Page 1

Modular and Scalable

“N

ow With

690VAC

for 60-700A

Models”

“N

ow With

690VAC

for 60-700A

Models”

Power Controller Family

Ideal for a Wide Range of

Applications

SPECIFICATION SHEET

ASPYRE® Power Controllers

Watlow’s new ASPYRE® power controller family is flexible

and scalable, and available with a variety of options allowing

one platform to be re-used across a wide range of applications,

which can help save time and money. ASPYRE models

available include sizes from 35 to 700 amps.

This power controller family features multiple advanced

microprocessor-based firing and control mode algorithms.

Combined with diagnostics and several communications

options the product enables equipment and factory

automation.

Controller firing modes include zero cross, burst firing,

single cycle, delayed triggering and phase angle. These

smart algorithms enable the product to easily control a

wide base of heater loads including nichrome, moly,

silicon carbide, tungsten quartz and infrared lamps and

transformer-coupled loads.

ASPYRE offers a comprehensive list of modular options that

deliver space and labor savings including controlled legs

(1, 2 or 3), semiconductor fusing, load current measurement,

amperage size and user interface.

Features and Benefits

Heater bakeout

• Protects heater on start up

• Eliminates labor and time associated with checking for

wet heaters

Integrated semiconductor fusing, current transformer and

user interface

• Saves installation time and eases setup and commissioning

• Delivers a user-friendly, intuitive interface

Industry-leading design and serviceability

• Offers a robust SCR design to meet a rugged industrial

environment’s high quality and reliability needs

• Provides quick and easy access to maintain and service

fuses and individual legs in minimal time

• Enables fast troubleshooting by providing helpful thermal

system diagnostics

Comprehensive power controller range

• Provides wide range of options from simple single-phase to

complex three-phase loads to 690V

100KA short circuit current rating (SCCR)

• Enables greater protection in the event of a short circuit

c-UL® 508 Listed

• Shortens project schedules, agency testing and expenses

Control modes: contactor, voltage, current or power

• Satisfies a wide range of demanding thermal applications

Load firing modes: zero-cross, burst fire, phase angle, soft

start, half-cycle, single-cycle, delayed triggering

• Handles a wide range of load types including nichrome,

medium and long waveform infrared lamps, moly

(Kanthal® Super), transformers, silicon carbide, UV lamps

and tungsten

• Protects and extends the life of connected loads

Wide range of communication protocols

• Enable factory and process automation with connectivity

access to process and equipment data using Modbus® RTU,

Modbus® TCP, EtherNet/IP™, Wi-Fi, Profibus, Profinet,

USB device (configuration and data file transfers)

Open heater and shorted SCR indication

• Minimizes production downtime with easy to understand,

intelligent, troubleshooting diagnostics

Integrated USB and user interface for configuration

• Easily and safely program configuration settings as the user

interface can be powered through USB connection

• Eliminates a user from having to work in a high voltage

hazard environment. High voltage to controller or

system panel can be turned off while setting controller

configuration

Typical Applications

• Furnace and ovens • Oil and gas

• Autoclaves • HVAC

• Kilns • Textiles

• Heat treatment • Plastics

• Glass industry • Packaging

• Semiconductor • Petrochemical

• Power generation • Dryers and curing

Page 2

Specifications

Power Bases

• Single-phase, 1 controlled leg (2 SCRs)

• Three-phase, 2 controlled legs (4 SCRs)

• Three-phase, 3 controlled legs (6 SCRs)

Load Amp Range

• 35A to 700A @ 40°C ambient

• Amperage derating curve for other ambient temperatures

SCR and Amperage Rating

• Latching current 1A min.

• Power dissipation: approximate 1.25 to 1.5 watts per amp

per controlled leg

• Leakage current: 15mA

• SCCR rating 100,000A up to 600VAC

Line and Load Voltage Range

• 24 to 480V

• 24 to 600V

• 24 to 690V

Voltages -/+ 10% min./max.

690VAC only available for 60A and greater models

• Isolation voltage 2500V

Voltage frequency

• 50 to 60Hz

• Automatically compensates for 47 to 70Hz

Controller Operating Supply Voltage

Nominal Line Voltage (VAC) RMS Max. Operating Range

• 100/120VAC • 90 to 135VAC

• 200/208/220/230/240VAC • 180 to 265VAC

• 277VAC • 249 to 305VAC

•

380/400/415/440/480VAC

•

600VAC

•

690VAC

Control Modes and Load Types

• Voltage, voltage squared, current, current squared, power,

open loop and external

• All control modes available with any ring type

combination

• Normal resistive loads: nichrome, infrared lamps;

medium and long waveform

• Others: Moly (Kanthal® Super), transformers, silicon

carbide, UV lamps, tungsten

Digital Inputs 1 and 2

• ON >=4VDC, OFF <= 1VDC

• 4-30VDC @ 5mA max.

• Digital input functions: enable, change to V feedback, local/

remote set point enable, change ring between phase

angle and default ring mode, ref 1 / 2 selection, log enable,

bakeout enable

• A switched VDC control output can be connected to the

digital input as an open loop control mode command signal

Output Control Firing Types

• Zero crossing

• Single cycle

• Burst ring with delayed triggering, safety ramp and peak

current limit options

• Burst ring with soft start option (phase angle soft start

switching over to burst ring)

• 342 to 528VAC

• 540 to 660VAC

• 621 to 759VAC

Output Control Firing Types (Con’t)

• Phase angle with soft start option

• 1-phase models will include phase angle ring

• 2-phase models are not available with phase angle ring

• 3-phase models from 60 to 500 amps will include phase

angle ring

• 3-phase models from 35 to 40 amp are not available with

phase angle ring

• All models capable of phase angle ring can include

Current Limiting and Heater Bake out functions

• Heater Bakeout and current limit functions require the

Current Limit Loop option

• Current Limit Loop can be ordered as an option in digit

10 of the part number

• If a model does not have phase angle ring it cannot do

Current Limiting, Heater Bakeout, Start Ramp, Safety

Ramp or Delayed Triggering

• Half cycle with start ramp and peak current limit options

Firing Type

Combinations Available

Zero Crossing

Zero Crossing + Start

Ramp

Zero Crossing + Start

Ramp + Soft Start

Zero Crossing + Soft Start X X X

Burst Firing X X X

Burst Firing + Soft Start X X X

Burst Firing + Start Ramp X X

Burst Firing + Start Ramp

+ Soft Start

Single Cycle X

Single Cycle + Soft Start X

Phase Angle X X

Phase Angle + Soft Start X X

Half Cycle X

Half Cycle + Soft Start X

Burst Firing + Delayed

Triggering + Soft Start

Burst Firing + Delayed

Triggering

Burst Firing + Delayed

Triggering + Safety Ramp

Burst Firing + Delayed

Triggering + Safety Ramp

+ Soft Start

Half Cycle + Safety Ramp X

Half Cycle + Safety Ramp

+ Peak Current Limit

1 Phase,

1 Controlled

Leg

X X X

X X

X X

X X

X X

X X

X X

X X

X

3 Phase,

2 Controlled

Legs

Analog Inputs 1 and 2

• Voltage

• 0-10VDC

• 15KΩ impedance

• Current

• 4-20mA, 0-20mADC

• 100Ω impedance

• Potentiometer

• 10KΩ min.

3 Phase,

3 Controlled

Legs

2

Page 3

Analog Output 1

• 0 to 20mA or 4 to 20mA into 500Ω max. load with 50μA

nominal resolution

• 0 to 10VDC into a 500Ω min. load with 50mV nominal

resolution

Analog Output Functions

• Retransmit: Load voltage, current, power or measured input

(Note: If using both Analog Retransmit (digit 10, options A

or D) and Additional Wired Communication (digit 12, options

1-5) an external power supply will be required.

Watlow power supply part number: 0847-0299-0000

Descriptions: AC/DC power supply converter for 90-263VAC to

24VDC, 1.30A, 31W.)

Electromechanical Relay Output

• Form C, 30VDC max. at 1A resistive load or 0.5A at 125VAC,

6000 cycles at 30VDC, 100,000 cycles at 120VAC

Relay Functions

• Alarm output options for heater open break, SCR short or

current limit, heat sink/ambient over-temperature

DC Power Supply for Digital Inputs and Potentiometer

remote set point input

• 10VDC @ 10mA max.

Fusing

• Integrated semiconductor fuse

• Refer to amperage chart for I2T fuse values

Diagnostics Annunciation Messages

• Heater break (open), SCR short circuit (closed), current

limit, thermal switch, SD card error, comms watchdog error,

bakeout in process, aux. voltage too low or high, voltage

line loss

Operator Interface

• 0.96 in. white OLED display with 128 x 64 pixel resolution

• L/R, F UP and DOWN arrow keys

• 4 discrete LED indicators for local/remote mode, enable,

communications and alarm

Connectivity

• EIA 485, Modbus® RTU

• Modbus® TCP Ethernet

• EtherNet/IP™

• Wi-Fi

• USB 2.0 device connection

• PROFIBUS DP

• PROFINET

(Note: If using both Analog Retransmit (digit 10, options A

or D) and Additional Wired Communication (digit 12, options

1-5) an external power supply will be required.

Watlow power supply part number: 0847-0299-0000

Descriptions: AC/DC power supply converter for 90-263VAC to

24VDC, 1.30A, 31W.)

Conguration

• PC software tool and RS485, USB port, or on-board keypad

and LED display

Integrated Data Logging

• Storage: 16 GB SD memory card

• .CSV le type

• User programmable logging intervals 1 to 255 seconds

• Up to 10 parameters selectable by user: line frequency,

output voltage (RMS), output current (RMS), output power

(average), status, commands, set point, current limit

set point (RMS), load resistance, input voltage (RMS)

Real Time Clock and Battery Back-up

• Typical battery life: 5 years at 77°F (25°C)

• CR2032 eld replaceable battery

Cooling mode

• Forced air (fan)

• 24VDC, 120 or 240VAC, 17 watts per fan used

Control Terminals

• Terminals are touch safe, removable, 12 to 22 AWG

Line and Load Terminals

• Compatible with crimp lug terminals or busbar

• Refer to user manual for wire size, compression and torque

requirements

Mounting

• Panel mounting with screws

• Must be mounted with heat sink ns in vertical orientation

Environment

• 0 to 40°C without derating

• 5 to 90% RH (relative humidity), non-condensing

• Up to 2000 meters above sea level max.

• Over 1000 meters of altitude reduce the nominal current by

2% for each 100 meters

• Storage temperature -25 to 70°C max.

Agency Approval and Regulatory

• cULus 508 Listed File E73741

• cUL® Listed to C22.2 No. 14

•

CE EMC Directive 2014-30-EU, EN 60947-4-3 Class A Emissions

• CE Safety Directive 2014-35-EU, EN 60947-4-1, -4-3

• IP20 with all covers in place

• RoHS 2011-65-EU

• W.E.E.E 2012-19-EU

• 690VAC units not covered by UL®

Accessories

• Free Watlow ASPYRE conguration software on the Watlow

website at http://www.watlow.com/en/resources-andsupport/Technical-Library/Software-and-Demos

• 6 ft USB 2.0 to micro USB device cable 0219-0480-0000

• Fuses - see table below

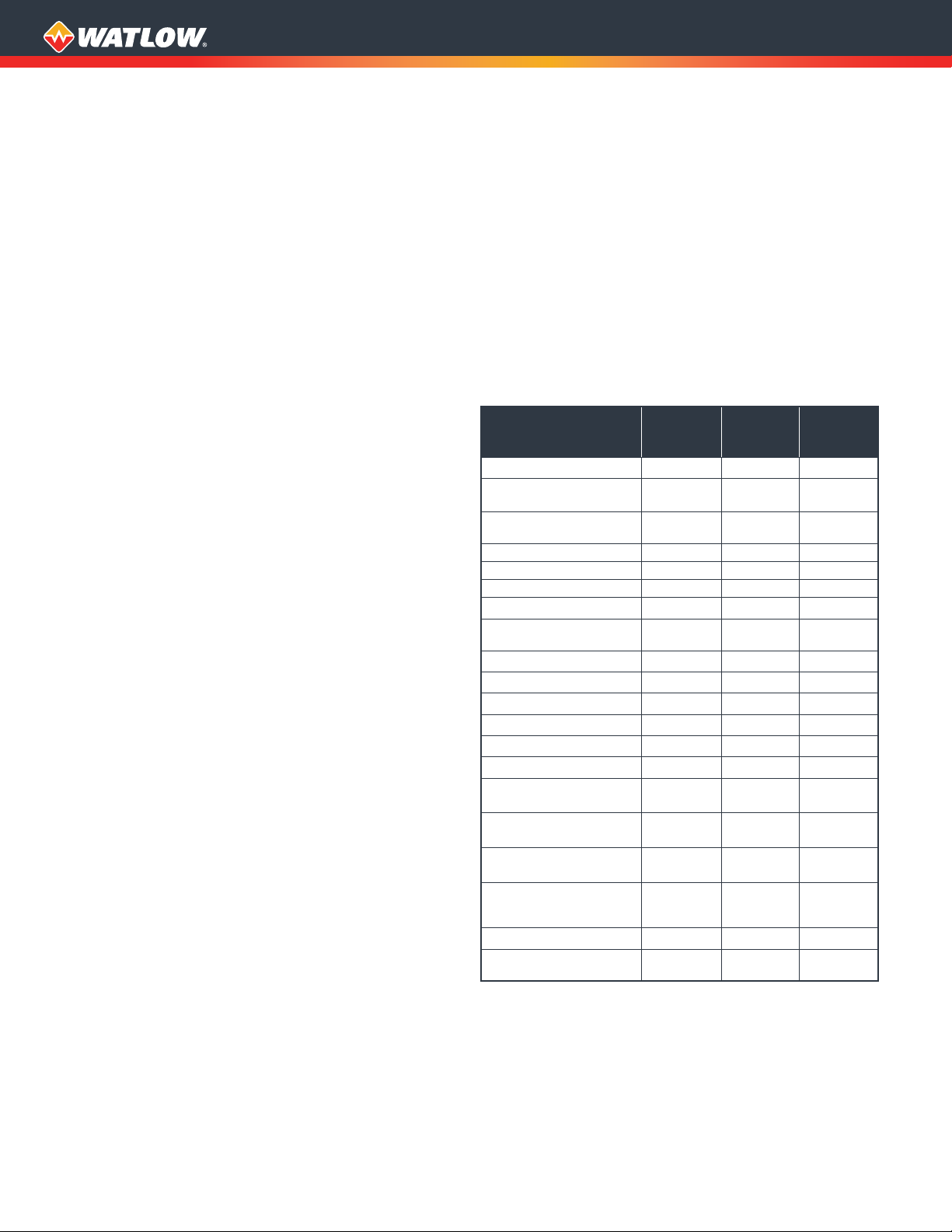

Fuses

ASPYRE

Model

Number

DT_ _ _ - 035 ...

DT_ _ _ - 040 ...

DT_ _ _ - 060 ...

DT_ _ _ - 090 ...

DT_ _ _ - 120 ...

DT_ _ _ - 150 ...

DT_ _ _ - 180 ...

DT_ _ _ - 210 ...

DT1_ _ - 300 ...

DT1_ _ - 400 ...

DT1_ _ - 500 ...

DT1_ _ - 600 ...

DT1_ _ - 700 ...

DT2_ _ - 300 ...

DT2_ _ - 400 ...

DT2_ _ - 450 ...

DT2_ _ - 500 ...

DT2_ _ - 600 ...

DT2_ _ - 700 ...

DT3_ _ - 300 ...

DT3_ _ - 350 ...

DT3_ _ - 400 ...

DT3_ _ - 450 ...

DT3_ _ - 500 ...

* One fuse per switched leg.

Qty.

Used

Per

Unit

1 to 3*

1 0808-0362-0000

1 0808-0358-0000

1 0808-0359-0000

4

4

3 0808-0357-0000 2055-5072

3 0808-0358-0000 0808-0358-0000

6

6

4

4

3 2055-5072

3

3

3

3

Watlow Fuse Part Number

480V and 600V 690V

17-8050

0808-0363-0160

0808-0363-0180

0808-0363-0200 2048-4405

0808-0363-0250 2048-4418

0808-0363-0315 2048-4426

0808-0363-0250 0808-0363-0250

0808-0360-0000 0808-0360-0000

0808-0357-0000

0808-0358-0000 0808-0358-0000

0808-0359-0000 0808-0359-0000

2048-2760

0808-0362-0000

0808-0358-0000

0808-0359-0000

0808-0357-0000

3

Page 4

I/O Functional Block Diagram

Profibus DP

Backup Power

•

User Interface

•

Communications

DC Power

Supply

•

Dry Contact

Switches

•

Potentiometers

Analog

Retransmit

•

User-Selectable

Retransmit Parameter

•

0 to 20mA or

4 to 20mA

•

0 to 10VDC

USB Device

•

Configuration

Software Connection

•

Data Log File Transfer

Wi-Fi

•

Configuration

•

Monitor Operation

Power Switching

•

1, 2 or 3 Legs

•

Back-to-Back SCR Switching

•

Replaceable Semiconductor Fuses

Analog

Input

2 Analog Inputs

•

Set Point

•

Feedback

•

Current Limit

2 Digital Inputs

•

Enable

•

Select Feedback

•

Local/Remote

•

Set Firing Type

Auxiliary Power

•

Controller

Electronics

•

Voltage Sensing

•

Zero-Cross Sensing

Analog

Input

Auxiliary

Power

* Current Limit

1-phase and 3-phase, 3-leg models only.

Not available on 35 amp and 40 amp, 3-phase 3-leg models.

(Optional)

+24VDC

Input

Voltage

Sensing

+10VDC

Output

Fan Power

Input

Fan Power

•

24VDC

•

120 or 240VAC

(Optional)

Analog

Retransmit

NCNO

Mechanical

Relay Output

•

Alarm Annunciation

(Optional)

Data

Logging

RS-485

Interface

•

Modbus TCP

•

2nd Modbus RTU (485)

•

(Optional)

Power

Demand

Loop

(Optional)

Current

Limit

Loop*

Current

Sensing

(Optional)

•

Profinet

•

EtherNet/IP™

(Optional)

(Optional)

Out to LoadIndustrial Communications

4

Page 5

Dimensions and Shipping Weight

Current and Voltages

35 and 40A

480 and 600VAC

1 Controlled Leg

1-Phase,

3-Phase,

2 Controlled Legs

3-Phase,

3 Controlled Legs

60, 90, 120, 150,

180 and 210A

480 and 600VAC

60, 90, 120, 150,

180 and 210A

690VAC

4.77 in. H x 2.84 in. W x

7.28 in. D - 2.6 lbs

10.6 in. (60A) or 10.79 in.

(90-210A) H x 3.66 in. W x

6.7 in. D - 9 lbs

4.77 in. H x 4.25 in. W x

7.28 in. D - 4 lbs

10.6 in. (60A) or 10.79 in.

(90-210A) H x 7.36 in. W x

6.7 in. D - 18 lbs

4.77 in. H x 5.67 in. W x

7.28 in. D - 5.5 lbs

10.6 in. (60A) or 10.79 in.

(90-210A) H x 11.1 in. W x

6.7 in. D - 27 lbs

1 and 2 leg:

300, 400, 500, 600 and 700A

3 leg:

300, 350, 400, 450 and 500A

480, 600 and 690VAC

17.33 in. H x 5.40 in. W x

10.63 in. D - 23 lbs

20.47 in. H x 5.4 in. W x

10.63 in. D - 33 lbs 20.47 in. H x 10.32 in. W x 10.63 in. D - 63 lbs

60-90A = 17.33 in. H x 5.40 in. W x 10.63 in. D - 23 lbs

120-210A = 17.33 in H x 10.32 in. W x 10.63 in. D - 40 lbs

5

Page 6

Ordering Information

Base model includes: power control loop for open loop, voltage, current or power control, two analog inputs (0-10VDC, 4-20mA selectable),

two digital inputs, semiconductor fusing and current transformers for each leg, mechanical relay heater break alarm, RS-485 Modbus®

communications, pixel OLED user interface and keypad, 10VDC auxiliary power supply

Part Number

① ②

③

④ ⑤

Max. Line

⑥ ⑦ ⑧

& Load

Model

Phase

Voltage

DT

③

1 =

1-phase, 1 controlled leg

2 =

3-phase, 2 controlled leg

3 =

3-phase, 3 controlled leg

④ ⑤

48 =

480VAC

60 =

600VAC

69 =

690VAC - Only available for 60A and greater models

⑧

⑥ ⑦

035 =

35A

040 =

40A

060 =

60A

090 =

90A

120 =

120A

150 =

150A

180 =

180A

210 =

210A

300 =

300A

350 =

350A - Not available for 1-phase, 1 leg or 3-phase, 2 leg models

400 =

400A

450 =

450A - Not available for 1-phase, 1 leg models

500 =

500A

600 =

600A - Not available for 3-phase, 3 controlled leg models

700 =

700A - Not available for 3-phase, 3 controlled leg models

⑨

1 =

100 or 120VAC 90-135V

2 =

200, 208, 220, 230 or 240VAC 180-265V

3 =

277VAC 249-305V

4 =

380, 400, 415, 440 or 480VAC 342-528V

5 =

600VAC 540-660V

6 =

690VAC* 621-759V

* 690VAC only available for 60A and greater models.

Watlow® and ASPYRE® are registered trademarks of Watlow Electric Manufacturing

Company.

Modbus® is a registered trademark of Schneider Automation Incorporated.

UL® and c-UL® are registered trademarks of Underwriter’s Laboratories, Inc.

Kanthal® Super is a registered trademark of Bulten-Kanthal Aktiebolag Joint Stock

Company.

EtherNet/IP™ is a trademark of Open DeviceNet Vendors Association.

Maximum Line and Load Voltage

Nominal Voltage Supplied to SCR

Nominal Maximum Operating Range

Amperage

–

Phase

Amperage

⑨

Nominal Voltage

Supplied to SCR

⑩

Additional

Options

⑪

Cooling

Fan

Voltage

⑫

Add’l Wired

Comms.

⑬

Wireless

Comm. &

Data Logging

Firmware Overlay, Preset

Parameters and Locked Code

–

⑩

A =

B =

C =

D =

Note 1: Current limit loop only available with 1-phase and 3-phase, 3-leg

models (DT1 and DT3). Exception: Current limit not available with the 35A

and 40A, 3-phase, 3-leg models (DT3xx-035xx-xxxxx and DT3xx-040xx-xxxxx).

Note 2: If using both Analog Retransmit (digit 10, options A or D) and

Additional Wired Communication (digit 12, options 1-5) an external power

supply will be required. Watlow power supply part number: 0847-0299-0000

Descriptions: AC/DC power supply converter for 90-263VAC to 24VDC, 1.30A,

31W.

Current Limit Loop

⑪

0 =

No fan - option only valid for models ≤60A

1 =

120VAC*

2 =

240VAC*

3 =

24VDC*

* Fan voltage required on models ≥90A, not valid option for

models ≤60A.

⑫

0 =

1 =

2 =

3 =

4 =

5 =

Note 1: All additional communication options include auxiliary 24VDC

backup power supply for communications.

Note 2: If using both Analog Retransmit (digit 10, options A or D) and

Additional Wired Communication (digit 12, options 1-5) an external power

supply will be required. Watlow power supply part number: 0847-0299-0000

Descriptions: AC/DC power supply converter for 90-263VAC to 24VDC, 1.30A,

31W.

⑬

2

Additional Wired Communication (Modbus® RTU-485

No Add’l

Comms.

Modbus®

TCP

X

Wireless Communications & Data Logging

Wi-Fi

A =

B =

C =

D =

*

40A and lower models do not include battery back-up or real

time clock.

⑭ ⑮

AA =

AB =

RC =

XX =

Custom Options - Firmware Overlay, Preset Parameters and

Standard with user manual documentation

Standard without user manual documentation

Replacement connector hardware only - for configuration entered

above

Contact factory - custom firmware, preset parameters, locked code

Additional Options

Yes Yes

No No

Yes No

No Yes

Cooling Fan Voltage

Comes Standard in all Models)

X

X

X X

nd

2

Modbus®

RTU 485

X

Locked Code

Analog Retransmit Output 1

Profibus

DP

X

*Data Logging With Battery

Back-Up and Real Time Clock

⑭ ⑮

Custom Options -

Profinet EtherNet/IP™

X

X

X

Powered by Possibility

To be automatically connected to the nearest

North American Technical Sales Oce:

1-800-WATLOW2 • www.watlow.com

inquiry@watlow.com

©2019 Watlow Electric Manufacturing Company all rights reserved.

6

International Technical Sales Offices:

Austria +43 6244 20129 0

China +86 21 3532 8532

France +33 1 41 32 79 70

Germany +49 7253 9400 0

India +91 40 6661 2700

Italy +39 02 458 8841

Japan +81 3 3518 6630

Korea +82 2 2169 2600

Mexico +52 442 256 2200

Singapore +65 6773 9488

Spain +34 91 675 1292

Taiwan +886 7 288 5168

UK +44 115 964 0777

WIN-ASP-0419

Loading...

Loading...