Page 1

8LS

User’s Guide

Watlow Controls

1241 Bundy Blvd.

Winona, MN 55987

Customer Service

Phone: (800) 414-4299

Fax: (800) 445-8992

Technical Support

Phone: (507) 494-5656

Fax: (507) 452-4507

Email: wintechsupport@watlow.com

Part No. 10585-00. Revision 9.2

July 1996

Page 2

Copyright © 1996

Watlow Anafaze

Information in this manual is subject to change without notice. No part of this publication may be

reproduced, stored in a retrieval system, or transmitted in any form without written permission

from Watlow Anafaze.

Warranty

Watlow Anafaze, Incorporated warrants that the products furnished under this Agreement will be

free from defects in material and workmanship for a period of three years from the date of shipment. The customer shall provide notice of any defect to Watlow Anafaze, Incorporated within one

week after the Customer's discovery of such defect. The sole obligation and liability of Watlow

Anafaze, Incorporated under this warranty shall be to repair or replace, at its option and without

cost to the Customer, the defective product or part.

Upon request by Watlow Anafaze, Incorporated, the product or part claimed to be defective shall

immediately be returned at the Customer's expense to Watlow Anafaze, Incorporated. Replaced or

repaired products or parts will be shipped to the Customer at the expense of Watlow Anafaze,

Incorporated.

There shall be no warranty or liability for any products or parts that have been subject to misuse,

accident, negligence, failure of electric power or modification by the Customer without the written

approval of Watlow Anafaze, Incorporated. Final determination of warranty eligibility shall be

made by Watlow Anafaze, Incorporated. If a warranty claim is considered invalid for any reason,

the Customer will be charged for services performed and expenses incurred by Watlow Anafaze,

Incorporated in handling and shipping the returned unit.

If replacement parts are supplied or repairs made during the original warranty period, the warranty

period for the replacement or repaired part shall terminate with the termination of the warranty

period of the original product or part.

The foregoing warranty constitutes the sole liability of Watlow Anafaze, Incorporated and the customer's sole remedy with respect to the products. It is in lieu of all other warranties, liabilities, and

remedies. Except as thus provided, Watlow Anafaze, Inc. disclaims all warranties, express or

implied, including any warranty of merchantability or fitness for a particular purpose.

Please Note: External safety devices must be used with this equipment.

Page 3

Contents

Overview 1

Introduction 5

System Diagram.....................................................................2

Parts List ..........................................................................2

Safety .....................................................................................3

Specifications.........................................................................7

Analog Inputs...................................................................7

Control Capability............................................................8

Digital Outputs.................................................................8

Digital Inputs ...................................................................8

Pulse Counting Input .......................................................8

Serial Interface .................................................................8

Power Supply...................................................................8

Installation 9

Read This Before Installation ................................................10

Mounting The 8LS.................................................................11

External Wiring................................................................13

General Wiring Requirements .........................................13

Cable Recommendations .................................................15

Noise Suppression............................................................16

Terminal Block And Connector Layout ..........................18

RTB Connections.............................................................19

Analog Inputs...................................................................20

Input Scaling ..........................................................................21

Resistor Installation .........................................................22

Voltage Inputs..................................................................23

Milliamp Inputs................................................................23

Thermocouple Inputs .......................................................23

RTD Inputs ......................................................................24

Infrared Non-contact Temp. Sensors ...............................24

Pulse Input .......................................................................25

Carbon Probe Input..........................................................25

Control Outputs......................................................................27

PID Output Termination TB (Primary) or

Flat Ribbon (Secondary)..................................................27

8LS User’s Guide i

Page 4

PID Control Relay Outputs..............................................28

Primary Screw Terminal Outputs ....................................28

Digital Outputs On The Screw Terminal Blocks.............29

Primary Analog Outputs ..................................................29

Analog Output Dip Switch Setting

for 0-5v/4-20mA ..............................................................30

CPU Dip Switch...............................................................31

Secondary Outputs 50 Pin Ribbon Cable ........................31

Communications Set-up and Connections.............................33

RS-232 Connections........................................................33

RS-485 Description And Connections.............................34

Using the 8LS 37

Front Panel.............................................................................37

Front Panel Keys..............................................................38

Displays .................................................................................40

Bar Graph Display ...........................................................40

Single Loop Display ........................................................41

Scanning Display .............................................................41

Alarm Display..................................................................41

Operator Menus .....................................................................43

Changing the Setpoint......................................................43

Selecting Status Mode .....................................................43

Autotune...........................................................................44

Ramp/Soak.......................................................................44

ii 8LS User’s Guide

Setup 45

How to enter the Setup menus? .......................................45

How to edit a menu? ........................................................45

Setup Global Parameters Menu .............................................47

Save as Job.......................................................................48

Restore a Job....................................................................48

Set Alarm Delay...............................................................48

Set R/S Time Base ...........................................................49

Lock Panel .......................................................................49

Power Up Output Status ..................................................49

Controller Address...........................................................50

Communication Error Checking......................................50

Communication Baud Rate..............................................51

Communication Protocol .................................................51

AC Line Frequency..........................................................51

EPROM Version ..............................................................52

Setup Inputs Menu .................................................................53

Page 5

Input Type........................................................................54

Pulse Sample Time ..........................................................55

Input Units .......................................................................55

Linear Scaling Menus ......................................................56

Input Offset ......................................................................58

Setup Control Menu...............................................................59

Heat/Cool PB ...................................................................60

Heat/Cool TI ....................................................................60

Heat/Cool TD...................................................................60

Heat/Cool Output Filter ...................................................60

Heat/Cool Spread .............................................................61

Setup Outputs Menu ..............................................................62

Output Type .....................................................................63

Cycle Time.......................................................................63

Output Action ..................................................................64

Output Limit ....................................................................64

Output Limit Time ...........................................................65

Nonlinear Output Curve...................................................65

Heat Output......................................................................66

Setup Alarms..........................................................................67

Alarm Types ....................................................................68

High Process Alarm Setpoint...........................................69

High Process Alarm Status ..............................................69

High Process Alarm Output Number...............................69

Deviation Band Alarm .....................................................70

Deviation Band Alarm Status ..........................................70

High Deviation Alarm Output Number ...........................70

Low Deviation Alarm Output Number............................71

Low Process Alarm Setpoint ...........................................71

Low Process Alarm Status...............................................71

Low Process Alarm Output Number ...............................72

Alarm Deadband ..............................................................72

Alarm Delay.....................................................................72

Test I/O ..................................................................................73

Digital Input Testing........................................................73

Test Output ......................................................................74

Digital Output Test ..........................................................74

Tuning and Control 75

Introduction............................................................................75

Control Modes .......................................................................76

Control Outputs................................................................78

Digital Output Control Forms..........................................78

8LS User’s Guide iii

Page 6

Setting Up and Tuning PID Loops ........................................80

General PID Constants by Application..................................82

Troubleshooting 85

Stand Alone Systems .............................................................85

Checking Control Outputs ...............................................85

Checking Digital I/O........................................................85

Computer Supervised Systems ..............................................86

Computer Problems .........................................................86

Computer Software ..........................................................86

Communications Problems ..............................................87

Serial Interface .................................................................87

Appendix A: Ramp Soak 89

Introduction............................................................................89

R/S Features.....................................................................89

Specifications...................................................................90

Configuring Ramp/Soak ........................................................90

Setting the R/S Time Base...............................................91

Editing R/S Parameters....................................................91

Choosing a Profile to Edit................................................91

Copying the Setup from Another Profile.........................92

Editing the Tolerance Alarm Time ..................................92

Editing the Ready Setpoint ..............................................93

Editing the Ready Event States........................................93

Choosing an External Reset Input ...................................94

Editing a Segment............................................................94

Setting Segment Time......................................................94

Setting a Segment Setpoint ..............................................95

Configuring Segment Events ...........................................95

Editing Event Outputs......................................................96

Changing Event States .....................................................96

Editing Segment Triggers ................................................96

Assigning an Input to a Trigger .......................................97

Changing a Trigger’s True State......................................97

Latching or Unlatching a Trigger ....................................97

Setting Segment Tolerance ..............................................98

Ending a Profile ...............................................................98

Repeating a Profile...........................................................98

Using Ramp/Soak ..................................................................99

Assigning a Profile to a Loop...........................................99

Running a Profile .............................................................100

Ramp/Soak Displays........................................................101

iv 8LS User’s Guide

Page 7

Holding a Profile or Continuing from Hold.....................103

Resetting a Profile............................................................104

Appendix B: 8LS-CP 105

Key Features ....................................................................105

System Configuration ............................................................106

Specifications.........................................................................108

Analog Inputs...................................................................108

Control Capability............................................................108

CP Control .............................................................................109

Trim Gas Temperature Alarm Output ...................................109

Recommended CP Trim Gas Alarm for Continuous

Applications .....................................................................109

Recommended CP Trim Gas Alarm for Batch Applications110

Carbon Probe .........................................................................111

General Guidelines ..........................................................111

Probe Burn Off.......................................................................112

Carbon Probe Burn Off Requirements: ...........................112

Burn Off Procedures ........................................................112

Burn Off Function............................................................113

Setup Menus ..........................................................................114

Setup Inputs .....................................................................114

Setup Carbon Burn Off ....................................................116

Setup Alarms....................................................................119

CP and DP Display ..........................................................119

Appendix C: 8LS Cascade 121

Introduction............................................................................121

8LS Cascade Menus...............................................................121

Cascade Main Menu ........................................................121

Choosing the Primary Loop.............................................122

Setting the High End of the Secondary Setpoint .............122

Setting the Low End of the Secondary Setpoint ..............122

Glossary 123

8LS User’s Guide v

Page 8

vi 8LS User’s Guide

Page 9

Overview

Overview

This manual describes how to install, setup, and operate an 8LS

controller. Included are six chapters, Appendixes describing the 8LS-CP

(Carbon Potential) and the 8LS-RS (Ramp/Soak), and a glossary of

terms. Each chapter covers a different aspect of your control system and

may apply to different users. The following describes the chapters and

their purpose.

•

Introduction: Gives a general description of the 8LS and its related

specifications.

•

Installation: Describes how to install the 8LS.

•

Using the 8LS: Provides an overview of system displays and opera-

tor menus.

•

Setup: Describes all the setup displays for the controller, and how to

access them.

•

Tuning and Control: Explains PID control and provides tips for

tuning your system.

•

Troubleshooting: Gives some basic guidelines for solving control

problems.

•

Appendix A: Describes the Ramp and Soak function in the 8LS con-

troller.

•

Appendix B: Describes the 8LS-CP controller

tures, and additional menus.

—

its function, fea-

8LS User’s Guide 1

Page 10

Overview

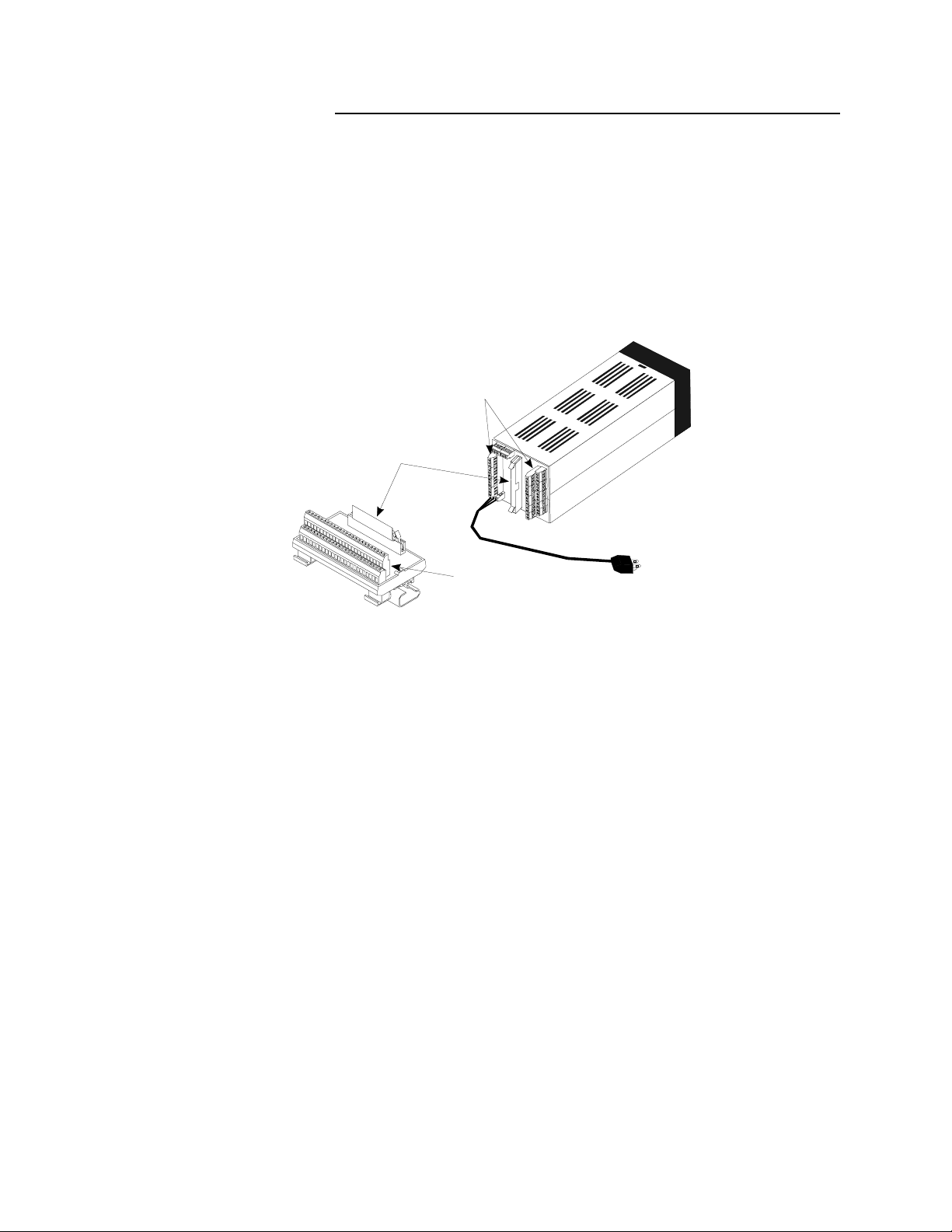

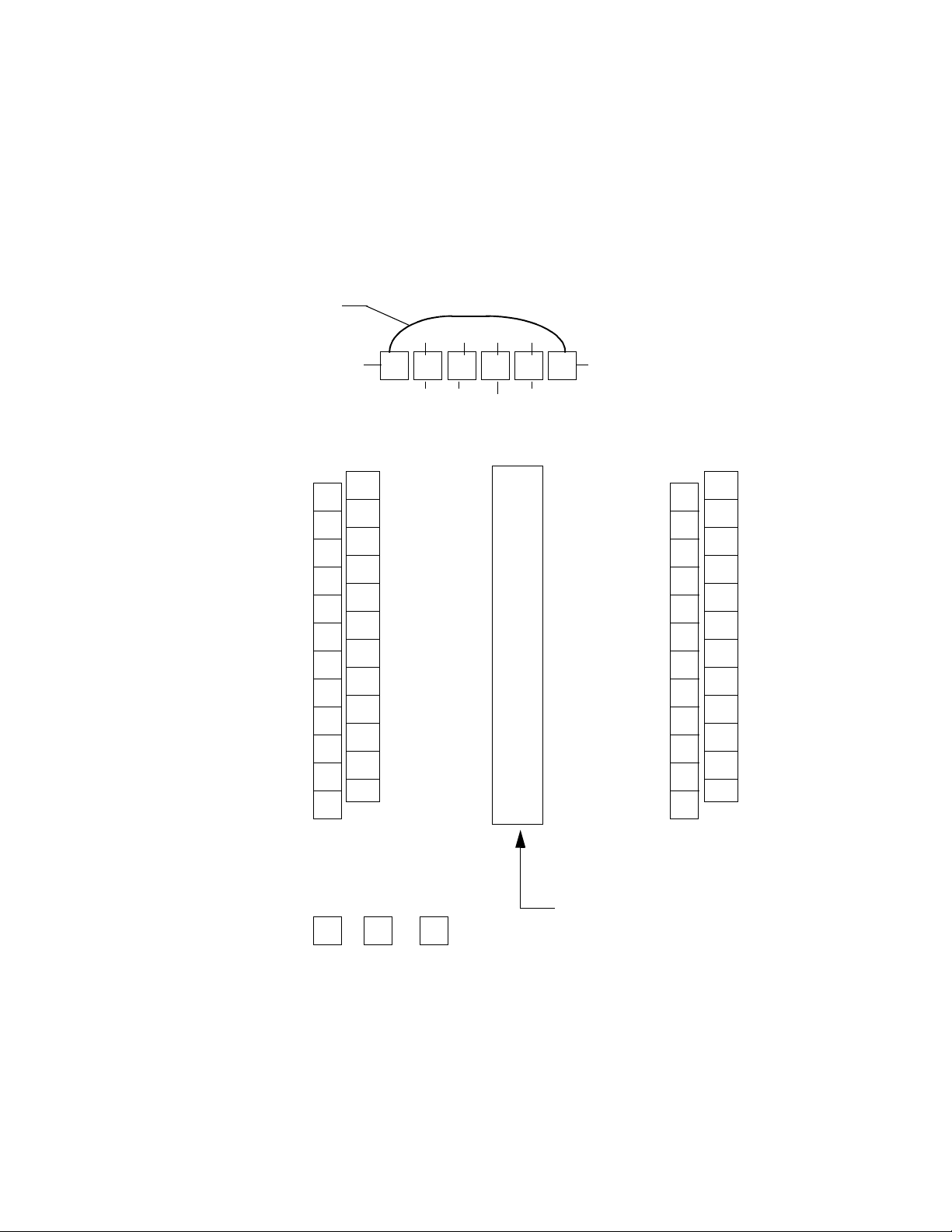

System Diagram

The illustration below shows how the parts of the 8LS are connected.

When unpacking your system, use the diagram and parts list below to

ensure all parts have been shipped. Please don’t hesitate to call Watlow

Anafaze’s Technical Service Department if you have problems with

your shipment, or if the 8LS components are missing or damaged.

Signal Inputs and

Primary Outputs

50-Pin Ribbon Cable

8LS to RTB

8LS

Parts List

50-Pin RTB

Secondary Outputs

and Alarms

•

8LS controller

•

Controller mount kit

•

RTB

•

50 pin flat ribbon cable

•

8LS manual

System Power

2 8LS User’s Guide

Page 11

Safety

Overview

Watlow Anafaze has made efforts to ensure the reliability and safety of

the 8LS

applications. Please note that, in any application, failures can occur.

These failures may result in full control outputs or other outputs which

may cause damage to or unsafe conditions in the equipment or process

connected to the 8LS controller.

Good engineering practices, electrical codes, and insurance regulations

require that you use independent external safety devices to prevent

potentially dangerous or unsafe conditions. Assume that the Watlow

Anafaze 8LS controller can fail with outputs full on, outputs full off, or

that other unexpected conditions can occur.

Install high or low temperature protection in systems where an

overtemperature or undertemperature fault condition could present a fire

hazard or other hazard. Failure to install temperature control protection

where a potential hazard exists could result in damage to equipment and

property, and injury to personnel.

controller and to recommend safe usage practices in systems

The 8LS includes a reset circuit that sets the control outputs off or to the

—

data stored in memory if the microprocessor resets

of a power failure and power return. If a memory-based restart will be

unsafe for your process, program the 8LS controller to restart with

outputs off. For additional safety, program the computer or other host

device to automatically reload the desired operating constants or process

values on return of operating power. However, these safety features do

not eliminate the need for external, independent safety devices in

potentially dangerous or unsafe conditions.

Watlow Anafaze also offers ANASOFT

program for IBM-AT

event of a reset, ANASOFT will reload the 8LS controller with the

current values in computer memory. The user must ensure that this reset

will be safe for the process. Again, use of ANASOFT does not eliminate

the need for appropriate external, independent, safety devices.

Contact Watlow Anafaze immediately if you have any questions about

system safety or system operation.

®

or IBM-PC® compatible computers. In the

®

normally the result

, an optional software

8LS User’s Guide 3

Page 12

Overview

4 8LS User’s Guide

Page 13

Introduction

The 8LS is a powerful 1/4 DIN controller that delivers 8 fully

independent loops of PID control. It can function as a stand alone

controller and as the key element in a computer supervised data

acquisition and control system. An LED front panel display and a touch

keypad are available for local entry of control and other operating

parameters. The 8LS can also be supervised by a computer or

programmable controller through the standard serial interface.

The 8LS features include:

Direct Connection of Mixed Sensors: Versatile analog inputs let you

directly connect most industrial T/C sensors. Thermocouple inputs

feature reference junction compensation, linearization, upscale break

detection, and a choice of

scaling resistors on the 8LS inputs.

Introduction

°

F or °C display. Other analog inputs require

Automatic Scaling: All sensors can be automatically scaled by

entering any two measurement points. For example, to scale a pressure

sensor, enter two points such as 28% is 80 PSI, and 82% is 260 PSI. All

subsequent values will be in PSI.

Selectable Control Outputs: Each PID primary control output can be

selected as digital for on/off, time proportioning, or as analog for

proportional 0-5vdc /4-20madc. The PID secondary output can be

selected as digital for on/off, time proportioning, or distributed zero

crossing. Each loop can be independently set for on/off, P, PI, or PID

control with reverse acting [heat] or direct acting [cool] output.

Complete Process Monitoring: A unique alarm capability is included.

You can set a deviation band alarm, and high and low process [fixed]

alarms independently for each loop. In addition to global annunciator

digital output, each alarm can include a single or grouped digital output.

For example, the digital output from all the high process alarms can be

directed to a single output for automatic process shutdown.

Front Panel or Computer Operation: You can set up and run the 8LS

from the front panel or from a local or remote computer. We offer

ANASOFT, an IBM PC or compatible menu driven program, to set the

8LS parameters. In addition, ANASOFT features graphic trend plotting,

process overviews, printouts, and data archiving.

Multiple Job Storage: You can store up to 8 jobs in protected memory

and access them by entering a single job number. Each job is a set of

operating conditions, including setpoints and alarms. Thus if a single

oven is producing multiple products, entry of the job number will setup

all the loops.

8LS User’s Guide 5

Page 14

Introduction

Dual Output Standard: The 8LS includes dual control outputs for

each loop with a second set of control constants for heating and cooling

applications.

Optional Ramp and Soak: The 8LS is available with a built in

powerful Ramp and Soak programmer for batch processing.

Optional Extruder or Carbon Potential: The 8LS is available with

built in Extruder or Carbon Potential parameters for controlling these

processes.

6 8LS User’s Guide

Page 15

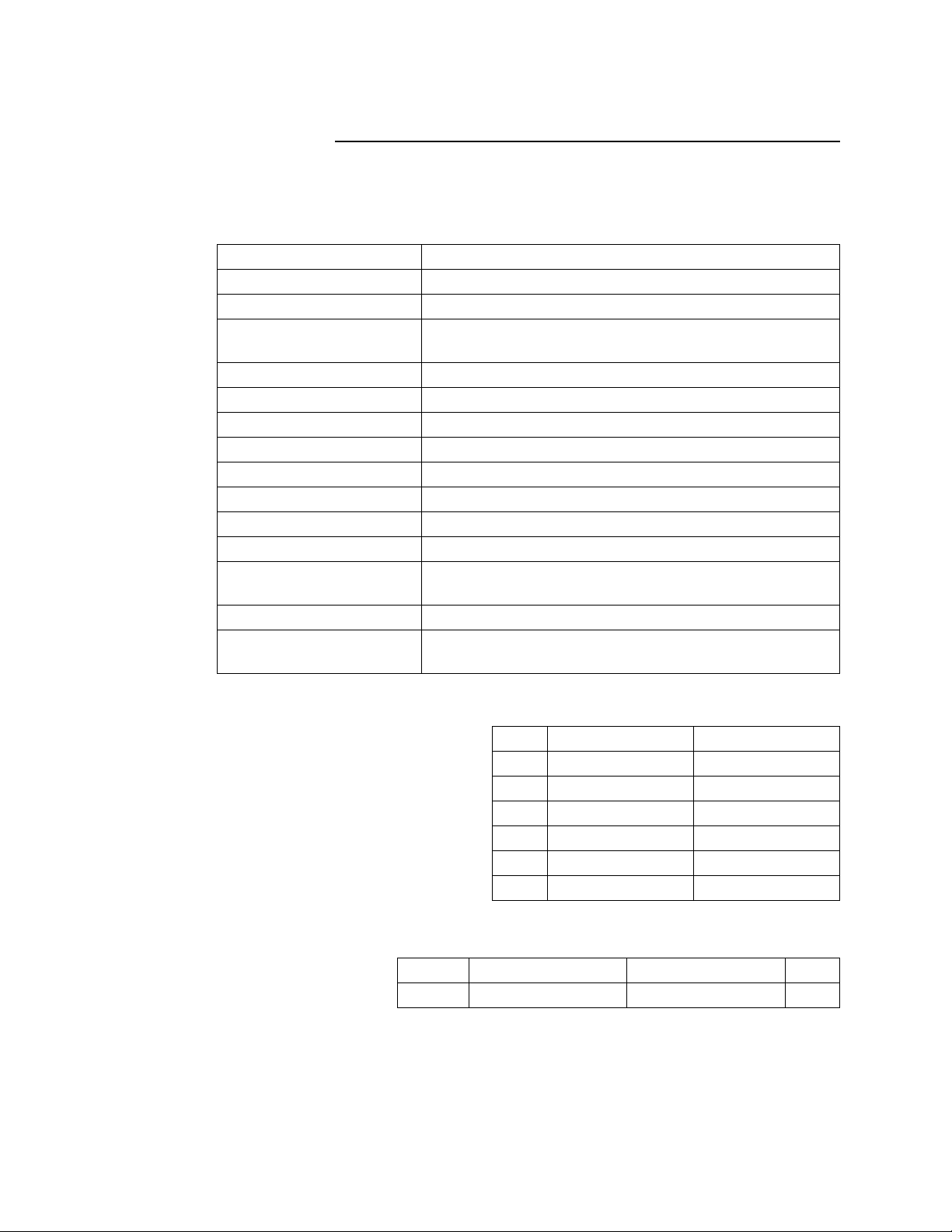

Specifications

Analog Inputs

Analog inputs 8, solid state, differential

Optical isolation 120 Vac between inputs; 175 Vac from input to ground

A/D converter Integrating voltage to frequency

DC voltage range -10 to 60 mV. You can change it with scaling resistors to

Resolution 0.02%, greater than 12 bits

Calibration Automatic zero and full scale

Temperature coefficient Less than 50 ppm/C, 0.005%/°C

Normal mode rejection 60 db at 60 Hz, full scale range maximum

Loop update time 2 times per second, every input

T/C burnout Full upscale reading of input standard

DC milliamp inputs 4-20 mA, 10-50 mA, 0-50 mA, etc., with scaling resistors

Input Range 0-1V, 0-5V, 0-10V, 0-12V, up to 0-25 Vdc, with scaling

Infrared inputs Power supply included, with scaling resistors

Source impedance Measurements are within specification with up to 500

Introduction

any range from 0 to 25V

Accuracy 0.05% at 25°C

resistors

ohms source resistance

Thermocouple Ranges

J -350 to 1400°F -212 to 760°C

K -450 to 2500°F -268 to 1371°C

T -450 to 750°F -268 to 399°C

B 150 to 3200°F 66 to 1760°C

S 0 to 3200°F -18 to 1760°C

R 0 to 3210°F -18 to 1766°C

N -450 to 2370°F -268 to 1299°C

RTD Ranges

RTD1 -148.0 to +572.0°F -100 to 300°C0.1°

RTD2 -184.0 to +1544.0°F -120 to 840°C0.2°

8LS User’s Guide 7

Page 16

Introduction

Control Capability

Number of loops 8, dual output

Control outputs Cycle Time Proportioning, Distributed Zero Crossing, On/Off or Ana-

Digital PID outputs Nominal 5 Vdc at 20 mA to drive optically-isolated solid-state relays

Analog PID outputs Selectable 0 to 5 Vdc at 20 mA maximum or 4 to 20 mAdc 500 ohm

Output resolution 12 bits

Digital Outputs

log; all independently selectable for each loop

Control action Reverse [heat] or Direct [cool], independently selectable for each

loop

Cycle time Programmable for each loop, 1-255 seconds

maximum load

Number 31

Configuration 1 Global Alarm (terminals)

30 for alarms or events (1-4 terminals, 5-30 RTB connector)

Digital Inputs

Pulse Counting Input

Serial Interface

Type RS-232 or RS-485 4 wire, jumper select

Isolation RS-232: optical

Baud Rate 2400 or 9600, menu selectable

Protocol Form of ANSI X3.28-1976, compatible with Allen Bradley

Error check BCC or CRC, menu selectable

No. of controllers Each communications line: 32 with RS-485, 1 with RS-232

Number 12

Configuration 12 for Ramp/Soak triggers

(1-8 RTB connector, 9-12 terminals)

Number Selectable 1 per unit

Type Open collector, 5 Vdc max.

Frequency 1 to 20 Khz

RS-485: To RS-485 Specification

PLC, full Duplex

Power Supply

8 8LS User’s Guide

Power input 85 to 132 Vac, .1A typical, 47 to 440 Hz

Page 17

Installation

Installation

This section explains how to install the 8LS. The instructions are written

for nontechnical users. If you are technically proficient and they seem

simple, at least skim all of the instructions, so you don’t miss anything

vital.

These symbols are used throughout this manual:

DANGER

This symbol warns you of a hazard to human life.

WARNING

This symbol warns you of possible damage to

property or equipment.

NOTE

This symbol denotes information you must know

in order to proceed.

8LS User’s Guide 9

Page 18

Installation

Read This Before Installation

DANGER

Shut off power to your process before you install

the 8LS. High voltage may be present even when

power is turned off! Reduce the danger of electric

shock after installation--mount the 8LS in an

enclosure that prevents personal contact with electrical components.

The 8LS measures input signals that are not normally referenced to ground, so the 8LS inputs and

other signal lines can have high voltage present

even when power is turned off. For example, if you

inadvertently short a thermocouple to the AC

power line.

WARNING

During installation and wiring, place temporary

covers over the housing slots and the rear of the

8LS so dirt and pieces of wire don't fall through

the slots. When you are finished with installation,

remove the covers.

Install the 8LS so the airflow to the slots in the

housing is not restricted after installation. Make

sure that other equipment does not block airflow

to the housing slots.

Use #20 or #22 AWG wires and trim wire insulation to 1/4" (5 mm). Wire should fit inside the

terminal with no bare wire exposed, to prevent

contact between wires and the grounded case. Tin

any stranded wire.

Support power, input and output cables to reduce

strain on the terminals and to prevent wire

removal.

NOTE

Choose a panel location that leaves enough clearance to install and remove the 8LS and its

components.

10 8LS User’s Guide

Page 19

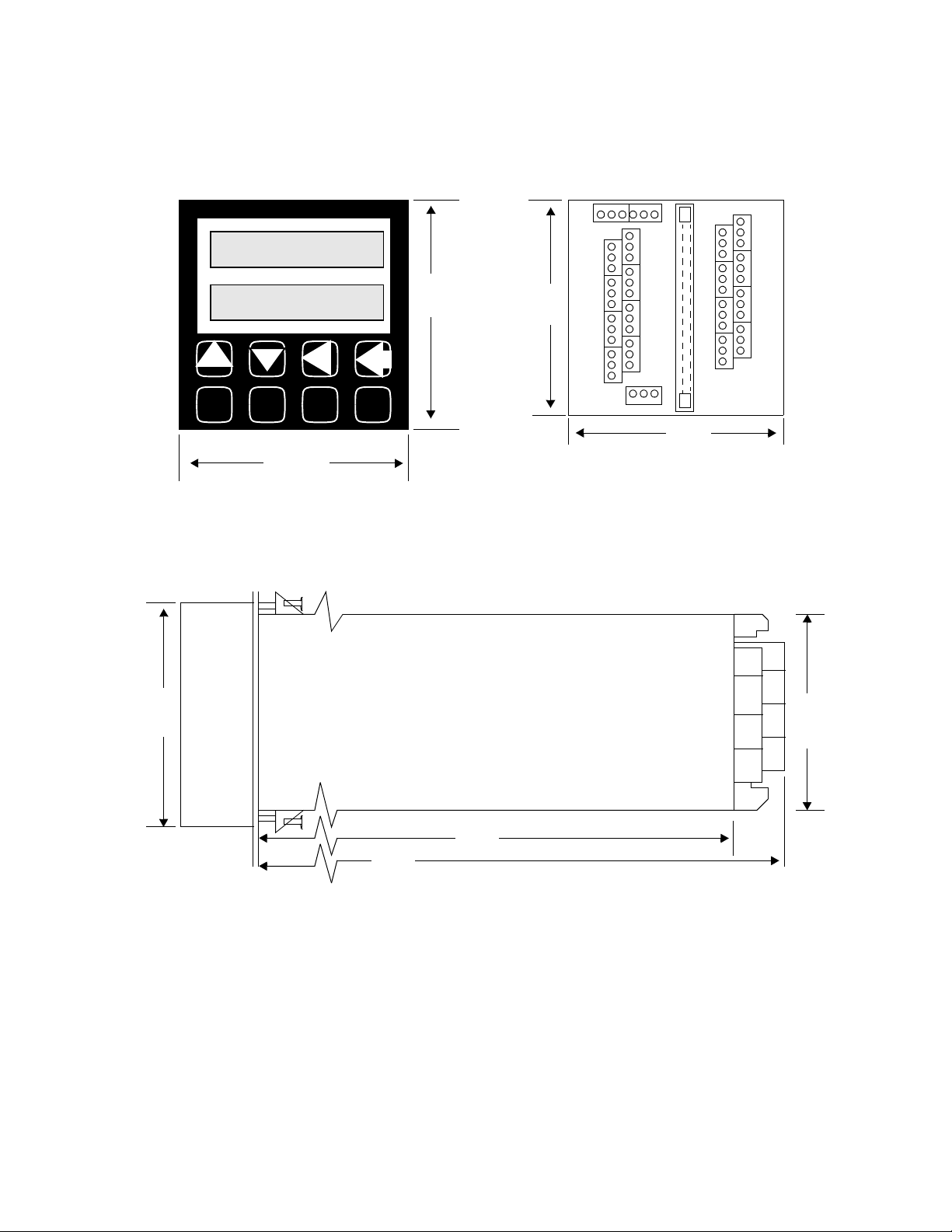

Mounting The 8LS

Installation

The 8LS consists of a 1/4 DIN housing with a front plug in electronics

module. The 8LS-OF (Open Frame) is suitable for sub-plate mounting

inside an enclosure without a front panel. An 8LS-DK will supply the

front panel keyboard with a 10-foot plug- in cable.

For optimum performance when directly connecting thermocouple

inputs, the unit should be protected from thermal shocks whenever

possible. This will minimize any temperature gradients across the

terminal strips and ensure the highest accuracy.

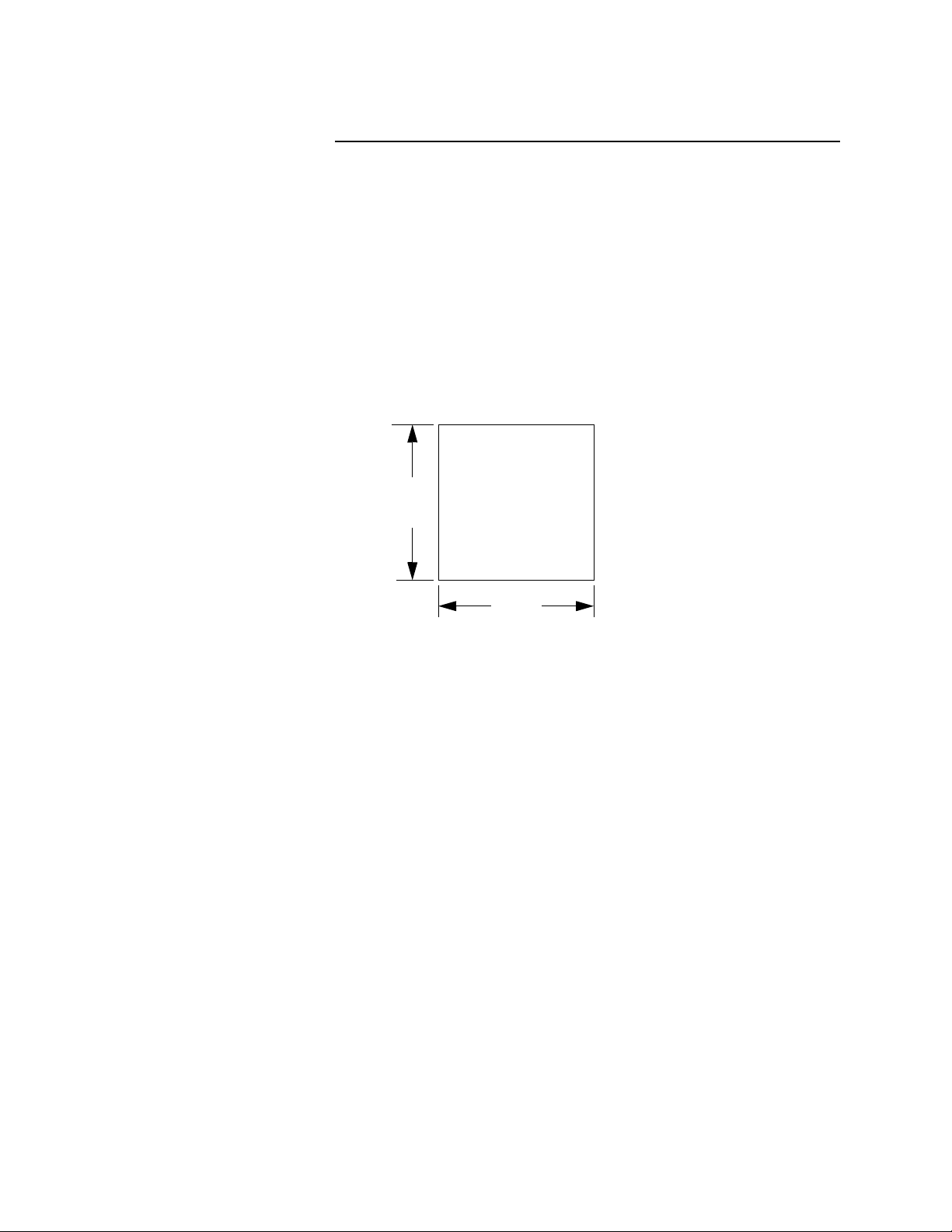

1. Use the dimensions below to cut a hole in the panel.

92 mm

3.6’’

92 mm

3.6 ’’

Cut the hole carefully; the 1/4 DIN specification only allows a front

panel of 96mm x 96mm [3.78in x 3.78in], so there’s not a lot of room

for error.

2. After the hole is cut, insert the 8LS through the front of the panel and

screw the top and bottom clamps into place. If excessive vibration is

anticipated a rear support may be required both for the 8LS and the

interconnecting cables.

8LS User’s Guide 11

Page 20

Installation

.

Front

LOOP PROCESS UNITS

1234 56 7 8

ALARM SETPOINT STATUS OUTPUT%

YES

ALARM

ACK

NO

CHNG

SP

3.78’’

96 mm

BACK

MAN

AUTO

ENTER

RAMP

SOAK

3.78’’

96 mm

3.58 ’

90.9 mm

Side

Rear

PIO

TB4

’

TB3

TB1

90.9 mm

TB2

3.58 ’’

3.78’’

96 mm

10.5’’

266.7mm

9.4’’

238.7mm

3.58’’

90.9

mm

12 8LS User’s Guide

Page 21

3.78’’

g

g

(

Installation

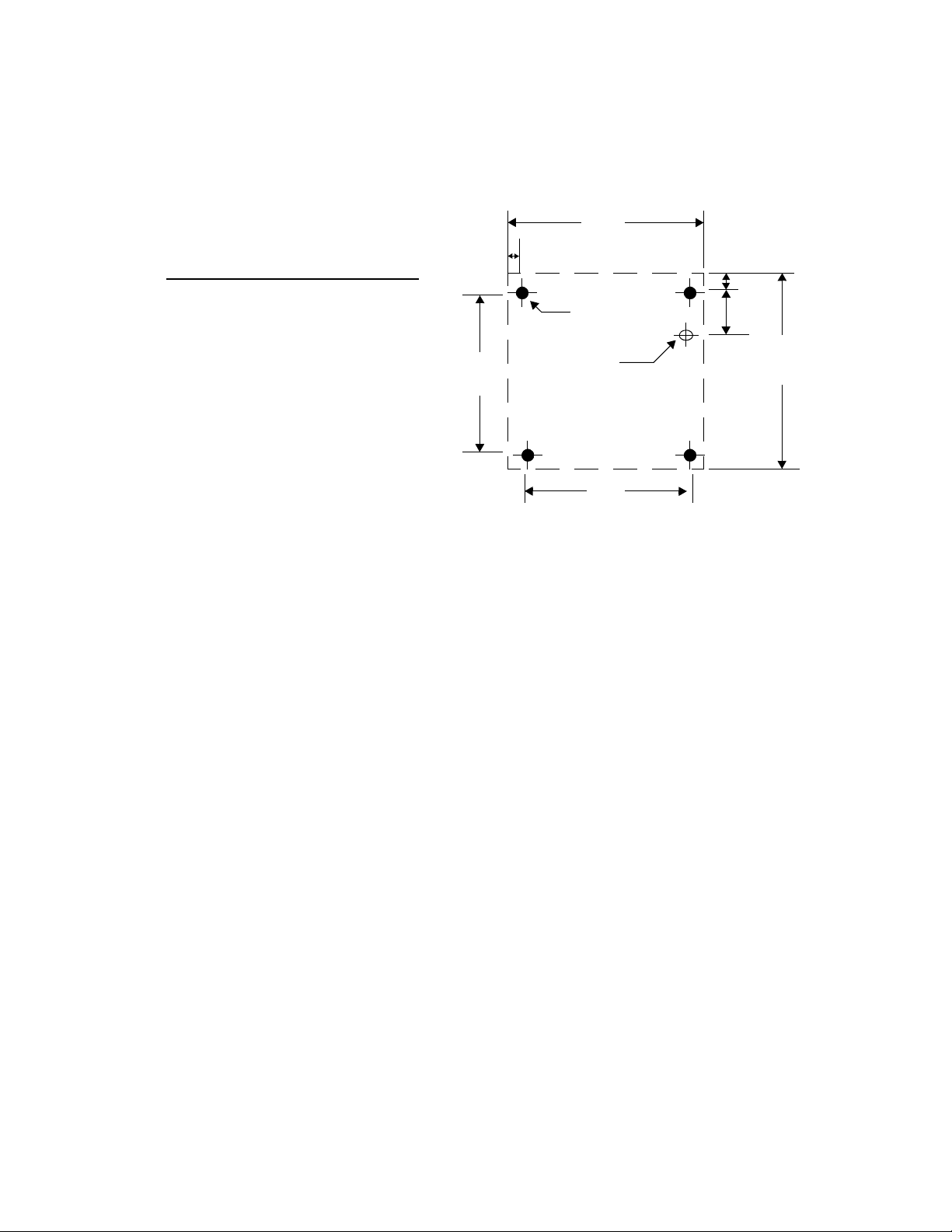

Remote Panel Mounting Dimensions

Notes:

1. Dashed line indicates panel outline.

2. Drill holes as indicated.

3. Install

rommet and feed wire

through grommet.

4. Attach panel usin

from behind).

4 #4 screws

External Wiring

During wiring, it is recommended that the 8LS electronics be removed

or that temporary covers be put over the housing slots to ensure pieces

of wire do not enter the housing and lodge in the electronics. Always

ensure that the housing is clean when the electronics is plugged in.

A successful installation of an 8LS control system depends on selecting

the proper equipment and using correct installation techniques with

appropriate material. One area of concern is the wiring type and

placement of the wiring.

0.29’’

3.20’’

To p

125 dia

4 places

7/16 dia

Insert grommet

3.20’’

0.29’’0.91’’

3.78’’

The wiring is selected according to the function of the wire, the

installation requirements, and the possible mechanical electrical

problems that may occur.

The function of the wire is divided into two basic categories:

Outputs

. The process control requirements will dictate the

Inputs

type

and

of

inputs and the outputs along with the mechanical electrical requirements

of the individual installation.

The term AC power is applied to the 120 VAC control supply. High

power is applied to 240 VAC or higher, primarily used for control loads.

General Wiring Requirements

1. Use stranded wire. Solid wire is recommended for fixed service

and tends to make intermittent connections when moving the field

wiring around for maintenance.

8LS User’s Guide 13

Page 22

Installation

2. Use 20 or 22 AWG size wire. The use of 16,18,20,22, or 24 AWG is

permissible also. The power requirement is not a factor in the wire

size. Only the mechanical strength and the ohmage of the wire may

be factors to consider. Smaller or larger sizes are not easily

installed, may be easily broken and/or cause intermittent connections.

3. Use shielded wire. The electrical shield is used primarily to protect

from unwanted electrical noise.

Normal use of the input wiring shield is to connect one end only to

the 120 VAC panel ground at the 8LS panel location. Another method

is to connect it at the sensor site ground and to the Analog Ground

terminal of the 8LS.

Normal use of the output wiring shield would be to connect one end

only to the 120 VAC panel ground in the panel that the 8LS is

mounted in. Actual use of the shields will be determined by the

installation requirement.

For additional noise suppression measures see NOISE SUPPRESSION FOR Digital Outputs.

4. Use Thermocouple Extension Wire for all thermocouple (T/C)

inputs. Most T/C Ext. Wire is solid wire unshielded. When using

such, the shield function cannot be utilized and only 16, 18, or 20

AWG should be used. Install all T/C wiring in its own conduit away

from AC Power and High Power wiring. Depending on type and wire

size up to 400-500 feet in length may be used to be within stated

accuracy and source impedance.

5. Use multiconductor stranded shielded cable for analog inputs. Most

inputs will use a shielded twisted pair, but some may require a 3 wire

input. Run all analog input wiring in its own conduit away from AC

Power and High Power wiring. Wire sizes of 20, 22, or 24 AWG may

be used.

6. Use multiconductor stranded shielded cable for analog outputs and

PID digital outputs connected to panel mount SSR's. The analog

output will normally use a twisted pair while the digital outputs will

be up to 9 or 20 conductors depending on wiring techniques. All

cables will be shielded. The wiring size will normally be 24 AWG.

The maximum length for the digital outputs should not exceed 25

feet. The maximum length for the analog outputs should not exceed

400 feet. All wiring must be in a separate conduit away from AC

Power and High Power wiring.

When using the 50 conductor flat ribbon cable for the I/O, use of

the 50-pin connector is recommended for both ends of the cable.

The wire is too small to withstand much flexing when connected to

a screw terminal. The cable length should not exceed 15 feet.

7. When installing communications wiring, by pulling in an extra pair, a

sound power phone system could be used for communications

between the 8LS and the computer. This could be used for maintenance, checking calibration and many other functions. A David Clark

#H5030 sound powered system has been used successfully in systems requiring this function.

8. When installing any I/O wiring to the 8LS inside a panel, it should

never be run in the same bundle as AC power wiring.

14 8LS User’s Guide

Page 23

Cable Recommendations

Installation

Wiring bundles of low power Watlow Anafaze circuits next to bundles of high power AC wiring should never be done. The physical

separation of the high power circuits from the controllers should be

of prime importance. In fact, most AC voltage high power circuits are

installed in a separate panel.

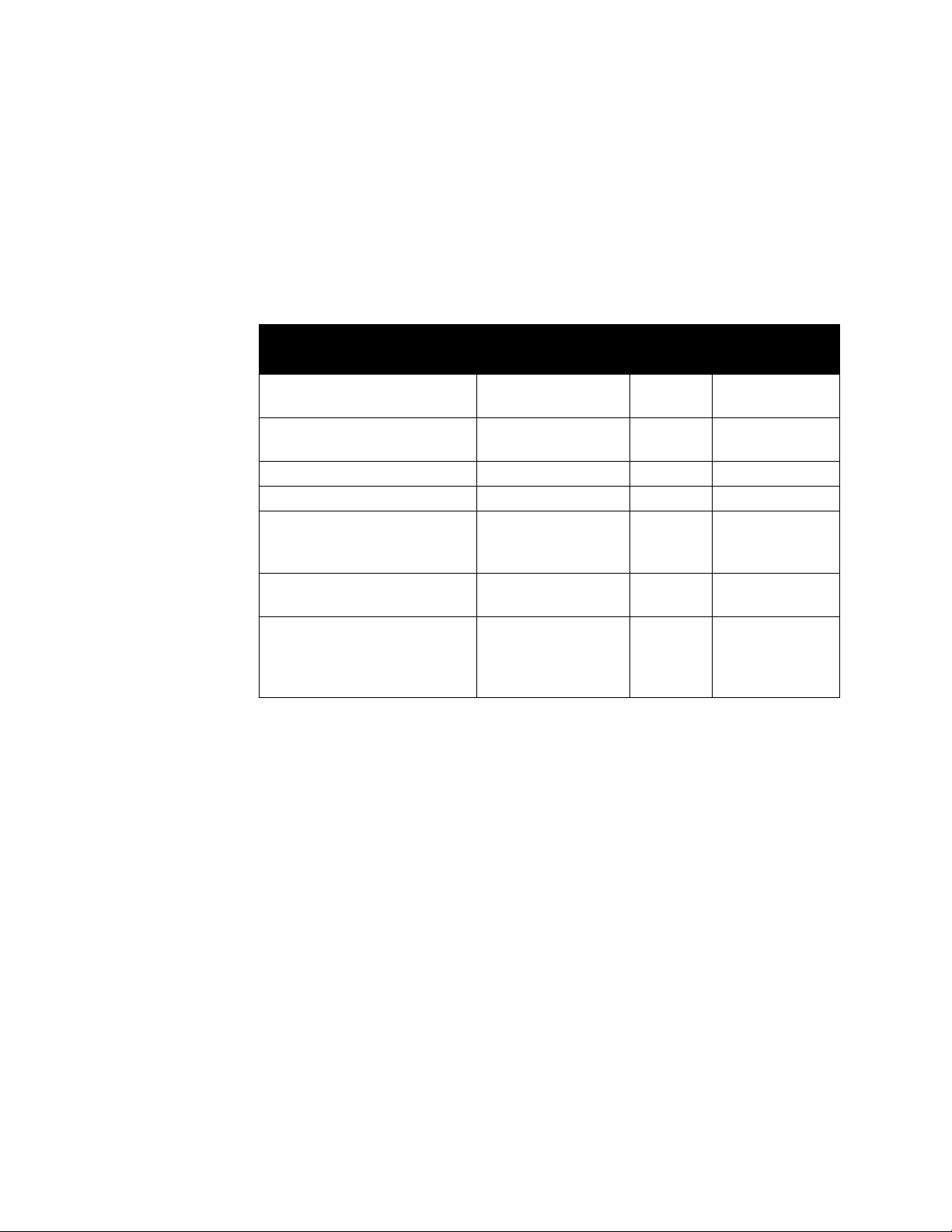

Use these cables or their equivalent.

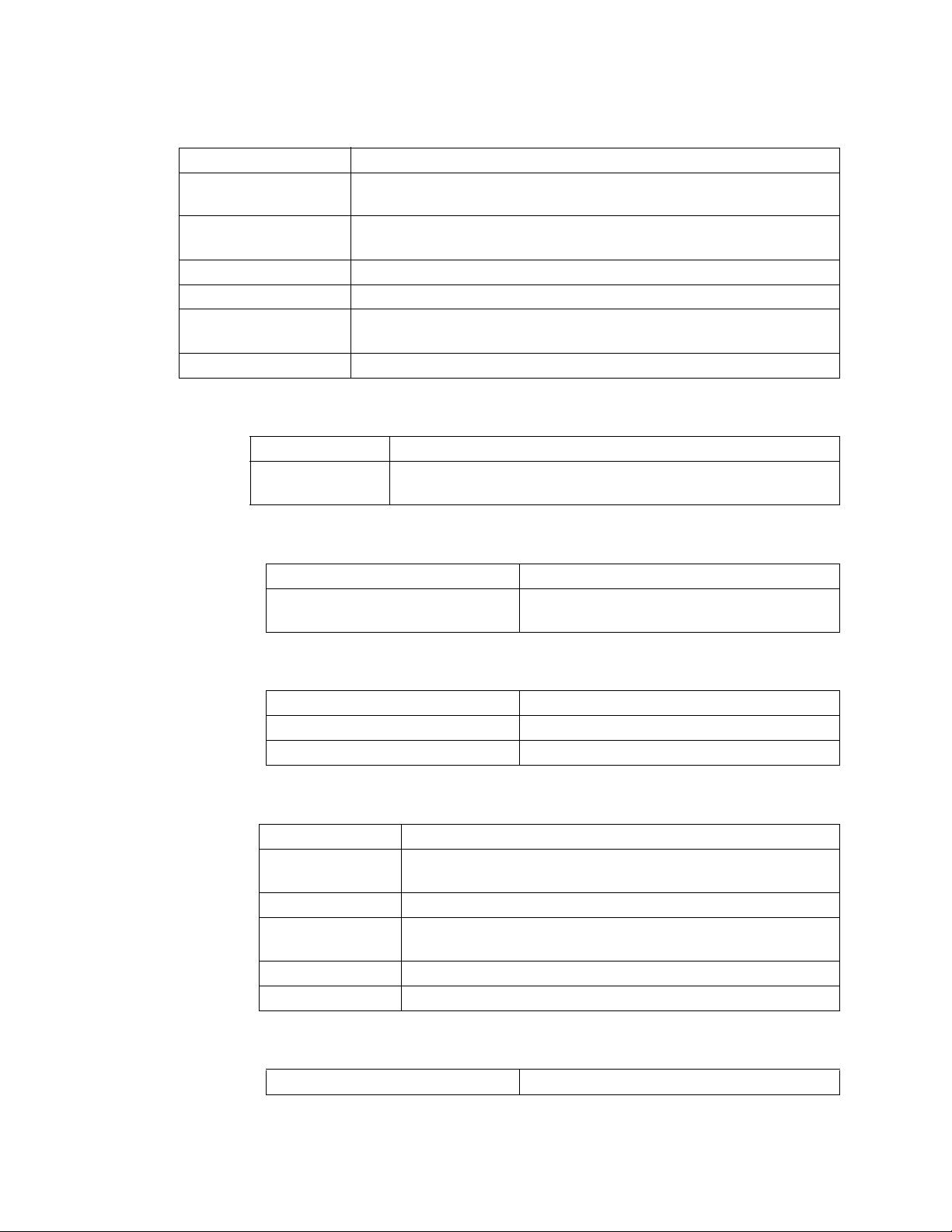

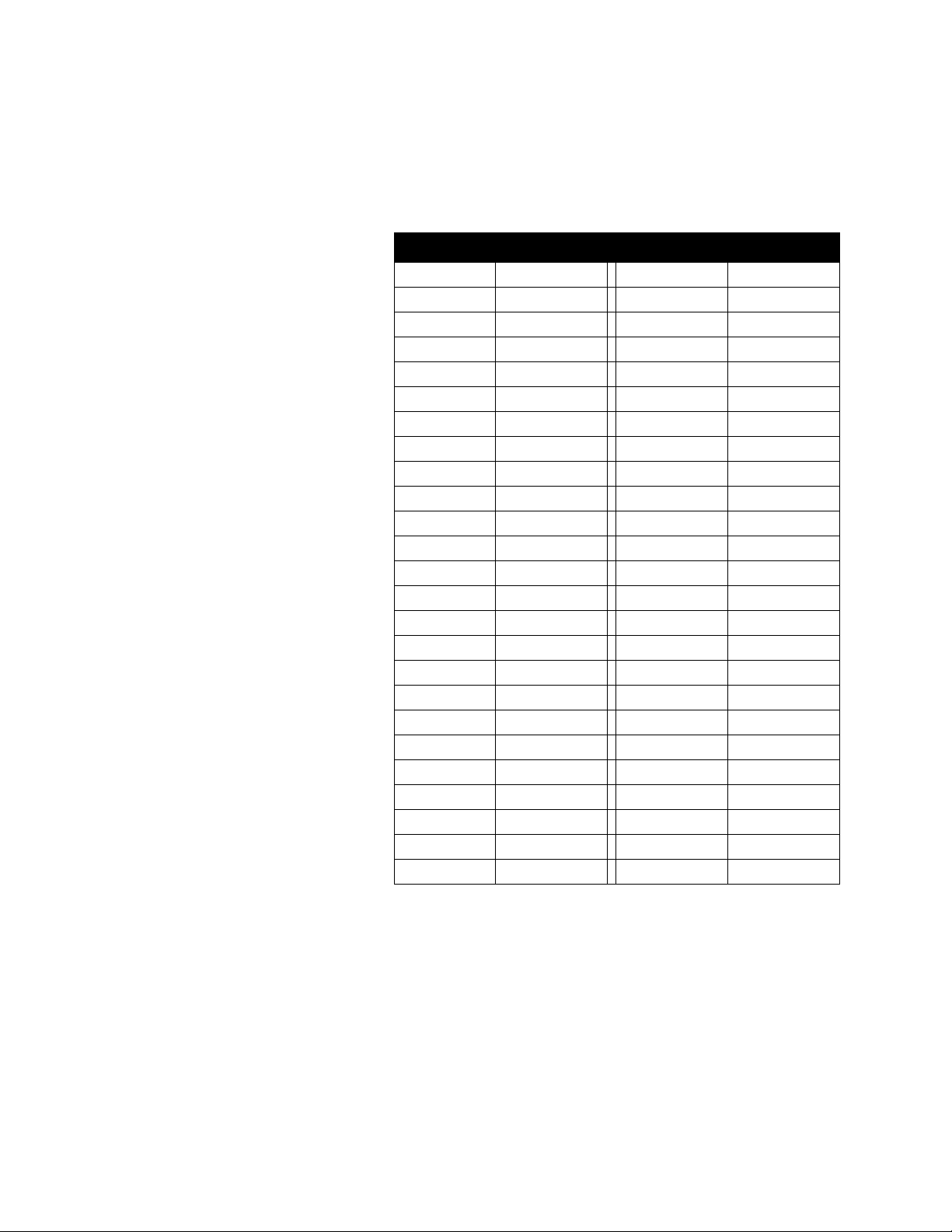

Function MFR P/N

Analog Inputs Belden #9154

Belden #8451

RTD Inputs Belden #8772

Belden #9770

T/C Inputs T/C Ext. Wire 2

Carbon Probe Input Belden #88760 2 18

Digital PID Outputs and Digital

I/O

Analog Outputs Belden #9154

Computer Communication:

RS232, RS422, RS485, or 20

mA

Belden #9539

Belden #9542

Ribbon Cable

Belden #8451

Belden #9729

Belden #9730

Belden #9842

Belden #9843

# of

Wires

2

2

3

3

9

20

50

2

2

4

6

4

6

AWG

20

22

20

22

24

24

20

22

24

24

24

24

8LS User’s Guide 15

Page 24

Installation

Noise Suppression

When using the digital outputs from Watlow Anafaze multiloop

controllers to energize dry contact electrical-mechanical relays with

inductive loads, generation of RFI may become a problem.

This may cause the 8LS display to blank out and then re-energize as if

power had been momentarily turned off. It may also cause the CPU in

the equipment to reset, losing the PID output levels. It may also damage

the digital output IC circuit, thus not being able to energize the digital

outputs. If the IC circuit is damaged, factory repair will be required.

The type of loads that may cause a problem are motor starters, alarm

horns, etc. The RFI is generated upon opening of the metallic relay

contacts.

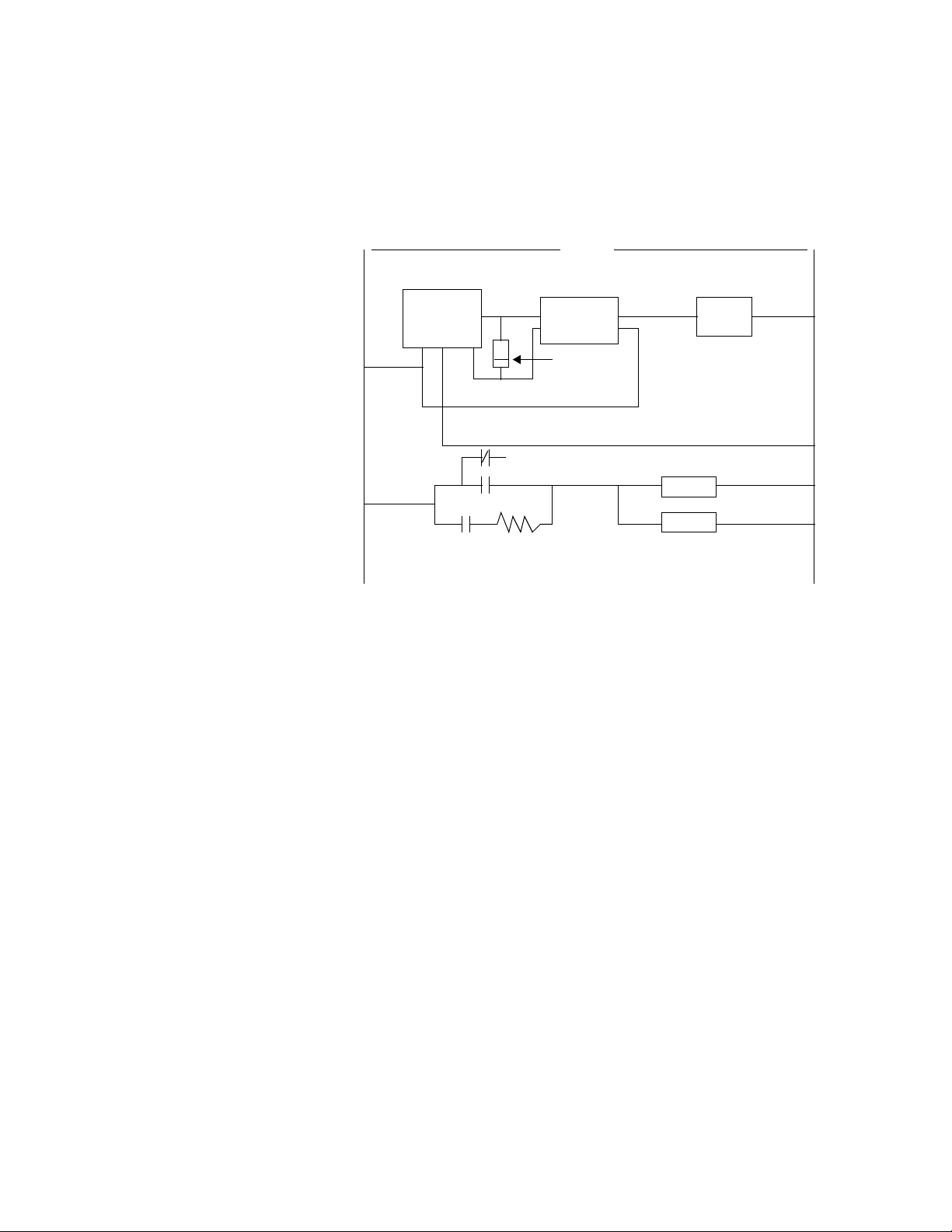

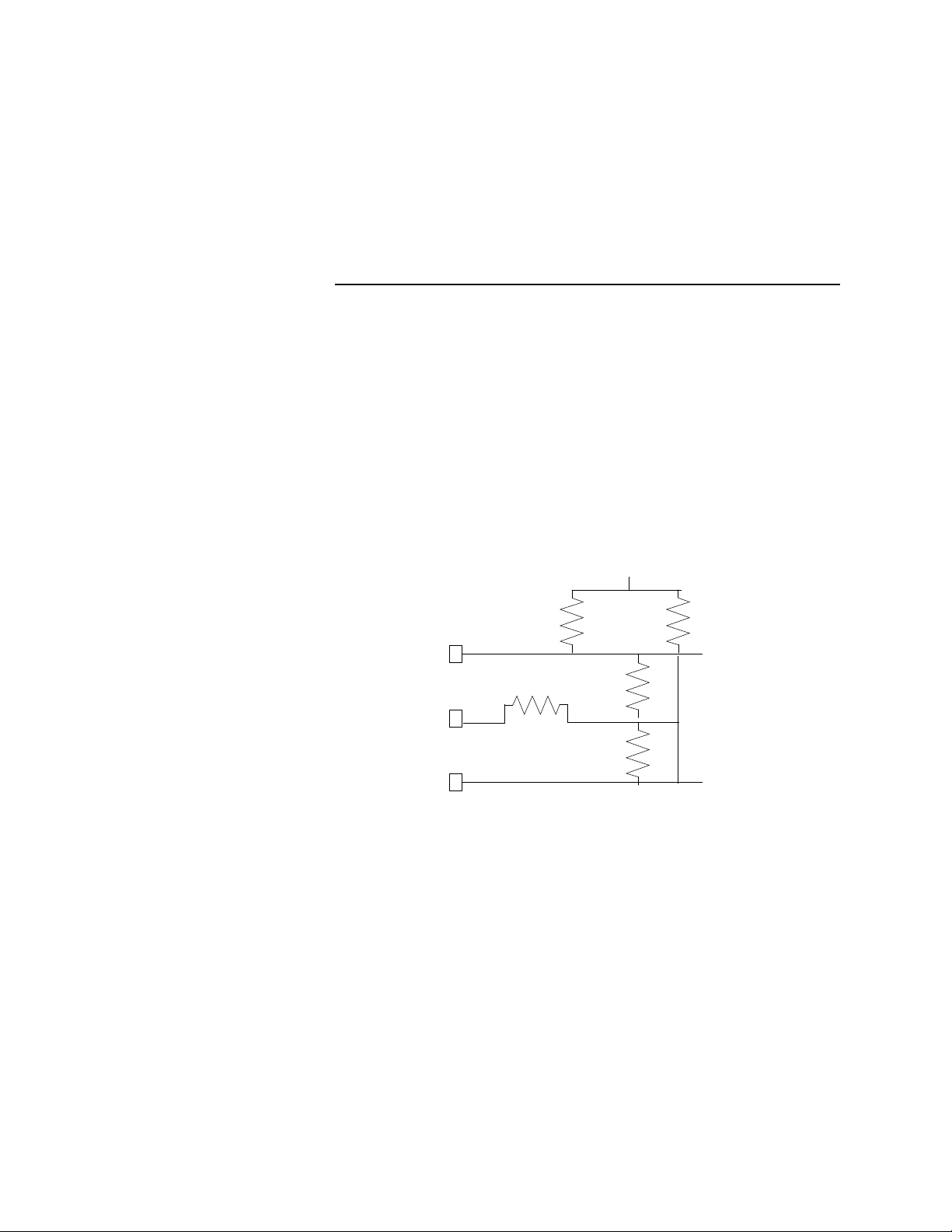

To correct the problem of RFI noise problems:

1. Use Solid State Relays (SSR) wherever possible in place of electricalmechanical relays (E-M relays).

2. When using E-M relays, if possible do not mount them in the same

panel as the Watlow Anafaze equipment.

3. Separate the 120 vac power leads from the low level input and outputs leads from the Watlow Anafaze. Do not run the digital outputs or

PID control outputs leads in the same wire bundle as any 120 vac

wires. Inputs leads should never be run in the same bundle with any

high power leads.

4. If E-M relays are required and must be in the same panel as the Watlow Anafaze equipment, use a .01 uF at 1000 vdc or higher vdc disk

capacitor in series with a 47 ohm 1/2 W resistor across the NO contacts of the relay load contacts. This is the most important step in suppressing RFI from relay contacts. This network is known as arc

suppressor or snubber networks.

5. Use of other voltage suppressing devices may also be used, but are

not normally required. A device known as a MOV rated at 130 vac

for 120 vac control circuits may be placed across the load. This will

limit the peak ac voltage to about 180 vac. A device known as a transorb (back to back zeners) may be used across the digital output. The

rating of 5 vdc should be used. This will limit the dc voltage to 5 vdc

on the digital output loop.

See diagrams for proper placement of the above devices. The parts for

RFI suppression are available from Watlow Anafaze.

16 8LS User’s Guide

Page 25

Installation

g

The above steps should eliminate any noise problems that might be

present with using E-M relays. If, problems persists and/or any

questions about the above steps arises, please call Watlow Anafaze

Technical Service Department at (408) 724 3800.

L 1

8LS

-

+

.01uf

1000 VDC

or higher

K1

NO

NC

47 ohm

1/2 W

120 VAC

-

SSR

+

5 V Transorb

L 2

K1

HORN

MOV

130 VAC ratin

8LS User’s Guide 17

Page 26

Installation

Terminal Block And Connector Layout

The 8LS terminal blocks and connectors are assigned according to the

following two pages. Subsequent sections provide detailed connection

descriptions.

Communications Terminal Block 4

Jumper*

Analog

Ana In 1-

Ana In 2-

Ana In 3-

Ana In 4-

Ana in 5-

Ana in 6-

Ana In 7-

Ana in 8-

Analog

Dig In 10

Logic

COM

COM

COM

Chas Gnd

Term inal

Block 1

2

4

6

8

10

12

14

16

18

20

22

24

1

3

5

7

9

11

13

15

17

19

21

23

Rx- Rx+ Tx- Tx+

6

5

COM

Rx

Analog

COM

Ana In 1+

Ana In 2+

Ana In 3+

Ana In 4+

Ana In 5+

Ana In 6+

Ana In 7+

Ana In 8+

Analog

COM

Dig In 9

Dig In 11

COM

50 Pin

Conn

RS-485 Connections

1234

SHLD

Tx

RS-232 Connections

Termina l

Block 2

10

12

14

16

18

20

22

24

1

2

3

4

5

6

7

8

9

11

13

15

17

19

21

23

PID 1 Out +

4950

R

PID 3 Out +

PID 4 Out +

PID 6 Out +

I

PID 7 Out +

B

B

O

N

Pulse In +

Dig In 12

Dig Out 1

Dig Out 2

Dig Out 3

Dig Out 4

12

Global

COM

Logic

+ PID 2 Out

COM

Logic

+ PID 5 Out

COM

Logic

+ PID 8 Out

COM

Logic

COM

Logic

COM

Logic

+5 Vdc

+5 Vdc

Alarm Out

* It is suggested with noisy electrical environments, a heavy gauge jumper wire be connected between the chassis ground and shield terminals on the rear terminal block as

shown.

18 8LS User’s Guide

Terminal block 3

1

Chas

Gnd

23

AC AC

Neutral

HOT

(green) (white) (black)

Red marker on flat ribbon cable

Page 27

RTB Connections

Installation

The RTB provides the control outputs and additional digital inputs and

outputs as follows:

Terminal Function Terminal Function

1 +5 Vdc 2 +5 Vdc

3 Logic COM 4 Logic COM

5 Spare 6 Spare

7 Spare 8 Spare

9 PID 1 Out 10 Dig 30 Out

11 PID 2 Out 12 Dig 29 Out

13 PID 3 Out 14 Dig 28 Out

15 PID 4 Out 16 Dig 27 Out

17 PID 5 Out 18 Dig 26 Out

19 PID 6 Out 20 Dig 25 Out

21 PID 7 Out 22 Dig 24 Out

23 PID 8 Out 24 Dig 23 Out

25 Dig 5 Out 26 Dig 22 Out

27 Dig 6 Out 28 Dig 21 Out

29 Dig 7 Out 30 Dig 20 Out

31 Dig 8 Out 32 Dig 19 Out

33 Dig 9 Out 34 Dig 18 Out

35 Dig 10 Out 36 Dig 17 Out

37 Dig 11 Out 38 Dig 16 Out

39 Dig 12 Out 40 Dig 15 Out

41 Dig 13 Out 42 Dig 14 Out

43 Dig 1 In 44 Dig 2 In

45 Dig 3 In 46 Dig 4 In

47 Dig 5 In 48 Dig 6 In

49 Dig 7 In 50 Dig 8 In

All digital outputs and the PID outputs on this ribbon connection are

Sink Outputs. They are in reference to the 5Vdc supply. The outputs will

be low when they are on.

All digital inputs are TTL level inputs and may be selected from

software if they will be high/false or low/true inputs.

8LS User’s Guide 19

Page 28

Installation

Analog Inputs

NOTE

When using the RTB, proper polarity of the flat

ribbon cable is necessary for correct pin terminations. Install the red marker indicating pin #1 to

the left when terminal #1 of the RTB is to the left.

The flat ribbon cable should have the red marker

down when installing it on the back of the 8LS. To

confirm proper polarity, check that pin #1 is +5vdc

with respect to pin #3.

Connecting analog signals to the 8LS is normally straightforward. Most

thermocouples can be directly connected and mixed in any order. Other

types of analog signals such as RTD's or mAdc or Vdc require scaling

resistors installed on the 8LS inputs. Some problems may occur that

could reduce accuracy and possibly damage the unit. Below are some of

the potential areas for concern.

Common Mode Voltage

Common mode voltage is the voltage between the ground at the sensor

and the ground at the 8LS. It can be an AC or DC voltage and appears

equally at the high and low input terminals. Frequently it is caused by

large currents flowing in the ground path between the 8LS and the

sensors. Use isolated sensors or ungrounded thermocouples and locate

the 8LS as close as possible to the sensors in order to minimize the

effects. Do not exceed the maximum common mode voltage of 175 Vac.

Normal Mode Voltage

Normal mode voltage appears across the terminals of the input and is

the signal from the sensor plus any undesirable noise. The major cause

of this noise is AC power line pick-up. The effects are reduced by the

8LS capacity to integrate the signal over a multiple of the power line

frequency. Further reduction can be achieved by locating the 8LS near

the sensors and by using twisted and shielded sensor wires.

To ensure accurate readings, the maximum of normal mode plus signal

should not exceed -10mv to +60mv.

Grounding

For best accuracy, observe the grounding recommendations for

connecting each input and output signal. The analog signal grounds

should be connected to the analog ground terminals. The

communication and control outputs should be connected to their

respective grounds. Do not mix the grounds or connect them together. If

possible, route the analog signal cables separately from the

communication, control and power cables.

20 8LS User’s Guide

Page 29

Input Scaling

g

Installation

Source Impedance

Each sensor has a certain output impedance which is effectively

connected across the 8LS input amplifier when a measurement is made.

To reach the rated accuracy, the maximum source impedance should not

exceed 500 ohms. Consult Watlow Anafaze for operation with higher

source impedance.

The 8LS contains an area that can be used to install resistors to scale

input voltages and convert milliamp inputs to match the -10 to 60mv (-

16.7% to 100%) input range. The input circuit is designed to enable

connection of current inputs (such as 4 to 20ma), voltage inputs, and 3Wire RTD. Watlow Anafaze will supply input scaling as needed -- order

option 8LS-SI-XX. The input circuit is shown below:

Ana In + = Analog signal + input

Ana In - = Analog signal - input

Ana Gnd = Analog signal ground

Terminal

Block

Ana In

Ana In

Ana Gnd

+

-

RA

+10 Vdc Reference

RC

RB

RD

RB Alternate

+

IN

Measurement

Input

-

IN

Ground

Analo

RA is shorted by a jumper on the PC board, REMOVE THIS JUMPER

TO INSTALL RA.

Resistors should be 0.1% metal film, 1/4 watt. Note that the resistors

must be stood on end due to the compact size of the unit. Other

components such as capacitors can be installed for signal conditioning.

Please consult Watlow Anafaze. The PC board silk screen shows the

resistor locations.

8LS User’s Guide 21

Page 30

Installation

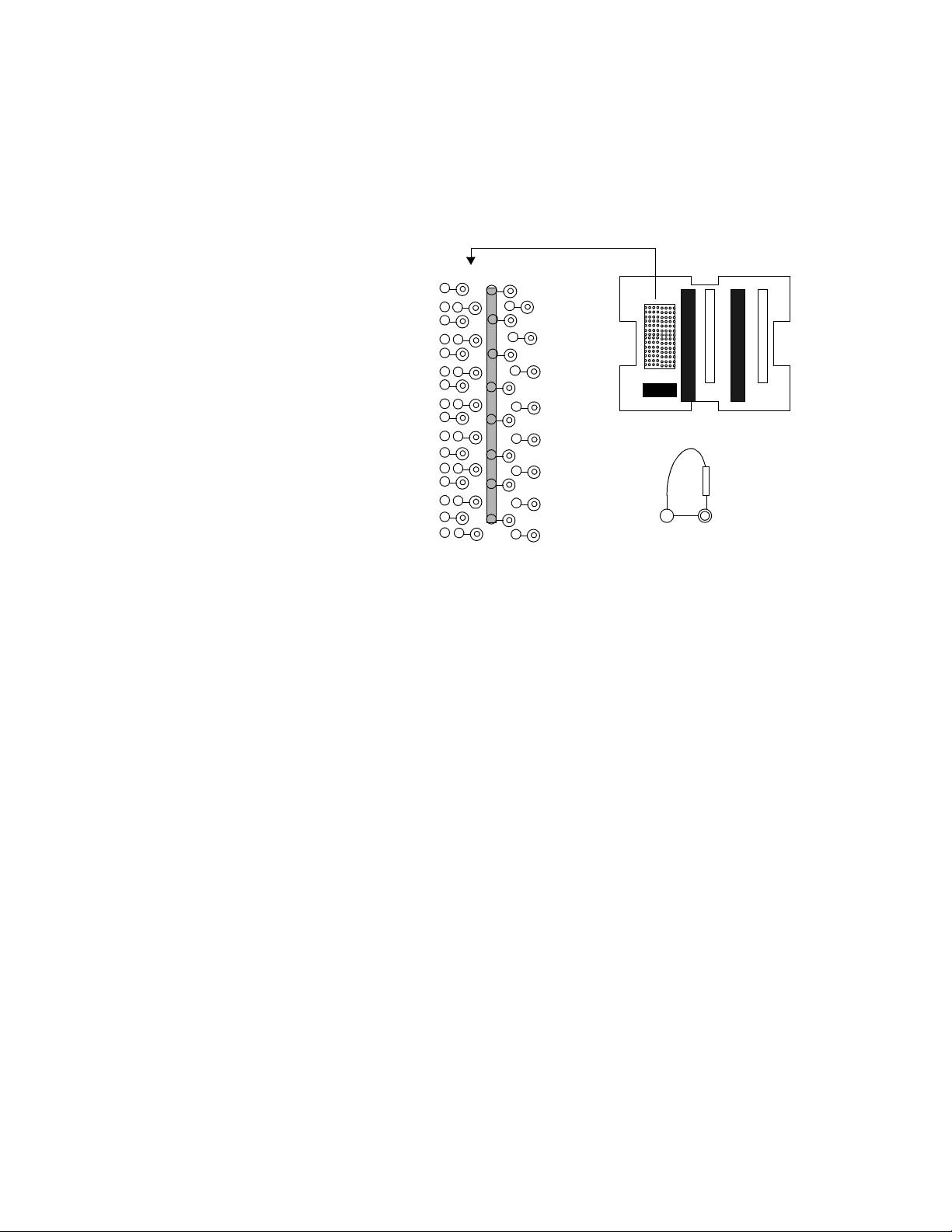

Resistor Installation

For scaling resistors the body of the resistor goes vertically into the hole

with the white silk screen. The lead on the top then goes into the

adjacent indicated hole. The resistor positions are highlighted.

RC1

RB1

RC2

RB2

RC3

RB3

RC4

RB4

RC5

RB5

RC6

RB6

RC7

RB7

RC8

RB8

RD1

RA1

RD2

RA2

RD3

RA3

RD4

RA4

RD5

RA5

RD6

RA6

RD7

RA7

RD8

RA8

22 8LS User’s Guide

Page 31

Voltage Inputs

Installation

DC Voltage inputs should be connected with the positive side to the

High

terminal and the negative side to the

range is -10 to +60 mV. Signals greater than 60 mv must be scaled with

resistors to match the input full scale to 60 mv. The scaling resistor RA

is selected as the voltage dropping and/or current limiting resistor. RB is

selected for the 60 mv full scale dropping resistor. It should normally be

less then 300Ω and no greater then 1000Ω. Any value above 1000Ω for

RB will cause error due to the upscale burnout circuit.

This table shows scaling resistors values.

Low

terminal. The input

Milliamp Inputs

Output

Voltage Range

0-100 mV 499

0-500 mV 5.49 K

0-1 V 6.91 K

0-5 V 39.2 K

0-10 V 49.9 K

The above values are .1% standard metal film resistor values and will

give an accuracy of +

stock. Any possible error due to resistor tolerance error may be

corrected by using the built in linear scaling. Remove the jumper in the

RA location to install RA.

Current inputs from transmitters are accommodated by placing resistors

in the input section to convert the current input into a voltage. Different

current input ranges are accommodated by selecting the proper resistor

values.

A single 0.1% resistor is used as follows:

0.25%. The above values at .1% are our factory

RA RB Accuracy

Ω

Ω

Ω

Ω

Ω

750

750

442

475

301

Ω

Ω

Ω

Ω

Ω

+ .1 %

+ .1 %

+ .2 %

- .2 %

- .1 %

Thermocouple Inputs

4 to 20 ma 0 to 10 ma

RB = 3.000 Ω RB = 6.000 Ω

All thermocouple types may be directly connected to the Watlow

Anafaze 8LS. Types J, K, T, R, S, B, and N linearization and cold

junction compensation are provided standard in the Watlow Anafaze

8LS. For other thermocouple types, optional input ranges are required.

Thermocouples should be connected with the positive lead to

terminal and the negative lead to

only resistor used for T/C inputs and it is a jumper.

Ana In-

terminal of TB1. RA is the

8LS User’s Guide 23

Ana In +

Page 32

Installation

RTD Inputs

The standard industrial RTD is a 100 ohm Platinum three wire

assembly. We highly recommend using the 3-wire RTD. The 8LS will

be configured for the standard three wire RTD input.

Watlow Anafaze offers two standard DIN 385 Curve RTD input ranges,

as shown in the table below:

RTD

Type

RTD1

RTD2

RTD Range resistors are Watlow Anafaze factory stock in .05%

tolerance.

Range RA RB Alternate RC

RTD1 80

RTD2 100

Infrared Non-contact Temp. Sensors

The IRSM (infrared sensing module) is ideally suited for many infrared

non-contact temperature applications. It can be supplied by Watlow

Anafaze as a fully integrated system with the 8LS configured to provide

power for up to four IRSM modules and for direct connection of the

IRSM output. The following connections are required if the IRSM

internal ambient sensor is not used:

Input

Range

-100.0 to +300.0

-148.0 to +572.0

-120.0 to 840.0

-184.0 to +1544.0

Ω

Ω

°

C

°

F

°

C

°

F

22 K

48 K

Display

Resolution

°

0.1

°

0.2

Ω

Ω

22 K

48 K

Ω

Ω

24 8LS User’s Guide

8LS

Signal

Analog In + A Orange Signal Out (0-10 mAdc)

Analog In - B White Signal Ground

Analog Gnd K Shield

+5 Vdc E Red +5 Vdc supply

Logic Gnd C Black Power Ground

Logic Gnd J Brown No Peak Hold

No Connection D Green +15 Vdc supply

No Connection F Blue Ambient Sensor

No Connection H Yellow Track and Hold

Pin Color Function

IRSM Wires

Page 33

Pulse Input

g

Installation

The range of the standard IRSM is 0-1000 degrees F with an output of

0-10ma dc. The input of the Watlow Anafaze 8LS is configured for a 010madc input.

To use more than four IRSM's with the 8LS, use an external power

supply of 8-15vdc.

If desired, a second input may be used to monitor the internal IRSM

ambient temperature. Consult Watlow Anafaze for more information.

The single pulse input is used when a speed or flow input is available as

a Open Collector signal of 5Vdc maximum from the transducer. The

frequency range of the input is from 1Hz to 20KHz. The sample time

period is adjustable from 1 to 20 seconds. To enable the pulse input,

select PLS for the input type of the loop that is to be used for the pulse

input. Do not use the analog input terminals. Connect the transducers

output using shielded wiring to the pulse input pin 12 of TB2 as shown:

Transducer

+

5 Vdc Maximum

-

8LS TB2

12

13

Pulse

Input

ic

Lo

Ground

Carbon Probe Input

The standard zirconia carbon probe as used by the metal treating

industry will have two outputs.

One is the T/C output. A type K, N, R, or S is used. This output will use

standard T/C Extension Wire connecting it to the 8LS.

The second output is the carbon probe output. This output requires using

a special cable due to the electrical and temperature requirements of the

probe and its environment. The cable requirements are two wire with

o

shield with a high ambient temperature rating of at least 150

C.

8LS User’s Guide 25

Page 34

Installation

The Belden cable part number 88760 is highly recommended for the

connection of the carbon probe to the 8LS. An equivalent cable may be

used.

Chas

Gnd

TB4

T/C

Probe

56

1

2

+

-

+

_

Shield

Probe Cable Belden #88760.

Connect Shield to TB4-6 Chassis Ground.

No. of CP

Loops

CP-1 1 2

CP-2 3 4

CP-3 5 6

CP-4 7 8

4

6

Loop Number

3

5

T/C input

1234

Carbon Probe Input

Loop No.

26 8LS User’s Guide

Page 35

Control Outputs

WARNING

Control outputs are connected to the 8LS logic

ground. Be careful when you connect external

devices that may have a low side at voltage other

than controller ground, since you may create

ground loops.

If you expect grounding problems, use isolated

solid state relays and isolate the control device

inputs.

PID Output Termination TB (Primary) or Flat Ribbon (Secondary)

Installation

The 8LS PID control outputs are Dual Outputs for each loop. For

identification these are called primary and secondary control outputs.

Therefore, each loop has control of two outputs, a primary and a

secondary. These are set by factory default to be for Heat/Cool

applications whether or not they will be used for heat/cool operation.

Primary simply means that it is physically implemented on the terminal

block instead of the 50 pin ribbon cable. This is because many

applications use only one output, and a user will not have to buy a

remote terminal block to use the primary output. Also, the primary

outputs are the only ones which can be programmed to analog. Primary

outputs cannot be programmed for DZC outputs.

The default output assignment is for the heat output to be on the primary

terminal outputs and the cool output to be on the secondary 50 pin

ribbon outputs. This can be changed, however, on an individual channel

basis by assigning the heat output to the ribbon cable. The primary and

secondary outputs do not have to be used for heat/cool since:

1. Each output may be individually programmed as a different type:

ON/OFF, TP (both outputs), DZC (secondary only) and ANALOG

(primary only).

2. Each output can be individually programmed to be direct or reverse

acting [both outputs can be the same].

3. There may be a deadband programmed for heat/cool, and in that

deadband both outputs will be off.

8LS User’s Guide 27

Page 36

Installation

g

g

Pid Control Relay Outputs

Primary Screw Terminal Outputs

Typical ON/OFF, TP, DZC control outputs utilize external opticallyisolated solid-state relays. These relays use a 3 to 32vdc input for

control and can be sized to switch up to 100amps at 480vac. For larger

currents these relays can be used to drive contactors.

The primary PID positive output for each loop is located on the screw

terminal blocks and labeled

Ctl Out 1+

through

Ctl Out 8+.

The

negative side of the output is Logic Ground.

NOTE

Primary control outputs are a source supplying

5vdc when the output is On. They should be connected to the positive (+) side of SSRs. Analog

outputs are positive with respect to logic ground.

Connections are made as follows:

Screw Terminal

Block 2

PID Ctl Out 1+

(TP or ON/OFF)

PID Ctl Out 2+

(TP or ON/OFF)

Lo

ic Ground

PID Ctl Out 3+

(Analo

4-20 mAdc)

Pin

#

SSR 1

SSR 2

++--

2

3

1

4

I/P

+-

28 8LS User’s Guide

Page 37

Digital Outputs On The Screw Terminal Blocks

g

g

y

g

NOTE

Alarms and events outputs are sinking +5vdc to

ground when the output is ON. They should be

connected to the minus (-) side of SSRs.

Connections are made as follows:

Installation

Primary Analog Outputs

Event

SSR 2

_

Control

SSR 3

++

__

+

Screw Terminal

Block 2

ital Out 1

Di

(Alarm ON/OFF)

Di

ital Out 2

(Event On/Off)

+5Vdc Suppl

PID Ctl Out 1+

(TP or On/Off)

ic Ground

Lo

Alarm

SSR 1

Pin

#

16

18

21

4

1

See Terminal Block and Connector Layout.

The 8LS provides either 4 to 20mA with 500 ohms maximum load or 05vdc at 5mA maximum. Selection is made on internal dip switches.

The control outputs are shipped as voltage outputs, and can be

converted from voltage to current by changing the dip switch settings on

the control output card. If you are using the output as a digital mode,

such as TPV, you should leave the output in voltage mode. These

switches are accessible from the top of the electronics assembly after it

has been removed from the housing.

There are two dip switch packages on the Output Card, each with 8

switches. Each channel requires two switches. The dip switch package

near the rear panel controls the odd numbered outputs, while the dip

switch package near the front panel controls the the even channels.

When the unit is viewed from the top, with the rear panels to the left, the

channels are in ascending order from left to right [See silk screen on the

printed circuit board].

For each channel, a switch pair will have the switches set in

complementary states. If the first switch of the pair is down and the

second is up, the output is in voltage mode. If the first is up and the

8LS User’s Guide 29

Page 38

Installation

second is down, the output is in current mode. Thus if switch 3 is down

and 4 is up on the dip switch package near the rear panel, then channel 3

is set for voltage.

Rear DIP Switch

F

18

O

o

F

18

Output switches are set to voltage mode; in CPU switch all special

features are set to Off.

Analog Output Dip Switch Setting for 0-5v/4-20mA

Loop Switch Position 0-5 Vdc 4-20 mA

1 Rear 1 O F

1 Rear 2 F O

3 Rear 3 O F

3 Rear 4 F O

5 Rear 5 O F

5 Rear 6 F O

7 Rear 7 O F

7 Rear 8 F O

2Front 1 O F

2Front 2 F O

4Front 3 O F

4Front 4 F O

6Front 5 O F

6Front 6 F O

8Front 7 O F

8Front 8 F O

Odd

CPU DIP Switch

Front DIP Switch

F

18

O

Even

30 8LS User’s Guide

O indicates an On switch, F indicates an Off switch.

Page 39

CPU Dip Switch

Installation

WARNING

Normal mode of operation is for all positions to be

Off. Positions that are On will effect the 8LS normal operation mode.

Position 1 ON--Clears the battery backed RAM and re-initializes the

factory default values into the RAM.

1. Turn off power.

2. Set DIP switch position 1 ON.

3. Turn on power for 10 seconds, and then turn it off.

4. Set DIP switch position 1 OFF.

5. Turn on power.

Positions 2 to 8 are not used for normal 8LS operations. All positions

must be OFF.

NOTE

Turn off the power before you set any DIP switch.

After the new settings, turn on the power to energize the new DIP switch settings.

Secondary Outputs 50 Pin Ribbon Cable

NOTE

Secondary control outputs are sinking +5vdc to

ground when the output is on. Connect them to the

minus (-) side of SSRs.

8LS User’s Guide 31

Page 40

Installation

Connections are made as follows:

Remote Terminal Block

Ribbon Cable Pin

PID Ctl Out 1

PID Ctl Out 2

+5Vdc Supply

Or

9

11

1

SSR 1

+-+-

SSR 2

32 8LS User’s Guide

Page 41

Communications Set-up and Connections

The 8LS offers two types of serial communications: RS- 232 and RS-

485. Up to 32 addresses can be set in the 8LS for one communication

line. RS-232 can not be used for more than 1 controller.

Unless otherwise specified in the purchase order, units are shipped

configured for RS-232. They may be easily modified to RS- 485 by

moving a cable and a jumper plug. These may both be reached from the

bottom of the electronics assembly after it has been removed from the

chassis. The cable has a 4 pin connector which plugs into 4 pins on an 8

pin header on the processor card. RS-232 is on the 4 pins closest to the

front panel, while RS-485 is on the 4 pins nearest to the rear panel. The

connector is always installed with the red lead nearest the front panel.

The jumper plug is located near the cable connector. The position

closest to the rear panel is for RS-232, while the position nearest the

front panel is for RS-485.

Installation

RS-232 Connections

RX Pin 3 RX Pin 2 TX Pin 2 White

TX Pin 2 TX Pin 3 RX Pin 4 Red

GND Pin 7 GND Pin 5 GND Pin 5 Black

The optically-isolated RS-232 interface is connected using the

Communications terminal block 1. See table below for connections.

Computer Connector 8LS Watlow Anafaze

DB 25 DB 9 TB 4 Pin No. Cable

The computer pins are for the normal 25 pin RS-232 connector [DB25]

and the normal 9 pin connector [DB9]. On some computers transmit TX

and receive RX may be reversed. Please check your computer manual

for details.

232

232485

485

8LS User’s Guide 33

Page 42

Installation

RS-485 Description And Connections

The RS-485 is a voltage balanced long distance multi-point

transmission interface. It may use 2 or 4 lines depending on system

requirements. The 8LS uses four lines [two lines can be accommodated

on special order -- contact Watlow Anafaze].

RS-485 Description

The EIA Standard RS-485 specifies only the electrical characteristics of

generators (transmitters) and receivers for use in digital multi-point

systems. The specification of transmission lines, signaling rates,

protocols, etc. is left entirely up to the user. The transmitters and

receivers selected by Watlow Anafaze also meet the requirements of

RS-422.

The following information is intended to make recommendations for the

application of the RS-485 interface to Watlow Anafaze equipment.

The maximum signaling rate used by the Watlow Anafaze 8LS and

associated equipment is 9600 baud. Since this is far below the

maximum signaling rate covered by the specification, satisfactory

performance may be expected without strict adherence to all of the

design rules. Watlow Anafaze has presented conservative

recommendations to insure reliable operation. If deviations are

necessary, please contact Watlow Anafaze.

Cable Recommendations

We recommend twisted shielded pairs for the RS-485 cables. The

transmitters and receivers specified in RS-485 are very tolerant of cable

characteristics, and some leeway is possible unless distances and

signaling rates push the specification limits.

One requirement is very important, as it impacts performance even

down to low frequency operation. The loop resistance of the

transmission line [wire only -- not terminating resistor] must not exceed

Ω

200

for a properly terminated line with a reasonable margin for noise.

Thus the following recommendations for distance and wire gauge

should be observed:

Distance Wire Gauge Recommended Cable

4000 ft. 24 AWG Belden # 9729/9842

6000 ft. 22 AWG Belden # 9184

The use of a shield depends on the noise environment and grounding

considerations. The above cables are shielded.

34 8LS User’s Guide

Page 43

Installation

RS-485 Connections

Connection of Watlow Anafaze controllers to a system computer

requires an interface at the computer to convert RS-232 levels to RS-

485. Watlow Anafaze recommends two options:

•

B&B Electronics 485OIC with 485PS2 or 485OISPR with 485PS.

•

Black Box Model LD485A. The LD485A should be configured for

DCE operation, with the RTS/CTS delay jumper in the "on" position. Watlow Anafaze can supply this converter configured and

checked out with the system on request.

Jumper setup for the B&B Electronics:

1. JP1 Off

2. JP2 Installed

Normal Operation LD485A installation setup:

1. DCE operation (Dip shunt in XW1A socket)

2. Normal operation (Front panel switch out)

3. Full Duplex operation (Jumper W8 on Full)

4. RTS/CTS Delay set to ON (Jumper W9 to ON)

5. Unterminated operation (Switch S2 to Unterm)

6. No jumper at position W7

The RS-485 specification is for "balanced line" operation, and is not

true differential. Thus a common connection is required between all

stations on the communication line. This can be accomplished by either

a 5th wire (which could be shield) or a common ground connection.

The Watlow Anafaze system more conveniently supports the common

ground connection, although 5th wire can be supported if required due

to common mode voltages generated in a given installation. The 3rd

wire connection would be required only if the "common mode" voltage

between stations exceeds the RS-485 specification of 7 volts peak.

To make sure the communication system works, the controller chassis

must be electrically tied to Earth ground, and the host computer

communication must be tied to Earth ground. If the host computer RS-

232 communication is not referenced to Earth ground, install the 100

resistor in W7 as recommended by Black Box.

Ω

The following diagram shows the recommended system hookup. The

transmitter from the host computer connects in parallel to the controller

receivers, and the host computer receiver connects in parallel to the

controller transmitters. A single "daisy chain" is recommended. Octopus

connections or "spurs" are discouraged.

8LS User’s Guide 35

Page 44

Installation

A termination resistor is required at each end of the transmission line.

This is accomplished by applying a 200

Ω

resistor across the line at the

farthest point from the computer transmitter. Check with Watlow

Anafaze for setting the Black Box SW2 to the "term" position to

terminate the computer receive line.

The fifth wire for RS-485 communications is recommended for noisy

environment.

NOTE

Connect the cable shields to equipment ground

only at the 8LS controller sites. Do not connect the

shield at the computer site to Ground. Connect a

200 ohm terminating resistor between RX- and

RX+ at the 8LS.

For multiple units connect the system in parallel as follows:

B&B Electronics

485OIS 485OIC

DB-25 Screws

#2

#14

TDA

TDB

Black Box

LD485A

TXA

TXB

8LS (1

+ # 4

RX

- # 5

RX

)

8LS (n)

RX

RX-

+ # 4

# 5

Or

#5

#17

The "fifth" 12 VDC Com 12 VDC Com Logic COM Logic COM

wire

RDA

RDB

RXA

RXB

TX

TX

+ # 2

- # 3

TX

TX

+ # 2

- # 3

200

36 8LS User’s Guide

Page 45

Using the 8LS

g

g

j

gg

j

g

g

g

g

This Chapter will show you how to use the 8LS from the front panel.

Front Panel

The 8LS front panel provides a convenient interface with the controller

for both viewing the process conditions and operating the controller.

You can program and operate the 8LS with the front panel keys shown

below, or you can use ANASOFT, a program designed specifically for

Watlow Anafaze controllers.

Using the 8LS

Yes

Select a menu

Answer Yes to Yes/No

prompts.

Increase a number or

choice

Alarm Ack

Acknowled

reset

e an alarm,

lobal alarm digital

output

No

Skip a menu

Answer No to Yes/No

prompts.

Decrease a number or

choice

LOOP PROCESS UNITS

1234 56 78

ALARM SETPOINT STATUS OUTPUT%

YES

NO

BACK

ENTER

Enter

Store Data or

choice after

editin

Proceed to the

next menu

ALARM

ACK

CHNG

SP

MAN

AUTO

RAMP

SOAK

Ramp/Soak

Assi

n R/S profile

to a loop

Perform operations

Change Setpoint

Ad

ust the setpoint

Man/Auto

To

le loop status

on existin

Back

Abort editin

Return to previous men

profile

u

between manual and

Auto.

ust output power level

Ad

of loops in Manual mode

8LS User’s Guide 37

Page 46

Using the 8LS

Front Panel Keys

YES

NO

BACK

Yes /U p

Press Yes to

•

Select a menu when prompt is blinking

•

Answer Yes to Yes/No prompts

•

Increase a number or choice you are editing

No/Down

Press No to

•

Skip a menu when prompt is blinking

•

Answer No to Yes/No prompts

•

Decrease a number or choice you are editing

Back

Press Back to

ENTER

ALARM

ACK

•

Abort editing

•

Return to a previous menu

Enter

Press Enter to

•

Store data or menu choice after editing

•

Proceed to the next menu

Alarm Ack

Press Alarm Ack to

•

Acknowledge an alarm condition, reset global alarm digital output

38 8LS User’s Guide

Page 47

CHNG

SP

MAN

AUTO

Chng SP

Press Chng SP to

•

Adjust the setpoint on displayed loop

Man/Auto

Press Man/Auto to

•

Toggle loop status between Manual and Auto

•

Adjust output power level of loops in Manual mode

Using the 8LS

RAMP

SOAK

Ramp/Soak

Press Ramp/Soak to

•

Assign a Ramp/Soak profile to selected loop

•

Perform operations on profile you have assigned

NOTE

If the Ramp/Soak function is not installed, this key

has no function.

8LS User’s Guide 39

Page 48

Using the 8LS

Displays

Bar Graph Display

The next section discusses the 8LS displays:

•

Bar Graph display

•

Single Loop display

•

Scanning display

•

Alarm display

This is the default display on power-up. It provides a system overview

by displaying a deviation bar graph for each loop. Loop status including

acknowledged alarms, manual or auto are also displayed.

LOOP PROCESS UNITS

1234 56 78

AAAAMM

A

M

ALARM SETPOINT STATUS OUTPUT%

The upper display shows the Bar Graph for each loop.

The highest and lowest level of the Bar Graph display are the upper and

lower deviation alarms. If deviation alarms are Off, the display range is

+

5% of setpoint. The intermediate levels are linearly spaced between

the upper and lower limits.

The lower display shows each loop’s status. The table below shows the

loop status symbols.

Loop Status Symbol

Loop

Function

AUTO A Single output loop is in automatic control mode.

HEAT H

COOL C

MANUAL M Loop is in manual control mode. Output power

Loop Display

T

L

The output power percentage displayed is for the

Dual output loop is in automatic control and the

heat output is active. The output power percentage

displayed is for the heat output.

Dual output loop is in automatic control and the

cool output is active. The output power percentage

displayed is for the cool output.

percentage displayed is for the heat output.

Description

heat output.

40 8LS User’s Guide

Page 49

Using the 8LS

The table below shows the status symbols for the Ramp and Soak

option.

Loop Status Symbol

Loop Function Loop Display

START S Ramp/Soak profile loaded, ready to start

RUN R Ramp/Soak profile is running

HOLD H Ramp/Soak profile is in hold

WAIT W Ramp/Soak loop is waiting for a trigger state to be

TOLERANCE

ERROR

Single Loop Display

Description

satisfied

T Ramp/Soak loop is out of tolerance and loop is in

hold

If an acknowledged alarm exists, the Bar Graph is replaced by an alarm

symbol.

Press Back to see the Single Loop display.

This display shows the detailed information for one loop at a time.

Press the Back key to return to the Bar Graph display.

LOOP PROCESS UNITS

8

1234 56 7 8

76 F

°

Scanning Display

Alarm Display

130

ALARM SETPOINT STATUS OUTPUT%

Pressing both Ye s and No arrow keys when you’re in Single Loop