Page 1

ERD–Electrically Released Brakes

P-229

819-0453

Installation Instructions

Page 2

Warner Electric’s ERD series spring set, elec-

trically released brakes are designed to hold a

load when the power to the brake is off. ERD

brakes are offered in eight different sizes and

the characteristics of each are described under

“Specifications”. Brake options include a manual release handle, dust cover, and thin or thick

friction flanges. A friction flange is to be mounted to the back of the brake on applications

where the mounting surface is not suitable for

use as a friction surface for repeated stopping

and holding. The manual release handle offers

the operator the ability for controlled load

release without energizing the electrical coil.

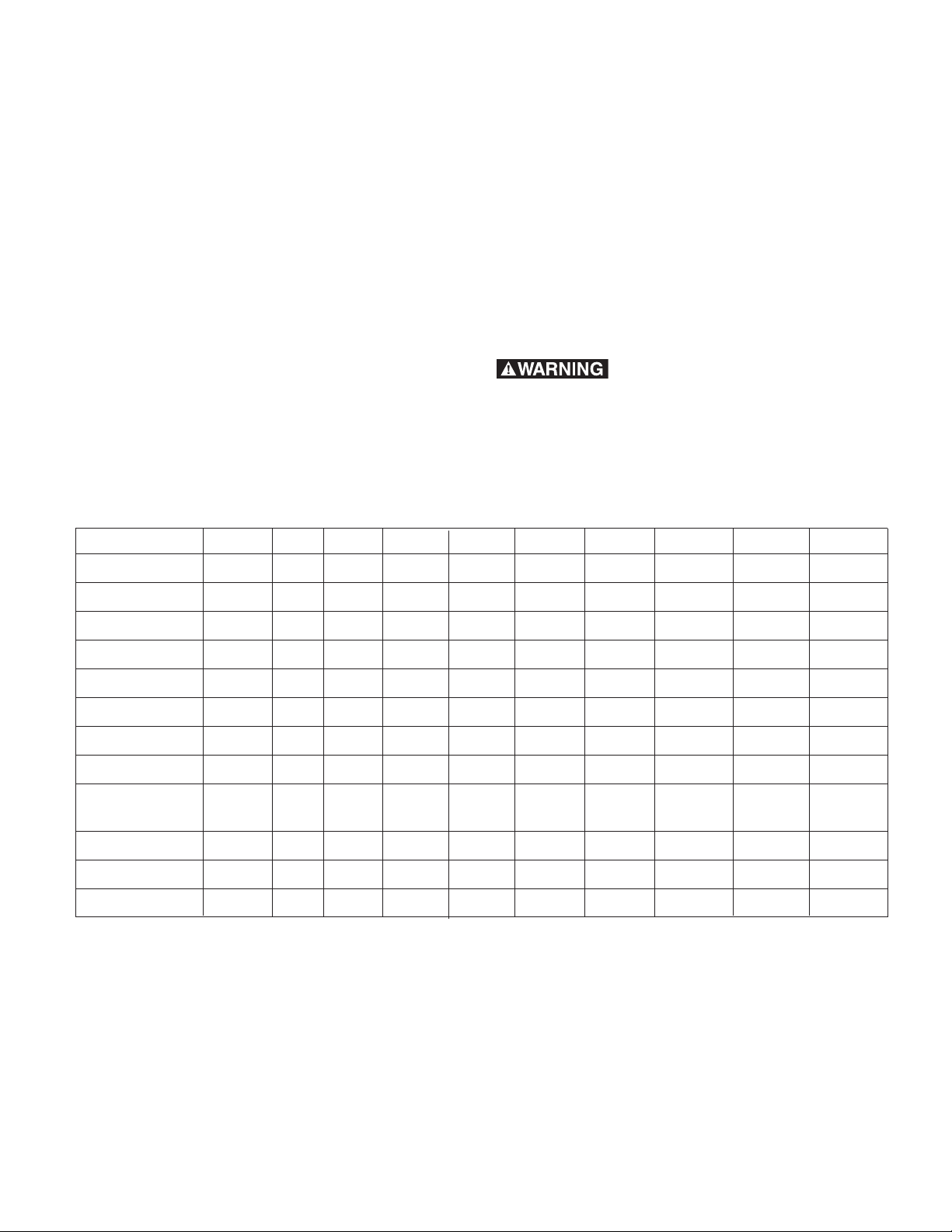

Specifications

Options Units ERD 5 ERD 10 ERD 20 ERD 35 ERD 60 ERD 100 ERD 170 ERD 300

Contents

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . .2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Electrical Connection . . . . . . . . . . . . . . . . . . . . .3

Torque Adjustment . . . . . . . . . . . . . . . . . . . . . . .4

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Brake Components . . . . . . . . . . . . . . . . . . . . . .5

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Warranty . . . . . . . . . . . . . . . . . . . . . . .Back Page

Failure to follow these instructions may r

ment damage, and serious or fatal injury to

personnel.

esult in product damage, equip-

Holding Torque in.lb. 45 85 175 310 530 890 1500 2650

Maximum Speed RPM 3600 3600 3600 3600 3600 3600 3600 3600

Nominal Airgap Inch .008 .008 .008 .012 .012 .012 .012 .012

Maximum Airgap Inch .020 .025 .020 .030 .030 .035 .035 .040

Current Draw Amps

24 VDC 0.83 1.03 1.22 1.61 1.94 2.35 2.73 4.11

90/96/103.5 96 VDC 0.21 0.26 0.31 0.41 0.49 0.569 0.69 1.122

190/207/215 190 VDC 0.11 0.13 0.16 0.21 0.27 0.38 0.38 0.61

Resistance at

Ambient Temp. 24 VDC Ohms 28.9 23.4 19.6 14.9 12.4 10.22 8.78 5.83

90/96/103.5 96 VDC 454 372 310 233 166.2 168.6 139.2 85.63

190/207/215 190 VDC 1775 1450 1209 912 648.1 628.5 507.2 315.6

Weight Ibs 2 4 7 10 14 22 34 57

Warner Electric • 800-825-9050 819-0453

2

Page 3

Installation

ERD brakes are supplied in kit form. The magnet

assembly is supplied with airgap factory adjusted. Brakes are designed for dry operation and

can be mounted horizontally or vertically.

o

Maximum ambient temperature is 104

F.

Customer Shall Maintain:

1. Squareness of flange mounting face with

shaft within 0.006 in. (0.15mm) T.I.R. measured at the mounting shaft.

2. Concentricity of flange mounting with mounting shaft within 0.006 in. (0.15mm) T.I.R.

3. The mounting surface should be made of

steel or cast iron, square to the shaft with a

surface finish of 125 microinches or a fine

turned finish over the contact area.

Step 1

If a friction flange is provided, mount it first.

Mounting dimensions ar

Thick flanges are typical.

Step 2

Install key into shaft. Slide hub onto shaft and

ovide a suitable axial stop. Stop collars are

pr

typical.

Step 3

Slide friction disc on to hub.

Step 4

Fit magnet assembly to friction plate or prepar

ed surface. If a hand release is to be used,

this should be installed at this time. Remove

the wedge pieces. Torque bolts to the following

specifications.

ERD Size 5 10 20 35 60 100 170 300

Torque, lb.in. 20 40 70 70 210 210 210 425

e provided on Page 7.

Secure bolts using a LOCTITE 270 type thermoplastic liquid.

If a rubber dust cover is to be used, install it

before installing the magnet.

Step 5

Apply power to magnet and cycle brake on several times to confirm friction disc r

otates freely.

Verify correct airgap.

Electrical Connection

Warner Electric ERD brakes are offered in 24,

96, 190, and 215 VDC versions. Energizing the

brake magnet with the proper voltage will cause

the magnetic field generated to overcome the

brake spring force and release the brake. Any

DC power source with adequate amperage will

operate the brake. Warner Electric offers 24

VDC controls to operate standard 24 VDC

brakes and full and half wave rectifiers to supply

96 or 190 VDC current for models with those

voltage ratings. Switches are customer supplied.

The magnets are not polarity sensitive, so any

magnet lead can be connected to any power

source lead.

Recommended Warner Electric 24 VDC controls:

Model Part Number

CBC-400-24 6006-448-002

CBC-450-24

CBC-500-24 6024-448-002

CBC-550-24 6024-448-005

Warner Electric Rectifiers:

AC Input DC Output

240/220 V 96 V Half Wave CG 830

A1P1

415/380 V 190 V

A1P1

240/220 V 190 V Full Wave CG 830

A1P2

110 V 96 V Full Wave CG 830

A1P2

6006-448-005

Rectifier Part No.

Half Wave CG 830

Warner Electric • 800-825-9050 819-0453

3

Page 4

Torque Adjustment

8

5

2

4

6

3

1

9

Maintenance

Each brake is factory set to its nominal torque

rating as listed under ‘Specifications”. VAR 02

brakes are factory set at 50% of listed torque.

The torque of Variation 2 can be reduced by

loosening the central nut to the extent listed

in Figure 2.

ERD Variation 2 - lb.in. Variation 2

Size Reduction per Number of detents

detent per complete revolution

5 4.5 4

10 11 4

20 11 4

35 21 4

60 16 6

100 22 6

170 27 8

300 38 8

Wear in the friction material causes an increase

in the airgap. Before reaching the maximum airgap, it should be readjusted (see specifications).

• The brake must remain free from oil, grease,

and abrasive dust at all times.

• Check the airgap periodically and reset as

required per instructions found in Step 5 on

page 3. Inspection interval(s) depend on the

frequency of brake application.

• Check friction material thickness periodically

per dimension M and replace when below the

minimum shown below.

The theoretical reduction in airgap for 0.5 turn of

the spacer screw will be as follows:

Brake Thread Reduction Inches

ERD5 M6 X 0.5 0.25 0.010

ERD10 M8 X 0.75 0.375 0.015

ERD20 M10 X 0.75 0.375 0.015

ERD35 M10 X 0.75 0.375 0.015

ERD60 M12 X 1 0.5 0.020

ERD100 M12 X1 0.5 0.020

ERD170 M12 X 1 0.5 0.020

ERD300 M16 X 1 0.5 0.020

Table 2: Airgap Adjustment Specifications

Minimum Minimum

VAR 2

Single torque adjustment nut

VAR 0

No torque adjustment possible

ERD Size Millimeters Inches

5 0.22 0.009

10 0.21 0.008

Thickness Thickness

20 0.31 0.012

orque reduction

• T

up to 50% by

loosening nut

• Available in all sizes

Figure 2 - Torque Adjustment)

vailable in all sizes

•A

35 0.22 0.009

60 0.24 0.009

100 0.24 0.009

170 0.31 0.012

300 0.32 0.013

Table 3: Minimum Acceptable Friction Carrier

Thickness in Inches

Warner Electric • 800-825-9050 819-0453

4

Page 5

Options

Dust Cover

Airgap Adjustment

Spacer Screws

Friction

Disc Carrier

Holding Screws

Central Nut (VAR 2)

Hub

Magnet Assembly

AA

BB

EE FF

CC

Release Angle

• Manual Release - This option is recommended in applications where the brake needs to

be released by hand. This is ideal for gradually and safely lowering suspended loads in

the event of a power failure. Note: This option

requires magnet VAR 2.

• Dust Cover - This option is recommended for

use in environments which cannot be contaminated with brake friction dust and in

harsh dust, dirt, and humidity environments

where the brake is in danger from the contaminants.

• Friction Disc Carrier - Sizes 5 and 10 are

available with an optional synthetic material

carrier. Metallic disc carriers are standard for

all sizes.

• Friction Flanges - A friction flange is to be

mounted to the machine or motor frame if its

surface does not meet these specifications:

1. Cast iron or steel material

2. Hardness 150 HB

3. Smooth to 125 microinch

4. Flat to .002 inches

ERD Brake Components

Figure 1

A friction flange is required if all of the specifications are not met. The correct flange is:

Thin friction flange

Used where surface is machined but unsuitable

for friction (eg. aluminum). Used in conjunction

with "Long screw kit". Only available through

size ERD 35 due to potential distortion with frictional heat input.

Thick friction flange

Used in the absence of a suitable machined

mounting surface.

Mounting Screw Kits:

1. Short Screw Kit - supplied with the thick

2. Long Screw Kit - supplied with the thin flange

flange for mounting on the external diameter

threaded holes.

for mounting through the flange on the external diameter holes. Can also be ordered separately for direct mounting without a flange.

Figure 4 - Hand Release Lever Mounting

ERD AA BB CC EE FF Release

Size Angle

5 3.86 2.09 0.67 3.46 .040 10

10 4.21 2.44 0.71 4.17 .040 9

20 5.08 2.99 0.98 5.20 .040 8

35 5.47 3.39 0.87 5.98 .050 8

60 7.44 4.09 1.57 6.54 .050 15

100 8.07 4.72 1.73 7.36 .050 15

170 9.57 5.51 2.09 8.78 .050 15

300 12.32 6.38 2.40 10.33 .050 20

Warner Electric • 800-825-9050 819-0453

5

Page 6

f

E

F

G

0.06

B

E

H

C

J

e

P

f

h

DD

L

E

M

S

A

D

U

K

N

W

Dimensions

Brake Unit (typical)

Thin Friction Plate

Thick Friction Plate

Brake Unit (VAR 0)

Dust Cover

Figure 3

Warner Electric • 800-825-9050 819-0453

6

Page 7

Dimensions

ERD A B C D E e f F G H h J

Size Max. Bolt Patter n Bolt Bolt

Clearance Clearance

Holes Holes

5 3.307 3.268 0.787 0.5 2.835 3xM4 3x0.177 1.654 3.425 1.181 3x0.315 0.079

10 4.016 3.937 1.181 0.625 3.543 3xM5 3x0.217 2.126 4.213 1.772 3x0.394 0.079

20 5.000 4.921 1.575 1 4.409 3xM6 3x0.256 2.362 5.217 2.205 3x0.433 0.118

35 5.787 5.709 1.772 1.125 5.197 3xM6 3x0.256 2.953 6.004 2.441 3x0.433 0.118

60 6.378 6.299 2.165 1.25 5.709 3xM8 3x0.335 2.913 3x0.551 0.118

100 7.402 7.283 2.559 1.500 6.693 3xM8 3x0.335 3.307 3x0.551 0.118

170 8.465 8.346 2.953 1.95 7.717 6xM8 6x0.335 3.937 6x0.551 0.118

300 9.921 9.843 3.543 2.125 9.055 6xM10 6x0.413 4.724 6x0.670 0.118

ERD K L M N P S U W DD

Size Max. +0.000/-0.008 +/-0.002

5 1.378 1.575 0.709 0.079 0.236 0.748 0.008 0.925 3.46

10 1.614 1.831 0.787 0.118 0.276 0.945 0.008 1.122 4.17

20 1.870 2.185 0.787 0.157 0.354 1.378 0.008 1.594 5.20

35 2.146 2.559 0.984 0.118 0.354 1.575 0.012 1.909 5.98

60 2.520 2.933 1.181 0.118 0.433 1.890 0.012 2.303 6.53

100 2.795 3.209 1.181 0.118 0.433 2.047 0.012 2.500 7.56

170 3.268 3.780 1.378 0.177 0.433 2.362 0.012 2.894 8.62

300 3.819 4.528 1.575 0.197 0.433 2.874 0.012 3.484 10.8

Warner Electric • 800-825-9050 819-0453

7

Page 8

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any

product manufactured and sold by it which proves to be defective in material or workmanship

within a period of one (1) year from the date of original purchase for consumer, commercial or

industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without

Warner Electric LLC’s prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation

charges prepaid, to the appropriate Warner Electric LLC factory. Additional warranty information

may be obtained by writing the Customer Satisfaction Department, Warner Electric LLC, 449

Gardner Street, South Beloit, Illinois 61080, or by calling 815-389-3771.

A purchase receipt or other proof of original purchase will be required before warranty service is

rendered. If found defective under the terms of this warranty, repair or replacement will be made,

without charge, together with a refund for transportation costs. If found not to be defective, you

will be notied and, with your consent, the item will be repaired or replaced and returned to you

at your expense.

This warranty covers normal use and does not cover damage or defect which results from

alteration, accident, neglect, or improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation

may not apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the

defective product and in no event shall Warner Electric LLC be liable for consequential, indirect,

or incidental damages of any kind incurred by reason of the manufacture, sale or use of any

defective product. Warner Electric LLC neither assumes nor authorizes any other person to give

any other warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH

THE CONSUMER MAY HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF

ORIGINAL CONSUMER PURCHASE. WITH RESPECT TO COMMERCIAL AND INDUSTRIAL

USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL

OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you. This warranty gives you specic legal

rights and you may also have other rights which vary from state to state.

Changes in Dimensions and Specifications

All dimensions and specications shown in Warner Electric catalogs are subject to change without

notice. Weights do not include weight of boxing for shipment. Certied prints will be furnished

without charge on request to Warner Electric.

Warner Electric LLC

31 Industrial Park Road • New Hartford, CT 06057

815-389-3771 • Fax: 815-389-2582

www.warnerelectric.com

P-229 819-0453 7/05 Printed in USA

Loading...

Loading...