Page 1

Data Communications with the Watlow

Series 988 Family of Controllers

User’s Manual

Includes:

981-984 Ramping

986-989 Temperature or Process

996-999 Dual Channel

W

A

TL

W

PROCESS

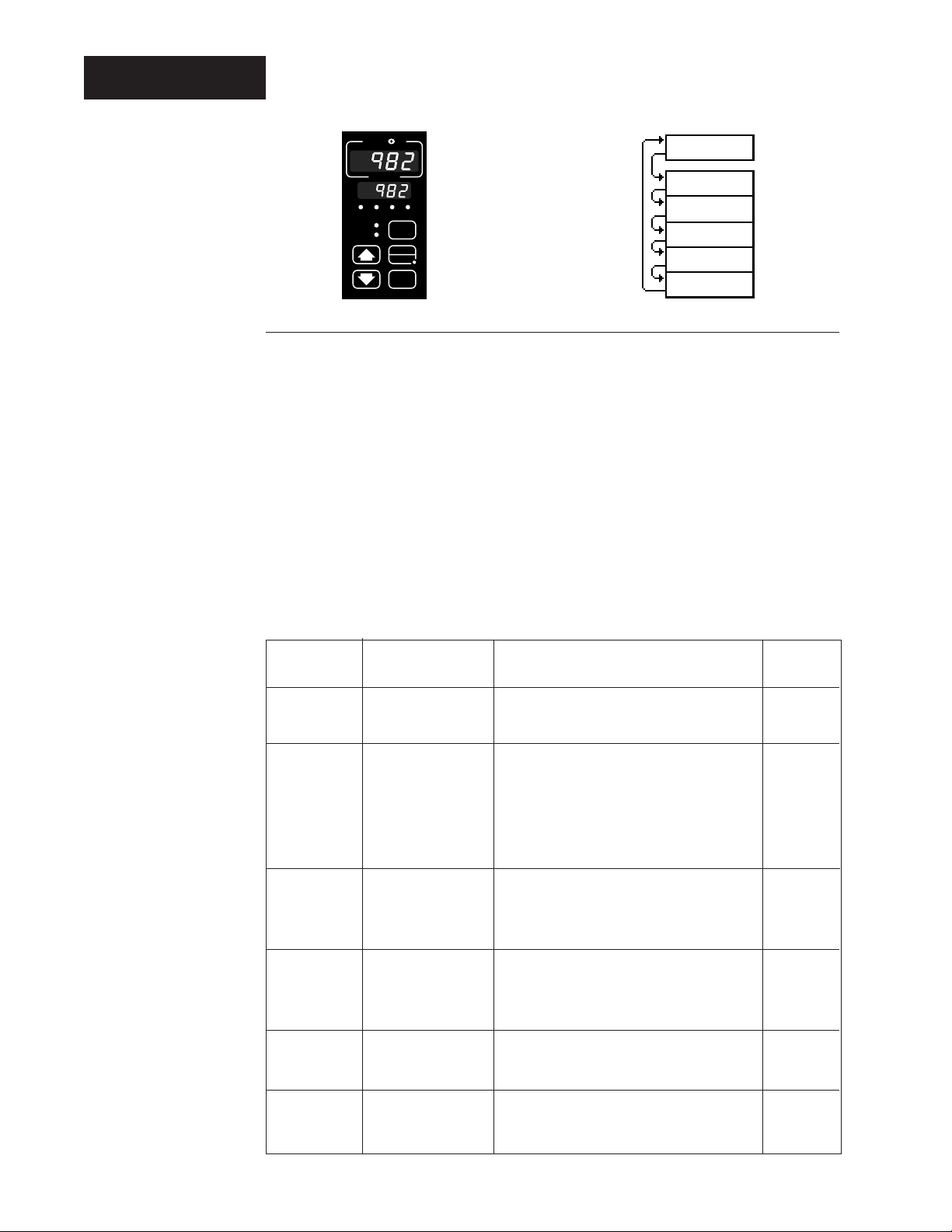

[`982]

L1 L2 L3 L4

DEV

% OUT

SERIES 982

DISPLAY

HOLD

RUN

MODE

SERIES 988

User Level Targeted:

• New User............................. Go to page 1.1

• Experienced User ................Go to page 2.1

• Expert User .........Go to page 5.1, 6.1 or 7.1

Installer:

• Wiring and installation.........Go to page 2.1

• Setup...................................Go to page 3.1

A

TL

W

PROCESS

[`988]

L1 L2 L3 L4

DEV

% OUT

DISPLAY

AUTO

MAN

MODE

W

W

PROCESS

W

A

TL

[`998]

1A 2A 1B 2B

CH A

CH B

SERIES 998

DISPLAY

AUTO

MAN

MODE

Watlow Controls

1241 Bundy Blvd., P.O. Box 5580, Winona, Minnesota 55987-5580; Phone: (507) 454-5300;

0600-0009-0004 Rev B

Supersedes: W98F-XUMN Rev A03

February 1998

Fax: (507) 452-4507

97

TOTAL

CUSTOMER

SATISFACTION

ISO 9001

Registered Company

Winona, Minnesota USA

$15.00

Made in the U.S.A.

Printed on Recycled Paper, 10% Post-consumer Waste.

Page 2

About This Manual

How to Use this Manual

We have designed this user’s manual to be a helpful guide to your new Watlow

controller. The headlines in the upper right and left corners indicate which tasks are

explained on that page. If you are a new user, we suggest that your read the first

four chapters of this manual.

Notes, Cautions and Warnings

We use notes, cautions and warnings throughout this book to draw your attention

to important operational and safety information.

A bold text “NOTE” marks a short message in the margin to alert you to an important detail.

A bold text “CAUTION” safety alert appears with information that is important for

protecting your equipment and performance. Be especially careful to read and

follow all cautions that apply to your application.

A bold text “WARNING” safety alert appears with information that is important for

protecting you, others and equipment from damage. Pay very close attention to

all warnings that apply to your application.

The ç symbol (an exclamation point in a triangle) precedes a general CAUTION

or WARNING statement.

The Ó symbol (a lightning bolt in a triangle) precedes an electric shock hazard

CAUTION or WARNING safety statement.

Technical Assistance

If you encounter a problem with your Watlow controller, review all of your configuration information for each step of the setup, to verify that your selections are

consistent with your applications.

If the problem persists after checking all the steps, call for technical assistance:

Watlow Controls, (507) 454-5300, between 7:00 a.m. and 5:00 p.m. Central

Standard Time. Ask for an applications engineer. When you call, have the following

information ready:

• the controller’s model number (the 12-digit number is printed on the top of the

stickers on each side of the controller case and on the right hand or top circuit

board);

• this user’s manual;

• all configuration information;

• the Diagnostics Menu readings.

Comments and Suggestions

We welcome your comments and opinions about this user’s manual and the Series

988 family of controllers. Send them to the Technical Editor, Watlow Controls, 1241

Bundy Boulevard, P.O. Box 5580, Winona, MN 55987-5580. Or call (507) 4545300 or fax them to (507) 452-4507.

Warranty and Returns

For information about the warranty covering the Series 988 family of controllers

see the Appendix.

The Data Communications User’s Manual for the Series 988 family is copyrighted

by Watlow Controls, Inc., © 1997, with all rights reserved. (1385)

Page 3

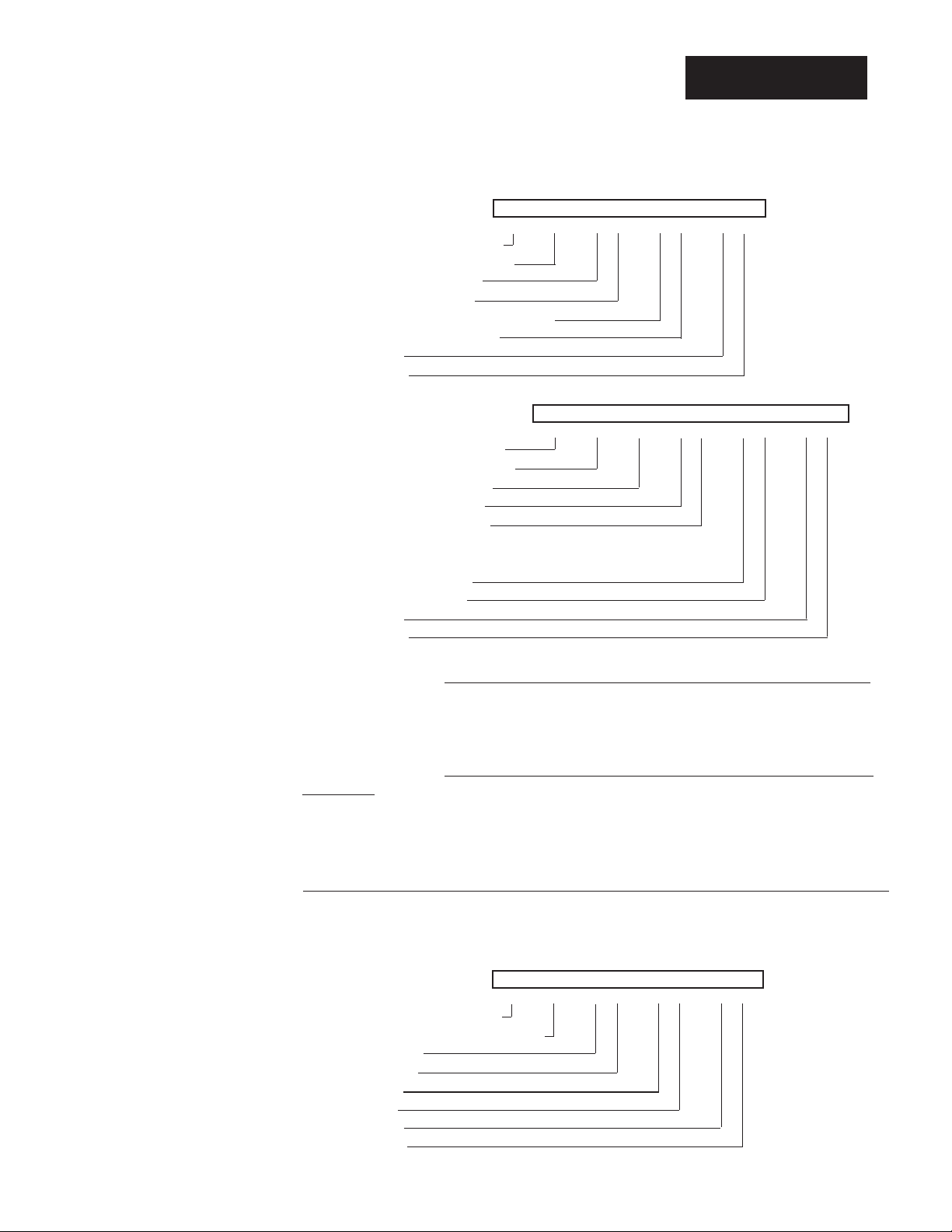

Table of Contents

Data Communications with the Watlow Series 988 Family of Controllers

Chapter 1

Introduction to Data Communications

1.1 Machine-to-Machine Communication

1.1 Protocol

1.1 A Protocol Example

1.3 EIA-232, EIA-485 and EIA-422 Interfaces

1.4 ASCII

1.4 Parity Bit

1.5 Start and Stop Bits

1.5 Baud Rate

1.5 Computer Languages

1.5 Syntax

1.6 ASCII Control Character Definitions

1.6 Data Communications Conversation

Chapter 2

Hardware and Wiring

2.1 Serial Hardware Interfaces

2.1 Your Computer’s Serial Interface

2.2 Communications Wiring

2.2 EIA-232 Interface Wiring

2.3 EIA-485 Interface Wiring

2.4 EIA-422 Interface Wiring

Chapter 3

Communications Setup

3.1 Connecting the Controller and Computer

3.1 Software Protocols and Device Addresses

3.1 Communications Software

3.2 Setup at the Controller's Front Panel

Chapter 4

Sending Commands

4.1 General Message Syntax

4.1 Message Syntax

4.1 Data Rules

4.1 Command List

4.2 Example Format

4.2 XON/XOFF Protocol for EIA-232

4.2 How to Communicate Using XON/XOFF

4.3 How to Communicate Using ANSI X3.28

4.4 Device Addresses

4.5 ANSI X3.28 Protocol Example

4.6 Modbus RTU

4.10 Cyclical Redundancy Checksum (CRC)

Algorithm

Chapter 5

Command Summary of the Series 981-984

5.1 Complete Parameter Download Sequence

5.2 Run/Hold Mode and Prompt Accessibility

5.3 Ramping Controller Prompt Table

5.12 Ramping Controller MTR Command

5.13 Ramping Controller STP Command

5.14 Ramping Controller Commands Table

5.16 982 Modbus RTU Address Table

Chapter 6

Command Summary of the Series 986-989

6.1 Complete Parameter Download Sequence

6.2 Temperature/process Controller Prompt Table

6.13 988 Modbus RTU Address Table

Chapter 7

Command Summary of the Series 996-999

7.1 Complete Parameter Download Sequence

7.2 Dual Channel Controller Prompt Table

7.12 998 Modbus RTU Address Table

Appendix

A.1 Handling Communications Error Codes

A.1 User Responsibility

A.2 ASCII Characters

A.3 Index

Table of Contents Data Communications with the Watlow Series 988 Family of Controllers

III

Page 4

Table of Contents

NOTES

IV

Table of ContentsData Communications with the Watlow Series 988 Family of Controllers

Page 5

Chapter 1 Introduction to Data Communications

Machine-to-Machine Communication

Humans use basic components to exchange messages. Computers and controllers

also use certain elements in order to communicate: a character set; a common

NOTE:

This manual applies

only to controllers

with the data

communications

option (9___-_____R__ or 9___-_____S__ or 9___-_____U__). Please use it

in conjunction with

the user's manuals.

data link, or interface; and a protocol, to prevent confusion and errors.

Serial communication is the exchange of data one bit at a time on a single data

line or channel. Serial contrasts with "parallel" communication, which sends several

bits of information simultaneously over multiple lines or channels. Not only is serial

data communication typically simpler than parallel, it generally costs less.

Computers need a connecting interface over which to communicate. They may

use one pair of wires to send information in one direction and another pair to send

in the opposite direction (full duplex). Or, they may use one pair to send in both

directions (half duplex).

Bit is simply the contraction of "binary digit," either a "1" or a "0." A byte is a string

of seven or eight bits, which a computer treats as a single "character." The ASCII

(pronounced "asky") character set uses a unique, seven-bit byte to represent each

letter, digit and punctuation mark.

Interfaces

Protocol

Now we need a few rules to "talk" by. Protocol determines who gets to talk when. A

protocol is a set of standards for formatting and timing information exchange

between electronic systems.

Protocol describes how to initiate an exchange. It also prevents two machines from

attempting to send data at the same time. There are a number of different data

communications protocols, just as there are different human cultural protocols that

vary according to the situation.

A Protocol Example

Let's assume that we have a computer and controllers linked together. They all use

ASCII and are connected via a common interface. In process control applications,

one device often has greater function and memory capability than the devices it is

communicating with. This "master" device always initiates exchanges between it

and the connected "remote" devices.

Here's what happens: Imagine "PC-1," the master computer, sitting at the end of a

long hallway with nine doors in it. Each door has a remote device behind it. PC-1

has a telephone line to all the devices. The remote devices are busy controlling

heaters to specific set points. PC-1 monitors and changes the instructions that

each remote device uses to control its heaters.

Introduction to Data Communications, Chapter 1 Data Communications with the Watlow Series 988 Family

1.1

Page 6

Interfaces

By your request PC-1 wants to talk with device "D-2" to change a set point. PC-1

must first identify D-2 on the line and inquire whether D-2 has time to talk. This

electronic knocking on D-2's door is the "connection."

One of three scenarios may occur when PC-1 calls:

1) D-2 answers saying, "This is D-2, go ahead," and PC-1 begins to talk.

2) D-2 answers and says, "I'm too busy to talk now. Wait until I tell you I'm

finished."

3) D-2 does not answer, which indicates a possible system malfunction.

Let's take the best-case scenario. Here is a simple version of what happens: D-2

answers and hears PC-1 say, "Hello, D-2. Do you have time to talk?"

D-2 acknowledges PC-1 with a "D-2 here, go ahead."

PC-1 then sends an ASCII-encoded message instructing D-2 to change a set point

to 1,000°F. (message)

When PC-1 is finished with its message, it says in effect, "That's all, your turn."

D-2 replies, "OK," and carries out the instruction. D-2 then takes the protocol lead,

and tells PC-1, "The new set point is 1,000°F." (message)

PC-1 says, "OK."

D-2 says, "That's all, your turn."

PC-1 then takes the protocol lead and says, "Thank you, that's all."

D-2 hangs up. (disconnect)

That's basically how the connect, message and disconnect protocols work in

Watlow data communications.

The hallway in this example is really a communications bus — a common connec-

tion among a number of separate devices. A communications system with multiple

devices on a common bus is called a multidrop system.

The exact connect-message-disconnect procedure assures that you are talking to

the correct device.

Protocol maintains system integrity by requiring a response to each message. It's

like registered mail — you know that your letter has been received because the

post office sends you a signed receipt.

In Watlow data communications, a dialog will continue successfully as long as the

messages are in the correct form and responses are returned to the protocol

leader. If the operator enters an incorrect message, or interference comes on to the

data line, there will be no response. In that case the operator or the master must

retransmit the message or go to a recovery procedure. If an operator continues to

enter an incorrect message or interference continues on the data line, the system

will halt until the problem is resolved.

1.2

Data Communications with the Watlow Series 988 Family

Introduction to Data Communications, Chapter 1

Page 7

Interfaces

EIA-232, EIA-485 and EIA-422 Interfaces

The three interfaces we're concerned with on this controller are EIA-232, EIA-485

and EIA-422.

An EIA-232 interface uses three wires: a single transmit wire; a single receive wire;

and a common line. Only two devices can use an EIA-232 interface. A -12 volt

signal indicates a 1 and a +12 volt signal indicates a 0. The EIA-232 signal is

referenced to the common line rather than to a separate wire, as in EIA-485 and

EIA-422. An EIA-232 cable is limited to 50 feet, due to noise susceptibility.

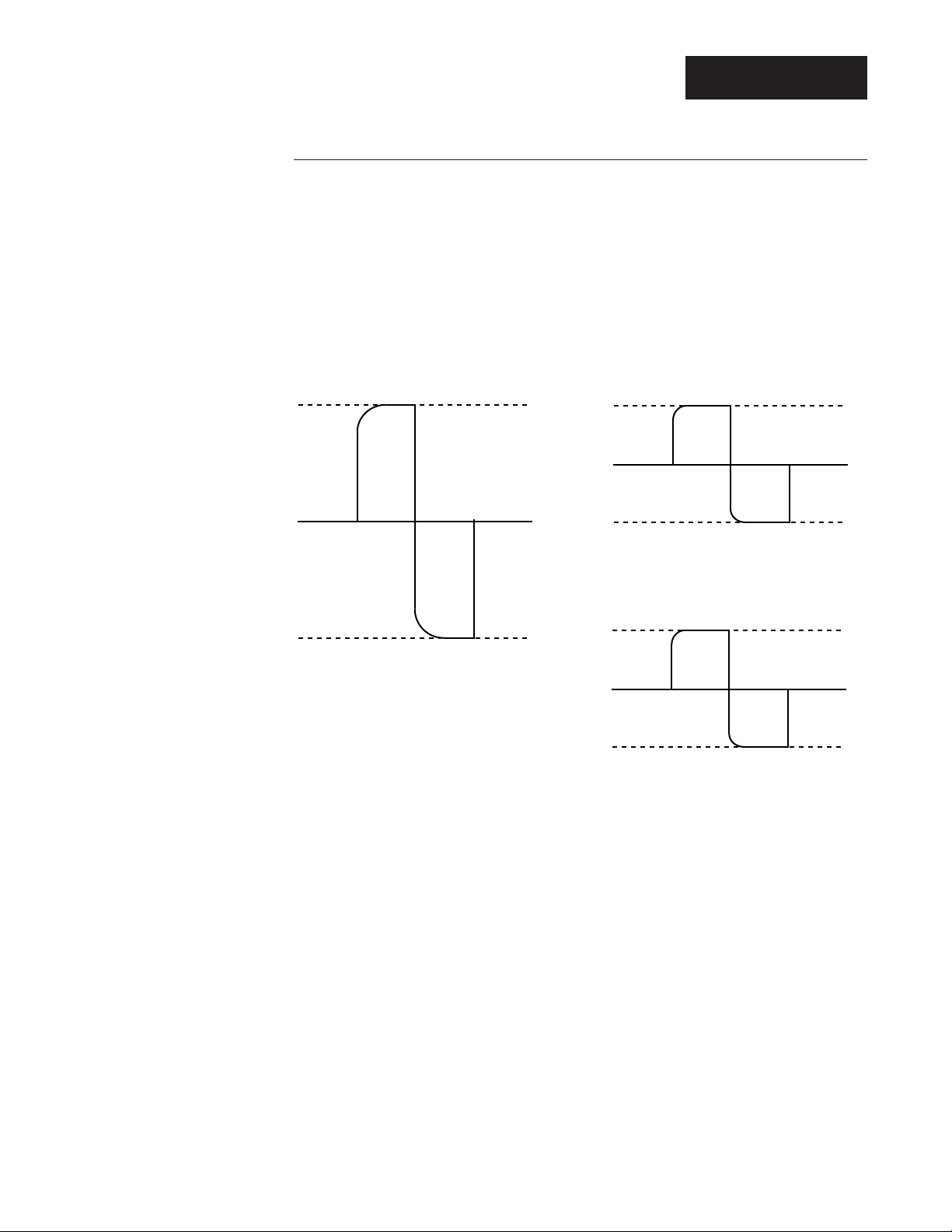

Figure 1.3 - Interface

bit signals.

0 bit

1 bit

Bit signals on an EIA-232 interface.

+12V

0 bit

1 bit

0V

Bit signals on an EIA-485 interface.

-12V

0 bit

1 bit

Bit signals on an EIA-422 interface.

+5V

-5V

+5V

-5V

An EIA-485 interface uses three wires: a T+/R+; a T-/R-; and a common line. A

-5-volt signal is interpreted as a 1, a +5-volt signal as a 0. Up to 32 remote devices

can be connected to a master on a multi-drop network up to 4,000 feet long.

0V

0V

The EIA-422 interface uses five wires: a "talk" pair; a "listen" pair; and a common

line. It can handle one master and up to ten remote devices in a multidrop network

up to 4,000 feet long. EIA-422 uses the difference in voltage between the two wires

to indicate a 1 or a 0 bit. A 1 is a difference of -5 volts, while a 0 is a difference of

+5 volts.

Of these three interfaces, EIA-485 has the lowest impedance, a multiple-device

capability, greatest noise immunity and the longest distance capability — up to

4,000 feet of total network cable length.

Introduction to Data Communications, Chapter 1 Data Communications with the Watlow Series 988 Family

1.3

Page 8

ASCII

Table 1.4 - Comparing Interfaces.

Maximum Maximum Cable

Net Length Controllers Type

EIA-232 50 feet 1 3-wire

EIA-485 4,000 feet 32 3-wire

EIA-422 4,000 feet 10 5-wire

NOTE:

The Modbus feature

on the Series 988

controllers allows up

to 247 controllers to

share one EIA-485

network, by using

network bridges.

See Chapter 6 for

more information on

Modbus.

ASCII

The ASCII code defines 128 separate 7-bit characters — one for each letter, digit

and punctuation mark. ASCII also includes control characters similar to those we

find on computer keys, like "backspace," "shift" and "return." It also has ten communications control characters for "identification," "enquiry" (inquiry), "start of text,"

"end of text," "end of transmission," "acknowledge," "negative acknowledge" and

"escape."

The ASCII code is sometimes written in a base-16 number system, called hexadecimal or "hex" for short. The first ten digits of this system are represented by the

numbers 0 through 9, and the final six digits are represented by the letters A

through F. The 128 ASCII character code with the decimal and hexadecimal

equivalents is listed in the Appendix.

Parity Bit

Remember that ASCII is a seven- or eight-bit code. What about that eighth bit? It's

called the "parity" bit. A parity bit is added to the ASCII character to verify the

accuracy of the first seven bits. Here's how: We are declaring that the number of 1s

in the 8-bit character frame will be either always odd or always even. To do that,

about half the time we'll have to add another 1 to get an odd or an even number of

ones. The other half of the time we'll need to add a 0 so we don't change the total

number of 1s.

This way we can detect a single error in the seven-bit group. Take a look at the

representation of the transmitted upper case "W." In this case we have selected

"odd" parity. The number of 1s in the first seven bits, plus the parity bit, must

always total an odd number. The total number of 1s in the binary character

1010111 (W) is 5, already an odd number. Thus our parity bit will be a 0.

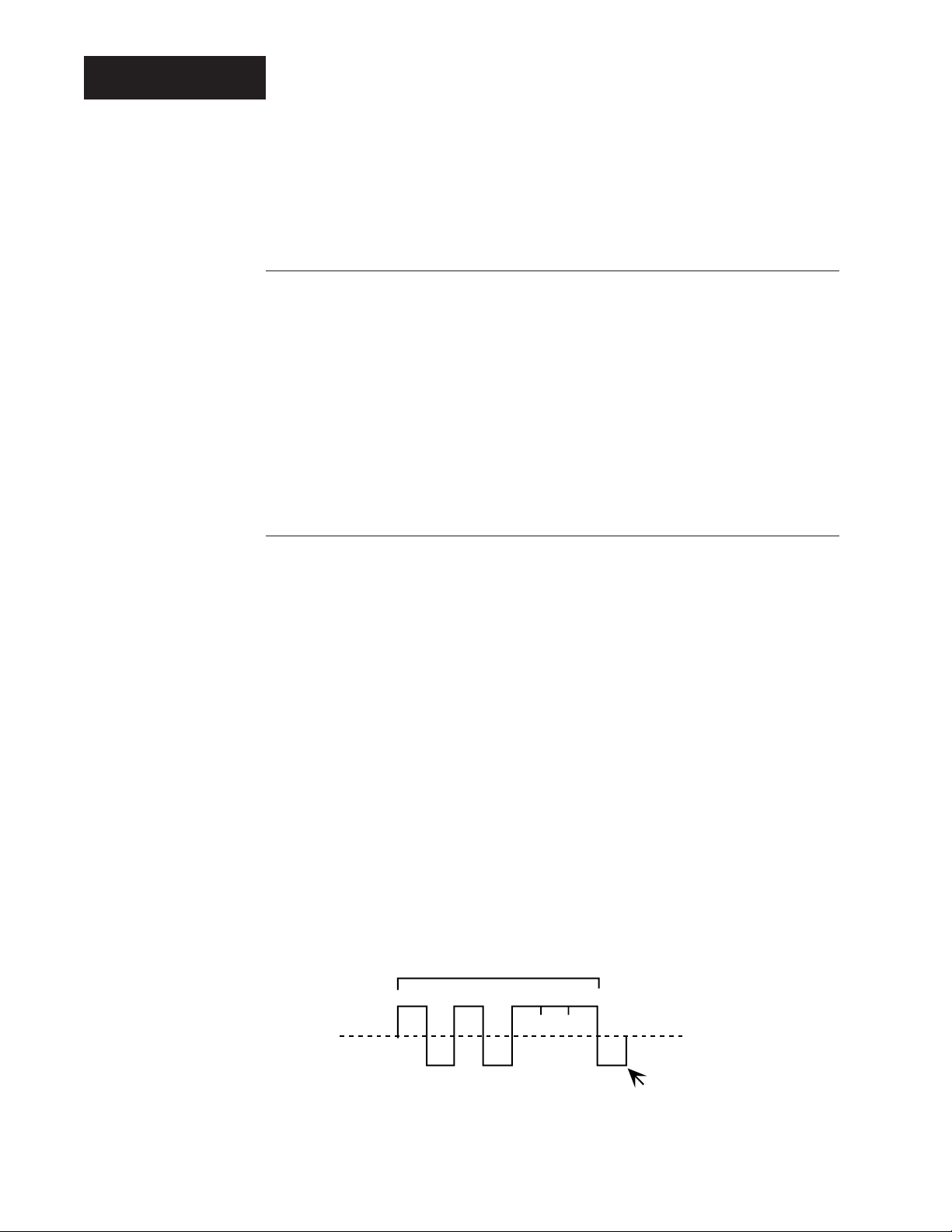

Figure 1.4 - ASCII

upper case "W"

(1010111).

1.4

Data Communications with the Watlow Series 988 Family

If we were transmitting the lower case "w" (binary 1110111), the parity bit would be

a 1 because the total number of 1's in the character frame is 6, an even number.

Adding the parity bit makes it odd, and consistent with the odd parity rule.

If a noise spike came onto the data line and changed the signal voltage level

enough to reverse a 1 to a 0 in the character frame, the receiver would detect that

7-bit character

+V

-V

bit position: 12345678

0

1

odd parity bit

Introduction to Data Communications, Chapter 1

Page 9

ASCII

error. The total number of 1s would be even and a violation of the odd-parity rule.

At Watlow, we use odd, even and no parity.

Odd parity sets the parity bit to 0 if there are an odd number of 1s in the first seven

bits.

Even parity sets the parity bit to 0 if there are an even number of 1s in the first

seven bits.

No parity ignores the parity bit.

Start and Stop Bits

A "start" bit informs the receiving device that a character is coming, and a "stop" bit

tells it that one is complete. The start bit is always a 0. The stop bit is always a 1.

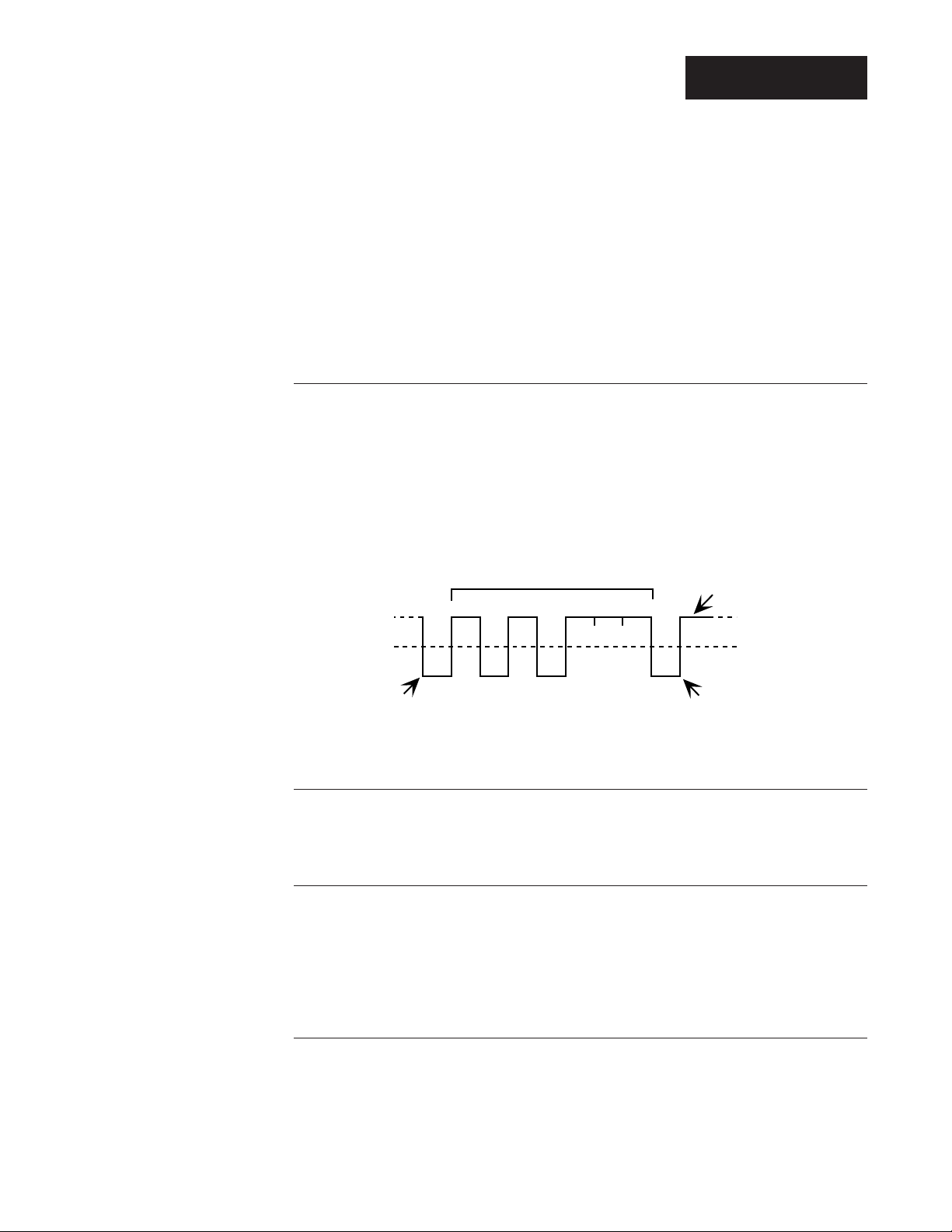

We've added the start and stop bits to the transmitted "W" example.

The human speaking equivalent of these bits could be a clearing of the throat to

get someone's attention (start bit); and a pause at the end of a phrase (stop bit).

Both help the listener understand the message.

Figure 1.5 - ASCII

upper case "W" with

start and stop bits.

-V

+V

idle line

1

0

start bit

7-bit character

12345678

stop bit

odd parity bit

Baud Rate

The baud rate refers to the speed of data transmission. When a change in signal

represents one data bit, baud rate is equal to bits per second (bps). Our rates on

the 988 Family of controllers are 300, 600, 1200, 2400, 4800 and 9600 baud.

Computer Languages

Computer languages are simply sets of symbols and rules for their use. There are

many computer languages and a wide variety of applications for them. Programmers use languages to enable computers to do real work. We're providing a pilot

program written in Quick BASIC to demonstrate data communications with Watlow

controllers. You can download the MS-DOS™ version files ("comms4.zip" and

"comms4tm.zip" and com5set.exe) from the Watlow BBS, (507) 454-3958.

Syntax

Syntax for a natural language dictates how we put words together to make phrases

and sentences. In data communications, syntax also dictates how we order the

parts of a message.

Introduction to Data Communications, Chapter 1 Data Communications with the Watlow Series 988 Family

1.5

Page 10

Syntax

For example, the Series 986-989 parameter for set point information is SP1. The

controller's panel will normally display SP1 and set point information whenever you

physically press the DISPLAY key to reach SP1 in the parameter sequence. For a

computer linked to a controller, "SP1" is part of the syntax for data communications.

If you type just "SP1" on the computer keyboard, the controller won't respond to

your computer with the current set point 1 data. The syntax requires spaces and

"fields" of specific size to be complete.

Plus, we need to add the protocol. It's like putting a message in an envelope and

addressing it. The entire syntax of the SP1 command includes the message

protocol's STX (Start of Text) control character, SP1, space, up to four decimal

places of set-point data, and a protocol ETX (End of Text) control character.

The whole phrase would look like this:

<STX> SP1 0500 <ETX>

ASCII Control Character Definitions

ENQ Enquiry (inquiry): Request for a data link.

ACK Acknowledge: Affirmative response from the receiver.

NAK Negative Acknowledge: Negative response from the receiver.

STX Start of Text: Precedes any message from the sender.

ETX End of Text: Follows any message from the sender.

EOT End of Transmission: Tells the other device that it is its turn to send a mes-

sage.

DLE Data Link Escape: Disconnect signal from the master to devices on the

network.

A Data Communications Conversation

Now that you have a general grasp of the basic ideas and terms behind data

communications, we'll take the example further to see how an actual conversation

would take place.

The example on the next page follows the exchange between a computer (master)

and a controller (remote) as the computer sends a set point data command to the

controller.

1.6

That's really all there is to it. Remember — only the "master" may initiate exchanges and every message requires a response.

Data Communications with the Watlow Series 988 Family

Introduction to Data Communications, Chapter 1

Page 11

An Example of a Data Communication Conversation

Syntax

The computer (the master) initiates an

exchange with controller #2 (the remote).

The computer tells the controller to

change its set point.

The computer queries the controller for

the new set point.

computer

2 <ENQ> (#2, are you there?)

controller

2 <ACK> (I'm #2, I'm here.)

computer

<STX> = <space> SP1 <space> 500 <return> <ETX>

("Here comes a message."

"Make SP1 = 500°."

"I'm done with the message.")

controller

<ACK> ("I understand.")

computer

<STX> ? <space> SP1 <return> <ETX>

("Here comes a message."

"What is SP1 value?"

"I'm done with the message.")

controller

<ACK> ("I understand [the question].")

The controller confirms that the new set

point.

The computer ends the session.

computer

<EOT> ("That's all, go ahead.")

controller

<STX> 500 <ETX>

( "Here comes the answer."

"The value is 500°."

"I'm done with the answer.")

computer

<ACK> ("I understand [the answer].")

controller

<EOT> ("That's all, go ahead.")

computer

<DLE> <EOT> ("Disconnect, please. That's all."

[master waits])

Introduction to Data Communications, Chapter 1 Data Communications with the Watlow Series 988 Family

1.7

Page 12

Introduction

Notes

1.8

Data Communications with the Watlow Series 988 Family

Introduction to Data Communications, Chapter 1

Page 13

Chapter 2 Hardware and Wiring

Serial Hardware Interfaces

The Series 981-984, 986-989 and 996-999 controllers are factory-configured to

function in a broad variety of applications. The specifics of each controller's configuration is encoded in its model number. Depending on your unit's model number,

you have one of three hardware interfaces:

1) EIA-232 (9___-____-_R__) provides one-on-one communication with a maxi-

NOTE:

This manual applies

only to controllers

with the data

communications

option (9___-_____R__ or 9___-_____S__ or 9___-_____U__). Please use it

in conjunction with

the user's manuals.

mum network length of 50 feet connecting one controller to one computer.

2) EIA-485 (9___-____-_S__) provides a "multidrop" or multiple-device network

with up to 32 addresses with a 4,000-foot network length limit. EIA-422 provides a multidrop network for up to ten devices with a 4,000-foot network

length limit. To select the multidrop interface, enter the Setup Menu

[`SEt]. Use the up-arrow or down-arrow key to advance to the Communica-

tions Menu [COM]. Press the MODE key until the interface prompt [IntF]

appears. Select either 485 or 422.

3) EIA-232/EIA-485 (9___-____-_U__) If your controller is supplied with a "U"

board, you can select via the comms menu either EIA-232 or EIA-485 operation. The [IntF] parameter is defaulted to EIA-232. To select the multidrop

interface, enter the Setup Menu [`SEt]. Use the up-arrow or down-arrow key

to advance to the Communications Menu [COM]. Press the MODE key until

the interface prompt [IntF] appears. (Controllers equipped with the EIA-

232 interface do not require an interface selection.)

Hardware

Your Computer's Serial Interface

You can connect a data communication-equipped Series 981-984, 986-989 or 996999 to any computer with an EIA-422, EIA-232 or EIA-485 serial interface. A

personal computer with an EIA-232 serial output card, for instance, can talk to a

single EIA-232 equipped controller.

For a multiple-controller network with one personal computer, you'll need a converter to act as a bus, or multiple connection point.

For data communications serial interface converters for EIA-232 (RS-232), we

recommend either of these two suppliers:

• DATAFORTH Corp. (formerly supplied by Burr-Brown):

3331 E. Hemisphere Loop, Tuscon, AZ 85706

Tel: 1-800-444-7644, or (520) 741-1404 or Fax: (520) 741-0762

For EIA-422 (RS-422), part number: LDM 422

with a power supply and the correct 25 pin connector for your computer.

For EIA-485 (RS-485), part number: LDM 485

with a power supply and the correct 25 pin connector for your computer.

• B & B Electronics Manufacturing Company

707 Dayton Road, PO Box 1040, Ottawa, IL 61350

Tel: (815) 433-5100 or Fax: (815) 434-7094 or Web: http://www.bb-elec.com

For EIA-422/ EIA-485 (RS-422/ RS-485), part number: 485OIC

with a power supply and the correct 25 pin connector for your computer.

Hardware and Wiring, Chapter 2

Data Communications with the Watlow Series 988 Family

2.1

Page 14

Wiring

NOTE:

The Electronic

Industry Association

(EIA) RS-232

standard recommends a maximum

50-foot total pointto-point distance.

Communications Wiring

The rest of the chapter explains how to connect your controller to a computer.

Consult the instruction manual for your computer's serial port or serial card for

detailed serial port pin information. Industrial environments often contain a lot of

electrical noise. Take care to isolate your control system.

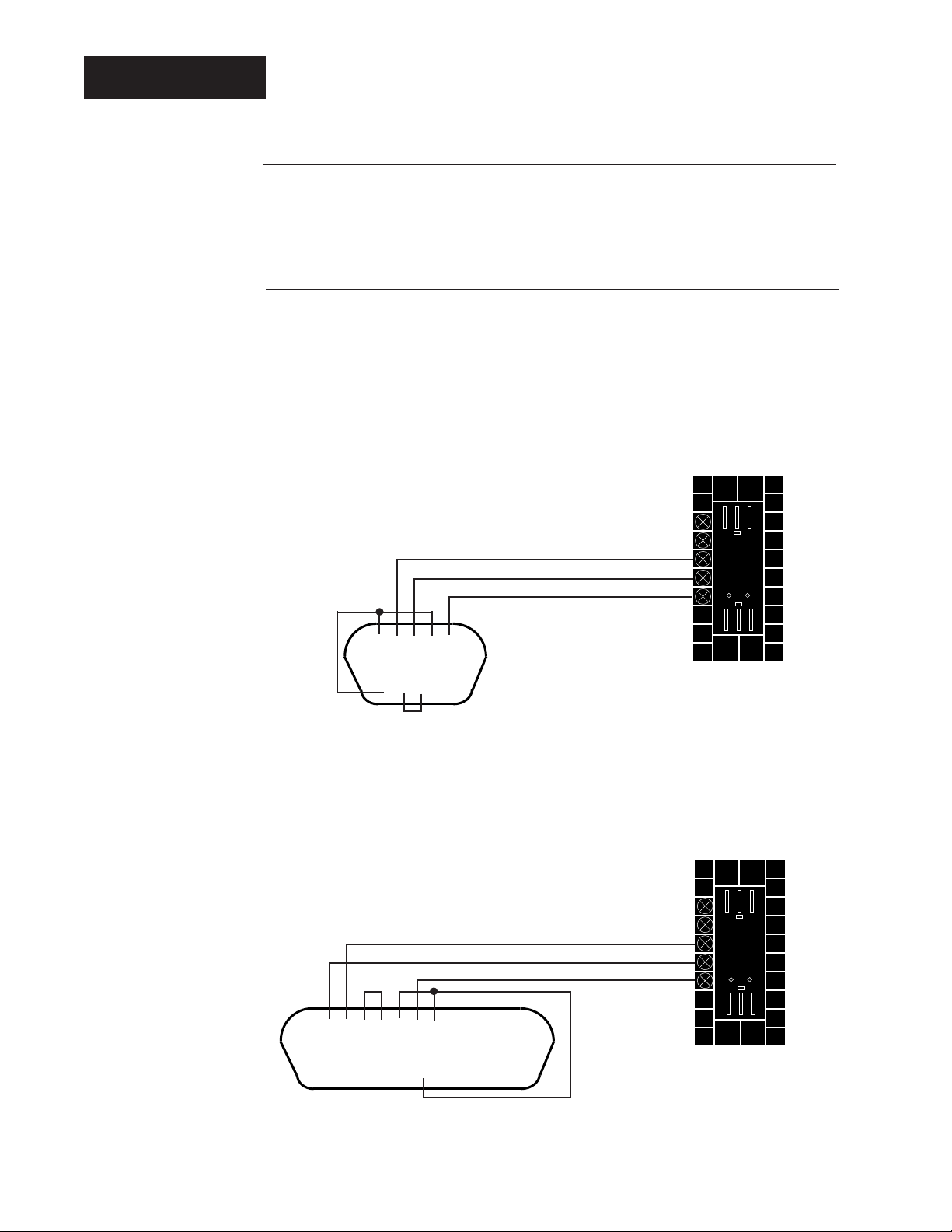

EIA-232 Interface Wiring

The EIA/-232 communications uses a three-wire, full-duplex system. There is a

separate line for transmitting data, a line for receiving data and a common line

between the computer and the controller. With EIA-232 you can have only one

controller connected to a single computer.

This diagram is a typical wiring example. The connections on the host computer

may vary, depending on the model. Refer to your computer or serial card user's

manual for specific information.

DB-9 Pinouts

1 DCD

2 receive

3 transmit

4 DTR

5 common

6 DSR

7 RTS

8 CTS

• • • • •

1 2 3 4 5

Transmit 5

Receive 6

Common 7

Figure 2.2 EIA-232 Interface

Wiring Diagrams.

6 7 8 9

• • • •

DB-9 female viewed from wire side

(typical connections with jumpers)

DB-25 Pinouts

2 transmit

3 receive

4 RTS

5 CTS

6 DSR

7 common

8 DCD

20 DTR

• • • • • • • • • • • • •

1 2 3 4 5 6 7 8 9 10 11 12 13

14 15 16 17 18 19 20 21 22 23 24 25

• • • • • • • • • • • •

DB-25 female viewed from wire side

(typical connections with jumpers)

Single Controller

Transmit 5

Receive 6

Common 7

Single Controller

2.2

Data Communications with the Watlow Series 988 Family

Hardware and Wiring, Chapter 2

Page 15

NOTE:

The Electronic

Industry Association

EIA-485 standard

recommends a

maximum total

network distance of

4,000 feet.

Wiring

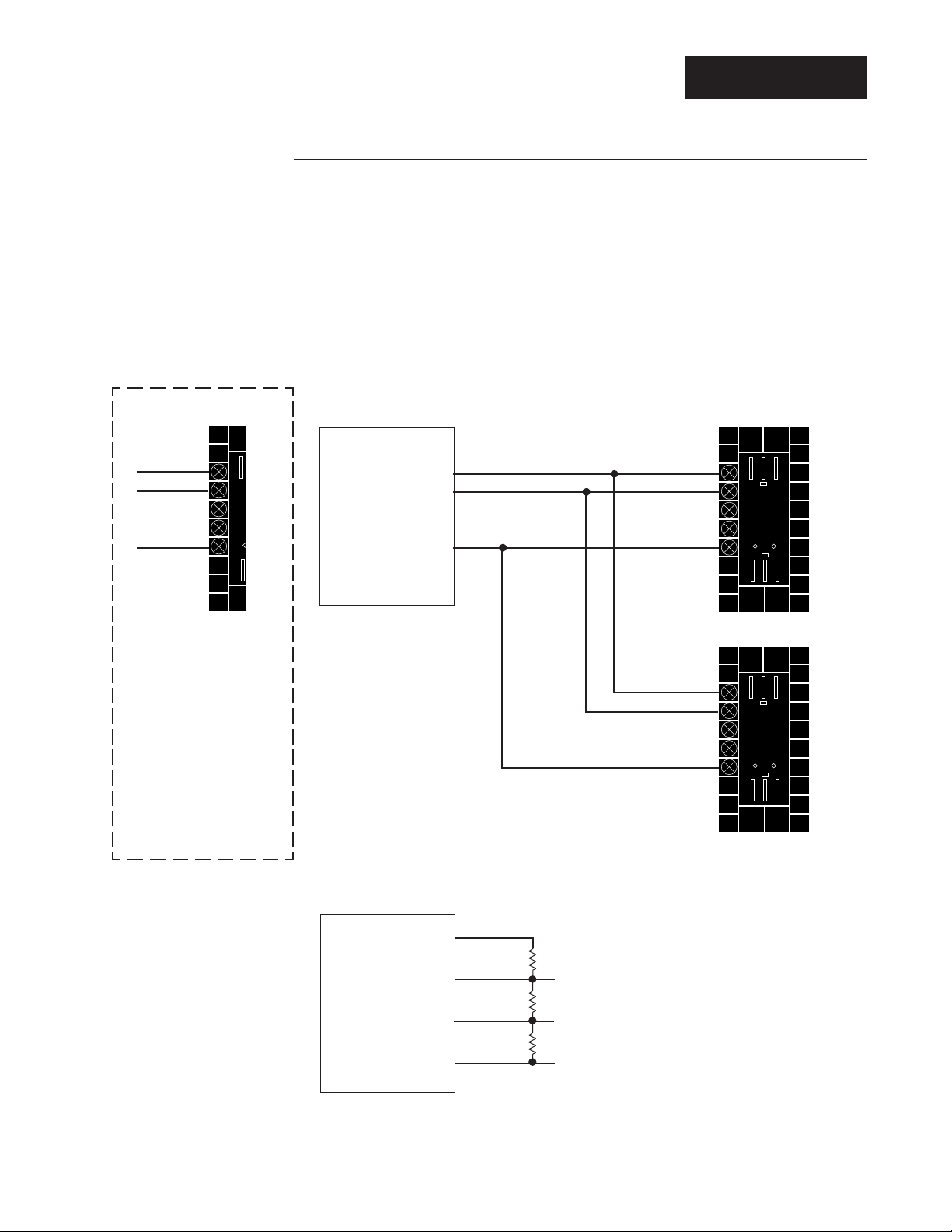

EIA-485 Interface Wiring

The EIA-485 communications uses a three-wire, half-duplex system. There are two

lines for transmitting and receiving and a common line. Only one device, the

computer or a controller, can be speaking at a time. The controller requires at

least a 7-millisecond delay between transmission and receipt of data. With

EIA-485 you can have from one to thirty-two controllers connected to a computer.

This diagram is a typical wiring example for units shipped after 1993 (see ç

Caution on this page). The connections on the host computer may vary, depending on the model. Refer to your computer user's manual for specific information.

As many as 32 units can be

connected to an EIA-485 network.

T-/R- 3

T+/R+ 4

Com 7

Controller

ç

CAUTION:

For older Series 986989 controllers with

a "date code" of

4693 or earlier,

terminal 3 is T-/R- (A)

and 4 is T+/R+ (B).

(See Diagnostics

Menu in the User's

Manual.)

B

A

Gnd

Converter Box or Card

T+/R+

T-/R-

Com

T+/R+ 3

T-/R- 4

Com 7

Controller #1

T+/R+ 3

T-/R- 4

Com 7

Controller #2

Figure 2.3 EIA-485 Interface

Wiring Diagrams.

Hardware and Wiring, Chapter 2

Converter box

or card

terminals with

termination,

pull-up and

pull-down

resistors.

+5V

Gnd

B

A

1KΩ

T+/R+

120Ω

T-/R-

1KΩ

Com

If the system does not work properly it

may need termination resistors at each

end of the network. A typical installation would require a 120-ohm resistor

across the transmit/receive terminals (3

and 4) of the last controller in the

network and the converter box or serial

card. Pull-up and pull-down resistors

may be needed to maintain the correct

voltage during the idle state.

Data Communications with the Watlow Series 988 Family

2.3

Page 16

Wiring

NOTE:

The Electronic

Industry Association

(EIA) RS-422

standard recommends a maximum

network distance of

4,000 feet.

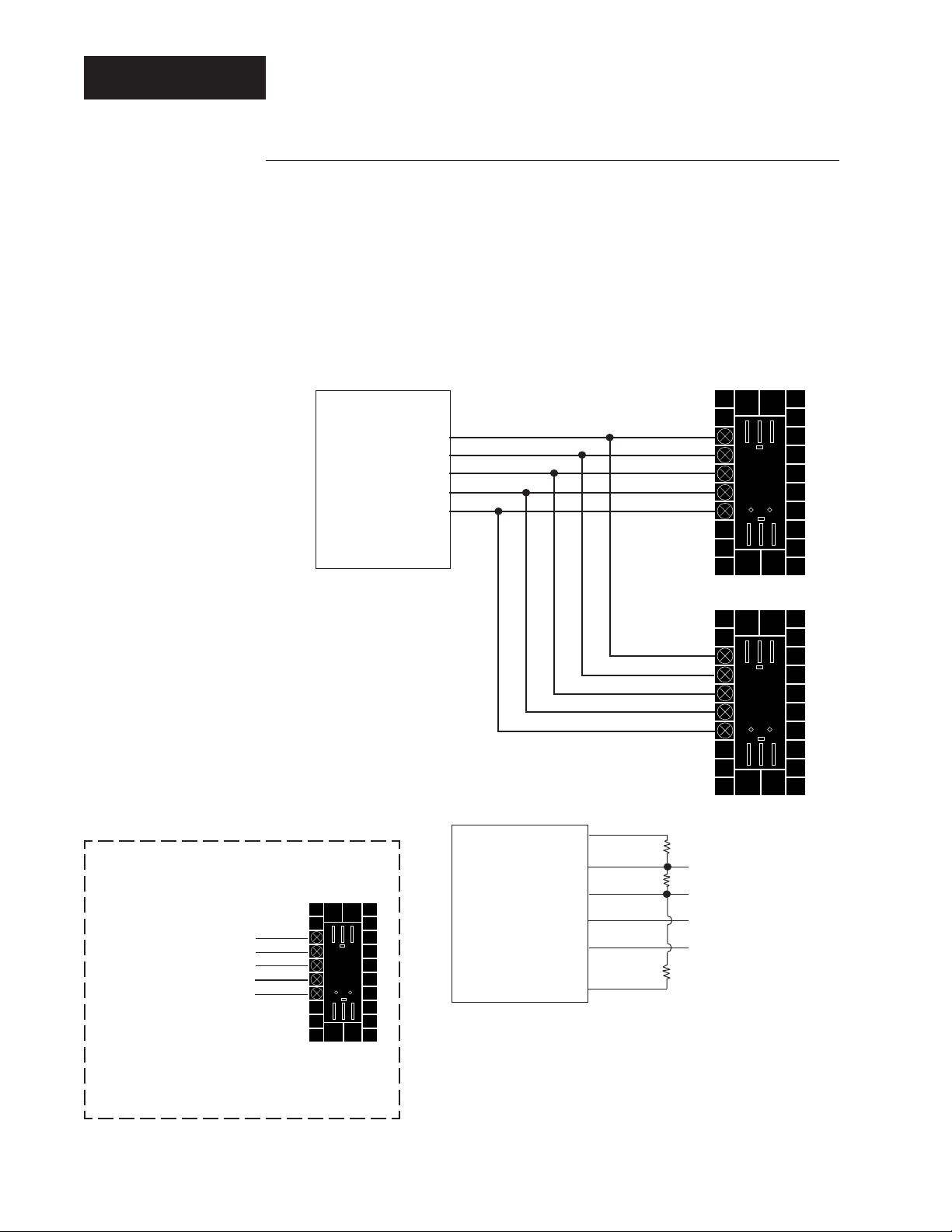

EIA-422 Interface Wiring

The EIA-422 communications uses a five-wire, full-duplex system. There are two

separate lines for transmitting, two lines for receiving and a common line between

the computer and the controller. With EIA-422 you can connect from one to ten

controllers to a single computer.

This diagram is a typical wiring example for units shipped after 1993 (see ç

Caution on this page). The connections to the converter box or computer may

vary, depending on the model. Refer to the documentation for specific information.

B'

A'

Gnd

R+

RT+

B

T-

A

Com

T+ 3

T- 4

R+ 5

R- 6

Com 7

Figure 2.4 EIA-422 Interface

Wiring Diagrams.

ç

CAUTION:

For older Series

986-989 controllers with a "date

code" of 4693 or

earlier, terminal

3 is T-, 4 is T+, 5

is R- and 6 is

R+. (See Diagnostics Menu in

the User's

Manual.)

T- 3

T+ 4

R- 5

R+ 6

Com 7

Converter Box or Card

As many as 10 units

can be connected to

an EIA-422 network.

Controller

Controller #1

T+ 3

T- 4

R+ 5

R- 6

Com 7

Controller #2

Converter

box with

termination

pull-up and

pull-down

resistors.

RD

TD

+5V

B

A

B

A

Gnd

1KΩ

240Ω

1KΩ

If the system does not work properly it may need

termination resistors across the receive A and B terminals at the converter. A typical value would be 240Ω.

Pull-up and pull-down resistors may be needed to

maintain the correct voltage during the idle state.

2.4

Data Communications with the Watlow Series 988 Family

Hardware and Wiring, Chapter 2

Page 17

Chapter 3 Communications Setup

Connecting the Controller and the Computer

Remove power from both the controller and your computer before connecting them

together. Assemble a cable and the appropriate wiring at your computer. Refer to

the wiring in Chapter 2. As soon as you connect the data communications lines,

you may apply power to your system.

Software Protocols and Device Addresses

There are three communications protocols you may use. Depending on the type of

network you need, you must use the correct combination of interface and protocol.

Modbus works with all three interfaces.

To run a network with multiple devices Watlow uses the ANSI X3.28 Protocol

(based on ANSI X3.28 - 1976 Subcategories 2.2, and A.3) with the EIA-422 and

EIA-485 interface. ANSI X3.28 Protocol provides a response to every message. It

will also work with the EIA-232 interface, but you are limited to one controller and a

host computer.

Setup

To run a two-device network with an EIA-232 interface, you can also use XON/

XOFF Protocol, a simpler protocol. XON/XOFF will also work with the EIA-422 and

EIA-485 interface, but the network is limited to two devices — one computer

and one controller. XON/XOFF Protocol does not require a device to respond to

messages it receives.

To select the protocol, go to the Setup Menu [`SEt]; use the up-arrow or downarrow key to advance to the Communications Menu [COM]. Press the MODE key

until the protocol prompt [Prot] appears. Select either [FULL], for ANSI X3.28 2.2

- A.3, [``On] for XON/XOFF, or [Mod], for Modbus RTU.

If you are using ANSI X3.28 Protocol, choose an address number for each controller using the address prompt [Addr], which follows the protocol prompt [Prot].

This prompt will only appear if [Prot] is set to [FULL] or [Mod].

Communications Software

Watlow offers a Windows based configuration and monitoring software package for

the 988/989 controllers. We also offer a simple MS-DOS™ communications

demonstration program for the Series 981-984, 986-989, and 996-999. Ask your

Watlow field sales representative for a copy of the "Comm 4" program, or you can

download the files ("comms4.zip" and "comms4tm.zip" and com5set.exe) from the

Watlow BBS, (507) 454-3958.

Communications Setup, Chapter 3

Data Communications with the Watlow Series 988 Family

3.1

Page 18

Setup

(

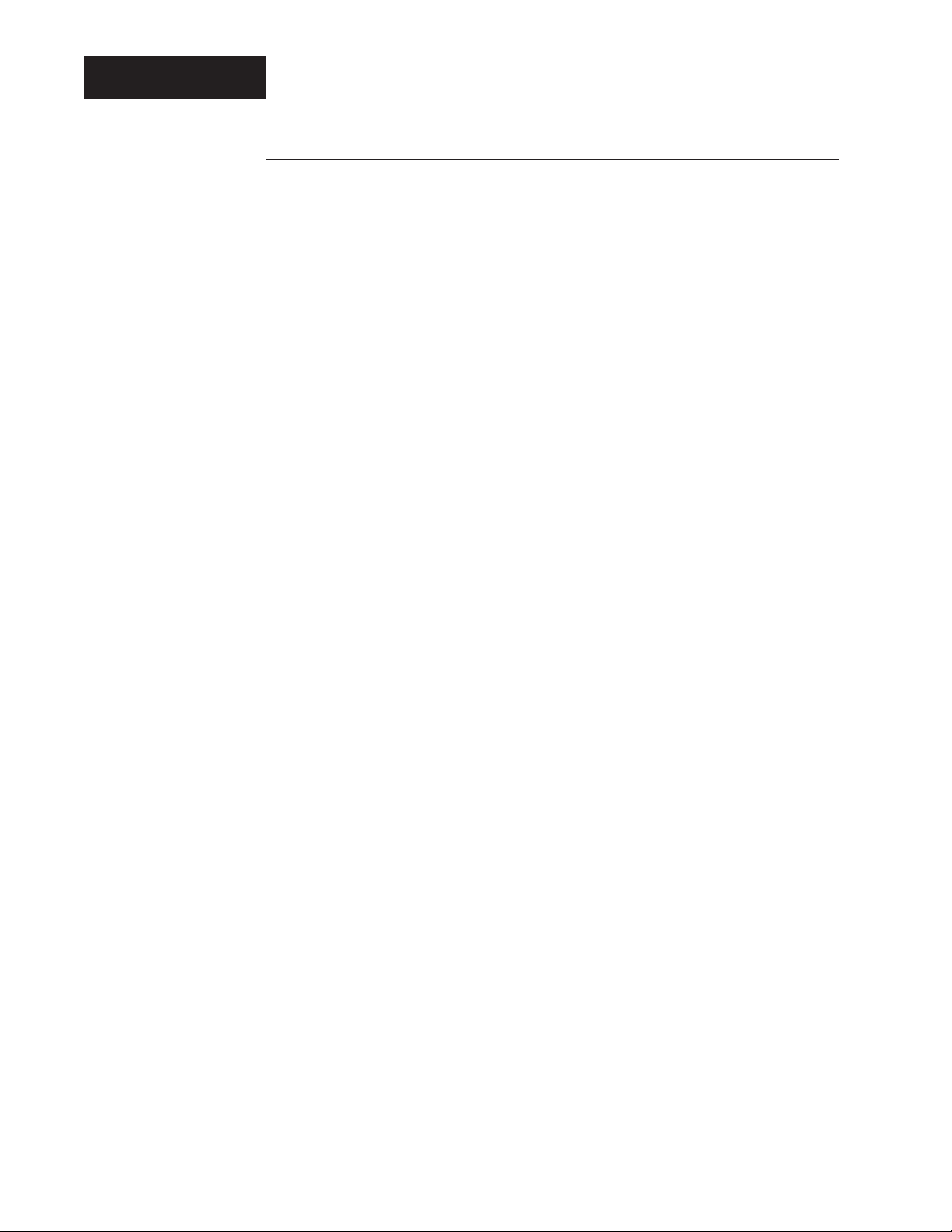

Figure 3.2 The Communications

Menu.

W

A

TL

W

PROCESS

L1 L2 L3 L4

DEV

DISPLAY

% OUT

HOLD

MODE

SERIES 988

RUN

Communications)

Baud rate

Data bits and parity

Protocol type

Address

Interface type

[COM]

(COM)

bAUd

[bAUd]

dAtA

[dAtA]

Prot

[Prot]

Addr

[Addr]

intF

[IntF]

( )

( )

( )

( )

( )

Setup at the Controller's Front Panel

• Press the < and > keys simultaneously for three seconds.

• The [SEt] prompt appears in the lower display.

• Press the < or > key until the [COM] prompt appears.

• Press the µ key to advance through the Communications Menu.

• Press the < or > key to select communications values from the table below.

NOTE:

Selecting [Mod]

automatically sets

[dAtA] to [``8n].

Table 3.2 Communications

Menu Prompts and

Descriptions.

• Document the setup parameters for each device on your network and label each

device.

• Press the ∂ key to exit.

Prompt Appears if… Range Factory

default

[bAUd] comms unit (Baud rate) [`300], [`600],

[1200], [2400], [4800], [9600] [9600]

[dAtA] comms unit [``7o] = 7 data bits, odd parity [``7o]

[``7E] = 7 data bits, even parity (see note)

[``8n] = 8 data bits, no parity

(Start bit = 1) (Fixed)

(Stop bit = 1) (Fixed)

[Prot] comms unit [FULL] = ANSI X3.28 2.2 - A.3 [FULL]

[``On] = XON / XOFF

[Mod] = Modbus

[Addr] [Prot] = [FULL] 0 to 31 (ASCII) if [IntF] = [`485] [```0]

or 0 to 9 (ASCII) if [IntF] = [`422] [```0]

[Prot] = [Mod] 1 to 247 if [IntF] = [Mod] [```1]

[IntF] "S" hardware [`485] = EIA-485 Interface type [`485]

[`422] = EIA-422 Interface type

[IntF] "U" hardware [`232] = EIA-232 Interface type [`232]

[`485] = EIA-485 Interface type

3.2

Data Communications with the Watlow Series 988 Family

Communications Setup, Chapter 3

Page 19

Chapter 4 Sending Commands

General Message Syntax

As soon as you link the devices, you can talk to the controllers using ASCII characters. They will respond to any Setup or Operation menu prompt, plus some others.

The controller will respond to either upper or lower case ASCII characters from

your computer.

Both protocol/interface combinations will respond to the general syntax if the

commands or queries are correctly transmitted. However, the ANSI X3.28 Protocol

requires beginning and ending characters, and the XON/XOFF protocol requires

ending characters.

Message Syntax

Messages from your computer to a controller must take this general form.

Command <space> data.1 <space> data.2 <space> data.3... data.N

"Command" is a character string. The brackets "<" and ">" enclose a non-literal

ç

CAUTION:

Avoid writing <=>

continuously, such

as ramping set

points or repetitive

loops, to the

controller's

EEPROM memory.

Continuous writes

may result in

premature control

failure, system

downtime and

damage to processes and equipment.

description. The space character, <space> or <sp>, is simply a delimiter, an ASCII

space character (hex 20). "Data fields" are prompts and values specific to the

command. The number of data fields depends on the particular command. The first

argument or parameter is abbreviated, "data.1," the next is "data.2," and so on.

In the syntax explanations that follow, we show you the specific arguments for each

command. It will speed the process if you remember this general syntax.

Data Rules

Data fields are prompts and values specific to particular commands. Specific data

for each command for each type of controller is listed after this chapter. These

rules govern their use:

• Data will include the characters 0 through 9; a decimal point if needed; or a

positive or negative sign.

• Data can include up to seven characters. A "+" or "-" sign, if used, must be first.

• Data can use leading zeros, up to the seven-character limit.

• The data.1 portion of message can be up to four total characters.

Sending Commands, Chapter 4

Command List

These commands, represented by their respective ASCII characters, will enable

you to program the controller from your computer. More detailed descriptions of the

commands are in Chapters 5, 6 and 7.

? Returns the value of a specific prompt from the controller.

= Sets a specific prompt in the controller to a specific value.

Data Communications with the Watlow Series 988 Family

4.1

Page 20

XON/XOFF

Example Format

This manual presents command examples in a consistent format. Information

bracketed by < > indicates a description, rather than literal characters. We show

each ASCII character that you must transmit to the controller, including space

between the characters. (A <space>, or <sp>, is itself an ASCII character, hex 20).

For instance, in the example below, you want to set the Alarm 2 Low [A2LO]

prompt to 500°. Notice how the syntax uses the "=" command.

= <space> A2LO <space> 500 <carriage return>

To send this message, key the ASCII characters into your computer, or write them

into your program. Remember, your computer will send the ASCII character string

for the number, not an actual number. The hex string for the line looks like this:

3D2041324C4F203530300D.

Notice that we have not mentioned protocol here, or any characters added to this

syntax by a protocol. With XON/XOFF, the message above can be transmitted with

only an additional carriage return <cr> (hex 0D) character at the end. However, the

ANSI X3.28 Protocol requires an envelope of Start of Text <STX> (hex 02) and

End of Text <ETX> (hex 03) characters around the information you see above. You

will learn how to do that in the following pages.

XON/XOFF Protocol for EIA-232

XON/XOFF (flow control) protocol allows a communicating device (either a

controller or the host) to suspend transmission of all messages from the other

device, and then to continue transmission when it's again ready.

The device that needs to suspend transmission sends the XOFF character

(hex 13) to stop the other device's transmission, and XON (hex 11) to restart it.

Any character will restart the transmission, but to avoid confusion use only the

XON character.

Messages transmit according to the syntax described in the XON/XOFF formats

that follow for each command.

The XON/XOFF protocol requires a carriage return <cr> character

(hex 0D) at the end of every message.

How To Communicate Using XON/XOFF

XON/XOFF protocol is used when one master is networked with only one controller. Your personal computer must generate the master’s messages.

4.2

Data Communications with the Watlow Series 988 Family Sending Commands, Chapter 4

Page 21

"=" Command Example

ANSI X3.28

ç

CAUTION:

Avoid writing <=>

continuously, such

as ramping set

points or repetitive

loops, to the

controller's

EEPROM memory.

Continuous writes

may result in

premature control

failure, system

downtime and

damage to processes and equipment.

Master:

Remote:

master must stay off line.)

Remote:

Note: The commands IN1, IN2 and CF may take up to two seconds to return this

character. Do not send another message until this character is received.)

“?” Command Example”

Master:

Remote:

off-line.)

Remote:

another message once the <cr> is received.)

message.)

For maximum communications speed:

• Do not use a typical delay to wait before looking for a response.

• Scan for returned characters until the correct response is received.

• Use a time out to end a session if a correct response is not received in three

= <sp> A2LO <sp> 500 <cr> (Set the A2LO prompt value to 500.)

<XOFF> (This will be returned once the device starts processing. The

<XON> (Processing is done. The master may send a new message.

? <sp> A2LO <cr> (Request the A2LO prompt value.)

<XOFF> (The remote is preparing the response. The master must stay

<XON> 500 <cr> (The value is returned and the master may send

or

<XON> (The message was not understood. The master may send a new

seconds.

How to Communicate Using ANSI X3.28

The ANSI X3.28 protocol provides high quality communications by requiring a

response to every message. With a multiple-device or "multidrop" network, this

protocol prevents confusion among the separate devices. Furthermore, if noise

occurs somewhere in the system, no prompt will change because noise cannot

comply with the protocol.

By placing messages inside a protocol envelope, the messages are protected. In

the following examples you'll see how this works.

ANSI X3.28 protocol rules:

• Every remote device must have a unique address.

• Only the master can initiate a communication session, by addressing a specific

remote device.

• Every message must be framed with an <STX> (start of transmission) character

and an <ETX> (end of transmission) character.

• The master must wait for the remote device to respond to every message within a

reasonable period. If no response occurs, retry the connection or pursue error

recovery.

Sending Commands, Chapter 4

Data Communications with the Watlow Series 988 Family

4.3

Page 22

ANSI X3.28

Table 4.4 Address to ASCII

Conversion for ANSI

X3.28 Protocol.

Device Addresses

A Watlow EIA-422 multidrop network can handle up to 10 devices with this protocol. EIA-485 can handle up to 32 devices. Set the address number of the controller

with the address prompt [Addr] under the Setup Menu [`SEt].

ASCII

Address Equivalent

00

11

22

33

44

55

66

77

88

99

10 A

11 B

12 C

13 D

14 E

15 F

16 G

17 H

18 I

19 J

20 K

21 L

22 M

23 N

24 O

25 P

26 Q

27 R

28 S

29 T

30 U

31 V

4.4

Data Communications with the Watlow Series 988 Family Sending Commands, Chapter 4

Page 23

ANSI X3.28

ANSI X3.28 Protocol Example

This example demonstrates communication between a master device and a remote

device at address 4. Your personal computer must generate the master’s messages.

Establish Communications Link

Master:

Remote:

End Communications Link

Master:

Remote:

“=” Command Example

Master:

Remote:

Note: The commands IN1, IN2 and CF may take up to 2 seconds to return this character.

Do not send another message until this character is received.)

“?” Command Example

Master:

Remote:

not send the <EOT> until this character has been received.)

Master:

Remote:

send a response until the <ETX> has been received.)

4 <ENQ> (Attempt to link with device 4.)

4 <ACK> (The link is established.)

<DLE> <ENQ> (End data link.)

No response.

<STX> = <sp> A2LO <sp> 500 <ETX> (Set A2LO prompt value to 500.)

<ACK> (This will be returned once the unit has completed the value change.

<STX> ? <sp> A2LO <ETX> (Request the A2LO prompt value.)

<ACK> (This will be returned once the device has the response ready. Do

or

<NAK> (The command was not understood. Re-send corrected message.)

<EOT> (The host gives the device permission to respond.)

<STX> 500 <ETX> (The device sends back the requested value. Do not

Master:

Remote:

until this character has been received.)

For maximum communications speed:

• Do not use a typical delay to wait before looking for a response.

• Scan for returned characters until the correct response is received.

• Use a time out to end a session if a correct response is not received in three seconds.

• Protocols are not flexible. Outside of the <STX> <ETX> framing only the defined

• End the communications link and re-establish it with <DLE> and <ENQ> only when

Sending Commands, Chapter 4

<ACK> (The host received the message correctly.)

or

<NAK> (The host did not understand the response.Device will re-send it.)

<EOT> (The device returns control to the host. Do not send a new message

Try again later.

protocol characters are allowed. Some programming languages add <cr> to the end

of transmissions. This must be disabled.

changing to a new device at a different address. The master can communicate

repeatedly with a specific device once the initial data link is established.

Data Communications with the Watlow Series 988 Family

4.5

Page 24

Modbus RTU

NOTE:

Modbus register

addresses are

listed in the

Controller Prompt

Table later in this

chapter and in the

Modbus RTU

Address Table at

the end of this

chapter.

Modbus Remote Terminal Unit (RTU)

Modbus RTU, available on the 988 family of controllers, expands the communications ability of the controller by enabling a computer to read and write directly to

registers containing the controller’s parameters.

Because of the wide array of choices available for setting up the 988 family of

controllers, only a subset of the prompts contain parameters in a given situation. The

Series 982, 988 and 998 User’s Manuals explain the interrelations between prompts.

If you try to write to an inactive prompt the controller will return an illegal data address message (02). (See “Exception Responses,” pg. 4.9.)

If you already have a software application that uses Modbus, you can simply skip to

the Temperature/process Controller Prompt Table or the Modbus RTU Address

Table in this chapter for the address information your program will need. The rest of

this section on the Modbus provides information for writing a software application that

uses Modbus.

Writing a Modbus Application

You need to code messages in eight-bit bytes, with no parity bit. Negative parameter

values must be written in two's complement format. Parameters are stored in twobyte registers accessed with read and write commands to a relative address.

Messages are sent in packets that are delimited by a pause at least as long as the

time it takes to send 30 bits. To determine this time in seconds, divide 30 by your

baud rate.

Because changing some parameters automatically changes or defaults other parameters, use the Complete Parameter Download Sequence table in this chapter to

order write commands.

Using a controller address of 0x00 for a write command broadcasts that command to

all the controllers in the network. This is a powerful feature if all the controllers on a

network use all or most of the same parameters. No response is given to broadcast

messages. Be sure to read each control to ensure it has received the command.

4.6

Packet Syntax

Each message packet begins with a one-byte controller address, from 0x01 to 0xF7.

The second byte in the message packet identifies the message command: read

(0x03 or 0x04); write (0x06 or 0x10); or loop back (0x08).

The next n bytes of the message packet contain register addresses and/or data.

The last two bytes in the message packet contain a two-byte Cyclical Redundancy

Checksum (CRC) for error detection.

Packet format: nn | nn | nnnn… | nnnn

∆∆∆∆ ∆∆

address

command

registers and/or data

CRC

Data Communications with the Watlow Series 988 Family Sending Commands, Chapter 4

Page 25

NOTE:

Because the read

command can

only read 32

registers, the high

byte for the

number of registers will always be

0.

Modbus RTU

Read Multiple Registers Command (0x03 or 0x04)

This command returns from 1 to 32 registers.

Packet sent to controller:| nn | 03 | nnnn | 00 nn | nn nn |

∆∆∆∆∆∆∆∆

controller address (one byte)

read command (0x03 or 0x04)

starting register high byte

starting register low byte

number of registers high byte (0x00)

number of registers low byte

CRC low byte

CRC high byte

Packet returned by controller: | nn | 03 | nn | nn nn … nn nn | nn nn |

∆∆∆∆∆∆∆∆∆

controller address (one byte)

read command (0x03 or 0x04)

number of bytes (one byte)

first register data low byte

first register data high byte

…

…

register n data high byte

register n data low byte

CRC low byte

CRC high byte

Example (988 only): Read register 0 (model number) of the controller at address 1.

Sent: 01 03 00 00 00 01 84 0A

Received: 01 03 02 03 DC B9 2D

Message: 988 (0x03DC).

Sending Commands, Chapter 4

Example (988 only): Read register 1 and 2 (Process 1 and 2 values) of controller at

address 5.

Sent: 05 03 00 01 00 02 94 4F

Received: 05 03 04 00 64 00 C8 FF BA

Message: 100 (0x0064) and 200 (0x00C8).

Write to a Single Register Command (0x06)

This command writes a parameter to a single register. The controller will echo back

the command. An attempt to write to a read-only parameter returns an illegal data

address error (0x02). (See “Exception Responses,” pg. 4.9.)

Packet sent to controller:| nn | 06 | nn nn | nn nn | nn nn |

∆∆∆∆∆∆∆∆

controller address (one byte)

write to a register command (0x06)

register high byte

register low byte

data high byte

data low byte

CRC low byte

CRC high byte

Data Communications with the Watlow Series 988 Family

4.7

Page 26

Modbus RTU

NOTE:

Because the read

command can only

read 32 registers,

the high byte for

the number of

registers will

always be 0.

Example (988 only): Set register 7 (SPI) to 200 (0x00C8) on controller at address 9.

Sent: 09 06 00 07 00 C8 38 D5

Received: 09 06 00 07 00 C8 38 D5

Write to Multiple Registers Command (0x10)

This command actually writes a parameter to only a single register. An attempt to

write to a read-only parameter returns an illegal data address error (0x02). (See

“Exception Responses,” pg. 4.9.)

Packet sent to controller:| nn | 10 | nnnn | 00 01 | 02 | nn nn | nn nn |

∆∆∆∆∆∆∆∆∆∆∆

controller address (one byte)

write to multiple registers command (0x10)

starting register high byte

starting register low byte

number of registers to write high byte (0x00)

number of registers to write low byte (must be 0x01)

number of data bytes (must be 0x02)

data high byte

data low byte

CRC low byte

CRC high byte

Packet returned by controller: | nn | 10 | nnnn | 00 01 | nn nn |

∆∆∆∆∆∆∆∆

controller address (one byte)

write to multiple registers command (0x10)

starting register high byte

starting register low byte

number of registers to write high byte (0x00)

number of registers to write low byte (must be 0x01)

CRC low byte

CRC high byte

4.8

Loop Back Command (0x08)

This command simply echoes the message. This serves as a quick way to check

your wiring.

Packet sent to controller:| nn | 08 | nnnn | nn nn |

∆∆∆∆∆∆

controller address (one byte)

loop back command (0x08)

data high byte

data low byte

CRC low byte

CRC high byte

Example: Run loop back test on controller at address 40 (0x28).

Sent: 28 08 55 66 77 88 31 B7

Received: 28 08 55 66 77 88 31 B7

Data Communications with the Watlow Series 988 Family Sending Commands, Chapter 4

Page 27

Commands

Exception Responses

When a controller cannot process a command it returns an exception response and

sets the high bit (0x80) of the command.

0x01 illegal command

0x02 illegal data address

0x03 illegal data value

Packet returned by controller: | nn | nn | nn | nn nn |

∆∆∆∆∆

controller address (one byte)

command + 0x80

exception code (0x01 or 0x02 or 0x03)

CRC low byte

CRC high byte

Messages with the wrong format, timing or CRC are ignored. A read command sent

to an inactive parameter returns 0x0000.

Example: Exception 01 - Command 02 is not supported.

Sent: 01 02 00 01 00 02 A8 0B

Received: 01 82 01 81 60

Example: Exception 02 - The parameter at register 45 (0x002D) is inactive.

Sent: 01 06 00 2D 00 01 D8 C3

Received: 01 86 02 C3 A1

Example: Exception 03 - Cannot write 12,000 (0x2EE0) to register 7, out of range,

illegal data value.

Sent: 01 06 00 07 2E E0 24 23

Received: 01 86 03 02 61

Sending Commands, Chapter 4

Data Communications with the Watlow Series 988 Family

4.9

Page 28

Commands

Cyclical Redundancy Checksum (CRC) Algorithm

This C routine, calc_crc(), calculates the cyclical redundancy checksum, CRC, for a

string of characters. The CRC is the result of dividing the string by 0xA001. Modbus

applications calculate the packet’s CRC then append it to the packet.

#define POLYNOMIAL 0xA001;

unsigned int calc_crc(unsigned char *start_of_packet, unsigned char

*end_of_packet)

{

unsigned int crc;

unsigned char bit_count;

unsigned char *char_ptr;

/* Start at the beginning of the packet */

char_ptr = start_of_packet;

/* Intitialize CRC */

crc = 0xffff;

NOTE:

When the CRC is

added to the

message packet

be sure to put the

low byte before

the high byte.

/* Loop through the entire packet */

do{

/* Exlusive-OR the byte with the CRC */

crc ^= (unsigned int)*char_ptr;

/* Loop through all 8 data bits */

bit_count = 0;

do{

/* If the LSB is 1, shift the CRC and XOR the poynomial mask with the CRC */

if(crc & 0x0001){

crc >>= 1;

crc ^= POLYNOMIAL;

}

/

* If the LSB is 0, shift the CRC only */

else{

crc >>= 1;

}

} while(bit_count++ < 7);

} while(char_ptr++ < end_of_packet);

return(crc);

}

4.10

Data Communications with the Watlow Series 988 Family Sending Commands, Chapter 4

Page 29

Ramping Controller Prompt Table

Chapter 5 Command Summary of the Series 981-984

Name Description Read (?) and/or Write (=) Syntax Range

data.1 data.2

Modbus

Address

Complete Parameter Download Sequence

When you download a complete set of parameters to a controller, you must load them

in this order. The user's manual has more information about prompt interaction.

ç

CAUTION:

Entering com-

*IN1

*IN2

RTD1

DFL

*CF

OT1

OT2

OT3

DEC1

RL1

RH1

CAL1

FTR1

RL2

RH2

CAL2

HUNT

PRC1

HYS1

PRC2

HYS2

AL2

LAT2

SIL2

AL3

HYS3

LAT3

SIL3

AOUT

PRC3

ARL

ARH

ACAL

ERR

EI1

EI2

ABSP

ANUN

LOP

HIP

ATSP

PTYP

GSD

POUT

IDSP

PSTR

A2LO

A2HI

A3LO

A3HI

PB1

RE1

IT1

RA1

DE1

CT1

PB2

RE2

IT2

RA2

DE2

CT2

DB

ENT3

SP1

LOC

mands out of

sequence will

produce unexpected results,

because some

prompts change

the values of other

prompts. Copy this

page and use the

checkboxes.

Table 5.1 Download

Sequence.

981, 982,

983, 984

* Wait at least two seconds after executing this command before going on to the next command.

Command Summary Series 981-984, Chapter 5 Data Communications with the Watlow Series 988 Family

5.1

Page 30

Ramping Controller Prompt Table

Name Description Read (?) and/or Write (=) Syntax Range

data.1 data.2

983, 984

Modbus

Address

Run/Hold Mode and Prompt Accessibility

Most Series 981-984 prompts are accessible via data communications while the

981, 982,

controller is in its hold mode. Several are accessible when the controller is in either

run or hold. A few are accessible only in the run mode. You can monitor the

controller’s mode with the RHS command.

ç

CAUTION:

Sending the Series

981-984 an invalid

prompt for its

present mode (run

or hold) will result

in a data communication error

code ER2. Use the

RHS prompt to

monitor the

controller mode.

Table 5.2 Run/Hold Mode

Commands.

Table 5.2 identifies the prompts accessible in run or hold, and those available in

run only. Others not specifically identified are accessible in the hold mode only.

RUN Only Mode RUN or HOLD MODE

? CSP ? ALM

? EJC ? C1

? ENSP ? C2

? MTR* ? ENT3

= HOLD 1 ? ENT4

Resetting the communication parameters is valid only in the hold mode.

* This command is accessible only in the run mode for software revisions before and

including REV H.

** These commands are accessible in the run and hold modes for software revisions

after and including REV I.

? ER

? ER2

? RHS

? SP1

? DEV**

? MTR**

? PWR**

= MOD x

= SP1

5.2

Data Communications with the Watlow Series 988 Family Command Summary Series 981-984, Chapter 5

Page 31

Ramping Controller Prompt Table

Command Summary Series 981-984 Data Communications

Name Description Read (?) and/or Write (=) Syntax Range

data.1 data.2

Modbus

Address

Name Description Read (?) and/or Write (=) Syntax Range

data.1 data.2

Modbus

Address

A2HI Output 2 Alarm High ? <sp> A2HI <cr> Process: A2LO to sensor high range

322 = <sp> A2HI <sp> data.2 <cr> Deviation: 0 to 9999°

A2LO Output 2 Alarm Low ? <sp> A2LO <cr> Process: sensor low range to A2HI

321 = <sp> A2LO <sp> data.2 <cr> Deviation: -999 to 0°

A3HI Output 3 Alarm High ? <sp> A3HI<cr> Process: A3LO to sensor high range

341 = <sp> A3HI <sp> data.2 <cr> Deviation: 0 to 9999°

A3LO Output 3 Alarm Low ? <sp> A3LO <cr> Process: sensor low range to A3HI

340 = <sp> A3LO <sp> data.2 <cr> Deviation: -999 to 0°

ABSP Abort Set Point ? <sp> ABSP <cr> off

1211 = <sp> ABSP <sp> data.2 <cr> RL to RH

ACAL Calibration Offset for ? <sp> ACAL <cr> -999°F to 999°F

746 Retransmit Output = <sp> ACAL <sp> data.2 <cr> -555°C to 555°C

AL2 Alarm 2 Type ? <sp> AL2 <cr> 0 = Process Alarm, Input 1

719 = <sp> AL2 <sp> data.2 <cr> 1 = Deviation Alarm, Input 1

AL3 Alarm 3 Type ? <sp> AL3 <cr> 0 = Process Alarm, Input 1

736 = <sp> AL3 <sp> data.2 <cr> 1 = Deviation Alarm, Input 1

ALM Alarm Status ? <sp> ALM <cr> 0 = No alarms occurring (0000 0000)

106 (Writing a 0 clears = <sp> ALM <sp> 0 <cr> Bit 1 = A2LO (0000 0001)

or next alarm.) Bit 2 = A2HI (0000 0010)

110 Bit 3 = A3LO (0000 0100)

AMB Ambient Terminal ? <sp> AMB <cr> Input 1 terminals in 0.0°F

1500 Temperature

Rate: 0 to 9999°/minute

Default: RH, 999°, or 999°/min.

Rate: -999 to 0°/minute

Default: RL, -999°, or -999°/min.

Rate: 0 to 9999°/minute

Default: RH, 999°, or 999°/min.

Rate: -999 to 0°/minute

Default: RL, -999°, or -999°/min.

999 to 999 units

Default: 0°F, 0°C, or 0 units

2 = Rate Alarm, Input 1

Default: 0

2 = Rate Alarm, Input 1

Default: 0

Bit 4 = A3HI (0000 1000)

106 = Alarm 2

0 = off

1 = HI

2 = LO

110 = Alarm 3

0 = off

1 = HI

2 = LO

Table 5.3 -

A2HI to AMB

ç

CAUTION:

Avoid writing <=>

continuously, such

as ramping set

points or repetitive

loops, to the

Series 981-984

EEPROM memory.

Continuous writes

may result in

premature control

failure, system

downtime and

damage to processes and

equipment.

NOTE:

The number of

decimal places

returned by many

of these commands is determined by the DEC1

or IN1 setting.

(This does not

apply to Modbus

Protocol.)

981, 982,

983, 984

Command Summary Series 981-984, Chapter 5 Data Communications with the Watlow Series 988 Family

5.3

Page 32

Ramping Controller Prompt Table

Name Description Read (?) and/or Write (=) Syntax Range

data.1 data.2

983, 984

Table 5.4 -

ANUN to DE1

981, 982,

ç

CAUTION:

Avoid writing <=>

continuously, such

as ramping set

points or repetitive

loops, to the

Series 981-984

EEPROM memory.

Continuous writes

may result in

premature control

failure, system

downtime and

damage to processes and

equipment.

NOTE:

The number of

decimal places

returned by many

of these commands is determined by the DEC1

or IN1 setting.

(This does not

apply to Modbus

Protocol.)

Modbus

Address

ANUN Alarm Annunciation ? <sp> ANUN <cr> 0 = off

725 = <sp> ANUN <sp> data.2 <cr> 1 = on

AOUT Analog Output 3 ? <sp> AOUT <cr> 0 = Retransmit Process Input 1

743 Retransmit Function = <sp> AOUT <sp> data.2 <cr> 1 = Retransmit Set Point 1

ARH Retransmit ? <sp> ARH <cr> ARL to 9999

745 Range High = <sp> ARH <sp> data.2 <cr> Default: RH1 or RH2 per AOUT

ARL Retransmit ? <sp> ARL <cr> -999 to ARH

744 Range Low = <sp> ARL <sp> data.2 <cr> Default: RL1 or RL2 per AOUT

ATSP Auto-tune ? <sp> ATSP <cr> 50 to 150%

304 Set Point % = <sp> ATSP <sp> data.2 <cr> Default: 90%

AUT Auto-tune ? <sp> AUT <cr> 0 = No auto-tuning

305 = <sp> AUT <sp> data.2 <cr> 1 = Tune PID

C1 Input 1 Value ? <sp> C1 <cr> Based on IN1 range ; RL1 to RH1

100

C2 Input 2 Value ? <sp> C2 <cr> Based on IN2 range ; RL2 to RH2

104

CAL1 Input 1 Calibration ? <sp> CAL1 <cr> -999°F to 999°F

605 Offset = <sp> CAL1 <sp> data.2 <cr> -555°C to 555°C

CAL2 Input 2 Calibration ? <sp> CAL2 <cr> -999°F to 999°F

615 Offset = <sp> CAL2 <sp> data.2 <cr> -555°C to 555°C

CF Degrees Select ? <sp> CF <cr> 0 = Display °F

901 Display Loop = <sp> CF <sp> data.2 <cr> 1 = Display °C

CSP Current Profile ? <sp> CSP <cr> RL1 to RH1

1202 Set Point

CT1 Cycle Time ? <sp> CT1 <cr> S.S. relay or open col:

506 Output 1 = <sp> CT1 <sp> data.2 <cr> 0.0 = Burst firing, or

CT2 Cycle Time ? <sp> CT2 <cr> S.S. relay or open col:

516 Output 2 = <sp> CT2 <sp> data.2 <cr> 0.0 = Burst firing, or

DATE Factory Test Date ? <sp> DATE <cr> xxyy

5 xx = week

DB Dead Band PID ? <sp> DB <cr> -999°F to 999°F

505 Heat/Cool = <sp> DB <sp> data.2 <cr> -555°C to 555°C

DE1 Derivative ? <sp> DE1 <cr> 0.00 to 9.99 minutes

503 Output 1 PID = <sp> DE1 <sp> data.2 <cr> Default: 0.00

Default: on

2 = off

3 = Retransmit Process Input 2

Default: 0

Default: off

-999 units to 999 units

Default: 0

-999 units to 999 units

Default: 0

Default: 0

0.1 to 999.9 sec. (time prop)

Mech relay: 5.0 to 999.9 sec.

Default: 1.0 or 10.0 sec.

0.1 to 999.9 sec. (time prop)

Mech relay: 5.0 to 999.9 sec.

Default: 1.0 or 10.0 sec.

yy = year

-999 units to 999 units

Default: 0°F, 0°C, or 0 units

5.4

Data Communications with the Watlow Series 988 Family Command Summary Series 981-984, Chapter 5

Page 33

Name Description Read (?) and/or Write (=) Syntax Range

data.1 data.2

Modbus

Address

Ramping Controller Prompt Table

981,

982,

983,

984

Command Summary Series 981-984, Chapter 5 Data Communications with the Watlow Series 988 Family

5.5

DE2 Derivative ? <sp> DE2<cr> 0.00 to 9.99 minutes

513 Output 2 PID = <sp> DE2 <sp> data.2 <cr> Default: 0.00

DEC1 Decimal Point ? <sp> DEC1 <cr> 0 = Decimal point 0

606 Process Input 1 = <sp> DEC1 <sp> data.2 <cr> 1 = Decimal point 0.0

2 = Decimal point 0.00

3 = Decimal point 0.000

Default: 0

DEV Process Deviation ? <sp> DEV <cr> Difference between SP1 and C1

211 Display Loop (IN 1)

DFL Default Unit Type ? <sp> DFL <cr> 0 = US units

900 = <sp> DFL <sp> data.2 <cr> 1 = Standard international units

EI1 Event Input 1 ? <sp> EI1 <cr> 0 = None

1060 Function = <sp> EI1 <sp> data.2 <cr> 1 = Lock out keyboard

2 = Alarm reset

3 = Turn control outputs off

4 = Hold profile

5 = Start file 1

6 = Start file 2

7 = Start file 3

8 = Start file 4

9 = ABSP

10 = Pause

11 = Waitfor Event

Default: 0

EI1S Event Input 1 Status ? <sp> EI1S <cr> 0 = Open (off)

201 1 = Closed (on)

EI2 Event Input 2 ? <sp> EI2 <cr> 0 = None

1062 Function = <sp> EI2 <sp> data.2 <cr> 1 = Lock out keyboard

2 = Alarm reset

3 = Turn control outputs off

4 = Hold profile

5 = Start file 1

6 = Start file 2

7 = Start file 3

8 = Start file 4

9 = ABSP

10 = Pause

11 = Waitfor Event

Default: 0

EI2S Event Input 2 Status ? <sp> EI2S <cr> 0 = Open (off)

213 1 = Closed (on)

EJC Elapsed Jump ? <sp> EJC <cr> 0 to 255

1203 Count

ENSP End Set Point ? <sp> ENSP <cr> RL1 to RH1

1204

ENT3 Event 3 Output State ? <sp> ENT3 <cr> 0 = off

1268 = <sp> ENT3 <sp> data.2 <cr> 1 = on

ER Error, Analog Input ? <sp> ER <cr> 0 = No error

209 (Multiple errors 1 = Input 1 A-D overflow

possible.) 2 = Input 1 overrange

3 = Input 1 underrange

4 = Input 1 A-D underflow

5 = Input 2 A-D overflow

6 = Input 2 overrange

7 = Input 2 underrange

8 = Input 2 A-D underflow

9 = Ambient error

Table 5.5 -

DE2 to ER

ç

CAUTION:

Avoid writing <=>

continuously, such

as ramping set

points or repetitive

loops, to the

Series 981-984

EEPROM memory.

Continuous writes

may result in

premature control

failure, system

downtime and

damage to processes and

equipment.

NOTE:

The number of

decimal places

returned by many

of these commands is determined by the DEC1

or IN1 setting.

(This does not

apply to Modbus

Protocol.)

Page 34

Ramping Controller Prompt Table

Name Description Read (?) and/or Write (=) Syntax Range

data.1 data.2

983, 984

Table 5.6 -

ER2 to HYS3

Modbus

Address

ER2 Error, ? <sp> ER2 <cr> 0 = No error

n/a Communications 1 = Transmit buffer overflow

981, 982,

ç

CAUTION:

Avoid writing <=>

continuously, such

as ramping set

points or repetitive

loops, to the

Series 981-984

EEPROM memory.

Continuous writes

may result in

premature control

failure, system

downtime and

damage to processes and

equipment.

NOTE:

The number of

decimal places

returned by many

of these commands is determined by the DEC1

or IN1 setting.

(This does not

apply to Modbus

Protocol.)

ERR Error, ? <sp> ERR <cr> 0 = Errors latching

607 Latching Enable = <sp> ERR <sp> data.2 <cr> 1 = Errors non-latching

FTR1 Filter Time Constant ? <sp> FTR1 <cr> -60 to 60 seconds

604 Process Input 1 = <sp> FTR1 <sp> data.2 <cr> Default: 0

GSD Guaranteed Soak ? <sp> GSD <cr> 0°F to 999°F

1205 Deviation = <sp> GSD <sp> data.2 <cr> 0°C to 999°C

HIP High Power Limit ? <sp> HIP <cr> LOP (%) to 100%

714 = <sp> HIP <sp> data.2 <cr> Default: 100 (heat/cool)

HOLD Simulate HOLD = <sp> HOLD <sp> data.2 <cr> 1 = Holds current file# and step#

1210 Key Press

HUNT Slidewire ? <sp> HUNT <cr> 0.1% to 100.0%

1905 Dead Band % = <sp> HUNT <sp> data.2 <cr> Default: 1.0%

HYS1 Output 1 Hysteresis ? <sp> HYS1 <cr> 0°F to 999°F

507 = <sp> HYS1 <sp> data.2 <cr> 0°C to 555°C

HYS2 Output 2 Hysteresis ? <sp> HYS2 <cr> 0°F to 999°F

517 = <sp> HYS2 <sp> data.2 <cr> 0°C to 555°C

720 0 units to 999 units

HYS3 Output 3 Hysteresis ? <sp> HYS3 <cr> 0°F to 999°F

737 = <sp> HYS3 <sp> data.2 <cr> 0°C to 555°C

2 = Receive buffer overflow

3 = Framing error

4 = Overrun error

5 = Parity error

6 = Talking out of turn

7 = Invalid reply error

8 = Noise error

20 = Command not found

21 = Prompt not found

22 = Incomplete command line

23 = Invalid character

24 = Number of chars. overflow

25 = Input out of limit

26 = Read only command

27 = Write allowed only

28 = Prompt not active

30 = Request to RUN invalid

31 = Request to HOLD invalid

32 = Command invalid in RUN Mode

33 = Command invalid in HOLD Mode

34 = Output 3 is not an Event

35 = Output 4 is not an Event

38 = Asterisk not allowed

39 = Infinite loop error

Default: 1

0 to 999 units

0 = (disabled)

Default: 0°F, 0°C, or 0 units

Default: 0 (cool only)

0 units to 999 units

Default: 3°F, 2°C, or 3 units

Default: 3°F, 2°C, or 3 units

0 units to 999 units

Default: 3°F, 2°C, or 3 units

5.6

Data Communications with the Watlow Series 988 Family Command Summary Series 981-984, Chapter 5

Page 35

Ramping Controller Prompt Table

Name Description Read (?) and/or Write (=) Syntax Range

data.1 data.2

Modbus

Address

IDSP Idle Set Point ? <sp> IDSP <cr> RL1 to RH1

308 After Power Outage = <sp> IDSP <sp> data.2 <cr>

IN1 Input 1 Type ? <sp> IN1 <cr> 1 = J t/c; 32 to 1500°F/0 to 816°C

601 = <sp> IN1 <sp> data.2 <cr> 2 = K t/c; -328 to 2500°F/-200 to 1371°C

3 = T t/c; -328 to 750°F/-200 to 399°C

4 = N t/c; 32 to 2372°F/0 to 1300°C

5 = E t/c; -328 to 1470°F/-200 to799°C

6 = C t/c (W3); 32 to 4200°F 0 to2316°C

7 = D t/c (W5); 32 to 4200°F/0 to2316°C

8 = Pt 2; 32 to 2543°F/0 to 1395°C

10 = R t/c; 32 to 3200°F/0 to 1760°C

11 = S t/c; 32 to 3200°F/0 to 1760°C

12 = B t/c; 1598 to 3300°F/870 to 1816°C

Caution: Writing to IN1 or IN2 resets most 14 = 1° RTD (DIN); -328 to 1472°F/-200 to 800°C

prompts to their default values. 15 = 0.1° RTD (DIN); -99.9 to 999.9°F/-99.9 to 700.0°C

17 = 4-20mA; -999 to 9999 units

18 = 0-20mA; -999 to 9999 units

19 = 0-5VÎ (dc); -999 to 9999 units

20 = 1-5VÎ (dc); -999 to 9999 units

21 = 0-10VÎ (dc); -999 to 9999 units

23 = 0-50mVÎ (dc); -999 to 9999 units

24 = 0-100mVÎ (dc); -999 to 9999 units

IN2 Input 2 Type ? <sp> IN2 <cr> 26 = Slidewire off

611 = <sp> IN2 <sp> data.2 <cr> 27 = Slidewire; 100 to 1200

32 = Event input 2 off

33 = Event Input 2 on

IT1 Integral for Output 1 ? <sp> IT1 <cr> 0.00 to 99.99 minutes per repeat

501 = <sp> IT1 <sp> data.2 <cr> Default: 10.00 minutes per repeat

IT2 Integral for Output 2 ? <sp> IT2 <cr> 0.00 to 99.99 minutes per repeat

511 = <sp> IT2 <sp> data.2 <cr> Default: 10.00 minutes per repeat

ITY1 Input 1 ? <sp> ITY1 <cr> 0 = None

8 Hardware Type 1 = t/c only

4 = Input off

5 = Universal RTD

6 = Universal high gain t/c

7 = Universal low gain t/c

8 = Universal millivolts

9 = Universal process

ITY2 Input 2 ? <sp> ITY2 <cr> 0 = None

9 Hardware Type 3 = Slidewire

4 = Input off

10 = Event input

LAT2 Alarm 2 Latching ? <sp> LAT2 <cr> 0 = Latching alarms

721 = <sp> LAT2 <sp> data.2 <cr> 1 = Non-latching alarms

Default: 1

LAT3 Alarm 3 Latching ? <sp> LAT3 <cr> 0 = Latching alarms

738 = <sp> LAT3 <sp> data.2 <cr> 1 = Non-latching alarms

Default: 1

Table 5.7 -

IDSP to LAT3

ç

CAUTION:

Avoid writing <=>

continuously, such

as ramping set

points or repetitive

loops, to the

Series 981-984

EEPROM memory.

Continuous writes

may result in

premature control

failure, system

downtime and

damage to processes and

equipment.

NOTE:

The number of

decimal places

returned by many

of these commands is determined by the DEC1

or IN1 setting.

NOTE:

(RTD setting)

For JIS curve, go

to rtd1 prompt

after selecting In1.

981, 982,

983, 984

Command Summary Series 981-984, Chapter 5 Data Communications with the Watlow Series 988 Family

5.7

Page 36

Ramping Controller Prompt Table

Name Description Read (?) and/or Write (=) Syntax Range

data.1 data.2

983, 984

Table 5.8 -

LOC to OT3

981, 982,

ç

CAUTION:

Avoid writing <=>

continuously, such

as ramping set

points or repetitive

loops, to the

Series 981-984

EEPROM memory.

Continuous writes

may result in

premature control

failure, system

downtime and

damage to processes and

equipment.

NOTE:

The number of

decimal places

returned by many

of these commands is determined by the DEC1

or IN1 setting.