Page 1

Garden Tractor Clutch

P-1097-6

819-0458

Troubleshooting and

Installation Guide

Page 2

Contents

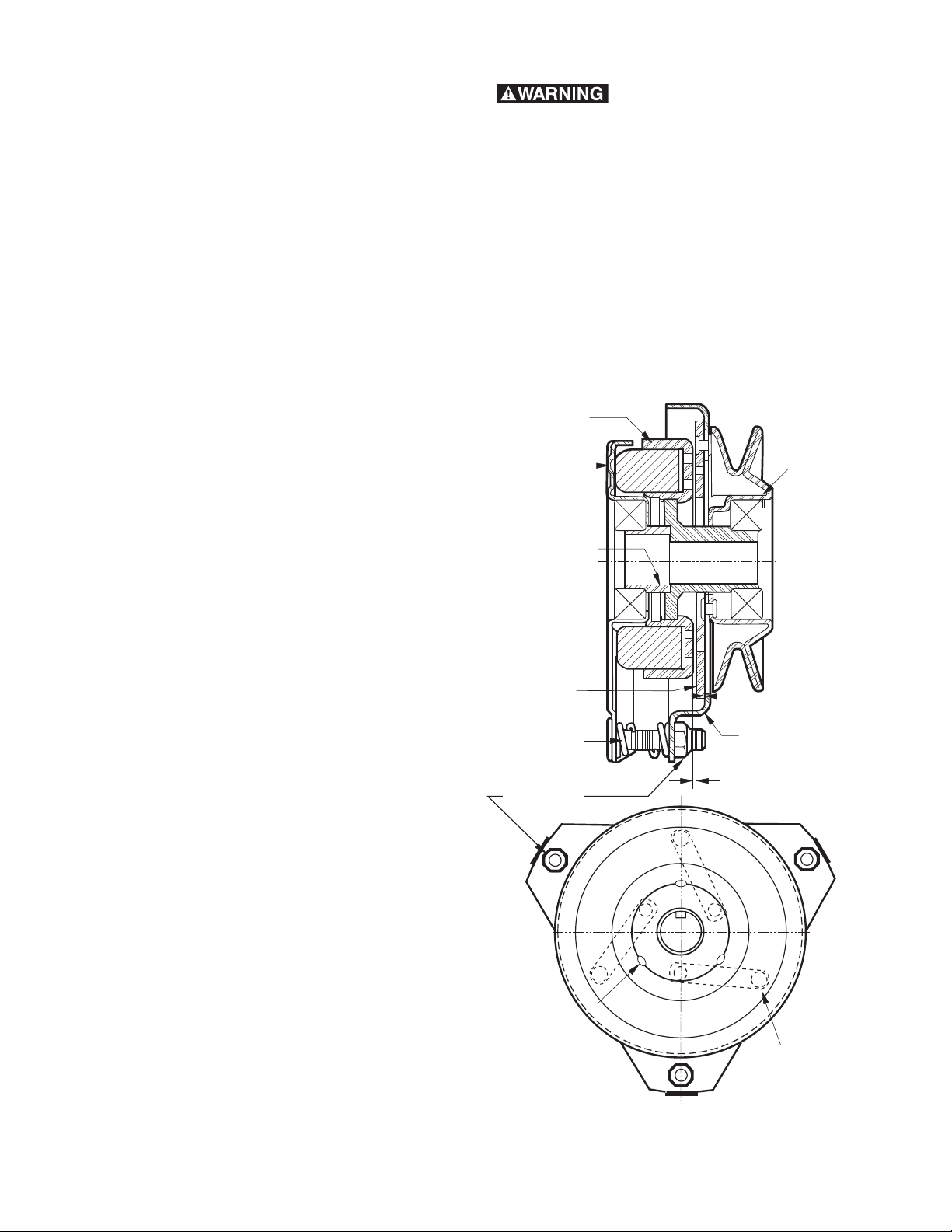

Coil

Springs

Field

Rotor

Top V iew

from Pulley

Armature

Assembly

Sleeve

Armature

Face

Armature/Brake

Plate Contact

Surfaces

Brake

Plate

Airgap

Preset at

Factory

Airgap

Adjustment

Nuts

Armature/Spring

Rivet joints are

located in line with

the bearing stakes

Three, equally

spaced, bearing

staking punch

marks

Failure to follow these

instructions may result in product damage,

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Troubleshooting Checklist . . . . . . . . . . . . . . . . 3

Electrical Evaluation. . . . . . . . . . . . . . . . . . . . . 4

Airgap Adjustment . . . . . . . . . . . . . . . . . . . . . . 6

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Antirotation . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Antirotation Requirements . . . . . . . . . . . . . . . 13

Warranty . . . . . . . . . . . . . . . . . . . . . . Back Page

equipment damage, and serious or fatal

injury to personnel.

Bearing Mounted Electric Clutch/Brake Assemblies and Operation

Components

An electric clutch/brake or clutch consists of

three primary components:

1. Field Assembly

The clutch's "power" source contains the

coil which generates magnetic force. Most

common applications require a 12 volt DC

coil, although other voltages are available.

2. Rotor Assembly

Generally, the input of the clutch. Includes a

keyed hub which mates with the keyway in

the drive shaft. The rotor transmits torque

from the drive shaft to the output, or

armature assembly.

3. Armature Assembly

Generally, the output of the clutch. Also

contains the mechanical brake in a

clutch/brake assembly. The armature

transmits torque from the rotor to the

driven load.

The sleeve is a secondary component. This

sleeve serves as a spacer between the rotor

and the field assembly, and is also a support

for the field assembly bearing.

Warner Electric • 800-825-9050 P-1097-6 • 819-0458

2

Bearing Mounted Clutch/Brake Assembly

Page 3

Troubleshooting PTO Clutches and Clutch/Brakes

A. Clutch Symptom: Clutch will not Engage

Problem Possible Causes

Low voltage supply • Defective battery

• Faulty charging system

• Bad wiring or connectors

Rotor/armature airgap too large • Rotor/armature wear, readjust airgap

Zero voltage • Broken lead wire

• Open clutch coil, check coil resistance

• Faulty switch

• Blown Fuse

B. Clutch Symptom: Clutch Slips

Problem Possible Causes

Low voltage supply • Defective battery

• Faulty charging system

• Bad wiring or connectors

Overloaded clutch • Improperly sized clutch

Contaminated friction surfaces • Engine oil leak on clutch

Clutch loose on shaft • Loose mounting bolt

• Mounting bolt too long and bottoms

in shaft before clamping clutch

• Mounting washer too thin and deforms

when bolt is tightened

Clutch not mounted square • Mounting shoulder not square

• Clutch integral key hitting end of keyway

• Chamfer too small on spacer or ground

drive pulley

Broken rivet joints • Loose mounting, replace clutch

C. Clutch Symptom: Noisy Clutch

Problem Possible Causes

Failed bearing • Loose mounting

• Operating Temperature above 250° F

• Bearing Preloaded Axially

Adapter plate rattles against • Some noise is normal: to reduce noise

antiorotation pin level, isolate antirotation pin from

frame with rubber

Warner Electric • 800-825-9050 P-1097-6 • 819-0458

3

Page 4

A

C

DB

Meter

Meter

Instructions for Evaluating VX Series Clutches

Windows

Bearing Mounted Field Clutches (self-contained

clutch/brake package)

Clutch to be at room temperature - 70° F - for

this check.

Step 1. Measure Clutch Coil resistance

1. Turn engine and PTO switch off.

2. Disconnect clutch wire connection.

3. Select meter to check ohms.

4. Connect meter lead wires to the wires in the

clutch connector. (Figure 1)

5. If meter reads below 2.40 ohms or above

2.90 ohms, then the clutch has failed and

needs to be replaced.

Figure 1

If the meter reads between 2.40 and 2.90 ohms,

proceed to step 2.

Step 2. Measure Clutch Current Draw - 12

Volt System

1. Turn engine off.

2. Disconnect clutch wire connection.

3. Select meter to check amps (10 amp scale).

4. Connect one meter lead wire to one wire in

clutch connector at A. (Figure 2)

5. Connect the other meter lead wire to the

corresponding wire in the mating connector

at C. (Figure 2)

6. Connect a short wire from D to B in both

connectors. (Figure 2)

Figure 2

Figure 3

7. Turn PTO switch on.

Warner Electric • 800-825-9050 P-1097-6 • 819-0458

4

Page 5

8. If meter reads below 4.0 amps, the problem

would be in the electrical system leading to

the clutch (battery, relay, switch, etc.).

Burnishing Procedure for Electric

Clutch/Brake to be performed with mower

deck attached.

If the meter reads 4.0 amps or above, proceed

to Step 3.

Step 3. Check Air Gap Setting

1. Turn engine and PTO switch off.

2. Locate the three "windows" or "notches"

where the air gap is checked. (Figure 3)

3. With feeler gauge check gap at all three

locations (minimum of two).

4. Factory air gap setting is .005" - .023".

5. If gap doesn't fall between .005" - .023" then

reset using a .012" feeler gauge.

Changing the air gap is achieved by tightening

and/or loosening the three nuts.

If you find after completing Steps 1, 2 and 3

that:

1. Run at 50% throttle.

2. Engage and disengage the clutch 5 times.

(10 seconds on/10 seconds off).

3. Increase to 75% throttle.

4. Engage and disengage the clutch 5 times.

(10 seconds on/10 seconds off).

Note: All values taken at room temperature.

Voltage at 12 VDC. As temperature increases,

nresistance increases, and current decreases.

1. The resistance falls between 2.40 and 2.90.

2. The amp draw is 4.0 or above.

3. The air gap is between .005" and .023" or

reset to .012". Then the electric clutch is

within factory specifications and is not the

source of the problem.

Warner Electric • 800-825-9050 P-1097-6 • 819-0458

5

Page 6

Airgap Adjustment

Top View

from Pulley

Armature/Spring

Rivet joints are located

on line with the bearing

stakes.

Airgap

Adjustment

Nuts

Three, equally

spaced, bearing

staking punch marks.

Windows

Brakeplate

Window

.012" Feeler

Gauge (3)

Required

Adjustment

Nut

G. Procedure for Airgapping Bearing

Mounted PTO Clutch/Brakes

Airgaps are preset at the factory and do NOT

require initial adjustment.

Bench setting:

1. Remove clutch from tractor.

2 Orient the clutch so it is viewed from the field

side.

3. Locate the three rivet joints in the armature

assembly which fasten the leaf springs to the

armature.

Figure 17

Location of Windows — Three Per Brakeplate

7. Insert a .012" feeler gauge through each

window, being careful to position the feeler

gauge between the rotor face and the

armature face.

Positioning Rivet Joints for Airgap Adjustment

4. Rotate the pulley until these three rivet joints

5. Do not disturb the orientation of the armature

6. Locate the three windows in the brakeplate,

Warner Electric • 800-825-9050 P-1097-6 • 819-0458

6

Figure 16

are located midway along the edge of the

triangular adapter, or halfway between each

stud. This prevents measuring the airgap over

a rivet joint.

assembly with respect to the field.

one at each stud.

Figure 18

Setting the Airgap

8. With all three feeler gauges in place, begin

to alternately tighten each nut an equal

amount.

9. Tighten each nut until the feeler gauges

begin to feel snug. Each gauge should

require an equal amount of force for

insertion and extraction.

10. Remove the feeler gauges. Turn the rotor

assembly to check for rotor/armature drag.

The rotor should turn freely.

Page 7

11. Due to dimensional variations, the airgap

between the rotor and armature may vary

on a clutch from .023/.005", even though

the gap at the three windows was set at

.012". This is an acceptable condition.

12. Using feeler gauges, check the airgap

through the three windows. If the airgap

does not fall between .023/.005", repeat the

above procedure. Remember: Never check

the airgap directly over a rivet joint.

Option 1: Setting on the engine crankshaft.

13. To help set the airgap, mount the

unairgapped unit directly to the engine

crankshaft, securing it to the shaft with the

appropriate bolt and washer with a

minimum thickness of .250". When going

from an unclamped state to a clamped

state, the clearance between the rotor and

armature is reduced about .002". A .012"

feeler gauge should still be used in the

clamped state. If a 3/8" diameter bolt is

used, tightening torque on the bolt should

be 340-45 lb.ft. Grade 8 bolt. If a 7/16"

diameter bolt is used, tightening torque on

this bolt should be 50-55 lb.ft. Grade 5 or 8

bolt.

14. As an alternative to mounting directly to the

crankshaft in setting the gap, an assembly

fixture consisting of a stub shaft with a

shoulder can also be used. This stub shaft

should duplicate the crankshaft dimensions.

Secure the clutch to this shaft as noted

above in Step 13.

Note: Care must be exercised when setting

the airgap with the clutch secured to the

shaft, as it is difficult to detect rotor/armature

drag when the engine is running.

Warner Electric • 800-825-9050 P-1097-6 • 819-0458

7

Page 8

Airgap Adjustment

Top View

from Pulley

Armature/Spring

Rivet joints are located

on line with the bearing

stakes.

Airgap

Adjustment

Nuts

Three, equally

spaced, bearing

staking punch marks.

Windows

Brakeplate

Window

.012" Feeler

Gauge (3)

Required

Adjustment

Nut

Locating the Rivet Joints

Warner Electric • 800-825-9050 P-1097-6 • 819-0458

8

Locating the Windows

Inserting the Feeler Gauges

Page 9

Crankshaft

Ground drive pulley or spacer

must be chamfered to clear this

radius on the crankshaft shoulder.

1.0"

Minimum shaft

engagement

1.340 Min Diameter

x .250 Min Thick

Washer

Ground

drive

pulley

Engine Face

Crankshaft

Shoulder

Note 2

Note 2

Failure to torque bolt

to requirements will

degrade clamping and

can allow the clutch to

separate from the

shaft, causing risk of

personal injury.

Thread size Torque required N-m

3/8-24" UNF* 40-45 lb.ft. 54-61

7/16-20" UNF** 50-55 lb.ft. 67-75

M 10 X 1.50 55-60 N-m 55-60

Note: All values are for dry (unlubricated) plated bolts,

please consult fastener manufacturer if any type of locking

element (thread lock compound, patch etc.) is to be used.

* 3/8 -24 UNF Grade 5 bolt is unacceptable

** 7/16-20 UNF Grade 5 or 8 bolt is acceptable

Mounting the Clutch/Brake

NOTE:

1. Proper bolt torque is critical.

2. Always bottom the clutch against a flat surface; never against a radius.

Warner Electric • 800-825-9050 P-1097-6 • 819-0458

9

Page 10

Antirotation Brackets

Suggested Configurations

(Figure 11)

1/4" x 5/8" Bent Flat

Steel Field Restraint

(Figure 13)

1/4" x 3/4" Rubber Stop

Field Restraint

(Figure 12)

5/16" Diameter Bent Steel

Rod Field Restraint

Wheel clearance

between brake/

clutch and steel

restraint 1/16”

required here.

(Figure 14)

1/8" x 3/4" Bent Flat

Steel Restraint

Warner Electric • 800-825-9050 P-1097-6 • 819-0458

10

Page 11

Antirotation Requirements

Axial motion parallel

to the shaft

must not be

restricted.

Field Bearing

Warning:

If axial motion

is restricted, this

bearing will be

improperly loaded

and may be subject

to failure.

Crankshaft

Centerline

Rotational Motion about the

centerline of the shaft must

be restricted, to prevent

tearing the lead wires out,

but not held rigidly.

Crankshaft

Centerline

Field restraint

slot

Do Not Restict the Field Assembly

Some movement is required

to prevent field bearing failure.

Warner Electric • 800-825-9050 P-1097-6 • 819-0458

11

Page 12

Warner Electric LLC

31 Industrial Park Road

815-389-3771

• Fax: 815-389-2582

• New Hartford, CT 06057

www.warnerelectric.com

P-1097-6 819-0458 8/11 Printed in USA

Loading...

Loading...