Page 1

P-2065-WE

SM409gb - rev 01/09

Centrifugal Brakes

FC-G-C410

Service Manual

Page 2

We, WARNER ELECTRIC EUROPE, 7, rue Champfleur, B.P. 20095, F-49182 St Barthélemy d’Anjou Cedex

declare that the torque limiters made in our factory from St Barthélemy d’Anjou,

and hereafter designated : FC-G-C410

are exclusively designed for incorporation into a machine and to be assembled with other equipments to create a machine. The operation of

the product is submitted to the conformity of the complete equipment, following the provisions of the machinery directive 98/37/EC Drawn up

in St Barthélemy d’Anjou, July 2002

E. PRAT, General Managing Director

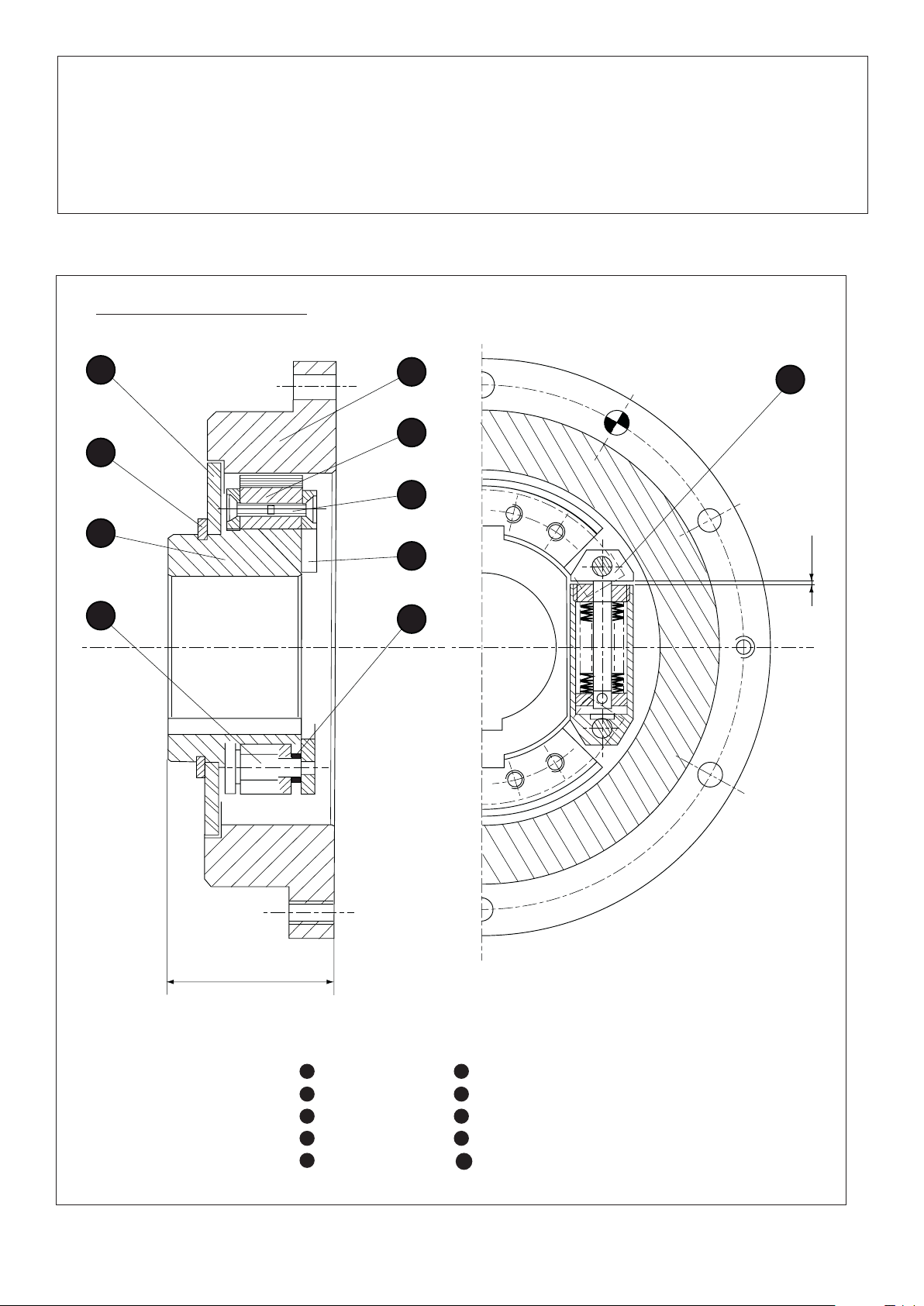

1 Technical specifications

8

10

3

2

9

7

1

6

4

5

“A”

L

1 Hub

2 Inertia Block

3 Spring

4 Axle

5 Spacer

2 Warner Electric Europe • +33 (0)2 41 21 24 24 P-2065-WE • 2/13

6 Flange

7 Fixing Screws

8 Closing Washer

9 Safety Ring

10 Drum

Fig. 1

Page 3

The FC-G - C140 centrifugal brake is a device

operating with delayed actuation that is to say, the

pressure between the friction surfaces is achieved by

the centrifugal force resul ting from the rotation of the

driving input. The engagement or disengagement is

therefore driven only by action upon the input side.

The device has no wear adjustment ; it operates only

in dry conditions ; the friction is of cast-iron-againstpacking type.

Example of description for a centrifugal device used

as brake with a zero torque at n = 1650 revolutions

per minute and a nominal torque of 20 m, daN for N

= 2700 revolu tions per minute.

Centrifugal brake, type FC 20 G - 1650/2700

4 ASSEMBLY

On our devices, hub and drum bores have

usually a H7 tolerance.

It can be mounted horizontally, vertically or in any

other position.

2 DESCRIPTION

The device consists of two main parts:

2.1 - The driving part includes:

- a hub fixed on the driving-shaft by means of a

key ;

- one, two or three sets of inertia-blocks

depending on the type) which are made integral

with the hub by means of the teeth ;.

- springs , which draw the inertia-blocks back

into the “disengaged or de-braked” position, are

articulated on the axles , are laterally kept

in position by the spacers and the flanges

and are fixed on the inertia-blocks by means

of the screws .

- a closing-washer , centered on the hub

and laterally kept in position by the safety-ring .

For fitting the device on the shaft, we advise to use

the js6 tolerance.

The width of the hub is key groove has the P9

tole rance.

The g6 tolerance is quite proper for the

centering designed to receive the drum .

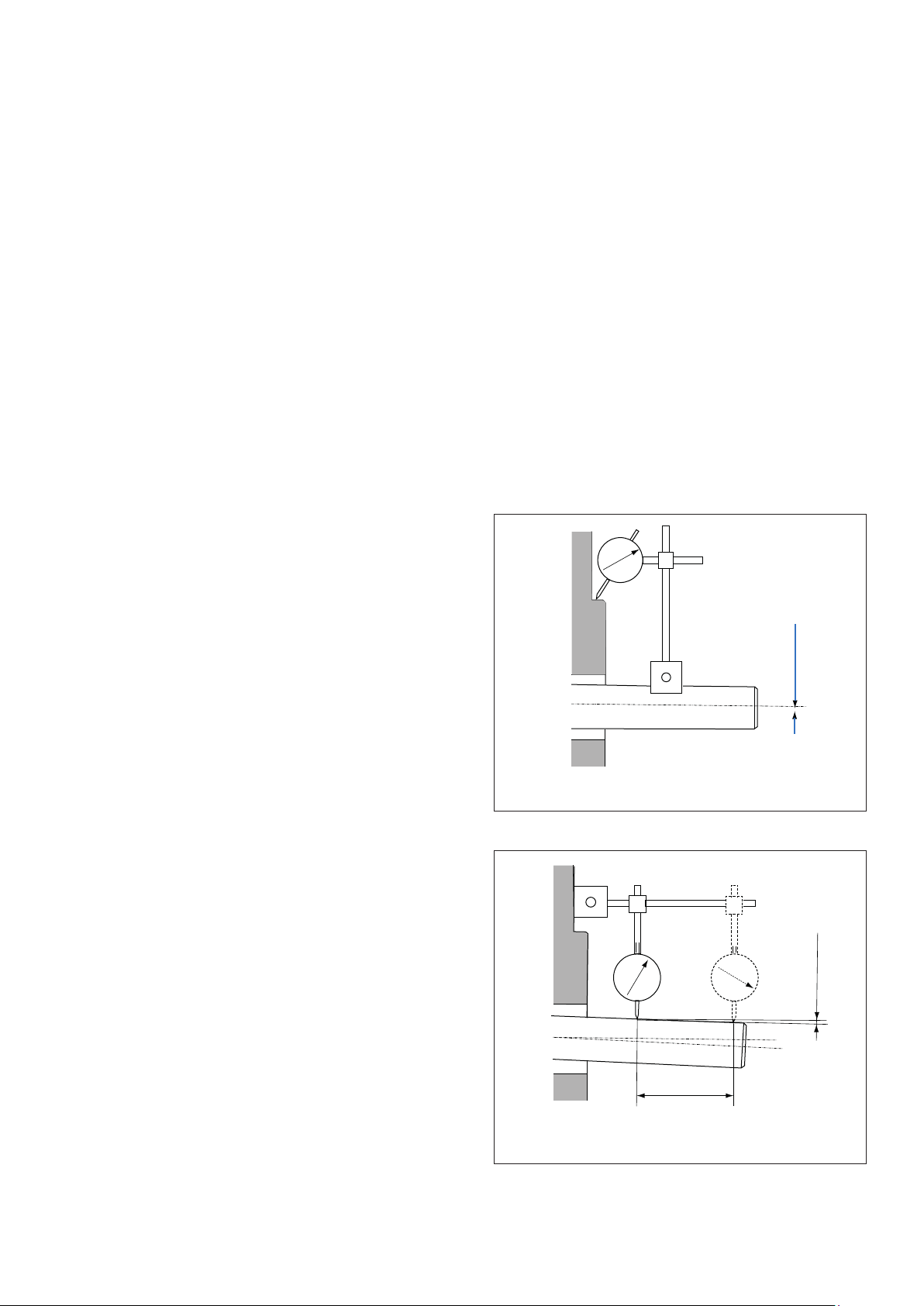

The shaft should not fall out of alignment with the

drum by a greater value than the one showed in

picture 3, while it should not be more eccentric than

in picture 2.

0,2 max.

2. 2 - The fixed part includes

- a drum centered on the driven member (clutch

use) or the frame o the machine (brake use) and

fixed by means of screws.

3 OPERATION

The device is rated to a zero torque for rotation

speeds of the driving-shaft below “n” revolutions per

minute, the iner tia-blocks being kept back by the

release springs .

For speeds greater than “n”, the inertia-blocks are

pushed into contact with the drum as a result of

the centrifugal force and the torque gradually grows

until it reaches its nominal value for “N” revolutions

per minute.

When the speed decreases, the torque gradually

decreases until it reaches its zero value for speeds

equal to or under “n” revolutions per minute.

NOTE - “n” and “N” values are engraved on every

device after the name of the type

Fig. 2

0,1 max.

100

Fig. 3

Warner Electric Europe • +33 (0)2 41 21 24 24 P-2065-WE • 2/13 3

Page 4

The device is supplied assembled.

For the mounting, prepare the unit as follows :

- remove the drum .

- take the safety-ring and the closing-ring

from the hub .

Mounting

6 ADJUSTMENT

The centrifugal device FC-G needs no further

adjustment since it is originally set for a given torque.

The wear of the packing depends on the work

absorbed by this device

For replacing of used inertia-blocks, remove the

block consisting of the hub , the inertia-blocks ,

the springs etc... from the machine.

After fitting the key into its housing :

- slide the driving member consisting of

the hub , the inertia-blocks , the springs

etc... on the shaft ;

- stop this block laterally by means of either a

nut with its lock washer, or a safety-ring or a ring

with a screw, which will have to be locked by using

a thermoplastic liquid like for example “LOCTITE

brake-normal thread”;

Warning

- For this setting process, never strike on the checks

and springs . Place a piece of soft alloy bet

ween the hub and the system chosen for

pushing the block on the shaft.

- Center the drum on the driven member or on

the frame of the machine and screw it into place.

Lock the screws energetically ;a thermoplastic

liquid like for example “LOCTITE brake-normal

thread” will provide for their stopping.

- Check in a few places, by using wedges, whether

the play between the inertia-blocks packing and

the internal diameter of the drum is roughly

regular.

- Fit the closing-washer and put the safety-ring

into its groove. To prevent the closing-washer

rubbing against the drum , keep the length

“L”.

- Counter-bore 2 holes opposite one another in

the driven member or in the frame of the machine

through the already existing ones in the

drum and slip elastic pins of, for example, the

“MECANINDUS” type into these holes. (except

special drum)

- Engage or brake a few times in getting the

machine to work.

6. 1 – Disassembly

- take away the safety-ring and the closing-

washer.

- remove the screws fixing the drum .

- dismount the drum by screwing two of the fixing

screws into the tapped holes specially designed

for this purpose. (except special drum)

- remove from the shaft, the block consisting

of the hub , the inertia-blocks the

springs etc...

After having removed the above sub-assembly

- Insert conical wedges into space “A”, namely

between the 2 moving parts of the release-spring

so that the inertia-blocks do not bear any

more on the periphery of the hub as a result of

the pressure from the springs . If the

device is equipped with traditional draw

springs, stretch these springs with pliers in

order to relieve the inertia-blocks from the

pressure exerted by the springs.

- Remove the screws on each face of the flanges

and withdraw the used inertia-blocks. Do not

reverse the assembling direction of the springs.

- Put the new inertia-blocks between the flanges

, install the screws while not for getting to

lock them by means of a thermoplastic liquid like,

for example, “LOCTITE brake-normal thread”.

- Drive away the conical wedges or let down

the draw-springs in order to bring the inertia blocks into contact with the hub .

- Reassemble the device on the machine. For this

process, see chapter 4 - ASSEMBLY.

5 NOTES

Keep the inertia-blocks packing off grease and

water, otherwise a reduction of the braking torque

could follow.

4 Warner Electric Europe • +33 (0)2 41 21 24 24 P-2065-WE • 2/13

Page 5

Theorical torque / speed

800

750

700

650

600

550

500

450

Nil torque (RPM) 1300

Nominal torque (RPM) 2500

400

(Nm)(Nm)

350

300

250

200

150

100

50

0

1300 1450 1600 1750 1900

80

40

20

2050 2200 2350 2500

(tr/min)

100

75

50

10

5

25

0

1300 1450 1600 1750 1900

(tr/min)

Warner Electric Europe • +33 (0)2 41 21 24 24 P-2065-WE • 2/13 5

2050 2200 2350 2500

Page 6

Theorical torque / speed

800

750

700

650

600

550

500

450

400

(Nm)

Nil torque (RPM) 1650

Nominal torque (RPM) 2700

350

300

250

200

150

100

50

0

1650 1800 1950 2100 2250

100

80

40

20

2400 2550 2700

(tr/min)

75

50

25

0

1650 1800 1950 2100 2250

6 Warner Electric Europe • +33 (0)2 41 21 24 24 P-2065-WE • 2/13

10

5

2400 2550 2700

(tr/min)

Page 7

Theorical torque / speed

800

750

700

650

600

550

500

450

Nil torque (RPM) 1850

Nominal torque (RPM) 2800

400

(Nm)

350

300

250

200

150

100

50

0

1850 2000 2150 2300 2450

80

40

20

2600 2750 2900

(tr/min)

100

75

10

50

5

(Nm)

25

0

1850 2000 2150 2300 2450

(tr/min)

Warner Electric Europe • +33 (0)2 41 21 24 24 P-2065-WE • 2/13 7

2600 2750 2900

Page 8

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any product manufactured and

sold by it which proves to be defective in material or workmanship within a period of one (1) year from the date of original

purchase for consumer, commercial or industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without Warner Electric LLC’s

prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation charges prepaid, to

the appropriate Warner Electric LLC factory. Additional warranty information may be obtained by writing the Customer

Satisfaction Department, Warner Electric LLC, 449 Gardner Street, South Beloit, Illinois 61080, or by calling 815-389-

3771.

A purchase receipt or other proof of original purchase will be required before warranty service is rendered. If found

defective under the terms of this warranty, repair or replacement will be made, without charge, together with a refund for

transportation costs. If found not to be defective, you will be notified and, with your consent, the item will be repaired or

replaced and returned to you at your expense.

This warranty covers normal use and does not cover damage or defect which results from alteration, accident, neglect, or

improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation may not apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the defective product and

in no event shall Warner Electric LLC be liable for consequential, indirect, or incidental damages of any kind incurred by

reason of the manufacture, sale or use of any defective product. Warner Electric LLC neither assumes nor authorizes any

other person to give any other warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH THE CONSUMER MAY

HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL CONSUMER PURCHASE. WITH

RESPECT TO COMMERCIAL AND INDUSTRIAL USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU

OF AND EXCLUDES ALL OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you. This warranty gives you specific legal rights and you may also have other rights which

vary from state to state.

Changes in Dimensions and Specications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without notice. Weights do not

include weight of boxing for shipment. Certified prints will be furnished without charge on request to Warner Electric.

Warner Electric Europe

7 rue Champfleur, B.P. 20095, St Barthelemy d’Anjou - France

+33 (0)2 41 21 24 24 • Fax: +33 (0)2 41 21 24 70

www.warnerelectric.com

Printed in USAP-2065-WE • 2/13

Loading...

Loading...