Page 1

0600-0045-0000 Rev C

*0600-0045-0000*

March 2004 $5.00

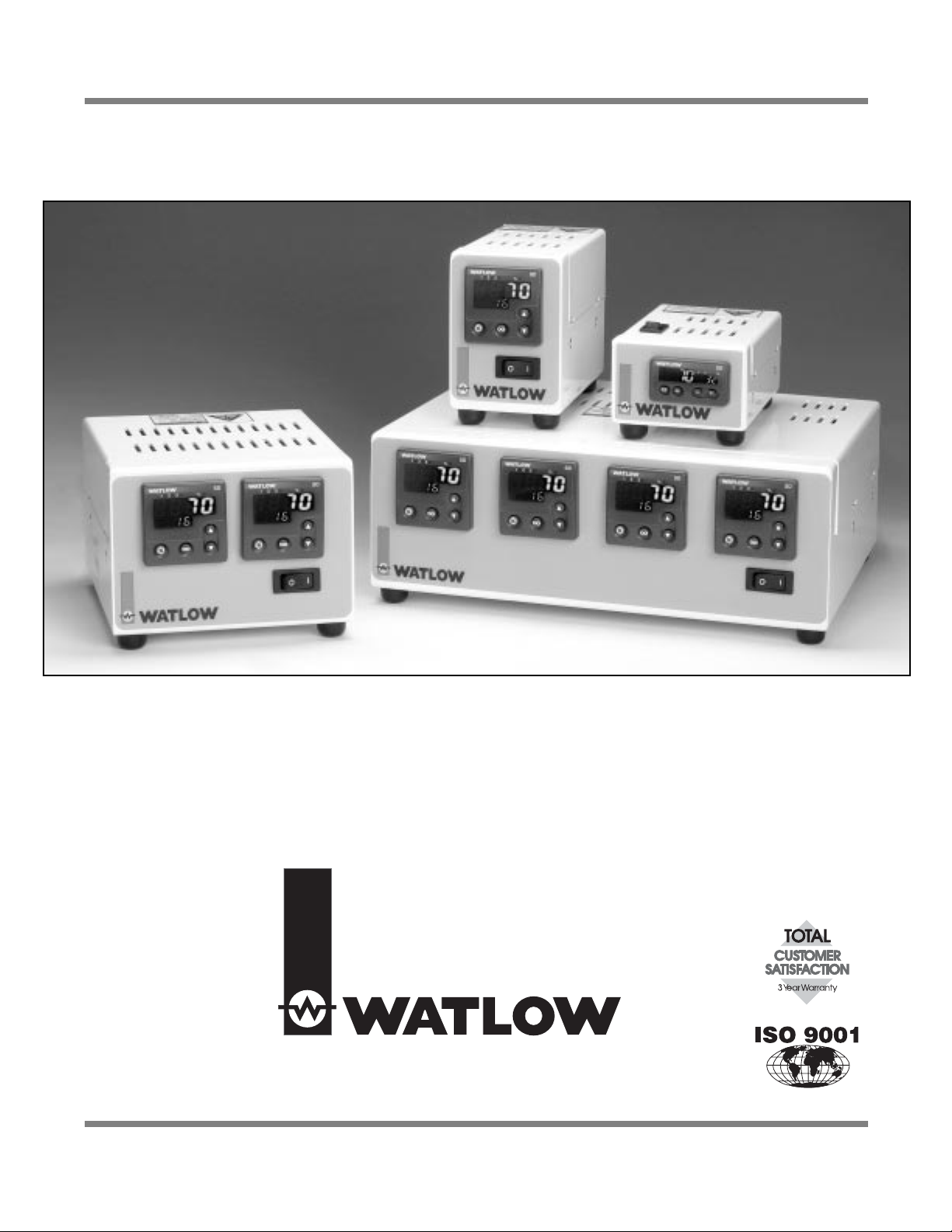

User’s Manual

Control Console

1241 Bundy Boulevard, Winona, Minnesota USA

Phone: +1 (507) 454-5300, Fax: +1 (507) 452-4507 http://www.watlow.com

Registered Company

Winona, Minnesota USA

Page 2

Safety Information

We use note, caution and warning symbols throughout this book to draw your attention to important

operational and safety information.

A "NOTE" marks a short message to alert you to an

important detail.

A "CAUTION" safety alert appears with information

that is important for protecting your equipment and

performance. Be especially careful to read and follow

all cautions that apply to your application.

A"WARNING" safety alert appears with information

that is important for protecting you, others and

equipment from damage. Pay very close attention to

all warnings that apply to your application.

The safety alert symbol, ç (an exclamation point in

a triangle), precedes a general CAUTION or WARNING statement.

The electrical hazard symbol, ∫ (a lightning bolt in

a triangle), precedes an electric shock hazard CAUTION or WARNING safety statement.

Technical Assistance

If you encounter a problem with this product, review

your configuration information to verify that your

selections are consistent with your application:

inputs, outputs, alarms, limits, etc. If the problem

persists, you can get technical assistance from your

local Watlow representative (see back cover), by emailing your questions to

wintechsupport@watlow.com or by dialing +1 (507)

494-5656 between 7 a.m. and 5 p.m., Central

Standard Time (CST). Ask for an Applications

Engineer. Please have the following information

available when calling:

• Complete model number

• All controller configuration information

• User's Manual

• Wiring diagram.

Warranty

This product is warranted free from defects in material and workmanship for 36 months after delivery

to the first purchaser for use, providing that the

units have not been misapplied. Since Watlow has

no control over their use, and sometimes misuse, we

cannot guarantee against failure. Watlow's obligations hereunder, at Watlow's option, are limited to

replacement, repair or refund of purchase price, and

parts that upon examination prove to be defective

within the warranty period specified. This warranty

does not apply to damage resulting from transportation, alteration, misuse or abuse.

Return Material Authorization (RMA)

1. Call Watlow Customer Service, +1 (507) 4545300, for a Return Material Authorization (RMA)

number before returning any item for repair. We

need this information:

• Ship to address

• Bill to address

• Contact name

• Phone number

• Method of return shipment

• Your P.O. number

• Detailed description of the problem

• Any special instructions

• Name and phone number of person returning

the product.

2. Prior approval and an RMA number, from the

Customer Service Department, is needed when

returning any unused product for credit. Make

sure the RMA number is on the outside of the

carton, and on all paperwork returned. Ship on a

Freight Prepaid basis.

3. After we receive your return, we will examine

the unit and try to verify the reason for the

return.

4. In cases of manufacturing defect, we will enter a

repair order, replacement order or issue credit

for material returned.

5. To return products that are not defective, goods

must be in new condition, in the original boxes

and they must be returned within 120 days of

receipt. A 20-percent restocking charge is applied

for all returned stock controls and accessories.

6. If the unit cannot be repaired, it will be returned

to you with a letter of explanation.

7. Watlow reserves the right to charge for no trouble found (NTF) returns.

The Control Console User's Manual is copyrighted

by Watlow Winona, Inc., copyright March 2004 with

all rights reserved.

Page 3

Watlow Control Console ■ 1

Chapter 1: Product Overview

Features and Benefits . . . . . . . . . . . . . . . . . .2

Control Console Architecture . . . . . . . . . . . . .2

Power Requirements . . . . . . . . . . . . . . . . . . .2

Sensor Input . . . . . . . . . . . . . . . . . . . . . . . . . .2

Heater Output . . . . . . . . . . . . . . . . . . . . . . . . .3

Communications . . . . . . . . . . . . . . . . . . . . . . .3

Console Elements . . . . . . . . . . . . . . . . . . . . .3

Chapter 2: Installation & Wiring

Pre-Installation . . . . . . . . . . . . . . . . . . . . . . . .4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Appendix

Specifications . . . . . . . . . . . . . . . . . . . . . . . . .6

Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Output Power Switching . . . . . . . . . . . . . . . . .6

Power Requirements . . . . . . . . . . . . . . . . . . .6

Sensor Input . . . . . . . . . . . . . . . . . . . . . . . . . .6

Operating Environment . . . . . . . . . . . . . . . . . .6

Dimensions of Enclosure . . . . . . . . . . . . . . . .6

Accessory Parts . . . . . . . . . . . . . . . . . . . . . . .7

Ordering Information . . . . . . . . . . . . . . . . . . . .8

How to Reach Us . . . . . . . . . . . . . . . . . . . . .10

List of Figures

Figure 1 — Thermal system using a Control Console

with a limit . . . . . . . . . . . . . . . . . . . . . . . . . .3

Figure 2 — Rear view of console without the

communications option . . . . . . . . . . . . . . . .4

Figure 3 — Control Console without a limit . .5

Control Console: Table of Contents

T

Page 4

2 ■ Control Console Watlow

Features and Benefits

• Fits easily into confined areas

• Easily transported

• Prewired output

• AMP Mate-'n'-Lok

® or twist-and-lock output con-

nector option on most configurations

• Miniature thermocouple connector

• Option of 1/32 or 1/16 DIN Series SD or Series 96

controllers.

• A 1/16 DIN size controller is not available in the

mini console.

• On-off rocker switch

• No external components required

• Quick installation and fast start up.

(Mate-'n'-lok

® is a registered trademark of AMP

Company.)

The Watlow Control Console offers a complete control solution consisting of the temperature control(s),

thermocouple input(s), power-switching device(s) and

heater output(s), in a small package. Installation is

quick and easy; as few as three simple connections

and the console is ready for use in your application.

Each unit is supplied with a line cord, heater output

connector mates, thermocouple connector mates and

an on-off rocker switch. A solid-state relay is utilized

for fast, reliable switching of the load. The white,

powder-coated enclosure has vent openings on the

top and bottom for internal heat dissipation.

Control Console Architecture

This product comes in one, two or four zone configurations. The power cord, your choice of heater output

connector(s), the thermocouple input connector(s)

and communications connector (if applicable) are

mounted in the rear of the enclosure. All remaining

components are inside the enclosure.

The console comes with 1/16 or 1/32 DIN Series SD

or Series 96 controller(s). A solid-state relay serves

as the output power-switching device and is powered

through the line cord.

Power Requirements

MINI, SNGL and Light Duty DUAL Control

Consoles are fused at 10 amps total, 8 amp maximum total load is recommended. The 120V Consoles

have a NEMA 5-15 plug. The 208/240V Consoles

have a NEMA 6-15 plug.

Heavy Duty DUAL Control Consoles are fused at 20

amps total. A 16 amp maximum total load is recommended. Each zone is individually fused at 10 amps

with 8 amps maximum load recommended.

The Heavy Duty DUAL contains a NEMA 5-20 plug.

Heavy Duty Controller/Limit Consoles are fused at

15 amps with 12 amps maximum load recommended.

Light Duty Controller/Limit Consoles are fused at 10

amps with 8 amps maximum load recommended.

QUAD consoles are fused at 20 amps total with 16

amps maximum load recommended. Each zone is

individually fused at 5 amps with 4 amps maximum

load recommended.

All models are available with 120V~ (ac) +10%/-15%

MINI, SNGL and Light Duty DUAL Consoles are

available with 208/240V~ (ac) +10%.

Sensor Input

The Consoles are ordered with a factory selectable

thermocouple (J, K or T) or 2-wire RTD.

The RTD option for the Series SD is only available

with a 100-ohm, platinum DIN curve.

The Series 96 has the option of JIS curve, which can

be selected by the user. Mating connectors are provided with the sensor input(s).

Chapter One: Product Overview

Page 5

Watlow Control Console ■ 3

Figure 1 — Thermal system using a Control Console with a limit.

Heater Output

The Consoles are ordered with a factory selectable

choice of AMP Mate-'n'-Lok® connector(s) or twist

and lock connector(s) for heater output(s). Mating

connector(s) are provided for the heater output(s).

Communications

EIA-232 Communications available on SNGL with a

Series 96 controller. EIA-485 Communications are

available on two and four zone Consoles. No mating

connector is provided for communications.

Console Elements

The Control Console contains the following elements

of the thermal system:

1. communications port for data acquisition included with consoles containing communications

(optional);

2. temperature controlling device;

3. heater output;

4. sensor input;

5. power switching device;

6. limit for consoles with controller/limit (optional).

Heat Transfer Medium

S

Data

Acquisition

S

e

e

n

n

s

s

o

o

r

r

Work

Load

Temperature

Controller

Sensor Input

Output

Power

Switching

Device

Limit

Heat

Source

Page 6

4 ■ Control Console Watlow

Chapter Two: Installation & Wiring

Pre-Installation

ç

CAUTION

High Temperature Limit: Only the Watlow Controller/Limit

console utilizes a high temperature limit control. Install

high temperature control protection in systems where an

overtemperature fault condition would present a fire hazard or other hazard. Failure to install temperature control

protection where a potential hazard exists could result in

damage to equipment and property, and injury to personnel.

ç WARNING

Fire Hazard: Extreme care should be taken to locate the

control console in a safe environment. Mounting the control console in atmospheres containing combustible

gasses and vapors should be avoided. According to

Article 501 of the National Electrical Code (NEC), the

maximum surface temperature of the enclosure shall not

exceed 80% of the auto-ignition of the surrounding

atmosphere when the control console is continuously

energized. Care should be taken to keep combustible

materials far enough away to be free of the effects of

high temperatures.

ç WARNING

Heater Output. Power is applied to the heater output terminals via the line cord. L1 is switched through the

solid-state relay to the connector and L2 is connected to

the heater output connector. DO NOT apply voltage to

the heater.

Installation

1. Wiring Connections

Wiring of the control consoles utilizes connections for

the thermocouple, input power and heater output.

The mating connectors are shipped with the consoles. It is the user's responsibility to properly size

and install feeder wire.

Refer to Figure 2 for 120V layout. Refer to Figure 3

for wiring diagram.

Figure 2 — Rear view of console without the communications option.

Page 7

Watlow Control Console ■ 5

Figure 3 — Control Console without a limit.

2. Heater Connections

The heater output(s) utilizes either AMP Mate-’n’Lok® connector(s) or twist-and-lock connector(s).

The mating connector and terminals are provided.

To ensure proper crimping of the AMP Mate-’n’-Lok®

terminals, the proper equipment should be used.

AMP recommends using part number 90300-2 for

terminal crimping and part number 458994-2 for

extraction of the terminals from the connector.

Please consult the TYCO-AMP Corporation at 1-800468-2023 for further information.

3. Thermocouple Connections

Using a small screwdriver, remove the two screws

holding the cover of the male miniature thermocouple connector(s). Loosen, but do not remove the +

and - terminal screws. The connector(s) can accommodate wire sizes up to 20-gauge, stranded wire.

Insert the red wire from the thermocouple to the (-)

terminal of the connector(s). Do not wrap the wire

around the terminal. Repeat the step for the positive

thermocouple lead.

4. Communication Connections

EIA-232 Communications

• Female DB9 connector mounted in box

• Pin 2: receive

• Pin 3: transmit

• Pin 5: common

EIA-485 Communications

• Female DB9 connector mounted in box

• Pin 2: T-/R-(A)

• Pin 3: T+/R+(B)

• Pin 5: common

* To ensure proper crimping of the DB9 terminal,

the proper equipment should be used. AMP recommends using part number 58448-2.

5. Start Up

For start up and function of the temperature controller, please refer to the user's manual for the

respective temperature controller that is included

with the Console.

Power Cord

In

In

Controller

Powe r Power

Input Input

Output

Output

Solid-state Relay

Vdc

Vdc

Vac

Vac

Ground

Output Connector

Out

Out

Input Connector

In

In

Ground

Out

Out

In

In

In

In

L1

L2

GND

Heater Element

Thermocouple

Page 8

6 ■ Control Console Watlow

Appendix

Specifications

Controllers

•Watlow Series 96 (Refer to Series 96 User's

Manual for controller specifications.)

•Watlow Series SD (1/16 or 1/32 DIN), (Refer to

Series SD User's Manual for controller/limit

specifications.)

•Watlow Series 97 (Refer to Series 97 User's

Manual for controller/limit specifications.)

Power Requirements and Output Power

Switching

• Utilizes solid-state relay.

• Output is powered through the line cord.

• MINI, SNGL, and Light Duty DUAL Control

Consoles are fused at 10 amps total, 8 amp maximum total load is recommended.

• 120V have NEMA 5-15 plug

• 208/240V have NEMA 6-15 plug

• Heavy Duty DUAL Control Consoles are fused at

20 amps total, 16 amp maximum total load is

recommended. Each zone is individually fused at

10 amps with 8 amps maximum load recommended.

• NEMA 5-20 plug

• Heavy Duty Controller/Limit Consoles are fused

at 15 amps with 12 amps maximum load recommended.

• Light Duty Controller/Limit Consoles are fused

at 10 amps with 8 amps maximum load recommended.

• QUAD consoles are fused at 20 amps total with

16 amps maximum load recommended. Each

zone is individually fused at 5 amps with 4 amps

maximum load recommended.

• All models are available with 120V~ +10%/-15%.

• MINI, SNGL and Light Duty DUAL consoles are

available with 208/240V~ +10%.

• 208/240V fused for domestic use only (both lines

fused).

Sensor Input

• Factory selectable thermocouple (J, K or T) or 2wire RTD.

• RTD for Series SD series only available as 100ohm, platinum DIN curve.

• Series 96 has option of DIN or JIS curve, which

can be selected by user.

• Choice of AMP Mate-'n'-Lok® connector(s) or

twist-and-lock connector(s) for heater output(s).

• Mating connector(s) provided.

• EIA-232 communications available in SNGL control consoles with a Series 96 controller.

• EIA-485 communications are available in DUAL

and QUAD Control Consoles with a Series 96

controller.

• EIA-485 to EIA-232 communications converters

and power supplies are available from Watlow.

Operating Environment

•0 to 45°C (32 to 113°F)

•0 to 90% RH, noncondensing

Dimensions of Enclosure

Console Height Width Depth

Mini 76 mm 90 mm 180 mm

3.0 in 3.5 in 7.1 in

Single 119 mm 76 mm 191 mm

4.7 in 3.0 in 7.5 in

Dual 121 mm 152 mm 187 mm

4.75 in 6.0 in 7.375 in (SD)

Quad 114 mm 305 mm 191 mm

4.5 in 12.0 in 7.5 in

Page 9

Watlow Control Console ■ 7

Mate-'n'-lok® is a registered trademark of AMP Company.

Watlow part number

0830-0473-0002

485PS2

MRS 232-485 Converter

B & B

Electronics

Watlow part number

0830-0473-0001

485SD9TBMRS 232-485 ConverterB & B

Electronics

Ship with1-66506-0DB9 (pins)Tyco-Amp

Ship with205204-1DB9 (male)Tyco-Amp

Ship with 208/240V

units

7485PlugHubbell

Ship with 120V units

7465VPlugHubbell

Ship with350550-1Mate-n-Lok® Plug

Tyco-Amp

Ship with

1-480698-0

Mate-n-Lok® PlugTyco-Amp

Relationship to

Console

Manufacturer’s Part

Number

DescriptionManufacturer

Accessory Parts

Page 10

8 ■ Control Console Watlow

Control Console: Dual

D

U A L - - 0 0

Two zones

Self-contained unit

Controllers

A Series 96 w ramp and soak

B Series 96/97 w ramp and soak

E Series 96 w EIA-485 comms

F Series SD (1/16 DIN) w EIA-485 comms

G Series SD (1/32 DIN) w EIA-485 comms

4 Series 96

5 Series SD (1/32 DIN)

7 Series SD (1/16DIN)

8 Series 96/97 Controller/Limit *

9 Series SD6C/SD6L Controller/Limit *

0 Series SD6C/SD3L Controller/Limit *

Input

JType J thermocoule

KType K thermocouple

TType T thermocouple

RRTD (2-wire)

Display Series 96/97/SD

RG Red/Green (only option on Series SD 1/32 DIN)

RR Red/Red

GG Green/Green (only available on Series 96 & 97)

GR Green/Red (only available on Series 96 & 97)

Output Connector

1 Amp Mate-’n’-Lok

®

2Twist and lock

Line Voltage

1 120VÅ (ac) (light duty: 4 A per zone; 8 A total)

2 208/240VÅ (ac) (light duty: 4 A per zone; 8 A total)

3 120VÅ (ac) (heavy duty: 8 A per zone; 16 A total)

*Control Limit

Light Duty: 8 A total

Heavy Duty: 12 A total

Ordering Information

To order, complete the model number using the

information below.

Control Console: Mini

M I N I - - 0 0 0 0

Single zone

Self-contained unit

Input

JType J thermocoule

KType K thermocouple

TType T thermocouple

RRTD (100 ohm, 2-wire)

Controllers

G Series SD (1/32 DIN) w EIA-485 comms

5 Series SD (1/32 DIN)

Display Color

R Red/Green

Line Voltage

1 120VÅ (ac)

2 208/240VÅ (ac)

Page 11

Watlow Control Console ■ 9

Control Console: Quad

Q U A D - - 0 0

Four zones

Self-contained unit

Controllers

A Series 96 w ramp and soak

E Series 96 w EIA-485 comms

F Series SD (1/16 DIN) w EIA-485 comms

G Series SD (1/32 DIN) w EIA-485 comms

4 Series 96

5 Series SD (1/32 DIN)

7 Series SD (1/16DIN)

Input

JType J thermocoule

KType K thermocouple

TType T thermocouple

RRTD (2-wire)

Display Series 96/SD

RG Red/Green (only option on Series SD 1/32 DIN)

RR Red/Red

GG Green/Green (only available on Series 96 & 97)

GR Green/Red (only available on Series 96 & 97)

Output Connector

1 Amp Mate-’n’-Lok

®

2Twist and lock

Line Voltage

1 120VÅ (ac)

Control Console: SNGL

S N G L - - 0 0

Single zone

Self-contained unit

Controllers

A Series 96 w ramp & soak

C Series 96 w ramp & soak, EIA-232 comms

G Series SD (1/32 DIN) w EIA-485 comms

4 Series 96

5 Series SD (1/32 DIN)

6 Series 96 w EIA-232 comms

7 Series SD (1/16DIN)

Input

JType J thermocoule

KType K thermocouple

TType T thermocouple

RRTD (2-wire)

Display Series 96/SD

RG Red/Green (only option on Series SD 1/32 DIN)

RR Red/Red

GG Green/Green (only available on Series 96)

GR Green/Red (only available on Series 96)

Output Connector

1 Amp Mate-’n’-Lok

®

2Twist and lock

Line Voltage

1 120VÅ (ac)

2 208/240VÅ (ac)

Page 12

How to Reach Us

Your Authorized Watlow Distributor:

United States (headquarters):

Watlow Electric Manufacturing Company

12001 Lackland Road

St. Louis, Missouri USA 63146

Telephone: +1 (314) 878-4600

Fax: +1 (314) 878-6814

Europe:

Watlow GmbH

Industriegebiet Heidig

Lauchwasenstr. 1, Postfach 1165,

Kronau 76709 Germany

Telephone: +49 7253-9400 0

Fax: +49 7253-9400 44

Watlow France S.A.R.L.

Immeuble Somag, 16 Rue Ampère,

Cergy Pontoise CEDEX 95307 France

Telephone: +33 (1) 3073-2425

Fax: +33 (1) 3073-2875

Watlow Italy S.R.L.

Via Meucci 14

20094 Corsico MI

Italy

Telephone: +39 (02) 4588841

Fax: +39 (02) 458-69954

Watlow Limited

Robey Close, Linby Industrial Estate,

Linby Nottingham England, NG15 8AA

Telephone: +44 (0) 115 9640777

Fax: +44 (0) 115 9640071

Latin America:

Watlow de México

Av. Fundición #5,

Col. Parques Industriales,

Querétaro, Qro. México CP-76130

Telephone: +52 (442) 217-6235

Fax: +52 (442) 217-6403

Asia/Pacific:

Watlow Australia Pty., Ltd.

23 Gladstone Park Drive,

Tullamarine, Victoria 3043 Australia

Telephone: +61 (39) 335-6449

Fax: +61 (39) 330-3566

Watlow China, Inc.

179, Zhong Shan Xi Road

Hong Qiao Cointek Bldg, Fl. 4, Unit P

Shanghai 200051 China

Telephone: +86 (21) 6229-8917

Fax: +86 (21) 6228-4654

Watlow Japan Ltd. K.K.

Azabu Embassy Heights 106,

1-11-12 Akasaka,

Minato-ku, Tokyo 107-0052 Japan

Telephone: +81 (03) 5403-4688

Fax: +81 (03) 5403-4646

Watlow Korea Co., Ltd.

Hanil Bldg., 3rd Floor

210-5 Yangje-Dong Seocho-Gu

Seoul, 137-130 Korea

Telephone: +82 (2) 575-9804

Fax: +82 (2) 575-9831

Watlow Malaysia Sdn Bhd

38B Jalan Tun Dr Awang

11900 Bayan Lepas

Penang Malaysia

Telephone: +60 (4) 641-5977

Fax: +60 (4) 641-5979

Watlow Singapore Pte. Ltd.

Ayer Rajah Crescent

#03-23 Ayer Rajah Industrial Estate

Singapore 139949

Telephone: +65 773 9488

Fax: +65 778 0323

Watlow Electric Taiwan

10F-1 No. 189

Chi-Shen 2nd Road,

Kaohsiung, Taiwan

Telephone: +886 (7) 288-5168

Fax: +886 (7) 288-5568

Loading...

Loading...