Page 1

ANASOFT

User’s Guide

Watlow Controls

1241 Bundy Blvd.

Winona, MN 55987

Customer Service

Phone: (800) 414-4299

Fax: (800) 445-8992

Technical Support

Phone: (507) 494-5656

Fax: (507) 452-4507

Email:

Part No. 21902-00, Revision 2.1

January 1996

wintechsupport@watlow.com

Page 2

Copyright © 1996

Watlow-Anafaze

Information in this manual is subject to change without n otice. No part of this publication m ay be

reproduced, stored in a retrieval system, or transmitted in any form without written permission

from Watlow-Anafaze.

Warranty

Watlow-Anafaze, Incorporated warrants that the products furnished under this Agreement will be

free from defects in material and w orkmanshi p for a per iod of t hree yearsf rom the dat e of shipm ent.

The customer shall provide notice of any defect to Watlow-Anafaze, Incorporated within one week

after the Customer's discovery of such defect. The sole obligation and liability of Watlow-Anafaze,

Incorporated under this warranty shall be to repair or replace, at its option and without cost to the

Customer, the defective product or part.

Upon request by Watlow-Anafaze, Incorporated, the product or part claimed to be defective shall

immediately be returned at the Customer's expense to Watlow-Anafaze, Incorporated. Replaced or

repaired products or parts will be shipped to the Customer at the expense of Watlow-Anafaze,

Incorporated.

There shall be no warranty or liability for any product s or parts that ha ve been subject to m isuse,

accident, negligence, failure of electric power or modification by the Customer without the written

approval of Watlow-Anafaze, Incorporated. Final determination of warranty eligibility shall be

made by Watlow-Anafaze, Incorporated. If a warranty claim is considered invalid for any reason,

the Customer will be charged for services performed and expenses incurred by Watlow-Anafaze,

Incorporated in handling and shipping the returned unit.

If replacement parts are supplied or repairs made during the original warranty period, the warranty

period for the replacement or repaired part shall terminate with the termination of the warranty

period of the original product or part.

The foregoing warranty constitutes the sole liability of Watlow-Anafaze, Incorporated and the customer's sole remedy with respect to t he products. I t is in lieu of all other warranties, liabilities , and

remedies. Except as thus provided, Watlow-Anafaze, Inc. disclaims all warranties, express or

implied, including any warranty of merchantability or fitness for a particular purpose.

Please Note: External safety devices must be used with equipment.

Page 3

Contents

Introduction 1

ANASOFT Versions .......................................................2

Computer Requirements .................................................3

Installation 5

Quick Installation ............................................................5

ANASOFT Files .............................................................5

File Locations .................................................................6

Installation Program ........................................................7

Installation Menu ............................................................8

Directory Paths ...............................................................9

Software Key Installation ...............................................10

Grouping Loops ..............................................................10

Start Up 13

Quick Start Up ................................................................13

Start Up Optional Modes ................................................13

Start Up Sequence ...........................................................14

Default Start Up Values ..................................................15

Start Up Errors ................................................................16

General Screen Displays 21

Changing Data ................................................................21

Print Screen .....................................................................22

Loop Overview 23

Getting Here ....................................................................23

Options ............................................................................23

Function Keys .................................................................25

Edit 27

Getting Here ....................................................................27

Function Keys .................................................................28

Loop Setup 29

Getting Here ....................................................................29

Function Keys .................................................................30

Parameters .......................................................................30

ANASOFT User’s Guide i

Page 4

System Setup 35

Getting Here ....................................................................35

System Errors ..................................................................36

System Software .............................................................37

Passwords ........................................................................38

System Parameters ..........................................................39

System Terminate ...........................................................41

System Start Up ..............................................................42

Data Logging ..................................................................44

Controller Comm. ...........................................................45

Digital Output Polarity ....................................................46

AIM Fail Output (MLS only) .........................................47

Job Setup 49

Getting Here ....................................................................49

Function Keys .................................................................49

View Alarms 51

Getting Here ....................................................................51

Function Keys .................................................................51

Alarm Screen Auto Switch .............................................52

Audible Alarm ................................................................52

Trend Plot 53

Getting Here ....................................................................53

Function Keys .................................................................54

Trend Plot Setup Screen .................................................54

Getting Here ....................................................................54

Print Trend Plot Screen ...................................................56

Appendix A: PID Tuning and Control 57

Introduction .....................................................................57

Control Modes ................................................................57

Control Outputs ...............................................................60

Digital Output Control Forms .........................................60

Setting Up and Tuning PID Loops .................................63

General PID Constants by Application ...........................65

Appendix B: Input Scaling 67

ii ANASOFT User’s Guide

Linear Input Scaling ........................................................67

Page 5

Appendix C: ANASOFT-RS 69

What is Ramp/Soak? .......................................................69

ANASOFT-RS Features .................................................69

Hardware Requirements .................................................70

Profile Assignment Screen ..............................................70

Getting Here ....................................................................70

Function Keys .................................................................70

Profile Edit Screens ........................................................71

Getting Here ....................................................................71

Function Keys .................................................................73

R/S Time Base ................................................................73

R/S Loop Face Plate Display ..........................................73

Power Failure Recovery ..................................................74

Glossary 75

ANASOFT User’s Guide iii

Page 6

iv ANASOFT User’s Guide

Page 7

Overview

Using This Guide

This manual describes how to install, setup, and operate ANASOFT.

ANASOFT is a DOS-based software program that allows you to

program and monitor multiple controllers from a single PC. Included is

data logging and trend plotting.

This guide is intended for both experienced and inexperienced users.

Experienced users may find some parts of this guide very simplistic; if

that’s you, please at least skim these parts to make sure you don’t miss

anything vital. If you’re an inexperienced user, please read this guide

carefully.

The following describes each section.

•

Introduction: Describes ANASOFT 3 and ANASOFT4 dif ferences

and computer requirements.

•

Installation: Covers how to install and setup ANASOFT.

•

Startup: Describes program loading and startup errors.

•

General Screen Displays: Provides an overview of the screen and

typical screen responses.

•

Loop Overview: Describes loop overview screen.

•

Edit: Describes the edit screen.

•

Loop Setup: Gives an overview of the loop setup screen. Included

are descriptions of control parameters.

•

System Setup: Describes the system setup screen.

•

Job Setup: Describes the job setup screen.

•

View Alarms: Describes alarms and how to view them.

•

Trend Plot: Covers tre nd plotting and reviewing trend plots.

•

Appendix A: Gives tips on tuning and control features.

•

Appendix B: Describes input scaling examples.

•

Appendix C: Describes the Ramp and Soak option.

ANASOFT User’s Guide v

Page 8

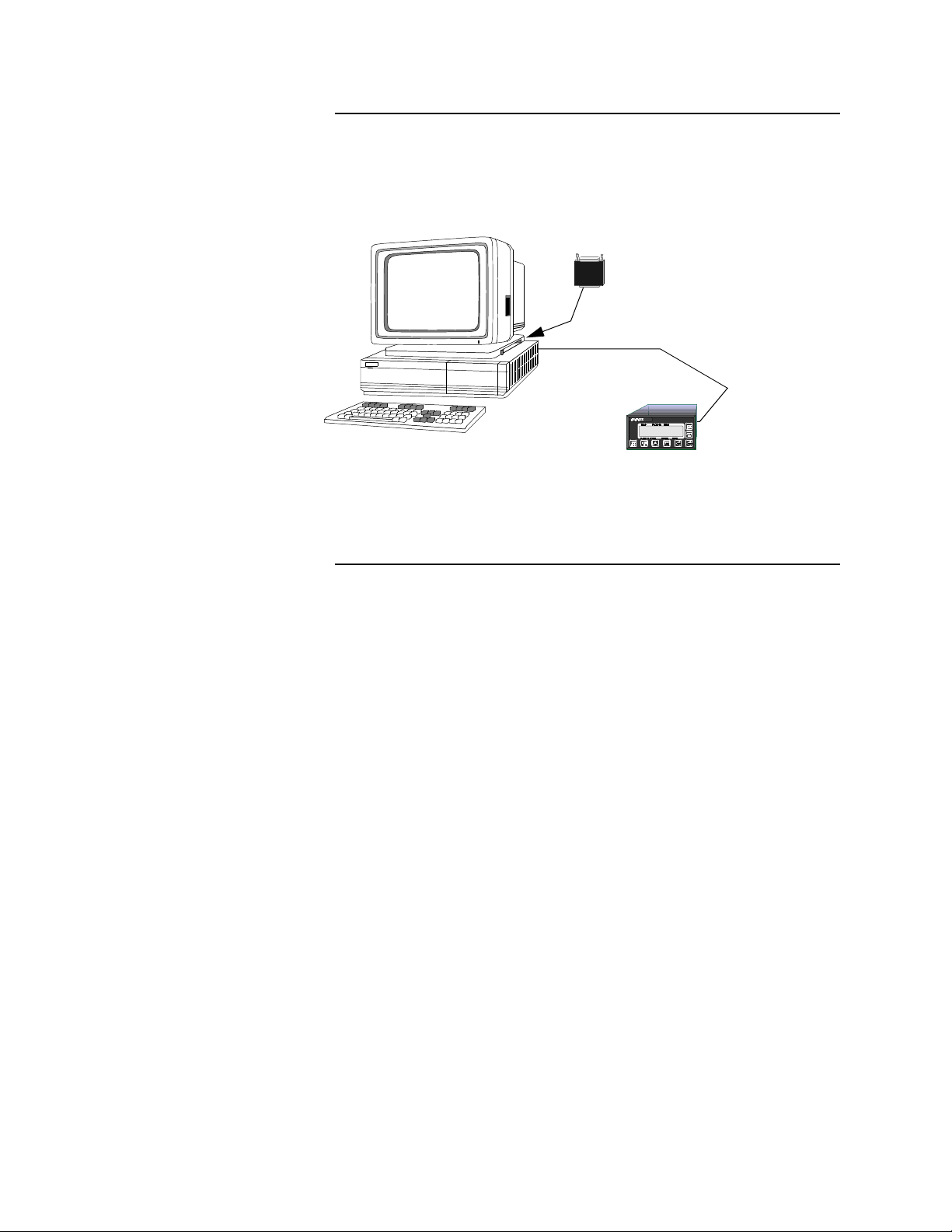

System Block Diagram

The following shows how the PC interface (with ANASOFT) to several

controllers.

Software Key (parallel port)

Communications

Cable (serial port 1 or 2)

1 or more controllers

Parts List

The following parts are included with ANASOFT.

•

ANASOFT on 3.5 inch Diskette. (5.25 in diskettes are available

upon request)

•

Software Key

•

RS-232 or RS-485 communications cable

vi ANASOFT User’s Guide

Page 9

Safety

Watlow-Anafaze has made efforts to ensure the reliability and safety of

ANASOFT. Note that in any application failures can occur.

Good engineering practices, electrical codes, and insurance regulations

require that you use independent external safety devices to prevent

potentially dangerous or unsafe conditions. Assume that ANASOFT can

fail or that other unexpected conditions can occur.

For additional process safety, program a computer or other host device

to automatically reload your desired operating parameters after a power

failure. However, this safety feature does not eliminate the need for

other external, independent safety devices in dangerous conditions.

In the event of a controller reset, ANASOFT will reload the controller

with the current values in computer memory. The user must ensure that

this reset will be safe for the process. Use of ANASOFT does not

eliminate the need for appropriate external, independent safety devices.

Please contact Watlow-Anafaze immediately if you have questions

about system safety.

ANASOFT User’s Guide vii

Page 10

viii ANASOFT User’s Guide

Page 11

Introduction

ANASOFT is a user friendly, menu driven software package. It

provides a powerful computer supervised measurement and control

system with data acquisition.

ANASOFT is the general name for two products: ANASOFT3 and

ANASOFT4. This User’s Guide is for the two products. It uses the

general name ANASOFT when referring to both.

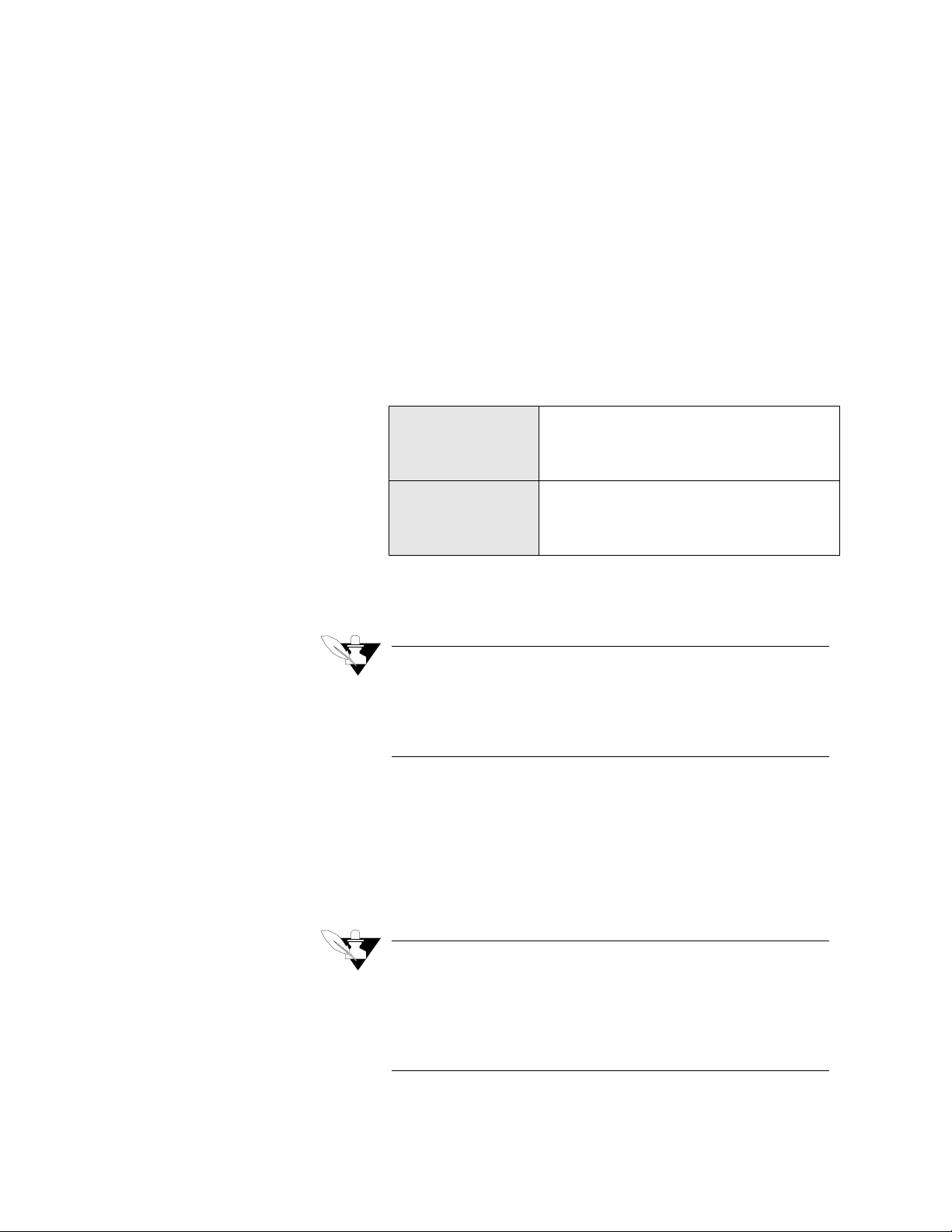

Each product communicates with different controllers, as shown below:

ANASOFT 3

ANASOFT 4

Introduction

Watlow-Anafaze 8LS

Watlow-Anafaze 12LS

Watlow-Anafaze SYSTEM 32

Watlow-Anafaze MLS

Watlow-Anafaze CLS

Watlow-Anafaze IRC2

The choice of controller type is selected when the installation program

is run. At present, controllers cannot be mixed on the same system.

NOTE

Watlow-Anafaze controllers are purchase d with vari ous options for mounting, input/output configurability

and application options. Make sure your controller’s

version and options match your ANASOFT v ersio n.

The system may have only one Watlow-Anafaze controller or a plant

wide system with numerous controllers. ANASOFT includes numeric

and graphic displays, data and alarm printing, data and alarm logging in

text or LOTUS compatible files, and graphic trending. It runs on an

IBM AT 286, 386, or 486, and true compatible computers. A question

and answer format enables users to quickly define and setup any

measurement or control application.

NOTE

ANASOFT is sold with a license agreement and can

be operated only on one computer. The license agreement requires registration with Watlow-Anafaze.

Watlow-Anafaze will send updates at no charge only

to registered users.

ANASOFT User’s Guide 1

Page 12

Introduction

ANASOFT Versions

ANASOFT-EV

•

Process overview screens (3 different formats)

•

Loop setup screen, individual loop parameters editing

•

Maintaining a directory of job files

•

Displaying and logging process variable alarms

•

Password protection for various levels of program

•

Software grouping of Loops

•

Graphic trend plotting of process variabilities points and output val-

ues in real time

•

Definable startup sequences

•

Power failure recovery

•

Printer and disk data and alarm logging

This version is recommended for central process supervision, data

acquisition, or any application where the computer is operated on-line

with an Watlow-Anafaze system.

ANASOFT-RS

provides timed control of Setpoints. Use this version with WatlowAnafaze 8LS, 12LS, CLS Ramp and Soak controllers.

- Expanded Version - provides these features:

is the Ramp Soak version of the ANASOFT-EV; it

Computer Requirements

ANASOFT-CP

it provides control of carbon control systems as used in the heat treating

industry. Use this version with Watlow-Anafaze 8LS and MLS carbon

controllers.

ANASOFT-CV

meet customer’s special requirements for any application. Please

contact Watlow-Anafaze or its representatives to provide pricing and

delivery on custom software packages.

Watlow-Anafaze sets these computer requirements for running

ANASOFT:

1. IBM AT 286, 386, 486 or other IBM Compatible Computer

2. DOS Version 3.3 or higher

is the Carbon Potential version of the ANASOFT-EV;

is a custom version of ANASOFT; it is designed to

2 ANASOFT User’s Guide

Page 13

Introduction

3. Speed: 25MHz or higher

This speed provides the best performance of the ANASOFT program; it enhances the response of the system to changes and maintains the best screen updates. However, it is not a factor in the

performance of the control system since this is maintained independently in each Watlow-Anafaze controller.

4. Memory: 580K bytes free memory or larger

5. Disk Drives: One 40MB hard disk. One 5.25 inch or 3.5 inch floppy

disk

6. Graphics Interface: EGA/VGA

7. RS-232 or RS-485 Serial Interface

The serial communication link required to communicate with more

than one Watlow-Anafaze controller or with a communication cable

longer than 50 feet is RS-485. Watlow-Anafaze recommends using

the standard serial interface of RS-232 with an external RS-485 converter.

A converter recommended by Watlow-Anafaze is the B&B Electronics RS-232/RS-485 optically isolated converter P/N 485OIC. This

converter has screw terminals for connecting the RS-485 wires and

the DB-25 Male connector for the RS-232 side.

Another recommended converter is the B&B Electronics optically

isolated with surge suppressors P/N 485OISPR. This converter has a

DB-25 Male connector for the RS-485 communication wires and a

DB-25 Female connector for the RS-232 side.

These converters are for both 2-wire/4-wire systems and may be used

with all Watlow-Anafaze controllers. The optical isolation should be

used with the MLS and CLS controllers, and it must be used with the

16CLS controller.

Other recommendations are the Black Box RS-232/RS-485 non-isolated converter P/N ME-836A. The ME-836A connections are the

same except the terminals are labeled with an X instead of a D. The

converter is used for both 2-wire/4-wire systems.

To provide optical isolation, the addition of Black Box opto-isolator

P/N SP400A is highly recommended. The SP400A will normally use

the factory DIP switch settings. All that needs to be done is to connect the cable and the power supply. The SP400A has been used

without any power supplies required as it will draw its power from

the computer and the ME-836A. Always use equi pment m anuf acture

factory recommendations.

T o us e a PC internal m oun ted RS-4 85 card, the B l ack Box Corp. P/N

IC030 has been used successfully in Watlow-Anafaze installations.

Caution must be taken when other communication devices are

installed so as not to conflict with the address or interrupt.

Another recommended PC internal optically isolated RS-485 serial

card is the B&B Electronics 3PXOCC1A

ANASOFT User’s Guide 3

Page 14

Introduction

8. Printer Parallel Interface

The printer parallel interface port is required for the Watlow-Anafaze

software key . The Watlow-Anafaze software key must be installed on

the printer port. System operation of the controllers is not possible

without the software key. [See Software key installation].

9. Battery backed up real time clock (usually battery backed CMOS

chip)

10. EGA/VGA Monitor

The EGA interface card will allow color trend plotting even with a

CGA monitor. The EGA/VGA monitor used with the EGA/VGA

interface provides improved text displays making all the screens easier to read. For systems that require frequent operator changes and

frequent observation, full EGA or VGA is recommended.

11. IBM Graphics Compatible Printer

This graphics printer is required for printing data and alarm logging

features of ANASOFT-EV. The printer is not needed for the software

key to operate, but if the printer is used, it must be ON LINE to operate ANASOFT.

4 ANASOFT User’s Guide

Page 15

Installation

Quick Installation

•

Create a new directory for ANASOFT.

•

Change directory to the one you have created and type Anasoft.exe. This self-extr actin g f ile contains the operating pr ogram

and the support files.

•

Type ANAINSTL from your ANASOFT directory. After pressing Enter, Installation Menu appears.

•

Change inputs in the Installation Menu by moving the cursor to

the desired parameters.

•

Install the Software Key.

•

You are ready for start up.

Installation

ANASOFT Files

WARNING

It is your responsibility to ensure that the entire

system is safe. Read the warning in the front of this

manual. If there is any possibility of an unsafe condition, use independent safety devices.

ANASOFT is provided on various floppy con figurations. Depen ding on

the version of ANASOFT, the disks include the following files:

README.BAT - contains information on how to install th e so ftwa re.

ANASOFT.EXE - a self-extracting file which contains

following files and all the support files:

•

ANA-EV.EXE - ANASOFT EV operating program

•

ANA-RS.EXE - ANASOFT-RS operating program

•

ANA-CP.EXE - ANASOFT-CP operating program

one

of the three

Support files:

ANAINSTL.EXE - ANASOFT installatio n program

INSTAL.DAT - installation parameters data file

LPGRP.DAT - loop group ing start up dat a file

SYSSU.DAT - system setup data file

ANASOFT User’s Guide 5

Page 16

Installation

STATUS.DAT - system start up status file

DIGIO.DAT - digital I/O screen data

DLOG.DAT - data logging data file

GRPINFO.DAT - group set up data file

HDR.WK1 - Lotus header set up file

PLOT.DAT - plot parameters data file

The following list contains files created from the software:

XXXXXXXX.J## - group job directory data file

NEWXX.PLT - plot files which were created within the last 24 hours.

OLDXX.PLT - older plot files

PXXXXXXX.TXT or WK1 process logging files

File Locations

AXXXXXXX.TXT or WK1 alarm logging files

ANASOFT-RS also includes:

XXXXXXXX.R## - R/S program assigned data file

XXXXXXXX.PRF - R/S program data file

WARNING

Make copies of disks before running the program,

and store the original ANASOFT disks in a safe

place. Use the copies to operate the system.

360k dual floppy disk system:

Watlow-Anafaze recommends that you store the ANASOFT operating

program file and the INSTAL.DAT file on drive A, and all other files on

drive B. Once the program ANAINSTL is run, you can remove

ANAINSTL.EXE from drive B to allow more room for data. Do not

remove files from the master disk.

6 ANASOFT User’s Guide

720k or higher floppy disk system:

Watlow-Anafaze recommends that you store all files of the ANASOFT

operating program on one drive such as A. Use the B drive to store all

recording data by setting up directories as shown in the hard disk

systems recommendations.

Page 17

Installation Program

Installation

Hard disk systems:

Watlow-Anafaze recommends setting up directories as follows:

ANASOFT - to contain the operating program, system data and job files

DATALOG - to contain data logging files generated by ANASOFT

ALARMLOG - to contain alarm logging files generated by ANASOFT

For easy removal of recorded data, you may install the DATALOG and

ALARMLOG directories on the B drive. If you use A drive for data

recording, you will not be able to use the automatic reboot

Copy all the supplied files to the ANASOFT directory.

The installation program, ANAINSTL.EXE, customizes each

ANASOFT p rogram for the application. When typing C:ANAINSTL (if

it’s on the hard disk), or B:ANAINSTL (if it’s on drive B), The

installation screen appears and enables you to select parameters used by

ANASOFT.

ANAINSTL.EXE stores the program setup parameters in a file called

INSTAL.DAT. When Run, the ANAINSTL program reads the

INSTAL.DAT fil e from the defau lt disk direct ory. If both files are on the

same disk directory, enter the directory and type ANAINSTL.

If the ANAINSTL.EXE and INSTAL.DAT file are on different

directories, enter the disk directory containing INSTAL.DAT and type

ANAINSTL preceded by the path to the disk directory containing

ANAINSTL. For example, if INSTAL.DAT is on drive A and

ANAINSTL.EXE on drive B, type :

B:>A: [Enter] to change the current default drive to A

A:>B:ANAINSTL [Enter] to start the installation program

If the installation program cannot find INSTAL.DAT, an error message

appears. Verify the location of INSTAL.DAT file.

ANASOFT User’s Guide 7

Page 18

Installation

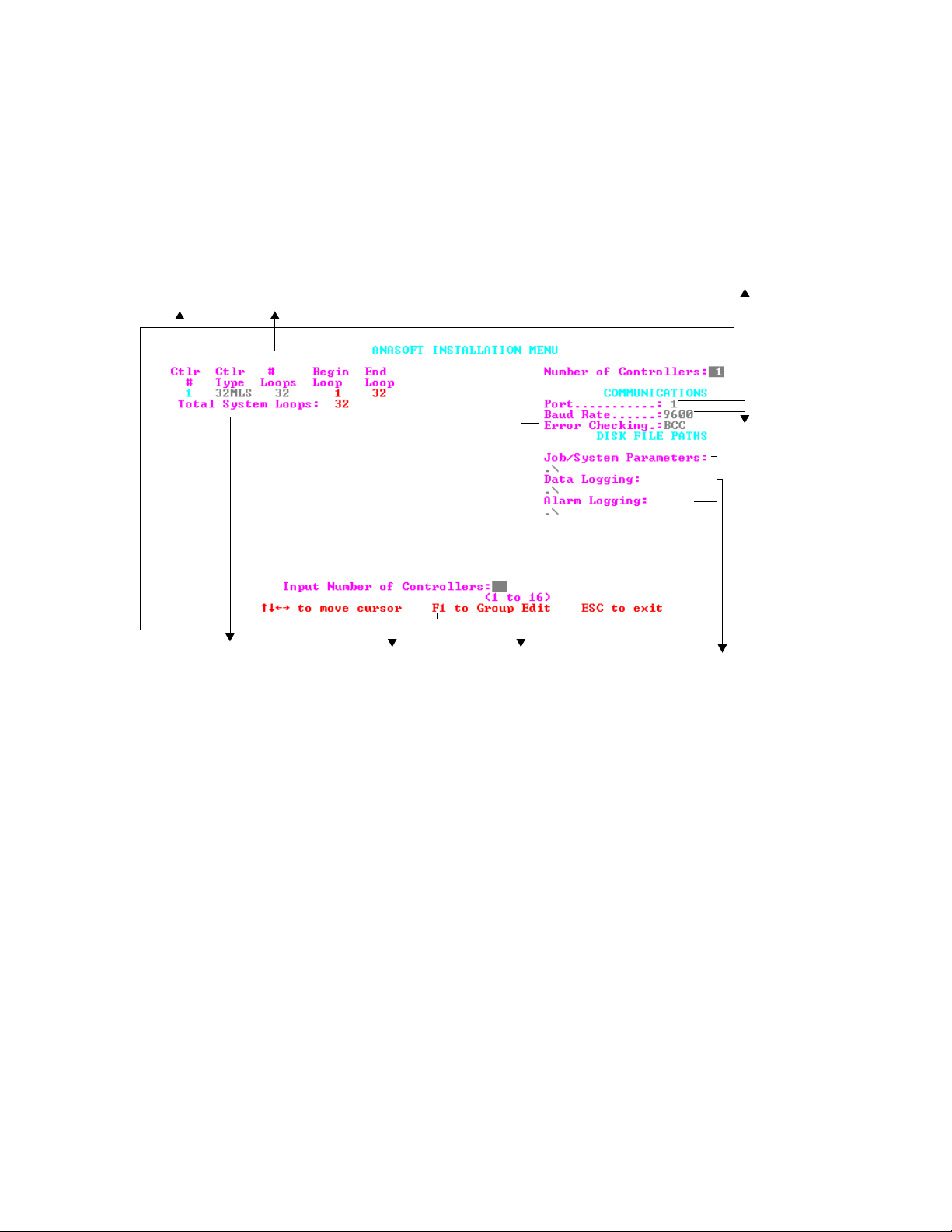

Installation Menu

1 to 16

This value is fixed for

each controller. See

table on the next page.

The computer’s serial

communication port to the

controller. Can be only 1

Can be either

2400 0r 9600.

Set all controllers to the

same value.

Only one type. Chan ging

one controller’s type

would change all others’.

Change the

screen to the

Loop group Edit

screen. See

Grouping Loops

in this section.

Set to either BCC (Block Check

Character) or CRC (Cyclic

Redundancy Check). Use BCC

for standard applications. CRC

ensures a higher degree of security but decreases the overall

communication rate. Use CRC

only when you anticipate severe

communication noise.

For these paths see the

next page.

8 ANASOFT User’s Guide

Page 19

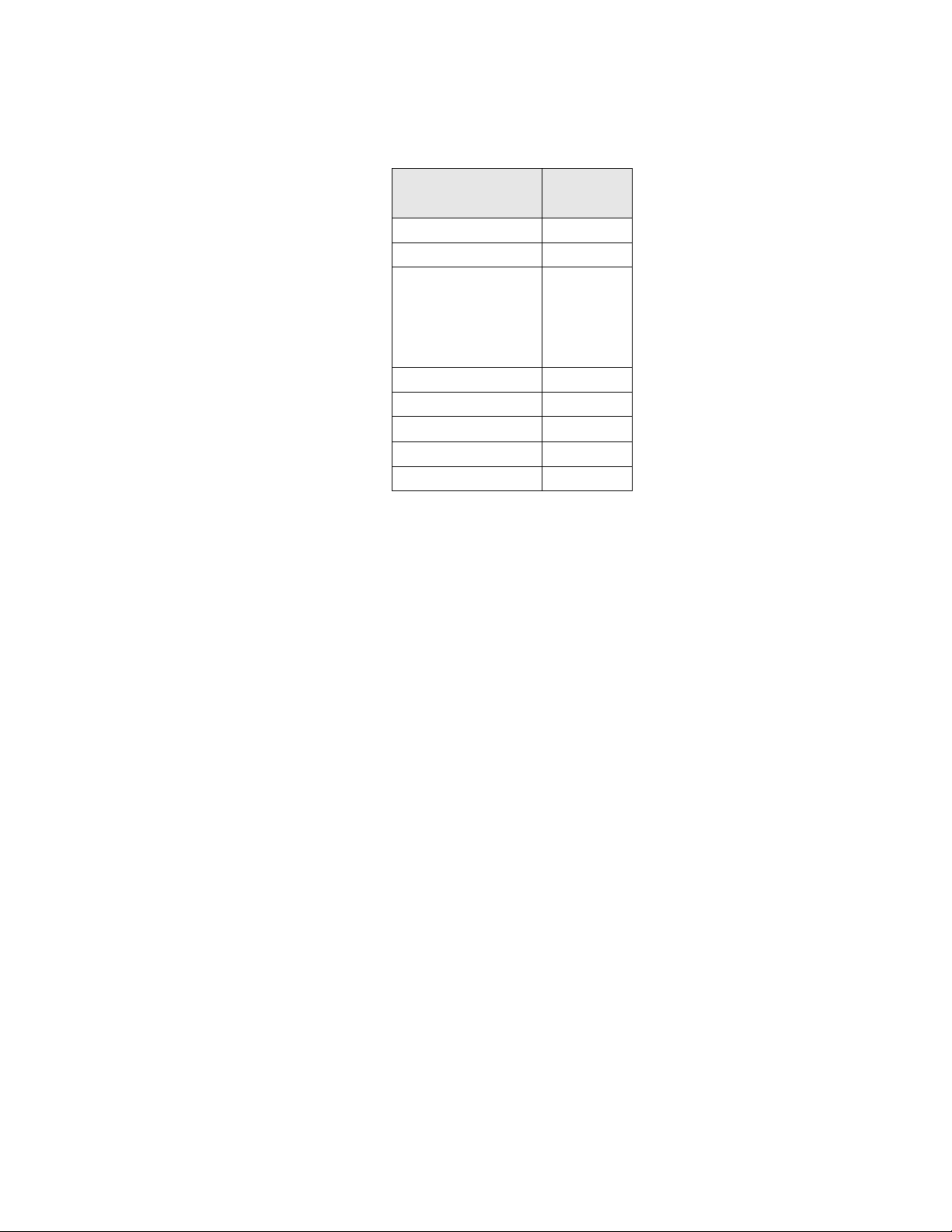

Number of loops

Installation

controller’s type

8LS 8

12LS 12

SYSTEM32* 16 or

16MLS 17

32MLS 33

4CLS** 5

8CLS** 9

16CLS** 17

* For SYSTEM 32, loop numbers greater than 32 are data acquisition

channels only, and cannot be used as control loops.

** In CLS controllers, the last loop is a pulse control loop.

ANASOFT d isplays the loops with system numbers. The system loop

numbers associated with the controller loops are indicated in the

installation program as the Begin Loop and End Loop for each

controller.

Number of

loops

32 or

48 or

64

Directory Paths

Job/Parameters path

This is the path to the disk directory containing the Job and System

Parameters Data Files. The path would normally be:

B:\ANASOF T\ or .\ current directory (If the system files are on drive B)

C:\ANASOFT\ or .\ current directory (If the system files are on the

hard disk). Notice that the last “\” is added automatically.

Data logging path

This is the path to the disk directory containing the LOTUS or text

[ASCII] data logging files generated by ANASOFT. This directory must

exist before running ANASOFT and turning on data logging.

B:\ANASOFT\DATALOG\ (for floppy disks)

C:\ANASOFT\DATALOG\ or.\DATALOG\ (for hard disks). Notice

that the last “\” is added automatically.

ANASOFT User’s Guide 9

Page 20

Installation

Software Key Installation

Alarm logging path

This is the path to the disk directory containing the Lotus or Text

(ASCII) alarm record files generated by ANASOF T. This directory must

exist before running ANASOFT and turning On alarm logging.

B:\ANASOFT\ALARMLOG\ (for floppy disks)

C:\ANASOFT\ALARMLOG\ or .\ALARMLOG\ (for hard disks).

Notice that the last “\” is added automatically.

Install the software key on the computer printer port.

Grouping Loops

If you are planning to use a pri nte r , f irst inst all the s oftwar e key and then

install the printer cable into the software key. Some computers require

that the printer should be O n Line before the software key will work.

When no software key is installed, an error message appears, and

ANASOFT termin ates.

Grouping inputs allows you to divide your system into subsystems. You

can group loops with a common purpose according to your specific

application requirements. One group might be for a furnace or a group

of furnaces; another group might be for common Jobs controllers share.

Only the loops of one group are displayed on the Overview screen at a

time. The job parameters are uploaded or downloaded to an individual

group independently. The number of controllers with their total number

of loops must match the number of loops in the grouping. The loop

numbering depends upon the type of controller selected in the

ANAINSTL program. The system loops are in a numerical sequence of

1 to 8 for the first 8LS controller and 9 to 16 for the second 8LS

controller, etc. The 12LS sequence is 1 to 12 for the first 12LS

controller, 13 to 24 for the second 12LS controller, etc. The SYSTEM

32 loop sequence is in units of 16 depending on the make-up of the

SYSTEM 32 Hardware. Loops of 16, 32, 48, or 64 may be available.

The same applies for the MLS, CLS and IRC2 controllers regardin g the

number of loops per controller.

10 ANASOFT User’s Guide

Page 21

Installation

After assigning the loop numbers from any controller in the system to

the group, select a type number of two digits up to 99. This number is

the job directory number for th e gro up and i ts l o ops . Al l gro ups w it h the

same type number will be assigned to the same job directory. Creating a

new type number creates a new job directory number in the ANASOFT

program.

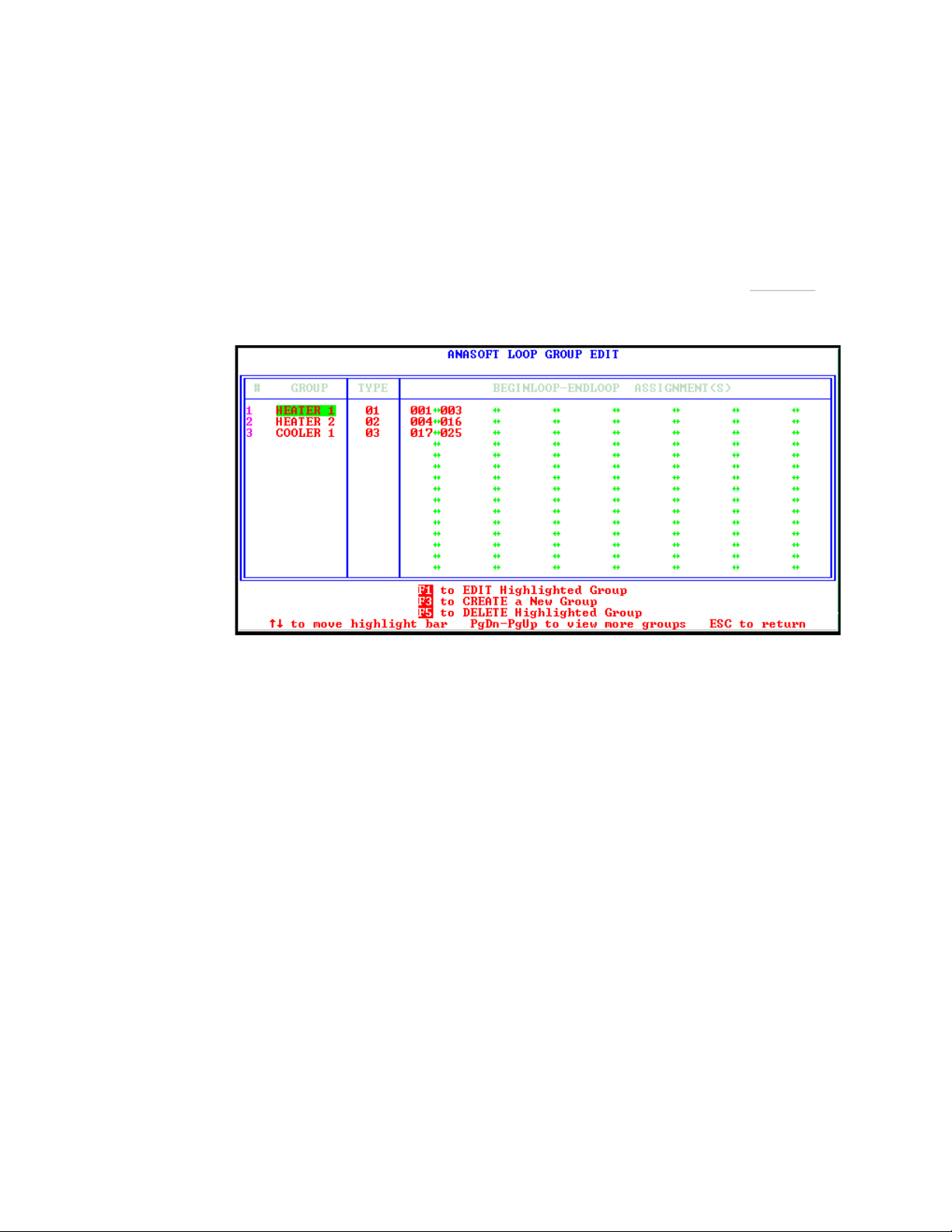

Group menu

General grouping rules

•

Create a group when you need to have the loops on the same Over-

view screen.

•

Assign the loops to the group you want to have on the same Over-

view screen.

•

Create a new type number for the new gro up. This ty pe number may

be assigned to more than one group, when the jobs that are saved to

the Job Directory are to be common to the groups that it is assigned

to.

When using the same type number for groups, the number of

loops must match. Otherwise a new type number must be used.

Grouping example

The application has two furnaces, one with four loops and one with two

loops in two separate areas. There are three presses with two loops each,

that share common ramp soak jobs. And, finally, an oven with two loops

of ramp soak control that has nothing in common with the presses ramp

soak jobs.

ANASOFT User’s Guide 11

Page 22

Installation

The hardware consists of the following:

Two Watlow-Anafaze 8LS-P-RS controllers.

Controller #1 will be installed to handle furnace 2A with four loops of

PID control in Area A, two loops of R/S oven control also located in

Area A. The last two loops of controller #1 will be used to p rovide R/S

control for one of the presses located in Area A.

Controller #2 will be installed in Area B for two loops of PID control for

furnace 5B and four loops of R/S control of the two presses located in

Area B. Two loops of the controller will not be used at this time.

•

Create group AREA A with Loops 1 to 6 and the type number 01.

This will provide an overview screen with four loops from controller #1 for Fu rn 2A and two Loops from controller #1 for oven in

AREA A.

•

Create group AREA B with Loops 9 to 10 and the type number 02.

This will display two Loops from controller #2 for Furn 5B on an

overview screen in AREA B.

•

Create group PRESS with Loops 7 to 8 and 11 to 14 and the type

number 03. This will display two Loops from controller #1 for the

press in AREA A, with four loops from controller #2 for the two

presses in AREA B.

12 ANASOFT User’s Guide

Page 23

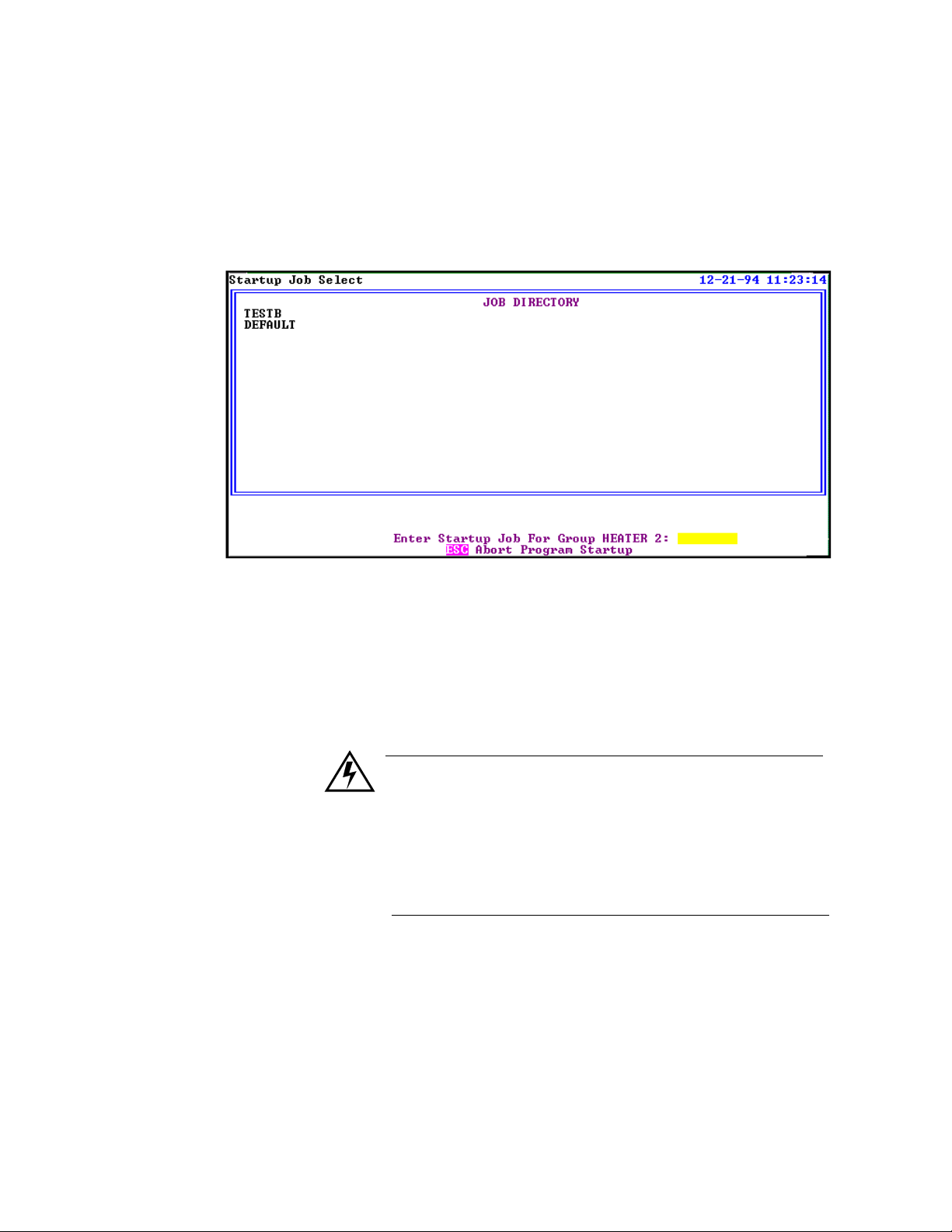

Start Up

Quick Start Up

•

•

•

•

•

•

Start Up

Make sure the software key is installed.

Set correctly time and date in your computer.

Type: ANA-EV or ANA-RS or ANA-CP depending on your

ANASOFT version. Job Select screen appears.

Type a job’s name. When starting the first time, enter DEFAULT.

Type D for downloading parameters to the controller, or U for

uploading. For initial testing in the Edit mode, enter D.

Overview screen appears.

Start Up Optional Modes

You can s tart ANASOFT in certain modes by adding parameters to the

command at start up. These command line options include:

•

/e

Operates the program in Edit mode. The program operates no rmally

but it does not communicate with the controllers or require the software key. You can operate the program in Edit mode without any

hardware connected to the computer. This mode is useful for initial

familiarization, training, and Off Line job editing.

•

/c

Forces the graphics display into CGA mode. This is necessary on

some computers which are not truly IBM compatible.

•

/d

Operates the program in the Debug mode. This is useful in debugging communications probl ems. Don’t use it for normal operations. All communications between the computer and controllers

are displayed on the printer. Therefore, in order to use this mode,

the printer must be connected and ready.

You can use capital or small letters in the command line, and more

than one command line option at a time. For example: Typing

ANA-EV /E /C [enter] will operate the program in Edit mode with

CGA graphics.

ANASOFT User’s Guide 13

Page 24

Start Up

Start Up Sequence

•

The program checks the computer system hardware, the access to

the system disk files, and the presence of the software key.

•

The program verifies communications to the controllers in the sys-

tem and the version of the controllers.

•

Job Directory screen appears.

•

The program prompts for the job to run. ANASOFT program is sup-

plied with a j ob named DEFAULT which contains all default control parameters and sets all control outputs off. When starting the

first time, enter the job name DEFAULT.

•

For systems with 8LS, 12LS, CLS, or MLS contro llers, the program

prompts whether to download parameters to the controllers or

upload parameters from the controllers. When SYSTEM 32 controllers are in the system, it automatically downloads.

WARNING

When controllers are in control of a process,

upload to install parameters into the ANASOFT

operating program. Downloading will install factory default values that will shut down the control

of the process. For Initial testing in the Edit mode,

enter Download.

•

After the downloading sequence is complete, the program displays

the Overview screen. If there is a problem in the program start up,

see start up errors in this section.

14 ANASOFT User’s Guide

Page 25

Default Start Up Values

Start Up

The program is shipped to you containing several parameters which are

set to initial factory default values. These should be set to desired values

by supervisory personal, and they include:

•

Passwords

•

Program startup sequences

•

Data logging parameters

•

Trend plotting parameters

See System Setup for detailed information.

ANASOFT User’s Guide 15

Page 26

Start Up

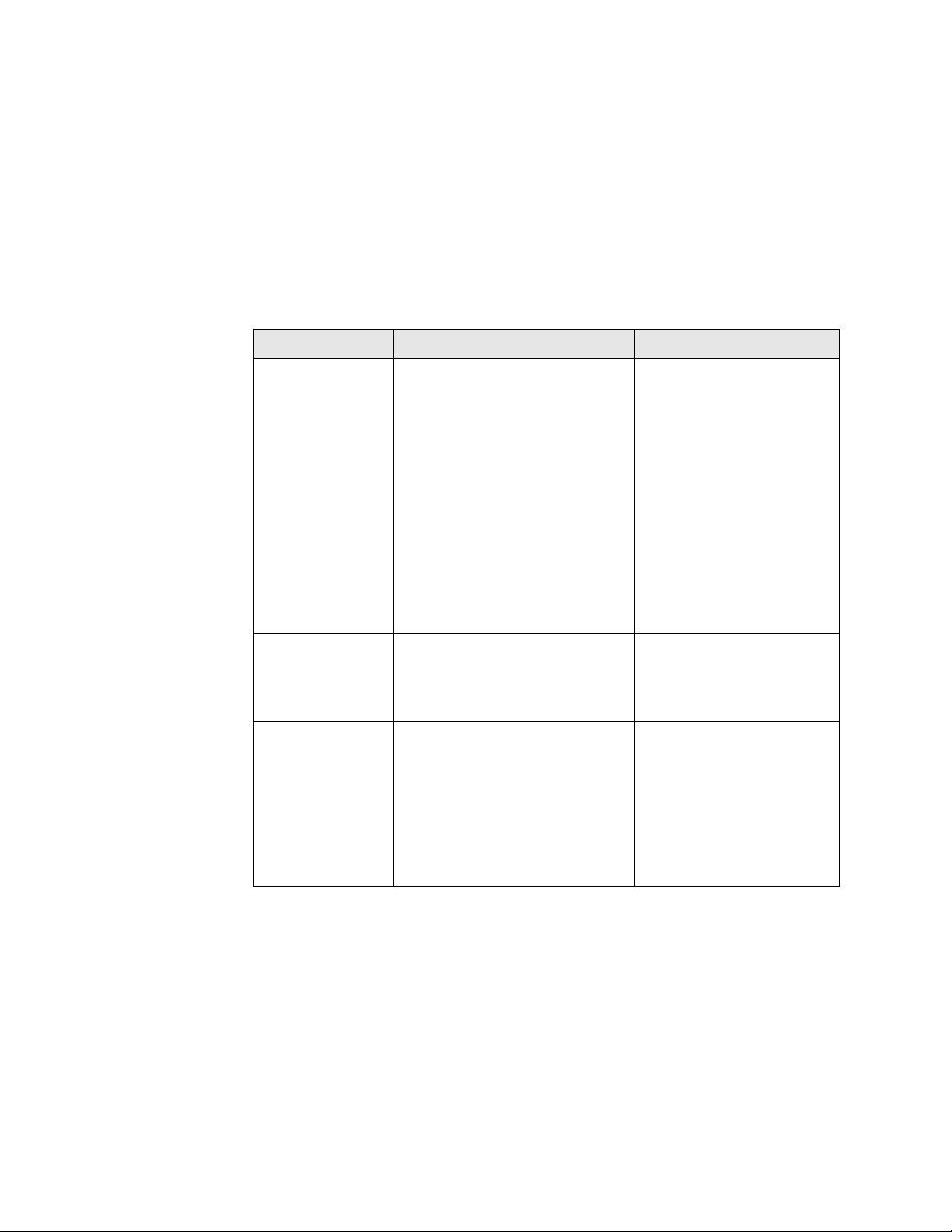

Start Up Errors

During Start up, various error messages may appear. The following

tables describe these messages, their causes and solutions.

Memory allocation errors

ANASOFT al locates computer memory for the loop parameters, based

on the number of loops and options in the system. When ANASOFT

reads in the system data files and finds there isn’t sufficient memory,

these messages may appear:

Message Cause Solution

•

Insufficient Memory

Not enough memory to allocate

data arrays required to run the program. The program cannot run and

it terminates.

Check the memory by

running the DOS command CHKDSK. At least

580K should be free.

•

Make sure your computer

has 640K memory, and

remove any memory resident programs and drivers. Check

AUTOEXEC.BAT file to

see if it runs any memory

resident programs. After

removing these programs,

re-boot the computer.

MEM ERROR:

Alarm Queue

Trend Logging

Disabled

Not enough memory to allocate the

alarm log memory . The prog ram

operates, but the view alarms

screen doesn’t display alarm queue.

Not enough memory to allocate

some or all of the trend logging

memory queues. The program

operates normally, but the trend

plotting i s not available.

Same as above.

•

Same as above.

•

Try running the program

and turning off scan outputs. This will save some

memory, but the program

will not plot the. Control

output values.

16 ANASOFT User’s Guide

Page 27

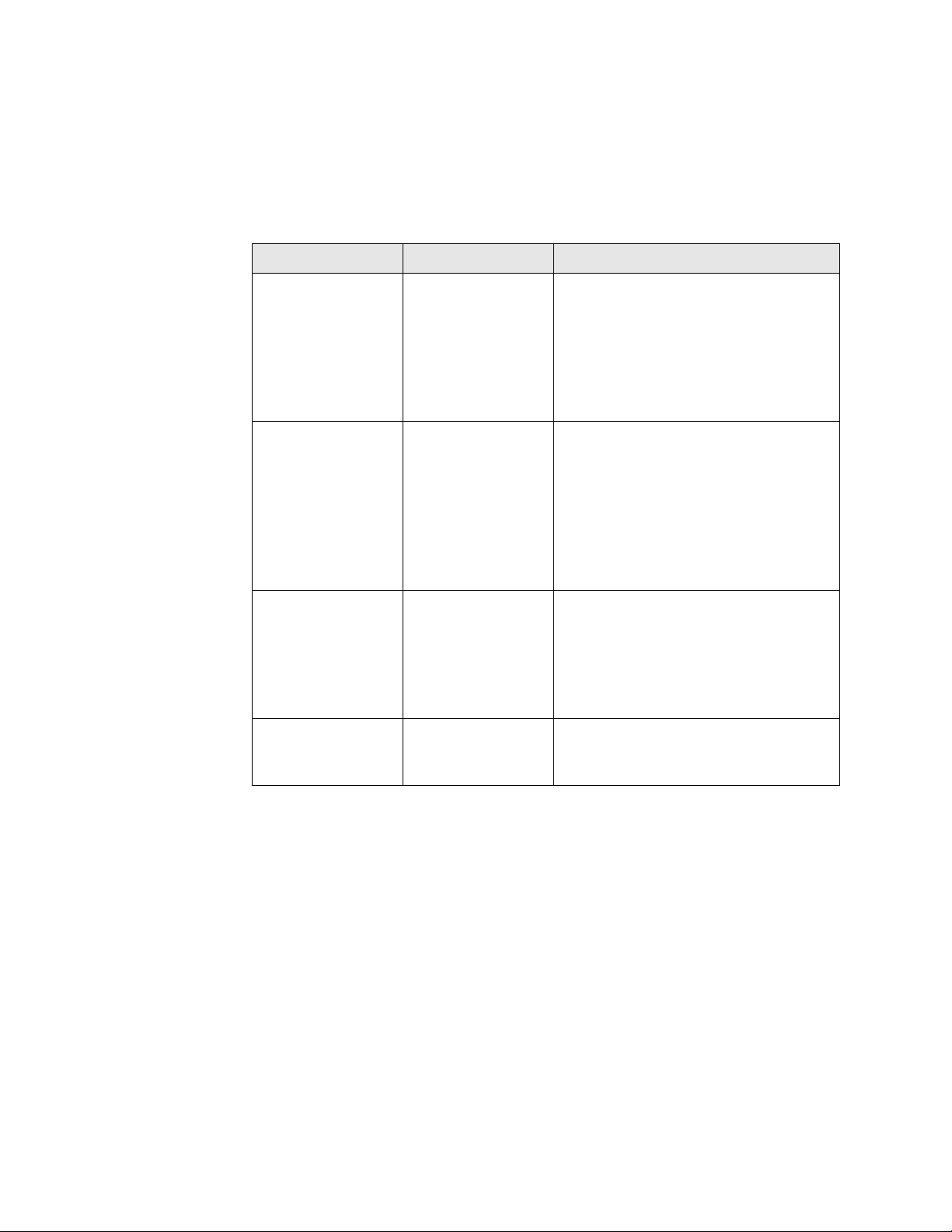

Disk file errors

While reading in the system files, several reading errors can occur. The

system files are SYSSU.DAT, INSTAL.DAT, and PLOT.DAT.

ANASOFT can not run without these files.

Message Cause Solution

Start Up

ERROR WHILE

READIN G DATA

FILE: xxxxxxxI

FILE NOT FOUND

ERROR WHILE

READIN G DATA

FILE:xxxxxxx

Drive not ready

Read fault

General failure

or

Access failure

ERROR WHILE

READIN G DATA

FILE:xxxxxxx

Path not valid

or

Invalid disk drive

INVALID DATA

FOUND ON DA TA

FILE:xxxxxxx

The system file does

not exist on the indicated disk and directory path.

There is a disk drive

hardware access failure.

The data disk path

that you set in the

ANAINSTL installation program is not

valid

There is corrupted or

invalid data in the

disk file.

The INSTAL.DAT file should be on the

default drive and directory. The other system files should be on the data file drive

and directory path as set in the installation

program. If these files are not in the right

directories, copy the system files from the

backup disks to the appropriate directories .

Run CHKDSK or other diagnostic program in order to verify that there is no disk

drive error.

For a floppy drive: make sure that there is

a disk in the right drive and that the drive

door is closed.

Run ANAINSTL and verify that the drive

and directory path exist and are valid.

Don’t forget to verify that “\” is at the end

of the path entry.

Copy the original data file sent with ANASOFT from the backup disks.

ANASOFT User’s Guide 17

Page 28

Start Up

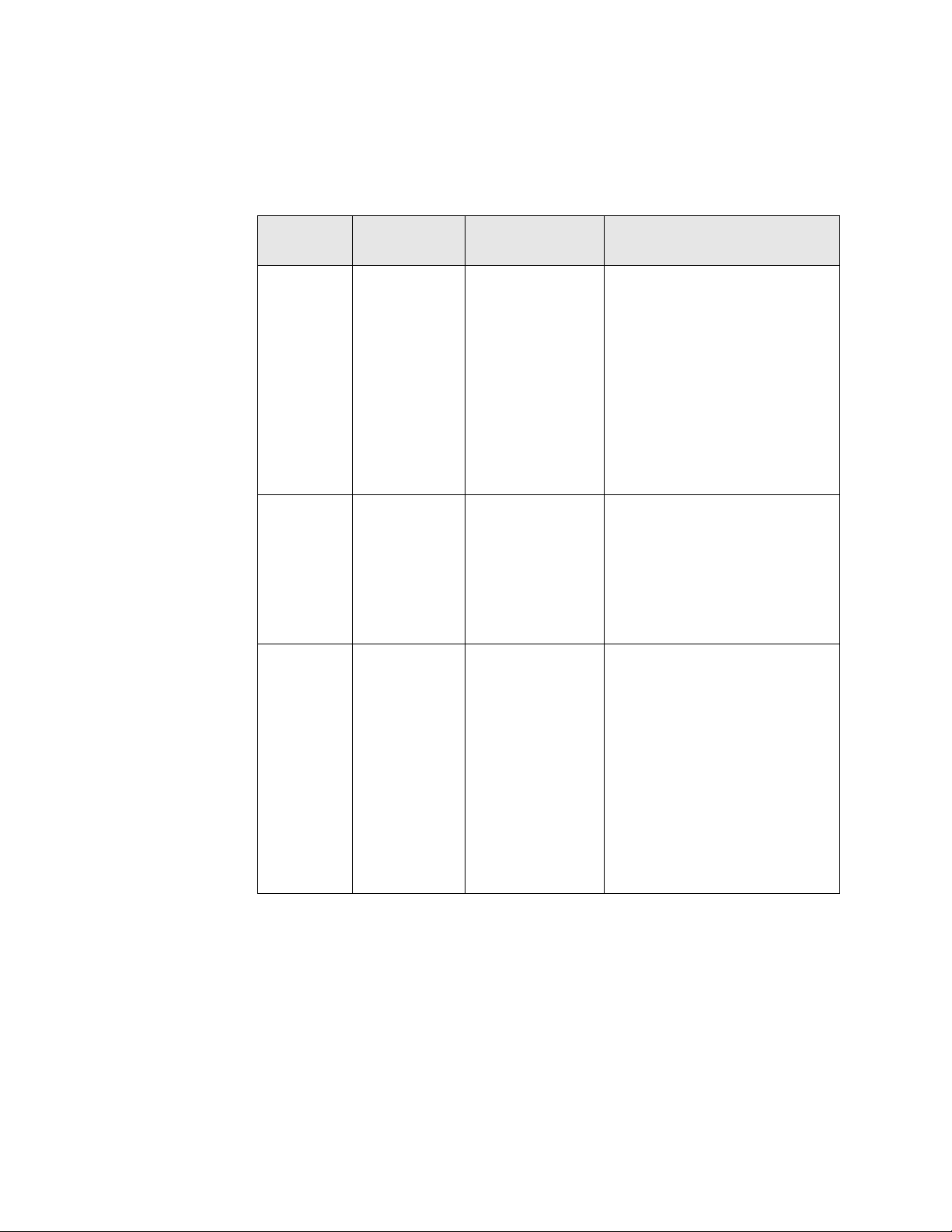

Extended start up sequence errors

ANASOFT reads in the status file STATUS.DAT which contains

information saved by ANASOFT th e last time it was running. Several

errors can occur when reading this file.

Message Cause

Could not

find STATUS.DAT

start up file

Invalid data

value on

STATUS.DAT

start up file

Power Failure Recovery

System

clock Error

The file could

not be found

on the data file

disk directory

set by

ANAINSTL.

The file may

have been

erased or corrupted.

The file contains some

invalid data,

and ANASOF T assumes

that the file

was corrupted.

The current

system time/

date as saved

in the STATUS.DAT file

were not in a

valid range .

The computer

system clock

is not set to

valid time a nd

date.

Program

Action

ANASOF T continues with the start

up, but since there

is no power failure

information available, ANASOFT

assumes the Over

Power Failure

Recovery time

Limit action and

starts in that mode.

Same as above. Same as above

Same as above. The automatic power failure

As the program is running, the

STATUS.DAT file will be established. Therefore, subsequent

starts shoul d have no problem.

recovery feature of ANASOFT

requires a correct clock/calendar

system. While the computer boots

up, verify the following:

•

There is a battery backed up

clock/calendar in the system.

•

The battery is good.

•

Time and date values are correctly loaded.

Solution

18 ANASOFT User’s Guide

Page 29

Software key problems

Message Cause Solution

Start Up

Software Key not

found on printer

port.

Cannot operate

program without

key.

1. Attempting to run the operating program without a software

key installed on the computer.

2. Installing the software key on

a computer connector other than

a valid printer port.

3. Installing an incorrect key

version. T here’s a single controller version and a multiple

controller version for accessing

more than one controller.

4. Attempting to run the program while the printer is not On

Line. (Rare).

Make sure you have installed the

software key properly on the

printer port.

Verify that you have the multiple

controller version if you want to

access more than one controller.

Communications problems

Message Cause Solution

failed Communications to

controller____

Abort start up

(Y/N):_____

ANASOFT can not

communicate with

one of the controllers

during the initial system communications

check or during the

job downloading/

uploading.

Verify that the communications por t set in

ANAINSTL is the one actually connected to

the controllers.

Verify that the communications parameter s

(baud rate and error checking mode) set in the

installation program are those set in the controllers. The 8L S, 12LS, MLS, and CLS communications parameters are set using the front

panel keys while in th e GLOBAL menu and the

SYSTEM 32, parameters are set by DIP

switches.

Verify that the address of each controller is

unique (for multiple controller systems).

Verify that you have the multi-controller key if

more than one controller is hooked up.

Verify that the correct version of ANASOFT is

running for the controllers being used.

Verify that the wiring is done correctly to the

controllers and the computer.

:

ANASOFT User’s Guide 19

Page 30

Start Up

NOTE

See the respective controller hardware manual for

assistance in checking the communication parameters

and verifying the communication wiring.

•

If there is more than one controller in the system, ANASOFT wil l

try supervising thos e co ntrol l ers whi ch are op erat i ng and co mmu ni cating correctly. After start up ANASOFT periodically re-checks

communications to the failed controller.

•

By continuing the start up, the controllers not communicating will

be listed by address on the System Errors window in the System

Setup screen. Check the controllers listed on the screen. Be sure the

address is correct as set on the controllers.

EPROM version error

If 8LS, 12LS, MLS, or CLS controllers are in the system, ANASOFT

checks the controller EPROM version at start up and verifies that it’s

acceptable to the version of ANASOFT. The following message may

appear:

Message Cause Solution

Unacceptable

controller

EPROM version

The EPROM version is

not acceptable to the

version of ANASOFT.

.

Contact Watlow-Anafaze to obtain

EPROM upgrade

20 ANASOFT User’s Guide

Page 31

General Screen Displays

General Screen Displays

Certain characteristics are maintained on all ANASOFT screens as

follows:

Title line. Includes screen’s name, current group and job, time

and date. When in Edit mode, the words “Edit Mode” appear.

Process status box. Four possible

messages:

1. Process OK (green).

2. Process warning (yellow).

There’s a warning on at least one

loop.

3. Process alarm (blinking red). An

alarm condition on at least one loop

hasn’t been acknowledged.

4. Process alarm (red). An alarm

condition on at least one loop. All

Changing Data

System status box. Re ports problems

of communications, printer access or

data logging disk access. T w o possible messages:

1. System OK.

2. In case of a problem, the appropri-

ate message (red).

•

Use the cursor to enter data in the editing screens.

•

Move the cursor to the variable you want to change. An editing

prompt appears at the bottom of the screen with a blue background

new value box. The allowable range of the variable is listed below

the new value box.

ANASOFT User’s Guide 21

Page 32

General Screen

Print Screen

•

Type the new desired value into the new value box.

•

Press Enter. The new value will be displayed over the original one,

and will be downloaded to the controller. If you made a mistake in

entering the value and have not pressed Enter yet, use the backspace key to correct.

•

Use the F4 Key to enter the Job Setup screen and save the changes.

If you don’t, upon a new start up, the Job data file will be read from

the disk along with the old parameter.

NOTE

The new value is sent first to the respective controller.

The display changes only after the controller accepts

the new value. This may cause a slight delay a fter

entry, especially on slow computers or when a large

number of controllers is connected.

•

You can print all ANASOFT screens on an IBM graphics compati-

ble dot matrix printer.

•

Use the PRTSC key. When the print scr een is initiated, the copy of

the current screen is transferred to a buffer and the screen will be

printed as a background task. The program continues operat ing and

you can display other screens while printing a screen.

•

When printing the Trend Plot screen, you will be asked for a title

before printing the screen.

22 ANASOFT User’s Guide

Page 33

Loop Overview

The Loop Overview screen provides an overview of the process

information. It is not password protected and is available at all times for

anyone who wishes to monitor the process variables.

Getting Here

This screen appears automatically after start up.

Options

The Overview screen has four display screens. Use the F6 key to switch

between displays.

1. Four-loop graph display.

Loop Overview

Single loop display *

* The single loop display is a detailed

front panel of a single loop. It includes

the loop’s name, setpoint and process

variable, setpoint spread for dual output

loops, alarm messages, manual/auto status with percent output, warning and

alarm setpoints, and optional r/s status.

ANASOFT User’s Guide 23

Page 34

Loop Overview

Single loop display

2. 16 loop display in a loop table with 7 loop parameters. 1 selectable

loop controller face plate.

Loop table. A list of 16, 32, or 48 loops. Includes the setpoint, process

variable, control status, alarm condition. For the 16-loop format it

includes also the loops’ names and alarm massages

3. 32 or 48 loop display in a loop table w ith 4 Loop para meters. 1 select able loop controller face plate.

Loop tableSingle loop display

24 ANASOFT User’s Guide

Page 35

Loop Overview

4. Digital I/O screen. This screen isn’t available with SYSTEM 32 controllers.

Function Keys

For an easy access from the Overview screen to all other screens, use

the function keys as shown below:

Key Function

TAB Change group. Switch to a new group in any screen. You

don’t need to go back to Overview screen.

F1 Edit screen. Change setpoint, manual/auto control status, and

set percent output manually.

F2 Loop Setup screen. Display and edit all loop parameters.

F3 System Setup screen. Display and edit various system

parameters (passwords, disk and printer data logging, start

up, etc.)

F4 Job Setup screen. Select, save and delete jobs.

F5 View alarms. Display on-screen alarm log. System Setup

allows selecting automatic switching to this screen in case of

an alarm.

ANASOFT User’s Guide 25

Page 36

Loop Overview

Key Function

F6 Switch displays. Change the Overview screen display to one

of its 4 options.

F7 Trend logging. display the graphic trend plot.

F8 (only in RS version) Display the r/s program for editing and assigning r/s profiles

to loops.

•

press ESC to view the next Group Overview screen. If you wish to

view another group, move the cursor to that group and press ESC.

•

If not all the loops are visible (in a large system), use the PgUp/

PgDn keys to view the other loops.

•

The Overview screen is automatically updated as data is collected

from the controllers. Measured data is displayed in engineering

units.

•

Normal readings are green, warnings are yellow, and alarms are

red.

•

If you edit the 8LS, 12LS, MLS or CLS controllers at their front

panels, the program displays the word “locked” in the single loop

Face plate and puts the letter “L” beside the process variable in the

Loop Table for the loops on the edited controller. Once the front

panel editing is complete, the display returns to normal.

26 ANASOFT User’s Guide

Page 37

Edit

Edit

The Edit screen enables you to change these three parameters in the

single loop display you have selected:

1. loop’s setpoint

2. Manual or Automatic control operation

3. Percent control output (only in Manual control).

The Edit screen uses the same format as the Overview screen, only here

you can move the cursor to change the values. This screen is not

password protected.

The Edit screen performs nearly the same functions as the change

setpoint and manual/auto keys on the 8LS, 12LS, MLS, or CLS

controllers front panel.

Getting Here

Press F1 from the Overview screen. You will enter an Edit screen with

the same display as the screen you were in before pressing F1. The

screen below is an Edit screen for the 16 loop display.

ANASOFT User’s Guide 27

Page 38

Edit

Function Keys

Key Function

PgUp/PgDn Display other loops for editing.

Tab Reach loops of other groups.

ESC Return to Overview screen.

28 ANASOFT User’s Guide

Page 39

Loop Setup

Getting Here

Loop Setup

The Loop Setup screen permits a total access to all the parameters of the

input, output, alarm settings and alarm functions of the single loop

display you have selected. Use this screen to change all available loop

parameters.

Watlow-Anafaze recommends that you protect this screen with a

password. Use the F3 System Setup screen Password window.

Press F2 from the Overview screen.

ANASOFT4

Loop graph display Input and output parameters

Alarm parameters and controller information

ANASOFT3

ANASOFT User’s Guide 29

Page 40

Loop Setup

Function Keys

NOTE

The Loop Setup screen in ANASOFT 3 looks slightly

different due to differences in parameters location on

the screen. However, the parameters are mostly the

same, unless indicated otherwise.

Key Function

F1 Copy all loop parameters into the loop currently displayed.

F7 Display the Graphic Trend Plot of the loop. Press Esc to return to the loop

Setup screen.

PgUp/

PgDn

TAB Change the display to other groups. Available only when there is more than

ESC Return to Overview screen.

Change the display to other loops within the group.

one group.

Parameters

To review all the parameters available in this screen, we have divided it

into three sections (shown in previous page): loop graph display, I/O

parameters, and alarm parameters and controller information.

Loop graph display

Output control action. Set to Manual, Auto, or

Process variable

Setpoint. Set to any value between the HiPV and

LoPV of the input type. Changing SP changes

deviation alarms and warnings.

An expression of the input type.

T/C or RTD--F or C.

Linear input--any three characters.

Loop title

Output levels. Edit only

when the loop is in manual

control.

Bar graph deviation

30 ANASOFT User’s Guide

Page 41

Process offset. Use it to make

up for input signal’s inaccu-

Digital filter. The average PV

over number of scans selected.

The spread between the heat

output and the cool output.

Enable or disable the output.

When controlling a process, at

least one loop should be

Set to Direct or Reverse.

Reverse action causes the output to increase while PV

decreases. Normally used in

heating control. Direct action

causes the output to increase

while PV increases. Normally

Loop Setup

Input and Output parameters

Input type. See table on the next

Proportional Band, Reset,

Rate. See PID Tuning.

TP--Time Proportioning

DZC--Distributed Zero Crossi ng

On/Off Control

ANA--Analog control (8LS)

Cycle time. Set in seconds the

time a controller takes to complete one on/off cycle. Use only

with TP output type.

Limits the PID control output for

heating and cooling.

Sets a time limit for the output

limit. Set between 1 and 999 seconds.

Nonlinear outputs. Use it to

match control outputs to special situations.The output

curves provide a gentle onset

of control action near the setpoint. Set to 0 for linear outputs, and to 1 or 2 according to

The output percentage when the

controller failed back to manual

mode.

NOTE

Set input type first. All Loop pertinent parameters are

in reference to the input type and engineering unit.

The input must be correct before setting SP, PB,

alarms SP etc.

ANASOFT User’s Guide 31

Page 42

Loop Setup

Input type

The input types you can select depend on the type and options installed

in the controllers. The input types available are displayed in the input

type editing prompt. Input types available in Watlow-Anafaze

controllers include:

•

Thermocouple: Various types are available. The range is deter-

mined in firmware and by the Engineering Units selected.

•

RTD: Four ranges are available for the 100 ohm Platinum Element

DIN Curve RTD. The range is determined in firmware and by the

Engineering Units selected. See 7.0.1 & 7.0.3.

•

Linear: This is a linear voltage input type. it can be used with any

linear output sensor that can be scaled to the linear input voltage

range of the Watlow-Anafaze controller.

•

Pulse: This allows devices which generate digital pulse signals such

as optical encoders to be connected to the loop.

The table below describes the input types and ranges.

Input Type F Range C Range

J -350 to 1400 -212 to 760

K -450 to 2500 -268 to 1371

T -450 to 750 -268 to 399

S 0 to 3200 -18 to 1760

R 0 to 3210 -18 to 1765

N -450 to 2370 -268 to 1299

B 150 to 3200 66 to 1760

RTD 1 -148.0 to 572.0 -100.0 to 300.0

RTD 2 -184 to 1544 -120 to 840

RTD 3 -76 to 572 -60 to 300

Standard IR (IR 1) -100 to 1600 -73 to 871

Heavy Duty IR (IR 2) -100 to 1600 -73 to 871

Skip loop is not scanned or displayed

Linear See appendix B.

Pulse 0-2KHz

32 ANASOFT User’s Guide

Page 43

Alarm digital output. Can be set for

g

g

high process, low process, high

deviation alarm, and low deviation

alarm. You can set these parameters

to one of three options:

The high and low values for your

high and low process alarms.

Loop Setup

Alarm parameters and controller information

The text you see on the Alarm

screen (F5). It’s the user

selected massage for alarms.

Alarm deadband. Applies to

the high process, low process, high deviation, and low

deviation. Use it to avoid

repeated or nuisance alarms

as the PV cycles slightly

The spread from setpoint for your

high and low deviation alarms.

Hi

High Alarm Limit

SP + Deviation

Setpoint

SP - Deviation

High deviation alarm on

The diagram below shows the different alarm types.

h process alarm on

Hi

h deviation alarm off

Controller information

High process alarm off

Low deviation alarm on

Delays all the alarms until the

alarm condition exists longer

than the delay time you set.

Low deviation alarm off

Deadband

}

Deadband

}

Deadband

}

Deadband

Low Alarm Limit

Low process alarm on

Low process alarm off

}

ANASOFT User’s Guide 33

Page 44

Loop Setup

34 ANASOFT User’s Guide

Page 45

System Setup

The System Setup screen enables you to

1. Monitor system errors and reset these errors.

2. View the version and options of your ANASOFT.

3. Protect your screens using passwords.

4. Edit various system parameters, such as video control and alarm display screen.

5. Terminate the program.

6. Choose additional options for Start Up sequence.

7. Control data logging feature.

8. View the controller communication status (enabled or disabled).

9. Set the polarity of the digital outputs used for alarms.

10. In MLS controllers: select the digital output that will be activated in

case communication fails between the MLS-AIM and the MLS-PM.

System Setup

Getting Here

The screen is divided into two sections: the left part of the screen is a list

of the available windows, depending on your ANASOFT version. An

arrow is pointing to the window currently d isplayed. The right part of

the screen displays one of the 8, 9, or 10 available windows. Each one

contains parameters for editing or viewing. You can view only one

window at a time.

Each window, except the System Errors window, can be either Locked

or Unlocked. If the window is Unlocked, you can change the

parameters. If the window is Locked, you can only view the p arameters.

You can unlock a window by entering the password.

Press F3 from the Overview screen.

ANASOFT User’s Guide 35

Page 46

System Setup

System Errors

•

This window describes any system error along with the date and

time it occurred. It also allows you to reset these errors.

•

If a printer error message is displayed, printer data logging is sus-

pended until you reset this error from the window. Similarly, if a

disk error message is displ ayed, disk data logging and statu s logging is suspended until you reset this error. Communications errors

are also displayed on this screen but you cannot reset them.

•

If there is a failed communication with a controller in the system,

ANASOFT will repeatedly retry communicating with the controller. While there is failed communication, an error message is displayed. When communication is established, the error message is

erased.

36 ANASOFT User’s Guide

Page 47

System Software

System Setup

Information about ANASOFT

Information about the controllers

•

This window display s the version and options of t he so ft wa re in th e

system.

•

The upper part of the window displays information about ANA-

SOFT. The lower part displays information about the controllers in

the system. The version number of the controllers in the system is

displayed only if they are communicating with ANASOFT.

ANASOFT User’s Guide 37

Page 48

System Setup

Passwords

•

This window allows you to edit passwords and lock the Syst em

Setup windows and some other ANASOFT screens.

•

Each window or screen can be either p assword protected ( LOCKED

status) or accessible for all (UNLOCKED status).

•

The passwords are all set to “PASSWORD” when ANASOFT is

shipped. Change the password status and password before running

a process.

•

Loosing or misplacing the Passwo rd Window password will require

an on-site service call by Watlow-Anafaze personnel.

NOTE

Passwords are not required for ANASOFT to function. However, we recommend that you protect

critical screens.

38 ANASOFT User’s Guide

Page 49

System Parameters

System Setup

•

This window allows you to edit various system parameters as

described below.

Video control

•

High Intensity.

taining a CGA monitor or better (as Watlow-Anafaze recommends), set to True. For some LCD or monochrome displays the

cursor display and prompt display may not appear correctly. In this

case, set to False.

•

Video Access.

access allows fast screen displays but produces “snow” on some

CGA video systems. BIOS access prevents “snow” but is slower.

Set to eithe r

Set to either

True

Direct

False

or

access or

. For most systems con-

BIOS

access. Direct

Alarm display screen

•

Auto Switch. Set to On or Off. When on, the screen automatically

switches to the View Alarms screen whenever a new alarm condition occurs. This calls maximum attention to a new alarm, and Watlow-Anafaze recommends automatic switching for normal

operation. When setting up a new process or for a short time, when

the process is first started, you may set automatic switching to Off.

The large alarm block will still indicate by flashing each new alarm,

but the system will not automatically switch to the alarm screen.

•

Audible Alarm. Set to On or Off. When on, the computer emits an

audible warning for each new alarm.

ANASOFT User’s Guide 39

Page 50

System Setup

Save to EPROM (SYSTEM 32 only)

To save all operating parameters to the EPROM memory of the

controllers, move the cursor to the Save Parameters and press Enter.

When the controllers are powered up, they will operate with the

operating parameters saved in the EPROM memory.

WARNING

The operating parameters saved in the EPROM

memory should be safe operating values. When

powered up, the controllers operate at these

parameters until the ANASOFT program is

started and download operating parameters. Watlow-Anafaze recommends saving to EPROM a job

with all outputs set to manual and outputs at zero

percent as a safe power up condition.

Controller parameters

•

Pulse Sample Time: This is the time base of the Pulse input (PLS).

It is adjustable from 1 to 20 seconds.

•

R/S Time Base: This is the time base for the Ramp Soak profiles

and is only available in the RS and CP versions. The range may be

in 999 hour:59 minute o r 999 minu te:5 9 second. It appli es to all t he

r/s profiles and all loops in r/s.

40 ANASOFT User’s Guide

Page 51

System Termin ate

System Setup

•

This window allows you to terminate ANASOFT.

•

Terminate Program (Y/N)?

If you have edited the current job without saving to disk, the following

message appears:

NOTE: The current job has been changed. To save changes to job file,

use the Save Job function of the Job Setup screen before terminating

the program.

If you entered Y, you will be asked whether to turn all outputs Off

before terminating.

Set Control Outputs Off (Y/N)?

Enter

Press

sage. The program prompts as follows:

when the cursor is on the “Terminate Program” mes-

WARNING

Turning control outputs off will shut down the

entire process.

•

The program terminates and returns to the operating system.

ANASOFT User’s Guide 41

Page 52

System Setup

System Start Up

WARNING

Do not terminate the program with SYSTEM 32

control outputs On, unless safe operation is absolutely certain without the computer.

•

If you terminate the program only for a short time, to change a disk

or to fix a computer problem, and safety devices are in the process,

you can leave the controllers On.

42 ANASOFT User’s Guide

This window allows you to set the two start up conditions:

•

Normal start-up

•

Power failure recovery:

under time limit

over time limit

For each of these conditions, you can select one of three start up actions:

Operator Select.

1.

you for the job to run.

Download Profile.

2.

fied profile.

Upload Profile.

3.

profile.

The program displays the job directory and prompts

The program automatically downloads the speci-

The program automatically uploads the specified

Page 53

System Setup

When you choose Download Profile or Upload Profile, you will be

asked for a job’s name. This can be either a specific job or the last job

running when ANASOFT was terminated.

Normal start up action

This is the start up action when the program starts up normally.

Power failure recovery

When the program starts up following a power failure, it determines the

time between the power failure and the start up. If the time is less than

the power failure recovery time limit, the program takes the under limit

start up action. If the time is greater than the power failure recovery time

limit, the program takes the ov er limit start up action. The time limit is

entered in hours and minutes.

NOTE

In order for the power fai lure recovery se quence to

operate, ANASOFT must be started automatically

when the computer is powered up. This is done using

an AUTOEXEC.BAT file which contains commands

which the computer executes at power up. See DOS

operating manual for description of

AUTOEXEC.BAT files. The file should contain as its

last commands:

1) a command to enter the disk directory containing

ANASOFT.

2) a command to stated executing the ANASOFT pro-

gram.

When recording data to floppy disk, use only the B

drive.

ANASOFT User’s Guide 43

Page 54

System Setup

Data Logging

Sets the logging function On or Off.

Directs the printer data logging

to one of the two printers that can

be connected to the computer.

Process logging interval. Set in

hours:minutes:seconds. The range

for disk logging is 00:00:05 to

99:59:59, and for printer logging--

•

This window controls the data logging features of ANASOFT.

•

Two types of logging are available:

1. Periodic process variable logging - periodically records the process

variable for all the loops in the system.

2. Alarm logging - records alarm conditions as they occur in the proces s.

Alarms are recorded on alarm occurrence, alarm acknowledge, and

alarm clearing.

Disk file name for the data

logging. Any DOS file

name up to 8 characters.

The name must not include

an extension since ANASOFT adds an extension

depending on the file’s

Lotus or Text. Lotus

files have WK1 extension and they can be

read directly in Lotus

123. T ext files have

TXT extension and they

can be printed or read

directly into a standard

44 ANASOFT User’s Guide

Page 55

Controller Comm.

System Setup

•

This window allows you to disable or enable the communication to

a controller.

•

Disable the communication i f you don’t want to send changes to the

controller.

•

When changing the status to Enabled, you are asked whether to

download or upload parameters.

ANASOFT User’s Guide 45

Page 56

System Setup

Digital Output Polarity

•

This window allows you to set the polarity of the digital outputs

used for alarms.

•

Two options are available when digital output is On:

1. O -- normally open (high)

2. C -- normally closed (low)

46 ANASOFT User’s Guide

Page 57

Aim Fail Output (MLS only)

System Setup

•

This window allows you to select the digital output that will be acti-

vated if communications fail between the MLS-Analog Input Module (AIM) and the MLS-processor Module (PM).

•

You can enter output number between 1 and 34 or N for None.

•

For more information on this feature, see the

MLS User’s Guide

.

ANASOFT User’s Guide 47

Page 58

System Setup

48 ANASOFT User’s Guide

Page 59

Job Setup

Getting Here

Job Setup

The Job Setup screen enables you to

1. Load a Job from the disk and download the parameters to the controllers.

2. Save the currently running job on the disk.

3. Delete a job from the disk.

The Job Setup screen displays a directory of up to 112 job names for

each group configured in the ANAINSTL as a different type number.

Press F4 from the Overview screen.

Function Keys

TAB Change to other groups in the system.

F1 Load a job from the disk, and download parameters to the con-

F2 Save job on disk. If the job name already exists, you will be

F3 Delete job from disk.

ESC Return to Overview screen.

Key Function

trollers.If you edited the current job after loading, you will be

asked to save before loading.

asked whether to overwrite the existing file.

ANASOFT User’s Guide 49

Page 60

Job Setup

50 ANASOFT User’s Guide

Page 61

View Alarms

The View Alarms screen offers an overview on the alarm and warning

conditions by providing detailed information on when they occurred,

acknowledged, or cleared. This screen also enables you to acknowledge

the alarms and warnings.

Getting Here

Press F5 from the Overview screen.

View A l arms

Four possible messages:

“Alarm Message”--alarm has occurred. You see

the message defined on the Loop Setup screen.

Alarms Acked--alarms acknowledged from

ANASOFT.

Alarms Remote Acked--alarms acknowledged

from the controllers.

Function Keys

F1 Clear log. Press after all alarms are acknowledged.

ESC Return to Overview screen.

Six possible types:

HP--high process

LP--low process

HD--high deviation alarm

LD--low deviation alarm

HW--high deviation warning

LW--low deviation warning

Key Function

ANASOFT User’s Guide 51

Page 62

View Alarms

Alarm Screen Auto Switch

Audible Alarm

If you set the Auto Switch On in the System Parameters menu, the

Alarm screen appears automatically for each new alarm. You will be

asked to acknowledge each alarm. After doing that you can press Esc to

return to the last screen displayed before the alarm condition occurred.

Acknowledging the alarms from View Alarms screen also

acknowledges the alarms at the controller. Acknowledging the alarms at

the controllers will acknowledge the alarms on the View Alarms screen.

If you set the Audible Alarm On in the System Parameters menu, the

computer emits an audible warning for each new alarm. Press Enter to

silence this alarm.

52 ANASOFT User’s Guide

Page 63

Trend Plot

Getting Here

Trend Plot

The Trend Plot screen offers graphic trending for both real time and past

history of up to 48 hours. Three parameters can be plotted: process

variable, output value, and setpoint. You can use any combination of

these values. You can also combine loops, and plot up to three different

loops at the same time.

The screen is a combination of past and real time trend plotting. The

past is on the left 5/6 of the screen and the real time is on the right 1/6.

If an EGA video card is installed in th e computer, the screen will be

colored for easier identification. If a CGA video card is installed, the

plot will be displayed in black and white only.

Press F7 from the Overview screen or the Loop Setup screen.

A legend for the

parameters being

plotted

One segment out of six in the time

scale. Set in minutes or hours.

Appears when the output value is plotted.

Ranges from -100% to

+100% for dual output

loops, and 0% to 100%

for others.

ANASOFT User’s Guide 53

Page 64

Trend Plot

Function Keys

Trend Plot Setup Screen

Getting Here

Key Function

F1 Plot setup. Enter the Plot Setup screen.

F2 Single loop. Display the trend plot for the loop being edited

when you entered the Trend Plot screen.

F3 Combine loops. Display the trend plot for the first group of

combined loops defined on the Plot Setup screen

ESC Return to the screen the trend plot was entered from.

The Plot Setup screen allows editing scales and parameters and

combining loops.

Press F1 from the Trend Plot screen. The screen is shown on the next

page.

54 ANASOFT User’s Guide

Page 65

Trend Plot

Information on 8 loops. You cannot

edit this part!

Window parameters: date,

time, size.

Combine up to 3 loops in

one graphic display.

Type in loop numbers

separated by spaces.

Edit here the loop plot range and

the three parameters of the plot.

Press N if you do not wish to plot

one of these parameters.

If you set to YES,

the output values

will be saved and

available for plot-

Values are recorded in

periodic intervals according to this time scale. The

available range is 1 to 255

seconds.

If you set to YES,

the plot will be displayed on a fine grid

for a quick referenc-

Indicates the density

of the print screens.

Set to single, double,

or quad.

ANASOFT User’s Guide 55

Page 66

Trend Plot

Print Trend Plot Screen

•

T o print the T rend P lot screen, you need an IBM graphic compat ible

printer.

•

Press

the Print Screen key. The program will ask for a title for the

print out.

•

Type

the title and press Enter. This title will be displayed at the

lower center of the screen and will be printed with the plot screen.

The printing of the screen at the moment of pressing Enter will be

transferred to a buffer and the screen will be printed as a background task. The Trend Plot screen will be updating and other

screens may be accessed.

•

Be sure

error will appear on the Systems Error window.

your printer is powered and On Line; otherwise, a printer

56 ANASOFT User’s Guide

Page 67

Appendix A: PID Tuning and

Appendix A: PID Tuning and

Control

Introduction

This chapter explains PID control and supplies some starting PID values

and tuning instructions, so that you can use control parameters

appropriate for your system. If yo u woul d li ke mor e infor mat ion on PID

control, consult the Watlow-Anafaze Practical Guide to PID.

The control mode dictates how the controller responds to an input

signal. The control mode is different from the type of control output

signal (like analog or pulsed DC voltage). There are several control

modes available: On/Off, Proportional (P), Proportional and Integral

(PI), Proportional with Derivative, and Proportional wi th Integral and

Derivative (PID). P, PI, or PID control are necessary when process

variable (PV) cycling is unacceptable or if the process or s etpoint (SP) is

variable.

Control Modes

NOTE

For any of these control modes to function, the lo op

must be in automatic mode.

The next sections explain the different modes you can use to control a

loop.

ANASOFT User’s Guide 57

Page 68

Appendix A: PID

On/Off Control

On/Off control is the simplest way to control a process; a controller