Page 1

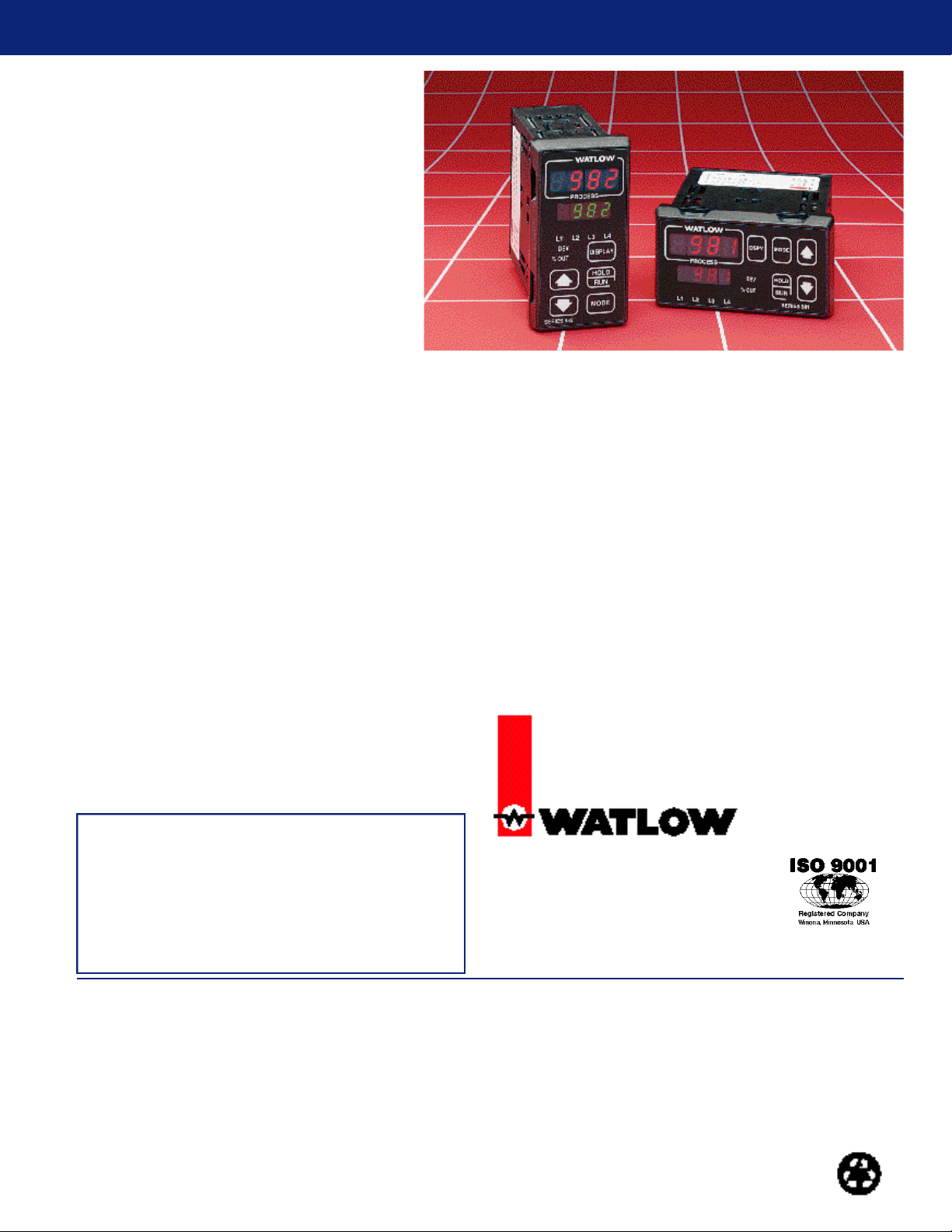

S E R I E S 9 8 1 / 9 8 2

Easy Operation

and Numerous

Uses Are

Constants For This

1/8 DIN Ramping

Controller

The Watlow SERIES 982 vertical 1⁄8 DIN-ramping controller and

its companion, the horizontal SERIES 981, offer four-file /

24-step program capability, or easy-to-use non-ramping set

point operation. The controller is designed with most typical

programming needs in mind. The SERIES 981/982 is among

the most easy-to-use ramping controllers.

Ramping operations include four files with six steps in each file.

Programming options include ramp-rate or time-based profiles,

guaranteed soak deviation, program looping and program

status selection after power outage. The files may be linked to

create a single 24-step program.

The primary analog input accepts 11 different thermocouple

types, RTD or scalable process inputs. A second analog input

can be factory configured for a slidewire feedback input

common in gas valve control. With up to two event inputs, the

SERIES 981/982 offers remote program start or hold capability

and allows the operator to program a wait-for event.

The SERIES 981/982 is packaged with a NEMA 4X front panel

to withstand harsh environments, four inch case depth and

touch-safe wiring terminal.

The SERIES 981/982 features a three-year warranty and four

day shipment, on all model, in limited quantities.

Features and Benefits

Four files / 24 steps

• Designed to meet the needs of most ramping applications

Auto-tuning

• One-step tuning of system parameters for easy operation

Optional dual auxiliary outputs

• Flexible time-based events or alarm outputs

Optional retransmit of set point or process variable

• For master programmer or chart recorder connection

Hardware and software parameter lockout options

• Provides several levels of operator security

NEMA 4X front panel

• Provides watertight corrosion resistance

10Hz sampling rate and burst-fire control

• Smooth, accurate control of the process

Slidewire feedback

• Interfaces with most slidewire input positioning devices

Your Authorized Watlow Distributor is:

1241 Bundy Boulevard

Winona, Minnesota 55987-5580 USA

Phone: +1 (507) 454-5300

Fax: +1 (507) 452-4507

Internet: www.watlow.com

e-mail: info@watlow.com

North American Sales Offices: Atlanta, (770)972-4948 • Austin, (512)249-1900 • Birmingham, (205)678-2358 • Charlotte, (704)573-8446 •

Chicago, (847)458-1500 • Cincinnati, (513)398-5500 • Cleveland, (330)467-1423 • Dallas, (972)620-6030 • Denver, (303)798-7778 •

Detroit, (248)651-0500 • Eastern Canada, (450)433-1309 • Houston, (281)440-3074 • Indianapolis, (317)575-8932 • Kansas City, (913)897-3973 •

Los Angeles, (714)935-2999 • Louisiana, (318)864-2864 • Maryland/Virginia, (215)345-8130 • Minneapolis/Manitoba, (952)892-9222 •

Nashville, (615)264-6148 • New England, (603)882-1330 • New York/New Jersey/Philadelphia, (215)345-8130 • New York, Upstate, (716)438-0454 •

Ontario, (905)979-3507 • Orlando, (407)351-0737 • Phoenix, (602)795-7712 • Pittsburgh, (412)322-5004 • Portland, (360)254-1009 •

Raleigh/Greensboro, (336)766-9659 • St. Louis, (314)878-4600 • Sacramento, (707)425-1155 • San Diego, (714)935-2999 •

San Francisco, (408)434-1894 • Seattle, (425)222-4090 • Tampa/St. Petersburg, (407)647-9052 • Tulsa, (918)496-2826 •

Western Canada, (604)444-4881 • Wisconsin, North (920)993-2161 • Wisconsin, South (262)723-5990

Asian Sales Offices: Australia, +61 (39) 335-6449 • China, +86 (21) 6277-2138 • Japan, +81 (03) 5403-4688 • Korea, +82 (02) 575-9804 •

Malaysia, +60 (4) 641-5977 • Singapore, +65 6773-9488 • Taiwan, +886 (0) 7-288-5168 European Sales Offices: France, +33 (01) 3073-2425 •

Germany, +49 (0) 7253-9400-0 • Italy, +39 (02) 458-8841 • Sweden, +46 31 7014959 • United Kingdom, +44 (0) 115-964-0777

Latin American Sales Office: Mexico, +52 (442) 217-6235

© 2003 Watlow Electric Manufacturing Company Printed in the USA on Recycled Paper, 15% Postconsumer Waste

WIN-981-0903

Page 2

Specifications

Control Mode

• Single input, quad output, optional retransmit of set point or process

variable.

• Programmable direct- and reverse-acting control outputs.

• 4-file, 6 steps per file, time/temperature profile or fixed-set-point control.

• Ramp-rate or time-based programming.

• Selectable control status following power loss.

Agency Approvals

• CE: 89/336/EEC Electromagnetic Compatibility Directive.

EN 50081-2: 1994 Emissions.

EN 50082-2: 1994 Immunity.

• 73/23/EEC Low Voltage Directive.

EN 61010-1: 1993 Safety.

• UL®#873, C-UL®File #E43684

• NEMA 4X

Operator Interface

• Dual, four digit LED displays. Upper: 0.4 in. (10 mm).

Lower: 0.3 in. (8 mm).

• Mode, Hold/Run, Display, Up and Down keys.

Sensors/Inputs

• Contact input for software function select (event input).

• Thermocouple Types B, C2, D2, E, J, K, N, R, S, T and Pt 22.

• RTD resolution in 1° or 0.1° RTD scales.

• Process variables: 0-20mA, 4-20mA, 0-5VÎ (dc), 1-5VÎ (dc),

and 0-10VÎ (dc).

• Slidewire or digital event input options.

• Sensor break protection de-energizes system for safety. Latching or

non-latching.

Input Range

Specified temperature ranges represent the controller's operational span.

Thermocouple

Available with basic or universal signal conditioner

Type C20 to 2316°C (32 to 4200°F)

Type D20 to 2316°C (32 to 4200°F)

Type E -200 to 799°C (-328 to 1470°F)

Type J 0 to 816°C (32 to 1500°F)

Type K -200 to 1371°C (-328 to 2500°F)

Type N 0 to 1300°C (32 to 2372°F)

Type T -200 to 399°C (-328 to 750°F)

2

Pt 2

Available with universal signal conditioner

Type B 870 to 1816°C (1598 to 3300°F)

Type R 0 to 1760°C (32 to 3200°F)

Type S 0 to 1760°C (32 to 3200°F)

RTD Resolution (DIN or JIS)

1° (DIN) -200 to 800°C (-328 to 1472°F)

1° (JIS) -200 to 630°C (-328 to 1166°F)

0.1° (DIN and JIS)

Process

-999 to 9999 units for all: 0-5VÎ(dc); 1-5VÎ(dc); 0-10VÎ(dc);

0-20mA; and 4-20mA.

Input 2 slidewire feedback

100 to 1200Ω.

Line Voltage/Power

• 100-240Vı(ac/dc) +10 percent, -15 percent; 50/60Hz, ±5 percent.

• 24 to 28Vı(ac/dc) +10 percent, -15 percent; 50/60Hz, ±5 percent.

• Fused internally (factory replaceable only) Slo-Blo®type (time-lag):

2A, 250V for high voltage versions; 5A, 250V for low voltage versions.

• Power consumption 16VA maximum.

• Non-volatile memory retains data if power fails.

Operating Environment

• 0 to 55°C (32 to 130°F), 0 to 90 percent RH, non-condensing.

Storage Temperature

• -40 to 85°C (-40 to 185°F).

Terminals

• #6 compression universal head screws, accepts 28-14 gauge wire.

Shipping Weight

• .35 kg lbs (3.01 lbs).

Sample/Update Rates

• 1 input, PID and control outputs: 10Hz.

• 2 inputs: 5Hz.

• Display: 2Hz.

• Retransmit, remote set point and alarm outputs: 1Hz.

1

Electromechanical relays warranted for 100,000 closures only.

Solid-state switching devices recommended for applications requiring

fast cycle times or extended service life.

2

Not an ANSI/ASTM symbol.

UL®and C-UL®are registered trademarks of the Underwriter’s

Labortories, Inc.

0 to 1395°C (32 to 2543°F)

-73.3 to 537.7°C (-99.9 to 999.9°F)

Ordering Information

To order, complete the code number with the information below:

SERIES 981/982 98_ C - _ _ _ _- _ _ _ _

Single chanel 1⁄8 DIN ramping controller,

vertical or horizontal mount

Power Supply & Mounting

1 = 100 to 240Vı(ac/dc) nominal,

horizontal mounting

2 = 100 to 240Vı(ac/dc) nominal,

vertical mounting

3 = 24 to 28Vı(ac/dc) nominal,

horizontal mounting

4 = 24 to 28Vı(ac/dc) nominal,

v e r t i c a l mounting

Software

C = Standard (4-file, 6 step per file,

program capability)

Input 1

1 = Basic thermocouple signal conditioner

(excluding Type B, R, and S)

2 = Universal signal conditioner (see range information)

Input 2

0 = None

3 = Slidewire feedback (see range information)

5 = Second digital event (one digital event is

standard on all units)

Output 1

B = Solid-state relay, Form A, 0.5A, with RC suppression

C = Switched dc or open collector, isolated

D = Electromechanical relay1, Form C, 5A with

RC suppression

E = Electromechanical relay1, Form C, 5A without

RC suppression

F = Universal process, 0-5VÎ(dc), 1-5VÎ(dc),

0-10VÎ(dc), 0-20mA, 4-20mA, isolated

K = Solid-state relay, Form A, 0.5A, without

RC suppression

Output 2

A = None

B = Solid-state relay, Form A, 0.5A, with RC suppression

C = Switched dc or open collector, isolated

D = Electromechanical relay1, Form C, 5A with

RC suppression

E = Electromechanical relay1, Form C, 5A without

RC suppression

F = Universal process 0-5VÎ (dc), 1-5VÎ(dc),

0-10VÎ(dc), 0-20mA, 4-20mA, isolated

K = Solid-state relay, Form A, 0.5A, without

RC suppression

T = External signal conditioner power supply,

5, 12 or 20VÎ(dc) @ 30mA

Output 3

A = None

B = Solid-state relay, Form A, 0.5A, with RC suppression

C = Switched dc, isolated

J = Electromechanical relay1, Form A or B, 5A without

RC suppression

K = Solid-state relay, Form A, 0.5A, without RC suppression

M = Retransmit, 0-20mAÎ(dc), 4-20mAÎ(dc)

N = Retransmit, 0-5VÎ(dc), 1-5VÎ(dc), 0-10VÎ(dc)

T = External signal conditioner power supply, 5, 12 or

20VÎ(dc) @ 30mA

Output 4

A = None

B = Solid-state relay, Form A, 0.5A, with RC suppression

C = Switched dc or open collector, isolated

D = Electromechanical relay1, Form C, 5A with RC suppression

E = Electromechanical relay1, Form C, 5A without RC suppression

K = Solid-state relay, Form A, 0.5A, without RC suppression

R = EIA/TIA-232 communications, opto-isolated

U = EIA/TIA-232, EIA/TIA-485 communications, opto-isolated

S = EIA/TIA-485, EIA/TIA-422 communications, opto-isolated

T = External signal conditioner power supply, 5, 12 or

20VÎ(dc) @ 30mA

Display Color (Upper/Lower)

GG = Green/Green RG = Red/Green

GR = Green/Red RR = Red/Red

Loading...

Loading...