Page 1

CBC-500 & 550 Series

Torque Adjustable Clutch/Brake Controls

P-239-24

819-0486

Installation Instructions

Page 2

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Control Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Switching Options . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Dimensional Diagrams . . . . . . . . . . . . . . . . . . . . . . . . 6

System Troubleshooting . . . . . . . . . . . . . . . . . . . . . . 7

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . 8

Mounting Templates. . . . . . . . . . . . . . . . . . . . . . . . . 10

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . back cover

Failure to follow these

instructions may result in product damage,

equipment damage, and serious or fatal

injury to personnel.

Introduction

Warner Electric's CBC-500 and CBC-550 series

clutch/brake controls are compact units

designed for operation with Warner Electric

90VDC and 24VDC clutches and brakes, including failsafe units. Dual channel torque adjustment is provided via on-board potentiometers

for soft starts and stops as well as accurate

release points for failsafe designs. These controls can operate with each channel either in

dual or single mode. Dual or single mode is controlled via an on board jumper for use in a variety of applications. A transformer is provided on

the CBC-550 series controls, extending the

input AC voltage range. Four models are

available:

CBC-500-90 120 VAC input

CBC-500-24 24-30 VAC input

CBC-550-90 120/220/240/380/480 VAC input

CBC-550-24 120/220/240/380/480 VAC input

Three optically isolated inputs provide full flexibility in interfacing customer supplied switching

schemes. Internal circuitry provides suppression

of transients during decay of the magnetic field

to assure rapid cycle rates. Two LED indicators

are provided on the control board for channel 1

and channel 2 indication.

Warner Electric • 800-234-3369 P-239-24

2

Page 3

Specifications

Input:

CBC-500-90: 120 VAC ± 10%, 50/60 Hz, 1 phase, 250 VA max.

CBC-500-24: 24-30 VAC, 50/60 Hz, 1 phase, 250 VA max.

CBC-550-90: 120/220/240/380/480 VAC ± 10%, 50/60 Hz, 1 phase, 250 VA max.

CBC-550-24: 120/220/240/380/480 VAC ± 10%, 50/60 Hz, 1 phase, 250 VA max.

Output:

CBC-500-90: 0-90 VDC full-wave rectified nominal,

1.0 amp per channel max., 2.0 amps total

CBC-500-24: 0-24 VDC full-wave rectified nominal,

5.0 amps per channel max., 5.0 amps total

CBC-550-90: 0-90 VDC full-wave rectified nominal,

1.0 amp per channel max., 1.2 amps total

CBC-550-24: 0-24 VDC full-wave rectified nominal,

4.0 amps per channel max., 4.0 amps total

Circuit Protection: (fusing)

CBC-500-90: 2.5 amp, 250 V fast-blo, 3AG

CBC-500-24: 6.3 amp, 250 V fast-blo, 5 x 20 mm

CBC-550-90: 1.5 amp, 250 V fast-blo, 3AG

CBC-550-24: 5 amp, 125 V fast-blo, 5 x 20 mm

Switching Inputs: (external to control, supplied by customer)

Three optically isolated, 10-30 VDC:

Channel 1 Input (adjustable voltage applied to channel 1)

Channel 2 Input (adjustable voltage applied to channel 2)

Channel 2 Override Input (full voltage applied to channel 1)

Maximum off-state leakage < 1 mA

Adjustments:

Channel 1 Voltage (via potentiometer)

Channel 2 Voltage (via potentiometer)

Jumper (selects simultaneous or alternate mode)

Frequency Adjustment: 60-400 Hz (via potentiometer)

Ambient Temperature:

-20° to 122°F (-29° to 50°C)

Auxiliary Supply:

12 VDC, 250 mA maximum

Enclosure:

Optional NEMA 13 enclosure available

Warner Electric • 800-234-3369 P-239-24

3

Page 4

Installation

1

1

2

3

4

5

6

7

1

2

3

4

5

6

7

8

8

1

1

2

2

2

3

3

3

4

4

4

5

5

5

6

6

6

7

7

8

8

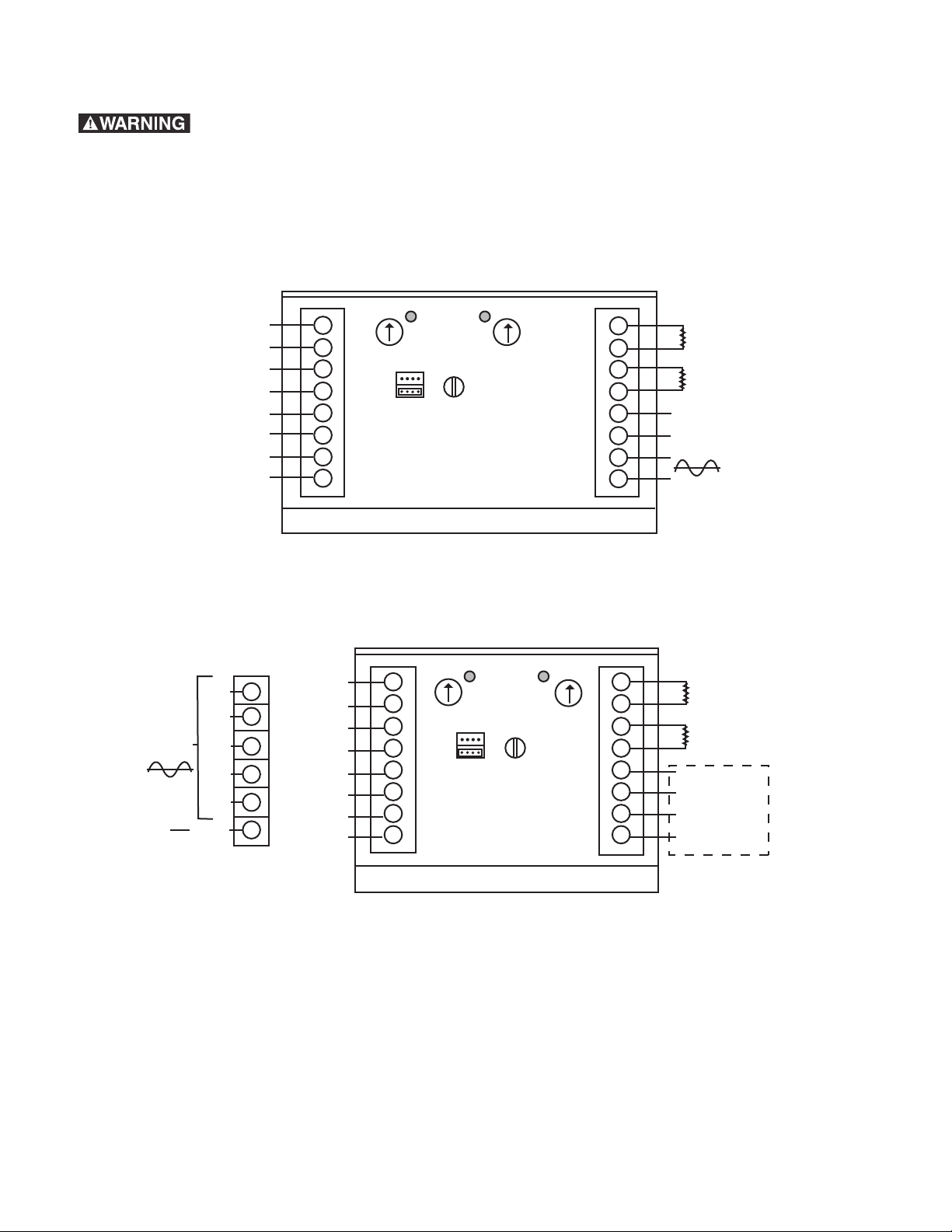

POWER/SWITCHING

SWITCHING

CHANNEL 2 INPUT

(10-30 VDC)

CHANNEL 1 INPUT

(10-30 VDC)

CHANNEL 2 OVERRIDE INPUT

(10-30 VDC)

AUXILARY SUPPLY

+12 VDC, 250 mA

+

+

+

+

–

–

–

–

(Channel 2 LED) (Channel 1 LED)

CBC-500

WARNER ELECTRIC

480

VAC

CHANNEL 2

INPUT

(10-30 VDC)

CBC-550

WARNER ELECTRIC

OUTPUT

CHANNEL 2

(CLUTCH OR BRAKE)

CHANNEL 1

(CLUTCH OR BRAKE)

Factory

Connections

DO NOT USE

CHANNEL 2

(CLUTCH OR BRAKE)

CHANNEL 1

(CLUTCH OR BRAKE)

SPARE

SPARE

CBC-500-90: 120 VAC

CBC-550-24: 24 VAC

CBC-550 Series

+

+

+

+

–

–

–

–

+

+

–

–

+

+

–

–

HOT

AC

(Channel 2 Adjust) (Channel 1 Adjust)

Dual

Single

(Jumper)

on Bottom 4 pins - Alternat

on Top 4 pins - Dual Output

(Frequency Adjust)

POWER/OUTPUT

(Channel 2 LED)

(Channel 1 LED)

(Channel 2 Adjust)

(Channel 1 Adjust)

Dual

Single

(Jumper)

on Bottom 4 pins - Alternat

on Top 4 pins - Dual Output

(Frequency Adjust)

0

VAC

380

VAC

240

VAC

220

VAC

120

VAC

- NEUTRAL

CHANNEL 1

INPUT

(10-30 VDC)

CHANNEL 2

OVERRIDE

(10-30 VDC)

AUXILARY

SUPPLY

12VDC

250 mA

The voltages present in this control can cause serious injury (even death). When

installing this control or any electrical equipment, make certain that the input power is off. Do

not apply power to this control until it is securely mounted and completely wired in accordance

with local codes and all installation work, including cleanup, has been completed.

Connection Diagrams

CBC-500 Series

CBC-550 Series

Control Adjustments

Channel 1 and Channel 2 Torque Adjustment: Provides adjustment of 0 to full rated voltage.

Jumper: Allows operation of alternate or simultaneous mode of operation. In the single mode,

Frequency Provides adjustment of 60 to 400 Hz. This adjustment is simply to reduce the

Adjustment: clutch/brake "hum" associated with machine frequencies.

Warner Electric • 800-234-3369 P-239-24

4

Channel 1 and Channel 2 function in an alternate mode. In the dual mode Channel 1

and Channel 2 function simultaneously. This mode will be employed in applications with

a clutch and a failsafe brake. The control is shipped with the jumper placed for the

single mode of operation. To change to dual mode, carefully remove the jumper and

reinsert it on the dual side of the terminal block.

Page 5

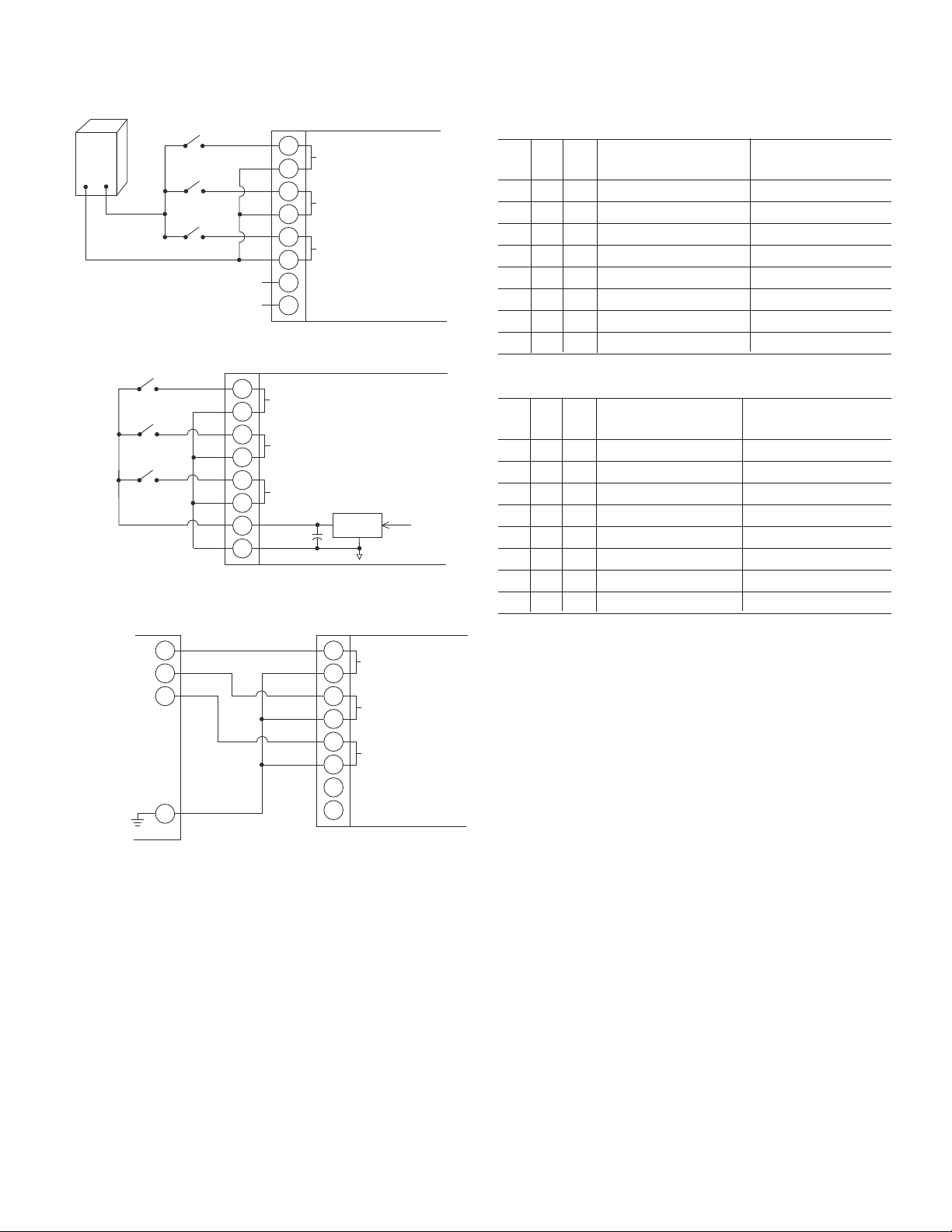

1

2

3

4

5

6

7

8

12 VDC

CH2 Input

Ch1 Input

Ch2 Override

Out IN

+

+

−

CH2 Input

Ch1 Input

Ch2 Override

1

2

3

4

5

6

7

8

1

2

3

10

Clutch/Brake

Control

Out 1

Out 2

Out 3

GND

PLC

1

2

3

4

5

6

7

8

− +

20VDC

Power

Supply

No Connection

No Connection

CH2 Input

Ch1 Input

Ch2 Override

Clutch/Brake

Control

Clutch/Brake

Control

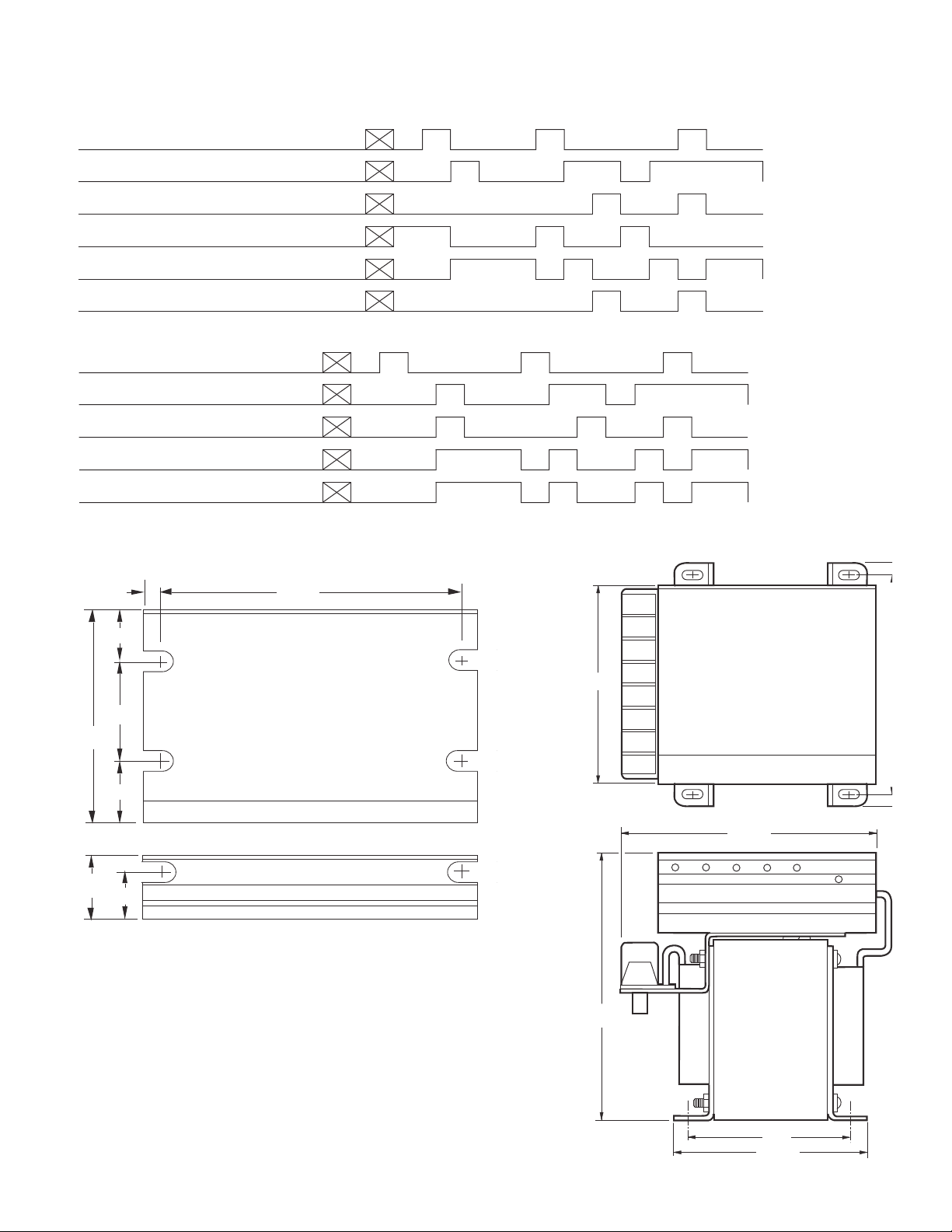

Switching Options

Option 1: External Power Supply

Option 2: Internal Power Supply

Mode Options

Single Mode

Ch1 Ch2 Ch2 Ch1 output Ch2 output

Ove

000 No change No change

0 01 On at full torque Off

010 Off On at full torque

011 On at full torque Off

100On at adjusted torque Off

101 Full torque Off

110On at adjusted torque Off

111 Full torque Off

Dual Mode

Ch1 Ch2 Ch2 Ch1 output Ch2 output

Ove

000 No change No change

001 Off Off

010On at adjusted torque On at adjusted torque

011 Off Off

100 Off Off

101 Off Off

110 Off Off

111 Off Off

Note 1: In single mode, when power is applied

to the control, Ch1 comes on at adjusted voltage until a logic input changes the output voltages.

Option 3: PLC

Note 1: The minimum "on time" or "close time"

of each switch is 10m seconds.

Note 2: The switches in the above schematics

can be replaced with any kind of dry contact

switches; or any kind of relays. Examples:

mechanical relays, momentary contact switches,

toggle switches, transistors, mosfets, solid state

relays, PLC outputs, etc.

Note 3: The logic inputs of the clutch/brake

control are optically isolated.

Note 2: In single mode the control can not “turn

off” both channels at the same time; or “turn

on” both channels at the same time.

Note 3: When voltage is applied to “Ch2 override”, Ch2 and Ch1 logic inputs are ignored and

the outputs are changed to:

Ch1 = full torque and Ch2 = off.

When power is removed from “Ch2 override”,

the control reads the logic inputs and changes

the voltage output accordingly. If no power is

applied to the logic inputs when power is

removed from Ch2 override, then the output

voltages remain at:

Ch 1 = full torque for Ch 1 and Ch2 = Off.

Example:

5

Page 6

Ch1 in

Ch2 in

Ch2 override in

Ch1 output at adjusted torque

Ch2 output at adjusted torque

Ch1 out=full torque and Ch2 out=off

Ch1 in

Ch2 in

Ch2 override in

Ch1 output at adjusted force

Ch2 output at adjusted force

Logic Inputs vs. Time Examples

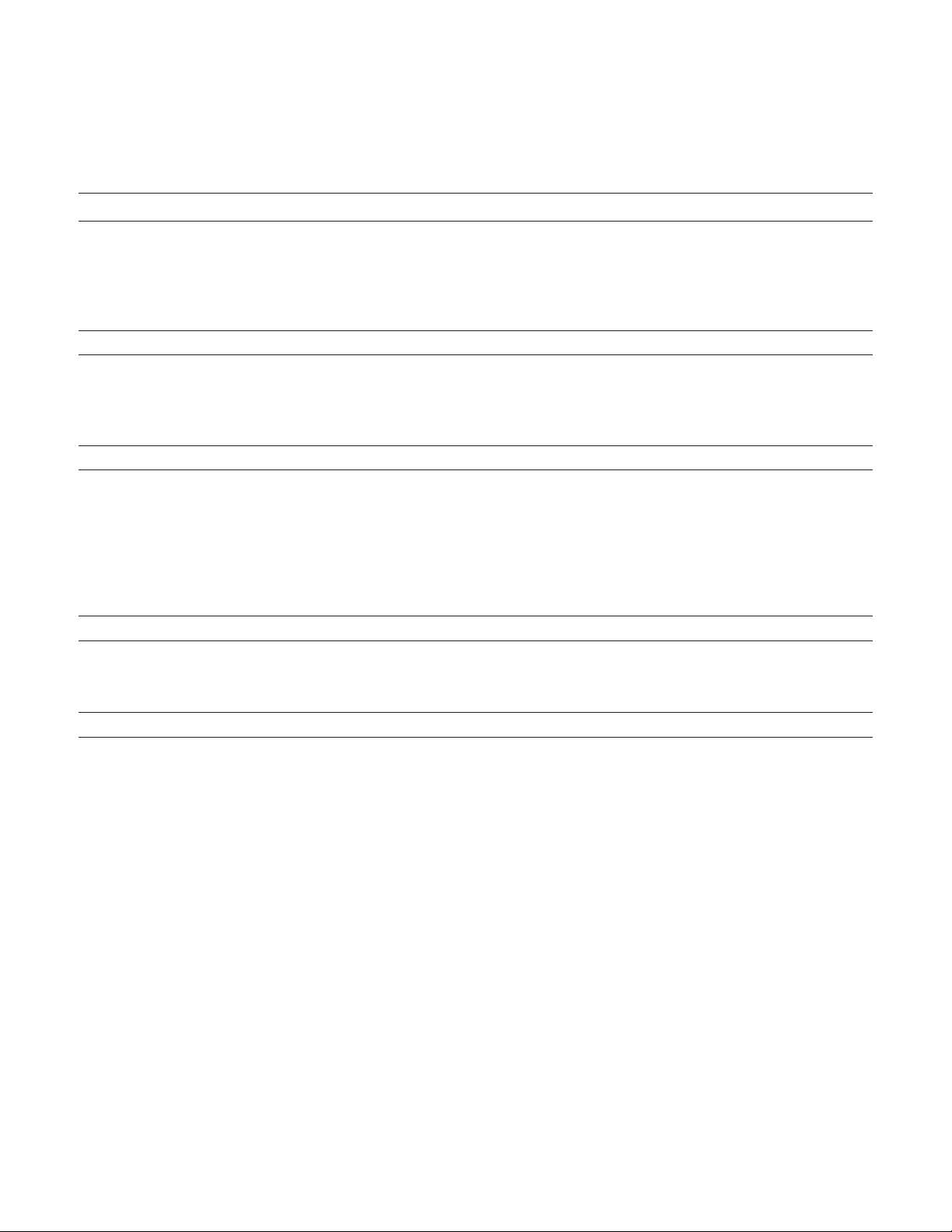

CBC-500

W

ARNER ELECTRIC

1.75"

0.90"

6.00"

0.20"

3.90"

1.15"

1.25"

1.40"

This control may be mounted on its base (two mounting slots) or on its back (four mounting slots).

Note: All dimensions nominal.

4.60"

2.85"

3.50"

4.72"

4.08"

3.90

Example: (Single Mode)

Example: (Dual Mode)

Dimensional Diagrams

CBC-500

CBC-550

Warner Electric • 800-234-3369 P-239-24

6

Page 7

System Troubleshooting

The chart below will be helpful when attempting to isolate problems which may occur in the control

system. It will also prove helpful when encountering problems during initial system start-up.

Symptom A: No output on either channel upon power-up.

Probable Cause Solution

Improper wiring Check wiring and correct if necessary.

No power available Check that AC power is available to control.

Blown fuse See Fuse keeps blowing, Symptom C.

Symptom B: Channel 2 activates upon power-up.

Probable Cause Solution

Improper wiring Check wiring and correct if necessary.

Faulty input switching circuit Check that input switching network is providing proper signal.

Symptom C: Fuse keeps blowing.

Probable Cause Solution

Improper wiring Check wiring and replace fuse.

Shorted brake/clutch coil Check coil resistance and replace if necessary.

Fuse too small Replace with proper fuse.

Improper AC line voltage Check line voltage and correct if necessary.

Improper magnet voltage Check magnet voltage rating and replace with correct magnet if necessary.

Symptom D: Magnets do not appear to have enough torque.

Probable Cause Solution

Magnets incorrectly sized Verify sizing by repeating the selection process.

Symptom E: Outputs don't switch; Inputs don't switch.

Probable Cause Solution

Incorrectly wired inputs Check wiring and correct if necessary.

Faulty switching device Check for proper operation and replace if defective.

Faulty control Replace control.

Reorder Information

Model Part No.

CBC-500-90 6024-448-003

CBC-500-24 6024-448-002

CBC-550-90 6024-448-006

CBC-550-24 6024-448-005

CBC-500 Series Enclosure 6042-101-004

CBC-550 Series Enclosure 6006-101-007

7

Page 8

DECLARATION OF CONFORMITY

WE: WARNER ELECTRIC

449 Gardner Street

South Beloit, IL 61080

declare under our sole responsibility that the products of the family

CBC 500-90 &CBC 500-24

CBC 550-90 & CBC 550-24

are exclusively designed for incorporation in another machine. The operation of

the product is submitted to the conformity of the complete equipment, following the provisions of the directive 89/392/EEC.

The conformity of the above specified products with the provisions of the

Directive 72/23/EEC is supported by the full respect of the standards EN

61010-1.

If the mounting and connecting instructions of the installation’s manual have

been respected, this product will be conform to the standards EN50081-1 and

EN50082-1 relating to the EMC directive 89/336/EEC.

South Beloit, IL 61080

VP and General Manager: S. O.

To avoid injury, always make certain all

power is off before attempting to install

or repair this control.

DO NOT TOUCH THE BOARD IF POWER IS APPLIED.

Mounting and Connecting Instructions

related to the EMC-directive 89/336/EEC

For Clutch and Brake Control

1. The control must be mounted in a closed metal cabinet.

2. The power connection between control and clutch/brake must be MADE

using shield cable.

3. The control connection must utilize shielded cables.

4. The shield of the cables must be grounded at both ends.

5. Power connections and control connection must be placed in separate

canals.

DECLARACION DE CONFORMIDAD

Nosotros: WARNER ELECTRIC

declaramos bajo nuestra propia responsabilidad que los productos de la familia

son diseñados exclusivamente para incorporarse en otra maquina. El funcionamiento de este producto esta sujeto al cumplimiento de todo el equipo

usado en la maquina, con los lineamientos de la norma 89/392/EEC.

El cumplimiento de los lineamientos de la norma 72/23/EEC con los productos

mencionados anteriormente, se basa y respeta los estandares EN 61010-1.

Si las instrucciones de montaje e instalación electrica del instructivo son

respetadas, este producto cumplirá con los estandares EN50081-1 y

EN50082-1 que se relacionan con la norma 89/336/EEC.

South Beloit, IL 61080

VP and General Manager: S. O.

instalar o reparar este control, siempre asegurese que

todas las fuentes de poder esten apagadas.

NO TOQUE EL CIRCUITO ELECTRICO SI LA FUENTE DE PODER

ESTA ENCEDIDA.

en relación a la norma de EMC 89/336/EEC

PARA CONTROLES DE CLUTCHES Y FRENOS

1. El control debe de instalarse adentro de una caja metalica.

2. Las conexiones electricas entre el control y el cluch/freno DEBEN hacerse

con cable blindado.

3. Las conexiones de bajo voltaje en el control deben utilizar cables blindados.

4. El blindaje de los cables debe de aterrizarse en ambos lados.

5. Las conexiones entre la fuente de poder, y las conexiones de bajo voltaje

deben de hacerse en diferentes cables.

449 Gardner Street

South Beloit, IL 61080

CBC 500-90 &CBC 500-24

CBC 550-90 & CBC 550-24

ADVERTENCIA:

Para evitar cualquier daño

personal, antes de intentar

INSTRUCCIONES DE MONTAJE Y

CONEXIONES ELECTRICAS

KONFORMITÄTSERKLÄRUNG

Wir: WARNER ELECTRIC

erkälren in alleiniger Verantwortung, daß die Prdukte der Familie

ausschließlich zum Einbau in eine andere Maschine bestimmt sind. Die

Inbetriebnahme ist solange untersagt, bis die Konformität des Endproduktes

mit der Richtlinie 89/392/EWG gegeben ist.

Die Übereinstimmung des bezeichneten Produktes mit den Vorschriften der

Richtlinie 72/23/EWG wird nachgewiesen durch die Einhaltung der Normen EN

61010-1.

Sofern die Montage-Anweisungen der Bedienungsanleitung eingehalten wurden, ist dieses Podukt knoform zu EN50081-1 und EN50082-1 und die EMV

somit gewährleistet - Richtlinie 89/3366/EWG.

South Beloit, IL 61080

VP and General Manager: S. O.

KARTE BEI EINGESCHALTETER STROMVERSORGUNG NICHT

BERÜHREN.

bezogen zu den EMW Richtlinic 89/336/EWG

FÜR STEURGERÃTE KUPPLUNGEN UND BREMSEN

1. Das Gerãt muß in einem gesclossenen metallschrank eingebaut werden.

2. Leistungsverbindungen Steuergerãte/Kupplungen - Bremsen mit

3. Steuerdeitungen, Ein-und Ausgãnge mittels abgeschimten Kabeln durch-

4. Abschirmung an beiden Enden des Kabels erden.

5. Leistungs-und Steuerverbindungen in separate Kabelkanãle durchziehen.

449 Gardner Street

South Beloit, IL 61080

CBC 500-90 &CBC 500-24

CBC 550-90 & CBC 550-24

WARUNG:

Vor Einbau oder Wartung des

Gerätes unbedingt die

Stromversorgung unterbrechen um Verletzungen zu vermeiden.

MONTAGE UND KABELVERBINDUNGEN

ANWEISUNGEN

abgeschim Kabel durchfubren.

führen.

DÉCLARATION DE CONFORMITÉ

Nous: WARNER ELECTRIC

déclarons sous notre seule responsabilité que les produits de la famille

sont uniquement destinés à l’intégration dans une machine. La mise en service de ces produits est subséquente à l’homologation de l’ensemble de

l’équipmement, conformément à la directive 89/392/CEE.

La conformité des produits spécifiés ci-dessus avec les exigences de la directive 72/23/CEE est supportée par le respect des normes EN 61010-1.

Si les instructions de montage et de câblage du manuel sont respectées, ce

produit est conforme aux normes EN50081-1 et EN50082-1 directive

89/336/CEE relative à la CEM.

South Beloit, IL 61080

VP and General Manager: S. O.

soit coupée avant installation ou intervention sur ces

équipements.

NE PAS TOUCHER LE CIRCUIT ÉLECTRONIQUE, SI LA PUISSANCE

EST APPLIQUÉE.

relatives à la CEM, directive 89/336/CEE

DES CONTROLES POUR EMBRAYAGES ET FREINS

1. L’ appareil doit être monté dans une armoire métallique close.

2. Liasion de puissance entre contrôle et embrayage/frein par cãble blindé.

3. Raccordements de consigne, entrées et sorties par cãbles blindés.

4. Les blindages sont reliés à la terre aux deux extrémités du cãble.

5. Les cãbles de commande et les cãbles de puissance ne seront pas placés

dans le mëme caniveau.

449 Gardner Street

South Beloit, IL 61080

CBC 500-90 &CBC 500-24

CBC 550-90 & CBC 550-24

ADVERTISSEMENT:

Afin d’éviter des blessures,

s’assurer que toute puissance

INSTRUCTIONS D’INSTALLATION

ET DE CABLAGE

Page 9

Mounting Template for CBC-500

Mounting Template for CBC-550

Warner Electric • 800-234-3369 P-239-24

9

Page 10

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any

product manufactured and sold by it which proves to be defective in material or workmanship

within a period of one (1) year from the date of original purchase for consumer, commercial or

industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without

Warner Electric LLC’s prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation

charges prepaid, to the appropriate Warner Electric LLC factory. Additional warranty information

may be obtained by writing the Customer Satisfaction Department, Warner Electric LLC, 449

Gardner Street, South Beloit, Illinois 61080, or by calling 815-389-3771.

A purchase receipt or other proof of original purchase will be required before warranty service is

rendered. If found defective under the terms of this warranty, repair or replacement will be made,

without charge, together with a refund for transportation costs. If found not to be defective, you

will be notified and, with your consent, the item will be repaired or replaced and returned to you

at your expense.

This warranty covers normal use and does not cover damage or defect which results from

alteration, accident, neglect, or improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation

may not apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the

defective product and in no event shall Warner Electric LLC be liable for consequential, indirect,

or incidental damages of any kind incurred by reason of the manufacture, sale or use of any

defective product. Warner Electric LLC neither assumes nor authorizes any other person to give

any other warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH

THE CONSUMER MAY HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF

ORIGINAL CONSUMER PURCHASE. WITH RESPECT TO COMMERCIAL AND INDUSTRIAL

USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL

OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you. This warranty gives you specific legal rights

and you may also have other rights which vary from state to state.

Changes in Dimensions and Specifications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without

notice. Weights do not include weight of boxing for shipment. Certified prints will be furnished

without charge on request to Warner Electric.

Warner Electric

31 Industrial Road

815-389-3771

www.warnerelectric.com

• New Hartford, CT 06057

• Fax: 815-389-2582

P-239-24 819-0486 2/12 Printed in USA

Loading...

Loading...