC

■ Inspeccione siempre el multímetro, las puntas de prueba, los conectores y los

accesorios antes de cada uso. No utilice ningún componente que esté dañado. ■

No se ponga Ud. a tierra cuando esté tomando medidas, y no toque nunca partes

expuestas de los circuitos. No utilice la cinta “Flex-Strap” para sujetar el

multímetro a su cuerpo. ■ Al medir corriente, conecte siempre el multímetro EN

SERIE con la carga - NUNCA EN PARALELO con una fuente de tensión. ■ Nunca

sustituya un fusible con otro que no tenga las mismas especificaciones. ■ No

utilice el instrumento en ambientes potencialmente explosivos.

PREPARACIÓN DEL MULTÍMETRO PARA SU USO - DESEMBALAJE

El embalaje debe contener: el multímetro, una funda con cinta flexible, un juego

de puntas de prueba (una negra y otra roja), una pila de 9 V (instalada), un fusible

de repuesto, una llave hexagonal puede mantenerse dentro del protector, y este

manual. Si falta algún componente u observa daños, devuelva el conjunto al lugar

donde lo adquirió para que se lo cambien.

- 37 -

Page 39

FUNDA PROTECTORA

La funda con pie integrado proporciona protección adicional a el medidor en caso

de caídas accidentales. Las puntas de prueba pueden fijarse a la funda.

INDICACIÓN DE SOBRECARGA

La sobrecarga de entrada (en la escala

superior en caso de selección automática de

escala) se indica mediante “I.OL” y un tono

continuo. Desconecte las puntas de prueba del

circuito de medida, ya que el nivel de entrada es

superior a la capacidad del medidor.

La sobrecarga del visualizador (la entrada supera la capacidad de la escala

seleccionada en modo manual) también se indica mediante “I.OL”. Seleccione

una escala más ata. Si ya está en la más alta, interrumpa la medida.

Nota: La indicación de sobrecarga es normal, durante la medida de OHMS,

cuando el circuito está abierto o la resistencia es demasiado alta.

VISUALIZADOR - SÍMBOLOS

Advertencia de “tensión peligrosa” (también doble “bip”). Indica

tensiones de entrada superiores a 30 Vca o 60Vcc.

Indicación de polaridad – Pila baja

FUNCIONES DE MENÚ, VER PÁGINA 44

AVISOS AUDIBLES

El medidor emite un “bip” cuando se cambia un parámetro, se pulsa una tecla

“válida” del panel frontal, o se actualizan los valores de Auto Min Max o Probe

Hold. Un doble “bip” indica una tensión de entrada peligrosa (30Vca o 60Vcc).

El medidor emite un tono continuo en caso de sobrecarga de entrada, y midiendo

continuidad cuando el valor de la resistencia es <50 Ω. Cuando se usa la entrada

de 10 A, el medidor emite un tono continuo si la corriente supera los 10 A.

BARRA ANALÓGICA

La barra analógica indica el porcentaje del fondo de escala que corresponde a la

lectura presentada en el visualizador. Al encender el instrumento se ilumina el

segmento de cero. Si la entrada es inferior al 40% del fondo de escala, cada

segmento representa el 1% de la escala. Si la entrada es superior al 40% del

fondo de escala, cada segmento representa el 10% de la escala. Ejemplo: una

- 38 -

Page 40

- 39 -

LCD de 4 dígitos; indicadores de unidades

Pila baja

Selector de

Función/Escala

HD160B

010203040

RANGE

MENU

OFF

V

V

A

10A

mA

COM

CACAT IIIT III

MAX

40mA MAX

FUSED

MAX

20A/10sec

FUSED

V

A

SAFETY

TESTER

500V AC

MAX

480V

240V

120V

50V

24V

SELECT

CLEAR

HOLD REL MAX MIN

mV

AM

AC

k

1500V

1000V

Barra de menú - vea “Funciones de menú”, página 46

Barra

analógica de

40 segmentos

Comprobador

de Securidad

Teclas de

menú (ver

página 46)

Entrada “alta”

para tensión y

resistencia

COM- entrada común o “baja” para todas las medidas

Entrada 10A

Entrada mA

Page 41

Comprobador de Seguridad (vea Fig. 1)

El comprobador de seguridad está diseñado para que suministre una medición

rápida totalmente segura cuando el voltaje tenga un valor hasta 480VDC ó RMS

en AC, indicando uno de los cinco niveles posibles, incluso cuando la batería

esté descargada o los fusibles abiertos. Forma de efectuar la comprobación: ❶

Ponga el selector de rango en la posición “SAFETY TESTER”; ❷ Conecte las

puntas de prueba entre “COM” y “Vohm” al circuíto a medir; ❸ Compruebe si

está(n) encendico (s) alguno(s) de los LED indicadores de nivel de voltaje.

- 40 -

entrada de 300 mV en la escala de 1 V (30%) se representa con 30 segmentos

( ); una entrada de 600 mV (60%) se representa con 6 segmentos

().

Excepción: en la escala de 40 mA, un segmento representa 1 mA.

0

0102030

240V

= 4 LEDs

120

3

roja

Sin indicación

120

HD160B

MENU

OFFOFF

V

V

A

10A

mA

COM

CACAT IIIT III

MAX

40mA MAX

FUSED

MAX

20A/10sec

FUSED

V

A

SAFETY

TESTER

500V AC

MAX

480V

240V

120V

50V

24V

SELECT

CLEAR

1500V

1000V

2

1

Fig. 1

Page 42

PRECAUCION El comprobador de seguridad, está diseñado como un elemento

más de seguridad del medidor, pero no debe ser creído cuando el medidor tenga

problemas o se sepa que está dañado. Podría tener algún tipo de problema oculto

que enmascarase la comprobación, como por ejemplo una punta de prueba

dañada internamente o un circuíto interno defectuoso, en tales casos llevar

inmediatamente a un servicio autorizado de Wavetek.

Procedimientos de medida

GENERAL: Encienda el instrumento, poniendo el selector de función/escala fuera

de OFF y seleccionando el parámetro que desee medir.

Escalas: este instrumento selecciona automáticamente la escala, poniéndose en

la que proporciona la mejor resolución para el valor que se va a medir. Es posible

fijar una escala desde el menú (vea Funciones de menú, pág. 46). La escala en

que está en un momento dado puede determinarse por la posición del punto

decimal y las unidades de medida.

Procedimientos generales: ■ Antes de conectar o desconectar las puntas de

prueba a/de un circuito, apague siempre el dispositivo o circuito sometido a

prueba y descargue todos los condensadores. ■ Observe estrictamente los

límites máximos de entrada. ■ No cambie de función mientras las puntas de

prueba estén conectadas a un circuito.

MEDIDAS DE TENSIÓN CC Y CA (DCV Y ACV) - (VEA FIG 2)

❶ Conecte la punta de prueba roja a la entrada V-Ω y la negra a la entrada COM.

❷ Ponga el selector de función en V o V . ❸ Toque con las puntas de

prueba los puntos de tensión (en paralelo con el circuito). ❹ Lea el valor en el

visualizador (y la polaridad en caso de CC: positiva implícita, negativa indicada).

Medidas de verdadero valor eficaz en CA: El modelo HD160B está medidor

de verdadero valor eficaz (TRMS), acoplado en CA. Miden el verdadero valor

eficaz de señales distorsionadas de tensión o corriente CA. En la Tabla 1 se indica

la capacidad de manejo de factores de cresta. El factor de cresta es la tensión de

pico dividida por la tensión eficaz.

Nota: Para medir con precisión una tensión CC que tenga una componente de

CA, mida en primer lugar la componente de CA poniendo el selector de función

en V . Tome nota del valor medido y la escala utilizada. Cambie a V , active el

bloqueo de escala (Range Lock, Funciones de menú, pág. 46) y seleccione una

escala igual o superior a la utilizada previamente en V . Observe la medida. El

resultado es la tensión de CA sobre la componente de CC medida. (La entrada

máxima es 1500 V para cualquier combinación).

- 41 -

Page 43

Tabla. 1

- 42 -

HD160B

010203040

MENU

OFF

V

V

A

10A10A

mAmA

COMCOM

CACAT IIIT III

MAX

40mA MAX

FUSED

MAX

20A/10sec

FUSED

V

A

SAFETY

TESTER

500V AC

MAX

480V

240V

120V

50V

24V

SELECT

CLEAR

V

1500V

1000V

roja

2

1

3

4

V o

V

> 20V

Fig. 2

Forma de onda, Factor de Cresta Corrección aditional para 1.5 a 5.0

5.0

4.0

3.0

2.5

1.0

Valor eficaz de entrada, % del fondo de escala

5%

4%

3%

2%

0%

100%806040200

Page 44

MEDIDAS DE CORRIENTE CC Y CA (DCA Y ACA) - (VEA FIG. 3)

❶ Conecte la punta de prueba roja a la entrada de 40mA para medidas de

corriente hasta 40 mA, o a la entrada de 10 A para medidas de corriente hasta 10

A. Conecte la punta de prueba negra a la entrada COM. ❷ Ponga el selector de

función en A o A , según se requiera. ❸ Abra el circuito en el que vaya a

medir la corriente. (la tensión entre este punto y tierra no debe superar los 600 V

a 10 A de entrada o 500 V con entrada en la gama de mA). Conecte con seguridad

las puntas de prueba, en serie con la carga. ❹ Conecte la alimentación del

circuito sobre el que va a medir. ➎Lea el valor de la corriente en el visualizador.

- 43 -

HD160B

010203040

MENU

OFF

V

V

A

10A10A

mAmA

COMCOM

CACAT III

MAX

40mA MAX

FUSED

MAX

20A/10sec

FUSED

V

A

SAFETY

TESTER

500V AC

MAX

480V

240V

120V

50V

24V

SELECT

CLEAR

A

1500V

1000V

Descargue los

condensadores

3b

3a

3c

3d

2

1

4

5

roja

A o A

Fig. 3

Page 45

HD160B

010203040

MENU

OFF

V

V

A

10A10A

mAmA

COMCOM

CACAT IIIT III

MAX

40mA MAX

FUSED

MAX

20A/10sec

FUSED

V

A

SAFETY

TESTER

500V AC

MAX

480V

240V

120V

50V

24V

SELECT

CLEAR

k

1500V

1000V

1

4

3

5

roja

2

Fig. 4

- 44 -

Nota: Es posible medir entre 10 y 20 A durante un máximo de 30 segundos.

Después deje transcurrir 10 minutos para que se enfríe el instrumento.

Aviso de entrada incorrecta: Aparece “FErr” cuando se conecta una punta de

prueba a la entrada de corriente y el selector no está en una escala de corriente.

Medidas de verdadero valor eficaz en CA: El modelo HD160B está medidor

de verdadero valor eficaz (TRMS), acoplado en CA. Mide el verdadero valor eficaz

de señales distorsionadas de tensión o corriente CA. En la Tabla 1 se indica la

capacidad de manejo de factores de cresta. El factor de cresta es la tensión de

pico dividida por la tensión eficaz.

MEDIDAS DE RESISTENCIA (VEA FIG.4)

Page 46

- 45 -

❶ Asegúrese de que no hay tensión aplicada a la resistencia y descargue los

condensadores. La presencia de tensión causará imprecisión en las medidas de

resistencia. ❷ Conecte la punta de prueba roja a la entrada V-Ω y la negra a la

entrada COM. ❸ Ponga el selector de función en la posición de Ω. ❹ Conecte

las puntas de prueba a la resistencia o circuito que vaya a medir. ➎Lea el valor

de la resistencia en el visualizador. Un circuito abierto se indicará como condición

de sobrecarga.

Nota: cuando esté midiendo resistencias muy bajas, utilice el modo relativo para

eliminar la resistencia de las puntas de prueba (vea Funciones de menú, pág. 46)

COMPROBACIÓN DE DIODOS Y TRANSISTORES (FIG 5)

HD160B

010203040

MENU

OFF

V

V

A

10A10A

mAmA

COMCOM

CACAT IIIT III

MAX

40mA MAX

FUSED

MAX

20A/10sec

FUSED

V

A

SAFETY

TESTER

500V AC

MAX

480V

240V

120V

50V

24V

SELECT

CLEAR

mV

1500V

1000V

DC

DC

Ánodo Cátodo

2

3

550 - 900mV

bien

Polarizaci n inversa

bien

mal

mal

<1V

Ánode Cátodo

1

roja

roja

4

5

Fig. 5

Page 47

- 46 -

En esta prueba se mide la caída de tensión en la unión del diodo. ❶ Conecte la

punta de prueba roja a la entrada V-Ω y la negra a la entrada COM. ❷ Ponga el

selector de función en la posición . ❸ Aplique el extremo de la punta de

prueba roja al ánodo del diodo, y el de la negra al cátodo. ❹ El visualizador

indica la caída de tensión directa (aproximadamente 0.6 V para diodos de silicio,

o 0.4 V para diodos de germanio). Una unión abierta se indica como condición de