Page 1

To Elevate Your System

with an intelligent power

controller family that simplifies

your application while offering

cutting-edge features

ASPYRE

®

Page 2

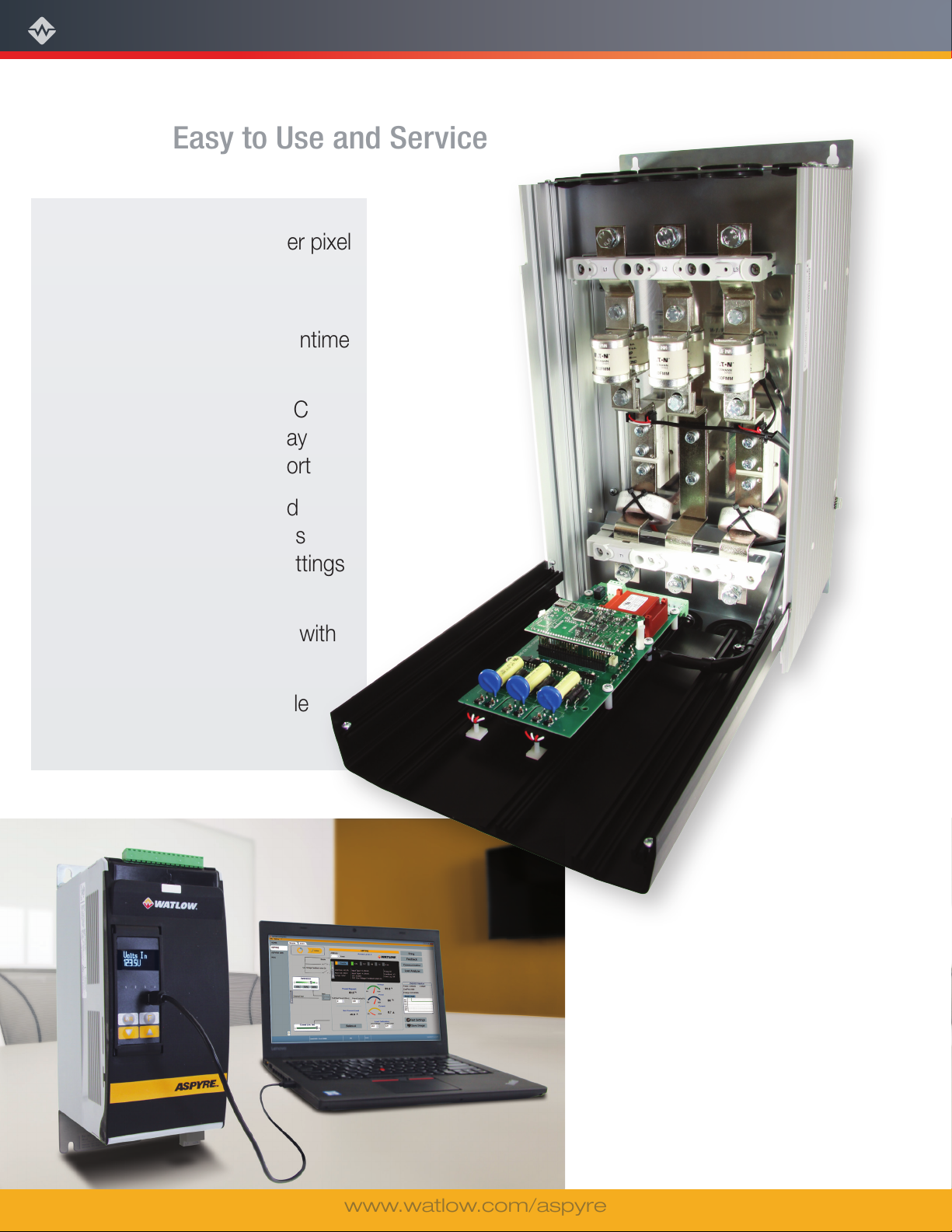

Easy to Use and Service

www.watlow.com/aspyre

Modular and Smart Design

>

Easy to read real character pixel

display

>

Quick access to SCRs

minimizes production downtime

>

Simple to configure with

ASPYRE® configuration PC

software and plug and play

access via USB device port

>

Intuitive application wizard

automatically recommends

controller configuration settings

Model

DT248-300

based on load type

>

Intelligent troubleshooting with

built-in diagnostics

>

Easy to access replaceable

semiconductor fuses

Model

DT148-060

Page 3

www.watlow.com/aspyre

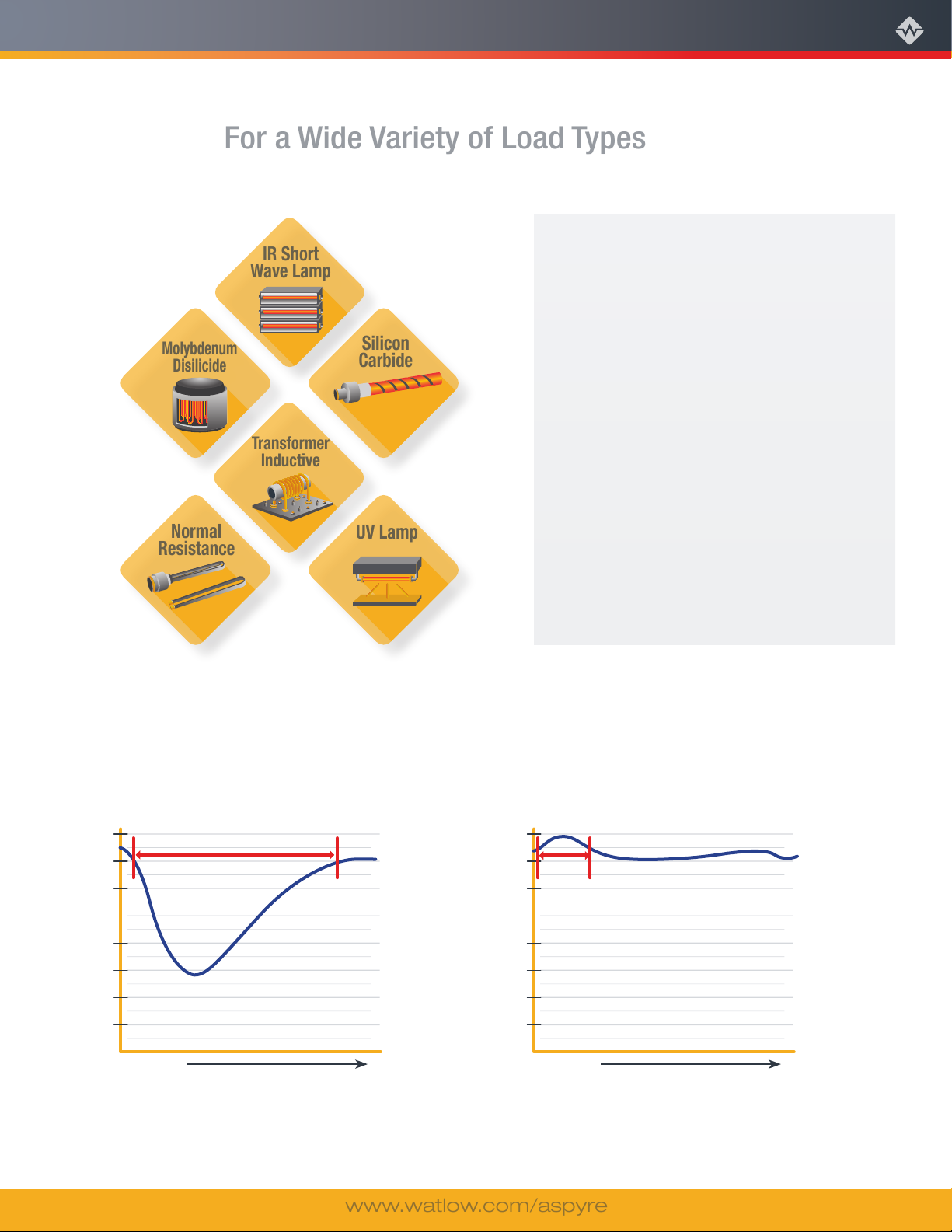

For a Wide Variety of Load Types

Improved Process Control

UV Lamp

Normal

Resistance

Transformer

Inductive

Molybdenum

Disilicide

IR Short

Wave Lamp

Silicon

Carbide

>

20 firing combinations to align

with a variety of load types

>

Advanced control modes

protect heater from damage

on start up and extends overall

heater element life

>

Six available power control

modes to maximize thermal

performance

>

Multiple digital and analog I/O

TEMPERATURE

to increase system control

functionality

Closed-Loop Temperature Control

Without Power

Control Feedback

With ASPYRE Power

Control Feedback

TEMPERATURE

TIME TIME

Power feedback can immediately adjust thermal performance to keep temperature constant

Page 4

Lower Ownership Costs

Integrated Functions

www.watlow.com/aspyre

Data

Logger

AC

Line Filters

Semi

Fuses

Voltage

Sensing

Current

Sensing

USB

Port

Fuse

Holder

Analog

Retransmit

Cooling

Fan

Alarm

Relay

Communication

Multi-

Meters

Closed

Loop Power

SCR

Closed

Loop Current

Model

DT348-300

NOCNC

>

UL® 508 rating results in reduced

labor and project costs

>

Smaller footprint and less weight than

legacy power controllers reduces

cabinet space and shipping expenses

>

Integrated design reduces system

All the

functionality of

multiple devices...

in a single

controller.

>

ASPYRE DT features SCR

switching, voltage sensor, data

logging, Wi-Fi, current sensor,

semiconductor fusing, user interface,

communications, relay alarm, cooling

fan, back-up power supply and more

in one device

complexity, inventory and labor to

install and wire

Page 5

Connectivity for Automation

Communication Access to Important Data

www.watlow.com/aspyre

Cloud

Computing

Scalability

Wi-Fi

Connected

Connectivity

Big Data

System

Integration

Value

Chain

IOT

Analytics

Automation

>

USB device port (file transfers configuration or data log)

>

Data logging

>

Wireless Wi-Fi and mobile

application

>

Communication protocols

485 Modbus® RTU (up to 2),

Modbus® TCP, Ethernet IP,

Profibus DP, Profinet

>

4-20mA retransmit

Page 6

For High Quality and Reliability

Industry-Leading Design

www.watlow.com/aspyre

High Performance Validated With Stringent Testing

Shock and vibration testing

>

3 year factory warranty

>

Robust SCR design with high

I2t rating

>

Passes rigorous Watlow test

standards

>

Agency compliance - UL®,

CE, RoHS, W.E.E.E.

>

100KA SCCR rating

>

UL® 508 rating

>

UL® 508 shortens project

schedules, agency testing

and expenses

Meets or Exceeds

Industrial Test Standards

EN 61326

EN 61326-1

EN 61000-4-2

EN 61000-4-3

EN 61000-4-4

EN 61000-4-5

EN 61000-4-6

EN 61000-4-8

EN 61000-4-11

EN 55011

EN 61000-3-2

EN 61000-3-3

Electrical equipment for measurement, control, and laboratory use EMC requirements

Electrical equipment for measurement, control, and laboratory use EMC requirements Updated 61000-4-3 to 3 GHz, Updated 61000-4-11

dips test, required by Feb 1, 2009.

Electrostatic discharge immunity test.

Radiated radio-frequency electromagnetic fields.

Electrical fast transient/burst immunity test.

Surge immunity test.

Conducted disturbances induced by radio-frequency fields.

Power frequency magnetic field immunity test.

Voltage dips, short interruptions and voltage variations immunity test.

Limits and methods of measurement of radio disturbance characteristics

of Industrial, Scientific, and medical (ISM) radio-frequency equipment.

Limits for harmonic current emissions (equipment £ 16 A per phase)

Limitation of voltage fluctuations and flicker in low-voltage supply

systems with equipment with rated current £ 16 A.

Model

DT248-035

Page 7

WATLOW ELECTRIC MFG CO.

WATROD™ Circulation Heater Installation & Maintenance Manual

I&M NUMBER: 316-42-5-1

Megohm precheck

During shipping and/or storage, the possibility of absorption by the insulation material

within the element is possible. To ensure proper megohm values a minimum 500 VDC

megohm meter (Megger) should be used to ensure that the megohm reading between the

heater terminal and the heater sheath is more than 10 megohms when the unit is at room

temperature.

If several units are interconnected, the megohm of the heater is obtained by taking the

reading and dividing by the number of interconnected elements. This reading should be

greater than 10 megohms.

If a low megohm value exists, two alternative methods can be used to remedy the situation.

The best method is to remove all terminal hardware including thermostat if provided,

and bake out the heater at no higher than 250°F (120°C) overnight or until an acceptable

reading is reached. The second method is to energize the unit at low voltage in air until the

megohm is at an acceptable reading. Care should be taken to prevent the heater sheath

from exceeding 750°F (398°C) for Incoloy® and steel elements and 400°F (204°C) for coper

elements. Both of these methods should be performed with the heater out of the tank. The

Page: 1

Rev: 5.00

1.

Protects Heaters on Start-Up

www.watlow.com/aspyre

Megohm heater circuit precheck

Wet Heater Bake Out

Reduces start up costs

and production delays

Megohm Test Proceedure

Watlow process heater bundle

Page 8

©2017 Watlow Electric Manufacturing Company WIN-ASP-BROCH-1017

Powered by Possibility

Find out more about Watlow and how we can

provide thermal solutions for your company:

Phone: 1-800-WATLOW2 (1-800-928-5692)

E-mail: inquiry@watlow.com

Website: www.watlow.com

Watlow Products and Technical Support Delivered Worldwide

North American Technical Support

& Sales Offices

United States & Canada 1-800-WATLOW2

(1-800-928-5692)

Asian Technical Support &

Sales Offices

China +86 21 3532 8532

India +91 40 6661 2700

Japan +81 3 3518 6630

Korea +82 2 2169 2600

Singapore +65 6773 9488

Taiwan +886 7 288 5168

European Technical Support &

Sales Offices

France +33 1 41 32 79 70

Germany +49 7253 9400 0

Italy +39 02 4588841

Spain +34 91 675 1292

United Kingdom +44 115 964 0777

Latin American Technical Support

& Sales Office

Mexico +52 442 256 2200

Loading...

Loading...