Page 1

W A T L O W

Tubular and

Process Assemblies

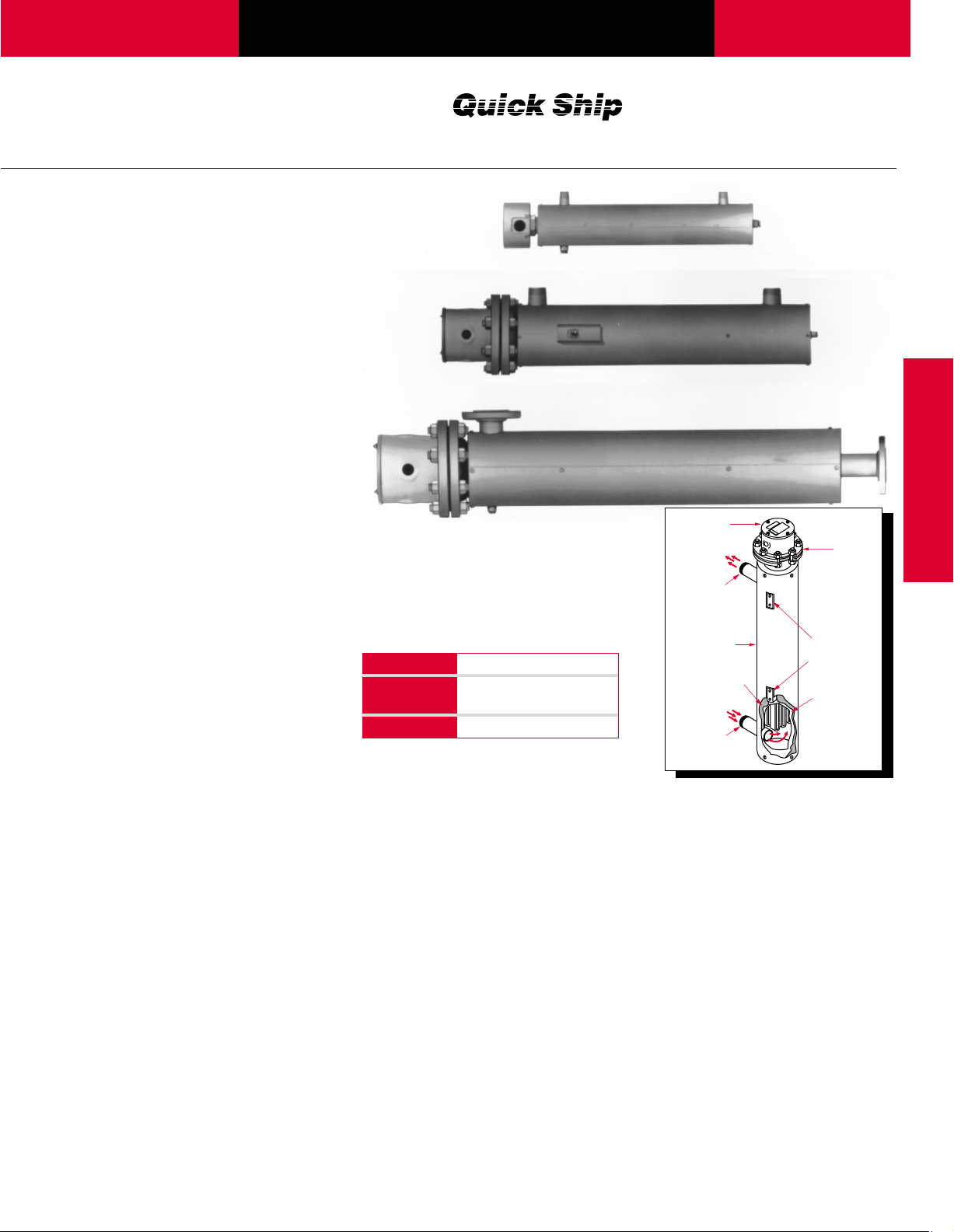

Circulation Heaters

Circulation heaters provide a readymade means to install electric

heating with a minimal amount of

time and labor. This is

accomplished by combining

heating elements, vessel, insulation,

terminal enclosure, mounting

brackets and inlet and outlet

connections into a complete

assembly.

Made from NPT screw plug or ANSI

flange heater assemblies mated

with a pressure vessel (tank),

circulation heaters are designed to

heat forced-circulation air, gases or

liquids. Ideal for either in-line or

side-arm operations, these

assemblies direct fluids past

FIREBAR

elements, to deliver fast response

and even heat distribution.

Watlow can meet virtually all your

circulation heater assembly needs

with made-to-order units. Made-toorder units can be made from a

wide range of heating element

sheath materials, wattages, vessel

sizes and materials, pressure

ratings, terminal enclosures and

controls.

Performance Capabilities

• Watt densities to 120 W/in

(18.6 W/cm2)

• Wattages to one megawatt

•UL

recognition to 480VÅ(ac) and

600VÅ(ac) respectively

• Ratings to 600 lb pressure class

• Incoloy®sheath temperatures to

1600°F (870°C)

• Passivated 316 stainless steel

sheath temperatures to 1200°F

(650°C)

• Steel sheath temperatures to

750°F (400°C)

• Copper sheath temperatures to

350°F (175°C)

®

or WATROD heating

®

and CSA component

2

Features and Benefits

• Standard screw plugs and

flanges feature a wide selection

of WATROD and FIREBAR

elements to meet specific

application requirements.

Type Sizes (inch)

NPT 1

Screw Plugs

ANSI flanges 3, 4, 5, 6, 8, 10, 12, 14

1

⁄4, 21⁄2

• Flange ratings meet recognized

agency standards. ANSI B16.5

Class 150 on:

Four or six inch FIREBAR

element flanges

Three to 14 inch WATROD

element flanges

• FIREBAR assemblies pack

more wattage in a smaller heater

bundle—replaces larger flanges

with round tubular elements, with

a smaller package.

• Compacted MgO insulation

filled elements maximize

dielectric strength, heat transfer

and life.

• One inch (25 mm) thermal

insulation, rated to 750°F

(400°C), reduces heat loss from

the vessel.

On stock chart units:

• Five to seven working days on all Assembly Stock

heaters

• 10 working days on special voltages and/or

wattages

• 15 working days on special element lengths

Flange

Assembly

Threaded

Pipe Outlet

Jacket

1" (25 mm)

Insulation

Threaded

Pipe Inlet

Gasket

Mounting

Lugs

Pressure

Vessel

• Heavy-gauge steel jacket

(shroud) protects thermal

insulation and heating vessel.

Comes with protective primer

coating.

• All catalog units rated to ANSI

pressure Class 150. Pressure

vessels (tanks) are either carbon

or 316 stainless steel.

• NPT or ANSI Class 150 nozzle

connections make installation

easy. Inlet and outlet nozzle

connections are:

Threaded MNPT on eight inch

and smaller tanks

Class 150 flanged connections

on 10 inch and larger tanks

Circulation Heaters

UL®is a registered trademark of

Underwriter's Laboratories, Inc.

Incoloy®is a registered trademark of

Special Metals Corporation.

367

Page 2

Tubular and

Ref

T

Process Assemblies

Circulation Heaters

Features and Benefits

• Mounting lugs are welded onto

the tank wall of all 21⁄2

and larger units. Lugs are flush

with outer insulation jacket and

provide mounting support.

Applications

• Water:

Deionized

Demineralized

Clean

Potable

Process

Options

Terminal Enclosures

General purpose (NEMA 1) terminal

enclosures, without thermostats, are

supplied on all Watlow circulation

heaters. Moisture and explosion

resistant ratings are available to

meet specific application needs. For

screw plug terminal enclosures,

inch NPT

• Flange mounting holes straddle

centerline to comply with industry

standards.

• Standard, general purpose

(NEMA 1) terminal enclosures

offer easy access to terminal

wiring.

• Industrial water rinse tanks

• Hydraulic oil, crude, asphalt

• Lubricating oils at API specified

watt densities

• Heat transfer oil

refer to pages 322 to 324. For

flange terminal enclosures, refer to

pages 340 to 341.

Stand-off Terminal Enclosures

Stand-off terminal enclosures help

protect terminal enclosures against

excessive temperatures. For details,

refer to page 340.

®

• UL

and CSA component

recognition under file numbers

E52951 and 31388 respectively.

See pages 268 to 271 for details.

• Branch circuits are subdivided

by National Electric Code (NEC)

requirements to a maximum of

48 amps per circuit.

• Paraffin

• Caustic cleaners

• Nitrogen, hydrogen and other

air/gas systems

• Superheating steam

CSA Certified Enclosures

To meet agency recognition

requirements, CSA certified

moisture and/or explosion resistant

terminal enclosures are available.

Consult your Watlow representative

for details.

Thermostats

To provide process temperature

control, Watlow offers optional

single and double pole thermostats.

Process Thermocouple in Nozzle

(Must specify which nozzle)

Thermostats are typically mounted

in the terminal enclosure. Optional

side mounting on vessel also

available.

Thermocouples

To sense process or element sheath

temperature, ASTM Type J or K

thermocouples are available.

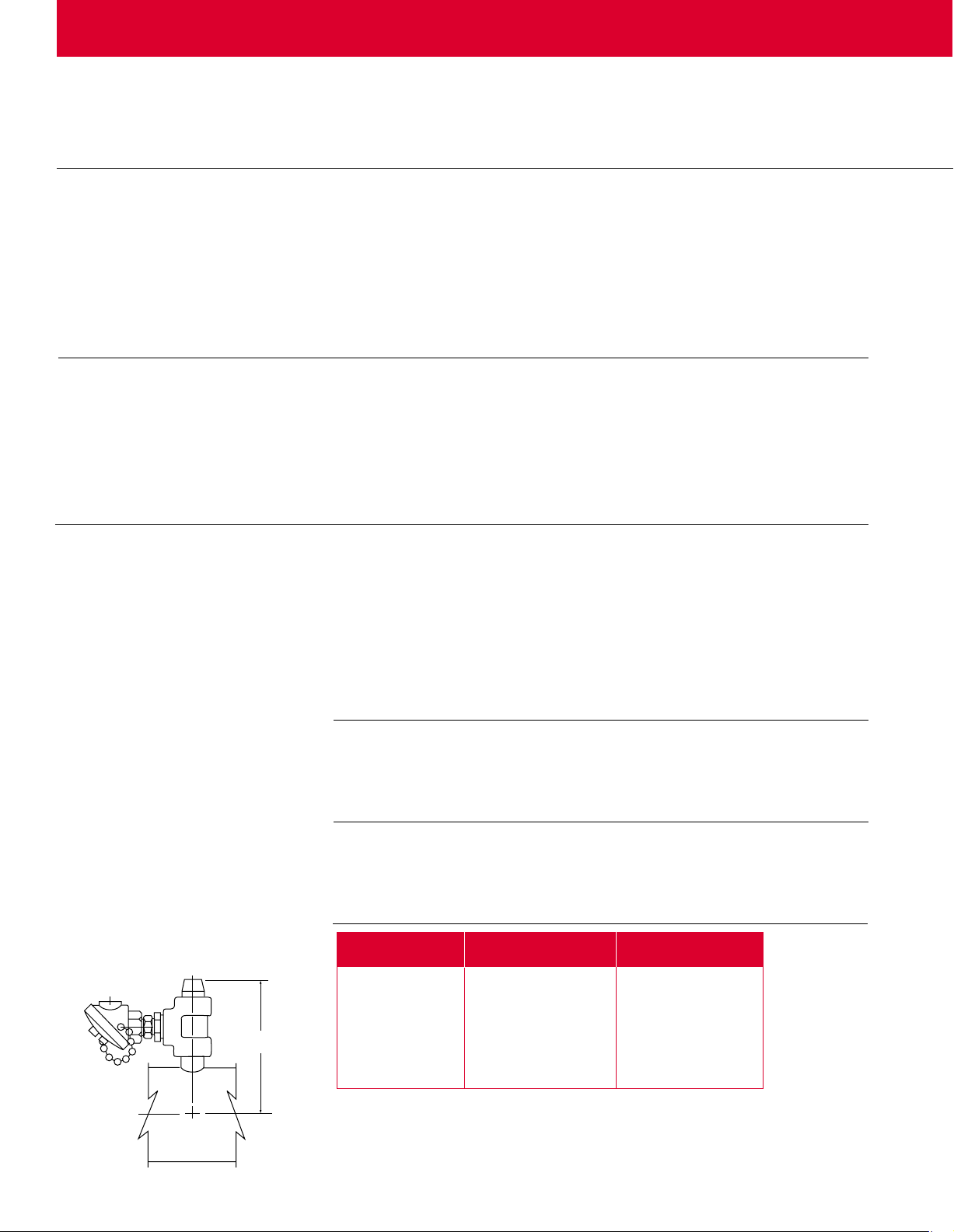

Ref. Ref. Dimension

Tank Size Nozzle Size "A"

1

1

⁄4

2 1⁄2

3 1 NPT 8 3⁄16

41

5 2 NPT 11 1⁄16

62

82

For 10 inch and larger tanks consult factory for dimension.

3

⁄4 NPT 8 3⁄16

1 NPT 8

1

⁄2 NPT 10 3⁄8

1

⁄2 NPT 13 3⁄8

1

⁄2 NPT 14 3⁄8

See Screw Plug Immersion

Heaters, page 324, and Flange

Immersion Heaters, on page 342

for details.

See Screw Plug Immersion

Heaters, page 325 and Flange

Immersion Heaters, on page 342

for details.

3

⁄16

368

Page 3

W A T L O W

Tubular and

Process Assemblies

Circulation Heaters

Options

Continued

Branch Circuits

Branch circuits are subdivided by

National Electrical Code (NEC)

requirements to a maximum of

Wattages and Voltages

Watlow routinely supplies circulation

heaters with 120 to 480VÅ(ac) as

well as wattages from 500 watts to

one megawatt. If required, Watlow

will configure circulation heaters

48 amps per circuit. Consult factory

for circuit requirements other than

those listed in the stock charts.

with voltages and wattages outside

these parameters.

For more information on special

voltage and wattage configurations,

consult your Watlow representative.

Circulation Heaters

Sheath Materials

The following sheath materials are

available on WATROD and

FIREBAR heating elements:

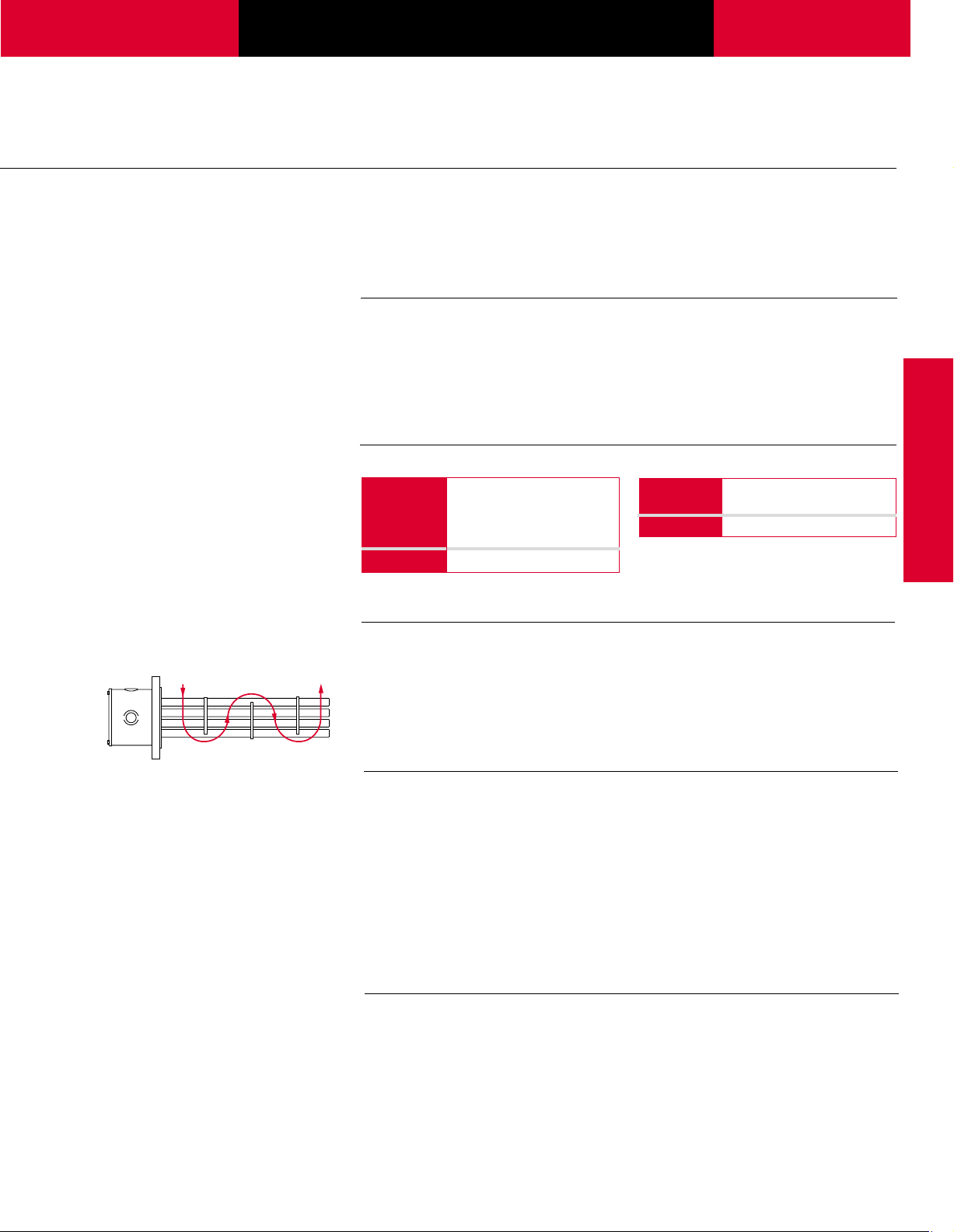

Baffles

Direction of Flow

Pressure Vessels

All standard pressure vessel (tank)

materials are rated to 150 lb and

made from:

• Carbon steel

• 316 stainless steel

All catalog pressure vessels (tanks)

are steel unless otherwise noted.

Standard Sheath Materials

WATROD Incoloy

FIREBAR Incoloy

®

316 stainless steel

Steel

Copper

®

Baffles mounted on the heating

element bundle enhance and/or

modify liquid or gas flow for better

heat transfer.

316 stainless steel pressure

vessels (tanks) are passivated on all

wetted surfaces. Available from

Assembly Stock on 2

1

⁄2 inch NPT

and four or six inch ANSI flange

circulation heaters.

Made-to-order units can be made in

a variety of materials, flange sizes

and pressure classes.

Made-to-Order Sheath Materials

WATROD 304 stainless steel

FIREBAR 304 stainless steel

Monel

®

Exotic Sheath Materials

Consult your Watlow representative

for details and availability.

For critical sheath temperature and

low flow conditions, baffles may be

required.

Consult your Watlow representative

for details.

To order, specify pressure

vessel (tank) size, material and

pressure class.

ANSI ratings to 600 lb are available

for high-pressure applications. For

pressure class ratings above

600 lb, as well as other vessel

materials, consult Watlow Process

Systems in Troy, Missouri.

Monel®is a registered trademark of

Special Metals Corporation.

Passivated Finish

For critical applications, passivation

will remove free iron from all wetted

surfaces.

Consult factory for details.

369

Page 4

Tubular and

Process Assemblies

Circulation Heaters

Options

ontinued

C

Gaskets

Rubber, asbestos-free and spiral

wound gaskets are available for all

heater flange, and inlet and outlet

flange sizes.

Watlow recommends ordering

spares in case replacement

becomes necessary.

and Outlet Nozzle Connections

Inlet

All inlet and outlet materials are

compatible with the pressure vessel

material and pressure class rating.

Vessel sizes from 11⁄4 to eight inches

are typically configured with MNPT

(Male National Pipe Thread)

nozzles. Optional NPT and flange

sizes can be supplied to mate with

existing piping.

To order, specify gasket type,

flange size/rating and process

operating temperature.

For details on gasket materials and

temperature ratings, see page 343.

10 inch and larger vessels are

supplied with Class 150 inlet and

outlet flanges. Optional Class 300 or

Class 600 can be provided to mate

with existing piping.

To order, specify type, size and

pressure class rating for both inlet

and outlet nozzle/flange

connections.

High Temperature Thermal Insulation

To further minimize heat loss, the

pressure vessel’s standard one inch

thermal insulation wrap may be

replaced with thicker or higher

temperature insulation. For more

information, consult your Watlow

representative.

Protective Steel Jacket (Shroud)

To protect circulation heaters from

weather or wash-down conditions,

fully welded (weatherproof) or

partially welded (standard) outer

protective steel jackets are

available. Standard steel, or madeto-order 304 or 316 stainless steel

Support Saddles

To mate with an existing installation,

customized support saddle(s)

and/or mounting lugs are available.

To order, specify insulation

thickness, standard or high

temperature insulation and

temperature rating.

Vessels may be supplied with a

primer coating without insulation.

To order, specify no insulation.

can be supplied. Jacket diameter is

dependent upon thermal insulation

thickness.

To order, specify protective steel

jacket, material type and

weatherproof, if desired.

To order, specify mounting lugs or

support saddles and supply a

dimensional drawing.

370

Page 5

W A T L O W

Tubular and

Process Assemblies

Circulation Heaters

Maximum V elocities

The rate at which a gas or liquid

flows through inlet and outlet pipes

is critical to maintaining the desired

output temperature. Pressure drop

through the circulation heater must

be considered to properly size

blowers or pumps. The Maximum

Velocity to Avoid Excessive

Pressure Drop chart gives

recommended maximum velocities,

in feet per second and meters per

second of gas or liquid being

heated and nominal pipe size.

Vessel Orientation

Guidelines

Correctly orienting the heating

vessel assures lower terminal

enclosure temperatures and

element immersion. Detailed

instructions on vessel orientation are

contained in the Installation and

Maintenance Instructions that

accompanies all circulation heaters.

The following are guidelines for

vessel orientation in liquid and gas

heating applications.

Maximum Velocity to Avoid Excessive Pressure Drop

Fluid Nominal Pipe Size Maximum Velocity

inch ft/sec (m/sec)

Gases All 200 (61.0)

Liquid 4 and smaller 10 (3.0)

Liquid 6-8 15 (5.0)

Liquid 10-12 19 (6.0)

Liquid 14-16 21 (6.4)

Liquid 18-20 23 (7.0)

Liquid 24 24 (7.3)

Liquids

Orient circulation heater:

• Horizontally with inlet and outlet

pipes pointing up

• Vertically with the terminal

enclosure up and the inlet pipe

on the bottom

These orientations ensure the

heating elements will be immersed

at all times and help prevent

premature failure.

Air or Gases

Orient circulation heater:

• Horizontally with the inlet nozzle

closest to the terminal enclosure.

• Vertically with terminal enclosure

at the bottom of the tank. Use the

nozzle nearest the bottom as the

inlet connection.

If installation constraints do not

allow mounting in accordance with

these guidelines, consult your

Watlow representative.

Circulation Heaters

Application Hints

• Select the recommended heating

element sheath material and watt

density for the substance being

heated. Use the Supplemental

Applications Chart on pages

263 to 266. If unable to

determine the correct heating

element type and material,

consult your Watlow

representative.

• Assure selecting proper vessel by

considering the pressure or flow

rate, process temperature and

corrosiveness of the media being

heated. If assistance with vessel

selection is required, consult your

Watlow representative.

• For maintenance/replacement

procedures, retain an area twice

the circulation heater’s overall

length to permit easy removal

and inspection of screw plug or

flange heater assemblies.

• Choose a FIREBAR assembly

when you require:

A smaller package

More kilowatts or lower watt

density in an equally sized

WATROD circulation tank.

• Minimize problems associated

with low flow or low liquid level

conditions with a low liquid level

sensor and/or sheath high-limit

control.

• Ensure wiring integrity by making

sure terminal enclosure

temperature does not exceed

400°F (205°C).

• Protect against electrical shock

by properly grounding the unit

per NEC requirements.

• One or more circulation heaters

may be connected in series to

achieve the desired total kilowatt

or temperature output.

371

Page 6

Tubular and

3

3

/4

"

(95 mm)

4

"

(100 mm)

Ref

A

Ref

6

7

/16

"

(164 mm)

3

/4

"

NPT Inlet & Outlet

B

Ref

3

1

/8

"

(79 mm)

Ref

C

1

/2

"

NPT

Process Assemblies

Circulation Heaters

Replacement Heater Assemblies

To help assure minimum process

downtime, it’s advisable to order

and keep on hand a replacement

flange or screw plug heater

assembly.

1

1

4" NPT

⁄

" NPT Screw Plug—WATROD Element

11⁄4

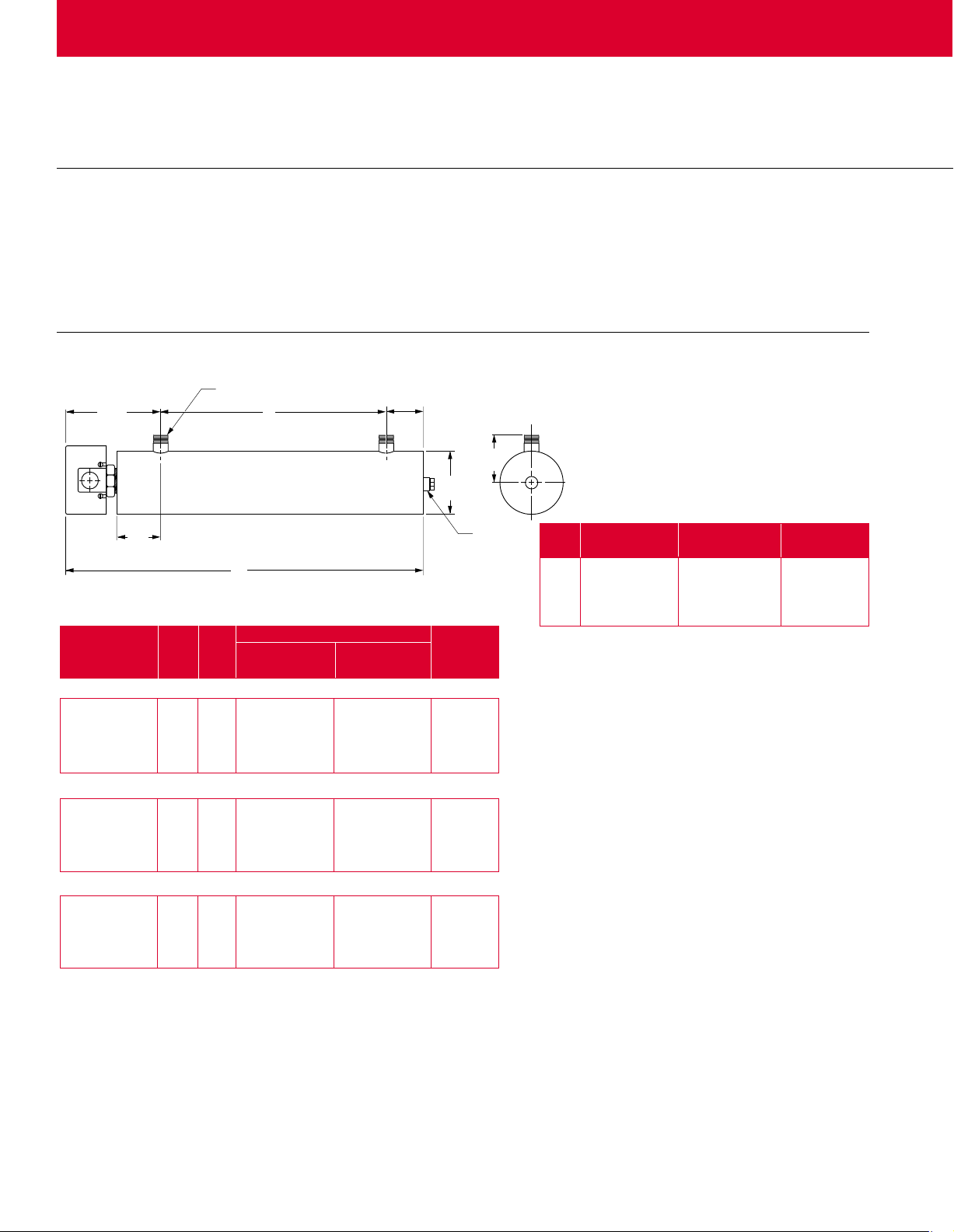

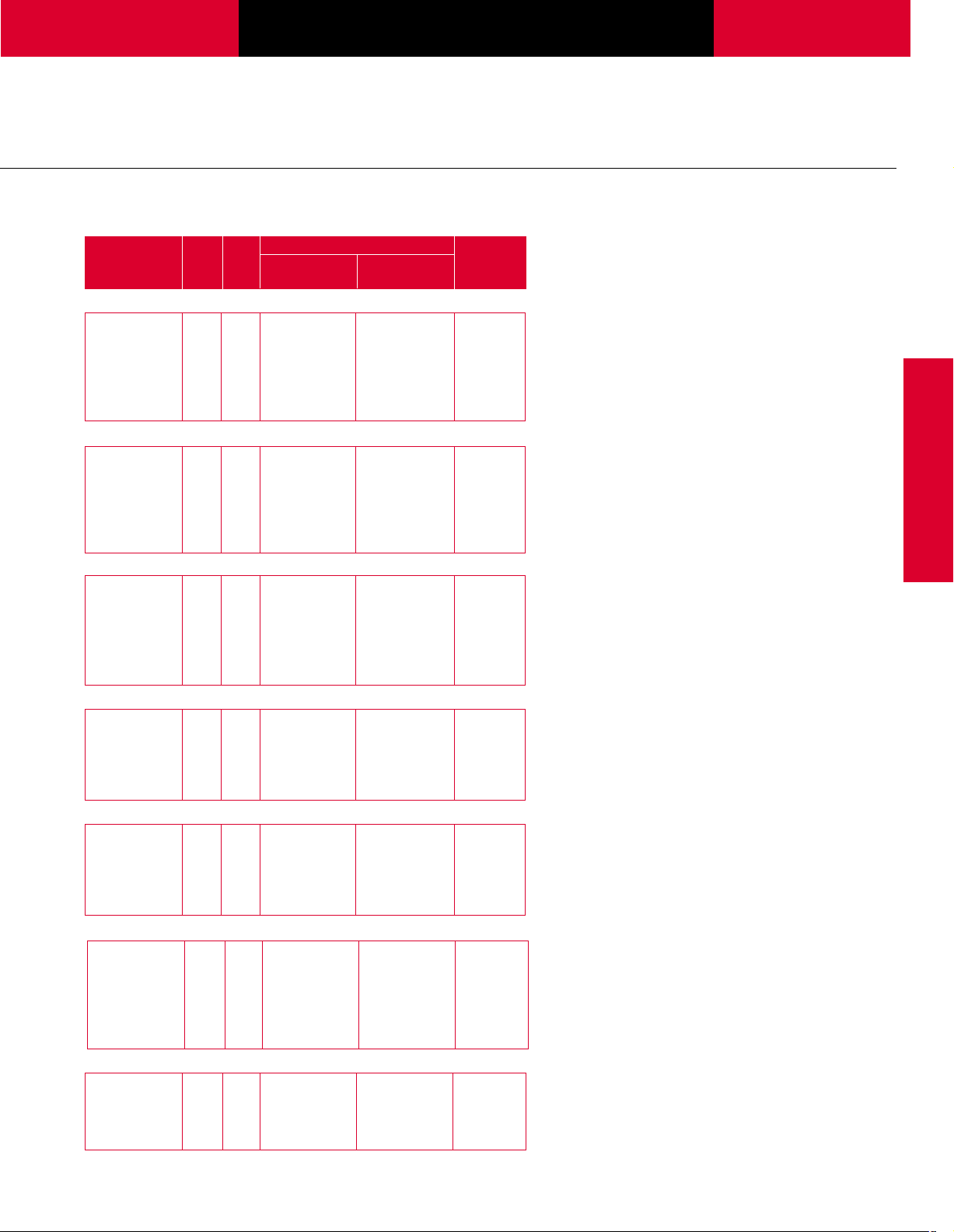

WATROD Code No. Est. Ship.

Description kW Fig. 120/240VÅ(ac) 240VÅ(ac) Weight

No. 1-Phase 1-Phase lbs (kg)

Application: Clean Water

60 W/in2➃ 3.0 1.1 CBEC15A6 23 (11)

Steel Tank 4.0 1.1 CBEC19A10 29 (14)

2-Copper 5.0 1.2 CBEC23J10 29 (14)

(9.3 W/cm2) 6.0 1.2 CBEC27J10 31 (14)

Applications: Forced Air and Gases, Caustic Solutions, Degreasing Solutions

23 W/in2➃ 1.0 1.1 CBEN13G6 21 (10)

Steel Tank 1.5 1.1 CBEN19A6 29 (14)

2-Incoloy

(3.6 W/cm

®

2.0 1.2 CBEN24G6 29 (14)

2

)

Applications: Lightweight Oils, Degreasing Solutions, Heat Transfer Oils

23 W/in2➃ 1.5 1.1 CBES19G6 29 (14)

Steel Tank 2.0 1.2 CBES25G6 29 (14)

2-Steel

(3.6 W/cm2)

All circulation heaters are Assembly Stock

unless otherwise noted.

Availability

Assembly Stock: Five to seven working days

Standard: 10 working days

Spare and/or replacement screw

plug or flange heaters can be

ordered by simply providing the

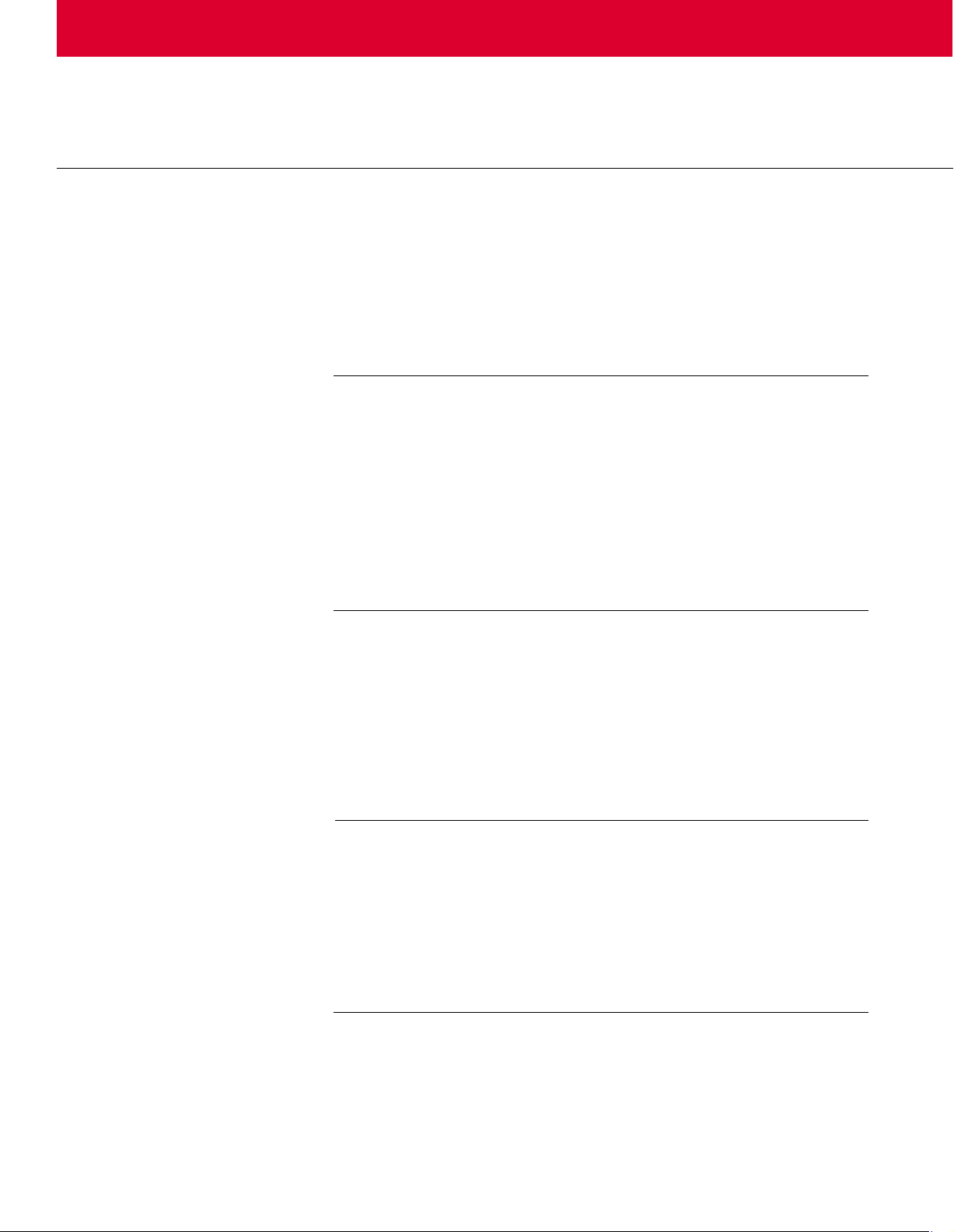

Fig. A Dimension B Dimension C Dimension

No. in (mm) in (mm) in (mm)

1.1 245⁄

1.2 32

1.3 425⁄8 (1083) 32 (813) 4 (102)

1.4 635⁄

➃ Wired for higher voltage.

F.O.B.: Hannibal, Missouri

complete circulation heater code

number and specifying

“replacement heater only.”

8 (625) 15 (381) 3

5

⁄8 (829) 23 (584) 3 (76)

8 (1616) 53 (1346) 4 (102)

1

8 (79)

⁄

372

Page 7

W A T L O W

Tubular and

Process Assemblies

Circulation Heaters

11⁄4" NPT Screw Plug—FIREBAR Element

FIREBAR Code No. Est. Ship.

Description kW Fig. 240VÅ(ac) 240VÅ(ac) 480VÅ(ac) 480VÅ(ac) Weight

No. 1-Phase 3-Phase 1-Phase 3-Phase lbs (kg)

Applications: Clean and Potable Water

90 W/in2➇ 1.5 1.1 CBDNF7R10bg CBDNF7R11bg 26 (12)

Steel Tank 3.0 1.1 CBDNF11G10bg CBDNF11G11b 26 (12)

1-Incoloy

(14 W/cm

Applications: Process Water, Ethylene Glycol (50%)

45 W/in2➇ 2.0 1.1 CBDNF13A27 25 (12)

Steel Tank 2.5 1.1 CBDNF15J27 26 (12)

1-Incoloy

(7 W/cm2) 4.0 1.2 CBDNF22J27 CBDNF22J28 31 (14)

Applications: Cooking Oils, Ethylene Glycol (100%)

30 W/in2➂ 1.7 1.1 CBDNF16G12 CBDNF16G13 26 (12)

Steel Tank 2.2 1.2 CBDNF19G12 CBDNF19G13 30 (14)

1-Incoloy

(4.7 W/cm2) 3.5 1.3 CBDNF29R12 CBDNF29R13 43 (20)

Applications: Heat Transfer Oils, Lubrication Oils, Mineral Oil, Degreasing Solutions

23 W/in2➇ 1.25 1.1 CBDNF16G20 26 (12)

Steel Tank 1.65 1.2 CBDNF19G20 30 (14)

1-Incoloy

(3.6 W/cm2) 2.65 1.3 CBDNF29R20 CBDNF29R19 43 (20)

®

5.0 1.1 CBDNF16G3 CBDNF16G5 26 (12)

2

) 6.5 1.2 CBDNF19G3 CBDNF19G5 30 (14)

8.5 1.2 CBDNF24L3 CBDNF24L5 31 (14)

10.5 1.3 CBDNF29R3 CBDNF29R5 43 (20)

12.75 1.3 CBDNF34R3 CBDNF34R5 44 (20)

17.0 1.4 CBDNF45G3 CBDNF45G5 69 (32)

21.5 1.4 CBDNF55R5 71 (33)

®

3.0 1.2 CBDNF18A27 30 (14)

5.0 1.3 CBDNF27J27 CBDNF27J28 43 (20)

6.0 1.3 CBDNF32J27 CBDNF32J28 44 (20)

8.0 1.4 CBDNF42A27 CBDNF42A28 69 (32)

10.0 1.4 CBDNF51J27 CBDNF51J28 71 (33)

®

2.8 1.2 CBDNF24L12 CBDNF24L13 31 (14)

4.25 1.3 CBDNF34R12 CBDNF34R13 44 (20)

5.7 1.4 CBDNF45G12 CBDNF45G13 69 (32)

7.2 1.4 CBDNF55R12 CBDNF55R13 71 (33)

®

2.15 1.2 CBDNF24L20 CBDNF24L19 31 (14)

3.20 1.3 CBDNF34R20 CBDNF34R19 44 (20)

4.25 1.4 CBDNF45G20 CBDNF45G19 69 (32)

5.40 1.4 CBDNF55R20 CBDNF55R19 71 (33)

CONTINUED

Circulation Heaters

All circulation heaters are Assembly Stock

unless otherwise noted.

Availability

Assembly Stock: Five to seven working days

Standard: 10 working days

Truck Shipment only

b Standard

c Must be operated 3-phase wye.

g Available in 1-phase only.

h Can be wired 1-phase.

373

Page 8

Tubular and

3

1

/8

"

(79 mm)

Ref

A

4

3

/8

"

(111 mm)

5

5

/8

"

(143 mm)

Ref

4

15

/16

"

(125 mm)

1" NPT Inlet & Outlet

3

/8

"

- 16 UNC Thread

(4 places)

3

/4

"

deep (19 mm)

Ref

3

1

/2

"

(89 mm)

11

3

/16

"

(284 mm)

C

1

1

/4

"

(32 mm)

1

/2

"

NPT

B

1

/2

"

NPT

7

3

/16

"

(183 mm)

Process Assemblies

Circulation Heaters

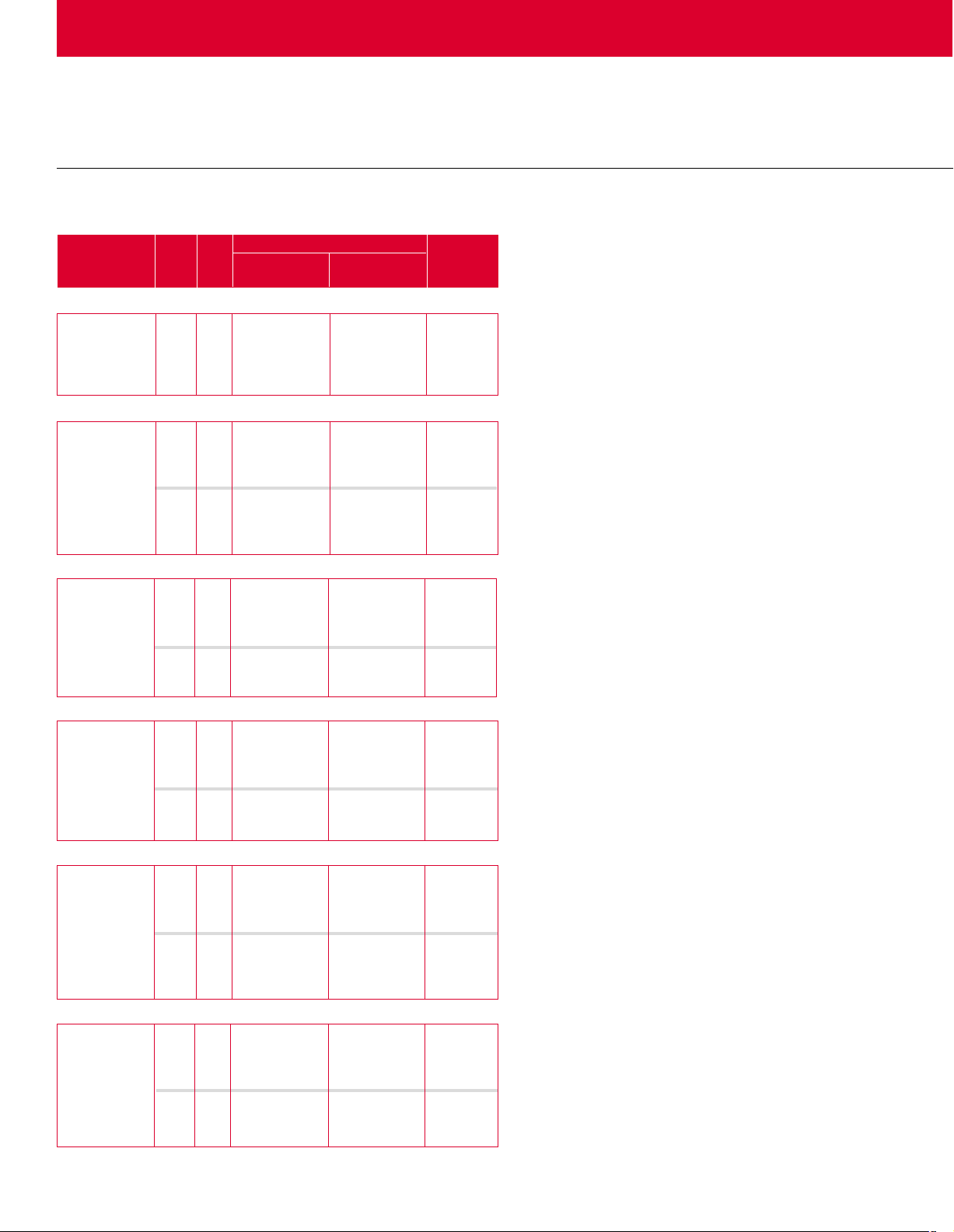

" NPT Screw Plug—FIREBAR Element

11⁄4

FIREBAR Code No. Est. Ship.

Description kW Fig. 240VÅ(ac) 240VÅ(ac) 480VÅ(ac) 480VÅ(ac) Weight

No. 1-Phase 3-Phase 1-Phase 3-Phase lbs (kg)

Applications: Medium Weight Oils, Heat Transfer Oils, Lube Oils, Liquid Paraffin

15 W/in2➂ 0.67 1.1 CBDNF13A29 25 (12)

Steel Tank 0.83 1.1 CBDNF15J29 26 (12)

1-Incoloy

(2.3 W/cm2) 1.33 1.2 CBDNF22J29 CBDNF22J30 31 (14)

Applications: Bunker C and #6 Fuel Oils, Asphalt

8 W/in2➂ 0.43 1.1 CBDNF16G22 26 (12)

Steel Tank 0.55 1.2 CBDNF19G22 30 (14)

1-Incoloy

(1.3 W/cm2) 0.88 1.3 CBDNF29R22 CBDNF29R21 43 (20)

All circulation heaters are Assembly Stock

unless otherwise noted.

Availability

Assembly Stock: Five to seven working days

Standard: 10 working days

®

1.00 1.2 CBDNF18A29 30 (14)

1.67 1.3 CBDNF27J29 CBDNF27J30 43 (20)

2.00 1.3 CBDNF32J29 CBDNF32J30 44 (20)

2.67 1.4 CBDNF42A29 CBDNF42A30 69 (32)

3.30 1.4 CBDNF51J29 CBDNF51J30 71 (33)

®

0.70 1.2 CBDNF24L22 CBDNF24L21 31 (14)

1.08 1.3 CBDNF34R22 CBDNF34R21 44 (20)

1.40 1.4 CBDNF45G22 CBDNF45G21 69 (31)

1.80 1.4 CBDNF55R22 CBDNF55R21 71 (32)

Truck Shipment only

➂ Must be operated 3-phase wye only.

2" NPT

21⁄

1

2

⁄2" NPT Screw Plug

Fig. A Dimension B Dimension C Dimension

No. in (mm) in (mm) in (mm)

2.1 3411⁄16 (881) 221⁄2 (572) 161⁄2 (419)

2.2 4411⁄16 (1135) 321⁄2 (1129) 261⁄2 (673)

2.3 573⁄

2.4 63

16 (1453) 45 (1143) 39 (991)

11

⁄16 (1618) 511⁄2 (1308) 461⁄2 (1181)

2.5 3411⁄16 (881) 221⁄2 (572) 161⁄2 (419)

374

2.6 4411⁄

2.7 57

(1135) 32

16

3

⁄16 (1453) 45 (1143) 39 (991)

1

(1129) 26

2

⁄

1

2

⁄

(673)

Page 9

W A T L O W

Tubular and

Process Assemblies

Circulation Heaters

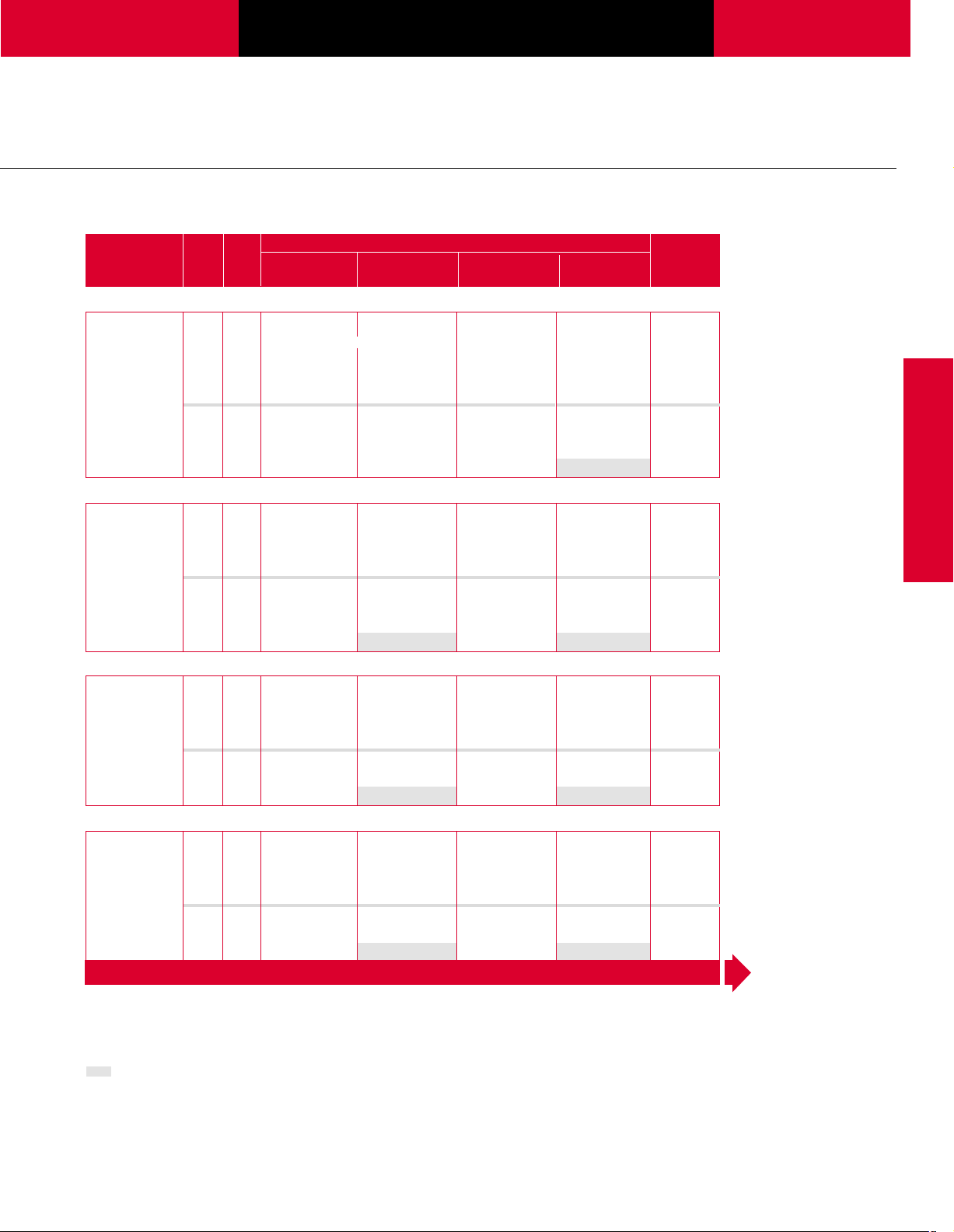

21⁄2" NPT Screw Plug—WATROD Element

WATROD Code No. Est. Ship.

Description kW Fig. 240VÅ(ac) 480VÅ(ac) Weight

No. 3-Phase 3-Phase lbs (kg)

Application: Clean Water

2

60 W/in

Steel Tank 7.5 2.5 CBLC717L3 CBLC717L5 24 (11)

3-Copper 9.0 2.5 CBLC720L3 CBLC720L5 26 (12)

(9.3 W/cm2) 12.0 2.6 CBLC726C3 CBLC726C5 27 (13)

Application: Deionized Water , Demineralized Water

2

60 W/in

316 SS Tank 7.5 2.5 CBLR717L3 CBLR717L5 24 (11)

3-316 SS 9.0 2.5 CBLR720L3 CBLR720L5 26 (12)

(9.3 W/cm2) 12.0 2.6 CBLR726C3 CBLR726C5 27 (13)

Passivated 15.0 2.6 CBLR731L3 CBLR731L5 29 (14)

Application: Process Water

2

48 W/in

Steel Tank 7.5 2.5 CBLN719R3 CBLN719R5 26 (12)

3-Incoloy

(7.5 W/cm2) 12.0 2.6 CBLN732G3 CBLN732G5 29 (14)

®

Applications: Forced Air and Gases, Caustic Solutions, Degreasing Solutions

23 W/in2➄➅ 3.0 2.5 CBLNA17G3 CBLNA17G5 24 (11)

Steel Tank 4.5 2.6 CBLNA24R3 CBLNA24R5 27 (13)

3-Incoloy

(3.6 W/cm

®

Applications: Lightweight Oils, Degreasing Solutions, Heat Transfer Oils

23 W/in2➅ 3.0 2.5 CBLS717E3 CBLS717E5 24 (11)

Steel Tank 4.5 2.5 CBLS724N3 CBLS724N5 27 (13)

3-Steel 6.0 2.6 CBLS732E3 CBLS732E5 29 (14)

(3.6 W/cm2) 7.5 2.7 CBLS739N3 CBLS739N5 31 (14)

Applications: Medium Weight Oils, Heat Transfer Oils, Lube Oils, Liquid Paraffin

16 W/in2➂ 2.0 2.5 CBLN717G12 CBLN717G13 24 (11)

Steel Tank 2.5 2.5 CBLN719R12 CBLN719R13 26 (12)

3-Incoloy

(2.5 W/cm2) 4.0 2.6 CBLN732G12 CBLN732G13 29 (14)

®

Applications: Bunker C and #6 Fuel Oils

8 W/in2➂ 2.0 2.6 CBLS732E12 CBLS732E13 29 (14)

Steel Tank 3.0 2.7 CBLS747E12 CBLS747E13 32 (15)

3-Steel

(1.3 W/cm2)

6.0 2.5 CBLC714L3 CBLC714L5 24 (11)

15.0 2.6 CBLC731L3 CBLC731L5 29 (14)

18.0 2.7 CBLC737C3 CBLC737C5 30 (14)

6.0 2.5 CBLR714L3 CBLR714L5 24 (11)

18.0 2.7 CBLR737C3 CBLR737C5 30 (14)

6.0 2.5 CBLN717G3 CBLN717G5 24 (11)

9.0 2.5 CBLN724R3 CBLN724R5 27 (13)

15.0 2.7 CBLN739R3 CBLN739R5 31 (14)

18.0 2.7 CBLN747G3 CBLN747G5 32 (15)

6.0 2.6 CBLNA32G3 CBLNA32G5 29 (14)

2

) 7.5 2.7 CBLNA39R3 CBLNA39R5 31 (14)

9.0 2.7 CBLNA47G3 CBLNA47G5 32 (15)

9.0 2.7 CBLS747E3 CBLS747E5 32 (15)

3.0 2.5 CBLN724R12 CBLN724R13 27 (13)

5.0 2.7 CBLN739R12 CBLN739R13 31 (14)

6.0 2.7 CBLN747G12 CBLN747G13 32 (15)

All circulation heaters are Assembly Stock

unless otherwise noted.

Availability

Assembly Stock: Five to seven working days

Standard: 10 working days

➂ Must be operated 3-phase wye only.

➄ 240VÅ(ac) can be wired wye and operated

at 480VÅ(ac) 3-phase to produce 1⁄3 more kW

and watt density.

➅ Can be wired wye to produce 1⁄3 of the

original kW and watt density

(3-phase only).

Circulation Heaters

375

Page 10

Tubular and

Process Assemblies

Circulation Heaters

21⁄2" NPT Screw Plug—FIREBAR Element

FIREBAR Code No. Est. Ship.

Description kW Fig. 240VÅ(ac) 480VÅ(ac) Weight

No. 3-Phase 3-Phase lbs (kg)

Applications: Clean and Potable Water

90 W/in2h 15.0 2.1 CBLNF15C3 CBLNF15C5 22 (10)

Steel Tank 20.0 2.1 CBLNF18C3 CBLNF18C5c 23 (11)

3-Incoloy

(14 W/cm2) 32.0 2.2 CBLNF28L5 34 (16)

Applications: Process Water, Ethylene Glycol (50%)

45 W/in2h 6.0 2.1 CBLNF12A27 21 (10)

Steel Tank 7.5 2.1 CBLNF14J27 22 (10)

3-Incoloy

(7 W/cm2) 12.0 2.1 CBLNF21J27 CBLNF21J28 31 (14)

Applications: Cooking Oils, Ethylene Glycol (100%)

30 W/in2c 5.0 2.1 CBLNF15C12 CBLNF15C13 22 (10)

Steel Tank 6.5 2.1 CBLNF18C12 CBLNF18C13 23 (11)

3-Incoloy

(4.7 W/cm2) 10.5 2.2 CBLNF28L12 CBLNF28L13 34 (16)

Applications: Heat Transfer Oils, Mineral Oil, Degreasing Solutions

23 W/in2h 3.8 2.1 CBLNF15C20 22 (10)

Steel Tank 4.9 2.1 CBLNF18C20 23 (11)

3-Incoloy

(3.6 W/cm2) 7.9 2.2 CBLNF28L20 CBLNF28L19 34 (16)

Applications: Medium Weight Oils, Heat Transfer Oils, Lube Oils, Liquid Paraffin

15 W/in2c 2.0 2.1 CBLNF12A29 21 (10)

Steel Tank 2.5 2.1 CBLNF14J29 22 (10)

3-Incoloy

(2.3 W/cm2) 4.0 2.1 CBLNF21J29 CBLNF21J30 31 (14)

Applications: Bunker C and #6 Fuel Oils, Asphalt

8 W/in2c 1.25 2.1 CBLNF15C22 22 (10)

Steel Tank 1.63 2.1 CBLNF18C22 23 (10)

3-Incoloy

(1.3 W/cm2) 2.63 2.2 CBLNF28L22 CBLNF28L21 34 (15)

®

25.0 2.1 CBLNF23C5 31 (14)

38.0 2.2 CBLNF33L5 35 (16)

®

®

®

®

®

9.0 2.1 CBLNF17A27 23 (11)

15.0 2.2 CBLNF26J27 CBLNF26J28 34 (16)

18.0 2.2 CBLNF31J27 CBLNF31J28 35 (16)

24.0 2.3 CBLNF41A28 44 (20)

30.0 2.4 CBLNF50J28 52 (24)

8.5 2.1 CBLNF23C12 CBLNF23C13 31 (14)

12.8 2.2 CBLNF33L12 CBLNF33L13 35 (16)

17.0 2.3 CBLNF44C12 CBLNF44C13 44 (20)

21.5 2.4 CBLNF54L13 52 (24)

6.4 2.1 CBLNF23C20 CBLNF23C19 31 (14)

9.6 2.2 CBLNF33L20 CBLNF33L19 35 (16)

12.8 2.3 CBLNF44C20 CBLNF44C19 44 (20)

16.1 2.4 CBLNF54L20 CBLNF54L19 52 (24)

3.0 2.1 CBLNF17A29 23 (11)

5.0 2.2 CBLNF26J29 CBLNF26J30 34 (16)

6.0 2.2 CBLNF31J29 CBLNF31J30 35 (16)

8.0 2.3 CBLNF41A29 CBLNF41A30 44 (20)

10.0 2.4 CBLNF50J29 CBLNF50J30 52 (24)

2.13 2.1 CBLNF23C22 CBLNF23C21 31 (14)

3.19 2.2 CBLNF33L22 CBLNF33L21 35 (16)

4.25 2.3 CBLNF44C22 CBLNF44C21 44 (20)

5.38 2.4 CBLNF54L22 CBLNF54L21 52 (24)

All circulation heaters are Assembly Stock

unless otherwise noted.

Availability

Assembly Stock: Five to seven working days

Standard: 10 working days

Note: Assembly Stock may be shipped same

day if ordered before 11:00 am CST.

c Must be operated 3-phase wye only.

h Can be wired 1-phase.

376

Page 11

W A T L O W

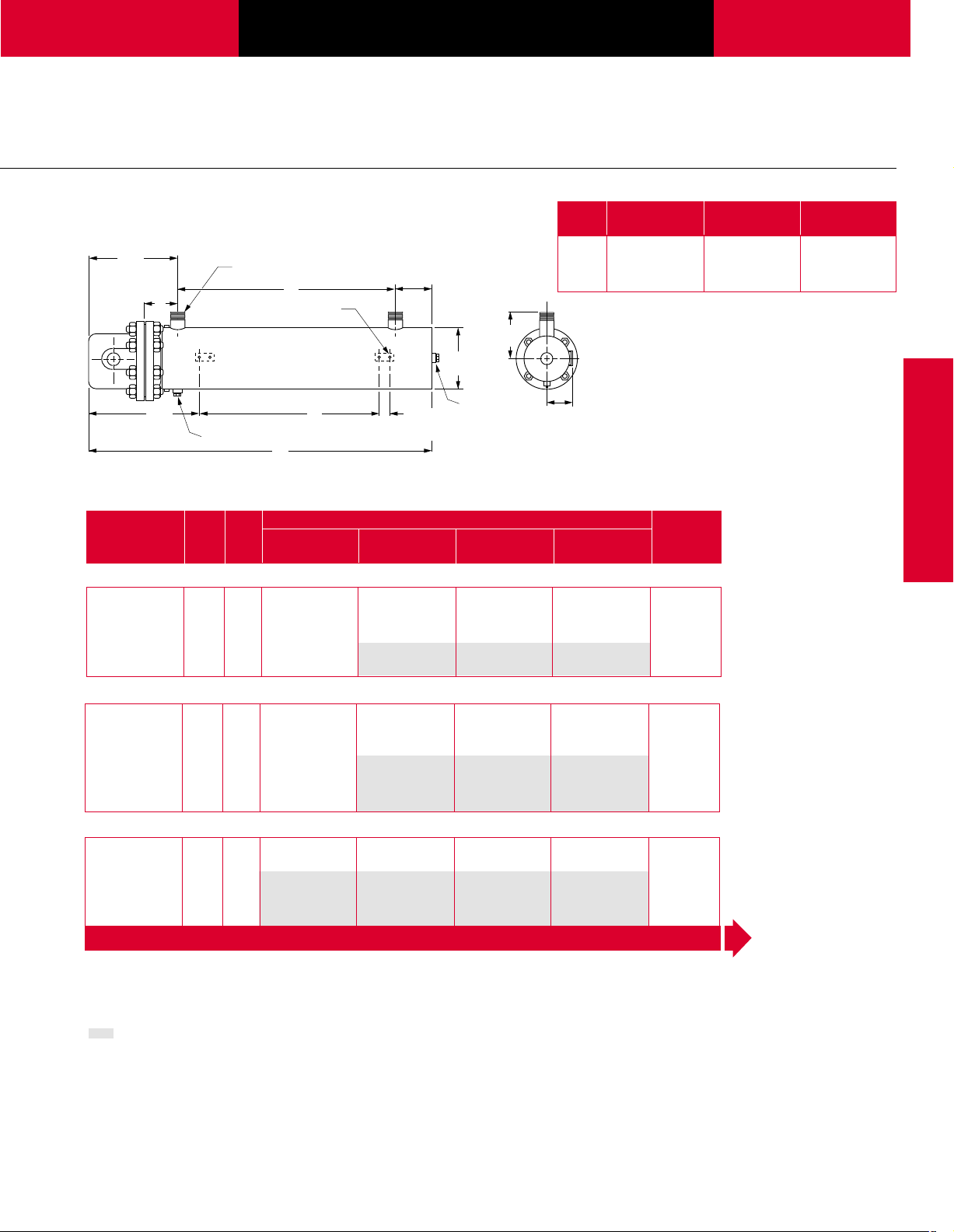

Ref

A

5

5

/8

"

(143 mm)

4

1

/8

"

(105 mm)

1" NPT Inlet & Outlet

3

/8

"

- 16 UNC Thread

(4 places)

3

/4

"

(19 mm) deep

(2 places)

1

1

/4

"

(32 mm)

Ref

5

"

(127 mm)

Ref

7

11

/16

"

(195 mm)

Ref

11

1

/2

"

(292 mm)

C

B

1

/2

"

NPT

1

/2

"

NPT

3

1

/8

"

(79 mm)

4

3

/8

"

(111 mm)

Tubular and

Process Assemblies

Circulation Heaters

3" Flange

3" 150 lb ANSI Flange—WATROD Element

Fig. A Dimension B Dimension C Dimension

No. in (mm) in (mm) in (mm)

3.1 35

3.2 45

3.3 57

3

16 (894) 22

⁄

3

⁄16 (1148) 321⁄2 (826) 261⁄2 (673)

11

⁄16 (1465) 45 (1143) 39 (991)

1

2 (573) 16

⁄

1

2 (419)

⁄

Circulation Heaters

WATROD Code No. Est. Ship.

Description kW Fig. 240VÅ(ac) 240VÅ(ac) 480VÅ(ac) 480VÅ(ac) Weight

No. 1-Phase 3-Phase 1-Phase 3-Phase lbs (kg)

Application: Clean Water

2

60 W/in

6.0 3.1 CFMC715J10 CFMC715J3 CFMC715J11 CFMC715J5 66 (30)

Steel Tank 9.0 3.1 CFMC721J10 CFMC721J3 CFMC721J11 CFMC721J5 70 (32)

3-Copper 12.0 3.2 CFMC727A3 CFMC727A11 CFMC727A5 80 (37)

2

(9.3 W/cm

) 15.0 3.2 CFMC732J3 CFMC732J11 CFMC732J5 96 (44)

18.0 3.3 CFMC738A3 CFMC738A11 CFMC738A5 98 (45)

Application: Process Water

48 W/in2➄ 6.0 3.1 CFMN718A10 CFMN718A3 CFMN718A11 CFMN718A5 68 (31)

Steel Tank 7.5 3.1 CFMN720J10 CFMN720J3 CFMN720J11 CFMN720J5 70 (32)

®

3-Incoloy

(7.5 W/cm

9.0 3.2 CFMN725J10 CFMN725J3 CFMN725J11 CFMN725J5 78 (36)

2

) 12.0 3.2 CFMN733A3 CFMN733A11 CFMN733A5 96 (44)

15.0 3.3 CFMN740J3 CFMN740J11 CFMN740J5 100 (46)

18.0 3.3 CFMN748A3 CFMN748A11 CFMN748A5 107 (49)

Applications: Forced Air and Gases, Caustic Solutions, Degreasing Solutions

23 W/in2➄➅ 3.0 3.1 CFMNA18A10 CFMNA18A3 CFMNA18A11 CFMNA18A5 68 (31)

Steel Tank 4.5 3.2 CFMNA25J10 CFMNA25J3 CFMNA25J11 CFMNA25J5 78 (36)

3-Incoloy

(3.6 W/cm2) 7.5 3.3 CFMNA40J10 CFMNA40J3 CFMNA40J11 CFMNA40J5 100 (46)

All circulation heaters are Assembly Stock

unless otherwise noted.

Availability

Assembly Stock: Five to seven working days

Standard: 10 working days

®

6.0 3.2 CFMNA33A10 CFMNA33A3 CFMNA33A11 CFMNA33A5 96 (44)

9.0 3.3 CFMNA48A10 CFMNA48A3 CFMNA48A11 CFMNA48A5 107 (49)

Truck Shipment only

➄ 240VÅ(ac) can be wired wye and

operated at 480VÅ(ac) 3-phase to

produce

➅ Can be wired wye to produce

original kW and watt density

(3-phase only).

1

more kW and watt density.

3

⁄

1

3

⁄

of the

CONTINUED

377

Page 12

Tubular and

Process Assemblies

Circulation Heaters

3" 150 lb ANSI Flange—WATROD Element

WATROD Code No. Est. Ship.

Description kW Fig. 240VÅ(ac) 240VÅ(ac) 480VÅ(ac) 480VÅ(ac) Weight

No. 1-Phase 3-Phase 1-Phase 3-Phase lbs (kg)

Applications: Lightweight Oils, Degreasing Solutions, Heat Transfer Oils

2

23 W/in

Steel Tank 4.5 3.1 CFMS725J10 CFMS725J3 CFMS725J11 CFMS725J5 78 (36)

3-Steel 6.0 3.2 CFMS733A10 CFMS733A3 CFMS733A11 CFMS733A5 96 (44)

(3.6 W/cm2) 7.5 3.3 CFMS740J10 CFMS740J3 CFMS740J11 CFMS740J5 100 (46)

Applications: Medium Weight Oils, Heat Transfer Oils, Lube Oils, Liquid Paraffin

16 W/in2➂ 2.0 3.1 CFMN718A12 CFMN718A13 68 (31)

Steel Tank 2.5 3.1 CFMN720J12 CFMN720J13 70 (32)

3-Incoloy

(2.6 W/cm

Applications: Bunker C and #6 Fuel Oils

8 W/in2➂ 2.0 3.2 CFMS733A12 CFMS733A13 96 (44)

Steel Tank 3.0 3.3 CFMS748A12 CFMS748A13 107 (49)

3-Steel

(1.3 W/cm2)

All circulation heaters are Assembly Stock

unless otherwise noted.

Availability

Assembly Stock: Five to seven working days

Standard: 10 working days

Truck Shipment only

3.0 3.1 CFMS718A10 CFMS718A3 CFMS718A11 CFMS718A5 68 (31)

9.0 3.3 CFMS748A10 CFMS748A3 CFMS748A11 CFMS748A5 107 (49)

®

3.0 3.2 CFMN725J12 CFMN725J13 78 (36)

2

) 4.0 3.2 CFMN733A12 CFMN733A13 96 (44)

5.0 3.3 CFMN740J12 CFMN740J13 100 (46)

6.0 3.3 CFMN748A12 CFMN748A13 107 (49)

➂ Must be operated 3-phase wye only.

378

Page 13

W A T L O W

Tubular and

Process Assemblies

Circulation Heaters

4" Flange

Fig. A Dimension B Dimension C Dimension

No. in (mm) in (mm) in (mm)

15

4.1 38

⁄16 (989) 201⁄2 (521) 17 (432)

4.2 497⁄16 (1256) 31 (787) 271⁄2 (699)

Ref

12

(321 mm)

11

/16

4

(119 mm)

5

"

/8

"

Ref

14

(365 mm)

/16

"

4.3 70

4.4 91

3

(94 mm)

1

"

1

/2

NPT Inlet & Outlet

B

3

"

/8

- 16 UNC Thread

3

"

(19 mm) deep

Ref

/4

C

A

(4 places)

3

"

/8

1

"

/2

NPT

Ref

11

/16

5

(144 mm)

(2 places)

1

(32 mm)

"

1

"

/4

5

"

6

/8

(168 mm)

1

/2

"

NPT

13

5

(148 mm)

7

⁄16 (1789) 52 (1321) 481⁄2 (1232)

7

⁄16 (2326) 73 (1854) 66 (1676)

11

"

/16

4" 150 lb ANSI Flange—WATROD Element

WATROD Code No. Est. Ship.

Description kW Fig. 240VÅ(ac)

No. 1-Phase

No. of

Circuits

240VÅ(ac)

3-Phase

Application: Clean Water

2

60 W/in

12 4.1 CFOC715J10 2 CFOC715J3 1 CFOC715J11 1 CFOC715J5 1 124 (57)

Steel Tank 18 4.1 CFOC721J10 2 CFOC721J3 1 CFOC721J11 1 CFOC721J5 1 127 (58)

6-Copper 24 4.2 CFOC727A10 2 CFOC727A3 2 CFOC727A11 1 CFOC727A5 1 160 (73)

2

(9.3 W/cm

) 30 4.2 CFOC732J3 2 CFOC732J11 2 CFOC732J5 1 163 (74)

36 4.3 CFOC738A3 2 CFOC738A11 2 CFOC738A5 1 229 (104)

50 4.3 CFOC751A5

60 4.4 CFOC760J5

Application: Deionized Water , Demineralized Water

2

60 W/in

12 4.1 CFOR716A10 1 CFOR716A3 1 CFOR716A11 1 CFOR716A5 1 124 (57)

316 SS Tank 18 4.1 CFOR722A10 2 CFOR722A3 1 CFOR722A11 1 CFOR722A5 1 127 (58)

6-316 SS 24 4.2 CFOR727J10 2 CFOR727J3 2 CFOR727J11 1 CFOR727J5 1 160 (73)

(9.3 W/cm2) 30 4.2 CFOR733A3 2 CFOR733A11 2 CFOR733A5 1 163 (74)

Passivated 36 4.3 CFOR738J3 2 CFOR738J11 2 CFOR738J5 1 229 (104)

50 4.3 CFOR751J5 2 234 (106)

60 4.4 CFOR761A5 2 297 (135)

Application: Process Water

2

48 W/in

Steel Tank 12 4.1 CFON718A10 2 CFON718A3 1 CFON718A11 1 CFON718A5 1 125 (57)

6-Incoloy

(7.5 W/cm

®

2

All circulation heaters are Assembly Stock

unless otherwise noted.

Availability

Assembly Stock: Five to seven working days

Standard:10 working days

Truck Shipment only

9 4.1 CFON713J10 1 CFON713J3 1 CFON713J11 1 CFON713J5 1 122 (56)

15 4.1 CFON720J10 2 CFON720J3 1 CFON720J11 2 CFON720J5 1 127 (58)

) 18 4.1 CFON725J10 2 CFON725J3 1 CFON725J11 1 CFON725J5 1 160 (73)

24 4.2 CFON733A10 2 CFON733A3 2 CFON733A11 1 CFON733A5 1 163 (74)

30 4.3 CFON740J3 2 CFON740J11 2 CFON740J5 1 229 (104)

36 4.3 CFON748A3 2 CFON748A11 2 CFON748A5 1 234 (107)

b Standard

No. of

Circuits

480VÅ(ac)

1-Phase

No. of

Circuits

480VÅ(ac)

3-Phase

No. of

Circuits

b

2 234 (107)

b

2 297 (135)

Weight

lbs (kg)

CONTINUED

Circulation Heaters

379

Page 14

Tubular and

Process Assemblies

Circulation Heaters

4" 150 lb ANSI Flange—WATROD Element

WATROD Code No. Est. Ship.

Description kW Fig. 240VÅ(ac)

No. 1-Phase

No. of

Circuits

240VÅ(ac)

3-Phase

Applications: Forced Air and Gases, Caustic Solutions, Degreasing Solutions

23 W/in2➄➅ 6 4.1 CFONA18A10 1 CFONA18A3 1 CFONA18A11 1 CFONA18A5 1 125 (57)

Steel Tank 9 4.1 CFONA25J10 1 CFONA25J3 1 CFONA25J11 1 CFONA25J5 1 160 (73)

6-Incoloy

(3.6 W/cm2) 15 4.3 CFONA40J10 2 CFONA40J3 1 CFONA40J11 1 CFONA40J5 1 229 (104)

®

12 4.2 CFONA33A10 2 CFONA33A3 1 CFONA33A11 1 CFONA33A5 1 163 (74)

18 4.3 CFONA48A10 2 CFONA48A3 1 CFONA48A11 1 CFONA48A5 1 234 (107)

25 4.4 CFONA64J3 2 CFONA64J11 2 CFONA64J5 1 298 (136)

30 4.4 CFONA77A3 2 CFONA77A11 2 CFONA77A5 1 306 (139)

Applications: Lightweight Oils, Degreasing Solutions, Heat Transfer Oils

2

23 W/in

Steel Tank 9 4.1 CFOS725J10 1 CFOS725J3 1 CFOS725J11 1 CFOS725J5 1 160 (73)

6-Steel 12 4.2 CFOS733A10 2 CFOS733A3 1 CFOS733A11 1 CFOS733A5 1 163 (74)

(3.6 W/cm2) 15 4.3 CFOS740J10 2 CFOS740J3 1 CFOS740J11 1 CFOS740J5 1 229 (104)

6 4.1 CFOS718A10 1 CFOS718A3 1 CFOS718A11 1 CFOS718A5 1 125 (57)

18 4.3 CFOS748A10 2 CFOS748A3 1 CFOS748A11 1 CFOS748A5 1 234 (107)

25 4.4 CFOS764J3 2 CFOS764J11 2 CFOS764J5 1 298 (136)

30 4.4 CFOS777A3 2 CFOS777A11 2 CFOS777A5 1 306 (139)

Applications: Medium Weight Oils, Heat Transfer Oils, Liquid Paraffin

16 W/in2➂ 3 4.1 CFON713J12 1 CFON713J13 1 122 (56)

Steel Tank 4 4.1 CFON718A12 1 CFON718A13 1 125 (57)

6-Incoloy

(2.6 W/cm2) 6 4.1 CFON725J12 1 CFON725J13 1 160 (73)

®

5 4.1 CFON720J12 1 CFON720J13 1 127 (58)

8 4.2 CFON733A12 1 CFON733A13 1 163 (74)

10 4.3 CFON740J12 2 CFON740J13 1 229 (104)

12 4.3 CFON748A12 1 CFON748A13 1 234 (107)

Applications: Bunker C and #6 Fuel Oils

8 W/in2➂ 5 4.3 CFOS740J12 1 CFOS740J13 1 229 (104)

Steel Tank 6 4.3 CFOS748A12 1 CFOS748A13 1 234 (106)

6-Steel 8 4.4 CFOS764J12 1 CFOS764J13 1 298 (135)

(1.3 W/cm2) 10 4.4 CFOS777A12 1 CFOS777A13 1 306 (139)

No. of

Circuits

480VÅ(ac)

1-Phase

No. of

Circuits

480VÅ(ac)

3-Phase

No. of

Circuits

Weight

lbs (kg)

All circulation heaters are Assembly Stock

unless otherwise noted.

Availability

Assembly Stock: Five to seven working days

Standard: 10 working days

Truck Shipment only

380

➂ Must be operated 3-phase wye only.

➄ 240VÅ(ac) can be wired wye and

operated at 480VÅ(ac) 3-phase to

produce 1⁄3 more kW and watt density.

➅ Can be wired wye to produce 1⁄3 of the

original kW and watt density

(3-phase only).

Page 15

W A T L O W

Tubular and

Process Assemblies

Circulation Heaters

4" 150 lb ANSI Flange—FIREBAR Element

FIREBAR Code No. Est. Ship.

Description kW Fig. 240VÅ(ac)

No. 3-Phase

No. of

Circuits

480VÅ(ac)

3-Phase

Applications: Process Water, Ethylene Glycol (50%)

2

45 W/in

Steel Tank 15.0 4.1 CFONF16A27 1 128 (58)

6-Incoloy

(7 W/cm2) 24.0 4.1 CFONF22R27 2 CFONF22R28 1 133 (61)

12.0 4.1 CFONF13G27 1 125 (57)

®

18.0 4.1 CFONF18G27 1 130 (59)

30.0 4.2 CFONF27R27 2 CFONF27R28 1 168 (77)

36.0 4.2 CFONF32R27 2 CFONF32R28 1 170 (78)

48.0 4.3 CFONF42G28 2 236 (107)

60.0 4.3 CFONF51R28 2 240 (109)

Applications: Cooking Oils, Ethylene Glycol (100%)

2

30 W/in

Steel Tank 13.0 4.1 CFONF19J12 1 CFONF19J13 1 130 (59)

6-Incoloy

(4.7 W/cm2) 21.0 4.2 CFONF30A12 2 CFONF30A13 1 168 (77)

10.0 4.1 CFONF16J12 1 CFONF16J13 1 128 (58)

®

17.0 4.1 CFONF24J12 1 CFONF24J13 1 133 (61)

25.5 4.2 CFONF35A12 2 CFONF35A13 1 170 (78)

34.0 4.3 CFONF45J12 2 CFONF45J13 1 236 (107)

43.0 4.3 CFONF56A13 2 240 (109)

Applications: Heat Transfer Oils, Mineral Oils, Degreasing Solutions

23 W/in2➃ 7.5 4.1 CFONF16J20 1 128 (58)

Steel Tank 10.0 4.1 CFONF19J20 1 130 (59)

6-Incoloy

(3.6 W/cm2) 15.8 4.2 CFONF30A20 1 CFONF30A19 1 168 (77)

®

12.8 4.1 CFONF24J20 1 CFONF24J19 1 133 (61)

19.0 4.2 CFONF35A20 1 CFONF35A19 1 170 (78)

25.0 4.3 CFONF45J20 2 CFONF45J19 1 236 (107)

32.3 4.3 CFONF56A20 2 CFONF56A19 1 240 (109)

Applications: Medium Weight Oils, Heat Transfer Oils, Lube Oils, Liquid Paraffin

15 W/in2➂ 4.0 4.1 CFONF13G29 1 125 (57)

Steel Tank 5.0 4.1 CFONF16A29 1 128 (58)

6-Incoloy

(2.3 W/cm2) 8.0 4.1 CFONF22R29 1 CFONF22R30 1 133 (61)

®

6.0 4.1 CFONF18G29 1 130 (59)

10.0 4.2 CFONF27R29 1 CFONF27R30 1 168 (77)

12.0 4.2 CFONF32R29 1 CFONF32R30 1 170 (78)

16.0 4.3 CFONF42G29 1 CFONF42G30 1 236 (107)

20.0 4.3 CFONF51R29 1 CFONF51R30 1 240 (109)

Applications: Bunker C and #6 Fuel Oils, Asphalt

8 W/in2➂ 2.5 4.1 CFONF16J22 1 128 (58)

Steel Tank 3.25 4.1 CFONF19J22 1 130 (59)

6-Incoloy

(1.3 W/cm2) 5.25 4.2 CFONF30A22 1 CFONF30A21 1 168 (77)

®

4.25 4.1 CFONF24J22 1 CFONF24J21 1 133 (61)

6.38 4.2 CFONF35A22 1 CFONF35A21 1 170 (77)

8.5 4.3 CFONF45J22 1 CFONF45J21 1 236 (107)

10.75 4.3 CFONF56A22 1 CFONF56A21 1 240 (109)

No. of

Circuits

Weight

lbs (kg)

Circulation Heaters

All circulation heaters are Assembly Stock

unless otherwise noted.

Availability

Assembly Stock: Five to seven working days

Standard: 10 working days

Truck Shipment only

➂ Must be operated 3-phase wye only.

➃ Wired for higher voltage.

381

Page 16

Tubular and

Process Assemblies

Circulation Heaters

5"Flange

Ref

12

(321 mm)

11

/16

4

(119 mm)

5

"

/8

"

Ref

E

2" NPT Inlet & Outlet

3

"

/8

(4 places)

1

"

NPT

/2

B

- 16 UNC Thread

3

"

/4

(19 mm) deep

25" (635 mm)

Ref

A

Ref

9

/16

6

(167 mm)

(2 places)

1

(32 mm)

"

1

/4

7

(194 mm)

"

9

5

/16

(141 mm)

5

"

/8

1

"

/2

NPT

5" 150 lb ANSI Flange—WATROD Element

WATROD Code No. Est. Ship.

Description kW Fig. 240VÅ(ac)

No. 1-Phase

No. of

Circuits

240VÅ(ac)

3-Phase

Application: Clean Water

2

60 W/in

24 5.1 CFNC727A10 3 CFNC727A3 2 CFNC727A11 3 CFNC727A5 1 140 (64)

Steel Tank 30 5.1 CFNC732J3 2 CFNC732J11 2 CFNC732J5 1 142 (65)

6-Copper 36 5.2 CFNC738A3 2 CFNC738A11 2 CFNC738A5 1 160 (73)

2

(9.3 W/cm

) 50 5.3 CFNC751A5 2 180 (82)

60 5.4 CFNC760J5

60 W/in

2

36 5.1 CFNC727A3X 3 CFNC727A11X 3 CFNC727A5X 1 145 (66)

Steel Tank 45 5.1 CFNC732J3X 3 CFNC732J11X 3 CFNC732J5X 3 147 (67)

9-Copper 54 5.2 CFNC738A3X 3 CFNC738A11X 3 CFNC738A5X 3 166 (76)

2

(9.3 W/cm

) 75 5.3 CFNC751A5X 3 188 (86)

90 5.4 CFNC760J5X

Application: Process Water

2

48 W/in

➄ 24 5.1 CFNN733A10 3 CFNN733A3 2 CFNN733A11 3 CFNN733A5 1 145 (66)

Steel Tank 30 5.2 CFNN740J3 2 CFNN740J11 2 CFNN740J5 1 167 (76)

6-Incoloy

(7.5 W/cm

48 W/in

Steel Tank 45 5.2 CFNN740J3X 3 CFNN740J11X 3 CFNN740J5X 3 173 (79)

9-Incoloy

(7.5 W/cm

®

2

2

®

2

36 5.3 CFNN748A3 2 CFNN748A11 2 CFNN748A5 1 180 (82)

)

36 5.1 CFNN733A3X 3 CFNN733A11X 3 CFNN733A5X 1 150 (68)

54 5.3 CFNN748A3X 3 CFNN748A11X 3 CFNN748A5X 3 188 (86)

)

No. of

Circuits

Fig. A Dimension B Dimension E Dimension

No. in (mm) in (mm) in (mm)

5.1 493⁄16

5.2 56

(1249) 30 (762) 14

3

⁄16 (1427) 37 (940) 189⁄16 (471)

5.3 6711⁄16 (1719) 481⁄2 (1232) 2415⁄16 (633)

5.4 811⁄

5.5 94

"

1

"

4

/4

(108 mm)

480VÅ(ac)

1-Phase

16 (2059) 61

1

⁄16 (2389) 747⁄8 (1902) 3715⁄16 (964)

No. of

Circuits

7

8 (1572) 30

⁄

480VÅ(ac)

3-Phase

Circuits

➁ 2 190 (87)

➁ 3 200 (91)

7

⁄8

7

8 (784)

⁄

No. of

CONTINUED

Weight

lbs (kg)

(378)

All circulation heaters are Assembly Stock

unless otherwise noted.

Availability

Assembly Stock: Five to seven working days

Standard: 10 working days

Truck Shipment only

382

➁ Standard

➄ 240VÅ(ac) can be wired wye and operated

at 480VÅ(ac) 3-phase to produce 1⁄3 more

kW and watt density.

Page 17

W A T L O W

Tubular and

Process Assemblies

Circulation Heaters

5" 150 lb ANSI Flange—WATROD Element

WATROD Code No. Est. Ship.

Description kW Fig. 240VÅ(ac)

No. 1-Phase

No. of

Circuits

240VÅ(ac)

3-Phase

Applications: Forced Air and Gases, Caustic Solutions, Degreasing Solutions

2

23 W/in

➄➅ 9 5.1 CFNNA25J10 1 CFNNA25J3 1 CFNNA25J11 1 CFNNA25J5 1 140 (64)

Steel Tank 12 5.2 CFNNA33A10 2 CFNNA33A3 1 CFNNA33A11 1 CFNNA33A5 1 145 (66)

6-Incoloy

(3.6 W/cm

23 W/in

Steel Tank 18 5.2 CFNNA33A10X 3 CFNNA33A3X 1 CFNNA33A11X 1 CFNNA33A5X 1 145 (68)

9-Incoloy

(3.6 W/cm

®

15 5.2 CFNNA40J10 2 CFNNA40J3 1 CFNNA40J11 1 CFNNA40J5 1 167 (76)

2

) 18 5.3 CFNNA48A10 2 CFNNA48A3 1 CFNNA48A11 1 CFNNA48A5 1 180 (82)

25 5.4 CFNNA64J3 2 CFNNA64J11 2 CFNNA64J5 1 195 (89)

30 5.5 CFNNA77A3 2 CFNNA77A11 2 CFNNA77A5 1 220 (100)

2

14 5.1 CFNNA25J10X 3 CFNNA25J3X 1 CFNNA25J11X 1 CFNNA25J5X 1 140 (66)

®

23 5.2 CFNNA40J10X 3 CFNNA40J3X 3 CFNNA40J11X 1 CFNNA40J5X 1 167 (79)

2

) 27 5.3 CFNNA48A10X 3 CFNNA48A3X 3 CFNNA48A11X 3 CFNNA48A5X 1 180 (86)

38 5.4 CFNNA64J3X 3 CFNNA64J11X 3 CFNNA64J5X 1 195 (94)

45 5.5 CFNNA77A3X 3 CFNNA77A11X 3 CFNNA77A5X 3 220 (106)

Applications: Lightweight Oils, Degreasing Solutions, Heat Transfer Oils

2

23 W/in

Steel Tank 15 5.2 CFNS740J10 2 CFNS740J3 1 CFNS740J11 1 CFNS740J5 1 167 (76)

6-Steel 18 5.3 CFNS748A10 2 CFNS748A3 3 CFNS748A11 1 CFNS748A5 1 180 (82)

(3.6 W/cm

2

23 W/in

Steel Tank 23 5.2 CFNS740J10X 3 CFNS740J3X 3 CFNS740J11X 1 CFNS740J5X 1 173 (79)

9-Steel 27 5.3 CFNS748A10X 3 CFNS748A3X 1 CFNS748A11X 3 CFNS748A5X 1 188 (86)

(3.6 W/cm

12 5.2 CFNS733A10 2 CFNS733A3 1 CFNS733A11 1 CFNS733A5 1 145 (66)

2

) 25 5.4 CFNS764J3 2 CFNS764J11 2 CFNS764J5 1 195 (89)

30 5.5 CFNS777A3 2 CFNS777A11 2 CFNS777A5 1 220 (100)

18 5.2 CFNS733A10X 3 CFNS733A3X 1 CFNS733A11X 1 CFNS733A5X 1 150 (68)

2

) 38 5.4 CFNS764J3X 3 CFNS764J11X 3 CFNS764J5X 1 206 (94)

45 5.5 CFNS777A3X 3 CFNS777A11X 3 CFNS777A5X 3 233 (106)

Applications: Medium Weight Oils, Heat Transfer Oils, Liquid Paraffin

2

16 W/in

➂ 8 5.1 CFNN733A12 1 CFNN733A13 1 145 (66)

Steel Tank 10 5.2 CFNN740J12 1 CFNN740J13 1 167 (76)

6-Incoloy

(2.6 W/cm

16 W/in

Steel Tank 15 5.2 CFNN740J12X 1 CFNN740J13X 1 173 (79)

9-Incoloy

(2.6 W/cm

®

12 5.3 CFNN748A12 1 CFNN748A13 1 180 (82)

2

)

2

➂ 12 5.1 CFNN733A12X 1 CFNN733A13X 1 150 (68)

®

18 5.3 CFNN748A12X 1 CFNN748A13X 1 188 (86)

2

)

Applications: Bunker C and #6 Fuel Oils

2

8 W/in

➂ 5 5.2 CFNS740J12 1 CFNS740J13 1 167 (76)

Steel Tank 6 5.3 CFNS748A12 1 CFNS748A13 1 180 (82)

6-Steel 8 5.4 CFNS764J12 1 CFNS764J13 1 195 (89)

(1.3 W/cm

8 W/in

Steel Tank 9 5.3 CFNS748A12X 1 CFNS748A13X 1 188 (86)

9-Steel 12 5.4 CFNS764J12X 1 CFNS764J13X 1 206 (94)

(1.3 W/cm

2

) 10 5.5 CFNS777A12 1 CFNS777A13 1 220 (100)

2

➂ 7.5 5.2 CFNS740J12X 1 CFNS740J13X 1 173 (79)

2

) 15 5.5 CFNS777A12X 1 CFNS777A13X 1 233 (106)

No. of

Circuits

480VÅ(ac)

1-Phase

No. of

Circuits

480VÅ(ac)

3-Phase

No. of

Circuits

Weight

lbs (kg)

Circulation Heaters

All circulation heaters are Assembly Stock

unless otherwise noted.

Availability

Assembly Stock: Five to seven working days

Standard: 10 working days

Truck Shipment only

➂ Must be operated 3-phase wye only.

➄ 240VÅ(ac) can be wired wye and operat-

ed at 480VÅ(ac) 3-phase to produce 1⁄3

more kW and watt density.

➅ Can be wired wye to produce 1⁄3 of the

original kW and watt density

(3-phase only).

383

Page 18

Tubular and

Process Assemblies

Circulation Heaters

6" Flange

Ref

12

(322 mm)

11

4

/16

(119 mm)

11

"

/16

"

14

(367 mm)

1

"

2

/2

NPT Inlet & Outlet

B

3

"

/4

- 10 UNC Thread

3

"

(4 places)

7

"

/16

1

"

/2

NPT

(19 mm) deep

/4

Ref

A

C

Ref

1

"

7

/4

(184 mm)

(2 places)

3

(89 mm)

(222 mm)

1

"

/2

5

"

6

/8

(168 mm)

3

"

8

/4

1

"

/2

NPT

6" 150 lb ANSI Flange—WATROD Element

WATROD Code No. Est. Ship.

Description kW Fig. 240VÅ(ac)

No. 1-Phase

No. of

Circuits

240VÅ(ac)

3-Phase

Application: Clean Water

2

60 W/in

24 6.1 CFPC715G10 3 CFPC715G3 2 CFPC715G11 2 CFPC715G5 1 212 (97)

Steel Tank 36 6.1 CFPC721G10 4 CFPC721G3 2 CFPC721G11 2 CFPC721G5 1 217 (99)

12-Copper 48 6.2 CFPC726R3 4 CFPC726R11 3 CFPC726R5 2 222 (101)

2

(9.3 W/cm

) 60 6.2 CFPC732G3 4 CFPC732G11 3 CFPC732G5 2 226 (103)

72 6.3 CFPC737R3 4 CFPC737R5 2 290 (132)

100 6.3 CFPC750R5 4 298 (136)

120 6.4 CFPC760G5 4 360 (164)

60 W/in

2

30 6.1 CFPC715G10X 3 CFPC715G3X 5 CFPC715G11X 3 CFPC715G5X 1 215 (98)

Steel Tank 45 6.1 CFPC721G10X 5 CFPC721G3X 5 CFPC721G11X 3 CFPC721G5X 5 223 (102)

15-Copper 60 6.2 CFPC726R3X 5 CFPC726R11X 3 CFPC726R5X 5 226 (103)

2

(9.3 W/cm

) 75 6.2 CFPC732G3X 5 CFPC732G11X 5 CFPC732G5X 5 288 (131)

90 6.3 CFPC737R3X 5 CFPC737R5X 5 296 (134)

125 6.3 CFPC750R5X 5 306 (139)

150 6.4 CFPC760G5X

Application: Deionized Water , Demineralized Water

2

60 W/in

24 6.1 CFPR715N10 3 CFPR715N3 2 CFPR715N11 2 CFPR715N5 1 212 (97)

316 SS Tank 36 6.1 CFPR721N10 4 CFPR721N3 2 CFPR721N11 3 CFPR721N5 1 217 (99)

12-316 SS 48 6.2 CFPR727E3 4 CFPR727E11 3 CFPR727E5 2 222 (101)

2

(9.3 W/cm

) 60 6.2 CFPR732N3 4 CFPR732N11 3 CFPR732N5 2 226 (103)

Passivated 72 6.3 CFPR738E3 4 CFPR738E5 2 290 (132)

100 6.3 CFPR751E5 4 298 (136)

120 6.4 CFPR760N5 4 360 (164)

60 W/in

2

30 6.1 CFPR715N10X 3 CFPR715N3X 5 CFPR715N11X 3 CFPR715N5X 1 215 (98)

316 SS Tank 45 6.1 CFPR721N10X 5 CFPR721N3X 5 CFPR721N11X 3 CFPR721N5X 5 223 (102)

15-316 SS 60 6.2 CFPR727E3X 5 CFPR727E11X 3 CFPR727E5X 5 226 (103)

2

(9.3 W/cm

) 75 6.2 CFPR732N3X 5 CFPR732N11X 5 CFPR732N5X 5 288 (131)

Passivated 90 6.3 CFPR738E3X 5 CFPR738E5X 5 296 (135)

125 6.3 CFPR751E5X 5 306 (139)

150 6.4 CFPR760N5X 5 370 (168)

All circulation heaters are Assembly Stock

➁ Standard

unless otherwise noted.

Availability

Assembly Stock: Five to seven working days

Standard: 10 working days

Truck Shipment only

384

No. of

Circuits

Fig. A Dimension B Dimension C Dimension

No. in (mm) in (mm) in (mm)

7

⁄16 (1027) 201⁄2 (521) 17 (432)

15

16 (1294) 31 (787) 27

⁄

15

⁄16 (1827) 52 (1321) 481⁄2 (1232)

16 (2361) 73 (1854) 66 (1676)

No. of

Circuits

480VÅ(ac)

3-Phase

➁

3

"

4

/4

(121 mm)

6.1 40

6.2 50

6.3 71

6.4 9215⁄

480VÅ(ac)

1-Phase

1

2 (699)

⁄

No. of

Circuits

Weight

lbs (kg)

5 370 (168)

CONTINUED

Page 19

W A T L O W

Tubular and

Process Assemblies

Circulation Heaters

6" 150 lb ANSI Flange—WATROD Element

WATROD Code No. Est. Ship.

Description kW Fig. 240VÅ(ac)

No. 1-Phase

No. of

Circuits

240VÅ(ac)

3-Phase

Application: Process Water

2

48 W/in

➄ 18 6.1 CFPN713G10 2 CFPN713G3 1 CFPN713G11 1 CFPN713G5 1 212 (97)

Steel Tank 24 6.1 CFPN717R10 3 CFPN717R3 2 CFPN717R11 2 CFPN717R5 1 214 (97)

12-Incoloy

(7.5 W/cm

48 W/in

Steel Tank 30 6.1 CFPN717R10X 3 CFPN717R3X 5 CFPN717R11X 3 CFPN717R5X 1 217 (99)

15-Incoloy

(7.5 W/cm

®

2

2

2

30 6.1 CFPN720G10 3 CFPN720G3 2 CFPN720G11 2 CFPN720G5 1 217 (99)

) 36 6.1 CFPN725G10 4 CFPN725G3 2 CFPN725G11 2 CFPN725G5 1 222 (101)

48 6.2 CFPN732R3 4 CFPN732R11 3 CFPN732R5 2 226 (103)

60 6.3 CFPN740G3 4 CFPN740G11 3 CFPN740G5 2 290 (132)

72 6.3 CFPN747R3 4 CFPN747R5 2 298 (136)

23 6.1 CFPN713G10X 3 CFPN713G3X 5 CFPN713G11X 1 CFPN713G5X 1 215 (98)

®

38 6.1 CFPN720G10X 5 CFPN720G3X 5 CFPN720G11X 3 CFPN720G5X 1 223 (102)

) 45 6.1 CFPN725G10X 5 CFPN725G3X 5 CFPN725G11X 3 CFPN725G5X 5 226 (103)

60 6.2 CFPN732R3X 5 CFPN732R11X 3 CFPN732R5X 5 288 (131)

75 6.3 CFPN740G3X 5 CFPN740G11X 5 CFPN740G5X 5 296 (135)

90 6.3 CFPN747R3X 5 CFPN747R5X 5 306 (139)

Applications: Forced Air and Gases, Caustic Solutions, Degreasing Solutions

2

23 W/in

➄➅ 12 6.1 CFPNA17R10 2 CFPNA17R3 1 CFPNA17R11 1 CFPNA17R5 1 214 (97)

Steel Tank 18 6.1 CFPNA25G10 2 CFPNA25G3 1 CFPNA25G11 1 CFPNA25G5 1 222 (101)

12-Incoloy

(3.6 W/cm

23 W/in

Steel Tank 23 6.1 CFPNA25G10X 3 CFPNA25G3X 5 CFPNA25G11X 1 CFPNA25G5X 1 226 (103)

15-Incoloy

(3.6 W/cm

®

2

2

2

24 6.2 CFPNA32R10 3 CFPNA32R3 2 CFPNA32R11 2 CFPNA32R5 1 226 (103)

) 30 6.3 CFPNA40G10 3 CFPNA40G3 2 CFPNA40G11 2 CFPNA40G5 1 290 (132)

36 6.3 CFPNA47R10 4 CFPNA47R3 2 CFPNA47R11 2 CFPNA47R5 1 298 (136)

50 6.4 CFPNA64G3 4 CFPNA64G11 3 CFPNA64G5 2 360 (164)

60 6.4 CFPNA76R3 4 CFPNA76R11 3 CFPNA76R5 2 368 (167)

15 6.1 CFPNA17R10X 3 CFPNA17R3X 1 CFPNA17R11X 1 CFPNA17R5X 1 217 (99)

®

30 6.2 CFPNA32R10X 3 CFPNA32R3X 5 CFPNA32R11X 3 CFPNA32R5X 1 288 (131)

) 38 6.3 CFPNA40G10X 5 CFPNA40G3X 5 CFPNA40G11X 3 CFPNA40G5X 1 296 (135)

45 6.3 CFPNA47R10X 5 CFPNA47R3X 5 CFPNA47R11X 3 CFPNA47R5X 5 306 (139)

63 6.4 CFPNA64G3X 5 CFPNA64G11X 3 CFPNA64G5X 5 370 (168)

75 6.4 CFPNA76R3X 5 CFPNA76R11X 5 CFPNA76R5X 5 381 (173)

No. of

Circuits

480VÅ(ac)

1-Phase

No. of

Circuits

480VÅ(ac)

3-Phase

No. of

Circuits

CONTINUED

Weight

lbs (kg)

Circulation Heaters

All circulation heaters are Assembly Stock

unless otherwise noted.

Availability

Assembly Stock: Five to seven working days

Standard: 10 working days

Truck Shipment only

➄ 240VÅ(ac) can be wired wye and

operated at 480VÅ(ac) 3-phase to

produce

➅

Can be wired wye to produce 1⁄3 of the

1

⁄3 more kW and watt density.

original kW and watt density

(3-phase only).

385

Page 20

Tubular and

Process Assemblies

Circulation Heaters

6" 150 lb ANSI Flange—WATROD Element

WATROD Code No. Est. Ship.

Description kW Fig. 240VÅ(ac)

No. 1-Phase

No. of

Circuits

240VÅ(ac)

3-Phase

Applications: Lightweight Oils, Degreasing Solutions, Heat Transfer Oils

2

23 W/in

Steel Tank 18 6.1 CFPS725G10 2 CFPS725G3 1 CFPS725G11 1 CFPS725G5 1 222 (101)

12-Steel 24 6.2 CFPS732R10 3 CFPS732R3 2 CFPS732R11 2 CFPS732R5 1 226 (103)

(3.6 W/cm

23 W/in

Steel Tank 23 6.1 CFPS725G10X 3 CFPS725G3X 5 CFPS725G11X 1 CFPS725G5X 1 226 (103)

15-Steel 30 6.2 CFPS732R10X 3 CFPS732R3X 5 CFPS732R11X 3 CFPS732R5X 1 288 (131)

(3.6 W/cm

2

2

2

12 6.1 CFPS717R10 2 CFPS717R3 1 CFPS717R11 1 CFPS717R5 1 214 (97)

) 30 6.3 CFPS740G10 3 CFPS740G3 2 CFPS740G11 2 CFPS740G5 1 290 (132)

36 6.3 CFPS747R10 4 CFPS747R3 2 CFPS747R11 2 CFPS747R5 1 298 (136)

50 6.4 CFPS764G3 4 CFPS764G11 3 CFPS764G5 2 360 (164)

60 6.4 CFPS776R3 4 CFPS776R11 3 CFPS776R5 2 368 (167)

15 6.1 CFPS717R10X 3 CFPS717R3X 1 CFPS717R11X 1 CFPS717R5X 1 217 (99)

) 38 6.3 CFPS740G10X 5 CFPS740G3X 5 CFPS740G11X 3 CFPS740G5X 1 296 (135)

45 6.3 CFPS747R10X 5 CFPS747R3X 5 CFPS747R11X 3 CFPS747R5X 5 306 (139)

63 6.4 CFPS764G3X 5 CFPS764G11X 3 CFPS764G5X 5 370 (168)

75 6.4 CFPS776R3X 5 CFPS776R11X 5 CFPS776R5X 5 381 (173)

Applications: Medium Weight Oils, Heat Transfer Oils, Liquid Paraffin

2

16 W/in

➂ 6 6.1 CFPN713G12 1 CFPN713G13 1 212 (97)

Steel Tank 8 6.1 CFPN717R12 1 CFPN717R13 1 214 (97)

12-Incoloy

(2.6 W/cm

16 W/in

Steel Tank 10 6.1 CFPN717R12X 1 CFPN717R13X 1 217 (99)

15-Incoloy

(2.6 W/cm

®

2

2

➂ 7.5 6.1 CFPN713G12X 1 CFPN713G13X 1 215 (98)

2

10 6.1 CFPN720G12 1 CFPN720G13 1 217 (99)

) 12 6.1 CFPN725G12 1 CFPN725G13 1 222 (101)

16 6.2 CFPN732R12 1 CFPN732R13 1 226 (103)

20 6.3 CFPN740G12 2 CFPN740G13 1 290 (132)

24 6.3 CFPN747R12 2 CFPN747R13 1 298 (136)

®

12.5 6.1 CFPN720G12X 1 CFPN720G13X 1 223 (102)

) 15 6.1 CFPN725G12X 1 CFPN725G13X 1 226 (103)

20 6.2 CFPN732R12X 5 CFPN732R13X 1 288 (131)

25 6.3 CFPN740G12X 5 CFPN740G13X 1 296 (135)

30 6.3 CFPN747R12X 5 CFPN747R13X 1 306 (139)

Applications: Bunker C and #6 Fuel Oils

2

8 W/in

➂ 8 6.2 CFPS732R12 1 CFPS732R13 1 226 (103)

Steel Tank 10 6.3 CFPS740G12 1 CFPS740G13 1 290 (132)

12-Steel 12 6.3 CFPS747R12 1 CFPS747R13 1 298 (136)

(1.3 W/cm

8 W/in

Steel Tank 12.5 6.3 CFPS740G12X 1 CFPS740G13X 1 296 (135)

15-Steel 15 6.3 CFPS747R12X 1 CFPS747R13X 1 306 (139)

(1.3 W/cm

All circulation heaters are Assembly Stock

unless otherwise noted.

Availability

Assembly Stock: Five to seven working days

Standard: 10 working days

2

) 16.5 6.4 CFPS764G12 1 CFPS764G13 1 360 (164)

20 6.4 CFPS776R13 1 368 (167)

2

➂ 10 6.2 CFPS732R12X 1 CFPS732R13X 288 (131)

2

) 21 6.4 CFPS764G12X 5 CFPS764G13X 1 370 (168)

25 6.4 CFPS776R12X 5 CFPS776R13X 1 381 (173)

➂ Must be operated 3-phase wye only.

Truck Shipment only

No. of

Circuits

480VÅ(ac)

1-Phase

No. of

Circuits

480VÅ(ac)

3-Phase

No. of

Circuits

Weight

lbs (kg)

386

Page 21

W A T L O W

Tubular and

Process Assemblies

Circulation Heaters

6" 150 lb ANSI Flange—FIREBAR Element

FIREBAR Code No. Est. Ship.

Description kW Fig. 240VÅ(ac)

No. 3-Phase

No. of

Circuits

480VÅ(ac)

3-Phase

Applications: Process Water, Ethylene Glycol (50%)

2

45 W/in

Steel Tank 37.5 6.1 CFPNF16A27 5 220 (100)

15-Incoloy

(7 W/cm2) 60 6.1 CFPNF22R27 5 CFPNF22R28 5 226 (103)

30 6.1 CFPNF13G27 5 217 (99)

®

45 6.1 CFPNF18G27 5 223 (102)

75 6.2 CFPNF27R27 5 CFPNF27R28 5 232 (106)

90 6.2 CFPNF32R27 5 CFPNF32R28 5 236 (107)

120 6.3 CFPNF42G28 5 304 (138)

150 6.3 CFPNF51R28 5 314 (143)

Applications: Cooking Oils, Ethylene Glycol (100%)

30 W/in2➂ 25 6.1 CFPNF16J12 5 CFPNF16J13 5 220 (100)

Steel Tank 32 6.1 CFPNF19J12 5 CFPNF19J13 5 223 (102)

15-Incoloy

(4.7 W/cm2) 52 6.2 CFPNF30A12 5 CFPNF30A13 5 232 (106)

®

42 6.1 CFPNF24J12 5 CFPNF24J13 5 226 (103)

64 6.2 CFPNF35A12 5 CFPNF35A13 5 236 (107)

85 6.3 CFPNF45J12 5 CFPNF45J13 5 304 (138)

110 6.3 CFPNF56A13 5 314 (143)

Applications: Heat Transfer Oils, Mineral Oil, Degreasing Solutions

23 W/in2➃ 19 6.1 CFPNF16J20 5 220 (100)

Steel Tank 24 6.1 CFPNF19J20 5 223 (102)

15-Incoloy

(3.6 W/cm2) 40 6.2 CFPNF30A20 5 CFPNF30A19 5 232 (106)

®

32 6.1 CFPNF24J20 5 CFPNF24J19 5 226 (103)

48 6.2 CFPNF35A20 5 CFPNF35A19 5 236 (107)

64 6.3 CFPNF45J20 5 CFPNF45J19 5 304 (138)

80 6.3 CFPNF56A20 5 CFPNF56A19 5 314 (143)

Applications: Medium Weight Oils, Heat Transfer Oils, Lube Oils, Liquid Paraffin

15 W/in2➂ 10 6.1 CFPNF13G29 5 217 (99)

Steel Tank 12.5 6.1 CFPNF16A29 5 220 (100)

15-Incoloy

(2.3 W/cm2) 20 6.1 CFPNF22R29 5 CFPNF22R30 5 226 (103)

®

15 6.1 CFPNF18G29 5 223 (102)

25 6.2 CFPNF27R29 5 CFPNF27R30 5 232 (106)

30 6.2 CFPNF32R29 5 CFPNF32R30 5 236 (107)

40 6.3 CFPNF42G29 5 CFPNF42G30 5 304 (138)

50 6.3 CFPNF51R29 5 CFPNF51R30 5 314 (143)

Applications: Bunker C and #6 Fuel Oils, Asphalt

8 W/in2➂ 6.3 6.1 CFPNF16J22 5 220 (100)

Steel Tank 8.1 6.1 CFPNF19J22 5 223 (102)

15-Incoloy

(1.3 W/cm2) 13.1 6.2 CFPNF30A22 5 CFPNF30A21 5 232 (106)

All circulation heaters are Assembly Stock

unless otherwise noted.

Availability

Assembly Stock: Five to seven working days

®

10.6 6.1 CFPNF24J22 5 CFPNF24J21 5 226 (103)

16 6.2 CFPNF35A22 5 CFPNF35A21 5 236 (107)

21.3 6.3 CFPNF45J22 5 CFPNF45J21 5 304 (138)

26 6.3 CFPNF56A22 5 CFPNF56A21 5 314 (143)

Truck Shipment only

➂ Must be operated 3-phase wye only.

➃ Wired for higher voltage.

No. of

Circuits

Weight

lbs (kg)

Circulation Heaters

387

Page 22

Tubular and

Ref

A

10

3

/4

"

(273 mm)

6

9

/16

"

(167 mm)

2

1

/2

"

NPT Inlet & Outlet

3

/4

"

- 10 UNC Thread

(4 places)

3

/4

"

(19 mm) deep

(2 places)

3

1

/2

"

(89 mm)

Ref 7

13

/16

"

(198 mm)

Ref

14

11

/16

"

(373 mm)

14

1

/2

"

(368 mm)

C

B

1

/2

"

NPT

1

/2

"

NPT

5

3

/4

"

(146 mm)

7

5

/8

"

(194 mm)

Process Assemblies

Circulation Heaters

8" Flange

8" 150 lb ANSI Flange— WATROD Element

WATROD Code No. Est. Ship.

Description kW Fig. 240VÅ(ac)

No. 1-Phase

No. of

Circuits

240VÅ(ac)

3-Phase

Application: Clean Water

2

60 W/in

50 7.1 CFRC721N3➁ 3 CFRC721N11 3 CFRC721N5 2 340 (155)

Steel Tank 75 7.2 CFRC729N3

18-Copper 100 7.3 CFRC737E3

2

(9.3 W/cm

) 125 7.4 CFRC745E3➁ 6 CFRC745E5➁ 3 410 (186)

150 7.5 CFRC752N5

175 7.6 CFRC760N5

200 7.7 CFRC768E5

Application: Process Water

2

48 W/in

➄ 50 7.2 CFRN725N3➁ 3 CFRN725N11➁ 3 CFRN725N5➁ 2 350 (159)

Steel Tank 75 7.3 CFRN735N3

®

18-Incoloy

(7.5 W/cm

100 7.4 CFRN744E3 6 CFRN744E5 3 410 (186)

2

) 125 7.5 CFRN754M3➁ 6 CFRN754M5➁ 6 445 (202)

150 7.6 CFRN763M5

175 7.7 CFRN773D5 6 530 (241)

200 7.7 CFRN782M5

48 W/in

2

67 7.2 CFRN726D3X➁ 4 CFRN726D11X➁ 3 CFRN726D5X➁ 2 358 (163)

Steel Tank 100 7.3 CFRN736D3X

®

24-Incoloy

(7.5 W/cm

133 7.4 CFRN744M3X➁ 8 CFRN744M5X➁ 4 425 (193)

2

) 167 7.5 CFRN754M3X➁ 8 CFRN754M5X➁ 8 463 (210)

200 7.6 CFRN763M5X

233 7.7 CFRN773D5X 8 554 (252)

267 7.7 CFRN782M5X

Applications: Forced Air and Gases, Caustic Solutions, Degreasing Solutions

2

23 W/in

➄➅ 30 7.2 CFRNA32N10➁ 3 CFRNA32N3➁ 2 CFRNA32N11➁ 2 CFRNA32N5➁ 1 370 (168)

Steel Tank 40 7.3 CFRNA43E3

18-Incoloy

(3.6 W/cm

23 W/in

Steel Tank 53 7.3 CFRNA43M3X

24-Incoloy

(3.6 W/cm

All circulation heaters are Assembly Stock

unless otherwise noted.

Availability

Assembly Stock: Five to seven working days

Standard: 10 working days

388

®

2

)

2

®

2

)

Truck Shipment only

50 7.4 CFRNA51M3➁ 3 CFRNA51M11 3 CFRNA51M5 2 440 (200)

40 7.2 CFRNA33D10X➁ 4 CFRNA33D3X➁ 4 CFRNA33D11X➁ 2 CFRNA33D5X➁ 2 382 (174)

67 7.4 CFRNA51M3X➁ 4 CFRNA51M11X➁ 3 CFRNA51M5X➁ 2 457 (207)

➁ Standard

➄ 240VÅ(ac) can be wired wye and

operated at 480VÅ(ac) 3-phase to

produce 1⁄3 more kW and watt density.

No. of

Circuits

➁ 6 CFRC729N5➁ 2 360 (164)

➁ 6 CFRC737E5 3 385 (175)

➁ 6 CFRN735N5➁ 2 380 (173)

➁ 8 CFRN736D5X➁ 4 392 (178)

➁ 3 CFRNA43E11➁ 2 CFRNA43E5➁ 2 410 (186)

➁ 4 CFRNA43M11X➁ 3 CFRNA43M5X➁ 2 425 (193)

Fig. A Dimension B Dimension C Dimension

No. in (mm) in (mm) in (mm)

7.1 47

7.2 55

7.3 623⁄16 (1580) 3911⁄16 (1008) 363⁄16 (919)

7.4 6913⁄

7.5 79

7.6 885⁄16 (2243) 6513⁄16 (1672) 625⁄16 (1583)

7.7 985⁄

480VÅ(ac)

1-Phase

3

(1199) 24

⁄16

3

⁄16 (1402) 3211⁄16 (830) 293⁄16 (741)

16 (1773) 47

5

⁄16 (2014) 5613⁄16 (1443) 535⁄16 (1354)

16 (2497) 75

No. of

Circuits

11

⁄16

5

16 (1202) 43

⁄

13

16 (1926) 72

⁄

480VÅ(ac)

3-Phase

(627) 21

No. of

Circuits

3

(538)

⁄16

13

16 (1113)

⁄

5

16 (1837)

⁄

Weight

lbs (kg)

➁ 6 440 (200)

➁ 6 465 (211)

➁ 6 510 (232)

➁ 6 490 (223)

➁ 6 560 (254)

➁ 8 511 (232)

➁ 8 587 (267)

CONTINUED

➅ Can be wired wye to produce 1⁄3 of the

original kW and watt density

(3-phase only).

Page 23

W A T L O W

Tubular and

Process Assemblies

Circulation Heaters

8" 150 lb ANSI Flange—WATROD Element

WATROD Code No. Est. Ship.

Description kW Fig. 240VÅ(ac)

No. 1-Phase

No. of

Circuits

240VÅ(ac)

3-Phase

Applications: Lightweight Oils, Degreasing Solutions, Heat Transfer Oils

2

23 W/in

Steel Tank 40.0 7.3 CFRS743E3

18-Steel 50.0 7.4 CFRS751M3 3 CFRS751M11 3 CFRS751M5 2 440 (200)

(3.6 W/cm

23 W/in

Steel Tank 53.0 7.3 CFRS743M3X

24-Steel 67.0 7.4

(3.6 W/cm

2

2

2

30.0 7.2 CFRS732N10

) 60.0 7.5 CFRS762D3

70.0 7.6 CFRS770M3

80.0 7.7 CFRS779M3

40.0 7.2 CFRS733D10X

➁

3 CFRS732N3

➁ 4 CFRS733D3X➁ 4 CFRS733D11X➁

CFRS751M3X➁ 4 CFRS751M11X➁ 3 CFRS751M5X➁

) 80.0 7.5

93.0 7.6 CFR

107.0 7.7

CFRS762D3X➁ 8 CFRS762D11X➁ 4 CFRS762D5X➁

S770M3X➁ 8 CFRS770M11X➁ 6 CFRS770M5X➁

CFRS779M3X➁ 8 CFRS779M5X➁

Applications: Medium Weight Oils, Heat Transfer Oils, Liquid Paraffin

2

16 W/in

➂

Steel Tank 25.0 7.3

18-Incoloy

(2.6 W/cm

16 W/in

Steel Tank 33.0 7.3

24-Incoloy

(2.6 W/cm

2

2

2

17.0 7.2

CFRN725N12➁ 1 CFRN725N13➁

CFRN735N12➁ 2 CFRN735N13➁

®

33.0 7.4 CFRN744E1

) 42.0 7.5 CFRN7

50.0 7.6 CFRN763M1

58.0 7.7 CFRN773D13 2 530 (241)

67.0 7.7 CFRN782M13

23.0 7.2 CF

54M12➁ 3 CFRN754M13➁

RN726D12X➁ 2 CFRN726D13X➁

CFRN736D12X➁ 2 CFRN736D13X➁

®

44.0 7.4

) 56.0 7.5

67.0 7.6 CFRN763M13X

77.0 7.7 CFRN773D13

89.0 7.7 CFRN782M13X

CFRN744M12X➁ 4 CFRN744M13X➁

CFRN754M12X➁ 4 CFRN754M13X➁

Applications: Bunker C and #6 Fuel Oils

2

8 W/in

➂

Steel Tank 16.5 7.4 CFRS751M12 1 CFRS751M13 1 440 (200)

18-Steel 20.0 7.5

(1.3 W/cm

8 W/in

Steel Tank 22.0 7.4 CFRS751M

24-Steel 27.0 7.5 CFRS76

(1.3 W/cm

2

2

➂

2

All circulation heaters are Assembly Stock

unless otherwise noted.

Availability

Assembly Stock: Five to seven working days

Standard: 10 working days

Truck Shipment only

12.5 7.3

CFRS743E12➁ 1 CFRS743E13➁

CFRS762D12➁ 2 CFRS762D13➁

) 24.0 7.6 CFRS770M12 2 CFRS770M13 1 530 (241)

27.0 7.7 CFRS779M

17.0 7.3 CFRS743

M12X➁ 1 CFRS743M13X➁

2D12X➁ 2 CFRS762D13X➁

) 32.0 7.6 CFRS770M12

36.0 7.7 CFRS779M1

➁ Standard

➂ Must be operated 3-phase wye only.

➁

➁

➁

➁

➁

2➁

No. of

Circuits

2 CFRS732N11

3 CFRS743E11

6 CFRS762D11

6 CFRS770M11 6 CFRS770M5 2 530 (241)

6 CFRS779M5

➁

4 CFRS743M11X

2 CFRN744E13 1 410 (186)

480VÅ(ac)

1-Phase

No. of

Circuits

➁

2 CFRS732N5

➁

2 CFRS743E5 2 410 (186)

➁

3 CFRS762D5

480VÅ(ac)

3-Phase

➁

➁

➁

2 CFRS733D5X

➁

3 CFRS743M5X

➁

➁

3➁

➁

➁

X➁

➁

12➁ 2 CFRS779M13➁

12X➁ 2 CFRS751M13X➁

X➁ 2 CFRS770M13X➁

2X➁ 2 CFRS779M13X➁

No. of

Circuits

Weight

lbs (kg)

1 370 (168)

2 480 (218)

3 610 (277)

2 382 (174)

2 425 (193)

2 457 (208)

4 461 (209)

4 554 (252)

4 636 (289)

1 350 (159)

1 380 (173)

2 445 (202)

2 490 (223)

2 560 (254)

1 358 (163)

1 392 (178)

2 425 (193)

2 463 (210)

2 511 (232)

2 554 (252)

4 587 (267)

1 410 (186)

1 480 (218)

1 610 (277)

1 425 (193)

1 457 (208)

1 461 (209)

1 554 (252)

1 636 (289)

Circulation Heaters

389

Page 24

Tubular and

Ref

A

7

9

/16

"

(192 mm)

12

1

/2

"

(318 mm)

1

"

(25 mm)

Ref

15

3

/4

"

(400 mm)

B

12

7

/8

"

(327 mm)

3" Flange Inlet & Outlet

12

15

/16

"

(329 mm)

11

1

/2

"

(292 mm)

Ref

9

"

(229 mm)

1

1

/4

"

X 3

"

(32 x 76 mm)

7

/8

"

(22 mm)

(2)

3

/4

"

- 10

UNC 2B

C

1

/2

"

(13 mm)

1

3

/4

"

(44 mm)

3

"

(76 mm)

1

/2

"

NPT

7

/8"

X 2"

Slot

(22 X 51 mm)

4"

(100 mm)

Process Assemblies

Circulation Heaters

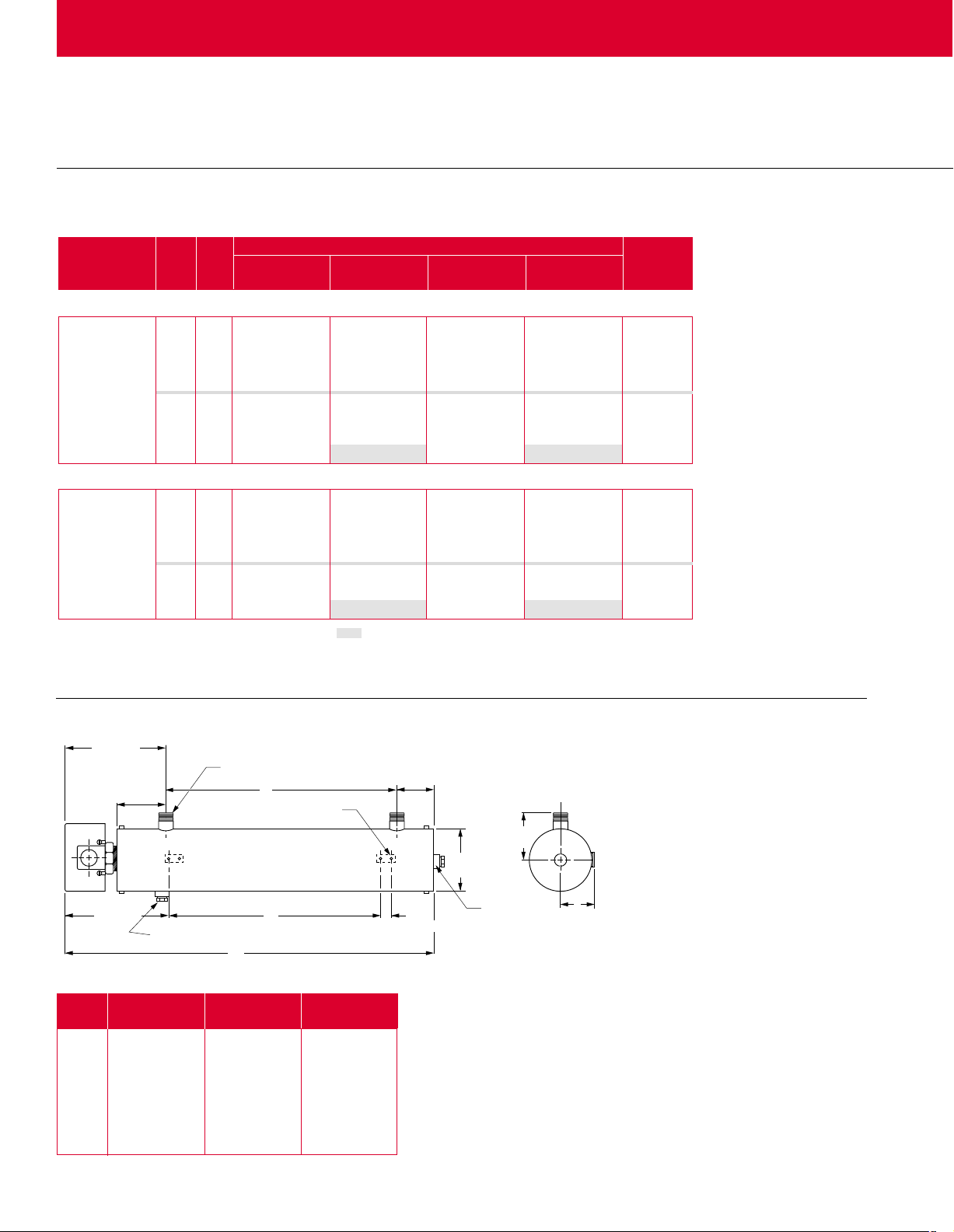

10" Flange

Fig. A Dimension B Dimension C Dimension

No. in (mm) in (mm) in (mm)

8.1 769⁄16 (1945) 6013⁄16 (1545) 679⁄16 (1716)

1

8.2 84

⁄16 (2135) 685⁄16 (1735) 751⁄16 (1907)

8.3 913⁄16 (2316) 757⁄16 (1916) 823⁄16 (2088)

8.4 99

8.5 106

1

⁄16 (2516) 835⁄16 (2116) 901⁄16 (2288)

9

⁄16 (2707) 9013⁄16 (2307) 979⁄16 (2478)

10" 150 lb ANSI Flange—WATROD Element

WATROD Code No. Est. Ship.

Description kW Fig. 240VÅ(ac)

No. 3-Phase

No. of

Circuits

480VÅ(ac)

3-Phase

Application: Process Water

48 W/in2➄ 262 8.5 CFSN773E5 9 600 (273)

Steel Tank

27-Incoloy

®

(7.5 W/cm2)

Applications: Forced Air and Gases, Caustic Solutions, Degreasing Solutions

23 W/in2➄➅ 60 8.1 CFSNA43N3➁ 3 CFSNA43N5➁ 3 515 (234)

Steel Tank 75 8.2 CFSNA51N3➁ 9 CFSNA51N5 3 530 (241)

27-Incoloy

®

(3.6 W/cm2)

Applications: Lightweight Oils, Degreasing Solutions, Heat Transfer Oils

2

23 W/in

90 8.3 CFSS762E5➁ 3 540 (245)

Steel Tank 105 8.4 CFSS770N5 3 600 (272)

27-Steel 120 8.5 CFSS778N5➁ 3 645 (293)

(3.6 W/cm2)

Applications: Medium Weight Oils, Heat Transfer Oils, Liquid Paraffin

16 W/in2➂ 75 8.3 CFSN763N13➁ 3 540 (245)

Steel Tank 87 8.5 CFSN773E13➁ 3 600 (273)

27-Incoloy

®

(2.6 W/cm2)

Applications: Bunker C and #6 Fuel Oils

8 W/in2➂ 30 8.3 CFSS762E12➁ 3 CFSS762E13➁ 1 540 (245)

Steel Tank 35 8.4 CFSS770N12 3 CFSS770N13 1 600 (273)

27-Steel 40 8.5 CFSS778N12➁ 3 CFSS778N13➁ 1 645 (293)

(1.3 W/cm2)

390

No. of

Circuits

Weight

lbs (kg)

All circulation heaters are Assembly Stock

unless otherwise noted.

Availability

Assembly Stock: Five to seven working days

Standard: 10 working days

Truck Shipment only

➁ Standard

➂ Must be operated 3-phase wye only.

➄ 240VÅ(ac) can be wired wye and operated

at 480VÅ(ac) 3-phase to produce

kW and watt density.

➅ Can be wired wye to produce

inal kW and watt density

(3-phase only).

1

of the orig-

⁄3

1

more

⁄3

Page 25

W A T L O W

Ref

A

7

15

/16

"

(202 mm)

12

1

/2

"

(318 mm)

1

"

(25 mm)

Ref

16

3

/16

"

(411 mm)

C

B

14

7

/8

"

(378 mm)

5" Flange Inlet & Outlet

14

"

(356 mm)

11

1

/2

"

(292 mm)

1

/2

"

(13 mm)

1

1

/4

"

X 3

"

(32 X 76 mm)

7

/8

"

(22 mm)

(2)

3

/4

"

- 10

UNC 2B

1

3

/4

"

(44 mm)

3

1

/4

"

(

83 mm)

Ref

9

1

/16

"

(230 mm)

1

/2

"

NPT

7

/8

X 2

" Slot

(22 X 51 mm)

4"

(100 mm)

Tubular and

Process Assemblies

Circulation Heaters

12" Flange

Fig. A Dimension B Dimension C Dimension

No. in (mm) in (mm) in (mm)

7

9.1 76

9.2 843⁄

9.3 91

⁄8 (1953) 6011⁄16 (1541) 6713⁄16 (1722)

8 (2143) 68

7

⁄8 (2334) 7511⁄16 (1922) 8213⁄16 (2103)

3

16 (1732) 75

⁄

5

16 (1913)

⁄

9.4 99 (2515) 8213⁄16 (2103) 8915⁄16 (2284)

9.5 1061⁄

2 (2705) 90

5

16 (2294) 97

⁄

7

16 (2475)

⁄

Circulation Heaters

12" 150 lb ANSI Flange—WATROD Element

WATROD Code No. Est. Ship.

Description kW Fig. 240VÅ(ac)

No. 3-Phase

No. of

Circuits

480VÅ(ac)

3-Phase

Application: Process Water

2

48 W/in

350 9.5 CFTN773C5 12 650 (295)

Steel Tank

36-Incoloy

®

(7.5 W/in2)

Applications: Forced Air and Gases, Caustic Solutions, Degreasing Solutions

2

23 W/in

80 9.1 CFTNA43L5➁ 3 565 (257)

Steel Tank 100 9.2 CFTNA51L5 3 585 (266)

36-Incoloy

®

(3.6 W/cm2)

Applications: Lightweight Oils, Degreasing Solutions, Heat Transfer Oils

2

23 W/in

140 9.4 CFTS770L5 4 650 (295)