Page 1

FM Series Foot Mounted Load Cells

AC10 Measuring System

A30 Single Range Tensioncells

B30 Single Range Tensioncells

C30 Single Range tensioncells

P-2012

Installation Instructions

Page 2

Contents

FM Series Foot Mounted Load Cells. . . . . . . . 3

Specifications . . . . . . . . . . . . . . . . . . . . . . . 4

Wiring Hookup . . . . . . . . . . . . . . . . . . . . . . 5

System Example. . . . . . . . . . . . . . . . . . . . . 5

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 6

AC10 Measuring System. . . . . . . . . . . . . . . . . 7

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . 8

System Overview . . . . . . . . . . . . . . . . . . . . 9

AC10 Tensioncells. . . . . . . . . . . . . . . . . . . 10

AC10 Electronics . . . . . . . . . . . . . . . . . . . 11

AC10 Specifciations . . . . . . . . . . . . . . . . . 12

Installation. . . . . . . . . . . . . . . . . . . . . . . . . 14

Pre-Installation . . . . . . . . . . . . . . . . . . . . . 14

Mechanical Installation . . . . . . . . . . . . . . . 14

Electrical Installation. . . . . . . . . . . . . . . . . 16

Electrical Connections . . . . . . . . . . . . . . . 16

Initial Electrical Checks. . . . . . . . . . . . . . . 18

AC10 Set up Procedure . . . . . . . . . . . . . . 19

Programmable Treshold Relay . . . . . . . . . 21

Reset Tare to Zero . . . . . . . . . . . . . . . . . . 21

Troubleshooting . . . . . . . . . . . . . . . . . . . . 22

Dimension Drawings. . . . . . . . . . . . . . . . . 24

AC10 Tensioncells. . . . . . . . . . . . . . . . . . . 24

Model Number Designation . . . . . . . . . . . 24

PSAC10. . . . . . . . . . . . . . . . . . . . . . . . . . . 24

C30 Single Range Tensioncells . . . . . . . . . . . 49

General Information . . . . . . . . . . . . . . . . . 50

Installation and Operation. . . . . . . . . . . . . 54

Adjustments . . . . . . . . . . . . . . . . . . . . . . . 56

Troubleshooting . . . . . . . . . . . . . . . . . . . . 56

Recalibration. . . . . . . . . . . . . . . . . . . . . . . 57

Dimension Drawing. . . . . . . . . . . . . . . . . . 59

Warranty. . . . . . . . . . . . . . . . . . . . . . Back Page

Failure to follow these instructions may result in product damage, equipment damage, and serious or fatal injury to

personnel.

A30 Single Range Tensioncells . . . . . . . . . . . 27

General Information . . . . . . . . . . . . . . . . . 28

Installation and Operation. . . . . . . . . . . . . 31

Adjustments . . . . . . . . . . . . . . . . . . . . . . . 33

Troubleshooting . . . . . . . . . . . . . . . . . . . . 34

Recalibration. . . . . . . . . . . . . . . . . . . . . . . 35

Dimension Drawing. . . . . . . . . . . . . . . . . . 36

B30 Single Range Tensioncells . . . . . . . . . . . 37

General Information . . . . . . . . . . . . . . . . . 38

Installation and Operation. . . . . . . . . . . . . 42

Adjustments . . . . . . . . . . . . . . . . . . . . . . . 43

Troubleshooting . . . . . . . . . . . . . . . . . . . . 44

Recalibration. . . . . . . . . . . . . . . . . . . . . . . 45

Dimension Drawing. . . . . . . . . . . . . . . . . . 47

Warner Electric • 800-825-9050 P-2012

2

Page 3

P-2012-1

819-0401

FM Series Foot Mounted Load Cells

Warner Electric • 800-825-9050 P-2012-1

3

Page 4

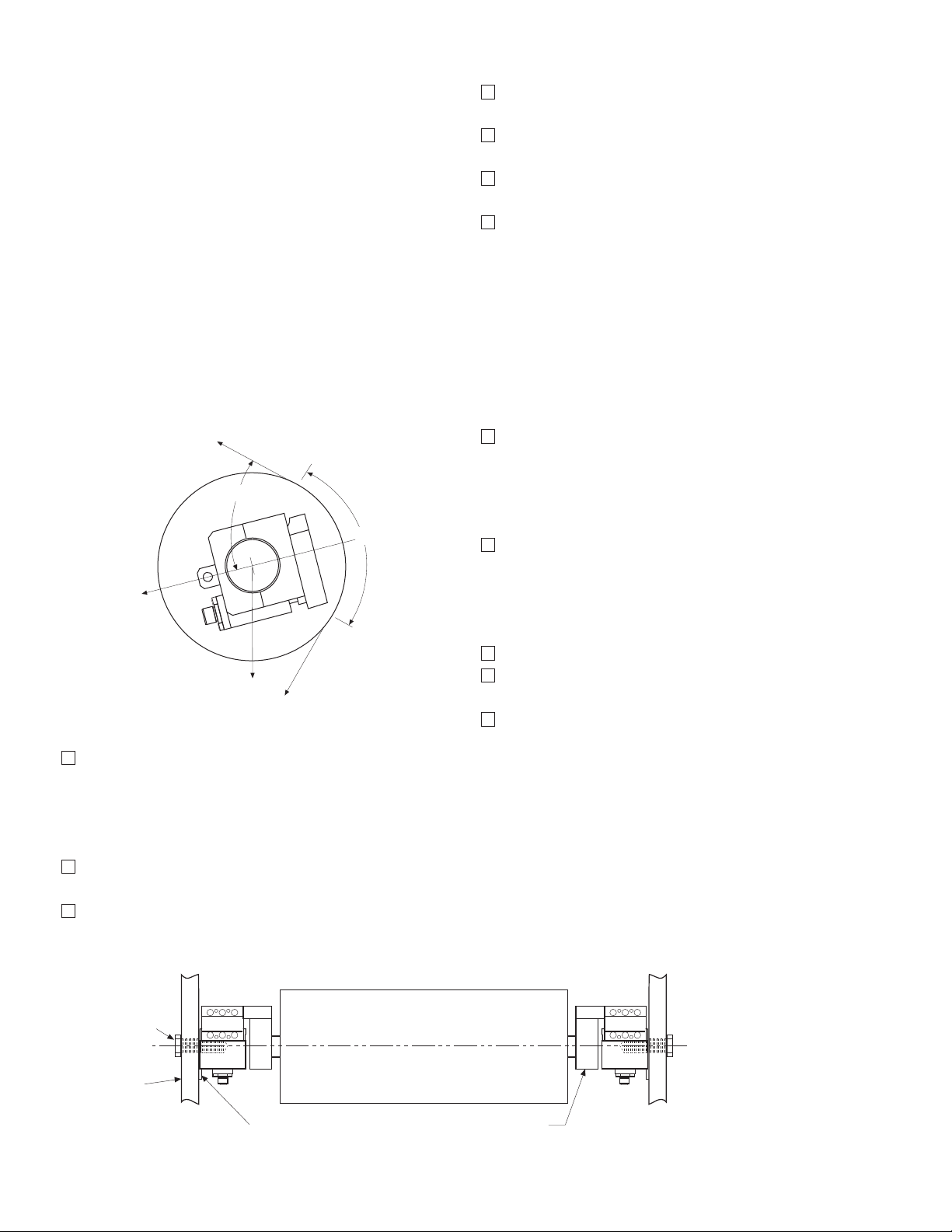

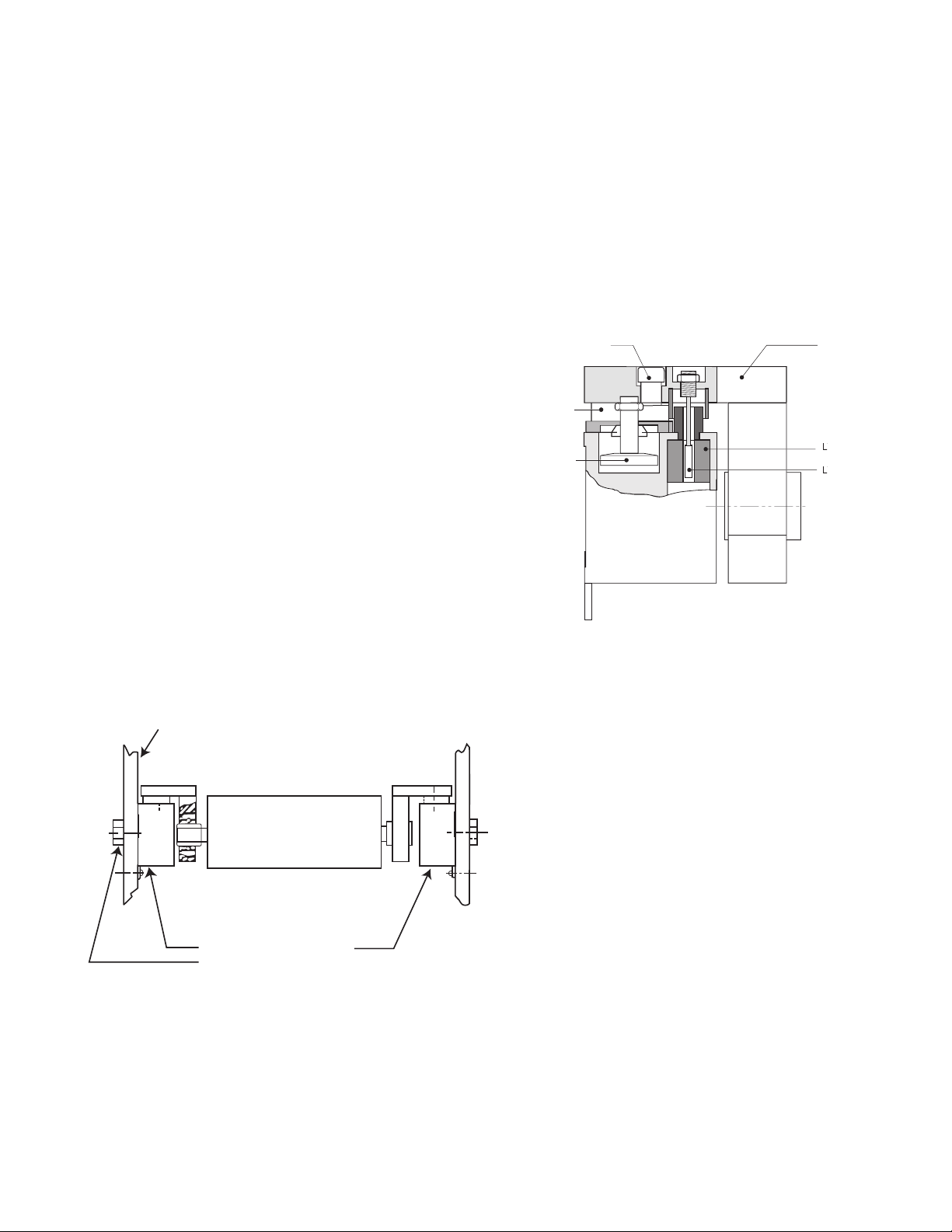

The FM style load cell provides easy and conven-

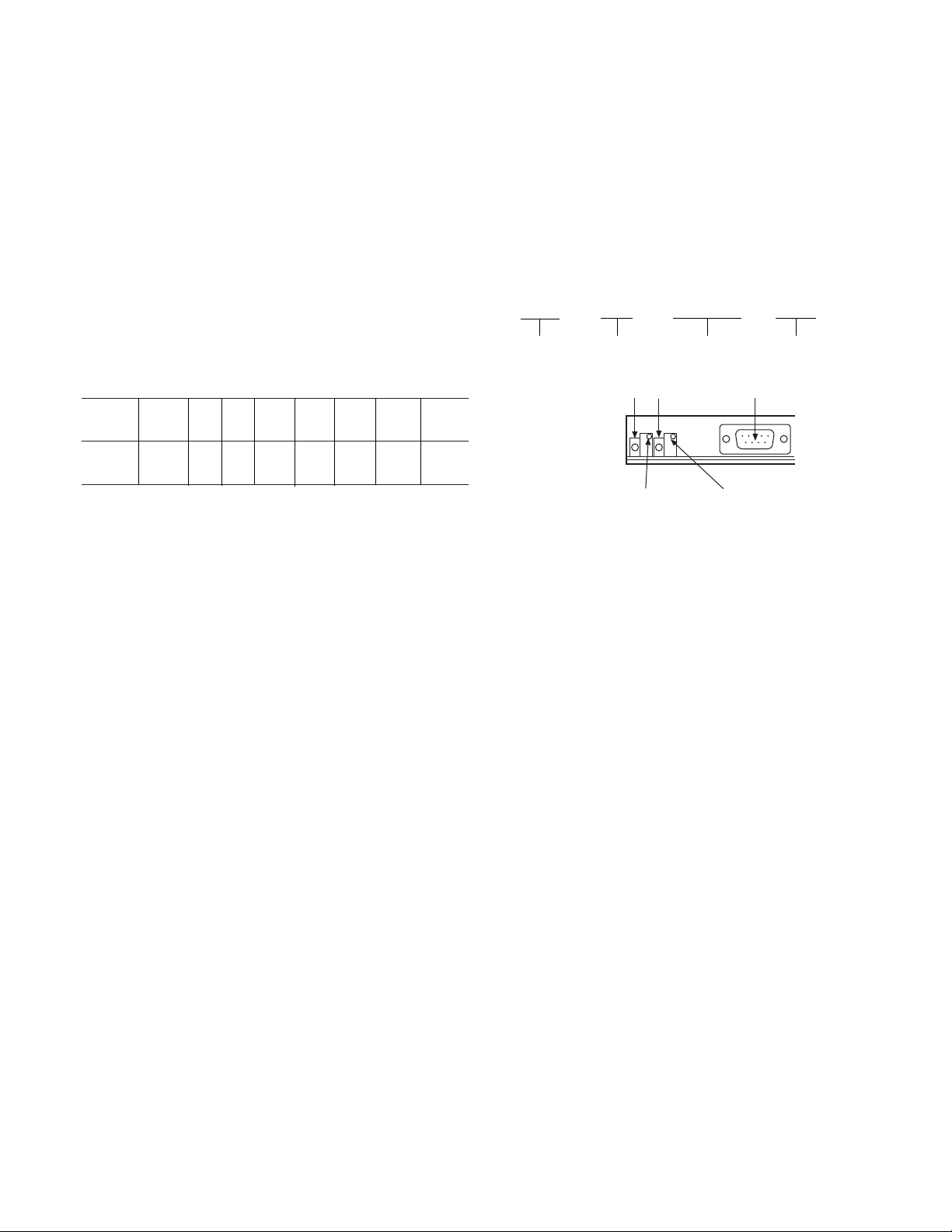

Zero setting:

Green LED ON

above 0 VDC

Gain setting:

Green LED ON

below 5 VDC

Green LED D-Sub connector

ient mounting to the roll that is being measured

(used with pillow blocks). The load cell is a strain

gauge style unit that is ideal for heavy tension

applications. It can be mounted regardless of orientation, but has to work in compression. Only

the perpendicular force (resultant) is measured by

the load cell. The perpendicular force can be at a

maximum permitted angle of +/- 30 degrees.

Correct load cell sizing must be adhered to so

potential overload forces do not damage cells.

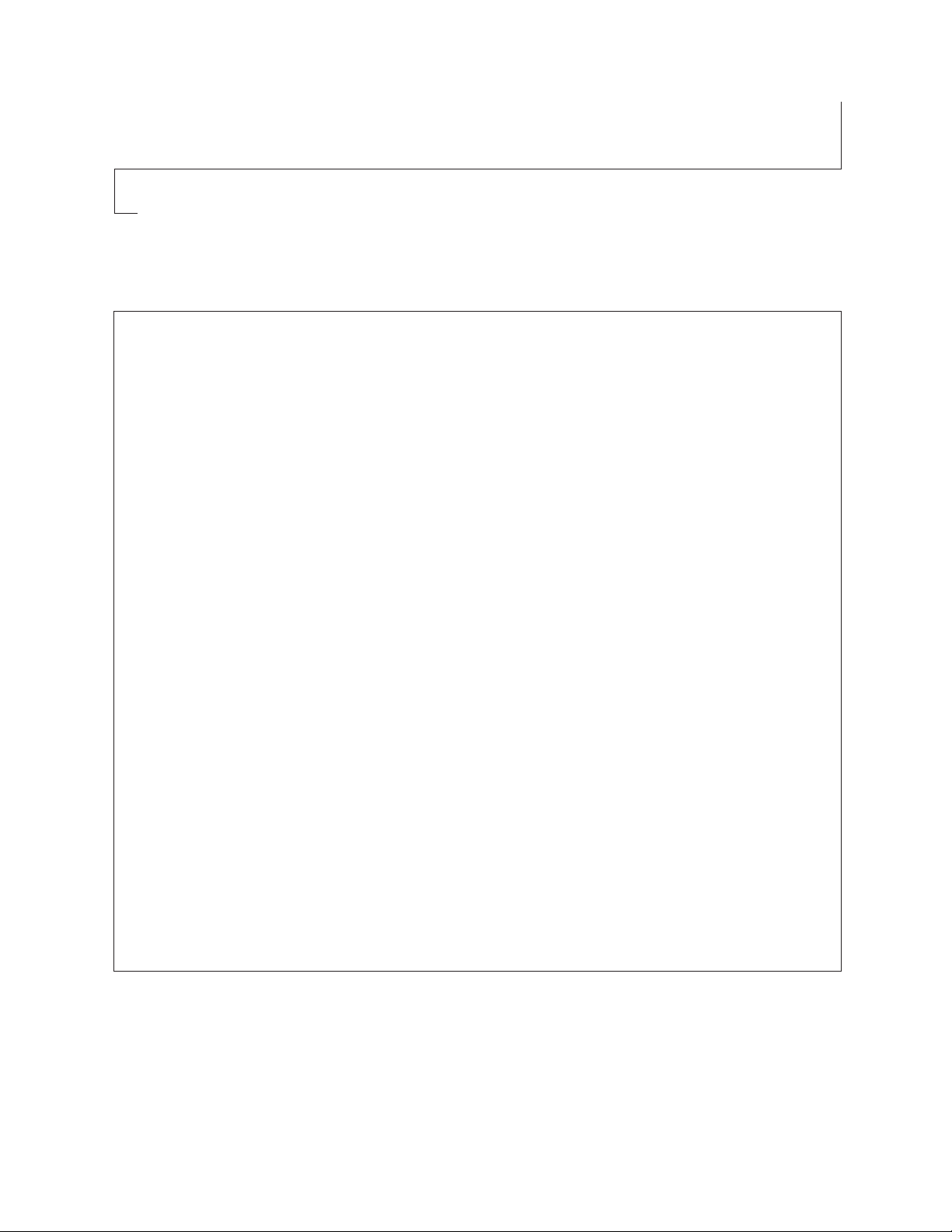

FM Series Part Numbers

F M 0 1 - 1 0 0 0 - A C

Specifications:

Load

Ratings N 100 250 500 1000 2500 5000 10000

(Lbs.) (22) (56) (112) (225) (562) (1124) (2248)

Size 01 01 01 01 01 01 02

Input Power

±12 to ±15 VDC

@ 45 MA ±5%

Output Signal

5VDC output at rated load

Temperature Range

0-70 degrees C

(32 -158 degree F)

Temperature drift

0.1 % of rating per degree C

Non-linearity and Repeatability

< 0.5%

Power Consumption

1 Watt

Cable

16 ft. provided with load cell

Maximum Load Ratings (See Figure 6)

Overload

120% of rated load

Compression Overload

150% of rated load

Horizontal Load

50% of rated load

Model Numbers/Part Numbers

FM01-100 6910-840-100

FM01-250 6910-840-102

FM01-500 6910-840-104

FM01-1000 6910-840-106

FM01-2500 6910-840-108

FM01-5000 6910-840-110

FM01-10K 6910-840-112

Warner Electric • 800-825-9050 P-2012-1

4

Model Size Load in N Amplifier built in

Alignment

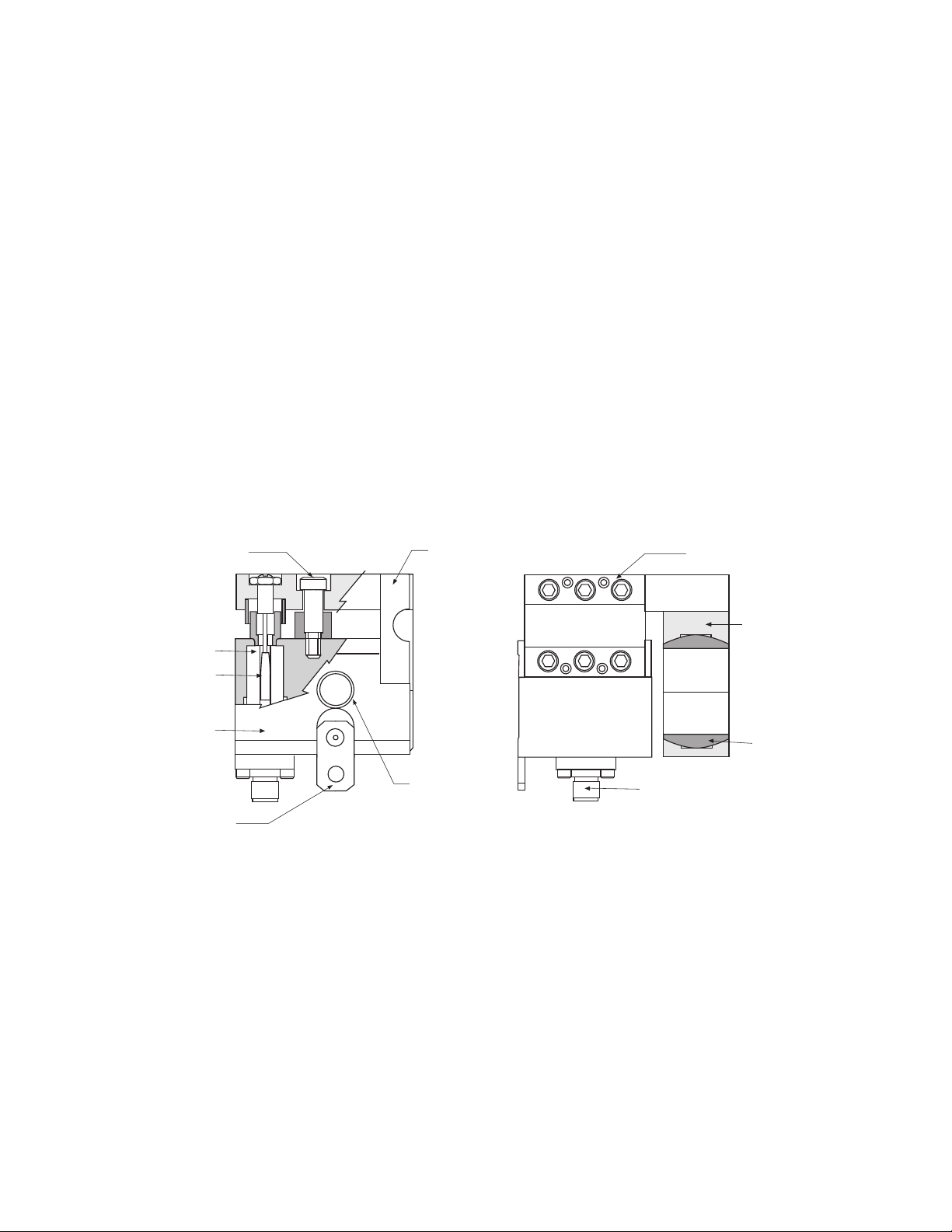

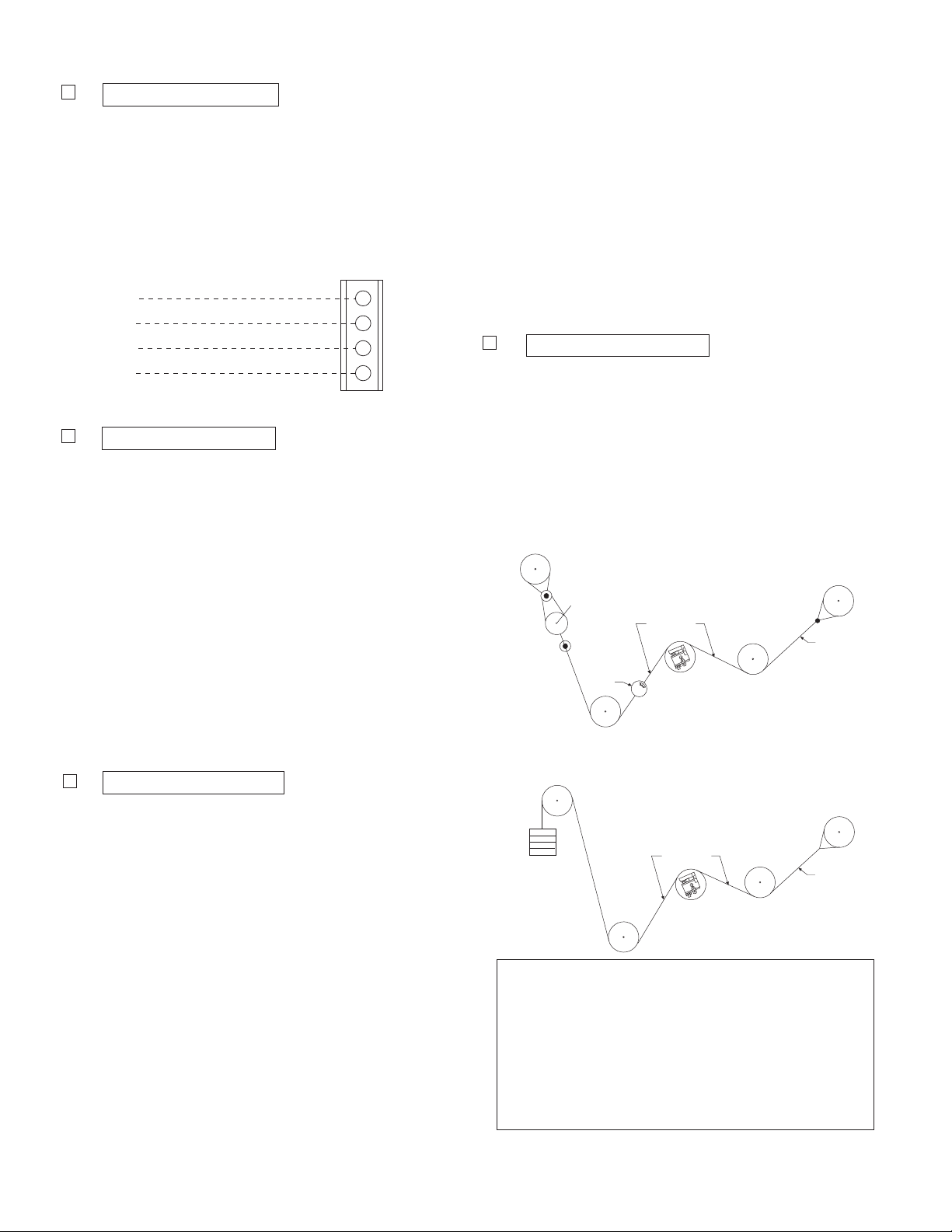

Figure 1

The sensor has been factory calibrated:

0VDC (No load)

5VDC (Rated load)

Two potentiometers and LED’s are located near

the “D” connector (See Figur

cation. When used in the nominal range, both

LED’s are “ON”. Although the load cell has been

factory calibrated. The unit may be rescaled if

necessary. It is recommended that a qualified

technician do this procedure.

Attach a digital volt meter between the signal

lead (yellow) and 0VDC (ground). With no load

on the cell adjust the zero potentiometer for a

0VDC output. The zero setting LED should be

“OFF”. Any voltage above 0VDC, the zero LED

will turn “ON”.

Apply the mazimum load to the cell. Adjust the

gain potentiometer for a 5VDC output reading.

The gain LED should be “OFF” at a 5VDC output

level. Remove the load and insure the gain LED

is “ON”.

The zero and gain adjustments may need to be

repeated a couple of times to insure proper setting.

e 1) for visual indi-

Page 5

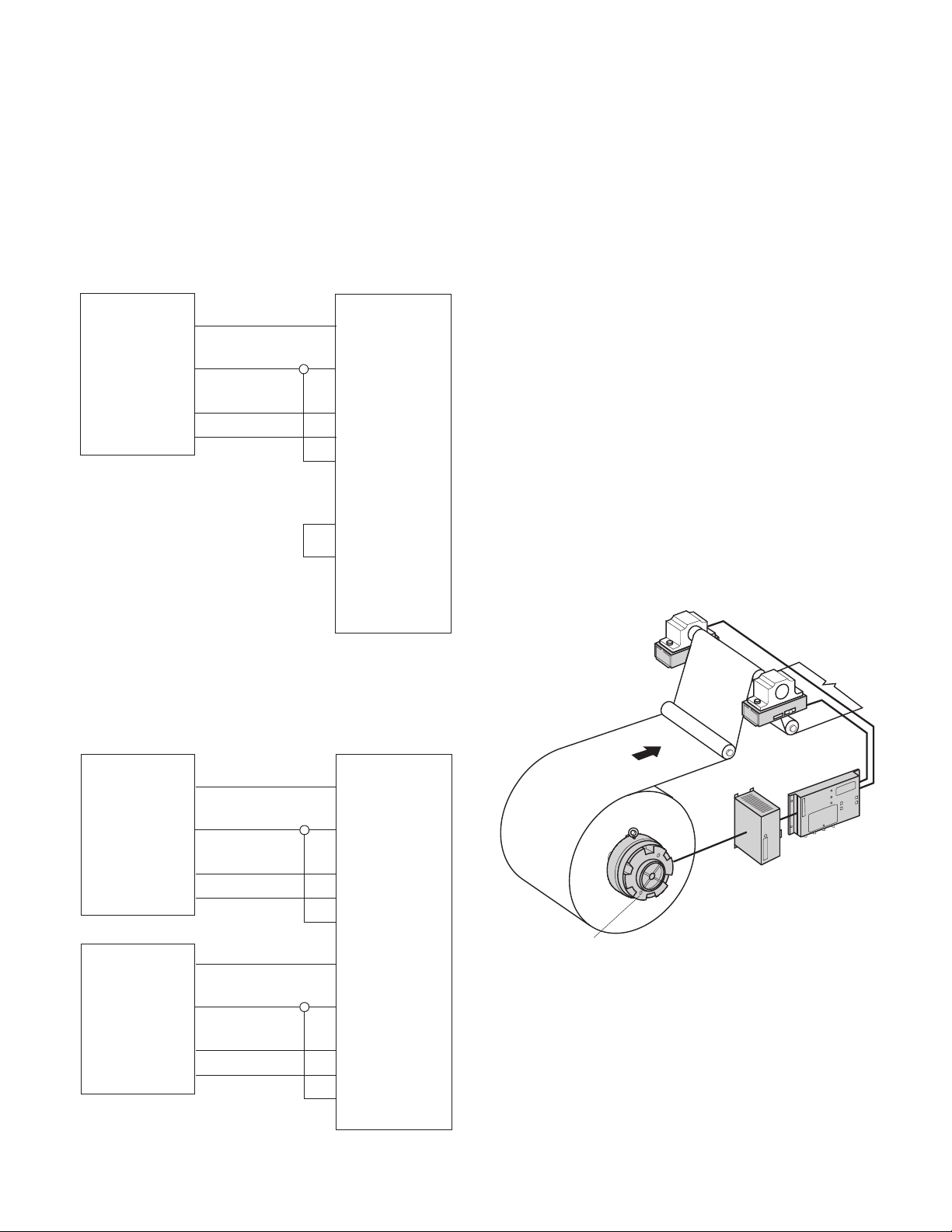

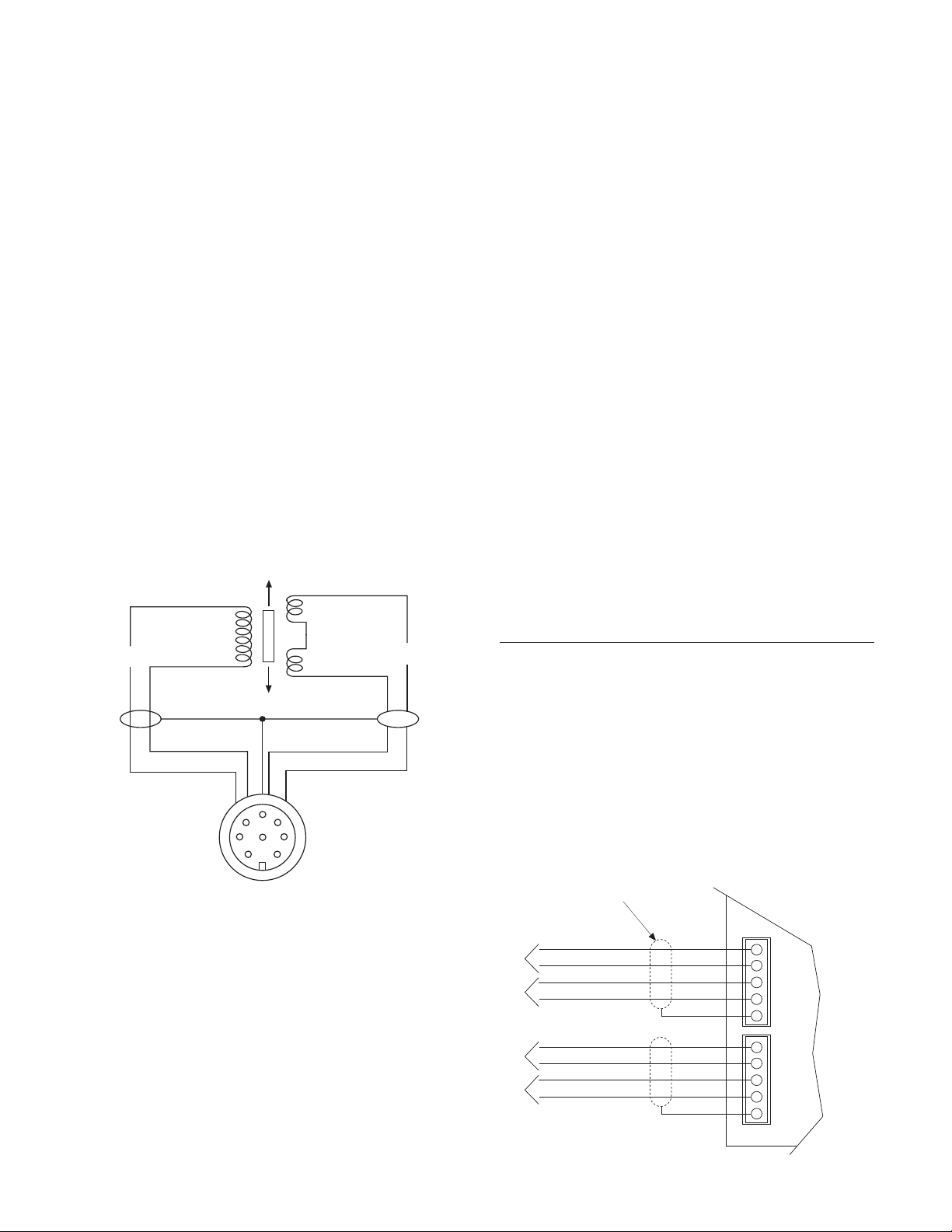

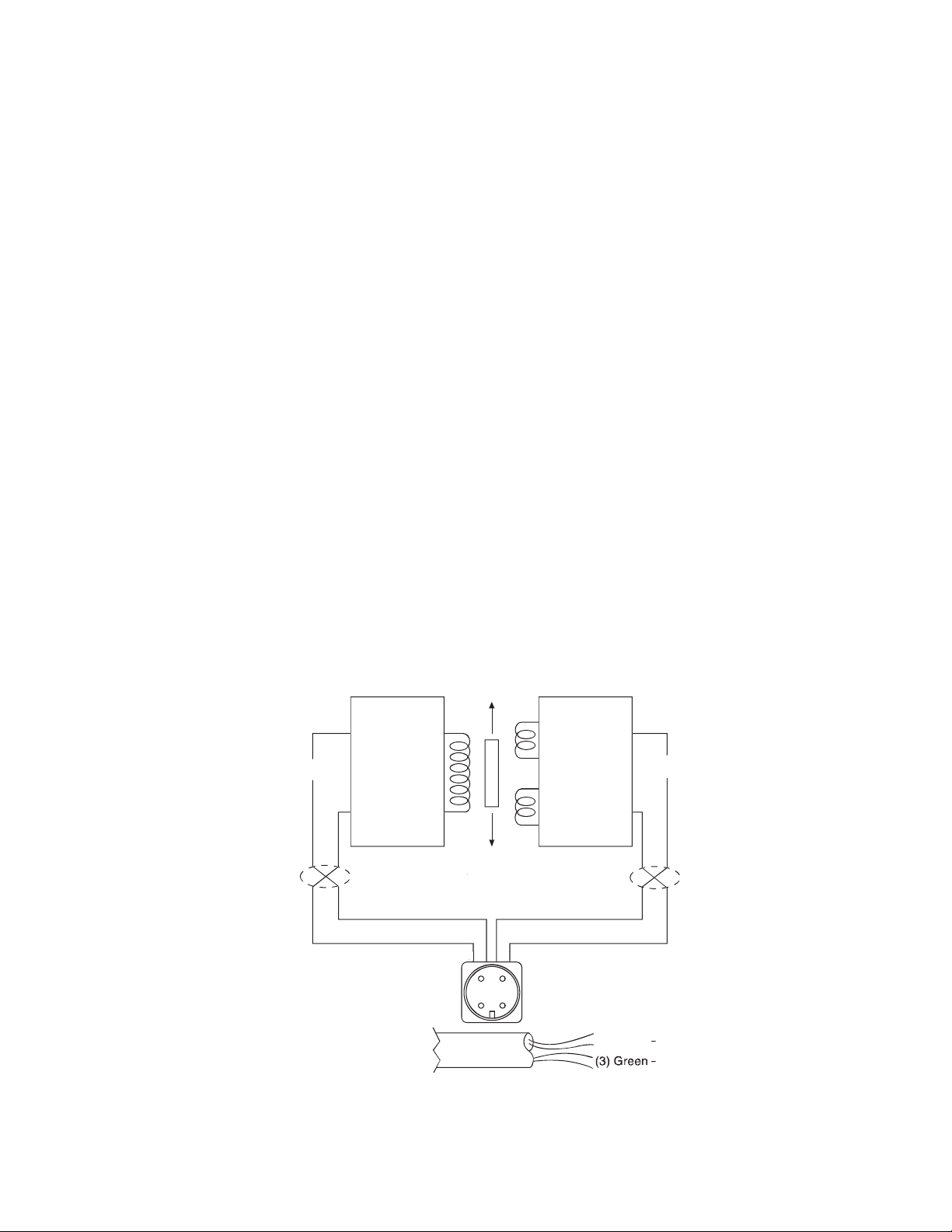

Wiring Hookup:

Red (+15V)

White (Ground)

Yellow (Signal)

BLUE (-15V)

+UCELL/SEN+

CELL1+/SENS IN

CELL1-

-UCELL/SENS

Ground (OV)

Shield

+UCELL

CELL2+

CELL2-

-UCELL

SHIELD

FM Series Load Cell

MCS2000-CTLC

No Connection

No Connection

No Connection

No Connection

Add Jumper

Red (+15V)

White (Ground)

Yellow (Signal)

Blue (-15V)

+UCELL/SEN+

CELL1+/SENS IN

CELL1-

-UCELL/SENS

Ground (OV)

Shield

+UCELL

CELL2+

CELL2-

-UCELL

Ground (OV)

Shield

Red (+15V)

White (Ground)

Yellow (Signal)

Blue (-15V)

N/C

N/C

FM Series Load Cell

FM Series Load Cell

MCS2000-CTLC

Magnetic Particle Brake

MCS2000-PSDRV

Power Supply

and Drive

MCS2000-

CTLC

FM Load

Cell

FM Load

Cell

The load cell requires a +15VDC and a -15VDC

power supply. The 5V/15V switch inside the

MCS2000-CTLC must set to +/-15VDC.

Terminate all unused wires from cable.

Wiring example using One Load Cell with the

MCS2000-CTLC contr

ol

Notes: It is recommended to use the load cell

in a compr

ession application. It must be fitted

on a flat surface in order to avoid original

sensitive plate stress. Do not load the sensor

before mounting it with screws on the

mounting surface.

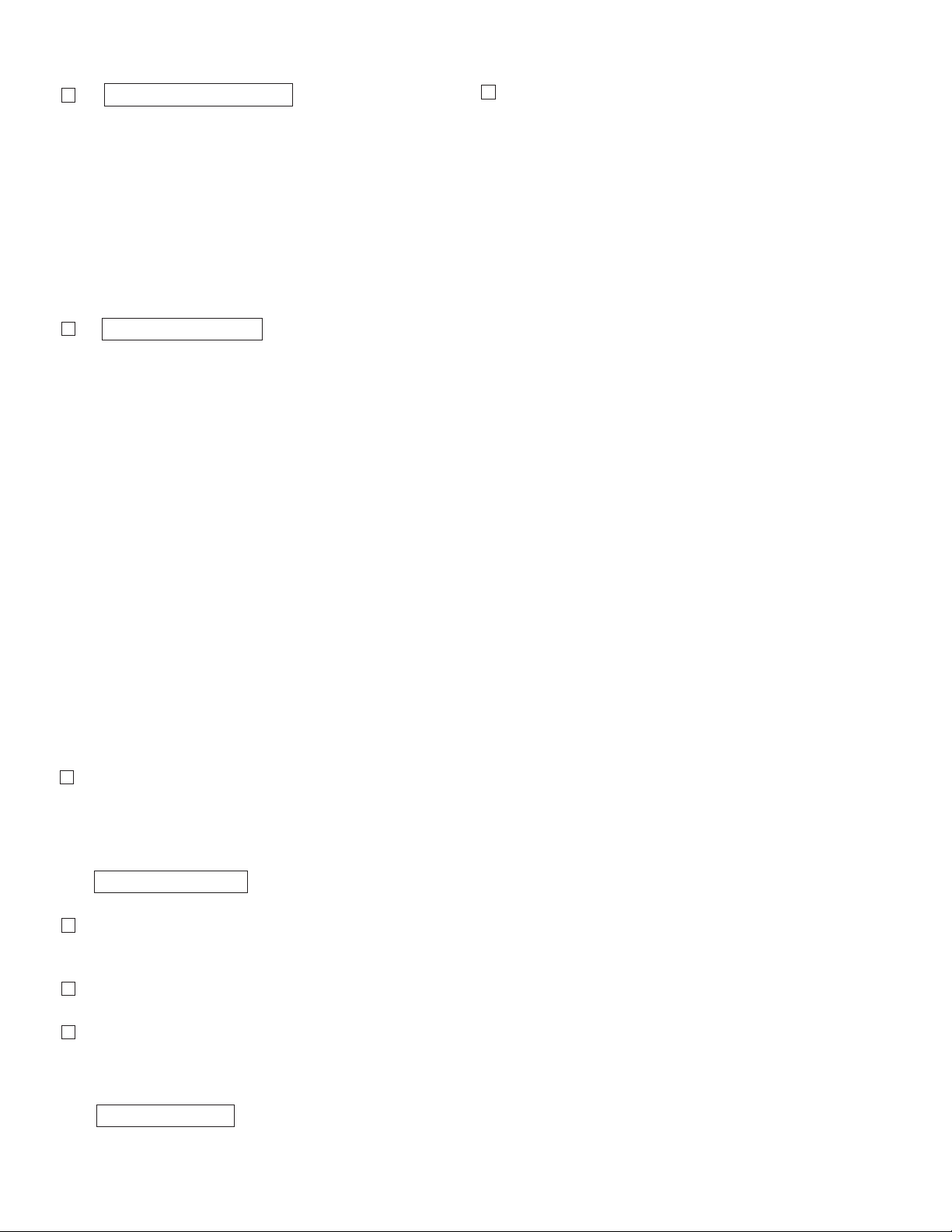

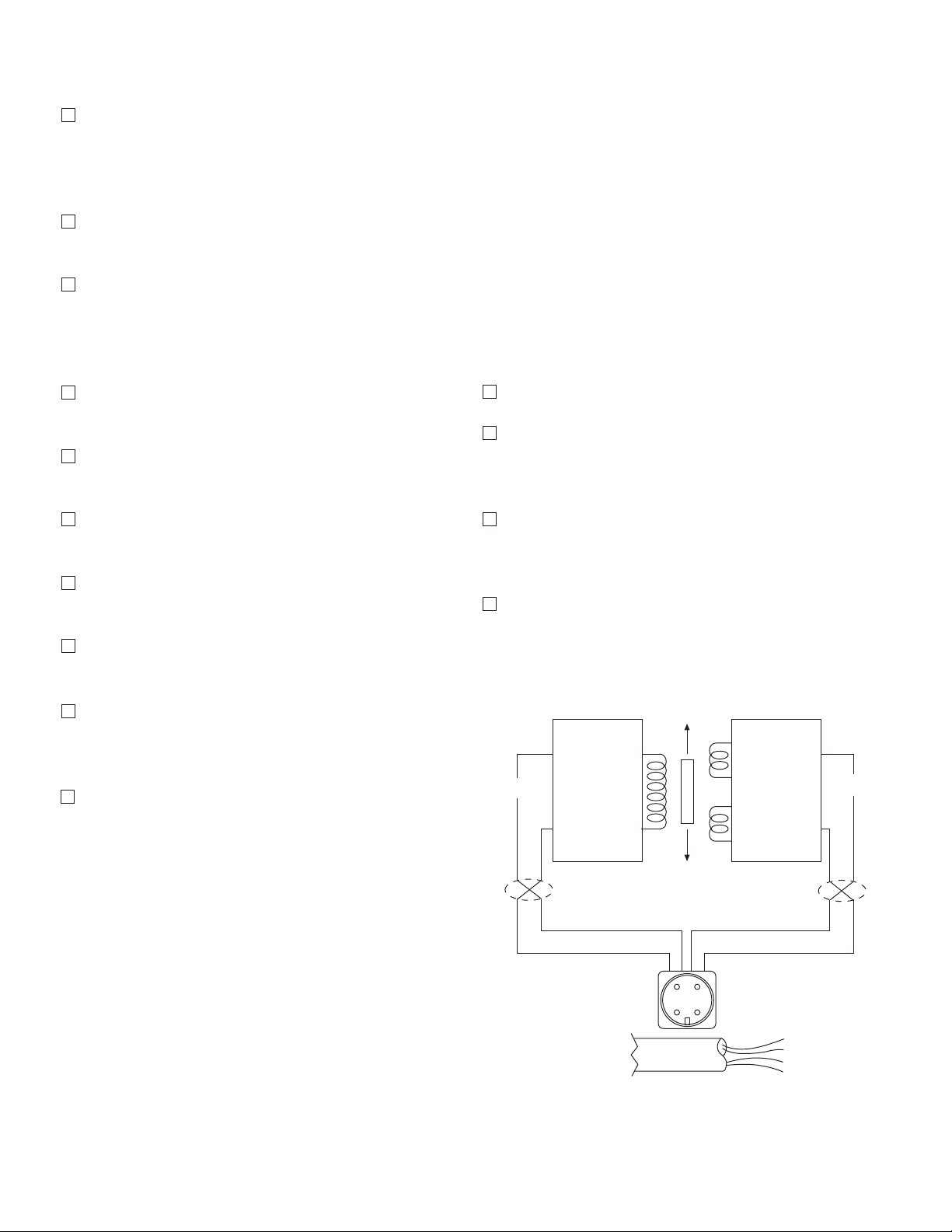

System Example:

FM Load Cell with an Electric Brake

This is a typical load cell unwind application

example. The electric brake varies the tension

on the web depending on the feedback fr

load cell. The load cell signal is amplified and

interpreted in the controller (MCS2000-CTLC).

The controller then puts out a corresponding

0-10 VDC signal to the power supply and drive

(MCS2000-PSDRV). The PSDRV then amplifies

and interprets the signal from the controller and

puts out a corresponding 0-24 VDC signal to the

brake to apply either more or less braking.

om the

Wiring example using 2 load cells with the

MCS2000-CTLC control

Warner Electric • 800-825-9050 P-2012-1

Figure 2

Figure 3

Figure 3

Figure 4

5

Page 6

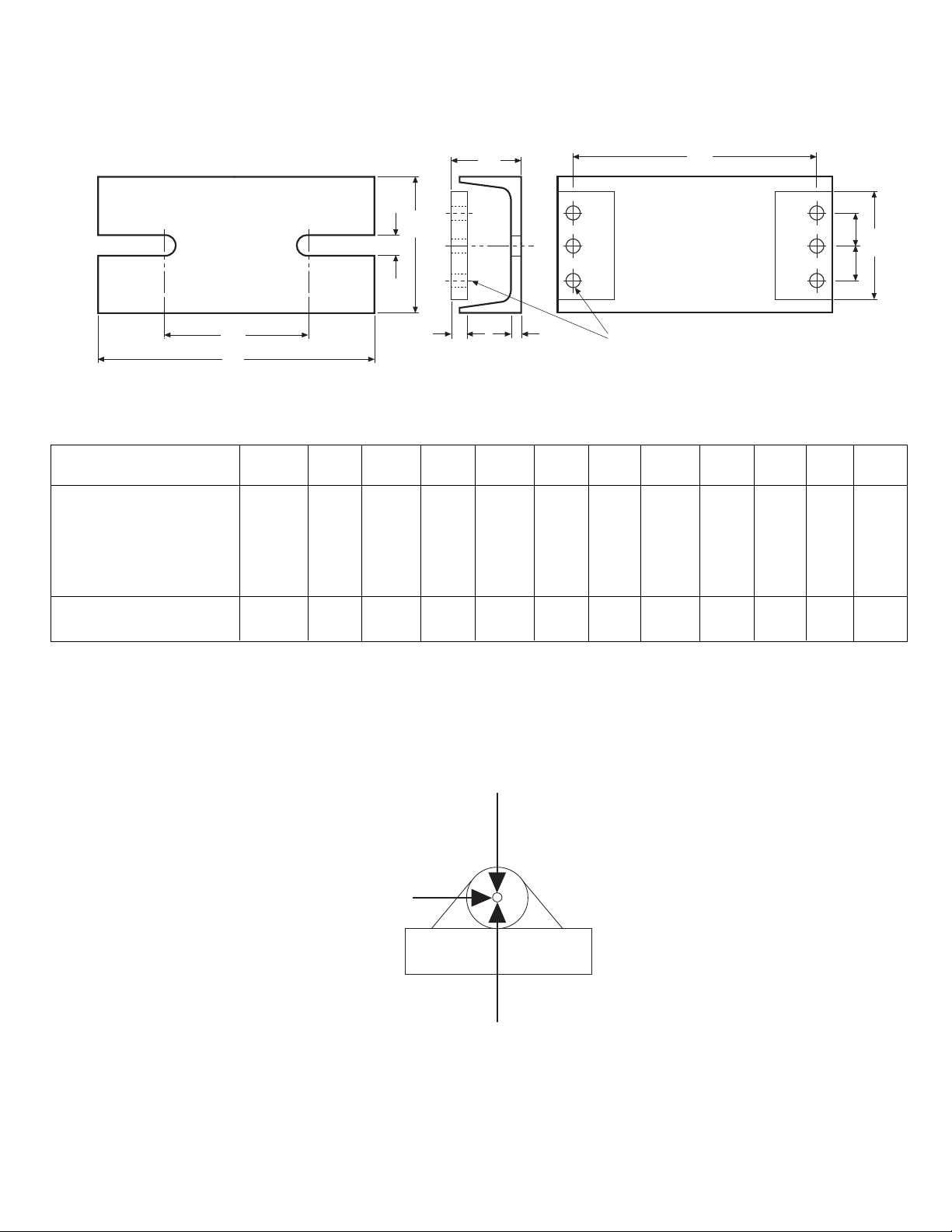

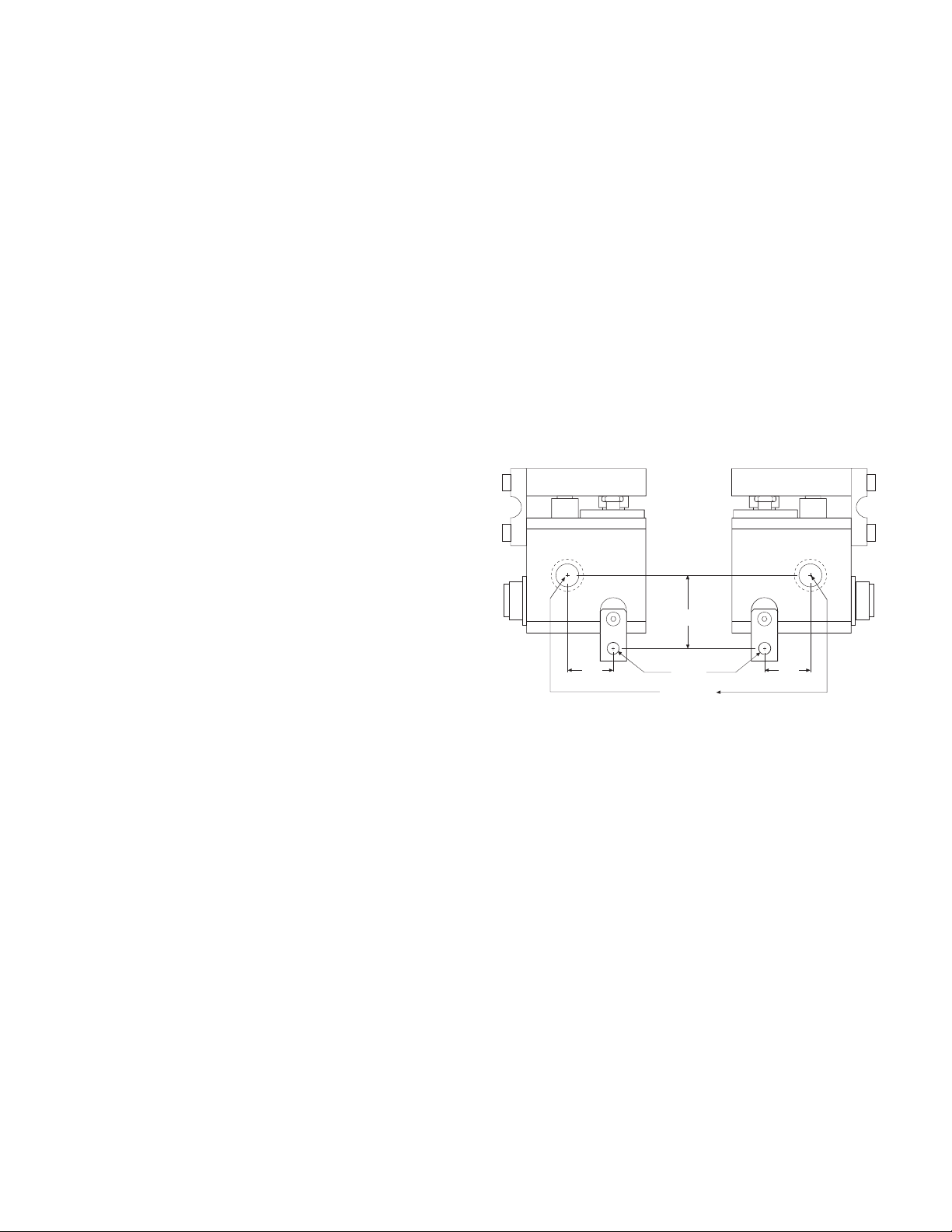

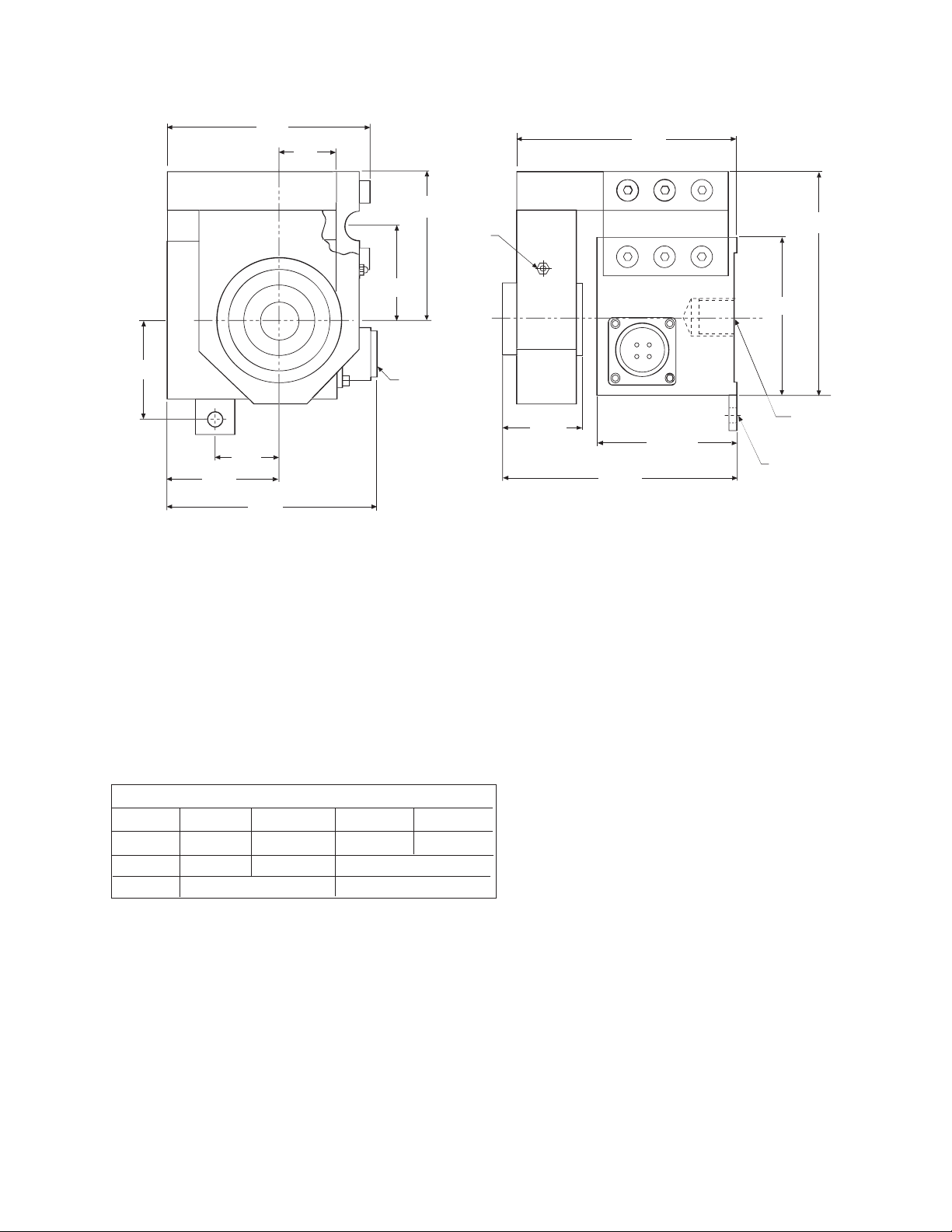

Dimensions

G

F

H

C

K

J

D

E

I

A

B

M10 Screw

11 mm dia. (6)

L

Max. extension overload =

120% from nominal load

Max. horizontal load =

50% from nominal load

Max. compression overload =

150% from nominal load

Tension sensor

FM Series

Foot mounted load cells

(–) Denotes millimeters

Size Load Ratings A B C D E F G H I J K L

N (lbs.)

100 (22)

250 (56)

01 500 (112) 4.055 7.874 6.890 .512 4.016 .984 .984 3.150 2.047 .472 .236 .433

1000 (225) (103) (200) (175) (13) (102) (25) (25) (80) (52) (12) (6) (11)

2500 (562)

5000 (1124)

5.591 8.858 7.677 .669 5.00 .984 .984 3.937 2.165 .709 .236 .433

02 10000 (2248) (142) (225) (195) (17) (127) (25) (25) (100) (55) (18) (6) (11)

Figure 5

Figure 6

Warner Electric • 800-825-9050 P-2012-1

6

Page 7

P-2012-2

819-0402

AC10 Measuring System

Warner Electric • 800-825-9050 P-2012-2

7

Page 8

Introduction

This manual is intended for use by qualified personnel to assist them in the safe setup and

operation of the Warner Electric AC10 Tension

Measuring System. Warner Electric has made

every effort to insure the accuracy and completeness of the information and recommends

that all procedures be read and understood

before performing them. Please contact Warner

Electric with any questions regarding any information contained in this manual.

Warner Electric • 800-825-9050 P-2012-2

8

Page 9

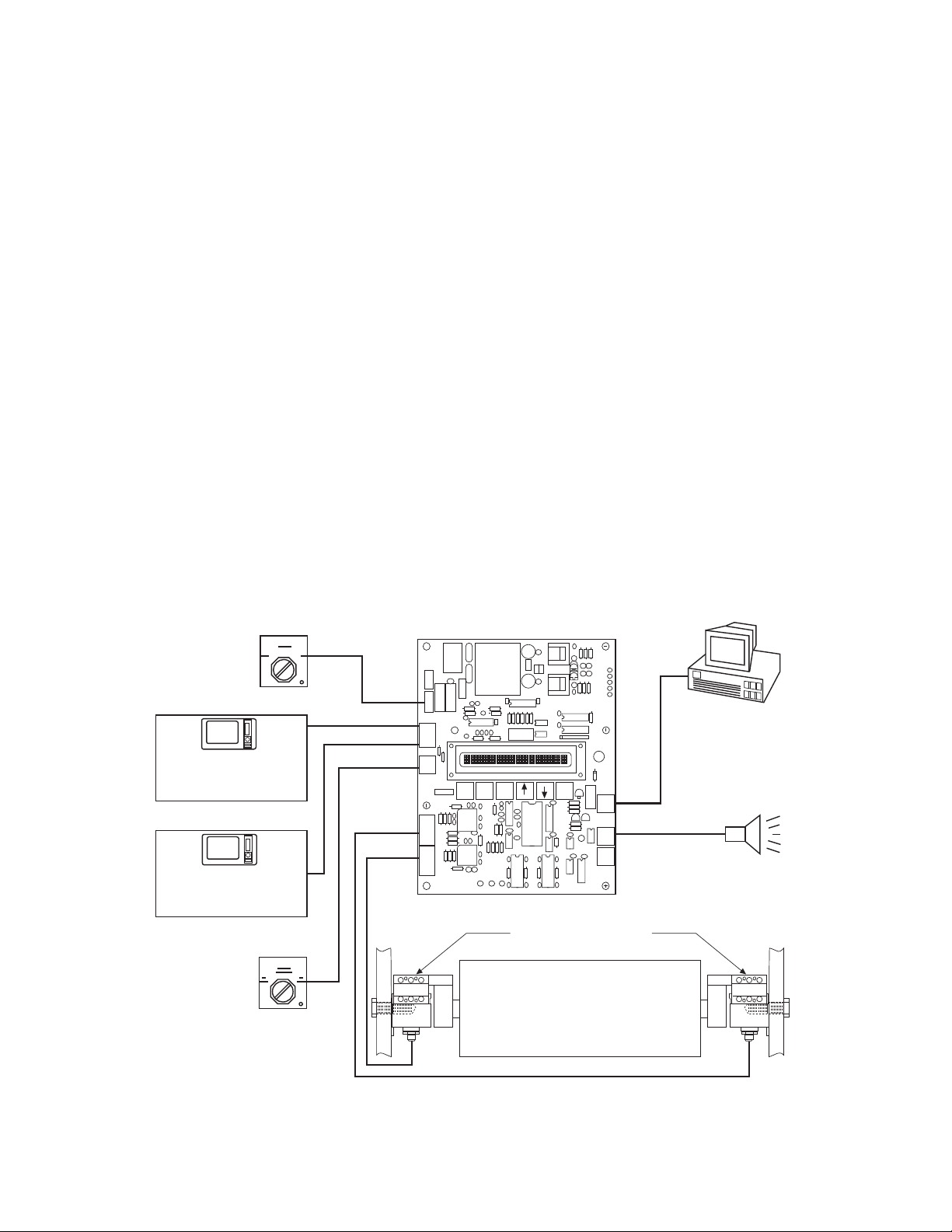

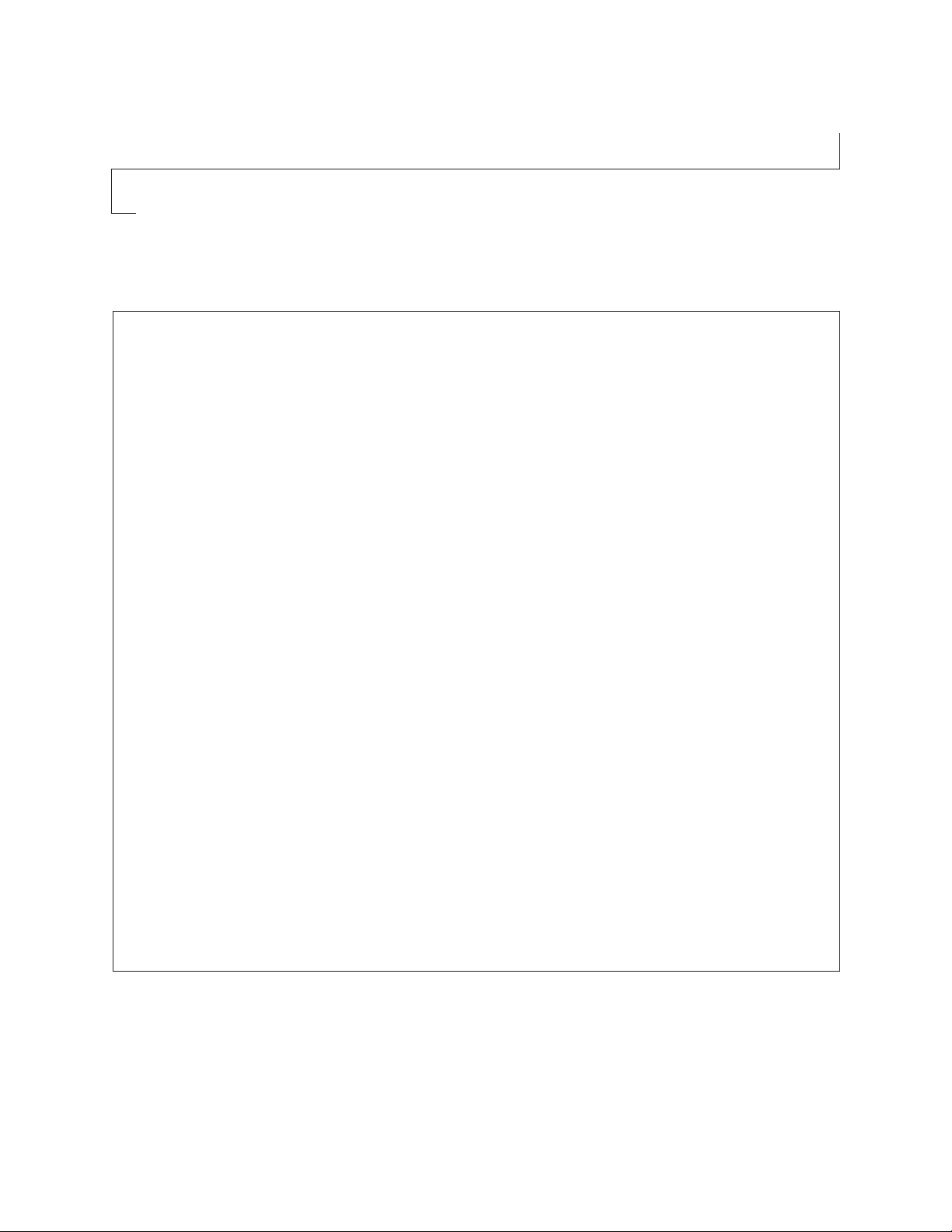

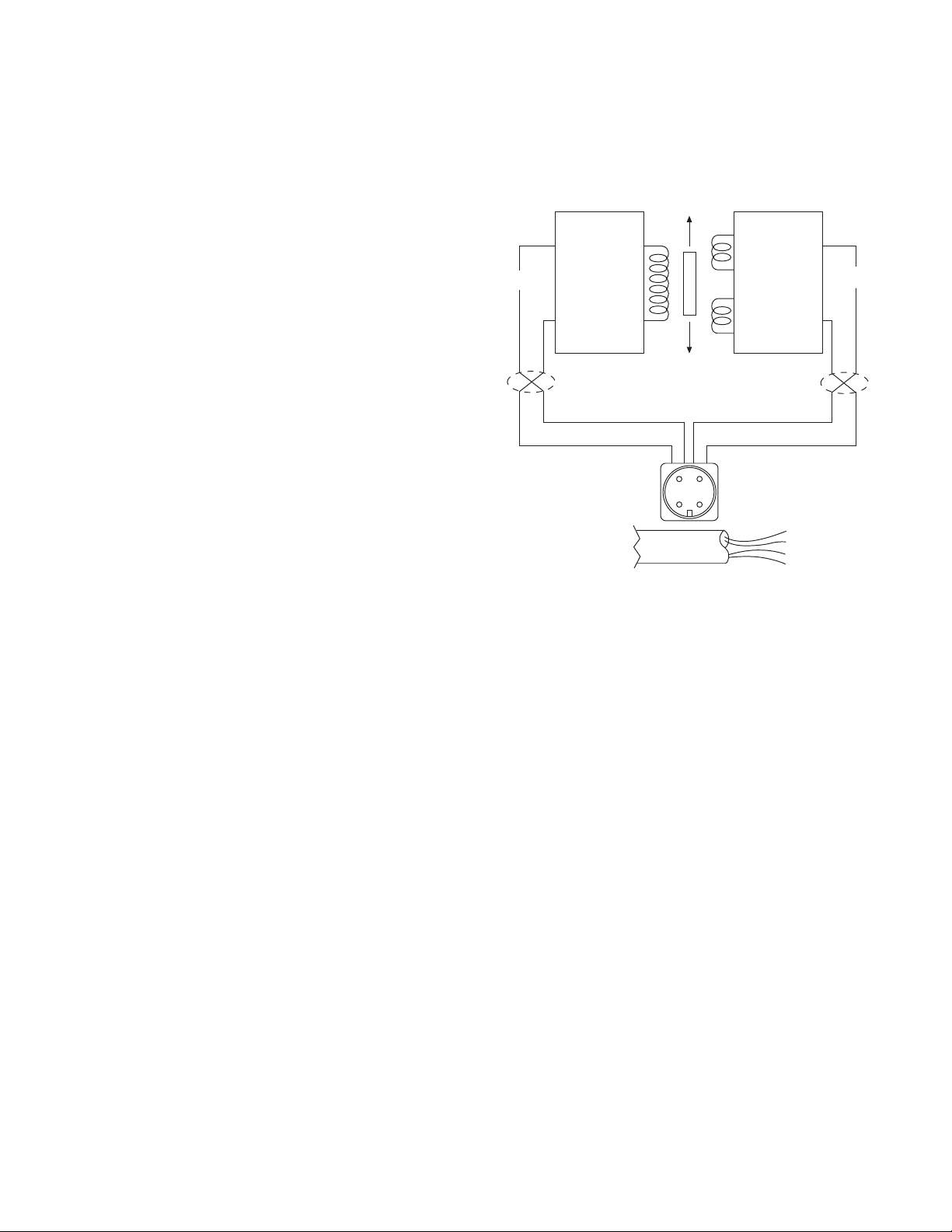

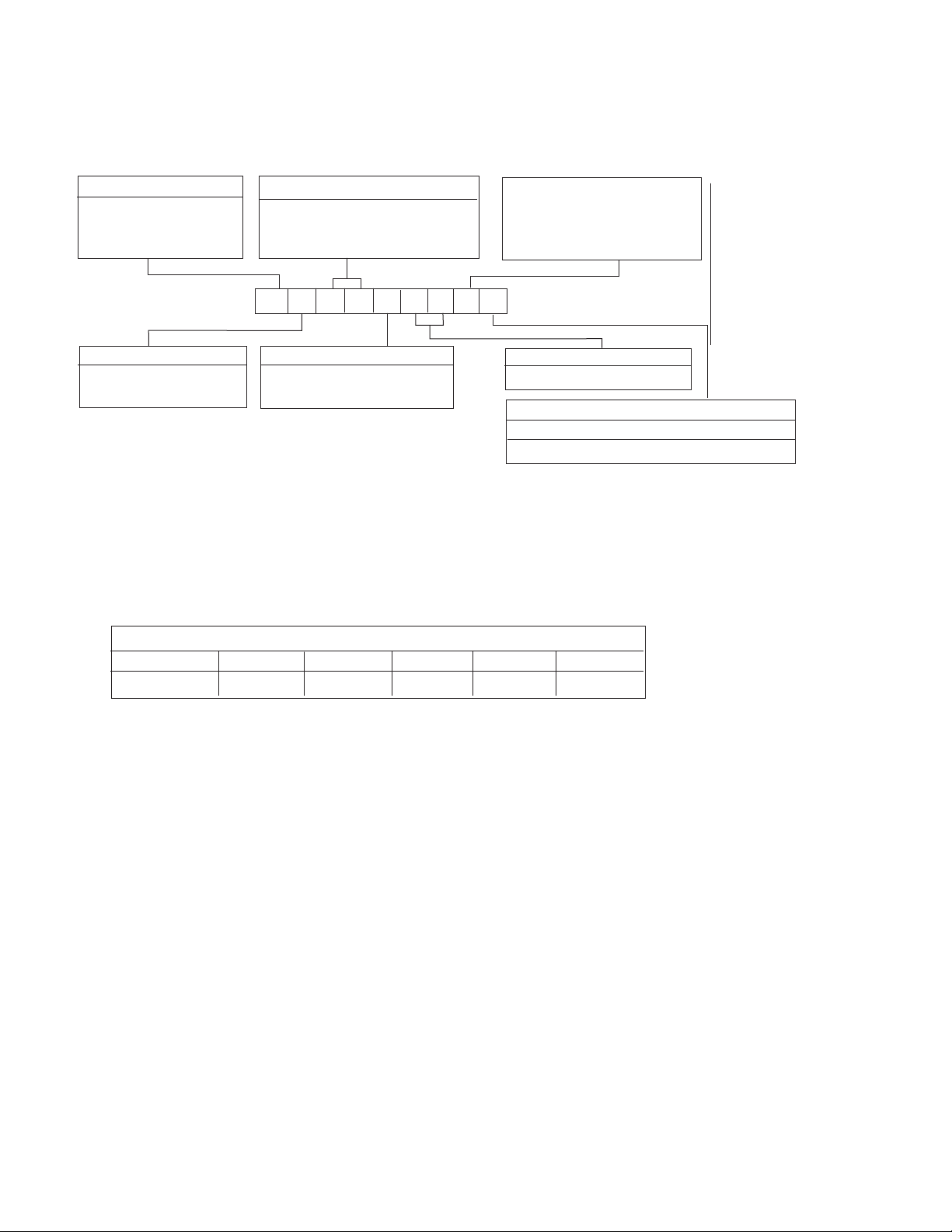

System Overview

J3

J4

J6

J5

Warner

Part# 80-165 Rev

Serial#

Setup

Rapid

Exit

Setup

Enter

J7

J8

J9

J1

J2

PSAC10 Board

Power

Switch

Output #1

Output #2

Control

Analog or Digital

Meter

Drive

Cell #1/Total/Cell #2

Switch

AC-10 Tensioncells

Threshold

Alarm

RS-422

Interface

MCS2000-CTDA

MCS2000-CTDA

Control

Analog or Digital

Meter

Drive

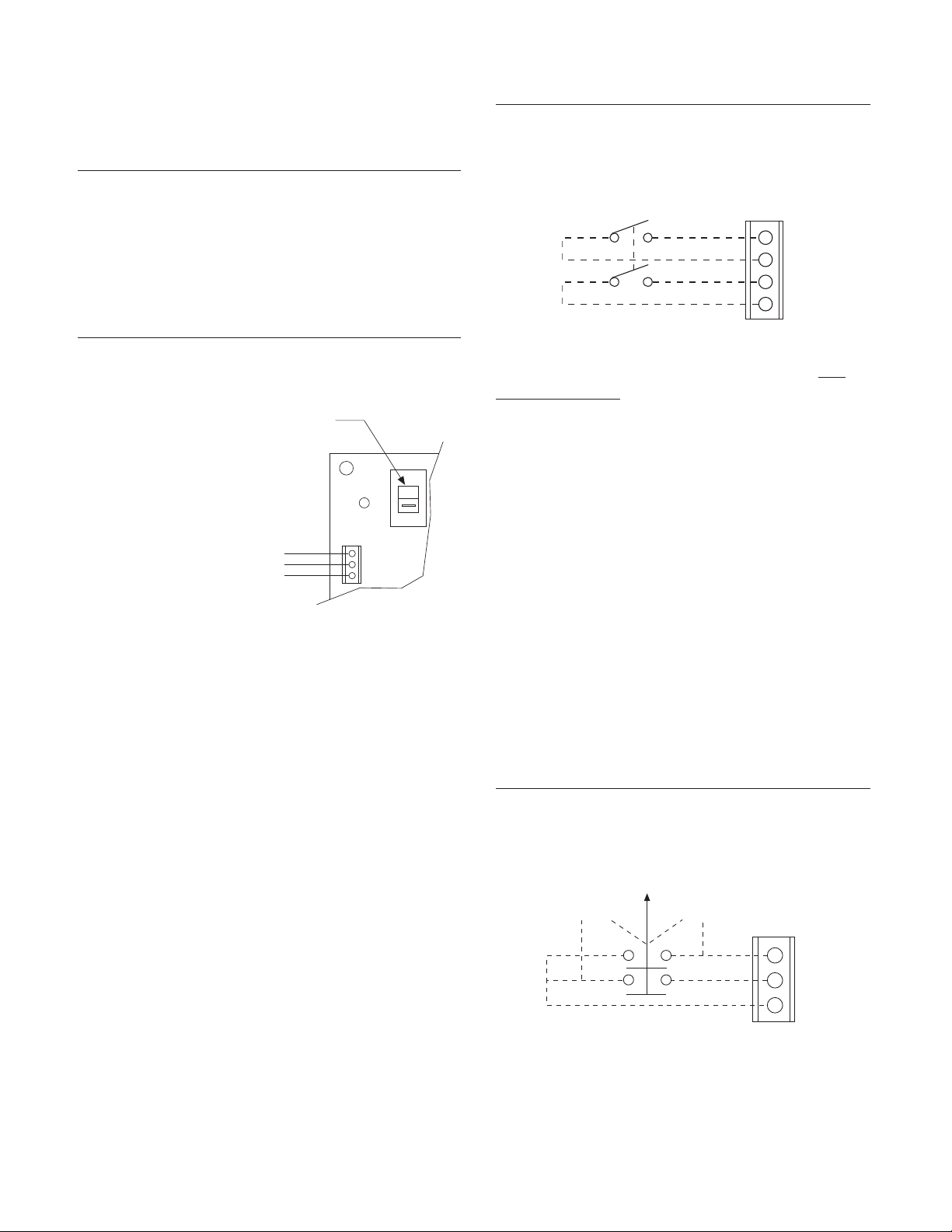

The AC10 Tension Measuring System is designed

to measure tension on continuous strip processing lines and equipment. The system consists of

two AC10 Tensioncells, the PSAC10 power supply

amplifier board, and two cables for connecting the

Tensioncells to the board.

AC10 Tensioncells are mounted in pairs, one at

each end of the measuring roll. During operation

the Tensioncells continuously measure the

mechanical tension force applied to the measuring

roll. When the force is applied, the load plate

deflects toward or away from the base block

depending on the resultant force acting upon the

Tensioncell. Deflection toward the base block is

defined as the "Compression Mode.” Deflection

away from the base block is defined as the

"Tension Mode." AC10 Tensioncells work equally

well in either mode.

The mechanical deflection of the load plate is

converted into an electrical output signal by the

AC Linear Variable Differential Transformer

(LVDT). Displacement of the LVDT core caused

by variations in web tension results in an output

signal to the PSAC10 board directly proportional

to the applied tension.

The analog outputs from the Tensioncells are converted into digital signals by the microprocessorbased electronics. The signals are conditioned,

processed, and summed to produce two individually scaleable, -10 to +10 volt DC analog outputs

to a tension indicator, drive or a MCS2000 CTDA

control which can be used to monitor or control

tension. The percent tension applied to each

Tensioncell and the total tension are displayed on

the board mounted 16-character liquid crystal

display (LCD).

Terminals are also provided for connecting a user

supplied On/Off power switch, 1-only 2-only

switch, and RS-422 PC interface. A threshold

alarm relay connection is also provided.

Note: When using the PSAC10 board, connect the outputs to the MCS2000 CTDA. There is no

need to use the MCS2000 CTLC, because the signal is amplified and summed in the PSAC10.

Warner Electric • 800-825-9050 P-2012-2

9

Page 10

AC10 Tensioncells

Shaft Support

Block

Self-Aligning

Shaft Support

Bushing

Electrical

Connector

5/8-1 1 UNC

Mounting

Hole

Load Plate

C-Flexure

Mechanical Stop

LVDT

LVDT Core

Base Block

Locating Tab

AC10 Tensioncells are available in three capacity ranges for non-rotating shaft applications

with maximum resultant force plus tare load of

60, 170, or 500 pounds respectively.

The rugged, all-steel construction of the AC10

Tensioncell includes four basic components: the

one-piece base block, the patented C-Flexure,

the load plate, and the shaft support block. The

factory-set mechanical stop provides overload

protection up to ten times the maximum rated

load capacity of the unit.

Each unit is wall mounted by means of a single

bolt located in line with the integral self-aligning,

stainless steel shaft support bushing and the

centerline of the roll shaft. This permits the

Tensioncell to be rotated and mounted at the

required angle around the axis of the measuring

roll. The locating tab at the bottom of the unit

locks it in position.

The primary conversion element between the

mechanical tension force and the electrical output signal is an AC Linear Variable Differential

Transformer (LVDT). The LVDT electrical elements are encapsulated and sealed against

shock, vibration, or tampering. Input and output

circuits are isolated from each other and from

the Tensioncell body. This permits the

Tensioncells to be used in floating ground electrical systems.

10

Warner Electric • 800-825-9050 P-2012-2

Page 11

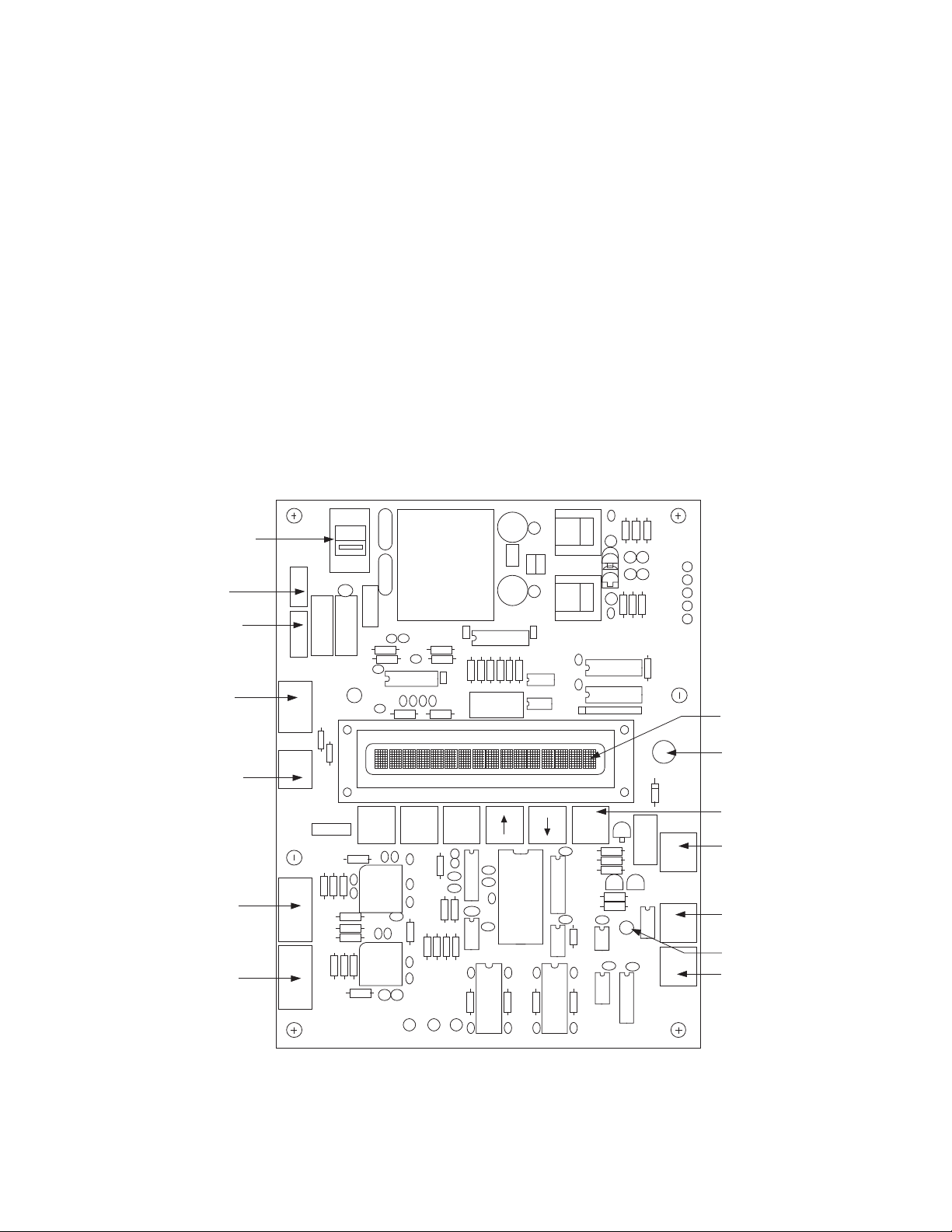

AC10 Electronics

J3

J4

J6

J5

Warner

Part# PSAC10

Serial#

Setup

Rapid

Exit

Setup

Enter

J7

J8

J9

J1

J2

Input Power

Selector Switch

Input Power

Terminal

Power On

Switch Terminal

Output #1

Output #2

Terminal

Cell #1/T otal/Cell#2

Switch Terminal

Tensioncell #1

Terminal

Tensioncell #2

Terminal

16-Character LCD

LCD Brightness

Adjustment

Pushbutton Keys

Threshold Relay

Terminal

RS-422 Output

Terminal

Run Mode LED

Spare

230V

The AC10 microprocessor-based electronics

adds ease of setup, versatility, and accuracy of

the overall system by eliminating the need for

potentiometers to adjust or setup the system.

All adjustments and system settings are performed by using the pushbutton keys on the

board. During setup, alphanumeric prompts are

displayed on the 16-character LCD to guide the

user through the setup procedure.

Other features of the PSAC10 board include:

Two individually scaleable -10 to +10 volt DC

outputs

Run Mode LED

Programmable threshold relay

Cell#1/Total/Cell#2 switch connection

LCD Brightness Adjustment

Switch selectable 115/230 volt AC input

power

An RS422 Serial Output terminal is also provided for interfacing the AC10 system with a PC to

monitor and/or record the percent tension

applied to each Tensioncell. Data is transferred

in ASCII text format. The RS422 output can be

converted to RS-232.

Warner Electric • 800-825-9050 P-2012-2

11

Page 12

Specifications

AC10 Tensioncells

Dimensions (I x w x h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.00" x 3.44" x 3.90"

Maximum Load Capacity (tension plus tar

AC10A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60 pounds

AC10B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .170 pounds

AC10C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .500 pounds

Minimum Tension Load Required for Setup

AC10A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 pounds

AC10B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 pounds

AC10C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 pounds

Standard Shaft Diameters (1/16" increments) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1/2" to 1-1/2"

Overload Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 times maximum rated load of unit

Maximum Deflection at Full Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.010"

LVDT

Operating Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .250°F maximum

Excitation Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15 Vrms @5KHz

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.2 volts AC/inch displacement / volt excitation

Excitation Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .335 Ohms ±5%

Output Signal Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100 Ohms ±5%

Linearity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.1% of full scale

Hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.1% of full scale

Repeatability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.1% of full scale

Temperature Drift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.02% per °C

PSAC10 Power Supply/Amplifier Board

Dimension (I x w) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.75" x 6.88"

Maximum

height of components above board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.5"

Operating Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32°F to +160°F (0°C to +70°C)

Input Voltage (switch selectable) . . . . . . . . . . . . . . . . . . . . . . . . . .115/230 VAC, 50-60 Hz, <1.0 Ampere

Output Voltage (two individually scaleable) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-10 to +10 VDC

Maximum cable distance between Tensioncell and board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100 feet

(The output load to the board must be 2 kΩ or greater)

Threshold Relay Contact . . . . . . . . . . . . . . . . . . .1A @ 24 VDC, 500mA@ 120 VAC, 250 mA @ 220 VAC

RS-422 Data Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .300bps, NP, 8, 1 stop bit

e)

Warner Electric • 800-825-9050 P-2012-2

12

Page 13

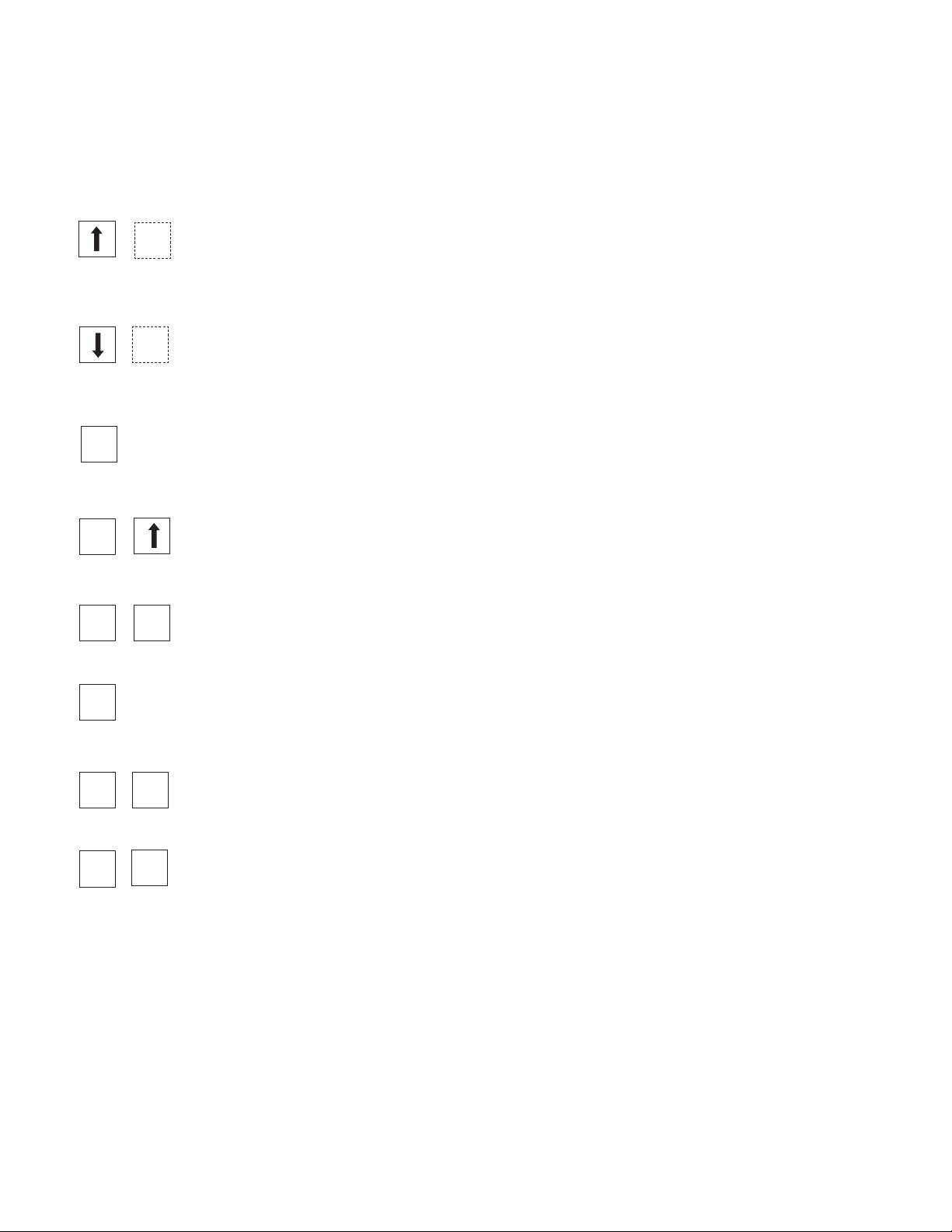

Pushbutton Key Functions

The six pushbutton keys on the PSAC10 board are used to enter and exit the Setup Mode and to

make adjustments during the procedure. This section describes the various key functions and combinations that are used while setting up the system.

The UP arrow key is used to toggle between selections. It is also used to incremental-

RAPID

ly increase the output voltage each time the key is pressed. When the UP arrow and

RAPID keys are pressed simultaneously, the voltage value will change continuously

until the keys are released or the upper limit is reached. (See note below.)

ENTER

SETUP

EXIT

SETUP

RAPID

ENTERSETUP

RAPID

The DOWN arrow key is used to toggle between selections and to incrementally

decrease the output voltage each time the key is pressed. When the DOWN arrow and

RAPID keys are pressed simultaneously, the voltage value will change continuously

until the keys are released or the lower limit is reached. (See note below.)

The ENTER key is used to make selections and store values before proceeding to the

next Setup step.

Pressing and releasing these keys simultaneously accesses the Setup Mode. An asterisk (*) will display next to the right tension value.

Press and release these keys simultaneously to start the Setup procedure when in the

Setup Mode.

Press and release this key to exit the Setup Mode at any time. The system will return

the settings entered during the last completed setup procedure.

Press and release these keys simultaneously to enter the settings for the

Programmable Alarm Output.

SETUP

EXIT

Press and release these keys simultaneously to zero the system.

Note: During setup, the output voltage value will change approximately 5 millivolts each time the

Up or Down arr

ow key is pressed and released. Pressing and releasing the RAPID key and the

Up or Down arrow key simultaneously will change the value approximately 200 millivolts.

Holding the Rapid key and an arrow key in, will continuously change the value until the keys are

released.

Warner Electric • 800-825-9050 P-2012-2

13

Page 14

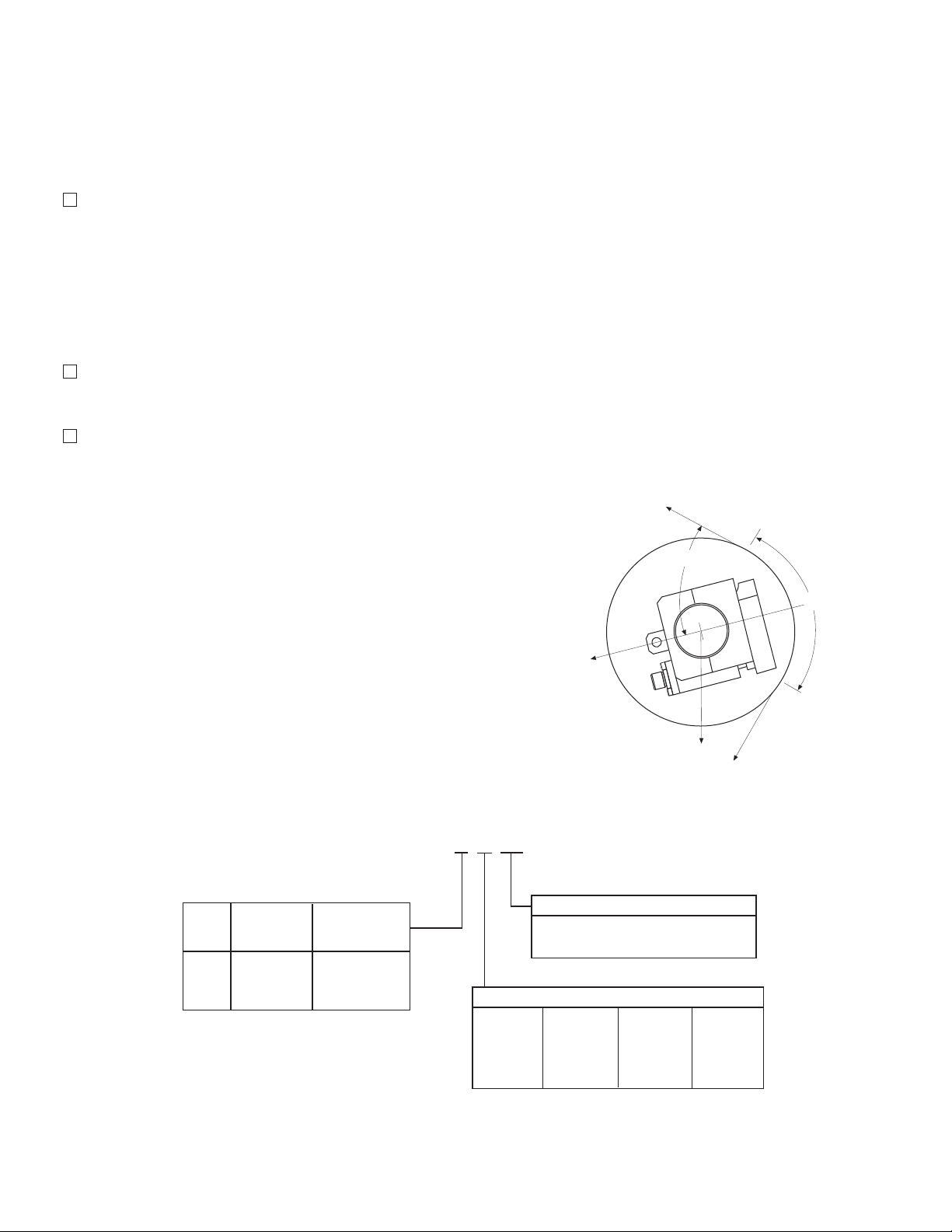

Installation

T

E

B

TW

T

RF

L

O

Tensioncell Model Number Designation

AC10B 18 W1

Code

A

B

C

Max. Load

Capacity

(pounds)

60

170

500

Min. Tension

Load for Setup

(pounds)

4

10

30

Example: AC10B18W1

AC10 = Side Mount Tensioncell

B = 170 pound capacity

18 = 1-1/8 inch shaft diameter

W1 = AC10 with split brushing

Support Bushing (AC10 only)

W1 = Split bushing for clamping

W2 = Solid bushing for expansion

08 1/2

09 9/16

10 5/8

11 11/16

12 3/4

13 13/16

14 7/8

15 15/16

16 1

17 1-1/16

18 1-1/8

19 1-3/16

20 1-1/4

21 1-5/16

22 1-3/8

23 1-7/16

24 1-1/2

Shaft Diameter

Pre-Installation Inspection

Before installing the AC10 system:

1. Insure all components are present. A typical

system consists of two AC10 Tensioncells,

one PSAC10 board, and two 30 foot lengths

of cable for connecting the Tensioncells to

the board. Refer to Model Number

Designation (Chart 1) below to verify load

capacity and shaft diameter.

2. Inspect all electrical and mechanical components for physical damage.

3. Promptly report any damage to the carrier

and Warner Electric.

Mechanical Installation – Tensioncells

The maximum rated load capacity must be

greater than or equal to (RF + TW) where W =

Tare Weight. The Web Resultant Force (RF) and

Tare Weight are always summed. Refer to the

Model Number Designation (Chart 1) below to

verify the shaft diameter, and that the maximum

rated load capacity of each unit.

Warner Electric also recommends the Resultant

Force (RF) be greater than 1/3 the maximum

load capacity of the Tensioncells.

Warner Electric side mount AC10 Tensioncells

are shipped in pairs designated W1 and W2.

The W1 unit has a split stainless steel, selfaligning bushing for clamping the measuring

roll. The bushing in the W2 unit is not split to

allow for shaft expansion.

AC10 Tensioncells are available in three capacity ranges. The rated load capacity should

always be larger than the maximum calculated

Tare Weight (W) plus the Resultant Force (RF).

To calculate the Resultant Force:

1. E = (180°-B/2) where B = Wrap Angle

2. RF = T x CosineE where T = Web Tension

Warner Electric • 800-825-9050 P-2012-2

14

Chart 1

Page 15

Before installing the Tensioncells, refer to

T

E

B

TW

T

RF

L

O

5/8-11 UNC

Mounting

Bolt

Machine

Frame

W1

Locating Tab

Centerline

Shaft Support

Block & Screws

W2

machine drawings, or other documentation

to determine the mounting angle. If the

mounting angle is not specified, mount the

Tensioncells so that the Tensioncell load line

(OL) bisects the wrap angle and aligns with

the Resultant Force (RF).

The Tensioncells are mounted to the machine

frame with a 5/8-11 UNC bolt. The bolt is in line

with the centerline of the shaft support bushing.

This allows the T

ensioncells to be rotated

around the centerline of the roll so that the

Tensioncell load line (OX) aligns with the

Resultant Force (RF).

To install the Tensioncells:

1. Drill a 5/8" diameter hole through each side

of the machine frame at the measuring roll

location. The holes must be in line with each

other and roll centerline to insure that the roll

is level.

2. Fasten the Tensioncell to the machine frame

with the 5/8-11 UNC mounting bolt.

3. Rotate the Tensioncell to the proper mount-

ing angle and tighten the mounting bolt.

4. Drill a #6 (.204) hole concentric with the 1/4"

hole in the locating tab.

5. Remove the Tensioncell to provide clearance

to tap the hole for a 1/4-20 thread.

6. Repeat steps 2 through 5 for the Tensioncell

for the other end of measuring roll shaft.

7. Loosen, but do not remove, the four screws

in the bottom of the shaft support block

enough to slide the Tensioncells on the roll

shaft.

Note: The mounting angle must be the

same for both T

ensioncells and the Load

Plate for both units must face in the same

direction.

8. Position the roll with the Tensioncells in the

machine and fasten them to the machine

frame with the mounting bolts. Tighten the

bolts enough to allow the T

ensioncells to be

rotated to the desired mounting angle.

9. Rotate the Tensioncells to align the locating

tab with the 1/4-20 threaded hole. Lock the

Tensioncells in position against the machine

frame using a 1/4-20 x 1/2 socket head cap

screw.

10. Tighten the mounting bolt on each unit.

11. Align the measuring roll so that there is no

mechanical binding or friction.

12. Tighten the four screws in the bottom of

each shaft support block.

Note: The mechanical stops are factory set

ovide 1000% overload protection.

to pr

Warner Electric • 800-825-9050 P-2012-2

15

Page 16

Electrical Installation

Oscillator

Demodulator

Shield to Pin H

Shield to Pin H

White to Pin G

Brown to Pin A

Pink to Pin E

Yellow to Pin C

Input

Output

P1

S1

S2

A

GH E C

A

H

G

C

D

E

FB

Sig

Sig

Exc

Exc

Gnd

Yellow

Pink

Brown

White

Shield

Yellow

Pink

Brown

White

Shield

Sig

Sig

Exc

Exc

Gnd

J2

J1

1

1

2

2

3

3

4

4

5

5

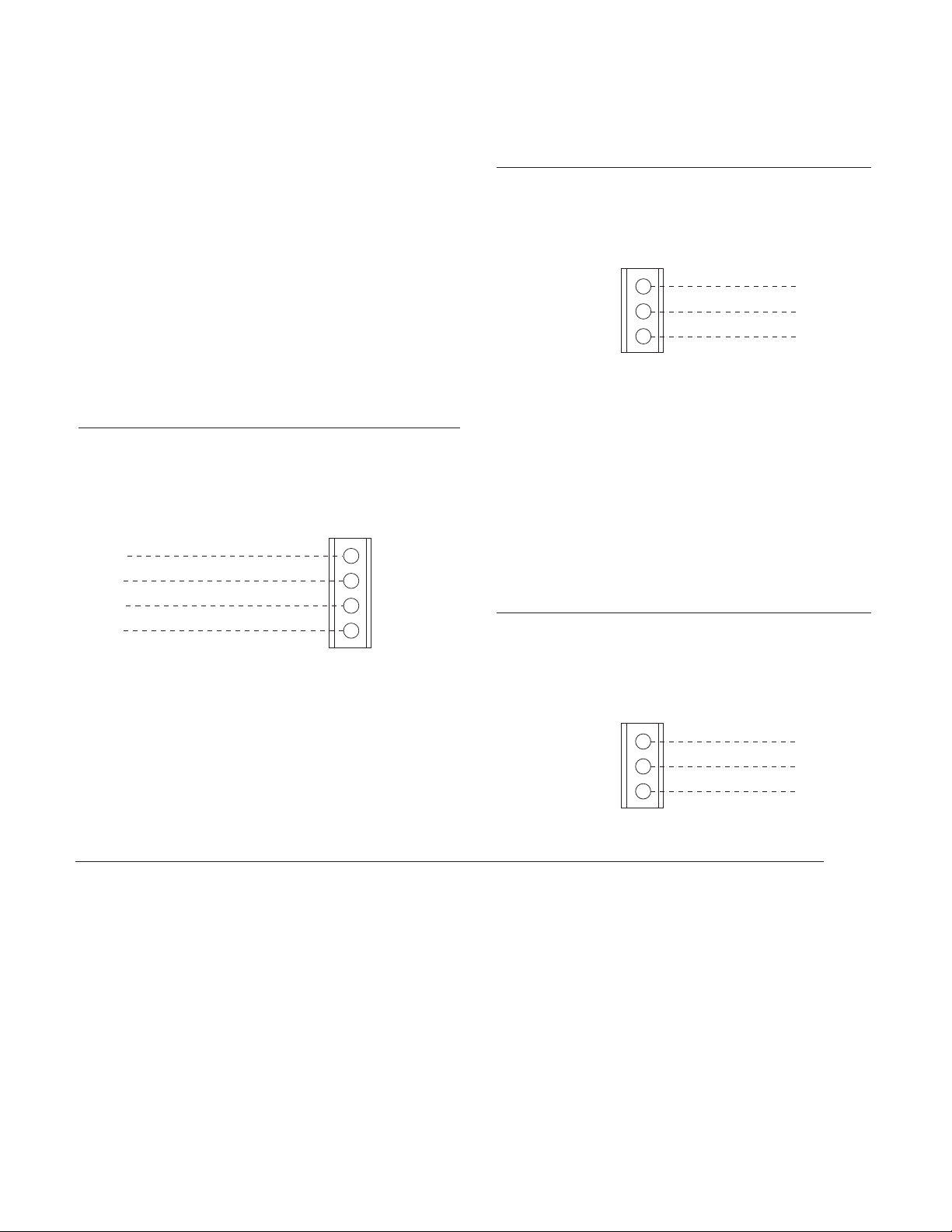

Electrical Connections

(Read the entire electrical installation procedure before proceeding.)

The PSAC10 Power Supply/Amplifier board

should be secur

ely mounted in a cabinet or

enclosure using the mounting holes and standoffs

INPUT provided. Refer to the dimension drawing

on Page 19 for mounting hole locations.

Two 30 foot cables are provided for connecting

the AC10 Tensioncells with the PSAC10 board. A

screw-on connector is provided at one end of

each cable for connecting to the AC10

Tensioncells.

Note: If the board must be located more than

30 feet away fr

om the Tensioncells, the cable

can be extended up to a total of 100 feet using

Belden #8723 (or equivalent) in a grounded steel

conduit.

Although either Tensioncell in the system can be

designated as Tensioncell #1 or #2, the following

electrical connections assume the AC10

Tensioncell marked W1 is Tensioncell #1 and the

Tensioncell marked W2 is Tensioncell #2.

Notes:

1. The wire color connections listed for J1 and

J2 will dif

fer if Belden #8723 (or equivalent)

cable is required. lnsure the correct wiring

connections are made with respect to the

connection made with the Warner Electric

supplied cable.

2. The Warner Electric supplied cable/connector assembly is an eight conductor cable.

However, only the yellow, pink, brown, and

white and shield wires used.

J1 to W1 Tensioncell Terminal Connection

with Warner Electric supplied cable

Terminal Label Description Wire Color

J1-1 Sig AC signal from LVDT Yellow

J1-2 Sig

AC signal from LVDT Pink

J1-3 Exc Excitation to LVDT Brown

J1-4 Exc Excitation to LVDT White

J1-5 Gnd Shield Shield

Note: Pins B, D & F are not used

Warner Electric Supplied Cable to Transducers

Tension signal from transducer 0-700mVAC, 5KHz

15 VAC, 5KHz excitation to the transducer

Tension signal from transducer 0-700mVAC, 5KHz

15 VAC, 5KHz excitation to the transducer

16

Warner Electric • 800-825-9050 P-2012-2

Page 17

J2 to W2 Tensioncell Connection with Warner

Gnd

L1

L2

J3

230V

1

2

3

X

X

2-Only

1-Only

Gnd

J5

Cell #2Cell #1

Total

1

2

3

2L1

1L1

2L2

1L2

J4

1

2

3

4

Electric supplied cable

Terminal Label Description Wire Color

J2-1

Sig AC signal from LVDT Yellow

J2-2 Sig AC signal from LVDT Pink

J2-3 Exc Excitation to LVDT Brown

J2-4 Exc Excitation to LVDT White

J2-5 Gnd Shield Shield

J3 Input Power (115/230 VAC, 1-PH, 50/60 Hz)

Terminal Label Description Wire Color

J3-1 Gnd Ground Green

J3-2 L1 L1 (230V) or Hot (115V) Black

J3-3 L2 L2 (230V) or Neutral (115V) White

Terminal Label Description

J4-1 2L1 (Switched) Line 1

J4-2 1L1 (Hot) Line 1

J4-3 2L2 (Switched) Line 2

J4-4 1L2 (Hot) Line 2

J5 Cell#1/Total/Cell#2 Switch Terminal (For

Output #2 only)

Make sure voltage select

switch is in proper position

Input Power single phase

115 or 230 VAC

The input voltage selector switch must correspond to the voltage of the input power

source.

J4 AC Power Switch and/or Power Indicator

Terminal

J4 provides the terminal connection for an external AC Power Switch and/or power indicator

. The

indicator should not draw more than 40 milliamps

of current. J4 may also be used to supply AC

power to a digital voltmeter by connecting the

meter between J4-2L1 and J4-2L2.

J5 provides the connections for an external

three-position switch with two normally open

contacts. When used in conjunction with a

remote meter, the switch allows the user to

monitor total tension or the tension applied to

either Tensioncell. The meter should be connected to Output #2 at J6, terminals Out2 and Gnd.

With the switch in the normally closed position,

Output #2 will indicate the total tension. In the

Cell#1 position, Output #2 switches to indicate

the tension measured by the W1 Tensioncell.

Changing to the Cell#2 position switches Output

#2 to indicate the tension applied to the W2

Tensioncell.

Terminal Label Description

J5-1 2-Only (Switched) tension W1

J5-2 1-Only (Switched) tension W2

J5-3 Gnd Ground

Note: If an ON-OFF switch is not used,

jumpers must be installed fr

om J4-2L1 to

J4-1L1 and from J4-2L2 to J4-1L2 for

proper operation.

Warner Electric • 800-825-9050 P-2012-2

17

Page 18

J6 Analog Outputs Terminal

Out 2

Gnd

Out 1

Gnd

J6

Output #2 ( -10 to +10 VDC)

Common

Output #1 ( -10 to + VDC)

Common

1

2

3

4

Normally Closed

Common

Normally Open

J7

NC

COM

NO

1

2

3

Ground

Data Line -

Data Line +

J8

Gnd

Tx-

Tx+

1

2

3

The J6 terminal provides the connections for the

two 10 volt DC outputs. Each output can provide

up to 30 milliamp current.

During setup, each output is individually

scaleable to meet the requirements needed to

calibrate the indicator, drive, or control connected to the board. The board circuitry is designed

to allow a switch to be connected at Terminal J5.

This switch allows the user to monitor the Output

#2 signal with respect to total tension, or the tension applied to either Tensioncell.

The contact may be wired to function in either

the normally open or normally closed state.

Terminal Label Description

J7-1 NC Normally Closed Contact

J7-2

J7-3 NO Normally Open Contact

COM Common

Terminal Label Description

J6-1 Out2 Scaleable -10 to +10 VDC Output

J6-2 Gnd Common

J6-3 Out1 Scaleable -10 to +10 VDC Output

J64 Gnd Common

J7 Threshold Relay Terminal

J7 provides the connections for utilizing the

AC10 Threshold Relay which is a form "C" dry

relay contact, rated at 1 Amp. During setup, the

threshold (percentage of total tension) is programmed to operate when the total tension is

either above or below the threshold value.

J8 RS232 Output Terminal

J8 provides the cable connections for interfacing the PSAC 10 board with a PC to monitor

total tension and tension applied to each

Tensioncell. Data is transferred in ASCII text format.

Terminal Label Description

J8-1 Gnd Ground

J8-2 Tx- Data Line +

J8-3 Tx+ Data Line-

J9 (Spare)

Initial Electrical Checks

Before applying power:

Note: Make sure that the Input Power Selector Switch matches the available input voltage.

Switch 1 2 3 4 5 6 7 8

Position ON ON ON ON OFF ON ON ON

Apply power.

The red Run Mode LED in the lower right hand corner of the board should be flashing.

Warner Electric • 800-825-9050 P-2012-2

18

V

erify that the 8-position dip switch is set as follows:

Page 19

AC10 Setup Procedure

Compression

Te nsion

Important: The input to any external device

wired to J6-3 Out1 or J6-1 Out 2 must be 10

VDC or less.

4. Press ENTER when the desired mode is displayed.

Steps 5 through 8 are performed with only

the tar

e load applied on the Tensioncells.

The following procedure assumes a digital voltmeter will be used when measuring and setting

the desired output voltages. If the outputs are

connected to a digital or analog indicating

device, which will be used during normal operation, these devices may be used during the setup

procedure.

Note: The voltage setting for Output #1 at

100% load must be mor

e positive than the

voltage setting at 0% load. The same

applies to the voltage settings for Output #2.

With power applied to the PSAC10 board, allow

the system to "warmup" for 20 minutes or

longer before proceeding with the setup procedure.

ess and release the SETUP and UP-

1. Pr

ARROW keys simultaneously. An asterisk (*)

will display next to the right tension value.

Note: To exit the SETUP mode at anytime during the following pr

ocedure, press and release

the EXIT key. The system will return to the settings entered during the last completed setup.

5. Apply Load 0%

Insure that the Tensioncells are properly

installed and the material is r

emoved from

the measuring roll.

6. Press ENTER.

0% 0% *0%

2. Press and release SETUP & ENTER simultaneously to start the SETUP pr

ocedure.

Note: The Run Mode LED should stop flashing.

Compression Mode

3. Select either the COMPRESSION MODE or

TENSION MODE using the UP or DOWN

arrow key to toggle between the two choices.

Select the COMPRESSION MODE if the

a.

direction of the tension force is toward the

base block.

b. Select TENSION MODE the direction on

the tension force is away from the base

block.

Warner Electric • 800-825-9050 P-2012-2

19

Page 20

7. Adjust Out 1 0%

Out 2

Gnd

Out 1

Gnd

J6

Output #2 ( -10 to +10 VDC)

Common

Output #1 ( -10 to + VDC)

Common

1

2

3

4

Scale

W eb Path

Roll

Rope

W eb Path

Roll

Rope

W eights for

Max. Tension

a. Connect a digital voltmeter between J6-3

Out 1 and J6-4 Gnd.

Press the UP or DOWN arrow key (and

b.

RAPID key if necessary) until the desired

no load output voltage is attained.

c. Press ENTER.

Note: All rolls used in the pull test

should be free running rolls.

c. With one end of the rope secured, hang a

weight equal to the full load tension. (50%

if selected)

A crane scale may be used to apply the

equired load.

r

d. Press ENTER.

10. Adjust Out 1 100%

a. Connect a digital voltmeter between J6-3

Out 1 and J6-4 Gnd.

8. Adjust Out 2 0%

a. Connect a digital voltmeter between J6-1

Out 2 and J6-2 Gnd.

Press the UP or DOWN arrow key (and

b.

RAPID key if necessary) until the desired

no load output voltage is attained.

c. Press ENTER.

Note: Steps 9 through 12 can be performed

with 50% or 100% load applied when setting

Output #1 and Output #2 voltage. Refer to

the table at the right for minimum r

esultant

load required for setup before proceeding.

9. Apply Load 100%

a. Press the UP or DOWN arrow key to tog-

gle between 50% or 100%. When desir

percentage is displayed.

ed

b. Pr

ess the UP or DOWN arrow key (and

RAPID key if necessary) until the desired

full load output voltage is attained.

c. Press ENTER.

b. Thread a non-stretchable rope over the

Warner Electric • 800-825-9050 P-2012-2

20

The illustrations at the right show two pull

test methods. These tests are used to

apply a load representative of the web

tension. The load should be equal to the

percentage of the full load selected (50%

or 100%).

center of the tension measuring roll simulating the web path.

Model Max Load Min. Tension

Capacity Load for Setup

(Pounds) (Pounds)

ACIDA 60 4

ACIDB 170 10

ACIDC 500 30

Table 2

Page 21

11. Adjust Out 2 100%

5. Press ENTER to select the desired mode.

a. Connect a digital voltmeter between J6-1

Out 2 and J6-2 Gnd.

Press the UP or DOWN arrow key (and

b.

RAPID key if necessary) until the desired

output voltage is attained.

c. Press ENTER.

12. Setup Complete

a. Press ENTER.

Programmable Threshold Relay

The Threshold Relay can be programmed to

Close on Higher (if the total tension goes above)

or Close on Lower (if the total tension goes

below) a preset programmable threshold

between 0% and 102% of the total tension. The

dry relay contact is rated at 1 amp @ 24VDC,

250mA @ 220 VAC, or 500 mA @ 120 VAC.

Note: The threshold may be set while the

web machinery is in operation. Although

the LCD will not be showing the tension,

Output #1, Output #2, and the serial output

will still be r

esponding to tension changes.

If the threshold value or mode is reset with the

equipment operating, the new value will take

fect immediately.

ef

Reset Tare to Zero

The tare value may be zeroed to compensate

for any offsets accumulated during normal operation. Press the SETUP and EXIT keys simultaneously to reset the tare to zero.

Note: Resetting tare to zero must be done

with no tension load applied.

A lamp may be connected between J7-3 NO (or

J7-1 NC) and J7-3 COM during setup, start up,

and/or normal operation to verify the relay is

operating properly.

To set the threshold value:

1. Press the SETUP & RAPID keys simultane-

ously. The display will show a message indicating the current value of the threshold. The

Run Mode LED will continue to flash.

Threshold 000%

2. Press the UP or DOWN arr

ow key until the

desired threshold value is displayed.

3. Press ENTER to select the value.

4. Press the UP or DOWN arrow key to toggle

between the CLOSE ON LOWER or CLOSE

ON HIGHER prompt.

Close on Lower

Warner Electric • 800-825-9050 P-2012-2

21

Page 22

Troubleshooting

Test Points

TP5, TP6, TP7,

TP8, TP9

Enter

J7

J8

J9

LCD Brightness

Adjustment

+5VDC

-5VDC

-5VDC

+5VDC

GND

Test Points

TP2, TP3, TP4

When properly installed in accordance with the

design specification and procedures outlined in

this manual, the AC10 Tension Measuring

System should require little or no regular maintenance or service. Certain conditions, however,

can impair the accuracy, reliability, and performance of the system. The following are some

conditions to consider which may effect the

mechanical and/or electrical components of the

system.

1. Have the system operating parameters

changed?

a. Has the web tension changed?

b. Does the tension plus tare load exceed

the maximum rated load capacity of the

unit?

9. Verify the following voltages.

TP3 to TP7 +10 volts DC

TP4 to TP7 +2.5 volts DC

TP5 to TP7 +15 volts DC

TP6 to TP7 +5volts DC

TP8 to TP7 -5 volts DC

TP9 to TP7 -15 volts DC

10. Are outputs responding to tension changes?

Check connections and voltages at J1, J2,

and J6.

11. Does the output signal(s) from the board

meet the voltage requirements for the

device(s) connected to it?

12. Is the Excitation Voltage to the LVDTs correct?

c. Has the Wrap Angle changed?

2. Are the Tensioncells mounted correctly and

securely?

3. Is the tension measuring roll properly aligned

and does it turn freely?

4. Is the line voltage present and the on-board

Input Power Selector Switch in the correct

position?

5. Is an external power switch connected and

operating correctly? If an external switch is

not used, are the jumpers properly installed

at J4? See page 11.

6. Are all fuses and/or circuit breakers installed

and functional? There are two 250V, 500mA

fuses on the board.

7. Is the Run Mode Indicator LED flashing? If

not, check if the system is in Setup mode.

8. Is the on-board display lit? Check LCD

Brightness Adjustment.

Warner Electric • 800-825-9050 P-2012-2

22

Page 23

a. Using an AC volt meter with at least

5Khz band width, measure the voltage

between J1-3 Exc and J1-4 Exc. The

meter should read 15Vrms ~ 5Khz ±

5%. If excitation voltage is low, turn off

power to the board and remove the J1

connector. Turn power back on and

recheck. If voltage is correct, check for a

short in Tensioncell cable assembly.

Repeat test for Cell #2 at J2.

b. With board power off, remove the J1

connector and measure the resistance

between the Yellow (J1-1 Sig) and Pink

(J1-2 Sig) wire terminals. The resistance

reading should be 335 ohms ± 5%. The

resistance between White (J1-3 Exc) and

Brown (J1-4 Exc) wire terminals should

be 100 ohms ± 5%. If readings are incorrect, disconnect cable at the Tensioncell

designated as Cell #1, and check resistance between pins C and E, and A and

G. Repeat test for Cell #2 at J2.

13. Does the system zero? Press the SETUP

and EXIT keys simultaneously.

14. Does repeating Setup procedure help?

15. If problem(s) persists, contact your local

Warner Electric Representative or the

factory.

Warner Electric • 800-825-9050 P-2012-2

23

Page 24

See Note

3.13

2.13

3.44

1.13

5/8-11 UNC

.93 Full Th’d

for Mounting

Bolt

Electrical

Connector

2.50

.25 Dia. Hole

For Locking

Screw

3.90

1.13

2.00

.75

3.00

Note:Stainless steel self-aligning bushing provided

for 1/2” to 1-1/2” diameter shafts in 1/16” increments.

+

.50

2.00

.25

1.31

1.44

W2 unit shown here.

W1 unit is available.

AC10 Tensioncell Dimensional Drawings

(Specifications and dimensions subject to change without notice.)

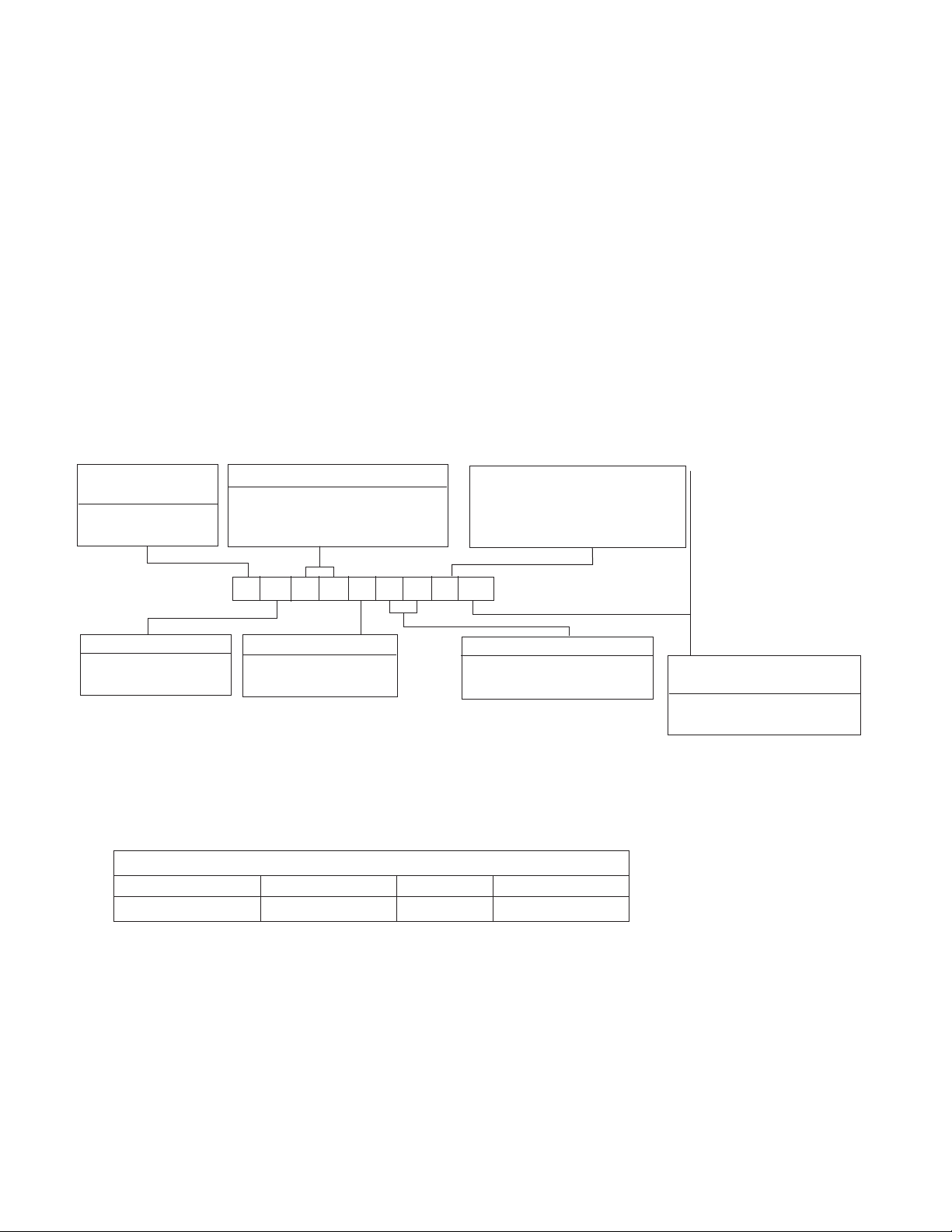

Tensioncell Model Number Designation

A C 1 0 B 1 6 W 1

Max.Load Min.Tension

Code Capacity Load for Setup Support Bushing (AC10 only)

(pounds) (pounds) W1 = Split bushing for clamping

A 60 4 W2 = Solid bushing for expansion

B 170 10 S = System, which includes one “W1” cell,

C 500 30 one “W2” cell, two 30 ft cables and a

Examine: AC10B16W1 Shaft Diameter

AC10 = Side Mount Tensioncell

B = 170 pound capacity 16 1

16 = 1 inch shaft diameter 20 1-1/4

W1 = AC10 with split bushing 23 1-7/16

12 3/4

PSAC10 board.

Warner Electric • 800-825-9050 P-2012-2

24

Note: Other shaft diameters are available.

Page 25

PSAC10 Board Dimensions

1.31

.31

.25

5.75

3.13

J3

J4

6.88

6.25

3.13

Mounting

Holes

.250 Dia.

(7) Places

J6

J5

8.25

Warner

Part# PSAC10

Serial#

Setup

Rapid

Exit

Setup

Enter

J7

8.75

J8

J9

J1

J2

Specifications and dimensions subject to change without notice.

Warner Electric • 800-825-9050 P-2012-2

25

Page 26

Warner Electric • 800-825-9050 P-2012-2

26

Page 27

P-2012-3

819-0403

A30 Single Range Tensioncells

Warner Electric • 800-825-9050 P-2012-3

27

Page 28

Description

Damper

C-Flexure

A. General Information

Warner Electric Series 30 Type A Tensioncells

are force transducers, specially designed to

measure and control tension on single strand

wire, cable or filaments, on continuous strip processing lines. They convert the mechanical

force of strand tension into an electrical signal,

which is directly proportional to the strand tension.

Type "A" Tensioncells are installed as single

units with a pulley or sheave (See Figures 1a

and Figure 1b). They are intended for NONROTATING shaft installations. Tensioncells can

be provided to accept shaft sizes from 3/4 inch

to 1-7/16 inch. (See Table 1-B, Page 11)

B. The Mechanical System

The mechanical system consists of a Patented

"C-Flexure Pivot Assembly" which incorporates

a mounting Base Block, frictionless elastic pivot

(or hinge), and Load Plate. (See Figure 2) When

a mechanical force is applied to the Load Plate,

the pivot permits its deflection toward or away

from the Base Block.

For our discussion here, deflection of the Load

Plate toward the Base Block is defined as the

"Compression Mode", while the opposite is

defined as the "Tension Mode". Tensioncells are

designed to operate equally well in either mode.

The Base Block contains an integral Mechanical

Stop to limit the amount of deflection in either

direction, and a Viscous Damper to allow control

of the tensioncell response to rapid changes in

apparent tension loads. (See Figure 2)

W1

Figure 1a Figure 1b

W1

Figure 2

Warner Electric • 800-825-9050 P-2012-3

28

Page 29

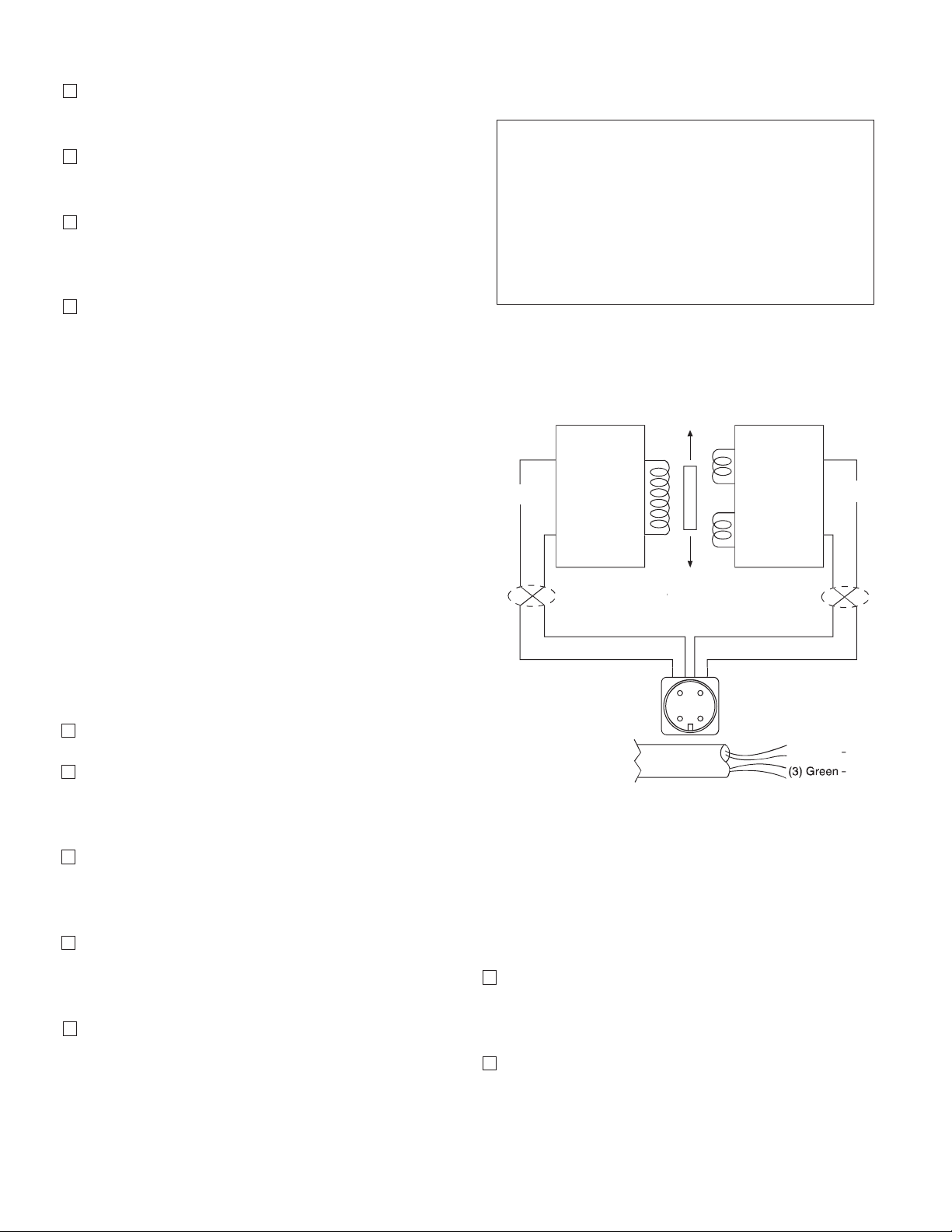

C. The Electrical System

Black - (2)

Red + (1)

Green (3)

Blue (4)

Input

Output

X Twisted Leads

A B

Oscillator Demodulator

P1

S1

S2

X

X

When Supplied

with Cable

(1) Red + DC

(2) Black – DC

(3) Green – Signal

(4) White + Signal

C D

BAC

D

.030

ion

Output vs Deflection

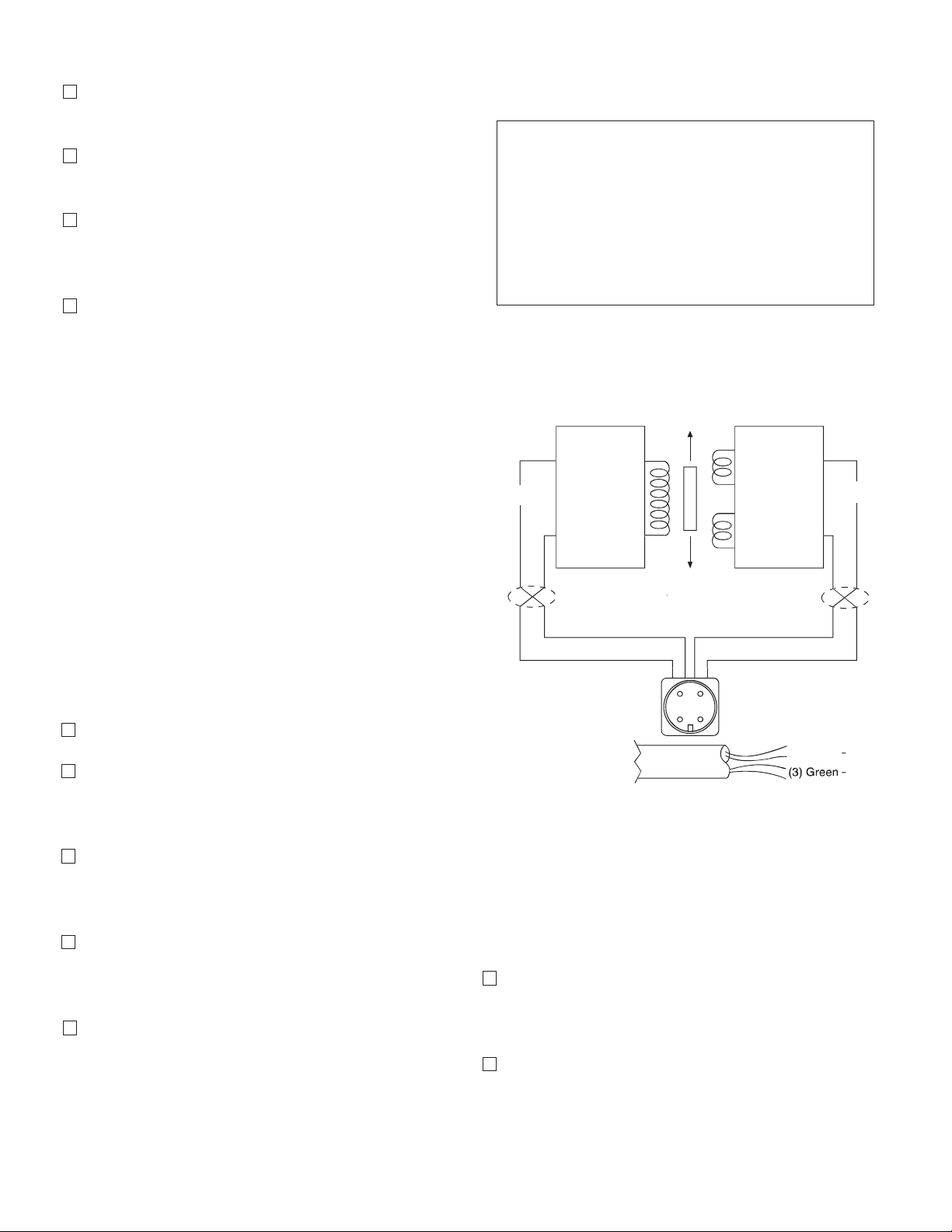

The electrical system consists of a Linear

Variable Differential Transformer (LVDT) which

converts the mechanical deflection of the Load

Plate into a useful electrical output signal. (See

Figure 3) The moveable core of the LVDT is

mechanically coupled to the Load Plate.

This core assemble is factory set and is not

accessible.

D. Type "K" DC LVDT

As illustrated in Figure 3, a DC LVDT consists of

the following components:

• An oscillator network, which converts the DC

input voltage into a high frequency alternating current for exciting the primary coil (P1)

• A Primary Coil (P1)

• A movable, permeable metallic core

• Two Secondary Coils (S1 and S2)

• A demodulator and summing network to rectify and integrate the currents from the

Secondary Coils

With Warner Electric LVDTs, the input and output circuits are electrically isolated from each

other and from the mechanical structure of the

tensioncell. Thus, they may be used in "floating

ground" or "ground return" systems. This eliminates the need for extra circuit boards which are

required for most straingage loadcells.

Tensioncells are factory adjusted to provide an

offset voltage with no load applied (no deflection). Using an input of 24 volts DC, the LVDT is

set to provide an output of 3.5 volts into a resistive load of not less than 100,000 ohms. The

voltage resulting from the maximum rated

deflection then adds to or subtracts from the 3.5

volt offset. This results in an output voltage of

3.5 to 6.5 volts in the Compression Mode and

3.5 to 0.5 volts in the Tension Mode. (See

Figure 4)

While acceptable performance may be obtained

over an input voltage range of 6.0 to 30.0 volts

DC, the output voltage will vary in direct proportion to the input voltage. Because of this, the

use of a well regulated constant voltage power

supply is essential for accurate and repeatable

tension measurement.

Warner Electric • 800-825-9050 P-2012-3

Figure 3

LVDT Output vs. Deflection Chart

Figure 4

29

Page 30

E. Description of Operation

E

D

H

E

RF

N

TW

T

T

The total resultant load per cell (RF) is calculated by resolving all force vectors acting upon the

Tensioncell, with respect to the Loading Line

(OL). (RF) is the resultant of both TENSION and

TARE loads, PER CELL!! (See Figure 5)

The intrinsic design of Warner Electric

Tensioncells allows the location of the Resultant

Load of Strip Tension (H) on any angle with

respect to the Load Line (OL). Note, however,

that the Total Force vector (RF) must always be

calculated on the line (OL).

Any force vector falling on the line (OR) (through

the pivot point of the C-Flexure) will produce no

deflection, and thus no electrical output.

Rotating the Tensioncell on its mounting bolt

changes the force vectors on the cell. This feature makes it possible to minimize the tare component and maximize the load signal output.

The resultant tare is minimized by mounting the

Tensioncell so that (N) is 31°. (See Figure 6)

Figure 5

Warner Electric • 800-825-9050 P-2012-3

30

Figure 6

Page 31

Installation and Operation

A. Inspection Upon Delivery

Warner Electric tensioncells are carefully packaged in sturdy reinforced cartons or wooden

boxes and are securely blocked or bolted in

place.

1. Upon receipt, examine the exterior of the container for obvious damage or tampering.

2. Check the contents against the packing list.

3. Promptly report any damage or shortage to

both the carrier and Warner Electric.

B. Handling

Tensioncells can be handled manually.

C. Long Term Storage

While Warner Electric loadcells are plated, exposure to weather, dirt, or moisture should be avoided when they are stored.

The locating tab prevents the Tensioncell from

rotating and secures it in a permanent location.

It also provides a means of repeating rotary

position when the Tensioncell needs replacement.

Note: Remove the 1/4" locking screw and

the 5/8" mounting bolt. This permits the r

assembly with Tensioncells to be lifted out

of the machine.

oll

D. Mechanical Installation

Note: Refer to the Dimension Drawing Pages

10 and 11 of this manual for detailed

identification of all parts.

Tensioncells are designated as W1 and W2, one

being the mirr

Warner Electric Wall Mounted Tensioncells are

mounted to the machine frame by a 5/8-11 UNC

bolt which is in line with the centerline of the

measuring roll shaft. This allows the Tensioncell to

be rotated around the centers of the measuring

roll and mounting bolt to achieve the proper

mounting angle. (Description of Operation on

Page 5)

or image of the other. (See Figure 7)

Figure 7

Warner Electric • 800-825-9050 P-2012-3

31

Page 32

To install Tensioncells:

Black - (2)

Red + (1)

Green (3)

Blue (4)

Input

Output

X Twisted Leads

A B

Oscillator Demodulator

P1

S1

S2

X

X

When Supplied

with Cable

(1) Red + DC

(2) Black – DC

(3) Green – Signal

(4) White + Signal

C D

BAC

D

1. Make sure a 5/8” diameter hole is drilled

through the machine frame in line with the

centerline of the measuring roll shaft for the

5/8-11 UNC mounting bolt.

E. Mechanical Alignment

Align the sectional measuring roll to avoid any

mechanical binding or friction. The measuring

roll must be level and perpendicular to the path

of the strip material for accurate measurement.

2. Fasten the Tensioncell to the machine frame

with the mounting bolt.

3. Rotate the Tensioncell to the proper mounting angle and tighten the mounting bolt.

(Refer to Y on the calibration sheet for the

proper mounting angle.)

4. Drill a #6 (.204) hole concentric with the 1/4"

hole in the locating tab.

5. Remove the Tensioncell and tap the hole for

a 1/4-20 thread.

6. Assemble the Tensioncells onto the ends of

the measuring roll shaft.

7. Position the roll with the Tensioncells on the

machine and fasten with the mounting bolts.

8. Rotate the Tensioncells to the proper mounting angle and tighten the mounting bolts.

The Mechanical Stops are fixed for the required

travel of the Load Table.

F. Electrical Installation

(Read the entire electrical wiring procedure

before proceeding.)

1. Turn off all electrical power to the loadcell.

2. Use twisted four conductor signal cable,

Belden 9402 or equivalent, in grounded steel

conduit from the LVDTs to the control panel.

3. Observing correct polarity, connect the positive (+) input lead to Pin A and the negative

(-) input lead to Pin B. (See Figure 8)

4. Connect the positive (+) output lead to Pin D

and the negative (-) output lead to Pin C.

(See Figure 8)

9. Lock the locating pad for each Tensioncell

against the machine frame using the 1/4-20

x 1/2 socket head cap screw.

10. Tighten the shaft in the mounting block on

the W1 unit.

Figure 8

Warner Electric • 800-825-9050 P-2012-3

32

Page 33

Set up and Adjustments Specifications

Roll

Rope

Web Path

Weights for

Type "K" 24 volt DC LVDT Specifications

Input . . . . . . . . . . . . . . . . . . . . . . . . .6-30 volts DC

Output . . .0.5-6.5 volts DC (nominal, open circuit)

Output Impedence . . . . . . . . . . . . . . . .2.5K ohms

Current Consumption . . . . . . . . . . . . . . . . . .40 mA

Recommended Load . . . . . .100K ohms or greater

Max. Operating Temp . . . . . . . . . . . . . . . . . .250°F

Note: Warner Electric loadcells are

calibrated for 24 volt DC input voltage to

ovide a 0.5 to 6.5 volts DC output signal.

pr

Full Load Adjustment

After the loadcell has been zeroed, a pull test

can be made to check the output voltage of the

loadcell at full load.

1. Run a non-stretchable rope over the center

of the tension roll simulating the web path.

(Note: The rolls should be free to turn.)

With one end of the rope secured, hang a

2.

known weight equally over the roll so that

the total tension is equal to the maximum

strip tension specified on the calibration

sheet, at the other end. (See Figure 9)

Electrical Zero Adjustment

(Read the complete Electrical Zero Adjustment

procedure before proceeding with the adjustment.)

1. Disengage strip from the measuring roll so

that no tension force is applied to the loadcell.

2. Connect a voltmeter to Pins C and D. (See

Figure 8)

Apply 24 volt DC electrical power to the

3.

loadcell observing the correct polarity. [Plus

(+) to Pin A and minus (-) to Pin B.] Do not

exceed the maximum rated input voltage.

Note: Allow 20 minutes for the loadcell to

warmup befor

insure accurate readings.

e taking first readings to

3. With a voltmeter connected to Pins C and D

of the connector, an output voltage will be

observed.

Warner Electric Ioadcells instrumentation provides the required signal conditioning and a reliable high level output signal for use as feedback

control of a tension drive system. The feedback

signal is directly proportional to the strip tension

applied. If a Warner Electric control is used,

refer to the control manual for further calibration.

Although the electrical output of Warner Electric

tensioncells are sufficient to drive most electrical

indicators, substantial signal conditioning is normally required for effective tension instrumentation system control. Refer to the documentation

available from the instrumentation supplier for

more information.

4. Measur

e the output voltage of the LVDT

between the Green and Blue leads for each

tensioncell with a volt meter with a sensitivity

of at least 100,000 ohms per volt. The output voltage should be between 0.5 and 6.5

volts.

5. Since Warner Electric Tensioncells cannot be

mechanically zeroed, refer to the Control

Manual for zeroing out the tare weight voltage.

Warner Electric • 800-825-9050 P-2012-3

(Figure 9)

33

Page 34

Trouble Shooting

Black - (2)

Red + (1)

Green (3)

Blue (4)

Input

Output

X Twisted Leads

A B

Oscillator Demodulator

P1

S1

S2

X

X

When Supplied

with Cable

(1) Red + DC

(2) Black – DC

(3) Green – Signal

(4) White + Signal

C D

BAC

D

3. Are LVDTs open or shorted?

When properly installed in accordance with the

original design specifications Warner Electric

tensioncells should require little or no regular

maintenance or service.

Certain conditions, however, can impair their

inherently accurate and reliable performance.

Therefore, if trouble should arise, the following

conditions should be checked.

1. Has the tension measuring system been

changed?

a. An increase or decrease in strip tension.

b. An increase or decrease in the wrap

angle.

If the above parameters have been

changed enough to prevent the unit from

operating within the limits of the fixed

Mechanical Stop, restore parameters to

previous condition or consult factory.

2. Is the loadcell mounted securely?

To check, turn off power and disconnect the

input and output leads. Check coil continuity

and resistance. (Refer to Figure 10)

Figure 10

a Pin A to Pin B (Primary Coil) should be in

excess of 2 megohms.

3. Is tension measuring roll in proper alignment

and does it turn freely?

4. Are bearings and seals free of all binding

and stickiness? Are they worn?

b. Pin A or Pin B to LVDT shell should be in

excess of 5 megohms.

c. Pin C to Pin D (Secondary Coil) should

be approximately 20,000 ohms.

d. Pin C or Pin D to LVDT shell should be in

Electrical

1. Are LVDTs receiving correct input voltage?

Check line voltage, fuses or circuit breakers,

and power switches. Check power supply

If LVDT circuits are open or shorted, replace

LVDT. Contact Warner Electric with tensioncell

model number and serial number.

excess of 5 megohms.

output and voltage to LVDTs.

2. Are all connections secure?

Check for continuity. Retighten all connec-

tions. Recheck operation.

Warner Electric • 800-825-9050 P-2012-3

34

Page 35

Recalibration After Installation

Wall Mounted Tensioncells can be relocated

around the center of the measuring roll. The theory of this operation is explained in the

Description of Operation on Page 5. If this procedure cannot accomplish the necessary

changes because the tension requirements are

extremely different than the original application,

it will be necessary to return the Tensioncells to

the factory for new cells.

Model Number Nomenclature Example

Electrical

Connection

B - MS Connector

Type

A - Pulley or Sheave

Note: For dual load cell applications “W1” and “W2” cell are required.

Series Number (2 Digits)

30 Wall Mount

B A 3 0 T 1 6 K W1

Capacity Range

See Table 1-A

K - DC LVDT with

Maximum 3 VDC

Output Change Including

Tare Displacement

Shaft Diameter

See Table I-B for Type A

Series 30, Type A Specifications – Non-Rotating Shaft Mounting

Series 30, Type A – Nominal Capacity Ranges

Code P T U

Pounds 0-20 0-50 0-90

Example Shown:

BA30T16KW1

B = MS Connector

A = Pulley Mount

30 = Series 30, Wall Mount

T = 0-50 lbs. Capacity

16 = 1” Diameter Shaft

K = K Type DC LVDT

W = Split Bushing

Shaft Mounting

Configuration

W1 Split bushing

W2 Solid bushing

Table I-A

Note: Other load ratings are available as special order .

Contact Warner Electric for other load ranges

available.

Warner Electric • 800-825-9050 P-2012-3

35

Page 36

3.75

for Locking

** Warner Electric wall mounted tensioncells are located by a 5/8-11 bolt at the roll centerline

and locating tab which maintains rotational position to the tensioncell. (See Page 5.)

Shaft Specifications

Code 3/4 1.0

1-1/4

Inches 12 16 20

Table I-B

Note: Other shaft diameters are available as special

. Contact Warner Electric for other shaft

order

diameter availiblilty.

Warner Electric • 800-825-9050 P-2012-3

36

Page 37

P-2012-4

819-0404

B30 Single Range Tensioncells

Warner Electric • 800-825-9050 P-2012-4

37

Page 38

Description

W1

W2

Machine

Frame

B30 Series Tonsioncell

Single Bolt Mounting

Internal

Bearing

Damper

C-Flexure

Far Side

Mechanical Stop

Load

Plate

LVDT

LVDT

Core

General Information

Warner Electric Series 30 Type B Tensioncells

are force transducers especially designed to

measure and control web tension on continuous

strip processing lines. They are normally

installed in matched pairs at each end of a

measuring roll. (See Figure 1)

A Tensioncell consists of a unique combination

of two integral systems (one mechanical, the

other electrical) for converting the mechanical

force of strip tension into an electrical signal

which is directly proportional to the strip tension.

Type "B" Tensioncells are intended for NONROTATING shaft installations. A self-aligning

shaft clamp assures proper alignment of the

measureing roll when the tension cells are bolted to the machine frame. Type "B" Tensioncells

are supplied in matched pairs, one to be mounted at each end of the tension measuring roll.

Note that the cell marked "W2" is a mirror image

of "W1". The 'W2" cell allows for thermal expansion of the shaft. (See Figure 1)

The Mechanical System

The mechanical system consists of a Patented

"C-Flexure Pivot Assembly" which incorporates

a mounting Base Block, frictionless elastic pivot

(or hinge), and Load Plate. (See Figure 2) When

a mechanical force is applied to the Load Plate,

the pivot permits its deflection toward or away

from the Base Block.

Figure 2

38

Type B - Bearings in Roll - Non-Rotating Shaft

Figure 1

Warner Electric • 800-825-9050 P-2012-4

Page 39

For our discussion here, deflection of the Load

DC

Signal

Plate toward the Base Block is defined as the

"Compression Mode", while the opposite is

defined as the "Tension Mode". Tensioncells are

designed to operate equally well in either mode.

The Base Block contains an integral Mechanical

Stop to limit the amount of deflection in either

direction, and a Viscous Damper to allow

control of the tensioncell response to rapid

changes in apparent tension loads. (See Page 3,

Figure 2)

Type "K" DC LVDT

As illustrated in Figure 3, a DC LVDT consists

of the following components:

• An oscillator, which converts the DC input

voltage into a high frequency alternating

current for exciting the primary coil (P1)

• A Primary Coil (P1)

• A movable, permeable metallic core

• Two Secondary Coils (S1 and S2)

The Electrical System

The electrical system consists of a Linear

Variable Differential Transformer (LVDT) which

converts the mechanical deflection of the Load

Plate into a useful electrical output signal. (See

Figure 3.) The movable core of the LVDT is

mechanically coupled to the Load Plate by

means of the Core Adjust Assembly. (See Figure

3) This adjustment is factory set and is not

accessible.

• A demodulator and summing network to

rectify and integrate the currents from the

Secondary Coils

Figure 3

Warner Electric • 800-825-9050 P-2012-4

39

Page 40

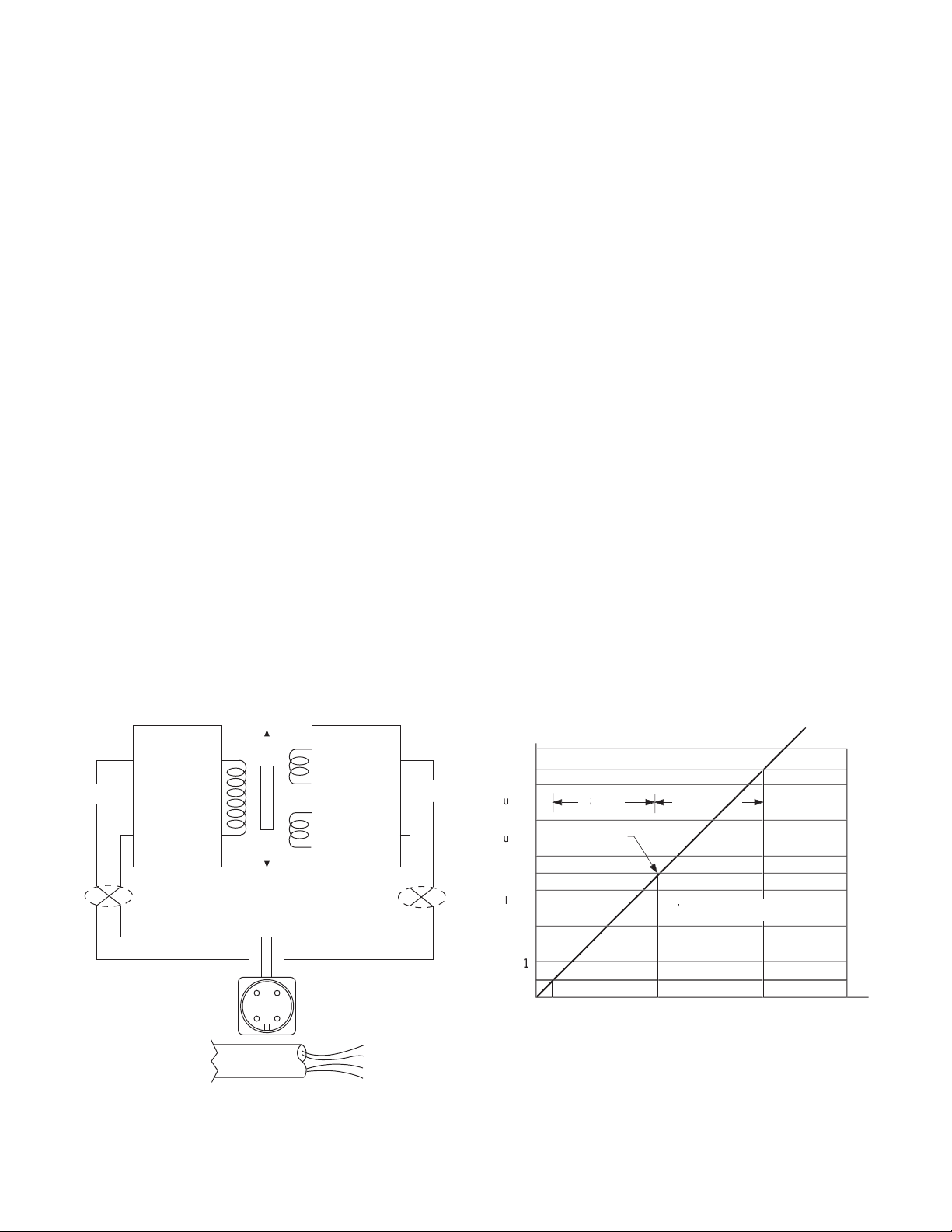

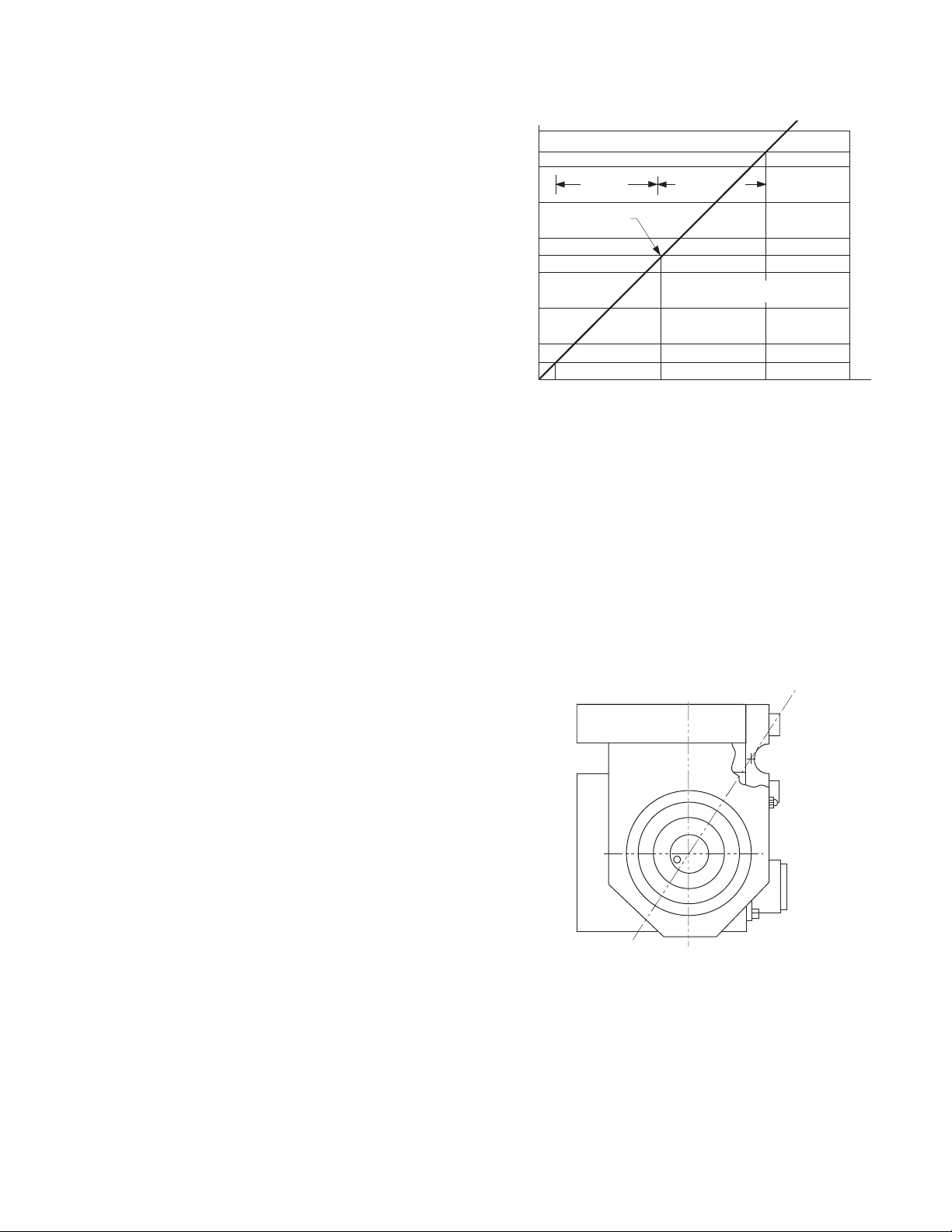

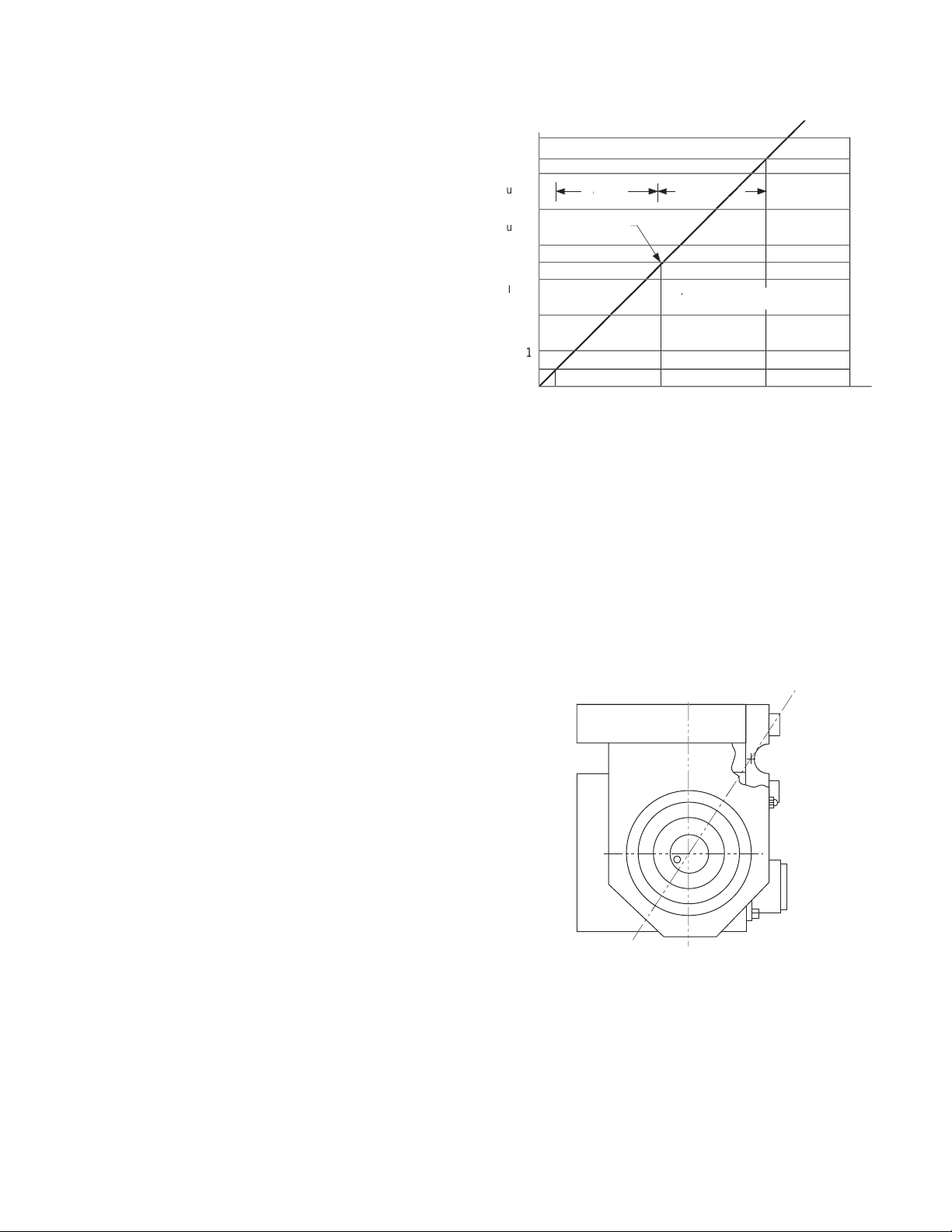

7

6

5

4

3

2

1

0

.030” 0.0 .030”

3.5 V. Set Point

Tension

Compression

LVDT Output vs Deflection

O

u

t

p

u

t

V

o

l

t

a

g

e

Deflection

With Warner Electric LVDTs, the input and output circuits are electrically isolated from each

other and from the mechanical structure of the

tensioncell. Thus, they may be used in "floating

ground" or "ground return" systems. This eliminates the need for extra circuit boards which are

required for most straingage loadcells.

Tensioncells are factory adjusted to provide an

offset voltage with no load applied (no deflection). Using an input of 24 volts DC, the LVDT is

set to provide an output of 3.5 volts into a resistive load of not less than 100,000 ohms. The

voltage resulting from the maximum rated

deflection then adds to or subtracts from the 3.5

volt offset. This results in an output voltage of

3.5 to 6.5 volts in the Compression Mode and

3.5 to 0.5 volts in the Tension Mode. (See

Figure 4)

LVDT Output vs. Deflection Chart

Figure 4

While acceptable performance may be obtained

over an input voltage range of 6.0 to 30.0 volts

DC, the output voltage will vary in direct proportion to the input voltage. Because of this, the

use of a well regulated constant voltage power

supply is essential for accurate and repeatable

tension measurement.

In standard applications, where two Tensioncells

are used, the inputs may be connected in parallel allowing the Tensioncells to be excited from

the same power supply. The LVDT outputs are

then summed to obtain a signal representing the

strip tension and tare loads distributed across

the roll.

Warner Electric • 800-825-9050 P-2012-4

40

Description of Operation

The total resultant load per cell (RF) is calculated

by resolving all force vectors acting upon the

Tensioncell, with respect to the Loading Line (OL).

(RF) is the resultant of both TENSION and TARE

loads, PER CELL!! (See Figure 5)

(Figure 5)

Page 41

TT

N

TW

D

T

T

H

J

E

E

Figure 6A

Figure 6B

T

T

TW

J

N

D

H

E

E

N

T

T

E

E

H

J

D

TW

Figure 7B

N

TW

E

E

H

T

J

T

D

Figure 7A

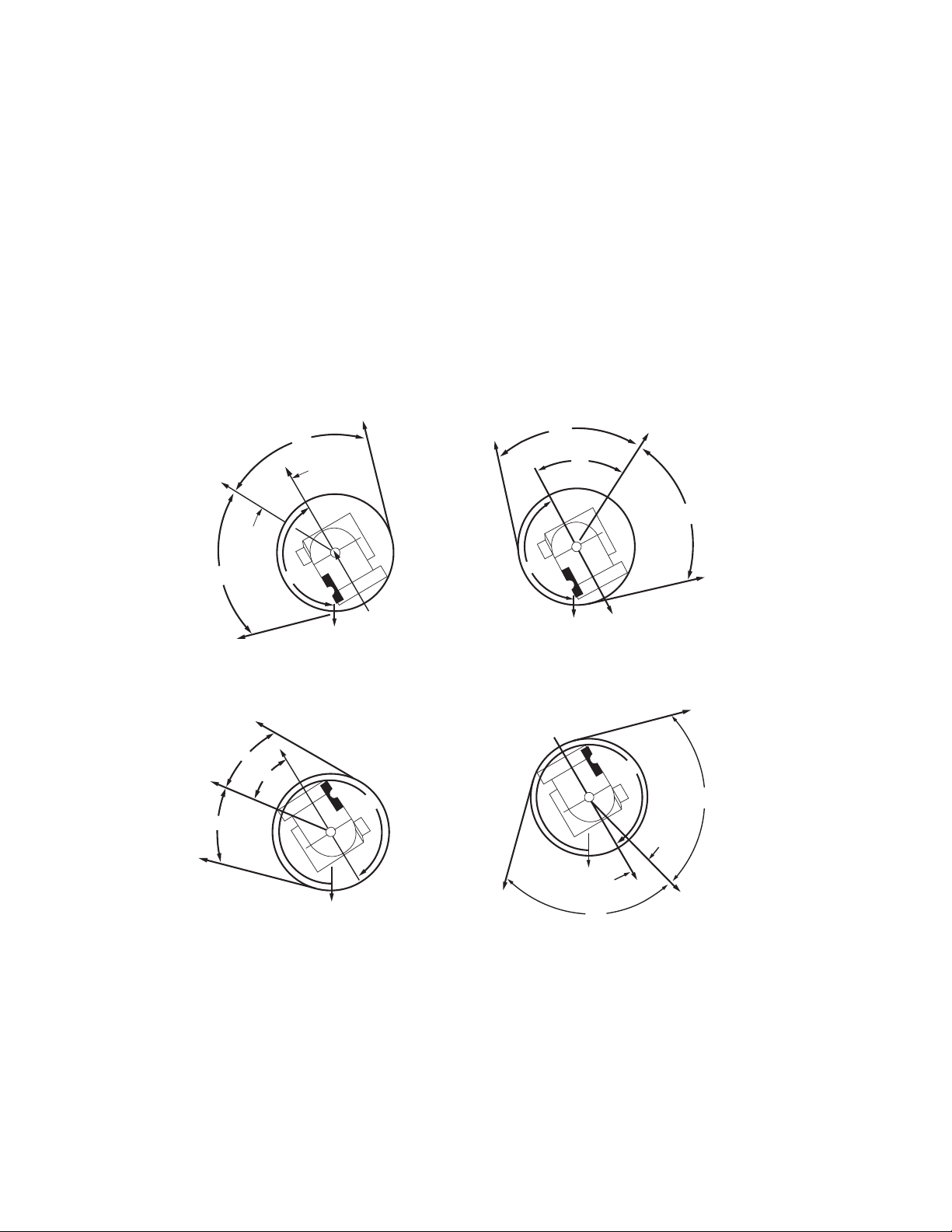

The intrinsic design of Warner Electric

Tensioncells allows the location of the Resultant

Load of Strip Tension (H) on any angle with

respect to the Load Line (OL). Note, however,

that the Total Force vector (RF) must always be

calculated on the line (OL).

Any force vector falling on the line (OR) (through

the pivot point of the C-Flexure) will produce no

deflection, and thus no change in electrical output.

Rotating the Tensioncell on its mounting bolt

changes the force vectors on the cell. This feature makes it possible to minimize the tare component and maximize the load signal output.

The resultant tare is minimized by mounting the

Tensioncell so that (N) is 149° (See Figures 6A

and 6B) or so that (N) is 329° (See Figures 7A

and 7B).

Warner Electric • 800-825-9050 P-2012-4

41

Page 42

Installation and Operation

Inspection Upon Delivery

Warner Electric Tensioncells are carefully packaged in sturdy reinforced cartons or wooden

boxes and are securely blocked or bolted in

place.

1. Upon receipt, examine the exterior of the

container for obvious damage or tampering.

2. Check the contents against the packing list.

3. Promptly report any damage or shortage to

both the carrier and Warner Electric.

Handling

Tensioncells can be handled manually.

Warner Electric Wall Mounted Tensioncells are

mounted to the machine frame by a 5/8-11 UNC

bolt which is in line with the centerline of the

measuring roll shaft. This allows the Tensioncell

to be rotated around the centers of the measuring roll and mounting bolt to achieve the proper

mounting angle (Description of Operation on

Page 5).

The locating tab prevents the Tensioncell from

rotating and secures it in a permanent location.

It also provides a means of repeating rotary

position when the Tensioncell needs replacement.

Note: Remove the 1/4" locking screw and

the 5/8" mounting bolt. This permits the r

assembly with Tensioncells to be lifted out

of the machine.

oll

Long Term Storage

While Warner Electric loadcells are plated,

exposure to weather, dirt, or moisture should be

avoided when they are stored.

Mechanical Installation

Note: Refer to the Dimension Drawing

Pages 11 and 12 of this manual for detailed

identification of all parts.

Tensioncells are designated as W1 and W2, one

being the mirror image of the other to pr

for mounting between two fixed walls. (See

Figure 8)

ovide

To install Tensioncells:

1. Make sure a 5/8” diameter hole is drilled

through the machine frame in line with the

centerline of the measuring roll shaft for the

5/8-11 UNC mounting bolt.

2. Fasten the Tensioncell to the machine frame

with the mounting bolt.

3. Rotate the Tensioncell to the proper mounting angle and tighten the mounting bolt.

(Refer to N on the calibration sheet for the

proper mounting angle.

4. Drill a #6 (.204) hole concentric with the 1/4"

hole in the locating tab.

5. Remove the Tensioncell and tap the hole for

a 1/4-20 thread.

6. Repeat steps 1 through 5 for the Tensioncell

to be mounted at the other end of the measuring roll.

42

7. Assemble the tensioncells onto the ends of

the measuring roll shaft.

Figure 8

Warner Electric • 800-825-9050 P-2012-4

Page 43

8. Position the roll with the Tensioncells on the

X

DC

Signal

machine and fasten with the mounting bolts.

9. Rotate the Tensioncells to the proper mounting angle and tighten the mounting bolts.

10. Lock the locating pad for each Tensioncell

against the machine frame using the 1/4-20

x 1/2 socket head capscrew.

11. Tighten the shaft in the mounting block on

the W1 unit. (The shaft end at W2 is left free

to allow it to move as the shaft expands with

temperature changes).

Mechanical Alignment

Align the sectional measuring roll to avoid any

mechanical binding or friction. The measuring

roll must be level and perpendicular to the path

of the strip material for accurate measurement.

Specifications

Type "K" 24 volt DC LVDT Specifications

Input . . . . . . . . . . . . . . . . . . . . . . . . .6-30 volts DC

Output . . .0.5-6.5 volts DC (nominal, open circuit)

Output Impedence . . . . . . . . . . . . . . . .2.5K ohms

Current Consumption . . . . . . . . . . . . . . . . .40 mA

Recommended Load . . . . .100K ohms or greater

Max. Operating Temp . . . . . . . . . . . . . . . . . .250°F

Note: Warner Electric loadcells are

calibrated for 24 volt DC input voltage to

ovide a 0.5 to 6.5 volts DC output signal.

pr

The Mechanical Stops are fixed for the required

travel of the Load Table.

Electrical Installation

(Read the entire electrical wiring procedure

before proceeding.)