Page 1

Circulation Heaters

Heaters Designed to Heat

Forced-Circulation Air,

Gases or Liquids

Circulation heaters provide a ready-made means to install

electric heating with a minimal amount of time and labor.

This is accomplished by combining heating elements, vessel,

insulation, terminal enclosure, mounting brackets and inlet

and outlet connections into a complete assembly.

Made from National Pipe Thread (NPT) screw plug or

ANSI flange heater assemblies mated with a pressure vessel

(tank), circulation heaters are designed to heat

forced-circulation air, gases or liquids. Ideal for either

in-line or side-arm operations, these assemblies direct

fluids past FIREBAR

®

or WATROD™ heating elements,

to deliver fast response and even heat distribution.

®

Watlow

meets virtually all circulation heater assembly needs

with made-to-order units. Watlow circulation heaters can be

made from a wide range of heating element sheath materials,

wattages, vessel sizes and materials, pressure ratings,

terminal enclosures and controls.

Performance Capabilities

• Watt densities up to 120 W/in2 (18.6 W/cm2)

• Wattages up to three megawatts

• UL® and CSA component recognition up to 690VAC

• Ratings up to ANSI Class 600 pressure class

• Alloy 800/840 sheath temperatures up to 1600°F (870°C)

• Passivated 316 stainless steel sheath temperatures

up to 1200°F (650°C)

• Steel sheath temperatures up to 750°F (400°C)

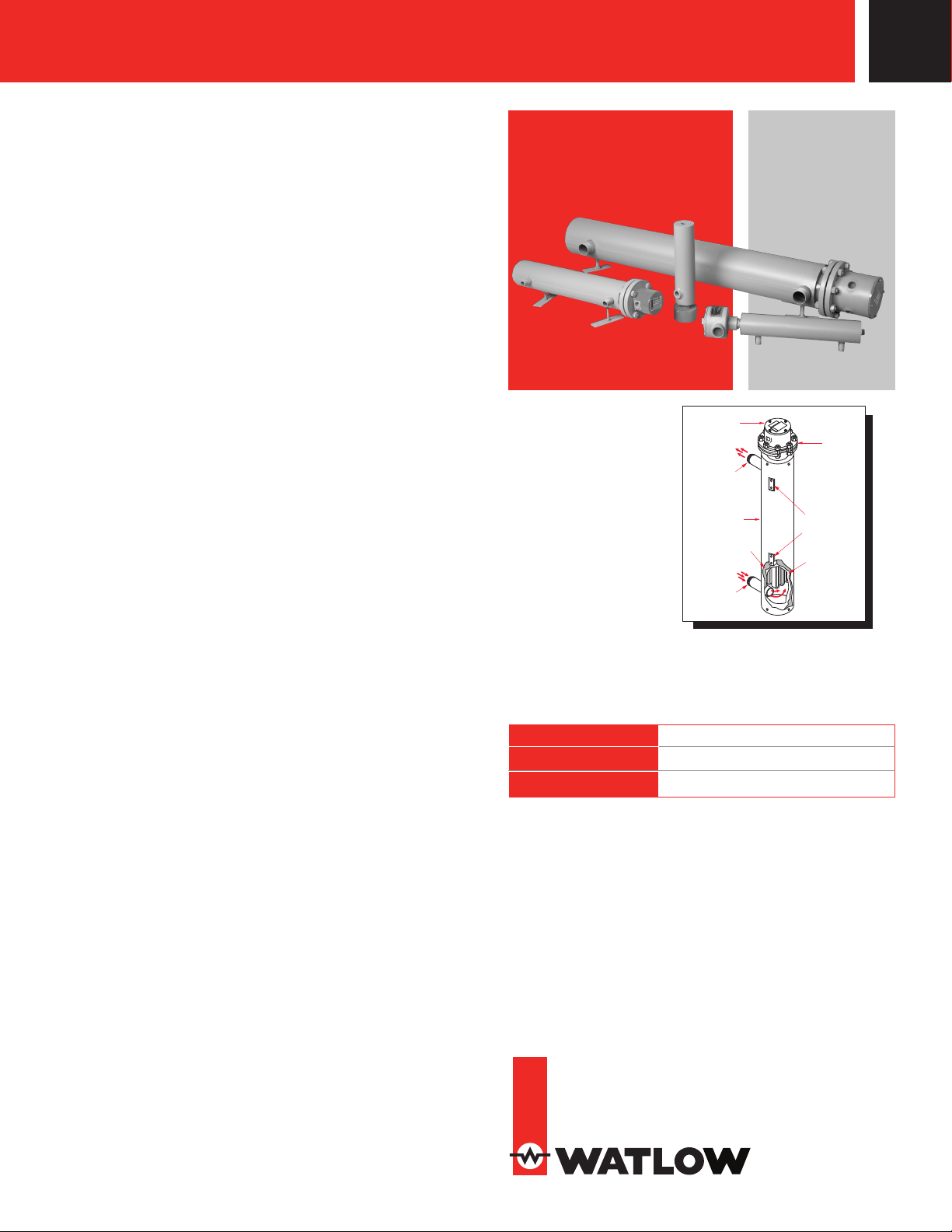

Flange

Assembly

Threaded

Pipe Outlet

Jacket

1 in. (25 mm)

Insulation

Threaded

Pipe Inlet

Gasket

Mounting

Lugs

Pressure

Vessel

Features and Benefits

Catalog screw plug and flange part numbers

• Provides a wide selection of WATROD and FIREBAR

elements to meet specific application requirements

Type Sizes (in.)

NPT Screw Plugs

ANSI flanges

ANSI B16.5 Class 150 on 4 or 6 inch FIREBAR

element flanges and 3 to 14 inch WATROD

element flanges

•

Meets recognized agency standards

FIREBAR assemblies pack more wattage in a smaller

heater bundle

• Replaces larger flanges with round tubular elements,

with a smaller package

Compacted MgO insulation filled elements

• Maximizes dielectric strength, heat transfer and life

11/4, 21/2

3, 4, 5, 6, 8, 10, 12, 14

© 2013 Watlow Electric Manufacturing Company, all rights reserved.

®

HAN-CIR-0713

Page 2

Features and Benefits (Continued)

Direction of Flow

Direction of Flow

Direction of Flow

1 inch (25 mm) thermal insulation rated to

750°F (400°C)

• Reduces heat loss from the vessel

Heavy-gauge steel jacket (shroud)

• Protects thermal insulation and heating vessel and

comes with protective primer coating

All catalog units are rated to ANSI pressure Class 150

• Provides pressure vessels (tanks) that are either carbon,

304 or 316 stainless steel

Standard offering includes units rated for up to and

including ANSI pressure class 600 (application review

required)

• Provides pressure vessels (tanks) available in carbon steel,

304 or 316 stainless steel materials

• Includes schedule 40, standard and 80 pipe used in the

pressure vessel construction

Catalog units provided with NPT or ANSI Class 150

nozzle connection

• Makes installation easy. Inlet and outlet nozzle connections

are threaded MNPT on 8 in. (203 mm) and smaller tanks.

Class 150 flanged connections on 10 in. (254 mm) and

larger tanks

Mounting lugs are welded onto the tank wall of all 21/2 in.

(64 mm) NPT and larger units

• Provides mounting support

General purpose, moisture resistant enclosures available

• Offers easy access to terminal wiring

Flange mounting holes

• Straddles centerline to comply with industry standards

UL® and CSA component recognition under file numbers

E52951 and 31388 respectively

• Meets industry safety standards

Typical Applications

Water:

• Deionized

• Demineralized

• Clean

• Potable

• Process

• Industrial water rinse tanks

• Hydraulic oil, crude, asphalt

• Lubricating oils at API specified watt densities

• Heat transfer oil

• Paraffin

• Caustic cleaners

• Nitrogen, hydrogen and other air/gas systems

• Superheating steam

Options

Terminal Enclosures

General purpose terminal enclosures, without

thermostats, are supplied on all Watlow circulation

heaters. Moisture and explosion resistant ratings are

available to meet specific application needs.

Stand-off Terminal Enclosures

Stand-off terminal enclosures help protect terminal

enclosures against excessive temperatures.

ASME Pressure Vessel Code Welding

Flange or screw plug assemblies can be provided with an

ASME Section VIII or Section I, Div. I pressure vessel stamp

upon request.

Branch Circuits

Branch circuits are designed for 48 amperes per circuit

maximum. Contact a Watlow representative for circuit

requirements other than those listed in the stock charts.

Certified Enclosures

CSA, ATEX or IECEx certified enclosures protect wiring in

hazardous gas environments. These terminal enclosures,

covered under CSA file number 61707, ATEX certificate

# SIRA 10ATEX 1155X or IECEx certificate # IECEx CSA

09.0010 are available on WATROD flange heaters.

For products that will be installed in hazardous locations,

please provide the following information:

• Operating conditions

• Minimum and maximum ambient temperatures for the

installation location

• Mounting orientation

Watlow must understand this information so that an

appropriate design can be provided.

Thermostats

To provide process temperature control, Watlow offers

optional single- and double-pole thermostats. Thermostats

are typically mounted in the terminal enclosure. Optional side

mounting on vessel also available.

Baffles

Direction of Flow

Baffles mounted on the heating element bundle enhance

and/or modify liquid or gas flow for better heat transfer.

For critical sheath temperature and low flow conditions,

baffles may be required.

Contact a Watlow representative for details.

Thermocouples

To sense process or element sheath temperature, ASTM

Type J or K thermocouples are available.

Page 3

Options (Continued)

Process Thermocouple in Nozzle

(Must specify which nozzle)

Ref

Passivated Finish

For critical applications, passivation will remove free iron

from all wetted surfaces.

Contact a Watlow representative for details.

Gaskets

T

Rubber, asbestos-free and spiral wound gaskets are

available for all heater flange, and inlet and outlet flange

sizes.

Watlow recommends ordering spares in case replacement

becomes necessary.

To order, specify gasket type, flange size/rating and

process operating temperature.

Ref. Ref. Dimension

Tank Size Nozzle Size “A”

11/4

21/2 1 NPT 83/16

3 1 NPT 83/16

4 11/2 NPT 103/8

5 2 NPT 111/16

6 21/2 NPT 133/8

8 21/2 NPT 143/8

For 10 in. (254 mm) and larger tanks contact your Watlow representative

for dimension.

3

/4 NPT 83/16

Sheath Materials

The following sheath materials are available on WATROD

and FIREBAR heating elements:

Standard Sheath Materials

WATROD Alloy 800/840

316 SS

Steel

FIREBAR Alloy 800, 304 SS

Made-to-Order Sheath Materials

WATROD 304 SS

Alloy 600

Titanium

Hastelly C276

Wattages and Voltages

Watlow routinely supplies circulation heaters with 120 to

690VAC as well as wattages from 500 watts to one megawatt.

If required, Watlow will configure circulation heaters with

voltages and wattages outside these parameters.

For more information on special voltage and wattage

configurations, contact a Watlow representative

Protective Steel Jacket (Shroud)

To protect circulation heaters from weather or wash-down

conditions, partially welded (standard) outer protective steel

jackets are available. Standard steel, or made-to-order 304

or 316 stainless steel or aluminum can be supplied. Jacket

diameter is dependent upon thermal insulation thickness.

To order, specify protective steel jacket, material type and

weatherproof, if desired.

.

Inlet and Outlet Nozzle Connections

All inlet and outlet materials are compatible with the

pressure vessel material and pressure class rating.

Vessel sizes from 1

1

⁄4 to 8 inches are typically configured

with Male National Pipe Thread (MNPT) nozzles. Optional

NPT and flange sizes can be supplied to mate with

existing piping.

10 inch and larger vessels are supplied with Class 150 inlet

and outlet flanges. Optional Class 300 or Class 600 can be

provided to mate with existing piping.

To order, specify type, size and pressure class rating for

both inlet and outlet nozzle/flange connections.

Support Saddles

To mate with an existing installation, customized support

saddle(s) and/or mounting lugs are available.

To order, specify mounting lugs or support saddles and

supply a dimensional drawing.

High-Temperature Thermal Insulation

To further minimize heat loss, the pressure vessel’s

standard one inch thermal insulation wrap may be replaced

with thicker and/or higher temperature insulation.

For more information, contact your Watlow representative.

To order, specify insulation thickness, standard or high

temperature insulation and temperature rating.

Vessels may be supplied with a primer coating

without insulation.

To order, specify no insulation.

Pressure Vessels

All catalog pressure vessel (tank) materials consist of

standard schedule and 150# class forged fittings and are

made from one of the following materials:

• Carbon steel

• 316 stainless steel

All catalog pressure vessels (tanks) are steel unless

otherwise noted.

316 stainless steel pressure vessels (tanks) are passivated

on all wetted surfaces. Available from assembly stock on

1

2

/2 inch NPT and 4 or 6 inch ANSI flange circulation

heaters.

Made-to-order units can be made in a variety of materials,

flange sizes and pressure classes. Ratings to ANSI class

2500 pressure class are available for high-pressure

applications.

Page 4

Ordering Information

Part Number

①

Stock Plug or

ANSI Flange

Part Number

②

Optional

Terminal

Enclosures

③

Optional

Process

Sensors

④

Sheath Limit

Sensors

①

Insert Part Number

Note: Catalog part numbers include optional enclosures and process

sensors. To order optional enclosures or sensors, substitute the

appropriate suffix.

②

S =

W =

E =

C =

Note: Catalog listings include either a general purpose enclosure or

moisture/explosion resistant enclosure. Substitute enclosure options

are noted.

Stock Plug or ANSI Flange Part Number

Optional Terminal Enclosure

General purpose enclosure

Moisture resistant enclosure

Explosion resistant enclosure

Moisture/explosion resistant enclosure

③

30 to 250°F (-1 to 121°C), SPST

2 =

3 =

175 to 550°F (79 to 288°C), SPST

4 =

40 to 110°F (-1 to 43°C), DPST

5A =

60 to 250°F (16 to 121°C), DPST (FIREBAR)

7A =

100 to 500°F (38 to 288°C), DPST (FIREBAR)

J =

Type J process thermocouple in thermowell

K =

Type K process thermocouple in thermowell

④

Type J high-limit thermocouple, horizontal mount

HJ =

TJ =

Type J high-limit thermocouple, vertical/housing at top

BJ =

Type J high-limit thermocouple, vertical/housing at bottom

HK =

Type K high-limit thermocouple, horizontal mount

TK =

Type K high-limit thermocouple, vertical/housing at top

BK =

Type K high-limit thermocouple, vertical/housing at bottom

Note: Heater orientation is critical to accurate sensing of limit

conditioners. Use the appropriate code to indicate heater mounting

orientations.

Optional Process Sensor

Sheath Limit Sensor

Watlow® and FIREBAR® are registered trademarks of Watlow Electric

Manufacturing Company.

WATROD™ is trademark of Watlow Electric Manufacturing Company.

UL® is a registered trademark of Underwriter’s Laboratories, Inc.

To be automatically connected to the nearest North American Technical Sales Office:

1-800-WATLOW2 • www.watlow.com • inquiry@watlow.com

International Technical Sales Offices: Australia, +61 3 9335 6449 • China, +86 21 3532 8532 • France, +33 1 41 32 79 70

Germany, +49 (0) 72 53 / 94 00-0 • India, +91 40 6661 2700 • Italy, +39 024588841 • Japan, +81 3 3518 6630 • Korea, +82 2 2628 5770

Malaysia, +60 3 8076 8745 • Mexico, +52 442 217 6235 • Singapore, +65 6773 9488 • Spain, +34 91 675 12 92

Taiwan, +886 7 288 5168 • United Kingdom, +44 (0) 115 964 0777

Loading...

Loading...