Page 1

TM

AnaWin

User’s Guide

Watlow Controls

1241 Bundy Blvd.

Winona, MN 55987

Customer Service

Phone: (800) 414-4299

Fax: (800) 445-8992

Technical Support

Phone: (507) 494-5656

Fax: (507) 452-4507

Email: wintechsupport@watlow.com

Part No. 22852-00. Revision 2.1

June 1997

Page 2

Copyright © 1997

Watlow Anafaze

Information in this manual is sub ject to ch ange wi t hou t noti ce. No part of thi s publ i cation may be reproduced, stored

in a retrieval system, or transmitted in any form without written permissio n from Watlow Anafaze.

License Agreement and Disclaimer of Warranty:

Read before opening diskette package. By breaking the seal on the disk package, you accept the terms of this license

agreement. This software is provided as is and without warranties as to performance. This program is provided without any expressed or implied warranties whatsoever. Because of the diversities of conditions and hardware under

which this program may be used, no warranty of fitness for any particular use is offered. The user is advised to test

the program thoroughly before relying on it. The user must assume the entire risk of using the program. In no event

will W atlow Electric Manufacturing Company or Anafaze, Inc. be held liable for incidental or consequential damages

arising out of use of this program.

Warning

This computer program is protected by copyright law and international treaties. Unauthorized reproduction or distri-

bution of this program, or any portion of it, may result in severe civil and criminal penalties, and will be prosecuted to

the maximum extent possible under the law.

Page 3

CONTENTS

Overview

Using this Guide .................................................................... 1

Online Help............................................................................ 2

Watlow Anafaze Technical Support...................................... 2

1 Installation and Setup

System Requirements ...........................................................1-1

Hardware Requirements .................................................1-1

Software Requirements ...................................................1-1

Parts List .........................................................................1-2

System Block Diagram .........................................................1-2

Safety ....................................................................................1-2

Installation ............................................................................1-3

System Setup .........................................................................1-3

Setting the Controller to ModBus Protocol ....................1-4

Configuring your Controllers ..........................................1-4

Channel Grouping ...........................................................1-6

Other Configuration Options ..........................................1-7

Monitoring the Configured Controllers ................................1-10

2 AnaWin Screen Displays

Screen Conventions ..............................................................2-1

Main Menu ............................................................................2-3

3 Exporting Data

Export Database ....................................................................3-1

Data Log Setup .....................................................................3-4

4 Setting System Parameters

Login .....................................................................................4-2

Logout ...................................................................................4-2

Preferences ............................................................................4-2

Normal Startup.................................................................4-3

i

Page 4

Power Fail Recovery .......................................................4-3

Miscellaneous System Parameters ..................................4-4

Setup Passwords .............................................................4-5

Default Recipe Comment ................................................4-8

Disable Recipe Download ..............................................4-9

Gauge Display Editable Parameters ...............................4-9

Communications ...................................................................4-9

Com Diags ............................................................................4-10

Configure ..............................................................................4-10

5 Setting Channel Parameters

Channel Parameters ..............................................................5-1

Channel Summary ..........................................................5-2

Real-time Trend Plot .......................................................5-3

Channel Setup Tabs ........................................................5-4

Ramp Soak Setup ..................................................................5-7

Assigning Profiles to Loops ............................................5-8

Using Special Ramp-Soak Functions .............................5-9

Editing Profiles ...............................................................5-12

6 Managing Recipes

New .......................................................................................6-2

Open ......................................................................................6-3

Save .......................................................................................6-3

Save As .................................................................................6-3

Remove .................................................................................6-4

Download ..............................................................................6-4

Calendar ................................................................................6-4

Recipe Start .....................................................................6-5

Monthly Calendar ...........................................................6-6

Scheduled Recipes ..........................................................6-6

Suspend Calendar Events ................................................6-6

7 Using the Trend Plot Screen

Trend Plot .............................................................................7-1

Trend Plot Screen Features .............................................7-2

Toolbar ............................................................................7-8

Trend Plot Settings ................................................................7-20

Data Sets .........................................................................7-20

Graphing Limits ..............................................................7-21

ii

Page 5

Time Range .....................................................................7-21

Trend Plot Storage ................................................................7-21

Disk Space Analysis .......................................................7-22

Recording Rate ...............................................................7-22

Maximum Days Stored on Disk.......................................7-22

8 Viewing Channels

Spreadsheet ...........................................................................8-1

Bar Graph Display ................................................................8-2

Gauge Display .................................................................8-2

Digital I/O .............................................................................8-4

Inputs ..............................................................................8-4

Outputs ............................................................................8-4

Overview Thumbnails ...........................................................8-5

Custom Overview Screens ....................................................8-6

9 Working with Log Files

View (Logs) ..........................................................................9-1

Log File ...........................................................................9-2

Time of Event .................................................................9-2

Event Numbers ...............................................................9-2

Event Description ...........................................................9-3

Search ..............................................................................9-4

Print .......................................................................................9-4

Copy to A: .............................................................................9-4

Remove (Logs) .....................................................................9-4

Closing a Log ........................................................................9-4

10 Using the Developer

Using the Developer Program ...............................................10-1

Design Custom Overview ...............................................10-3

User Variables .................................................................10-20

11 Working with System Alarms

Interpreting the Alarm Screen ...............................................11-1

Date/Time .......................................................................11-2

Group Name ....................................................................11-2

Channel Name .................................................................11-2

Alarm Message ...............................................................11-2

iii

Page 6

Alarm Type .....................................................................11-2

Alarm Symbol .................................................................11-3

Clear View ......................................................................11-3

Print (Alarms) .................................................................11-3

Acknowledging Alarms ........................................................11-4

A Using AnaMator

AnaMator Overview .............................................................A-1

B User Variable Operators and Functions

Available Operators ..............................................................B-1

Available Functions ..............................................................B-2

C AnaWin OLE Server

AnaWin OLE Server Features ..............................................C-1

OLE Server Exposed Methods .............................................C-1

Getting Data ....................................................................C-2

Setting Data .....................................................................C-2

Getting Parameter Names ...............................................C-3

Getting Recipe Names ....................................................C-3

Downloading Recipes .....................................................C-3

Getting Download Status ................................................C-3

Registering as a Client ....................................................C-4

OLE Server Constant Values ................................................C-5

CLS/MLS Channel Parameters .............................................C-6

CLS/MLS Global Parameters ...............................................C-8

Glossary

Index

iv

Page 7

Overview

Using this Guide

This guide describes how to install, set up, and operate AnaWin.

AnaWin32 is Windows

monitor one or more controllers from a single PC. AnaWin allows you

to log data to disk, graph data, schedule automatic recipe changes,

manage alarms, manage recipes, configure control parameters, create

custom overview screens, and use the advanced control features of your

Watlow Anafaze controller through a graphical user interface.

This guide is intended for both experienced and inexperienced users. If

you are an experienced user , you ma y want to skim par ts of this guide. If

you are an inexperienced user, you should read the entire guide

carefully. We assume that AnaWin users have a basic knowledge of

Windows95.

The information in this guide is organized into the following chapters.

•

Chapter 1, Installation and Setup: Describes how to install

AnaWin and how to use the Configuration program to connect to

one or more controllers, create loop/channel groups, and customize

channel, parameter, and I/O names.

•

Chapter 2, AnaWin Screen Displays: Describes basic screen con-

ventions and how to navigate the main menu.

•

Chapter 3, Exporting Data: Describes how to export data from

AnaWin to other applications, including how to specify when data is

logged and which channels are included in the log file.

®

95 software that allows you to program and

AnaWin User’s Guide 1

Page 8

Overview

•

Chapter 4, Setting System Parameters: Describes how to use the

system menu, to set preferences and configure AnaWin to operate

with your controller.

•

Chapter 5, Setting Channel Parameters: Describes how to use t he

Channel Setup screen to configure a controller.

•

Chapter 6, Managing Recipes: Describes the Recipe menu, and

how to create, store and use recipes through AnaWin.

•

Chapter 7, Using the Trend Plot Screen: Des c ribes AnaWin’s

trend plotting features.

•

Chapter 8, Viewing Channels: Describes different ways of viewing

system data in AnaWin.

•

Chapter 9, Working with Log Files: Describes event logs and how

to view them.

•

Chapter 10, Using the Developer: Describes how to design and use

custom overview screens and how to define user

variables.

•

Chapter 11, Working with System Alarms: Describes the AnaWin

Alarm screen and how to acknowledge alarms.

•

Appendix A, Using AnaMator: Describes how to use the AnaMator

application to create animations w hich y ou can add t o you r AnaWin

custom overview screens.

•

Appendix B, User Variable Operators and Functions: Lists the

operators and functions that may be used in the user variables

spreadsheet.

•

Appendix C, AnaWin OLE Server: Describes OLE (Object Link-

ing and Embedding), which is used in the interchange of data with

other Windows95 applications.

Online Help

Watlow Anafaze Technical Support

2 AnaWin User’s Guide

AnaWin provides a comprehensive Help system which you can access

from the Help menu, or by pressing F1. Pressing F1 provides contextsensitive help related to the part of the software that is displayed at the

time.

We have made every effort to ensure that you will be able to install, set

up and maintain AnaWin using the information in this guide and in the

online help. Should you need further assistance, call Watlow technical

support.

Page 9

Installation and

Setup

This chapter describes how to install AnaWin on your computer and

how to use the Configuration program to set up AnaWin to

communicate with your controller(s).

System Requirements

The following components are required to operate AnaWin.

Hardware Requirements

Pentium 100MHz or greater with a minimum of 16MB of RAM

•

(Pentium 133 with 32 MB recommended for animation)

Hard drive with 20MB of free space (500 MB is recommended for

•

logging and trending)

3.5 inch HD floppy drive

•

SVGA display (high-color recommended)

•

Communications port capable of 19.2 Kbaud (with 16550 UART)

•

1

Software Requirements

Microsoft®-compatible sound card (recommended for voice-annun-

•

ciated and customized alarm sounds, but not required)

Microsoft-compatible pointing device (mouse or trackball)

•

Windows95 or WindowsNT 4.0

•

AnaWin User’s Guide 1-1

Page 10

Installation and Setup

Parts List

The following parts are included with AnaWin:

•

AnaWin on 3.5 inch disket te s .

•

AnaWin User’s Guide

System Block Diagram

Figure 1-1 shows how a PC (using AnaWin) interfaces with one, or

more, controllers.

FIGURE 1-1

Communications

Cable (to any serial port)

one or more controllers

System Block Diagram

Communication to a single controller can be made using an RS-232

connection to one of the PC’s serial ports.

The serial communication link required to communicate with more than

one Watlow Anafaze controller or with a communication cable longer

than 50 feet is RS-485. We recommend using the standard serial

interface of RS-232 with an external RS-485 converter.

We recommend using a B&B Electronics RS-232/RS-485 optically

isolated converter P/N 485OIC. This converter has screw terminals for

connecting the RS-485 wires and a DB-25 Male connector for the RS232 side. You can reach B&B Electronics at (815) 434-0846.

Safety

1-2 AnaWin User’s Guide

Contact the factory for other available converters.

While Watlow Anafaze has made every effort to ensure the reliability

and safety of its controllers and AnaWin, AnaWin—like any other

application—can fail, and other unexpected conditions can occur.

Page 11

Installation

Installation and Setup

Good engineering practices, electrical codes, and insurance regulations

require you to use independent external safety devices to prevent

potentially dangerous or unsafe conditions. Use of AnaWin does not

eliminate the need for appropriate external, independent safety devices.

For additional process safety, use AnaWin to automatically reload your

desired operating parameters after a power failure.

Please contact Watlow Anafaze immediately if you have questions

about system safety.

To install AnaWin, follow these steps:

1. Click on the Windows95 Task Bar with the right mouse button,

then choose Properties, then Autohide.

2. Insert the disk labeled AnaWin Disk 1 in the floppy drive.

3. Click on Start and Run at the bottom of the screen.

4. Type a:\setup or b:\setup.

5. The Setup program prompts you through the installation process.

Follow the instructions on the screen.

The first time you run AnaWin, you are prompted to enter your

serial number. You must enter the serial number printed on

AnaWin disk 1. You will also need this serial number any time you

request technical support.

System Setup

AnaWin loads the Configuration program and displays the controller

setup screen. Ref er to “Syst em Setup,” below, for instructions on using

the controller setup screen.

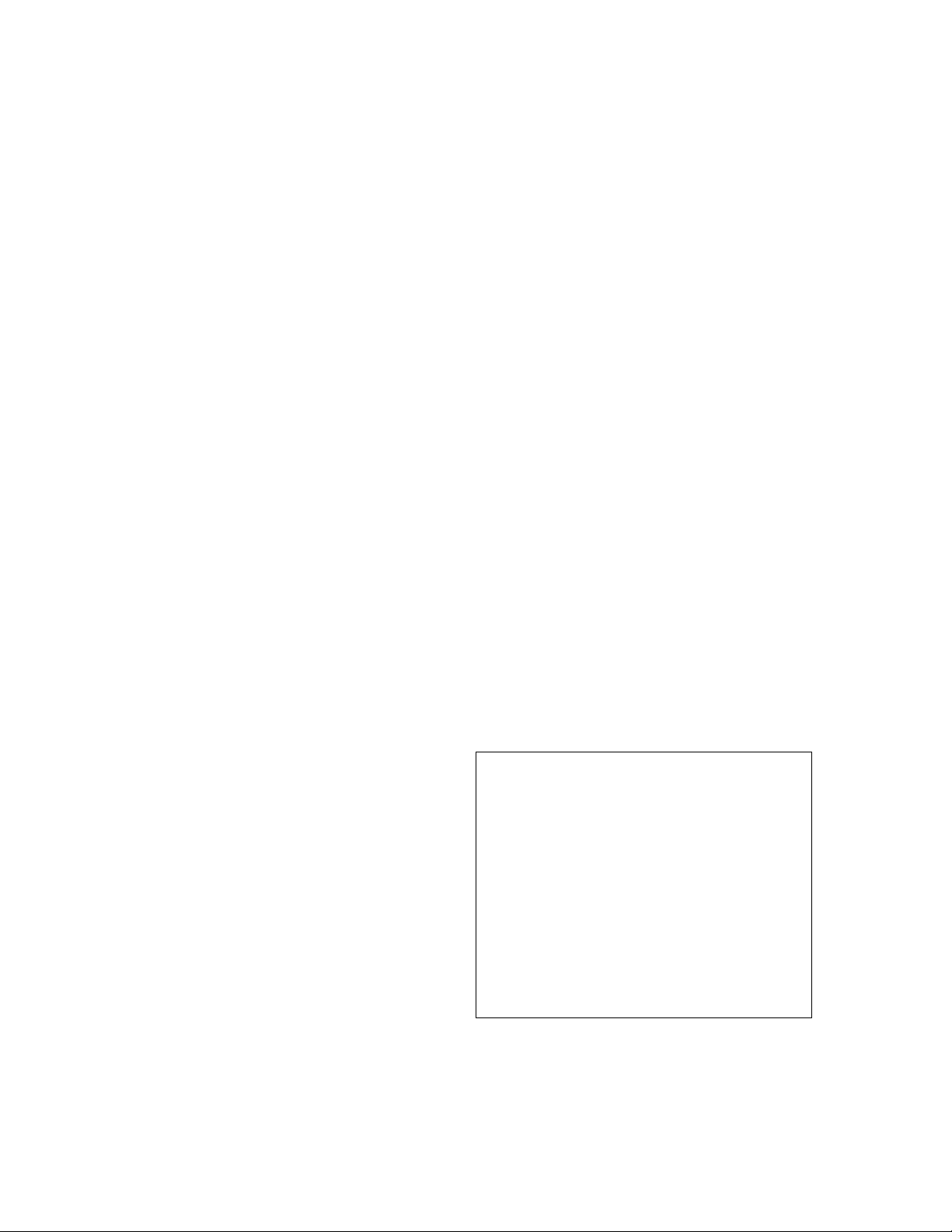

The controller setup screen, shown in Figure 1-2, allows you to set the

software parameters to match t he controller(s). When you first install

AnaWin, this screen appears automatically after a successful install. If

AnaWin has been previously installed, you can access the controller

setup screen by selecting Configure from the System menu.

AnaWin User’s Guide 1-3

Page 12

Installation and Setup

FIGURE 1-2

Controller Setup Screen

Setting the Controller to ModBus Protocol

Before configuring the software, set your controller(s) to ModBus

Protocol. Do this using the controller keypad and display shown in

Figure 1-3. Select the Global Parameters menu and set the

Communication Protocol screen to MOD, as show in the figure. Set a

unique address in each controller. Refer to your controller manual for

more detailed instructions.

LOOP PROCESS UNITS

COMMUNICATIONS

PROTOCOL? MOD

ALARM SETPOINT STATUS OUT%

FIGURE 1-3

Setting a Controller to ModBus Protocol

Configuring your Controllers

To configure AnaWin to communicate with your controller(s), follow

these steps:

1. On the Controller Setup screen set the total number of controllers,

with which Anawin must communicate.

1-4 AnaWin User’s Guide

2. Set the series number of the first controller you wish to

configure.

Page 13

Installation and Setup

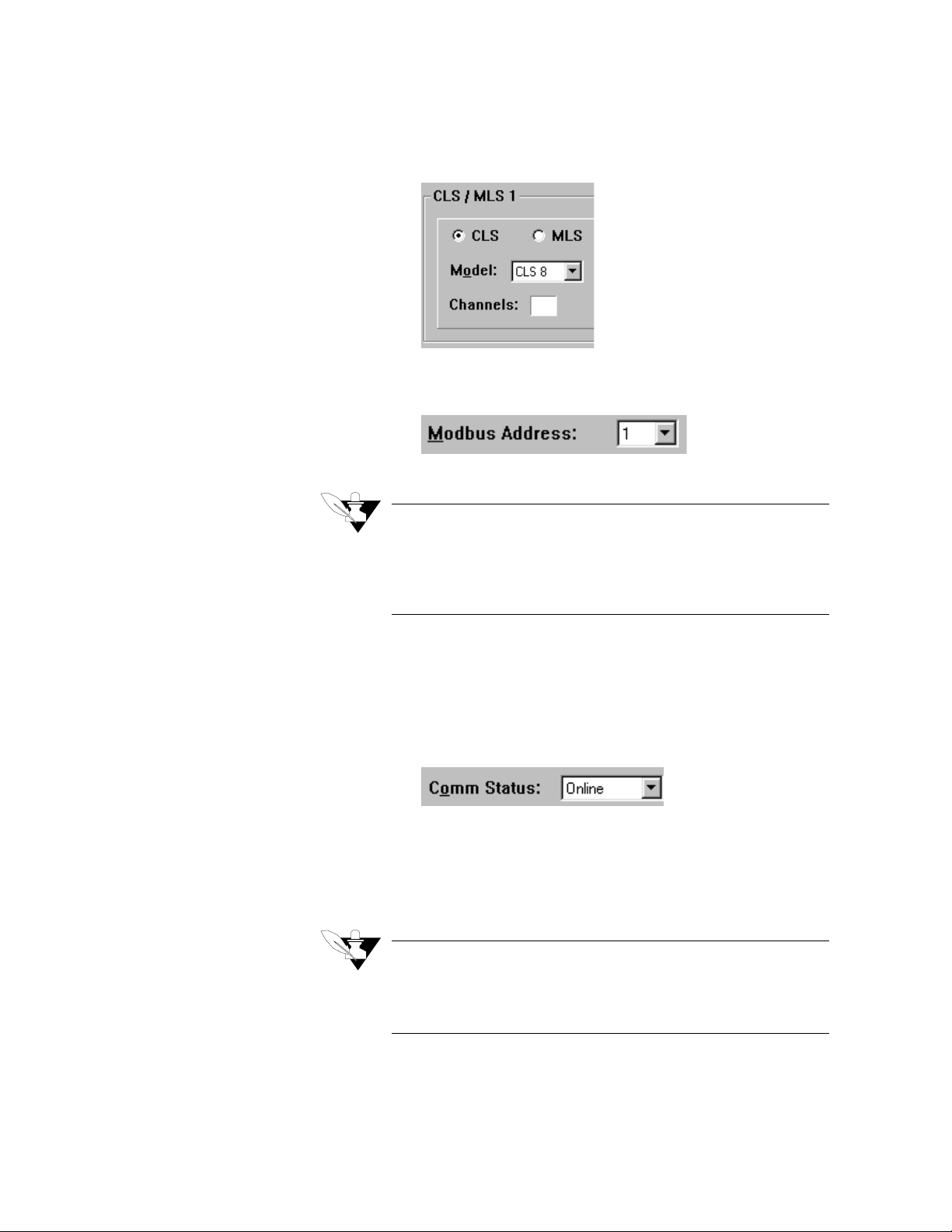

3. Choose the controller type and model. AnaWin automatically sets

the number of channels based on this data.

9

4. Set the ModBus address for the controller. Note that each controller

must have a unique ModBus address.

NOTE

You can use the Detect button to automatically set up each ModBus

address, but this operation takes considerable time to complete.

Refer to “Other Configuration Options” later in this chapter for

details about the Detect button.

5. If the controller is equipped for ramp/soak, select the Ramp Soak

Option check box.

6. Ensure the Comm Status of the controller has been set to Online.

Set a controller Off-line to speed up communications when you

remove the controller from the system or at other times when it cannot communicate.

7. If necessary, repeat steps 2-5 to configure other controllers.

8. If desired, set up channel grouping or other configuration options,

as described in the following subsections.

9. Click Save to save the configuration.

NOTE

When changing the number of controllers or controller type,

AnaWin will automatically restart itself when the information is

saved.

AnaWin User’s Guide 1-5

Page 14

Installation and Setup

Channel Grouping

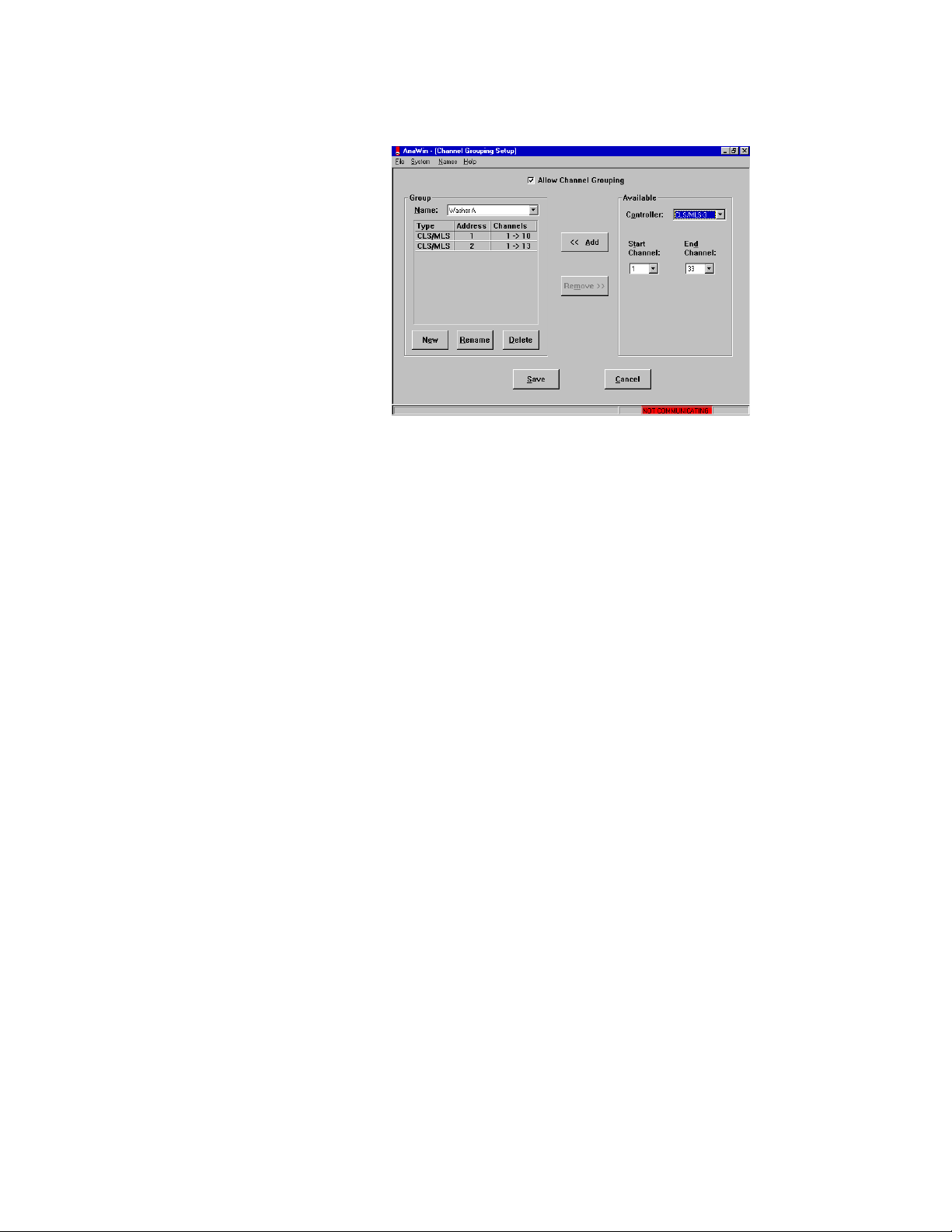

Select Channel Grouping from the System menu to display the Channel

Grouping setup screen, shown in Figure 1-4. This screen allows you to

set up channel groups. Select Allow Channel Grouping in order to allow

channel grouping.

When channels are grouped, the spreadsheet v iew show s only o ne gr oup

of channels at a time. Recipes and recipe management are also groupspecific—each group has its own set of recipes.

NOTE

Setting up channel groups deletes pre-existing recipes and logged

data. Group channels only if you want separate recipe control for

certain channels.

By default, AnaWin creates one group with all the controllers’ loops. To

separate channels into defined groups, follow these steps:

1. Select Allow Channel Grouping.

2. Select the Default group in the Group Name field.

3. Click Delete to delete the Default group.

4. Click New and enter a Name for the new group.

5. Select a Controller in the Available panel.

6. Use the Start channel and End Channel fields to define a sequence

of channels to be included in the group.

7. Click Add to add the specified channels for the selected controller to

the group. The channels you add are listed in the group panel.

8. Repeat steps 4-7 to create additional groups until you have put all

the channels into a group. Any channels that you do not put in a

group will not be available in AnaWin.

1-6 AnaWin User’s Guide

NOTE

A group must consist of contiguous sets of loops from within any

one controller, though it may contain sets of contiguous sets of

loops from several controllers

Allow Channel Grouping

You must select the Allow Channel Grouping option in order to be able

to group channels. With channel grouping, you can establish related

blocks of channels for display and editing purposes. These groups can

cross more than one controller, but must be in sequence. For instance,

one group might include channels 1 to 10, and another, channels 11 to

16 etc. But you would not be able to have a group that included channels

2, 5, 6, 7, and 9, because they are not all in sequence.

Page 15

Installation and Setup

FIGURE 1-4

Channel Grouping Setup Screen

Group Parameters

•

Name: Displays the name of the group currently selected in the list.

•

New: Lets you create a new group to add to the list.

•

Rename: Lets you rename a group.

•

Delete: Lets you delete a group.

Add and Remove Buttons

These buttons allow you to add channels to and remove channels from a

group.

Add: Lets you add the sequence of channels defined by the Start

Channel and End Channel fields to the current group.

Remove: Lets you remove the channels selected in the list in the Group

panel from the current group.

Available Controllers and Channels

The Available panel allows you to select a controller and block of

channels for grouping. The Start Channel and End Channel fields

define the sequence of channels to add to the group. Click Add to add

these channels to the group. When you add a sequence of channels, the

channel names are listed in the Group panel.

Other Configuration Options

You can perform the following optional configuration options.

•

Automatically set up each ModBus address.

•

Configure communications options.

•

Customize displayed parameter, channel, and/or digital I/O names.

AnaWin User’s Guide 1-7

Page 16

Installation and Setup

The following subsections describe these options.

Automatic ModBus Address Setup

Click Detect to direct AnaWin to automatically attempt to communicate

to each ModBus address. AnaWin checks each address and sets up any

controllers it finds.

Configuring Communications Options

Use the Communications option on the System menu to select the port to

which you have connected your controller(s) and the baud rate for

which you have configured your controller(s).

•

From the System menu, select Communications, then Port to select

the port to which you have connected the controller(s).

•

From the System menu, select Communications, then Baud Rate to

select the baud rate for which you have configured your controller(s).

Customizing Displayed Names

Use the options on the Names menu to customize displayed names of

specific global and channel parameters or names of channels and digital

inputs and outputs.

From the Names menu, select Parameter Names to display the

Parameter Names screen, shown in Figure 1-5. Use this screen to

customize channel, global, and ramp/soak parameter names.

1-8 AnaWin User’s Guide

FIGURE 1-5

Parameter Names Screen

Page 17

Installation and Setup

To customize parameter names follow these steps:

1. Use the Parameter Type radio buttons to select a group of parameters to rename (Channel, Global, or Ramp Soak).

2. Use the Parameter pull-down list box to choose the first parameter

of the selected type that you want to rename.

3. Enter your custom name in the Display Name field.

4. Repeat steps 2 and 3 for the other parameters of the selected type

that you want to rename.

5. If desired, repeat steps 1- 5 to ren ame param e ters o f a di fferent type.

NOTE

The Data Table Ref field on the Parameter Names screen is a read-

only field that refers to the CLS Data Table. Refer to the Communications Specifications manual for details.

•

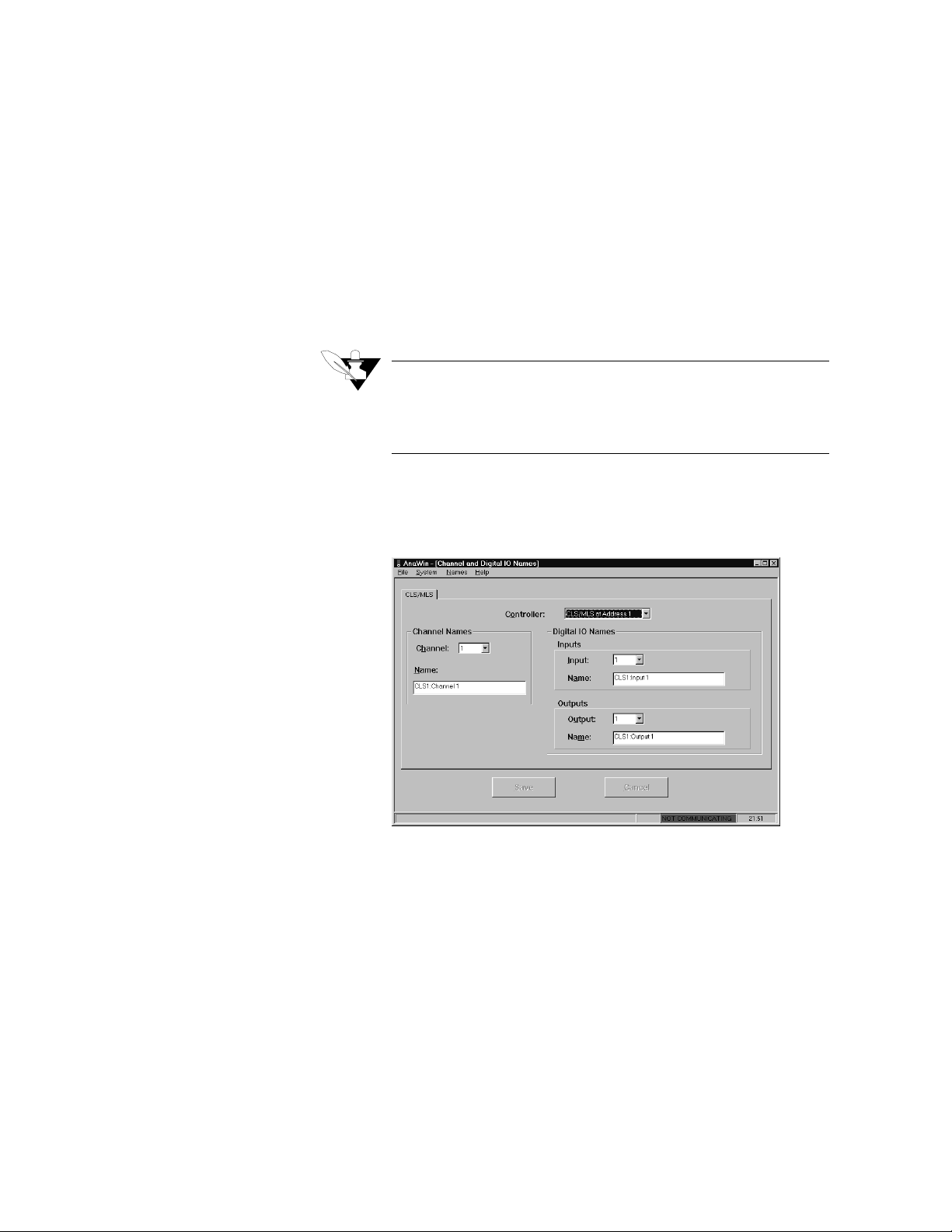

From the Names menu, select Channels & DIO, to display the Chan-

nel and Digital IO Names screen, shown in Figure 1-6. Use this

screen to customize channel and digital input and output names.

FIGURE 1-6

Channel and Digital IO Names Screen

Use the Channel Names panel to customize channel names. One by one,

select the channels you want to rename from the Channel pull-down list

box, then enter your custom name in the Name field.

Use the Digital IO Names panel to customize digital input and o utput

names. One by one, select the input or output you want to rename from

the Input or Output pull-down list box, then enter your custom name in

the Name field.

AnaWin User’s Guide 1-9

Page 18

Installation and Setup

Monitoring the Configured Controllers

Once you have used the Configure program to configure your

controllers, select Return from the File menu to return to AnaWin and

begin monitoring the controllers you have configured, as described in

the remaining chapters of this guide.

1-10 AnaWin User’s Guide

Page 19

AnaWin Screen

Displays

This chapter describes the features common to most AnaWin screens

and lists the options available from the AnaWin main menu bar.

Screen Conventions

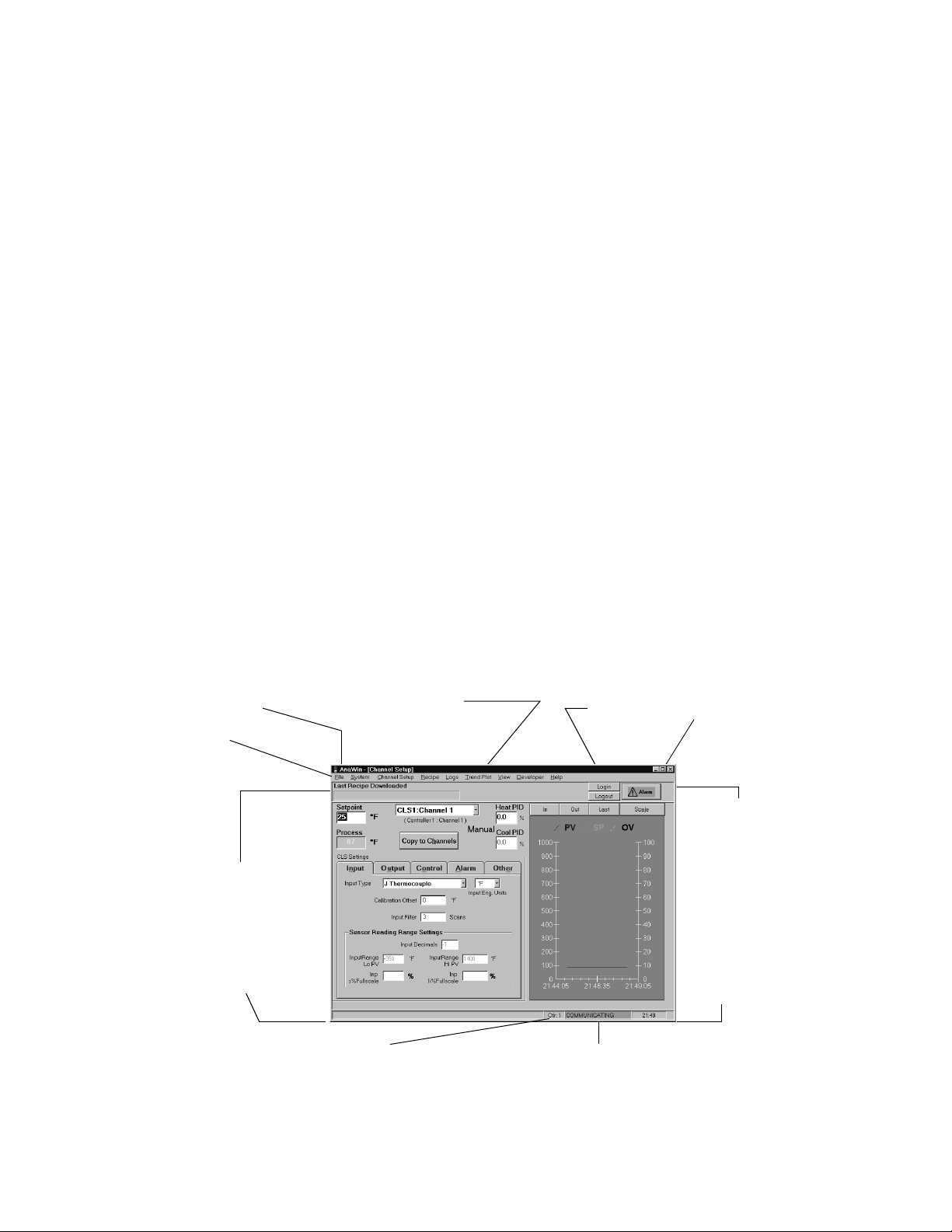

Figure 2-1 shows a typical AnaWi n screen.

Caption

Main Menu

Name of Last

Recipe Downloaded

Current Group

(if enabled)

Login/Logout

Buttons

2

Minimize/Maximize

Screen

Alarm Button/

Indicator

Message box (description of cursor locatio n or

current operation)

Communicating Controller

FIGURE 2-1

Current Time

Communication Status

AnaWin Screen Conventions

AnaWin User’s Guide 2-1

Page 20

AnaWin Screen Displays

The following standard features appear on most AnaWin screens:

Caption: The name of the current screen.

Main Menu: Displays the AnaW in menus. Refer to “Main Menu,” later

in this chapter for a diagram of the menu options on the main menu.

Last Recipe Downloaded: Displays the name of the last recipe

downloaded to the controller.

Current Group: The name of the group currently selected for display.

Refer to “Channel Grouping,” in Chapter 1 for details about creating

channel groups.

Login Button: Click Login to identify yourself to AnaWin. Refer to

“Login,” in Chapter 4, for details.

Logout Button: Click Logout to ensure unauthorized personnel are not

able to access AnaWin features without logging in. Refer to “Logout,”

in Chapter 4, for details.

Alarm Button: Click Alarm to display the Alarm screen. The color of

the Alarm button also serves as an alarm indicator:

Green = No alarms

Yellow = Ch annel in deviation

Red = Channel in alarm

Refer to Chapter 11 for details about viewing and acknowledging

alarms.

Cursor/Location Description: Displays a description of the current

cursor location or current operation.

Communicating Controller: Indicates the controller with which

AnaWin is currently communicating.

Communication Status Indicator: Displays the current

communication status. The communication status is indicated both by

the text on this bar and the color of the bar:

Green = Communicating

Red = Not communicating

2-2 AnaWin User’s Guide

Yellow = Incomplete communication: AnaWin is communicating with

some, but not all, of the cont rollers for which is has been configured.

This status occurs if one or more controllers is set offline or a

communication has failed with one or more controllers.

Page 21

Main Menu

AnaWin Screen Displays

Time: Displays the current time.

Maximize/Minimize: Click the Minimize and Maximize buttons to

minimize and maximize the screen.

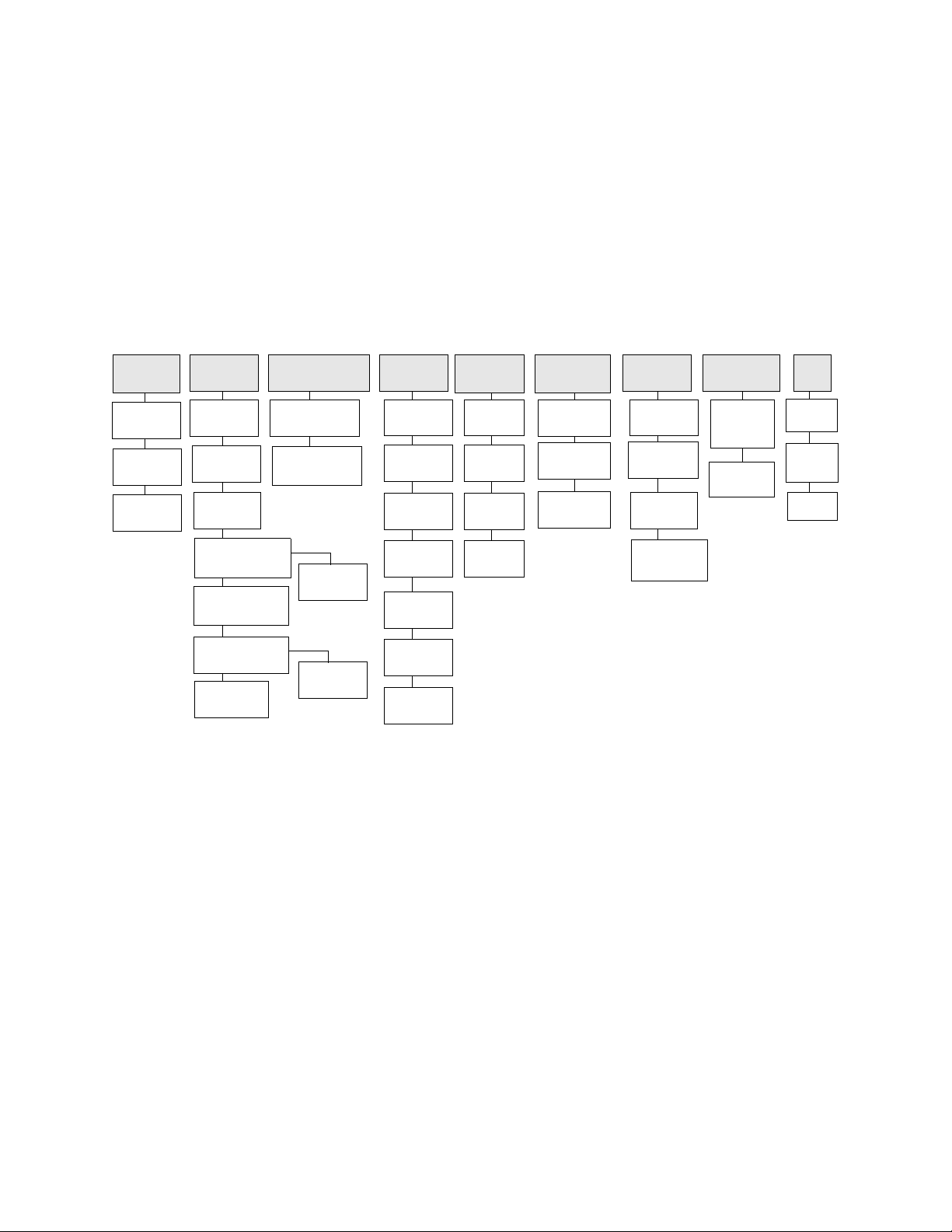

You use the main menu to access AnaWin screens and to perform basic

operations with the controller. Figure 2-2 shows the options available

from the main menu. The following chapters describe the features

available from the menus.

File System Channel Setup Recipe Logs Trend Plot View Developer

Export

Database

Data Log

Setup

Exit

Login

Logout

Preferences

Communications

Com Diags

Snapshot

Configure

Channel

Parameters

Ramp/Soak

Setup

Enable

Disable

Save

Restore

FIGURE 2-2

New

Open

Save

Save As

Remove

Download

Calendar

View

Print

Copy to A:

Remove

AnaWin Main Menu Options

Trend Plot

Settings

Trend Plot

Storage

Trend Plot

Spread

Sheet

Bar Graph

Digital I/ O

(Custom

Overviews)

Design

Custom

Overview

User

Variables

Help

Contents

Search

Help On...

About

AnaWin User’s Guide 2-3

Page 22

AnaWin Screen Displays

2-4 AnaWin User’s Guide

Page 23

Exporting Data

This chapter explains how to use the data export features on AnaWin’s

menu. While AnaWin provides comprehensive trend plotting

File

capabilities, you may need to export data to other applications. Two

options are available for exporting:

.

Setup

Export Database

and

3

Data Log

Export Database

Using the

customize when data is logged and which channels are included in the

log file. You can then use these data logs with programs other than

AnaWin to report or analyze your process performance or history. You

might, for example, import data into a spreadsheet app lication and graph

it for a report.

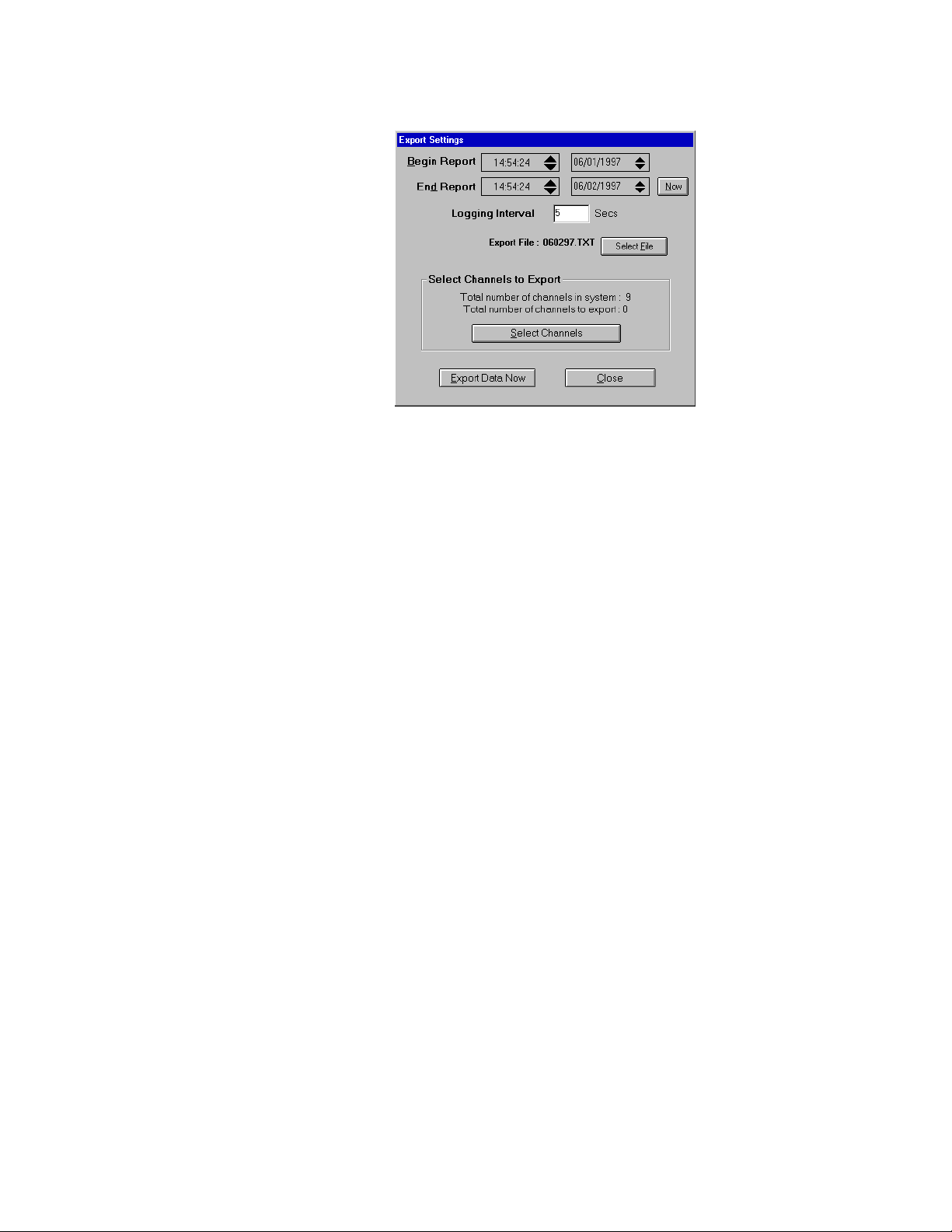

Select

Figure 3-1. From this screen, you can export a block of process data int o

a text file. This option is a one-time export of data, based on a block of

time and channels you set from data accumulated for trend plotting.

Export Database

Export Database

and

Data Log Setup

to display the Export Settings screen, shown in

options, you can

AnaWin User’s Guide 3-1

Page 24

Exporting Data

FIGURE 3-1

Export Settings Screen

Setpoint, process variable, and heat and cool output power are logged

whenever AnaWin communicates with one or more controllers. The

maximum sampling frequency is determined by the parameters set

through the Trend Plot menu. Refer to “Trend Plot Settings.” in Chapter

7, for information on how to set the frequency for data collection.

Set the following parameters on the Export Settings screen to set up

export to a database file.

Begin Report

Use the Begin Report fields to define the time (Hou rs, minutes, seconds)

and the day (day, month, year) serving as the starting point of your data

log file. The time is in 24-hour format.

T o ch ang e a value, either over type the ex isting value u sing the key boar d

or move the cursor to the left of the value you want to change and click

on the up/down arrows to increase or decrease the values.

End Report

Use the End Report fields to define the time (Hours, minutes, seconds)

and the day (day, month, year) serving as the ending point of your data

log file.

3-2 AnaWin User’s Guide

Click on the up/down arrows to the right of the value you want to

change, and to increase or decrease the values.

Now

If you want your data logging file to end at the current moment, click

Now instead of using the up/down arrows.

Page 25

Exporting Data

Logging interval

The logging interval is the span of time (in seconds) for the data points

to be exported. The default value is 5, meaning that exported data

represents the state of the process variables every five seconds between

the starting and ending points. Increase or decrease the Logging Interval

by entering a new value and pressing Enter. If you do not press Enter,

the old value will re-appear.

Export file

The Export File field lists the file name for the default text file. The

default file name consists of the date, expressed in 6 figures, and th e

suffix TXT.

Select File

Click the Select button to set the name and location of th e file to be

created when data is exported. The data you have selected is saved in

the file you indicate. Figure 3-2 shows a sample exported data file.

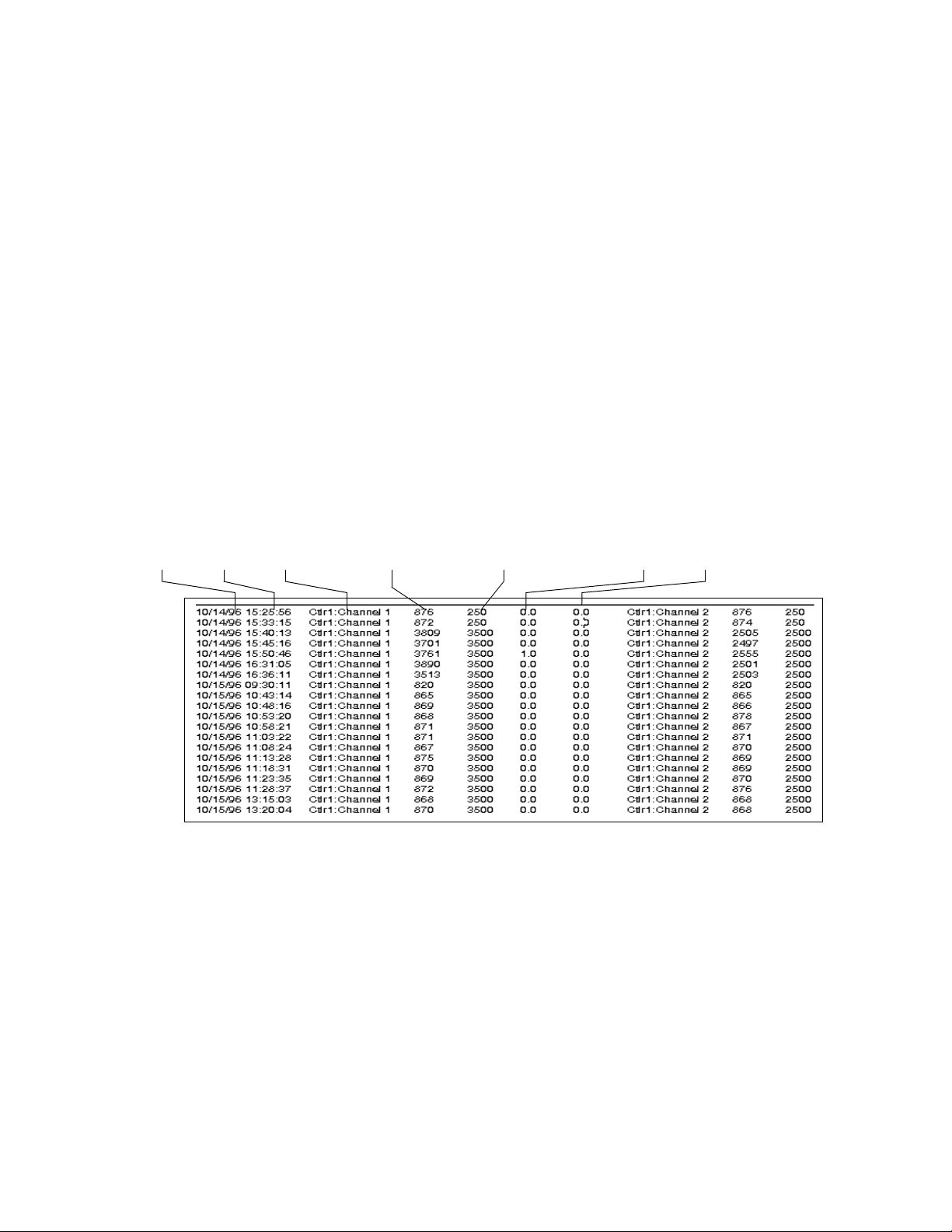

Date Time Setpoint Process Variable Output1 Output2Channel Name

FIGURE 3-2

Exported Data File Sample

Select Channels to Export

The data export file can include all the channels in the system, or only

some of them, according to your needs. Use the Select Channels button

in the Select Channels to Export panel, to select the channels you wish

to export.

Press the Select Channels button to select the channels you wish to

export.

AnaWin User’s Guide 3-3

Page 26

Exporting Data

The Select Channels to Export panel lists the total num ber of channels

in the system and the total number of channels currently selected for

export. Click Select Channels to select specific channels from the total.

Select the channels you wish to export, then click OK.

Export Data Now

Click Export Data Now to expor t data to the selected text f ile using the

specified export settings.

Data Log Setup

Select Data Log Setup to display the Data Log Settings screen, shown in

Figure 3-3. From this screen, you can set AnaWin to regularly log data

to a database file.

FIGURE 3-3

Data Log Settings Screen

Data Logging Status

The data logging status (ON or OFF) appears at the top of the screen. If

the data log ging status is OFF, no continuou s data logging will occur.

Set the data logging status to ON, to begin continuous logging.

Logging Interval

Set the frequency of data logging. Setpoint, process variable, and two

output variables for each selected channel are logged according to the

period defined in this field.

Select Channels to Log

The data logging file can include all the channels in the system, or only

some of them, according to your needs. Use this field to select the

channels you want to log.

3-4 AnaWin User’s Guide

Page 27

Start

Click Start to begin data logging.

Stop

Click Stop to end data logging.

Done

Click Done to leave the screen with no changes.

Exporting Data

AnaWin User’s Guide 3-5

Page 28

Exporting Data

3-6 AnaWin User’s Guide

Page 29

Setting System

Parameters

4

This chapter explains how to use the options on the

preferences and configure AnaWin to operate controller(s). If password

protection has been enabled, you can also access login and logout

screens.

The

Login

•

Logout

•

Preferences

•

Com Enabled

•

Com Diags

•

Configure

•

AnaWin provides numerous customizable features which can help you

adapt the program to work in a way that fits your needs. You can

establish intelligent connections between your process and your

AnaWin interface by:

Enabling and configuring password protection to help ensure each

•

user is only presented with the screens and commands he or she has

been trained to use.

Setting startup preferences that allow AnaWin to bring up your pro-

•

cess appropriately after a normal shutdown and differently after a

power failure.

Customizing how the interface reacts when an alarm occurs.

•

Customizing the comment prompt displayed when a recipe is saved.

•

Configuring a digital input or output to prevent recipe downloading.

•

menu includes the following options:

System

System

menu to set

AnaWin User’s Guide 4-1

Page 30

Setting System Parameters

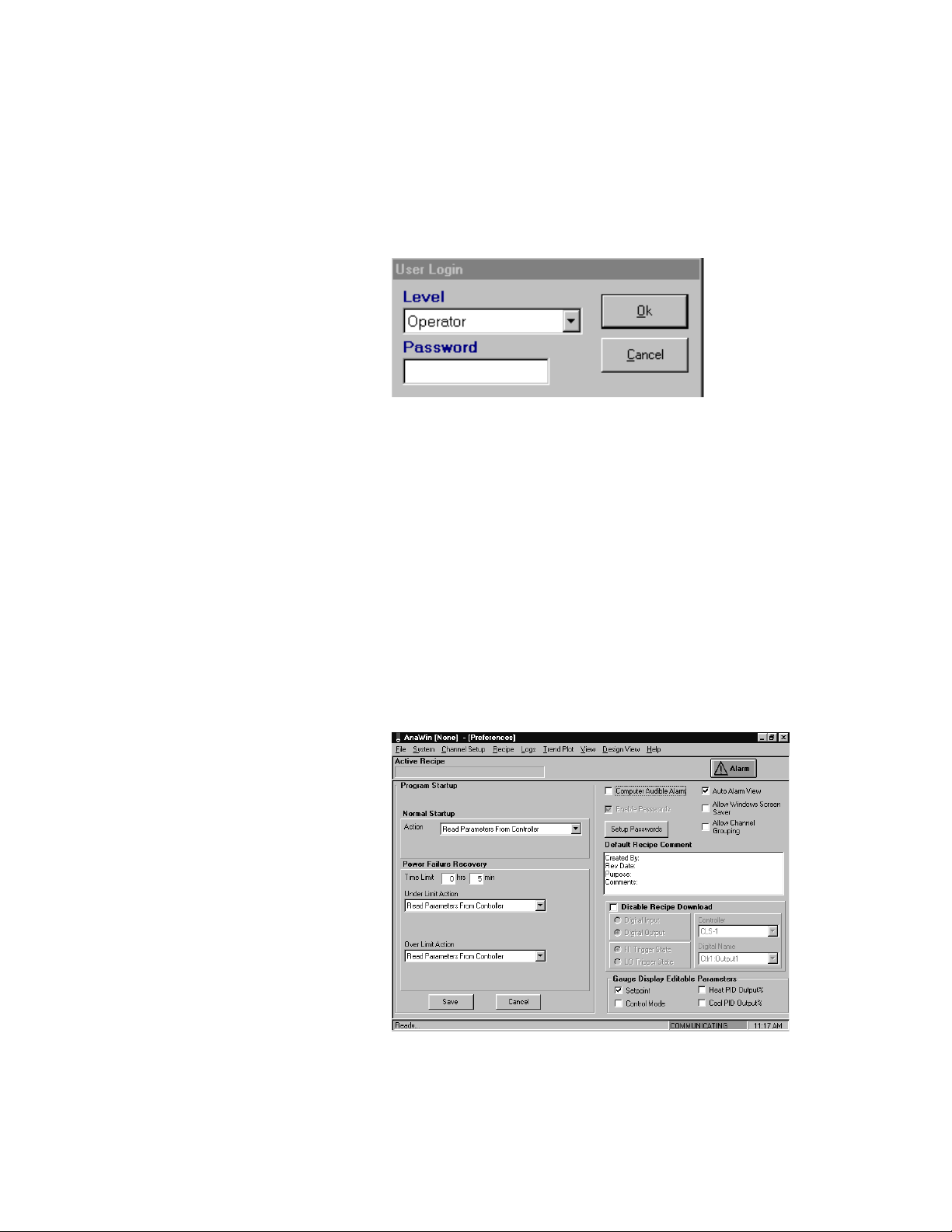

Login

Select Login to display the User Login screen, shown in Figure 4-1. This

screen allows you to log in to the system or identify yourself to

AnaWin. Note that the User Login screen appears only if Enable

Passwords is selected on the Preferences screen. Refer to

“Preferences,“later in this chapter, for details.

Logout

Preferences

FIGURE 4-1

User Login Screen

Select your Level and type your Password. Refer to “Setup Passwords,”

later in this chapter, for details.

Select Logout to log out of the system.

Select Preferences to displ ay t he Preferences s creen , sh own i n Figu re4-2.

This screen allows you to set startup options and other AnaWin

operational parameters. These settings allow you to customize

AnaWin’s features.

4-2 AnaWin User’s Guide

FIGURE 4-2

Preferences Screen

Page 31

Normal Startup

Setting System Parameters

The Normal Startup panel, shown in Figure 4-3, allows you to specify

what actions will occur when you launch AnaWin.

FIGURE 4-3

Power Fail Recovery

Normal Startup Panel on Preferences Screen

You can set one of these three Actions:

•

Read Parameters From Controller: Reads the operational parame-

ters from the controller on bootup.

•

Send Parameters to Controller: Downloads parameters from

AnaWin to the controller(s). If you select this option, you can either

have AnaWin load the last recipe which was downloaded or any of

the recipes saved on the PC’s hard disk.

•

Operator Select on Startup: Prompts the opera tor to choos e to read

parameters from the controller or download a recipe when AnaWin

is launched.

The Power Failure Recovery panel, shown in Figure 4-4, allows you to

specify how AnaWin will respond after a sudden loss of power. Set a

time limit and appropriate startup actions. If AnaWin is launched within

the time limit, it executes the Under Limit Action. If AnaWin is

launched after the time limit elapses, it executes the Over Limit Action.

FIGURE 4-4

Power Failure Recovery Panel on Preferences Screen

AnaWin User’s Guide 4-3

Page 32

Setting System Parameters

Under Limit Action: Sets a startup operation if the amount of time

AnaWin is powered down is less than the specified time limit.

Over Limit Action: Sets a startup operation if the amount of time

AnaWin is powered down is greater than the specified time limit.

You can choose from three options for the under and over limit actions:

•

Read Parameters From Controller: Reads the operational parame-

ters from the controller on bootup.

•

Send Parameters to Controller: Downloads parameters from

AnaWin to the controller(s). If you select this option, you can either

have AnaWin load the last recipe which was downloaded or any of

the recipes saved on the PC’s hard disk.

•

Operator Select on Startup: Prompts the opera tor to choos e to read

parameters from the controller or download a recipe when AnaWin

is launched.

Save

Click Save to save the Program Startup options you have set. Changes

made to other portions of the Preferences screen are saved immediately

when you make the changes.

Cancel

Click Cancel to cancel changes in the Program Startup panel.

NOTE

When using channe l groupin g, set opti ons in the Progr am Startup

panel for each group.

Miscellaneous System Parameters

Figure 4-5 shows the miscellaneous system parameters available on the

Preferences screen. The following subsections describe these

parameters.

4-4 AnaWin User’s Guide

FIGURE 4-5

Miscellaneous Parameters on the Preferences Screen

Page 33

Setting System Parameters

Computer Audible Alarm

Sets the computer’s audible alarm to respond when an alarm condition

occurs.

Auto Alarm View

Sets the alarm screen to appear automatically any time an alarm occurs.

Enable Passwords

Turns on password protection and enables the Setup Passwords button.

Refer to “Setup Passwords” later in this chapter for details about setting

up password s.

Allow Windows Screen Saver

Normally, AnaWin disables the Windows screen saver. Select this

option to allow a Windows screen saver to run.

Setup Passwords

Use password protection to limit access to certain menus and screens.

To enable password protection, select the Enable Passwords check box

on the Preferences screen (AnaWin is shipped with passwords

disabled.) Click Setup Passwords to display the Password Setup screen,

shown in Figure 4-6. Note that you must have Supervisor rights to

access the Password Setup screen. A default password has been

assigned to each password level.

NOTE

The default password is control (all lower-case letters).

FIGURE 4-6

Password Setup Screen

AnaWin User’s Guide 4-5

Page 34

Setting System Parameters

You can set password protection by user Level (operator, supervisor,

engineer, or none), or by specific User.

•

Level: Select Level to divide password protection bet ween Operator,

Engineer, Supervisor, or None user levels.

•

User: Select User to set up passwords for users by name. If you

select the User option, you mu st as si gn a us er l evel and pas swor d t o

each user. Do this in the User Information section of the screen as

described under “Setting Passwords by Level,” later in this chapter.

NOTE

If you misplace or forget the Supervisor password, call Technical

Support for a one-day only master password.

Setting Passwords by Level

If you select the Level option, you can set three passwords: Operator,

Engineer, or Supervisor. You can set access for each level in the

Password Le vel Required panel, as described below.

FIGURE 4-7

Password Level Required: The Password Level Required panel,

shown in Figure 4-7, allows you to assi gn acces s ri ghts fo r u ser levels to

portions of AnaWin.

Password Level Required Panel

When you double-click All Menus, the AnaWin menu tree appears as

shown in Figure 4-8. Select the portions of the menu tree to password

protect. To enable password protection, highlight a menu item and click

the button corresponding to the user level. The None designat or changes

to the selected user level.

4-6 AnaWin User’s Guide

Page 35

Setting System Parameters

FIGURE 4-8

FIGURE 4-9

AnaWin Menu Tree with Assigned User Levels

Level Passwords: The Level Passwords panel, shown in Figure 4-9

allows you to set the passwords for the three user levels.

Level Passwords Panel

Setting Passwords by User

If you select the User option, the user information panel, shown in

Figure 4-10, appears on the Password Setup screen, and you can assign

a password and security level to each user. User security mode allows

you to assign each user a unique password. In user security mode, the

Administrator user is always present. Change the default password to

prevent unauthorized access.

FIGURE 4-10

User Information Panel

AnaWin User’s Guide 4-7

Page 36

Setting System Parameters

T o add a user, follow these steps:

1. Enter the user’s name in the User Name field.

2. Enter a password for that user in the Password field.

3. Use the Level pull-down list box to select a security level for that

user.

4. Click Add User. The user’s name now appears in the list under the

User Name field.

To delete a user, follow these steps:

1. Select the user’s name from the list under the User Name field.

2. Click Delete User.

To change a user’s password or security level, follow these steps:

1. Select the user’s name from the list under the User Name field.

2. Enter a new Password and/or select a new security Level.

3. Click Modify User.

Default Recipe Comment

The Default Recipe Comment field allows yo u to edit the default recip e

comment text. To change the text of the default comment, shown in

Figure 4-11, use the keyboard to delete and add text. Note that any

changes you make will appear in the comment section when a new

recipe is saved.

FIGURE 4-11

T e xt for Def a ult Recipe Comment

4-8 AnaWin User’s Guide

Page 37

Disable Recipe Download

Select Disable Recipe Download and set the as sociated options, shown

in Figure 4-12, to set the software to prevent recipe downloads under the

specified conditions.

Setting System Parameters

FIGURE 4-12

Disable Recipe Download Options

Select a digital input or output and state (high or low), as the condition

that will prevent recipe downloads.

Gauge Display Editable Parameters

Use the Gauge Display Editable Parameters panel, shown in Figure 4-13,

to specify which parameters on the Gauge Display screen are editable.

Place a check mark in the box corresponding to each parameter you

want to be editable.

FIGURE 4-13

Gauge Display Editable Parameters Panel

Communications

From the System menu, select Communications, then Enabled or

Disabled to enable or disable communications with one or more of the

controllers.

When you select Enabled or Disabled, a selection window appears.

From this window, select the controller for which you want to enable or

disable communications, then click OK.

When communication is enabled, the indicator shown in Figure 4-14

appears in the bottom right-hand portion of the screen. This indicates

that AnaWin is communicating with the controller(s).

FIGURE 4-14

Communication Enabled Indicator

AnaWin User’s Guide 4-9

Page 38

Setting System Parameters

When communication is disabled or communication with all controllers

has failed, the indicator shown in Figure 4-15 appears on the bottom

right-hand portion of the screen. This indicates that AnaWin is not

communicating with the controller(s).

Com Diags

FIGURE 4-15

When AnaWin is set up to communicate with multip le controllers, and

some controllers are not communicating, the indicator displays

“INCOMPLETE COMM”.

Select Com Diags to display the Communication Diagnostics screen,

shown in Figure 4-16. This screen displays the cumulative

communications errors encountered within the specified time limit. Use

the Evaluation Time Window field to set the time limit.

Communication Disabled Indicator

Configure

4-10 AnaWin User’s Guide

FIGURE 4-16

Select Configure to leave AnaWin and launch the Configure program.

Refer to the Chapter 1 for details about using the Configur e pro gram.

Snapshot

Select Snapshot to save or restore a snapshot of a selected controller’s

settings. A snapshot is a backup of the controller’s data table. When

snapshot save is selected, the entire data table is read and stored on the

computer’s hard disk. Restoring a snapshot puts a controller back to a

previously saved state which is especially useful after a controller

firmware update or when a controller is replaced.

Communication Diagnostic s Scre en

Page 39

Setting System Parameters

Save

Select Snapshot, then Save to select the controller for which you want to

save a snapshot. You can save one snapshot for each controller. Select

the desired controller, then click OK to save a snapshot of the

controller’s current settings—including any changes you have made in

the current session.

Restore

Select Snapshot, then Restore to restore a snapshot. Select the desired

controller, then click OK to restore the snapshot of the controller’s

settings before you made any changes.

AnaWin User’s Guide 4-11

Page 40

Setting System Parameters

4-12 AnaWin User’s Guide

Page 41

Setting Channel

Parameters

This chapter explains how to use the options on the Chann el Setup men u

to configure channel parameters and set up ramp soak options. The

Channel Setup menu includes the following options:

Channel Parameters

•

Ramp Soak Setup

•

The channel parameter and ramp/soak screens simplify and streamline

the task of setting up your controllers. The channel copy feature, for

example, can save you literally hours of tedious data entry. Graphical

displays group related parameters and present them more clearly than is

possible on the controller front panel interface.

Channel Parameters

Select Channel Parameters to display the Channel Setup screen, shown

in Figure 5-1. Use this screen to set the input, output, control, and alarm

parameters for each channel. The Channel Setup screen also includes a

real-time plot screen that displays the process variable and output

variable as you make changes.

5

AnaWin User’s Guide 5-1

Page 42

Setting Channel Parameters

Channel Summary

Channel Setup

Tabs

Channel Summary

FIGURE 5-1

Real-time Trend

Plot

Channel Setup Screen

The top portion of the Channel Setup screen, shown in Figure 5-2,

allows you to choose a channel to set up and provides some basic

information about the channel being edited.

FIGURE 5-2

Top Portion of Channel Setup Screen

Channel Number

Use the channel number pull-down list box to choose the channel you

want to edit or view.

Setpoint

Use the Setpoint field to enter a setpoint for the selected loop. The

setpoint range appears at the bottom of the screen when you p os ition the

cursor over the field. If you enter a setpoint that is out of the defined

range, the controller will assign the closest number within the range.

Press the Enter key to send your new setpoint to the controller.

Process

The Process field displays the process variable in real time. It is a read

only field.

5-2 AnaWin User’s Guide

Page 43

Setting Channel Parameters

NOTE

If Allow Channel Grouping is selected on the Controller Setup

screen, only the channels assigned to the curre nt group will be

available for selection.

Copy to channels

Click Copy to Channels to copy the displayed channel’s setup to another

channel. This feature enables fast and easy channel setup. You cannot

copy the setup of a pulse channel to a non-pulse channel, and vice versa.

When you click Copy to Channels, the chann el list sh own in Figure 5 -3

appears. Highlight the desired channel(s), then click OK. The

parameters from the current channel are copied to each of the selected

channels.

FIGURE 5-3

Real-time Trend Plot

Selecting Channels to which to Copy Parameters

Control Mode and Ramp/Soak Status

The right side of the Channel Setup screen’s channel summary area

displays the control modes Manual, Auto, or Tune. Use the Control tab

in the Channel Setup Tabs panel to change the control made. Refer to

“Control,” under “Channel Setup Tabs,” for details. If Manual mode is

selected, you can use the Heat PID and Cool PID fields to change the

power percentages; otherwise, if a ramp/soak profile is assigned to the

channel, the ramp/soak status —Start, Run, or Hold—is displayed. Refer

to “Control,“under “Channel Setup Tabs,” for details about how to set

the ramp/soak status.

The real-time trend plot on the right of the Channel Setup screen

provides real-time graphic trending.

AnaWin User’s Guide 5-3

Page 44

Setting Channel Parameters

The trend plot displays the last five minutes of the process for the

current channel. Three parameters are plotted: Process Variable (PV),

Output Value (OV), and Setpoint (SP).

The real-time trend plot screen is not editable. You cannot change the

parameters being plotted (PV, OV, SP) or change the time frame of the

graph. Use the plot for a quick view of your process, and as an aid when

tuning your control process.

In: Increases the plot’s vertical axis resolution.

Out: Decreases the plot’s vertical axis resolution.

Last: Returns the plot to the last vertical axis scal ing val ues .

Scale: Scales the trend plot to fit into the size of the plot window.

Channel Setup Tabs

The Channel Setup screen contains five tabs, shown in Figure 5-4, that

allow you to set the parameters for the channels. Refer to your controller

manual for setup information.

FIGURE 5-4

FIGURE 5-5

Channel Setup Tabs

Input

Use the Inpu t tab, shown in Figure 5-5, t o choose the se nsor type and

other input parameters.

Channel Setup Input Tab

When you choose Skip, you cannot edit any of the parameters.

When you choose Linear or Pulse as the input type, the four Sensor

Reading Range Settings fields become available.

5-4 AnaWin User’s Guide

Page 45

Setting Channel Parameters

Output

Use the Output tab, shown in Figure 5-6, to enable or disable outputs

and to choose the output signal type.

FIGURE 5-6

FIGURE 5-7

Channel Setup Output Tab

The Output tab includes two panels: one for output #1 (generally for

heat) and one for output #2 (generally for cool). When you select Time

Proportioning output, another field appears in which you can enter the

cycle time for the TP output. If you select SDAC output, the SDAC

Settings panel, shown in Figure 5- 7, appears.

SDAC Settings Panel

Control

Use the Control tab, shown in Figure 5-8, to select a control mode

(Auto, Manual, or Tune) or the ramp/soak status (Start, Run, or Hold).

The mode or status you select here appears in the upper part of the

Channel Setup screen, in the channel summary area, as described in this

chapter.

AnaWin User’s Guide 5-5

Page 46

Setting Channel Parameters

FIGURE 5-8

Channel Setup Control Tab

In addition, the Control tab also includes the following fields that allow

you to set control parameters for output #1 and output #2:

Prop Band: The range in which the proportioning function of the

control is active.

Integral: A control action that automatically eliminates offset, or droop,

between setpoint and actual process temperature.

Derivative: A control action that anticipates the rate of change of the

process and compensates to minimize overshoot and undershoot. This

value is measured in seconds.

PID Filter: The time constant for the output filter. The heat or cool

output filter prevents oscillations by dampening the output’s response.

The output responds to a step change by going approximately 2/3 of its

final value within the number of scans that are set.

For loops with a ramp/soak profile assigned, the following information

is displayed:

Tim Rem: Time remaining for the profile.

5-6 AnaWin User’s Guide

Total T i m e: Time the profile has been running.

Seg Time: Time remaining in the current segment.

Cycle: Cycle number; the cycle’s number out of the total cycles. Refer

to “Ramp Soak Setup,” later in this chapter, for further details about the

ramp/soak feature.

Alarm

Use the Alarm tab, shown in Figure 5-9, to enable alarms, set alarm

limits and alarm delays, customize alarm messages, and assign digital

outputs to alarms.

Page 47

Setting Channel Parameters

FIGURE 5-9

FIGURE 5-10

Ramp Soak Setup

Channel Setup Alarm Tab

Other

Use the Other tab, shown in Figure 5-10, to edit additional output

parameters.

Channel Setup Other Tab

AnaWin’s ramp/soak feature turns your controller into a powerful and

flexible batch controller, which you can program to change a process’

setpoint in a preset pattern over time. This pattern, or temperature

profile, consists of up to twenty segments. During a segment, the

temperature goes from the previous segment’s setpoint to the current

segment’s setpoint.

•

If the current segment’s setpoint is larger or smaller than the previ-

ous segment’s setpoint, the segment is called a ramp.

•

If the current segment’s setpoint is the same as the previous seg-

ment’s setpoint, the segment is called a soak.

AnaWin User’s Guide 5-7

Page 48

Setting Channel Parameters

Each segment can have up to two triggers (digital inputs). If enabled,

these triggers must be tru e b efor e the segment can start. When n eithe r o f

the triggers is true, the profile is in the trigger wait state. Y ou can use the

same trigger for more than one loop or one profile.

Using AnaWin’s ramp/soak feature, you can:

•

Assign new ramp/soak profiles.

•

Synchronize l oops.

•

Modify segment times.

•

View and modify profiles.

•

Save profiles to disk.

Your controllers must include the ramp/soak option in order to use

AnaWin’s ramp/soak feature. In addition, you must enable ramp/soak in

the Configuration program—by selecting the Ramp Soak Option check

box on the Controller Setup screen—in order to activate the ramp/soak

screens. If you do not select this op tion, the ramp/soak screens will not

be available.

Assigning Profiles to Loops

Select Ramp Soak Setup from the Channel Setup menu to display the

Ramp Soak Assignment s creen, shown in Figure 5-11. From this screen,

you assign profiles to loops.

NOTE

If you do not have any ramp/so ak cont rollers connected t o your sys tem, you will get an error message when you select Ramp Soak

Setup.

5-8 AnaWin User’s Guide

FIGURE 5-11

The Ramp Soak Assignment screen consists of a table in which each

row corresponds to a channel.

Ramp Soak Assignment Screen

Page 49

Setting Channel Parameters

Location

Use the Location column to select a memory location in the controller to

which to download a profile.

Profile Name

The Profile Name column indicates whether or not a profile has been

assigned to the corresponding channel.

If the Profile Name button is blank, clicking the column displays the

Select File window, shown in Figure 5-12. Use this window to assign a

profile to the loop.

FIGURE 5-12

Select File Window

•

T o assign a an existing p rofile to the loop, select a file name f rom the

list of valid profiles, then click OK to return to the Ramp Soak

Assignment screen.

•

To create a new profile with default values, type in a non-existent

profile name in the File Name field, then click OK to return to the

Ramp Soak Assignment screen.

If a valid profile is Assigned, clicking the Profile Name button displays

the Special Ramp-Soak Functions screen, shown in Figure 5-13.

Refer to “Using Special Ramp/Soak Functions,” below for details about

the menu options and screens you can access from the Special RampSoak Functions screen.

Using Special Ramp-Soak Functions

To display the Special Ramp-Soak Functions window, shown in

Figure 5-13, click the Profile Name column on the Ramp Soak

Assignment screen for a channel to which a profile has been assigned.

AnaWin User’s Guide 5-9

Page 50

Setting Channel Parameters

p

y

y

p

y

y

y

play

y

y

p

y

p

.

FIGURE 5-13

The menus on the S

s

When

Ram

Synchronize

Select

S

Special Ramp-Soak Funct i ons Window

ecial Ramp-Soak Functions window allow you to

nchronize loops, modify segment times, and jump to other segments.

ou are done using these menus, click

Done

from the Special

-Soak Functions window to return.

Loops

from the

Synchronize

menu to display the Channel

nchronization Setup window, shown in Figure 5-14, which allows

ou to synchronize loops.

5-10 AnaWin User’s Guide

FIGURE 5-14

To s

1. Click

2. From the list box, select the desired channels, then click OK to

3. Use the

4. Click

Channel Synchronization Setup Window

nchronize loops, follow these steps:

Select Channels

to dis

a pull-down list box from which

ou can select the channels you want to synchronize.

return to the Channel S

Ramp-Soak mode to be downloaded

select the mode

Download

to download the selected mode for the selected

channels and return to the S

nchronization Setup window.

ull-down list box to

ou want to download for the selected channels.

ecial Ramp-Soak Functions window.

Page 51

Setting Channel Parameters

Jump

Select Jump from the menu bar to display the Jump to Ramp-Soak

Functions window, shown in Figure 5-15. From this screen, you can

jump to a different segment or modify the time remaining in the current

segment.

FIGURE 5-15

To jump to a different segment, follow these steps:

1. Click Select Channels to display a pull-down list box from which

2. From the list box, select the desired channels, then click OK to

3. Enter the segment number for the segment to which you want to

4. Click Download to jump to the specified segment and return to the

To modify the time remaining for the segment that is currently runni ng

on the selected loop, follow these steps:

1. Use the Time remaining in segment fields to modify the time

2. Enter current segment number in the Advance to segment field.

3. Click Download to download your modification and return to the

Status

Jump to Ramp-Soak Functions Window

you can select the channels you want to jump to a different segment.

return to the Jump to Ramp-Soak Segment window.

jump in the Advance to segment field.

Special Ramp-Soak Functions window.

remaining.

Special Ramp-Soak Functions window.

Use the Status column to specify whether a profile is Assigned or Not

Assigned to the loop. An Assigned loop operates as a ramp/soak loop. A

Not Assigned loop operates as a standard control loop. Refer to “Profile

Name,” earlier in this section, for details about how to associate a

profile with a loop.

AnaWin User’s Guide 5-11

Page 52

Setting Channel Parameters

Edit/View Profile

The Edit/View Profile button allows you to access the Ramp Soak Edit

screen, on which you can view and modify a selected profile.

To display the Ramp Soak Edit screen, follow these steps:

1. Click Edit/View Profile to display the Select File window, shown

earlier in Figure 5-12, from which you can select a profile to edit or

view.

2. Select the file name for the profile you want to edit or view, or type

in a non-existent file name to create a new profile with default values.

3. Click OK to display the Ramp Soak Edit screen for that profile.

The following section tells you how to use the Ramp Soak Edit screen to

edit profiles.

Editing Profiles

Figure 5-16 shows the Ramp Soak Edit screen. Using this screen—and

other screens and windows that you access from it, you can modify the

profile view displayed on the screen; define segment information—

including triggers and events—for the segments in a profile; and define

a profile’s ready state. When you are done using the Ramp Soak Edit

screen, click Save to save your changes and return to the Ramp Soak

Assignment screen.

5-12 AnaWin User’s Guide

FIGURE 5-16

The top portion of the Ramp Soak Edit screen displays the profile

view—a graphical view of the selected profile, showing time on the

horizontal axis and process setpoint on the vertical axis. Use the

following controls to modify the profile view:

Spin: Use the buttons in the Spin panel to r otate the profile gro up Left

or Right. These buttons do not work if Show Segs is selected.

Ramp Soak Edit Screen

Page 53

Setting Channel Parameters

Show Segs: Select Show Segs to display the segment boundaries of the

profile. You can display up to 20 segments.

Segs Displayed: Use the First and Last fields in the Segs Displayed

panel to specify which segments you want to view.

The bottom portion of the Ramp Soak Edit screen displays a table of

information and editable parameters for the running segments in the

profile. Use the scroll bar at the bo ttom of the screen to scroll through

the segments. Refer to “Defining Segment Information,” below, for

details about using the segment table.

Defining Segment Information

Each column in the table at the bottom of the Ramp Soak Edit screen

represents a segment. The rows display the following:

Segment #: The Segment # row displays th e segment numb er. This is a

read-only field.

Name: Use the Name row to enter a name for the segment.

Seg Time: Use the Seg Time row to enter a time (duration) for the

segment. Segment time is unitless —it depends on how the ramp/soak

time base field is set in the controller at the time the profile is run. The

time base is either hours:minutes or minutes:seconds.

Total T i m e : The Total Time ro w displays the cumulative time for all

the segments up to the edited segment. This is a read-only field.

Setpoint: Use the Setpoint row to enter the setpoint you want at the end

of the segment.

Tolerance: Use the To le r an c e row to enter the segment setpoint’s

tolerance. If the difference between the PV and the setpoint is greater

than the tolerance, the loop goes into tolerance wait state until the PV is

back within setpoint tolerance. If you do not want to set a tolerance for

the segment, enter 0 in this field.

AnaWin User’s Guide 5-13

Page 54

Setting Channel Parameters

Trigger (#1 and #2): You can define up to two triggers per segment.

Click Trigger #1 or Trigger #2 to display the Trigger window for that

trigger. Figure 5-17 shows a sample Trigger window.

FIGURE 5-17

To define a trigger, follow these steps:

1. Use the options in the State panel to specify whether the trigger is

2. Use the Input Number pull-down list box to select the input number

3. Click Save to sav e the trig ger and return to the Ramp Soak Edit

Event (#1, #2, #3, and #4): You can define up to four events per

segment. An event is a digital output. Click Event #1, Event #2, Event

#3 or Event #2 to display the Event window for that event. Figure 5-18

shows a sample Event window.

Trigger Window

latched or unlatched and whether or not the trigger must be on.

•

Select Latched to define a latched trigger. Deselect Latched

to define an unlatched trigger. A latched trigger, once it

becomes active, is not checked again for the duration of the

segment. An unlatched trigger is checked continuously during the segment.

•

Select Must be ON if you want to requir e a di g ital input to be

on. Deselect Must be ON to require a digital input to be off.

for which you want to set the trigger. Select NONE for no trigger

condition.

screen. A notation repr esenting the trigger you de fined now app ears

in the Trigger row. For example, the notation

1-ON-U

indicates a

trigger for input number 1 that is on and unlatched.

5-14 AnaWin User’s Guide

FIGURE 5-18

Event Window

Page 55

Setting Channel Parameters

To define an event, follow these steps:

1. Use the Output ON check box—in the State panel—to specify

whether the digital output is on or off. Select Output ON to set the

digital output to On. Deselect Output ON to set the digital output to

Off.

2. Use the Output Number pull-down list box to select the output

number you wish to toggle at the end of the segment you are editing.

3. Click Save to save the even t and return to the Ramp Soak Edit

screen. A notation representing the event you defined now appears

in the Event row. For example, the notation

an event will turn output 16 on.

16-ON

indicates that

Defining Profile Ready States

Click the Ready button in the upper left corner of the Ramp Soak

Edit screen to display the Ramp Soak Ready State screen, shown in

Figure 5-19. From this screen you can define the profile’s ready state—

the setpoint and event outputs you want before the profile starts (i.e.

before the timer starts ticking). When you are done defining the ready

state, click the Segment Editor button to return to the Ramp Soak Edit

screen.

FIGURE 5-19

The Ramp Soak Ready State screen includes a three-dimensional profile

view and the following controls that allow you to define the profile’s

ready state:

Ready Setpoint: Use the Ready Setpoint field to enter the setpoint you

want before the profile starts.

Number of repeat cycles: Use the Number of Repeat Cycles field to

enter the number of cycles (1 to 99) that you want the profile to repeat

automatically. For continuous cycling, enter 0.

Ramp Soak Ready State Screen

AnaWin User’s Guide 5-15

Page 56

Setting Channel Parameters

Displayed Precision: Use the Displayed Precision field to set the

number of decimal places for setpoints in a profile that will be run on a

channel with input type set to linear. Channels with TC inputs always

use a precision of -1.

Last Segment: Use the Last Segment field to enter th e number of the

last segment that will be executed in the profile.

Tolerance Time-Out Period: Use the Tolerance Time-Out Period field

to enter the length of the tolerance time-out. If the PV is out of tolerance

for longer than the amount of time you specify, an alarm occurs.

Digital Output States: Use the Digital Output States pull-down list

boxes to set the event output (ON or OFF) that you want for each dig ital

output before the profile starts.

5-16 AnaWin User’s Guide

Page 57

Managing Recipes

6

This chapter explains how to use the options on the

manage all recipes. A recipe is a set of operating conditions for a

process that can be stored on the co mputer hard disk and tr ansmitted to

the controller.

Recipe management allows you to create and store complete sets of

operating parameters appropriate for each of the processes you run or

tasks you perform. Comments saved with each recipe help you ensure

the correct recipe is used each time. You can also schedule recipes to

download automatically according to a schedule to set up using the

calendar download feature.

Using the options on the

rename and delete existing recipes; download a recipe to the controller;

and set up the program to do wnload recipes automatically o n a daily or

hourly basis.

The

New

•

Open

•

Save

•

Save As

•

Remove

•

Download

•

menu includes the following options:

Recipe

menu, you can create new recipes; save,

Recipe

Recipe

menu to

Calendar

•

AnaWin User’s Guide 6-1

Page 58

Managing Recipes

NOTE

If you have enable d channe l groupi ng, you will c hoose a group to

work with immediately after selecting

Download

tained for each group.

from the

Recipe

menu. Separate sets of recipes are m ain-

New, Open, Remove

New

New

Select

this screen, you can create new recipes based on an existing recipe.

When you select

the current controller values.

to display the Recipe Editor screen, shown in Figu re 6-1. From

New

, the grid on the Recipe Editor screen is filled with

, or

FIGURE 6-1

Recipe Editor Screen

Recipe Spread Sheet

The Recipe Editor screen includes a spread sheet that allows you to

create a recipe. The parameters in the spreadsheet vary, depending on

the controller. Refer to your controller manual for information about the

various parameters.

To create a recipe using the spreadsheet, enter the desired operating

parameters by double-clicking a cell with a numeric value and typing a

new value or by using the pull-down selection boxes. Use the scroll bars

to access parameters (columns) and channels (rows) beyond the borders

of the Recipe Editor screen. You can also use the normal Windows

editing keys: cut (Ctrl-X), copy (Ctrl-C), and paste (Ctrl-V).

NOTE

Editing recipe parameters has no effect on the controller(s) until the