Page 1

ANASCAN

User’s Guide

Watlow Controls

1241 Bundy Blvd.

Winona, MN 55987

Customer Service

Phone: (800) 414-4299

Fax: (800) 445-8992

Technical Support

Phone: (507) 494-5656

Fax: (507) 452-4507

Email: wintechsupport@watlow.com

Part No. 10852-10. Revision 2.1

July 1997

Page 2

Copyright © 1997

Watlow Anafaze

Information in this manual is subject to change without notice. No part of this publication may be

reproduced, stored in a retrieval system, or transmitted in any form without written permission

from Watlow Anafaze.

Warranty

Watlow Anafaze, Incorporated warrants that the products furnished under this Agreement will be

free from defects in material and workmanship for a period of three years from the date of shipment. The customer shall provide notice of any defect to Watlow Anafaze within one week after the

Customer's discovery of such defect. The sole obligation and liability of Watlow Anafaze under this

warranty shall be to repair or replace, at its option and without cost to the Customer, the defective

product or part.

Upon request by Watlow Anafaze, Incorporated, the product or part claimed to be defective shall

immediately be returned at the Customer's expense to Watlow Anafaze. Replaced or repaired products or parts will be shipped to the Customer at the expense of Watlow Anafaze.

There shall be no warranty or liability for any products or parts that have been subject to misuse,

accident, negligence, failure of electric power or modification by the Customer without the written

approval of Watlow Anafaze. Final determination of warranty eligibility shall be made by Watlow

Anafaze. If a warranty claim is considered invalid for any reason, the Customer will be charged for

services performed and expenses incurred by Watlow Anafaze in handling and shipping the

returned unit.

If replacement parts are supplied or repairs made during the original warranty period, the warranty

period for the replacement or repaired part shall terminate with the termination of the warranty

period of the original product or part.

The foregoing warranty constitutes the sole liability of Watlow Anafaze and the customer's sole

remedy with respect to the products. It is in lieu of all other warranties, liabilities, and remedies.

Except as thus provided, Watlow Anafaze disclaims all warranties, express or implied, including

any warranty of merchantability or fitness for a particular purpose.

Please Note: External safety devices must be used with this equipment.

Page 3

Contents

INTRODUCTION 1

ANASCAN Features .......................................................1

Computer Requirements .................................................2

INSTALLATION 5

Quick Installation ............................................................5

ANASCAN Files ............................................................5

File Locations .................................................................6

Installation Program ........................................................7

Installation Menu ............................................................8

Directory Paths ...............................................................8

Grouping Channels .........................................................9

START UP 11

Quick Start Up ................................................................11

Start Up Optional Modes ................................................11

Start Up Sequence ...........................................................12

Default Start Up Values ..................................................13

Start Up Errors ................................................................14

GENERAL SCREEN

DISPLAYS 19

Changing Data ................................................................20

Print Screen .....................................................................20

CHANNEL OVERVIEW 21

Getting Here ....................................................................21

Options ............................................................................21

Function Keys .................................................................23

EDIT 25

Getting Here ....................................................................25

Function Keys .................................................................25

CHANNEL SETUP 27

Getting Here ....................................................................27

Function Keys .................................................................28

Parameters .......................................................................28

ANASCAN User’s Guide i

Page 4

SYSTEM SETUP 33

Getting Here ....................................................................33

System Errors ..................................................................34

System Software .............................................................35

Passwords ........................................................................35

System Parameters ..........................................................36

System Terminate ...........................................................37

System Start Up ..............................................................38

Data Logging ..................................................................40

Controller Comm. ...........................................................41

Digital Output Polarity ....................................................42

JOB SETUP 43

Getting Here ....................................................................43

Function Keys .................................................................44

VIEW ALARMS 45

Getting Here ....................................................................45

Function Keys .................................................................46

Alarm Screen Auto Switch .............................................46

Audible Alarm ................................................................46

TREND PLOT 47

Getting Here ....................................................................47

Function Keys .................................................................48

Trend Plot Setup Screen .................................................48

Getting Here ....................................................................48

Print Trend Plot Screen ...................................................50

APPENDIX: Input Scaling 51

Linear Input Scaling ........................................................51

ii ANASCAN User’s Guide

Page 5

Overview

Using This Guide

This manual describes how to install, setup, and operate ANASCAN.

ANASCAN is a DOS-based software program that allows you to

program and monitor multiple CAS and CAS200 scanners from a single

PC. Hereafter, both the CAS and CAS200 scanners are referred to as

CAS scanners.

This guide is intended for both experienced and inexperienced users.

Experienced users may find some parts of this guide very simplistic; if

that’s you, please at least skim these parts to make sure you don’t miss

anything vital. If you’re an inexperienced user, please read this guide

carefully.

The following describes each section.

•

Introduction: Describes ANASCAN and its computer require-

ments.

•

Installation: Covers how to install and setup ANASCAN.

•

Startup: Describes program loading and startup errors.

•

General Screen Displays: Provides an overview of the screen and

typical screen responses.

•

Channel Overview: Describes the channel overview screen.

•

Edit: Describes the edit screen.

•

Channel Setup: Gives an overview of the channel setup screen.

Included are descriptions of system parameters.

•

System Setup: Describes the system setup screen.

•

Job Setup: Describes the job setup screen.

•

View Alarms: Describes alarms and how to view them.

•

Trend Plot: Covers trend plotting and reviewing trend plots.

•

Appendix: Describes input scaling examples.

ANASCAN User’s Guide iii

Page 6

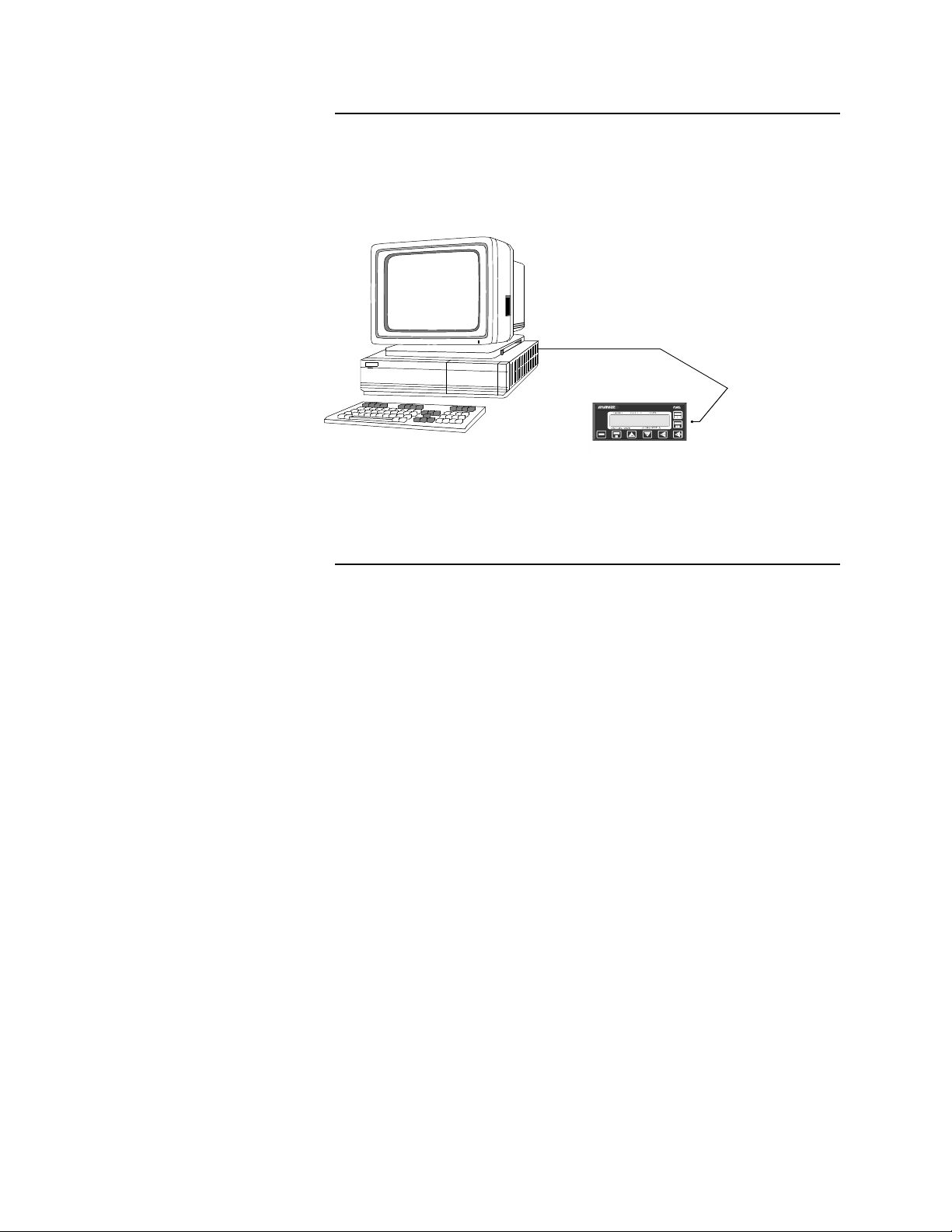

System Block Diagram

The following shows how the PC interface (with ANASCAN) to several

units.

Communications

Cable (serial port 1 or 2)

1 or more CAS units

Parts List

The following parts are included with ANASCAN.

•

ANASCAN on 3.5 inch Diskette. (5.25 in diskettes are available

upon request)

•

RS-232 or RS-485 communications cable

iv ANASCAN User’s Guide

Page 7

Safety

Watlow Anafaze has made efforts to ensure the reliability and safety of

ANASCAN. Note that in any application failures can occur.

Good engineering practices, electrical codes, and insurance regulations

require that you use independent external safety devices to prevent

potentially dangerous or unsafe conditions. Assume that ANASCAN

can fail or that other unexpected conditions can occur.

For additional process safety, program a computer or other host device

to automatically reload your desired operating parameters after a power

failure. However, this safety feature does not eliminate the need for

other external, independent safety devices in dangerous conditions.

In the event of a CAS reset, ANASCAN will reload the unit with the

current values in computer memory. The user must ensure that this reset

will be safe for the process. Use of ANASCAN does not eliminate the

need for appropriate external, independent safety devices.

Please contact Watlow Anafaze immediately if you have questions

about system safety.

ANASCAN User’s Guide v

Page 8

vi ANASCAN User’s Guide

Page 9

INTRODUCTION

ANASCAN is a user friendly, menu driven software package. It

interfaces the Compact Alarm Scanner (CAS) system to monitor inputs

and alarms for up to 16 independent channels.

You may have only one CAS or a plant wide system with numerous

units. ANASCAN includes numeric and graphic displays, data and

alarm printing, data and alarm logging in text or LOTUS compatible

files, and graphic trending. It runs on an IBM AT 286, 386, or 486, and

true compatible computers. A question and answer format enables

users to quickly define and setup any measurement or application.

NOTE

ANASCAN is sold with a license agreement and can be operated

only on one computer. The license agreement requires registration

with Watlow Anafaze. Watlow Anafaze will send updates at no

charge only to registered users. See registration form at the end of

this manual.

INTRODUCTION

ANASCAN Features

ANASCAN provides these features:

•

Process overview screens

•

Channel setup screen, individual channel parameters editing

•

Maintaining a directory of job files

•

Displaying and logging process variable alarms

•

Password protection for various levels of program

•

Software grouping of Channels

•

Graphic trend plotting of process variabilities points and output val-

ues in real time

•

Definable startup sequences

•

Power failure recovery

•

Printer and disk data and alarm logging

ANASCAN User’s Guide 1

Page 10

INTRODUCTION

Computer Requirements

Watlow Anafaze sets these computer requirements for running

ANASCAN:

1. IBM AT 286, 386, 486 or other IBM Compatible Computer

2. DOS Version 3.3 or higher

3. Speed: 25 MHz or higher

This speed provides the best performance of the ANASCAN program; it enhances the response of the system to changes and maintains the best screen updates. However, it is not a factor in the

performance of the system since this is maintained independently in

each Watlow Anafaze controller.

4. Memory: 580K bytes free memory or larger

5. Disk Drives: One 40MB hard disk. One 5.25” and/or 3.5” floppy disk

6. Graphics Interface: EGA/VGA

7. RS-232 or RS-485 Serial Interface

The serial communication link required to communicate with more

than one CAS or with a communication cable longer than 50 feet is

RS-485. Watlow Anafaze recommends using the standard serial

interface of RS-232 with an external RS-485 converter.

A converter recommended by Watlow Anafaze is the B&B Electronics RS-232/RS-485 optically isolated converter P/N 485OIC. This

converter has screw terminals for connecting the RS-485 wires and

the DB-25 Male connector for the RS-232 side.

Other recommendations are the Black Box RS-232/RS-485 non-isolated converter P/N ME-836A. The ME-836A connections are the

same except the terminals are labeled with an X instead of a D. The

converter is used for both 2-wire/4-wire systems.

To provide optical isolation, the addition of Black Box opto-isolator

P/N SP400A is highly recommended. The SP400A will normally use

the factory DIP switch settings. All that needs to be done is to connect the cable and the power supply. The SP400A has been used

without any power supplies required as it will draw its power from

the computer and the ME-836A. Always use equipment manufacture

factory recommendations.

To use a PC internal mounted RS-485 card, the Black Box Corp. P/N

IC030 has been used successfully in Watlow Anafaze installations.

Caution must be taken when other communication devices are

installed so as not to conflict with the address or interrupt.

Another PC internal optically isolated RS-485 serial card is BB Electronics model # 3PX0CC1A.

2 ANASCAN User’s Guide

Page 11

INTRODUCTION

8. Printer Parallel Interface

The printer parallel interface port is required for the Watlow Anafaze

software key. The Watlow Anafaze software key must be installed on

the printer port. System operation of the CAS is not possible without

the software key. [See Software key installation].

9. Battery backed up real time clock (usually battery backed CMOS

chip)

10. EGA/VGA Monitor

The EGA interface card will allow color trend plotting even with a

CGA monitor. The EGA/VGA monitor used with the EGA/VGA

interface provides improved text displays making all the screens easier to read. For systems that require frequent operator changes and

frequent observation, full EGA or VGA is recommended.

11. IBM Graphics Compatible Printer

This graphics printer is required for printing data and alarm logging

features of ANASCAN.

ANASCAN User’s Guide 3

Page 12

4 ANASCAN User’s Guide

Page 13

INSTALLATION

Quick Installation

•

Create a directory on your hard disk and change to that directory.

•

Type A:\ANASCAN2. The file will self-extract into the directory.

•

Type SCANINST from your ANASCAN directory (If you copied the

file to the hard disk. If you didn’t, type the appropriate drive).

•

Press Enter. Installation menu appears.

•

Change inputs in the installation menu by moving the cursor to the

desired parameters.

•

You are ready for start up.

INSTALLATION

ANASCAN Files

WARNING

It is your responsibility to ensure that the entire system is safe.

Read the warning in the front of this manual. If there is any

possibility of an unsafe condition, use independent safety

devices.

ANASCAN2.EXE - a self extracting program that contains the program

files.

SCANINST.EXE - ANASCAN installation program

ANASCAN.EXE - a file that contains the main program software.

Support files:

INSTAL.DAT - installation parameters data file

LPGRP.DAT - channel grouping start up data file

SYSSU.DAT - system setup data file

STATUS.DAT - system start up status file

DIGIO.DAT - digital I/O screen data

DLOG.DAT - data logging data file

GRPINFO.DAT - group set up data file

HDR.WK1 - Lotus header set up file

ANASCAN User’s Guide 5

Page 14

INSTALLATION

PLOT.DAT - plot parameters data file

Files created by ANASCAN:

XXXXXXXX.J## - group job directory data file

NEWXX.PLT - plot files which were created within the last 24 hours.

OLDXX.PLT - older plot files

PXXXXXXX.TXT or WK1 process logging files

AXXXXXXX.TXT or WK1 alarm logging files

WARNING

Make copies of disks before running the program, and store the

original ANASCAN disks in a safe place. Use the copies to operate the system.

File Locations

360k dual floppy disk system:

Watlow Anafaze recommends that you store the ANASCAN operating

program file and the INSTAL.DAT file on drive A, and all other files on

drive B. Once the program SCANINST is run, you can remove

SCANINST.EXE from drive B to allow more room for data. Do not

remove files from the master disk. This recommendation ensures that

the autoboot feature will bring up the program automatically in the

occurance of a power outage.

720k or higher floppy disk system:

Watlow Anafaze recommends that you store all files of the ANASCAN

operating program on one drive such as A. Use the B drive to store all

recording data by setting up directories as shown in the hard disk system

recommendations.

Hard disk systems:

Watlow Anafaze recommends setting up directories as follows:

ANASCAN - to contain the operating program, system data and job

files

6 ANASCAN User’s Guide

DATALOG - to contain data logging files generated by ANASCAN

ALARMLOG - to contain alarm logging files generated by ANASCAN

Page 15

Installation Program

INSTALLATION

For easy removal of recorded data, you may install the DATALOG and

ALARMLOG directories on the A or B floppy drives. For automatic

reboot use the B drive recording data to the floppy.

Copy all the supplied files to the ANASCAN directory.

The installation program, SCANINST.EXE, customizes each

ANASCAN program for the application. When typing C:SCANINST

(if it’s on the hard disk), or B:SCANINST (if it’s on drive B), The

installation screen appears and enables you to select parameters used by

ANASCAN.

SCANINST.EXE stores the program setup parameters in a file called

INSTAL.DAT. When run, the SCANINST program reads the

INSTAL.DAT file from the default disk directory. If both files are on

the same disk directory, enter the directory and type SCANINST.

If the SCANINST.EXE and INSTAL.DAT file are on different

directories, enter the disk directory containing INSTAL.DAT and type

SCANINST preceded by the path to the disk directory containing

SCANINST. For example, if INSTAL.DAT is on drive A and

SCANINST.EXE on drive B, type :

B:>A: [Enter] to change the current default drive to A

A:>B:SCANINST [Enter] to start the installation program

If the installation program cannot find INSTAL.DAT, an error message

appears. Verify the location of INSTAL.DAT file.

ANASCAN User’s Guide 7

Page 16

INSTALLATION

Installation Menu

1 to 16 This value is fixed

for the CAS

Total number of

channels (this

will vary due to

the number of

CAS systems

installed)

Selects the Group Edit Screen.

See Grouping channels in this

section.

Select 9600 or

2400 Baud.

Set to either BCC (Block Check

Character) or CRC (Cyclic

Redundancy Check). Use BCC

for standard applications. CRC

ensures a higher degree of security but decreases the overall

cummunication rate. Use CRC

only when you anticipate severe

communication noise.

The PC’s serial communications

port to the controller (can only

be 1 or 2)

For these paths,

refer to the next

page

Directory Paths

8 ANASCAN User’s Guide

Number of channels

ANASCAN displays 16 channels with system numbers. The system

channel numbers associated with the CAS channels are indicated in the

installation program as the Begin Channel and End Channel for each

scanner. A 17th channel is reserved for pulse monitoring.

Job/Parameters path

This is the path to the disk directory containing the Job and System

Parameters Data Files. The path would normally be:

B:\ANASCAN\ or .\ current directory (If the system files are on drive

B)

Page 17

INSTALLATION

C:\ANASCAN\ or .\ current directory (If the system files are on the

hard disk). Notice that the last “\” is added automatically.

Data logging path

This is the path to the disk directory containing the LOTUS or text

[ASCII] data logging files generated by ANASCAN. This directory

must exist before running ANASCAN and turning on data logging.

B:\ANASCAN\DATALOG\ (for floppy disks)

C:\ANASCAN\DATALOG\ or.\DATALOG\ (for hard disks). Notice

that the last “\” is added automatically.

Alarm logging path

This is the path to the disk directory containing the LOTUS or Text

(ASCII) alarm record files generated by ANASCAN. This directory

must exist before running ANASCAN and turning On alarm logging.

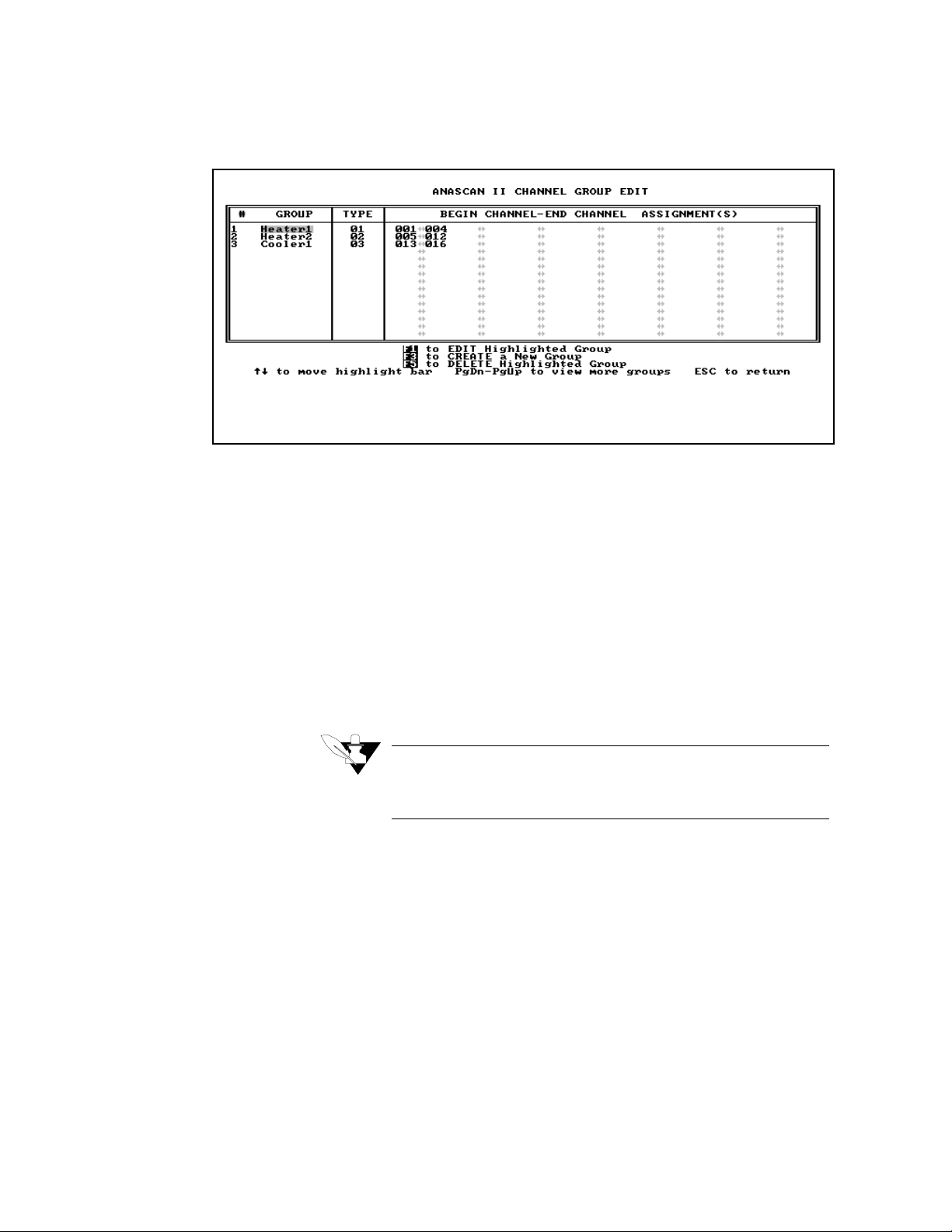

Grouping Channels

B:\ANASCAN\ALARMLOG\ (for floppy disks)

C:\ANASCAN\ALARMLOG\ or .\ALARMLOG\ (for hard disks).

Notice that the last “\” is added automatically.

Grouping inputs allows you to divide your system into subsystems. You

can group channels with a common purpose according to your specific

application requirements. One group might be for a furnace or a group

of furnaces; another group might be for common Jobs shared between

devices.

Only the channels of one group are displayed on the Overview screen at

a time. The job parameters are uploaded or downloaded to an individual

group independently. The number of controllers with their total number

of channels must match the number of channels in the grouping. The

channel numbering depends upon the type of input selected in the

SCANINST program.

After assigning the channel numbers to a group, select a type number of

two digits up to 99. This number is the job directory number for the

group and its channels. All groups with the same type number will be

assigned to the same job directory. Creating a new type number creates

a new job directory number in the ANASCAN program.

ANASCAN User’s Guide 9

Page 18

INSTALLATION

Group menu

General grouping rules

•

Create a group when you need to have the channels on the same

Overview screen.

•

Assign the channels to the group you want to have on the same

Overview screen.

•

Create a type number for the new group. This type number can be

assigned to more than one group if they share common jobs through

the ANASCAN.EXE program. However, when using the same

type number for groups, the number of channels must match.

Otherwise a new type number must be used.

NOTE

Type value is used to store jobs specific for that type. The Default

job is only stored under type 01.

10 ANASCAN User’s Guide

Page 19

START UP

Quick Start Up

•

Ensure time and date are correct in your computer.

•

Type: ANASCAN. Job Select screen appears.

•

Type a job’s name. When starting the first time, enter DEFAULT.

•

Type D for downloading parameters to the CAS, or U for uploading. For

initial testing in the Edit mode, enter D.

•

Overview screen appears.

Start Up Optional Modes

You can start ANASCAN in certain modes by adding parameters to the

command at start up. These command line options include:

•

/e

Operates the program in Edit mode. The program operates normally

but it does not communicate with the CAS. You can operate the

program in Edit mode without any hardware connected to the computer. This mode is useful for initial familiarization, training, and

Off Line job editing.

•

/c

Forces the graphics display into CGA mode. This is necessary on

some computers which are not truly IBM compatible.

•

/d

Operates the program in the Debug mode. This is useful in debugging communications problems. Don’t use it for normal operations. All communications between the computer and the CAS are

displayed on the printer. Therefore, in order to use this mode, the

printer must be connected and ready.

You can use capital or small letters in the command line, and more than

one command line option at a time. For example:

Typing ANASCAN /E /C [enter] will operate the program in Edit mode

with CGA graphics.

ANASCAN User’s Guide 11

Page 20

START UP

Start Up Sequence

•

The program checks the computer system hardware and the access

to the system disk files.

•

The program verifies communications to each CAS in the system

and their versions.

•

Job Directory screen appears.

•

The program prompts for the job to run. ANASCAN program is

supplied with a job named DEFAULT which contains all the

default parameters and setups. When starting the first time, enter

the job name DEFAULT.

WARNING

When the CAS is monitoring, upload to install parameters into

the ANASCAN operating program. Downloading will install

factory default values. For Initial testing in the Edit mode,

enter Download.

•

After the downloading sequence is complete, the program displays

the Overview screen. If there is a problem in the program start up,

see start up errors in this section.

12 ANASCAN User’s Guide

Page 21

Default Start Up Values

START UP

The program is shipped to you containing several parameters which are

set to initial factory default values. These should be set to desired values

by supervisory personal, and they include:

•

Passwords

•

Program startup sequences

•

Data logging parameters

•

Trend plotting parameters

See System Setup for detailed information.

ANASCAN User’s Guide 13

Page 22

START UP

Start Up Errors

During Start up, various error messages may appear. The following

tables describe these messages, their causes and solutions.

Memory allocation errors

ANASCAN allocates computer memory for the channel parameters,

based on the number of channels and options in the system. When

ANASCAN reads in the system data files and finds there isn’t sufficient

memory, these messages may appear:

Message Cause Solution

Insufficient

Memory

MEM ERROR:

Alarm Queue

Trend Logging

Disabled

Not enough memory to allocate

data arrays required to run the program. The program cannot run and

it terminates.

Not enough memory to allocate the

alarm log memory. The program

operates, but the view alarms

screen doesn’t display alarm queue.

Not enough memory to allocate

some or all of the trend logging

memory queues. The program

operates normally, but the trend

plotting is not available.

•

Check the memory by

running the DOS command CHKDSK. At least

580K should be free.

•

Make sure your computer

has 640K memory, and

remove any memory resident programs and drivers. Check

AUTOEXEC.BAT file to

see if it runs any memory

resident programs. After

removing these programs,

re-boot the computer.

Same as above.

Same as above.

14 ANASCAN User’s Guide

Page 23

Disk file errors

While reading in the system files, several reading errors can occur. The

system files are SYSSU.DAT, INSTAL.DAT, and PLOT.DAT.

ANASCAN cannot run without these files.

Message Cause Solution

ERROR WHILE

READING DATA

FILE: xxxxxxxI

FILE NOT FOUND

ERROR WHILE

READING DATA

FILE:xxxxxxx

Drive not ready

Read fault

General failure

or

Access failure

ERROR WHILE

READING DATA

FILE:xxxxxxx

Path not valid

or

Invalid disk drive

INVALID DATA

FOUND ON DATA

FILE:xxxxxxx

The system file does

not exist on the indicated disk and directory path.

There is a disk drive

hardware access failure.

The data disk path

that you set in the

SCANINST installation program is not

valid.

There is corrupted or

invalid data in the

disk file.

The INSTAL.DAT file should be on the

default drive and directory. The other system files should be on the data file drive

and directory path as set in the installation

program. If these files are not in the right

directories, copy the system files from the

backup disks to the appropriate directories.

Run CHKDSK or other diagnostic program in order to verify that there is no disk

drive error.

For a floppy drive: make sure that there is

a disk in the right drive and that the drive

door is closed.

Run SCANINST and verify that the drive

and directory path exist and are valid.

Don’t forget to verify that “\” is at the end

of the path entry.

Copy the original data file sent with

ANASCAN from the backup disks.

START UP

ANASCAN User’s Guide 15

Page 24

START UP

Extended start up sequence errors

ANASCAN reads in the status file STATUS.DAT which contains

information saved by ANASCAN the last time it was running. Several

errors can occur when reading this file.

Message Cause

Could not find

STATUS.DAT

start up file

Invalid data

value on STATUS.DAT start

up file

Power Failure

Recovery

System clock

Error

The file could

not be found

on the data file

disk directory

set by SCANINST. The file

may have been

erased or corrupted.

The file contains some

invalid data,

and

ANASCAN

assumes that

the file was

corrupted.

The current

system time/

date as saved

in the STATUS.DAT file

were not in a

valid range.

The computer

system clock

is not set to

valid time and

date.

Program

Action

ANASCAN continues with the

start up, but since

there is no power

failure information available,

ANASCAN

assumes the Over

Power Failure

Recovery time

Limit action and

starts in that mode.

Same as above. Same as above

Same as above. The automatic power failure

As the program is running, the

STATUS.DAT file will be

established. Therefore, subsequent starts should have no

problem.

recovery feature of

ANASCAN requires a correct clock/calendar system.

While the computer boots up,

verify the following:

•

•

•

Solution

There is a battery backed

up clock/calendar in the

system.

The battery is good.

Time and date values are

correctly loaded.

16 ANASCAN User’s Guide

Page 25

Communications problems

Message Cause Solution

Failed Communications to CAS

Abort start up

(Y/N):

ANASCAN cannot communicate with one of the

CAS during the initial system communications

check or during the job

downloading/uploading.

•

Verify that the communications

port set in ANAINSTL is the one

actually connected to the CAS.

•

Verify that the communications

parameters (baud rate and error

checking mode) set in the installation program are those set in

the CAS. The CAS communications parameters are set using the

front panel keys while in the

GLOBAL menu.

•

Verify that the address of each

CAS is unique (for multiple CAS

systems).

•

Verify that the correct version of

ANASCAN is running for the

CAS being used.

•

Verify that the wiring is done

correctly to the CAS and the

computer.

START UP

NOTE

See the respective CAS hardware manual for assistance in checking

the communication parameters and verifying the communication

wiring.

•

If there is more than one CAS in the system, ANASCAN will try

supervising those CAS which are operating and communicating

correctly. After start up ANASCAN periodically re-checks communications to the failed CAS.

•

By continuing the start up, the CAS not communicating will be

listed by address on the System Errors window in the System Setup

screen. Check the unit listed on the screen. Be sure the address is

correct as set on the CAS.

ANASCAN User’s Guide 17

Page 26

START UP

EPROM version error

ANASCAN checks the CAS EPROM version at start up and verifies

that it’s acceptable to the version of ANASCAN. The following

message may appear:

Message Cause Solution

Unacceptable

CAS EPROM

version

The EPROM version is

not acceptable to the

version of ANASCAN.

.

Contact Watlow Anafaze to obtain EPROM

upgrade

18 ANASCAN User’s Guide

Page 27

GENERAL SCREEN

DISPLAYS

Certain characteristics are maintained on all ANASCAN screens as

follows:

Title line. Includes screen’s name, current channel and job, and the time and

date. When in Edit mode, "Edit Mode" will appear at this location.

Process status box. Four possible

messages:

1. Process OK (green).

2. Process warning (yellow).

there is a warning on at least one

channel.

3. Process alarm (blinking red). An

alarm condition on at least one

channel has not been acknowledged.

4. Process alarm (red). An alarm

condition on at least one channel. All

alarms have been acknowledged.

System status box. Reports problems

of communications, printer access,

or data logging disk access. Two

possible messages:

1. System OK

2. In case of a problem, the appropri-

ate message (red).

ANASCAN User’s Guide 19

Page 28

GENERAL SCREEN DISPLAYS

Changing Data

•

Use the cursor to enter data in the editing screens.

•

Move the cursor to the variable you want to change. An editing

prompt appears at the bottom of the screen with a blue background

new value box. The allowable range of the variable is listed below

the new value box.

•

Type the new desired value into the new value box.

•

Press Enter. The new value will be displayed over the original one,

and will be downloaded to the CAS. If you made a mistake in entering the value and have not pressed Enter yet, use the backspace key

to correct.

•

Use the F4 Key to enter the Job Setup screen and save the changes.

If you don’t, upon a new start up, the Job data file will be read from

the disk along with the old parameter.

NOTE

A value you enter may be slow to change due to computer processing time or communications delays. If a value you entered is not

accepted or changes back after entry it may be that the value is not

in the range for the parameter or not acceptable in the present mode

or circumstances.

Print Screen

•

You can print all ANASCAN screens on an IBM graphics compati-

ble dot matrix printer.

•

Use the PRTSC key. When the print screen is initiated, the copy of

the current screen is transferred to a buffer and the screen will be

printed as a background task. The program continues operating and

you can display other screens while printing a screen.

•

When printing the Trend Plot screen, you will be asked for a title

before printing the screen.

20 ANASCAN User’s Guide

Page 29

CHANNEL OVERVIEW

The Channel Overview screen provides an overview of the process

information. It is not password protected and is available at all times for

anyone who wishes to monitor the process variables.

Getting Here

This screen appears automatically after start up.

Options

The Overview screen has four display screens. Use the F6 key to switch

between displays.

1. Four-channel graph display. Each channel includes a range of parameters.

Single channel display *

* The single channel display includes the channel name, setpoint, process variable, alarm

messages, warning and alarm setpoints.

ANASCAN User’s Guide 21

Page 30

CHANNEL OVERVIEW

Single channel display

2. 16 channel display in a channel table with 7 channel parameters. 1

selectable channel CAS face plate.

Channel table. A list of 16 channels includes the setpoint, process

variable, and alarm condition. It also includes channel names and

alarm messages.

Single channel display

3. 32 channel display in a channel table with 4 Channel parameters. 1

selectable channel CAS face plate.

Loop table

22 ANASCAN User’s Guide

Page 31

CHANNEL OVERVIEW

4. Digital I/O screen. This screen shows the status of your digital inputs

and outputs.

Function Keys

TAB Change group. Switch to a new group in any screen. You

F1 Edit screen. Change setpoint.

F2 Channel Setup screen. Display and edit all channel parame-

F3 System Setup screen. Display and edit various system

F4 Job Setup screen. Select, save and delete jobs.

F5 View alarms. Display on-screen alarm log. System Setup

F6 Switch displays. Change the Overview screen display to one

F7 Trend logging. Display the graphic trend plot.

For an easy access from the Overview screen to all other screens, use

the function keys as shown below:

Key Function

don’t need to go back to Overview screen.

ters.

parameters (passwords, disk and printer data logging, start

up, etc.)

allows selecting automatic switching to this screen in case of

an alarm.

of its 4 options.

•

Press ESC to view the next Group Overview screen. If you wish to

view another group, move the cursor to that group and press ESC.

•

If not all the channels are visible (in a large system), use the PgUp/

PgDn keys to view the other channels.

•

The Overview screen is automatically updated as data is collected

from the CAS. Measured data is displayed in engineering units.

ANASCAN User’s Guide 23

Page 32

CHANNEL OVERVIEW

•

Normal readings are green, warnings are yellow, and alarms are

red.

•

If you edit the CAS at its front panel, the program displays the word

“locked” in the single channel Face plate and puts the letter “L”

beside the process variable in the Channel Table for the channels on

the edited CAS. Once the front panel editing is complete, the display returns to normal.

24 ANASCAN User’s Guide

Page 33

EDIT

Getting Here

The Edit screen enables you to change the setpoint of the single channel

display you have selected:

The Edit screen uses the same format as the Overview screen, only here

you can move the cursor to change the values. This screen is not

password protected.

The Edit screen performs the same functions as the change setpoint on

the CAS front panel.

Press F1 from the Overview screen. You will enter an Edit screen with

the same display as the screen you were in before pressing F1. The

screen below is an Edit screen for the 16 channel display, and the

additional 17th channel for pulse.

Function Keys

PgUp/PgDn Display other channels for editing.

Tab Reach channels of other groups.

ESC Return to Overview screen.

Key Function

ANASCAN User’s Guide 25

Page 34

ANASCAN User’s Guide 26

Page 35

CHANNEL SETUP

From the Channel Setup screen you can select inputs, assign channel

names, and set the ranges and functions of alarms for each single

channel display you have selected. Use this screen to change all

available channel parameters.

Watlow Anafaze recommends that you protect this screen with a

password. Use the F3 System Setup screen Password window.

Getting Here

Press F2 from the Overview screen.

Channel Graph Display

Input Parameters

Alarm Parameters

ANASCAN User’s Guide 27

Page 36

C H A N N E L S E T U P

Function Keys

Parameters

Key Function

F1 Copy all channel parameters into the channel currently displayed.

F7 Display the Graphic Trend Plot of the channel. Press Esc to return

to the channel Setup screen.

PgUp/

PgDn

TAB Change the display to other groups. Available only when there is

ESC Return to Overview screen.

Change the display to other channels within the group.

more than one group.

To review all the parameters available in this screen, we have divided it

into three sections (shown in previous page): Channel Graph Display,

Input Data, and Alarm Output Data.

28 ANASCAN User’s Guide

Page 37

Process variable

CHANNEL SETUP

Channel Graph Display

Channel title

Alarm message

space

Setpoint. Set to any value

between the HiPV and LoPV

of the input type. Changing

the setpoint changes deviation

alarms and warnings.

An expression of the input

type.

Input Data

Input type. See table

below.

High process value.

Refers to the highest

value of the process

range in engineering

units.

Low process value. Refers

to the lowest value of the

process range in engineering units.

High reading. Sets

the highest percentage of input value.

Bar graph deviation

Low reading. Sets

the lowest percentage of input value.

Adjusted Decimal

(-3 to 4).

Field Name Selections Notes

Input Type * J, K, T, S, B, R, N,

PL-II

L Linear (see description)

X Skip

Pulse (Channel 17 Only ( see

PV Offset -300 to 300

Default = 0

High PV -9999 to 30000

Default = 1000

Default = 0

Thermocouple inputs (refer

to table on following page)

description)

Linear and Pulse only,

Adjustable decimalLo PV -9999 to 30000

ANASCAN User’s Guide 29

Page 38

C H A N N E L S E T U P

Field Name Selections Notes

Hi RDG -99.9 to 999.9

Default = 1000

Default = 0

* The input types you can select depend on the type and options

installed in the CAS. The input types available are displayed in the input

type editing prompt. Input types available in the CAS:

•

Thermocouple: Various types are available. The range is deter-

mined in firmware and by the Engineering Units selected.

•

Linear: This is a linear voltage input type. it can be used with any

linear output sensor that can be scaled to the linear input voltage

range of the CAS.

•

Pulse: This allows devices which generate digital pulse signals such

as optical encoders to be connected to the channel.

The table below describes the input types and ranges.

Linear and Pulse only,

Adjustable decimalLo RDG -99.9 to 99.9

Input Type

J -350 to 1400 -212 to 760

K -450 to 2500 -268 to 1371

T -450 to 750 -268 to 399

S 0 to 3200 -18 to 1760

R 0 to 3210 -18 to 1765

N -450 to 2370 -268 to 1299

B 150 to 3200 66 to 1760

PL-II +50 to 2012 +10 to 1100

Skip channel is not scanned or displayed

Linear See Appendix.

Pulse 0-2KHz

°

F Range

°

C Range

30 ANASCAN User’s Guide

Page 39

Alarm Output Data

Field Name Selections Notes

High Process

Alarm

High Process

Alarm Setpoint

High Process

Alarm Output

Low Process

Alarm

Low Process

Alarm Setpoint

Low Process

Alarm Output

O = OFF (default) No alarm

L = Latched If the system is in a Non-Alarm-

ing state, the alarm can be

acknowledged by pressing the

ENTER key from the alarm

screen when the Process Alarm

indicator is flashing. Reset the

alarm by pressing F10 and entering each affected channel number

individually. This can also be

accomplished by pressing the

ALARM RESET button on the

CAS front panel.

U = Unlatched Digital output activates on alarm,

and deactivates when channel is

in a Non-Alarming state. Press

ENTER to acknowledge the global alarm.

-350 to 1400

default = 1000

N, 1 to 34

default = NONE

O = OFF(Default)

L = Latched

U = Unlatched

-350 to 1400

default = 0

N, 1 to 34

default = NONE

Depends on input type selected.

N = NONE

See above descriptions.

Depends on input type selected.

N = NONE

CHANNEL SETUP

ANASCAN User’s Guide 31

Page 40

C H A N N E L S E T U P

}

}

}

}

g

g

Field Name Selections Notes

High and Low

Deviation

Alarms

O = OFF

L =

Latched(Default)

See above descriptions.

U = Unlatched

High and Low

Deviation Alarm

N, 1 to 34

default = NONE

N = NONE

Outputs

Alarm Deadband 0 to 255

See figure below.

default = 0

Alarm Deviation 0 to 255

See figure below.

default = 25

Alarm Delay 0 to 255

See figure below.

default = 0

The diagram below shows the different alarm types.

High Alarm Limit

SP + Deviation

Setpoint

SP - Deviation

Low Alarm Limit

Hi

h process alarm on

High deviation alarm on

h deviation alarm off

Hi

High process alarm off

Deadband

Deadband

Low deviation alarm off

Deadband

Low deviation alarm on

Deadband

Low process alarm on

Low process alarm off

32 ANASCAN User’s Guide

Page 41

SYSTEM SETUP

The System Setup screen enables you to

1. Monitor system errors and reset these errors.

2. View the version and options of your ANASCAN.

3. Protect your screens using passwords.

4. Edit various system parameters, such as video control and alarm display screen.

5. Terminate the program.

6. Choose additional options for Start Up sequence.

7. Control data logging feature.

8. View the CAS communication status (enabled or disabled).

9. Set the polarity of the digital outputs used for alarms.

The screen is divided into two sections: the left part of the screen is a list

of the available windows. An arrow is pointing to the window currently

displayed. The right part of the screen displays one of the available

windows. Each one contains parameters for editing or viewing. You can

view only one window at a time.

Getting Here

Each window, except the System Errors window, can be either Locked

or Unlocked. If the window is Unlocked, you can change the

parameters. If the window is Locked, you can only view the parameters.

You can unlock a window by entering the password.

Press F3 from the Overview screen.

ANASCAN User’s Guide 33

Page 42

S YS T EM S ET U P

System Errors

•

This window describes any system errors along with the date and

time it occurred. It also allows you to reset these errors.

•

If a printer error message is displayed, printer data logging is sus-

pended until you reset this error from the window. Similarly, if a

disk error message is displayed, disk data logging and status logging is suspended until you reset this error. Communication errors

are also displayed on this screen but you cannot reset them.

•

If there is a failed communication with a CAS in the system,

ANASCAN will repeatedly retry communicating with the CAS.

While there is failed communication, an error message is displayed.

When communication is established, the error message is erased.

34 ANASCAN User’s Guide

Page 43

System Software

SYSTEM SETUP

Passwords

•

This window displays the version and options of the software in the

system.

•

The upper part of the window displays information about

ANASCAN. The lower part displays information about the CAS.

•

This window allows you to edit passwords and lock the System

Setup windows and some other ANASCAN screens.

•

Each window or screen can be either password protected (LOCKED

status) or accessible for all (UNLOCKED status).

ANASCAN User’s Guide 35

Page 44

S YS T EM S ET U P

System Parameters

•

The passwords are all set to “PAS SW ORD ” when ANASCAN is

shipped. Change the password status and password before running

a process.

NOTE

Passwords are not required for ANASCAN to function. However,

we recommend that you protect critical screens.

This window allows you to edit various system parameters as described

below.

Video control

•

High Intensity. Set to either Tru e or False. For most systems con-

taining a CGA monitor or better (as Watlow Anafaze recommends),

set to True. For some LCD or monochrome displays the cursor

display and prompt display may not appear correctly. In this case,

set to False.

•

Video Access. Set to either Direct access or BIOS access. Direct

access allows fast screen displays but produces “snow” on some

CGA video systems. BIOS access prevents “snow” but is slower.

Alarm display screen

•

Auto Switch. Set to On or Off. When on, the screen automatically

switches to the View Alarms screen whenever a new alarm condition occurs (latched alarms and thermocouple breaks only). This

calls maximum attention to an alarm, and Watlow Anafaze recommends automatic switching for normal operation. When setting up a

36 ANASCAN User’s Guide

Page 45

System Terminate

SYSTEM SETUP

new process or for a short time, when the process is first started,

you may set automatic switching to Off. The large alarm block will

still indicate by flashing each new alarm, but the system will not

automatically switch to the alarm screen.

•

Audible Alarm. Set to On or OFF. When on, the computer emits an

audible warning for each new alarm.

•

This window allows you to terminate ANASCAN.

•

Press Enter when the cursor is on the “Terminate Program” mes-

sage. The program prompts as follows:

Terminate Program (Y/N)?

If you have edited the current job without saving to disk, the following

message appears:

NOTE: The current job has been changed. To save changes to job file,

use the Save Job function of the Job Setup screen before terminating the

program.

•

The program terminates and returns to the operating system.

•

If you terminate the program only for a short time, to change a disk

or to fix a computer problem, and safety devices are in the process,

you can leave the CAS On.

ANASCAN User’s Guide 37

Page 46

S YS T EM S ET U P

System Start Up

This window allows you to set the two start up conditions:

•

Normal start-up

•

Power failure recovery:

under time limit

over time limit

For each of these conditions, you can select one of three start up actions:

1. Operator Select. The program displays the job directory and prompts

you for the job to run.

2. Download Profile. The program automatically downloads the specified profile.

3. Upload Profile. The program automatically uploads the specified

profile.

When you choose Download Profile or Upload Profile, you will be

asked for a job’s name. This can be either a specific job or the last job

running when ANASCAN was terminated.

Normal start up action

This is the start up action when the program starts up normally.

Power failure recovery

38 ANASCAN User’s Guide

When the program starts up following a power failure, it determines the

time between the power failure and the start up. If the time is less than

the power failure recovery time limit, the program takes the under limit

start up action. If the time is greater than the power failure recovery time

limit, the program takes the over limit start up action. The time limit is

entered in hours and minutes.

Page 47

SYSTEM SETUP

NOTE

In order for the power failure recovery sequence to operate,

ANASCAN must be started automatically when the computer is

powered up. This is done using an AUTOEXEC.BAT file which

contains commands which the computer executes at power up. See

DOS operating manual for description of AUTOEXEC.BAT files.

The file should contain as its last commands:

1) a command to enter the disk directory containing ANASCAN.

2) a command to stated executing the ANASCAN program.

ANASCAN User’s Guide 39

Page 48

S YS T EM S ET U P

Data Logging

Sets the logging function On or Off.

Directs the printer data logging

to one of the two printers that can

be connected to the computer.

Process logging interval. Set in

hours:minutes:seconds. The range

for disk logging is 00:00:05 to

99:59:59, and for printer logging-00:00:15 to 99:59:59.

•

•

1. Periodic process variable logging - periodically records the process

variable for all the channels in the system.

2. Alarm logging - records alarm conditions as they occur in the process.

Alarms are recorded on alarm occurrence, alarm acknowledge, and

alarm clearing.

Disk file name for the data

logging. Any DOS file

name up to 8 characters.

The name must not include

an extension since

ANASCAN adds an extension depending on the file’s

type.

This window controls the data logging features of ANASCAN.

Two types of logging are available:

Lotus or Text. Lotus

files have WK1 extension and they can be

read directly in Lotus

123. Text files have

TXT extension and they

can be printed or read

directly into a standard

text editor.

40 ANASCAN User’s Guide

Page 49

Controller Comm.

SYSTEM SETUP

•

This window allows you to disable or enable the communication to

a CAS.

•

Disable the communication if you don’t want to send changes to the

CAS.

•

When changing the status to Enabled, you are asked whether to

download or upload parameters.

ANASCAN User’s Guide 41

Page 50

S YS T EM S ET U P

Digital Output Polarity

•

This window allows you to set the polarity of the digital outputs

used for alarms.

•

Two options are available when digital output is On:

1. O — normally open (high)

2. C — normally closed (low)

42 ANASCAN User’s Guide

Page 51

JOB SETUP

The Job Setup screen enables you to

1. Load a Job from the disk and download the parameters to the CAS.

2. Save the currently running job on the disk.

3. Delete a job from the disk.

The Job Setup screen displays a directory of up to 112 job names for

each group configured in the SCANINST as a different type number.

Getting Here

Press F4 from the Overview screen.

ANASCAN User’s Guide 43

Page 52

Function Keys

TAB Change to other groups in the system.

F1 Load a job from the disk, and download parameters to the

F2 Save job on disk. If the job name already exists, you will be

F3 Delete job from disk.

ESC Return to Overview screen.

JOB SETUP

Key Function

CAS.If you edited the current job after loading, you will be

asked to save before loading.

asked whether to overwrite the existing file.

ANASCAN User’s Guide 44

Page 53

VIEW ALARMS

The View Alarms screen offers an overview on the alarm and warning

conditions by providing detailed information on when they occurred,

acknowledged, or cleared. This screen also enables you to acknowledge

the alarms and warnings.

Getting Here

Press F5 from the Overview screen.

Four possible messages:

“Alarm Message”--alarm has occurred. You see

the message defined on the Channel Setup

screen.

Alarms Acked--alarms acknowledged from

ANASCAN.

Remote Acked--alarms acknowledged from the

CAS.

Alarms Reset--alarms reset from ANASCAN.

Remote Reset--alarms reset from the CAS.

Process Normal--alarm was cleared.

Possible types:

HP--high process

LP--low process

HD--high deviation alarm

LD--low deviation alarm

TB--T/C Break

ANASCAN User’s Guide 45

Page 54

VIEW ALARM S

Function Keys

Alarm Screen Auto Switch

Key Function

F1 Clear log. Press after all alarms are acknowledged.

F10 Resets Latched alarms by channel number.

ESC Return to Overview screen.

If you set the Auto Switch On in the System Parameters menu, the

Alarm screen appears automatically for each new latched alarm. You

will be asked to acknowledge each alarm. After doing that you can press

Esc to return to the last screen displayed before the alarm condition

occurred.

Acknowledging the alarms from View Alarms screen also

acknowledges the alarms at the controller. Acknowledging the alarms at

the controllers will acknowledge the alarms on the View Alarms screen.

Audible Alarm

If you set the Audible Alarm On in the System Parameters menu, the

computer emits an audible warning for each new alarm. Press Enter to

silence this alarm.

46 ANASCAN User’s Guide

Page 55

TREND PLOT

The Trend Plot screen offers graphic trending for both real time and past

history of up to 48 hours. Two parameters can be plotted: process

variable and setpoint. You can use any combination of these values.

You can also combine channels, and plot up to three different channels

at the same time.

The screen is a combination of past and real time trend plotting. The

past is on the left 5/6 of the screen and the real time is on the right 1/6.

If an EGA video card is installed in the computer, the screen will be

colored for easier identification. If a CGA video card is installed, the

plot will be displayed in black and white only.

Getting Here

Press F7 from the Overview screen or the Channel Setup screen.

A legend for the

parameters being

plotted

One segment out of six in the time

scale. Set in minutes or hours.

ANASCAN User’s Guide 47

Page 56

TREND PLOT

Function Keys

Trend Plot Setup Screen

Key Function

F1 Plot setup. Enter the Plot Setup screen.

F2 Single channel. Display the trend plot for the channel being

edited when you entered the Trend Plot screen.

F3 Combine channels. Display the trend plot for the first group of

combined channels defined on the Plot Setup screen

ESC Return to the screen the trend plot was entered from.

The Plot Setup screen allows editing scales and parameters and

combining channels.

Getting Here

Press F1 from the Trend Plot screen. The screen is shown on the next

page.

48 ANASCAN User’s Guide

Page 57

TREND PLOT

Information on 8 channels. You cannot edit this part!

Window parameters: date,

time, size.

Combine up to 3 channels in one graphic display. Type in channel

numbers separated by

spaces.

Edit here the channel plot range

and the two parameters of the plot.

Press N if you do not wish to plot

one of these parameters.

If you set to YES,

the plot will be displayed on a fine grid

for a quick referencing.

Values are recorded in

periodic intervals according to this time scale. The

available range is 1 to 255

seconds.

Indicates the density

of the print screens.

Set to single, double,

or quad.

ANASCAN User’s Guide 49

Page 58

TREND PLOT

Print Trend Plot Screen

•

To print the Trend Plot screen, you need an IBM graphic compatible

printer.

•

Press the Print Screen key. The program will ask for a title for the

print out.

•

Type the title and press Enter. This title will be displayed at the

lower center of the screen and will be printed with the plot screen.

The printing of the screen at the moment of pressing Enter will be

transferred to a buffer and the screen will be printed as a background task. The Trend Plot screen will be updating and other

screens may be accessed.

•

Be sure your printer is powered and On Line; otherwise, a printer

error will appear on the Systems Error window.

50 ANASCAN User’s Guide

Page 59

APPENDIX: Input Scaling

All inputs use the automatic scaling function of the Mx+B calculation.

The end points of that calculation are set by HiPV, LoPV, HiRDG, and

LoRDG. The default values are set by the input Type selection. Do not

adjust these values until you completely understand what those

adjustments will do.

The T/C ranges are set in the firmware, and you don’t need to adjust

those ranges for a proper operating hardware or software. The default

values provide correct operating parameters as to stated accuracy and

Alarm settings.

For Linear inputs the scaling of the input is required to obtain correct

engineering units of the input. This must be done before setting SP and

Alarm settings.

Linear Input Scaling

A linear input of 60 mv or less is scaled according to the engineering

unit and mv range of the input signal. The CAS has a -10 to 60 mvdc

analog input range. All linear inputs must be scaled to that range by

scaling resistors on the input.

The HiPV and LoPV is the range of the engineering unit, while the

HiRDG is the % of the Hi end signal level mv with reference to 60 mv

and the LoRDG is the % of the Lo end signal level with reference to 60

mv.

Example 1

Situation

A pressure sensor that generates a 4-20 milliamp signal is connected to

the CAS. The specifications of the sensor state that it generates 4

milliamps at 0.0 PSI and 20 mA at 50.0 PSI.

Setup

The sensor is connected to a channel input set up with a resistor scaling

network to produce 60 millivolts at 20 mA. (See the Inputs section of

the Installation section of this manual for more information on scaling

networks.)

The sensor measures PSI in tenths, so the appropriate display format is -

999.9 to +3000.0.

ANASCAN User’s Guide 51

Page 60

APPENDIX: Input Scaling

This table shows the input readings.

PV

Displayed

50.0 psi 20 100%

0.0 4 100% x (4ma/20ma) = 20%

The scaling values are therefore:

Parameter Low Value High Value

Process Value (PV) 0.0 psi 50.0 psi

Input Reading (RDG) 20.0 100.0

Sensor Input Reading (%FS)

Example 2

Situation

A flow sensor connected to the CAS measures the flow in a pipe. The

sensor generates a 0-5V signal. The sensor's output depends on its

installation. Independent calibration measurements of the flow in the

pipe indicate that the sensor generates 0.5 volts at three gallons per

minute (GPM) and 4.75 volts at 65 GPM. The calibration instruments

are precise to ±1 gallon per minute.

Setup

The sensor is connected to a channel input set up with a resistor voltage

divider network to produce 60 millivolts at 5 volts. (See the Inputs

section of the Installation chapter for information on scaling networks.)

The calibrating instrument is precise to ±1 gallon per minute, so the

appropriate display format is -999 to +3000.

This table shows the input readings.

PV

Displayed

65 GPM 4.75 (4.75 V/ 5.00 V) x 100% = 95%

3 GPM 0.5 (0.5 V/ 5.00 V) x 100% = 10%

The scaling values are therefore:

Parameter Low Value High Value

Process Value (PV) 3 GPM 65 GPM

Input Reading 10.0 95.0

Sensor Input Reading (%FS)

Example 3

Situation

52 ANASCAN User’s Guide

Page 61

APPENDIX: Input Scaling

A pulse encoder which measures the movement of a conveyor is

connected to the CAS. The encoder generates 900 pulses for every inch

the conveyor moves. You want to measure conveyor speed in feet per

minute (f/m).

Setup

The encoder input is connected to the CAS pulse input. An one second

sample time gives adequate resolution of the conveyor's speed.

The resolution is:

1 pulse

------------- -------1 ondsec

60 ondssec

------------ ------------- -1minute

1 inch

------------ --------------

××

900pulses

1 foot

------------- ----------

×

12inches

0.006 fm

=

so a display format of -99.99 to +300.00 is appropriate.

The input readings are as follows.

At the maximum pulse rate of the CAS (2000 Hz):

200pulses

------------- ------------1 ondsec

60 ondssec

--------------------------1minute

1 inch

------------- -------------

××

900pulses

1 foot

-----------------------

×

12inches

11.11 fm

=

At zero hertz, the input reading will be 0.00 f/m.

Therefore, the scaling values are:

Parameter Low Value High Value

Process Value (PV) 0 f/m 1.11 f/m

Input Reading (RDG) 0 Hz 2000 Hz

⁄

⁄

ANASCAN User’s Guide 53

Page 62

ANASCAN User’s Guide 54

Loading...

Loading...