Page 1

Series 965

User's Manual

96

1/16 DIN

Microprocessor-Based

Auto-tuning Control

Watlow Controls

TOTAL

CUSTOMER

SA TISFACTION

3 Y ear W arranty

ISO 9001

Registered Company

Winona, Minnesota USA

Watlow Controls, 1241 Bundy Blvd., P.O. Box 5580, Winona, MN 55987-5580, Phone: 507/454-5300, Fax: 507/452-4507

0600-0003-0000 Rev. C

July 1998

Supersedes: 0600-0003-0000 Rev. B

Printed on Recycled Paper

$10.00

Made in the U.S.A.

Page 2

About This Manual

Starting Out

How to Use this Manual

We have designed this user's manual to be a helpful guide to your new Series 965. The

headlines in the upper right and left corners indicate which tasks are explained on that

page.

Notes and Safety Information

NOTE:

Details of a "Note"

appear here, in the

narrow box on the

outside of each

page.

We use notes, cautions and warnings throughout this book to draw your attention to

important information.

Notes are printed in bold in the margin to alert you to an important detail.

ç

A Caution symbol (an exclamation point in a triangle) appears with information that is

ç

CAUTION:

Details of a "Caution" appear here, in

the narrow box on

the outside of each

page.

important to protect equipment and performance. Read and follow all cautions that apply

to your application.

Ó

A Warning symbol (a lightning bolt in a diamond) appears with information that is

important to protect people and equipment from damage. Pay very close attention to all

warnings that apply to your application.

Ó

WARNING:

Details of a "Warning" appear here, in

the narrow box on

the outside of each

page.

T echnical Assistance

If you encounter a problem with your Watlow controller, review all of your configuration

information for each step of the setup, to verify that your selections are consistent with

your applications.

If the problem persists after checking all the steps, call for technical assistance: Watlow

Controls at (507) 454-5300, between 7:00 a.m. and 5:30 p.m. Central Standard Time.

Ask for an applications engineer. When you call, have the following information ready:

• the controller's model number ( the 12-digit number is printed on the top of the

stickers on each side of the controller's case and on the top or right side of the circuit

board);

• this user's manual;

• all configuration information;

• the Diagnostics Menu readings.

W arranty and Returns

For information about the warranty covering the Series 965, see page 37.

Comments and Suggestions

We welcome your comments and opinions about this user's manual and the Series 965.

Send them to the Technical Editor, Watlow Controls, 1241 Bundy Blvd., P.O. Box 5580,

Winona, MN 55987-5580. Or call (507) 454-5300. Or fax them to (507) 452-4507.

WATLOW Series 965 User's Manual2

(1459).

How to Use the Manual

Page 3

Contents

Starting Out

Page Item

Chapter 1

4 Starting Out With The Watlow Series 965

4 General Description

Chapter 2

5 Install And Wire The Series 965

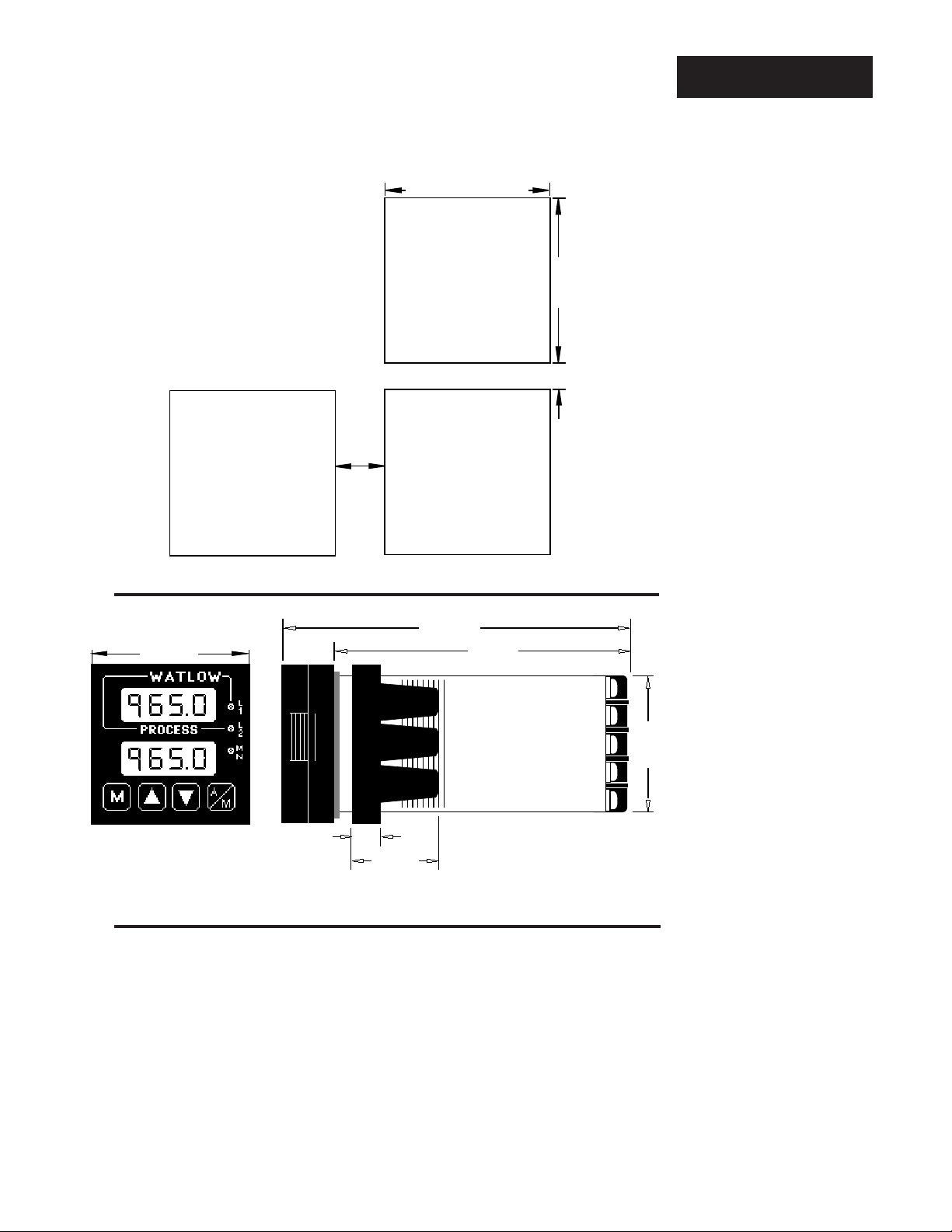

5 Panel Cutout

5 Dimensions

5 Installation Procedure

7 Wiring the Series 965

8 Sensor Installation Guidelines

8 Input Wiring

10 Output 1 Wiring

11 Alarm Wiring

12 System Wiring Example

Chapter 3

13 How To Use The Keys And Displays

13 Keys, Displays & LEDs

Chapter 4

14 How To Set Up The Series 965

14 Setting the Input Type DIP Switch

15 Entering Setup Menu

16 Setup Parameters

18 Setup Menu Table

19 Operation Parameters

20 Operation Menu Table

Chapter 5

21 How To Tune And Operate

21 Auto-tuning

22 Manual Tuning

23 Manual and Automatic Operation

24 Using Alarms

25 Error Code Messages

Appendix 1

27 Noise Sources

27 Decreasing Noise Sensitivity

28 Eliminating Noise

Appendix 2

29 Entering the Calibration Menu

30 Restoring Factory Calibration

30 Calibration Menu

31 Calibration Procedures

34 Glossary

36 Index

37 Warranty and Returns

38 Specifications

39 Model Number Information

40 Declaration of Conformity

41 Quick Reference

Figures & Tables

Page Figure Item

4 Series 965 Input & Output Overview 1

5 Multiple Panel Cutout Dimensions 2

5 Series 965 Dimensions 3

6 Mounting, Case Side View & Collar 4

6 Case, Rear View & NEMA 4X Seal Example 5

7 High Voltage Power Wiring 6

7 Low Voltage Power Wiring 7

8 Thermocouple Sensor Input Wiring 8

8 0-5VÎ (dc) Process Sensor Input Wiring 9

9 2- or 3-wire RTD Sensor Input Wiring 10

9 4-20mA Process Sensor Input Wiring 11

10 Switched DC Output Wiring 12

10 5A Mechanical Relay Wiring 13

10 4-20mA Process Wiring 14

10 0.5A Solid-state Relay w/o Suppression Wiring 15

11 Switched DC Output Wiring 16

11 5A Mechanical Relay Wiring 17

11 0.5A Solid-state Relay w/o Suppression Wiring 18

12 System Wiring Example 19

13 Series 965 Keys and Displays 20

14 DIP Switch Location & Orientation 21

15 Entering the Setup Menu 22

15 The Setup Menu 23

19 The Operation Menu 24

21 Auto-tuning at a 200°F Set Point 25

24 Alarm Display Examples 26

29 Entering the Calibration Menu 27

30 Calibration Menu 28

Tables

18 Input Ranges 1

18 Setup Menu Prompts/Description 2

20 Operation Menu Prompts/Description 3

41 Quick Reference Sheet (Perforated)

How to Use the Manual

3WATLOW Series 965 User's Manual

Page 4

Starting Out

Starting Out

Chapter 1

Starting Out With The Watlow Series 965,

A Microprocessor-Based Control

Single Input Type J, K, T, N or S

Thermocouple,

RTD or Process

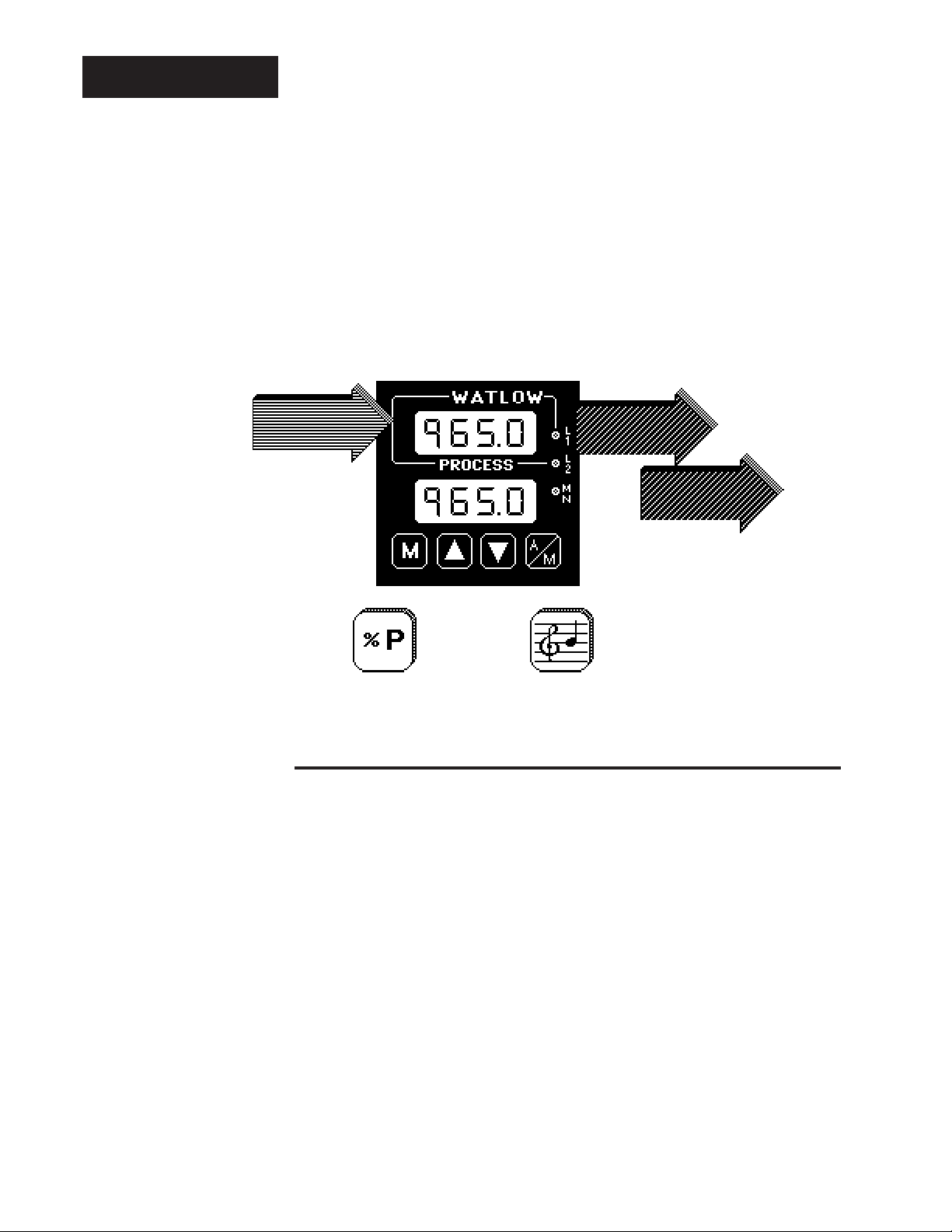

Figure 1 Series 965 Input and

Output Overview

Output 1 or 2

Percent Power

General Description

Dual Control Output-

PID or on/off, User Selectable

Output 1 Heat or Cool

Output 2 Heat, Cool, Alarm

or None

Auto-tuning

for Heat &

Cool PID

Settings

Welcome to the Watlow Series 965, a 1/16 DIN microprocessor-based temperature control. The 965 has a single input which accepts type J, K, T, N or S

thermocouple, RTD or process input.

With dual output, the primary can be heating or cooling while the secondary can

be a control output opposite the primary output (heat or cool), alarm or none.

Both outputs can be selected as either PID or on/off. PID settings include

proportional band, reset/integral, and rate/derivative. Setting the proportional

band to zero makes the Series 965 a simple on/off control with switching

differential selectable under the HSC parameter.

Special 965 features include the NEMA 4X rating, dual four digit displays in

either red or green, optional low volt power supply, auto-tuning for both heat

and cool outputs, ramp to set point for gradual warm-up of your thermal system,

and automatic/manual capability with bumpless transfer.

Operator-friendly features include automatic LED indicators to aid in monitoring

and setup, as well as a calibration offset at the front panel. The Watlow Series

965 automatically stores all information in a non-volatile memory.

4 Getting Started, Chapter 1

WATLOW Series 965 User's Manual

Page 5

Chapter 2

(

)

Install and Wire the Series 965

1.77" to 1.79"

(44.96mm to 45.47mm)

Panel Cutout

NOTE:

Measurements

between panel

cutouts are the

minimum

recommended.

0.85"

(20mm)

Your Panel

Thickness

0.06" to 0.38"

(1.5 to 9.7 mm)

1.77" to 1.79"

(44.96mm

to 45.47mm)

0.38"

(9.65mm)

Minimum

Installation

Figure 2 Series 965

Multiple Panel

Cutout Dimensions

4.7"

2.1"

(53 mm)

0.40"

(10mm)

1.21"

31mm

(119mm)

4.1"

(104mm)

Installation Procedure

Follow this procedure to mount the Watlow Series 965 temperature control:

1. Make a panel cutout per the dimensions in Figure 2.

2. Remove the 965 chassis from its case. Holding each side of the bezel,

press in firmly on the side grips until the tabs release. Pull the chassis out

of the case and set aside for later installation.

1.76"

(45mm)

Figure 3 Series 965

Dimensions

NOTE: For rapid

mounting, use

Greenlee punch

#60020 and die

#60021, or hand

hydraulic unit, Kit

#7306. All available

from Grainger.

3. Make sure the rounded side of the external case gasket is facing the panel

surface. Check to see that the gasket is not twisted, and is seated within

the case bezel flush with the panel. Place the case in the cutout you just

made. Make sure the gasket is between the panel cutout and the case

bezel. See Figure 4A.

Install and Wire, Chapter 2

5WATLOW Series 965 User's Manual

Page 6

Installation

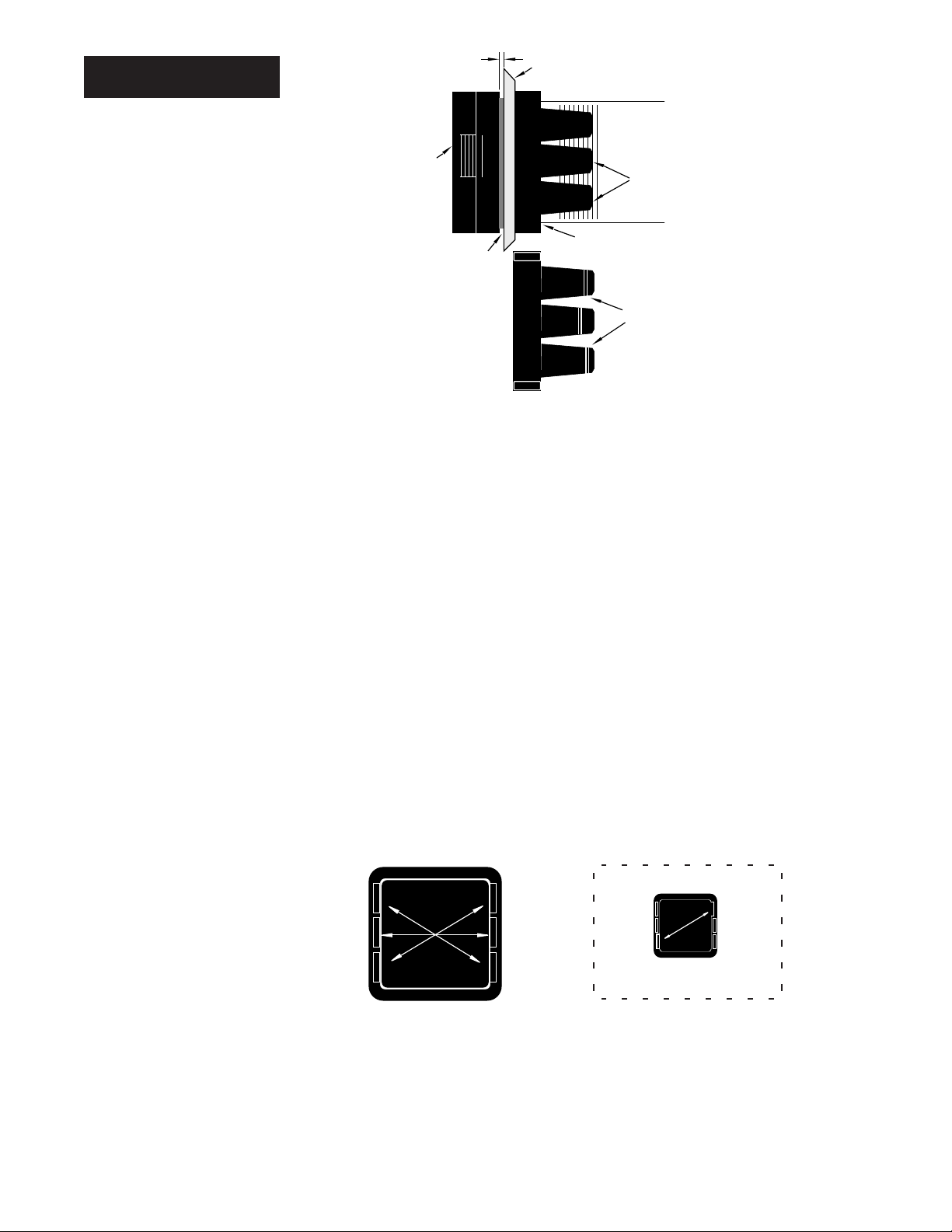

Figure 4 Mounting, Case Side

View & Collar Cross

Section

4A

0 to 0.019 space

(0 to 0.483 mm)

Bezel

Panel

Ridges

Tabs

NOTE:

To guarantee a

proper NEMA 4X

seal, make sure

the gasket

between the panel

and the rim of the

case is not twisted

and is seated

properly.

PRESS FIRMLY.

External Gasket

4B

Mounting Collar

Teeth

Mounting Collar

Cross Section

(notice the offset teeth

on each tab)

4. While pressing the front of the case firmly against the panel, slide the

mounting collar over the back of the control. The tabs on the collar must

line up with the mounting ridges on the case for secure installation. See

Figure 4A again. Slide the collar firmly against the back of the panel getting

it as tight as possible. Make sure you cannot move the case within the

cutout; if you can you do not have a NEMA 4X seal.

Now let's make sure we have a tight seal. Use your thumb to lock the tabs

into place while pressing the case from side to side. Don't be afraid to apply

enough pressure to install the control. The tabs on each side of the collar

have teeth which latch into the ridges. See Figure 4B. Each tooth is staggered at a different height, so only one of the tabs on each side are ever

locked into the ridges at any time.

Looking at Figure 5, you see that the tabs on one side of the collar correspond with those on the opposite side. Make sure that the two corresponding tabs are the only ones locked in the ridges at the same time. If the

matching tabs are not holding the case at the same time you will not have

a NEMA 4X seal. You can make a visual check, or use your finger nail to

pull out on each tab. Only one on each side is engaged, and they must

be corresponding as in Figure 5. The space between the bezel and

panel must be between 0 and 0.019" (0.48 mm).

Figure 5 Case Rear View and

NEMA 4X Seal

Example

WATLOW Series 965 User's Manual

Make sure that the two correspond-

ing tabs below are locked in the

ridges at the same time.

NEMA 4X Seal Example.

When removing the mounting collar, we suggest sliding a thin tool such as

a putty knife or screwdriver under all three tabs on each side at once and

pulling it back off the case.

5. Insert the control chassis into its case and press the bezel to seat it. Make

sure the inside gasket is also seated properly and not twisted. The hardware installation is complete. Proceed to the wiring section from here.

Install and Wire, Chapter 26

Page 7

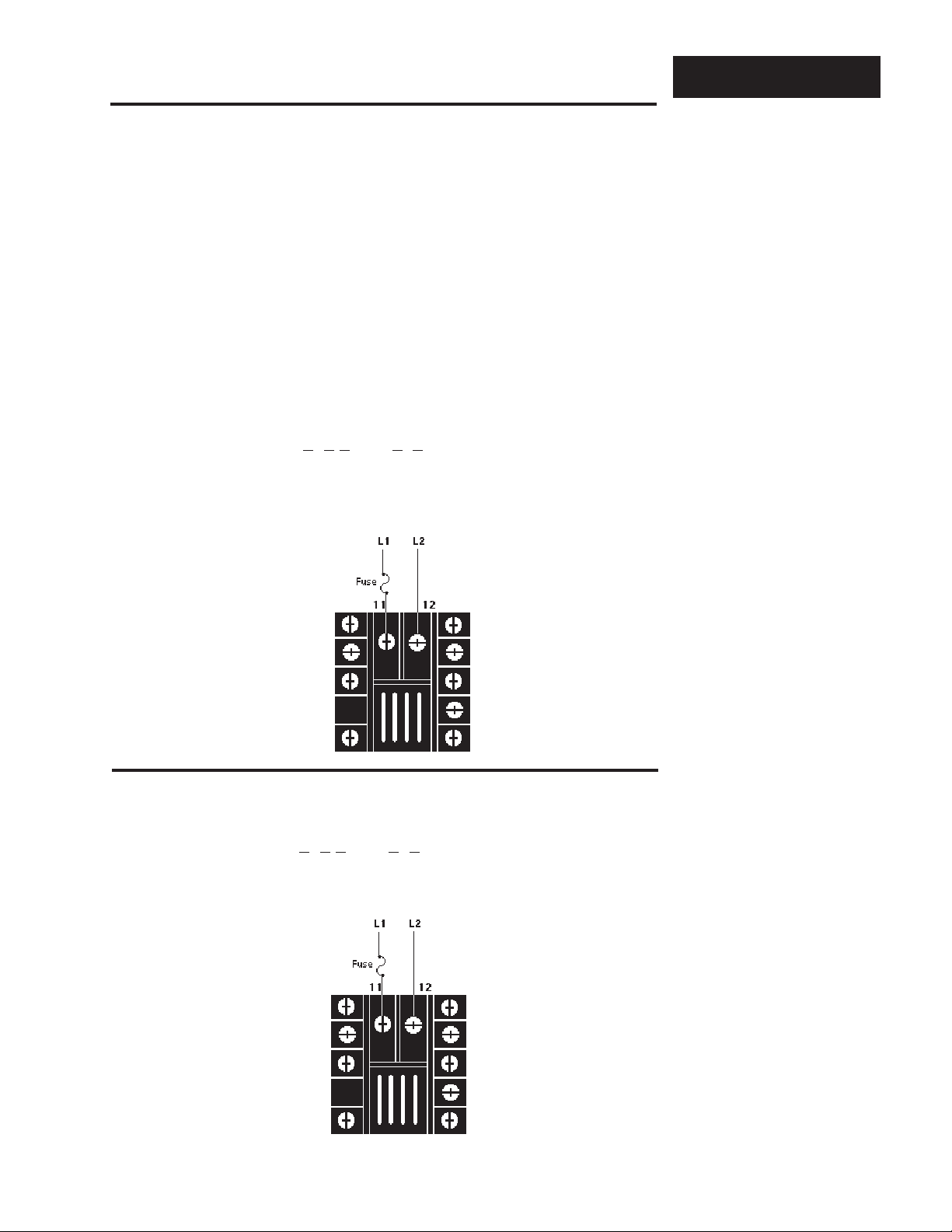

How to Wire the Series 965

The Series 965 wiring is illustrated by model number option. Check the unit

sticker on the control and compare your model number to those shown here

and also the model number breakdown in the Appendix of this manual.

All outputs are referenced to a de-energized state. The final wiring figure is a

typical system example.

When you apply power without sensor inputs on the terminal strip, the Series

965 displays [----] in the upper display, and a [```0] in the lower display,

except for 0-5VÎ (dc) or 4-20mA process input units. Press the A/M key twice,

and [ER`7] is displayed for one second. This error indicates an open sensor or

A/D error. Remove power to the control and connect the sensor properly, see

pages 8 and 9. All wiring and fusing must conform to the National Electric Code

and to any locally applicable codes as well.

Power Wiring

Ó

WARNING:

To avoid potential

electric shock, use

National Electric

Code (NEC) safety

practices when

wiring and connecting this unit to a

power source and to

electrical sensors or

peripheral devices.

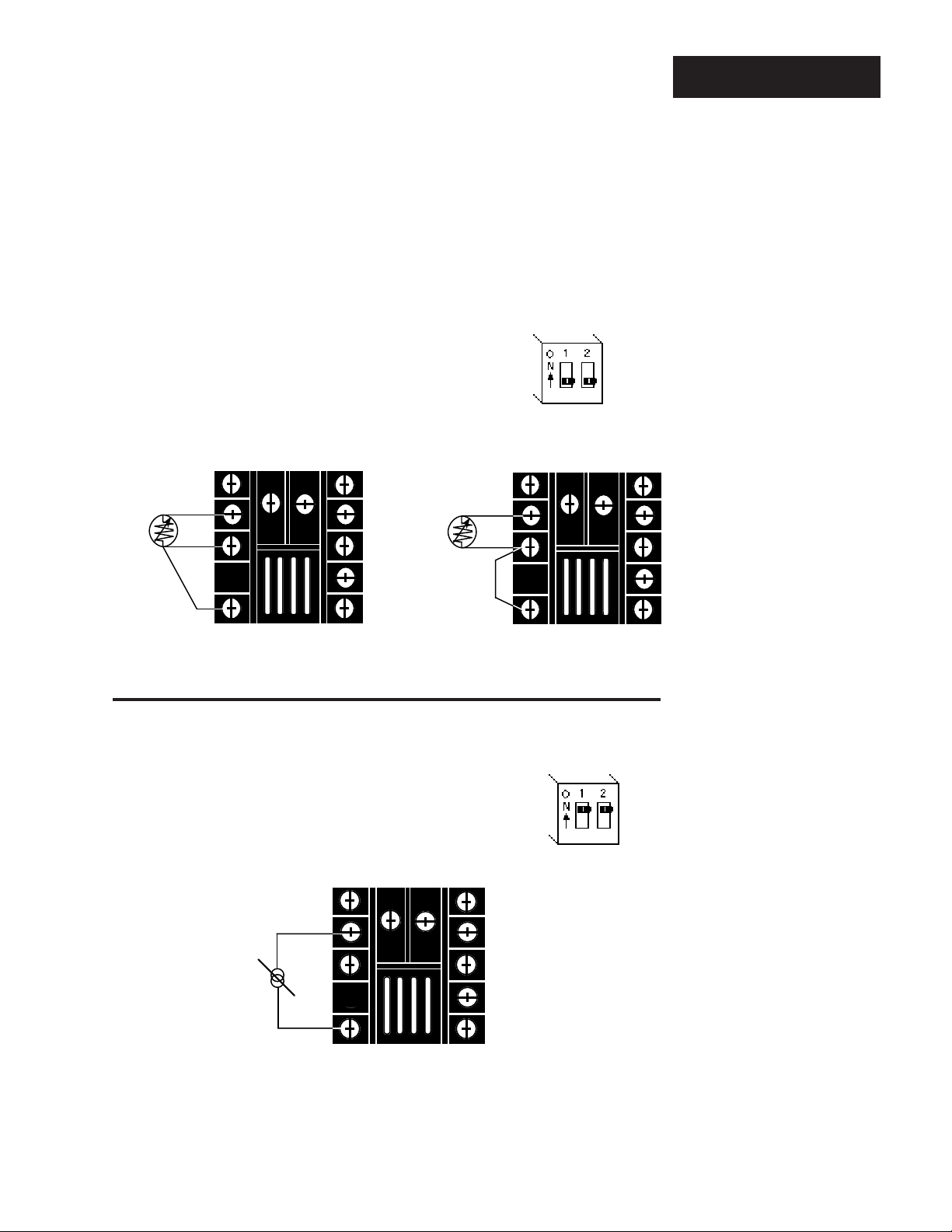

High V oltage

Model # 965A - 3 0 - 00 .

100 to 240 VÅ (ac),

nominal

(85 to 264 actual)

Low V oltage

Model # 965A - 3 1 - 00 .

Ó

12-24V‡ (ac/dc)

NOTE:

Taking the unit out

of the case is not a

normal operating

condition and

should only be done

by a qualified

maintenance

installation technician. Power to the

case should be

disconnected before

removing or installing the controller

into its case.

Figure 6 High Voltage

Power Wiring

Figure 7 Low Voltage

Power Wiring

Install and Wire, Chapter 2

Ó

WARNING:

If high voltage is

applied to the low

voltage unit,

irreversible damage

will occur.

WATLOW Series 965 User's Manual

7

Page 8

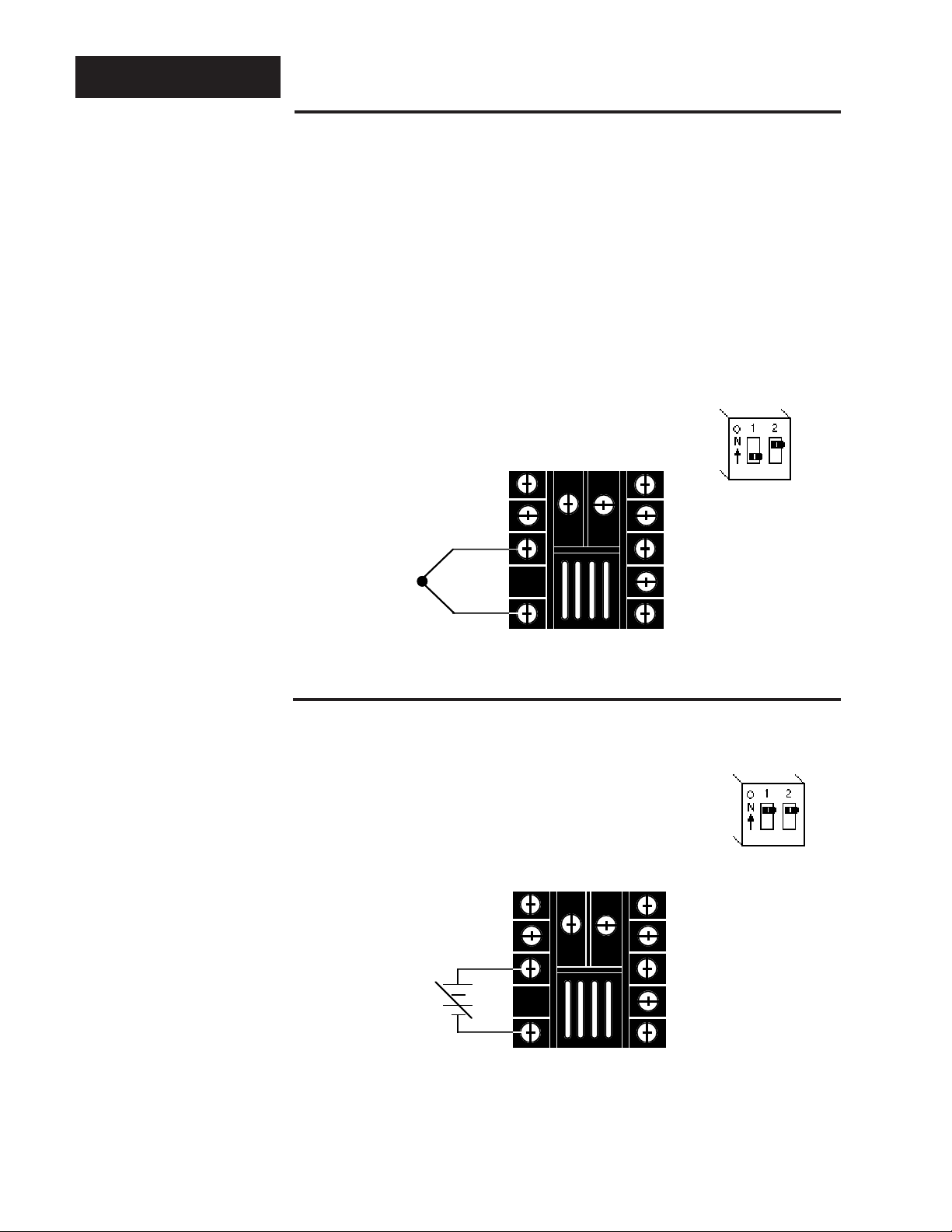

Input Wiring

Sensor Installation Guidelines

We suggest you mount the sensor at a location in your process or system

where it reads an average temperature. Put the sensor as near as possible to

the material or space you want to control. Air flow past this sensor should be

moderate. The sensor should be thermally insulated from the sensor mounting.

See Chapter 4 for more information on DIP switch location and orientation.

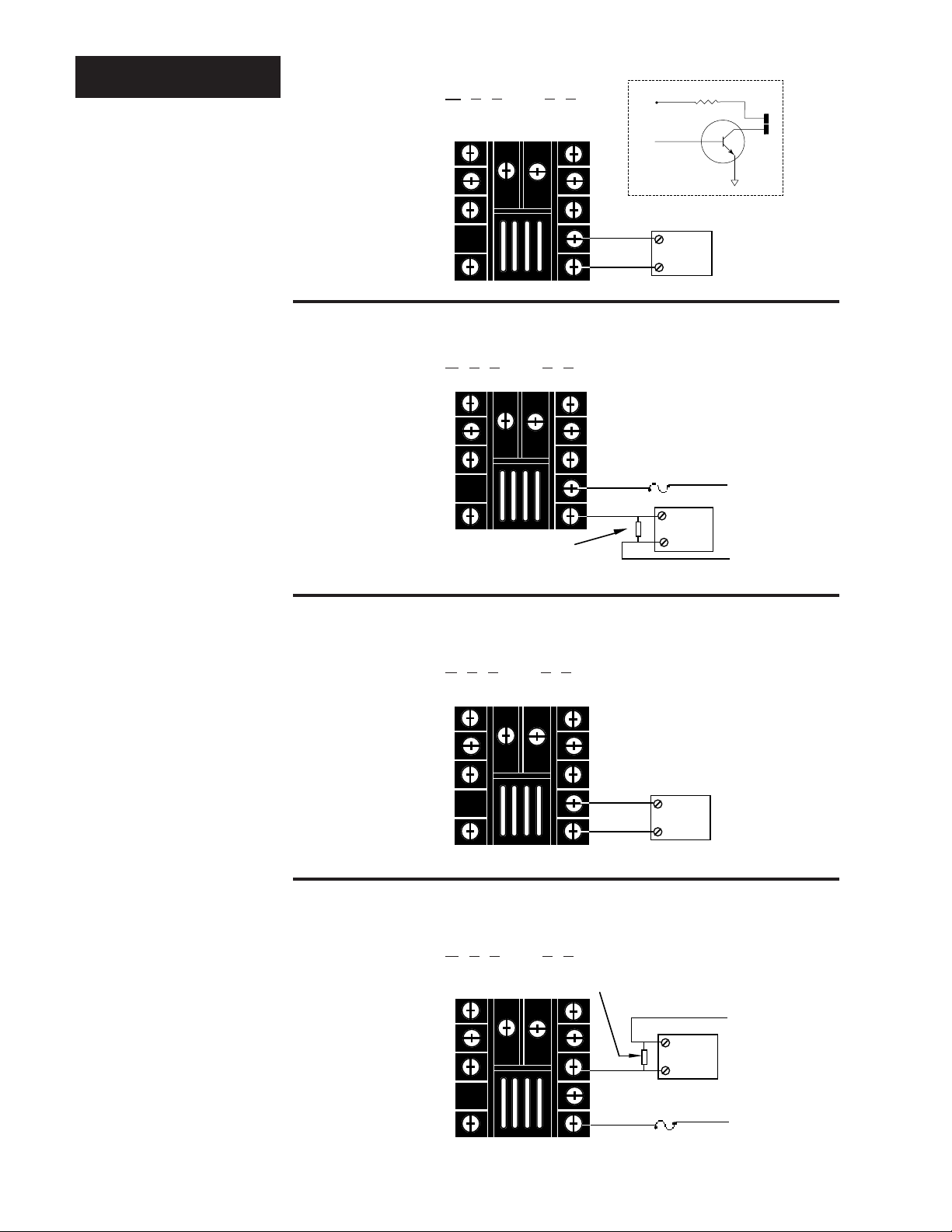

Thermocouple Input

NOTE:

When an external

device with a nonisolated circuit

common is connected to the 420mA or dc output,

you must use an

isolated or ungrounded thermocouple.

Figure 8 Thermocouple

Sensor Input Wiring

ç

CAUTION:

Process input does

not have sensor

break protection.

Outputs can remain

full on.

Extension wire for thermocouples must be of the same alloy as the thermocouple itself to limit errors.

DIP Switch

Orientation

+

3

T/C

-

5

0-5VÎ (dc) Process Input

ç

DIP Switch

Orientation

Figure 9 0-5V

(dc) Process

Î

Sensor Input Wiring

WATLOW Series 965 User's Manual

8

+

V

dc

-35

Input impedance: 10K

Ω

Install and Wire, Chapter 2

Page 9

RTD, 2- or 3-wire

There could be a + 2°F input error for every 1Ω of lead length resistance when

using a 2-wire RTD. That resistance, when added to the RTD element resistance, will result in erroneous input to the instrument. To overcome this problem, use a 3-wire RTD sensor, which compensates for lead length resistance.

When extension wire is used for a 3-wire RTD, all wires must have the same

electrical resistance (i.e. same gauge, copper stranded, same length).

DIP Switch

Orientation

S1

3-wire RTD

S2

S3

2

3

2-wire RTD

Jumper

Terminals

5

3 and 5.

S1

S2

S3

2

3

5

Input Wiring

Figure 10 2- or 3-wire RTD

Sensor Input Wiring

4 - 20mA Process Input

I

dc

Install and Wire, Chapter 2

-

2

+

5

Input impedance: 5

ç

ç

CAUTION:

Process input does

not have sensor

DIP Switch

Orientation

Ω

WATLOW Series 965 User's Manual

break protection.

Outputs can remain

full on.

Figure 11 4-20mA Process

Sensor Input Wiring

9

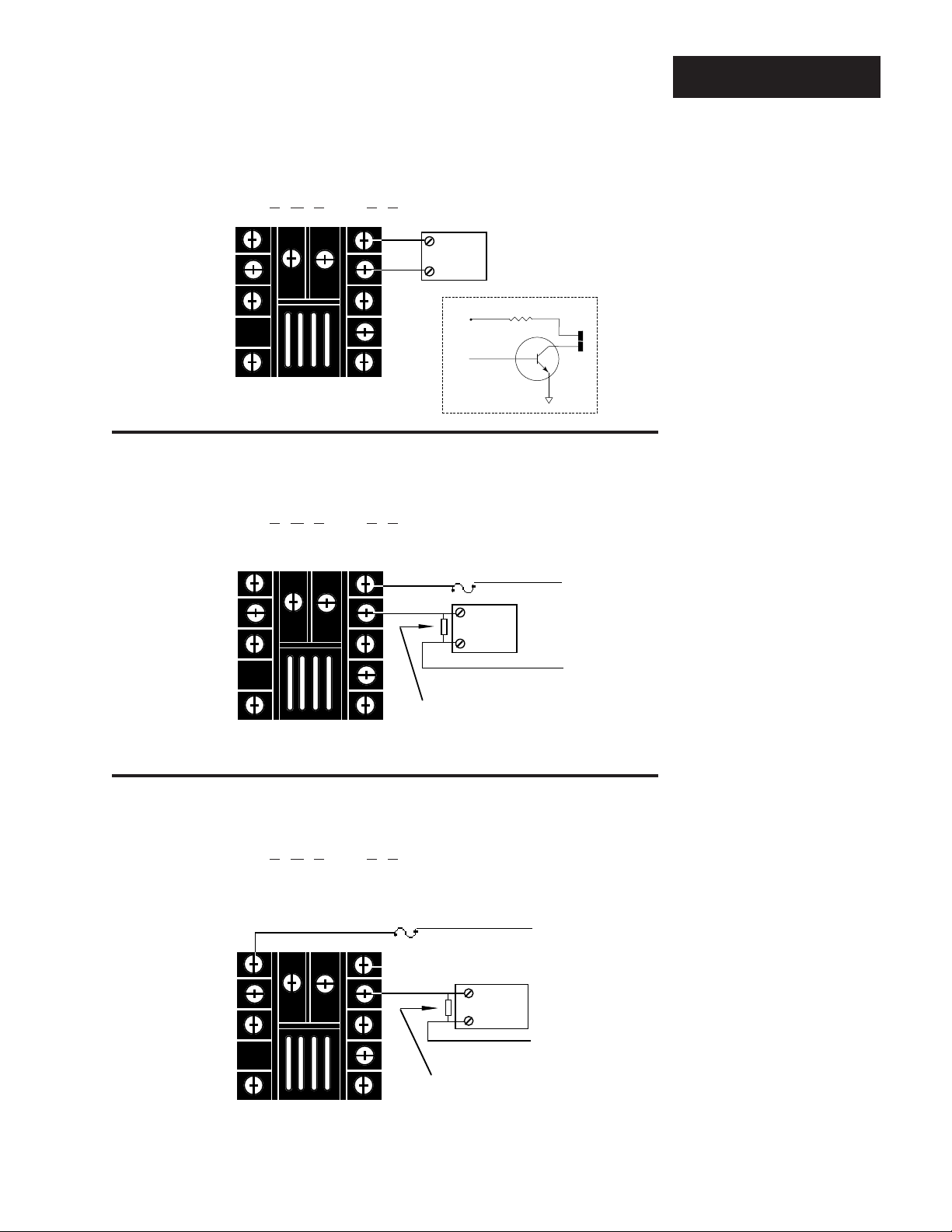

Page 10

Output 1 Wiring

External

Load

109NO

COM

8 NC

Fuse

L1

L2

Customer Supplied

Quencharc

10

unregulated

V+

V—

9

Internal Circuitry

Figure 12 Switched dc Output

Wiring

Switched DC Output

Model # 965A - 3

C - 00 .

NOTE:

When an external

device with a nonisolated circuit

common is connected

to the 4-20mA or

Switched dc output,

you must use an

isolated or ungrounded thermocouple.

Figure 13 5 Amp Mechanical

Relay Wiring

NOTE:

Switching inductive

loads (relay coils,

solenoids, etc.) with

the mechanical

relay, switched dc or

solid-state relay

output options

requires using an

R.C. suppressor.

Watlow carries the

R.C suppressor

Quencharc brand

name, which is a

trademark of ITW

Pakron. Watlow Part

No. 0804-0147-0000.

Figure 14 4-20mA Process

Wiring

+

9

External

-

10

Load

Mechanical Relay Without Contact Suppression, Form C, 5 Amp

Model # 965A - 3

D - 00 .

Process, 4-20mA

Model # 965A - 3

F - 00 .

+

9

-

10

Maximum load

resistance:

800

Ω

External

Load

Figure 15 -

0.5 Amp Solid-state

Relay Without

Contact Suppression

Wiring

10

Solid-state Relay Without Contact Suppression, 0.5 Amp

Model # 965A - 3

WATLOW Series 965 User's Manual

K - 00 .

Custommer Supplied

Quencharc

8

10

SS1

SS1

L2

External

Load

Fuse

L1

Install and Wire, Chapter 2

Page 11

Output 2 Wiring

7

unregulated

V+

V—

6

Internal Circuitry

Switched DC Output

Model # 965A - 3

C - 00 .

+

6

External

-

7

Load

Mechanical Relay Without Contact Suppression,

Form C, 5 Amp

Model # 965A - 3 D - 00 .

1NC

6

7

Customer Supplied

COM

NO

Quencharc

Fuse

External

L1

Load

L2

Solid-state Relay Without Contact Suppression, 0.5 Amp

Model # 965A - 3

K - 00 .

NOTE:

For more information on alarms see

page 24.

Figure 16 Switched dc Output

Wiring

Figure 17 5 Amp Mechanical

Relay Wiring

NOTE:

Switching inductive

loads (relay coils,

solenoids, etc.) with

the mechanical

relay, switched dc or

solid-state relay

output options

requires using an

RC suppressor.

Watlow carries the

RC suppressor

Quencharc brand

name, which is a

trademark of ITW

Pakron. Watlow Part

No. 0804-0147-0000.

Install and Wire, Chapter 2

SS2

1

Fuse

L1

NOTE:

Output is in open

State in Alarm

Condition.

7

SS2

External

Load

L2

Figure 18 -

0.5 Amp Solid-state

Relay Without

Customer Supplied

Custommer Supplied

Quencharc

Quencharc

WATLOW Series 965 User's Manual

Contact Suppression Wiring

11

Page 12

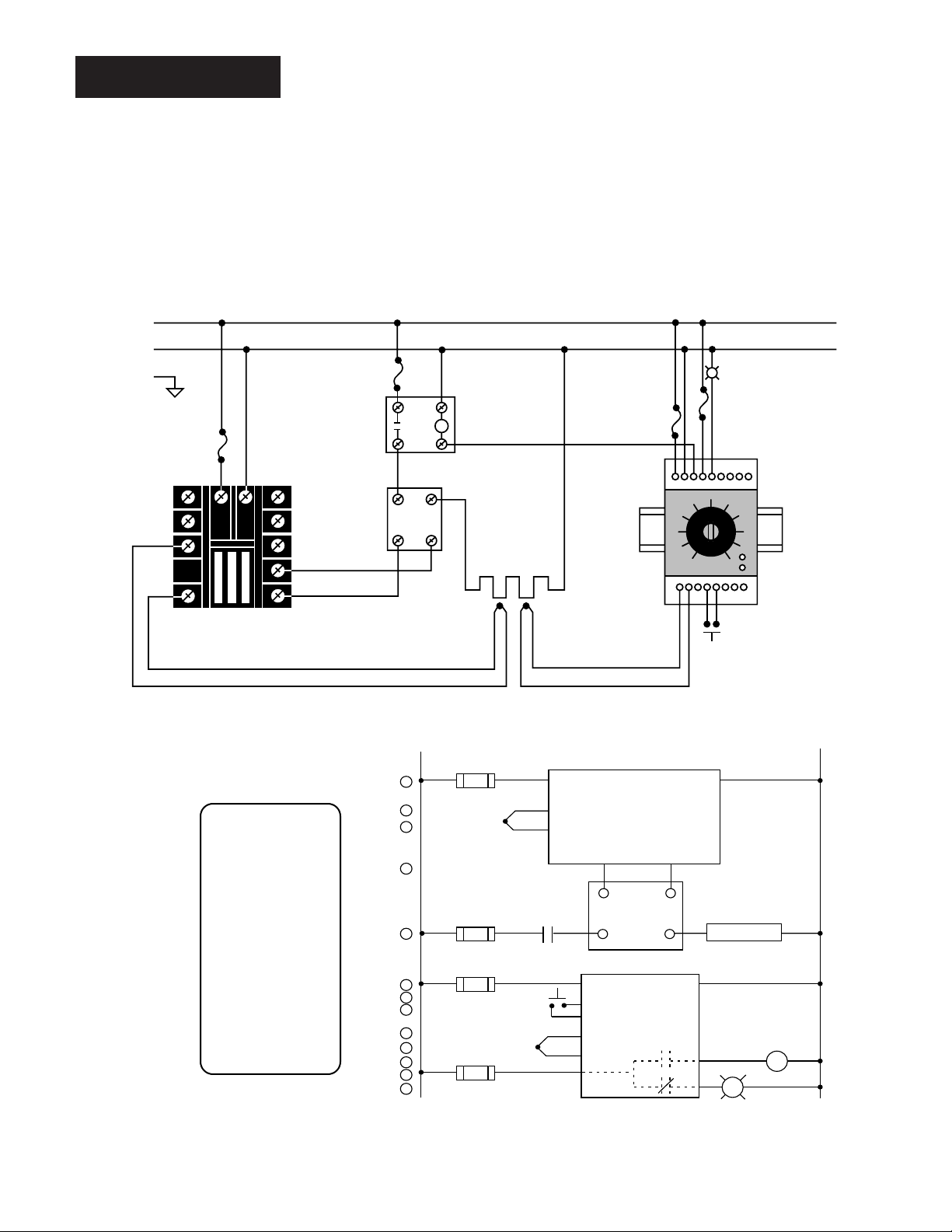

Wiring Example

1

120VÅ (VAC)

L1

L2

2

3

5

4

5

1 2

1

2

(+)

(-)

3

11

18

12

13

14

15

2

1CR

16

High Temperature

Light

1

2

3

4

8

9

10

11

12

R

SSR-240-10A-DC1

DC Input Solid-state Relay

17

1

8

Heater

(+)

(-)

1 CR-1

910

2

910

67

11 12

5

6

7

Limit Control

Series 965

965A-3CA0-0000

Temperature control

Series 92

92A3-1DJ1-0000

13

4

3

5

11

12

13

14

10

(+)

(-)

3-32V

Î

(dc)

In

Out

24-240V

Å

(ac)

Figure 19 System Wiring

Example

L1

120VÅ (VAC)

L2

Earth Ground

Fuse

ÓWARNING:

All wiring and fusing must conform to the National Electric Code NFPA70. Contact

your local board for additional information. Failure to observe NEC safety guidelines could result in injury to personnel or damage to property.

ç CAUTION:

Watlow mercury relay loads must have a unity power factor.

For RESISTIVE LOADS ONLY.

High Temperature

Light

Coil

High Limit

Mechanical

Controller

3 (+)

5 (-)

11 12

Red

965A-3CA0-0000

Rear View

SSR-240-10A-DC1

dc Input

SSR

9 +

10 -

Process Sensor

Out

2

1

3

4

Limit Control

In

Heater

13 14

11

10

-

+

92A3-1DJ1-0000

Limit Sensor

Optional

Normally Open

Momentary Switch

965A-3CA0-0000

1 Not Used

2 S1, I3 S2, TC+, V+

4 Not Used

5 S3, TC-, V-, I+

6 Not Used

7 Not Used

8 Not Used

9 DC +1

10 DC -1

11 L1

12 L2

WATLOW Series 965 User's Manual

12

Install and Wire, Chapter 2

Page 13

Chapter 3

How to Use the Keys and Displays

After one minute with no key activations, the control reverts to the process

value in the upper display and the set point in the lower display.

Keys/Displays

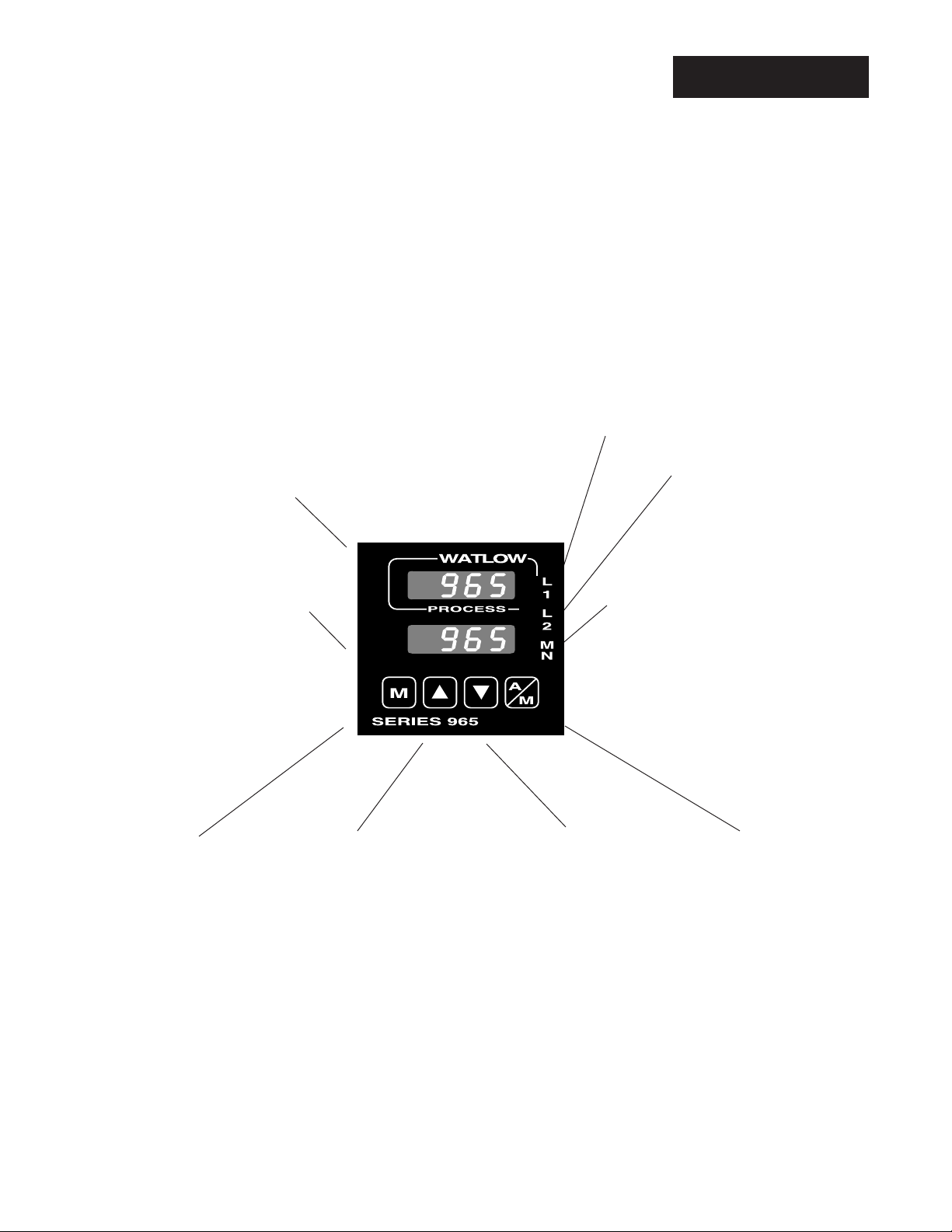

Figure 20 Series 965 Keys

and Displays

Upper Display

Red or green, 0.3" (8 mm) high, seven segment,

four digit LED display, indicating either process,

actual temperature, the operating parameter values or an open sensor. When powering up, the

Process display will be blank for five seconds.

This display can be blank by setting [`dSP] to

[`SEt]. See page 18.

Lower Display

Red or green, 0.3" (8 mm)

high, seven-segment, fourdigit LED display, indicating

the set point, output value,

parameters for data in the

upper display, or error and

alarm codes. This display can

be blank by setting [`dSP] to

[`Pro]. See page 18.

L1

When lit, this LED

tells you when Output 1 is energized.

L2

When lit, this LED tells

you when Output 2 is

active. This output can

be configured as a control or alarm output.

MN

Lit when the control is in Manual operation. Press the A/M key twice to

enter Automatic operation. When

blinking, this indicates that pressing

the A/M key toggles between Auto

and Manual. After five seconds without pressing the A/M key, the LED

stops blinking, and returns to its previous state.

Mode Key

Steps the control through

the Operating Menu; also,

in the Auto mode, new data

is self entering in five seconds.

Keys & Displays, Chapter 3 WATLOW Series 965 User's Manual

Up-arrow Key

Increases the value of the

displayed parameter. A

light touch increases the

value by one. Holding the

key down increases the

value at a rapid rate. New

data is self entering in

five seconds.

Up-arrow/Down-arrow Keys

When pressed simultaneously for three seconds, the

Setup Menu appears displaying the [`LOC] parameter.

Continue to press the Up-arrow/Down-arrow keys, and

the Calibration Menu appears.

Down-arrow Key

Decreases the value of

the displayed parameter.

A light touch decreases

the value by one. Holding

the key down decreases

the displayed value at a

rapid rate. New data is

self entering in five seconds.

A/M Key

Pressed once, it clears

any latched alarms and

toggles between Auto

and Manual mode. If

pressed again within five

seconds it will change

from Auto to Manual or

vice versa. While in

Manual mode, percent

power is in the lower display.

13

Page 14

Setup

Ó

WARNING:

Remove power from

the control before

removing the

chassis from the

case or changing

the DIP switches.

Chapter 4

How To Set Up The Series 965

Setting up the Series 965 is a simple process. First set the DIP switches to

match your input type. Refer to the orientation below and Page 16 for the In

parameter. Next, configure the 965's features to your application in the Setup

Menu, then enter values in the Operating Menu. Both tasks use the MODE key

to move through the menus and the Up-arrow/Down-arrow keys to select data.

Before entering information in the Setup menu, set the dFL parameter.

If selected as US: °F, proportion band in degrees, reset rate are the defaults.

If selected as SI: °C, proportional band in % of span, derivative and integral

are the defaults. Changing the dFL prompt will set parameters to their

factory default. Document all current parameter settings first. See

Appendix 2 in the calibration section to change this parameter.

How to Set the Input Type DIP Switch

The Series 965 input type can be user selectable at any time via a Dual In-line

Package (DIP) switch inside the control, located on the left (viewed from the

bottom). To set the DIP switch, remove the control chassis from the case.

Holding each side of the bezel, press in firmly on the side grips until the tabs

release. You may need to rock the bezel back and forth several times to

release the chassis.

The locations of the board and switches appear in Figure 21. Refer to the input

types below for DIP switch orientation. DIP switch selection must match the

sensor selected under the In parameter in the Setup Menu. Set the software

selection for the input type to match. See Page 16.

Figure 21 DIP Switch Location

and Orientation

14

WATLOW Series 965 User's Manual

Control Chassis -

Bottom View

Input Types

Thermocouple RTD Process

Setup, Chapter 4

Page 15

w

h

n

g

e

Entering the Setup Menu

The Setup Menu displays the parameters that configure the Series 965's features

to your application.

Enter the Setup Menu by pressing the Up-arrow and Down-arrow keys simultaneously for 3 seconds. The lower display shows the LOC parameter, and the

upper display shows its current level. All keys are inactive until you release both

keys. You can reach the LOC parameter from anywhere.

Setup

Figure 22 Entering the Setup

Menu

You will not see all parameters in this menu, depending on the unit's configuration and model number. After stepping through the menu it returns to the control

set point parameter under the Operation Menu.

= Parameter may or may not

appear depending on your

control configuration.

75

( )

Output 2 alarm hysteresis

Output 2 hysteresis

( )

Latching for alarm

( )

Silence alarm

( )

RTD calibration curve

( )

Ramp functio

( )

Ramp rate

( )

% Power limitin

( )

Display

HSA

LAt

SIL

rtd

rP

rt

PL

dSP

Control Set Point

LOC

In

dEC

C _ F

rL

rH

Ot 1

HSC

Ot2

( )

( )

( )

( )

( )

( )

( )

( )

( )

M

Mode Key

User lock out

Input type

Decimal plac

Celcius__Fahrenheit

Range lo

Range hig

Output 1

Control hysteresis

Output 2

NOTE:

While in the Setup

Menu, all outputs

are off.

Figure 23 The Setup Menu

Setup, Chapter 4

WATLOW Series 965 User's Manual

15

Page 16

Setup

Setup Parameters

When you are at the top of the menu, the Series 965 displays the user level of

operation in the upper display, and the LOC parameter in the lower display.

Press the MODE key and the value of the next parameter appears in the upper

display, and the parameter appears in the lower display.

LOC

NOTE:

Set the LOC parameter value as the

final step in programming the

Series 965 controller to prevent

locking yourself out

of the Operations

and Setup Menu

during initial

programming.

NOTE:

Process input does

not have sensor

break protection or

bumpless transfer.

Lock: Selects the level of operator lock-out as defined below.

Range: 0 - 4 Default: 0

LOC 0: All operating parameters may be viewed or changed. Manual operation

is permitted. When in manual operation, percent power is adjustable. Bumpless

transfer to manual mode can occur on sensor break.

LOC 1: The set point, actual, and alarm settings are the only visible parameters,

set point is adjustable in this level. Manual operation and auto-tune are permitted. When in manual operation, percent power is adjustable. Bumpless transfer

to manual mode can occur on sensor break.

LOC 2: The set point, actual, and alarm settings are the only visible parameters,

set point is adjustable in this level. Manual operation is permitted. When in

manual operation, percent power is adjustable. Bumpless transfer to manual

mode can occur on sensor break.

LOC 3: The set point and actual are the only visible parameters, set point is

adjustable in this level. Manual operation is not permitted. Bumpless transfer is

defeated and outputs are disabled on sensor break.

LOC 4: The set point and actual are the only visible parameters, set point is not

adjustable in this level of lock-out. Manual operation is not permitted. Bumpless

transfer is defeated and outputs are disabled on sensor break.

16

In

Input: Selects the sensor input type. The internal DIP switch must also match

the In parameter. See Figure 21 on Page 14 for DIP switch orientation, and see

Table 1 on Page 18 for input type temperature ranges.

Range: J, K (appears as H), t, n, S, rtd, rt.d, 0-5, 420 Default: J

dEC

Decimal: Selects the location of the decimal point for all process related data.

This parameter only appears if the In parameter is 0-5 or 420. Make sure the

internal DIP switch matches the In parameter.

Range: 0, 0.0, 0.00 Default: 0

C _ F

Celsius _ Fahrenheit: Selects the units of temperature measurement for the

control. This parameter only appears if the In parameter is a thermocouple or

RTD input. The default is dependent on the dFL parameter located in the Calibration menu. Refer to the Appendix. Range: C or F

If dFL = US: Default: F If dFL = SI: Default: C

rL

Range Low: Selects the low limit of the set point. Also used to set the low end

of the process input. 0.0VÎ (VDC) and 4mA represent Range Low (rL) for

process input. The process input is linearly scaled between rL and rH. See the

model number and specification in the Appendix for range values, or refer to

Table 1 on Page 18. Range: Sensor range low to rH

Default: Low limit of sensor type/-500 for process input

WATLOW Series 965 User's Manual

Setup, Chapter 4

Page 17

Setup

Range High: Selects the high limit of the operating range. Also used to set the

high end of the process input. 5.0VÎ (dc) and 20mA represent Range High (rH)

for process input. The process input is linearly scaled between rL and rH. See

the model number and specification information in the Appendix for your range

values, or refer to Table 1 on Page 18. Range: Sensor range high to rL Default:

High limit of sensor type/9999 for process input

Output 1: Selects the action for the primary output. Action in response to the

difference between set point and process variable. Select ht (heat) for reverse

acting or select CL (cool) for direct acting. Range: ht, CL Default: ht

Hysteresis-Control: Selects the switching hysteresis for Output 1 and 2 when

you select 0 (ON/OFF) under the Pb1 parameter and Ot2 = Con.

Range: 1 to 99, 0.1 to 9.9, 0.01 to 0.99/1 to 55, 0.1 to 5.5, 0.01 to 0.55

Default: 3, 0.3, 0.03°F/2, 0.2, 0.02

Output 2: Selects the output action for the secondary output.

Range: Con Control mode opposite Output 1 (heat or cool) Default: Con

PrA Process alarm with alarm message displayed

Pr Process alarm with no alarm message displayed

dEA Deviation alarm with alarm message displayed

dE Deviation alarm with no alarm message displayed

no None

Hysteresis - Alarm: Selects the switching hysteresis for Output 2 when Ot2 is an

alarm. This parameter only appears if Ot2 ≠ Con or no. See Page 19 for the Pb1

parameter. Range: 1 to 9999, 0.1 to 999.9, 0.01 to 99.99/1 to 5555, 0.1 to 555.5,

0.01 to 55.5 Default: 3, 0.3, 0.03/2, 0.2, 0.02

rH

Ot1

HSC

Ot2

HSA

Latching: Selects whether the alarm is latching or non-latching. Latching alarms

must be cleared before the alarm output will reset. Non-latching automatically

resets the alarm output when the condition clears. This parameter will not appear

if Ot2 = Con or no. Range: LAt or nLA Default: nLA

Silencing: Selects alarm silencing (inhibit) for the alarm. This parameter appears

only when Ot2 = dEA or dE. For more information see Chapter 5, "Using Alarms."

Range: On or OFF Default: OFF

RTD: Selects the RTD calibration curve for RTD inputs. This parameter

will not appear unless In = rtd or rt.d. JIS = 0.003916Ω/Ω°C,

DIN = 0.003850Ω/Ω°C. Range: din or JIS Default: din

Ramping: Choose Str, and the set point ramps at the selected rate in °/hr from

process (actual) temperature to set point, when power is applied to the control

(start up). It will not ramp with a set point change. On is the same as Str plus it

ramps

at the selected ramp rate. OFF is for no ramping action. When ramping, the lower

display alternately flashes rP. The set point displayed is the desired end set point.

The ramping setpoint is not shown. Entering the Setup menu or manual operation

disables the outputs and ramp. Once you exit either one, the 965 controls to the

last entered set point. Range: Str, On, OFF Default: OFF

Rate: Selects the ramping rate in degrees per hour. This parameter will not

appear if rP = OFF. Range: 0 to 9999 Default: 100°/hr

with

a set point change. It ramps from the previous set point to a new one

LAt

SIL

rtd

r P

r t

Setup, Chapter 4

WATLOW Series 965 User's Manual

17

Page 18

Setup

P L

Range: Dependent on output type. -100 to100 Default: 100

Display: Selects which displays are active or viewable. Five seconds after

Power Limiting: The power limiting function in % power for heat.

dSP

selected, the appropriate display goes blank. Press MODE, Up-arrow or

Down-arrow to override this feature and cause the current value to be displayed for 5 seconds.

Range: nor Normal displays Default: nor

SEt Set Point - Lower display only

Pro Process - Upper display only

Table 1 Input Ranges.

Table 2 Setup Menu

Prompts and

Descriptions.

Input Type Sensor Range Low Sensor Range High

J32°F/0°C 1382°F/750°C

K (appears as H) -328°F/-200°C 2282°F/1250°C

t -328°F/-200°C 662°F/350°C

n32°F/0°C 2282°F/1250°C

S32°F/0°C 2642°F/1450°C

rtd (1°) -328°F/-200°C 1292°F/700°C

rt.d (0.1°) -199.9/199.9 999.9/700.0

4-20mA 4mA/-999 units 20mA/9999 units

VÎ (dc) 0VÎ (dc)/-999 units 5VÎ (dc)/9999 units

0-5

Setup Menu

Do not enter any values here; make photocopies instead.

Parameter Value Range Factory Default Appears If:

LOC 0 - 4 0

In J, K (appears as H), t, n, S, rtd, J DIP switch

rt.d, 0-5, 420 selectable.

dEC 0, 0.0, 0.00 0 In = 0-5 or 420

C _ F C or F Dependent on dFL. In = J,K,t,n,S,rtd,rt.d

rL rL to rH Input dependent.

rH rH to rL Input dependent.

Ot1 ht or CL ht

HSC 1 - 99, 0.1 - 9.9, 0.01 - 0.99 3, 0.3, 0.03

1 to 55, 0.1 to 5.5, 0.01 to 0.55 3, 0.3, 0.03/2, 0.2, 0.02

Ot2 Con = Control Con

PrA = Process Alarm

Pr = Process with no alarm message

dEA = Deviation alarm

dE = Deviation with no alarm message

no = None

HSA 1 - 9999, 0.1 - 999.9, 0.01 - 99.99 3, 0.3, 0.03°F Ot2 ≠ Con or no

1 - 5555, 0.1 - 555.5, 0.01 - 55.55 2, 0.2, 0.02°C

LAt LAt or nLA nLA Ot2 ≠ Con or no

SIL On or OFF OFF Ot2 = dEA or dE

rtd JIS or din din In = rtd or rt.d

r P Str = Ramping on power up OFF

rt 0 to 9999 100°/hr rP ≠ OFF

P L 0 to 100 100

dSP nor = normal nor

18

WATLOW Series 965 User's Manual

on = Ramping to set point at all times

OFF = None

SEt = Set Point (lower only)

Pro = Process (upper only)

Setup, Chapter 4

Page 19

Operation

= Prompt appears or not according

to control configuration.

M

75

Pb1

rE1/It1

rA1/dE1

Ct1

Pb2

Control Set Point

( )

Proportional band 1

( )

Reset 1/Integral

( )

Rate 1/Deviative 1

( )

Cycle time 1

( )

Proportional band 2

rE2/It2

rA2/dE2

Ct2

ALO

AHI

CAL

AUt

( )

Reset 1/Integral 1

( )

Rate 2/Deviative 2

( )

Cycle time 2

Alarm low

( )

( )

Alarm high

( )

Calibration offset

( )

Auto-tune

Operation Parameters

Set Point: Sets the operating set point for Output 1. Represents the process

value the system tries to achieve for Output 1. "SP" does not appear, the control set point value will. The lower display may be blank if dSP = Pro. If in a

ramping mode, the lower display alternately flashes the desired end set point

and rP.

NOTE:

The upper display

will always return to

the process value

after 1 minute

without key strokes.

Figure 24 The Operation Menu.

[

SP

]

Proportional Band 1 & 2 : A proportional band expressed in degrees or % of

span, within which a proportioning function is active for Output 1 or 2. When

Pb1 = 0, the unit functions as an on/off control on Output 1 and 2. Pb2 will not

appear if Pb1 = 0 or Ot2 ≠ Con. The switching differential is determined by the

HSC parameter.

If dFL = US: Range Pb1: 0 to 999°F/0 to 555°C/0 to 999 Units; 0.0 to 9.9°F/

0.0 to 5.5°C/0.0 to 9.9 units, Pb2: The same as Pb1 except lower limit is 1.

Defaults:

If dFL = SI: Range: 0 to 999.9% of span Defaults:

Pb1 =

25°F/2.5°F

Pb2 =

25

Pb1 =

3.0%

Pb2 =

3.0%

Reset /Integral 1 & 2: An integral control action for Output 1 or 2 that automatically eliminates offset, or "droop," between set point and actual process

temperature. rE1/It1: Will not appear if Pb1 = 0. rE2/It2: Appears if Pb1 ≠ 0

and Ot2 = Con. Either reset (rE) or integral (It) will appear depending on how

the dFL parameter is set in the Calibration menu. See Appendix II.

If dFL = US: Range: 0 to 9.99 repeats/minute Default: 0.00

If dFL = SI: Range: 00.1 to 9.99 minutes per repeat Default: 0.00

Rate /Derivative 1 & 2 : The rate (derivative) function for Output 1 or Output

2. Eliminate over shoot on start up, or after the set point changes. rA1/dE1:

Will not appear if Pb1 = 0. rA2/dE2: Appears if Pb1 ≠ 0 and Ot2 = Con.

Either rate (rA) or derivative (dE) appears depending on how dFL is set in the

Calibration menu. If dFL = US or SI: Range: 0 to 9.99 minutes Default: 0.00

Cycle Time 1 & 2: Time for a controller to complete one time proportioned

cycle for Output 1 or Output 2; expressed in seconds. Ct1: Will not appear if

Pb1 = 0, or Output 1 is 4-20mA. Ct2: Will not appear if Pb1 = 0 or Ot2 ≠ Con.

If a mechanical relay or contactor is switching power to the load, a longer

cycle time may be desirable to minimize wear on the mechanical components. Typical life of a mechanical relay is 100,000 cycles.

Range: 0.1 to 999.9 Default: 5.0

Pb1

Pb2

rE1/It1

rE2/It2

rA1/dE1

rA2/dE2

Ct1

Ct2

Setup, Chapter 4

WATLOW Series 965 User's Manual

19

Page 20

Operation

ALO

AHI

CAL

AUt

Table 3 Operation Menu

Prompts and

Descriptions.

Alarm Low: Represents the low process alarm or low deviation alarm. This

parameter will not appear if Ot 2 = no or Con.

If Ot2 = dEA or dE: Range: -999 to 0 Default: -999

If Ot2 = PrA or Pr: Range: rL to AHI Default: rL

Alarm High: Represents the high process alarm or high deviation alarm. This

parameter will not appear if Ot2 = no or Con.

If Ot2 = dEA or dE: Range: 0 to 999 Default: 999

If Ot2 = PrA or Pr: Range: ALO to rH Default: rH

Calibration Offset: Adds or subtracts degrees from the input signal.

Range: -180°F to 180°F/-100°C to 100°C/-180 units to 180 units; or

-18.0°F to 18.0°F/-10.0°C to 10.0°C Default: 0

Auto-Tune: Initiates auto-tune.

Range: 0 = off, 1 = slow, 2 = medium, 3 = fast Default: 0

Operation Menu

Use this page as a master copy for your Series 965 Operation Parameters.

Do not enter any values here; make photocopies instead.

Operation Parameters Value Range Factory Default

Pb1 If dFL = US:

0 - 999°F/0 - 555°C/0 - 999 Units 25°F

0 - 99.9°F/0 - 55.5°C/0 - 99.9 Units 2.5°F

0=ON/OFF control. HSC =switch diff.

If dFL = SI:

0.0 to 999.9% of span 3%

rE1 0.00 to 9.99 repeats/minute 0.00 repeats/minute

0.00 = No Reset. Won't appear if Pb1 = 0

or dFL = SI.

It1 0.0 - 99.9 minutes/rpt. 0.00 = No Integral. 00.0 minutes/repeat

Won't appear if Pb1 = 0 or dFL = US.

rA1 0.00 to 9.99 minutes 0.00 minutes

0.00 = No Rate. Will not appear if Pb1 = 0

or dFL = SI.

dE1 0.00 - 9.99 minutes. 0.00 = No Derivative. 0.00 minutes

Won't appear if Pb 1 = 0 or dFL = US.

Ct1 0.1 to 999.9 5.0 seconds

Won't appear if Pb1 = 0, or 4-20mA.

Pb2 Same as Pb1. Pb2 lower limit = 1, 0.1, 0.01

rE2 Same range as rE1.

It2 Same range as It1.

rA2 Same range as rA1.

dE2 Same range as dE1.

Ct2 Same range as Ct1.

ALO - Deviation dE -999 to 0 -999

Process Pr rL to AHI rL

Will not appear if Ot2 = no or Con.

AHI - Deviation dE 0 to 999 999

Process Pr ALO to rH rH

Will not appear if Ot2 = no or Con.

CAL ±18°F/±10°C/±18 Units 0

AUt 0-3 0

20

WATLOW Series 965 User's Manual

Setup, Chapter 4

Page 21

Chapter 5

How to Tune and Operate

Auto-tuning (Heat and/or Cool)

The Series 965 can automatically tune the PID parameters to fit the characteristics of your particular thermal system.

The auto-tuning procedure operates on a thermal response value — slow,

medium, or fast. Use the slow thermal response when your process does not

need to reach set point too rapidly, or if it usually does not often exceed set

point. A fast thermal response produces a rapid temperature change over a

short period of time.

Once the auto-tune sequence has begun, the Output 1 heat proportional band

is set to 0 and the control goes into an on/off mode of control at 90% of the

established set point. The displayed set point remains unchanged.

Tuning

NOTE:

Set the HSC parameter under the Setup

Menu to 3

before auto-tuning

your control.

°F/2°C

Once the control finishes "learning" the system, it returns to a standard PID

control with the PID values automatically set as a result of auto-tuning. See

Manual Tuning on the next page to set the cool PID parameters. Any change

of the set point, while in auto-tune, re-initiates the auto-tune procedure.

Auto-tuning at a Set Point of 200°F

200

180

°Temp

100

Auto-tune

Begins

Process

90% of

Set Point

°Time

Auto-tune

Complete

Set Point

Figure 25 Auto-tuning at a

Set Point of 200

°F.

In order for the 965 to successfully complete auto-tune, the process must cross

90% of set point four times within 80 minutes after auto-tune has started. If this

does not happen within the 80 minute time limit, the Pb remains at 0 and the

control functions in an on/off mode.

Tuning and Operating, Chapter 5

WATLOW Series 965 User's Manual

21

Page 22

Tuning

To start auto-tuning:

1. Press the MODE key until the AUt prompt appears in the data display.

2. Select a thermal response value, 1=slow, 2=medium, and 3=fast, using

the Up-arrow/Down-arrow keys. A thermal response value of 2 satisfactorily tunes most thermal systems.

3. Press the MODE key. While the control is in the tuning mode, the lower

display alternately displays the normal information and the prompt At. The

time between alternations is 1 second.

4. When tuning is complete, the displays return to their previous state and

AUt reverts to 0. The 965 installs appropriate PID tuning parameters and

saves them in the non-volatile memory. If a mechanical relay or

contactor is switching power to the load, a longer cycle time may be

desirable to minimize wear on the mechanical components. Typical

life of a mechanical relay is 100,000 cycles.

To abort auto-tuning either reset the AUt parameter to 0, press the A/M key

twice, or cycle power off and on. In all cases, aborting auto-tune restores all

values to those previous to auto-tuning.

Manual Tuning

For optimum control performance, tune the Series 965 to your thermal system.

The tuning settings here are for a broad spectrum of applications; your system

may have somewhat different requirements. NOTE: This is a slow procedure,

taking from minutes to hours to obtain optimum value.

NOTE:

Tune heating outputs at a set point

Tune cooling outputs at a set point

1. Apply power to the Series 965 and enter a set point. Begin with these

Operation parameters: Pb = 1, rE/It = 0.00, rA/dE = 0.00, Ct = 5.0, CAL = 0,

AUt= 0.

2. Proportional Band Adjustment: Gradually increase Pb until the upper

display temperature stabilizes to a constant value. The process temperature

will not be right on set point because the initial reset value is 0.00 repeats per

minute. (When Pb = 0; rE/It and rA/dE1 are inoperative, and the 965 functions as a simple ON/OFF control.) The HSC parameter determines the

switching differential value.

3. Reset/Integral Adjustment: Gradually increase rE, or decrease It until the

upper display temperature begins to oscillate or "hunt." Then slowly decrease

rE or increase It until the upper display stabilizes again near set point.

above ambient temperature.

below ambient temperature.

22

WATLOW Series 965 User's Manual

4. Cycle Time Adjustment: Set Ct as required. Faster cycle times sometimes

achieve the best system control. However, if a mechanical contactor or

solenoid is switching power to the load, a longer cycle time may be desirable

Tuning and Operating, Chapter 5

Page 23

to minimize wear on the mechanical components. Experiment until the

cycle time is consistent with the quality of control you want. Ct will not

appear on units with a process output.

5. Rate/Derivative Adjustment: Increase rA/dE to 1.00 minute. Then raise

set point by 20° to 30°F, or 11° to 17°C. Observe the system's approach to

set point. If the load temperature overshoots set point, increase rA/dE to

2.00 minutes.

Raise set point by 20 to 30°F, or 11 to 17°C and watch the approach to the

new set point. If you increase rA/dE1 too much, approach to set point is

very sluggish. Repeat as necessary until the system rises to the new set

point without overshooting or approaching the set point too slowly.

6. Calibration Offset Adjustment: You may want your system to control to

a temperature other than the value coming from the input sensor. If so,

measure the difference between that temperature (perhaps at another point

in the system) and the process value showing in the upper display. Then

enter the CAL offset value you want. Calibration offset adds or subtracts

degrees from the value of the input signal.

Manual and Automatic Operation

To change from auto to manual operation, press the A/M key twice.

Manual operation provides open loop control of the outputs from a range of

-100% (full cooling) to 100% (full heating) power. The 965 allows a negative

output value only with a Cl (Cool) selection on either Ot1 or Ot2 = Con. Automatic operation provides closed loop on/off or PID control. When the operator

transfers from a closed loop to an open loop, the 965 retains the power level

from the closed loop control, referred to as bumpless transfer. When the 965

returns to closed loop control, it restores the previous set point temperature.

Tuning/Operation

NOTE:

Process input does

not have sensor

break protection or

bumpless transfer.

Outputs selected as

Ht (reverse acting)

will be full on if

sensor break

occurs.

The MN LED indicates auto or manual operation. When the LED is on, the

control is in manual operation. When the LED is off, it is in automatic operation.

When the LED flashes, press the key again within five seconds to complete the

change in operation.

When a sensor opens, the 965 switches from automatic to manual operation if

LOC = 0, 1 or 2.

• If LOC = 0, 1 or 2 and the bumpless transfer conditions are met, process has

stabilized at a ± 5% power level for a 2 minute period prior to sensor break

provided the power level is less than 75%. The 965 switches to manual

operation at the last automatic power level.

• If LOC = 3 or 4, the 965 switches into manual operation at 0% power (outputs

disabled).

When transferring from auto to manual operation, the control output(s) remains

stable ("bumpless," smooth transition). When transferring from manual to

automatic operation, the control output(s) may change significantly. In manual

operation, the output value appears in the lower display; in automatic operation,

the set point appears.

Tuning and Operating, Chapter 5

WATLOW Series 965 User's Manual

23

Page 24

Auto/Man-Alarms

Using Alarms

The Series 965 has two alarm types, Process or Deviation. A process alarm

sets an absolute temperature. When the process exceeds that absolute temperature limit an alarm occurs. The process alarm set points may be independently

NOTE:

When the alarm

output is deenergized, the NO

contact is open in

the alarm condition.

set high and low. Under the Setup Menu, select the type of alarm output with the

Ot2 parameter. PrA = Process Alarm Pr = Process alarm with no alarm

message displayed

A Deviation alarm alerts the operator when the process strays too far from set

point. The operator can enter independent high and low alarm settings. The

reference for the deviation alarm is the set point. Any change in set point causes

a corresponding shift in the deviation alarm. dEA = Deviation Alarm

dE = Deviation alarm with no alarm message displayed

Example: If your set point is 100°F/38°C, and a deviation alarm is set at +7°F/

4°C as the high limit, and -5°F/3°C as the low limit, the high alarm trips at 107°F/

41.6°C, and the low alarm at 95°F/35°C. If you change the set point to 130°F/

54.4°C, the alarms follow the set point and trip at 137°F/59°C and 125°F/51.6°C.

Under the Setup Menu, select the type of alarm output with the Ot2 parameter.

dEA = Deviation Alarm dE = Deviation alarm with no alarm message displayed

Figure 26 Alarm Display

Examples

Both process and deviation alarms can be latching or non-latching. When the

alarm condition is removed a non-latching alarm automatically clears the alarm

output. You must manually clear a latching alarm before it will disappear.

Flashing "LO" or "HI" in the lower display indicates an alarm when Ot2 = PrA or

dEA. The lower display alternately shows information from the current parameter

and the "LO" or "HI" alarm message at one second intervals. The alarm output is

de-energized and the L2 LED is lit.

To clear an alarm…

• First correct the alarm condition, then…

• If the alarm is latching…

Clear it manually; press the A/M key once as soon as the process

temperature is inside the HSA parameter alarm limit.

• If the alarm is non-latching…

The alarm clears itself automatically as soon as the process

temperature is inside the HSA parameter alarm limit.

Press once -

Clear

a latched

and

corrected

alarm.

24

WATLOW Series 965 User's Manual

Tuning and Operating, Chapter 5

Page 25

Alarm Silencing is available with the deviation alarm. When SIL is selected as

"on," the operator must manually disable the alarm by pressing the A/M key

once on initial power up (in either the latching or non-latching mode). Alarm

silencing disables the alarm output relay. However, the L2 LED (also the lower

display when Ot2 = dEA) shows an alarm condition until the process value is

within the "safe" region of the deviation alarm band. Once the process value

crosses into the "safe" region, both a latching or a non-latching alarm is ready.

Any future deviation outside this safe band triggers an alarm.

Error Code Messages ç

Four dashes, "- - - -", in the upper display indicate a Series 965 error. The error

code is visible in the lower display.

Error Codes

NOTE:

An alarm display will

be masked by an

error condition or

when the control is

in the Calibration or

Setup Menus.

Er 2 - Sensor underrange error (only applies to RTD units)

The sensor input generated a value lower than the allowable signal range, or the

A/D circuitry malfunctioned. Enter a valid input. Make sure the In parameter

(selected in the Setup menu) and the DIP switch settings both match your

sensor. Refer to the table below for the appropriate input type and range.

Er 4 - Configuration error

The unit's microprocessor is faulty; call the factory.

Er 5 - Non volatile checksum error

The nonvolatile memory checksum discovered a checksum error. Unless a

momentary power interruption occurred while the unit was storing data, the

nonvolatile memory is bad. Call the factory.

Er 6 - A/D underflow error

The A/D circuit is underrange. An open or reversed polarity sensor is the most

likely cause. Check the sensor; if the connection is good and functions properly,

call the factory. The A/D underrange voltage is too low to convert an A/D signal.

Make sure the In parameter matches your sensor and DIP switches are set

accordingly.

Er 7 - A/D overflow error

The A/D circuit is overrange. An open or reversed polarity sensor is the most

likely cause. Check the sensor; if the connection is good, and the sensor

functions properly, call the factory. The A/D overrange voltage is too high to

convert an A/D signal. Make sure the In parameter matches your sensor and

DIP switches are set accordingly.

ç

CAUTION:

Electrical noise or a

noise event, vibration or excess

environmental

moisture or temperature may cause

Series 965 errors to

occur. If the cause

of an error is not

otherwise apparent,

check for these.

Tuning and Operating, Chapter 5

WATLOW Series 965 User's Manual

25

Page 26

Error Codes

Error Code Actions

• Er 2, Er 6, Er 7 result in these conditions:

• If operator access is LOC 0, 1 or 2 ...

…and the control was in AUTO operation when the error occurred, it goes

into manual (% power) operation. If the output power is less than 75%

power, and a <5% change in power occurred within the last two minutes,

the 965 switches into manual operation at the last automatic power level

(bumpless transfer). If the control was in manual operation, it remains

there. Press A/M twice to see the error code. The alarm output (if present) is in its alarm state (LED lit). The upper display reads "- - -". The

lower display indicates the error code.

If the control was operating with stable output values when the error

occurred, it continues to operate at those levels on a % power basis. If

output values were not stable, the control outputs go to 0% power (OFF).

• If operator access is LOC 3 or 4…

The control remains in auto operation and the outputs go off. The A/M and

MODE keys are inactive. The Up-arrow/Down-arrow keys may be used

simultaneously to enter the Setup Menu. The alarm output (if present) is in

its alarm state (LED lit). The upper display reads "- - - -". The lower

display indicates the error code.

• To clear a corrected error…

• Press M (Mode key).

• Er 4 and Er 5 result in these conditons:

• The control is in auto operation with both outputs off.

• The alarm output, if present, are in their alarm state (de-energized with the

LED lit).

• The upper display indicates the process value.

• The lower display indicates the error code.

• All keys are inactive.

• All Setup Menu parameters return to default values.

• The above conditions occur regardless of the value of LOC, or the

presence of the Setup or Calibration Menus.

• To clear a corrected error…

• Cycle power to the control.

26

WATLOW Series 965 User's Manual

Tuning and Operating, Chapter 5

Page 27

Appendix 1

Noise and Installation Guidelines

For wiring guidelines, refer to the IEEE Standard No. 518-1982, available from

IEEE, Inc. 345 East 47th Street, New York, NY 10017.

Noise Sources

• Switches and relay contacts operating inductive loads such as motors, coils,

solenoids, and relays, etc.

• Thyristors or other semiconductor devices which are not zero crossover-fired

(randomly-fired or phase angle-fired devices).

• All welding machinery and heavy current carrying conductors.

• Fluorescent and neon lights.

Noise Guidelines

Decreasing Noise Sensitivity

• Physical separation and wire routing must be given careful consideration in

planning the system layout. For example, ac power supply lines should be

bundled together and physically kept separate from input signal lines (sensor

lines). A 12" (305 mm) minimum separation is usually effective. Keep all

switched output signal lines (high power level) separate from input signal

lines (sensor lines). Cross other wiring at 90° angles whenever crossing

lines is unavoidable.

• Look at the system layout; identify and locate electrical noise sources such

as solenoids, relay contacts, motors, etc. Route the wire bundles and cables

as far away as possible from these noise sources. Don't mount relays or

switching devices close to a microprocessor control. Don't have phase

angle-fired devices in the same electrical enclosure or on the same power

line with the control.

• Shielded cables should be used for all low power signal lines to protect from

magnetic and electrostatic coupling of noise. Some simple pointers are:

◊ Whenever possible, run low level signal lines unbroken from signal source

to the control circuit.

◊ Connect the shield to the control circuit common at the control end only.

Never leave the shield unconnected at both ends. Never connect both

shield ends to a common or ground.

◊ Maintain shield continuity at daisy chain connection points by reconnecting

the broken shield.

◊ Assume no electrostatic shielding when using the shield as a signal return.

If you must do this, use triaxial cable (electrostatically shielded coaxial

cable).

Appendix

27WATLOW Series 965 User's Manual

Page 28

Wiring Guide

• Use twisted pair wire any time control circuit signals must travel over two feet,

or when you bundle them parallel with other wires.

• Select the size or gauge of wire by calculating the maximum circuit current

and choosing the gauge meeting that requirement. Using greatly larger wire

sizes than required generally increases the likelihood of electrostatic (capacitance) coupling of noise.

• Eliminate ground loops in the entire control system. You can spot the

obvious loops by studying the "as-built" wiring diagram. There are also notso-obvious ground loops resulting from connecting internal circuit commons

in the manufacturer's equipment.

• Do not daisy chain ac power (or return) lines, or output signal (or return) lines

to multiple control circuits. Use a direct line from the power source to each

input requiring ac power. Avoid paralleling L1 (power lead) and L2 (return

lead) to load power solenoids, contactors, and control circuits. If an application uses L1 (power lead) to switch a load, L2 (return lead) has the same

switched signal and could couple unwanted noise into a control circuit.

• Tie all ground terminals together with one lead (usually green wire) tied to

ground at one point. Don't connect ground to the control case if the control is

in a grounded enclosure (preventing ground loops).

• Do not confuse chassis grounds (safety ground) with control circuit commons

or with ac supply L2 (return or neutral line). Each return system wiring must

be separate. Absolutely never use chassis ground (safety) as a conductor to

return circuit current.

Eliminating Noise

• Use "snubbers" (QUENCHARC™ P/N: 0804-0147-0000) to filter out noise

generated by relays, relay contacts, solenoids, motors, etc. A snubber is a

simple filter device using a 0.1µf, 600 volt, non-polarized capacitor in series

with a 100Ω, 1/2 watt resistor. The device can be used on ac or dc circuits

to effectively dampen noise at its source.

• The ultimate protection is an "uninterruptable" power supply. This "senses"

the ac power line; when the line fluctuates, a battery powered 60Hz

inverted circuit takes over, supplying power within one-half to one cycle of

the ac line; very expensive.

WATLOW Series 965 User's Manual

Appendix28

Page 29

Appendix 2

Calibration

Before attempting to calibrate, make sure you read through

the procedures carefully and have the proper equipment

called for in each procedure. Make sure the DIP switches are

in the proper position per input type. See Figure 21, Page 14.

Entering the Calibration Menu

In the Calibration Menu, various input signals must be supplied for the control to

go through its auto calibration. The calibration menu can only be entered from

the LOC parameter in the Setup Menu. Press the Up-arrow/Down-arrow keys

simultaneously for 3 seconds (± 1 second). The CAL parameter appears in the

lower display with "no" in the upper display.

Calibration

Figure 27 Entering the

Calibration Menu.

Any inadvertent change in the displayed data, when pressing the Up-arrow/

Down-arrow keys, is ignored. Calibration values won't be retained unless you

are in the manual mode. Press the Up-arrow/Down-arrow key to change the

upper display to “YES.” Press MODE to enter the calibration sequence.

Upon entering the calibration menu, the upper display window indicates CAL.

It continues to indicate CAL (with the exception of calibration of the 4-20mA

output) while the operator walks through the entire calibration parameter list.

While calibrating the 4-20mA output, the upper display contains a numeric

value to be slewed up or down until the output value is correct. The control

uses the lower display to prompt the user as to what the input should be.

With the dFL parameter, select either U.S. parameters which include displaying

°F, rate, reset, and proportional band in degrees or units. Or select SI (System

International) and the displayed parameters are °C, integral, derivative, and

proportional band in % of span.

NOTE:

Calibration values

will not be retained

unless you are in the

MANUAL mode. Do

not enter the MANUAL mode until you

are at the correct

input parameters.

NOTE:

While in the Calibration Menu, the

control output(s) go

off and the alarm

output (if present) is

on.

Once the information has been properly established and maintained for at least

5 to 10 seconds, the MODE key may then be used to display the next prompt.

After the final input is established, press the MODE key twice to return the unit

to the configuration menu at the top of the parameter list.

Appendix

WATLOW Series 965 User's Manual

29

Page 30

Calibration

Restoring Factory Calibration

The rSt parameter restores the factory calibration values to the Series 965. If

you calibrate your control incorrectly, you have the option to default to the

original values. Once you leave the CAL menu, the values are entered.

1. Press the Up-arrow/Down-arrow keys simultaneously for three seconds.

The LOC parameter appears in the lower display. Continue holding the Uparrow/Down-arrow keys until the lower display reads CAL.

2. Press the Up-arrow key until YES appears in the upper display.

3. MODE through the calibration menu until rSt appears in the lower display.

4. Press the Up-arrow key until YES appears in the upper display.

5. Press the MODE key and the 965 advances to test the displays.

This procedure is used only to restore calibration, it is not meant to clear values.

Calibration Menu

( )

CAL

YES to calibrate, No skips to display test.

Figure 28 Calibration

Parameters

No

0.00

50.0

tC

440

255

0.00

5.00

4.00

20.0

4A0

2A0

rSt

dSP

dFL

MEM

Yes

( )

Input 0.00mV for low input.

( )

Input 50.00mV for high input.

Connect a Type "J" ambient compensator with inputs shorted.

( )

Set the low resistance to 44.01Ω.

( )

Set the high resistance to 255.42Ω.

( )

Set the voltage source to 0.000 volts.

( )

Set the voltage source to 5.000 volts.

( )

Set the current source to 4.00mA.

( )

Set the current source to 20.00mA.

( )

Enter 4-20mA output calibration value for 4mA.

( )

Enter 4-20mA output calibration value for 20mA.

( )

Restores factory calibration values.

( )

Factory use only.

Select US (rate, reset, proportional band in degrees or units, °F) or

( )

SI (integral, derivative, proportional band in % of span, °C)

Factory use only.

ç

Before attempting to calibrate,

make sure you have the proper

equipment called for in each procedure.

The Series 965 is calibrated and tested

before leaving the factory.

30 WATLOW Series 965 User's Manual Appendix

Page 31

Thermocouple Field Calibration Procedure

Equipment Required

• Type "J" Reference Compensator with reference junction at 32°F/0°C, or

Type "J" Thermocouple Calibrator set at 32°F/0°C.

• Precision millivolt source, 0-50mV min. range, 0.01mV resolution

Setup And Calibration

1. Connect the AC line voltage L1 and L2 to the proper terminals.

2. Connect the millivolt source to Terminal 5 Negative and Terminal 3 Positive on the

Series 965 terminal strip. Use regular 20 - 24 gauge wire. Make sure the DIP switch

is set for thermocouple input, see Chapter 4.

3. Apply power to the unit and allow it to warm up for 15 minutes. After warm-up put the

unit in the CAL menu. See Figure 27 on Page 29. Select YEs.

4. Press the A/M key twice to enter the MANUAL mode. The unit is calibrating when

MN LED is on. Make sure the unit is in MANUAL mode only when you are in the

correct parameters.

5. At the 0.00 prompt, enter 0.00mV from the millivolt source to the control. Allow at

least 10 seconds to stabilize. Press the MODE key.

6. At the 50.0 prompt, enter 50.00mV from the millivolt source to the Series 965. Allow

at least 10 seconds to stabilize. Press the MODE key.

7. At the tC prompt, disconnect the millivolt source, and connect the reference

compensator or T/C calibrator to Terminal 5 Negative, and Terminal 3 Positive on the

Series 965 terminal strip. If using a compensator, turn on and short the input wires. If

using "J" calibrator, set to simulate 32°F/0°C. Allow 10 seconds for the control to

stabilize. The unit will leave the CAL mode if 1 minute passes between key

activations. To conclude the T/C calibration, advance the MODE key to the next

prompt or exit the CAL menu. Press the A/M key twice to exit the MANUAL mode.

RTD Field Calibration Procedure

Equipment Required

•1KΩ precision decade resistance box with 0.01Ω resolution.

Setup And Calibration

1. Connect the ac line voltage L1 and L2 to the proper terminals.

2. Connect the decade resistance box to Terminal 2, 3 and 5 on the terminal strip. Use

regular 20 - 24 gauge wire of the same length and type. Make sure the DIP switch is

set for RTD input, see Chapter 4.

T/C Calibration

NOTE:

Before calibration

on an installed

control, make sure

all data and

parameters are

documented. See

Setup and Operation

Tables, Pages 18

and 20.

NOTE:

When the MN LED is

on, the unit is

automatically

calibrating. Your

sequence is VERY

important. Always

move to the next

parameter before

changing the

calibration equipment.

3. Apply power to the unit and allow it to warm up for 15 minutes. After warm-up put

the unit in the CAL menu. See Figure 27 on Page 29. Select YEs. Press the MODE

key until the 440 prompt is displayed.

4. Press the A/M key twice to enter the MANUAL mode. The unit is calibrating when the

MN LED is on. Make sure the unit is in MANUAL mode only when you are in the

correct parameters.

5. At the 440 prompt, set the decade resistance box to 44.01. Allow at least 10 seconds

to stabilize. Press the MODE key to enter the calibration data. Press the A/M key

twice to exit the MANUAL mode. The unit will leave the CAL mode if 1 minute passes

between key activations. To conclude the RTD calibration, advance the MODE key

to the next prompt or exit the CAL menu.

6. At the 255 prompt, set the decade resistance box to 255.42. Allow at least 10

seconds to stabilize. Press the MODE key.

Appendix

WATLOW Series 965 User's Manual

31

Page 32

Process Input

NOTE:

Before calibration

on an installed

control, make sure

all data and

parameters are

documented. See

Setup and Operation

Charts, Pages 18

and 20.

0-5 Volt Input Field Calibration Procedure

Equipment Required:

• Precision DC voltage source 0-5 volt minimum range with 0.001 volt resolution.

Setup and Calibration

1. Connect the AC line voltage L1 and L2 to the proper terminals on the 965.

2. Connect the voltage/current source to Terminal 3 (+) and 5 (-) on the Series 965

terminal strip. Use regular 20 - 24 gauge wire. Make sure the DIP switch is set for

process input, see Chapter 4.

3. Apply power to the unit and allow it to warm up for 15 minutes. After warm-up put

the unit in the CAL menu. See Figure 27 on Page 29. Select YEs. Press the

MODE key until 0.00 is displayed.

4. Press A/M twice to enter the MANUAL mode. The unit is calibrating when the MN

LED is on. Make sure the unit is in the MANUAL mode only when you are in the

correct parameters. See Figure 28 on Page 30.

5. At the 0.00 parameter, set the voltage source to 0.000 volts. Allow at least 10

seconds to stabilize. Press the MODE key.

NOTE:

When the MN LED is

on, the unit is

automatically

calibrating. Your

sequence is VERY

important. Always

move to the next

parameter before

changing the

calibration equipment.

6. At the 5.00 parameter, set the voltage source to 5.000VÎ (VDC). Allow at least 10

seconds to stabilize. The unit leaves the CAL mode if 1 minute passes between key

activations. Press A/M twice to exit the MANUAL mode. To conclude the 0-5 Volt

calibration, advance the MODE key to the next prompt or exit the CAL menu.

4-20mA Input Field Calibration Procedure

Equipment Required:

• Precision current source 0-20mA minimum range with 0.01mA resolution.

Setup and Calibration

1. Connect the AC line voltage L1 and L2 to the proper terminals on the 965.

2. Connect the current source to Terminal 2 (-) and 5 (+) on the Series 965 terminal

strip. Use regular 20 - 24 gauge wire. Make sure the DIP switch is set for process

input, see Chapter 4.

3. Apply power to the unit and allow it to warm up for 15 minutes. After warm-up put

the unit in the CAL menu. See Figure 27 on Page 29. Select YEs. Press the

MODE key until 4 is displayed.

4. Press A/M twice to enter the MANUAL mode. The unit is calibrating when the MN

LED is on. Make sure the unit is in the MANUAL mode only when you are in the

correct parameters. See Figure 28 on Page 30.

5. At the 4.00 parameter, set the current source to 4.00mA. Allow at least 10 seconds

to stabilize. Press the MODE key.

6. At the 20.0 parameter, set the current source to 20.00mA. Allow at least 10 seconds

to stabilize. The unit leaves the CAL mode if 1 minute passes between key activations. Press A/M twice to exit the MANUAL mode. To conclude, advance the MODE

key to the next prompt or exit the CAL menu.

32 WATLOW Series 965 User's Manual Appendix

Page 33

4-20mA Output Field Calibration Procedure

Equipment Required:

• 300Ω, 1/2 watt 10% resistor.

• 4 - 1/2 digit Digital Multimeter.

Setup And Calibration

1. Connect the ac line voltage L1 and L2 to the proper terminals of the 965. See

Chapter 2. Set the multimeter to measure current.

2. Connect the multimeter in series with the 300Ω resistor to Terminal 9 Positive and 10

Negative on the Series 965 terminal strip. Use regular 20 - 24 gauge wire.

3. Apply power to the unit and allow it to warm up for 15 minutes. After warm-up put

the unit in the CAL menu. Press the MODE key until the 4A0 prompt is displayed.

4. Press the A/M key twice to enter the MANUAL mode. The unit is calibrating when the

MANUAL LED is on.

5. At the 4A0 prompt, the multimeter should read approximately 4mA. Allow at least 10

seconds to stabilize.

4-20mA Output

NOTE:

Before calibration

on an installed

control, make sure

all data and

parameters are

documented. See

Setup and Operation

Charts, Pages 18

and 20.

6. Use the

multimeter for 3.85mA ± 0.10mA. Press the MODE key.