Page 1

EnclosedUniModuleInstallationandTechnical

ProceduresRegularandWashdownModels

EUM-50/EUM-100/EUM-180/EUM-210/EUM-215

P-226

819-0355

Installation & Operating Instructions

Page 2

Contents

Introduction

Pre-Installation Instructions . . . . . . . . . . . . . . . . 2

Installation Instructions . . . . . . . . . . . . . . . . . . . 3

Electrical Coil Data, Mechanical Data . . . . . . . . 7

Overhung Load Data. . . . . . . . . . . . . . . . . . . . . 7

Pre-Burnishing & Maintenance . . . . . . . . . . . . . 8

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . 9

Dimensions EUM-1020 . . . . . . . . . . . . . . . . . . 10

Dimensions EUM-2030 . . . . . . . . . . . . . . . . . . 11

EUM Parts List/1020 Combinations . . . . . . . . 12

EUM Parts List/2030 Combinations . . . . . . . . 14

Warranty. . . . . . . . . . . . . . . . . . . . . . Back Cover

Failuretofollowthese

instructionsmayresultinproduct

damage,equipmentdamage,and

seriousorfatalinjurytopersonnel.

This manual covers installation, wiring and

troubleshooting of regular and washdown models

of Enclosed UniModule clutch/brake sizes 50,

100, 180, 210, and 215. Washdown models are

designed to be liquid tight under normal

washdown conditions and the special instructions

required to install these products follow with the

instructions for the regular units. Mechanical and

electrical specifications and dimension drawings

are included.

Makesureallpoweristurned

offtothisequipmentwheninstalling,as

injury(orevendeath)mayresultfromcontact

withlivewiresorrotatingshafts.

Pre-InstallationInstructions

A. The Enclosed UniModule has been designed to

NEMA standards and can be installed with all

standard power transmission drive

systems.

B. Before installing the Enclosed UniModule to a

motor or reducer, make certain that the EUM

size and NEMA frame dimensions match

according to the chart on the right.

C. Check the motor for shaft endplay. If the shaft

can be moved axially .030" or more, the

module should not be installed since excessive

thrust may occur between the rotor and field.

The motor should not be used unless the

endplay can be reduced.

Corresponding

NEMAFrameSize C-Face

EUM Old New Shaft Pilot

Size NEMA NEMA Dia. Dia.

50 56 C 48 Y 5/8" 4-1/2"

100 56 C 48 Y 5/8" 4-1/2"

180 182 C 143 TC 7/8" 4-1/2"

184 C 145 TC

210 213 C 182 TC 1-1/8" 8-1/2"

215 C 184 TC

215 213 TC 1-3/8" 8-1/2"

215 TC

Warner Electric • 800-825-9050 P-226 • 819-0355

2

Page 3

FortheseEUMcombinations: Usetheseinstallationsteps:

Enclosed UniModule Clutch-Brake Between

C-Face Motor and Reducer – 1020 1, 2, 3, 4, 7

Enclosed UniModule Clutch-Brake – 2030 4, 7

Motor Mount Enclosed UniModule Clutch-Brake

On C-Face Motor – 1020-M 1, 2, 3, 6, 7

Base-Mounted

Enclosed UniModule Clutch-Brake – 2030-B 5, 7

InstallationInstructions

Warner Electric’s Enclosed UniModule has been

designed to NEMA standards and can be

installed with all standard power transmission

drive systems. Before installing the Enclosed

UniModule to a motor or reducer, make certain

that the EUM size and NEMA frame dimensions

match according to the chart.

Install your specific modular combination

according to the installation steps specified in

the table on page 2. Use only those steps

indicated for each combination.

Note:The equipment covered by this service

manual must be installed in accordance with

these instructions. Failure to do so may

damage the equipment and void the warranty.

Note: Special plugs and plastic screws are

provided with each washdown kit. All unused

holes are to be plugged to prevent debris

buildup and to ensure that the clutch/brake

stays dry.

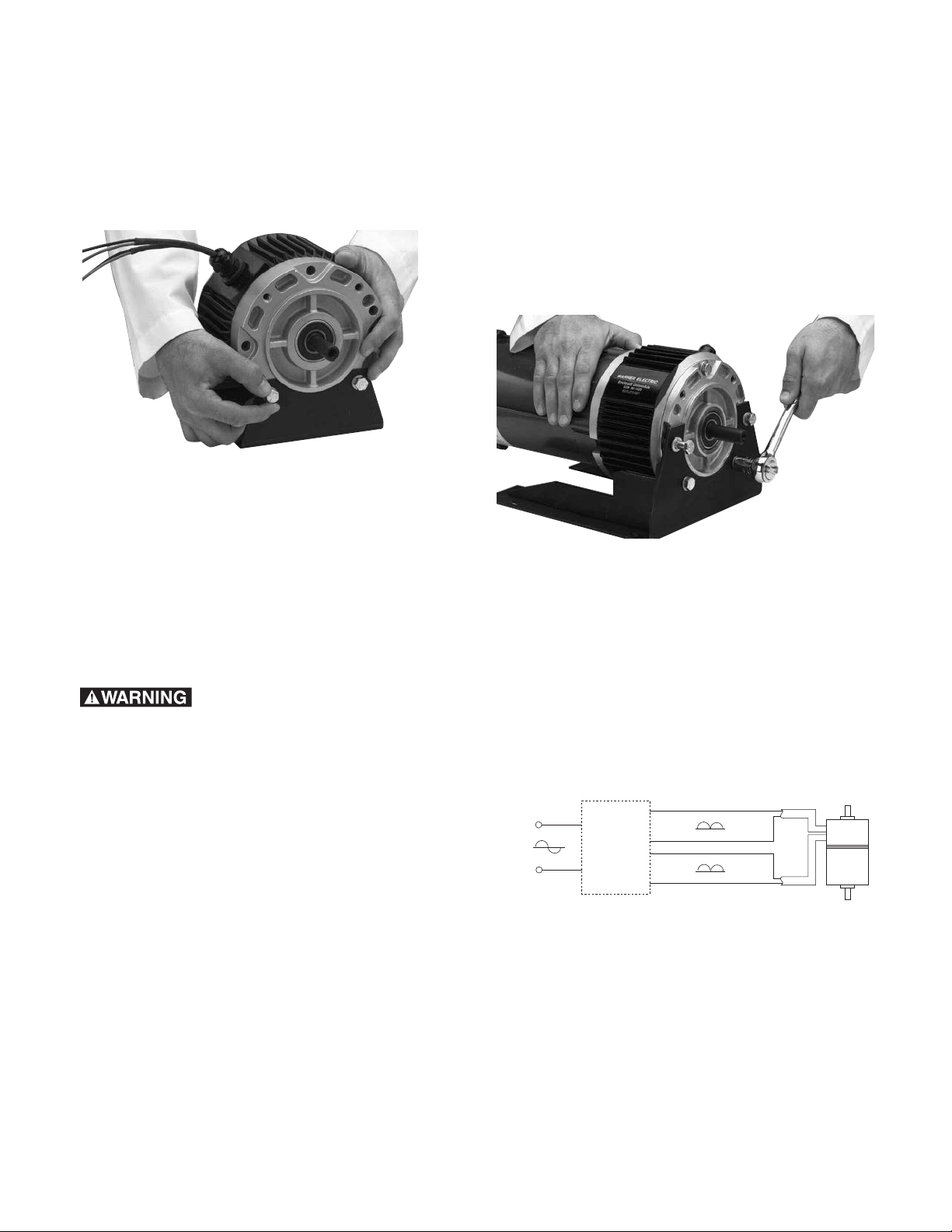

MountingToAMotor

Step1:

A. For Washdown Models Only:

1. Slip rubber shield (seal) over clutch and end

of module; exact position of rubber band is

described in step 3.B. Place gasket

between motor and clutch end; be sure to

select correct gasket to match clutch end.

Warner Electric • 800-825-9050 P-226 • 819-0355

3

Page 4

B. For All UniModule Models

Note: The 1020 UniModule is furnished with

a special key already assembled in the rotor

hub. Do not use another key!

1. Before sliding UniModule onto motor, align

set screws on rotor input hub to access

slots on clutch side of module. Insert into a

set screw and slide assembly onto motor

shaft as shown in Figure 2. Align key in

UniModule with motor shaft keyway.

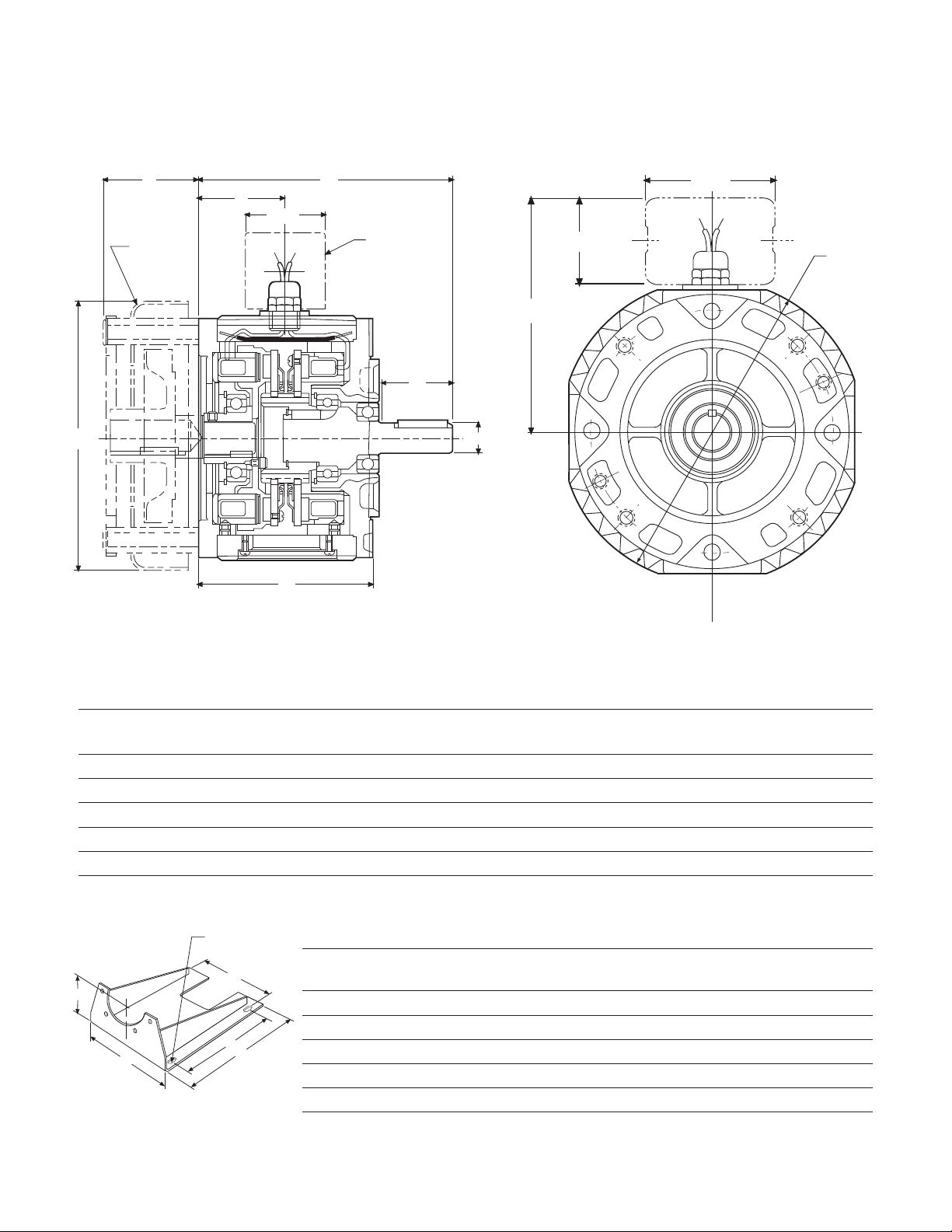

tapped holes on motor face. Tighten

alternately and securely to 30 to 35 ft. lbs.

torque. See Figure 3.

Figure 3

Step3:

A. For All UniModule Models

1. Tighten both set screws on the module

input hub with prepositioned Allen wrench

alternately and securely to 80 to 85 in. lbs.

for all sizes. See Figure 4.

Figure 2

Do not use force. If UniModule does not

slide on freely, polish motor shaft sufficiently

to achieve a slip fit.

Note: Sizes 100, 210 and 215 UniModules

require an adapter ring to be mounted to

the motor prior to mounting the 1020

UniModule. Adapter and mounting

hardware are provided with the

UniModule assembly.

Step2:

A. For UniModule Models Other Than

Washdown

1. Insert four large capscrews with lock

washers provided through mounting holes in

housing and into tapped holes on motor

face. Tighten alternately and securely to 30

to 35 ft. lbs. torque. See Figure 3.

B. For Washdown Models Only

1. Insert four large capscrews provided

through the large plastic washers and

through mounting holes in housing and into

Figure 4

B. For Washdown Models Only

1. After tightening set screws on the rotor

input hub, Figure 3, use plastic screws

provided in the kit to plug threaded holes

and position rubber seal to cover all slots.

Step4: Mounting to a Reducer

The output side of a UniModule may be mounted

directly to a reducer.

Warner Electric • 800-825-9050 P-226 • 819-0355

4

Page 5

A. For Washdown Models Only

1. Place a gasket between reducer and

clutch/brake; select correct gasket to match

brake end configuration. See Figure 5.

Figure 5

B. For All UniModule Models

1. Align output shaft and key of UniModule

with corresponding shaft hole and keyway

of reducer. Slide assembly together,

matching pilot diameter on UniModule with

a pilot diameter on reducer. See Figure 6.

Step5:Installing the Base Mount on 2030

UniModules

A. For All UniModule Models

1. Mount each UniModule so that base is

located below ventilation holes. A pilot

diameter on end of each UniModule mates

with pilot diameters on base. See Figure 7.

2. Secure base to UniModule with the bolts

provided. Tighten to 18 to 22 ft. lbs. torque

for 50 and 180 sizes, 40 to 45 ft. lbs. torque

for 210 and 215 sizes.

Figure 7

Step6: Installing the Motor Mount (M)

Motor Mount (M) can be installed to output end of

UniModule to provide a foot mounting for

complete assembly of UniModule and motor.

A. For All UniModule Models

Sizes 50, 100 and 180

1. Remove the four set screws plugging the

mounting holes. Remove the two long hex

head bolts from side of UniModule toward

ventilation holes.

2. Mount UniModule on Motor Mount so base

of Motor Mount is underneath UniModule

and motor. See Figure 8. A pilot diameter on

Figure 6

UniModule mates with a pilot diameter on

Motor Mount.

2. Bolt UniModule to reducer flange. The four

bolts required (3/8-16 UNC-2A) are normally

furnished with the reducer. Tighten to 18 to

22 ft. lbs. torque for 50 and 180 size, 40 to

45 ft. lbs. torque for 210 and 215 sizes.

3. Secure Motor Mount in place with two

longer mounting bolts. Tighten to 30 to 35

ft. lbs. torque and two shorter bolts tighten

18 to 22 ft. lbs. torque, all provided in kit.

Sizes 210 and 215

1. Mount UniModule on Motor Mount so base

of Motor Mount is underneath UniModule

Warner Electric • 800-825-9050 P-226 • 819-0355

5

Page 6

and motor. See Figure 8. A pilot diameter on

Clutch/Brake

Control

AC

Clutch

Brake

White

Black

Red

Red

Black

Black

DC

DC

Voltage

Voltage

Voltage

UniModule mates with a pilot diameter on

Motor Mount.

2. Secure Motor Mount to the UniModule with

three bolts provided and tighten to 40 to 45

ft. lbs. torque.

Figure 8

B. For Washdown Models Only

1. If any mounting bolts are not used, make

sure the mounting holes are plugged with

the .437 diameter plugs provided. For 210

and 215 size units, make sure holes on

circumference are plugged with the .375

plugs provided.

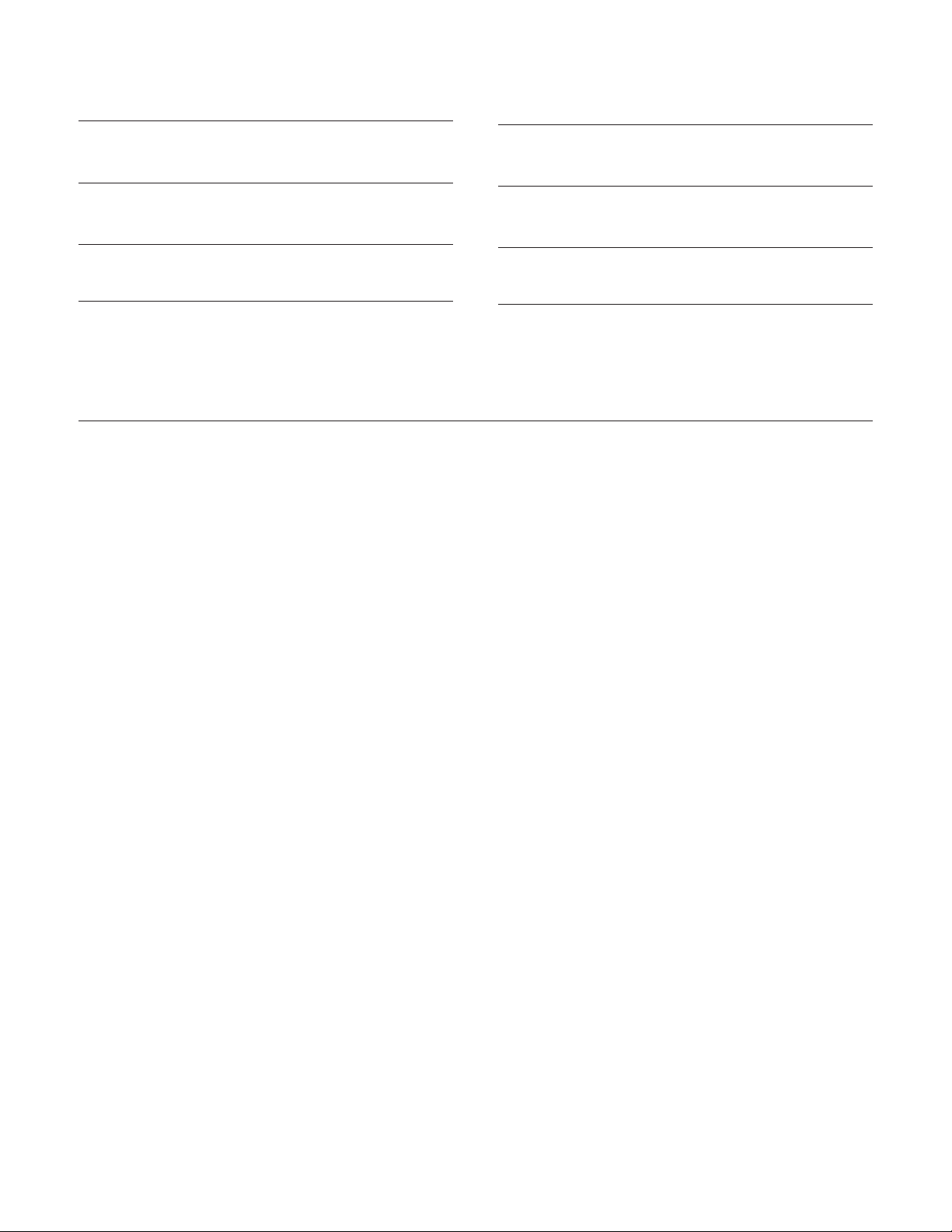

Step7: Electrical Connections

Toavoidinjury(orevendeath)

alwaysmakecertainallpowerisoffbefore

attemptingtoinstallorservicethiscontrolor

anyelectricalequipment.

Electric control show the proper electrical

connections.

Please refer to Figure 9 for the proper

UniModule electrical connections. Clutch

andbrakeleadsareidentifiedwith

labels.

B. For Washdown Model Only

1. Use only liquid tight connectors with flexible

tubing for connections.

Figure 9

After wiring, your Enclosed UniModule is now

ready to operate. If your clutch/brake control has

torque control, the torque adjust potentiometer(s)

should be set for rapid and complete load take

up. Excessive slippage of the brake or clutch can

cause overheating and premature wear. For

additional information, including the armature

adjustment which is occasionally required for

new installations, see page 7 of this manual.

A. For All UniModule Models

1. The UniModule is provided with one conduit

connection hole, threaded for standard 1/2"

conduit connectors. Both the clutch and

brake lead wires are brought out through

this opening. The conduit box accessory kit,

P/N 5370-101-042 for non-washdown

models, and 5370-101-045 for washdown

models, provides two conduit connection

holes for standard 1/2" conduit connectors.

The clutch and brake coils operate on DC

voltage. Warner Electric offers a full line of

AC voltage powered controls to meet the

needs of almost every clutch/brake

application. The service and installation

instructions included with each Warner

Warner Electric • 800-825-9050 P-226 • 819-0355

6

Page 7

ElectricalCoilData

MechanicalData

Clutch Brake Clutch Brake Clutch Brake

Voltage–D.C. 90 90 24 24 66

Resistance EUM-50 452 452 31.8 31.8 1.86 1.86

(OHMS) EUM-100 362 362 26.7 26.7 1.9 1.9

EUM-180 362 362 26.7 26.7 1.9 1.9

EUM-210 264 264 17.9 17.9 1.33 1.33

EUM-215 264 264 17.9 17.9 1.33 1.33

Amperes EUM-50 .199 .201 .755 .755 3.23 3.23

EUM-100 .249 .249 .896 .896 3.1 3.1

EUM-180 .249 .249 .896 .896 3.1 3.1

EUM-210 .341 .341 1.34 1.34 4.5 4.5

EUM-215 .341 .341 1.34 1.34 4.5 4.5

WATTS EUM-50 18 18 18 18 19 19

EUM-100 22 22 21.5 21.5 19 19

EUM-180 22 22 21.5 21.5 19 19

EUM-210 30.7 30.7 32 32 27 27

EUM-215 30.7 30.7 32 32 27 27

Build Up EUM-50 52 53 52 53 52 53

(Milli- EUM-100 72 75 72 75 72 70

seconds) EUM-180 72 75 72 75 72 70

EUM-210 120 100 120 100 110 100

EUM-215 120 100 120 100 110 100

Decay EUM-50 6.2 5.0 6.2 5.0 6.5 5.0

(Milli- EUM-100 12 10 12 10 12 10

seconds) EUM-180 12 10 12 10 12 10

EUM-210 20 10 20 10 20 10

EUM-215 20 10 20 10 20 10

Static Torque 16 lb. ft. 16 lb. ft. 30 lb. ft. 95 lb. ft. 95 lb. ft.

EUM-50 EUM-100 EUM-180 EUM-210 EUM-215

Maximum Speed 3600 rpm 3600 rpm 3600 rpm 3600 rpm 3600 rpm

Average Wt.-lbs.

Motor Clutch 3.4 lbs. 5.1 lbs. 5.1 lbs. 9.1 lbs. 9.1 lbs.

Brake 6.6 8.1 8.1 21.5 21.5

Input Clutch 6.4 8.4 8.4 19.8 19.8

Output Clutch 4.9 5.2 5.2 15.2 15.2

Inertia – WR

Armature .007 .018 .018 .081 .081

lb. ft. lb. ft. lb. ft. lb. ft. lb. ft.

Armature hub .002 .003 .003 .021 .021

Shaft .001 .002 .002 .017 .017

Rotor w/Fan

and hub .020 .046 .046 .188 .188

OverhungLoadData

Overhung load data is provided in this manual for

the design engineer concerned with specific

requirements in this area. The maximum allowable

overhung load which can be applied to the shaft

of a UniModule may be determined by the use of

the accompanying chart.

DistanceLoadisApplied Maximum

fromHousingFace LoadRating

ModuleSize “A”Inches “R”lbs.

EM-50 1'' – Center of Shaft 177

EUM-50 2'' – End of Shaft 123

3'' 95

EM-100 1'' – Center of Shaft 177

EUM-100 2'' – End of Shaft 123

3'' 95

EM-180 1'' – Center of Shaft 192

EUM-180 2'' – End of Shaft 134

3'' 104

EM-210 1-3/8'' – Center of Shaft 386

EUM-210 2-3/4'' – End of Shaft 271

4-1/8'' 208

EM-215 1-3/8'' – Center of Shaft 386

EUM-215 2-3/4'' – End of Shaft 271

4-1/8'' 208

Based on 10,000 Hour Life at 3600 RPM.

The minimum pitch diameter pulley or sprocket that

can be used, for satisfactory bearing life, is

determined from the formula:

Min. P.D. = 2 T K

R

T – Torque (in. lbs.). This is the torque actually being

transmitted, not necessarily the maximum torque

capacity of the Electro-Module.

Torque = 63025 x HP

RPM

K – The safety factor for the tension in the type of

drive.

Use: 1 chain and sprocket

1 for timing belt

2 for V-belt

3 for flat belt

R – Radial load allowable (values at various distance

from the housing face are given in the chart).

Example: What is the minimum V-belt pulley that

can be applied to the center of the shaft of an EM50 module. The torque requirement is 112. in. lbs.

Min. P.D. = 2 x 112 x 2

= 2'' minimum P.D. pulley

224

Warner Electric • 800-825-9050 P-226 • 819-0355

7

Page 8

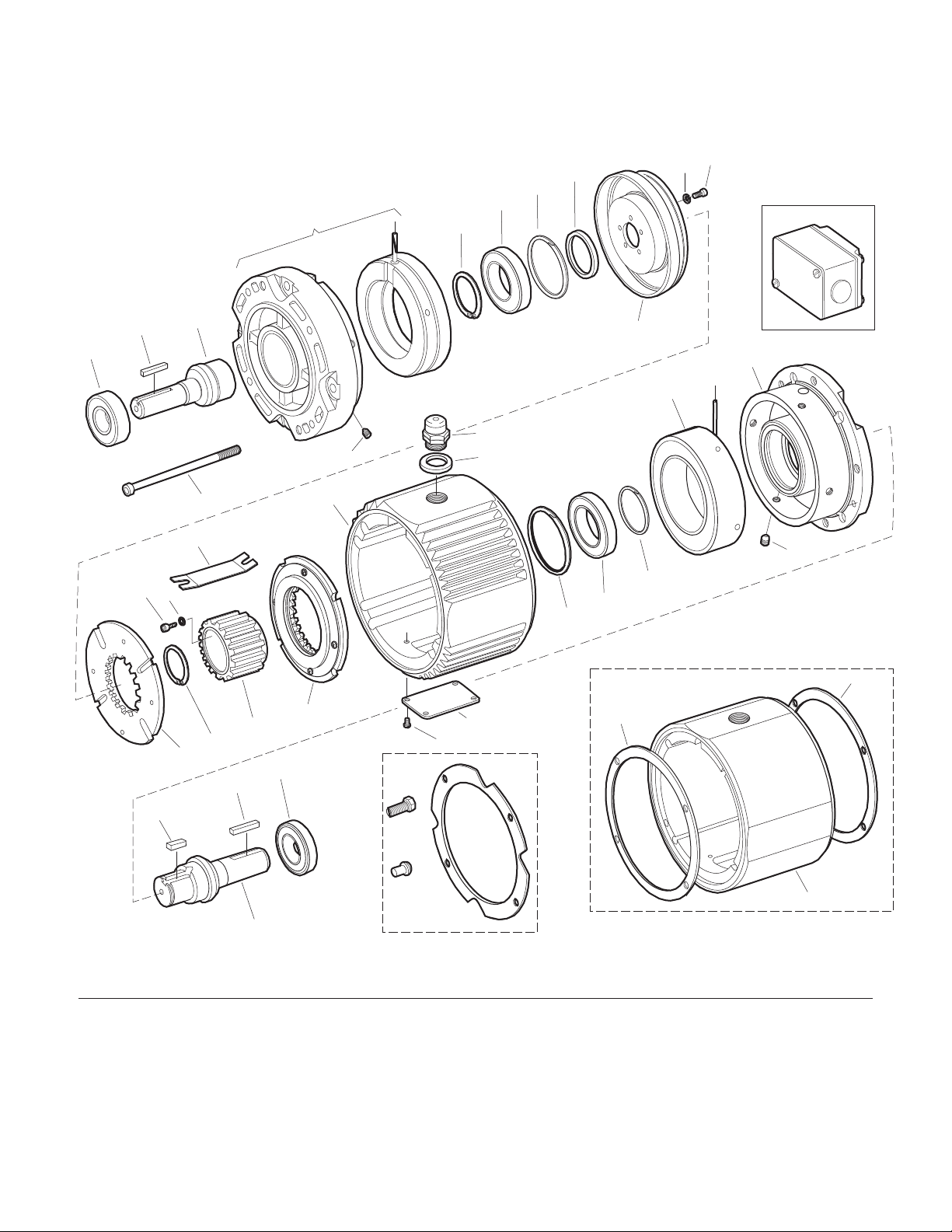

Pre-BurnishingandMaintenance

Pre-Burnishing

All Warner Electric UniModules are pre-burnished

before leaving the factory and are designed to pull

full torque as shipped. Like all friction based

products, their consistency will improve after a

short break-in period.

Maintenance

As with any friction-type device, some initial care

should be given to wear rate, as minor

adjustments in actuation time can sometimes

extend the life of the unit.

The exploded views and drawing illustrate and

describe the various components in each

Electro-Module.

Wear Pattern

Wear grooves appear on the friction surfaces.

This is a normal wear condition, and does not

impair functioning of the unit. Never machine the

friction surfaces to remove grooves or score

marks resulting from normal wear.

Torque Loss

If a brake or clutch module slips or loses torque

completely, the initial check should be the input

voltage to the magnet or field as follows:

90-Volt: Connect a DC voltmeter with a range of

0-100 volt directly across the magnet or field

terminals. With the power on and the

potentiometer turned up, a normal reading is 90

volts, although 85 to 95 is satisfactory. The

reading should drop as the potentiometer

control is adjusted counterclockwise.

6-Volt: Use a DC voltmeter of approximately 0-15

volt range. A normal reading is from 5.5 to 6.5

volts, depending on the power supply.

The above checks normally are sufficient. Further

checks may be made as follows: a low range

ammeter, when connected in series with one

magnet lead, will normally indicate 0.2 to .35

amperes for the 90 volt units and 3.0 to 4.5 for

the 6 volt series. These readings are with the

power on and the potentiometer control in the

maximum position.

Heat

Excessive heat and high operating temperatures

are causes of rapid wear. Units, therefore, should

be ventilated as efficiently as possible, especially if

the application requires fast, repetitive cycle

operation.

Foreign Materials

Do not spray internal friction surfaces with oil.

EUMs will withstand humid, wet environments.

The washdown version is able to withstand high

pressure wash applications.

Ohmmeter checks should be made with the

power off and the circuit open. (To be certain,

disconnect one lead to the magnet.) Compare

resistance to the data on page 8.

If the above checks indicate that the proper

voltage and current is being supplied to the coil,

mechanical parts should be checked to assure

that they are in good operating condition and

properly installed.

Warner Electric • 800-825-9050 P-226 • 819-0355

8

Page 9

Troubleshooting

With the motor at rest and locked out, check the

following:

A. Spin the output shaft by hand to ensure that it

turns freely.

B. If the unit fails to engage, first check the power

supply. Then remove the four screws of the

access panel on the side of the unit. With full

voltage applied to the clutch or brake, switch

back and forth between the clutch and brake

and observe the armatures (plates) through the

access hole. They should move back and forth

approximately 1/32'' when switched.

C. If a scraping sound is noted when the output

shaft is spun, it means an armature is dragging

slightly because of shock and displacement

during shipment. This is easily corrected.

Figure 10

Remove the four screws of the access panel

on the side of the unit. Insert a screwdriver

through the access hole and pry the dragging

armature (clutch or brake as observed) away

from the mating surface evenly all the way

around as far as it will move. Then apply power

to the magnet and insert the screwdriver

between the two armatures (back to back) to

nudge them evenly back into complete

contact. Pry only on the outer edge of the

armature to avoid damaging the autogap

assembly. This will reset the autogap in the

proper position and the unit should now be

ready for further assembly in the drive system

and normal operation. See Figure 10.

Replace the access panel on the assembly.

Warner Electric • 800-825-9050 P-226 • 819-0355

9

Page 10

EnclosedUniModuleCombinations

E

3.125

2.188

G

C

min.

D

B

20

Brake

10

Motor

Clutch

H

Optional

Fan Kit

I

F

A

2.203

Optional

Conduit Box

E

F (4) slots

B

D

C

A

DimensionsEUM-1020

Note:Washdown Unimodules (EUM-W) do not have a finned housing.

EUM1020 Motor mounted UniModules

E

Size AB CDEUM EUM-W FGHI

50 6.750 4.844 1.813 .625 7.270 6.915 2.427 5.936 7.687 2.430

100 6.750 4.844 1.890 .625 7.270 6.915 2.427 5.936 7.687 2.430

180 6.828 4.844 1.890 .875 7.270 6.915 2.427 5.936 7.687 2.430

210 8.891 5.922 2.500 1.125 10.000 10.00 3.053 7.146 10.187 3.375

215 8.891 5.922 2.500 1.375 10.000 10.00 3.053 7.146 10.187 3.375

MotorMount(M)

Size ABCDE F EUM EUM-W

50 9.250 8.250 11.000 8.000 3.500 .796 x .406 5370-101-010 5370-101-048

100 9.250 8.250 11.000 8.000 3.500 .796 x .406 5370-101-010 5370-101-048

180 9.250 8.250 11.000 8.000 4.500 .796 x .406 5370-101-012 5370-101-049

210 11.500 10.500 12.000 9.000 5.250 .750 x .406 5371-101-012 5371-101-026

215 11.500 10.500 12.000 9.000 5.250 .750 x .406 5371-101-012 5371-101-026

PartNo.

Warner Electric • 800-825-9050 P-226 • 819-0355

10

Page 11

EnclosedUniModuleCombinations

C

min.

D

30

Input

Clutch

B

Optional

Base Mount

D

C

min.

Optional

Conduit Box

A

F

2.203

3.125

2.188

E

G

H

Optional

Base Mount

E

F (4) slots

A

D

C

B

DimensionsEUM-2030

Note: Washdown UniModules (EUM-W) do not have a finned housing.

EUM2030 Base mounted UniModules

Size AB CDEUM EUM-W FGHI

50 9.516 5.719 1.813 .625 7.270 6.915 3.164 5.936 3.670 7.119

180 9.516 5.719 1.890 .875 7.270 6.915 3.164 5.936 4.484 8.119

210 12.969 7.719 2.500 1.125 10.000 10.00 4.514 7.146 5.234 10.234

E

Base(B)

Size AB C D E F EUM EUM-W

50 6.000 5.000 5.672 4.000 2.171 .750 x .406 5370-101-062 5370-101-046

100 6.000 5.000 5.672 4.000 2.171 .750 x .406 5370-101-062 5370-101-046

180 6.625 5.000 5.672 4.000 3.000 .750 x .406 5370-101-002 5370-101-047

Warner Electric • 800-825-9050 P-226 • 819-0355

210 9.000 7.750 8.203 6.000 3.375 .750 x .531 5371-101-001 5371-101-025

215 9.000 7.750 8.203 6.000 3.385 .750 x .531 5371-101-001 5371-101-025

PartNo.

11

Page 12

EnclosedUniModulePartsList

10

19

9a

17

17a

18

11a

11

Optional

21

21W

5

4

23

1

3

2

1

14

20

20W

22

6a

13a

13

7a

6b

7b

16a

16

16W

2a

Optional

12

12W

9a

8

9

26W

26W

14W

Optional

15

15W

1020Combinations

Specifications EUM-50 EUM-100 EUM-180 EUM-210 EUM-215

Voltage – DC 6, 24 or 90 6, 24 or 90 6, 24 or 90 6, 24 or 90 6, 24 or 90

Static Torque – lb.ft. 16 30 30 95 95

Maximum Speed – RPM 3600 3600 3600 3600 3600

Average Weight – lbs. 10.0 13.2 13.2 30.6 30.6

Total cycled inertia

– WR2(lb.ft.2) .017 .041 .041 .20 .202

Warner Electric • 800-825-9050 P-226 • 819-0355

12

Page 13

UniModuleAssemblies

PartNumbers Washdown

Unit Enclosed(EUM) EUM-W)

Size Voltage UniModule UniModule

50-1020 6V 5370-273-058 5370-273-100

24V 5370-273-059 5370-273-101

90V 5370-273-057 5370-273-099

100-1020 6V 5370-273-092 5370-273-108

24V 5370-273-093 5370-273-109

90V 5370-273-091 5370-273-107

Unit Enclosed(EUM) (EUM-W)

Size Voltage UniModule UniModule

210-1020 6V 5371-273-028 5371-273-056

24V 5371-273-029 5371-273-057

90V 5371-273-027 5371-273-055

215-1020 6V 5371-273-048 5371-273-064

24V 5371-273-049 5371-273-065

90V 5371-273-047 5371-273-063

PartNumbers Washdown

180-1020 6V 5370-273-066 5370-273-116

24V 5370-273-067 5370-273-117

90V 5370-273-065 5370-273-115

ComponentParts

Item Description EUM-50 EUM-100 EUM-180 EUM-210 EUM-215

1 Armature Assembly 5370-111-011 (2) 5370-111-013 (2) 5370-111-013 (2) 5371-111-005 (2) 5371-111-005 (2)

2 Armature Hub 540-1638 540-1642 540-1642 540-0741 540-0741

2a Key 590-0043 590-0084 590-0084

3 Retaining Ring 748-0445 748-0676 748-0676

4 Lockwasher 950-0121 (6) 950-0121 (6)

5 Capscrew 797-0081 (6) 797-0081 (6)

6a Retaining Ring 748-0113 (2) 748-0101 748-0101 748-0112 748-0112

6b Retaining Ring 748-2002 748-2002

7a Ball Bearing 166-0149 166-0101 166-0101 166-0142 166-1042

7b Ball Bearing 166-0155 166-0143 166-0143 166-0144 166-0144

8 Endbell/Brake 456-1014 456-1019 456-1019 456-1017 456-1017

9 Brake Magnet

6 Volt 5370-631-037 5370-631-002 5370-631-002 5371-631-002 5371-631-002

24 Volt 5370-631-038 5370-631-005 5370-631-005 5371-631-005 5371-631-005

90 Volt 5370-631-036 5370-631-003 5370-631-003 5371-631-003 5371-631-003

9a Set Screws 797-0471 (4) 797-1386 (4) 797-1386 (4) 797-0103 (4) 797-0103 (4)

10 Clutch Field/End Bell Assembly

6 Volt 5370-451-077 5370-451-086 5370-451-086 5371-451-033 5371-451-044

24 Volt 5370-451-078 5370-451-087 5370-451-087 5371-451-034 5371-451-045

90 Volt 5370-451-076 5370-451-085 5370-451-085 5371-451-032 5371-451-046

11 Rotor/Hub Assembly 5370-751-023 5370-751-035 5370-751-024 5371-751-014 5371-751-028

11a Set Screws 797-1098 (2) 797-1249 (2) 797-1249 (2) 797-1098 (2) 797-1098 (2)

12 Mounting Accessory Kit 5370-101-040 5370-101-040 5370-101-040 5371-101-040 5371-101-024

13 Cover Plate 686-1055 686-1055 686-1055 686-1055 686-1055

13a Cover Plate Screws 797-0575 (4) 797-0575 (4) 797-0575 (4) 797-0575 (4) 797-0575 (4)

14 Center Housing 535-0176 535-0176 535-0176 535-0177 535-0177

15 Conduit Box 5370-101-042 5370-101-042 5370-101-042 5370-101-042 5370-101-042

16 Shaft 798-0046 798-0128 798-0085 798-0051 798-0255

16a Key 590-0029 590-0029 590-0029 590-0019 590-0124

17 Retaining Ring 748-0101 (2) 748-0101 748-0101 748-0558 748-0558

17a Ball Bearing 166-0150 166-0300 166-0300 166-0168 166-0168

18 Retaining Ring 748-0018 748-0018 748-0018 748-0067 748-0067

19 Assembly Bolts 797-1433 (2) 797-1433 (2) 797-1433 (2) 797-1438 (2) 797-1438 (2)

20 Connector 280-0038 280-0038 280-0038 280-0038 280-0038

21 Accessory Fan 5370-101-055 5370-101-055 5370-101-054 5371-101-029 5371-101-034

22 Washer 950-0441 950-0441 950-0441 950-0441 950-0441

23 Insulator 572-0327 572-0327 572-0327 572-0327 572-0327

EUM-WUniqueParts

12W Washdown Mounting Kit 5370-101-052 5370-101-052 5370-101-052 5371-101-041 5371-101-028

14W Center Housing for Washdown 535-0181 535-0181 535-0181 535-0182 535-0182

15W Conduit Box Kit 5370-101-045 5370-101-045 5370-101-045 5370-101-045 5370-101-045

16W Shaft 798-0263 798-0265 798-0262 798-0259 798-0267

20W Conduit Connector 280-0058 280-0058 280-0058 280-0058 280-0058

21W Fan Kit 5370-101-060 5370-101-060 5370-101-061 5371-101-033

26W Gasket/Seal Repair Kit 5370-101-058 5370-101-058 5370-101-058 5371-101-032 5371-101-032

Warner Electric • 800-825-9050 P-226 • 819-0355

13

Page 14

EnclosedUniModulePartsList

22

16a

12

12W

9a

10

19

18

21

17

23

11b

11a

11

Optional

15

15W

9a

8

9

6b

7

6a

20

20W

25

14

13a

13

1

26

2

3

1

5

4

2a

16a

24

16

16W

(2)

req'd.

(6)

req'd.

(8)

req'd.

27W

28W

28W

14W

2030Combinations

Specifications EUM-50 EUM-180 EUM-210

Voltage – DC 6, 24 or 90 6, 24 or 90 6, 24 or 90

Static Torque – lb.ft. 16 30 95

Maximum Speed – RPM 3600 3600 3600

Average Weight – lbs. 13 16.5 41.3

Total cycled inertia

– WR

2

(lb.ft.2) .017 .041 .20

Warner Electric • 800-825-9050 P-226 • 819-0355

14

Page 15

UniModuleAssemblies

Partnumbers

Unit Enclosed(EUM) Washdown(EUM-W)

Size Voltage UniModule UniModule

50-2030 6V 5370-273-062 5370-273-104

24V 5370-273-063 5370-273-105

90V 5370-273-061 5370-273-103

180-2030 6V 5370-273-070 5370-273-120

24V 5370-273-071 5370-273-121

90V 5370-273-069 5370-273-119

210-2030 6V 5371-273-032 5371-273-060

24V 5371-273-033 5371-273-061

90V 5371-273-031 5371-273-059

ComponentParts

Item Description EUM-50 EUM-180 EUM-210

1 Armature Assembly 5370-111-011 (2) 5370-111-013 (2) 5371-111-005 (2)

2 Armature Hub 540-1638 540-1642 540-0741

2a Key 590-0043 590-0084

3 Retaining Ring 748-0445 748-0676

4 Lockwasher 950-0121 (6)

5 Capscrew 797-0081 (6)

6a Retaining Ring 748-0113 748-0101 748-0112

6b Retaining Ring 748-2002

7 Ball Bearing 166-0149 166-0101 166-0142

8 Endbell/Brake 456-1014 456-1019 456-1017

9 Brake Magnet

9a Set Screws

10 Clutch Field/End Bell Assembly

11 Rotor 5370-751-033 5370-751-034 5371-751-006

11a Screw 797-1294 (4) 797-1214 (5) 797-0081 (6)

11b Washer 950-0102 (4) 950-0102 (5) 950-0121 (6)

12 Shaft/Clutch 798-0047 798-0124 798-0123

13 Cover Plate 686-1055 686-1055 686-1055

13a Screws 797-0575 (4) 797-0575 (4) 797-0575 (4)

14 Center Housing 535-0176 535-0176 535-0177

15 Conduit Box 5370-101-042 5370-101-042 5370-101-042

16 Shaft/Brake 798-0046 798-0085 798-0051

16a Key 590-0029 (2) 590-0029 (2) 590-0019 (2)

17 Retaining Ring 748-0113 (2) 748-0101 748-0112

18 Retaining Ring 748-0017 748-0202

19 Assembly Bolts 797-1477 (2) 797-1477 (2) 797-1476 (2)

20 Connector 280-0038 280-0038 280-0038

21 Bearing 166-0149 166-0101 166-0142

22 Bearing 166-0155 166-0143 166-0144

23 Spacer 807-0062 807-0061

24 Bearing 166-0155 166-0143 166-0144

25 Washer 950-0441 950-0441 950-0441

26 Insulator 572-0327 572-0327 572-0327

EUM-WUniqueParts

12W Shaft/Clutch 798-0264 798-0261 798-0260

14W Center Housing for Washdown 535-0181 535-0181 535-0182

15W Conduit Box Kit 5370-101-045 5370-101-045 5370-101-045

16W Shaft/Brake 798-0263 798-0262 798-0259

20W Conduit Connector 280-0058 258-0058 258-0058

27W Washdown Mounting Kit 5370-101-051 5370-101-051 5371-101-027

28W Gasket/Seal Repair Kit 5370-101-058 5370-101-058 5371-101-032

6 Volt 5370-631-037 5370-631-002 5371-631-002

24 Volt 5370-631-038 5370-631-005 5371-631-005

90 Volt 5370-631-036 5370-631-003 5371-631-003

6 Volt 5370-451-082 5370-451-090 5371-451-002

24 Volt 5370-451-083 5370-451-091 5371-451-005

90 Volt 5370-451-081 5370-451-089 5371-451-003

Warner Electric • 800-825-9050 P-226 • 819-0355

15

Page 16

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any

product manufactured and sold by it which proves to be defective in material or workmanship within a

period of one (1) year from the date of original purchase for consumer, commercial or industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without

Warner Electric LLC’s prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation

charges prepaid, to the appropriate Warner Electric LLC factory. Additional warranty information may

be obtained by writing the Customer Satisfaction Department, Warner Electric LLC, 449 Gardner

Street, South Beloit, Illinois 61080, or by calling 815-389-3771.

A purchase receipt or other proof of original purchase will be required before warranty service is

rendered. If found defective under the terms of this warranty, repair or replacement will be made,

without charge, together with a refund for transportation costs. If found not to be defective, you will be

notified and, with your consent, the item will be repaired or replaced and returned to you at your

expense.

This warranty covers normal use and does not cover damage or defect which results from

alteration, accident, neglect, or improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation may

not apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the

defective product and in no event shall Warner Electric LLC be liable for consequential, indirect,

or incidental damages of any kind incurred by reason of the manufacture, sale or use of any defective

product. Warner Electric LLC neither assumes nor authorizes any other person to give any other

warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH THE

CONSUMER MAY HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL

CONSUMER PURCHASE. WITH RESPECT TO COMMERCIAL AND INDUSTRIAL USES OF THE

PRODUCT, THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER

WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR OTHERWISE,

INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you. This warranty gives you specific legal rights and

you may also have other rights which vary from state to state.

ChangesinDimensionsandSpecifications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without

notice. Weights do not include weight of boxing for shipment. Certified prints will be furnished without

charge on request to Warner Electric.

Warner Electric

31 Industrial Park Road • New Hartford, CT 06057

815-389-3771 • Fax: 815-389-2582

www.warnerelectric.com

P-226 819-0355 8/11 Printed in USA

Loading...

Loading...