Page 1

Coil/Cable Heaters

Low Mass with

High Versatility

The versatile Watlow® coil/cable heater can be formed into

a variety of shapes. Small diameter, high performing cable

heaters are fully annealed and readily bent to a multitude of

configurations.

The heater can be formed into a compact, coiled nozzle

heater supplying a full 360 degrees of heat with optional

distributed wattage. A straight cable heater can snake

through an equipment application. Flat, spiral configurations

can be used in high-tech manufacturing while a star wound

cable can be used for air and gas heating.

Different applications require different construction

methods, including one, two or four resistance wires;

parallel coil or straight wire; drawn or swaged sheaths; with

or without internal thermocouples; leads exiting from one

or both ends, and round, rectangular or square cable cross

sectionals.

Whatever the application requirement, a Watlow coil/cable

heater can be shaped to fit.

Performance Capabilities

• Continuous operating temperatures up to 1200°F (650°C)

with intermittent operating periods achieving up to 1500°F

(815°C) dependent on the type of element wire used

• Sheath watt densities on the cable to 30 W/in2

(4.65 W/cm2), and as high as 75 W/in2 (11.62 W/cm2)

subject to factory approval

• Maximum voltage up to 240V

Features and Benefits

High ductility

• Allows the heater to be cold-formed into almost

any shape

Low mass

• Allows quick response in both heating and cooling

Constructed with no open seams

• Enables operation in unusual environments, including

cryogenic and sub-freezing temperatures, high vacuum,

gaseous and liquid immersion heaters

• Decreases opportunity for corrosion

Straight Resistance Wire

OR

Welded

End Cap

Compacted MgO by

Swaging or Drawing

Sheath

With or Without a No-Heat Tail Section

Swaged Adapter

Crimp Ring

Parallel Coiled

Resistance Wire

Optional SS Hose

Lead Protection

Lead Wires

Constructed of standard 304 stainless steel, optional

316 stainless steel or alloy 600

• Provides high-temperature corrosion and oxidation

resistance along with ideal expansion properties

Heater sheath can be brazed

• Allows the permanent attachment of mounted fittings to

the heater, contact a Watlow representative for further

information

Sizes range from 0.040 in. (1.02 mm) to 0.188 in.

(4.8 mm) diameter

• Delivers a high volume of heat into a tiny space

Internal construction options

• Allows internal thermocouples and no-heat sections (not

available in all sizes)

©2013 Watlow Electric Manufacturing Company, all rights reserved.

®

STL-CAB-0813

Page 2

Typical Applications

• Plastic injection molding nozzles

• Semiconductor manufacturing and wafer processing

• Hot metal forming dies and punches

• Sealing and cutting bars

• Medical, analytical and scientific instruments

• Restaurant and food processing equipment

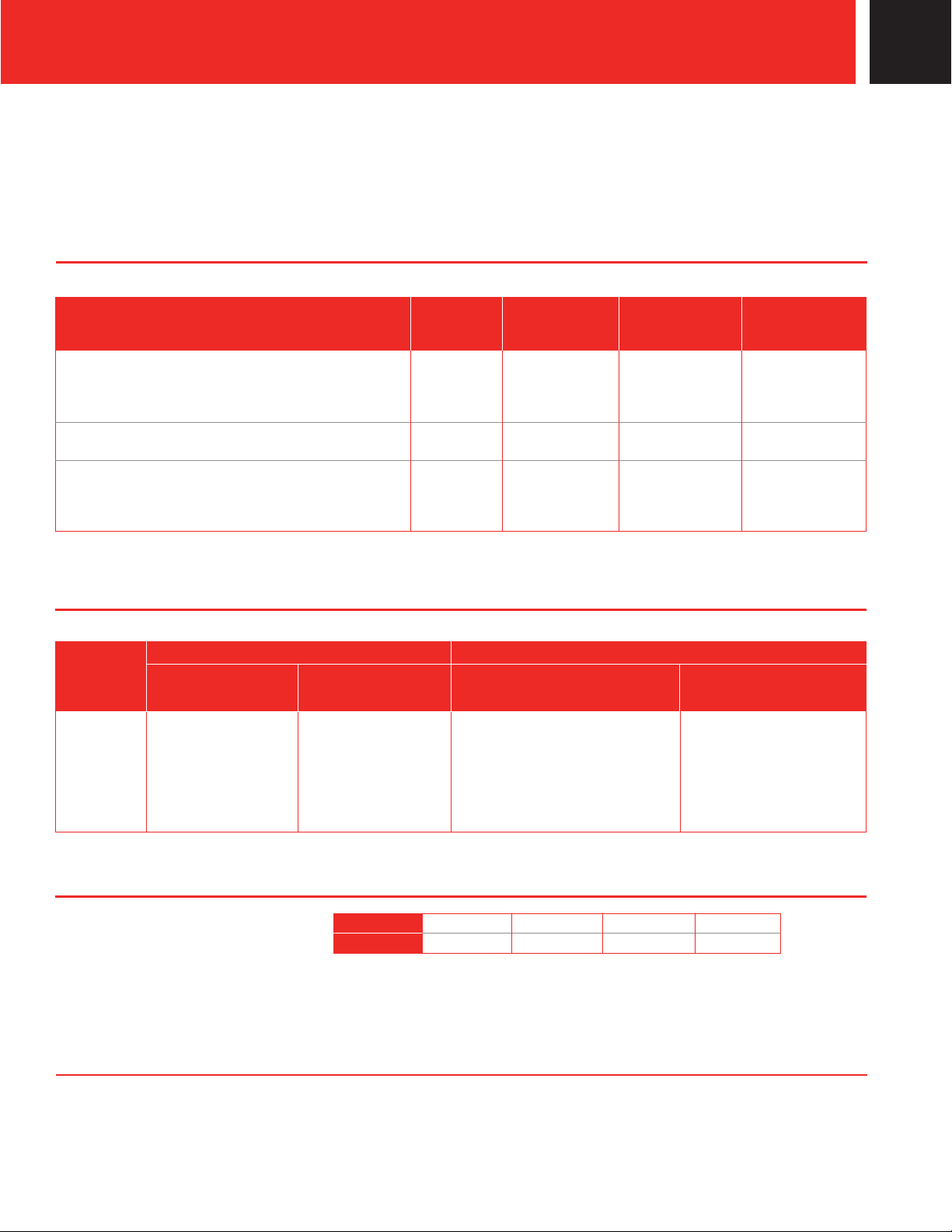

Electrical Data and Coiling Limits

Sheath Surface Area Per Min. Bend Min. Coiled

Diameter Max. Linear Foot Radius Inside Diameter

in. (mm) Voltage in. (cm) in. (mm) in. (mm)

0.040 ± 0.002 (1.016 ± 0.051) 48 1.51 (9.740) 1/16 (1.6) 1/8 (3.2)

0.062 ± 0.002 (1.575 ± 0.051) 120 2.34 (15.098) 1/8 (3.2) 1/4 (6.0)

0.094 + 0.002 - 0.003 (2.388 + 0.051 - 0.076) 240 3.54 (22.840) 3/16 (4.8) 3/8 (9.5)

0.102 square ± 0.003 (2.591 ± 0.076) 240 4.90 (31.615) 1/4 (6.0) 1/2 (13.0)

0.102 ± 0.003 x (2.591 ± 0.076) x

0.156 ± 0.005 rectangular (3.962 ± 0.127) 240 6.19 (39.938) 1/4 (6.0) 1/2 (13.0)

0.125 ± 0.003 (3.175 ± 0.076) 240 4.71 (30.389) 1/4 (6.0) 1/2 (13.0)

0.157 ± 0.004 (3.988 ± 0.102) 240 5.92 (38.196) 5/16 (7.9) 5/8 (15.9)

0.188 + 0.003 - 0.006 (4.775 + 0.076 - 0.152) 240 7.09 (45.745) 3/8 (9.5) 3/4 (19.0)

0.128 square ± 0.003 (3.251 ± 0.076) 240 6.31 (40.712) 1/4 (6.0) 1/2 (13.0)

In most cases 30 W/in2 (4.65 W/cm2) is the safe allowable limit for cable watt density. Please contact your Watlow representative prior to

ordering >30 W/in2 cables.

Resistance/Wattage Tolerance ±10%.

Cable heaters can run on both ac and dc. Contact your Watlow representative for amperage limitations.

• Cast-in heaters

• Laminating and printing presses

• Air heating

• Textile manufacturing

• Heating in a vacuum environment

Coiling Tolerances

Coiled Width Tolerances Coiled I.D. Tolerances

Cable

Diameters

All Diameters Below 6 (152) + 0 - 1/8 (+0.00 - 3.18) Below 0.625 (Below 15.88) +0.000 - 0.015 (+0 - 0.38)

6 to 10 (152 to 254)

Over 10 (Over 254)

2.000 to 2.999 (51 to 76.18) +0.000 - 0.125 (+0 - 3.18)

3.000 to 3.999 (76 to 101.58) +0.000 - 0.250 (+0 - 6.35)

4.000 to 4.999 (102 to 126.98) +0.000 - 0.375 (+0 - 9.53)

5.000 and Over (127 and Over) +0.000 - 0.500 (+0 - 13.00)

When the O.D. of the coil is required as the critical dimension, it must be specified at the time of ordering so that proper coiling procedures can

be determined. I.D. and O.D. dimensions cannot be held on the same unit. Please contact your Watlow representative prior to ordering coiled

cable heaters requiring other than standard tolerances.

in. (mm) in. (mm) in. (mm) in. (mm)

Cable Straight Length Tolerances

Coiled Width Tolerances Coil I.D. Range Tolerances

+ 1/8 - 3/8

(+3.18 - 9.53) 0.625 to 0.999 (15.88 to 25.38) +0.000 - 0.030 (+0 - 0.76)

+ 1/4 - 1/4

(+6.35 - 6.35) 1.000 to 1.999 (25 to 50.78) +0.000 - 0.062 (+0 - 1.58)

Length

Tolerance

≤ 24 in. >24 in. ≤ 60 in. >60 in. ≤ 100 in. >100 in.

±3/8

in. ±1/2

Watlow® is a registered trademark of Watlow Electric Manufacturing Company.

in. ±1 in. ±1%

To be automatically connected to the nearest North American Technical Sales Office:

1-800-WATLOW2 • www.watlow.com • inquiry@watlow.com

International Technical Sales Offices: Australia, +61 3 9335 6449 • China, +86 21 3532 8532 • France, +33 1 41 32 79 70

Germany, +49 (0) 72 53 / 94 00-0 • India, +91 40 6661 2700 • Italy, +39 024588841 • Japan, +81 3 3518 6630 • Korea, +82 2 2628 5770

Malaysia, +60 3 8076 8745 • Mexico, +52 442 217 6235 • Singapore, +65 6773 9488 • Spain, +34 91 675 12 92

Taiwan, +886 7 288 5168 • United Kingdom, +44 (0) 115 964 0777

Loading...

Loading...