Page 1

ERS Electrically Released Brakes

P-219

819-0337

Installation Instructions

Page 2

2

Warner Electric • 800-825-9050 819-0337

Contents

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Drive Hub Data . . . . . . . . . . . . . . . . . . . . . . . . 5

Troubleshooting Information . . . . . . . . . . . . . . 5

Warranty . . . . . . . . . . . . . . . . . . . . . Back Cover

The Warner Electric ERS brake you purchased has been designed to provide long and trouble free

service. It’s a rugged, simple unit which is easy to install and requires no adjustment or maintenance.

This service manual includes detailed installation instructions, complete product dimensions,

performance data, and troubleshooting information.

Installation

1. Remove your ERS brake from its shipping

carton and inspect it thoroughly to ensure

that it has arrived in good condition. An

accessory kit included with your brake

contains screws and insulator boots for the

electrical termination. In addition, you may

have ordered the optional splined drive hub,

mounting flange, and/or conduit box.

2. If used, install the Warner Electric conduit

box in accordance with the instructions furnished with the conduit box accessory.

3. The ERS brake is shipped fully assembled

and ready to mount. No adjustments or

brake run-in are necessary. The mating

mounting holes in your mounting surface

must be within 0.014 inch diameter of true

position to the shaft center line and the

mounting surface must be within .005” of

perpendicular to the shaft axis. If you are

mounting your brake with through-bolts (see

Mounting Options below) you will need four

of the following fasteners:

Maximum

Brake Fastener Size Fastener Torque

ERS-26 #6-32 20 in.lbs.

ERS-42 #8-32 35 in.lbs.

ERS-49 #10-32 75 in.lbs.

ERS-57 1/4”-20 120 in.lbs.

ERS-68 3/8”-16 150 in.lbs.

Through-Bolt

Mounting through the brake

magnet provides rigid

support for the unit with a

space equal to the outside

diameter of the brake. May

be mounted on either end.

Your ERS Brake is designed to

self-engage in case of an electrical power

failure. Replace only with an identical unit.

Do not disassemble. Brake parts are under

high spring pressure. Failure to follow these

instructions may result in product damage,

equipment damage, and serious or fatal

injury to personnel.

If the optional Warner Electric mounting flange is

being used, assemble with the supplied screws

into the tapped holes in the back of the brake.

You will need to provide a mounting hole pattern

in the flange that corresponds to your application.

Brake Mounting Options

ERS Brakes can accommodate different mounting

orientations. The following mountings are possible

with the standard ERS brake:

Page 3

3

Warner Electric • 800-825-9050 819-0337

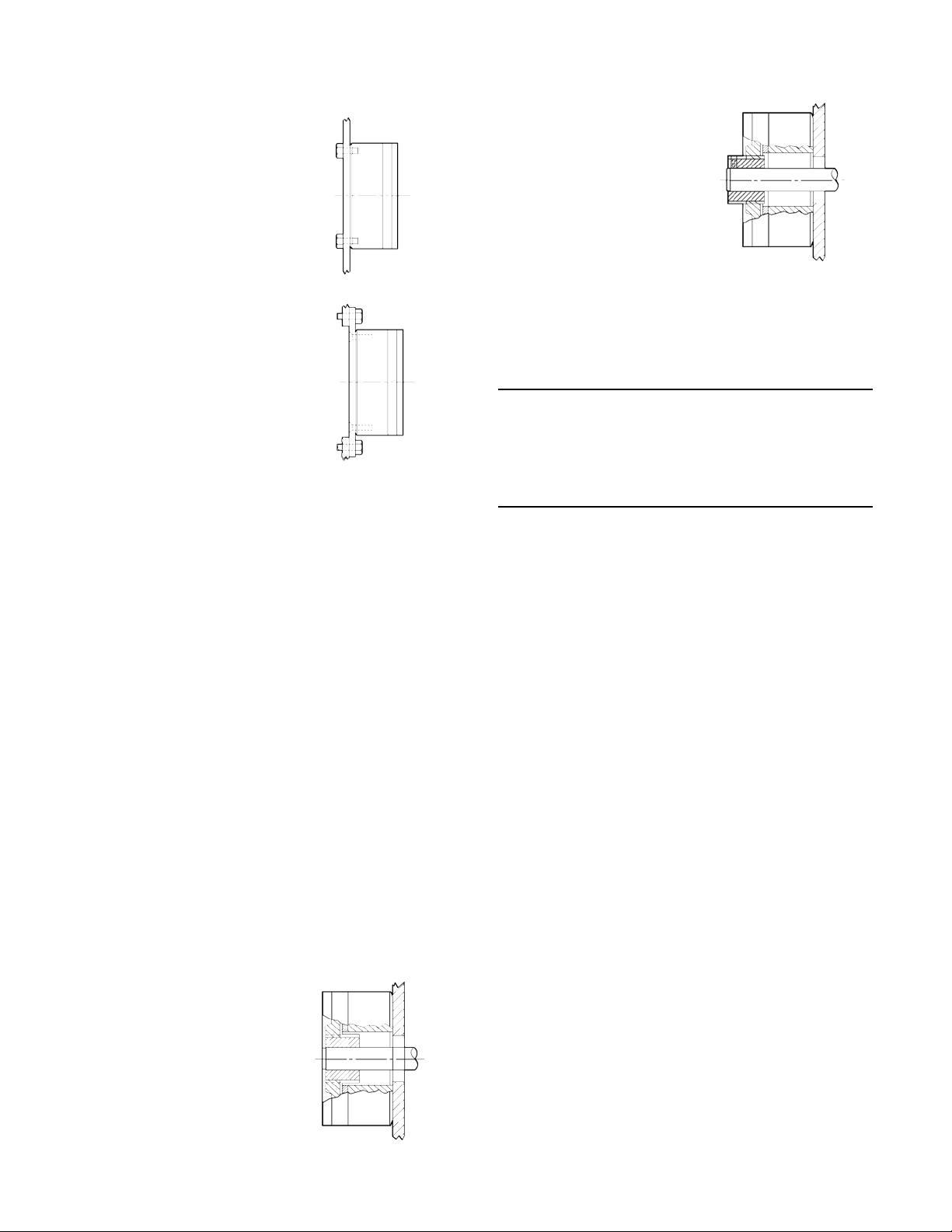

Tapped Holes

Mounting the brake by

drawing it into a housing or

cavity again provides the rigid

support in an area no larger

than the outside diameter of

the brake. It is used where

through-bolt mounting is

impractical.

Flange

Mounting flanges can be

attached to the base design

using the tapped holes

provided.

Since the mating spline (either the Warner

Electric splined hub or your splined shaft) is

smaller than the brake bore, either end of the

brake can be positioned against the mounting

surface when using through bolts. If a Warner

Electric conduit box is being used and the back

of the brake must be against the mounting

surface, a relief in the mounting surface will be

required to accommodate the conduit box

mounting plate. (See page 4 for details).

Hub Mounting Options

If the Warner Electric splined drive hub is to be

used, it can be mounted in either of the

following sequences:

Note: Full spline engagement contact is

required between the splined hub or splined

shaft and the splined brake disc. The disc

must be able to move freely on the hub.

Recessed Hub

Mounting the hub on the

driving member prior to

mounting the brake

allows the splined hub to

be recessed in the brake

bore for maximum space

efficiency.

Extended Hub

Mounting the hub on the

driving member after

mounting the brake allows

the splined hub to extend

beyond the brake where

space allows.

When the splined hub has been located on the

shaft with its appropriate key, tighten the set

screws to the following torque values:

Brake Torque

ERS-26 10 lb. in.

ERS-42 20 lb. in.

ERS-49 35 lb. in.

ERS-57 35 lb. in.

ERS-68 85 lb. in.

Loc-tite

®

242 may be applied on screw threads

to minimize chances of screws backing off

under severe vibration.

4. After the brake and hub are secured in place,

attach the DC power source to the brake

terminals. Feed the wires through the brake

insulator boots before attaching them. After

the terminal screws are tightened (torque to

15 lb. in.), slide the boots over the screws

and terminals to insulate the electrical

connection.

Either terminal can be connected to the + or side of the power source. If a Warner Electric

CBC-100 or other Warner Electric control is

used, follow the wiring instructions supplied

with the control.

5. Your ERS brake is now ready for its static

test. Apply the rated DC voltage to the brake.

It should disengage and the shaft should

rotate freely.

Your ERS Brake is now ready to run.

Page 4

4

Warner Electric • 800-825-9050 819-0337

Dimensions

*Available only on the ERS-49, 57, and 68 sizes.

AB CDE FGH JK L M N PQ

Model Max. Max. Dia. Dia.

ERS-26 2.460 1.515 1.375 1.125 .860 1.250 – – – – – 2.125 .172/.164 4-40 .375

(63) (39) (35) (28) (22) (32) (54) (4) –

ERS-42 3.520 1.595 2.000 1.600 1.375 1.255 – – – – – 3.125 .200/.190 6-32 .400

(90) (41) (51) (41) (35) (32) (79) (5) –

ERS-49 4.270 1.767 2.600 1.750 1.500 1.332 3.625 4.625 1.000 1.625 3.750 3.750 .228/.218 8-32 .400

(109) (45) (66) (44) (38) (34) (92) (117) (25) (41) (95) (95) (6) –

ERS-57 5.020 1.937 3.240 2.100 1.750 1.503 4.000 5.000 1.170 1.625 3.750 4.500 .288/.278 10-24 .400

(128) (49) (82) (53) (44) (38) (102) (127) (30) (41) (95) (114) (7) –

ERS-68 6.520 2.030 4.504 2.800 2.425 1.565 4.750 5.750 1.265 1.625 3.750 5.875 .413/.404 1/4-20 .500

(166) (52) (114) (71) (62) (40) (121) (146) (32) (41) (95) (149) (10) –

(–) denotes millimeters

Note: Mating holes for mounting brake to be within .014 diameter true position, max. material condition, to the center of shaft.

Page 5

5

Warner Electric • 800-825-9050 819-0337

Drive Hub Data

A Mating Key B C Set

Model Bore (Not furnished) Nom. Nom. Screws Size Torque

ERS-26 .2525/ .2505 1/16 x 1/16 .600 .135 6-32 10

.3150/ .3130 1/16 x 1/16 x 1/8 lb. in.

.3775/ .3755 3/32 x 3/32

ERS-42 .3775/ .3755 3/32 x 3/32 .700 .150 8-32 20

.5025/ .5005 1/8 x 1/8 x 3/16 lb. in.

.6275/ .6255 3/16 x 3/16

.7525/ .7505 3/16 x 3/16

ERS-49 .3775/ .3755 3/32 x 3/32 .800 .160 10-32 36

.5025/ .5005 1/8 x 1/8 x 3/16 lb. in.

.6275/ .6255 3/16 x 3/16

.7525/ .7505 3/16 x 3/16

.8775/ .8755 3/16 x 3/16

ERS-57 .5025/ .5005 1/8 x 1/8 .800 .160 10-32 36

.6275/ .6255 3/16 x 3/16 x 3/16 lb. in.

.7525/ .7505 3/16 x 3/16

.8775/ .8755 3/16 x 3/16

1.0025/1.0005 1/4 x 1/4

ERS-68 1.0025/1.0005 1/4 x 1/4 .900 .190 1/4-20 87

1.1275/1.1255 1/4 x 1/4 x 1/4 lb. in.

1.2525/1.2505 1/4 x 1/4

1.3775/1.3755 5/16 x 5/16

1.5025/1.5005 3/8 x 3/8

Note: Hub may be located in any position on shaft as long as the external

and internal splines are 100% engaged.

ABCD

Model Nom. Nom. Holes Nom.

ERS-26 4.000 .935 #4 .100

(101.6) (23.7) (2.6)

ERS-42 5.000 1.450 #6 .144

(127.0) (36.8) (3.7)

ERS-49 6.250 1.575 #8 .193

(158.8) (40.0) (4.9)

ERS-57 7.500 1.825 #10 .193

(190.5) (46.4) (4.9)

ERS-68 9.500 2.500 1/4 .224

(241.3) (63.5) (5.7)

(—) denotes millimeters

Note: Holes for attaching flange to mounting

surface to be provided by customer.

Troubleshooting

Symptom Check

Brake will not release a. Proper voltage at the brake terminal(s).

b. Correct unit voltage matched to power supply.

c. Coil continuity if proper voltage is at the brake leads.

d. Spline for binding. Friction disk must be able to move freely on mating spline.

If the above checks do not determine the cause of the failure, the brake is non-operational and must be replaced.

Page 6

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any

product manufactured and sold by it which proves to be defective in material or workmanship

within a period of one (1) year from the date of original purchase for consumer, commercial or

industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without

Warner

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation

charges prepaid, to the appropriate Warner Electric LLC factory. Additional warranty information

may be obtained by writing the Customer Satisfaction Department, Warner Electric LLC, 449

Gardner Street, South Beloit, Illinois 61080, or by calling 815-389-3771.

A purchase receipt or other proof of original purchase will be required before warranty service is

rendered. If found

without charge, together with a refund for transportation costs. If found not to be defective, you

will be notified and, with your consent, the item will be repaired or replaced and returned to you

at your expense.

This warranty covers normal use and does not cover damage or defect which results from

alteration, accident, neglect, or improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation

may not apply to you.

Electric LLC’s prior consent.

defective under the terms of this warranty, repair or replacement will be made,

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the

defective product and in no event shall Warner Electric LLC be liable for consequential, indirect,

or incidental

damages of any kind incurred by reason of the manufacture, sale or use of any

defective product. Warner Electric LLC neither assumes nor authorizes any other person to give

any other warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH

THE CONSUMER

MAY HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF

ORIGINAL CONSUMER PURCHASE. WITH RESPECT TO COMMERCIAL AND INDUSTRIAL

USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL

OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you. This warranty gives you specific legal

rights and you may also have other rights which vary from state to state.

Changes in Dimensions and Specifications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without

notice. W

eights do not include weight of boxing for shipment. Certified prints will be furnished

without charge on request to Warner Electric.

Warner Electric LLC

31 Industrial Park Road t New Hartford, CT 06057

815-389-3771 t Fax: 815-389-2582

www.warnerelectric.com

An Altra Industrial Motion Company

P-211 819-0043 9/11 Printed in USA

P-219 819-0337 9/11 Printed in USA

Warner Electric LLC

31 Industrial Park Road t New Hartford, CT 06057

815-389-3771 t Fax: 815-389-2582

www.warnerelectric.com

An Altra Industrial Motion Company

Loading...

Loading...