Page 1

Ceramic Fiber Heaters

®

Heated Insulation

Package

Ceramic fiber heaters offer some of the highest temperature

heating element capabilities in the Watlow

®

family of heaters.

Heating units constructed with ceramic fiber insulation isolate

the heating chamber from the outside. Ceramic fiber heaters

are extremely low mass, high insulation value units with

self-supported heating elements. Many applications benefit

from the convenience of the heating element and insulation

combined into one package. Lightweight, low-density

properties make Watlow’s ceramic fiber heaters ideal for

high-temperature applications requiring low thermal mass.

Features and Benefits

High temperature ICA resistance elements

• Bounds integrally into required position

• Allows five element configurations

Lightweight, low-density alumina-silica composition

molded into shape

• Acts as an insulation to isolate the heating chamber from

the outside

• Provides low shrinkage fiber and inorganic binder

• Assures a firm, thermal shock resistant, self-supporting

unit at all operating temperatures

Operating temperatures up to 2200°F (1204°C)

• Provides high temperature performance that cannot be

achieved with many other heater types

Low mass ceramic fiber insulation of 10 to 15 lb/ft

(160 to 240 kg/m3)

• Allows the heater to reach process temperature quickly

• Enables the energy to heat the load instead of wasting

energy on itself

Works directly off common power line voltages

• Eliminates the need for expensive transformers or

complex power control systems

• Enables compatibility with the full range of Watlow

temperature controllers and power switching devices

3

High

Temperature

ICA Heating

Element

Lightweight

AluminaSilica Fiber

Composition

Ductile Alloy

Additional

Coating for

Added Strength

and Surface

Hardness

Thin, Tough, High Temperature Ceramic

Coating over Embedded Elements, plus

Optional High Emissivity Coating

Strip Leads

Performance Capabilities

• Operates at temperatures up to 2200°F (1204°C)

2

• Allows watt densities from 5 to 30 W/in

(0.8 to 4.6 W/cm2)

• Uses “radiant” heat transfer exclusively

Typical Applications

• High temperature furnaces

• Metal melting, holding and transfer

• Semiconductor processing

• Glass, ceramic and wire processing

• Analytical instrumentation

©2001, 2011 Watlow Electric Manufacturing Company, all rights reserved.

COL-CFH-0311

Page 2

Options

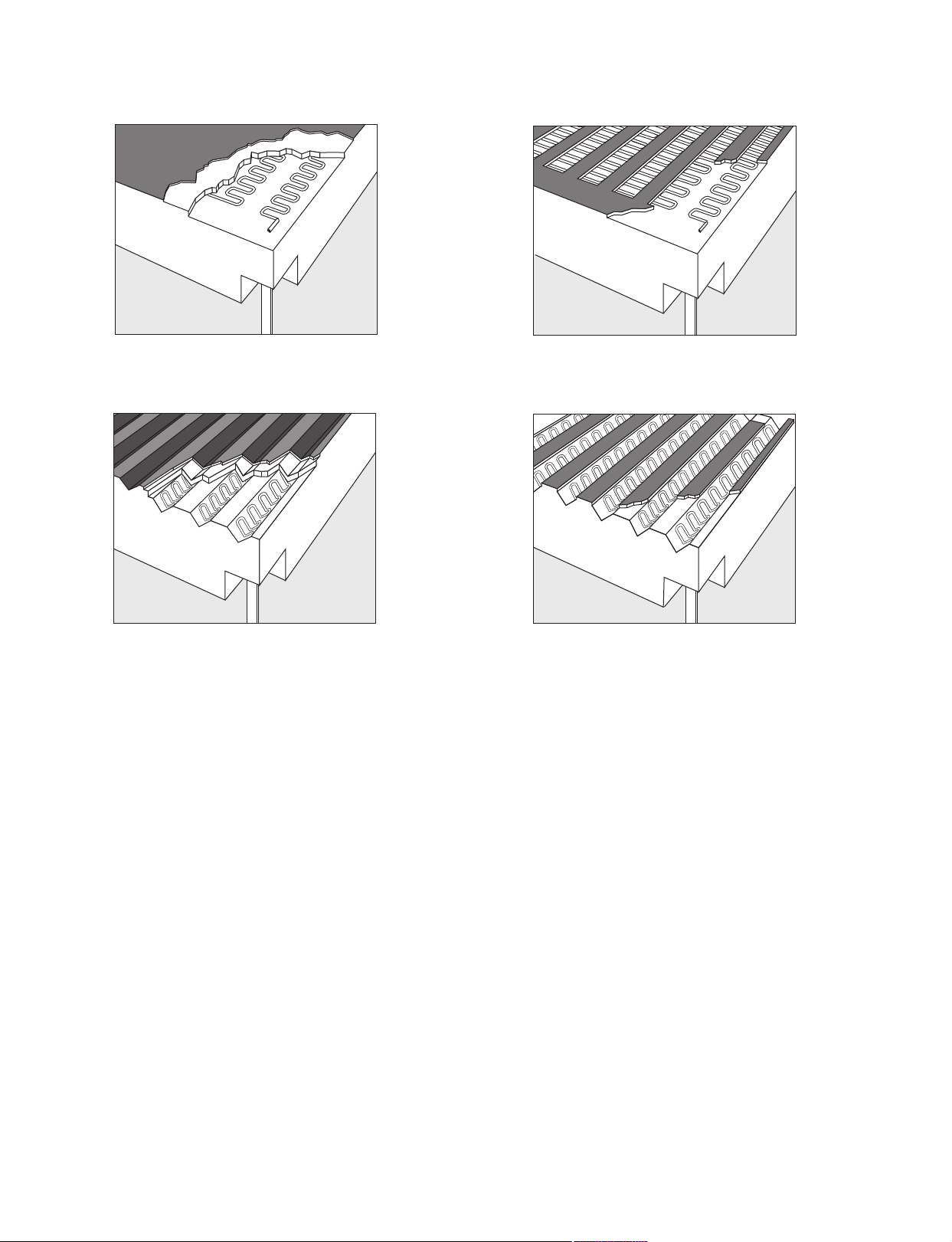

Embedded Sinuated Elements

Exposed Sinuated Elements

Flat Sinuated

V-Sinuated

• Available in either flat or V-sinuated element configurations

• An advanced V-sinuated element configuration allows up

to 27 percent additional watt density over embedded flat

sinuated elements

• Performs best at medium to high temperatures at medium

watt density power requirements

• Use in partially enclosed to fully enclosed applications

• Especially suited for large, flat units; semi-cylindrical units

above 5 in. (125 mm) inside diameter; and full cylinders

above 4 in. (100 mm) inside diameter.

• Offers greater effective insulation thickness than coiled

element designs

• Enhances “heated insulation” concept of operational use

• Features high emissivity coating on new high-watt density

series units.

Flat Sinuated

V-Sinuated

•

Available in either flat or V-sinuated element configurations

• Advanced V-sinuated element configuration allows up to

20 percent additional watt density over that of exposed

flat sinuated elements

• Offers the lowest possible wire-to-chamber temperature

difference for maximum heater life

• Provides optimum heat-up/cool-down and recovery times

as well as maximum efficiency of operation

• Higher current handling capabilities possible

• Minimizes the number of circuits and connections in large

furnaces

• Especially well suited for large, flat surface area units and

large inside diameter curved units

• Exposed elements are available on special order as a

variation of the embedded sinuated element normally

provided on stock and standard units.

Page 3

Style A Lead

(Type 1 or 2 Unit)

Style A

(Type 3 or 4)

Pocket

Cold

Face

Stub

Strip Lead

(add-on)

Vestibule

Style B Lead

(Type 1 or 2)

Style B

(Type 3 or 4)

Style A Lead (Type 5)

Style B (Type 5)

Style A (Type 6)

Style B (Type 6)

Style C (Type 6)

Style A (Type 8)

Style B (Type 8)

Style C (Type 8)

Style C (Type 5)

Pocket

Cold

Face

Stub

Strip Lead

(add-on)

Length

Width

Flexible

Stranded

MGT Insulated

Nickel Lead Wire

(450°C Rated)

Solid NiCr

Wire

Stub on

Heater

in Pocket

(Typ.)

Termination Options

Watlow offers variations of electric leads to meet particular

wiring requirements. To understand the termination options

available, it is necessary to understand the different ways

electrical leads can be applied.

Ceramic fiber heater electrical leads are welded to stubs –

the metal parts that interface between the heating element

wire and the add-on electrical leads. These stubs exit the

heater at the lead pockets. Pockets are small cavities, below

the cold face plane (outside surface) and generally located at

or near the corners.

Watlow ceramic fiber heaters are equipped with either strip

leads or double twisted wire leads. Strip leads are most

commonly used, unless otherwise specified. The various

lead styles refer to the lead’s exit orientation relative to the

pocket used on a given type of heater.

Strip Leads

Flat and semi-cylindrical ceramic fiber heaters are available

with the termination options shown. When ordering

termination options for catalog units, the specific strip lead

Style must be specified. To determine the desired style, refer

to the illustrations shown on this page. Otherwise, Style A

leads will be provided and the length will be 12 in. (305 mm).

Additional lengths are possible using add-on leads, which

are priced per pair, per inch, for the three different widths.

See the ordering charts for data on which lead width is used

on a specific heater.

Strip leads are shipped with a

of the lead. Use #10-24 screws, nuts and washers, or other

wiring connections. Caution should be exercised when

making connections. Leads are susceptible to loosening due

to thermal expansion and contraction as the heater cycles.

Special Lead Orientation

If the various standard strip lead orientations and pocket

configurations are not suitable, special designs are possible.

Leads Bent 90 Degrees

The double twisted leads of full cylinder heaters can be bent

90 degrees to lay into slots and exit to the sides of the unit.

Special Add-On Lead Configurations

The two options illustrated can be welded onto the stub at

the heater pocket, or for a better installation, welded on at

the end of a specified length of the regular strip lead. The

strip lead length can vary from zero to the value necessary to

get away from the hot zone. The length of the add-on lead

option eliminates the need for a custom product and

satisfies a greater range of wiring requirements.

13

⁄64 in. (5 mm) hole at the end

Flat Units

Semi-Cylindrical Units

Page 4

Accessories.

Inside

Outside

Metal Wall

or Shroud

Overall O.D. Head

Overall

Length

Shank

Int.

Ext.

Wire Dia.

Double Twisted

and Flexible Leads

Strip Leads

Ceramic fiber heater orders can also include the following

accessory items.

Rigidizer

Rigidizer is primarily used to recoat soft, cut edges of

ceramic fiber heaters and ceramic fiber insulation panels.

Various degrees of hardening can be achieved with additional

applications.

B.T.E. Closed-End Thermocouple Tubes

Horizontal thermocouple tube between the elements. Two

sizes are available: 0.140 in. (3.6 mm) and 0.265 in. (6.7 mm),

both 6 in. (152 mm) long with closed end.

Black Surface Coat

Black high emissivity coating is used to raise emissivity

closer to 1.0.

Ceramic Tubes

Ceramic tubes are available in four nominal sizes:

and1⁄2 in. (3.2, 6, 9.5 and 13 mm) inside diameter and lengths

of 0.9 in. (22 mm) and 1.9 in. (48 mm) long. Ceramic tubes

have several uses, including thermocouple mounting holes,

mounting pin sleeves and lead coverings.

Dry Heating Surface Mix

Dry heating surface mix is used to make the hot face of all

heaters, including those with the high emissivity coating. It

can also be used with rigidizer to make a very high

temperature paste for touch ups of the hot face area.

Patch Kit

To easily repair small breaks or cracks, the patch kit contains

one pint (0.47 L) of powered ceramic fiber, four ounces (0.118 L)

of black surface coat. Order CFPATCHKIT.

Ceramic Fiber Insulation Blanket

Additional insulation value for ceramic fiber heaters is available

with a ceramic fiber insulation blanket. This 6 lb/ft

ceramic fiber blanket contains no organic binders. It is suitable

for applications up to 2300°F (1260°C) and is sold in full rolls or

cut by the square foot.

Powdered Ceramic Fiber

Powdered ceramic fiber is used primarily to improve surface

finish in critical areas. It can also be used to repair damaged

units by filling voids, cracks and broken corners. Use powdered

ceramic fiber with rigidizer to make an easily applied paste.

High Temperature Coating and Electrical Potting Cement

Two different high purity, high temperature cements have multiple

uses: mount thermocouple tubes, provide extra surface

hardening, bond ceramic fiber gaskets and affix lightweight

ceramic fiber insulation blanket to panels, as well as attach

edge-spacer blocks and custom vestibules.

1

⁄8,1⁄4,3⁄8

3

(96 kg/m3)

Strip Lead Porcelain Bushings

Strip lead porcelain bushings are primarily used to protect heater

power leads when passing through the metal walls and furnace

structures. Bushings are available for use with double twisted

leads and the three standard strip lead widths.

Watlow®is a registered trademark of Watlow Electric Manufacturing Company.

To be automatically connected to the nearest North American Technical Sales Office:

1-800-WATLOW2 • www.watlow.com • inquiry@watlow.com

International Technical Sales Offices: Australia, +61 3 9335 6449 • China, +86 21 3381 0188 • France, +33 1 41 32 79 70

Germany, +49 (0) 72 53 / 94 00-0 • Italy, +39 024588841 • Japan, +81 3 3518 6630 • Korea, +82 2 2628 5770

Malaysia, +60 3 8076 8745 • Mexico, +52 442 217 6235 • Singapore, +65 6773 9488 • Spain, +34 91 675 12 92

Taiwan, +886 7 288 5168 • United Kingdom, +44 (0) 115 964 0777

Loading...

Loading...