Page 1

Series 920

Microprocessor-Based

Ramping Control

User’s Manual

Watlow

Controls, 1241 Bundy Blvd., Winona, MN 55987, Phone:

W920-MA60-9302

January, 1993

Supersedes:

W920-MC5A-8944

507/454-5300,

Made in the U.S.A.

0

Printed

0

Fax:

507-452-4507

$10.00

on

Recycled

Paper

Page 2

First...

This manual will

tion is a good way to become familiar with the Series 920. Here’s an overview:

make

your

job

easier.

Reading it and applying the

informa-

Starting

Front Panel

Running a Program

lnstall/Wire

Tune

Programming

Alarms

Appendix

Quick Reference

Out

Introduction, Chapter 1.

Keys and Displays, Chapter 2.

Sample Program, Chapter 3.

Installation and Wiring, Chapter 4.

How to Tune, Chapter 5.

How to Program, Chapter 6.

How to Use Alarms, Chapter 7.

Specifications

Glossary

Calibration

Warranty

Series 920 error codes and prompts, inside and outside back covers.

Notes

The user’s manual contains informational notes to alert you to important details. When you

see a note

icon,

look for an explanation in the margin.

J

or fl NOTE:

Details of a

appear here, in the

narrow box on the

outside of each page.

f

0

n

Details of a “Caution”

appear here, in the

narrow box on the

outside of each page.

0

Details of a “Warning”

appear here, in the

narrow box on the

outside of each page.

2

“Note”

CAUTION:

WARNING:

WATLOW

Series 920

Safety Information

Boldface safety information protects both you and your equipment.

them. Here are explanations:

The CAUTION symbol (exclamation point) in the wide text column alerts you to a

TION”,

a safety or functional hazard which could affect your

A full explanation is in the narrow column on the outside of the page.

equipment

Please be attentive to

‘CAU-

or its performance.

0

The WARNING symbol (lightning bolt) in the wide text column alerts you to a ‘WARNING”,

A full explanation is in the

P.0. Box

.

5580,

Winona,

Techni-

MN 55987-5580,

are

bir

0193

a safety hazard which could affect you and the equipment.

narrow

column

on the outside of the page.

Your comments or suggestions on this manual are welcome, please send them to:

cal Writer,

or phone

copyrighted by Watlow Winona, Inc.,© 1987 with all rights reserved.

User's

Watlow

507/454-5300.

Manual

Controls, 1241 Bundy Blvd.,

The Watlow Series 920 User’s Manual and integral software

Page 3

Page

Item

6

6

7

7

8

8

9

10

10

11

11

11

12

13

13

14

14

14

15

15

16

16

17

17

18

I8

19

19

Starting out with the Watlow Series 920 - Chapter 1

General Description

Packing List

Put Your Control to Work-Three Steps

How to Open the 920

How to Set the DIP Switches

Changing the Position of a DIP Switch

Overview of the Three Operating Modes

Where To Go From Here

How to Use the Keys and Displays - Chapter 2

Display, Key and LED-Location and Explanation

Front Panel Information

Actual and Alphanumeric Display Area

Keyboard Area

Where To Go From Here

-

Learning the Series 920

A Brief

Overview

Chapter 3

Clear Memory, Set DIP Switches

Enter Real Time of Day

Before Entering Your Program

Programming File 1

Running Your Program

Editing Your Program

Adding an

LIN

King Files

The

AUTOSTART

WAITFOR

Step Type

Step

Running Your Series 920

Where To Go From Here

Starting Out

Front Panel

Sample Program

20

20

20

21

22

22

22

24

24

25

26

27

27

28

30

32

Contents

How to Install and Wire the Series 920 - Chapter 4

Sensor Installation Guidelines

Input Power Wiring

The Do’s and

Don’ts

of Clean Input Power

How to Check for Ground Loops

Noise Suppression Devices Available from Watlow

Line Filtering Configurations For Controls

Installation Information

Installation Procedure

How to Wire the Series 920

Power Wiring

Input Wiring

Auxiliary Output Wiring

Output 1 Wiring

Output 2 Wiring

System Wiring Example

Install and Wire

WATLOW Series 920 User’s Manual

3

Page 4

Page

Item

Tuning

Programming

Alarms

33

33

33

33

34

35

35

36

36

36

36

37

37

38

39

40

42

49

54

54

54

55

56

57

58

58

58

How to Tune the Series 920 - Chapter

5

Recommended Tuning Reference

Using a Chart Recorder

Load

LEDs

Tuning

The LOPWR and

HIPWR

Parameters

Where To Go From Here

H

OW

to Program the Series 920 - Chapter

6

Write Out Your Program

Programming in General

Select the Proper DIP Switch Settings

Event Ouputs

Guaranteed Soak

The Four

JUMPLOOP

Types

Rules to Follow

SYSTEM Menu

SETUP Menu

PROGRAM Menu

How to Use the Series 920 Alarms - Chapter

Alarm

Relay Configuration

Number of Alarms

Alarm Types

The Operating Band

Alarm

Limits

Alarm

Function, Latching or Non-Latching

Clearing an Alarm Message

An Alarm And The State Of The Alarm Relay

7

Appendix

Terminology

Quick Reference

WATLOW Series 920 User’s

59

59

60

62

63

64

66

67

75

77

77

77

78

80

Appendix

Specifications

Model Number Information

J, K, & T Thermocouple Field Calibration Procedure

R, S, &

B Thermocouple Field Calibration Procedure

RTD Field Calibration Procedure

Process Field Calibration Procedure

Glossary

Index

Warranty

Returning Merchandise

Shipping Claims

Series 920 Error Codes/Alarms

Series 920 Quick Reference

Manual

Contents

Page 5

Figures, Tables and Charts

Page

.

6

8

9

10

12

12

13

19

23

23

23

24

25

25

26

27

27

28

28

29

29

30

30

30

31

31

32

37

40

42

49

55

55

57

57

62

63

64

66

Item

Series 920 Input and Output Overview

How to Open the Series

920

DIP Switch Location and Orientation

Overview

of the Three Operating Modes

Series 920 Front Panel Information

Actual and Alphanumeric Display Front Panel Information

Keyboard Front Panel Information

RUN Key Flow Diagram

Differential Mode Filter Diagram

Common Mode Filter Diagram

Combination Differential-common Mode Filter Diagram

Series 920 Faceplate Dimensions

Series 920 Dimensions (side view)

Series 920 Panel Cutout Dimensions

Series 920 Power Wiring

Input Options Wiring Diagram

Auxiliary Wiring Diagram

Output 1, S.S. Relay, Wiring Diagram

Output 1, S.S. Switch, Wiring Diagram

Output 1,

Output 1,

Output

Mech.

Relay, Wiring Diagram

Triac,

Wiring Diagram

1,4-20mA,

Wiring Diagram

No Output 2

Output 2, S.S. Relay, Wiring Diagram

Output 2, S.S. Switch, Wiring Diagram

Output 2,

Mech. Relay,

Wiring Diagram

System Wiring Example

Guaranteed Soak (GS) Example

SYSTEM Key Flow

SETUP Key Flow

PROGRAM Key Flow

Alarm Type for

Alarm 1

is “process” alarm

Alarm Type for Alarm 1 is a “deviation” alarm

Alarm limits for Alarms 1 and 2 with “process” type alarm

Alarm limits for Alarms 1 and 2 with “deviation” type alarm

J, K, T Reference Compensator to 920 Connection Diagram

“R"

Reference Compensator to 920 Connection Diagram

Decade Resistance Box to Series 920 Connection Diagram

Voltage/Current Source to Series 920 Connection Diagram

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5

Figure 6

Figure 7

Figure 8

Figure 9

Figure 10

Figure 11

Figure 12

Figure 13

Figure 14

Figure 15

Figure 16

Figure 17

Figure 18

Figure 19

Figure 20

Figure 21

Figure 22

Figure 23

Figure

24

Figure 25

Figure 26

Figure 27

Figure 28

Figure 29

Figure 30

Figure 31

Figure 32

Figure 33

Figure 34

Figure 35

Figure 36

Figure 37

Figure 38

Figure 39

9

16

17

17

18

18

22

41

43

50

56

65

53

Contents

DIP Switch Selection

Series 920 Ramp and Soak Program

Editing Your Program, Steps 4-7

Adding the AUTOSTART Step

LlNKing

The

to Another File

WAITFOR

Step

Noise Suppression Device Ratings

SYSTEM Prompts and Description

SETUP Prompts and Description

Table 1

Table 2

Table 3

Table 4

Table 5

Table 6

Table 7

Table 8

Table 9

PROGRAM Prompts and Description Table 10

Operating Band Limits and Ranges

RTD Calibration Settings for

JIS

Master Step Chart

Table 11

Table 12

Chart 1

WATLOW Series

920

User’s

Manual

5

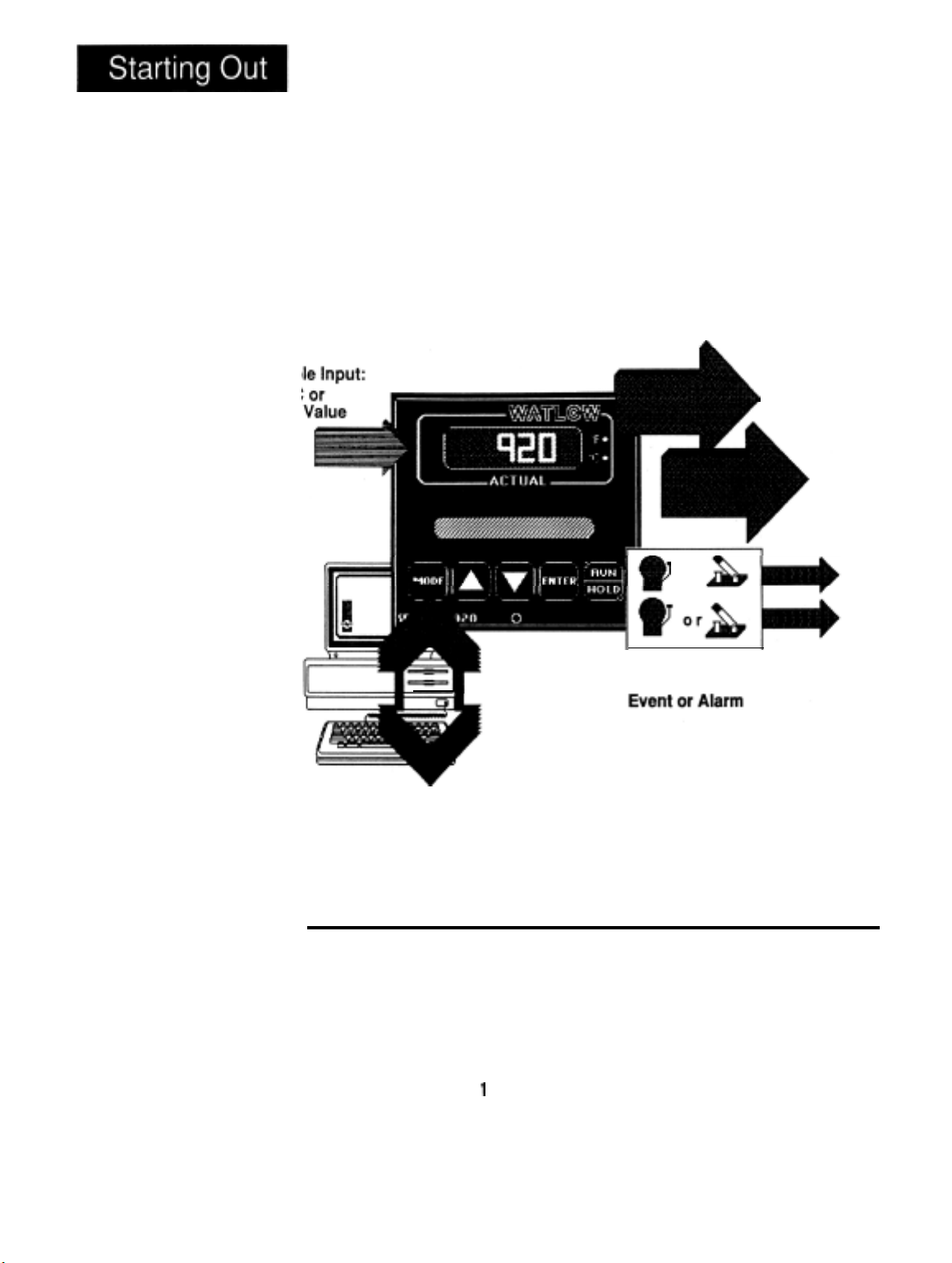

Page 6

Figure

Series

output

l-

920 Input

Overview

Selectab

RTD,

T/C

Process

and

Chapter 1

Starting out with the

Watlow Series 920:

A Microprocessor-Based Control

or

Dual

PID

or

ON/OFF

outputs

FF

Two Auxiliary Outputs

RS-422A

Optional Computer Interface

or

RS-423A (RS-232C

Compatible)

General Description

Congratulations, you’re about to become a fully-qualified user of the Watlow

Series

simple to learn. A ramp progresses from one set point to another set point over a

period of time.

920 and its operation.

Figure 1 is a simplified view of the Series

microprocessor-based, 1/4 DIN-sized ramping temperature control. The 920

accepts a single, front panel-selectable input. This includes Type

or B thermocouple input, a 1° or 0.1°

has a full control temperature range, offset calibration, and a front panel lock-out

feature.

6

WATLOW Series 920

User’s

920!

This versatile microprocessor-based ramping control is powerful, yet

In this chapter of the user’s manual, you’ll get an overview of the

920’s

capabilities. It is a dual output,

J,

K, T, R, S,

RTD

input, or one of two process inputs. It

Starting

Out,

Chapter

Manual

1

Page 7

The Series 920 is a

PID

controller. You may input two complete sets of

PID

parameters on the front panel for heat/cool applications. This includes rate,

reset, proportional band and cycle time. By setting the proportional band(s) to

zero, the Series 920 becomes a simple

ON/OFFcontrol

with a

3°F

or

1.7°C

switching differential.

The 920s auxiliary outputs may be alarms or events. An event is an ON/OFF

auxiliary output relay signal. You can use events, based on time, temperature,

or other process variables, to trigger peripheral equipment or processes.

Operator-friendly features include automatic entry codes or “prompts” to aid in

setup. When there’s a power outage, the Watlow Series 920 stores all information in a non-volatile memory.

When you first apply power, the unit will “come up” with default values for set

points, alarm points and control

parameter.

These default values provide

minimum operating information for the control until you program in the desired

data. The default values are listed in the Master Step Menus and Charts,

pp.

41-50.

Remove the Series 920 carefully from its shipping container. Be sure to set

this literature aside where it will not be discarded.

Packing List

Included with your Watlow Series 920 are two mounting brackets with integral

screws, and this manual.

If your unit has communications, the “How to Use

Data Communications with the Watlow Series 922” manual is also included.

Put Your Control to Work-Three Steps

Once your control is installed and wired, getting the Series 920 “up and run-

ning” is a three-part process:

l

First, match the control’s “personality”, to your system in what we call the

SETUP menu; input type, units of measure, range, calibration offset, output

action, alarm type, lock-out.

l

Second, tune the control making final

l

Third, enter up to ten separate profiles in the PROGRAM menu.

PID

entries.

WATLOW Series 920 User’s Manual

7

Page 8

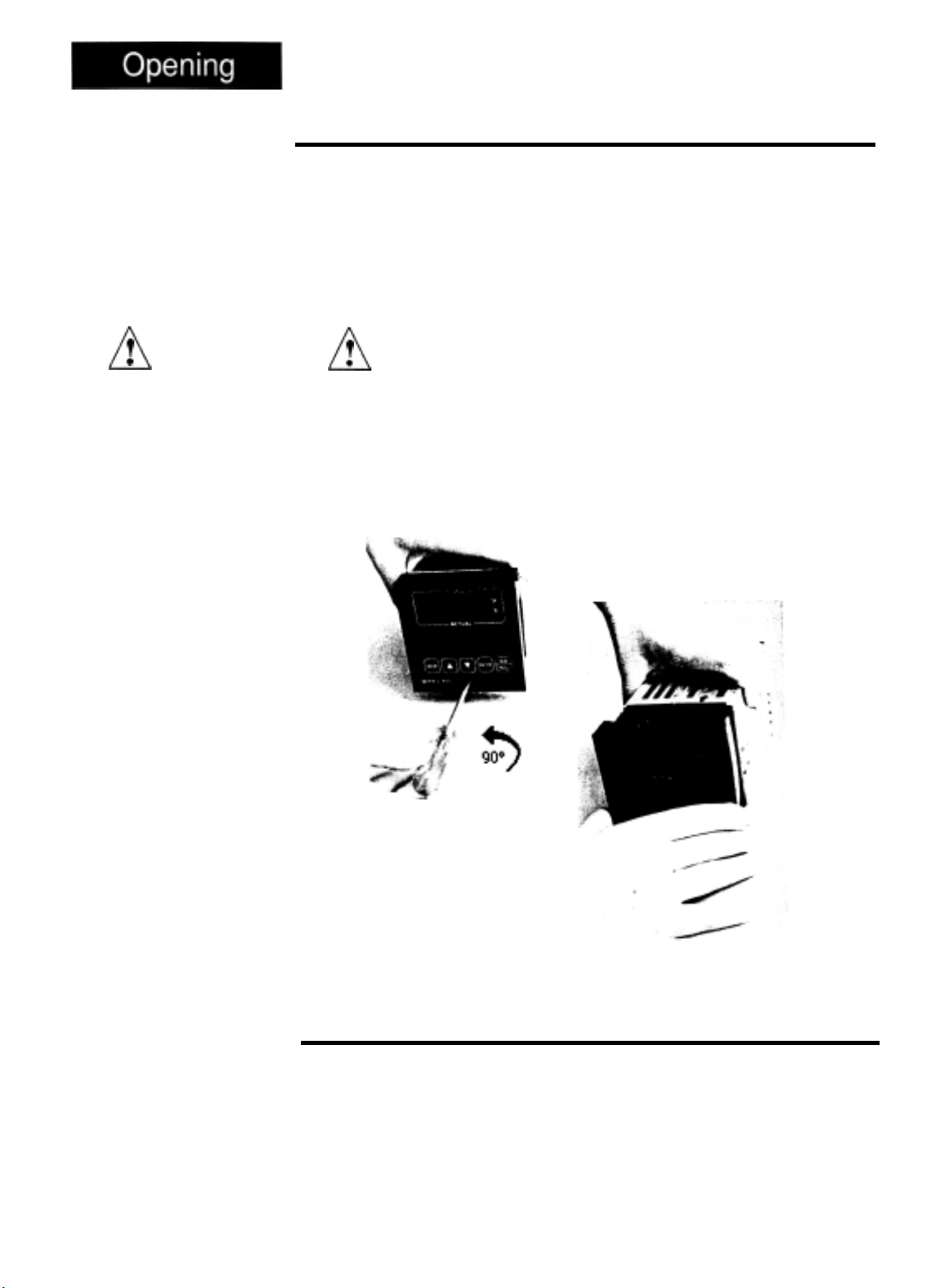

How to Open the 920

7

0

A

The front panel

screw turns

only. Do not apply

excessive force or

turn the screw more

than

CAUTION:

90°

90°.

Before going further, open the Series

case. Here’s how:

The control chassis fastens to the case with a single screw located on the

lower front panel. See Figure

Three or four strip connector

power and signals through the back of the casing to the triple terminal strip.

These plugs will let go as you pull.

f

l

A

When removing the Series

When returning the control to the case, be sure you have the top up to match

the plugs with the case. The 920 will not fit in to the case upside down. Always check to see that it is oriented correctly.

the front panel screw clockwise to secure it.

2.

plugs, in the rear of

920

control from its case, pull firmly but gently.

920

and pull the control chassis from its

Turn the screw counterclockwise to loosen it.

the control chassis, feed

Press the unit in firmly, then turn

Figure 2

How to Open the

Series 920.

-

How to Set the DIP Switches

The Watlow Series 920 has a Dual In-line Package (DIP) switch inside the

control on circuit board

appear in Figure 3. The switches are clearly numbered from left to right. You

will use DIP switches #1 and 3 - 8; #2 is not used. Table 1 on the next page

shows the DIP switch selections.

AOO7-1699.

The locations of the board and switch

8

WATLOW Series 920 User’s Manual

Starting Out Chapter 1

Page 9

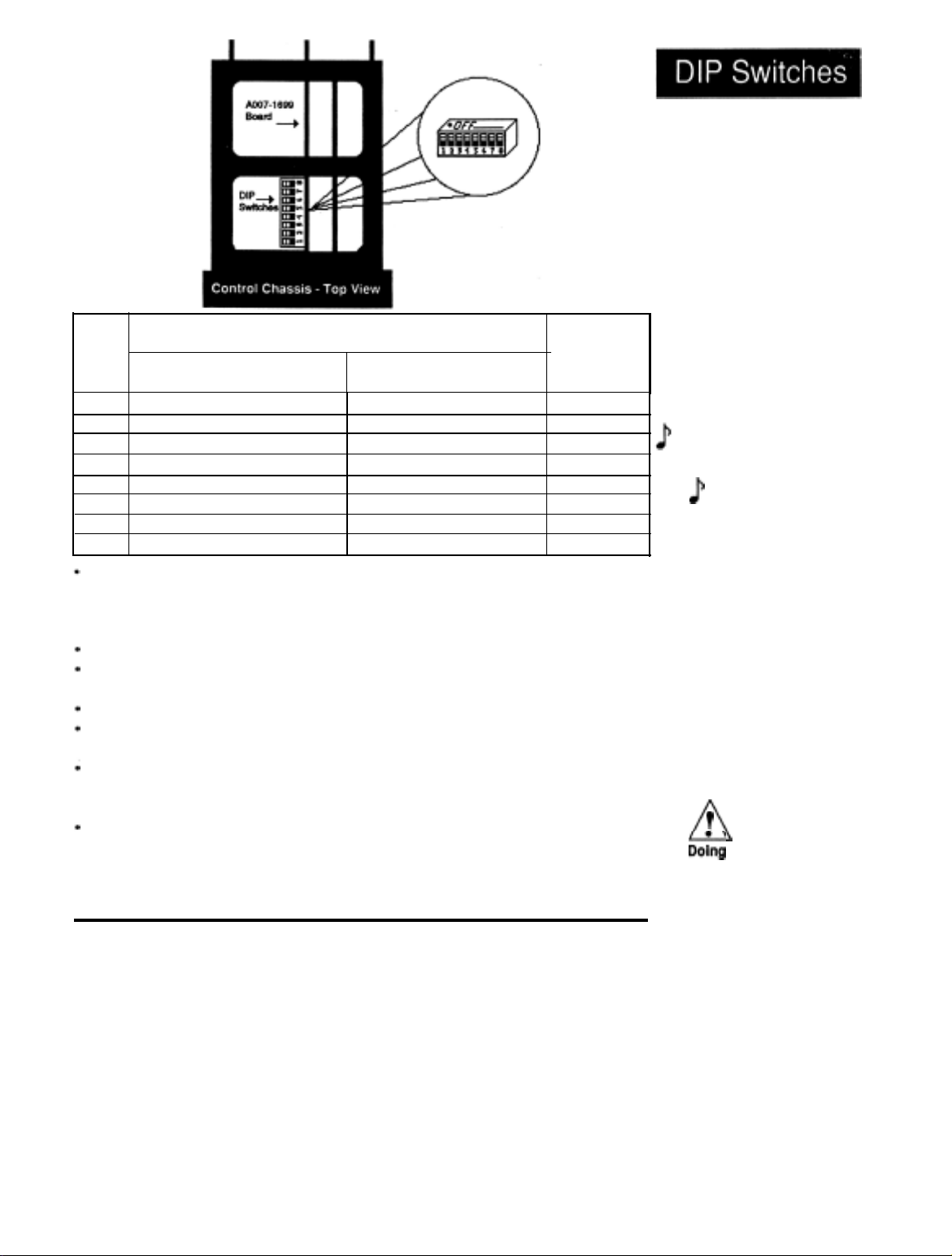

Figure 3

DIP Switch Location

and

-

Orientation.

DIP

SW#

ON

1

2

3

4

5

6

7

8

Cold Start

Not Used

Tenths of units displayed

0-5VDC/0-20mA

Primary output is

LEDs

are load indicators

Selected SPCLFUNC promts

Factory Test/Calibrate

DIP switch #1 determines a warm or cold start. A

grammed information in the 920s memory back-up protection. A “cold” start is a

“clean” startup condition; all user-programmed information is lost. The Series

920 leaves the factory programmed for a warm start.

DIP switch #2 is not used.

DIP switch #3 determines if the decimal point is displayed in tenths of units for

process inputs.

DIP switch #4 is for

DIP switch #5 is for units with

set switch #5 ON for the Primary output.

DIP switch #6 determines the function of the front panel

actual display. When ON, these

or system troubleshooting, see Page 12 and 33.

DIP switch #7 is OFF, all SPCLFUNC prompts are displayed, when ON,

factory selected prompts appear. See Page 42. DIP switch #8 is a factory

calibrate switch.

Function

input

4-20mA

0-5VDC/0-20mA

4-20mA

LEDs

Normal

Operating

OFF

Warm Start

Not Used

No decimal displayed

l-5VDC/4-20mA

Primary output is not 4-20

LEDs

are °F or

All SPCLFUNC prompts

Normal

input or

output.

can be used as a diagnostic tool for tuning

Operation

l-5VDC/4-20mA

input

°C

“warm”

If your unit has

LEDs

Position

OFF

OFF

Choose

Choose

Model #

Choose

Choose

OFF

start saves all pro-

input selection.

4-20mA

to the right of the

Dep,

output,

only

test/

Changing the Position of a Switch

Whenever you change the position of a DIP switch, follow this procedure:

1.

Remove power from the 920. Turn the front panel screw

2.

Grip the front panel bezel and pull it straight out from the control case.

The control chassis will come out of the case as you pull the bezel.

90°counterclockwise.

Table 1

DIP Switch

Selection.

J

For units with

process input only.

If

have process input,

DIP Switch #3

should be in the OFF

position.

n

Dokg

will cause all setup

parameters and files

to be lost. DO NOT

put DIP switch #1 in

the ON position

unless all

programmed

information is to be

cleared.

-

NOTE:

your unit does not

T

WARNING:

a cold start

user-

3.

Set the DIP switch to the position you want.

4.

Return the control chassis to the case. Be sure you have it oriented correctly. It will not fit in upside down, but check just the same. Press

firmly, but gently, to seat the chassis.

Secure the front

5.

Starting

Out,

Chapter 1

panel

screw and re-apply power to the 920.

WATLOW Series 920

User’s Manual

9

Page 10

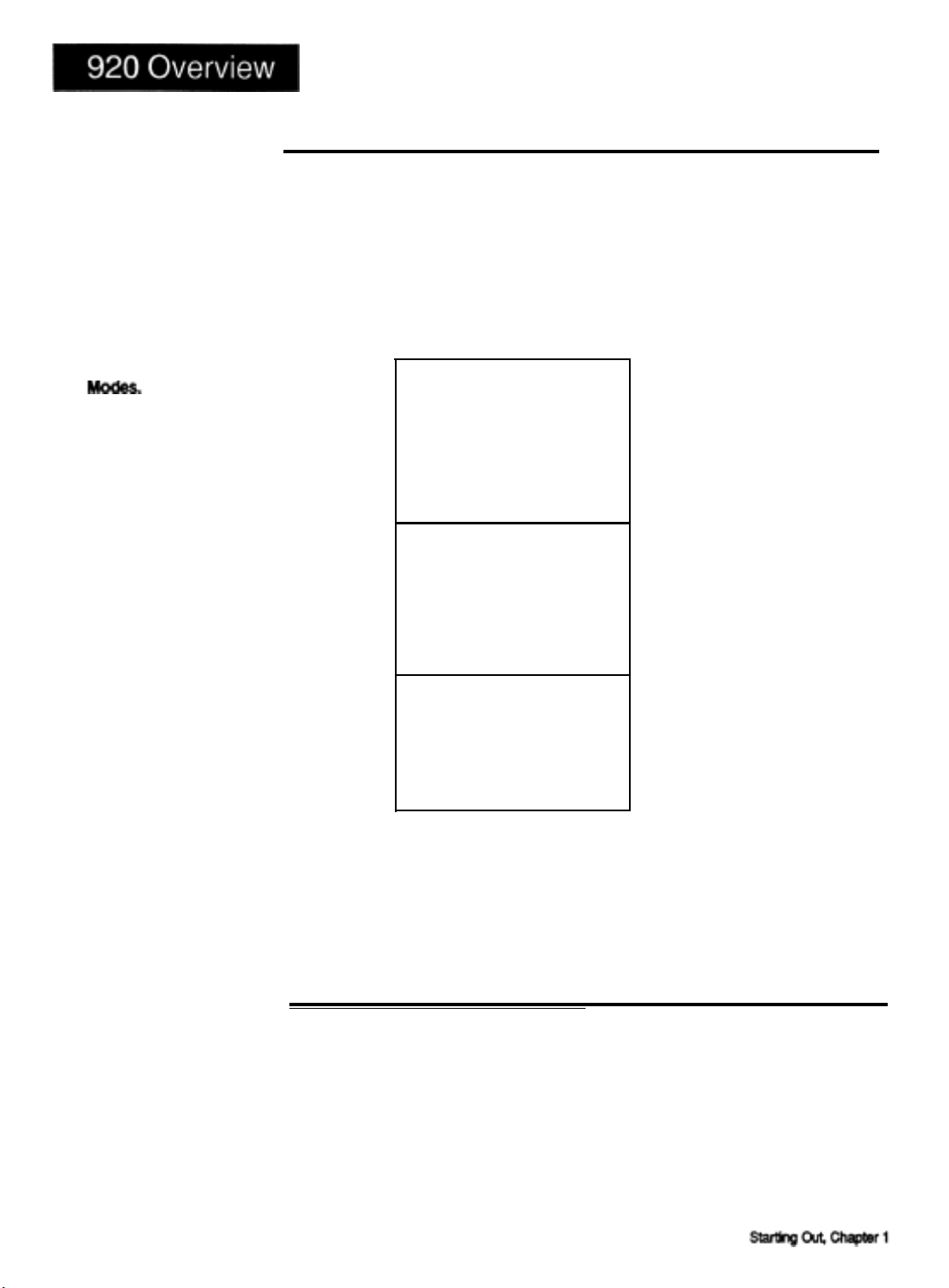

Overview of the Three Operating Modes

Operating

Before getting into the details of the Series 920s keys and displays, take a look

at Figure 4 showing the three different modes. After you feel comfortable with

the names of the modes and their functions, go ahead to learn the keys and

displays.

Figure

Overview of the

Series 920

O

perating

4

-

Series 920: Three Mode Types

Manually

Control

outputs

Enter

Program

Steps & View

Program

Set Up

Your

System

SYSTEM

PROGRAM

SETUP

SYSTEM

Generates a

ramping set point

(fixed), and can

manipulate events,

clear alarms and

error codes.

Mode

non-

PROGRAM Mode

Enter or view step type,

program loops,

wait for...

points, auxiliary

(event) outputs ON/OFF,

and step duration.

conditions,

set

SETUP Mode

Set up or change

system-operating

parameters such as

real time, high/low

range,

alarm points,

settings, RS-422

address.

alarm

types,

PID

10 WATLOW

Where To Go From Here:..

You are now ready to find out more about the Series 920s keys and displays.

Continue to Chapter 2.

Series

920 User’s Manual

Page 11

Chapter

2

How to Use the Keys and Displays

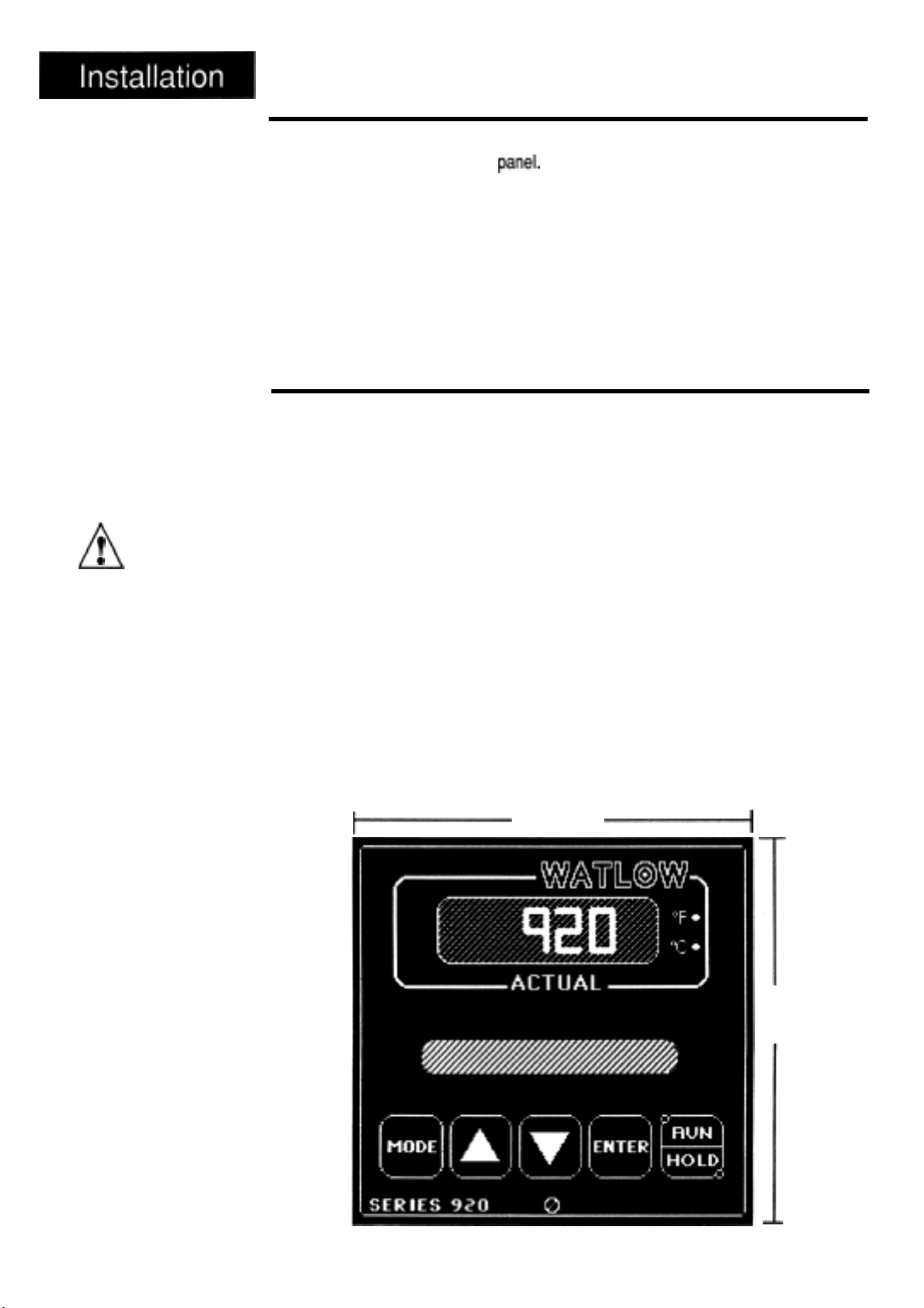

This chapter will show you the Series 920 front panel, and the function of each

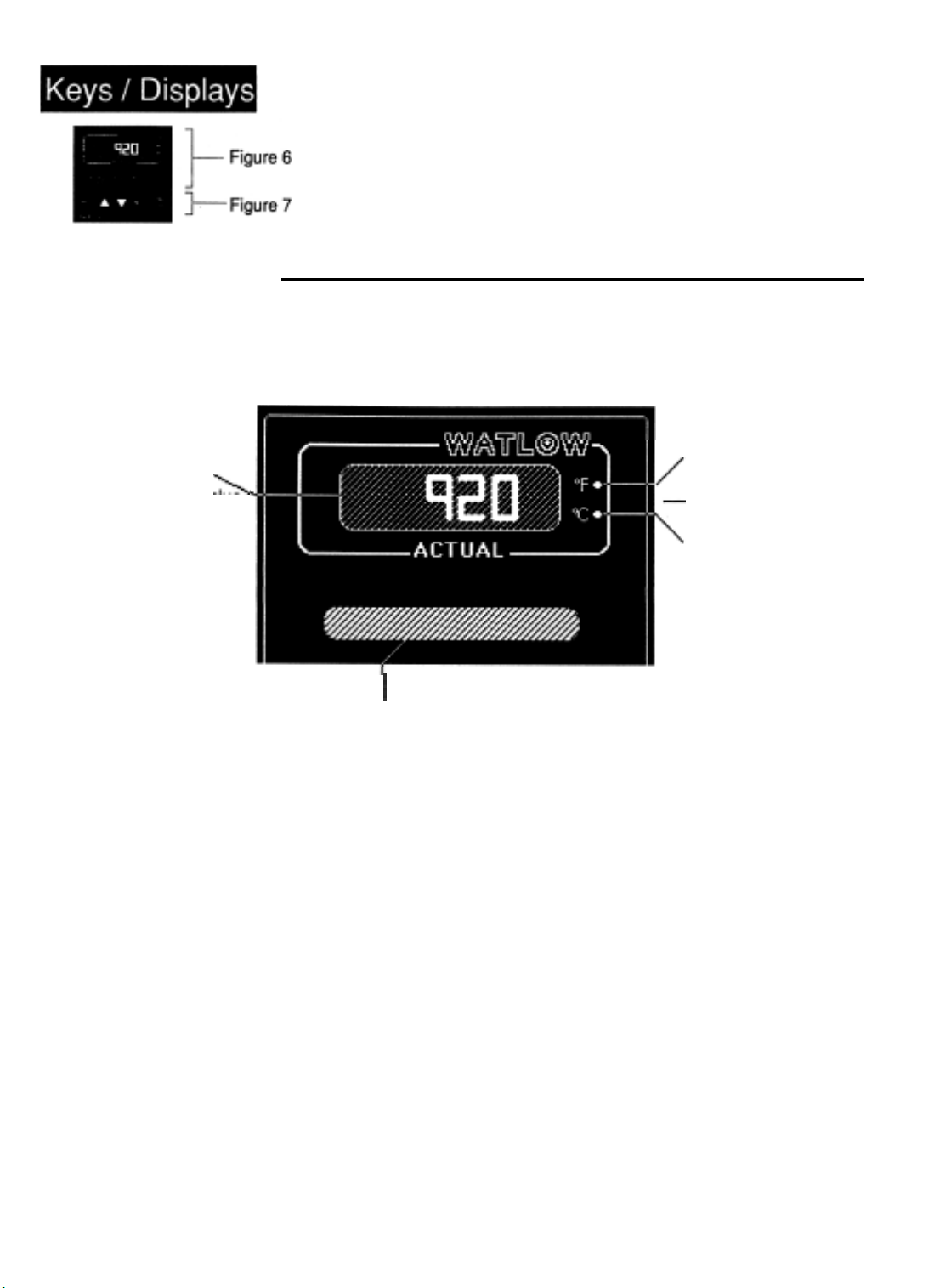

display, key and LED. Figures 6

Display, Key and LED-Location and Explanation

The

Watlow

ACTUAL display at the top of the unit, and the smaller alphanumeric display

below. You set up the Series 920s characteristics in the alphanumeric display

window. On the right of the ACTUAL display there is a red OF LED and a red

°C

LED, indicating the temperature scale ACTUAL is displaying. If neither of

these

Units

The 920 has five touch-membrane keys along the bottom edge of the front

panel: (from left to right) a MODE key, an UP key, a DOWN key, an ENTER

key, and a RUN/HOLD key.

Series 920 Ramping Control has two main displays, the process

LEDs

are showing, the ACTUAL display is showing Process Variable

(PVU’s).

and 7

explain the 920 front panel.

The MODE key steps the processor through the entry prompts.

The UP and DOWN keys increase and decrease or change values in the

alphanumeric display. A single touch to either of these keys will change the

least significant digit by one. Continuous pressure will change the value in the

alphanumeric display at an increased rate. The ENTER key places the value,

in the alphanumeric display, into the processor’s memory.

An alphanumeric display value will flash (when changed with the UP or DOWN

keys) until you press ENTER, placing the value in the processor

The RUN/HOLD key will execute or halt a program.

memory.

Front Panel Information

Use Figures 6 and 7 to assist you in learning the locations and functions of the

front panel components.

How

to Use Keys and Displays, Chapter 2

WATLOW Series 920

User’s

Manual

11

Page 12

Use the following figures to learn the nature and function of the Series 920s

keys and displays.

Figure 5

Series 920 Front

Panel Information.

ACTUAL Display

-

X,

Shows the actual value

of the process variable

up to four digits.

Figure 6

Actual and

Alphanumeric

Display

Front Panel

lnformation.

-

Actual and Alphanumeric Display Area

°F

LED

When DIP switch #6 is

OFF, it indicates the value

in the ACTUAL display is

temperature in degrees

Fahrenheit. When DIP

switch #6 is ON, it indicates

Output 1 is energized.

When DIP switch #6 is

OFF, both °F and

LEDs

is displaying Process

Variable Units

°C

LED

When DIP switch #6 is

OFF, it indicates the value

in the ACTUAL display is

I

Alphanumeric Display

Shows entry prompts

and the parameter

values in alphanumerics.

temperature in degrees

Celsius. When DIP switch

#6

is ON, this LED indicates

Output 2 is energized.

°C

are OFF. The 920

(PVUs).

12

WATLOW Series 920

User's

Manual

How to Use Keys

and

Displays, Chapter

2

Page 13

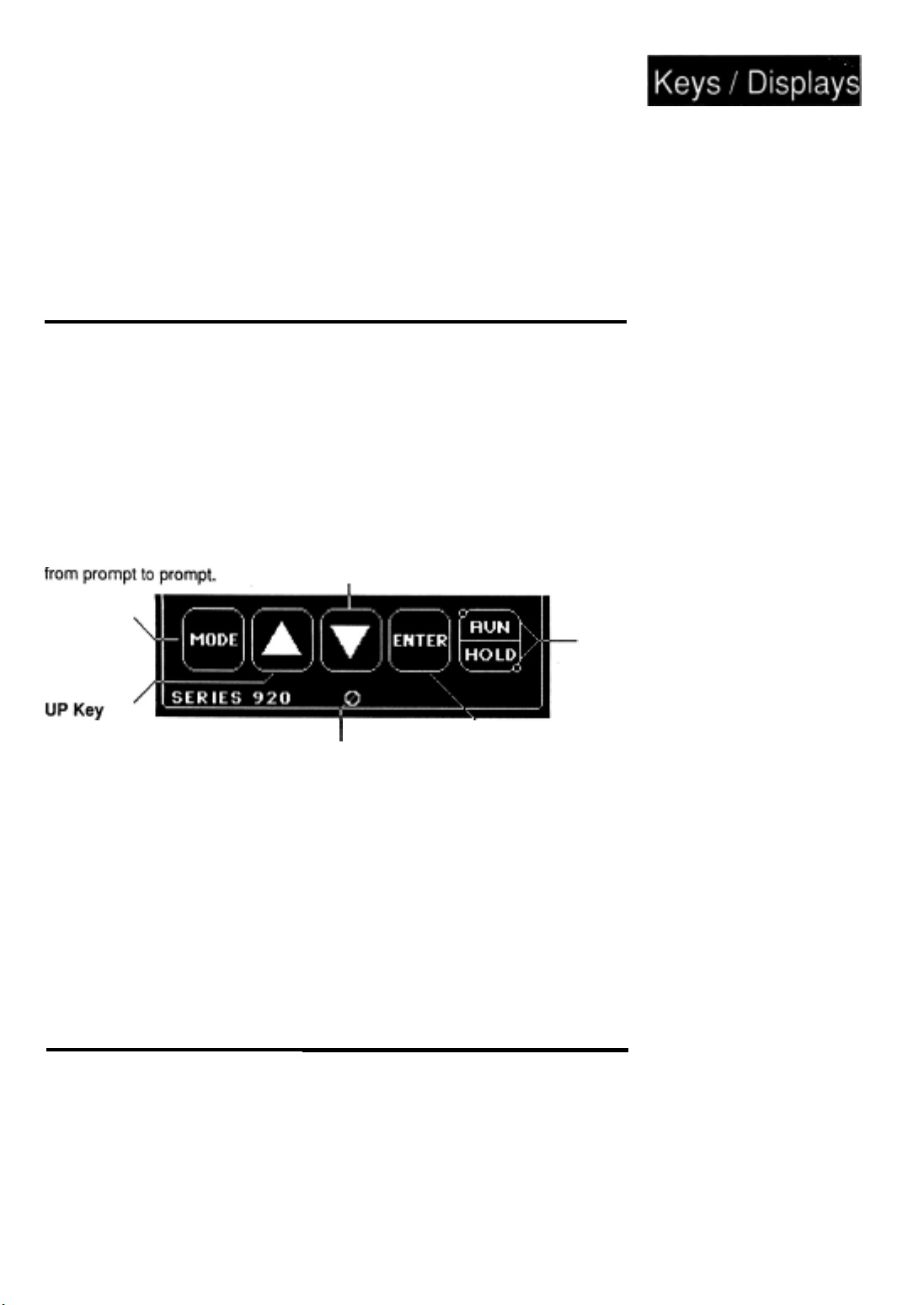

Keyboard Area

MODE Key

This key steps the

Series 920 in sequence

DOWN Key

Acts opposite the UP

key. Decreases the

value in the alphanumeric display. A light

touch decreases the

value by one digit. Hold

the key down to

decrease the displayed

value at a rapid rate.

Figure 7

Keyboard

Panel Information.

Front

RUN/HOLD Key

Executes or holds a

program from the

SYSTEM menu.

Run/Hold

When the HOLD LED is

ON steady, the 920 is in

a HOLD condition.

When the HOLD LED

flashes, the unit is

holding for a

Increases the value

in the alphanumeric

display. A light

touch increases the

value by one digit.

Hold the key down

to increase the

displayed value at

a rapid rate.

I

90°

Front Panel Screw

Secures the control

chassis in its case with

a

1/4

turn clockwise or

releases the chassis

with a

1/4

turn counter-

clockwise.

ENTER Key

Enters selected

(flashing) data into

the microprocessor

memory, or will mask

an error code or

latched alarm for

1

minute.

condition, or a guaranteed soak condition.

When the RUN LED is

ON the 920 is in the

RUN condition.

Where To Go From Here

Now that you have a good idea where everything is on the faceplate of the

Series 920, continue to Chapter 3 for the Sample Program. If you skip the

sample program, do not forget to check the position of DIP switch #1 before

you begin programming your control after installation. With DIP switch #1

OFF, the 920 saves your program whenever power is removed (warm start).

With DIP switch #1 ON, the 920 will clear its memory of all programmed

information whenever power is removed, substituting default values (cold

start).

How to Use Keys and Displays, Chapter

2

WATLOW Series 920 User’s Manual

LEDs

WAITFOR

13

Page 14

Chapter

3

m

WARNING:

Doing a cold start

will cause all setup

parameters and files

to be lost. DO NOT

put DIP switch #1 in

the ON position

unless all

programmed

information is to be

cleared.

user-

Learning

the Series 920

-

A Sample Program in Action

This chapter

can quickly grasp the necessary terms and concepts by entering and

exercise.

If you feel that your

program to learn the Series 920, skip this chapter.

A Brief Overview

This sample program wilt teach you the fundamentals of creating a ramping profile,

along with ways to expand that profile to its greatest versatility.

The program example will start with a simple ramp and soak profile. A ramp progresses from one set point to another set point over a period of time, or ramp rate,

expressed in degrees/time. Soaking then controls the length of time the temperature

is held at this level.

We will, then expand it to

form an AUTOSTART, LINK to another profile, and finally perform a

At this point make copies of your Master Step Chart on Page 53.

to keep track of your program as you go.

exactly what you want your program to do.

will

guide you through an easy sample program for the Series 920. You

knowledge

multiple

observing

of profiling controllers does not require a sample

ramp and soaks, add

It is also a good idea to sit down and define

JUMPLOOP

functions, per-

It is a good practice

WAITFOR

this

step.

14

WATLOW

Enter Real Time of Day

First, set the Series 920s “real time-of-day,

key is used to progress through the menus. The UP/DOWN keys are used to select

parameters and values, and remain flashing until you press the ENTER key.

Press the MODE key until the SETUP menu appears. Press the ENTER key.

1.

2.

At ACCESS, enter (0) with the UP/DOWN keys; press ENTER. This is your

Series

calibration

3.

Press the MODE key until HOUR appears in the alphanumeric display and press

ENTER. Note that hours are in a 24 hour format.

920 User’s

Manual

(CALIB)

menu.

24-hour

clock.” Remember the MODE

Sample

Program, Chapter

3

Page 15

2

4.

Use the UP/DOWN keys to place hours into the display. The display will flash

until you press ENTER.

5.

J

Press MODE to continue to the

rect value for minutes and press ENTER.

6.

Press the MODE key several times to return to the top of the ACCESS (0) menu.

At the top of the ACCESS (0), which is the

Time (Tl) displayed.

7.

Continue to press MODE until

SYSTEM.

Before Entering Your Program

Before we begin to program your Series

parameters to enter. Verify that DIP switch #7 is OFF. If you have not tried any

programming since your cold start, the C/F/U (Celsius/Fahrenheit/Units) and GS

(Guaranteed Soak) parameters are set to their appropriate values.

sary for a more detailed definition.

parameters and entering values, it might be a

to see that the values are correct.

1.

Press the MODE key until SETUP appears. Press ENTER. Once again you see

the ACCESS parameter. Use the UP/DOWN keys to enter (5) and press ENTER;

this is the Special Function (SPCLFUNC) menu.

MIN

parameter and press ENTER.

CALIB

menu, you

you

reach RETURN. Press ENTER to return to

Enter the cor-

will

see the Real

a

920,

there are a few other initial SETUP

Refer to the glos-

If you have already tried stepping through the

good

idea to go back and double check

J

NOTE:

When either the

hours or minutes are

entered,

seconds are set to 0.

J3

DIP switch #7 must

be OFF to access all

SPCLFUNC

ters.

internal

NOTE:

parame-

2.

Press MODE again until you see the C/F/U parameter. This parameter will defautt

to F. Use the UP/DOWN keys to enter degrees F (Fahrenheit). Press ENTER..

3.

Continue through the SPCLFUNC menu

Enter a value of (0); press ENTER. This parameter has a default of 0.

4.

Press the MODE key to move to the RETURN parameter. Press ENTER to return

to SYSTEM.

5.

Good job! You have completed the initial setup, and are ready to program the 920.

Programming. File

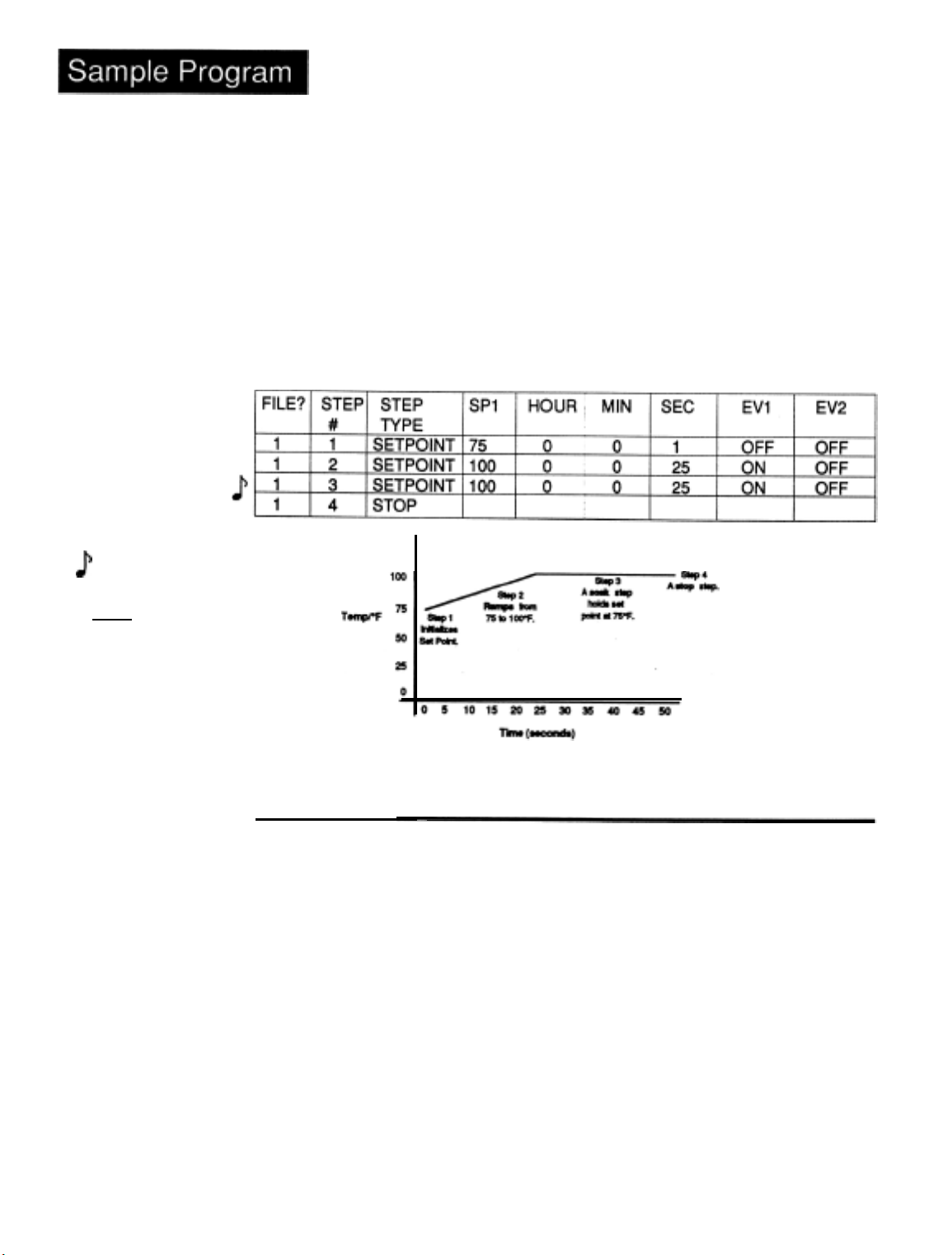

Our first step in programming will be to make a short ramp and soak program. Step

initializes the set point to a known starting point for the ramp, Step 2 is a short ramp,

Step 3 is a soak step, which holds the programmed set point constant for the pro-

grammed time.

1.

From the SYSTEM menu, press MODE until you see the PROGRAM menu.

Press ENTER.

2.

The Series 920 asks you for a FILE?. Your 920 should already say (I), but if you

have entered any values, it may be different. Make sure it says (1). Press ENTER.

Step 4 will be a STOP step which signals the end of a file.

1

until you see GS

(Guaranteed Soak).

1

3.

Press the MODE key and you are asked for a STEP. ENTER (1) if it is not already

there.

Sample Program, Chapter 3

WATLOW Series 920 User’s Manual

15

Page 16

Press the MODE key. Use the UP/DOWN keys to select the step type and

4.

values.

Use Table 2 to enter the corresponding parameters and values. The parameters

5.

appear from

progress through the menus. After the step # is selected, use the UP/DOWN

keys to select a step type. Press ENTER. Use the UP/DOWN keys to select

parameters and values, they remain flashing until you press the ENTER key.

At the end of each menu, rather than pressing ENTER to go back to SYSTEM, press

MODE for the STEP prompt. The 920 automatically increments to the next step

number, with the step number flashing. Press ENTER.

left

to right on the table.

Remember that the MODE key is used to

Table 2

Series 920

Ramp and Soak

Program.

J

Step 4 must be

entered

even though it

defaults to a STOP

step.

-

NOTE:

as a step

125

Running Your Program

1.

Return to SYSTEM using the ENTER key at the RETURN prompt.

RUN/HOLD key.

Press

the

16

2.

The Series 920 now asks you what

not already entered.

Press the MODE

3.

Again, press (1) if it is not already there, and press ENTER.

The Series 920

LED is now lit. After each step is completed, the next step that the Series 920

performs will appear.

You may step through the parameters to see what the step-type is and what the

parameters are set at. The Time Remaining is also displayed at the end of the menu.

Once the Time Remaining reaches 00:00:00, it will show you what step it has progressed to. Refer to the Run menu on Page

WATLOW Series 920 User's Manual

quickly

FlLE?

you would like to run. Enter (1) if it is

key. The 920 asks you what step you would like to start on.

shows you the SP (Set Point) and jumps to Step 1. The

19.

Sample Program, Chapter 3

RUN

Page 17

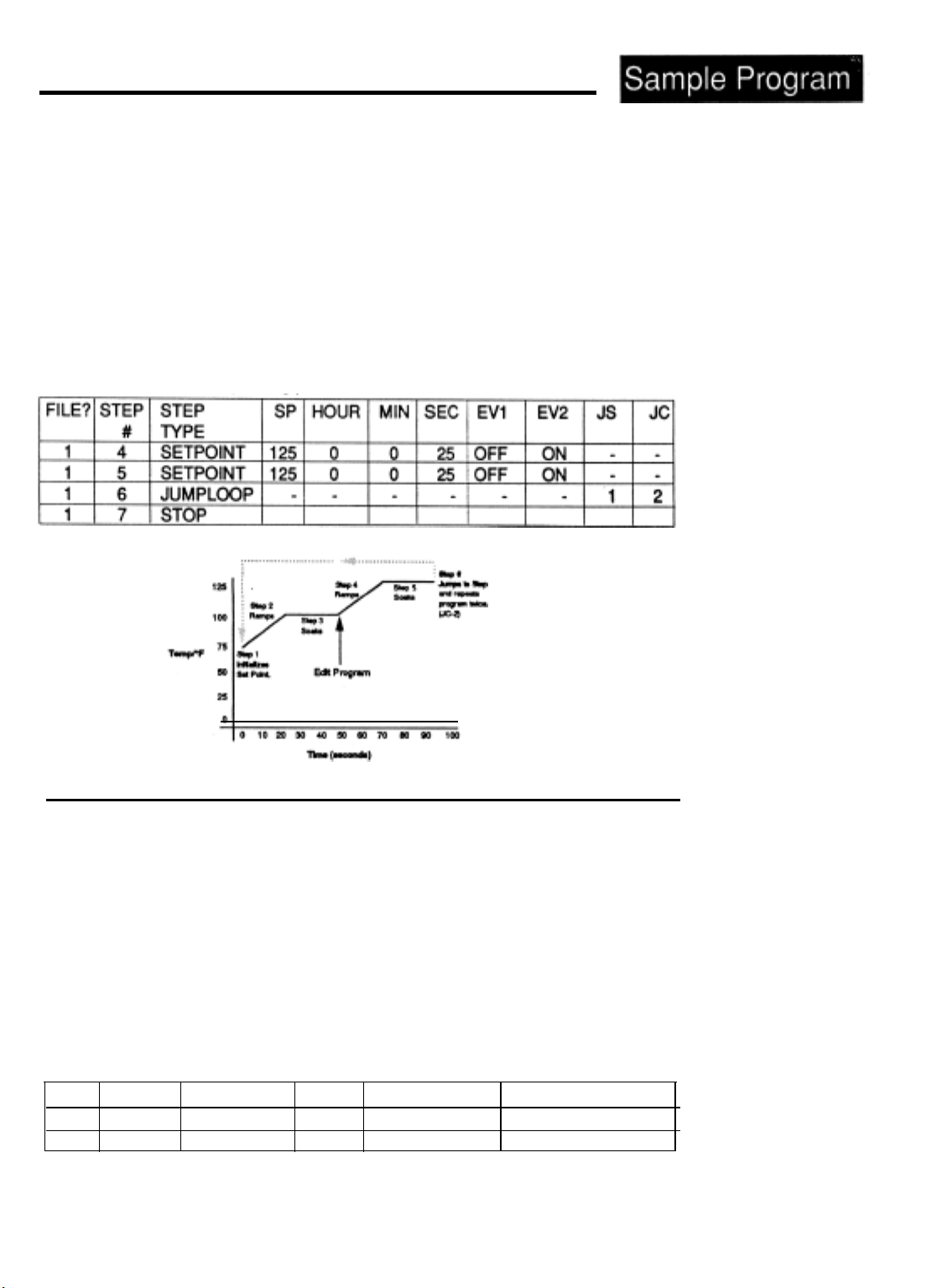

Editing Your Program

Let’s try editing the program by expanding it with another ramp and soak step and

adding a jump loop. We’ll jump to Step 1 and repeat Steps 1 - 6 two more times. This

is accomplished by programming a Jump Step (JS) = 1 and Jump Count (JC) = 2.

When your 920 goes through the program and reaches Step 6, it jumps back to Step

and repeats the program two more times.

By this time you should understand the basic concept of the Series 920 and be able to

get around on your own. Remember that the MODE key takes you through the menus.

Use the UP/DOWN keys to select parameters and values, and press ENTER.

1.

Return to the PROGRAM menu.

2.

Enter FILE?

step to a

(1),

Step (4). We are going to change this step type from a STOP

SETPOINT

step. This will be our second ramp. Use Table 3 to enter

values into the corresponding parameters.

3.

Once you have edited your program, run it again and watch its progress.

1

Table 3 Editing

Program,

Steps 4-7.

Your

1

Adding an AUTOSTART Step Type

The Series 920 can also automatically start your program, or a step, on a specified

day and time. When you use AUTOSTART, it stops your program, and waits for the

day and time you entered under the AUTOSTART step type. The Series 920 then

executes the next sequential step. AUTOSTART allows you to wait up to seven days

in the future; day 0 is always the current day.

1 every time the Real Time clock goes from 2359 to

DAY, and the Real Time clock is greater than the programmed AUTOSTART time,

the AUTOSTART waits 6 days along with the programmed time. If day is left blank,

the program begins each day at the real time programmed, regardless of the day.

Go to the PROGRAM menu.

Edit Step 7 from a STOP step to an AUTOSTART step.

Follow the table below for input values. This step will wait for approximately five

minutes in the future.

The

days accumulated increases by

0O:OO.

If 0 is programmed for

FILE

1

1

STEP#

7

8

STEP TYPE DAY

AUTOSTART 0

STOP

HOUR

Current Hours

MIN

Current Minutes +

5

Run this file starting at Step 7 and observe. The Series 920 will now wait until the

real time of day matches the programmed value.

Sample Program, Chapter 3

WATLOW Series 920 User’s Manual

Table 4

Adding the

AUTOSTART Step.

-

17

Page 18

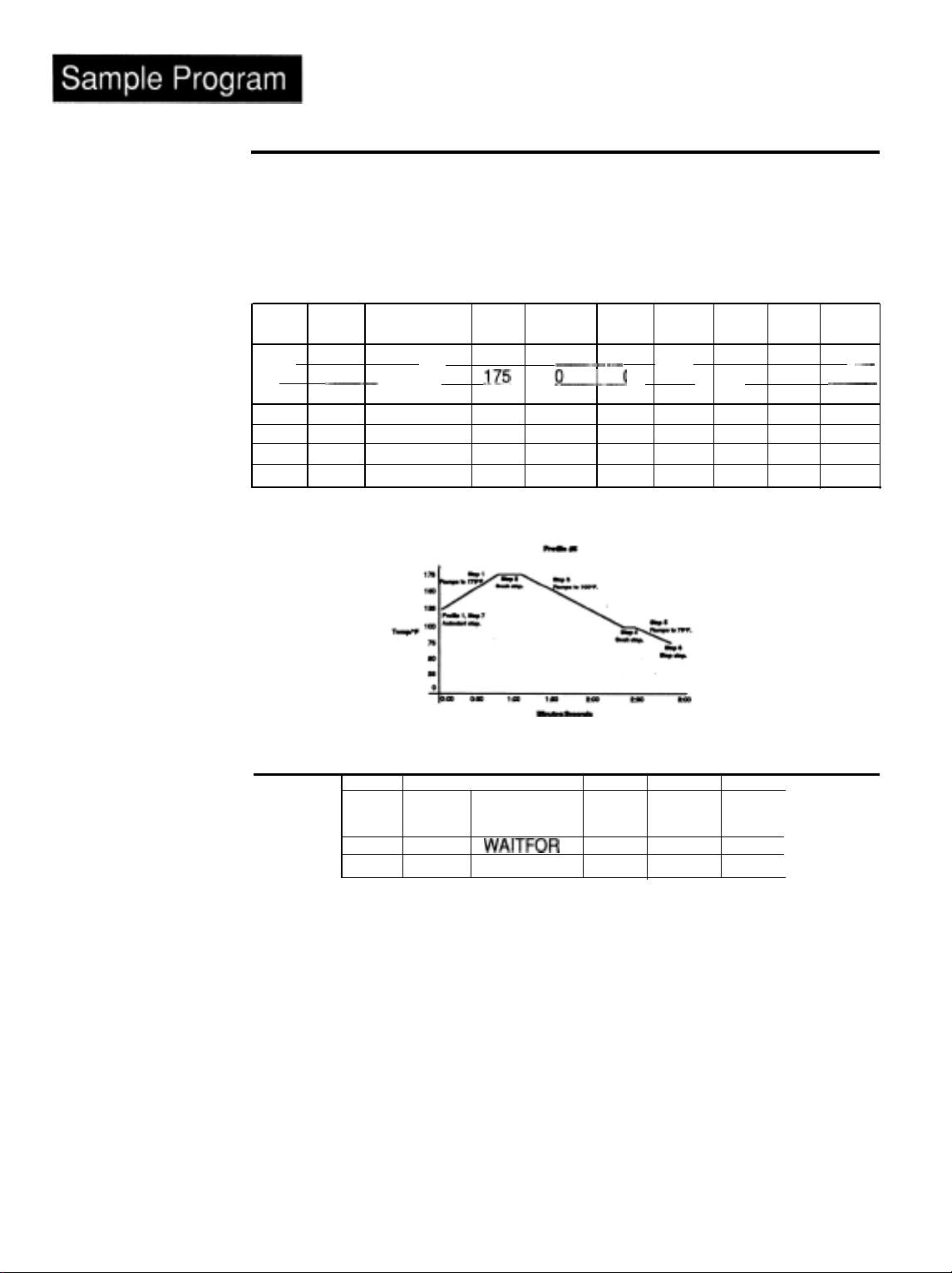

LlNKing

Files

Table 5

LlNKing

Another File.

-

to

The Series 920 enables you to link

files

together. The LINK step allows you to link the

last step of a profile to the first step of another profile.

Lets edit the program again by adding a LINK step at the end of the profile. But first,

lets create another file.

you’ll receive

ER2

If you run your program with a LINK going to a

non-existing

file,

0036, the “no file found“ error. Follow Table 5 to add a LINK and a

new FILE to your program.

FILE? STEP STEP SP HOUR

#

TYPE

1

5

5 2

5. 3

5 4

5

5

8

1

--_-

5

6

LINK .._

SETPOINT

SETPOINT

SETPOINT

SETPOINT

SETPOINT

STOP

_I75

175 0

100 0

100 0

75 0

----_

&___-._.

MIN

SEC

0

.

0

1

0

0

50..

20

15

10

25

EVl

EV2 FILE?

ON ON

ON ON

ON OFF

ON OFF

OFF OFF

_~

5

..~--

Run your program again beginning at FILE 1, STEP 8. Step through the menu to see

the step type you’re on, and time remaining. See what happens at the end of File

1.

Table 6

The

WAITFOR

18

Step.

WATLOW Series 920 User’s

The

WAITFOR

FILE STEP

The last step type we will work with is the

Step

5 6

5 7

#

STEP

NPE

WAITFOR

STOP

WPV

WHR

75

WAITFOR

step. This is a test step.

WMN

-

It compares a specified temperature with the process temperature, before continuing the

program.

It also waits for programmed time to elapse before continuing with the pro-

gram. After the test is successful, the program continues to the next sequential step.

Return to PROGRAM and enter FILE? (5). Add a

WHR and WMN are unprogrammed. To program a

for WHR and WMN. The programmed

WAITFOR

taneously. Once a

process variable (WPV), and time

WAITFOR

condition is satisfied, it won’t have to be performed again.

WAITFOR

WAITFOR

WAITFOR

step to the end of that file.

time, enter your values

time waits that time duration. Both

(WHR,WMN)

can be programmed simul-

Run your program from FILE 5, STEP 1. If you don’t want to go through the entire

program, START your program at any STEP in FILE 1 or 5. When the program reaches

FILE 5, STEP 6, the HOLD LED begins flashing. This means the program is still

running, but is

HOLDing,

Manual

to

WAITFOR

the ACTUAL temperature to equal the

Sample Proqram Chapter

3

Page 19

WAITFOR

Your program then continues to the last step, a STOP step, and HOLD

To change a programmed step, return to the PROGRAM menu, and enter the FILE

and STEP number to change.

and press ENTER. Under a step type, to clear all parameters of the current values,

return to that step type and press ENTER. All parameters will return to

Process Variable

(WPV).

When equal, the HOLD LED stops flashing.

S

again.

Use the UP/DOWN keys to select another step type

their

defaults.

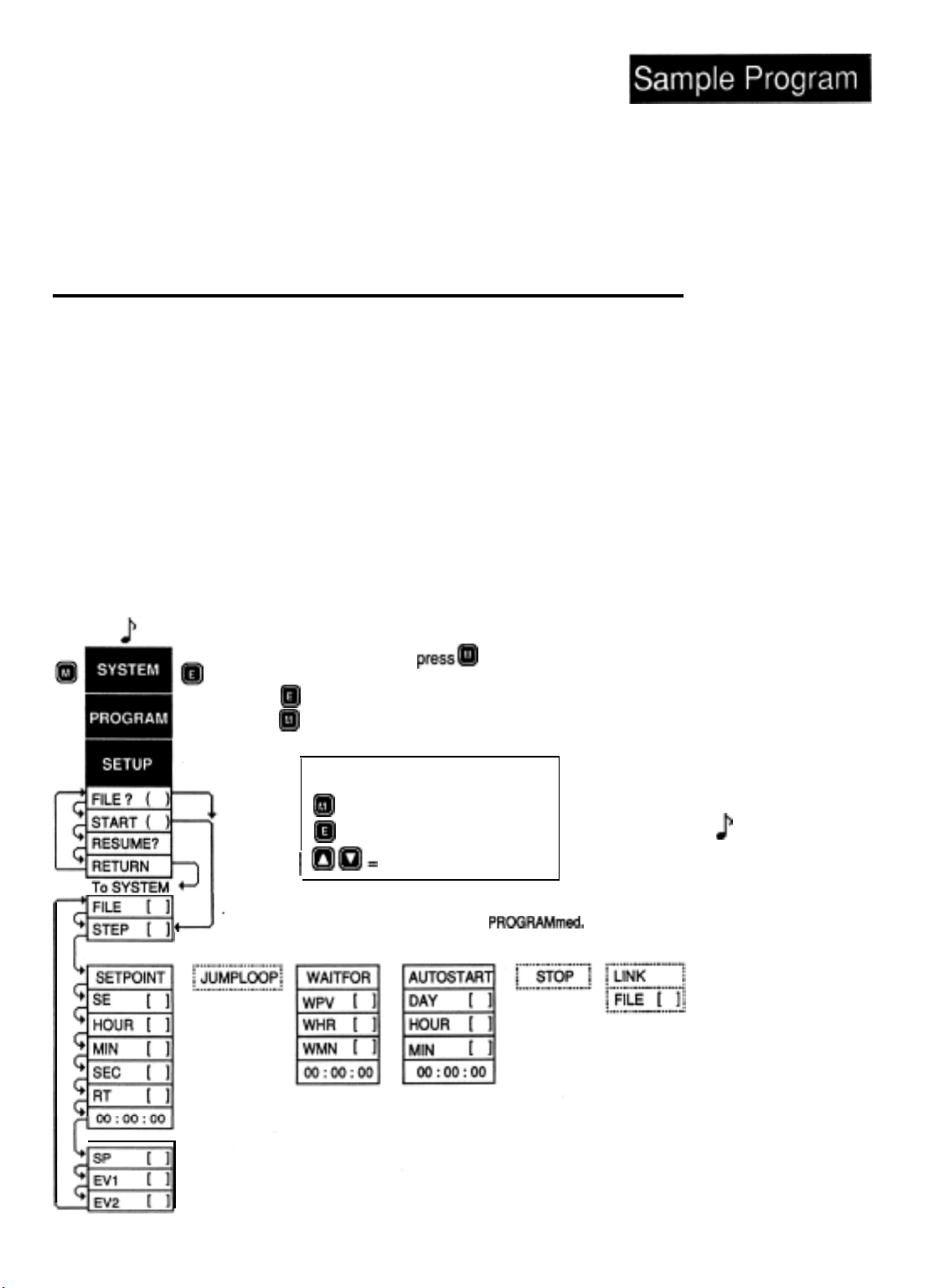

Running Your Series 920

To run the Series 920, you must be at one of the three main level operating parameter

menus, SYSTEM, PROGRAM, or SETUP. Press the RUN/HOLD key. The Series 920

asks you what file

the file and step number, the program begins and the RUN LED is lit. While in the

RUN mode, you can only view the current file and step.

you’d like

to run, and asks what step to begin with. After entering

To change your program, you must be in the HOLD mode. To

any time, press HOLD. When returning to your program, the Series 920 asks if

like to

been changed, generates an

the START prompt and begin the program again.

When in the PROGRAM menu, SP is programmed to the steps ending set point.

When in

the

RESUME? on the step you left off on. Trying to RESUME on a file that has

“ER2

0040”; this is a “Change File Error.” Advance to

the

RUN mode it shows the current set point. In the RUN mode, SE

steps ending set point. Refer to Pages 51 - 52 for definitions of other prompts.

At the SYSTEM prompt,

Press @ to enter the PROGRAM parameter values, or

press @ to continue to SETUP.

Graphics Key

@B

83

1 aa=

One of the three step types will be displayed

J

JUMPLOOP, STOP, and LINK step types are immediate, and will not be visible.

depending on the type of step

=

=

pressm

MODE Key

ENTER Key

UP/DOWN

stop your

program

at

you’d

shows

to continue to PROGRAM mode.

PROGFMMmed.

Figure 8

RUN Key Flow

Diagram.

1

Shaded parameters

may not

your control.

parameters are

dependent on how

your control is

configured. See

Chapter 6

information.

-

NOTE:

appear on

for

These

more

Sample Program, Chapter 3

WATLOW

Series 920 User’s

ManuaI

19

Page 20

Chapter 4

How to Install and Wire the Series 920

This chapter tells you how to install the Series 920.

information is right here.

“burned in” before leaving the factory, the Series 920 is ready to install when you

receive it.

But before you begin working or cutting holes in

chapter to gain an understanding of the entire installation. Consider sensor

installation carefully. You’ll need to look at the noise reduction guidelines before

making your panel cutout.

Because

Watlow

controls are thoroughly tested, and

All

mounting and wiring

panels,

read through this

Sensor Installation Guidelines

We suggest that you mount the sensor at a location in your process or system

where it reads an average temperature. Put the sensor as near as Possible to

the material or space that you want to control. Air flow past this sensor should be

moderate. The sensor should be thermally insulated from the sensor mounting.

Excessive lead length

combat this, use a three wire sensor in long lead applications.

in a two-wire

RTD

sensor can create indication

errors.

To

Input Power Wiring

Microprocessors are in a way

like trout...

20

WATLOW Series

They require a clean environment to be successful and to prosper. A clean

environment means on one level an environment that is free of excessive dust,

moisture and other airborne pollutants. But primarily it means a “clean” source

of input power from which to base all its operations. What is “clean power”?

Clean power is simply a steady, noise-free line voltage source that

rating specifications of the hardware using it. Wiihout clean power to the

integrated circuitry, any microprocessor chip

Just as the water you get from a tap nowadays may not be

in some locales, so the line voltage coming into your facility may not be acceptable for your microprocessor devices. You may have to fitter or “clean” the

water or the power. In industrial environments, the potential for pollutants

increases, especially electrical noise due to high level power

occurring in one place.

The recommendations we are providing for you are ways to achieve a minimum

level of clean input power protection.

remove the potential for input power problems.

ures and still do not get results, please feel free to call us at the factory. We

are here to see that our control products work well and do the job they were

designed to do.

920 User’s Manual

In almost all cases these

isdoomed

If you’ve applied these meas-

to failure.

acceptable

HoHow w to Install and Wire, Chapter 4

How to Install and Wire, Chapter 4

meets

to drink

consumption

guidelines

the

Page 21

Definitions

Ground Loop - A condition created when two or more paths for electricity are

created in a ground line, or when one or more paths are created in a shield.

Earth Ground - The starting point for safety and computer grounds.

a copper rod driven into the earth.

Safety Ground - A ground line run with electrical power wiring to protect personnel.

Computer Ground

or microprocessor-based systems. This line is isolated from safety ground.

Common Mode Line Filter - A

power

line legs with respect to ground.

Differential Mode Line Filter - A device to filter noise signals present

between the two power lines themselves.

The D

Do

interference pick up.

Do use twisted pair wire and possibly shielded wire from line filters to the control to

keep the line “clean”.

Do keep low power control wires physically separated as far as possible from line

voltage wires. Also keep all controller wiring separate from other nearby wiring.

Physical separation is extremely effective. A 12 inch

usually effective.

OS

and

keep line filters as close to the control as possible to minimize the area for

-

A ground line for the ground connections to computers

device

to filter noise signals present on both

Don’ts

of Clean Input Power

(304.8mm)

It is usually

minimum separation is

Do use common mode, differential mode or a combination of the two filters

wherever power may have electrical interferences.

Do cross other wiring at

Do have a computer ground line separate from all other ground lines. This computer

ground line should terminate at the ground rod where the electrical service is grounded.

Don’t connect computer ground to safety ground or any other ground points in

the electrical system, except at the ground rod.

Don’t

mount relays or switching devices close to a microprocessor control.

Don’t run wires carrying line voltage with signal wires (sensor, communications or

other low power lines) going to the control.

Don’t use conduit for computer ground.

Don’t

have phase angle-fired devices in the same electrical enclosure or on the

same power line with the control.

Don’t

connect ground to the control case if the control is mounted in a grounded

enclosure (prevent ground loops).

Don’t fasten common mode line filters or filters with metal cases to metal that is at

ground potential. This prevents ground loops and maintains filter

How to Install and Wire, Chapter 4

90°

angles whenever crossing lines is unavoidable.

effectiveness.

WATLOW Series

920 User's

Manual

21

Page 22

How to Check for Ground Loops

To check for ground loops, disconnect the ground wire at the ground termination. Measure the resistance from the wire to the point where it was

The ohmmeter should read a high ohm value. If you have a low ohm value

across this gap, that means there is at least one ground loop present in your

system.

connected-

Table 7

Noise

Device Ratings.

-

Suppression

Also, check for continuity; your reading should be “open”.

If you do find conti-

nuity, you must now begin looking for the ground loops. Begin disconnecting

grounds in the system one at a time, checking for continuity after each disconnection. When continuity reads “open” you have eliminated the ground loop(s).

Also as you reconnect grounds, keep making the continuity test. It is possible

to reconnect a ground loop.

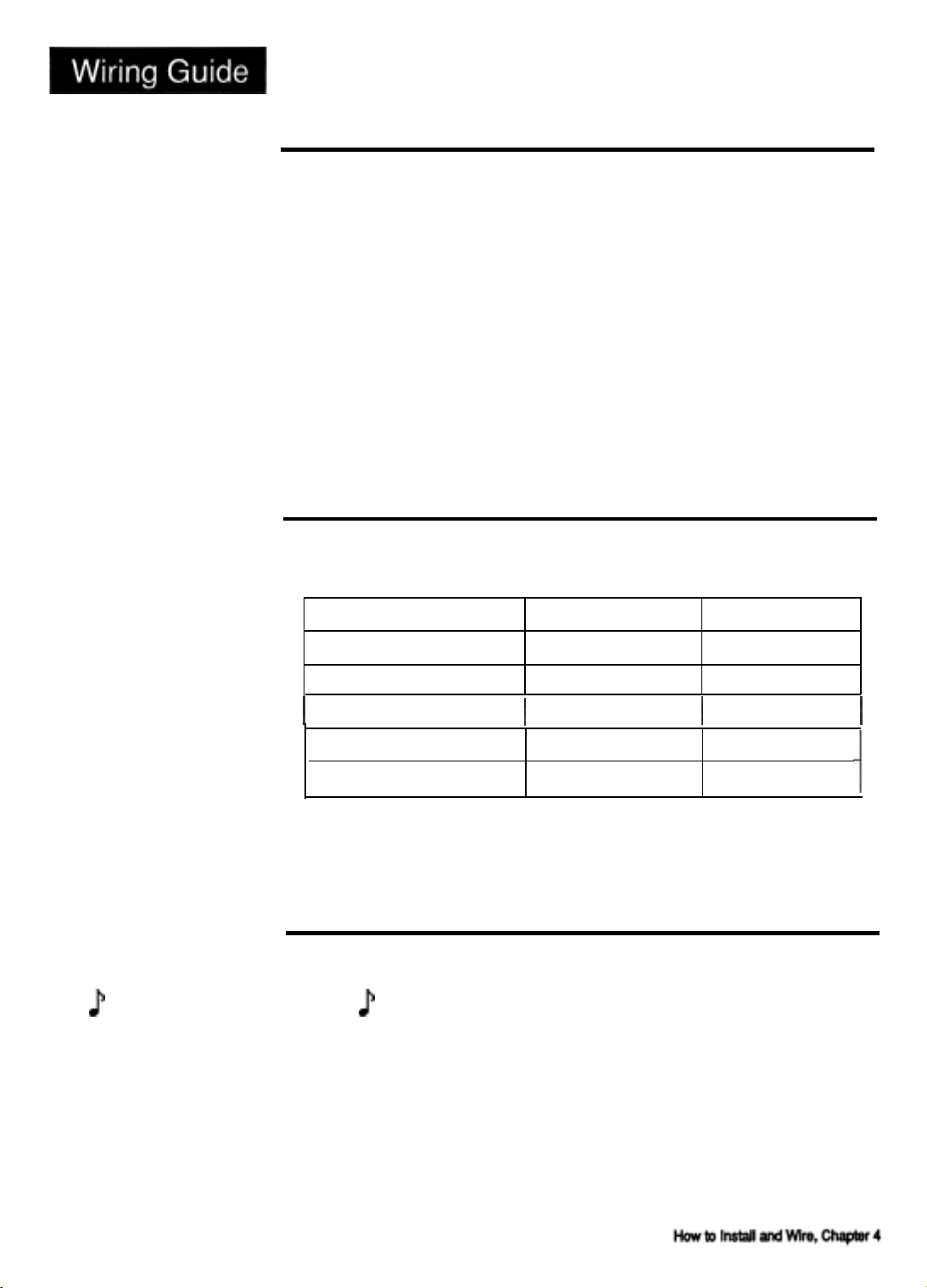

Noise Suppression Devices

Available from Watlow

Watlow Controls stocks a few key noise suppression parts. You may order

these by calling your local Watlow distributor.

Item

Common Mode Line Filter

Metal

Oxide

Varistor

MOV

I

MOV

MOV

Electrical

250V,

15OV,

130V,

I

275V,

275V,

Ratings

3 Amp

80

Joule

38 Joule

75 Joule

140 Joule

Part Number

0804-0196-0000

0802-0273-0000

1 0802-0304-0000 1

0802-0266-0000

0802-0405-0000

J

NOTE:

For

very

“dirty” or

critical

use micro-computer-regulated

power

Uninterruptable

Power Supply

(U.P.S.)

22

applications,

supply

of

WATLOW

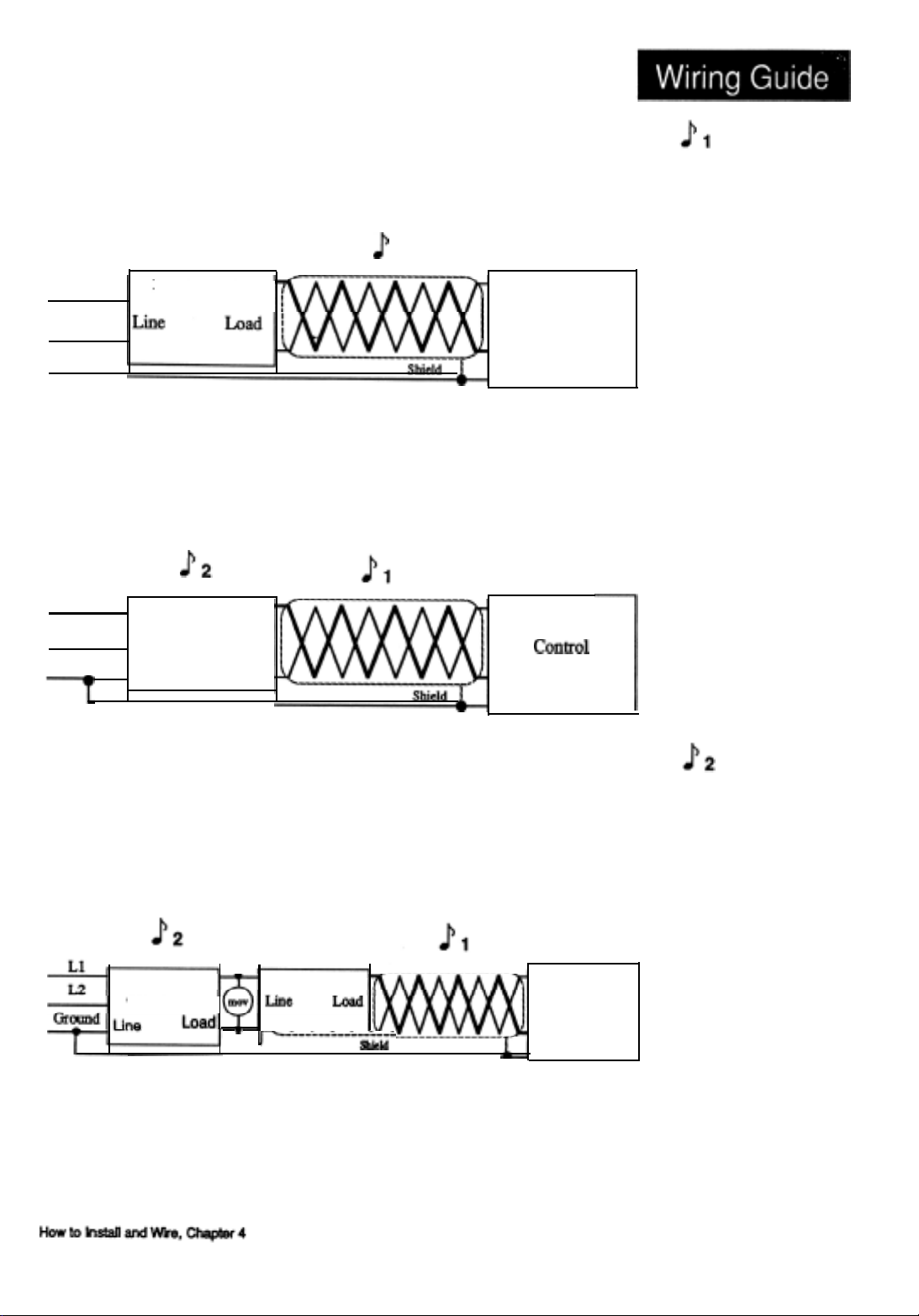

Line Filtering Configurations For Controls

These three diagrams show you filter configurations for removing input power

noise. Choose the one best suited for your system if you are unsure which one

to use.

920 User's

j

Series Manual

Maual

Page 23

Ll

L2

Ground

D.M. Line Filter

Keep filters

inches

12

(304.8mm)

or

less from the

control. Minimize

the line distance

J

1

where noise can be

w-introduced to the

control.

Control

Figure 9

Differential Mode

Filter Diagram.

-

Ll

L2

Ground

C.M.

Line

Line

C.M.Line Filter

Filter

Load

- 1

rL-___L:_k_-&~

D.M.

Line

Filter

Control

Control

Figure I0

-

Common Mode

Filter Diagram.

To

prevent

ground

loops, do not fasten

common mode line

filters or filters with

metal cases to metal

that is at ground

potential. Doing so

will reduce filter

effectiveness.

Figure 11

-

Combination

Differential-Common

Mode Filter Diagram.

WATLOW

Series

920 User’s

Manual 23

Page 24

Installation Information

T

0

n

The front panel

screw turns

only. Do not apply

excessive force or

turn the screw more

than

CAUTION:

90°

90°.

The Series 920 mounts in a

hold

the case against

are 3.56 in.

deep.If your unit has a

Figure 12 shows the dimensions of the front

lbs. (1.25Kg).

For unit dimensional and mounting information, including the location of mounting brackets and size of the front

panel’s thickness can be from 0.06

(90.42mm)

panel

cutout with two brackets. These brackets

the

front

panel.

The Series 920 behind-panel dimensions

high by 3.56 in.

triac

output, add another 2.5 in

(90.42mm)

panel

cutout, see Figures 13 and 14. Your

(1.5mm)

wide by 6.0 in.

panel bezel.

to 0.25 in.

(152.4mm)

(63.5mm)

The 920 weighs 2.75

(6.3mm).

to the depth.

Installation Procedure

Follow

this procedure to mount the

1.

Make a

2.

Remove the 920 from its case by turning the front

clockwise

the case.

3.

Place the case in

4.

Attach the mounting brackets either to the top and bottom, or to both sides

of the unit.

5.

Tighten the mounting brackets securely against your panel.

panel

cutout per the dimensions in Figure 14.

(CCW).

Grip the bezel

the

cutout you just made.

Watlow

firmly

Series 920 Temperature Control:

panel

and

screw

pull

the control chassis out of

90°

counter-

Figure 12

Series 920 Faceplate

Dimensions.

-

6.

Insert the

the front

hardware installation is complete. Go on to the wiring section from here.

1~

control

panel

chassis into its case and press the bezel to seat it. Turn

screw

90°

clockwise (CW) to

3.81 Sq.

(96.77mm) ‘-1

lock

the control in place. The

1

3.81 Sq.

(96.77mm)

I

24

WATLOW

Series

920

User’s

Manual

How to

Install

and Wire, Chapter 4

Page 25

(23.37mm)

1

&-Bezel

3.56 ±

0.015

(90.42mm

3 ±0.381

t

3.81

(96.77mm)

Your Panel

Thickness

0.06 to 0.25

(1.524 to

Mounting

6.35mm)

Bracket

3.622 to 3.653

(92.00 to

Panel

cutout

3.625 x 3.625

(92.08 x

Nominal

92.79mm)

92.08mm)

3.622 to 3.653

(92.00 to

I

92.79mm)

How to Wire the Series 920

This section has all the information you need to

the Series 920 and your system. Please read the Safety Information in the

narrow column on the outside of each page. You will find internal circuits on

the left in the following diagrams, and external circuits on the right.

output options are listed by model number. Refer to the unit sticker on your

control to be sure that you are wiring from the corresponding diagram. We

suggest that you read through the entire section

Then proceed, starting with the sensor inputs, auxiliary outputs, then control

outputs, data communications, and finally, power wiring.

complete

before

a good wiring job on

beginning your hookup.

In addition,

0

It is very important to enter a system set point in the Series 920 before

power to the load circuitry.

applying

Figure 13

Series 920

Dimensions.

(side

Figure 14

Series 920

Panel Cutout

Dimensions.

0

To

shock, make all

connections on the

back

before

power to the control.

Also, disconnect

power before

opening

920.

load power to the

output circuits until

you have entered a

system set

-

view)

-

WARNING:

avoid electric

of the control

connecting

the

Series

Do not apply

point

l

In all wiring diagrams, internal circuits are on the left and external

circuits

How to Install and Wire, Chapter 4

are on the right.

WATLOW Series 920 User's Manual

25

Page 26

1

0

To

electric shock, use

National Electric

Code safety practices when wiring

and connecting this

source and to

WARNING:

avoid potential

unit to a power

electrical sensors or

peripheral devices.

Power Wiring

01

1

NOTE:

For

jumper 18

230VAC,

@2

to

19

0;

J3

A

NOTE:

For

jumper 17 to 19

and jumper l8 to 20

115VAC,

0

2 WARNING:

To avoid electric

shock, connect the

chassis ground

terminal to “Earth

Ground.”

Figure 15

Series 920 Power

Wiring.

n

Remove the short

green ground

jumper on the back

of the 920

your control is

mounted in a metal

panel connected to

safety (chassis)

ground. Removing

the jumper will

prevent ground

loops. OR

Leave the short

green ground

jumper in place if

the Series 920 case

is not connected to

safety (chassis)

ground.

?

0

-

CAUTION:

(T-21)

if

Chassis

GND

Green

GND

k

Wire

0

Disconnecting the green ground jumper

present on the metal case.

Connect the AC power lines and the jumper wires to the power supply terminal

strip of the Series 920. Study the strip connections carefully before beginning.

Be sure to use these jumpers on the power supply

jumper 18 to 19. For

All wiring and fusing should conform to the National Electric Code and to any

locally applicable codes also.

When you apply power without sensor inputs on the Signal Conditioner termi-

nal strip, the Series 920 alternately flashes from SYSTEM to

is an error code indicating an open sensor. These are

unit without sensors.

Before applying power, open the Series 920 and set DIP Switch #1 “ON” for a

Cold Start.

the unit. (This clears all previously entered information from the 920; it is a

“clean” or “cold” start.)

Now remove power again, open the unit, and set the Switch #1 to OFF, (This

will make the next

information in the processor’s memory.) Close the 920.

3 WARNING:

Replace the control chassis in the enclosure and apply power to

start

Ll

Ground

wire

could allow A.C. voltages to be

115VAC,

jumper 17 to 19 and jumper 18 to 20.

a “warm” one, retaining all subsequently entered

17

18

19

20

terminal

normal

strip.

ERl

displays for a

Ll

Ground

For

230VAC,

00XX. This

26

WATLOW Series 920 User's Manual

How to Install and Wire, Chapter 4

Page 27

Input Options: Terminals 1 - 8 Apply One Input Only

RTD

k

l For

RTD

input, use

Terminals 1,2

and 3.

1

NOTE:

For a

two-wire

use Terminals 1 and

2 for the RTD, and

jumper Terminal 2 to

Terminal 3.

RTD,

l For

0-5VDC, 0-20mA

or

1-5VDC, 4-20mA

input, use Terminals

4 and 5.

l

T.C. Compensation

For T/C input, use

Terminals 6 and 8.

Front-Panel Input Selection Also Required

Auxiliary Output: Terminals 9 - 13

Figure 16

input Options

Wiring Diagram.

See model number

information, p. 61,

for the input option

that applies to your

unit.

Figure 17

Auxiliary Wiring

Diagram.

See model number

information, p. 61,

for the alarm output

option that applies

to your unit.

-

-

Terminals 9 & 10

are Auxiliary Output

1

NOTE:

Auxiliary outputs go to a de-energized

state when in an

How to Install and Wire, Chapter 4

alarm

condition.

WATLOW Series 920 User's Manual

#2.

12, & 13 are

iary

NOTE:

Terminals 11,

Auxil-

Output

#1.

27

Page 28

Output #1 Option B, Terminals 22 - 24

Figure 18

Output 1, S.S. Relay,

Option "B", Wiring

-

Diagram.

Figure 19

-

Output 1

S.S. Switch,

Option

Wiring Diagram

"C",

Model#92OA-_

i

!

S.S.

B _

m

,

m

I

I

m

I

m

k

I

_-_000

output

#1 to

Load from

S.S. Relay,

23 N.O.

(MT2)

0.5A

Output #1 Option C, Terminals 22 - 24

Model #92OA-_

C _ _-_000

28

WATLOW Series 920 User’s

Manual

Output

Load from

S.S. Switch, 20mA

22

Switched DC (open

23

+

Unreg.

#1 to

collector)

(20VDC @ 20mA

max.)

-

Switched

+ 3-32VDC

Solid State

Page 29

Output #1 Option D, Terminals 22 - 24

Model #92OA-_

D_ _-_000

Output #1 to

Load

from

6A SPDT Relay

;~~~~~~~~~~~~_~_~_______,

i

Mechanical

:

Relay

:t

:

:

I

:

:

I.1

II

l+

I

:

:

I

:

Output #1 Option E, Terminals 22 - 24

m

/?\

Figure 20

Output 1

Relay,

Wiring Diagram.

A

n

L2

If you use normally

closed

Ll

the mechanical

relay, you may need

to add an external

snubber (Watlow

Part #

0000) across the

normally closed

contacts to avoid

Option "D",

T

0

CAUTION:

contacts

0804-0147-

-

Mech.

of

RF

noise and potential

malfunction.

mally

open contacts

are

protected

internally.

Nor-

Model #92OA-_

E_

_-_000

Back of the control

15ATriac

Figure 21Output 1, Trlac,

Option “E",

Wiring Diagram.

j

NOTE:

Terminal #24

not

have load wires

connected to it. It is

used

only

for the

gate of the

L2

located

on the back

of the control.

should

triac

How

to Install and Wire,

Chapter

4

WATLOW

Series 920

User's Manual 29

Page 30

1

NOTE:

Current for the

4-20mA

sourced

the control.

Use ungrounded

sensors only.

Figure 22

output

Option

Wiring Diagram.

loop

is

internal to

1,4-20mA

"F",

Output, #l

Option F, Terminals 22 - 24

Model #920A-_

F _ _-_000

Output #1 to

Load from

4-20mA

1

24

source

mA

Figure 23

No Output 2.

Figure 24

output 2

Option

Diagram.

-

-

S.S. Relay,

"B",

Wiring

Output #2 Option A, Terminals 14 -

Model #92OA-

--

A_-_000

14 Not Used

16 Not Used

16

Output #2 Option B, Terminals 14 - 16

Model #920A-

--

B_-_000

Output

Load from

S.S.

Relay,

#2 to

0.5A

30

WATLOW Series 920 User’s

Manual How to Install and Wire, Chapter 4

D

I

m

I

I

D

14 N.O.

(MT2)

16 COM (MT1)

LOT+*

I

_

L2

l

L1

Page 31

Output #2 Option C, Terminals 14 - 16

Model #920A- _ _ C - _ 000

Output

Load

S.S.

14 Switched DC

15+ Unreg. (20VDC @ 20mA max.

#2 to

from

Switch,

20mA

(optn collector

Figure 25

Output 2

S.S.

Option "C",

Wiring Diagram.

-

switched

+ 3-32VDC

Input

-

Switch,

a

3 to 32VDC

input

Output #2 Option D, Terminals 14 - 16

Model #92OA-

_ _D_-_000

6A SPDT Relay

?

0

n

If

you

closed contacts of

the

relay,

to

snubber

Part #

0000)

normally closed

contacts to

RF noise and

potential

tion.

open contacts

protected

Figure

Output 2

Relay, Option

Wiring Diagram.

CAUTION:

use normally

mechanical

you may need

add

an external

(Watlow

0804-01479

across the

avoid

malfunc-

Normally

are

internally.

26

-

Mech.

“D”,

How

to Install and

Wire, Chapter 4

WATLOW Series 920

User's Manual

31

Page 32

System Wiring Example

Figure 27

System Wiring

Example.

-

This example shows a typical Series 920 wiring scheme.

of many output configurations.

92OA-2DDO-A003

Temperature Conrol

L1

Control

Power

L 2 115VAC

Earth Ground

it represents only one

r

L1

High Limit

Control Power

L2

r

120 VAC

140A-16XX-6000

High Limit Control

32

WATLOW

Series 920

User's Manual

How to Install and Wire, Chapter4

Page 33

Chapter

5

How to Tune the Series 920

This chapter will explain tuning the Series 920 to the system it controls.

Recommended Tuning Reference

There are a number of quality references on the art of tuning electronic control-

lers

to the systems they control.

qualified to tune thermal systems, we suggest that you obtain and become

familiar with the reference below before attempting to tune your system.

Remember that the

of control you

need.

time

you spend tuning your system is relative to the quality

If you are not an instrument technician

Process Control Instrumentation Technology - Third Edition

by Curtis D. Johnson

ISBN:

0-471-05789-4 approx. $37.00

“Its overall objective is to provide instructional material for a general understanding of process control characteristics such as elements, modes, and

stability along with detailed knowledge of measurement technique, control

mode implementation, and final control element functions.” Johnson

hard cover, 1982,497 pp.

-

Using A Chart Recorder

The tuning procedure will be greatly simplified if you use a chart recorder to

assist in tuning the Series 920. While the Series 920 itself will not drive a chart

recorder, there are several Watlow controls and indicators which will. Your

Watlow sales engineer or distributor can help you select one.

drive sensor near the Series 920 sensor so that the recorder is reading the

same system response.

If you don’t have a chart recorder available, you can still plot the time vs.

temperature system response. Record the 920’s ACTUAL display readings on

graph paper with an x, y

Load

LEDs

axis to

accomplish the same thing.

Place the chart

The °F/°C

DIP Switch #6 to the ON position for load indication. The °F LED now

tions as an LED for Load 1 and the °C LED functions as an LED for Load 2.

These

a constant rate. When

determine the interaction between heating and cooling.

How To Tune The Series

LEDs

LEDs

also function as load indicators. When tuning your control set

func-

help you

determine

used

920, Chapter

when the system has stabilized by cycling at

in a heat/cool application, these

5

LEDs

help

WATLOW Series 920

User's

Manual

33

Page 34

Tuning

For optimum control performance, tune the 920 to a thermal system. The tuning

settings here are meant for a broad spectrum of applications; your system may

have somewhat different requirements.

grams and definitions on Pages

J

NOTE:

When tuning in the Heat

41,45 -

mode, use

point above ambient.

When tuning in the Cool mode, use

point below ambient.

1.

Apply power to the Series 920 and enter a set point in the SYSTEM

menu. Next, go into the SETUP mode, and enter ACCESS (1), the

parameter Using the MODE, UP/DOWN, and ENTER keys, set the

ing Parameters initially: (Proportional Band) PB H (C)

=

0.00, (Rate) RT H

(C) =

0.00, (Cycle Time) CT H (C) = 5, (Rate band) RBH

(C) = 2. Under ACCESS (0) enter CAL = 0.

Refer to the key flow charts and dia-

47 for prompt location and description.

PID

prompts followed by H. Set the set

PID

prompts followed by C. Set the set

PID

Operat-

=

0, (Reset) RS H (C)

Allow actual

process temperature to stabilize at or near Set Point

(SP). The

ACTUAL display will indicate when the load is stabilized near set point.

2.

Proportional Band Adjustment: Gradually increase PB until the ACTUAL

display temperature stabilizes to a constant value. The temperature will not

be right on set point because the initial reset value is 0.00 repeats per

minute. When tuning in the heat mode, the ACTUAL temperature will

stabilize below the desired set point. When tuning in the cooling mode, the

ACTUAL temperature stabilizes above set point. (When PB = 0,

RS, RT,

and CT are inoperative, and the 920 functions as a simple ON/OFF control

with a 3°F or 1.7°C switching

3.

Reset Adjustment: Gradually increase

differential.)

RS

until the ACTUAL display

temperature begins to oscillate or “hunt”. Then slowly decrease RS until the

ACTUAL display stabilizes again near set point NOTE: This is a slow

procedure, taking from minutes to hours to obtain optimum value.

4.

Cycle Time Adjustment: Set CT as required. Optimum system control is

always achieved with faster cycle times. However, if a mechanical contactor

or solenoid is switching power to the load, a longer cycle time may be

desirable to minimize wear on the mechanical components. Experiment until

the cycle time is consistent with the

5.

Rate Adjustment: Increase RT to 1.00 min. Then raise SP by

quality

of control you want.

20°

to

34

WATLOW

Series 920 User’s

Manual

HowToTune The Series 92O,Chapter5

Page 35

30°F,

or 11° to

17°C. Observe

the system’s approach to SP. If the load

temperature overshoots SP, increase RT to 2.00 minutes.

Then raise SP by 20 to

the new set point.

30°F,

or 11 to

17°C

and watch the approach to

If RT is advanced too far, approach to the set point will

be very sluggish. Repeat as necessary until the system rises to the new

set point without overshooting or approaching the set point too slowly.

6.

Calibration Offset Adjustment: You may want your system to control

to a temperature other than the value coming from the input sensor.

measure the difference (as much as

perature,

perhaps at another point in the system, and

±90°F

or

±50°C)

between that tem-

the

process value

If so,

showing in the alphanumeric display. Then enter the amount of CAL offset

you want. Calibration offset adds or subtracts degrees from the value of

the input signal.

The LOPWR and HIPWR Parameters

The LOPWR and HIPWR parameters allow you to limit the duty cycle of the

beat output to minimum and maximum values. The LOPWR parameter is used

to generate a minimum duty cycle regardless of the duty cycle

the

PID

circuit.

LOPWR Example:

LOPWR = 20%

calculated

by

The

PID

circuit calls for a duty cycle of 10%. The LOPWR parameter overrides

the

PID

circuit and outputs a duty cycle of 20%.

For the HIPWR parameter, a maximum duty cycle is generated regardless

the duty cycle calculated by the

HIPWR Example:

The

PID

circuit calls for a duty cycle of 100%. The HIPWR parameter over-

rides the

PID

circuit and outputs a duty cycle of 80%. These two parameters

HIPWR = 80%

PID

circuit.

of

help insure that an “idle” duty cycle is always applied, or that the heaters

cannot apply full power to the thermal system.

Where To Go From Here

Once you have tuned your Series 920, continue to Chapter 6 to learn how to

program your Series 920 for your system.

How To Tune The Series 920, Chapter

5

WATLOW

Series 920 User’s Manual

35

Page 36

Chapter 6

How To Program The Series 920

This chapter will enable you to set up the Series 920 quickly and easily.

explain why it’s a good idea to write out your parameter values.

shows you flow diagrams of the programming process.

Chapter 6 also

Write Out Your Program

The Watlow Series 920 controls temperature for a specific heating and/or cooling

process. Your setup parameter values, when they’re entered, give the Series 920

orders for the work you want it to

Since the amount of information in the setup is extensive, we suggest that you write

the value on a copy of the Master Step Chart on Page 53. This will enable you to set

up the Series 920 quickly and without mistakes. The chart makes a good record of

your values.

perform.

Programming in General

Programming the Series 920 is easy as 1 - 2 - 3:

1. Use the MODE key to select the alphanumeric display prompt you want.

2. Use the UP/DOWN keys to select data or prompts in the alphanumeric display.

3. Press ENTER.

It will

Select the Proper DIP Switch Settings

Prior to programming and operating the Series 920, you must set the DIP Switches.

DIP Switch #1 sets a “warm” or “cold” start following power removal from the 920.

With the DIP switch in the OFF position for a “Warm Start”, the micro-processor uses

previously programmed information as if power had not been removed. A Cold Start

starts “clean” or completely cleared of all user-programmed information when the DIP

switch is in the ON position. All parameters will be empty or set to the default limits.

DIP switch #2 is not used. Set it to the OFF position.

DIP switch #3 selects tenths of units displayed for process inputs.

DIP switch #4 is ON for

DIP switch #5 is for units with

position.

DIP switch #6 determines whether the front panel LED’s to the right of the actual

display are load indicators or

indicators.

DIP switch

factory selected parameters are displayed.

#7, when

0-5VDC/0-20mA

4-20mA

OF/%

OFF, displays all SPCLFUNC parameters. When ON, only

input & OFF for

output. If you have this unit, set #5 to the ON

indicators. When OFF, the

1-5VDC/4-20mA

LEDs

are

input.

°F/°C

36

WATLOW

Series 920

DIP switch #8 is for factory test and calibration, it must be OFF.

How To

User’s

Manual

Program

the Series 920, Chapter 6

Page 37

Event Outputs

Another feature of the Series

920

is its capability for two event outputs. An

“event output” is simply a pre-programmed ON/OFF event per program step.

The event may turn any number of peripheral devices ON or OFF to

assist you

in

controlling your process, system or environment.

For instance, in an environmental chamber, you might wish to circulate air at a

given time in

your program

for one or more steps. You might want to turn lights

ON or OFF, or signals, or lock out your humidifier, or you could activate a video

recorder.

EV1

and EV2 will not be visible

under

the SYSTEM menu until you SETUP

AUX1

and AUX2 as events (EV).

Enter the SETUP menu, and enter ACCESS (5). This is the

cial Function) parameter. Press the MODE key until you reach the

rameter and press ENTER. The default for

AUX1

and AUX2 is AL

SPCLFUNK

AUX1

(Alarms).

(Spe-

pa-

Change the value to EV (Events) if it hasn’t already been done.

If you return to the SYSTEM menu,

turned ON or OFF from here.

SETPOINT

parameter in the PROGRAM menu.

If the events are programmed

EV1

and EV2 will be visible,

EV1

and EV2 can also be

for one step and left unprogrammed for the next

viewed

and can be

under

the

step, the events will maintain the last programmed status.

These event outputs are mechanical relays rated at 6 amps up to

240VAC

Guaranteed Soak

The Series 920 Guaranteed Soak (GS) feature insures that the process temperature tracks a programmed ramp. The Guaranteed Soak acts as a

alarm. The program clock halts if the ACTUAL temperature exceeds the Guaranteed Soak value. At this time the HOLD LED flashesand the clock starts once

the process variable is within the GS deviation value. Programmed in degrees or

process units, GS is in the SETUP menu under ACCESS (5). Entering a value of

(0)

disables the Guaranteed Soak function. Figure 28 is an example of the

Guaranteed Soak function.

Temperature

Guaranteed Soak

Window Around Set

Point

deviation

Programmed Ramp

Figure

Guaranteed Soak

(GS) Example

1

If the program is put

in the HOLD mode

while holding for a

guaranteed soak

and restarted at

another step, the GS

has to be met for the

previous step,

before the program

can continue.

28 -

NOTE:

How To Program the Series 920, Chapter 6

Time

WATLOW

Series 920 User’s Manual

37

Page 38

The Four

JUMPLOOP

Types

The Series 920 gives you the capability to perform four basic