Page 1

P-2067-WE

SM320gb - rev 02/09

Hydraulic Multi-Disc Brake

H420

Service Manual

Page 2

We, WARNER ELECTRIC EUROPE, 7, rue Champfleur, B.P. 20095, F-49182 St Barthélemy d’Anjou Cedex

declare that the brakes made in our factories from St Barthélemy d’Anjou,

and hereafter designated : H420

are intended to be incorporated in an installation or to be assembled with other machinery with a view to constituting a machine to which

direc tive 98/37/EC.

Drawn up in St Barthélemy d’Anjou, July 2002

E. PRAT, General Managing Director

CONTENTS

1 Technical specification 2

2 Precautions and restrictions on use 2

2.1 Restrictions on use 2

2.2 Precautions in use 2

and safety measures

3 Installation 3

3.1 Transport - storage 3

3.2 Handling 3

3.3 Installation 3

3.4 Manual release 3

4 Maintenance 3

4.1 Maintenance 3

4.2 Spare parts 3

4.3 Dismantling / reassembling 3-4

5 Hydraulic connection 4

5.1 Important recommendations 4

5.2 Hydraulic oils 4

5.3 Connection diagrams 5

6 Appendix 6

7 Troubleshooting 6

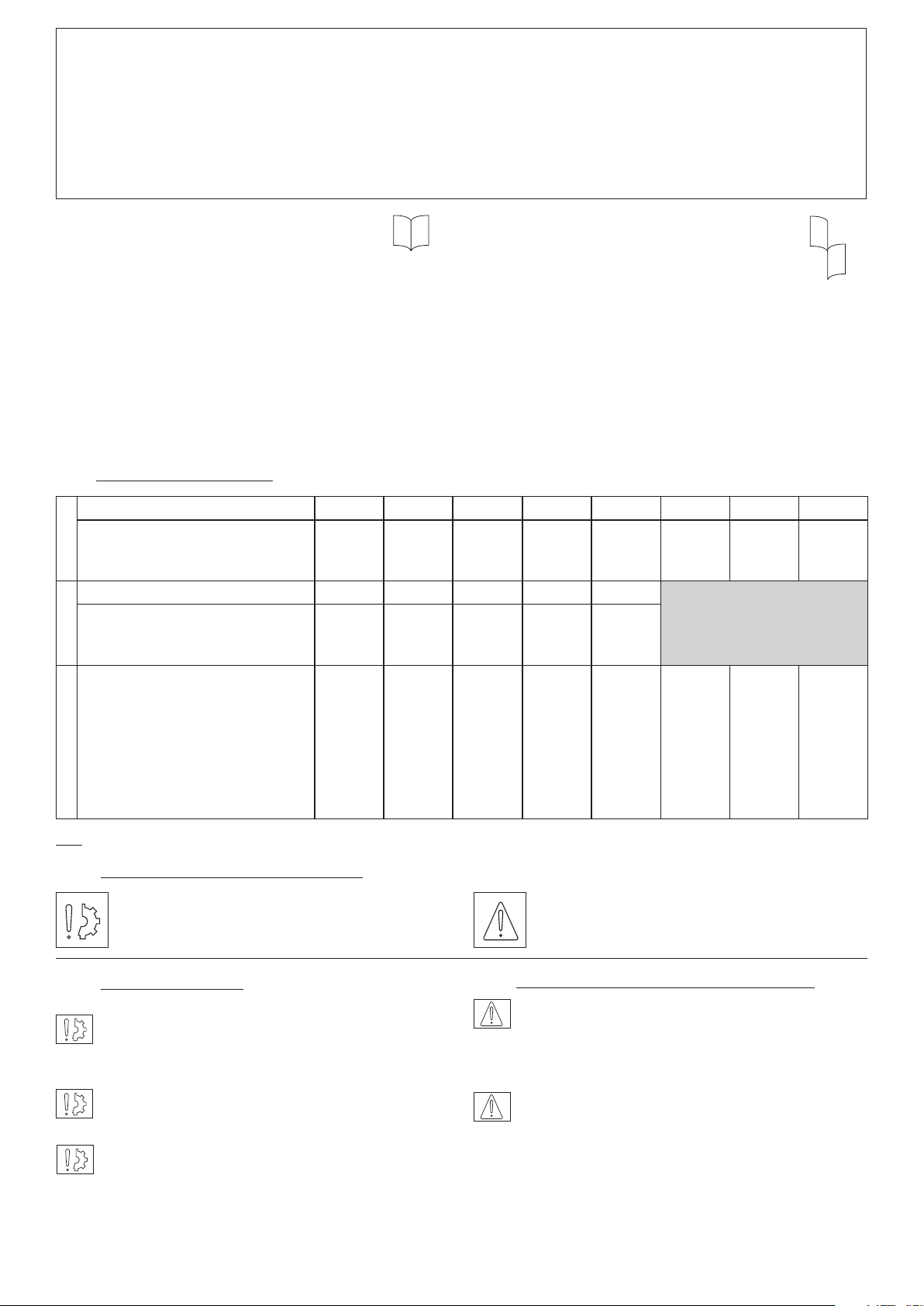

1 Technical specifications

STANDARD Size 90 150 250 550 1000 3200 6400 12800

Max speed min

P min. bar

VAR 00VAR 01

P max. bar

-1

5000

29

320

5000

24

320”

4200

21

320

3500

“23

320

2500

22

320

1700

22

350

1400

35

350

HIGH TORQUE Size 150 220 330 730 1600

Max speed min

P min. bar

P max. bar

Hydraulic connection NF E03-004 Locking screws (909) Tightening torque Nm

Releasing screw Length mm

Oil change, ling and oil level cap -

-1

5000

48

320

RP 1/8”

12 x M8

38

2 x M6

20

2 x M8

5000

36

320

RP 1/8”

12 x M8

38

3 x M6

20

3 x M8

4200

28

320

RP 1/4”

12 x M8

38

3 x M6

25

3 x M8

3500

31

320

RP 1/4”

12 x M10

75

3 x M8

30

3 x M12

2500

36

320

RP 1/4”

12 x M12

130

3 x M8

30

3 x M12

RP 3/8”

12 x M16

325

3 x M10

35

3 x M14

RP 1/2”

12 x M20

637

3 x M16

40

3 x M20

(936, 937, 939)

Weight Kg

6,0

8,2

12,0”

20,0

37,5

119

196

1100

35

350

RP 1/2”

12 x M24

700

6 x M16

80

3 x M20

360

NB: Data for catalogue equipment Table 1

2 Precautions and restrictions on use

Symbol designating an action that

might damage the apparatus

2.1 Restrictions on use

This equipment is designed for the disc stack to run

in oil. Dry operation is possible, but only in a

static application.

2.2 Precautions in use and safety measures

During maintenance, ensure that the mechanism

Symbol designating an action that

might be dangerous to human safety

to be braked by the equipment is at rest and

that there is no risk of accidental start-up.

All intervention have to be made by qualified

Exceeding the maximum rotation speed stated in the

catalogue invalidates the warranty.

This equipment is designed to run with the shaft

horizontal.

personnel, owning this manual.

Any modification made to the brake without

the express authorisation of a representative of

Warner Electric, in the same way than any use

out of the contrac tual specifications accepted by

“Warner Electric”, will result in the warranty being

invalidated and Warner Electric will no longer be

liable in any way with regard to conformity.

2 Warner Electric Europe • +33 (0)2 41 21 24 24 P-2067-WE • 2/13

Page 3

3 Installation

In the case of operation in oil only:

3.1 Transport / storage

The brakes are supplied in packaging

guaranteeing a preservation period of 6 months

with land or air transport, or after transport by

ship to neighbouring continents (with out crossing

the tropics).

3.2 Handling

The brake is supplied assembled, the hub (515)

pre centred in place.

Be careful not to release the disk stack before

assembly.

Avoid any impacts on the equipment so as not to

alter their performance.

3.3 Installation

The hub (515) is normally supplied to H7

tolerances for bore and P9 for the width of the

keyway (in accordance with NF E 22-175 / DIN

6885 / BS 4235 / ISO R773).

• Locate the hub on the shaft (after adjusting the

key) and fix it axially

NB: For VAR00 sizes 90 / 150 / 250 and VAR01

sizes 150 / 220 / 330, the hub (515) should be

fitted in the right direction: the largest diameter

towards the shoulder of the shaft.

• Slide the equipment into position in the

centring provided, having first directed the

supply to the top position of the vertical axis,

while presenting the hollows of the steel or

sintered inner disc (308) or (309) opposite to

the hub teeth (515)

• Pivot the assembly until the fixing holes

coincide with the bolt ways in the brake.

• Fix the brake with the bolts provided for the

purpose

Do not forget to tighten the locking screws (909)

to the torque (table 1) and to secure them with a

Loctite 243 type or equivalent product.

• Connect the hydraulics (see table 1)

• Remove the filling cap (937) and oil level cap

(939) (the lowest of the plugs located at the

back). Pour in the oil (see chap. 5 for the

choice) up to the level required. Replace the

caps

3.4 Manual Release

Brakes in the H420 range can be released

manually so as to put the brake out of operation,

in the event of a fault in the hydraulic circuit

or for maintenance. To do this, the caps (939)

must be removed so as to access the tapped

holes provided in the piston (402). Fit a set of

bolts (given in table 1) and screw them right in to

compress the springs.

4 Maintenance

4.1 Maintenance

There is practically no wear on the discs of units

in the H420 range if the running conditions are

complied with (operation in oil, oil temperature,

rotation speed, etc.). Disc wear is automatically

compensated for, up to the wear limit, by the

movement of the piston. It is however necessary

to:

• Regularly check the piston seal (402) and in the

event of a leak or after 5 years use, change the

seals (703, 704) and back-up rings (722, 723)

In the case of operation in oil only:

• Change the oil after 40 h running from first use,

then every year of normal running.

4.2 Spare parts

For all orders of spare parts, state the size of the

equipment with its code number, the part number

(see Appendix) and the quantity required.

4.3 Dismantling / reassembling

During the maintenance period, ensure that the

mechanism to be braked by the equipment is at

rest and that there is no risk of accidental start-

up. Also ensure that the hydraulic supply is shut

off.

Warner Electric Europe • +33 (0)2 41 21 24 24 P-2067-WE • 2/13 3

Page 4

After removing the equipment from the shaft,

proceed as follows:

• Where the equipment is running in oil, drain it

• Remove the manual braking screws and

replace the caps (939)

• Refit the brake as described in paragraph 3.3

• Manually release the equipment’s brake

• Remove the pre-assembly screws and remove

the closing plate (359) with the piston (402) and

springs (740)

Changing the disk stack:

• Remove the flange (357)

• Remove the worn disk stack

• Put the new set of disks in place, starting with

an outer disc (303 or 304), followed by an inner

disc (308 or 309) and ending with an outer disc

• Do not forget to seal fhe faces of the flange

(357) and of the closing plate (359), with an an

anareobic material (Loctite 549, for exemple)

Changing the seals:

• Do not forget to replace the back-up rings

(722)and (723) with the seals (703) and (704)

situated on the pressure chamber side

• Before reassembling, lightly oil slip surfaces

with control oil

• Reassemble the closing plate (359) with the

piston (402)

• Equipment of sizes 3200 to 12800 contain

seals (706) fitted on the flange (357) and

closing plate (359): check their condition and

change if necessary

Do not forget to tighten the fixing bolts to torque

(see Table 1) and to secure them with a Loctite

243 or equivalent type product.

5.1 Hydraulic connection 5-1Important

recommendations

Ensure compliance with the operating

pressure so as to get the equipment’s nominal

performance.

Ensure that the maximum pressure is not

exceeded (see table 1).

We recommend filtration of the control of about

10 microns so as to guarantee trouble-free run

ning and a correct life of the hydraulic

components.

The disc lubricating oil should not exceed 80°C in

operation.

5.2 Hydraulic Oils

The types of oil to use for lubricating the discs

should ful fil the following criteria:

• Good resistance to oxidation

• No additives modifying friction

• No additives that could corrode the bronze

friction surfaces (1a or 1b NF M07-015)

• Compatible with the materials used for the

hydraulic seals

Do not damage the seals during reassembly.

• Replace the fixing bolts in the closing plate

(359)

• Use the hub (515) to align the teeth of the

interior disc stack.

• High viscosity rating (>80)

The oils listed below meet these characteristics,

this list is not exhaustive and can be added to

by other oils. The viscosity of the oil to choose

varies according to temperature and running

speed (measured on the ext. dia. of the cylinder).

Mineraloil ATF

Viscosity

Running Speed

BP

ESSO

MOBIL

SHELL

ELF

4 Warner Electric Europe • +33 (0)2 41 21 24 24 P-2067-WE • 2/13

ISO VG 22

> 12 m/s

Nuto H22

DTE 22

Tellus 22

ISO VG 32

> 12 m/s

Energol HLP-D32

Nuto h 32

DTE Oil Light

Tellus 32

Polytelis 32

ISO VG 46

> 12 m/s > 12 m/s

Energol HLP-D46

Nuto H 46

Autran MBX

AT Dexron II

DTE Oil Medium

Tellus 46

Donax TM Elfmatic

Polytelis 46

ATF 220

G2”

Page 5

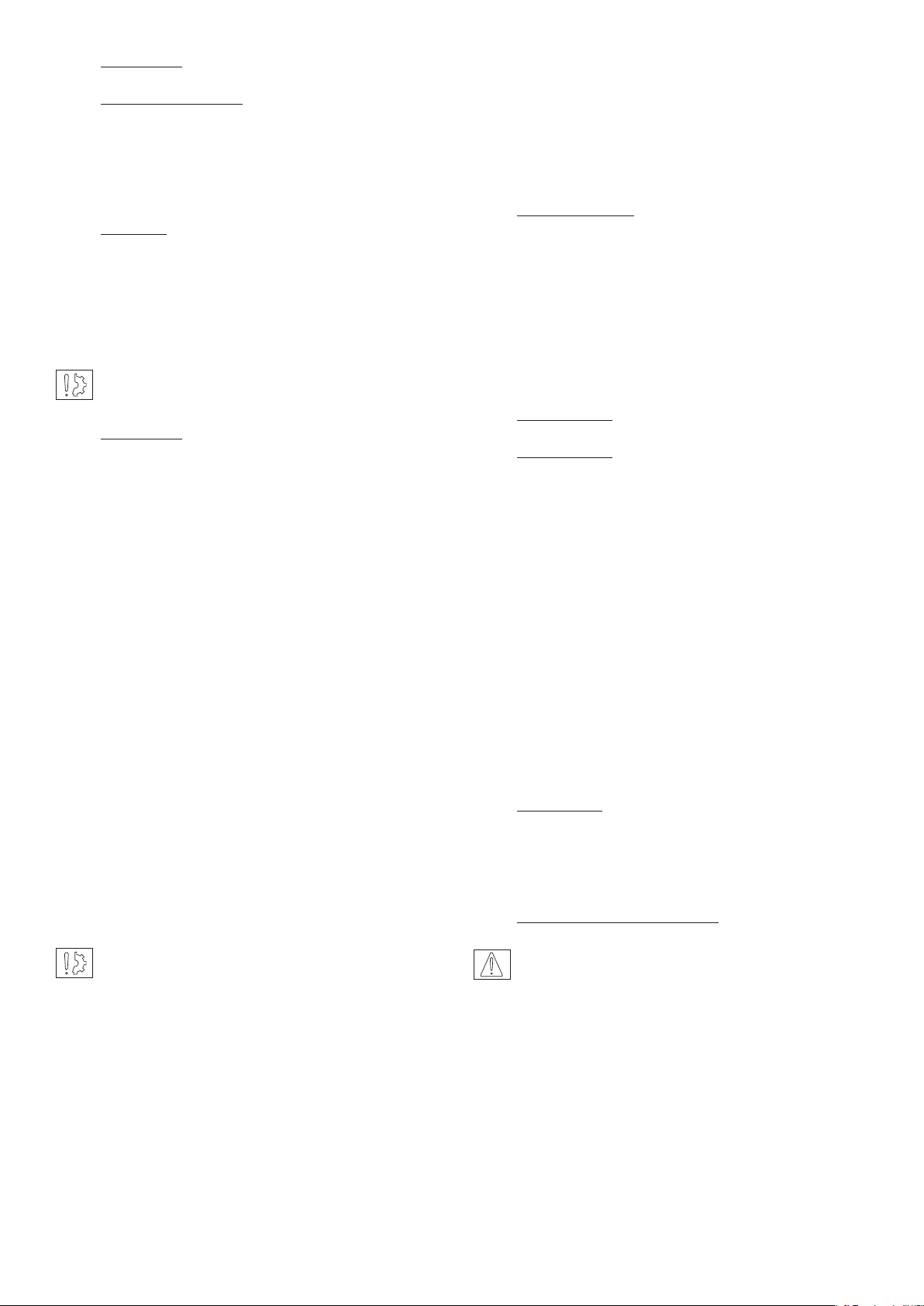

Figure 1

Figure 1: Basic circuit for multidisc brake with hydraulic release

a: Reservoir

g

f

b: Pump

c: Filter

d

e

d: Pressure gauge

e: Pressure limiter

c

f: Distributor

g: Brake

The brake is lubricated by splashed non renewed oil.

M

b

Figure 2

a

Figure 2: Hydraulic release, multidisc brake assembly in

open circuit with hydraulic motor

a: Reservoir

f

g

d

h

b: Pump

c: Filter

d: Pressure gauge

e: Pressure limiter

f: Distributor

c

e

g: Brake

h: Flow restricter with non-return valve

The distributor in central position causes the oil to return to the

reservoir and the brake to close. Going to one of the two other

M

b

a

positions causes the brake to open and the hydraulic motor to

rotate, in one or other direction, according to the position of the

slider.

p

n

g

f

Figure 3

d

e

Figure 3: Hydraulic release, multidisc brake assembly in

closed circuit with hydraulic motor

a: Reservoir g: Brake

b: Pump h: Pump

c: Filter n: Distributor

d: Pressure gauge o: Calibrated non-return valve

e: Pressure limiter p: Hydraulic motor

M

o

h

c

f: Distributor

The distributor for the hydraulic motor and brake are controlled

simultaneously causing the brake to release and the motor to rotate.

M

b

Warner Electric Europe • +33 (0)2 41 21 24 24 P-2067-WE • 2/13 5

a

Page 6

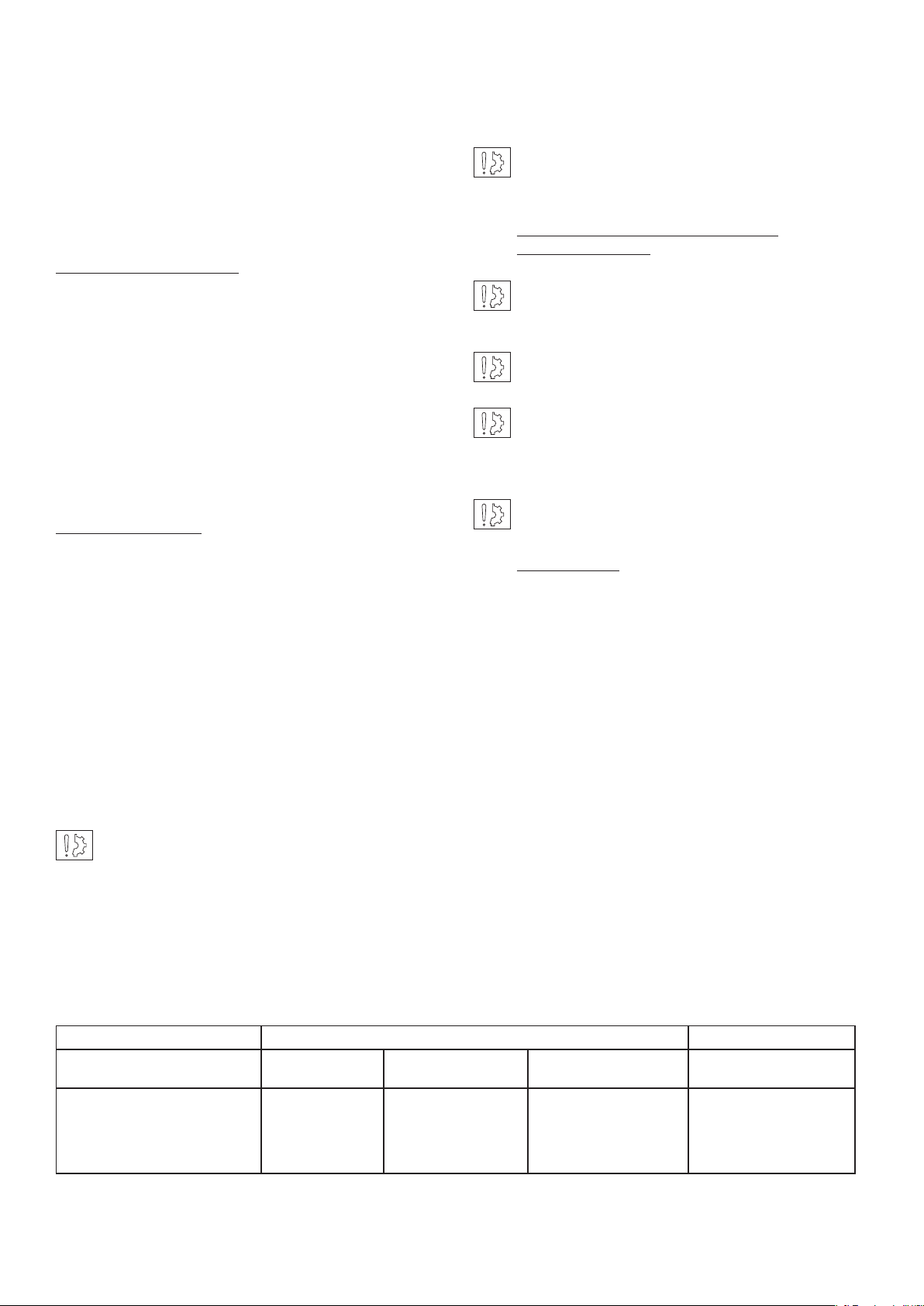

6 Appendix

Size 90 to 12800 : VAR00

Size 150 to 1600 : VAR01

308 or 309

723

357

515

303

or

304

7 Troubleshooting

7229 09

09

401

740

402

939

705

359704703936 or 937

NO. Description

303

304

308

309

357

359

401

402

515

703

704

705

722

723

740

909

936

937

939

Steel outer disc

Stintered outer disc

Steel inner disc

Stintered inner disc

Flange

Closing plate

Cylinder

Piston

Hub

Cylinder Quad ring seal

Piston Quad ring seal

Flat ring

Back up ring piston

Back up ring cylinder

Spring

Locking screw

oil chang cap

Filling cap

Oil level cap

Troubleshooting

Problem Possible Causes Remedies

The brake does

not brake

The brake does

not release

• Brake under hydraulic pressure

• Manual release screw in position

• Disc worn or damaged

• Piston seals worn or damaged

• No pressure

• No sufcient pressure

• Check the circuit control

• Remove the manual release screws

• Change the disc

• Change the seals

• Check the hydraulic circuit and control

• Increase the pressure

6 Warner Electric Europe • +33 (0)2 41 21 24 24 P-2067-WE • 2/13

Page 7

NOTES

Warner Electric Europe • +33 (0)2 41 21 24 24 P-2067-WE • 2/13 7

Page 8

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any product manufactured and

sold by it which proves to be defective in material or workmanship within a period of one (1) year from the date of original

purchase for consumer, commercial or industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without Warner Electric LLC’s

prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation charges prepaid, to

the appropriate Warner Electric LLC factory. Additional warranty information may be obtained by writing the Customer

Satisfaction Department, Warner Electric LLC, 449 Gardner Street, South Beloit, Illinois 61080, or by calling 815-389-

3771.

A purchase receipt or other proof of original purchase will be required before warranty service is rendered. If found

defective under the terms of this warranty, repair or replacement will be made, without charge, together with a refund for

transportation costs. If found not to be defective, you will be notified and, with your consent, the item will be repaired or

replaced and returned to you at your expense.

This warranty covers normal use and does not cover damage or defect which results from alteration, accident, neglect, or

improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation may not apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the defective product and

in no event shall Warner Electric LLC be liable for consequential, indirect, or incidental damages of any kind incurred by

reason of the manufacture, sale or use of any defective product. Warner Electric LLC neither assumes nor authorizes any

other person to give any other warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH THE CONSUMER MAY

HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL CONSUMER PURCHASE. WITH

RESPECT TO COMMERCIAL AND INDUSTRIAL USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU

OF AND EXCLUDES ALL OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you. This warranty gives you specific legal rights and you may also have other rights which

vary from state to state.

Changes in Dimensions and Specications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without notice. Weights do not

include weight of boxing for shipment. Certified prints will be furnished without charge on request to Warner Electric.

Warner Electric Europe

7 rue Champfleur, B.P. 20095, St Barthelemy d’Anjou - France

+33 (0)2 41 21 24 24 • Fax: +33 (0)2 41 21 24 70

www.warnerelectric.com

Printed in USAP-2067-WE • 2/13

Loading...

Loading...