Page 1

W A T L O W

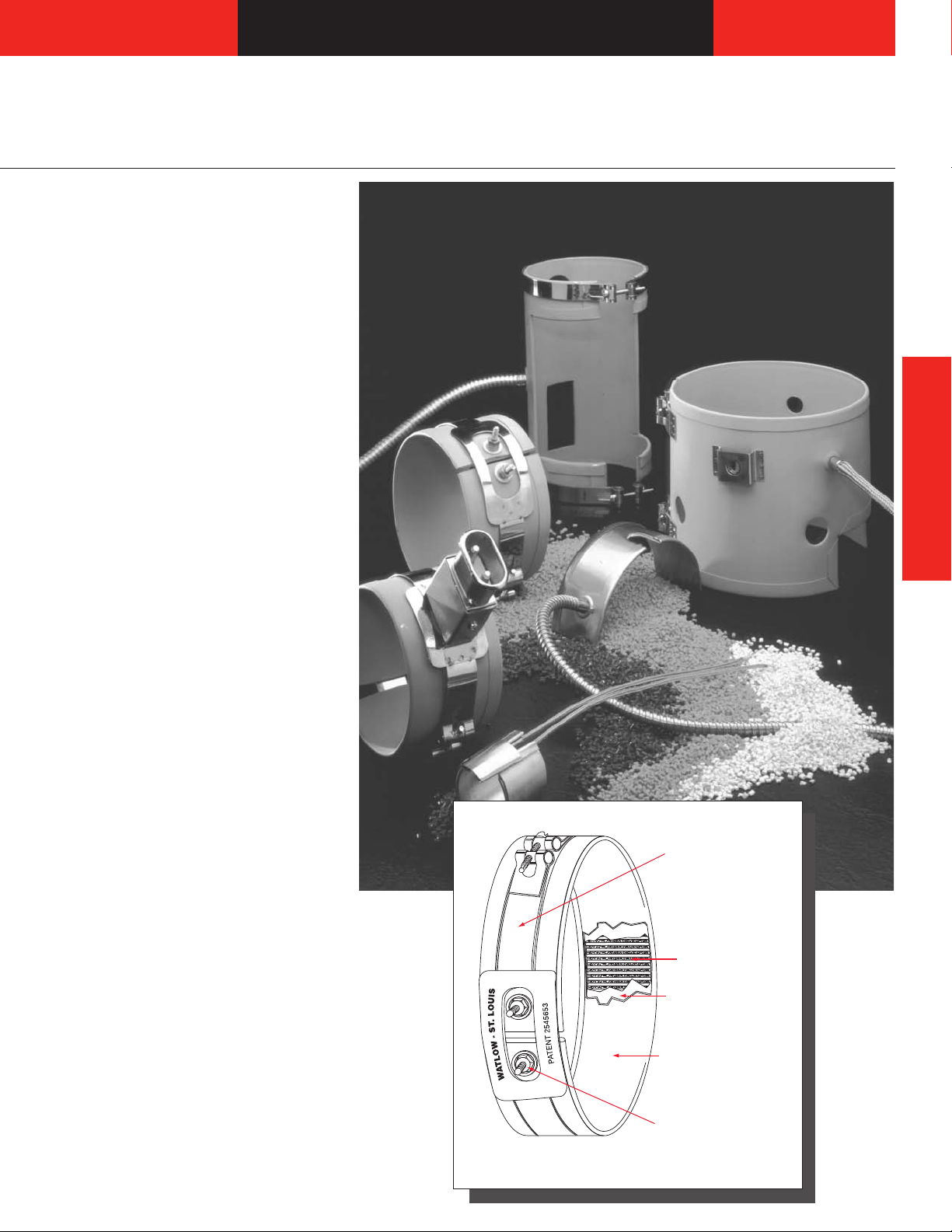

SST. Strap

Resistance Ribbon

Mica Insulation

Zinc Steel

Post Terminals

Band Heaters

Special Mica

Barrel and Nozzle

For over 80 years, Watlow has been

solving complex and unique

application problems with standard

mica barrel and nozzle heaters.

Watlow is continuously improving

design and application knowledge

through engineering expertise and

experience with numerous OEM and

end-user applications.

This has resulted in the development

of many specialty variations in

construction resulting in the best

heat solutions. This catalog contains

a sampling of what can be done.

Please contact a local Watlow sales

engineer for custom applications.

Performance Capabilities

• Sheath temperatures to 480°C

(900°F)

• Watt densities to 55 W/in

(8.5 W/cm2)

Features and Benefits

UL®component recognition

• Available for applications up to

480°C (900°F)

Patented clamping strap

• Assures efficient heat transfer

w mass design

Lo

• Allows fast heat-up and quick

response

Design variations

• Provides user convenience and

heater protection

Applications

• Extruders

• Blown film dies

• Injection molding machines

• Other cylinder heating

applications

2

Band Heaters

UL®is a registered trademark of

Underwriter’s Laboratories, Inc.

1

Page 2

20 30 40 50

Watt Density—W/in

2

700

500

300

800

900

1000

1100

600

400

200

10 60

500

400

300

200

24 68

100

Cylinder Temperature—°F

Cylinder Temperature—°C

Watt Density—W/cm

2

10 in. (254 mm) Dia.

3 in. (76.2 mm) Dia.

1

1

/

2

in. (38.1 mm) Dia.

Band Heaters

Special Mica

Barrel and Nozzle

Applications and Technical Data

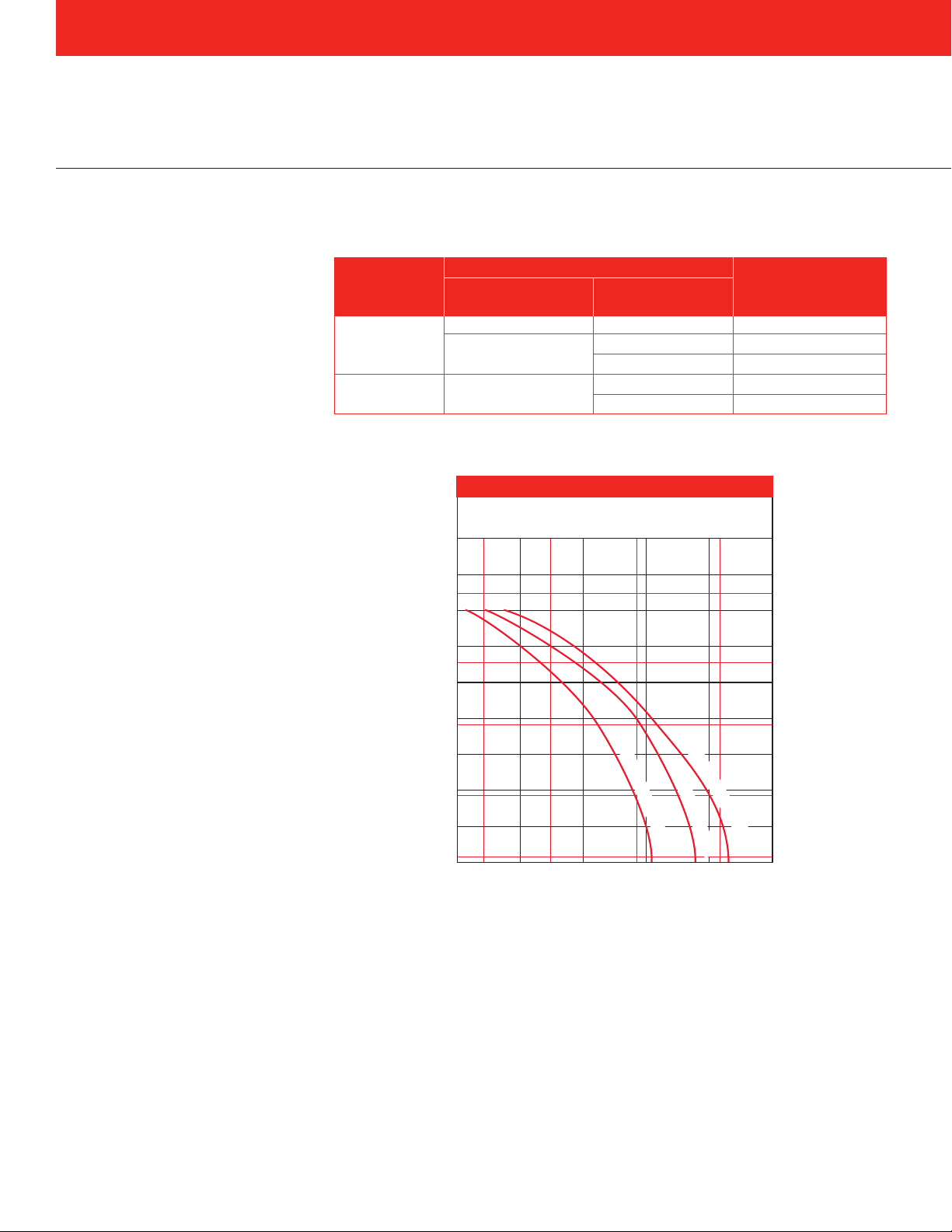

Operating Factors

Use lowest watt density per the graph

below. A close match of the heat

supplied to the actual requirements will

reduce temperature over-shoot, reduce

cycling and increase the life of any

band heater used.

Calculate the

for the heater using:

Heated Area x Maximum

Watt Density

Calculate the heated area of the band

heater by subtracting the no-heat area

from the total area in contact with the

cylinder (3.14 x I.D. x width). Subtract

the no-heat area at the terminals

(from table) and any additional

no-heat area caused by holes, slots

or oversize gaps.

Determine the maximum watt density

of the heater from the Maximum

Allowable Watt Density graph.

The curves are based on narrow

heaters mounted on a smooth, steel

cylinder. Apply the necessary

correction factors:

• For heaters 21⁄4 inches (57 mm) to

ve inches wide (127 mm), multiply

fi

watt density by 0.8.

• For high expansion cylinders

(aluminum or brass), r

watt density by 3 W/in2(0.46 W/cm2).

• For heaters 21⁄4 inches to five inches

wide installed on a high expansion

cylinder, reduce watt density by a

total of 3 W/in2(0.46 W/cm2) only.

•

For r

than smooth, machined finish,

reduce watt density by 3 W/in

(0.46 W/cm2).

• For heaters that will be insulated

or enclosed, contact Watlow for

specific watt densities.

safe maximum wattage

egular cylinder sur

educe the

faces other

2

No-Heat Area for Special Mica Band (Post Terminals)

Heater Size No-Heat Area

Heater

Type in. (mm) in. (mm) in. (mm)

One Piece

Two Piece 3 (76.2) or more

Diameter Width

Less than 2 (50.8) Up to 6 (152.4) 1 (25.4) x width

2 (50.8) or more

MMaaxxiimmuumm AAlllloowwaabbllee WWaatttt DDeennssiittyy

Up to 3 (76.2) 11⁄2 (38.1) x width

More than 3 (76.2) 1 (25.4) x width

Up to 3 (76.2) 3 (76.2) x width

e than 3 (76.2) 2 (50.8) x width

Mor

at Terminals

2

Page 3

W A T L O W

Band Heaters

Special Mica

Barrel and Nozzle

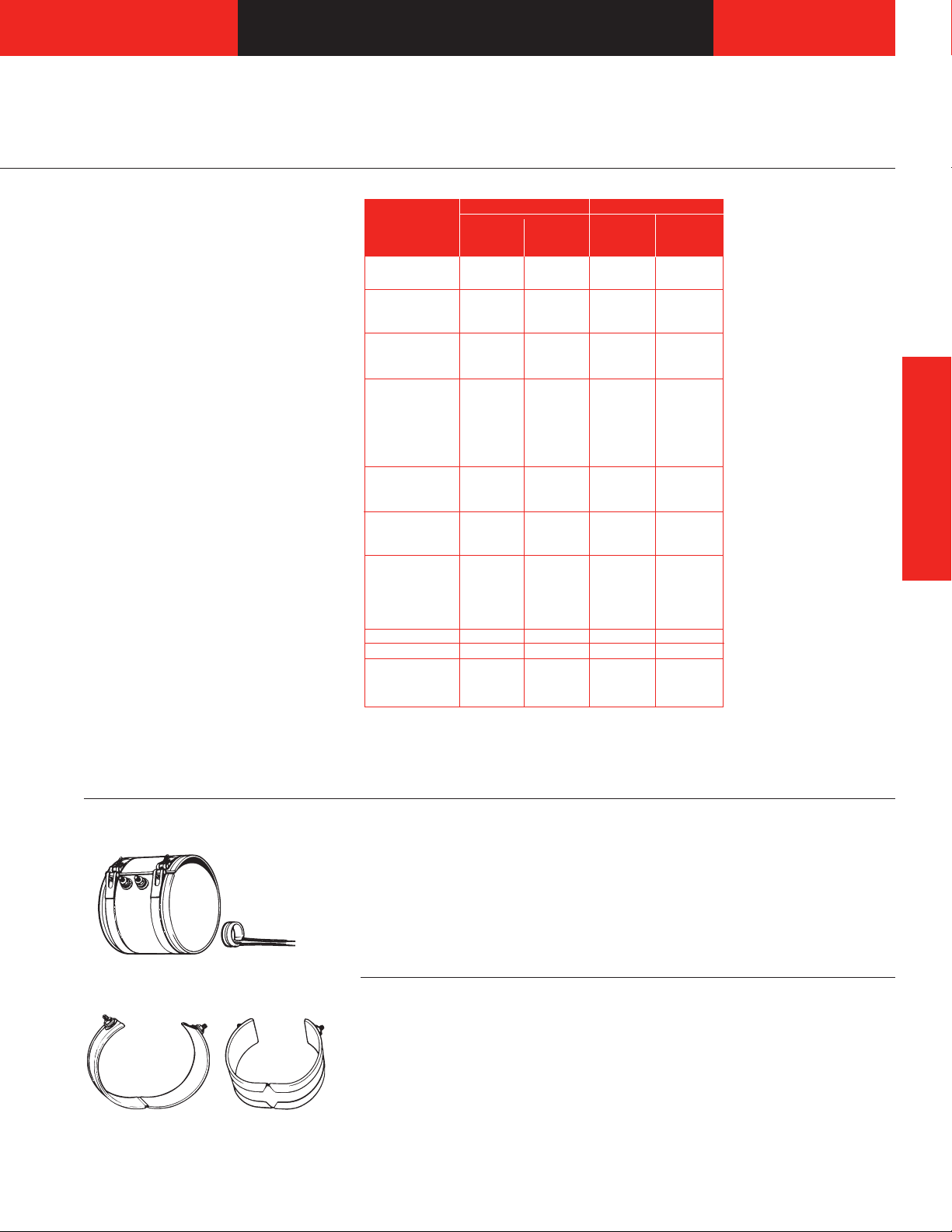

Physical Limitations of Variations

Check the table to be certain the

variations and lead arrangements

being ordered are available on the

heater size required. If you need to

exceed any limitations, please

contact a Watlow representative.

hysical Limitations of Variations

P

Heater Type Min. Max. Min. Max.

1 pc. 15⁄16 (33.3) 22 (559)

2 pc. 3 (76.2) 44 (1117)5⁄8 (15.8) 15 (381)

Expandable:

Narrow 13⁄4 (44.4) — — 1 (25.4) 3 (76.2)

Wide 13⁄4 (44.4) — — 2 (50.8) 6 (152.4)

O.D. heater

1 pc. 3 (76.2) 22 (559) 1 (25.4) 6 (76.2)

2 pc. 3 (76.2) 44 (1117) 1 (25.4) 6 (76.2)

Type K leads

Type L leads

Type E leads 1

Type F leads 11⁄2 (38.1) 22 (559)

Type H leads 11⁄2 (38.1) 22 (559)

Type B leads 11⁄2 (38.1) 22 (559)

Post terminals 15⁄16 (33.3) — — 1 (25.4) 15 (381)

Type A leads

Type C leads 1

Terminal box 31⁄2 (88.9) — — 13⁄8 (34.9) 15 (381)

Plug w/bracket 3 (76.2) — — 31⁄2 (88.9) 15 (381)

3-phase — — — — 3 (76.2) 15 (381)

European plug

1 pc. vertical 1

1 pc. horizontal 3 (76.2) 22 (559) 2 (50.8) 15 (381)

2 pc. vertical 3 (76.2) 44 (1117) 1 (25.4) 15 (381)

2 pc. horizontal 3 (76.2) 44 (1117) 2 (50.8) 15 (381)

HV Wedge-Lok 1 (2.5.4) 3 (76.2) 1 (25.4) 6 (76.2)

Clamping tabs 2 (50.8) — — 1 (25.4) 15 (381)

Welded barrel nuts

1 pc. 2 (50.8) 22 (559) 1 (25.4) 15 (381)

2 pc. 4 (101.6) 44 (1117) 1 (25.4) 15 (381)

Diameter Width

in. (mm) in. (mm) in. (mm) in. (mm)

5

⁄8 (15.8) 15 (381)

3

⁄4 (19.05) — — 1 (25.4) 15 (381)

3

⁄4 (19.05) — —

1

⁄2 (38.1) 22 (559)

3

⁄4 (19) — —

5

⁄16 (33.3) — — 1 (25.4) 15 (381)

5

⁄16 (33.3) 22 (559) 1 (25.4) 15 (381)

5

⁄8 (15.8) 15 (381)

5

⁄8 (15.8) 15 (381)

5

⁄8 (15.8) 15 (381)

5

⁄8 (15.8) 15 (381)

3

⁄4 (19.05) 15 (381)

5

⁄8 (15.8) 15 (381)

Band Heaters

Variations

Note: Some combinations of maximum and minimums cannot

occur on the same heater.

Standard gap is 1⁄4 inch (6.35 mm)

Different Widths

The 11⁄2 inch (38 mm) wide heater is

the most ef

ficient due to maximum

clamping action. Heaters are

available in widths from 5⁄8 inch

(16 mm) to 15 inches (381 mm).

Multiple clamping straps ar

for heaters more than three inches

(76 mm) wide.

Expandable Heaters

Heaters three inches (76 mm) wide

or less are constructed with a

notched sheath. Heaters wider than

e constructed with an

ee inches

thr

ar

shipped open and should not be

closed and r

twice. To order, specify

expandable.

expansion seam. These heaters are

eopened mor

ovided

e pr

e than

3

Page 4

Band Heaters

0.625 in.

(16 mm)

1

7

/

16

in.

(37 mm)

3

1

/

2

in. for 3

1

/

2

-5

15

/

16

in. I.D.

4" for 6-39

15

/

16

in. I.D.

1

13

/

16

in.

(46 mm)

Special Mica

Barrel and Nozzle

Variations

Continued

Holes and Notches

An economical way to provide

access for instrumentation is to

specify an oversize gap between

the heater ends. Holes and notches

in the sheath should be specified

only when all the cylinder surface

adjacent to the hole or notch must

be heated. Required holes may be

provided in nearly any location as

Two Piece Band Heaters

long as there is at least one inch

(25 mm) between the hole and one

side of the heater. Standard hole

sizes up to two inches (51 mm)

diameter. For proper hole and/or

notch location, a

dimensional

drawing or customer supplied

sample heater is required.

Two-piece construction is available

on heaters three inches (76 mm) or

greater in diameter. Heaters three

inches wide or less with post

terminals have one terminal on each

end. Heaters over three inches wide

with post terminals have the two

terminals side by side on one end.

On two-piece units with leads, also

specify the power supply voltage. The

power supply voltage is the voltage to

Outside Diameter

This variation is specially designed

and constructed to heat the inside

diameter of cylinders, i.e., large

diameter blown film dies. All the

terminations and mounting hardware

are located on the I.D. of the heater.

which the heater will be wired. For

example, a two-piece band that is

240VÅ(ac) per half may be wired in

series to a 480VÅ(ac) power supply.

In this case the band heater lead wire

insulation must be rated for

480VÅ(ac). To order, specify two

piece band heater, with volts and

watts per half and power supply

voltage.

Consult W

and terminations.

atlow for available sizes

To order, specify

outside diameter heater.

4

Metallic Terminal Box

erminal boxes are attached to the

T

heater to cover the terminals for an

added safety feature. Conduit may

be attached to the box through 7⁄8

inch (22 mm) diameter holes in the

ends of the box. T

erminal box is

available on two-piece heaters.

When ordering, specify

terminal

box.

Page 5

W A T L O W

13/4 in.

(

44 mm)

25/16 in.

(

59 mm)

21/

1

6

in.

(

52 mm)

21/4 in.

(57 mm)

113/

1

6

in.

(

46 mm)

15/

1

6

in.

(33 mm)

Band Heaters

Special Mica

Barrel and Nozzle

Variations

Continued

High Temperature “Quick Disconnect” European Style Plugs

These plugs provide the simplest

and safest way to apply power to

band heaters. The combination of

high temperature male and female

quick disconnect plug assemblies

eliminates all live exposed terminals

and electrical wiring that can be a

potential hazard to employees or

machine. Maximum 15 amps at

Å(ac), maximum 240 volts.

240V

To order, specify vertical or

horizontal European plug.

Band Heaters

Vertical

Right Angle

Code # N6027AF049

Horizontal

Code # N6027ZZ028

Special Construction Variations

Straight

High Temperature “Quick Disconnect” European Style Female Adapters

Available as an accessory item that

must be used in conjunction with

high temperature “quick

disconnect” European style plugs.

Specify code number N6027AF049

or N6027ZZ028 and quantity.

Ceramic Terminal Covers

Stock Option

A convenient and economic way to

insulate post terminals and are

sized for standard length posts.

Ceramic terminal covers also have

a 10-24 screw thread size. These

are supplied as an accessory item

. Specify

Square,

Code # Z-4918

Rectangular and He

and shipped separately

Z-4918 and quantity.

x Bands

Squar

e and r

ectangular heaters are

made in either one or two-piece

construction. These units are ideal

for heating dies on plastic extruders

or the barr

extruders. Hex-shaped heaters are

commonly used on the hex-shaped

els of twin scr

ew

tion of the nozzle injection

por

molding machines. Hex-shaped

heaters are made to exact customer

cations. To order, specify

specifi

square or rectangular heaters. A

dimensional drawing or customer

supplied sample heater is

required.

5

Page 6

Band Heaters

Designed to Accomodate

Standard Bayonet Adapter

Figure 1 Figure 2 Figure 3

"

B"

"A"

"B"

"

A"

"B"

"

A"

Special Mica

Barrel and Nozzle

Special Construction

Variations

Continued

Square, Rectangular and Hex Bands (continued)

Clamping Styles

The preferred clamping style is

illustrated in Figure 1 showing bentup flange clamping. This clamping

style applies a uniform clamping

force at the corners.

Figure 2 shows bent-up flanges or

built-in strapping bracket at the

side.

The least preferred clamping style is

shown in Figure 3. The one-piece

heater does not apply a uniform

clamping force.

Hinged Two-Piece Band

The hinged, two-piece band heater

is connected with a reinforced

hinge. It can be opened and closed

as often as necessary resulting in

easy installation and removal.

To order, specify

hinged two-piece

band and watts and volts per each

half.

6

Thermocouple Bracket

The thermocouple bracket

simplifies the installation of an

external thermocouple with a

bayonet adapter. The standard

location for the adapter is 90

degrees from the gap. Sizes

available are 1⁄8 (3.18 mm),

1

⁄4 (6.3 mm) and 3⁄8 (9.53 mm)

To order, specify thermocouple

bracket.

Page 7

W A T L O W

Top ID

B

ottom ID

Height

1 to 3 in.

Diameter

Less than 2 in. wide:

5

/

16

in. (8 mm)

More than 2 in. wide:

1

1

/

3

2

in. (9 mm)

in. (14 mm)

9

/

16

0.563 in.

(14 mm)

Spot Welded

Band Heaters

Special Mica

Barrel and Nozzle

Special Construction

Variations

Continued

Clamping Variations

Cone Shapes

Cone shaped heaters are ideal for

applications where heat is required

for hoppers or funnels. The

preferred method of attachment is

with bent-up flange clamping. Cone

shaped heaters are made to exact

customer specifications.

To order, specify

cone shape

adapter. A dimensional drawing

or customer supplied sample

heater is required.

HV Wedge-Lok

HV wedge-lok is designed to

provide excellent clamping where

mounting space is limited. It is available with Type A and L leads only.

Clearance from I.D. of the heater to

the outside edge of the wedge-lok is

5

⁄16inch (8 mm) nominal. Available on

certain sizes from stock. To order,

specify

HV wedge-lok.

Band Heaters

Standard and Low-Profile

Clamping Strap

The standard clamping strap

requires 9⁄16 inch (14 mm) clearance

above the heated surface, at the

barrel nuts. When clearance is

limited, smaller barrel nuts can be

used which require only 3⁄8 inch

(9 mm) clearance. The clearance

required by the clamping screw

Welded Barrel Nuts

An ideal way to provide access

for instrumentation is to specify an

oversized gap between the heater

es

ends. If the clamp strap inter

fer

with the positioning of the

instrumentation device,

depends on the screw length and

the diameter of the heater. The lowprofile clamping strap is standard on

units less than 13⁄8 inches (45 mm)

wide and utilizes a 1⁄2 inch (13 mm)

wide strap. Consult Watlow for more

information. To order, specify low-

profile clamping strap.

welded barrel nuts are recommended.

Maximum gap is one inch (25 mm)

Specify

welded barrel n

dimensional location

uts with

and gap

dimension when ordering.

7

Page 8

Band Heaters

(19 mm)

in. (11 mm)

(11 mm)

1 in.

(25 mm)

(17 mm)

3

/4 in.

7

/16 in.

11

/16 in.

7

/

16

A

s required

Clamping Pad

Special Mica

Barrel and Nozzle

Clamping Variations

Continued

Non-Stock Option

Clamping Tabs

Tabs—or lock-up flanges—are

available. However, the special mica

band heater and strap design

provides superior clamping and

improved heat transfer and should

be used whenever possible. To

order, specify

clamping tabs.

Clamping Pads

Clamping pads have a hole to allow

easy fastening to machine barrel.

Clamping pads are used when an

obstruction hinders a standard

clamping strap from fitting

completely around the machine

barrel.

To order, specify

clamping pads

and degrees coverage.

Termination Variations

Post Terminal Options

Standard post terminals have a

7

threaded length of

and require

3

⁄16 inch (11 mm)

⁄4 inch (19 mm)

clearance from the cylinder.

Terminals with 11⁄16 inch (17 mm)

threaded lengths are available that

r

equire one inch of clearance. Button

terminals require only 7⁄16 inch (11 mm)

clearance. Maximum amperage for

post ter

minals is 35 amps. To order,

specify standard, long or button

terminals.

Three-Phase or Dual Voltage

A third terminal can be added

to provide dual voltage or

three-phase.

Standard terminal location on

heaters three inches (76 mm) wide

or less is one terminal at each end

of the heater centered on the width.

Standard

Long

Button

On heaters thr

, the ter

wider

ee inches wide or

minals ar

e located

side-by-side on one end. Special

minal locations are available. To

ter

or

der

, specify

dual v

olta

e

g

or

three-phase.

8

Page 9

W A T L O W

0.38 in.

(9 mm)

0.30 in

(8 mm)

Band Heaters

Special Mica

Barrel and Nozzle

Termination Variations

Continued

Heaters rated at less than 250 volts

use UL

for operations to 250˚C (482˚F) as

standard. Lead insulation UL®rated

for operation to 450˚C (850˚F) may

be required in high temperature

applications where the leads are

shrouded or enclosed with the

heater. All heaters rated at more

than 250V

®

approved lead insulation

Å(ac) use this wire.

Type B

Two fiberglass-insulated lead wires

exit in a single metal braid for good

abrasion protection, lead flexibility

and wiring convenience. Leads are

two inches (51 mm) longer than

braid. To order, specify

and length.

Type E

Type B

Type C

Two fiberglass lead wires exit a

single tightly woven metal braid for

good abrasion protection, lead

flexibility and wiring convenience.

Leads are two inches (51 mm)

longer than the braid. To order,

specify

Type F

Type C and length.

Band Heaters

Loose metal braid encloses two

fiberglass leads for good abrasion

protection, lead flexibility and wiring

convenience. Leads are two inches

(51 mm) longer than the braid. To

order, specify

Type H

A stainless steel, fl

encloses the leads for superior

mechanical protection where lead

abrasion is a par

Leads are two inches (51 mm)

longer than the conduit. To order,

specify Type H

Type E and length.

exible conduit

ticular pr

and length.

oblem.

Loose fiberglass sleeving encloses

berglass leads for additional

two fi

insulation protection where high

temperature or minor abrasion is

Leads ar

esent.

pr

(51 mm) longer than the sleeving. To

order, specify T

Type K

Flexible lead wires exit vertically

from the heater. These leads can be

bent adjacent to the heater for a

quick and easy connection. To

order, specify Type K and length.

e two inches

ype F

and length.

9

Page 10

Band Heaters

11/4 in.

(32 mm)

1

1

/4

in.

(32 mm)

15/8 in.

(41 mm)

1

/2 in. N.P.T.

Special Mica

Barrel and Nozzle

Termination Variations

Continued

Right Angle Armor Cable

Armor cable provides superior

protection to lead wires where

abrasion can cause damage. The

standard leads are 12 inches

(304.8 mm) of armor cable over

14 inches (355.6 mm) of flexible

Removable Armor Cable

leads. Right angle armor cable is

available on any clamping or

construction variation.

To order, specify

.

cable

right angle armor

Installation Procedures

1.Install heaters over a clean

surface.

Install clamp straps, tightening

2.

until screw cannot be tightened

additionally. On heaters with

multiple straps, alternately tighten

each strap until no additional

tightening occurs.

3.To insure that the heater is

properly seated on the barrel, it is

advisable to tap around the

circumference of heater with a soft

mallet. This will result in a final

ming of the heater to the

confor

cylinder. Generally after this is

done, operators can get an

additional tur

n or two on the

Removable armor cable is

recommended on applications

where removable armor is required.

It is available on any clamping or

construction variation. The fitting will

clamp screw. Each screw should

have an ultimate torque value as

in below chart.

4.When installing terminal lugs,

torque the top nut to 12 in.-lbs.

The bottom nut should be held

by a wrench when tightening the

top nut.

5.After the machine has been run

accept the standard armor cable

connector. The standard flexible

leads are 14 inches (355.6 mm).

To order, specify removable armor

cable.

Note: This retightening must be

done when the heaters are cold. If

the heater becomes loose due to

normal operating and cycling the

strap can be r

although frequent adjustments are

not advisable. It is advisable to

check bands for tightness every

three to four months.

for its initial heat up, it is

advisable to retighten the

clamping bands.

Clamp Strap Torque Specifications

Strap Width Strap Allen Pan Head

in. (mm) Screw Type Type

7

⁄8 (22.2)

5

⁄8 (15.8) 10 - 24 30 - 35 lb/in 30 - 35 lb/in

1

⁄2 (12.7) 8 - 32 25 lb/in 25 lb/in

10 - 24

60 - 75 lb/in

30 - 35 lb/in

etightened,

10

Loading...

Loading...