Wascomat FL125, FL185 Manual

OPERATING & MAINTENANCE MANUAL

WASCOMAT FLEX-O-MATIC FL 125 WASCOMAT FLEX-O-MATIC FL 185

471 1562-68/02

96.01

Up to machine No. FL125 -96/28011

FL185 -96/13444

WARNING: ALL OPERATING AND MAINTENANCE PROCEDURES SHOWN ON THE NEXT PAGE OF THIS MANUAL MUST BE FOLLOWED DAILY FOR PROPER OPERATION OF YOUR WASCOMAT MACHINE.

PLEASE ENTER THE FOLLOWING INFORMATION AS IT APPEARS ON THE MACHINE(S) DATA PLATE(S).

MACHINE TYPE OR MODEL

MACHINE SERIAL NUMBER(S)

ELECTRICAL CHARACTERISTICS: ________ VOLTS, _______ PHASE, ______ HZ.

MAKE CERTAIN TO KEEP THIS MANUAL IN A SECURE PLACE FOR FUTURE REFERENCE.

II

NOTICE TO: OWNERS, OPERATORS AND DEALERS OF WASCOMAT MACHINES

IMPROPER INSTALLATION AND INADEQUATE MAINTENANCE, POOR HOUSEKEEPING AND WILLFUL NEGLECT OR BYPASSING OF SAFETY DEVICES MAY RESULT IN SERIOUS ACCIDENTS OR INJURY. TO ASSURE THE SAFETY OF CUSTOMERS AND/OR OPERATORS OF YOUR MACHINE, THE FOLLOWING MAINTENANCE CHECKS MUST BE PERFORMED ON A DAILY BASIS.

1.Prior to operation of the machine, check to make certain that all operating instructions and warning signs are affixed to the machine and legible. (See the following page of this manual for description and location of the signs.) Missing or illegible ones must be replaced immediately. Be sure you have spare signs and labels available at all times. These can be obtained from your dealer or Wascomat.

2.Check the door safety interlock, as follows:

(a)OPEN THE DOOR of the machine and attempt to start in the normal manner: For coin-operated models, insert the proper coins to start the machine.

For manually operated models, place the ON-OFF switch in the ON position and press the Start switch.

For FL and EX models, insert a program card, turn the starter knob to the Start position and place the ON-OFF switch in the ON position.

For HI-TEK microprocessor models, turn the key switch to the RUN position, choose a program and press the START button.

For SELECTA 28 models, select a wash program and press the Start button.

THE MACHINE(S) SHOULD NOT START !

(b)CLOSE THE DOOR to start machine operation and, while it is operating, attempt to open the door without exerting extreme force on the door handle. The door should remain locked!

If the machine can start with the door open, or can continue to operate with the door unlocked, the door interlock is no longer operating properly. The machine must be placed out of order and the interlock immediately replaced.

(See the door interlock section of the manual.)

3.DO NOT UNDER ANY CIRCUMSTANCES ATTEMPT TO BYPASS OR REWIRE ANY OF THE MACHINE SAFETY DEVICES AS THIS CAN RESULT IN SERIOUS ACCIDENTS.

4.Be sure to keep the machine(s) in proper working order: Follow all maintenance and safety procedures. Further information regarding machine safety, service and parts can be obtained from your dealer or from Wascomat through its Teletech Service Telephone - 516/ 371-0700.

All requests for assistance must include the model, serial number and electrical characteristics as they appear on the machine identification plate. Insert this information in the space provided on the previous page of this manual.

5.WARNING: DO NOT OPERATE MACHINE(S) WITH SAFETY DEVICES BYPASSED, REWIRED OR INOPERATIVE! DO NOT OPEN MACHINE DOOR UNTIL DRUM HAS STOPPED ROTATING!

SAFETY AND WARNINGS SIGNS

Replace If Missing Or Illegible

One or more of these signs must be affixed on each machine as indicated, when not included as part of the front instruction panel.

LOCATED ON THE OPERATING INSTRUCTION SIGN OF THE MACHINE:

CAUTION

1.Do not open washer door until cycle is completed, operating light is off, and wash cylinder has stopped rotating.

2.Do not tamper with the door safety switch or door lock.

3.Do not attempt to open door or place hands into washer to remove or add clothes during operation. This can cause serious injury.

MACHINE SHOULD NOT BE USED BY CHILDREN

PRECAUCION

1.No abra la puerta de la máquina lavadora sino hasta que la máquina haya terminado su ciclo, la luz operativa esté apaga da y el cilindro de lavado haya completamento terminado de girar.

2.No interferia o manipule el switch o la cerradura de la puerta.

3.No trate de abrir la puerta o meta las manos dentro de la máquina para meter o sacar ropa mientras la máquina está en operación, pues puede resultar seriamento herido.

LAS MÁQUINAS NO DEBEN SER USADAS POR NIÑOS

LOCATED AT THE REAR OF THE MACHINE:

INSTALLATION AND MAINTENANCE WARNINGS

1.This machine MUST be securely bolted to an uncovered concrete floor, according to the installation instructions, to reduce the risk of fire and to prevent serious injury, or damage to the machine.

2.If installed on a floor of combustible material, the floor area below this machine must be covered by a metal sheet extending to the outer edges of the machine.

3.This machine MUST be connected to a dedicated electrical circuit to which no other lighting unit or general purpose receptacle is connected. Use copper conductor only.

4.This machine MUST be serviced and operated in compliance with manufacturer's instructions. CHECK DOOR LOCKS EVERY DAY FOR PROPER OPERATION TO PRE VENT INJURY OR DAMAGE. IF THE DOOR LOCK FAILS TO OPERATE PROPERLY, PLACE THE MACHINE OUT OF ORDER UNTIL THE PROBLEM IS CORRECTED.

5.Disconnect power prior to servicing of machine.

6.To remove the top panel for service on those models on which it is secured by screws at the rear, first remove the screws. Be certain to reinstall them when remounting the top panel. To remove the top panel for service on those models on which it is secured by one or two keylocks, use the keys originally shipped in the drum package. Be certain to relock after remounting the top panel.

MANUFACTURED BY WASCATOR

DISTRIBUTED BY WASCOMAT INWOOD, NEW YORK, USA

471 76 62 03-01

LOCATED ON THE DOOR:

WARNING !

If you need to order more safety or warning signs, call Wascomat's parts department at 516-371-2000, or call your local dealer.

DO NOT ATTEMPT TO OPEN DOOR UNTIL PROGRAM HAS FINISHED AND

DRUM HAS STOPPED ROTATING.

471 7651-17

FLEX-O-MATIC FL 125, FL 185 |

23 |

|

|

Contents |

|

Introduction ...................................................................... |

1 |

Technical data .................................................................. |

2 |

Installation ........................................................................ |

5 |

Safety rules .................................................................... |

16 |

Mechanical and electrical design ................................... |

17 |

Procedure for use........................................................... |

32 |

Card programming ......................................................... |

36 |

Maintenance................................................................... |

41 |

Trouble-shooting ............................................................ |

42 |

The manufacturer reservs the right to make changes to design and material specifications.

Safetyinstructions

•This machine is designed for water washing only.

•This machine must not be used by children.

•All installation operations are to be carried out by qualified personnel. Licensed personnel are necessary for all electric power wiring.

•The interlock of the door must be checked daily for proper operation and must not be bypased.

•All seepage in the system, due to faulty gaskets etc., must be repaired immediately.

•All service personnel must be fully familiar with the operating manual before attempting any repair or maintenance of the machine.

•This machine must not be sprayed with water, otherwise short circuiting may occur.

•Fabrics softener with volatile or inflammable fluids are not to be used in the machine.

Introduction |

1 |

|

|

Introduction

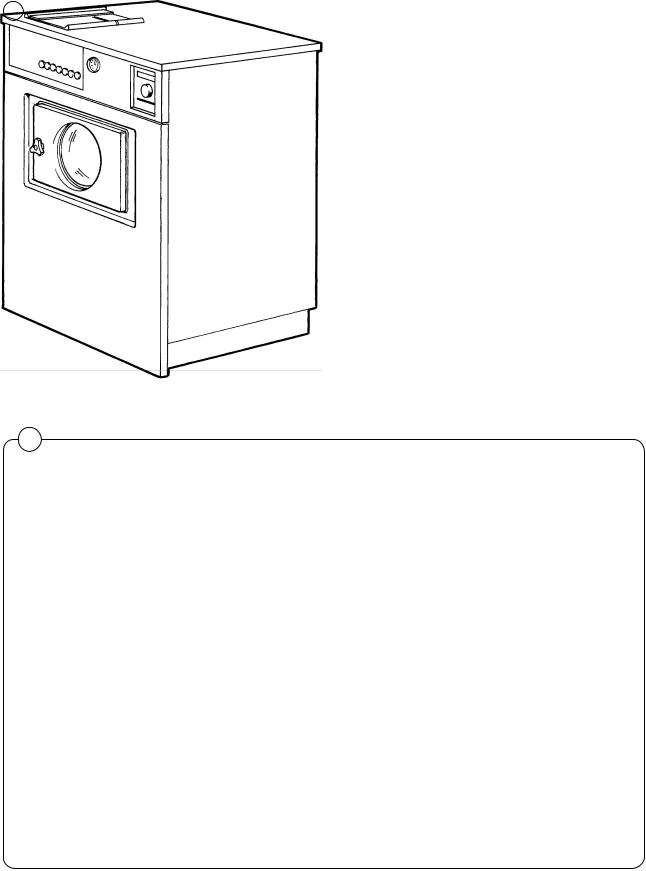

Fig. The Flex-O-Matic models washer/extractors have been developed to cover

1the heavy duty requirements of hotels, motels, nursing homes, hospitals, professional laundries, restaurants, airlines, ships, schools, colleges and all on-premises laundries where flexibility and quick formula variation coupled with high quality automatic washing are required.

The card-programmed FL-model allows for complete programming of water temperatures (only heated machines), water levels, wash and extraction periods and supply injections. The machine is designed for connection to hot and cold water supplies and may be used with free-standing powder or liquid supply injectors which can be activated by signals from the machine.

All parts of the machine which come into contact with the items being washed are made of heavy gauge surgical stainless steel, ensuring long life and lasting beauty, as well as full protection for no-iron fabrics. All electrical components are made accessible for servicing by simply removing the top panel.

This manual contains a technical description of the machine and instructions for its installation, operation and maintenance. Together with the wiring diagram which accompanies each individual machine it should be kept in a safe place for easy reference.

When ordering spare parts or contacting the manufacturer for any purpose always give the machine serial number, model, voltage and other electrical characteristics appearing on the dataplate at the rear of the machine.

1

1720

2 |

Technical data |

|

|

|

|

|

|

Technical data FL 125 |

|

|

|

Dry load capacity |

up to |

16 kg |

35 lbs |

Overall dimensions |

Width |

745 mm |

29 11/32 in |

|

Depth (at the top) |

910 mm |

35 13/16 in |

|

Height |

1196 mm |

47 3/32 in |

|

Net weight |

210 kg |

462 lbs |

|

Dyn force |

2.4 ± 4.8 kN |

576 ± |

|

|

|

1192 lbs force |

Crated dimensions |

Volume |

1,06 m3 |

39 cu.ft |

|

Weight |

222 kg |

489 lbs |

Inner drum dimensions |

Diameter |

620 mm |

24 1/2 in |

|

Depth |

520 mm |

20 1/2 in |

|

Volume |

157 litre |

5.65 cu.ft |

Speed of rotation |

Wash |

52 r.p.m. |

|

|

Extraction |

500 r.p.m. |

|

G-factor |

During wash |

0.9 |

|

|

During extraction |

87 |

|

Motor speed |

During wash |

330 r.p.m. |

|

|

During extraction |

3450 r.p.m. |

|

Voltage requirements |

Choice: |

|

|

|

208-240 V 1-Phase 60 Hz or |

|

|

|

208-240 V 3-Phase 60 Hz |

|

|

Rated output power |

Motor, wash, |

300 W |

|

|

|

0.4 HP |

|

|

Motor, extract. 3-phase |

1300 W |

|

|

|

1.8 HP |

|

|

Motor, wash 1-phase |

280 W |

|

|

|

0.4 HP |

|

|

Motor, extract. 1-phase |

1300 W |

|

|

|

1.8 HP |

|

Overcurrent protection |

Three-phase |

15 A |

|

|

Single-phase |

20 A |

|

Water connections |

|

|

|

Recommended water pressure |

2 - 6 kp/cm2 |

25 - 85 psi |

|

Hose connection, water |

DN 20 |

3/4" |

|

Hose connection, drain |

74 mm |

3" |

|

Hose connection, steam |

DN15 |

1/2'' |

|

Recommended steam pressure |

4-6 kp/cm |

50-85 psi |

|

|

Technical data |

|

3 |

Technical data FL 185 |

|

|

|

Dry load capacity |

up to |

23 kg |

51 lbs |

Overall dimensions |

Width |

827 mm |

32 5/8 in |

|

Depth (at the top) |

960 mm |

37 13/16 ın |

|

Height |

1315 mm |

51 3/4 in |

|

Net weight |

264kg |

582 lbs |

|

Dyn force |

3.1 ± 5.2 kN |

744 ± |

|

|

|

1248 lbs force |

Crated dimensions |

Volume |

1,42 m3 |

50.2 cu.ft. |

|

Weight |

275 kg |

606 lbs |

Inner drum |

Diameter |

700 mm |

27 9/16 in |

|

Depth |

600 mm |

23 5/8 in |

|

Volume |

230 litre |

8.1 cu.ft |

Speed of rotation |

Wash |

45 r.p.m. |

|

|

Extraction |

455 r.p.m. |

|

G-factor |

During wash |

0.8 |

|

|

During extraction |

81 |

|

Motor speed |

During wash |

360 r.p.m. |

|

|

During extraction |

3480 r.p.m. |

|

Voltage requirements |

Choice: |

|

|

|

208-240 V 3-Phase 60 Hz or 208-240 V 1 -phase 60 Hz |

||

Rated output power |

Motor, wash, 3-phase |

400 W |

0.55 HP |

|

Motor, extract, 3-phase |

2000 W |

2.7 HP |

|

Motor, wash 1-phase |

400 W |

0.55 HP |

|

Motor, extract, 1-phase |

1800 W |

2.4 HP |

Overcurrent protection |

Three-phase |

15 A |

|

|

Single-phase |

20 A |

|

Water connections |

|

|

|

Recommended water pressure |

2-6 kp/cm2 |

25-85 psi |

|

Hose connection, water |

DN 20 |

3/4" |

|

Hose connection, drain |

74 mm |

3" |

|

Hose connection, steam |

DN15 |

1/2'' |

|

Recommended steam pressure |

4-6 kp/cm |

50-85 psi |

|

4 |

Technical data |

|

|

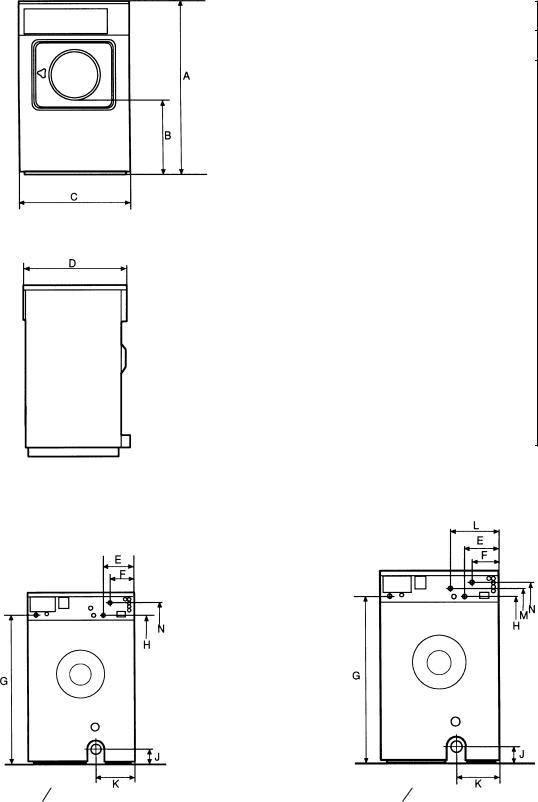

Outline and dimensions

1 |

1 |

FL 125 |

FL 185 |

1852

Installation

Installation |

2 |

Machine foundation

The machines are designed to be bolted in position to a concrete floor or specially prepared concrete foundation. A template showing the size of the foundation and positioning of the foundation bolts is delivered with each machine.

For installation on an existing concrete floor, the floor must be at least 8" thick and of good quality. If the floor does not meet these requirements, then a 6-8" high concrete foundation should be made. A prefabricated steel base is available for mounting of machines without an additional foundation.

Follow the instructions below when making a concrete foundation:

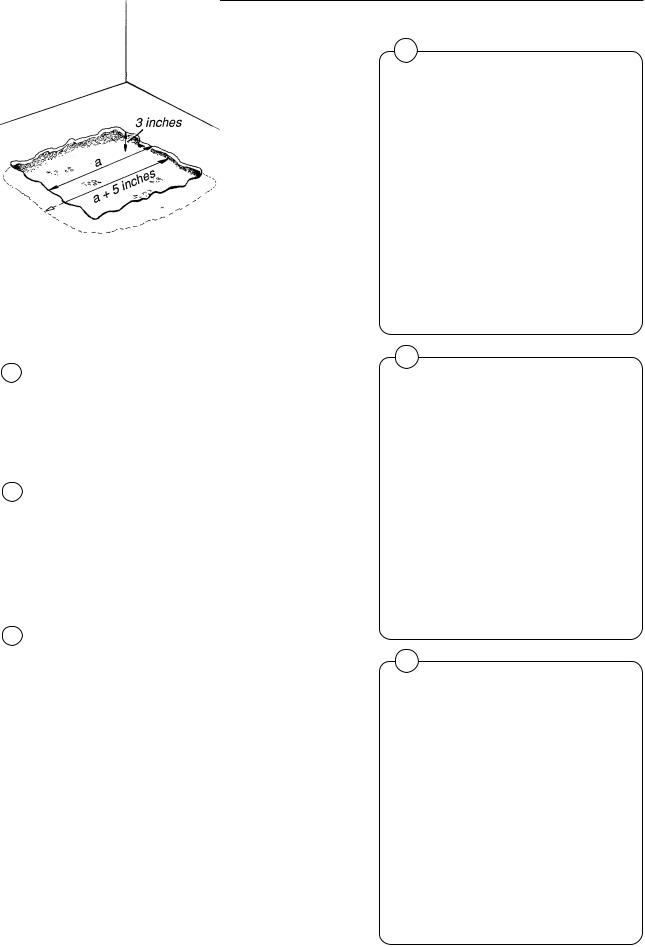

Fig. 1. Decide where to place the machine and

2consider maintenance requirements, i.e. determine a suitable distance from the rear of the foundation to the wall, and the distance from the foundation to the nearest side wall. The distance should be at least 16 and 12 inches, respectively.

Fig. 2. Break up the floor to a depth of 3 inches,

3making sure that the sides of the hole slope inwards - the bottom of the hole should be 5 inches longer than the upper length.

3.Wet the hole well. Brush the bottom and sides with cement grout.

4.Prepare a casing and fill with concrete to form foundation. Make sure the foundation is level.

Fig. 5. Use the template to position the foundation

4bolts correctly - bolts are to extend 1 1/2" above concrete.

NOTE: A prefabricated steel frame, designed to be placed in the concrete instead of the individual mounting bolts, is available.

|

FL 125 |

FL 185 |

||

|

mm |

inches |

mm |

inches |

|

|

|

|

|

A |

508 |

20 |

600 |

23 2/3 |

B |

910 |

35 13/16 |

960 |

37 3/4 |

C |

950 |

37 13/32 |

1000 |

39 3/8 |

D |

102 |

4 |

102 |

4 |

E |

600 |

23 5/8 |

700 |

27 9/16 |

F |

745 |

29 11/32 |

827 |

32 5/8 |

G |

800 |

31 1/2 |

880 |

34 2/3 |

H |

786 |

30 15/16 |

922 |

36 1/8 |

I |

991 |

39 |

1090 |

42 7/8 |

K |

281 |

11 |

236 |

9 7/16 |

|

|

|

|

|

3

4

F = machine G = foundation

5

0271

1677

1132

6 |

Installation |

Mechanical installation

Fig. • Place wide steel shims on the concrete foun- 5 dation over the bolts.

•Lift the machine and lower it in position. Never use the door or the door handle to lift or lower the machine.

Fig. • Check that the machine is level front-to-rear

6and side-to-side and standing firmly on the six supporting points. Spacing washers must be mounted if one or more of these points is not resting against the floor/foundation.

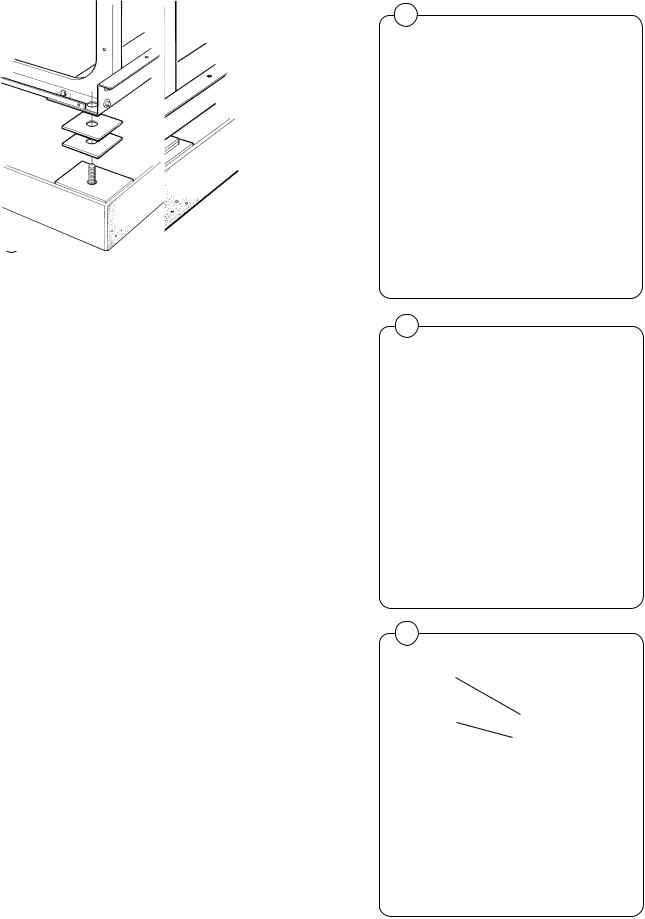

Fig. • Place flat washers over the foundation bolts

7and secure the machine in position by tightening the self-locking nuts. See illustration below.

•Check and tighten the nuts every week for the first month.

5

0274

6

0950

7

selflocking nut

flat washer

1133

Installation |

7 |

Electrical installation

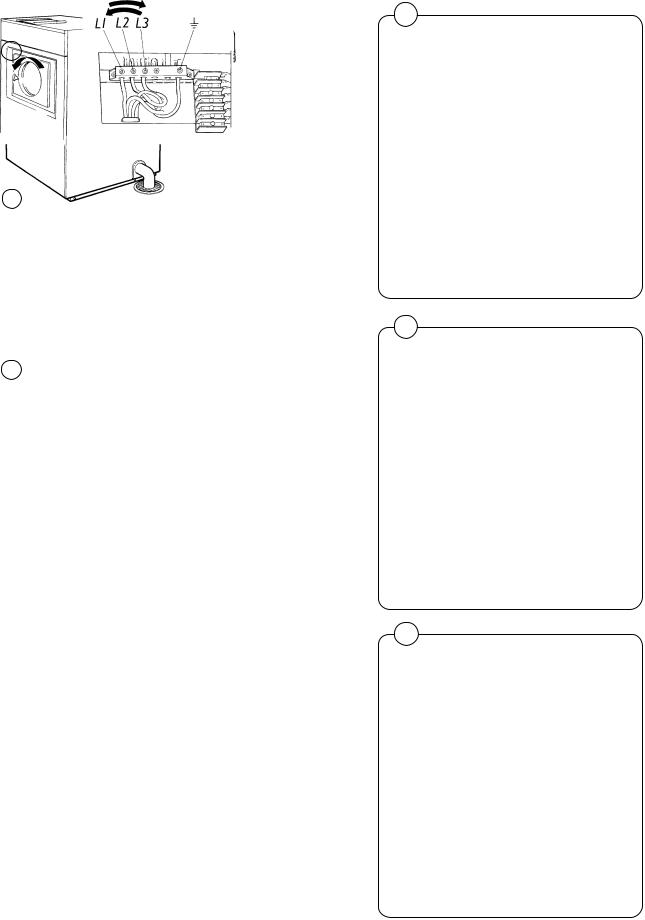

Fig. Although the machines are fitted with a thermal

8overload in the motor windings and a separate fuse for the control circuit, a separate threephase common-trip circuit breaker must be installed for all three-phase machines.

For proper overcurrent protection, check the data plate at the rear of the machine. Also consult local electrical code for special requirements.

Fig. Connect L1, L2, L3 and ground wires according

9to the markings of the terminal block. The cable is to hang in a large loose loop, supported by the clip of the terminal block.

After installation, do the following for 3-phase machines

Check the incoming power for a high voltage leg. If present, connect that line to L2 on the terminal block.

Fig. Start the machine and check that the drum

10rotates in the proper direction during extraction, i.e. counter-clockwise when seen from the front. If the drum rotates in the wrong direction intercharge line L1 and L3 at the power connection terminal.

8

1830

9

1838

10

1839

8 |

Installation |

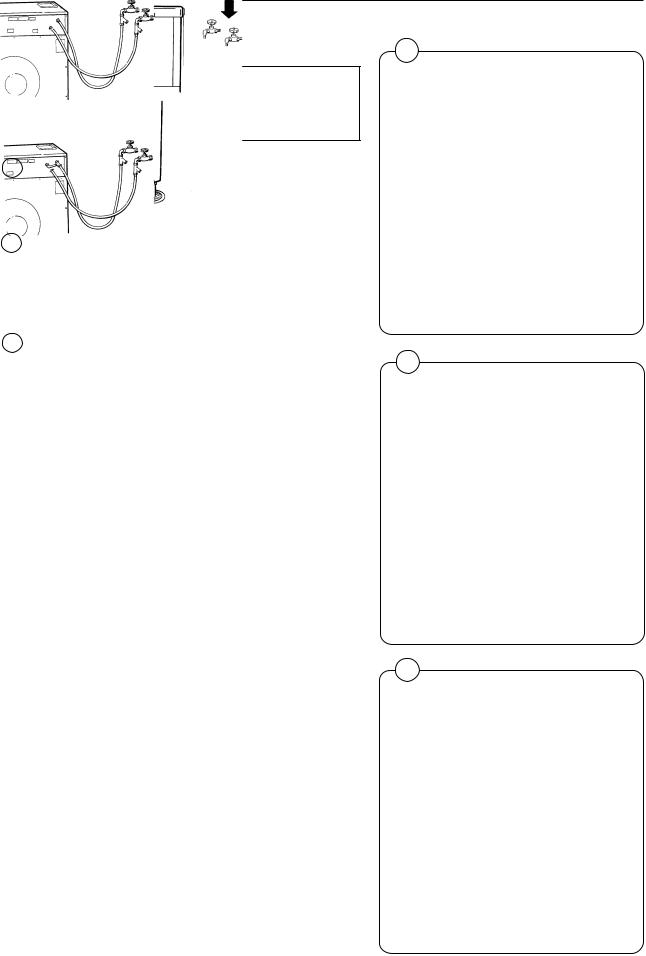

Water connection |

11 |

|

Fig.

11

Fig.

12

Fig.

13

NOTE

All plumbing must conform to national and local plumbing codes.

Incoming water lines do not require non-return or back-suction valves, as the machine is already fitted with a siphon breaker. However, all incoming lines must be fitted with shut-off valves.

•Water inlets are labelled for hot and cold water connection.

•Flush the water system thoroughly and check that the filter at the machine inlet is fitted correctly.

•Connect the machine to the water mains with 3/4" reinforced rubber hosing not to exceed 6 ft in length. Hang the hosing in a large loop.

Do not use rigid piping.

1832

12

FL 125

FL185

1870

13

FL 125

hot water |

cold water |

1846

FL185

hot water cold water hot water

(to detergent supply box)

1844

Installation

Steam connections |

14 |

|

The steam supply to the machine should be fitted with manual shut-off valves and filters to facilitate installation and servicing.

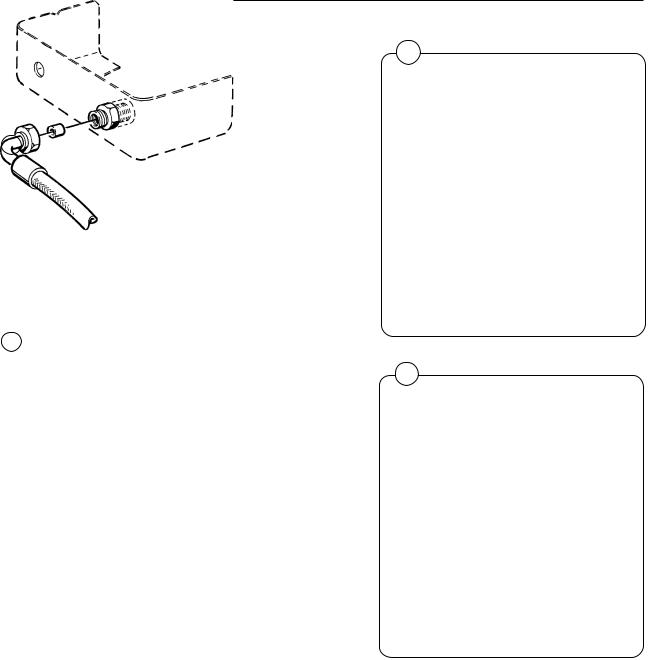

Fig. Fit the filter supplied to the manual cut-off valve.

14The connection hose must be of type ISO/13071983 or equivalent. Connection size at filter: DN 15 (BSP 1/2'').

Steam pressure required:

•minimum: 10 psi (0.5 kp/cm2)

•maximum: 115 psi (8 kp/cm2)

Check there are no sharp angles or bends in the connection hose.

Fig. |

For steam pressures in excess of 85 psi, the |

|

15 |

nozzle supplied should be installed between the |

|

|

stem injector and the steam hose. The nozzle is |

15 |

|

installed inside the steam injector. |

9

0956

2171

10 |

Installation |

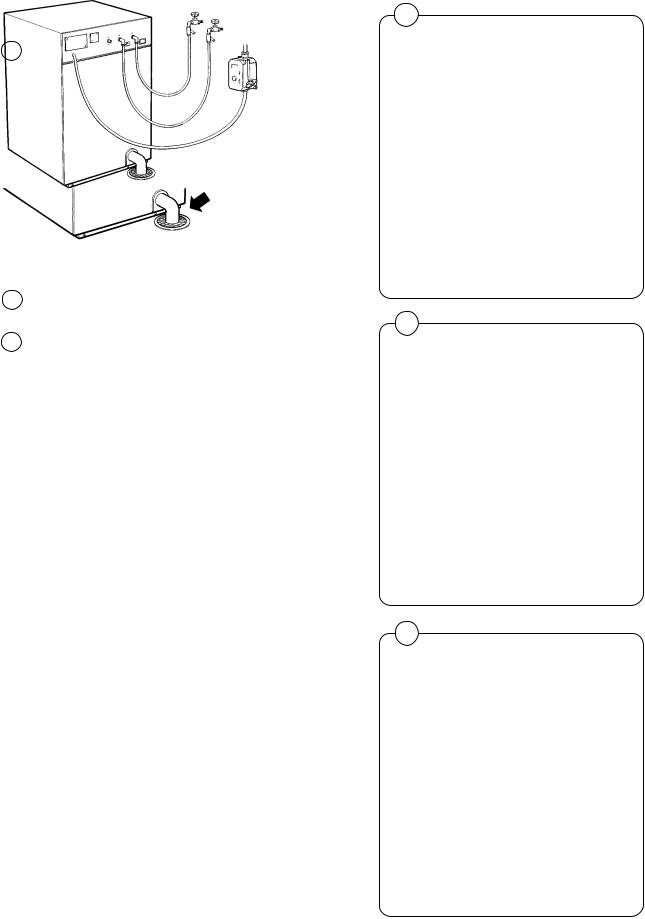

Drain connection

Fig. Connect a 3" (75 mm) flexible hose to the drain

16outlet of the machine.

The drain hose must not have sharp bends and must slope from the machine to assure proper drainage. The outlet must open freely to the main drains.

Do not reduce the size of the drain connection from the machine to the waste line.

Start-up and safety checklist

Before initial start-up of a Wascomat washerextractor, the following safety checks must be performed:

Fig. • Make sure the machine is properly bolted to 17 the floor.

Fig. • Make sure that all electrical and plumbing

18connections have been made in accordance with applicable local codes.

•Use only flexible water fill and drain hoses of the proper length to avoid sags and kinks.

•Make sure the machine is properly grounded electrically.

16

1833

17

1140

18

1869

Installation |

11 |

Connection of external liquid supply |

19 |

Fig.

19

Fig.

20

Fig.

21

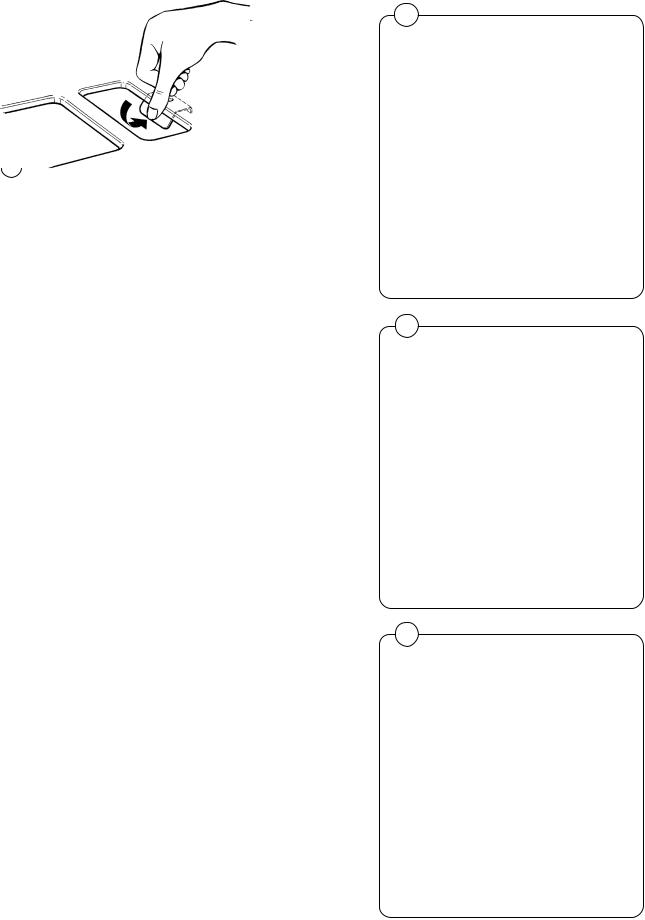

Remove cover and cover support over the soap box.

Bend all the way back the metal plate in compartment 3.

Pull the knobs up and forward.

1. |

Loosen both knobs so that one side of the |

|

|

metal fingers underneath can slide under the |

|

|

top lid of the machine, within the supply box. |

|

2. |

Fit the supply injector into the supply box so |

|

|

that both sides are held securely in places by |

|

|

the metal fingers. |

|

|

|

|

|

Note: |

|

|

If the supply injector does not fit turn it around. |

|

|

You have it in backwards. |

1336 |

|

|

|

20

1334

21

1333

12 |

Installation |

|

|

Fig. |

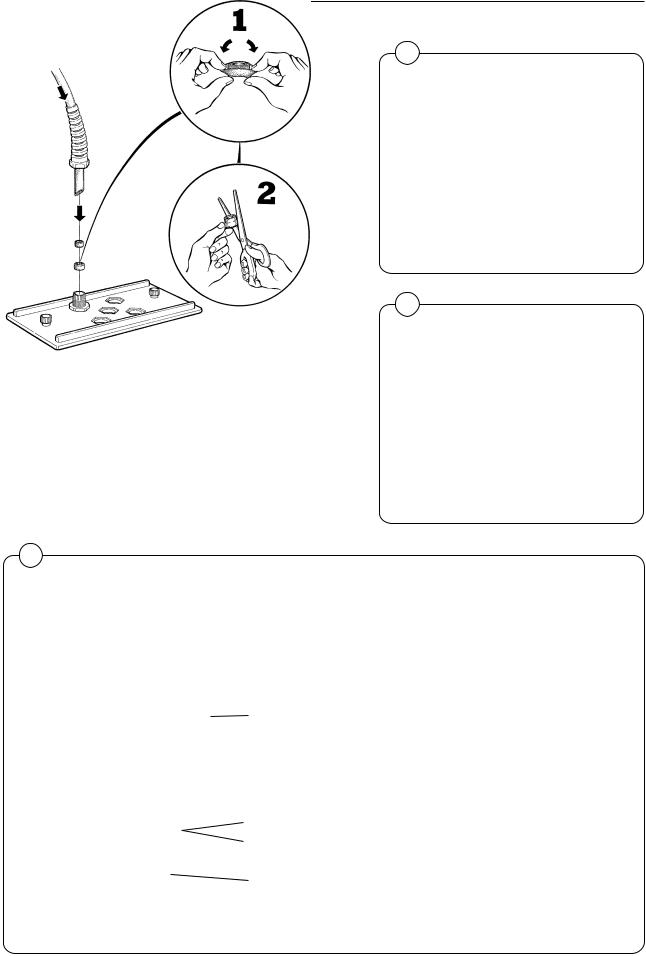

1. Drop the knop into the larger opening in the |

22 |

|

22 |

supply injector lid. |

||

|

2.Tighten securely. Do not overtighten! Do not use pliers or other tools to tighten the knobs!

Fig. 1. Stretch the multi-rubber ring B and select the

23correct size ring which will fit snugly on the chemical tube you are using. Ring A is used for tubes with Ø1/3'' (8 mm).

2.Use scissors or a razor to carefully cut out the proper size rubber ring. Wrap the rubber ring around each tube after threading each tube through the plastic nipple. Run the tube through the compression nut to the bottom of

the compartment. Cut the end of the tube at an

angle. Hand tighten the plastic nipple on to the 23 compression nut.

23

Multi-rubber ring

Plastic nipple

Cut to fit on tube

Rubber |

A |

rings |

B |

Compression |

|

nut |

|

Supply injector

1332

1331

1331

Installation |

13 |

|

|

Electrical connection

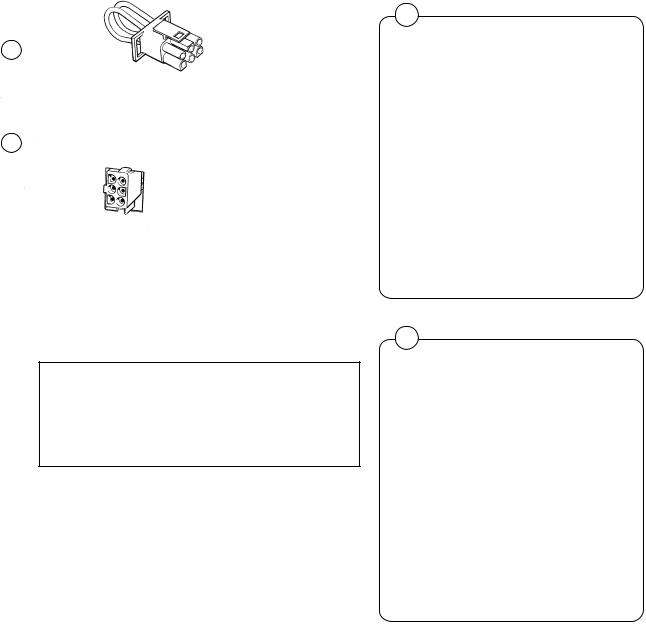

Fig. At the electrical connection of the machine is one

24quick connector. When using external supply, disconnect.

Pump connection

Fig. On the right side of the terminal connection is the

25connection for pumps. Depending on the number of pumps to be connected, they shall be connected from 1-5 and C (common) on resp. connection. The pumps obtain signals from the program card via the connections.

Rib A controls connection 1

Rib F |

–’’– |

2 |

Rib E |

–’’– |

3 |

Rib G |

–’’– |

4 |

Rib I |

–’’– |

5 |

Note!

Remember that it is only a signal which is obtained from the machine to the pumps and not time controlling.

24

1840 B

25

1

2

3

4

5

C

1922

Loading...

Loading...