Page 1

Series 988LF

1/8 DIN Microprocessor-Based Temperature/Process Controller

0600-0009-0000 Rev C

October 1999

Supersedes: 0600-0009-0000 Rev B

$10.00

Made in the U.S.A.

Printed on Recycled Paper 10% Postconsumer Waste

User’s Manual

Includes 986L, 987L, 988L, and 989L

User Level Targeted:

• New User .............................. go to page i

• Experienced User................... go to page 2.1

• Expert User............................. go to page A.8

Installers:

• Setup ..................................... go to page 4.1

• Wiring & Installation................ go to page 2.1

Watlow Controls

1241 Bundy Boulevard, P.O. Box 5580, Winona, Minnesota USA 55987-5580

Phone: (507) 454-5300, Fax: (507) 452-4507 http://www.watlow.com

CUS

CTI

SATISFACTI

96

TOTAL

CUS

TOMER

3 Y ear W arranty

ON

ISO 9001

Registered Company

Winona, Minnesota USA

Page 2

Introduction to the Watlow Series 988LF

Controllers

ii Using this Manual

ii Document Every Step

iii Notes, Cautions and Warnings

iii Technical Assistance

iii We Value Your Feedback

Chapter 1

Hardware Setup

1.1 Dip Switch Locations and Functions

Chapter 2

Installation and Wiring

2.1 Panel Cutout and Dimensions

2.2 Installing the Series 988LF

2.3 Wiring the Series 988LF

2.3 Input-to-output Isolation

2.3 Power Wiring

2.3 Sensor Installation Guidelines

2.4 Wiring 0-20mA and 4-20mA

Process Inputs

2.5 Wiring Example

2.7 Input 1 Wiring

2.8 Remote Set Point Option Wiring

2.9 Output 1 Wiring

2.10 Output 2 Wiring

Chapter 3

Front Panel and Display Loop

3.1 Keys and Displays

3.2 Display Loop

Chapter 4

The Setup Menus

4.1 Navigating the Setup Menus

4.2 Setup Prompts

Chapter 5

The Operation Menus

5.1 Navigating the Operation Menus

5.2 Display Prompts

Chapter 6

The Factory Menus

6.1 Reaching the Diagnostics Menu

6.5 Reaching the Calibration Menu

Chapter 7

Tuning, Manual Operation,

Alarms and Error Codes

7.1 Auto-tuning (Heat and/or Cool)

7.2 Manual Tuning

7.3 Manual and Automatic Operation

7.4 Using Alarms

7.5 Error Code E1 and E2 Messages

7.6 Error Code Actions

Appendix

A.1 Warranty and Returns

A.2 Glossary

A.4 Index

A.6 Specifications

A.7 Model Number

A.8 Menu Overview

A.9 Declaration of Conformity

Table of Contents

Table of Contents WATLOW Series 988LF User’s Manual

Page 3

WATLOW Series 988LF User’s Manual i

Introduction

Introduction To The Watlow

Series 988LF Controllers

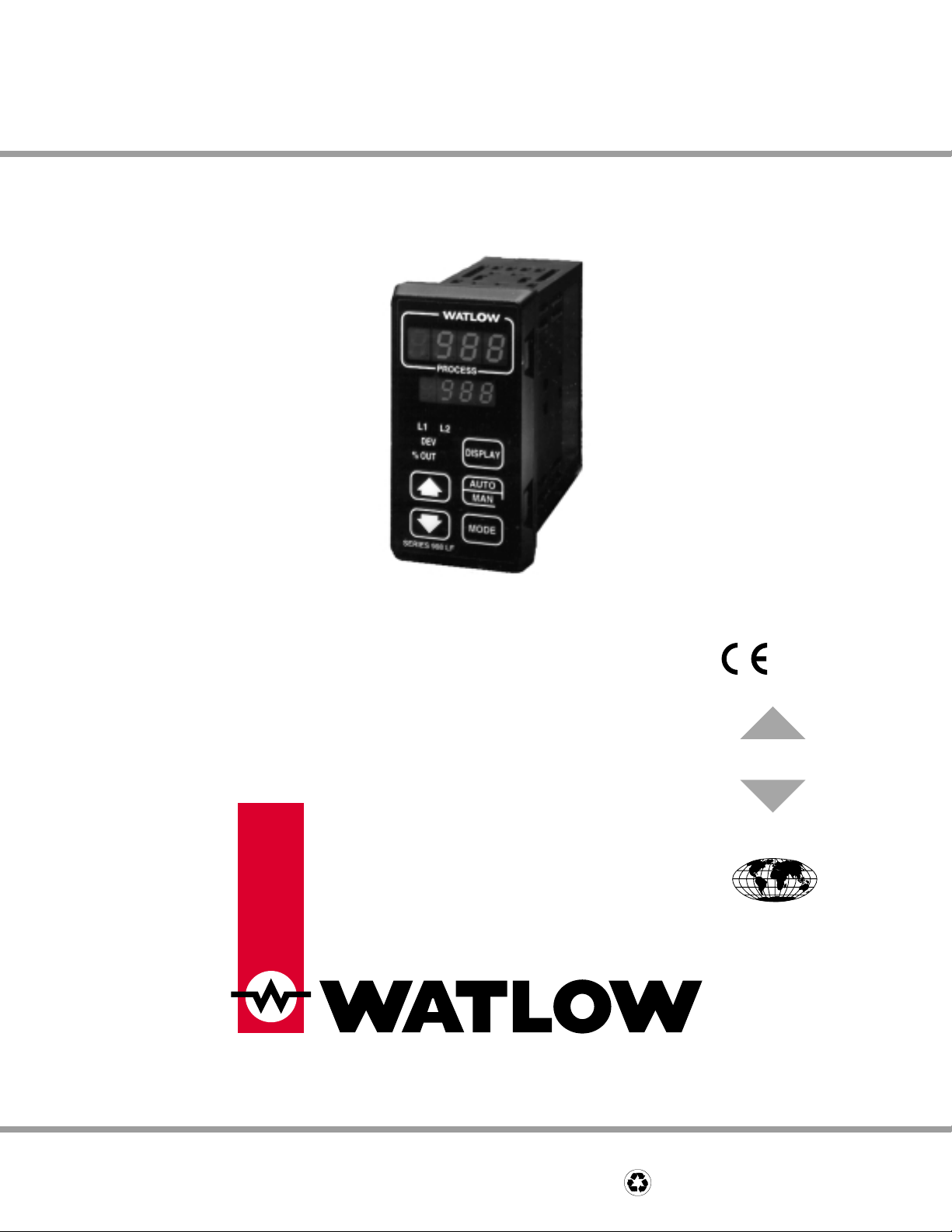

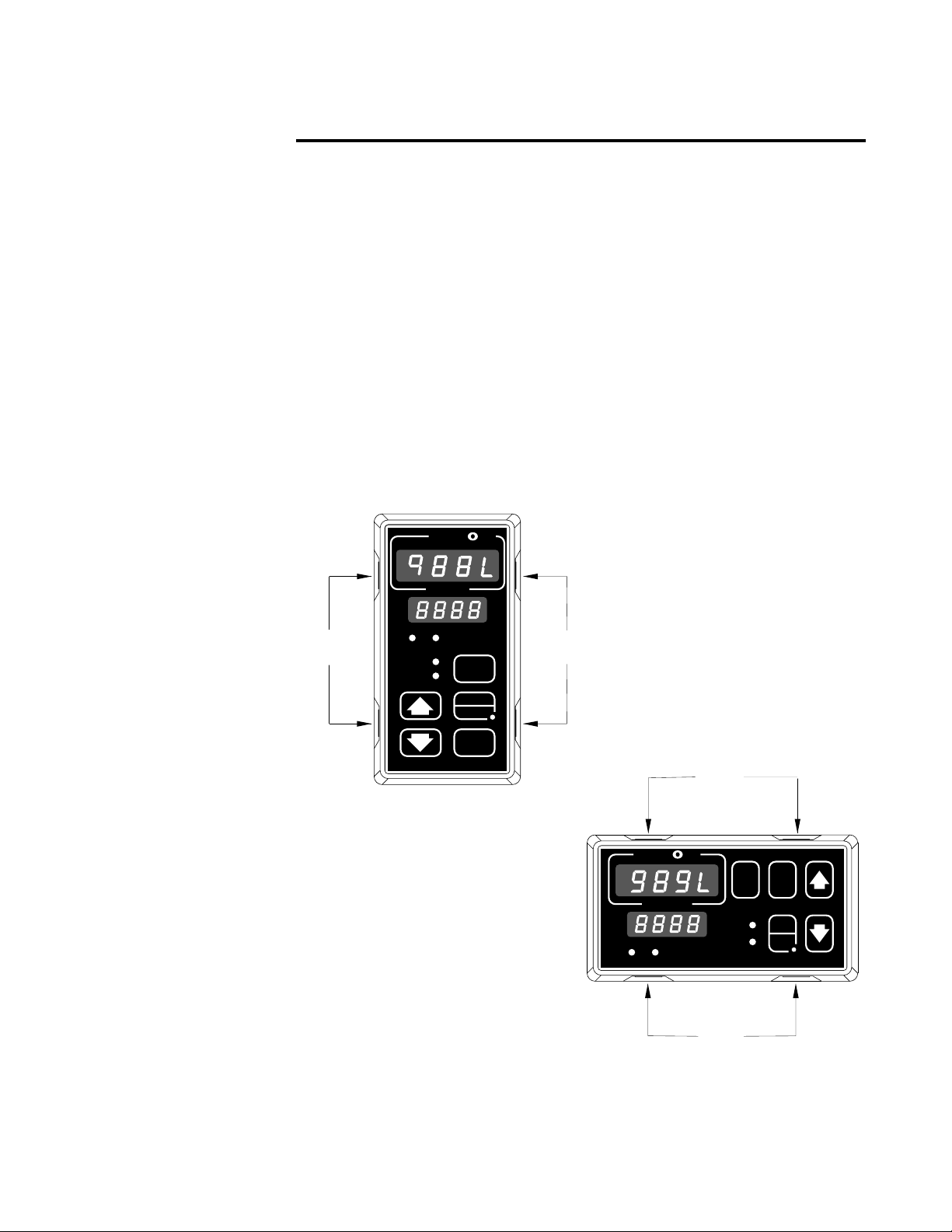

Figure Int.1 The Series 988LF

Features.

Welcome to the Watlow Series 988LF, a dual output, single input, microprocessor-based, 1/8 DIN, auto-tuning temperature control, featuring

automatic/manual capability with bumpless transfer. In the Auto mode,

the control has closed loop control with sensory feedback, while the

Manual mode has open loop control with user defined output power level.

The 988LF accepts a wide range of thermocouple sensors, along with RTD,

and process inputs. The primary output is Heating or Cooling, while the

secondary output can be Heating, Cooling, or Alarm.

With the Series 988LF, you can select either PID or ON/OFF for output 1

or Output 2. You may input a complete set of PID parameters for both

outputs, or select automatic tuning for both heat and cool from the front

panel. This includes proportional band, reset, rate, and cycle time. By

setting either output’s proportional band to zero, the Series 988LF

becomes a simple ON/OFF control with a 3°F or 1.7°C switching differential, 0.3°F or 0.17°C for 0.1° RTD.

Operator-friendly features include automatic LED indicators to aid in

monitoring and setup, as well as a calibration offset at the front panel.

The Watlow Series 988LF automatically stores all information in a nonvolatile memory.

TL

W

W

A

PROCESS

L1 L2

DEV

% OUT

DISPLAY

SERIES 988LF

MODE

AUTO

MAN

Output 1

Control

Heat/Cool

Output 2

Control

Heat/Cool

Alarm

Input 1

Sensor Input

Input 2

Remote Set

Point Option

Auto-Tune

Heat/Cool

Process Deviation

from Set Point

Percent Power

Page 4

ii WATLOW Series 988LF User’s Manual

Introduction

Introduction

Using this Manual

This manual provides the information you will need to install and operate

a Series 988LF controller.

If you need information about Series 988LF configurations and model

numbers, refer to the Appendix of this manual.

This manual explains the five steps of setting up a Series 988LF controller:

1. Set and document all of the DIP switches, if applicable: Chapter 1.

2. Mount the controller: Chapter 2.

3. Wire and document the controller wiring: Chapter 2.

4. Configure and document the controller software: Chapters 3-6.

5. Run, test and adjust your application. Update documentation.

The Appendix provides definitions and specifications, along with

application examples to help you optimize the safety and performance of your application. Use the Table of Contents and Index to

find specific information.

Document Every Step

The Series 988LF provides powerful control features. Carefully document

each step of the setup and any subsequent changes. This will make it

much easier to change, adjust and troubleshoot your application.

Make the configuration documentation available to engineers and technicians, on all shifts, who may need to work with the Series 988LF. We provide space in this manual to record configurations. You may prefer to

photocopy the blank forms and keep them in a separate binder. However,

you maintain your documentation; be sure to replace all old copies of the

documentation with updated versions whenever the controller configuration is changed.

NOTE:

The Menu Overview

in the Appendix

shows all of the

menus and

prompts.

NOTE:

The 12-digit number

is printed on the top

of the stickers on

each side of the

controller’s case

and on the righthand or top circuit

board.

Page 5

Introduction

WATLOW Series 988LF User’s Manual iii

Introduction

Notes, Cautions and Warnings

We use note, caution and warning symbols throughout this book to draw

your attention to important operational and safety information.

A bold text “NOTE” marks a short message in the margin to alert you to

an important detail.

A bold text “CAUTION” safety alert appears with information that is

important for protecting your equipment and performance. Be especially

careful to read and follow all cautions that apply to your application.

A bold text “WARNING” safety alert appears with information that is

important for protecting you, others and equipment from damage. Pay

very close attention to all warnings that apply to your application.

The ç symbol (an exclamation point in a triangle) precedes a general

CAUTION or WARNING statement.

The Ó symbol (a lightening bolt in a triangle) precedes an electric shock

hazard CAUTION or WARNING safety statement.

Technical Assistance

If you encounter a problem with your Watlow controller, review all of your

configuration information for each step of the setup to verify that your

selections are consistent with your applications.

If the problem persists, an Application Engineer can discuss your application with you.

Before calling, please have the complete model number and user’s manual

available. You can get technical support by dialing 507/494-5656, 7 a.m.

to 7 p.m. Central Standard Time, or e-mail to wintechsupport@watlow.com.

We Value Your Feedback

Your comments and suggestions on this manual are welcome. Please send

them to, Technical Writer, Watlow Controls, P.O. Box 5580, Winona, MN

55987-5580, or call (507) 454-5300, or fax (507) 452-4507. The Series

988LF User’s Manual is copyrighted by Watlow Winona, Inc., © October

1999, with all rights reserved. (1831)

Page 6

iv WATLOW Series 988LF User’s Manual

Introduction

Notes

Page 7

WATLOW Series 988LF User’s Manual 1.1

Hardware Setup, Chapter 1

Chapter 1 Hardware Setup

DIP Switch Locations and Functions

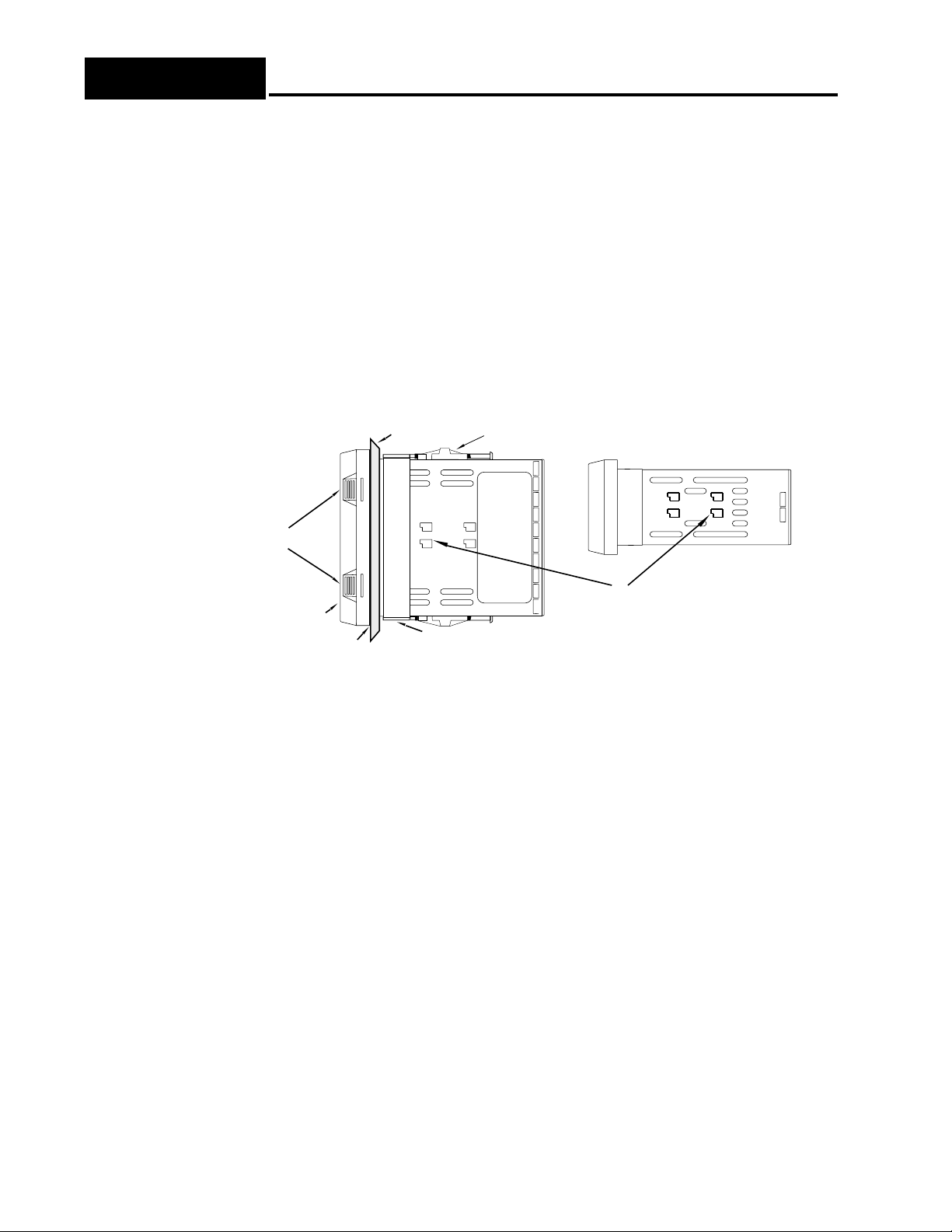

The Watlow Series 988LF has at least one and as many as three dual inline package (DIP) switches inside the controller, depending on the model

number. They allow users to configure the controller for a variety of

input sensors, or to lockout front panel access to some functions.

To set any DIP switch:

• Remove the controller from the case by pressing firmly on the two

release tabs on one side or the top of the bezel until they unsnap. Then

firmly press the two release tabs on the opposite side or the bottom of

the control until they unsnap. You will need to gently rock the bezel

back and forth to release it from the chassis.

• Use the illustrations on the following pages to locate and set each DIP

switch.

Figure 1.1 - Press

the release tabs to

remove the controller chassis.

Release

Tabs

PROCESS

L1 L2

DEV

% OUT

SERIES 988LF

W

A

TL

DISPLAY

AUTO

MODE

MAN

W

Release

Tabs

Release

Tabs

W

A

TL

W

MODE

DSPY

PROCESS

AUTO

DEV

% OUT

L1 L2

MAN

SERIES 989LF

Release

Tabs

Page 8

1.2 WATLOW Series 988LF User’s Manual

Hardware Setup, Chapter 1

DIP Switches

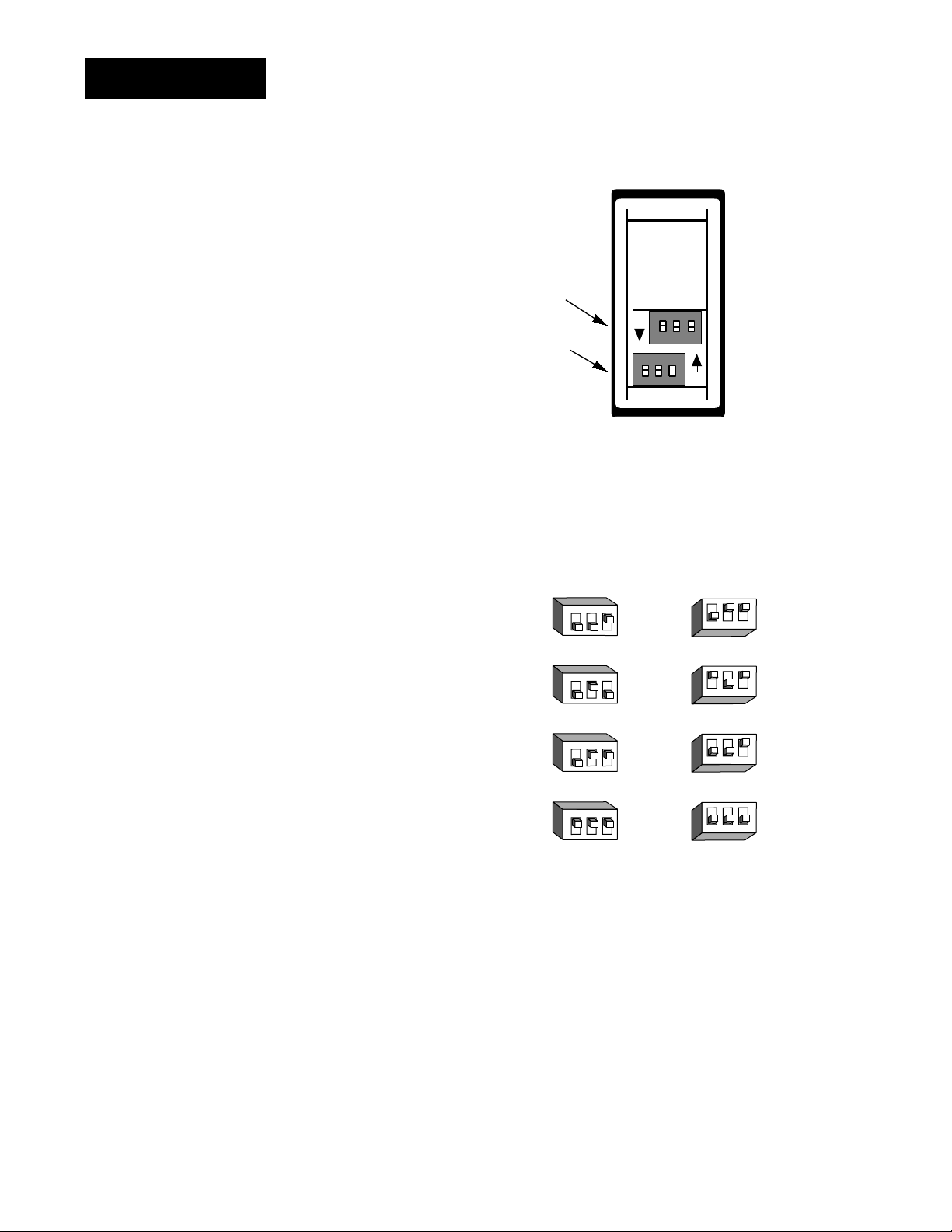

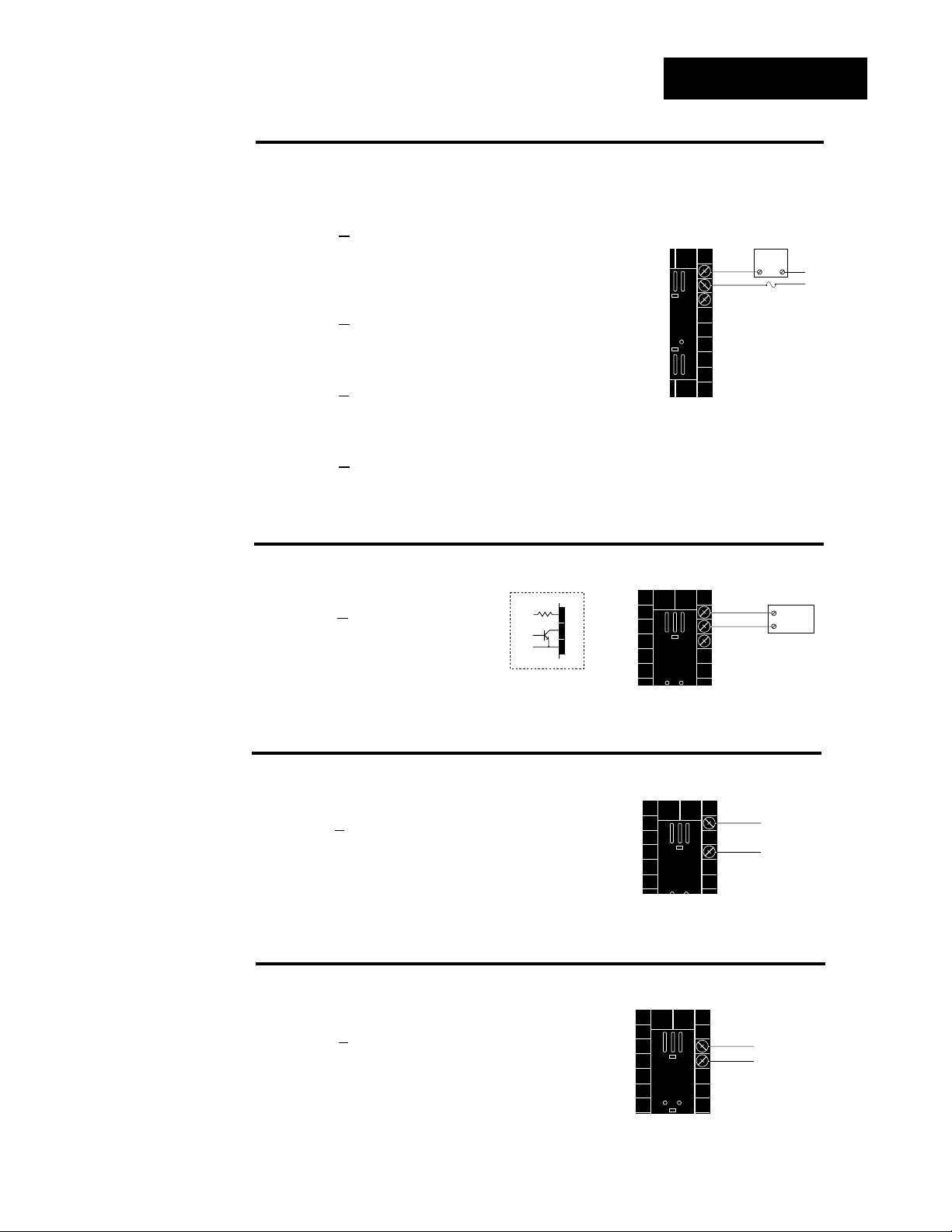

Figure 1.2 Input DIP switches.

Input 1 Input 2

(Remote Set Point)

(98_L-2___-AA__) (98_L-_2__-AA__)

RTD

thermocouple: R, S or B

thermocouple: J, K, T, N, E, C, D, Pt2

or 0-50mV (high impedance)

0-20 or 4-20mA; 0-5, 1-5 or 0-10V

❶ Set the input DIP

switches to match the sen-

sors you are using in your

application. Only controllers with model number 98_L-2___-AA__ or

98_L-_2__-AA__ have an

input DIP switch.

NOTE:

The Input 2 DIP

switch is mounted

upside down.

NOTE:

Only controllers

with the indicated

model numbers

have these DIP

switches.

Input 2 DIP

ON

Input 1 DIP

ON

Controller Chassis

Rear View

123

O

N

↑

123

O

N

↑

↑

N

O

123

↑

N

O

123

123

O

N

↑

123

O

N

↑

↑

N

O

123

↑

N

O

123

Page 9

WATLOW Series 988LF User’s Manual 1.3

Hardware Setup, Chapter 1

DIP Switches

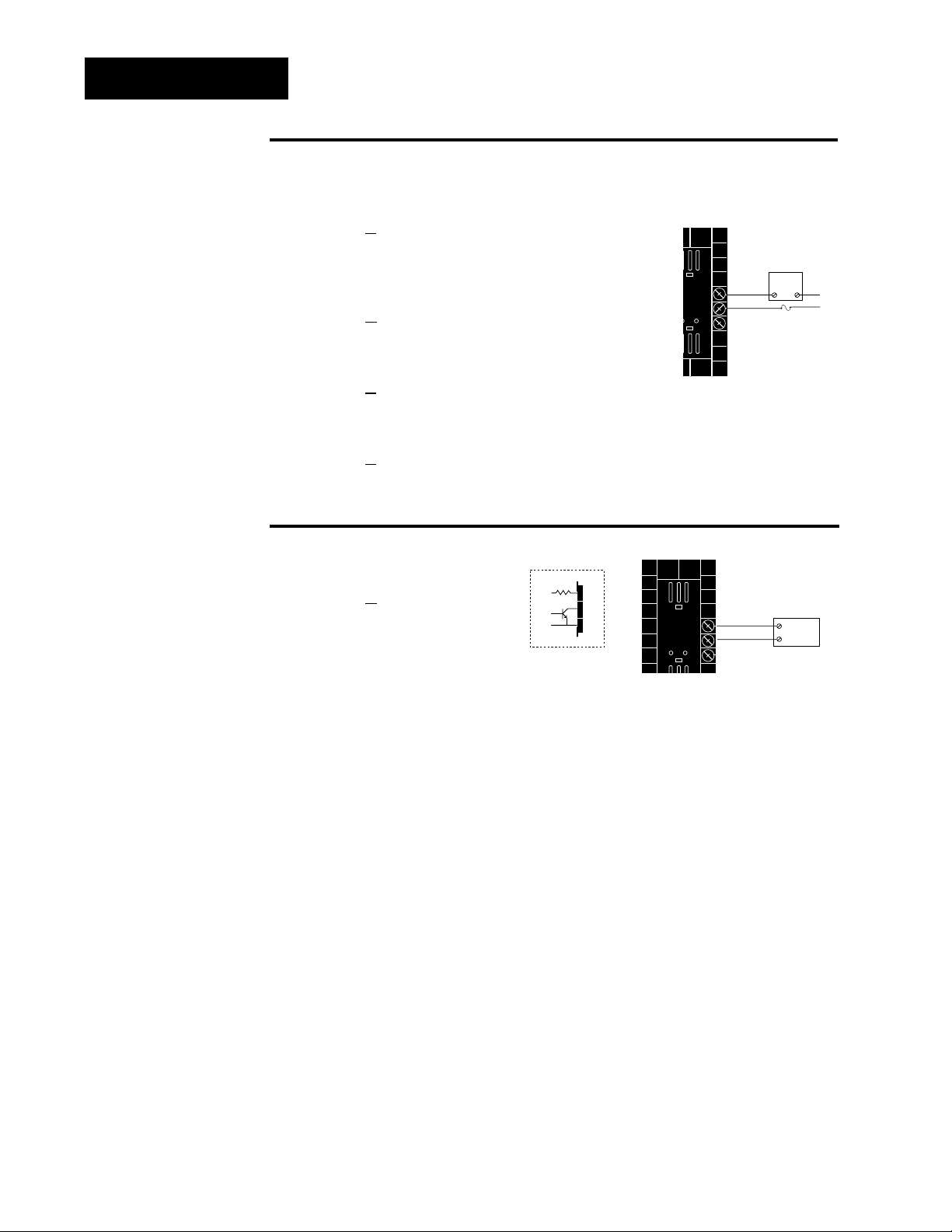

Figure 1.3 Lockout DIP switch.

no hardware lockout or

(Switch 1 has no effect.)

lockout Setup and Factory menus or

(Switch 1 has no effect.)

Control Chassis

Top View (986LF & 988LF)

Left-side View (987LF & 989LF)

Lockout

DIP

ON

OFF

❷ The lockout DIP switch

hides the Setup Menu and the

Factory Menus (Diagnostics

and Calibration). All units

have a lockout DIP switch.

ç

CAUTION:

The lockout DIP

switch makes the

Setup and Factory

menus unavailable.

Configure all the

Setup and Factory

menus before locking them out.

Failure to do so

could result in damage to equipment in

the event of a setup

error.

12

O

N

↑

12

O

N

↑

12

O

N

↑

12

O

N

↑

Page 10

1.4 WATLOW Series 988LF User’s Manual

Hardware Setup, Chapter 1

Notes

Page 11

WATLOW Series 988LF User’s Manual 2.1

Installation and Wiring, Chapter 2

Chapter 2 Installation and Wiring

Figure 2.1 Series 988LF and

Series 989LF

dimensions.

NOTE:

Adjustable mounting brackets can be

side-mounted.

NOTE:

Space panel

cutouts at least 1.66

inches (42.2mm)

apart.

NOTE:

Holes can be cut in

the panel using a

Greenlee 1/8 DIN

Hydraulic Kit

#60068 (punch

#60069, die #60070).

W

A

TL

PROCESS

L1 L2

DEV

% OUT

SERIES 988LF

(55 mm)

W

2.18"

DISPLAY

AUTO

MAN

MODE

4.03"

(102mm)

W

PROCESS

L1 L2

4.03"

(102mm)

W

A

TL

DSPY

DEV

% OUT

MODE

AUTO

MAN

SERIES 989LF

2.18"

(55 mm)

Panel Cutout

Maximum Panel

Thickness

0.38" (9.65mm)

3.62" + 0.03 -0.00

(92mm + 0.8)

1.77 + 0.02 -0.00

(45mm + 0.6)

0.68"

(17 mm)

Panel

4.06"

(103 mm)

Adjustable

Mounting Bracket

Page 12

2.2 WATLOW Series 988LF User’s Manual

Installation and Wiring, Chapter 2

Installation

Installing the Series 988LF

Installing and mounting requires access to the back of the panel.

1. Make a panel cutout.

2. To remove the controller chassis from its case, press in firmly on the two

tabs on one side or the top of the bezel until they unsnap, then unsnap

the two tabs on the opposite side or the bottom. Pull the chassis out of

the case by gently rocking it.

3. Slide the case into the panel cutout. Check to see that the gasket is

not twisted, and is seated within the case bezel flush with the panel.

Slide the mounting collar over the back of the control.

Panel

Adjustable

Mounting Bracket

Bezel

External Gasket

Mounting Collar

Release Tabs

Top and Bottom (986LF or 988LF)

or Side (987LF or 989LF) View

Mounting Slots

Side (986LF or 988LF)

or Top and Bottom (987LF or 989LF) View

4. Loosen the mounting bracket screws enough to allow for the mounting

collar and panel thickness. Place each mounting bracket into the

mounting slots (head of the screw facing the back of the controller).

Push each bracket backward then down to secure it to the control

case. To guarantee a proper NEMA 4X seal, Series 986LF and

988LF units (vertical) must have the mounting brackets located on

either side of the unit. When installing Series 987LF and 989LF

units (horizontal) the brackets must be on the top and bottom of

the unit.

5. Make sure the case is seated properly. Tighten the installation screws

firmly against the mounting collar to secure the unit. To ensure a

NEMA 4X seal, there should be no space between the bezel and

panel. Overtightening the screws will distort the case and make it dif-

ficult to remove or replace the controller.

6. Insert the controller chassis into its case and press the bezel until all

four tabs snap. Make sure the inside gasket is seated properly and

not twisted.

7. To release the mounting brackets, loosen the mounting bracket screws

and push the brackets forward, then pull it up and out.

NOTE:

Removing the controller chassis from

its case makes

mounting easier.

Figure 2.2 Side and top view.

ç

CAUTION:

Follow the installation procedure

exactly to guarantee

a proper NEMA 4X

seal. Make sure the

gasket between the

panel and the rim of

the case is not

twisted and is seated properly. Failure

to do so could

result in damage to

equipment.

Page 13

WATLOW Series 988LF User’s Manual 2.3

Installation and Wiring, Chapter 2

Wiring

Wiring the Series 988LF

Wiring options depend on the model number and DIP switch settings.

Check the terminal designation stickers on either side of the controller

and compare your model number to those shown here and with the model

number breakdown on the inside back cover of this manual.

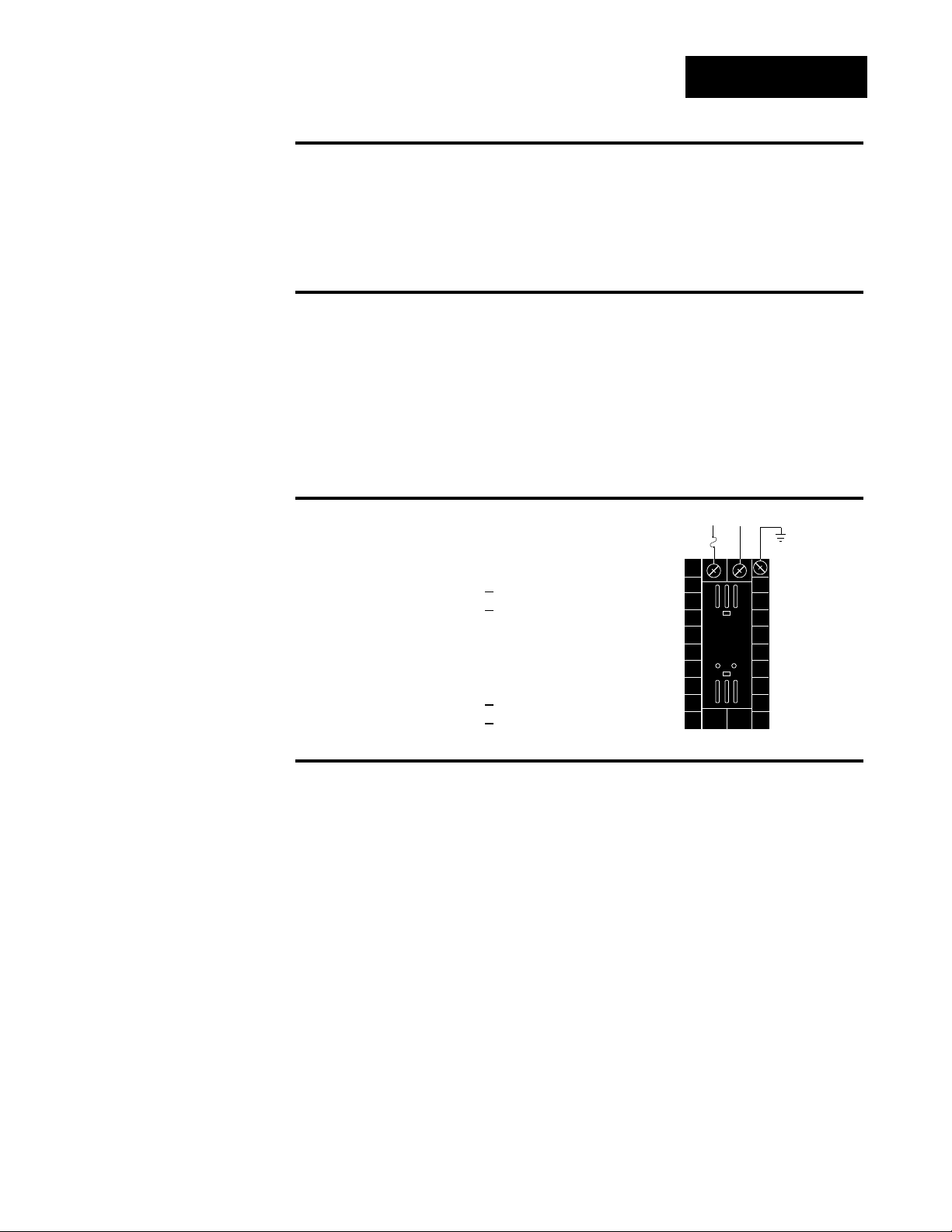

Input-to-output Isolation

The Series 988LF uses optical isolation between the analog inputs and the

controller outputs. This isolation provides a 500V~ (ac) barrier to prevent

ground loops when using grounded sensors and/or peripheral equipment.

Here is a breakdown of the isolation barriers:

• Analog inputs 1 and 2 are grouped together.

• Outputs 1 and 2 are grouped together.

Power Wiring

100 to 240 V~ (ac), nominal (85 to 264 actual)

Vertical Package 98 8

L - _ _ _ _ - A A _ _

Horizontal Package 98 9 L - _ _ _ _ - A A _ _

24 to 28 V‡‡(ac/dc), nominal (20 to 30 actual)

Vertical Package 98 6

L - _ _ _ _ - A A _ _

Horizontal Package 98 7 L - _ _ _ _ - A A _ _

Sensor Installation Guidelines

Thermocouple input: Extension wire for thermocouples must be of the

same alloy as the thermocouple itself to limit errors.

Using grounded thermocouples for both input 1 and remote set point

option may create ground loop problems. To correct this problem, replace

at least one of the grounded thermocouples with an ungrounded thermocouple. If the application requires grounded thermocouples, use an isolated transmitter, such as a Watlow Gordon 5702 isolated transmitter.

RTD input: Each 1Ω of lead wire resistance can cause a +2°F error when

using a two-wire RTD. A three-wire RTD sensor overcomes this problem.

All three wires must have the same electrical resistance (i.e., same gauge,

same length, multi-stranded or solid, same metal).

Process input: Maintain isolation between input 1 and input 2 to prevent

a ground loop. A ground loop may cause incorrect readings, dashes

across the upper display or the display of error codes.

fuse

22

21

earth ground

11

L2L1

+

-

∫

WARNING:

To avoid potential

electric shock, use

National Electric

Code (NEC) safety

practices when

wiring and connecting this unit to a

power source and

to electrical sensors

or peripheral

devices. Failure to

do so could result

in injury or death.

Figure 2.3 Power wiring.

ç

CAUTION:

The Series 988LF

will not function

with two grounded

thermocouple

inputs. Avoid using

a grounded thermocouple for both

input 1 and input 2.

Failure to follow this

guideline could

result in damage to

equipment.

Page 14

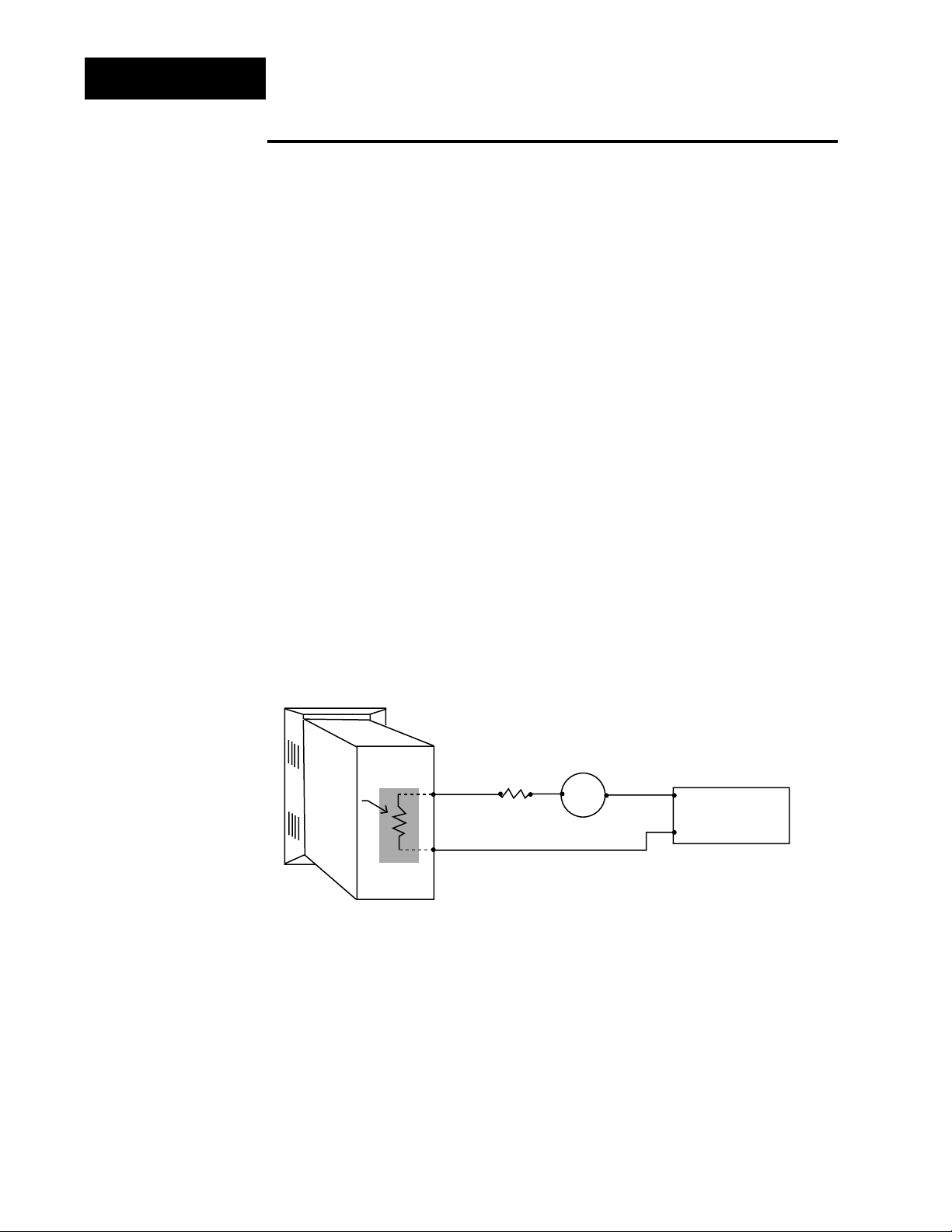

Wiring 0-20 and 4-20mA Process Inputs

Certain “transmitters” used in process input applications are producing

internal resistor failures in the Watlow Series 988 family of controllers.

This is only apparent with the Series 988 family 1/8 DIN units with

Process Inputs selected (0-20mA or 4-20mA dc only).

We are noticing that an external resistor is required to prevent a high

in-rush current which burns out the Series 988 family controllers’ 7-ohm

internal resistor. This high in-rush current occurs initially on “power-up.”

If the transmitter turns full on for a split second during power-up, the

available current weakens or damages the internal resistor.

Example: 20V / 7 ohms = 2,857mA (too much!).

The wiring diagram example below shows an application where a customer

is using a 4-20mA dc transmitter and power supply to feed the input of a

Series 988 controller. The Rx range (100 to 400 ohms) for the external

resistor is recommended. We suggest starting with 250 ohms.

Example: Customer is using a 24VÎ (dc) power supply to power up the

4-20mA dc transmitter that inputs to the Series 988 terminals 8 (-) and 10

(+). To figure out what the internal Series 988’s handling current is for the

0-20mA or 4-20mA dc input to the Series 988 controllers, we need to

apply Ohm’s Law: The square root of Watts divided by Resistance equals

Current. Applying that formula to the example below produces the following: Square Root of (0.125 Watts / 7 ohms) = 134 mA dc (handling input

current). This is the acceptable input current for the Series 988 universal

input board.

Reminder, the input impedance of 7 ohms handles the majority of our

customer applications; the external resistor (Rx) is only for certain transducers/transmitters that spike on power-up or power-down. Please make

sure your customer’s transmitter / transducer fall within our Series 988

family (1/8 DIN) of controllers’ Process Input specification of 7 ohms input

impedance.

Figure 2.4 Process wiring

example.

2.4 WATLOW Series 988LF User’s Manual

Wiring

988 Process

Input Control

4-20mA dc

Internal

Resistor

7Ω

1/8 Watt

+

—

R

100 to 400

ohms

x

Transmitter

—

+

+

24VÎ (dc)

Power Supply

—

Page 15

WATLOW Series 988LF User’s Manual 2.5

Installation and Wiring, Chapter 2

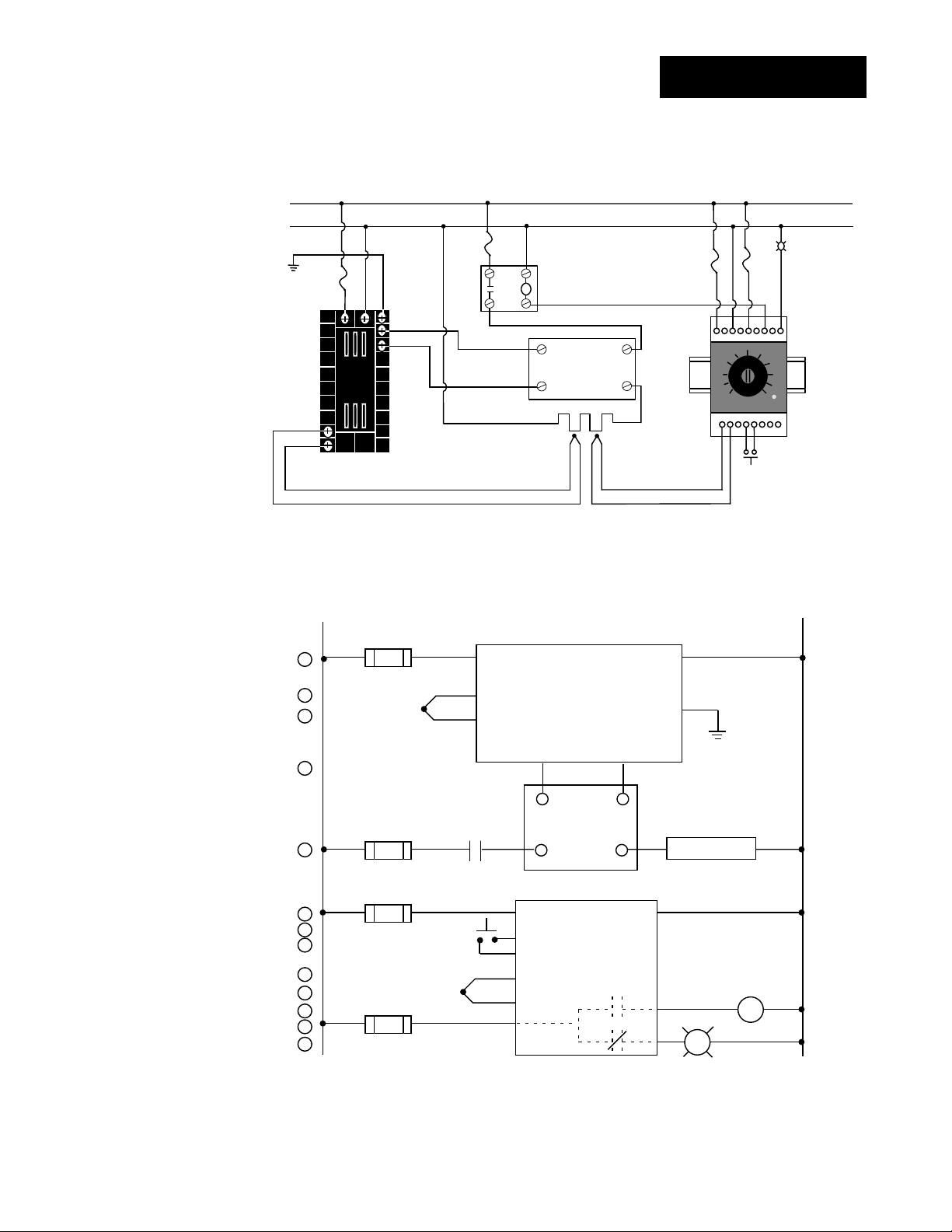

Wiring Example

Figure 2.5 System wiring

example.

∫

WARNING:

To avoid potential

electric shock, use

National Electric

Code (NEC) safety

practices when

wiring and connecting this unit to a

power source and

to electrical sensors or peripheral

devices. Failure to

do so could result

in injury or death.

ç

WARNING:

Install high or low

temperature limit

control protection

in systems where

an over temperature fault condition

could present a fire

hazard or other hazard. Failure to

install temperature

limit control protection where a potential hazard exists

could result in damage to equipment,

property and injury

to personnel.

ç

WARNING:

To avoid damage to

property and equipment, and/or injury

of loss of life, use

National Electric

Code (NEC) standard wiring practices to install and

operate the Series

988LF. Failure to do

so could result in

such damage,

and/or injury or

death.

L1

120 VÅ (ac)

L2

earth ground

(+)

9

10

(-)

red

120VÅ (ac)

1

2

3

4

5

6

7

8

9

10

11

12

13

high limit

mechanical

fuse

11

2221

(+)

12

(-)

13

988L-10CA-AARR

rear view

L1

1

1

1 2

1

process sensor limit sensor

3

4

(+)

5

(-)

1 CR-1

8

11

17

coil

contactor

31

+

SSR-240-10A-DC1

solid state relay

-

21 22

9

10

910

12

13

(+)

14

(-)

15

Series 988LF

988L-10CA-AARR

Temperature Control

12 + 13 -

3

3-32VÎ (dc)

(+)

12

48-260VÅ (ac)

13

13

146D-1J1F-1100

14

Temperature Limit

10

11

5

heater

in

out

Series 146

24

4

SSR-240-10A-DC1

Solid State Relay

(-)

7

9

high temperature light

fuse

11

heater

R

18

fuse

C NO NC

1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17

(+)

(-)

normally open

momentary switch

1CR

16

optional

high

temp limit

light

Series 146

limit control

146D-1J1F-1100

L2

2

2

2

2

Page 16

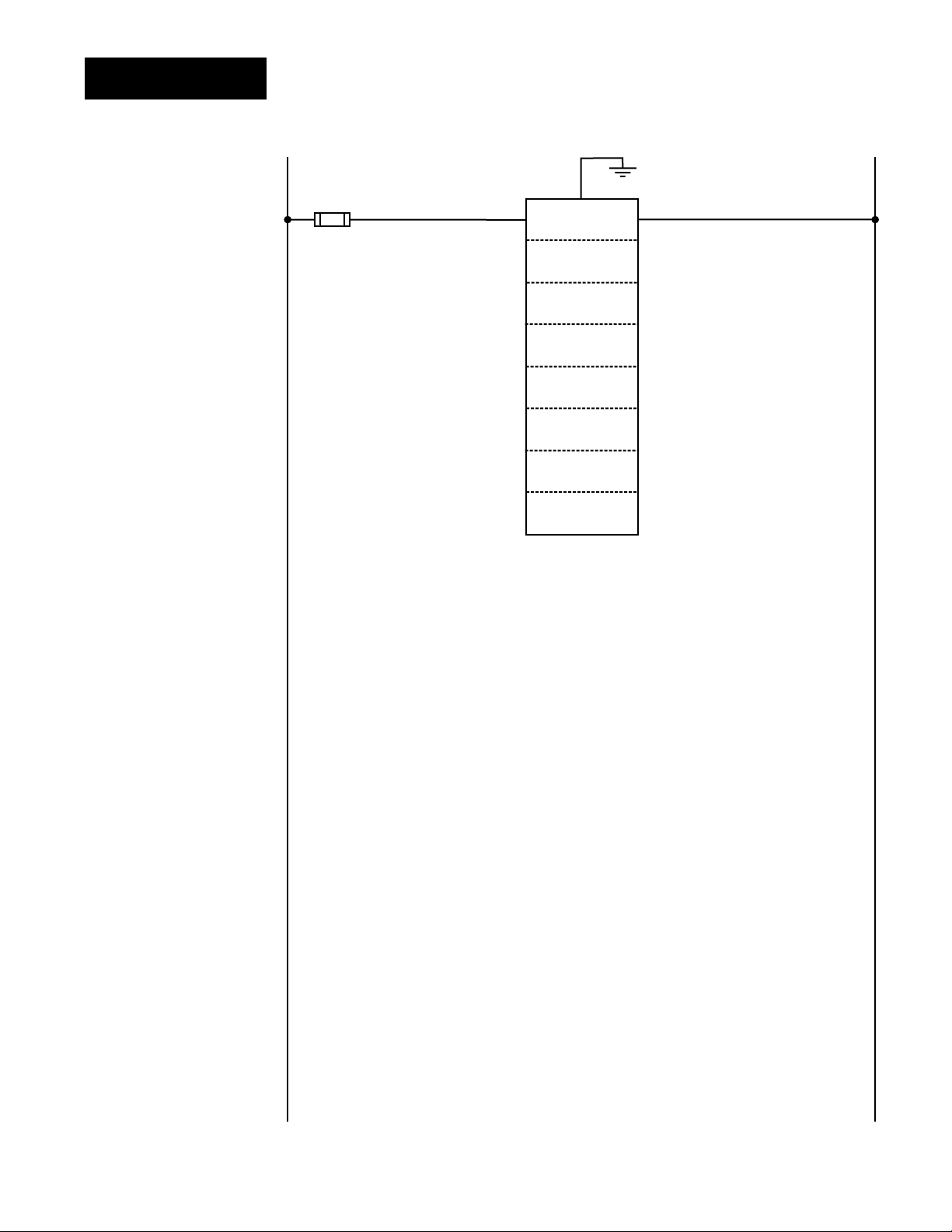

Wiring Notes

ç

WARNING:

To avoid damage to

property and equipment, and/or injury

of loss of life, use

National Electric

Code (NEC) standard wiring practices to install and

operate the Series

988LF. Failure to do

so could result in

such damage,

and/or injury or

death.

Figure 2.6 Wiring notes.

NOTE:

Sketch in your application on this page or

a copy of it. See

wiring examples in

this chapter and in

the Appendix.

2.6 WATLOW Series 988LF User’s Manual

Installation and Wiring, Chapter 2

L1 L2

earth ground

11

21 22

power

Page 17

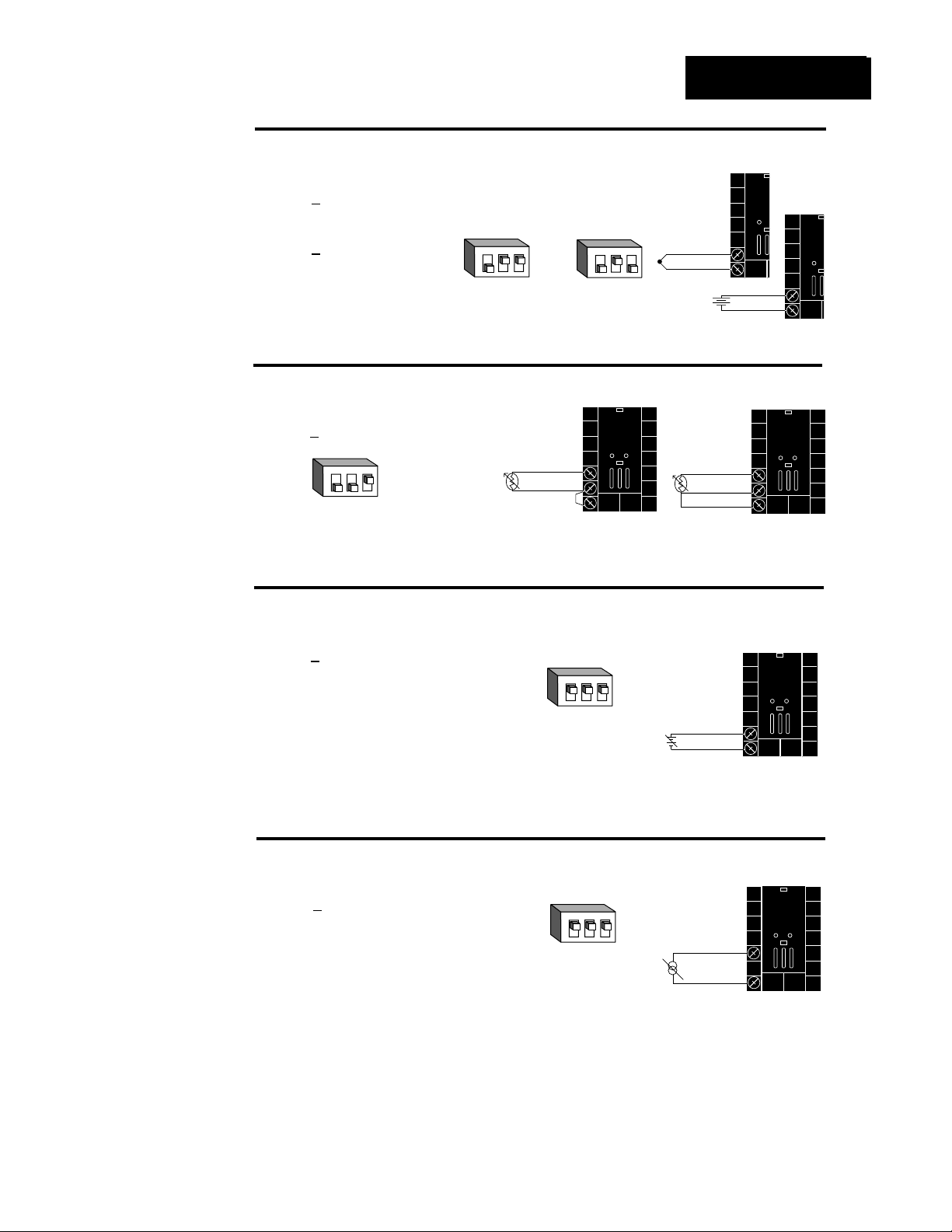

WATLOW Series 988LF User’s Manual 2.7

Installation and Wiring, Chapter 2

Figure

2.7c — 0-5V

ÎÎ

, 1-5VÎÎor 0-10VÎÎ(dc) Process

Universal signal conditioner

98 _ L - 2 _ _ _ - A A _ _

Input impedance: 10KΩ

Figure 2.7a — Thermocouple or 0-50mV (high impedance)

Thermocouple only

98 _ L - 1 _ _ _ - A A _ _ (no DIP switches)

Universal signal conditioner

98 _ L - 2 _ _ _ - A A _ _

Input impedance: 20MΩ

Figure 2.7

b — RTD (2 or 3 Wire) 100Ω

Universal signal conditioner

98 _ L - 2 _ _ _ - A A _ _

9

10

+

-

0-50mV

Figure 2.7d — 0-20mA or 4-20mA Process

Universal signal conditioner

98 _ L - 2 _ _ _ - A A _ _

Input impedance: 7Ω

DIP Switch

Setting

R, S, B

DIP Settings

J, K, T, N, C, E, D, Pt2,

0-50mV DIP Settings

DIP Switch

Setting

DIP Switch

Setting

NOTE:

Successful installation requires five

steps:

• Model number and

software choice

(Appendix);

• DIP switch settings (Chapter 1);

• Sensor match

(Chapter 2 and

Appendix);

• Sensor installation

(Chapter 2); and

• Wiring (Chapter 2).

Jumper

#9 to #10

for 2 wire

RTD

Input 1 Wiring

ç

CAUTION:

An external resistor

is required for

0-20mA and 4-20mA

process wiring to

prevent a high inrush current which

could burn out the

controller’s 7-ohm

resistor. See page

2.4 for recommendations.

123

O

N

↑

123

O

N

↑

S1

S2

O

N

↑

8

9

10

123

+

9

-

10

8

S1

9

S2

10

S3

123

O

N

↑

123

O

N

↑

9-+

10

-

8

10

+

Page 18

2.8 WATLOW Series 988LF User’s Manual

Installation and Wiring, Chapter 2

Figure 2.8d —

0-20mA or 4-20mA Process

Universal signal conditioner

98 _ L - _ 2 _ _ - A A _ _

Input impedance: 7Ω

Remote Set Point Option

Figure 2.8c —

0-5VÎÎ, 1-5VÎÎor 0-10VÎÎ(dc) Process

Universal signal conditioner

98 _ L - _ 2 _ _ - A A _ _

Input impedance: 10KΩ

Remote Set Point Option

Figure 2.8b — RTD (2 or 3 Wire) 100Ω

Universal signal conditioner

98 _ L - _ 2 _ _ - A A _ _

Remote Set Point Option

20

19-+

Figure 2.8a —

Thermocouple or 0-50mV (high impedance)

Universal signal conditioner

98 _ L - _ 2 _ _ - A A _ _

Input impedance: 20MΩ

Remote Set Point Option

Jumper

#19 to #20

for 2 wire

RTD

19

20

18

S2

S1

DIP Switch

Setting

R, S, B

DIP Settings

J, K, T, N, C, E, D, Pt2,

0-50mV DIP Settings

DIP Switch

Setting

19

20

18S2S1

S3

DIP Switch

Setting

NOTE:

Successful installation requires five

steps:

• Model number and

software choice

(Appendix);

• DIP switch settings (Chapter 1);

• Sensor match

(Chapter 2 and

Appendix);

• Sensor installation

(Chapter 2); and

• Wiring (Chapter 2).

Input 2 Wiring

ç

CAUTION:

An external resistor

is required for

0-20mA and 4-20mA

process wiring to

prevent a high inrush current which

could burn out the

controller’s 7-ohm

resistor. See page

2.4 for recommendations.

↑

N

O

123

↑

N

O

123

↑

N

O

123

19

+

-

20

0-50mV

19

+

-

20

↑

N

O

123

↑

N

O

123

-

18

20

+

Page 19

WATLOW Series 988LF User’s Manual 2.9

Installation and Wiring, Chapter 2

Figure 2.9a — AC Outputs

Solid-state Relay with Contact Suppression

98 _ L - _ _ B _ - A A _ _

0.5 amps, minimum off-state impedance: 20KΩ

Electromechanical Relay with Contact Suppression

(NO and COM contacts only)

98 _ L - _ _ D _ - A A _ _

Form C, 5 amps, minimum off-state impedance: 20KΩ

Electromechanical Relay without Contact Suppression

98 _ L - _ _ E _ - A A _ _

Form C, 5 amps off-state impedance: 31MΩ

Solid-state Relay without Contact Suppression

98 _ L - _ _ K _ - A A _ _

0.5 amps, off-state impedance: 31MΩ

Output 1 Wiring

Figure 2.9b — Switched DC, Open Collector

98 _ L - _ _ C _ - A A _ _

Minimum load resistance: 500Ω

Figure 2.9d — 0-5V

ÎÎ

, 1-5VÎÎand 0-10VÎÎ(dc) Process

98 _ L - _ _ F _ - A A _ _

Minimum load impedance: 1KΩ

Figure 2.9c — 0-20mA and 4-20mA Process

98 _ L - _ _ F _ - A A _ _

Maximum load impedance: 800Ω

14

-

+

12

14

-

+

13

NOTE:

Successful installation requires five

steps:

• Model number and

software choice

(Appendix);

• DIP switch settings (Chapter 1);

• Sensor match

(Chapter 2 and

Appendix);

• Sensor installation

(Chapter 2); and

• Wiring (Chapter 2).

External

Load

NO

12

13

COM

14

NC

(#14 for D & E outputs only)

Fuse

L2

L1

19 to 32VÎ (VDC)

+ VDC

790Ω

Internal Circuitry

12

13

14

12

+

External

-

13

14

Load

COM

Page 20

Figure 2.10a — AC Outputs

Solid-state Relay with Contact Suppression

98 _ L - _ _ _ B

- A A _ _

0.5 amps, minimum off-state impedance: 20KΩ

Electromechanical Relay with Contact Suppression

(NO and COM contacts only)

98 _ L - _ _ _ D - A A _ _

Form C, 5 amps, minimum off-state impedance: 20KΩ

Electromechanical Relay without Contact Suppression

98 _ L - _ _ _ E - A A _ _

Form C, 5 amps off-state impedance: 31MΩ

Solid-state Relay without Contact Suppression

98 _ L - _ _ _ K - A A _ _

0.5 amps, off-state impedance: 31MΩ

2.10 WATLOW Series 988LF User’s Manual

Installation and Wiring, Chapter 2

Figure 2.10b —

Switched DC, Open Collector

98 _ L - _ _ _ C - A A _ _

Minimum load resistance: 500Ω

NOTE:

Successful installation requires five

steps:

• Model number and

software choice

(Appendix);

• DIP switch settings (Chapter 1);

• Sensor match

(Chapter 2 and

Appendix);

• Sensor installation

(Chapter 2); and

• Wiring (Chapter 2).

Output 2 Wiring

19 to 32VÎ (VDC)

+ VDC

Internal Circuitry

790Ω

15

16

17

External

NO

COM

NC

COM

Load

Fuse

+

-

15

16

17

(#17 for D & E outputs only)

15

16

17

External

Load

L2

L1

Page 21

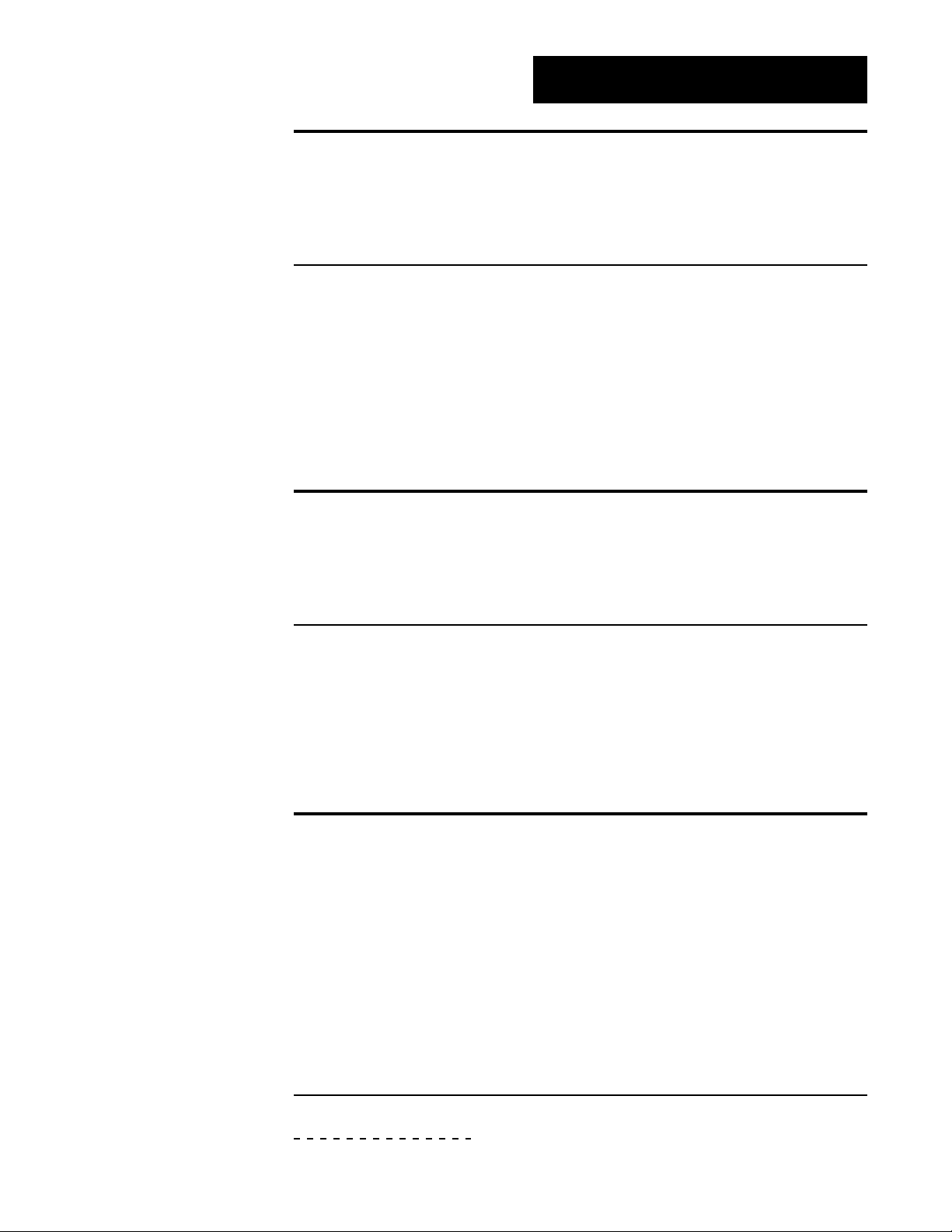

WATLOW Series 988LF User’s Manual 3.1

Front Panel and Display Loop, Chapter 3

Upper Display

Indicates the actual process value,

prompt parameter value or error

code.

DEV LED

When lit, the lower display shows

the current deviation from the set

point.

% OUT LED

When lit, the lower display shows

the current percent output.

Up-arrow Key

Increases the value or changes the

parameter in the upper display

(except for set point changes in the

Display Loop, which occur in the

lower display). Hold the key down

to increase the value rapidly. New

data takes effect in five seconds or

when the Mode key or Display key

is pressed.

Up + Down Keys

Press simultaneously for three seconds to go to the Setup Menu.

Continue to press both keys for

another three seconds to go to the

Factory Menu. Access to the Setup

and Factory menus can be disabled with lockout DIP switch.

Lower Display

Indicates the set point, deviation,

percent power, temperature unit,

menu prompt name or alarm code.

L1, L2

These LED’s indicate when output

1 or 2 are active. Outputs can be

configured as:

Ot1 Control

Ot2 Control or Alarm

Display Key

Pressing this key enters the

Display Loop. Press the Display

key at any time to return to this

loop. The next page has more

information on the Display Loop.

Auto/Man Key

In Manual mode the lower display

shows percent output. Pressed

once, it clears a latched alarms. If

pressed again within five seconds

it will toggle between Auto and

Manual mode.

Auto/Man LED

Lit when the control is in Manual

operation. Press the Auto/Man key

twice to enter Automatic operation.

When blinking, press the Auto/Man

key to toggle between Auto and

Manual. After five seconds without

pressing the Auto/Man key, the

LED stops blinking and returns to

its previous state.

Mode Key

Enters new data and steps to

the next prompt in the current

menu.

Mode + Up-arrow Keys

Hold the Mode key then press

the Up-arrow key to move

backwards through the current menu. Scrolling stops

when you reach the top of the

menu.

Figure 3.1 Series 988LF Keys and Displays

Down-arrow Key

Decreases the value or changes

the parameter in the upper display

(except for set point changes in the

Display Loop, which occur in the

lower display). Hold the key down

to decrease the value rapidly. New

data takes effect in five seconds or

when the Mode key or Display key

is pressed.

Chapter 3 Front Panel and Display Loop

Keys and Displays

W

TL

W

A

PROCESS

L1 L2

DEV

% OUT

DISPLAY

AUTO

MAN

MODE

SERIES 988LF

Page 22

3.2 WATLOW Series 988LF User’s Manual

Front Panel and Display Loop, Chapter 3

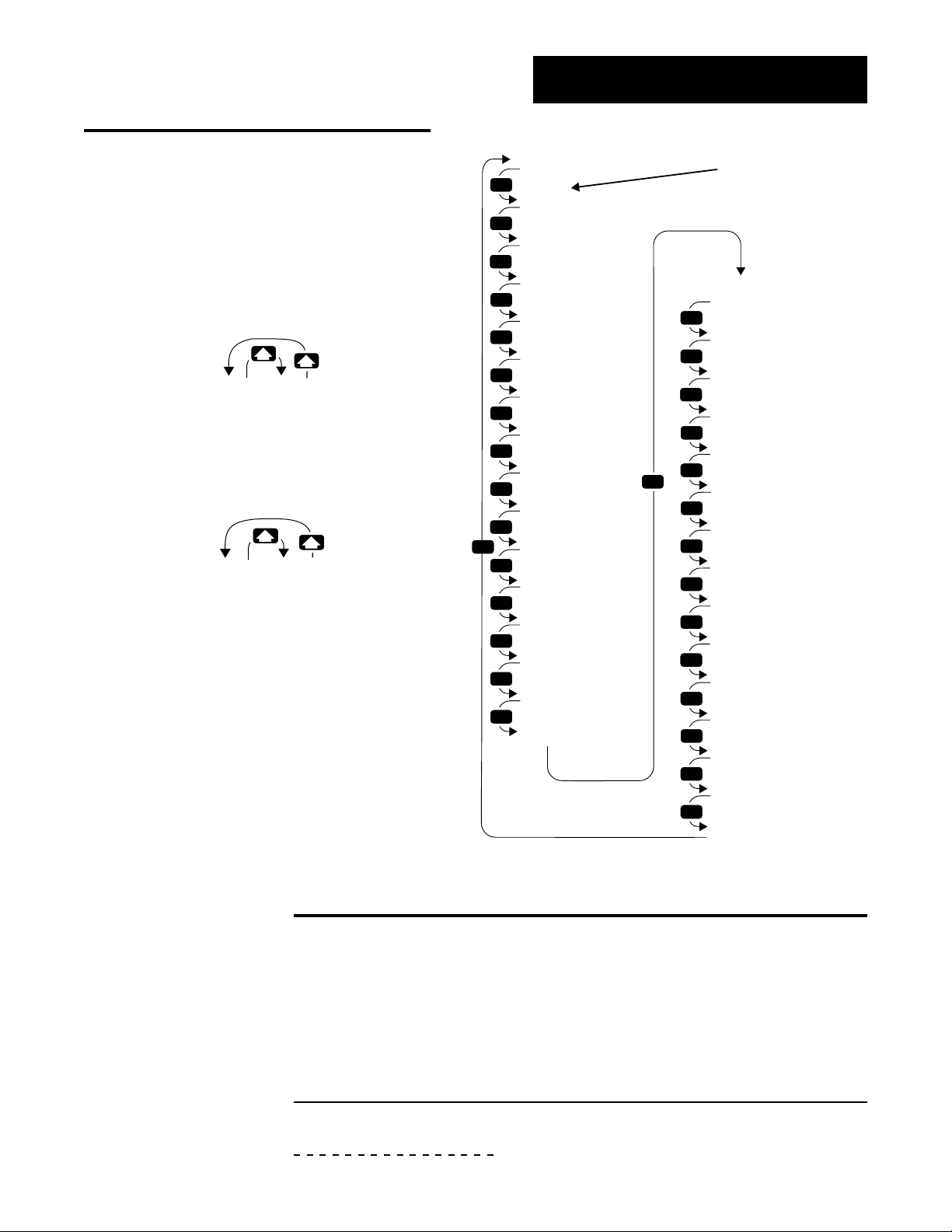

Display Loop

Display Loop

The Display Loop is the “home” state of the Series 988LF controller. Pressing the

Display key ∂ returns the controller to the Display Loop from any prompt in any

menu. The controller automatically returns to the Display Loop from any menu

when a minute passes without any keys being pressed.

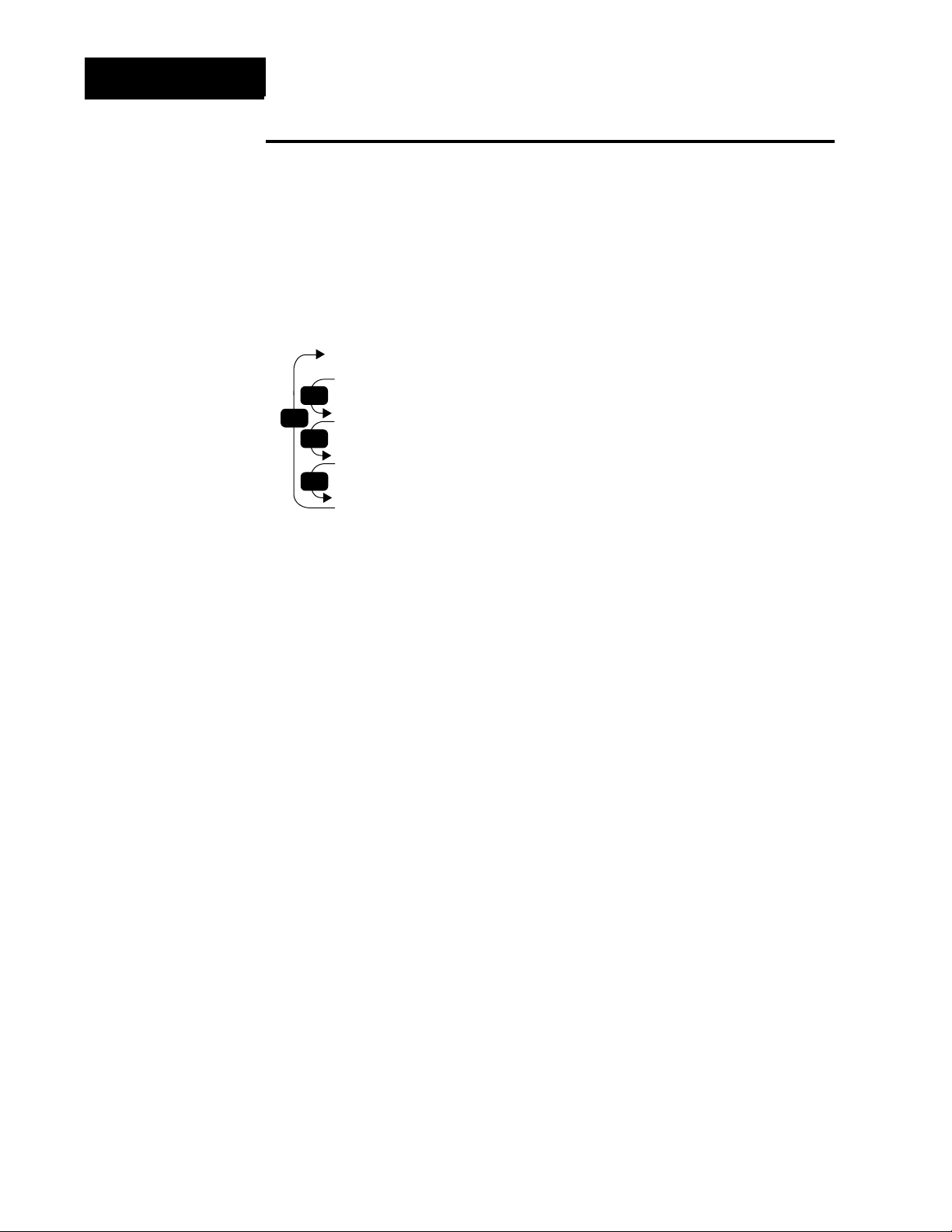

Figure 3.2 The Display Loop

NOTE:

For information on

input 1 [`In1]

ranges, refer to

Chapter 4.

DISPLAY

DISPLAY

DISPLAY

DISPLAY

[`988]

[`988]

[`988]

[`988]

[`988]

[`100]

[`988]

[``°C]

current input 1 reading

set point 1 (change with Up-arrow > or Down-arrow < key)

current input 1 reading

deviation from set point, process 1 minus set point 1 (DEV light on)

current input 1 reading

percent output (%OUT light on)

current input 1 reading

units selected (units, °F or °C)

Page 23

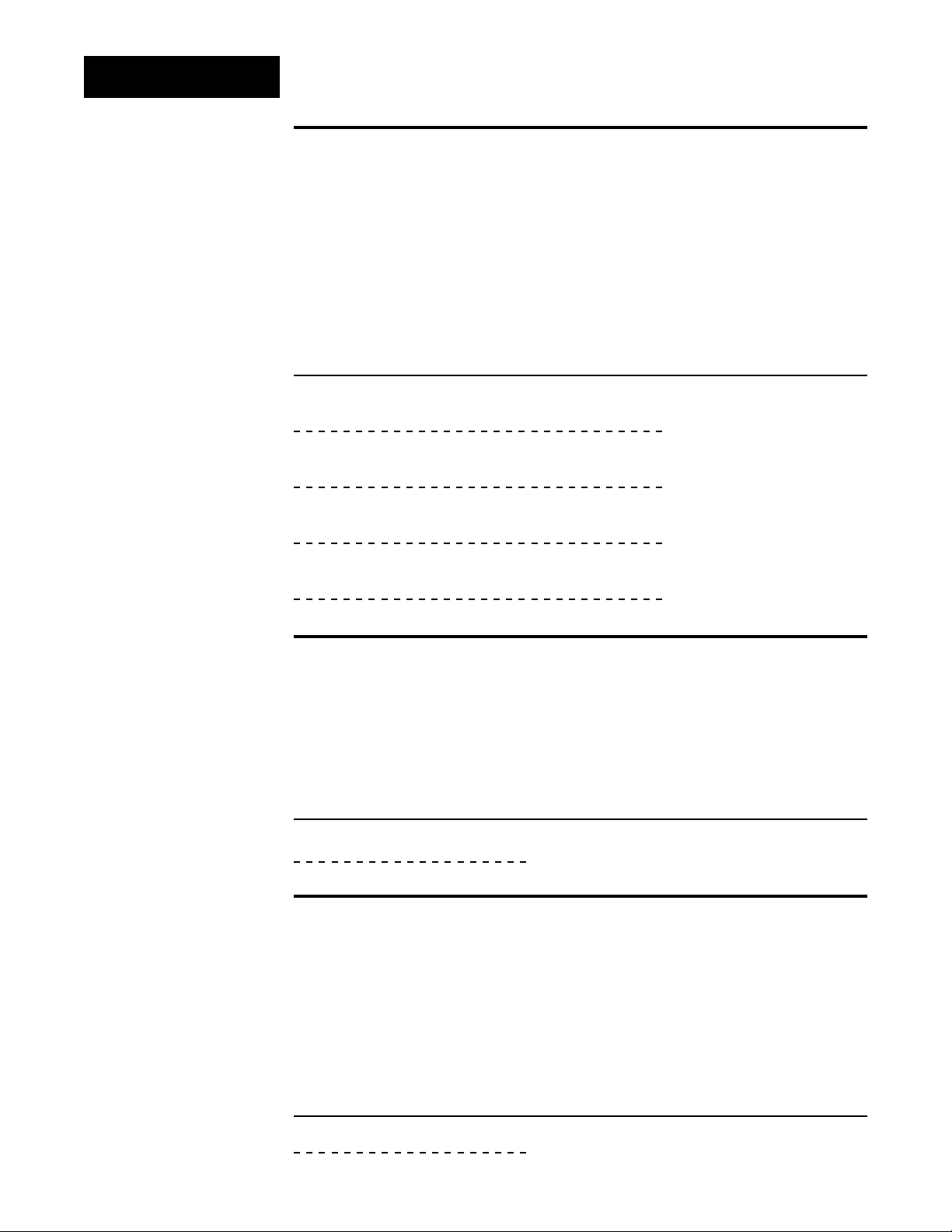

Chapter 4 The Setup Menu

TL

Navigating the Setup Menu

The Setup Menu displays the parameters that configure the Series 988LF’s

features to your application.

W

TL

W

[```0]

[`LOC]

[```1]

[`LOC]

[```2]

[`LOC]

❷ Press the Up-arrow > or the

Down-arrow < key to select one

of the prompt values

Figure 4.1 The Setup Menu

[```3]

[`LOC]

L1 L2

DEV

% OUT

SERIES 988LF

A

PROCESS

DISPLAY

AUTO

MAN

MODE

❶ To enter the Setup Menu, press the Up-arrow >

and Down-arrow < keys for three seconds. The

lower display shows the LOC [`LOC] prompt, and the

upper displays shows its current level. All keys are

inactive until you release both keys.

[`LOC]

MODE

[`In1]

MODE

[`rL1]

MODE

[`rH1]

MODE

[`rtd]

MODE

[`dEC]

MODE

[`rSp]

MODE

[`rL2]

MODE

[`rH2]

MODE

[`C_F]

MODE

[`Ot1]

MODE

[Prc1]

MODE

[`Ot2]

MODE

[`ALt]

MODE

[`Lat]

MODE

[`SIL]

Lock

Input 1

Range Low 1

Range High 1

RTD Calibration Curve

Decimal

Remote Set Point

Range Low 2

Range High 2

C or F

Output 1

Process 1

Output 2

Alarm Type

Latching

Silencing

Setup

Enter your settings,

from the controller's

upper display.

Setup Menu, Chapter 4 WATLOW Series 988LF Users Manual 4.1

Page 24

Setup

Setup Prompts

NOTE:

Decimal points may not

always be in the

position specified

depending on the

settings in the Decimal

[`dEC] parameters in

the Setup Menu.

❸ Use the Mode key µ to advance through the

Setup Menu. You will not see every prompt in the

Setup menu; the unit’s configuration and model

number determine which prompts appear.

L1 L2

DEV

% OUT

SERIES 988LF

W

A

PROCESS

TL

DISPLAY

AUTO

MAN

MODE

W

❹ Use the Up-arrow > and Down-arrow < keys

to change the prompt setting. To move backwards

through the menu hold the Mode key µ down

and press the Up-arrow key >. Refer to the

Appendix for model number options.

L1 L2

DEV

% OUT

SERIES 988LF

W

A

PROCESS

TL

DISPLAY

AUTO

MAN

MODE

W

[`LOC]

ç

Caution:

Setting [`LOC] to

[```2] or [```3]

disables the Auto/Man

å and will force

key

the controller into

manual mode if an open

sensor occurs. Verify

that the controller is

operating in the desired

mode (auto or manual)

before setting the

lockout level. Failure to

do so could result in

damage to equipment

and/or property.

Front Panel Lockout

Sets the lockout level for the front panel. This allows you to disable

keys on the front of the controller.

• [```0] enables all keys.

• [```1] disables the Mode key µ.

• [```2] disables the Mode key µ and the Auto/Man key å.

• [```3] disables all keys.

[`LOC] This prompt always appears.

Default

↓

[```O] [```1] [```2] [```3]

[`LOC] [`LOC] [`LOC] [`LOC]

4.2 WATLOW Series 988LF Users Manual Setup Menu, Chapter 4

Page 25

Setup

[`In1]

ç

Caution:

Changing the value of

[`In1] changes most

other prompts to the

factory default values.

Verify the correct

sensor type before

making a change.

Failure to follow this

guideline could result in

damage to equipment or

property.

Input 1

Select sensor input type. This selection must match the sensor type

connected to terminals 8, 9 and 10. See Appendix for more information

about sensors.

• Changing the value of [`In1] changes all other prompts to the

factory default values, [`LOC] Lock prompt and the [`C_F] prompt

in the Setup Menu. If you change the value, the default warning

[[

[dFLt] will flash in the upper display.

[[

• Changes do not take effect automatically after five seconds; you must

press the Mode key µ to enter the selector type change and advance to

the next prompt.

[`In1] This prompt always appears.

If Default

↓↓

98_L-1___-AA__

no DIP J K T N E W5 W3 Pt2 0-50mV

[``J] [``H] [``t] [``n] [``E] [``C] [``d] [`Pt2] [0-50]

thermocouple [``n] [`In1] [`In1] [`In1] [`In1] [`In1] [`In1] [`In1] [`In1]

only

98_L-2___-AA__

Input 1 DIP J K T N E W5 W3 Pt2 0-50mV

thermocouple [``J] [``H] [``t] [``n] [``E] [``C] [``d] [`Pt2] [0-50]

123

O

N

↑

[``n] [`In1] [`In1] [`In1] [`In1] [`In1] [`In1] [`In1] [`In1]

Input 1 DIP R S B

thermocouple [``r] [``S] [``b]

123

O

N

↑

[`In1] [`In1] [`In1]

Input 1 DIP RTD RTD(0.1°)

RTD [`rtd] [`r†d]

123

O

N

↑

[[`In1] [`In1]

Input 1 DIP 4-20mA 0-20mA 0-5VÎ 1-5VÎ 0-10VÎ (dc)

process [4-20] [0-20] [`0-5] [`1-5] [0-10]

123

O

N

↑

[`In1] [`In1] [`In1] [`In1] [`In1]

Setup Menu, Chapter 4 WATLOW Series 988LF Users Manual 4.3

Page 26

Setup

[`rL1]

[`rH1]

NOTE:

These values do not

affect the low or the high

set point limit for

process alarms.

Range Low and Range High

Select the low and high range for input 1. These prompts limit the

adjustment range for the set points. The default values are the same as

the limits of the sensor you selected by setting the input DIP switch and

selecting a value for Input [`In1].

• Process inputs are scaled by these values. Range high is the value

displayed when the maximum process signal is present at the input.

Range low is the value displayed when the minimum process signal is

present at the input.

Example: Set [`In1] to [4-20] mA.

Set [`rL1] to [`100].

Set [`rH1] to [`500].

A 4mA input will display [`100].

A 12mA input will display [`300].

A 20mA input will display [`500].

• The low and high values of each sensor type are listed on the specifications page of the Appendix.

• Choose between Fahrenheit and Celsius at the [`C_F] prompt in the

Setup Menu.

NOTE:

When high impedance

[`0-50] is selected for

Input 1, the range high

for both [``°C] and

[``°F] can be extended

to [9999]. The range

low, when [``°C] is

selected, can be extended to [-999]

[`rL1]

[`rH1]

Range Low and Range

High continued on next

page.

[`rL1] [`rH1] These prompts always appear.

Default Default Default Default

↓↓ ↓↓

``°F] [`°C]

[`rL1] [`rH1] [`rL1] [`rH1]

[```J] [``32]…[1500] [```0]…`816] 98_L-1__-AA__ or

[`in2] [`rL1] [`rH1] [`rL1] [`rH1] 98_L-2__-AA__

(K)

[```H] [-328]…[2500] [-200]…[1371]

[```t] [-328]…[`750] [-200]…[`399]

[```n] ``32]…[2372] [```0]…[1300]

[```E] [-328]…[1470] [-200]…[`799]

(W5)

[```C] [``32]…[4200] [```0]]]…[2316]

(W3)

[```d] [``32]…[4200] [```0]]]…[2316]

[`Pt2] [``32]…[2543 [```0]]…[1395]

high impedance

[0-50] [-999]…[[`999] [-573]…[`573]

[```r] [``32]…[3200] [```0]]…[1760] 98_L-2__-AA__ only

[```S] [``32]…[3200] [```0]…[1760]

4.4 WATLOW Series 988LF Users Manual Setup Menu, Chapter 4

Page 27

Setup

[`rL1]

[`rH1]

Range Low and Range

High continued from

previous page.

NOTE:

The range high [`rH1]

value for process

inputs can be extended

to [9999].

Default Default Default Default

↓↓ ↓↓

``°F] [`°C]

[`rL1] [`rH1] [`rL1] [`rH1]

[```b] [``32]…[3300] [```0]…[1816]

[`rtd] [-328]…[1472] [-200]…[`800]

[`r†d] [-9(9]…[99(9] [-7#3]…[53&7]

process

[4-20] [-999]…[`999] units

[0-20] [-999]…[`999] units

[`0-5] [-999]…[`999] units

[`1-5] [-999]…[`999] units

[0-10] [-999]…[`999] units

[0-50] [-999]…[`999] units

[`rtd]

RTD Calibration Curve

Select the RTD calibration curve. The RTD input uses either the

European (DIN, 0.003850 ohms/ohms/°C) or Japanese (JIS, 0.003916

ohms/ohms/°C) linearization standard.

[`rtd] This prompt appears only if you have set [`In1] to [`rtd] or

[`r†d].

Default

↓

[`din] [`J15]

[`rtd [`rtd

Setup Menu, Chapter 4 WATLOW Series 988LF Users Manual 4.5

Page 28

Setup

[`dEC]

[`rSP]

Decimal

Select the decimal point location for process type input 1 data. This

prompt, in conjunction with the Range Low and Range High prompts,

allows you to format and limit units of measure for process 1.

• All prompts with units of measure related to input 1 will display in the

selected decimal format.

• This affects propbands, alarm set points, process set points, calibration

offsets, deadbands and ranges.

[`dEC] This prompt appears only if you have set input 1 [`In1] to a

process input or a thermocouple input set to [0-50] mV.

Default

↓

[```)] [``)0] [`)00} [)000]

[`dEC] [`dEC] [`dEC] [`dEC]

Remote Set Point Input

[`rSP]

Remote Set Point Input

continued on next page.

Enable a remote set point signal. The remote set point input selection

switches are set to process at the factory.

[`rSP] This prompt appears only on controllers equipped with Remote Set

Point Input hardware (98 _ L-_ 2__-AA__).

If Default

↓↓

RSP Input DIP J K T N E W3 W5 Pt2 0-50mV

123

O

N

↑

[`OFF] [``J] [``H] [``t] [``n] [``E] [``C] [``d] [`Pt2] [0-50

[`rSP] [`rSP] [`rSP] [`rSP] [`rSP] [`rSP] [`rSP] [`rSP] [`rSP] [`rSP

thermocouple

RSP Input DIP RSB

123

O

N

↑

[`OFF] [```r] [```S] [``b]

[`rSP] [`rSP] [`rSP] [`rSP]

thermocouple

RSP Input DIP RTD RTD(0.1°)

123

O

N

↑

[`OFF] [`rtd] [`r†d]

[`rSP] [`rSP] [`rSP]

RTD

4.6 WATLOW Series 988LF Users Manual Setup Menu, Chapter 4

Page 29

Setup

[`rSP]

Remote Set Point Input

continued from previous

page.

[`rL2]

[`rH2]

If Default

↓↓

RSP Input DIP 4-20mA 0-20mA 0-5VÎ 1-5VÎ 0-10VÎ(VDC)

123

O

N

↑

[`OFF] [4-20] [0-20] [`0-5] [`1-5] [0-10]

[`rSP] [`rSP] [`rSP] [`rSP] [`rSP] [`rSP]

process

(Factory Preset)

RSP Input DIP 4-20mA 0-20mA 0-5VÎ 1-5VÎ 0-10VÎ(VDC)

123

O

N

↑

[`OFF] [4-20] [0-20] [`0-5] [`1-5] [0-10]

[`rSP] [`rSP] [`rSP] [`rSP] [`rSP] [`rSP]]

mV process

Range Low 2 and Range High 2

Select the low and high range for Remote Set Point Input. These

prompts limit the adjustment range for the set points. The default values

are the same as the limits of the sensor you selected by setting the input 2

DIP switch and selecting a value for Input 2 [`In2].

[`rL2]

[`rH2]

Range Low 2 and Range

High 2 continued on next

page.

[`rL2] [`rH2] These prompts appear only on controllers equipped with

Remote Set Point Input hardware (98 _ L-_ 2__-AA__).

• Process inputs are scaled by these values. Range high is the value

displayed when the maximum process signal is present at the input.

Range low is the value displayed when the minimum process signal is

present at the input.

Example: Set [`rSP] to [4-20]mA.

Set [`rL2] to [`100].

Set [`rH2] to [`500].

A 4mA input will display [`100].

A 12mA input will display [`300].

A 20mA input will display [`500].

• The low and high values of each sensor type are listed on the specifications page of the Appendix.

• Choose between Fahrenheit and Celsius at the [`C_F] prompt in the

Setup Menu.

[`rL2] [`rH2] These prompts appear only if the controller is equipped

with Remote Set Point Input hardware and with Remote Set Point Input

[`rSP] not set to [`OFF].

Default DefaultDefault Default

↓↓ ↓↓

``°F] [`°C]

[`rL2] [`rH2] [`rL2] [`rH2]

[```J] [``32]…[1500] [```0]…`816] 98_L-1__-AA__ or

[`in2] [`rL2] [`rH2] [`rL2] [`rH2] 98_L-2__-AA__

Setup Menu, Chapter 4 WATLOW Series 988LF Users Manual 4.7

Page 30

Setup

[`rL2]

[`rH2]

Range Low 2 and Range

High 2 continued from

previous page.

NOTE:

These values do not

affect the low or the high

set point limit for

process alarms.

NOTE:

When high impedance

[`0-50] is selected for

Input 1, the range high

for both [``°C] and

[``°F] can be extended

to [9999]. The range

low, when [``°C] is

selected, can be

extended to [-999]

Default Default Default

↓↓ ↓↓

(K) ``°F] [`°C]

[```H] [-328]…[2500] [-200]…[1371]

[```t] [-328]…[`750] [-200]…[`399]

[```n] ``32]…[2372] [```0]…[1300]

[```E] [-328]…[1470] [-200]…[`799]

(W5)

[```C] [``32]…[4200] [```0]]]…[2316]

(W3)

[```d] [``32]…[4200] [```0]]]…[2316]

[`Pt2] [``32]…[2543 [```0]]…[1395]

high impedance

[0-50] [-999]…[[`999] [-573]…[`573]

[```r] [``32]…[3200] [```0]]…[1760] 98_L-2__-AA__ only

[```S] [``32]…[3200] [```0]…[1760]

[```b] [``32]…[3300] [```0]…[1816]

[`rtd] [-328]…[1472] [-200]…[`800]

NOTE:

The range high [`rH2]

value for process

inputs can be extended

to [9999].

[`C_F]

[`r†d] [-9(9]…[99(9] [-7#3]…[53&7]

process

[4-20] [-999]…[`999] units

[0-20] [-999]…[`999] units

[`0-5] [-999]…[`999] units

[`1-5] [-999]…[`999] units

[0-10] [-999]…[`999] units

[0-50] [-999]…[`999] units

[0=00] [-999]…[`999] units

Celsius-Fahrenheit

Select which temperature scale the controller will use.

[`C_F] This prompt appears only on controllers with either Input 1 set

to something other than a process input.

Default

↓

[``°f] [``°C]

4.8 WATLOW Series 988LF Users Manual Setup Menu, Chapter 4

[`C_F] [`C_F]

Page 31

Setup

[`Ot1]

[Prc1]

Output 1

Set the way that output 1 will respond to a difference between the set

point and an input variable.

• [``Ht](Heat) select reverse action, so that output 1 responds when the

input signal is less than the setpoint.

• [``CL](Cool) select direct action, so that output 1 responds when the

input signal is more than the setpoint.

[`Ot1] This prompt always appears.

Default

↓

[``Ht] [``CL]

[`Ot1] [`Ot1]

Process 1

Select the process range for output 1.

• [Prc1] This prompt appears only on controllers equipped with output 1

process hardware (98__-__F_-___).

[`Ot2]

Default

↓

4-20mA 0-20mA 0-5VÎ 1-5VÎ 0-10VÎ (dc)

[4-20] [0-20] [`0-5] [`1-5] [0-10]

[Prc1] [Prc1] [Prc1] [Prc1] [Prc1]

Output 2

Selects the secondary output action

• [``AL] de-energizes output 2 in an alarm condition.

• [`ALn] energizes output 2 in an alarm condition.

• [``Ht](Heat) selects reverse action, so that output 2 responds when the

input signal is less than the set point.

• [``CL](Cool) selects direct action, so that output 2 responds when the

input signal is more than the set point.

[`Ot2] This prompt appears only on controllers equipped with output 2

hardware (not 98_L-___A-AA__).

Default

↓

[``no] [``AL] [`Aln] [``Ht] [``CL]

[`Ot2] [`Ot2] [`Ot2] [`Ot2] [`Ot2]

Setup Menu, Chapter 4 WATLOW Series 988LF Users Manual 4.9

Page 32

Setup

[`ALt]

[`LAt]

Alarm Type

Selects the alarm type when Output 2 has been selected as an alarm.

• [``Pr] uses the process signal from input 1.

• [``de] uses a deviation from the input 1 signal.

[`ALt This prompt appears only on controllers equipped with output 2

hardware (not 98_L-___A-AA__). and with [`Ot2] set to [``AL] or [`ALn].

Default

↓

[``Pr] [``de]

[`ALt] [`ALt]

Latching

Select whether alarm for output 2 will be latching or non-latching. A

latching alarm [`LAt] must be turned off manually. A non-latching alarm

[`nLA] turns off when an alarm condition no longer exists.

[`SIL]

[`LAt] This prompt appears only on controllers equipped with output 2

hardware (not 98_L-___A-AA__) and with [`Ot2] set to [``AL] or [`ALn].

Default

↓

[`nLA] [`LAt]

[`LAt] [`LAt]

Silencing

Select silencing to inhibit alarm for Output 2 on startup and to allow

the operator to reset the alarm output, not the visual display.

• Silencing disables the alarm until the signal is between [A2LO] and

[`AHI].

[`AL2] This prompt appears only on controllers equipped with output 2

hardware (not 98_L-___A-AA__) and with [`Ot2] set to [``AL] or [[`ALn].

Default

↓

[`OFF] [``On]

[[`SIL] [[`SIL]

4.10 WATLOW Series 988LF Users Manual Setup Menu, Chapter 4

Page 33

Chapter 5 The Operation Menu

TL

Navigating the Operation Menus

Operations

NOTE:

Press the Display Key

∂

to return to the

Display Loop from any

point in any menu.

❷ Use the Up-arrow > or the

Down-arrow < key to select one

of the prompt values.

Figure 5.1 Navigating the

Operations Menu.

PROCESS

L1 L2

DEV

% OUT

SERIES 988LF

W

TL

A

DISPLAY

AUTO

MAN

MODE

W

❶ To reach the Operation Menus, begin in the

Display Loop and press the Mode key µ.

Depending on the controller configuration, either the

Set Point 2 prompt [`SP2], or the Proportional

Band, Output 1 prompt [`Pb1] will appear in the

lower display. You will not see every prompt in the

Operation Menu; the unit’s configuration and model

number determine which prompts appear.

Enter your settings,

from the controller's

upper display.

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

[`SP2]

[`Pb1]

[`rE1]

[`rA1]

[`Ct1]

[`Pb2]

[`rE2]

[`rA2]

[`CT2]

[``dB]

[`ALO]

[`AHI]

[`CAL]

[`AUT]

[`L-r]

Set Point 2

Proportional Band 1

Reset 1

Rate 1

Cycle Time 1

Proportional Band 2

Reset 2

Rate 2

Cycle Time 2

Deadband

Alarm Lo

Alarm Hi

Calibration Offset

Auto-tune

Local-remote

Operations Menu, Chapter 5 WATLOW Series 988LF Users Manual 5.1

Page 34

Operations

TLTL

W

W

A

PROCESS

L1 L2

DEV

% OUT

DISPLAY

SERIES 988LF

MODE

AUTO

MAN

NOTE:

Decimal points may not

always be in the

position specified below

depending on the

settings in the Decimal

dECdEC

dEC

parameters in the

dECdEC

Setup Menu.

Display Prompts

❸ Use the Mode key µ to advance through the Operations

Menu. You will not see every prompt in the Operations

menu; the unit’s configuration and model number determine

which prompts appear.

❹ Use the Up-arrow > and Down-arrow <

keys to change the prompt setting. To move

backwards through the menu hold the Mode

key µ down and press the Up-arrow key >.

Refer to the Appendix for model number

options.

L1 L2

DEV

% OUT

SERIES 988LF

W

PROCESS

TL

A

DISPLAY

AUTO

MAN

MODE

W

[`SP2]

[`Pb1]

Set Point 2

Select a second set point that will activate output 2. This allows you

to boost the heating (reverse acting) or cooling (direct acting) action of the

output 1 device.

• The range and default settings depend on the [`In1], [`rL1], and

[`rH1] settings (Setup Menu).

[`SP2] This prompt appears only if [`Ot1] and [`Ot2] (Setup Menu) are

both set to [`Ht] or [`CL].

[`rL1] … [`rH1]

[`SP2] [`SP2]

Proportional Band, Output 1

Select the proportional band for PID output 1. If set to [```0] it

functions as an on/off control with a 3°F or 1.7°C switching differential for

ranges displayed in whole degrees, and 0.3°F or 0.17°C for ranges

displayed on 0.1°. The default is 25°F/17°C.

[`Pb1] This prompt always appears.

If Default

↓↓

[``°F] [```0] … [``25] … [9999]

[`C_F] [`Pb1] [`Pb1] [`Pb1]

(Setup Menu)

[`r†d] [``)0] [[``25] [99(9]

Input 1 [`Pb1] [`Pb1] [`Pb1]

(Setup Menu)

[``°C] [```0] … [``14] … [9999]

[`C_F] [`Pb1] [`Pb1] [`Pb1]

(Setup Menu)

[`r†d] [``)0] … ``14] … [99(9]

Input 1 [`Pb1] [`Pb1] [`Pb1]

Setup Menu)

5.2 WATLOW Series 988LF Users Manual Operations Menu, Chapter 5

Page 35

Operations

[`rE1]

[`rA1]

Reset, Output 1

Tune the control action to eliminate the offset or droop between the

set point and the actual process value for PID output 1.

[`rE1] This prompt appears only if [`Pb1] is set to greater than [```0].

Default

↓

[`0)0] … [99(9] repeats/min.

[`rE1] [`rE1]

Rate, Output 1

Tune the rate to eliminate overshoot on startup or after the set point

changes for Output 1. The rate setting will not influence the percent

power if the process value is more than twice the proportional band from

the set point.

[`RA1] This prompt appears only if [`Pb1] is set to greater than [```0].

[`Ct1]

Default

↓

[`)00] … [`(99] min.

[`rA1] [`rA1]

Cycle Time, Output 1

Select the time, in seconds, of a complete on/off cycle.

[`Ct1] This prompt appears only if [`Pb1] is set to greater than [```0].

This prompt does not appear if Output 1 is a process output.

If Default

↓↓

mechanical [``%0] … [`1)0] … [99(9] min.

relay [`Ct1] [`Ct1] [`Ct1]

outputs

open collector [brSt] [``)1] … [``!0] … [99(9] min.

or solid-state [`Ct1] [`Ct1] [`Ct1] [`Ct1]

relay outputs

Operations Menu, Chapter 5 WATLOW Series 988LF Users Manual 5.3

Page 36

Operations

[`Pb2]

Proportional Band, Output 2

Select the proportional band for PID output 2. If set to [```0] it

functions as an on/off control. If set to [```0] it functions as an on/off

control with a 3°F or 1.7°C switching differential for ranges displayed in

whole degrees, and 0.3°F or 0.17°C for ranges displayed on 0.1°. The

default is 25°F/17°C.

[`Pb2] This prompt appears if Output 2 [`Ot2] (Setup Menu) is set to

[``Ht] or [``CL].

If Default

↓↓

[``°F] [```0] … [``25] … [9999]

[`C_F] [`Pb2] [`Pb2] [`Pb2]

(Setup Menu)

[`r†d] [``)0] [[``25] [99(9]

Input 1 [`Pb2] [`Pb2] [`Pb2]

(Setup Menu)

[``°C] [```0] … [``17] … [9999]

[`C_F] [`Pb2] [`Pb2] [`Pb2]

(Setup Menu)

[`r†d] [``)0] … [``17] … [99(9]

Input 1 [`Pb2] [`Pb2] [`Pb2]

(Setup Menu)

[`rE2]

[`rA2]

Reset, Output 2

Tune the control action to eliminate the offset or droop between the

set point and the actual process value for PID output 2.

[`rE2] This prompt appears only if [`Pb2] is set to greater than [```0].

Default

↓

[`0)0] … [99(9] repeats/min.

[`rE2] [`rE2]

Rate, Output 2

Tune the rate to eliminate overshoot on startup or after the set point

changes for Output 2. The rate setting will not influence the percent

power if the process value is more than twice the proportional band from

the set point.

[`RA2] This prompt appears only if [`Pb2] is set to greater than [```0].

Default

↓

[`)00] … [`(99] min.

[`rA2] [`rA2]

5.4 WATLOW Series 988LF Users Manual Operations Menu, Chapter 5

Page 37

Operations

[`Ct2]

[``db]

Cycle Time, Output 2

Select the time, in seconds, of a complete on/off cycle.

[`Ct2] This prompt appears if Output 2 [`Ot2] (Setup Menu) is set to

[``Ht] or [``CL], and if [`Pb2] is set to greater than [```0].

If Default

↓↓

mechanical [``%0] … [`1)0] … [99(9] min.

relay [`Ct2] [`Ct2] [`Ct2]

outputs

open collector [brSt] [``)1] … [``!0] … [99(9] min.

or solid-state

relay outputs

[`Ct2] [`Ct2] [`Ct2] [`Ct2]

Dead Band

Select the width of the zone between the action of the heating

(reverse acting) output and the cooling (direct acting) output. This

shifts the cool setpoint by the dead band value entered. If you select a

positive value the heat and cool outputs cannot be energized at the same

time. If you select a negative value, both outputs can be energized at the

same time.

If Default

↓↓

[``°F] [-999] … [```0] … [`999]

[`C_F] [``db] [``db] [``db]

(Setup Menu)

[``°C] [-555] … [```0] … [`555]

[`C_F] [``db] [``db] [``db]

a process [-999] … [```0] … [`999] units

input is selected [``db] [``db] [``db]

Operations Menu, Chapter 5 WATLOW Series 988LF Users Manual 5.5

Page 38

Operations

[`AL0

Alarm Lo

Select the low trigger value for the output 2 alarm. Represents the low

process alarm or low deviation alarm.

[`ALO] This prompt appears only if [`Ot2] parameter is set to [``AL] or

[`ALn].

If Default

↓↓

lowest value of

[`Pr1] value of … [`rL1] (or [`rL2])… [`AHI]

[`AL0] sensor in Setup Menu [`ALO]

range

[`dE1] [-999] … [```0]

`AL0] [`ALO] [`ALO]

[`AHI]

Alarm Hi

Select the high trigger value for the output 2 alarm. Represents the

high process alarm or high deviation alarm.

[`AHI] This prompt appears only if [`Ot2] parameter is set to [``AL] or

[`ALn].

If Default

↓↓

[``Pr] [`ALO] … [`rH1] (or [`rH2]) … value of

[`AL0] [`AHI] in Setup Menu sensor

[``dE] [```0] … [`999] … [9999]

[`AL0] [[`AHI] [[`AH]1 [`AH1]

value of highest

range

5.6 WATLOW Series 988LF Users Manual Operations Menu, Chapter 5

Page 39

Operations

[`CAL]

[`AUt]

NOTE:

For more information on

auto-tune, see Chapter

7.

Calibration Offset

Add or subtract degrees from the input signal. This allows you to

compensate for lead resistance, sensor errors, or other factors.

[`CAL] This prompt always appears.

If Default

↓↓

[-999] [```0] [9999]

[`CAL] [`CAL] [`CAL]

[`r†d] [-9(9] [```0] [99(9]

[``In] [`CAL] [`CAL] [`CAL]

Auto-tune

Initiate an auto-tune.

[`AUt] This prompt always appears.

Default

↓

[`L-r]

[`OFF] [``On]

[`CAL] [`AUt]

Local-remote

Selects a local or remote set point. With [```r] selected the controller

displays the remote set point rather than the internal (local) set point, and

the set point cannot be changed with the Up-arrow > or Down-arrow <

key.

[`L-r] This prompt appears if [`rSP] (Setup Menu) is not equal to [`OFF].

Default

↓

[```L] [```r]

[`L-r] [`L-r]

Operations Menu, Chapter 5 WATLOW Series 988LF Users Manual 5.7

Page 40

Operations

Notes

5.8 WATLOW Series 988LF Users Manual Operations Menu, Chapter 5

Page 41

Chapter 6 The Factory Menus

[

Reaching the Diagnostics Menu

❶ Press the Up-arrow > and Down-arrow < keys together and hold

until the [`LOC] prompt appears in the lower display. Press and hold again

until the [Fcty] prompt appears in the lower display.

[diAg][`CAL]

[Fcty] [Fcty]

Diagnostics Calibration

Menu Menu

p. 6.1 p 6.5

❷ Use the Up-arrow > key to

step from the Calibration Menu

[`CAL] to the Diagnostics Menu

[diag].

❸ Press the Mode key µ to

step through the prompts.

[``no][`YES]

[diSP] [diSP]

`OFF][out1][out2]

[tout] [tout] [tout]

❹ Press the Up-arrow key > or

the Down-arrow key < to

select one of the prompt values.

In the Diagnostics Menu only

the values of [dISP], [tout],

and [OPLP] can be changed.

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

MODE

[Diag]

[Fcty]

?

[date]

?

[SOft]

?

[Sn--]

?

[AMB]

?

[Acnt]

?

[`gnd]

?

[cnt1]

?

[cnt2]

?

[ity1]

?

[ity2]

?

[Oty1]

?

[Oty2]

?

[dISP]

?

[tout]

?

[OPLP]

Factory Prompt

Factory Ship Date

Software Revision

Serial Number

Ambient Temperature

Ambient A/D count

Ground A/D count

Input 1 A/D count

Input 2 A/D count

Input 1 Module Type

Input 2 Module Type

Output 1 Module Type

Output 2 Module Type

Test Display

Test Outputs

Open Loop

Document your settings,

from the controller's

upper display.

Figure 6.1

The Diagnostics Menu

Factory Menus, Chapter 6 WATLOW Series 988LF Users Manual 6.1

Page 42

Factory-Diagnostics

[dAtE]

[SOFt]

[Sn--]

Factory Ship Date

Shows the date that the final factory control test was performed. The

first two digits represent the week as numbered from [01``] to [52``].

The second two digits represent the year [``97], [``98], etc…

[dAtE] This prompt always appears.

Software Revision

Shows the controller’s software revision code. This letter indicates the

software revision of your controller; [50`d].

[SOFt] This prompt always appears.

Serial Number

Shows the controller’s serial number. The first two letters in the upper

display are to indicate that the controller is in serial number mode. The

right half of the upper display shows the first two digits of the serial number. The lower display shows the last four digits of the serial number.

[AMb]

[Acnt]

[`gnd]

[Sn34]

[5678]

This is what the controller with the serial number 0988345678 would

display.

[Sn``] This prompt always appears.

Ambient Temperature

Shows the ambient temperature at the Input 1 terminals. The temperature is shown in °F in the form [00)0] regardless of the settings of

[deC1], [deC2], [`dfL], or [`C_F].

[AMb] This prompt always appears.

Factory Use Only

These prompts are used only at the factory.

[Acnt] [`gnd] [cnt1] [cnt2] These prompts always appear.

[cnt1]

[cnt2]

6.2 WATLOW Series 988LF Users Manual Factory Menus, Chapter 6

Page 43

Factory-Diagnostics

[ity1]

[ity2]

[Oty1]

[Oty2]

Inputs 1 and 2 Module Types

Displays which input module is installed in the controller. Please

document this value before contacting the factory for technical assistance.

Input Types

• [none] No input module

• [``tc] Thermocouple only module

• [UOFF] Universal off

• [Urtd] Universal rtd

• [Utch] Universal high-gain thermocouple

• [UtcL] Universal low-gain thermocouple

• [UMu] Universal millivolts

• [UPrc] Universal process

[ity1] [ity2] These prompts always appear.

Outputs 1 and 2 Module Types

Displays which output module is installed in the controller. Please

document this value before contacting the factory for technical assistance.

[diSP]

Output Types

• [none] no output module

• [SSr1] 0.5A solid-state relay

• [SS1S] 0.5A solid-state relay with suppression

• [``dc] switched DC output

• [rLcS] form C relay with suppression

• [Proc] process output (Output 1 only)

[Oty1] [Oty2][Oty1] [Oty2]

[Oty1] [Oty2] These prompts always appear.

[Oty1] [Oty2][Oty1] [Oty2]

Test Displays

Runs a brief test of the controller’s displays and LEDs. To run the test,

scroll through the Diagnostics Menu until [disp] is shown in the lower

display. Use the Up-arrow key > or Down-arrow key < to select

[`YES] from the upper display and press the mode key µ.

The controller will run pattern tests, blink all the LEDs on and off, and

end with the model number in both displays.

[diSP] This prompt always appears.

Default

↓

[``no] [`yes]

[disp] [disp]

Factory Menus, Chapter 6 WATLOW Series 988LF Users Manual 6.3

Page 44

Factory-Diagnostics

[tout]

[OPLP]

Test Outputs

This prompt tests each output. To run the test, scroll through the

Diagnostics Menu until [tout] is shown in the lower display. Use the Uparrow key > or Down-arrow key < to select an output [out1] or

[out2]. The LED for that output should light after a second or two indicating that the output has been successfully energized. Do not press the

mode key µ to activate the test; it starts automatically when anything

other than [`OFF] is selected.

If any of the LEDs fail to light contact the factory.

[tout] This prompt always appears.

Default

↓

[`OFF] [out1] [out2]

[tout] [tout] [tout]

Open Loop

Checks the control loop, consisting of the controller output, power

control, heater and sensor. With open loop enabled, the controller moni-

tors the output power level and checks for a change in the process input

value. If the output power is at maximum for a period of time equal to the

reset time and the process input has not changed by at least ±5°F, the

controller will switch to manual mode at 0% output power and [OPLP] will

be displayed in the lower display.

To clear this error, enter the Setup Menu and press the display key ∂. To

get back into auto mode, press the Auto/Man key å.

[OPLP] This prompt always appears.

Default

↓

[`OFF] [``On]

[OPLP] [OPLP]

6.4 WATLOW Series 988LF Users Manual Factory Menus, Chapter 6

Page 45

]

Factory-Calibration

t

s

[`CAL]]

Reaching the Calibration Menu

❶ Press the Up-arrow > and Down-arrow

< keys together and hold until the [`LOC]

prompt appears in the lower display. Press

and hold again until the [Fcty] prompt

appears in the lower display.

❷ Use the Up-arrow key > to select the

Calibration Menu [`CAL] in the upper

display.

[diAg][`CAL]

[Fcty] [Fcty]

Diagnostics Calibration

Menu Menu

p. 6.1 p 6.5

❸ Press the Mode key µ to step through

the prompts.

[``no][`YES

[`rSt] [`rSt]

❹ Press the Up-arrow key > or the Down-

arrow key < to select one of the prompt

values.

Refer to Calibrating Watlow Process Controls

for information about the Calibration Menu.

ç

CAUTION:

Before attempting to calibrate, make sure you have the

proper equipment called for in each procedure. The

Series 988LF is calibrated and tested before it leaves

the factory. Attempting to calibrate the controller

without the proper equipment could result in damage

to property and/or equipment.

Diagnostics Prompt

[Fcty]

MODE

?

[A`50]

MODE

?

[A`00]

MODE

?

[``tc]

MODE

?

[a`0H]

MODE

?

[A`20]

MODE

?

[A`15]

MODE

?

[A380]

MODE

?

[A10U]

MODE

?

[A`0U]

MODE

?

MODE

MODE

MODE

MODE

MODE

MODE

[A20A]

?

[A`4A]

?

[A`OU]

?

[A100]

?

[b`50]

?

[b`00]

MODE

Document your set

from the controller'

upper display.

?

[[b`0H]

MODE

?

[b`20]

MODE

?

[b`15]

MODE

?

b380]

MODE

?

[b10U]

MODE

?

[b`0U

MODE

?

[b20A]

MODE

?

[b`4A]

MODE

?

[b`0U]

MODE

?

[b100]

MODE

?

[1`4`]

MODE

?

[1`20]

MODE

?

[1`0`]

MODE

?

[1`10]

MODE

?

[`rSt]

Restore

Figure 6.5 The Calibration Menu

[`rSt]

Restore

Restores the original factory calibration values. This is a simple way to

recover from a mistake made while calibrating the controller.

[`rSt] This prompt always appears.

Default

↓

[``no] [`yes]

[`rSt] [`rSt]

Factory Menus, Chapter 6 WATLOW Series 988LF Users Manual 6.5

Page 46

Notes

6.6 WATLOW Series 988LF Users Manual Factory Menus, Chapter 6

Page 47

Chapter 7 Tuning, Manual Operation,

Alarms and Error Codes

Auto-tuning (Heat and/or Cool)

NOTE:

A useful reference on

tuning is Tuning of

Industrial Control

Systems by Armando B.

Corripio, published by

the Instrument Society of

America.

Figure 7.1 Auto-tuning example

The Series 988LF can automatically tune the PID parameters to fit the

characteristics of your particular thermal system.

Once the auto-tune sequence has begun, all PID values for both heat and

cool are set to [```0] and the control goes into an on/off mode of control

at 90% of the established set point. The displayed set point remains

unchanged.

Auto-tuning at a set point of 200°F

200°

180°

Temperature

100°

auto-tune

begins

process

90% of

set point

Time

auto-tune

complete

set point

ç

CAUTION:

If a mechanical relay or

contactor is switching

power to the load, a

longer cycle time may

be desirable to

minimize wear on the

mechanical

components. The

typical life of a

mechanical relay is

100,000 cycles. Verify

that the cycle time

selected is appropriate

for the output device

type. Failure to do so

could result in damage

to equipment and/or

property.

When the control finishes “learning” the system, it resumes standard PID

control using the PID values established by the auto-tuning process.

Changing the set point during an auto-tune restarts the auto-tune

procedure.

During auto-tuning the process must cross the set point four times within

an 80-minute time span for the Series 988LF to successfully complete the

auto-tune. If this does not happen within the 80-minute time limit, the

Series 988LF chooses PID values based on the 80-minute tuning cycle

performed.

To start auto-tuning:

1. Press the Mode key µ to advance through the Operations menu

until the [`AUt] prompt appears in the lower display.

2. Use the Up-arrow > or Down-arrow < key to select [``On] or

[`OFF].

3. Press the Display key ¥. While the control is in the tuning mode

the lower display alternates every second between the normal

information and the [tunE] prompt.

Tuning, Manual Operation, Alarms, and Error Codes, Chapter 7 WATLOW Series 988LF Users Manual 7.1

Page 48

T uning

4. When tuning is complete, the displays return to their previous state

and [`AUt] reverts to [`OFF]. The Series 988LF installs the PID tuning

parameters it has calculated and saves them in non-volatile memory.

To abort auto-tuning either reset the [`AUt] prompt to off, press the Auto/

Man key å twice, or cycle power off and on. In all cases, aborting autotune restores all values to their state before auto-tuning began.

Manual Tuning

For optimum control performance, tune the Series 988LF to your thermal