Page 1

SERIES 988/989

The Series 988/989

Offers More

Features, Greater

Versatility

Than Any Other

1

⁄8 DIN Control

Watlow’s Series 988/989 is truly an innovation in the control

field. The Series 988/989 is the first to combine so many key

features into a single, 1⁄8 DIN size package. No other control

offers the flexibility, compact size and durability of the

Series 988/989.

This control meets a wide variety of needs in the process

industries. Its broad range of I/O options allows control of

virtually any process variable.

From the long list of product features, the Series 988/989’s

ability to provide single unit cascade control of a process is

perhaps the most unique. The Series 988/989 is the only

1

⁄

8 DIN

control with this feature. Other features include heater current

monitoring, remote set point input, differential or ratio control.

Valve control via slidewire feedback is another popular feature.

The Series 988/989 has all the standard characteristics you

expect from a Watlow control and more. We expanded the

auto-tuning capabilities and increased the alarm functionality.

The Series 988/989 offers several unique control algorithms.

The Series 988/989 features a three-year warranty and four day

shipment on all model numbers in limited quantities.

Your Authorized Watlow Distributor is:

Windows®is a registered trademark of Microsoft Corporation.

Modbus™ is a trademark of AEG Schneider Automation.

1241 Bundy Boulevard, P.O. Box 5580

Winona, Minnesota 55987-5580 USA

Phone: +1 (507) 454-5300

Fax: +1 (507) 452-4507

Internet: www.watlow.com

e-mail: info@watlow.com

WIN-988/989-0603

© 2003 Watlow Electric Manufacturing Company Printed in the USA on Recycled Paper, 15% Postconsumer Waste

Features and Benefits

Two universal analog inputs and one event input

• Provides greater application versatility

Compact size 103 mm (4.06 in.) behind panel depth

• Fits easily in confined areas

10Hz sampling rate

• Improves control

Windows

®

configuration software and Modbus™ serial

communications

• Offers remote operation

Slidewire feedback input

• Monitors valve position and offers precision control

Burst firing output

• Provides smooth process control

Signal conditioner power supply

• Eliminates the need for an external drive

NEMA 4X front panel

• Provides watertight and corrision resistance

ISO 9001

ISO 9001

Registered Company

Winona, Minnesota USA

Page 2

TLTL

W

W

A

PROCESS

L1 L2 L3 L4

DEV

% OUT

DISPLAY

MODE

AUTO

MAN

SERIES 988

Analog

Input 1

Analog

Input 2

4-20mA Valve Control Output

Material A

Controlled Stream

Material B

Wild Stream

Material C

Mixed Material

Flow Sensor

Flow Sensor

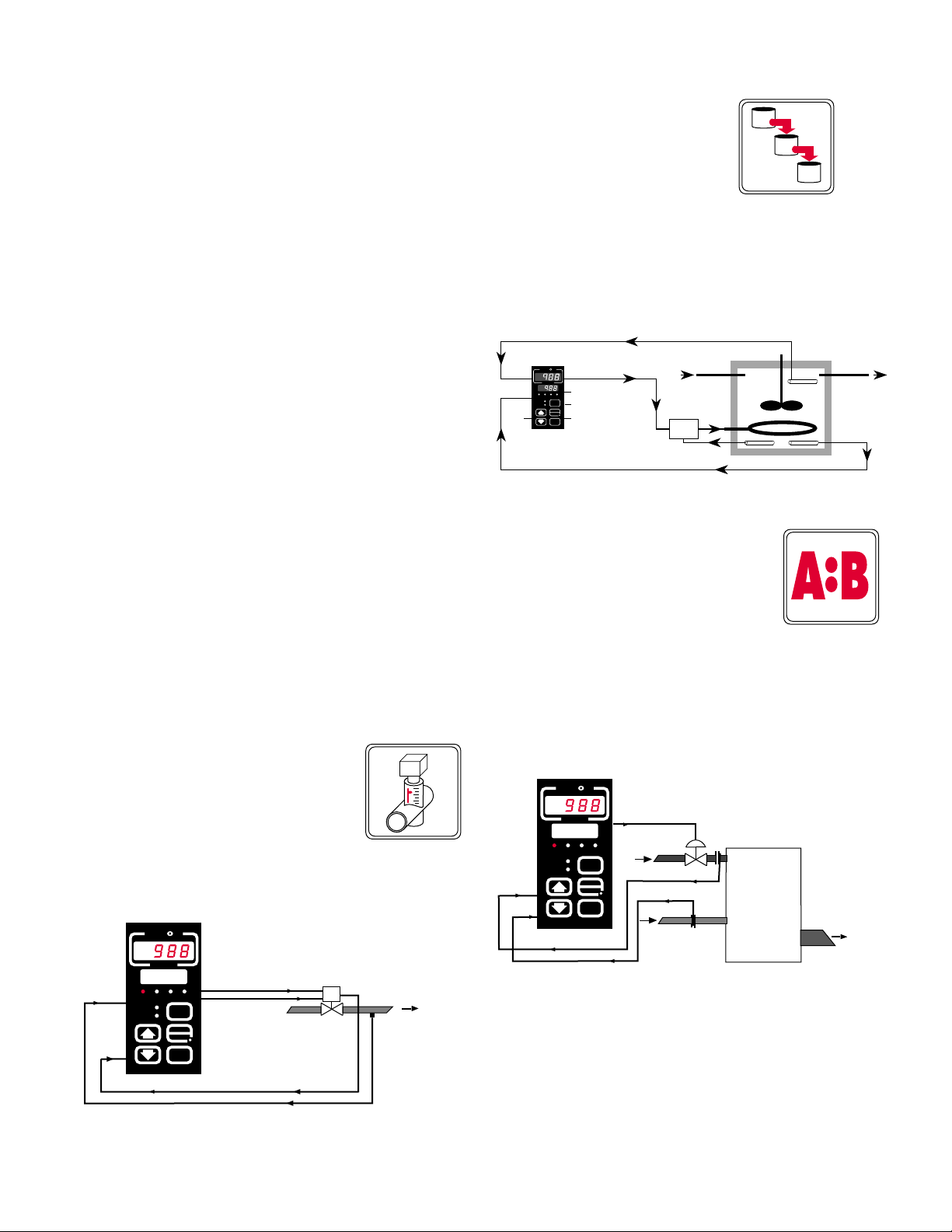

Ratio Control

Whether mixing materials or controlling

temperature indirectly, ratio control with

the Series 988/989 provides automatic set

point adjustments in response to

system changes.

• Simplified process control; one control does

the work of two

• Low cost solution; one control,

display access - both process variables

• One control for many applications

• Easy set-up; increased operator productivity

Product Highlights

Easy to Operate

The Series 988/989’s operator interface features the simplicity

you expect from a Watlow control. The display key allows the

operator to view information pertinent to the process,

including deviation from set point, percent output and units

of measurement.

The display key also returns the operator to the process

and set point display from anywhere in the menu system.

The setup menu is segmented into input, output, global and

communication parameters, allowing movement forward or

backward throughout the parameter sequence.

Use Up To Four Outputs

The control can have up to four outputs total, including the

standard Watlow output options, along with retransmit and

communications. Up to three outputs can be defined as a

power supply output to power external signal conditioners,

eliminating the need for an external power supply. The output

types are recognized by the control to simplify control setup

and operation, with no need for DIP switches.

Three Inputs Allow Greater Flexibility

To accommodate unique system configurations, the Series

988/989 offers two universal analog inputs and one event

(digital) input. The analog input applications are explained in

detail below. The event input allows the operator to select a

function at the close of a switch. This can lock out the front

panel, switch PID values, go to a remote or second set point,

etc. The inputs are optically isolated from all outputs,

eliminating the need for external isolation circuitry.

Cascade Control

Cascade control provides precise,

two-variable process control.

By measuring the secondary

variable, the control can

"feed forward," and automatically

determine the primary variable set point.

• Precise control via cascade configuration

• Display of both process variables

• Low cost; one unit does the work of two

• Increased operator productivity with fast set-up

TLTL

W

W

A

PROCESS

L1 L2 L3 L4

DEV

% OUT

DISPLAY

MODE

AUTO

MAN

SERIES 988

Input 1

Input 2

Slide Wire Feedback / Position Sensor

Thermocouple

CCW - Open

CW - Close

Slidewire Feedback Valve Control

Valve positioning feedback

(% open, % close) provides precise

process control. The Series 988/989 is

configurable for a wide variety of valves.

• Accepts virtually any valve input

• Front panel valve position display

• Increased valve life with anti-hunting parameter

• Greater process efficiency with precise control

• Easy set-up; increased operator productivity

TL

Input 1

Input 2

W

PROCESS

L1 L2 L3 L4

DEV

% OUT

SERIES 988

Outer-Loop

Thermocouple

W

A

TL

Output 1

DISPLAY

AUTO

MAN

MODE

Limit

Limit Sensor

Oil In

Heater

Lube Oil Ta nk

Oil Out

Inner-Loop

Thermocouple

Page 3

Output Selection Table

1234

Solid State Relay

0.5A, with suppression

Switched dc,

open collector

Electromechanical Relay, 5A

Form C, with suppression

Electromechanical Relay, 5A

Form C, w/o suppression

Universal Process

0-20mA, 4-20mA, 0-5

VÎ(dc)

,

1-5

VÎ(dc)

, 0-10

VÎ(dc)

Process Retransmit

0 -20mA, 4-20mA

Process Retransmit

0-5

VÎ(dc)

, 1-5

VÎ(dc)

,

0-10

VÎ(dc)

Electromechanical Relay, 5A

Form A/B, w/o suppression

External Transmitter

Power Supply

EIA-232 Communications

EIA-485/EIA-422

TL

W

W

A

PROCESS

L1 L2 L3 L4

DEV

% OUT

DISPLAY

MODE

AUTO

MAN

SERIES 988

Current

Transformer

Analog

Input 2

Analog

Input 1

Control

Output

Circulation

Heater

Power Control

Thermocouple

Alarm

Output

Current Monitor

Current Monitor

Current monitoring provides system

performance and status information.

The Series 988/989 accepts current

transformer signal with no conditioning.

• Easily accessible heater status

• System performance data for troubleshooting or

design enhancements

• System protection; fast shut down with overcurrent

• Easy setup; no external signal conditioner required

Specifications

Control Mode

• Dual input, quad output, optional retransmit of set point or

process variable

• Programmable direct and reverse acting control outputs

• One step auto-tuning

Operator Interface

• Local/Remote set point capability

• Dual, four digit LED displays. Upper: 10 mm (0.4 in.),

Lower: 8 mm (0.3 in.)

• MODE, AUTO/MAN, DISPLAY, UP and DOWN keys

Input

• Contact input for software function select.

• Type J, K, T, N, C, D, E, R, S, B, Pt 2 thermocouple, 1° or

0.1° RTD, or 0-50mV, 0-100mV, 0-20mA,

4-20mA, 0-5VÎ(dc), 1-5VÎ(dc), 0-10VÎ(dc), slidewire,

digital event input or heater current options

• Sensor break protection de-energizes control output to

protect system or selectable bumpless transfer to manual

operation. Latching or non-latching

• °F or °C display or process units, user selectable

Output Options

• Solid state relay, 0.5A @ 24VÅ(ac) min., 253VÅ(ac) max.,

opto-isolated, zero cross switching. With or without contact

suppression

• Switched dc signal provides a minimum turn on voltage of

3VÎ(dc) into a minimum 500Ω load; maximum on voltage

not greater than 32VÎ(dc) into an infinite load

• Electromechanical relay, Form C, 5A @ 120/240VÅ(ac),

6A @ 28VÎ(dc),

1

⁄8 hp. @ 120VÅ(ac), 125VA @ 120VÅ(ac).

With or without contact suppression

• Process, 0-20mA, 4-20mA, 0-5VÎ(dc), 1-5VÎ(dc), or

0-10VÎ(dc) reverse acting

• Electromechanical relay, Form A/B, 5A @ 120/240VÅ(ac),

6A @ 28VÎ(dc),

1

⁄8 hp. @ 120VÅ(ac), 125VA @ 120VÅ(ac).

Without contact suppression

• External transmitter power supply, 5V @ 30mA,

12V @ 30mA, or 20V @ 30mA

• EIA-232 communications or EIA-485/EIA-422

communications, opto-isolated

Accuracy

• Calibration accuracy & sensor conformity: ± 0.1 percent of

span, ±1 LSD, 77°F ± 5°F (25°C ± 3°C) ambient & rated line

voltage ±10 percent

• Accuracy span: 540°C/1000°F minimum

• Temperature stability: 0.1°C/°C (± 0.2°F/°F) change

in ambient

• Voltage stability: ± 0.01 percent of span / percent of rated line

voltage

Agency Approvals

• UL

®

, C-UL®File #43684

• CE approved

89/336/EEC Electromagnetic Compatibility Directive

EN 50081-2: 1994 Emissions

EN 50082-2: 1995 Immunity

73/23/EEC Low-Voltage Directive

EN 61010-1: 1993 Safety

• NEMA 4X

Terminals

• #6 compression universal head screws, accepts

20-14 gauge wire

Power

• 100 - 240

VÅ(ac) +10 percent/-15 percent, 50/60Hz,

± 5 percent.

• 16VA maximum ac 10VA maximum, low power

• Data retention upon power failure via non-volatile memory

Operating Environment

• 0 to 65°C (32 to 149°F), 0 to 90 percent RH, non-condensing

Mechanica

l

•1⁄8 DIN panel mount, NEMA 4X (IP65 equivalent) front panel

• Overall width x height x depth

Horizontal; 4.03 in. x 2.18 in. x 4.74 in.

(102 mm x 55 mm x 120 mm)

Vertical; 55 mm x 102 mm x 120 mm

(2.18 in. x 4.03 in. x 4.74 in.)

• Depth behind panel; 103 mm (4.06 in.)

• Weight less than or equal to 0.40 kg (14.0 oz)

✓

✓

✓

✓

✓ ✓ ✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

•

UL®is a registered trademark of Underwriter’s Laboratories, Inc.

Page 4

Thermocouple

Type B 870 to 1816°C

(1598 to 3300°F)

Type C

2

0 to 2316°C

(32 to 4200°F)

Type D

2

0 to 2316°C

(32 to 4200°F)

Type E -200 to 799°C

(-328 to 1470°F)

Type J 0 to 816°C

(32 to 1500°F)

Type K -200 to 1371°C

(-328 to 2500°F)

Type N 0 to 1300°C

(32 to 2372°F)

Type R 0 to 1760°C

(32 to 3200°F)

Type S 32 to 3200°F

(0 to 1760°C)

Type T -200 to 399°C

(-328 to 750°F)

Pt 2

2

0 to 1395°C

(32 to 2543°F)

RTD Resolution (DIN or JIS)

1° (DIN) -200 to 800°C

(-328 to 1472°F)

1° (JIS): -200 to 630°C

(-328 to 1166°F)

0.1°(DIN and JIS)

-73.3 to 537.7°C

( -99.9 to 999.9°F)

Process

0-5VÎ(dc) -999 to 9999 units

1-5VÎ(dc) -999 to 9999 units

0-10VÎ(dc) -999 to 9999 units

0-20mAÎ(dc) -999 to 9999 units

4-20mAÎ(dc) -999 to 9999 units

0-50mVÎ(dc) -999 to 9999 units

Slidewire 100 to 1200Ω

Current 0 to 50mA

Potentiometer 0 to 1200Ω

Ordering Information

To order, complete the model number to the right with the information below:

9 8 _ _ - ____- ____

Series 988/989 = Single channel, temperature/process controller,

2 inputs, 4 outputs, 2 digital inputs.

Power Supply & Mounting

6 = 24 to 28Vı(ac/dc) nominal, vertical mounting

7 = 24 to 28Vı(ac/dc) nominal, horizontal mounting

8 = 100 to 240Vı(ac/dc) nominal vertical mounting

9 = 100 to 240Vı(ac/dc) nominal horizontal mounting

Software

A = Standard (Includes Modbus™)

B = Enhanced (Includes cascade, ratio, differential, duplex, dual PID set)

#1 Input

1 = Thermocouple only (Excluding Type B, R and S)

2 = Universal signal conditioner

#2 Input

0 = None

1 = Thermocouple only (Excluding Type B, R and S)

2 = Universal signal conditioner

3 = Slidewire feedback

4 = Current transformer

c

5 = Second digital contact event (One digital event is standard on all units)

#1 Output

B = Solid state relay, Form A, 0.5A, with RC suppression

C = Switched dc or open collector, isolated

D = Electromechanical relaya, Form C, 5A with RC suppression

E = Electromechanical relaya, Form C, 5A without contact suppression

F = Universal process, 0-5VÎ(dc), 1-5VÎ(dc), 0-10VÎ(dc),

0-20mA (dc), 4-20mAÎ(dc), isolated

K = Solid state relay, Form A, 0.5A, without contact suppression

#2 Output

A = None

B = Solid state relay, Form A, 0.5A, with RC suppression

C = Switched dc or open collector, isolated

D = Electromechanical relaya, Form C, 5A with RC suppression

E = Electromechanical relaya, Form C, 5A without contact suppression

F = Universal process 0-5VÎ(dc), 1-5VÎ(dc), 0-10VÎ(dc)VÎ(dc),

0-20mAÎ(dc), 4-20mAÎ(dc), isolated

K = Solid state relay, Form A, 0.5A, without contact suppression

T = External signal conditioner power supply, 5, 12 or 20VÎ(dc) @ 30mA

#3 Output

A = None

B = Solid state relay, Form A, 0.5A, with RC suppression

C = Switched dc or open collector, isolated

J = Electromechanical relay

a

, Form A or B, 5A without contact suppression

K = Solid state relay, Form A, 0.5A without contact suppression

M = Retransmit, 0-20mAÎ(dc), 4-20mAÎ(dc)

N = Retransmit, 0-5VÎ(dc), 1-5VÎ(dc), 0-10VÎ(dc)

T = External signal conditioner power supply, 5, 12 or 20VÎ(dc) @ 30mA

#4 Output

A = None

B = Solid state relay, Form A, 0.5A, with RC suppression

C = Switched dc or open collector, isolated

D = Electromechanical relaya, Form C, 5A with RC suppression

E = Electromechanical relaya, Form C, 5A without contact suppression

K = Solid state relay, Form A, 0.5A without contact suppression

R = EIA/TIA-232 communications, opto-isolated

S = EIA/TIA-485 and EIA/TIA-422 communications, opto-isolated

U = EIA/TIA-232 and EIA/TIA-485 communications, opto-isolated

T = External signal conditioner power supply, 5, 12 or 20VÎ(dc) @ 30mA

Display

GG = Green/Green displays

GR = Green/Red displays

RG = Red/Green displays

RR = Red/Red displays

XX = Custom overlays or default settings

a

Electromechanical relays warranted for

100,000 closures only. Solid state switching

devices recommended for applications

requiring fast cycle times or extended

service life.

b

Not an ANSI symbol.

c

A current transformer input cannot be used

in conjunction with a process output

installed on output #1.

Slo-Blo®is a registered trademark of Littelfuse, Inc.

Modbus™ is a trademark of AEG Schneider

Accuracy Range

North American Sales Offices: Atlanta, (770)972-4948 • Austin, (512)249-1900 • Birmingham, (205)678-2358 • Charlotte, (704)573-8446 •

Chicago, (847)458-1500 • Cincinnati, (513)398-5500 • Cleveland, (330)467-1423 • Dallas, (972)620-6030 • Denver, (303)798-7778 •

Detroit, (248)651-0500 • Eastern Canada, (450)433-1309 • Houston, (281)440-3074 • Indianapolis, (317)575-8932 • Kansas City, (913)897-3973 •

Los Angeles, (714)935-2999 • Louisiana, (318)864-2864 • Maryland/Virginia, (215)345-8130 • Minneapolis/Manitoba, (952)892-9222 •

Nashville, (615)264-6148 • New England, (603)882-1330 • New York/New Jersey/Philadelphia, (215)345-8130 • New York, Upstate, (716)438-0454 •

Ontario, (905)979-3507 • Orlando, (407)351-0737 • Phoenix, (602)298-6960 • Pittsburgh, (412)322-5004 • Portland, (503)245-9037 •

Raleigh/Greensboro, (336)766-9659 • St. Louis, (314)878-4600 • Sacramento, (707)425-1155 • San Diego, (714)935-2999 •

San Francisco, (408)434-1894 • Seattle, (425)222-4090 • Tampa/St. Petersburg, (407)647-9052 • Tulsa, (918)496-2826 •

Western Canada, (604)444-4881 • Wisconsin, North (920)993-2161 • Wisconsin, South (262)723-5990

Asian Sales Offices: Australia, +61 (3) 9335-6449 • China, +86 (21) 6277-2138 • Japan, +81 (03) 5403-4688 • Korea, +82 (02) 575-9804 •

Malaysia, +60 (4) 641-5977 • Singapore, +65 777-9488 • Taiwan, +886 (0) 7-288-5168 European Sales Offices: France, +33 (01) 3073-2425 •

Germany, +49 (0) 7253-9400-0 • Italy, +39 (02) 458-8841 • Sweden, +46 31 7014959 • United Kingdom, +44 (0) 115-964-0777

Latin American Sales Office: Mexico, +52 (442) 217-6235

Loading...

Loading...