Page 1

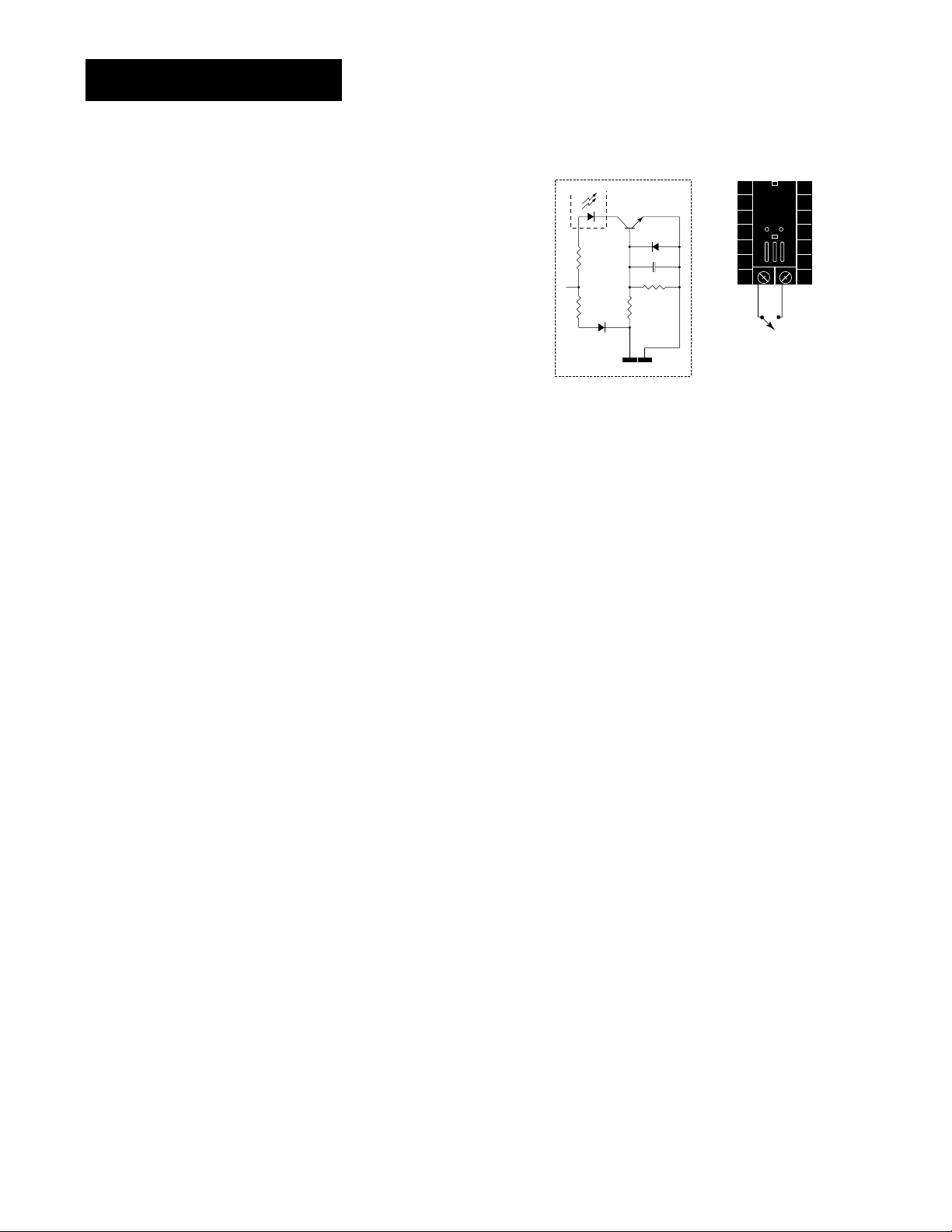

Series 982

1/8 DIN Microprocessor-Based, Ramping Controller

$10.00

Made in the U.S.A.

Printed on Recycled Paper 10% Postconsumer Waste

User’s Manual

Includes 981, 982, 983 and 984

User Levels:

• New User............................................go to page 1.1

• Experienced User ...............................go to page 2.1

• Expert User.........................................go to page 4.1

Installers:

• Set-up .................................................go to page 1.3

• Wiring & Installation............................go to page 2.1

Watlow Controls

1241 Bundy Boulevard, P.O. Box 5580, Winona, Minnesota USA 55987-5580

Phone: (507) 454-5300, Fax: (507) 452-4507 http://www.watlow.com

CUS

ER

TISF

CTI

96

CUS

SATISF

ISO 9001

Registered Company

Winona, Minnesota USA

TOTAL

TOMER

ACTI

3 Year Warranty

ON

0600-0009-0008 Rev R

January 2007

Supersedes: 0600-0009-0008 Rev P

Page 2

How to Use this Manual

We have designed this user’s manual to be a helpful guide to your new Watlow controller. The headlines in the upper right and left corners indicate which tasks are

explained on that page. If you are a new user, we suggest that your read through the

whole manual. If you are experienced, you may want to begin reading on page 2.1.

Notes, Cautions and Warnings

We use note, caution and warning symbols throughout this book to draw your

attention to important operational and safety information.

A bold text “

NOTE” marks a short message in the margin to alert you to an impor-

tant detail.

A a bold text “

CAUTION” safety alert appears with information that is important for

protecting your equipment and performance. Be especially careful to read and fol-

low all cautions that apply to your application.

A bold text “WARNING” safety alert appears with information that is important for

protecting you, others and equipment from damage. Pay very close attention to

all warnings that apply to your application.

The ç symbol (an exclamation point in a triangle) precedes a general CAUTION or

WARNING statement

.

The Ó symbol (a lightning bolt in a triangle) precedes an electric shock hazard

CAUTION or WARNING safety statement.

Technical Assistance

If you encounter a problem with your Watlow controller, review all of your configuration information for each step of the setup to verify that your selections are consistent with your applications.

If the problem persists after checking all the steps, you can get technical assistance

by calling Watlow Controls at (507) 494-5656, between 7 a.m. and 7 p.m. CST, and

asking for an applications engineer; or by e-mailing your questions to wintechsup

port@watlow.com. When you call, have the following information on hand: the controller’s model number (the 12-digit number is printed on the top of the stickers on

each side of the controller’s case and on the right-hand or top circuit board); your

user’s manual; all configuration information; and the Diagnostics Menu readings.

Warranty and Returns

For information about the warranty covering the Series 982 Family of controllers

see the Appendix.

Comments and Suggestions

We welcome your comments and opinions about this user’s manual and the Series

982 Family of controllers. Send them to the Technical Editor, Watlow Controls,

P.O. Box 5580, Winona, MN 55987-5580. Or call (507) 454-5300 or fax them to

(507) 452-4507. The Series 982 User’s Manual is copyrighted by Watlow Winona,

Inc., © February 2006, with all rights reserved.

About This Manual

ii WATLOW Series 982 User’s Manual

Page 3

WATLOW Series 982 User’s Manual iii

Contents

Table of Contents

Chapter 1

Starting Out With the Watlow Series 981/982

1.1 Starting Out With the Watlow Series 981/982

1.2 Menu Overview

1.3 DIP Switch Locations and Functions

1.4 Setting the Hardware Lockout DIP Switch

1.5 External Power Supply DIP Switches

1.6 Input Type DIP Switches

Chapter 2

Install and Wire the Series 981/982

2.1 Panel Cutout

2.1 Dimensions

2.2 Installation Procedure

2.3 Wiring the Series 981/982

2.4 I/O Isolation

2.4 Power Wiring

2.4 Sensor Installation Guidelines

2.5 Wiring 0-20mA and 4-20mA Process Inputs

2.6 Wiring Example

2.7 Wiring Notes

2.8 Input 1 Wiring

2.9 Input 2 Wiring

2.9 Digital Event Input 2

2.10 Digital Event Input 1

2.11 Output 1 Wiring

2.12 Output 2 Wiring

2.13 Output 3 Wiring

2.14 Output 4 Wiring

Chapter 3

Front Panel and Display Loop

3.1 Front Panel Guide

3.2 Display Loop

Chapter 4

The Setup Menus

4.1 Entering the Setup Menus

4.2 Input Menu

4.3 Input Prompts

4.12 Output Menu

4.13 Output Prompts

4.28 Global Menu

4.29 Global Prompts

4.38 Communications Menu

4.39 Communications Prompts

Chapter 5

The Operation Menus

5.1 Entering the Operation Menus

5.2 System Menu

5.3 System Prompts

5.10 PID Menu

5.11 PID Prompts

Chapter 6

The Factory Menus

6.1 Entering the Factory Menus

6.2 Diagnostics Menu and Prompts

6.7 Calibration Menu and Prompts

Chapter 7

The Run Menu

7.1 Program Menu

7.1 Program Prompts

7.5 Running a Series 982 Profile

7.5 Resume a Profile

7.6 Run and Pre-Run Menus

7.6 Event Outputs

7.7 Guaranteed Soak Deviation

7.8 Jump-loops

7.8 Programming a Ramping Profile

7.10 Running your Profile

7.10 Editing your Profile

7.12 Linking Profiles

7.13 Waitfor Functions

7.14 Master Step Chart

Chapter 8

Operation, Tuning, Alarms and Error Codes

8.1 Auto-tuning

8.2 Manual Tuning

8.3 Changing the Output 3 Jumper

8.4 Using Alarms

8.5 Error Code E1 and E2 Messages

8.6 Error Code Actions

Chapter 9

Software

9.2 Burst Fire

9.4 Communications

9.6 Dead Band

9.8 Digital Events

9.10 Input Filter

9.12 Input Linearization

9.14 Retransmit

9.16 Slidewire Feedback

Appendix

A.1 Warranty and Returns

A.2 Glossary

A.5 Index

A.8 Specifications

A.9 Ordering Information

A.10 Declaration of Conformity

WATLOW Series 982 User’s Manual

Page 4

iv WATLOW Series 982 User’s Manual

Contents

Notes

Page 5

WATLOW Series 982 User’s Manual 1.1

Starting Out with the Watlow Series 982, Chapter 1

Watlow’s Series 982, a 1/8 DIN microprocessor-based ramping controller, is

truly an innovation in the controller field. The Series 982 provides 6-step program capability, with up to 4 files possible.

The new controller meets a wide variety of needs in the process industries.

Its broad range of I/O options allows control of virtually any process variable. In addition to the standard Watlow features, the Series 982 has

expanded auto-tuning capabilities and increased alarm functionality.

If you are unfamiliar with general controller operation, it’s a good idea to

read through the entire manual. The manual is organized in chronological

order with each chapter broken down by wiring, menus, operation and

applications. If you understand the concept of process/temperature controllers and feel comfortable skipping around through the manual, use the

index or the black tabs at the top of each page to quickly scan the pages

and find the topic you are looking for.

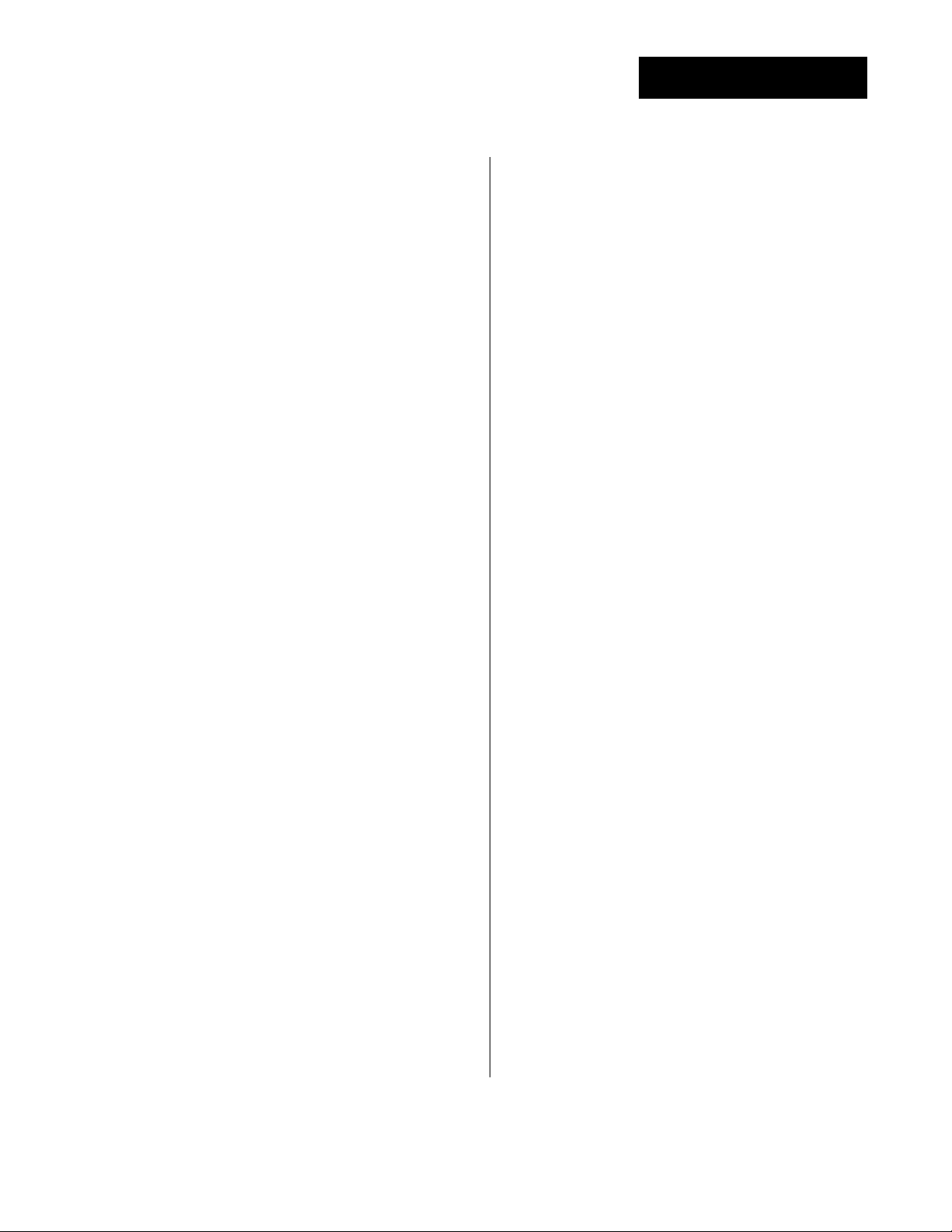

The map on the next page provides an overview of all menus and prompts

and how to navigate between them. There are three main prompts Setup,

Operation and Factory (

[`SEt], [OPEr] and [Fcty]). Beneath these

prompts there are several menus. The Display Loop can be reached from

anywhere using the Display key.

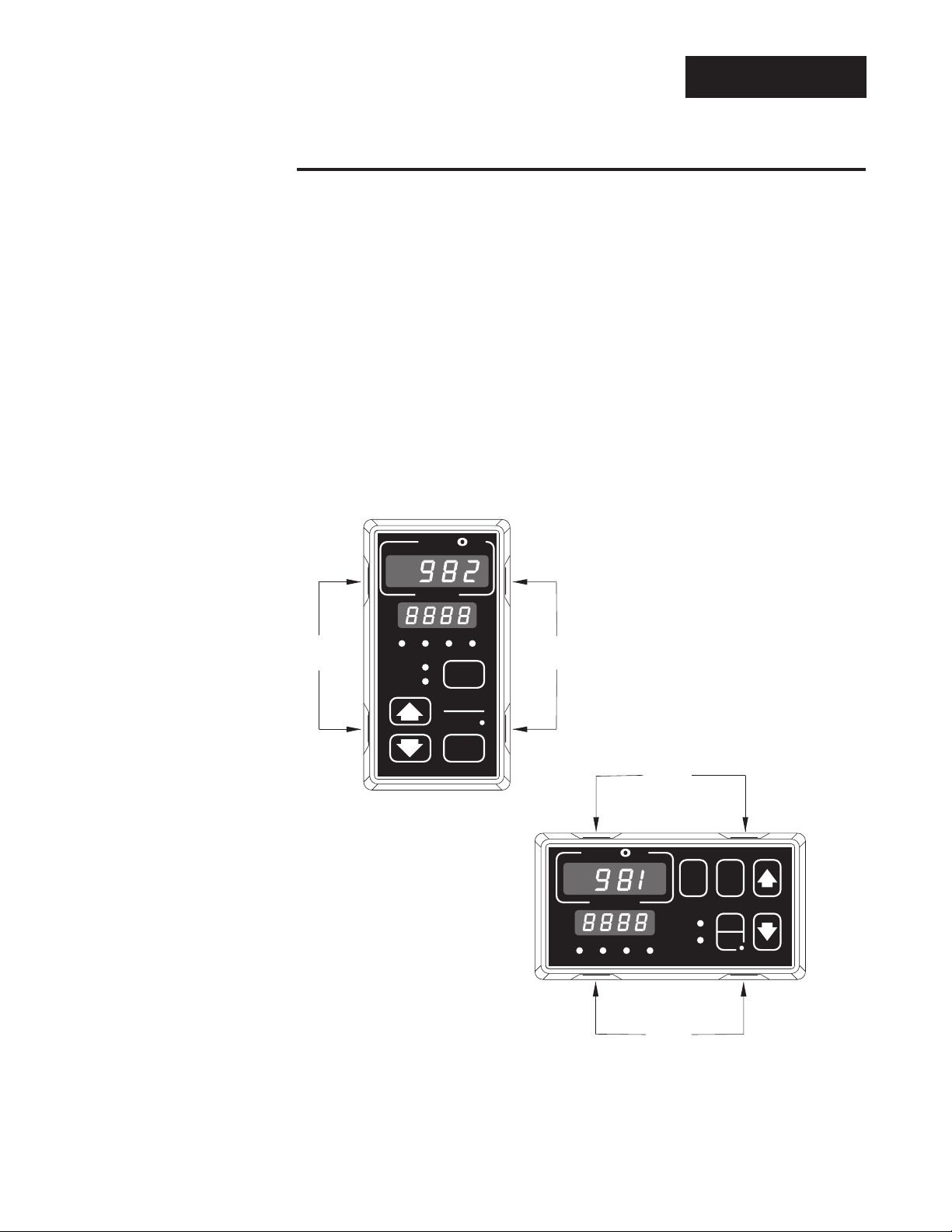

Chapter 1 Starting Out with the

Watlow Series 982

Figure 1.1 Watlow Ramping

Controllers.

Page 6

Factory Fcty ( )

1.2 WATLOW Series 982 User’s Manual

Starting Out with the Watlow Series 982, Chapter 1

Menu Overview

˜

NOTE:

This is a complete

listing of all Series

982 prompts.

Not all prompts will

appear on your

control. They are

dependent on your

configuration and

model number.

Figure 1.2 The Series 982 Map.

7550°F0% OUT LED on

DEV LED on

Process units

Set point 1

Pr2

Process input 2

(SyS)

Alarm 2 low

Alarm 2 high

Alarm 3 low

Alarm 3 high

(System)

Event input 1 statusEi1S

A2LO

A2HI

A3LO

A3HI

A4LO

AUt

A4HI

( )

( )

( )

( )

( )

( )

( )

( )

Auto-tune

Alarm 4 high

Alarm 4 low

( )

( )

( )

Event input 2 status

Ei2S

Event output 3 statusEnt3

Event output 4 statusEnt4

(Pid)

Output 1 integral

Output 1 reset

Output 1 rate

Output 1 derivative

Output 1 cycle time

(PID)

Output 1 proportional band

Pb1

It1

rA1

dE1

Ct1

rE1

Pb2

It2

rA2

rE2

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

Output 2 integral

Output 2 reset

Output 2 rate

Output 2 proportional band

Ct2

db

dE2

( )

( )

( )

Output 2 cycle time

Output 2 derivative

Dead band

e

Operation Menus

Display Loop

(Lower Display)

Setup Menus

Factory Menus

To navigate:

Press ∂ to return

to the Display Loop

from any location and

to advance through

the Display Loop.

Press

> or < to

move between the

menus.

Press

µ to

advance through a

menu.

Hold

µ while

pressing

> to move

backwards through

the menus.

Press

> or < to

select prompt values.

At the SEt prompt,

press

> and <

another 3 seconds to

enter the Factory

menus.

From the Display

Loop, press

µ to

advance to the

OPEr prompt.

Press

∂ to exit any

menu and reach the

Display Loop at any

time.

Operation OPEr

( )

><

From the Display

Loop, press

> and

< for 3 seconds to

enter the Setup

menus.

><

Setup

><

.

.

.

(See Chapter 7

for all the

Program menus.)

(InPt)

(Input)

In1 ( )

Input 1

dEC1 ( )

Decimal place 1

rL1 ( )

Range low 1

Range high 1

rH1 ( )

Calibration offset 1

CAL1 ( )

rtd1 ( )

Rtd calibration curve 1

Ftr1 ( )

Input 1 software filter

Input 2

In2 ( )

rL2 ( )

Range low 2

rH2 ( )

Range high 2

LmL ( )

Learn low

LmH ( )

Learn high

CAL2 ( )

Calibration offset 2

Hunt ( )

Hunt

SHyS ( )

Slidewire hysteresis

(OtPt)

Ot1 ( )

Prc1 ( )

HyS1 ( )

Ot2 ( )

Prc2 ( )

HyS2 ( )

AL2 ( )

LAt2 ( )

SIL2 ( )

Ot3 ( )

AL3 ( )

HyS3 ( )

LAt3 ( )

SIL3 ( )

Ot4 ( )

AL4 ( )

HyS4 ( )

LAt4 ( )

SIL4 ( )

Aout ( )

Prc3 ( )

ArL ( )

Arh ( )

ACAL ( )

SEt ( )

(Output)

Output 1

Process 1

Hysteresis 1

Output 2

Process 2

Hysteresis 2

Alarm 2

Latching for alarm 2

Silence alarm 2

Output 3

Alarm 3

Hysteresis 3

Latching for alarm 3

Silence alarm 3

Output 4

Alarm 4

Hysteresis 4

Latching for alarm 4

Silence alarm 4

Analog output

Process 3

Retransmit low limit

Retransmit high limit

Retransmit calibration offset

(gLbL)

C_F ( )

Err ( )

Ei1 ( )

Ei2 ( )

AbSP ( )

Anun ( )

LoP ( )

HiP ( )

AtSP ( )

PtyP ( )

gSd ( )

Pout ( )

IdSP ( )

PStr ( )

LOC ( )

(Prog)

( )

FiLE

( )

StEP

( )

StyP

(Global)

Celcius_Fahrenheit

Error Latching

Event input 1

Event input 2

Abort Set Point

Annunciator

Low power limit

High power limit

Auto-tune set point

Program type

Guaranteed soak deviation

Power outage

Idle set point

Profile start

Lockout

bAUd ( )

dAtA ( )

Prot ( )

(Program)

File number

Step number

Step type

(COM)

Addr ( )

intF ( )

( Communication)

Baud rate

Data bit and parity

Protocol type

Address

Interface type

dAtE

SOFt

Sn

AMb

Acnt

gnd

cnt1

cnt2

ity1

ity2

Oty1

Oty2

Oty3

Oty4

dISP

tout

(diAg)

(Diagnostics)

( )

Factory ship date

( )

Software revision

( )

Serial number

( )

Ambient temperatur

( )

Ambient A/D count

( )

Ground A/D count

( )

Input 1 A/D count

( )

Input 2 A/D count

( )

Input 1 module

( )

Input 2 module

( )

Output 1 module

( )

Output 2 module

( )

Output 3 module

( )

Output 4 module

( )

Test displays

( )

Test output

A 50

A 00

tc

A 4H

A 20

A 15

A380

A10u

A 0u

A20A

A 4A

A 0u

A100

(CAL)

(Calibration)

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

bu15

b380

1 4

1 20

1 0

1 10

2 4

2 20

2 0

2 10

3 LO

3 HI

rSt

dFL

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

( )

Restore factory values

Default prompts

Page 7

WATLOW Series 982 User’s Manual 1.3

DIP Switches

Starting Out with the Watlow Series 982, Chapter 1

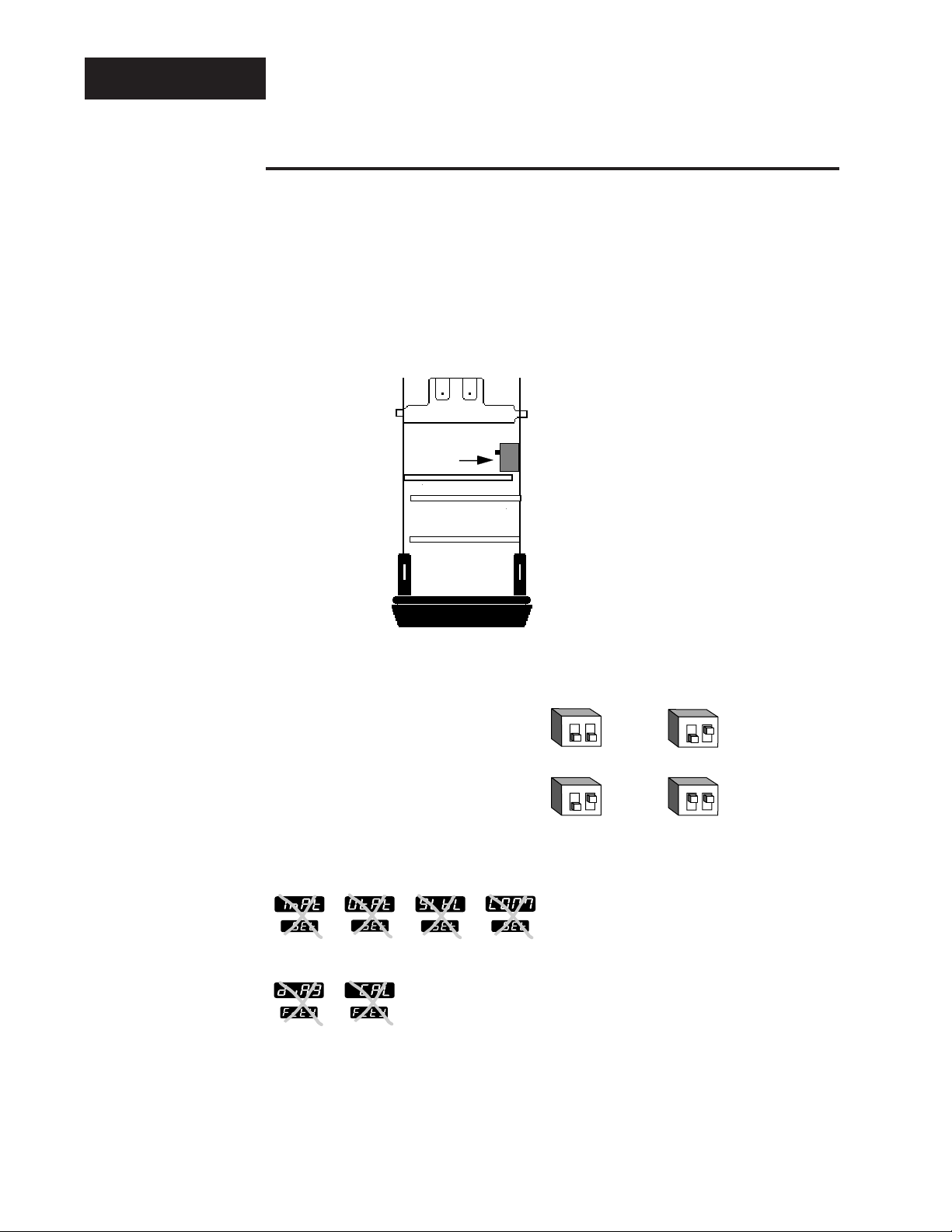

DIP Switch Locations and Functions

The Series 982 has several Dual In-line Package (DIP) Switches inside the

control. Depending on your model number, your unit can have as few as

one DIP switch or as many as five DIP switches. Use the rest of this chapter as a DIP switch reference guide.

To set any DIP switch:

1. Remove the control chassis from the case. Release the two tabs on one

side of the bezel, by pressing in firmly on each until you hear the tab

snap. Release the two tabs on the opposite side of the control. You

may need to rock the bezel back and forth several times to release the

chassis.

2. Use the following graphics in the rest of the chapter to locate and identify

each DIP switch and the desired settings.

TLTL

W

W

A

PROCESS

L1 L2 L3 L4

DEV

% OUT

DISPLAY

SERIES 988

MODE

HOLD

RUN

Release

Tabs

Release

Tabs

Figure 1.3 Press the release

tabs to remove the

controller chassis.

TL

Release

Tabs

W

A

TL

W

MODE

DSPY

PROCESS

HOLD

DEV

% OUT

L1 L2 L3 L4

Release

Tabs

RUN

SERIES 989

Page 8

1.4 WATLOW Series 982 User’s Manual

Starting Out with the Watlow Series 982, Chapter 1

DIP Switches

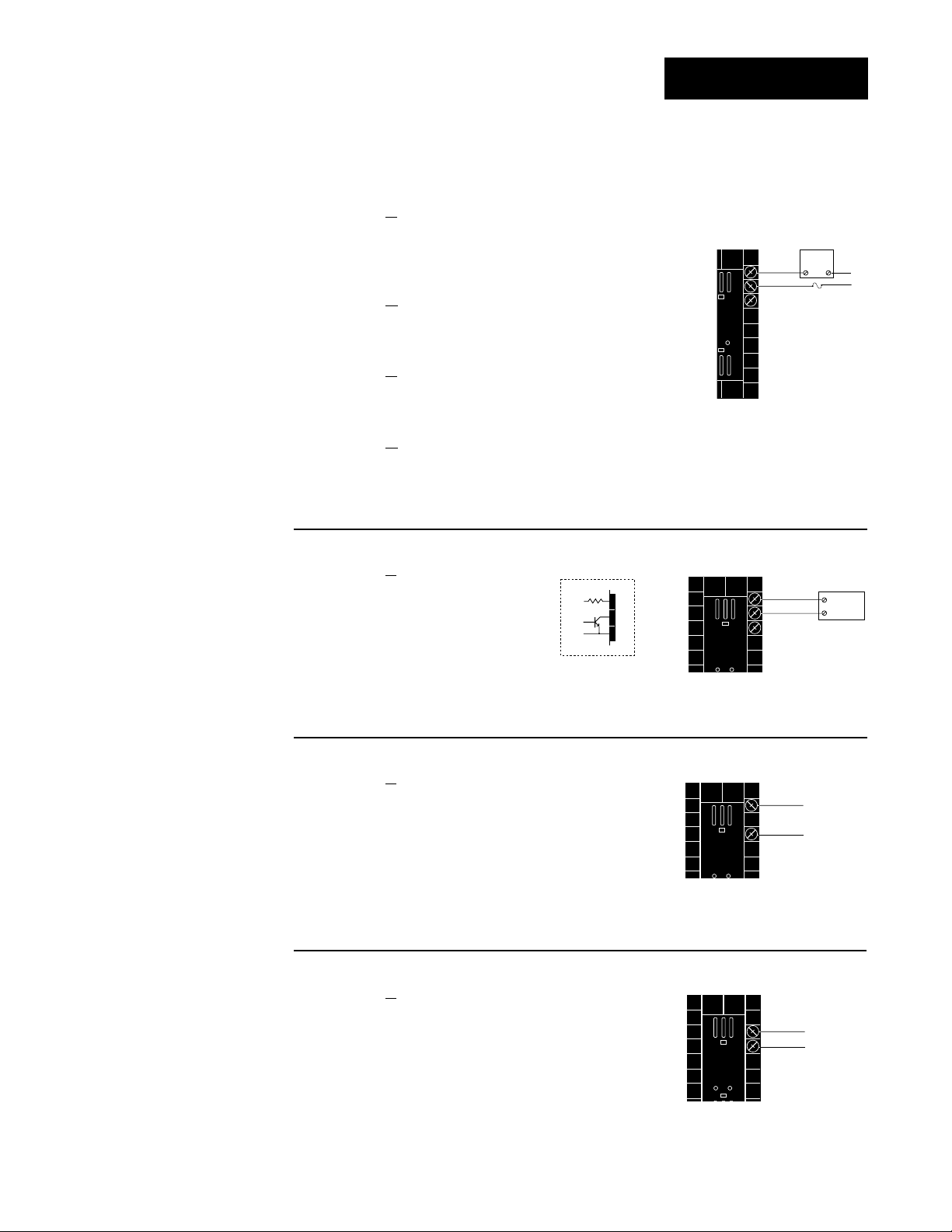

The Hardware Lockout/Battery Backup DIP Switch

All units are equipped with a DIP switch for hardware lockout of the SEt

and Fcty prompt menus, and to enable battery backup of the Run parameters. The location of the board and switch appear below. The switches are

clearly numbered, and are labeled on the outside of the board. When

Switch #1 is on, battery backup is enabled. When Switch #2 is on, the

menus under the SEt prompt (Input, Output, Global and Communications)

and Fcty prompt (Diagnostics and Calibration) cannot be viewed. When the

control leaves the factory switch #1 is off and switch #2 is off.

Control Chassis

Top View (982 & 984)

Left-side View (981 & 983)

Lockout

DIP

On

Off

Figure 1.4 Battery backup and

hardware lockout

DIP switches.

battery backup of Run prompts or

lockout Setup and Factory menus or

ç

CAUTION:

There is danger of

an explosion if the

battery is incorrectly replaced. This

battery is factory

replaceable only.

Dispose of used

batteries according

to manufacturer’s

recommendations.

12

O

N

Input

Output Global

Communications

↑

12

O

N

↑

Diagnostics Calibration

12

O

N

↑

12

O

N

↑

Page 9

WATLOW Series 982 User’s Manual 1.5

DIP Switches

Starting Out with the Watlow Series 982, Chapter 1

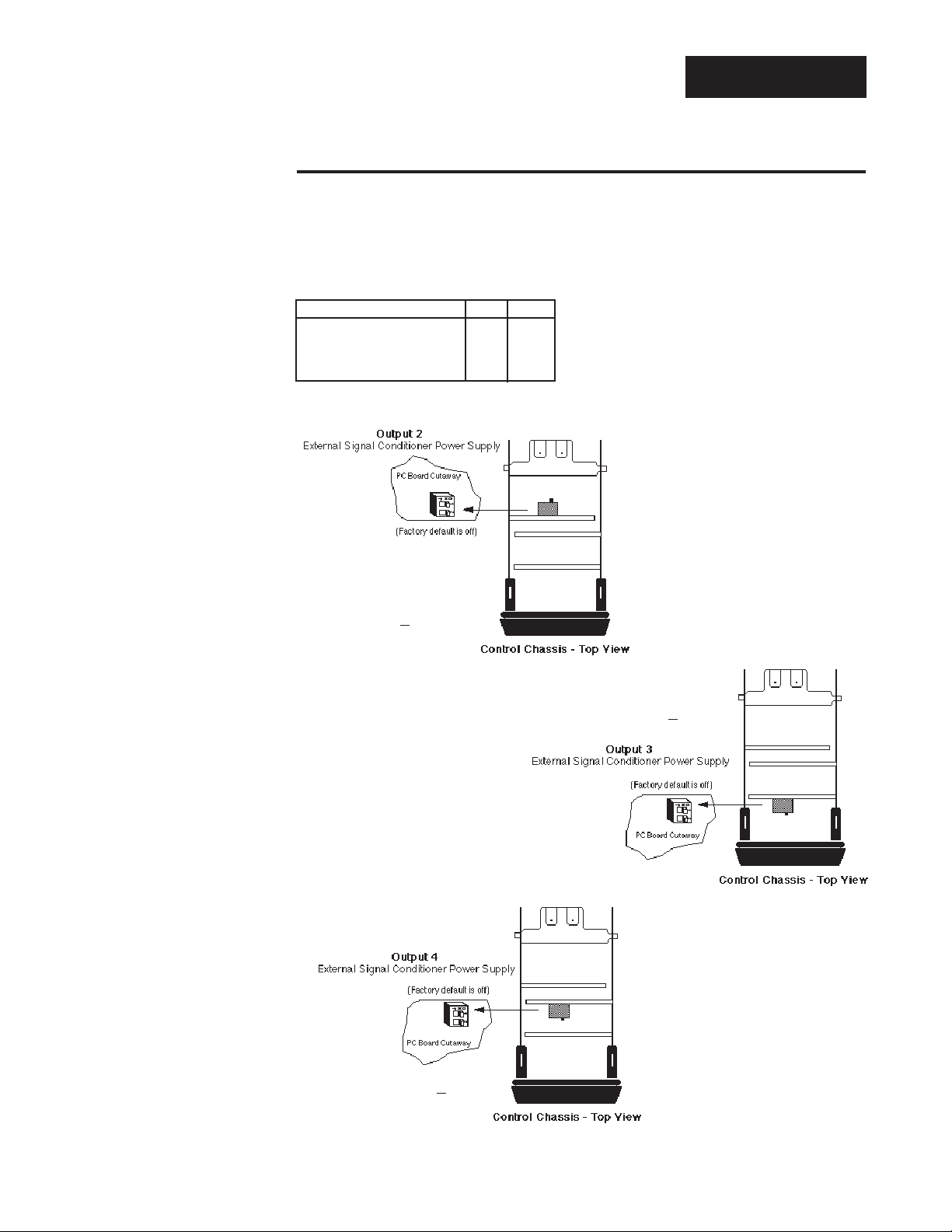

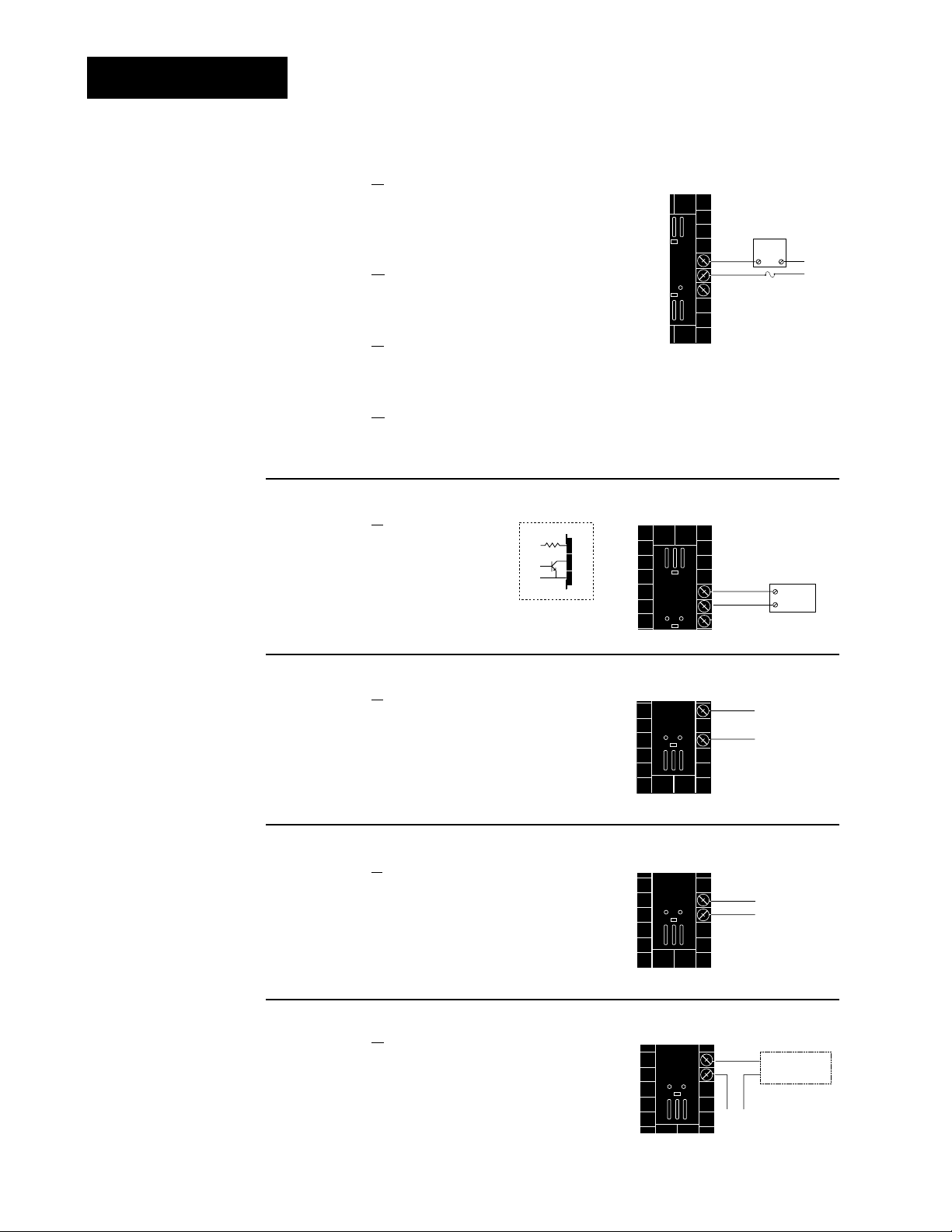

External Power Supply DIP Switches (Option “T”)

Models equipped with an external signal conditioner power supply (Option

“T”), have a DIP switch for selecting the power supply voltage. Output 2, 3

or 4 can be ordered with the external power supply. The location of each

board and DIP switch appear below. When the control leaves the factory,

both switches are off. The figures below show a PC board cutaway for each

DIP switch. See the table to the left

for the power supply switch settings. The settings can be used for

all three output DIP switches. For

other voltage or current ratings contact the factory.

Figure 1.5a Output 2

External Signal

Conditioner

Power Supply.

Figure 1.5b Output 3

External Signal

Conditioner

Power Supply.

Figure 1.5c Output 4

External Signal

Conditioner

Power Supply.

98 _ C - _ _ _ T - _ _ _ _

98 _ C - _ _ _ _ - T _ _ _

98 _ C - _ _ _ _ - _ T _ _

Voltage/Load Current S1 S2

5V ±5% @ 30mA On On

12V ±5% @ 30mA On Off

20V ±5% @ 30mA Off Off

Table 1.5 Power Supply DIP

Switch Settings.

Page 10

1.6 WATLOW Series 982 User’s Manual

Starting Out with the Watlow Series 982, Chapter 1

DIP Switches

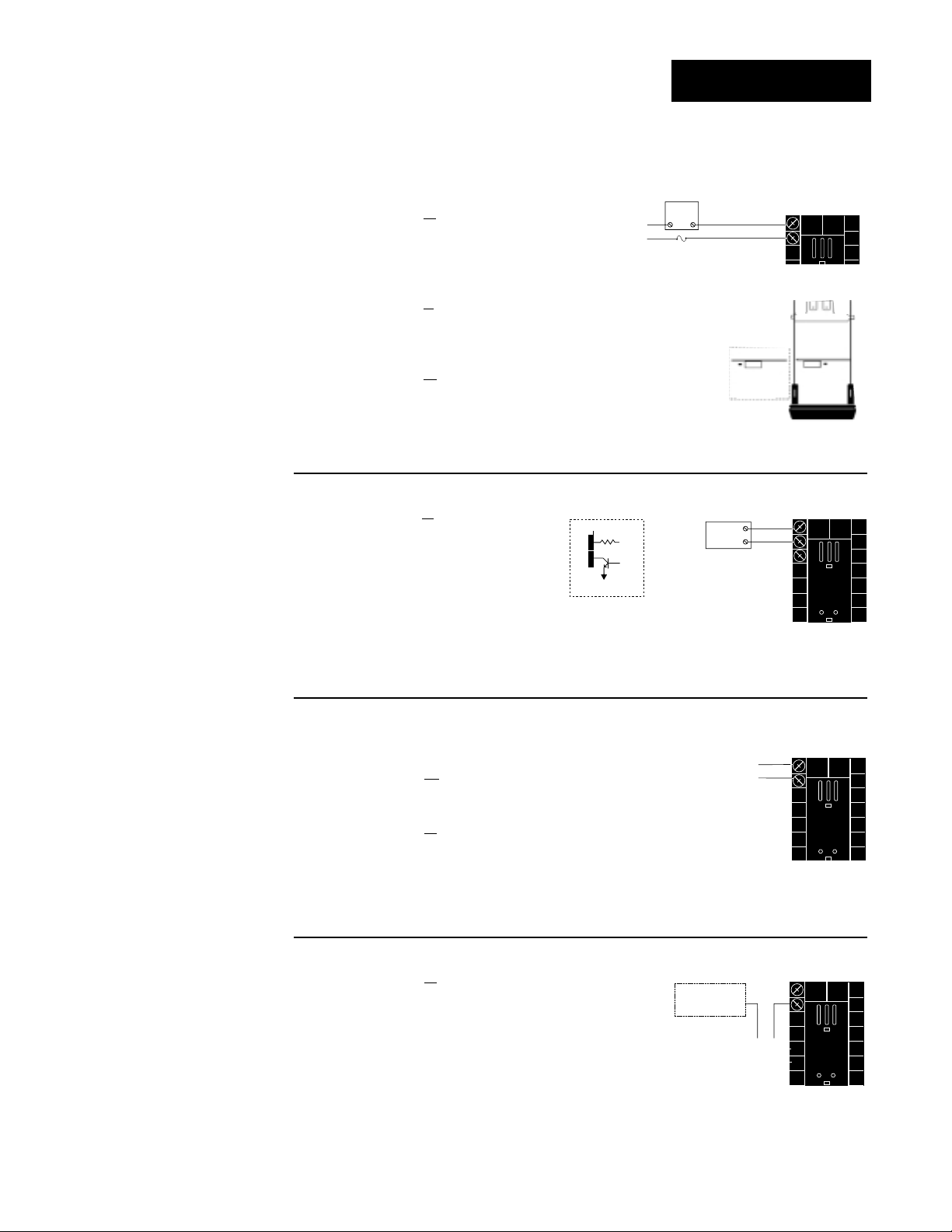

J, K, T, N, C, E, Pt2, D

Thermocouple Input

R, S, B

Thermocouple Input

RTD Input

0-5V, 1-5V or 0-10V Input

0-20mA or 4-20mA Input

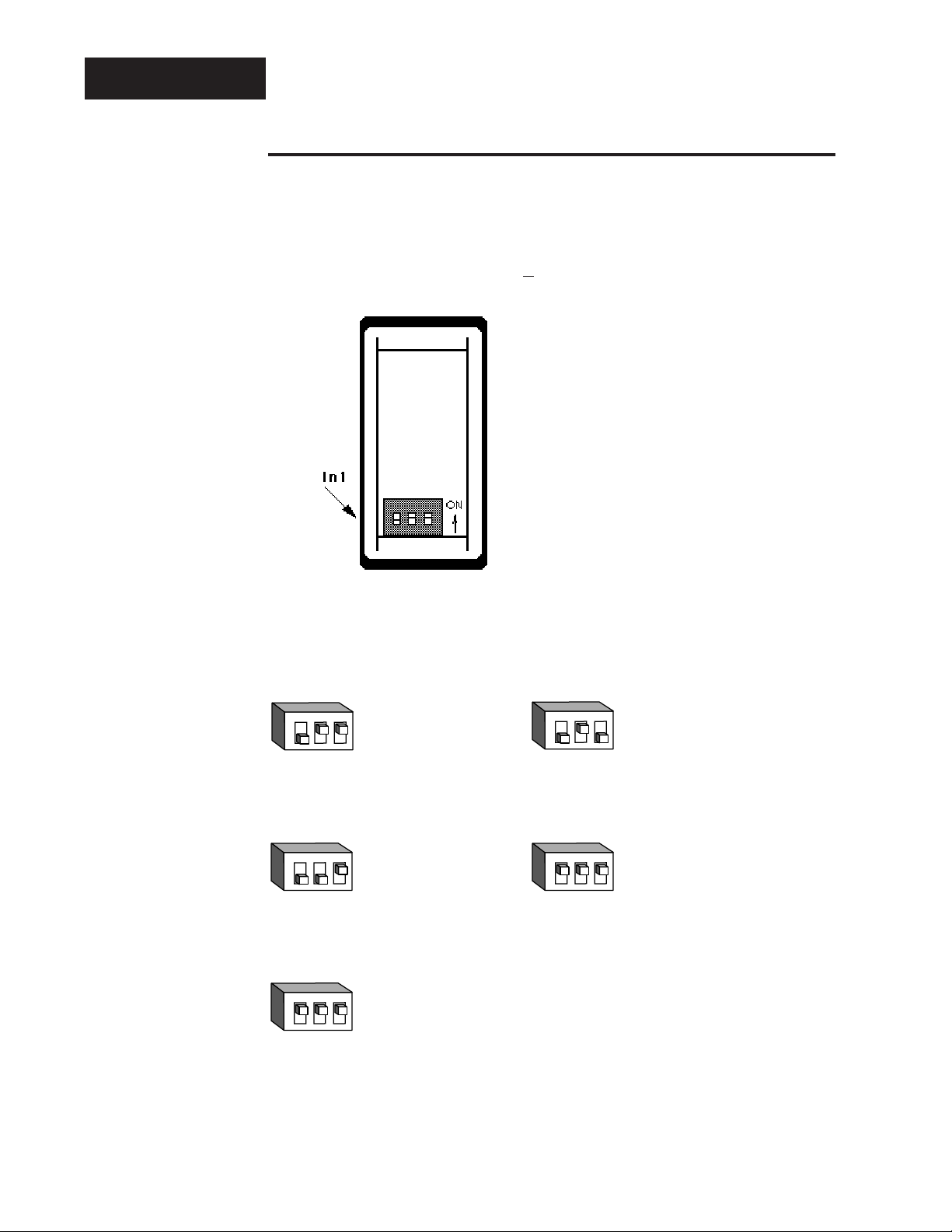

Universal Signal Input Type DIP Switches

Remove the chassis from the case. Looking at the back of the control, the

input #1 (In1) switch is located at the base of the unit. Set the DIP switches to match the appropriate sensor input types will automatically match

the DIP switch settings.

If you have model number

98_ C- 1 _ _ _-_ _ _ _

, there is no In1 DIP

switch.

Figure 1.6a Input DIP Switch

Locations.

Figure 6b Input DIP Switch

Settings.

Single Input Unit

98_ C - 2_ _ _ - _ _ _ _

123

O

N

↑

123

O

N

↑

123

O

N

↑

123

O

N

↑

123

O

N

↑

Page 11

WATLOW Series 982 User’s Manual 2.1

Installation and Wiring, Chapter 2

Chapter 2 Installation and Wiring

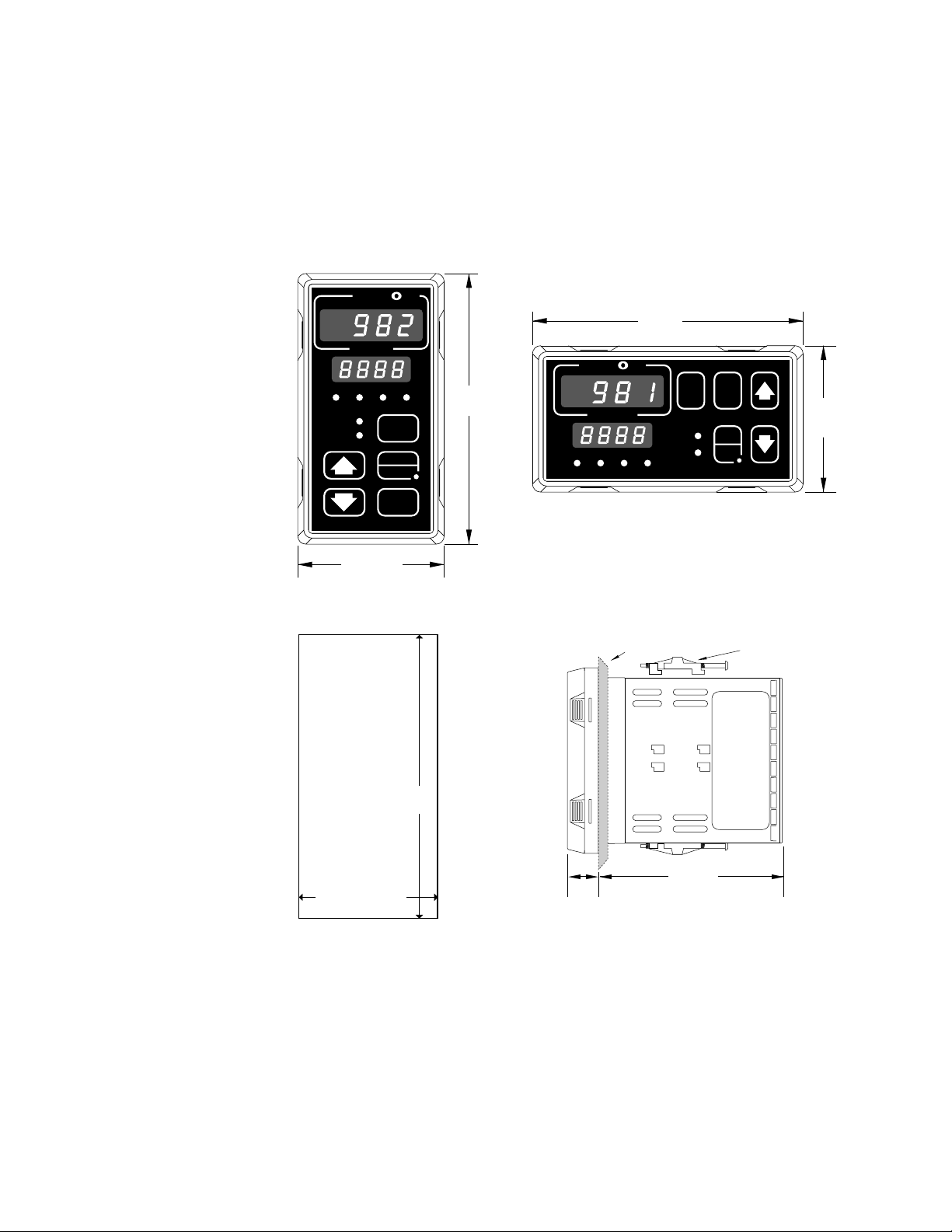

Figure 2.1 Series 981 and

Series 982

dimensions.

˜

NOTE:

Adjustable mounting brackets can be

side-mounted.

˜

NOTE:

Space panel

cutouts at least 1.66

inches (42.2mm)

apart.

˜

NOTE:

Holes can be cut in

the panel using a

Greenlee 1/8 DIN

Hydraulic Kit

#60068 (punch

#60069, die #60070).

W

A

TL

W

PROCESS

L1 L2 L3 L4

DEV

% OUT

SERIES 988

2.18"

(55 mm)

DISPLAY

HOLD

RUN

MODE

4.03"

(102mm)

(102mm)

W

A

TL

W

PROCESS

L1 L2 L3 L4

4.03"

DSPY

DEV

% OUT

MODE

HOLD

RUN

SERIES 989

2.18"

(55 mm)

Panel Cutout

Maximum Panel

Thickness

0.38" (9.65mm)

3.62" + 0.03 -0.00

(92mm + 0.8)

1.77 + 0.02 -0.00

(45mm + 0.6)

0.68"

(17 mm)

Panel

4.06"

(103 mm)

Mounting Bracket

Adjustable

Page 12

2.2 WATLOW Series 982 User’s Manual

Installation and Wiring, Chapter 2

Installation

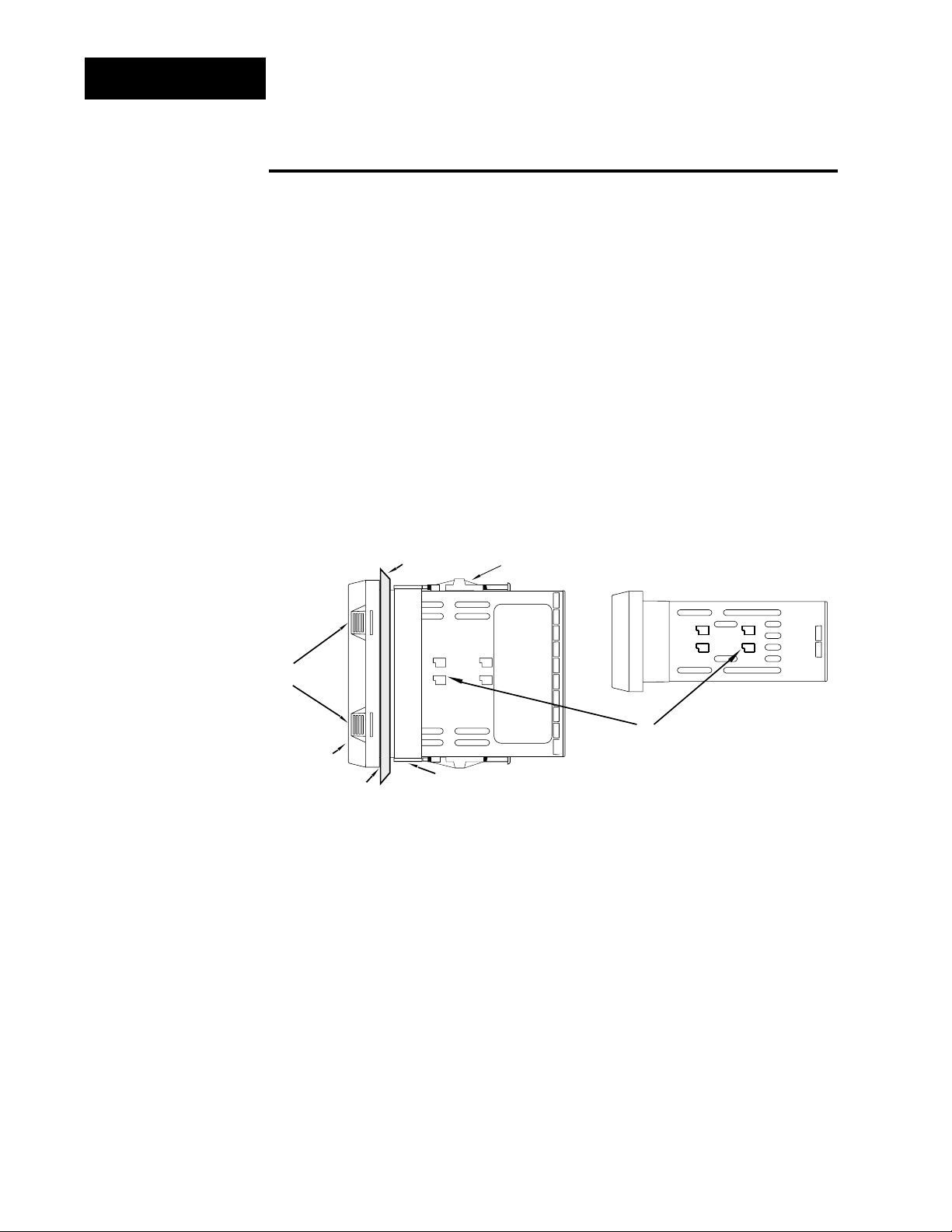

Installing the Series 982

Installing and mounting requires access to the back of the panel.

1. Make a panel cutout.

2. To remove the controller chassis from its case, press in firmly on the two

tabs on one side or the top of the bezel until they unsnap, then unsnap

the two tabs on the opposite side or the bottom. Pull the chassis out of

the case by gently rocking it.

3. Slide the case into the panel cutout. Check to see that the gasket is not

twisted, and is seated within the case bezel flush with the panel. Slide

the mounting collar over the back of the control.

Panel

Adjustable

Mounting Bracket

Bezel

External Gasket

Mounting Collar

Release Tabs

Top and Bottom (982 or 984)

or Side (981 or 983) View

Mounting Slots

Side (982 or 984)

or Top and Bottom (981 or 983) View

˜

NOTE:

Removing the controller chassis from

its case makes

mounting easier.

Figure 2.2 Side and top view.

Page 13

WATLOW Series 982 User’s Manual 2.3

Installation and Wiring, Chapter 2

4. Loosen the mounting bracket screws enough to allow for the mounting

collar and panel thickness. Place each mounting bracket into the

mounting slots (head of the screw facing the back of the controller).

Push each bracket backward then down to secure it to the control

case. To guarantee a proper NEMA 4X seal, Series 982 and 984

units (vertical) must have the mounting brackets located on either

side of the unit. When installing Series 981 and 983 units (horizontal) the brackets must be on the top and bottom of the unit.

5. Make sure the case is seated properly. Tighten the installation screws

firmly against the mounting collar to secure the unit. To ensure a

NEMA 4X seal, there should be no space between the bezel and

panel. Overtightening the screws will distort the case and make it diffi-

cult to remove or replace the controller.

6. Insert the controller chassis into its case and press the bezel until all

four tabs snap. Make sure the inside gasket is seated properly and not

twisted.

7. To release the mounting brackets, loosen the mounting bracket screws

and push the brackets forward, then pull it up and out.

ç

CAUTION:

Follow the installation procedure

exactly to guarantee

a proper NEMA 4X

seal. Make sure the

gasket between the

panel and the rim of

the case is not

twisted and is seated properly. Failure

to do so could

result in damage to

equipment.

Installation

Page 14

2.4 WATLOW Series 982 User’s Manual

Installation and Wiring, Chapter 2

Wiring

Wiring the Series 982

Wiring options depend on the model number and DIP switch settings.

Check the terminal designation stickers on either side of the controller

and compare your model number to those shown here and with the model

number breakdown on the inside back cover of this manual.

Input-to-output Isolation

The Series 982 uses optical isolation between the analog inputs and the

controller outputs/digital input. This isolation provides a 500VÅ (VAC)

barrier to prevent ground loops when using grounded sensors and/or

peripheral equipment.

Here is a breakdown of the isolation barriers:

• Analog inputs 1 and 2 are grouped together.

• Outputs 1 through 4 and the standard event input are grouped together.

This does not apply to Output 4 when configured as communications.

• The digital communications output (4) is separate from the above

groups.

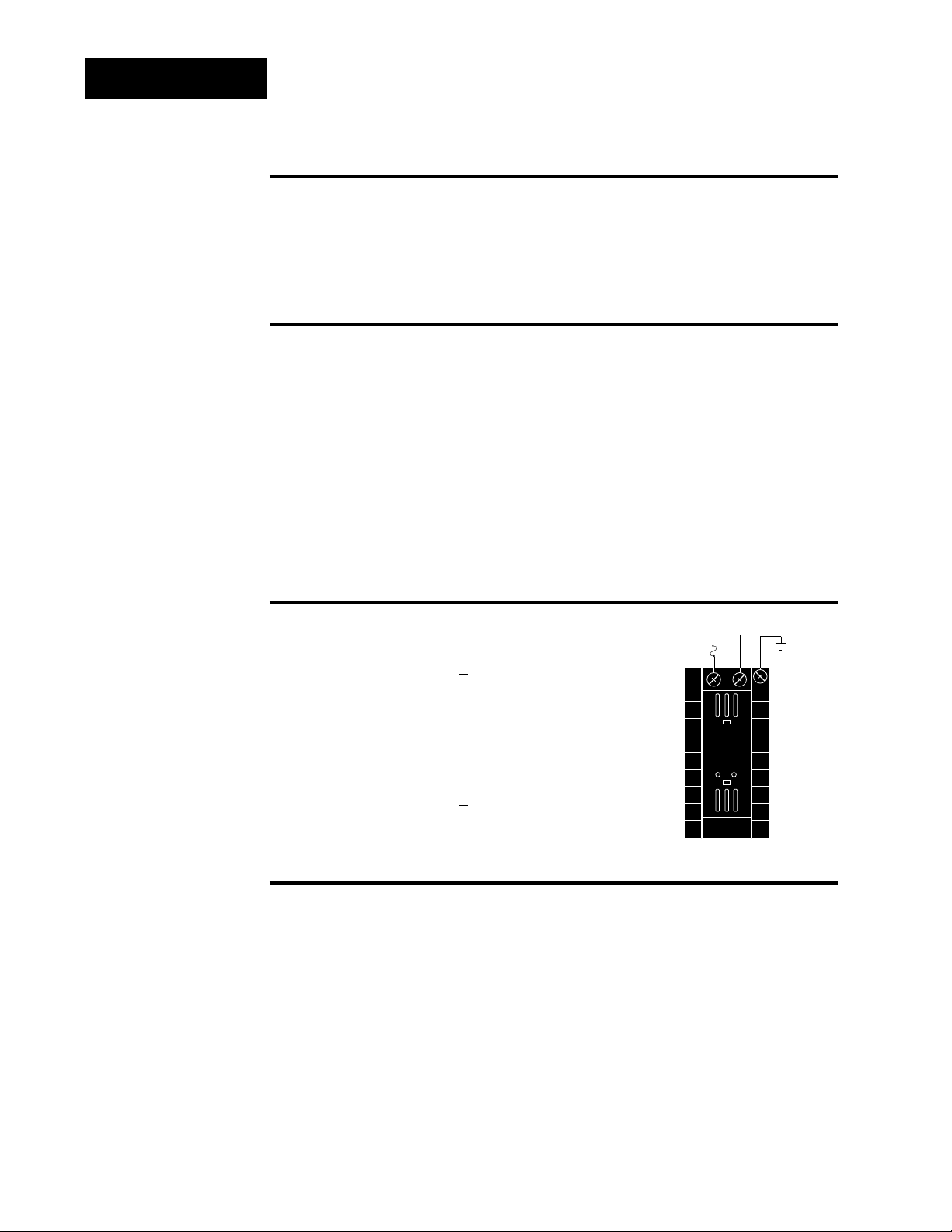

Power Wiring

100 to 240 VÅÅ(ac), nominal (85 to 264 actual)

Horizontal Package 98 1

C - _ _ _ _ - _ _ _ _

Vertical Package 98 2 C - _ _ _ _ - _ _ _ _

24 to 28 V‡‡(ac/dc), nominal (21 to 30 actual)

Horizontal Package 98 3

C - _ _ _ _ - _ _ _ _

Vertical Package 98 4 C - _ _ _ _ - _ _ _ _

Sensor Installation Guidelines

Thermocouple input: Extension wire for thermocouples must be of the

same alloy as the thermocouple itself to limit errors.

100 Ω RTD input: Each 1Ω of lead wire resistance can cause a +2°F

error when using a two-wire RTD. A three-wire RTD sensor overcomes this

problem. All three wires must have the same electrical resistance (i.e.,

same gauge, same length, multi-stranded or solid, same metal).

Maintain isolation between input 1 and input 2 to prevent a ground loop.

A ground loop may cause incorrect readings, dashes across the upper display or the display of error codes.

fuse

22

21

earth ground

11

L2L1

+

-

∫

WARNING:

To avoid potential

electric shock, use

National Electric

Code (NEC) safety

practices when

wiring and connecting this unit to a

power source and

to electrical sensors

or peripheral

devices. Failure to

do so could result

in injury or death.

˜

NOTE:

Input-to-output isolation is defeated

when the external

signal conditioner

power supply option

is used to power a

transmitter connected to input 1.

Figure 2.4 Power wiring.

ç

CAUTION:

If high voltage is

applied to the low

voltage unit, irreversible damage

will occur.

Page 15

WATLOW Series 982 User’s Manual 2.5

Installation and Wiring, Chapter 2

Wiring

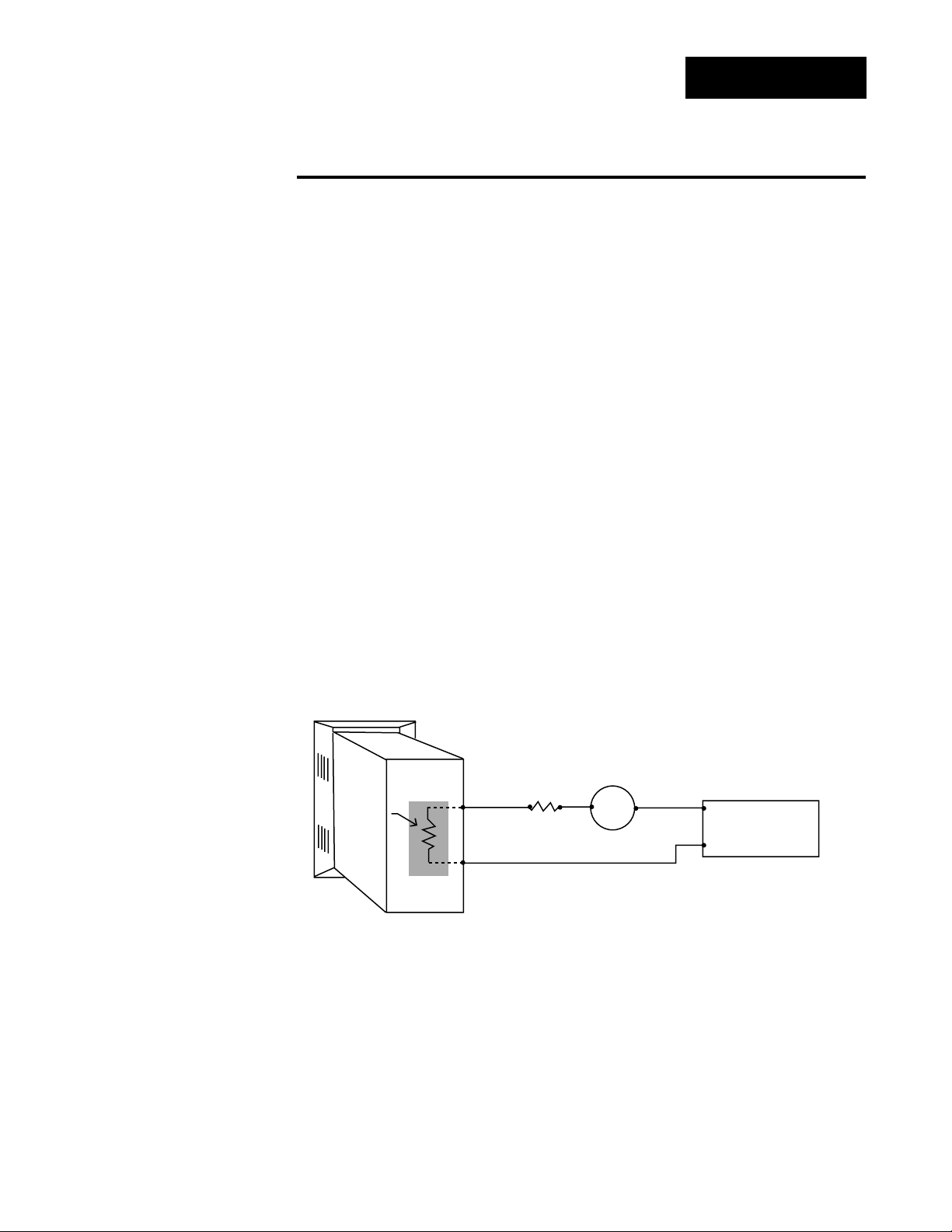

Wiring 0-20 and 4-20mA Process Inputs

Certain “transmitters” used in process input applications are producing

internal resistor failures in the Watlow Series 988 family of controllers.

This is only apparent with the Series 988 family 1/8 DIN units with

Process Inputs selected (0-20mA or 4-20mA dc only).

We are noticing that an external resistor is required to prevent a high

in-rush current which burns out the Series 988 family controllers’ 7-ohm

internal resistor. This high in-rush current occurs initially on “power-up.”

If the transmitter turns full on for a split second during power-up, the

available current weakens or damages the internal resistor.

Example: 20V / 7 ohms = 2,857mA (too much!).

The wiring diagram example below shows an application where a customer

is using a 4-20mA dc transmitter and power supply to feed the input of a

Series 988 controller. The Rx range (100 to 400 ohms) for the external

resistor is recommended. We suggest starting with 250 ohms.

Example: Customer is using a 24VÎ (dc) power supply to power up the

4-20mA dc transmitter that inputs to the Series 988 terminals 8 (-) and 10

(+). To figure out what the internal Series 988’s handling current is for the

0-20mA or 4-20mA dc input to the Series 988 controllers, we need to

apply Ohm’s Law: The square root of Watts divided by Resistance equals

Current. Applying that formula to the example below produces the following: Square Root of (0.125 Watts / 7 ohms) = 134 mA dc (handling input

current). This is the acceptable input current for the Series 988 universal

input board.

Reminder, the input impedance of 7 ohms handles the majority of our

customer applications; the external resistor (Rx) is only for certain transducers/transmitters that spike on power-up or power-down. Please make

sure your customer’s transmitter / transducer fall within our Series 988

family (1/8 DIN) of controllers’ Process Input specification of 7 ohms input

impedance.

Figure 2.5 Process wiring

example.

988 Process

Input Control

4-20mA dc

Internal

Resistor

7Ω

1/8 Watt

+

—

R

100 to 400

ohms

x

Transmitter

—

+

+

24VÎ (dc)

Power Supply

—

Page 16

2.6 WATLOW Series 982 User’s Manual

Installation and Wiring, Chapter 2

Wiring Example

Figure 2.6 System wiring

example.

∫

WARNING:

To avoid potential

electric shock, use

National Electric

Code (NEC) safety

practices when

wiring and connecting this unit to a

power source and

to electrical sensors or peripheral

devices. Failure to

do so could result

in injury or death.

ç

WARNING:

Install high or low

temperature limit

control protection

in systems where

an over temperature fault condition

could present a fire

hazard or other hazard. Failure to

install temperature

limit control protection where a potential hazard exists

could result in damage to equipment,

property and injury

to personnel.

Ó

WARNING:

To avoid damage to

property and equipment, and/or injury

of loss of life, use

National Electric

Code (NEC) standard wiring practices to install and

operate the Series

982. Failure to do

so could result in

such damage,

and/or injury or

death.

L1

120 VÅ (ac)

L2

eart h ground

(+)

9

10

(-)

red

120VÅ (ac)

1

2

3

4

5

6

7

8

9

10

11

12

13

high limit

mec hanical

fuse

2221

11

12

(+)

(-)

13

982C- 10CA- AARR

rear view

L1

1

1

1 2

1

proc ess sens or li mit sensor

3

4

(+)

5

(-)

1 CR-1

8

11

17

coil

contactor

heater

Series 92

limit control

R

18

15

13 14

10+11

-

norm ally open

mom entary swit ch

1CR

16

SSR-240-10A-DC1

out

12

43

in

21 22

9

10

910

12

13

(+)

14

(-)

15

DC input

SSR

heater

Series 982

982C-10CA-AARR

temperature control

12 13

67

12

13

14

10

11

4

in

3-32VÎ (dc)

(+)

out

24-240VÅ (ac)

92A3-1D J1- 0000

limit control

11

SSR-240-10A-DC1

solid-state relay, DC input

(-)

92A3-1DJ1-0000

3

5

high temperature light

high

tem peratur e

li ght

optional

2

2

2

2

L2

Page 17

WATLOW Series 982 User’s Manual 2.7

Installation and Wiring, Chapter 2

Wiring Notes

ç

WARNING:

To avoid damage to

property and equipment, and/or injury

of loss of life, use

National Electric

Code (NEC) standard wiring practices to install and

operate the Series

982. Failure to do

so could result in

such damage,

and/or injury or

death.

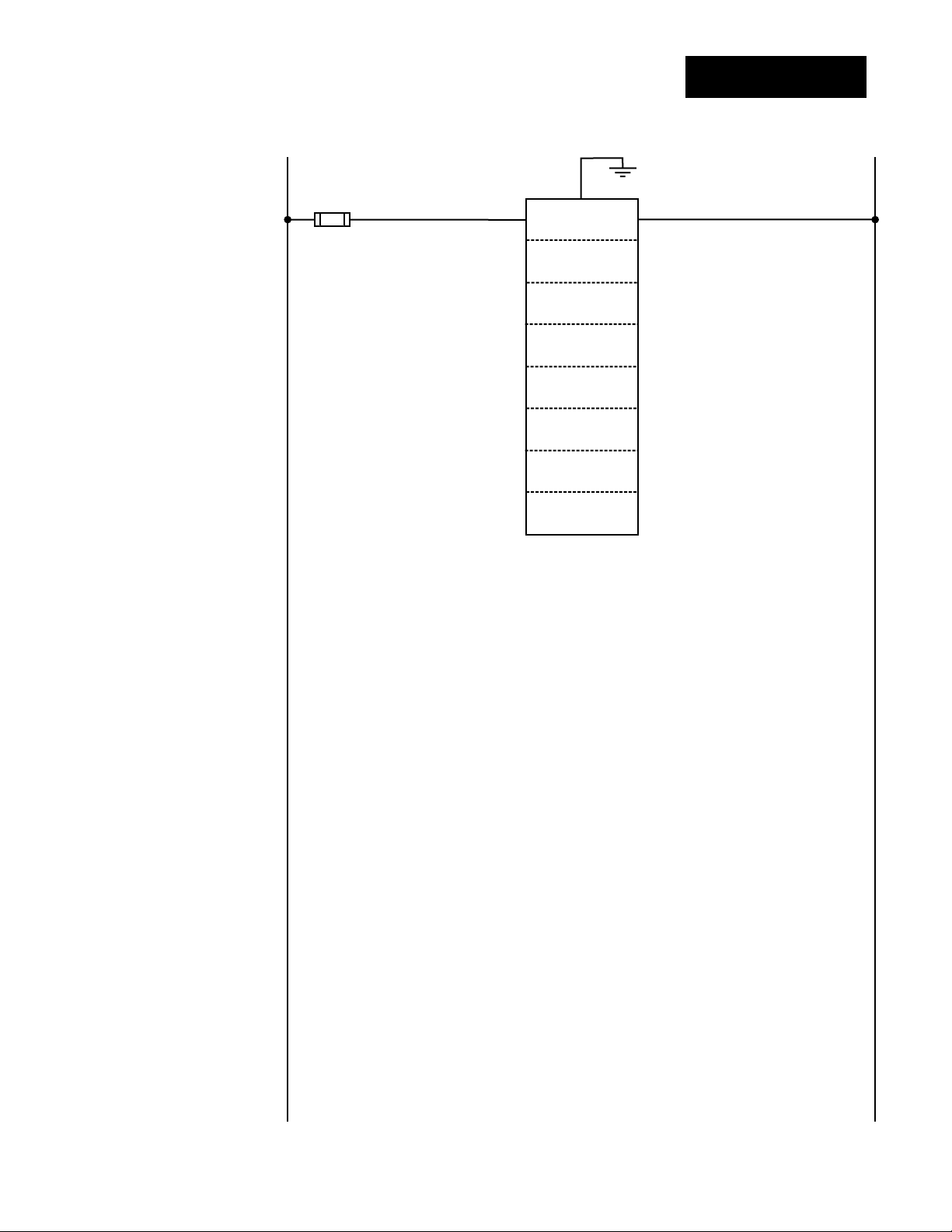

Figure 2.7 Wiring notes.

˜

NOTE:

Sketch in your

application on this

page or a copy of it.

See wiring examples in this chapter.

L1 L2

earth ground

11

21 22

power

Page 18

2.8 WATLOW Series 982 User’s Manual

Installation and Wiring, Chapter 2

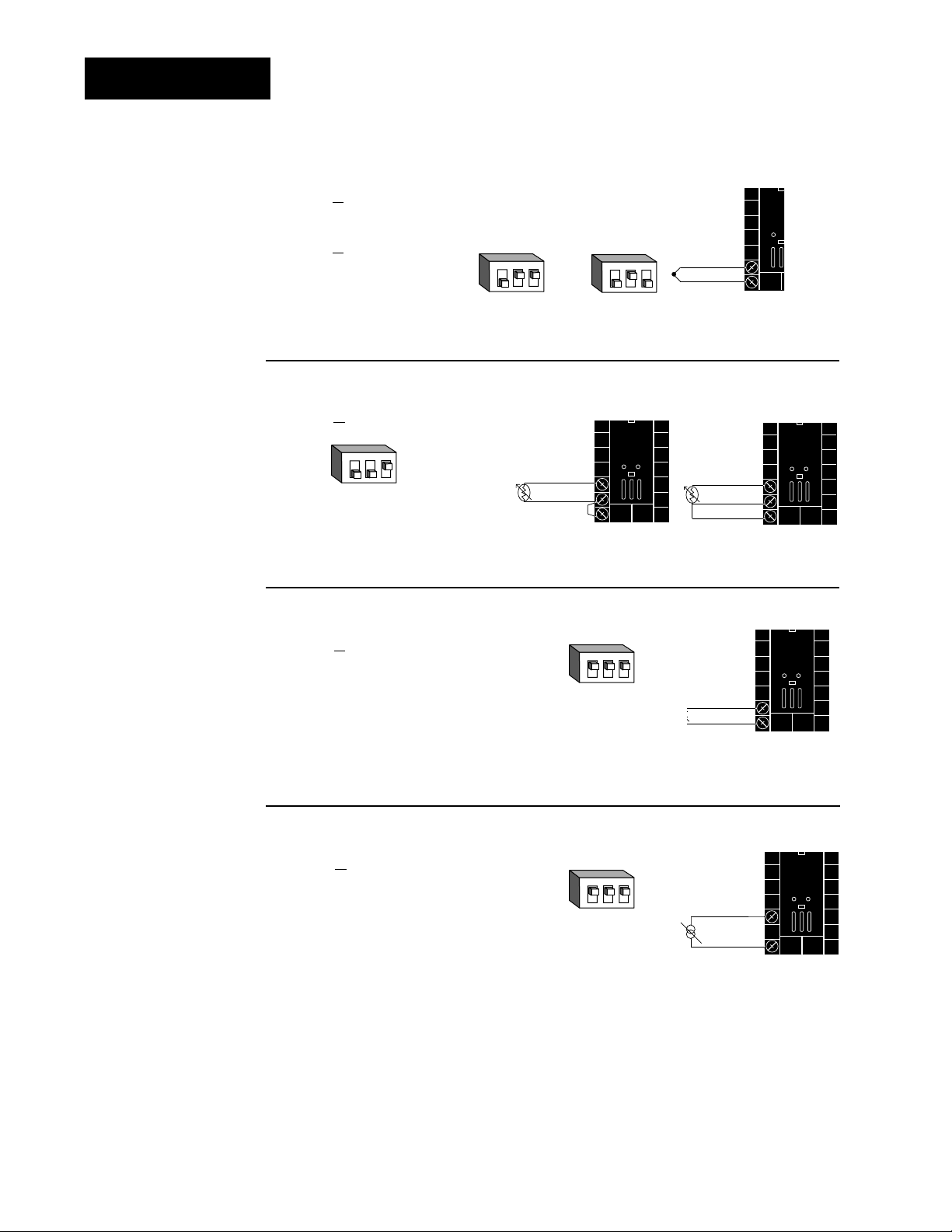

Input 1 Wiring

Figure 2.8c —

0-5VÎÎ, 1-5VÎÎor 0-10VÎÎ(dc) Process

Universal signal conditioner

98 _ C - 2 _ _ _ - _ _ _ _

Input impedance: 10KΩ

Figure 2.8a —

Thermocouple

Thermocouple only

98 _ C - 1 _ _ _ - _ _ _ _ (no DIP switches)

Universal signal conditioner

98 _ C - 2 _ _ _ - _ _ _ _

Input impedance: 20MΩ

Figure 2.8b — RTD (2- or 3-wire)

Universal signal conditioner

98 _ C - 2 _ _ _ - _ _ _ _

Figure 2.8d — 0-20mA or 4-20mA Process

Universal signal conditioner

98 _ C - 2 _ _ _ - _ _ _ _

Input impedance: 7Ω

DIP Switch

Setting

R, S, B

DIP Settings

J, K, T, N, C, E, D, Pt2,

DIP Settings

DIP Switch

Setting

DIP Switch

Setting

˜

NOTE:

Successful installation requires five

steps:

• Model number and

software choice

(Appendix);

• DIP switch settings (Chapter 1);

• Sensor match

(Chapter 2 and

Appendix);

• Sensor installation

(Chapter 2); and

• Wiring (Chapter 2).

Jumper

9 to 10

for 2-wire

RTD

ç

CAUTION:

An external resistor

is required for

0-20mA and 4-20mA

process wiring to

prevent a high inrush current which

could burn out the

controller’s 7-ohm

resistor. See page 2.5

for recommendations.

123

O

N

↑

123

O

N

↑

S1

S2

O

N

↑

8

9

10

123

O

N

↑

123

+

9

-

10

8

S1

9

S2

10

S3

9-+

10

123

O

N

↑

-

8

10

+

Page 19

WATLOW Series 982 User’s Manual 2.9

Installation and Wiring, Chapter 2

Input 2 Wiring

˜

NOTE:

Successful installation requires five

steps:

• Model number and

software choice

(Appendix);

• DIP switch settings (Chapter 1);

• Sensor match

(Chapter 2 and

Appendix);

• Sensor installation

(Chapter 2); and

• Wiring (Chapter 2).

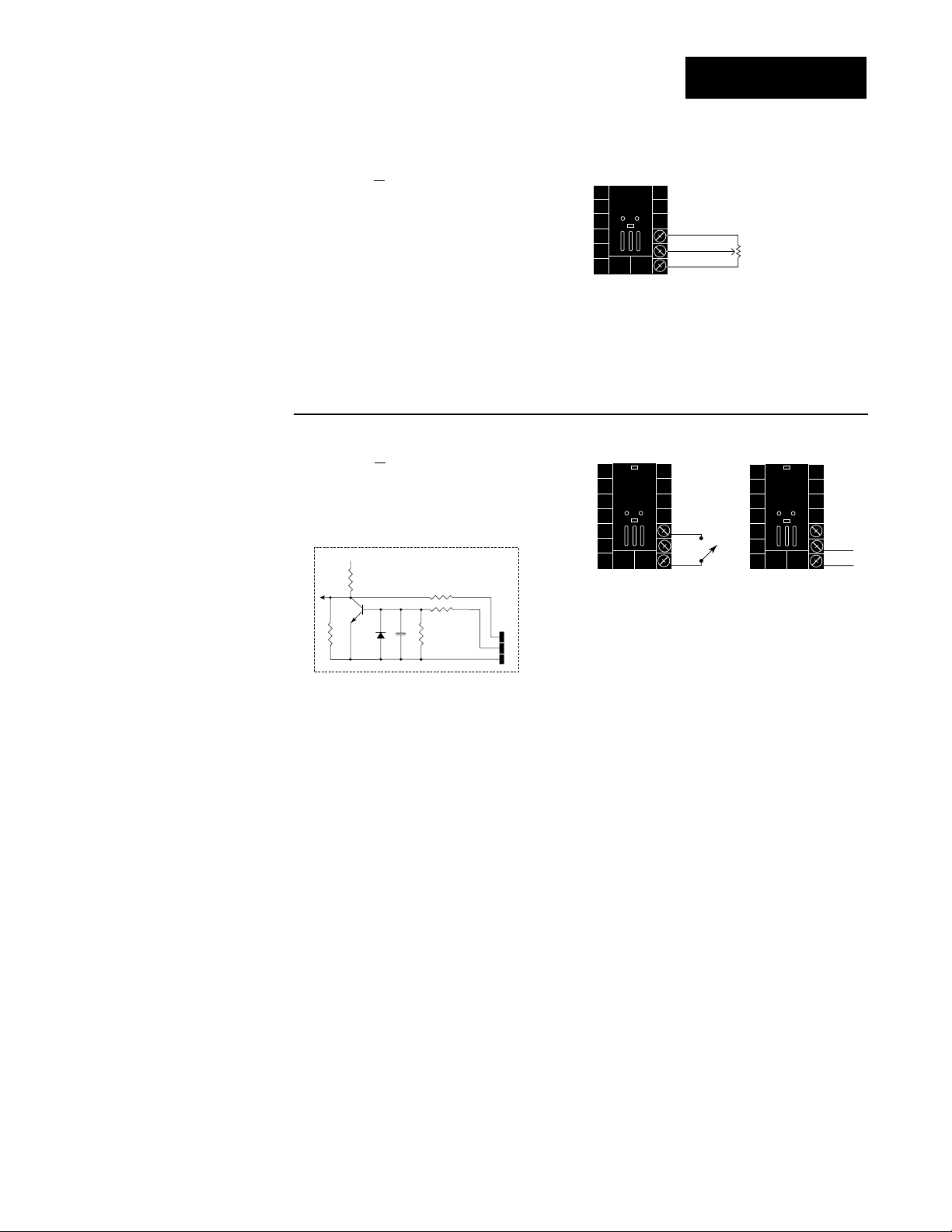

Figure 2.9a — Slidewire Feedback or Potentiometer Input

98 _ C - _ 3 _ _ - _ _ _ _

Slidewire resistance: 100 to 1,200Ω

19

20

18

CW

CCW

Wiper

˜

NOTE:

See Chapter 9 for

information on

slidewire feedback.

Figure 2.9b — Digital Event Input 2

98 _ C - _ 5 _ _ - _ _ _ _

0-3VÎ (dc) Event Input 2 off (open)

14-36VÎ (dc) Event Input 2 on (closed)

18

+5VÎ (dc)

Internal Circuitry

1KΩ

1KΩ

.01µf

750Ω

100Ω

4.7KΩ

20

18

19

20

19

20

+

-

Page 20

2.10 WATLOW Series 982 User’s Manual

Installation and Wiring, Chapter 2

Figure 2.10 —

Digital Event Input 1

Available on all units.

14-36VÎ (dc) Event Input 1 off (open)

0-3VÎ (dc) Event Input 1 on (closed)

˜

NOTE:

Successful installation requires five

steps:

• Model number and

software choice

(Appendix);

• DIP switch settings (Chapter 1);

• Sensor match

(Chapter 2 and

Appendix);

• Sensor installation

(Chapter 2); and

• Wiring (Chapter 2).

Event Input 1 Wiring

4.99KΩ

+24VÎ (dc)

10KΩ

Internal Circuitry

OPTO

ISOLATOR

23

4.99KΩ

24

750Ω

.01µf

23 24

+-

Page 21

WATLOW Series 982 User’s Manual 2.11

Installation and Wiring, Chapter 2

˜

NOTE:

Successful installation requires five

steps:

• Model number and

software choice

(Appendix);

• DIP switch settings (Chapter 1);

• Sensor match

(Chapter 2 and

Appendix);

• Sensor installation

(Chapter 2); and

• Wiring (Chapter 2).

Figure 2.11a —

AC Outputs

Solid-state Relay with Contact Suppression

98 _ C - _ _ B _ - _ _ _ _

0.5 amps, minimum off-state impedance: 20KΩ

Electromechanical Relay with Contact Suppression

(NO and COM contacts only)

98 _ C - _ _ D _ - _ _ _ _

Form C, 5 amps, minimum off-state impedance: 20KΩ

Electromechanical Relay without Contact Suppression

98 _ C - _ _ E _ - _ _ _ _

Form C, 5 amps off-state impedance: 31MΩ

Solid-state Relay without Contact Suppression

98 _ C - _ _ K _ - _ _ _ _

0.5 amps, off-state impedance: 31MΩ

Output 1 Wiring

Figure 2.11b — Switched DC, Open Collector

98 _ C - _ _ C _ - _ _ _ _

Minimum load resistance: 500Ω

Figure 2.11d — 0-5V

ÎÎ

, 1-5VÎÎand 0-10VÎÎ(DC) Process

98 _ C - _ _ F _ - _ _ _ _

Minimum load impedance: 1KΩ

Figure 2.11c — 0-20mA and 4-20mA Process

98 _ C - _ _ F _ - _ _ _ _

Maximum load impedance: 800Ω

14

-

+

12

14

-

+

13

19 to 32VÎ (dc)

+ Vdc

790Ω

Internal Circuitry

12

13

14

External

Load

NO

12

13

COM

14

(#14 for D & E outputs only)

Fuse

NC

12

+

External

-

13

14

COM

L2

L1

Load

Page 22

2.12 WATLOW Series 982 User’s Manual

Installation and Wiring, Chapter 2

Output 2 Wiring

Figure 2.12b — Switched DC, Open Collector

98 _ C - _ _ _ C - _ _ _ _

Minimum load resistance: 500Ω

Figure 2.12d — 0-5V

ÎÎ

, 1-5VÎÎand 0-10VÎÎ(DC) Process

98 _ C - _ _ _ F - _ _ _ _

Minimum load impedance: 1KΩ

Figure 2.12c — 0-20mA and 4-20mA Process

98 _ C - _ _ _ F - _ _ _ _

Maximum load impedance: 800Ω

15

+

-

17

16

+

-

17

Figure 2.12e — External Signal Conditioner Power Supply

98 _ C - _ _ _ T - _ _ _ _

Figure 2.12a —

AC Outputs

Solid-state Relay with Contact Suppression

98 _ C - _ _ _ B - _ _ _ _

0.5 amps, minimum off-state impedance: 20KΩ

Electromechanical Relay with Contact Suppression

(NO and COM contacts only)

98 _ C - _ _ _ D - _ _ _ _

Form C, 5 amps, minimum off-state impedance: 20KΩ

Electromechanical Relay without Contact Suppression

98 _ C - _ _ _ E - _ _ _ _

Form C, 5 amps off-state impedance: 31MΩ

Solid-state Relay without Contact Suppression

98 _ C - _ _ _ K - _ _ _ _

0.5 amps, off-state impedance: 31MΩ

˜

NOTE:

Successful installation requires five

steps:

• Model number and

software choice

(Appendix);

• DIP switch settings (Chapter 1);

• Sensor match

(Chapter 2 and

Appendix);

• Sensor installation

(Chapter 2); and

• Wiring (Chapter 2).

˜

NOTE:

Input-to-output isolation is defeated

when the external

signal conditioner

power supply is

used to power a

transmitter connected to input 1.

˜

NOTE:

See Chapter 1 for

DIP switch location

and settings.

NOTE:

This output cannot

be configured as an

event ouput.

NOTE:

If [SLid] is selected

for [`In2], [`Ot2]

prompt will not

appear.

19 to 32VÎ (dc)

+ Vdc

790Ω

Internal Circuitry

15

16

17

External

Load

15

NO

COM

16

Fuse

NC

17

(#17 for D & E outputs only)

15

+

External

-

16

17

COM

L2

L1

Load

15

+

16

-

-

+

Input

1 or 2

1

2

Transmitter

+V

4-20mA out

-V

Page 23

WATLOW Series 982 User’s Manual 2.13

Installation and Wiring, Chapter 2

Figure 2.13c —

Process Retransmit

0-20mA, 4-20mA, Load impedance: 600Ω max.

98 _ C - _ _ _ _ - M _ _ _

0-5VÎÎ, 1-5VÎÎ, 0-10VÎÎ(dc), Load impedance: 500Ω min.

98 _ C - _ _ _ _ - N _ _ _

˜

NOTE:

Input-to-output isolation is defeated

when the external

signal conditioner

power supply is

used to power a

transmitter connected to input 1.

˜

NOTE:

Successful installation requires five

steps:

• Model number and

software choice

(Appendix);

• DIP switch settings (Chapter 1);

• Sensor match

(Chapter 2 and

Appendix);

• Sensor installation

(Chapter 2); and

• Wiring (Chapter 2).

Figure 2.13d — External Signal Conditioner Power Supply

98 _ C - _ _ _ _ - T _ _ _

Figure 2.13a — AC Outputs

Solid-state Relay with Contact Suppression

98 _ C - _ _ _ _ - B _ _ _

0.5 amps, minimum off-state impedance: 20KΩ

Electromechanical Relay without Contact

Suppression

98 _ C - _ _ _ _ - J _ _ _ _

Form A or B, 5 amps, off-state impedance: 31MΩ

Solid-state Relay without Contact Suppression

98 _ C - _ _ _ _ - K _ _ _ _

0.5 amps, off-state impedance: 31MΩ

Figure 2.13b — Switched DC

98 _ C - _ _ _ _ - C _ _ _

Minimum load resistance: 500Ω

Form B

Form A

Form A or B

alarm jumper

settings (98_C____-J___ only)

Output 3 Wiring

˜

NOTE:

See Chapter 1 for

DIP switch location

and settings.

19 to 32VÎ (dc)

1

790Ω

2

Internal Circuitry

+ Vdc

NC Form B

External

2

1

Fuse

Load

NO Form A

COM

or

External

Load

1

2

1

+

2

-

Transmitter

4-20mA out

+

-

+V

-V

-

+

Input

1 or 2

1

2

1

+

2

-

Page 24

Figure 2.14b — Switched DC, Open Collector

98 _ C - _ _ _ _ - _ C _ _

Minimum load resistance: 500Ω

Figure 2.14a — AC Outputs

Solid-state Relay with Contact Suppression

98 _ C - _ _ _ _ - _ B _ _

0.5 amps, minimum off-state impedance: 20KΩ

Electromechanical Relay with Contact Suppression

(NO and COM contacts only)

98 _ C - _ _ _ _ - _ D _ _ _

Form C, 5 amps, minimum off-state impedance: 20KΩ

Electromechanical Relay without Contact Suppression

98 _ C - _ _ _ _ - _ E _ _ _

Form C, 5 amps, off-state impedance: 31MΩ

Solid-state Relay without Contact Suppression

98 _ C - _ _ _ _ - _ K _ _ _

0.5 amps, off-state impedance: 31MΩ

2.14 WATLOW Series 982 User’s Manual

Installation and Wiring, Chapter 2

Output 4 Wiring

Figure 2.14c —

External Signal Conditioner Power Supply

98 _ C - _ _ _ _ - _ T _ _

5

6

+

-

+V

-V

Transmitter

4-20mA out

Input

1 or 2

+

-

For data communications wiring refer to Data Communications

with the Watlow Series 988 Family of Controllers.

˜

NOTE:

Input-to-output isolation is defeated

when the external

transmitter power

supply is used to

power a signal conditioner connected

to input 1.

˜

NOTE:

See Chapter 1 for

power supply DIP

switch information.

˜

NOTE:

Successful installation requires five

steps:

• Model number and

software choice

(Appendix);

• DIP switch settings (Chapter 1);

• Sensor match

(Chapter 2 and

Appendix);

• Sensor installation

(Chapter 2); and

• Wiring (Chapter 2).

19 to 32VÎ (dc)

+ Vdc

5

790Ω

6

7

Internal Circuitry

External

Load

2

1

Fuse

(#7 for D & E outputs only)

External

Load

COM

+

COM

-

5

NO

6

7

NC

5

6

7

Page 25

WATLOW Series 982 User’s Manual 3.1

Keys & Displays, Chapter 3

After 1 minute with no key activations, the control reverts to the Display Loop. The

process value appears in the upper display and the set point is in the lower display.

For more information on the Display Loop, see the next page.

Upper Display

Indicates either actual process value, the operating

prompt values, or error codes. When powering up,

the Process display will be blank for 3 seconds. Red

or green, 0.4” (10mm) high, seven segment, four

digit LED display.

Dev LED

When lit, the deviation from the

current set point is shown in the

lower display.

% Out LED

When lit, the current percent output is shown in the lower display.

Up Key

Increases the value of the displayed prompt. A light touch

increases the value by one.

Holding the key down increases

the value at a rapid rate. New

data is self entering in 5 seconds

or once the Mode key or Display

key is pressed.

Down Key

Decreases the value of the displayed prompt. A light touch

decreases the value by one.

Holding the key down decreases

the displayed value at a rapid

rate. New data is self entering in

5 seconds or once the Mode key

or Display key is pressed.

Up + Down Keys

When pressed simultaneously for

3 seconds, the Setup (SEt)

prompt appears. Continue to

press the Up/Down keys for

another 3 seconds and the

Factory (Fcty) prompt appears.

Lower Display

Indicates the set point, deviation, percent

power temperature unit, menu prompts, or

alarm codes. Red or green, 0.3” (8mm) high,

seven segment, four digit LED display.

L1, L2, L3, L4

When lit, these LEDs indicate

when Output 1, 2, 3, or 4 are

active respectively. Outputs can

be configured as:

Ot1 Control

Ot2 Control or Alarm

Ot3

Alarm, Event or Retransmit

Ot4 Alarm, Event or Com-

munications (flashes on

transmit and receive.)

Display Key

Pressing this key enters the

Display Loop. The Display key

can be pressed at any time to

return to this loop. For more

information on the Display Loop,

see the next page.

Hold/Run Key

Pressed once, it clears a latched

alarm without altering the

Hold/Run status. To run or halt a

program see Chapter 7 for

details.

Hold/Run LED

Lit when the program is running.

When blinking, press the

Hold/Run key again to begin

running. When not lit, the controller is in fixed set point mode

or single.

Mode Key

Steps the control through

the menus. New data is

entered once the Mode

key is pressed.

Mode + Up Key

To move backwards

through the menus, hold

down the Mode key, then

press the Up key to scroll.

The Mode key must be

pressed first and held

before the Up key will

begin scrolling. Scrolling is

disabled once the keys are

released or you reach the

top of the menu.

Figure 3.1 Series 982 Keys

and Displays.

Chapter 3 Front Panel and Display Loop

L1 L2 L3 L4

DEV

% OUT

SERIES 982

A

TL

W

PROCESS

DISPLAY

W

HOLD

RUN

MODE

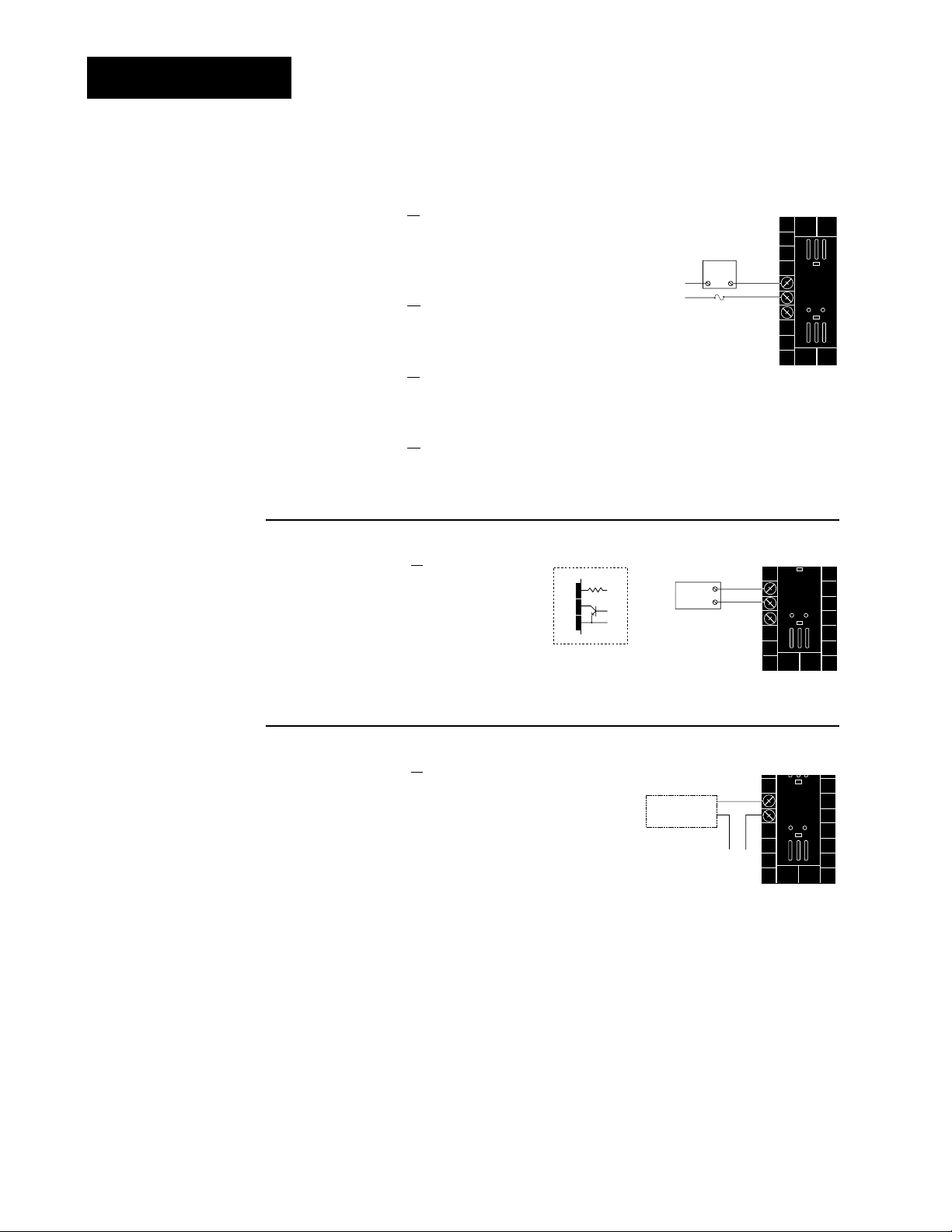

Page 26

3.2 WATLOW Series 982 User’s Manual

Keys & Displays, Chapter 3

Display Loop

Display Loop

The Display Loop is the “home” state of the Series 982 controller. Pressing

the Display key ∂ returns the controller to the Display Loop from any

prompt in any menu. The controller automatically returns to the Display

Loop from any menu when a minute passes without any keys being

pressed.

Figure 3.2 The Display Loop.

˜

NOTE:

If [``no] is selected

for [`In2], in the

Input Menu, the

[Pr`2] prompt will

not appear.

˜

NOTE:

For information on

Input 1 [`In1] and

Input 2 [`In2]

ranges, refer to

Chapter 4.

Single Set Point

When a program is not running, you can adjust the set point, shown in

the lower display, by pressing the Up-arrow or Down-arrow key or through

serial communications. You can de-engergize all outputs, including event

outputs, by lowering set point 1 to the range low setting minus one, which

will display [`OFF] in the lower display.

Ramping

When a program is running, the set point is controlled by the program.

You can view this set point, but cannot change it while the program is

running. You can select the event output status for each step.

current input 1 reading

set point 1 (change with Up-arrow and Down-arrow keys)

DISPLAY

DISPLAY

DISPLAY

DISPLAY

DISPLAY

DISPLAY

current slidewire percent reading

input 2 process (appears only if controller equipped with slidewire option)

current input 1 reading

deviation from set point, process 1 minus set point 1 (DEV light on)

current input 1 reading

percent output (%OUT light on)

current input 1 reading

units selected (units, °F or °C)

Page 27

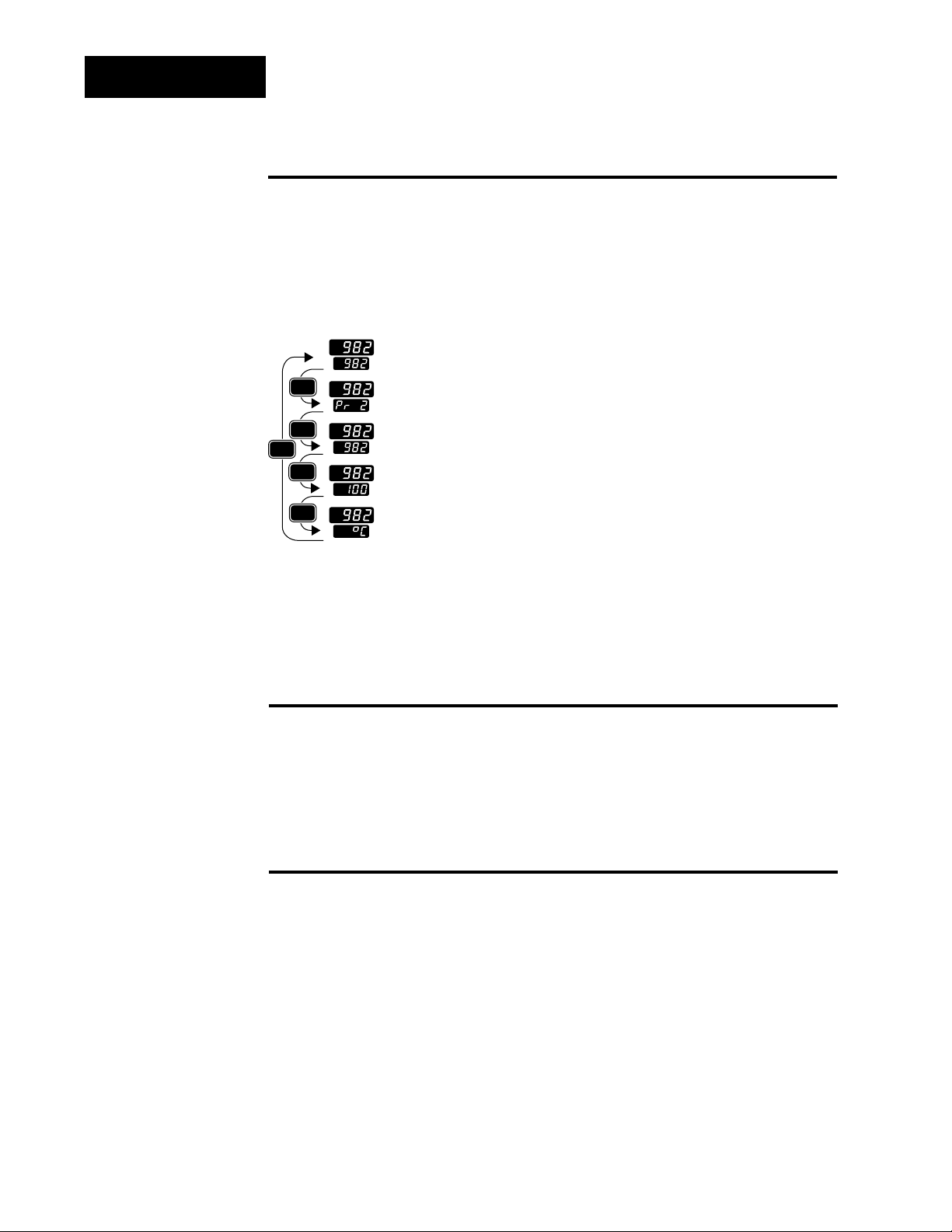

WATLOW Series 982 User’s Manual 4.1

Setup Menus, Chapter 4

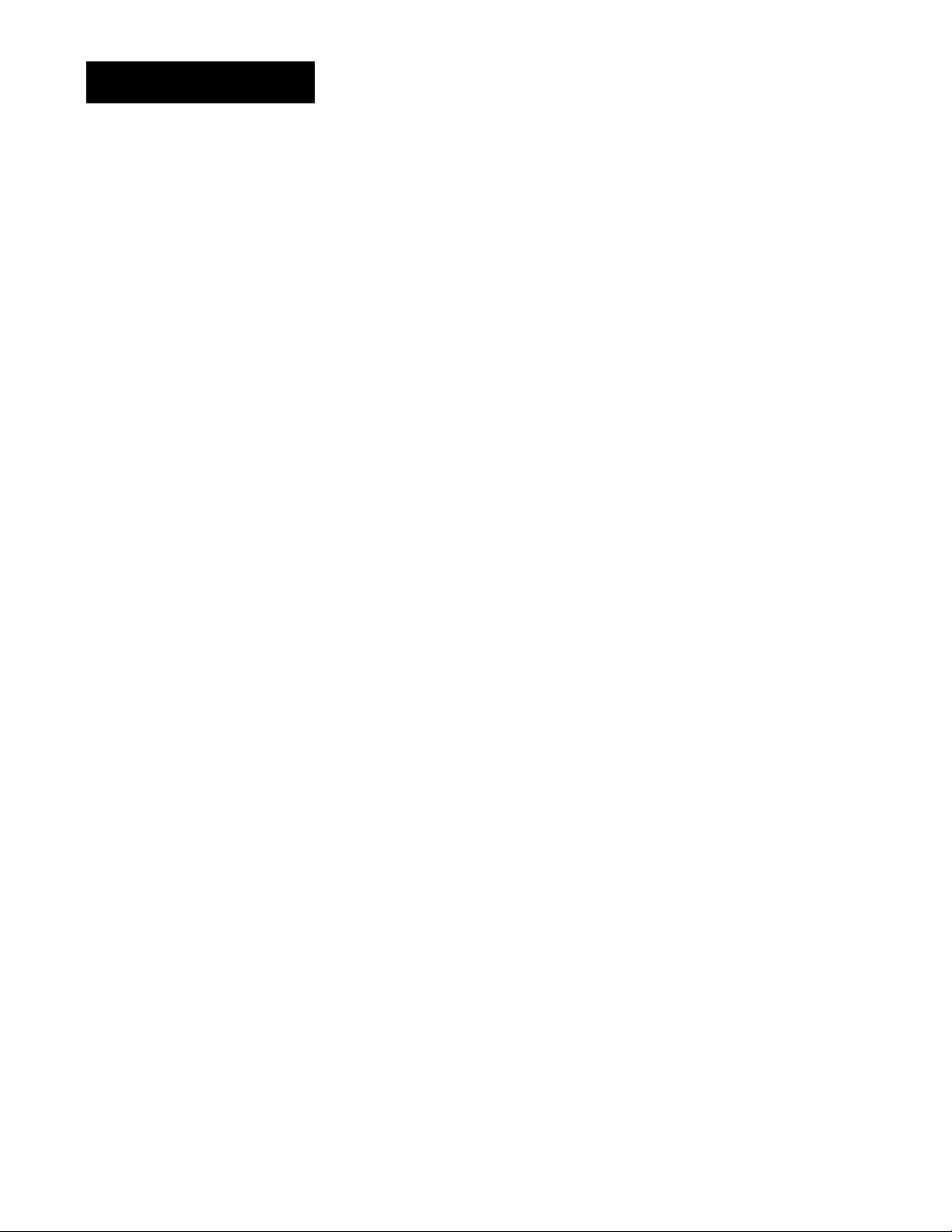

Navigating the Setup Menus

To reach the Setup Menus, begin in the Display Loop and press both the Uparrow > and Down-arrow < keys for three seconds. The Setup Menu

prompt [`SEt] will appear in the lower display, and the Input Menu prompt

[InPt]] will appear in the upper display. The four Setup Menus are: Input

[InPt]; Output [OtPt]; Global [GLbL]; and Communications [COM]. Use the

Up-arrow > or Down-arrow < key to select a menu and the Mode key µ

to step through a menu. The Communications Menu appears only on units

equipped with the data communications option.

You will not see every prompt in any of these menus. The unit’s configuration

and model number determine which prompts appear. After stepping through

each menu, the Series 982 returns to the Setup Menu prompt [`SEt]. Use

the Up-arrow > and Down-arrow < keys to select the next menu, or use

the Mode key µ to advance through the same menu again. To move backwards through the menu hold the Mode key µ down and press the Uparrow key >. Use the Up-arrow > or Down-arrow < key to change the

prompt setting.

Refer to the Appendix for model number options. For information about

communications and the communications prompts, refer to the supplemental manual Data Communications with the Watlow Series 988 Family of

Controllers.

Chapter 4 The Setup Menus

Figure 4.1 Navigating the

Setup Menus.

❶ Begin in the Display Loop, and press the Up-arrow

> and Down-arrow < keys simultaneously to

reach the Setup Menus.

❷ Press the Up-arrow key > to select one of the

Setup Menus.

˜

NOTE:

The lockout DIP

switch hides the

Setup Menus. See

Chapter 1.

ç

CAUTION:

When navigating

thru Setup Menus,

outputs will be disabled.

˜

NOTE:

Press the Display

key ∂ to return to

the Display Loop

from any point in

any menu.

PROCESS

L1 L2 L3 L4

DEV

% OUT

SERIES 982

L1 L2 L3 L4

DEV

% OUT

SERIES 982

W

A

W

PROCESS

TL

DISPLAY

HOLD

RUN

MODE

TL

A

DISPLAY

HOLD

MODE

W

Input

Menu

p. 4.2

W

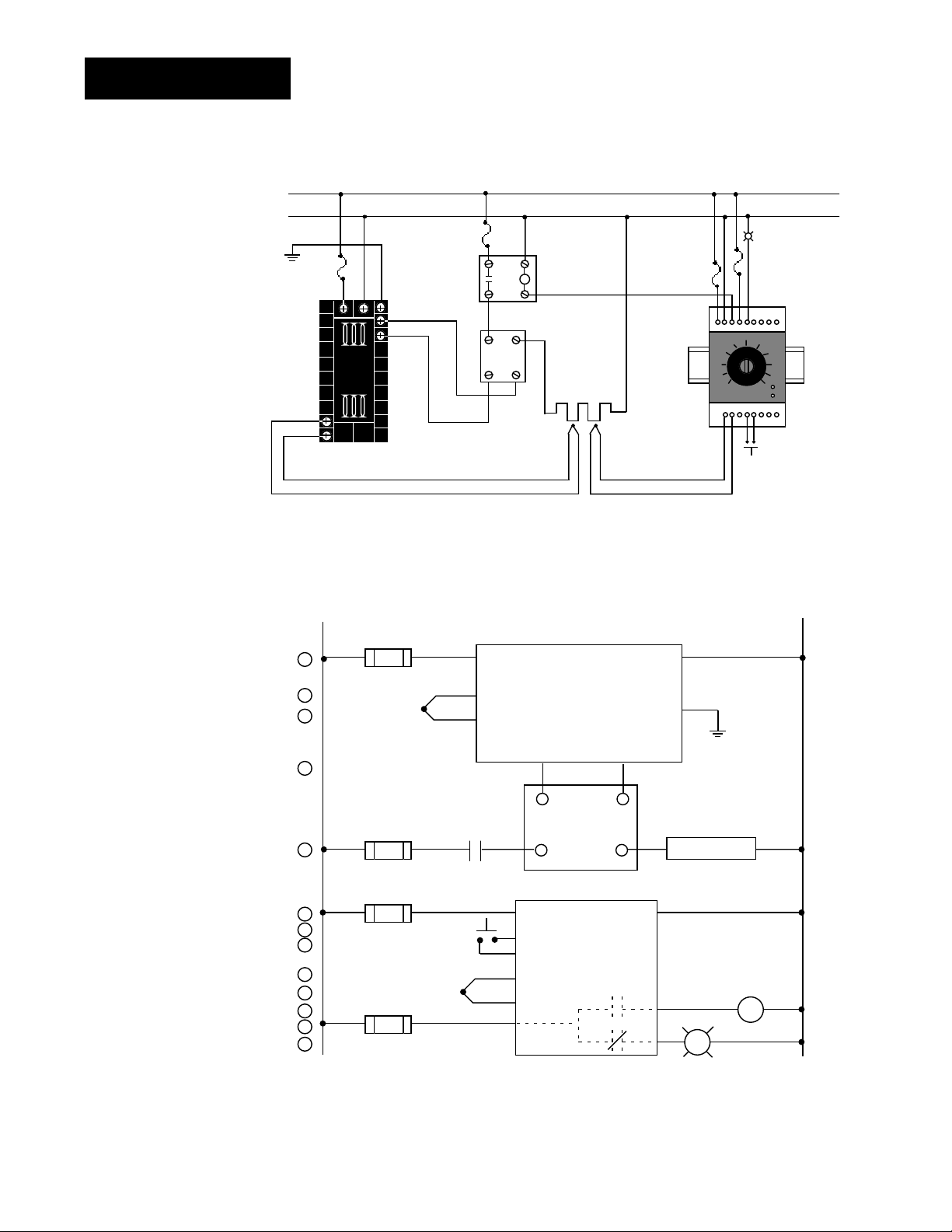

Output

Menu

p. 4.12

Global

Menu

p. 4.28

Communications

Menu

p. 4.38

RUN

Page 28

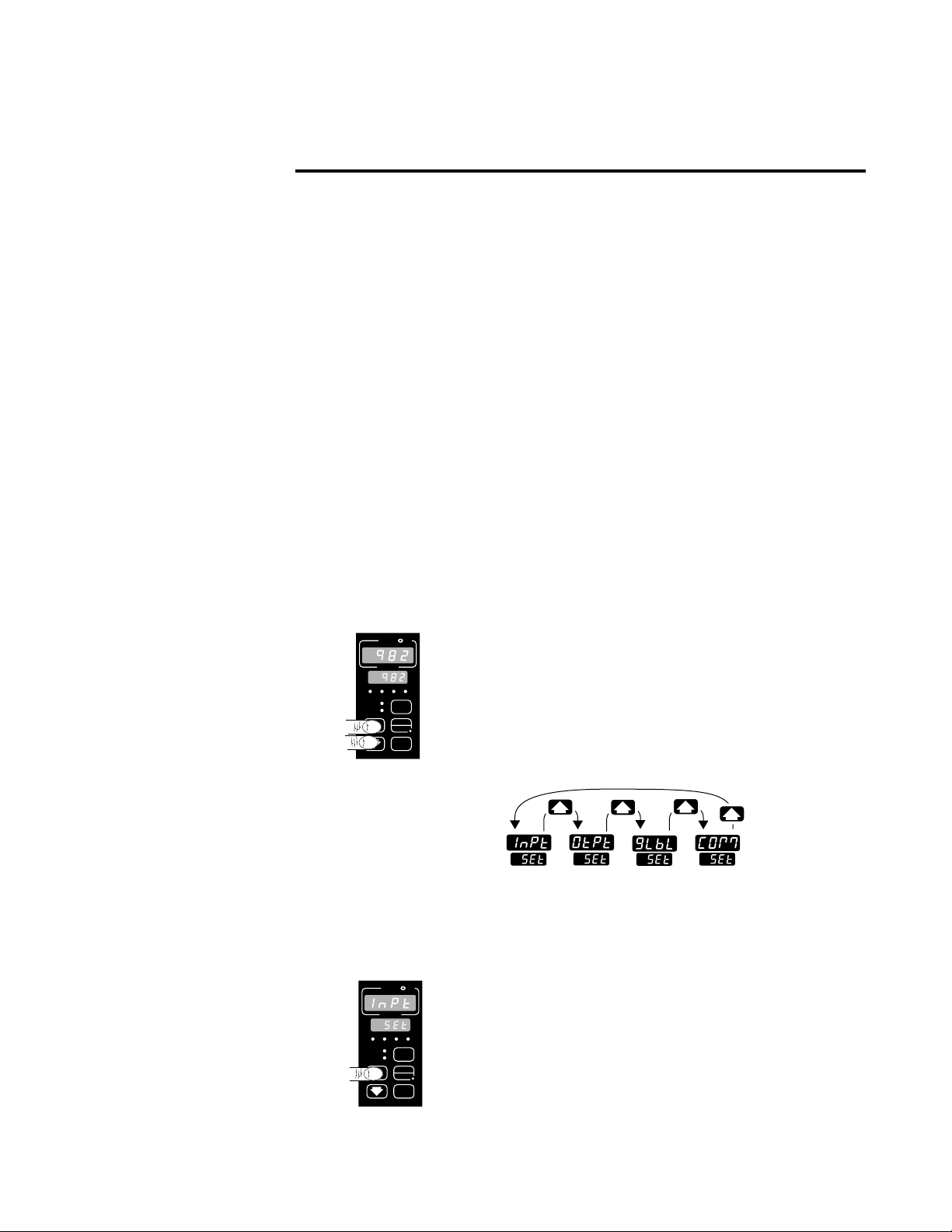

4.2 WATLOW Series 982 User’s Manual

Setup Menus, Chapter 4

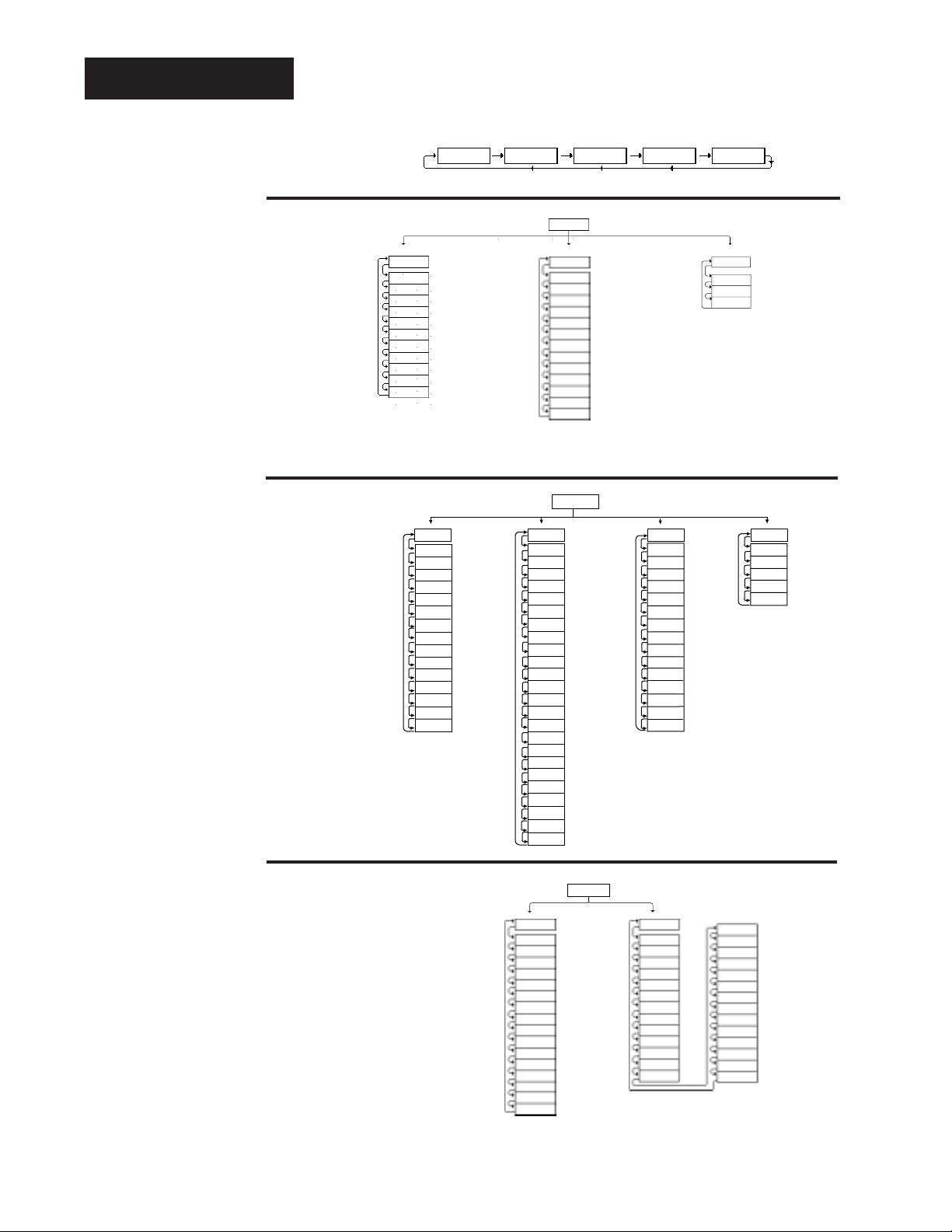

Figure 4.2 The Input Menu.

Setup-Input

❸ Select the Input Menu, then

press the Mode key µ to step

through the prompts.

❹ Press the Up-arrow key > or

the Down-arrow key < to select

one of the prompt values.

*Prompts may not appear, depending

on controller configuration.

Reaching the Input Menu

→ [InPt] Input Menu

↑ µ

[`SEt] Setup Menus

↓

?

µ

[`In1] Input 1 (page 4.3)

↓ ?

µ

[dEC1] *Decimal 1

↓ ?

µ

[`rL1] Range Low 1

↓ ?

µ

[`rH1] Range High 1

↓ ?

µ

[CAL1] Calibration Offset 1

↓ ?

µ

[rtd1] *RTD Calibration Curve 1

↓ ?

µ

[Ftr1] Input 1 Software Filter

↓

?

µ

[`In2] *Input 2 (page 4.8)

↓ ?

µ

[`rL2] *Range Low 2

↓ ?

µ

[`rH2] *Range High 2

↓ ?

µ

[LrnL] *Learn Low

↓ ?

µ

[LrnH] *Learn High

↓ ?

µ

[CAL2] *Calibration Offset 2

↓ ?

µ

[Hunt] *Hunt (page 4.11)

↑

↓

?

←µ [SHYS] *Slidewire Hysteresis

Enter your settings,

from the controller’s

upper display.

W

TL

W

A

PROCESS

L1 L2 L3 L4

DEV

DISPLAY

% OUT

HOLD

RUN

MODE

SERIES 982

…

…

…

Page 29

Input Prompts

When you are in the Setup menus, the Series 982 displays the menu selection ( [InPt], [OtPt], [GLbL] or [COM] ) in the upper display, and [`SEt] in

the lower display.

The Up-arrow > or Down-arrow key < selects another menu. Press the

Mode key µ to display the prompt in the lower display and its value in the

upper display. Use the Up-arrow > or Down-arrow < key to change the

value in the upper display. The new value will not take effect until after a

five-second delay or until you press the Mode key µ.

Input 1

Select sensor type for input 1. This selection must match the sensor type

connected to terminals 8, 9 and 10. See Appendix for more information

about sensors.

• Changing the value of [`In1] changes all other prompts to the factory

default values, except the Communications and Lockout menus, the

[`C_F] prompt in the Global Menu and the [`dFL] prompt in the

Calibration Menu. If you change the value, the default warning [dFLt]

will flash in the upper display.

• Changes do not take effect automatically after five seconds; you must

press the Mode key µ to enter the sensor type change and advance to

the next prompt.

[`In1] This prompt always appears.

If Default

↓ ↓

98__-1___-____

no DIP J K T N E W5 W3 Pt2

[```J] [```H] [```t] [```n] [```E] [```C] [```d] [`Pt2]

thermocouple [`In1] [`In1] [`In1] [`In1] [`In1] [`In1] [`In1] [`In1]

only

98__-2___-____

Input 1 DIP J K T N E W5 W3 Pt2

[```J] [```H] [```t] [```n] [```E] [```C] [```d] [`Pt2]

[`In1] [`In1] [`In1] [`In1] [`In1] [`In1] [`In1] [`In1]

thermocouple

Input 1 DIP

RSB

[```r] [```S] [```b]

[`In1] [`In1] [`In1]

thermocouple

O

N

↑

123

O

N

↑

123

WATLOW Series 982 User’s Manual 4.3

Setup Menus, Chapter 4

Setup-Input

˜

NOTE:

Decimal points may

not always be in the

position specified

below depending on

the the settings in

the Decimal 1

[dEC1] parameter in

the Input Menu.

ç

CAUTION:

Changing the value

of [`In1] changes

most other prompts

to the factory

default values and

clears all program

steps. Verify the

correct sensor type

before making a

change. Document

all settings before

changing sensor

type. Failure to follow this guideline

could result in damage to equipment or

property.

[`In1]

Input 1 continued

on next page.

[`In1]

Page 30

4.4 WATLOW Series 982 User’s Manual

Setup Menus, Chapter 4

[`In1]

Input 1 continued

from previous

page.

Setup-Input

If Default

↓↓

Input 1 DIP RTD RTD(0.1°)

[`rtd] [`r†d]

[`In1] [`In1]

RTD

Input 1 DIP 4-20mA 0-20mA 0-5VÎ 1-5VÎ 0-10VÎ (dc)

[4-20] [0-20] [`0-5] [`1-5] [0-10]

[`In1] [`In1] [`In1] [`In1] [`In1]

process

Decimal 1

Select the decimal point location for process type input 1 data. This

prompt, in conjunction with the Range Low and Range High prompts,

allows you to format and limit units of measure for process 1.

• All prompts with units of measure related to input 1 will display in the

selected decimal format.

• This affects propbands, alarm set points, process set points, calibration

offsets, deadbands and ranges.

[dEC1] This prompt appears only if you have set input 1 [`In1] to a

process input.

Default

↓

[```)] [``)0] [`)00] [)000]

[dEC1] [DEC1] [dEC1] [dEC1]

O

N

↑

123

O

N

↑

123

[dEC1]

Page 31

WATLOW Series 982 User’s Manual 4.5

Setup Menus, Chapter 4

Setup-Input

˜

NOTE:

These values do not

affect the low or the

high set point limit

for process alarms.

Range Low 1 and Range High 1

Select the low and high limits for input 1. These prompts limit the

adjustment range for the set points. The default values are the same as

the limits of the sensor you selected by setting the input 1 DIP switch and

selecting a value for Input 1 [`In1].

• Process inputs are scaled by these values. Range high is the value displayed when the maximum process signal is present at the input. Range

low is the value displayed when the minimum process signal is present

at the input.

Example: Set [`In1] to [4-20]mA.

Set [`rL1] to [`100].

Set [`rH1] to [`500].

A 4mA input will display [`100].

A 12mA input will display [`300].

A 20mA input will display [`500].

• The low and high values of each sensor type are listed on the specifications page of the Appendix.

• Choose between Fahrenheit and Celsius at the [`C_F] prompt in the

Global Menu.

[`rL1] [`rH1] These prompts always appear.

Default Default Default Default

↓↓ ↓↓

[``°F] [``°C]

[`rL1] [`rH1] [`rL1] [`rH1]

[```J] [``32]…[1500] [```0]…[`816] 98__-1__-___ or

[`in1] [`rL1] [`rH1] [`rL1] [`rH1] 98__-2__-___

(K)

[```H] [-328]…[2500] [-200]…[1371]

[```t] [-328]…[`750] [-200]…[`399]

[```n] [``32]…[2372] [```0]…[1300]

[```E] [-328]…[1470] [-200]…[`799]

(W5)

[```C] [``32]…[4200] [```0]…[2316]

(W3)

[```d] [``32]…[4200] [```0]…[2316]

[`Pt2] [``32]…[2543 [```0]…[1395]

[`rL1]

[`rH1]

Range Low 1 and

Range High 1

continued on next

page.

[`rL1]

[`rH1]

Page 32

4.6 WATLOW Series 982 User’s Manual

Setup Menus, Chapter 4

Setup-Input

˜

NOTE:

These values do not

affect the low or the

high set point limit

for process alarms.

[`rL1]

[`rH1]

Range Low 1 and

Range High 1

continued from

previous page.

[``°F] [``°C]

[`rL1] [`rH1] [`rL1] [`rH1]

[```r] {``32]…[3200] [```0]…[1760] 98__-2__-___ only

[`in1]

[```S] [``32]…[3200] [```0]…[1760]

[```b] [``32]…[3300] [```0]…[1816]

[`rtd] [-328]…[1472] [-200]…[`800]

[`r†d] [-9(9]…[99(9] [-7#3]…[53&7]

[4-20] [-999]…[`999] units

[0-20] [-999]…[`999] units

[`0-5] [-999]…[`999] units

[`1-5] [-999]…[`999] units

[0-10] [-999]…[`999] units

Calibration Offset 1

Offset the input 1 signal by a positive or negative value. This allows you

to compensate for lead resistance, sensor errors or other factors.

[CAL1] This prompt always appears.

If Default

↓↓

[``°F [-999] … [```0] … [`999]

[`C_F] [CAL1] [CAL1] [CAL1]

(Global Menu)

[``°F]&[`r†d] [-9(9] … [[``)0] … [`9(9]

[`C_F] [`In1] [CAL1] [CAL1] [CAL1]

(Global Menu) (Input Menu)

[``°C] [-555] … [[```0] … [`555]

[`C_F] [CAL1] [CAL1] [CAL1]

(Global Menu)

[``°C]&[`r†d] [-5%5] … [[``)0] … [`5%5]

[`C_F] [`In1] [CAL1] [CAL1] [CAL1]

(Global Menu) (Input Menu)

[-999] … [```0] … [`999]

units

a process input

[CAL1] [CAL1] [CAL1]

is selected

[CAL1]

Page 33

RTD Calibration Curve 1

Select the calibration curve for the RTD 1 input. The RTD input uses

either the European (DIN, 0.003850Ω/Ω/°C) or the Japanese (JIS,

0.003916Ω/Ω/°C) linearization standard.

[rtd1] This prompt appears only if you have set [`In1] to [`rtd] or

[`r†d].

Default

↓

[`din] … [`JIS]

[rtd1] [rtd1]

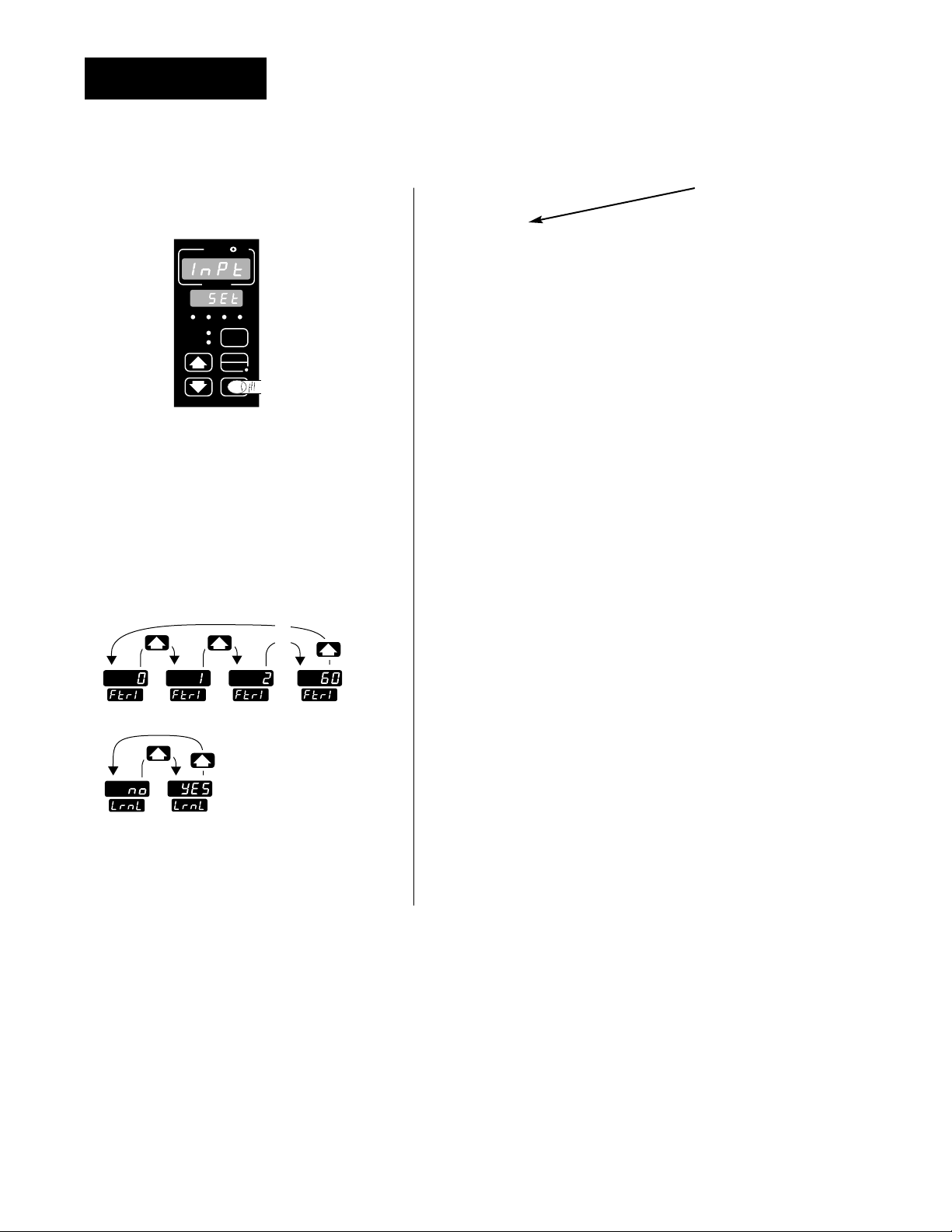

Software Filter 1

Select the filter time constant, in seconds, for input 1. This smooths a

rapidly changing input signal for display or control purposes.

• Select a positive value to filter only the display.

• Select a negative value to filter the input signal.

• Set the value to [```0] to disable the filter.

[Ftr1] This prompt always appears.

Default

↓

[`-60] … [```0] … [``60]

[Ftr1] [Ftr1] [Ftr1]

WATLOW Series 982 User’s Manual 4.7

Setup Menus, Chapter 4

Setup-Input

[rtd1]

[Ftr1]

Page 34

4.8 WATLOW Series 982 User’s Manual

Setup Menus, Chapter 4

Setup-Input

NOTE:

If [``no] is selected

for [`In2] none of

the other input 2

prompts will

appear.

Input 2

Select sensor type for input 2. This selection must match the sensor

type connected to terminals 18, 19 and 20. See Appendix for more information about sensors.

• Changing the value of [`In2] changes all other prompts to the factory default values, except the Communications and Lockout menus,

the [`C_F] prompt in the Global Menu and the [`dFL] prompt in the

Calibration Menu. If you change the value, the default warning

[dFLt] will flash in the upper display.

• Changes do not take effect automatically after five seconds; you must

press the Mode key µ to enter the sensor type change and advance to

the next prompt.

[`In2] This prompt and other Input 2 prompts appear only on controllers

equipped with input 2 hardware (not 98__-_0__-____).

If Default

↓ ↓

98__-3___-____

no DIP slidewire

[``no] [SLid]

resistance [`In2] [`In2]

only

98__-5___-____

no DIP event 2

[``no] [`Ei2]

digital event [``In2] [`In2]

only

Range Low 2

Select the low resistance of the slidewire potentiometer.

[`rL2] This prompt appears only on controllers with [`In2] (Input Menu)

set to [SLiD].

Default

↓

[```0] … [`rH2]

[`rL2] [`rL2]

[`In2]

ç

CAUTION:

Changing the value

of [`In2] changes

most other prompts

to the factory

default values and

clears all program

steps. Verify the

correct sensor type

before making a

change. Document

all settings before

changing input

type. Failure to follow this guideline

could result in damage to equipment or

property.

NOTE:

See Chapter 9 for

more information

on slidewire feedback.

[`rL2]

NOTE:

These values do not

affect the low or the

high set point limit

for process alarms.

NOTE:

If [SLid] is selected

for [`In2], [`Ot2]

prompt will not

appear.

Page 35

WATLOW Series 982 User’s Manual 4.9

Setup Menus, Chapter 4

Setup-Input

Range High 2

Select the high resistance of the slidewire potentiometer.

[`rH2] This prompt appears only on controllers with [`In2] (Input Menu)

set to [SLiD].

Default

↓

[`rL2] … [```0] … [1200]

[`rH2] [`rH2] [`rH2]

Learn Low

Write the low-end resistance of the slidewire potentiometer to the

range low 2 parameter.

[LrnL] This prompt appears only on controllers with [`In2] (Input Menu)

set to [SLiD].

Default

↓

[``no] [`YES]

[LrnL] [LrnL]

Learn High

Write the high-end resistance of the slidewire potentiometer to the

range low 2 parameter.

[LrnH] This prompt appears only on controllers with [`In2] (Input Menu)

set to [SLiD].

Default

↓

[``no] [`YES]

[LrnH] [LrnH]

[`rH2]

NOTE:

See Chapter 9 for

more information

on slidewire feedback.

[LrnL]

[LrnH]

NOTE:

These values do not

affect the low or the

high set point limit

for process alarms.

Page 36

4.10 WATLOW Series 982 User’s Manual

Setup Menus, Chapter 4

Setup-Input

Calibration Offset 2

Offset the input 2 signal by a positive or negative value. This allows

you to compensate for lead resistance, sensor errors or other factors.

[CAL2] This prompt appears only on controllers with [`In2] (Input Menu)

set to [SLiD].

If Default

↓↓

[``°F [-999] … [```0] … [`999]

[`C_F] [CAL2] [CAL2] [CAL2]

(Global Menu)

[``°F]

&

[`r†d] [-9(9] … [[``)0] … [`9(9]

[`C_F] [`In1] [CAL2] [CAL2] [CAL2]

(Global Menu) (Input Menu)

[``°C] [-555] … [[```0] … [`555]

[`C_F] [CAL2] [CAL2] [CAL2]

(Global Menu)

[``°C]

&

[`r†d] [-5%5] … [[``)0] … [`5%5]

[`C_F] [`In1] [CAL2] [CAL2] [CAL2]

(Global Menu) (Input Menu)

[-999] … [```0] … [`999]

units

a process input

[CAL2] [CAL2] [CAL2]

is selected

Hunt

Set the deadband, as a percentage of output, to keep the valve from

hunting.

• The slidewire hysteresis [SHYS] setting provides additional control over a

valve.

[Hunt] This prompt appears only on controllers with [`In2] (Input Menu)

set to [SLiD].

Default

↓

[``)1] … [``!0] … [10)0]

[Hunt] [Hunt] [Hunt]

[CAL2]

˜

NOTE:

See Chapter 9 for

more information

on slidewire feedback.

[Hunt]

Page 37

Slidewire Hysteresis

Set the inner hysteresis, the point at which the valve output turns

off.

• The figure below illustrates the interaction between slidewire hysteresis

[SHYS] and hunt [Hunt].

[SHYS] This prompt appears only on controllers with [`In2] (Input Menu)

set to [SLiD].

Default

↓

[```0] [Hunt]

[SHYS] [SHYS]

WATLOW Series 982 User’s Manual 4.11

Setup Menus, Chapter 4

Setup-Input

[SHYS]

Figure 4.11 Hunt and slidewire

inner hysteresis.

Hunt

Slidewire

Hysteresis

turn-off point (open)

turn-off point (close)

turn-on point (open)

turn-on point (close)

slidewire position

set point

Page 38

4.12 WATLOW Series 982 User’s Manual

Setup Menus, Chapter 4

Setup-Output

❸ Press the Mode key µ to

step through the prompts.

❹ Press the Up-arrow key > or

the Down-arrow key < to

select one of the prompt values.

❶ Begin in the Display Loop,

and press the Up-arrow > and

Down-arrow < keys simultaneously for three seconds to

reach the Setup Menus.

❷ Press the Up-arrow key > to

select one of the Setup Menus.

Reaching the Output

Menu

Figure 4.12 Navigating the

Output Menu.

*Prompts may not

appear, depending

on controller configuration.

→

[OtPt] Output Menu

↑

µ

[`SEt] Setup Menus

↓

?

µ

[`Ot1] Output 1 (page 4.13)

↓ ?

µ

[Prc1] *Process 1

↓ ?

µ

[HYS1] Hysteresis 1

↓

?

µ

[`Ot2] *Output 2 (page 4.15)

↓ ?

µ

[Prc2] *Process 2

↓ ?

µ

[HYS2] *Hysteresis 2

↓ ?

µ

[`AL2] *Alarm 2

↓ ?

µ

[LAt2] *Latching 2

↓ ?

µ

[SIL2] *Silencing 2

↓

?

µ

[`Ot3] *Output 3 (page 4.19)

↓ ?

µ

[`AL3] *Alarm 3

↓ ?

µ

[HYS3] *Hysteresis 3

↓ ?

µ

[LAt3] *Latching 3

↓ ?

µ

[SIL3] *Silencing 3

→

→

?

µ

[`Ot4] *Output 4 (page 4.22)

↓ ?

µ

[`AL4] *Alarm 4

↓ ?

µ

[HYS4] *Hysteresis 4

↓ ?

µ

[LAt4] *Latching 4

↓ ?

µ

[SIL4] *Silencing 4

↓

?

µ

[Aout] *Analog Output (page 4.25)

↓ ?

µ

[Prc3] *Process 3

↓ ?

µ

[`ArL] *Retransmit Low Limit

↓ ?

µ

[ArH] *Retransmit High Limit

↑

↓ ?

←µ [ACAL] *Retransmit Calibration Offset

Enter your settings,

from the controller’s

upper display.

Input

Menu

p. 4.2

Output

Menu

p. 4.12

Global

Menu

p. 4.28

Communications

Menu

p. 4.38

…

…

…

Page 39

WATLOW Series 982 User’s Manual 4.13

Setup Menus, Chapter 4

Setup-Output

Output Prompts

When you are in the Setup menus, the Series 982 displays the menu

selection ( [InPt], [OtPt], [GLbL] or [COM] ) in the upper display, and

[`SEt] in the lower display.

The Up-arrow > or Down-arrow key < selects another menu. Press the

Mode key µ to display the first prompt in the lower display and its value

in the upper display. Use the Up-arrow > and Down-arrow < keys to

change the value in the upper display. The new value will not take effect

until after a five-second delay or until you press the Mode key µ.

Output 1

Set the way that output 1 will respond to a difference between the set

point and an input variable.

• [``Ht] select reverse action, so that output 1 responds when the input

signal is less than the set point.

• [``CL] select direct action, so that output 1 responds when the input

signal is more than the set point.

[`Ot1] This prompt always appears.

Default

↓

[``Ht] [``CL]

[`Ot1] [`Ot1]

˜

NOTE:

Decimal points may

not always be in the

position specified

below depending

on the the settings

in the Decimal 1

[deC1] parameters

in the Input Menu.

[`Ot1]

Page 40

4.14 WATLOW Series 982 User’s Manual

Setup Menus, Chapter 4

Setup-Output

Process 1

Select the process range for output 1.

[Prc1] This prompt appears only on controllers equipped with output 1

process hardware (98__-__F_-____).

Default

↓

4-20mA 0-20mA 0-5VÎ 1-5VÎ 0-10VÎ (dc)

[4-20] [0-20] [`0-5] [`1-5] [0-10]

[Prc1] [Prc1] [Prc1] [Prc1] [Prc1]

Hysteresis 1

Select the switching hysteresis for output 1. This determines the

change in temperature or process units needed to turn the output from

full on to full off.

[HYS1] This prompt does not appear on controllers equipped with output 1

process hardware (98__-__F_-____).

If Default

↓↓

[``°F [```1] … [```3] … [`999]

[`C_F] [HYS1] [HYS1] [HYS1]

(Global Menu)

[``°F]

&

[`r†d] [``)1] … [[``#0] … [`9(9]

[`C_F] [`In1] [HYS1] [HYS1] [HYS1]

(Global Menu) (Input Menu)

[``°C] [```1] … [[```2] … [`555]

[`C_F] [HYS1] [HYS1] [HYS1]

(Global Menu)

[``°C]

&

[`r†d] [``)1] … [[``@0] … [`5%5]

[`C_F] [`In1] [HYS1] [HYS1] [HYS1]

(Global Menu) (Input Menu)

[```1] … [```3] … [`999]

units

a process input

[HYS1] [HYS1] [HYS1]

is selected

[HYS1]

[Prc1]

Page 41

WATLOW Series 982 User’s Manual 4.15

Setup Menus, Chapter 4

Setup-Output

Output 2

Set the way that output 2 will respond to a difference between the set

point and an input variable.

• [`AL2] de-energizes output 2 in an alarm condition.

• [AL2n] energizes output 2 in an alarm condition.

• [``Ht] select reverse action, so that output 2 responds when the input

signal is less than the set point. This prompt only appears if [`Ot1] is set

to [``CL].

• [``CL] select direct action, so that output 2 responds when the input

signal is more than the set point. This prompt only appears if [`Ot1] is

set to [``Ht].

[`Ot2] This prompt appears only on controllers equipped with output 2

hardware (not 98__-___A-____). [`AL2] and [AL2n] do not appear if output 2

is a process output (98__-___F-____). [``Ht] and [``CL] do not appear if

[AL90] (in the Global Menu) is set to [dUPL].

Default

↓

[``no] [`AL2] [Al2n] [``Ht] or [``CL]

[`Ot2] [`Ot2] [`Ot2] [`Ot2] [`Ot2]

Process 2

Select the process range for output 2.

[Prc2] This prompt appears only on controllers equipped with output 2

process hardware (98__-___F-____) and with [`Ot2] not set to [``no].

Default

↓

4-20mA 0-20mA 0-5VÎ 1-5VÎ 0-10VÎ (dc)

[4-20] [0-20] [`0-5] [`1-5] [0-10]

[Prc2] [Prc2] [Prc2] [Prc2] [Prc2]

[`Ot2]

[Prc2]

NOTE:

[`Ot2] prompt will

not appear if

[SLid] is selected

for [`In2].

Page 42

4.16 WATLOW Series 982 User’s Manual

Setup Menus, Chapter 4

Setup-Output

Hysteresis 2

Select the switching hysteresis for output 2. This determines the

change in temperature or process units needed to turn the output from

full off to full on.

• If [`AL2] is set to [rAtE] settings for [HYS2] will be in degrees per

minute or units per minute.

• If the input referenced by [`AL2] is set to [`r†d] the range is affected as

listed below.

[HYS2] This prompt appears only on controllers equipped with output 2

hardware and with [`Ot2] not set to [``no]. This prompt does not appear

on controllers with [`In2] set to [SLid] or on controllers equipped with

output 2 process hardware.

If Default

↓↓

[``°F [```1] … [```3] … [`999]

[`C_F] [HYS2] [HYS2] [HYS2]

(Global Menu)

[``°F]

&

[`r†d] [``)1] … [[``#0] … [`9(9]

[`C_F] [`In1] [HYS2] [HYS2] [HYS2]

(Global Menu) (Input Menu)

[``°C] [```1] … [[```2] … [`555]

[`C_F] [HYS2] [HYS2] [HYS2]

(Global Menu)

[``°C]

&

[`r†d] [``)1] … [[``@0] … [`5%5]

[`C_F] [`In1] [HYS2] [HYS2] [HYS2]

(Global Menu) (Input Menu)

[```1] … [```3] … [`999]

units

a process input

[HYS2] [HYS2] [HYS2]

is selected

[HYS2]

Page 43

WATLOW Series 982 User’s Manual 4.17

Setup Menus, Chapter 4

Setup-Output

Alarm 2

Select the alarm type for alarm 2. Select the trigger points for the alarm

with the [A2LO] and [A2HI] settings in the System Menu [`SYS].

• [`Pr1] uses the process signal from input 1. Changing the set point

does not change the alarm response.

• [`dE1] uses a deviation from the input 1 signal. Changing the set point

changes the alarm response.

• [rAtE] uses the rate of change at input 1 in degrees per minute.

[`AL2] This prompt appears only on controllers equipped with output 2

hardware (not 98__-___A-____), and with [`Ot2] set to [`AL2] or [AL2n].

Default

↓

[`Pr1] [`de1] [rAtE]

[`AL2] [`AL2] [`AL2]

Latching 2

Select whether alarm 2 will be latching or non-latching. A latching

alarm [`LAt] must be turned off manually. A non-latching alarm [`nLA]

turns off when an alarm condition no longer exists.

[LAt2] This prompt appears only on controllers equipped with output 2

hardware (not 98__-___A-____) and with [`Ot2] set to [`AL2] or [AL2n].

Default

↓

[`nLA] [`LAt]

[LAt2] [LAt2]

˜

NOTE:

See Chapter 8 for

more information

on alarms.

[`AL2]

[LAt2]

Page 44

[`Ot3]

4.18 WATLOW Series 982 User’s Manual